Page 1

M2Z P

MODULE 2 ZONES PLANCHER

2-ZONE FLOOR MODULE

MODULO A 2 ZONE PER IMPIANTO A PAVIMENTO

MÓDULO 2 ZONAS SUELO

HYDRAULIK - MODUL FÜR 2 ZONEN FUSSBODEN

(HEIZUNG ODER KÜHLUNG)

MÓDULO 2 ZONAS SOALHO

Mars 2009

10 1

1 465 - F

.GB.I.E.D.P

- 02

(Etiquette signalétique)

F

GB

I

E

D

P

NOTICE

D’INSTALLATION

INSTALLATION

INSTRUCTION

MANUALE

D’INST

ALLAZIONE

MANUAL

DE INSTALACIÓN

AUFSTELLUNGS-

HANDBUCH

INSTRUÇÕES

DE INSTALAÇÃO

Page 2

GB

2

CONTENTS

1 - General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 - Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3 - Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

4 - Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

5 - Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

6 - Maintenance Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

7 - Electrical diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1 - GENERAL

1.1 - GENERAL SUPPLY CONDITIONS

• Generally speaking, the material is transported at the consignee's risk.

• The consignee must immediately provide the carrier with written reserves if any damage caused during transport is found.

1.2 - RECOMMENDATIONS

• Prior to any intervention on the unit, installation, commissioning, operation or maintenance, the personnel performing these

operations must be familiar with all instructions and recommendations provided in this installation manual, as well as the

elements presented in the project's technical data package.

• The personnel in charge of receiving the unit should conduct a visual inspection to detect any damage to the unit caused

during transport.

• The unit must be installed, commissioned, maintained, and serviced by qualified personnel in compliance with the

requirements of all current directives, laws and regulations and according to recognized trade practices.

1.3 - VOLTAGE

• Before all operation, check that the voltage indicated on the appliance rating plate corresponds with that of the mains supply.

1.4 - USE

• This unit is designed for use on water distribution type heating / air-conditioning installations, exclusively within the scope

of systems used in conjunction with the following residential applications:

- 2 zones, floor heating / cooling.

This appliance is not designed to be used by people (including children) whose physical, sensory or mental

capacities are impaired, or who lack experience or knowledge, unless they are supervised or have received

instructions on how to use the appliance by a person who is responsible for their safety. Children must be

supervised to ensure that they do not play with the appliance or its accessories.

1.5 - OPERATING CONDITIONS

• This product is designed for use exclusively with a PHR type generator.

MARKING

This product marked conforms to the essential requirements of the Directives:

- Low voltage no. 2006/95/EC.

- Electromagnetic Compatibility no. 89/336 EEC, modified 92/31 and 93/68 EEC.

IMPORTANT

Page 3

GB

3

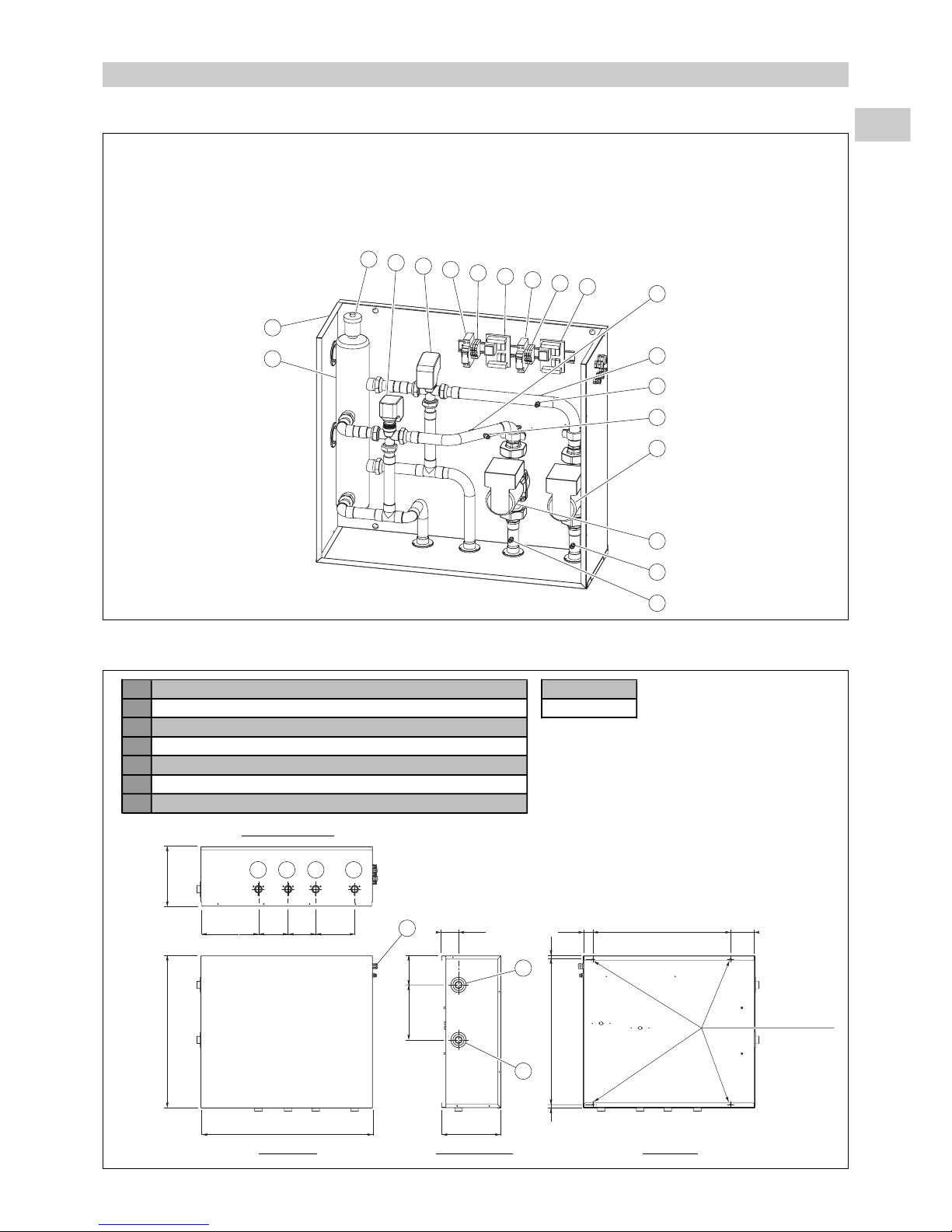

16

3

5

4

9

11

13

8

10

12

17

1

2

6

15

14

7

16

17

1 - Housing

2 - Mixing cylinder

3 - Automatic air vent valve

4 - Motorised, 3-way valve, zone 1

5 - Motorised, 3-way valve, zone 2

6 - Circulator, zone 1

7 - Circulator, zone 2

8 - Circuit breaker, zone 1

9 - Circuit breaker, zone 2

10 - Circulator terminal strip, zone 1

11 - Circulator terminal strip, zone 2

12 - Control board, zone 1

13 - Control board, zone 2

14 - Outlet water sensor, zone 1

15 - Outlet water sensor, zone 2

16 - Pressure taps for water output measurement, zone 1

17 - Pressure taps for water output measurement, zone 2

2 - PRESENTATION

2.1 - DESCRIPTION

74.5 43 107600

750 260

665

251.5 170130 120

63515 15

185.5

240

127.5

6 5 4 3

7

2

1

2.2 - DIMENSIONS AND WEIGHT

1 Module water inlet connection (generator side) Weight (kg)

2 Module water outlet connection (generator side) 39

3 Outgoing connection, zone 1

4 Outgoing connection, zone 2

5 Return connection, zone 1

6 Return connection, zone 2

7 Holes for electric cables

All connections are 1” male.

4 ø 9 holes

for wall

mounting

Front view Left side view Rear view

View from below

Page 4

GB

4

3 - INSTALLATION

• Protection rating of the module: IP 31.

• The module must be installed in a sheltered location.

• Remove the module's front panel (6 screws on the sides).

• Secure the module to the wall. See the position of the 4 mounting holes in paragraph 2.2.

4 - CONNECTIONS

4.1 - HYDRAULIC CONNECTION

• The module is to be connected on the installation's outgoing line, at the heating module outlet. The module is entered from

above. Connect the outgoing and return line of each zone.

4.2 - ELECTRICAL CONNECTIONS

4.2.1 - GENERAL

• Class 1 apparatus, intended for an installation equipped with a neutral point connection (TT as per NFC 15-100) in

domestic applications.

• Breaking capacity of the circuit breakers for the module: 3 kA as per NFC 61-410.

• Voltage variation tolerance: +/- 10% in operation.

• The electrical connection conduits must be secured.

• Use the cable glands mounted on the unit - see § 4.2.4.

• Ensure that all installation grounds are interconnected.

• Cables are not supplied.

• Consult the module electrical diagram.

• Also consult the installation manuals of the generator and the heater module, and the control’s technical manual.

4.2.2 - DESCRIPTION OF CONNECTIONS

4.2.2.1 - MAINS SUPPLY

• 230 V, single-phase, 50 Hz, input amperage = 1.6 A.

• The electrical power supply must come from protection and disconnecting means (not

supplied) in compliance with the standards and regulations in force. The circuit must be

protected by a two-pole circuit breaker.

• Cable 3G 1.5 mm

2

.

• Power supply to be connected directly on the zone 1 circuit breaker (“Q1”) located in the

module.

4.2.2.2 - CONTROL CONNECTIONS

- Refer to the diagrams in § 4.2.3.

Outgoing line, zone 1

Outgoing line, zone 2

Return, zone 1

Return, zone 2

Generator

Heating module

2-zone floor module

Plate exchanger

NPh

230 Vac

PE

Q1

Caution:

To avoid problems related to electromagnetic disturbances, do not route these cables near power cables.

Page 5

GB

5

P

Q Q

P

A BUS BUS

BUS

Control box

With built-in ambient temperature sensor.

To be installed in zone 1.

Water

temperature,

zone 2

Heating

board

2-ZONE FLOOR MODULE

Water

temperature,

zone 1

Ambient

temperature,

zone 2

Ambient

temperature,

zone 1

Board, zone 2

A2

Board, zone 1

A1

Possible accessory

70250065

(If control box is installed

outside zone 1)

A BUS

- 2-conductor cable, min. size 1 mm

2

.

- Total length of the BUS connection: 40 meters (heating board / control box connection + heating board / zone board if

any connection).

- To be connected on the terminal strip of the boards, zones A1 and A2, located in the module.

A2 A1

Heating

board

Caution:

Be sure to respect

the polarities + and -

P Zone ambient temperature sensor

- For zone 2, Floor: mandatory, supplied with the module.

- For zone 1, Floor: required only if the control unit is not placed in a

location that is representative of the temperature in zone 1.

Caution

:

In this case, the remote zone 1 sensor must be activated through

parameterisation on the control unit (refer to control’s technical manual).

This sensor is proposed as accessory 70250065.

- Wall mounting: the sensor is designed to be mounted in a "Mosaïc" type

(45 x 45), flush-mounted electrical box (not supplied).

It is to be installed in a location that is representative of the temperature

in the zone.

- The sensor must not be installed in corners, on shelves or behind

curtains, near sources or heat or directly exposed to sunlight.

The unit should be installed approximately 1.5 m above the floor.

- Use a 2-conductor cable for installation, minimum size: 0.5 mm

2

and max. length: 25 meters.

- To be connected directly on the corresponding zone board (terminals C and S5).

Q Water temperature probe (Floor zone outgoing line)

- Indicated for informational purposes as it is already connected in the module.

1.50 m

20 cm min.

Ambient Sensor

HEATING MODULE

2-ZONE FLOOR MODULE

HEATING MODULE

Page 6

GB

6

230 V power supply

BUS A

Zone ambient

sensor(s) P

5 - START-UP

5.1 - VERIFICATIONS

• Ensure that the hydraulic connections are properly tight and that the hydraulic system operates correctly:

- purge of circuits,

- valve position,

- hydraulic pressure (1.5 to 3 bar).

• No leaks.

• Proper machine stability.

• Electrical cables and wires are well secured to their connection terminals. Loose terminals can cause heat build-up on the

terminal board and malfunctions.

• Ensure that the electric cables are properly protected from all sheet metal edges or metal parts that could damage them.

• Ensure that control cables and power cables are properly separated.

• Check that the unit is properly grounded.

• Make sure that no tools or any other objects have been left in the machine.

5.2 - CONFIGURATION / SETTING

• Set the button on the installation's control box to OFF.

• Turn installation and module power on.

• On the control unit, configure the system for the "2 Floor Zones" application (parameter 70 = 2); then check and adapt the

parameterization to the installation conditions (consult the control’s technical manual).

• Check that the setpoint settings of the generator regulator are compatible with the "2 Floor Zones" application.

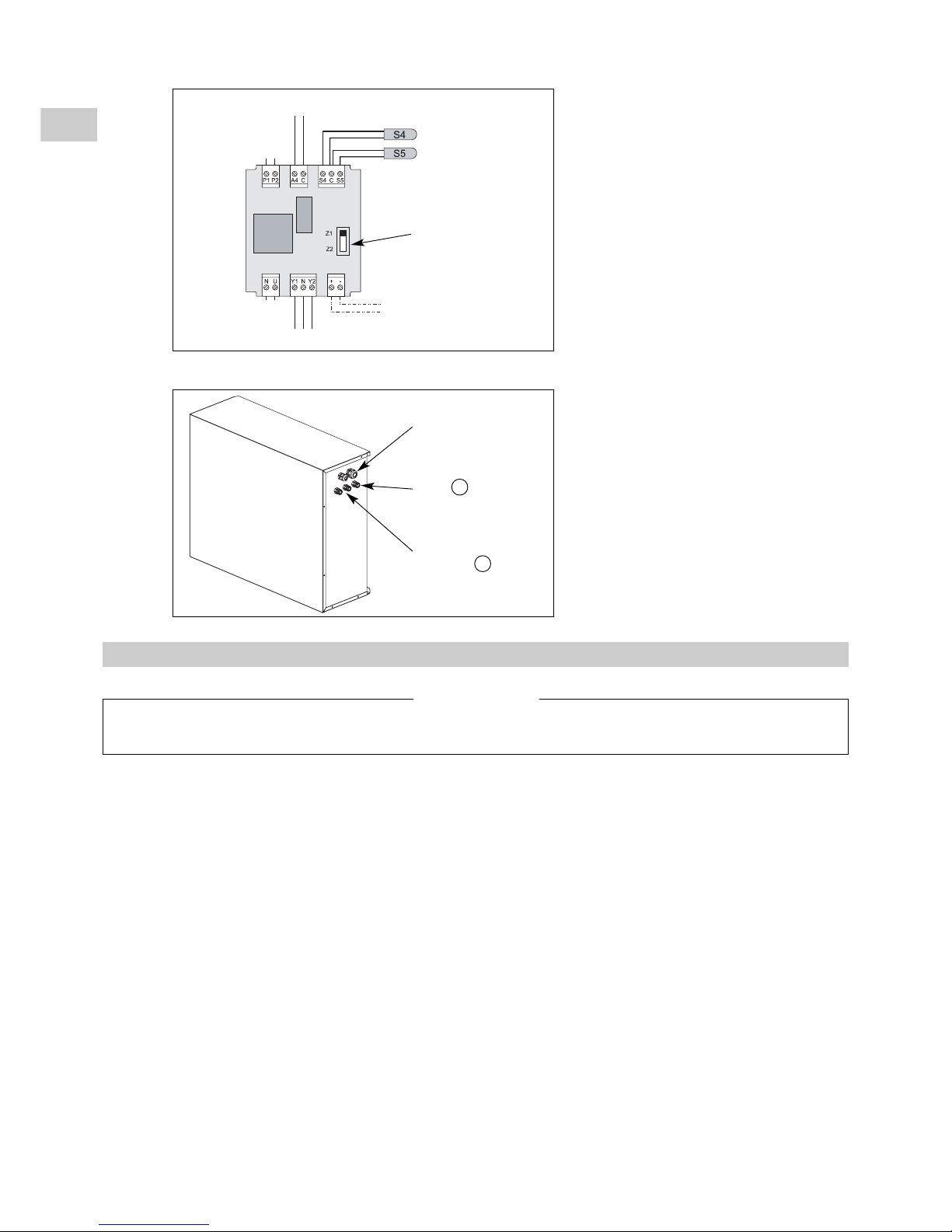

• Check the position of the zone addressing micro-switches (Z1/Z2), see the diagram in § 7.

Before carrying out any work on the machine, make sure that it is switched off and that access to it is prevented.

Any work must be carried out by personnel qualified and authorised to work on this type of machine.

IMPORTANT NOTE

4.2.3 - ZONE BOARD CONNECTION DETAIL

4.2.4 - CABLE ROUTING

230 Vac

BUS

Zone ambient

temperature sensor

Valve control

Pump

control

Valve contact input

Zone addressing

micro-switch

Water temperature sensor

(floor outgoing line)

Page 7

GB

7

5.3 - OPERATION

• Check circulator operation in the generator and the operation of the 2 circulators of the module. Adapt the speed of the

circulators in order to respect the flow rates. For the generator, refer to the corresponding installation manual.

Note:

When the system is off, operation can be forced by changing the parameterization:

- of zone 1 (accelerator on and control valve open) with parameter 65,

- of zone 2 (accelerator on and control valve open) with parameter 66,

- of the generator with parameter 67.

• Check that water is properly circulating in the installation (valve position).

Note:

The mixing valves of each of the module's floor zone outgoing lines are delivered in full open position

(position “1”).

They are equipped with a “3-point” motor for 230 VAC controlled by the zone board:

- Y1 = open control signal,

- N = neutral (common),

- Y2 = close control signal.

When off, it is possible to open the valves by actuating the motor using a 3 mm Allen wrench.

• Purge the installation. Check the bleeders located in the 2-zone module and heating module.

CAUTION:

An incorrect purge could result in malfunctions and damage to the heater of the heating module.

0

10

20

30

40

50

60

70

80

90

00.511.522.53

Water flowrate (m3/h)

Manometric delivery head (kPa) of the circulator

Speed 1

Speed 2

CIRCULATOR SXM 32 - 55

Speed 3

6 - MAINTENANCE INSTRUCTIONS

• Before doing any work on the installation, make sure it is switched off and all power supplies locked out.

• Any work must be carried out by personnel qualified and authorised to work on this type of machine.

IMPORTANT NOTE

• Water flowrate: The module's outgoing water lines

are equipped with 1/4 SAE pressure taps at the inlet

and outlet of each circulator, to enable the pressure

loss to be measured using a hydraulic pressure

gauge. Use the following circulator curves below

(circulator SXM 32 - 55) to find the water flowrate.

• Start the system in the desired operating mode using the control box button (consult the control’s technical manual and the

control box user's guide).

Caution:

At the end of testing and before starting the installation, the forced configuration must be deactivated

and parameters 65, 66 and 67 returned to zero.

Page 8

GB

8

7 - ELECTRICAL DIAGRAM

A1 Control board, zone 1

A2 Control board, zone 2

EV1 Control valve, zone 1

EV2 Control valve, zone 2

M1 Circulator, zone 1

M2 Circulator, zone 2

Q1 Circuit breaker, zone 1

Q2 Circuit breaker, zone 2

S4 Water temperature sensor (outgoing line, zone 1)

S41 Water temperature sensor (outgoing line, zone 2)

S5 Temperature ambiance sensor (zone 1)

Accessory

S51 Temperature ambiance sensor (zone 2)

Component symbols

Q2

PE

XA

Z1

Z2

P2P1 A4 C S4 C S5

NU Y1 N Y2 +-

A2

S41

S51

M2

1

~

N

U

12

XA

11

XA

EV2

BUS

BUS

P2P1 A4 C S4 C S5

NU Y1 N Y2 +-

A1

S4

S5

M1

1

~

N

U

2

XA

1

XA

EV1

Q1

12

11

12

11

12

11

12

11

Z1

Z2

PE N Ph

ELECTRICAL DIAGRAM - M2Z P

10 05 807 - 03

Power supply

230V / 1 / 50

Pump

Water probe

Ambiance

sensor

Pump

Water probe

Ambiance

sensor

(accessory)

GENERAL MAINTENANCE

All equipment must be properly maintained in order to provide optimum performance over time. Faulty maintenance can result in

the cancellation of the product guaranty. Depending on the products, maintenance operations consist in the cleaning of filters (air,

water), internal and external exchangers, casings, and the cleaning and protection of condensate tanks. Treating odours and the

disinfection of room surfaces and volumes also contributes to the cleanliness of the air breathed by users.

• Perform the following operations at least once per year (the frequency of operations depends on the installation and

operating conditions):

- Check the composition and condition of the coolant.

- Check operating points and setpoints.

- Check the safety devices:

- Dusting of electrical boxes.

- Ensure that all electrical connections are properly tight.

- Check the ground connections.

- Check the hydraulic system (cleaning of the filter, water quality, purge, flowrate, pressure etc.).

Page 9

GB

9

Page 10

F

GB

D

P

I

E

Page 11

F

GB

D

P

I

E

Page 12

F

GB

D

P

I

E

Par souci d'amélioration constante, nos produits peuvent être modifiés sans préavis.

Due to our policy of continuous development, our products are liable to modification without notice.

Per garantire un costante miglioramento dei nostri prodotti, ci riserviamo di modificarli senza preaviso.

En el interés de mejoras constantes, nuestros productos pueden modificarse sin aviso prévio.

Unsere Produkte werden laufend verbessert und können ohne V

orankündigung abgeändert werden.

Com o objectivo de uma melhoria constante, os nossos produtos podem ser modificados sem aviso prévio.

R.D. 28 Reyrieux BP 131 01601 Trévoux CEDEX France

Tél. 04 74 00 92 92 - Fax 04 74 00 42 00

T

el. 33 4 74 00 92 92 - Fax 33 4 74 00 42 00

R.C.S. Bourg-en-Bresse B 759 200 728

Loading...

Loading...