Technibel iSeries, GR9FI30LTR5IAA, GR9FI40LTR5IAA, GR9FI50LTR5IAA Technical Data & Service Manual

Page 1

TECHNICAL DATA

& SERVICE MANUAL

OUTDOOR UNIT:

GR9FI30LTR5IAA

GR9FI40LTR5IAA

GR9FI50LTR5IAA

SPLIT SYSTEM AIR CONDITIONER

May 2016

iSeries

GR9FI30LTR5IAA

AEI1G 30 LT

AEI1G 40-50 LT

GR9FI4-50 0LTR5IAA

Page 2

TABLE OF CONTENTS

1 SCOPE...................................................................................................................................4

2 DIMENSIONAL DATA AND EXTERIOR APPEARANCE........................................... 5

3 TECHNICAL SPECIFICATIONS .....................................................................................7

4 REFRIGERANT CIRCUIT ............................................................................................... 10

5 ELECTRICAL WIRING DIAGRAM ...............................................................................13

6 PRINCIPLE OF FUNCTIONING...................................................................................15

7 COMPONENTS OPERATION......................................................................................... 17

8 DEFROST............................................................................................................................19

9 PROTECTIONS .................................................................................................................21

10 COMPONENT DESCRIPTION .......................................................................................23

11 DIAGNOSTIC TABLE ......................................................................................................26

12 TROUBLESHOOTING...................................................................................................... 27

13 COMPONENT REPLACEMENT ......................................................................................30

14 PACKAGING...................................................................................................................... 39

15 LABELS ...............................................................................................................................41

Page 3

REVISION NOTES

Rev. Date Author Checked Comments

00 01/10/2014

MDG GV First release.

01 14/11/2014

02 20/01/2015

GV MDG

Added Scope, Packaging and Labels sections. Added

exterior appearance description. Fixed CDT sensor table.

GV MDG

30-40-50

Page 4

1 Scope

This specification document is applied to the outdoor units mentioned below used for air to air heat

pump to be delivered

UNIT MODEL TABLE

DECLARATION OF CONFORMITY “CE”

Units described in this document conform to the protection requirement of the following EC directives:

•••• EMC Directive 2004/108/EC

•••• LVD (Low Voltage Directive) 2006/95/EC

•••• RoHS 2 Directive 2011/65/EU

Standards:

• EN378-2:2008 + A1:2009

• EN 60335-1:2002+A11:2004+A12:2006+A13:2008+A14:2010

• EN 60335-2-40 :2003+A11:2004+A12:2009+A1:2006

• EN 55014-1:2006 + A1:2009

• EN 55014-2:1997 + A1:2001+ A2:2008

• EN 61000-3-2:2006+A1:2009+A2:2009

• EN 61000-3-3:2008

• EN 61000-3-11:2000

• EN 61000-3-12:2005

CODICE

TECHNIBEL

387107115

387107116

387107117

GR9FI30LTR5IAA

GR9FI40LTR5IAA

GR9FI50LTR5IAA

Page 5

2 Dimensional data and exterior appearance

Exterior appearance – color Top/front and side/rear panel: silver

(F1936)

Fan Guard and valve covering: gray

(RAL7042)

Material Panel: zinc-coated steel sheet

Fan guard and valve covering: polypropylene

Painting 2 layers,

20 µ or more for electro coating (lower layer)

40 µ or more for polyester powder paint coating (top layer)

Total Coating thickness is 60 µ or more.

240 hrs salt spray test

GR9FI30LTR5IAA

Page 6

Exterior appearance – color Top/front and side panel: silver

(F1936)

Fan Guard and valve covering: gray

(RAL7042)

Material Panel: zinc-coated steel sheet

Fan guard and valve covering: polypropylene

Painting 2 layers,

20 µ or more for electro coating (lower layer)

40 µ or more for polyester powder paint coating (top layer)

Total Coating thickness is 60 µ or more.

240 hrs salt spray test

GR9FI40LTR5IAA

GR9FI50LTR5IAA

Page 7

3 Technical specifications

AIR AIR

COOLING Pdesignc W 2680

+35°C SEER 6,11

A++

HEATING Pdesignh W 3030

Average -10°C SCOP 3,82

A

ERP Ecodesign - EN14825

COOLING

Minimum W 1370

+35°C OU / 27/19°C IU

Maximum W 3650

HEATING

Minimum W 930

+7/6°C OU / +20°C IU

Maximum W 3880

-7°C/-8°C OU / + 20° C IU Maximum W 2650

-10°C/-11°C OU / + 20° C IU Maximum W 2350

-22°C/-21°C OU / + 20° C IU Maximum W 2150

EN14511

Power supply V/Ph/Hz 230/1/50

Power input (max.) W/A 1550/6,90

R410A standard refrigerant charge kg 0,81

Compressor type Single Rotary

Fan speed Auto

Sound pressure (max.) dB(A) 40

Liquid pipe mm (inch") 6,35 (1/4")

Gas pipe mm (inch") 9,52 (3/8)"

Total lenght of pipes (standard load) m 7,5

Total lenght of pipes (additional load) m 15

Maximum lenght difference (total) m 10

GR9FI30LTR5IAA

Page 8

AIR AIR

COOLING Pdesignc W 3670

+35°C SEER 6,06

A++

HEATING Pdesignh W 4020

Average -10°C SCOP 4,01

A

ERP Ecodesign - EN14825

COOLING

Minimum W 1010

+35°C OU / 27/19°C IU

Maximum W 4060

HEATING

Minimum W 910

+7/6°C OU / +20°C IU

Maximum W 4870

-7°C/-8°C OU / + 20° C IU Maximum W 3510

-10°C/-11°C OU / + 20° C IU Maximum W 3250

-22°C/-21°C OU / + 20° C IU Maximum W 2980

EN14511

Power supply V/Ph/Hz 230/1/50

Power input (max.) W/A 1550/6,90

R410A standard refrigerant charge kg 1,1

Compressor type Single Rotary

Fan speed Auto

Sound pressure (max.) dB(A) 44

Liquid pipe mm (inch") 6,35 (1/4")

Gas pipe mm (inch") 9,52 (3/8)"

Total lenght of pipes (standard load) m 7,5

Total lenght of pipes (additional load) m 15

Maximum lenght difference (total) m 10

GR9FI50LTR5IAA

Page 9

AIR AIR

COOLING Pdesignc W 5215

+35°C SEER 6,74

A++

HEATING Pdesignh W 4070

Average -10°C SCOP 4,16

A

ERP Ecodesign - EN14825

COOLING

Minimum W 900

+35°C OU / 27/19°C IU

Maximum W 5650

HEATING

Minimum W 1030

+7/6°C OU / +20°C IU

Maximum W 5290

-7°C/-8°C OU / + 20° C IU Maximum W 3900

-10°C/-11°C OU / + 20° C IU Maximum W 3300

-22°C/-21°C OU / + 20° C IU Maximum W 3040

EN14511

Power supply V/Ph/Hz 230/1/50

Power input (max.) W/A 1790/7,80

R410A standard refrigerant charge kg 1,3

Compressor type Twin Rotary

Fan speed Auto

Sound pressure (max.) dB(A) 41

Liquid pipe mm (inch") 6,35 (1/4")

Gas pipe mm (inch") 12,77 (1/2)"

Total lenght of pipes (standard load) m 7,5

Total lenght of pipes (additional load) m 20

Maximum lenght difference (total) m 10

GR9FI50LTR5IAA

Page 10

4 Refrigerant circuit

Note:

- In heating mode the refrigerant flow is in the opposite direction of the COOL arrows

- INV: 4-way valve

- EXP: Electronic Expansion Valve

- COM: Compressor

GR9FI30LTR5IAA

Page 11

Note:

- In heating mode the refrigerant flow is in the opposite direction of the COOL arrows

- INV: 4-way valve

- EXP: Electronic Expansion Valve

- COM: Compressor

GR9FI40LTR5IAA

Page 12

Note:

- In heating mode the refrigerant flow is in the opposite direction of the COOL arrows

- INV: 4-way valve

- EXP: Electronic Expansion Valve

- COM: Compressor

GR9FI50LTR5IAA

Page 13

5 Electrical wiring diagram

Legend

A1 Control pcb OAT Outdoor Air Sensor

F1 Main fuse

6,3x32 - 10A / 250V

CDT Compressor Discharge Sensor

F2 Comm. Fuse, RS485 bus cable

5x20 - 100mA / 250V

OCT Outdoor Coil Sensor

SW1 Dip-switch EEV Electronic Expansion Valve

JP1/2/3 Jumpers CCH Crankcase Heater

EF Electromagnetic Interference

Filter

ER Drip tray heater

CM Compressor CWP Condensate water pipe heater

FM Fan motor EI PFC Inductor

INV 4-way valve

Page 14

Settings

Jumpers

JP1: Factory use. Default: open.

JP2: Defrost type selection. Default: closed.

JP3: Heating only option. Default: open (heating and cooling).

Dip-switch:

SW1: Factory use. Default: 1=Off, 2=Off.

Note:

Jumper and dip-switch settings can be changed only when unit is powered off.

Page 15

6 Principle of functioning

Heating mode

When the unit is in heating mode, the system will regulate the heating capacity delivered to the room to

increase the room air temperature (RAT) to the set point (SPT) and to balance the thermal load of the

room to keep the set point temperature.

The following rules apply to heat mode functioning:

- Compressor and fan start when RAT is 1°C or more below the SPT

- Compressor and fan stop if RAT is 2°C or more above the SPT, or if RAT is 1°C above the SPT for

more than 1 hour

During the first 3 minutes of operation:

- Compressor and fan run at a fixed speed (2 minutes at low speed and 1 minute at intermediate

speed)

- EEV is open at a fixed value

After the first 3 minutes of operation, compressor and fan speeds are regulated by:

- the thermal load calculation

- the level of protecion of the system

During heating mode, 4-way valve is active.

Cooling mode

When the unit is in cooling mode, the system will regulate the cooling capacity delivered to the room to

decrease the room air temperature (RAT) to the set point (SPT) and to balance the thermal load of the

room to keep the set point temperature.

The following rules apply to cool mode functioning:

- Compressor and fan start when RAT is 1°C or more above the SPT

- Compressor and fan stop if RAT is 2°C or more below the SPT, or if RAT is 1°C below the SPT for

more than 1 hour

During the first 3 minutes of operation:

- Compressor and fan run at a fixed speed (2 minutes at low speed and 1 minute at intermediate

speed)

- EEV is open at a fixed value

After the first 3 minutes of operation, compressor and fan speeds are regulated by:

- the thermal load calculation

- the level of protecion of the system

During cooling mode, 4-way valve is deactivated.

Page 16

Dehumidification (dry) mode

When the unit is in dry mode, the system will operate according to the following table:

Notes:

- When dry mode is active, the temperature of the room could decrease below the setpoint

temperature if the thermal load of the room is low.

- During dry mode, 4-way valve is deactivated.

Auto mode

When the unit is in auto mode (auto cooling or auto heating), the system will switch between heating

and cooling mode to maintain the room air temperature (RAT) to the set point temperature (SPT).

The system will switch between heating and cooling mode if one of the following conditions is met:

- Cooling Heating if at least 3 minutes have passed since the compressor was stopped and ∆T ≤ -3

- Cooling Heating if at least 1 hour have passed since the compressor was stopped and ∆T ≤ -1

- Heating Cooling if at least 3 minutes have passed since the compressor was stopped and ∆T ≥ 3

- Heating Cooling if at least 1 hour have passed since the compressor was stopped and ∆T ≥ 1

where:

- ∆T = RAT – SPT

Fan mode

When system is in fan mode:

- Compressor and fan are stopped.

- 4-way valve is deactivated

- Indoor fan runs at the selected speed

RAT DRY LEVEL DESCRIPTION

≥ SPT + 2°C 0 Unit operates normally in cooling mode.

< SPT + 2°C

≥ SPT - 1°C

1

Unit operates with a fixed cooling demand.

Indoor fan switches between very low speed and

low speed every 30 seconds.

< SPT - 1°C

≥ 10°C

2

Unit cycles between a period of operation with a

fixed cooling demand (3 minutes) and a period of

non operation (9 minutes).

Indoor fan switches between very low speed and

low speed every 30 seconds.

< 10°C DRY OFF Unit is off.

Page 17

7 Components operation

Compressor

The compressor runs if the following conditions are met:

- At least 3 minutes have passed since the power supply was switched on

- At least 3 minutes have passed since the compressor was stopped

- At least 6 minutes have passed since the previous compressor start

- There is no active alarm on the outdoor and indoor units

- There is no active protection

- There is a thermal load demand in the room

Compressor stops if:

- At least 3 minutes have passed since compressor start

- There is no capacity demand

or if:

- At least 3 minutes have passed since compressor start

- Protection level is too high

or if there is any alarm active.

Fan

The fan runs only when the compressor is running and starts right after the compressor.

The fan can also run without compressor in the following conditions:

- Overheating on the outdoor heat exchanger (cooling or dry mode)

- Overheating on the power electronics

Electronic Expansion Valve (EEV)

EEV is managed based on the system conditions to meet the maximum efficiency point of operation and

to guarantee a safe operation of the system.

Every time power supply is switched on, or once per day if compressor is not running, EEV runs a reset

cycle necessary to find the correct position of the valve. During this reset cycle, EEV is completely closed

and then reopened to a fixed value.

4-way valve

4-way valve is activated when:

- System is in heating mode

4-way valve is deactivated when:

- System is in cooling, dry or fan only mode

- System is off

- Defrost is active

Page 18

Crankcase heater

Crankcase heater around the compressor is used to prevent refrigerant migration and mixing with

crankcase oil when the unit is off, and to prevent condensation of refrigerant in the crankcase of the

compressor. The crankcase heater keeps refrigerant at a temperature higher than the coldest part of the

system.

Crankcase heater is activated if the following conditions are met:

- Compressor is stopped

- OAT il lower than 5°C

- Difference between CDT and OAT is lower than 18,5°C

When crankcase is active, it will be deactivated if one of the following condition is met:

- Compressor starts

- OAT increases above 5°C

- Difference between CDT and OAT is higher than 21,5°C

Drip tray heater (built-in) and condensation water heater (accessory)

The drip tray heater and the condensation water heater prevent condensation freezing on the drip tray

and the condensation water pipe.

The heaters are activated if the system is in heating mode and one or more of the following conditions

are met:

- OAT is lower than 0°C

- Defrost is active

- Less than 5 minutes have passed since last defrost

When heaters are active, they will be deactivated if all of the following conditions are met:

- OAT is higher than 2°C

- Defrost is not active and more than 5 minutes have passed since last defrost

Page 19

8 Defrost

A defrost starts if one of these conditions is satisfied (see graph below):

- OCT falls below L1 line and compressor is running for at least 35 minutes without defrost

- OCT falls below L2 line and compressor is running for at least 60 minutes without defrost

A defrost ends if one of these conditions is satisfied:

- OCT rise above 14°C and defrost has been active for at least 2 minutes

- defrost has been active for 12 minutes

Removing the jumper JP2, the defrost end contitions will change according to the following:

- OCT rise above 24°C and defrost has been active for at least 5 minutes

- defrost has been active for 15 minutes

Page 20

Before reversing the cycle at the beginning and at the end of the defrost, the compressor ramps down to

decrease the pressure inside the circuit:

When defrost is active:

- 4-way valve is deactivated

- Compressor runs at a fixed speed (if no protection is active)

- EEV is open at a fixed value

- Fan is off

When defrost ends:

- 4-way valve is reactiavted

- EEV is opened at a fixed value for 5 minutes

Page 21

9 Protections

The unit is equipped with an automatic system of protections. These protections, if active, will limit the

speed of the compressor in order to run the system in a safe operating area.

Protections, when active, reduce the speed of the compressor linearly down to its minimum speed. If the

level of protection is too high, compressor is stopped until no protection will be active.

Overheating on outdoor unit heat exchanger

This protection checks the temperature on the outdoor coil (OCT) to avoid overheating and overpressure

of the heat exchanger.

This protection is active only in cooling or dry mode and starts to limit the compressor speed when OCT

is higher than 55°C.

Overheating on indoor unit heat exchanger

This protection checks the temperature on the indoor coil (ICT) to avoid overheating and overpressure of

the heat exchanger and reduces the high pressure noise inside the indoor unit.

This protection is active only in heating mode and starts to limit the compressor speed when ICT is

higher than 40°C(*).

Notes:

- (*) ICT threshold may vary depending on the model of the indoor unit

- If High Power option is active, protection will start at higher values of ICT, increasing the heating

capacity

Freeze-up on indoor unit heat exchanger

This protection checks the temperature on the indoor coil (ICT) to avoid freezing of the indoor unit heat

exchanger.

This protection is active only in cooling or dry mode and starts to limit the compressor speed when ICT

is lower than 8°C.

Furthermore, if the unit is stopped because of this protection, in order to drip away all the condensed

water on the indoor coil, it will not restart until ICT is higher than 8°C.

Overheating on the compressor

This protection checks the compressor’s discharge temperature (CDT) to avoid overheating of the

compressor.

This protection is always active and starts to limit the compressor speed when CDT is higher than 90°C.

Overheating on the power electronic

This protection checks the temperature of the electronic power module connected to the heatsink. The

temperature sensor is built into the module, so there is no direct access to it.

This protection is always active and starts to limit the compressor speed when power electronic

temperature is higher than 90°C.

Page 22

Over power consumption from the power supply

This protection checks the power consumption of the outdoor unit (but not of the indoor unit) to avoid

an excessive power consumption than can damage the pcb and the unit.

This protection is always active and limits the compressor speed to keep the outdoor unit power

consumption below 1800W.

Overcurrent of the compressor

This protection checks the current consumption of the compressor to avoid damage to the compressor

and to the pcb.

This protection is always active and limits the compressor speed to keep the current consumption of the

compressor below 8A.

Page 23

10 Component description

Compressor

type HERMETIC, SINGLE ROTARY, DC INVERTER

model 5RS102XBE01

oil RB68A or Freol Alpha 68M

refrigerant R410A

motor BRUSHLESS MOTOR

n. of poles 6

rated output 700 W

winding resistance

(@20 °C)

U-V: 0,858 Ω V-W: 0,858 Ω U-W: 0,858 Ω

overload protector CS-7L 115 (WAKO ELECTRIC OR EQUIVALENCE)

Fan Motor

model ZW465B58 ( ) – ZW465B57 ( )

motor BRUSHLESS MOTOR

n. of poles 8

rated output 20 W

rpm variable, 200 ÷ 850

winding resistance

(@25 °C)

BRN (W) - BLK (U) :

206 Ω

WHT (V) - BLK (U) :

206 Ω

BRN (W) - WHT (V) :

206 Ω

4-way Valve

model SHF-4H-23U (valve) - SHF-4-10L3 (coil)

coil rating AC 220-240V 50/60Hz

coil resistance 1440 Ω ± 7% at 20°C

Electronic Expansion Valve

model CAM-BD15EX-1 (valve) - ZCAM-MD12EX-9M-B (coil)

coil rating DC 12V

coil resistance 46 Ω ± 4% at 20°C

Crankcase Heater

power 30 W

resistance 1760 Ω ± 10% at 20°C

Drip Tray Heater

power 75 W

resistance 700 Ω ± 10% at 20°C

GR9FI30LTR5IAA

GR9FI40LTR5IAA

MOD.30

MOD.40

Page 24

Compressor

type HERMETIC, TWIN ROTARY, DC INVERTER

model SNB130FGBMT

oil FV 50S

refrigerant R410A

motor BRUSHLESS MOTOR

n. of poles 6

rated output 900 W

winding resistance

(@20 °C)

U-V: 0,98 Ω V-W: 0,98 Ω U-W: 0,98 Ω

overload protector EXTERNAL

Fan Motor

model ZW465B57

motor BRUSHLESS MOTOR

n. of poles 8

rated output 20 W

rpm variable, 200 ÷ 850

winding resistance

(@25 °C)

BRN (W) - BLK (U) :

206 Ω

WHT (V) - BLK (U) :

206 Ω

BRN (W) - WHT (V) :

206 Ω

4-way Valve

model SHF-7K-34U (valve) - SHF-4-10L3 (coil)

coil rating AC 220-240V 50/60Hz

coil resistance 1440 Ω ± 7% at 20°C

Electronic Expansion Valve

model CAM-BD15EX-1 (valve) - ZCAM-MD12EX-9M-B (coil)

coil rating DC 12V

coil resistance 46 Ω ± 4% at 20°C

Crankcase Heater

power 30 W

resistance 1760 Ω ± 10% at 20°C

Drip Tray Heater

power 75 W

resistance 700 Ω ± 10% at 20°C

GR9FI50LTR5IAA

Page 25

Sensors

OCT: Outdoor Coil Temperature. Used for:

- EEV management

- Fan management

- Protection against overheating of the heat exchanger (cooling or dry mode)

- Defrost cycle management (heating mode)

OAT: Outdoor Air Temperature. Used for:

- EEV management

- Fan management

- Defrost cycle management

- Crankcase heater management

- Base heater management

CDT

: Compressor Discharge Temperature. Used for:

- EEV management

- Protection against overheating of the compressor

- Crankcase heater management

T OCT CDT OAT

[°C]

Resistance

[Kohm]

Voltage

[Vdc]

Resistance

[Kohm]

Voltage

[Vdc]

Resistance

[Kohm]

Voltage

[Vdc]

-40

351,078 2,442 351,078 2,470 349,100 2,442

-35

251,577 2,402 251,577 2,462 250,300 2,402

-30

182,451 2,351 182,451 2,451 181,600 2,350

-25

133,827 2,286 133,827 2,437 133,300 2,285

-20

99,221 2,206 99,221 2,419 98,860 2,205

-15

74,316 2,111 74,316 2,396 74,408 2,111

-10

56,202 2,000 56,202 2,367 56,050 1,999

-5

42,894 1,875 42,894 2,331 42,800 1,874

0

33,024 1,737 33,024 2,287 32,970 1,736

5

25,607 1,590 25,607 2,234 25,570 1,589

10

20,017 1,439 20,017 2,171 20,000 1,438

15

15,769 1,288 15,769 2,099 15,760 1,287

20

12,513 1,141 12,513 2,016 12,510 1,141

25

10,000 1,002 10,000 1,924 10,000 1,002

30

8,045 0,873 8,045 1,823 8,048 0,873

35

6,514 0,756 6,514 1,715 6,518 0,756

40

5,306 0,652 5,306 1,602 5,311 0,652

45

4,348 0,560 4,348 1,485 4,353 0,560

50

3,583 0,480 3,583 1,367 3,588 0,480

55

2,968 0,411 2,968 1,250 2,973 0,411

60

2,472 0,352 2,472 1,137 2,477 0,352

65

2,068 0,301 2,068 1,028 2,073 0,302

70

1,739 0,258 1,739 0,925 1,743 0,258

75

1,469 0,221 1,469 0,829 1,473 0,222

80

1,246 0,190 1,246 0,741 1,250 0,191

85

1,061 0,164 1,061 0,660 1,065 0,164

90

0,9078 0,141 0,9078 0,587 0,911 0,142

95

0,7795 0,122 0,7795 0,521 0,782 0,123

100

0,6718 0,106 0,6718 0,463 0,674 0,107

Page 26

11 Diagnostic table

When unit is working properly:

- DL3 is solid ON

- DL4 is solid ON if the indoor unit is switched ON, otherwise it’s OFF

Page 27

12 Troubleshooting

ERROR LIST

Rank Meaning

System

behaviour

Cause Solution

Power supply surge or

over voltage.

Power supply voltage

dip or interruption.

Power supply fast

transient or burst.

Check the quality of the power

supply.

Bad earth connection. Check that all the earth cables are

correctly connected, expecially the

outdoor pcb's earth cable and the

compressor's earth.

Bad connection

between outdoor and

the heatsink.

Check that the outdoor pcb is

properly connected to the heatsink

and that the screws on the pcb are

properly mounted with the right

torque. Check that there is enough

thermal paste between the pcb and

the heatsink.

EEV damaged. Check the EEV functioning. A

malfunctioning on the expansion

valve may cause liquid flood back on

the compressor.

1 PFC (Power Factor

Controller)

protection:

automatic

protection against

power supply

disturbances and

instabilities.

Compressor and fan

are stopped.

The system restarts

automatically after

3 minutes.

Outdoor pcb damaged. Only if the error is recurrent, change

the outdoor pcb.

Bad communication bus

connection between

outdoor and indoor

unit.

Check that connections between C1

and C2 on outdoor and indoor

terminal block is consistent (C1

terminals connected together, C2

terminals connected together).

Normal cable used

instead of shielded

cable.

Be sure to use a shielded

communication cable for serial

connection.

Wrong communication

address.

Be sure to have set the correct

address on every indoor unit. Follow

unit specific installation instructions.

2 Communication

error between the

outdoor unit and

the indoor unit.

Compressor and fan

are stopped after

30 seconds of

missing

communication.

The system restarts

automatically as

soon as the

communication is

recovered.

Bad earth connections. Check that earth cables are properly

connected to every terminal.

Check that the shield of the

communication cable is properly

connected to every terminal.

Chech that all internal earth cable are

properly connected.

Page 28

Communication fuses

blown.

Check the communication fuse on

outdoor unit.

Check the communication fuse on

indoor unit (only certain models).

Indoor unit not

powered on.

Check that the indoor unit has power

supply and that the unit is working.

Outdoor or indoor unit

pcb out of order.

Check that all the pcbs are powered

on.

Be sure that power supply has not

been connected to the

communication terminals.

Check that there are no burnt signes

on the pcbs, in particular close to

communication cables.

Compressor damaged. Check that there is no continuity

between the phases of the

compressor and the earth (dielectric

strength).

3 Error on the indoor

unit.

Compressor and fan

are stopped.

The system restarts

automatically as

soon as the error

on the indoor unit is

solved.

An error occurred on

the indoor unit.

Follow specific indoor unit

troubleshooting.

Bad connection

between the fan

motor's module and the

heatsink, or missing fan

module's heatsink.

Check that the fan motor module is

properly connected to the heatsink

and that the screws on the module

are properly mounted with the right

torque. Check that there is enough

thermal paste between the fan

module and the heatsink.

The rear of the outdoor

unit is obstructed.

Remove the obstruction.

4 Automatic

protection against

overheating on the

power electronics

(fan motor

module).

Compressor and fan

are stopped.

The system restarts

automatically after

3 minutes.

Incorrect fan operation.

Check that fan works properly.

Fan motor

disconnected.

Check the fan motor connector.

Fan motor blocked /

obstructed.

Remove the obstruction.

Fan motor damaged. Check if the fan motor starts. If it

does not start correctly, change the

fan motor.

5 Automatic

protection against

fan motor

overcurrent.

Compressor and fan

are stopped.

The system restarts

automatically after

3 minutes.

Outdoor pcb damaged. Only if the error is recurrent, change

the outdoor pcb.

Page 29

Bad connection

between the outdoor

pcb and the heatsink.

Check that the outdoor pcb is

properly connected to the heatsink

and that the screws on the pcb are

properly mounted with the right

torque. Check that there is enough

thermal paste between the pcb and

the heatsink.

The rear of the outdoor

unit is obstructed.

Remove the obstruction.

6 Automatic

protection against

overheating on the

power electronics

(compressor

module).

Compressor and fan

are stopped.The

system restarts

automatically after

3 minutes.

Incorrect fan operation.

Check that fan works properly.

Power supply surge or

under voltage.

Check the quality of the power

supply.

There is some air or

moisture inside the

refrigerant circuit.

Be sure to have correctly pulled the

vacuum of the system. In case, pull

the vacuum again and recharge the

outdoor unit with the correct amount

of refrigerant.

Damaged compressor. Check windings of the compressor.

Bad earth connection. Check that all the earth cables are

correctly connected.

Fan damaged. Check that fan motors of indoors and

outdoor units work properly.

7 Automatic

protection against

compressor

overcurrent.

Compressor and fan

are stopped.

The system restarts

automatically after

3 minutes.

Lack of refrigerant in

the refrigerant circuit.

Check the refrigerant amount in the

unit, find and repair a possible

leakage and recharge the unit with

the correct refrigerant amount.

8 OCT (Outdoor Coil

Temperature)

sensor fault.

Compressor and fan

are stopped.

The system restarts

as soon as the

sensor is repaired.

Sensor out of order or

disconnected (check

wiring diagram).

Reconnect or replace the sensor.

9 OAT (Outdoor Air

Temperature)

sensor fault.

Compressor and fan

are stopped.

The system restarts

as soon as the

sensor is repaired.

Sensor out of order or

disconnected (check

wiring diagram).

Reconnect or replace the sensor.

10 CDT (Compressor

Discharge

Temperature)

sensor fault.

Compressor and fan

are stopped.

The system restarts

as soon as the

sensor is repaired.

Sensor out of order or

disconnected (check

wiring diagram).

Reconnect or replace the sensor.

Page 30

13 Component replacement

GR9FI30LTR5IAA

Page 31

GR9FI 30-40-50LTR5IAA

Page 32

GR9FI30LTR5IAA

Page 33

GR9FI30LTR5IAA

Page 34

GR9FI30LTR5IAA

Page 35

GR9FI40-50 LTR5IAA

Page 36

GR9FI40-50 LTR5IAA

Page 37

GR9FI40-50 LTR5IAA

Page 38

GR9FI40-50 LTR5IAA

Page 39

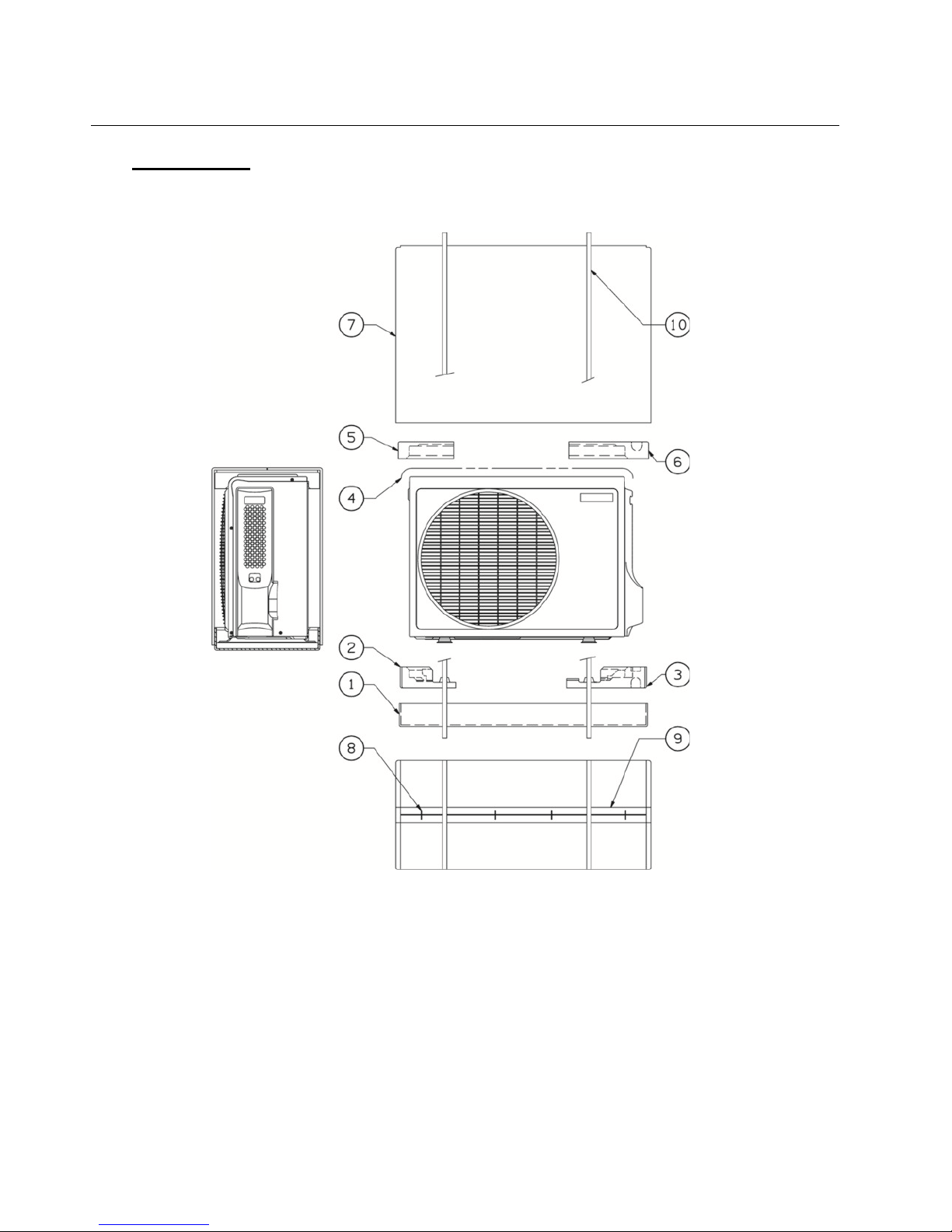

14 Packaging

1: bottom carton box 6: upper right PS shield

2: lower left PS shield 7: carton box

3: lower right PS shield 8: staple

4: polietylene sheet 9: scotch tape

5: upper left PS shield 10: PP band

GR9FI30 LTR5IAA

Page 40

1: bottom carton box 6: upper left PS shield 11: PP band

2: lower left PS shield 7: upper right PS shield

3: lower PS shield 8: carton box

4: lower right PS shield 9: staple

5: polietylene sheet 10: scotch tape

GR9FI40-50 LTR5IAA

Page 41

15 Labels

Energy labels

GR9FI30 LTR5IAA

Page 42

GR9FI40 LTR5IAA

Page 43

GR9FI50 LTR5IAA

Page 44

Rating labels

Page 45

Technibel is a TRADE mark of NIBE ENERGY SYSTEMS FRANCE, used under licence.

.

IMPORTED & DISTRIBUTED BY

ARGOCLIMA SPA - Via Alfeno Varo, 35 - Alfianello (BS) Italy

Loading...

Loading...