Technibel HKE 189R5I, HKE 369R57I, HKE 259R57I, HKE 709R7I, HKE 909R7I Installation Manual And Operating Instructions

...Page 1

GB

INSTALLATION MANUAL

Inverter split air to water heat pump - Indoor unit

HKE 189R5I

HKE 259R57I

HKE 369R57I

HKE 489R57I

HKE 609R57I

HKE 709R7I

HKE 909R7I

Page 2

2

GB

IMPORTANT!

Please read before installation

This air conditioning system meets strict safety and

operating standards.

For the installer or service person, it is important to install or

service the system so that it operates safely and efficiently.

For safe installation and trouble-free operation, you must:

• Carefully read this instruction booklet before beginning.

• Follow each installation or repair step exactly as shown.

• Observe all local, state and national electrical codes.

• Pay close attention to all warning and caution notices given in

this manual.

•The unit must be supplied with a dedicated electrical line.

This symbol refers to a hazard or unsafe practice which can

result in severe personal injury or death.

This symbol refers to a hazard or unsafe practice which can

result in personal injury or product or property damage.

If necessary, get help

These instructions are all you need for most installation sites

and maintenance conditions.

If you require help for a special problem, contact our sale /

service outlet or your certified dealer for additional instructions.

In case of improper installation

The manufacturer shall in no way be responsible for improper

installation or maintenance service, including failure to follow the

instructions in this document.

SPECIAL PRECAUTIONS

• During installation, connect before the refrigerant system and

then the wiring one; proceed in the reverse orden when

removing the units.

When wiring

ELECTRICAL SHOCK CAN CAUSE SEVERE

PERSONAL INJURY OR DEATH. ONLY A

QUALIFIED, EXPERIENCED ELECTRICIANS

SHOULD ATTEMPT TO WIRE THIS SYSTEM.

•

Do not supply power to the unit until all wiring and tubing are

completed or reconnected and checked, to ensure the grounding.

• Highly dangerous electrical voltages are used in this system.

Carefully refer to the wiring diagram and these instructions

when wiring.

Improper connections and inadequate grounding can cause

accidental injury and death.

• Ground the unit following local electrical codes.

• The Yellow / Green wire cannot be used for any connection

different from the ground connection.

• Connect all wiring tightly. Loose wiring may cause overheating

at connection points and a possible fire hazard.

• Do not allow wiring to touch the refrigerant tubing,

compressor, or any moving parts of the fan.

• Do not use multi-core cable when wiring the power supply and

control lines. Use separate cables for each type of line.

When transporting

Be careful when picking up and moving the indoor and outdoor

units. Get a partner to help, and bend your knees when lifting to

reduce strain on your back. Sharp edges or thin aluminium fins

on the air conditioner can cut your fingers.

When installing...

... In a room

Properly insulate any tubing run inside a room to prevent

"sweating", which can cause dripping and water damage to walls

and floors.

... In moist or uneven locations

Use a raised concrete base to provide a solid level foundation

for the outdoor unit.

This prevents damage and abnormal vibrations.

... In area with strong winds

Securely anchor the outdoor unit down with bolts and a metal

frame. Provide a suitable air baffle.

... In a snowy area (for heat pump-type systems)

Install the outdoor unit on a raised platform that is higher than

drifting snow. Provide snow vents.

When connecting r

efrigerant tubing

• Keep all tubing runs as short as possible.

• Use the flare method for connecting tubing.

• Apply refrigerant lubricant to the matching surfaces of the flare

and union tubes before connecting them; screw by hand and

then tighten the nut with a torque wrench for a leak-free

connection.

• Check carefully for leaks before starting the test run.

NOTE:

Depending on the system type, liquid and gas lines may be

either narrow or wide. Therefore, to avoid confusion, the

refrigerant tubing for your particular model is specified as narrow

tube for liquid, wide tube for gas.

When servicing

• Turn the power OFF at the main power board before opening

the unit to check or repair electrical parts and wiring.

• Keep your fingers and clothing away from any moving parts.

• Clean up the site after the work, remembering to check that no

metal scraps or bits of wiring have been left inside the unit

being serviced.

• Ventilate the room during the installation or testing the

refrigeration system; make sure that, after the installation, no

gas leaks are present, because this could produce toxic gas

and dangerous if in contact with flames or heat-sources.

WARNING

CAUTION

WARNING

NOTE: This symbol mark and recycle system are applied only to EU countries and not applied to the countries in the other area

of the world.

Your product is designed and manufactured with high quality materials and components which can be recycled and reused.

This symbol means that electrical and electronic equipment, at their end-of-life, should be disposed separately from your household

waste.

Please dispose of this equipment at your local community waste collection / recycling centre.

In the European Union there are separate collection systems for used electrical and electronic products.

Please help us to conserve the environment we live in!

Page 3

3

GB

SUMMARY

1 - GENERALITIES

1.1 - GENERAL SUPPLY CONDITIONS

• Generally speaking, the material is transported at the consignee’s risk.

• The consignee must immediately provide the carrier with written reserves if he finds any damage caused during transport.

1.2 - RECOMMENDATIONS

• Prior to all servicing or other actions on the equipment, installation, commissioning, operation, or maintenance, the

personnel in charge of these operations shall become familiar with the instructions and recommendations provided in the

installation manual of the unit as well as the elements of the project's technical file.

• The personnel responsible for receiving the unit must conduct a visual inspection in order to identify all damage to which

the unit may have been subjected during transport: refrigerating circuit, electrical cabinet, cassis and cabinet.

• The unit must be installed, started, maintained, serviced by qualified and authorised personnel, in compliance with the

requirements of all directives, laws and regulations and in accordance with standard trade practices.

• During installation, troubleshooting and maintenance operations, the use of pipes as a step: under the stress, the pipe may

rupture and the refrigerant may cause serious burns

1.3 - VOLTAGE

• Before carrying out any operation, check that the voltage indicated on the unit corresponds to the mains voltage.

• Before initiating maintenance or servicing on the installation, check that its power supply is disconnected and locked out.

1.4 - USE OF EQUIPMENT

• This device is designed for heating buildings.

This appliance is not designed to be used by people (including children) whose physical, sensory or mental

capacities are impaired, or who lack experience or knowledge, unless they are supervised or have received

instructions on how to use the appliance by a person who is responsible for their safety. Children must be

supervised to ensure that they do not play with the appliance or its accessories.

1.5 - OPERATING CONDITIONS

• Refer to the technical specifications, the nominal conditions and operating limitations in the technical manual.

MARKING

This product marked conforms to the essential requirements of the Directives:

- Low voltage no. 2006/95/EC.

- Electromagnetic Compatibility no. 2004/108/EC.

1 - Generalities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 - Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 - Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4 - Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5 - Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6 - Starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7 - Maintenance instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

8 - Wiring diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1 - Only the following indoor units are to be used with the outdoor units indicated below:

Indoor units Outdoor units

HKE 189R5I ----> GRFP 189R5I

HKE 259R57I ----> GRFP 259R5I or R7I

HKE 369R57I ----> GRFP 369R5I or R7I

HKE 489R57I ----> GRFP 489R5I or R7I

HKE 609R57I ----> GRFP 609R5I or R7I

HKE 709R7I ----> GRFP 709R7I

HKE 909R7I ----> GRFP 909R7I

2 - See the combinations allowed for the NF PAC (Heat Pump) label in the technical instructions.

3 - For the installation of the outdoor unit, please consult the manual supplied with the unit.

NOTE

IMPORTANT

- Water system drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 4

Page 4

4

GB

2 - PRESENTATION

2.1 - DESCRIPTION

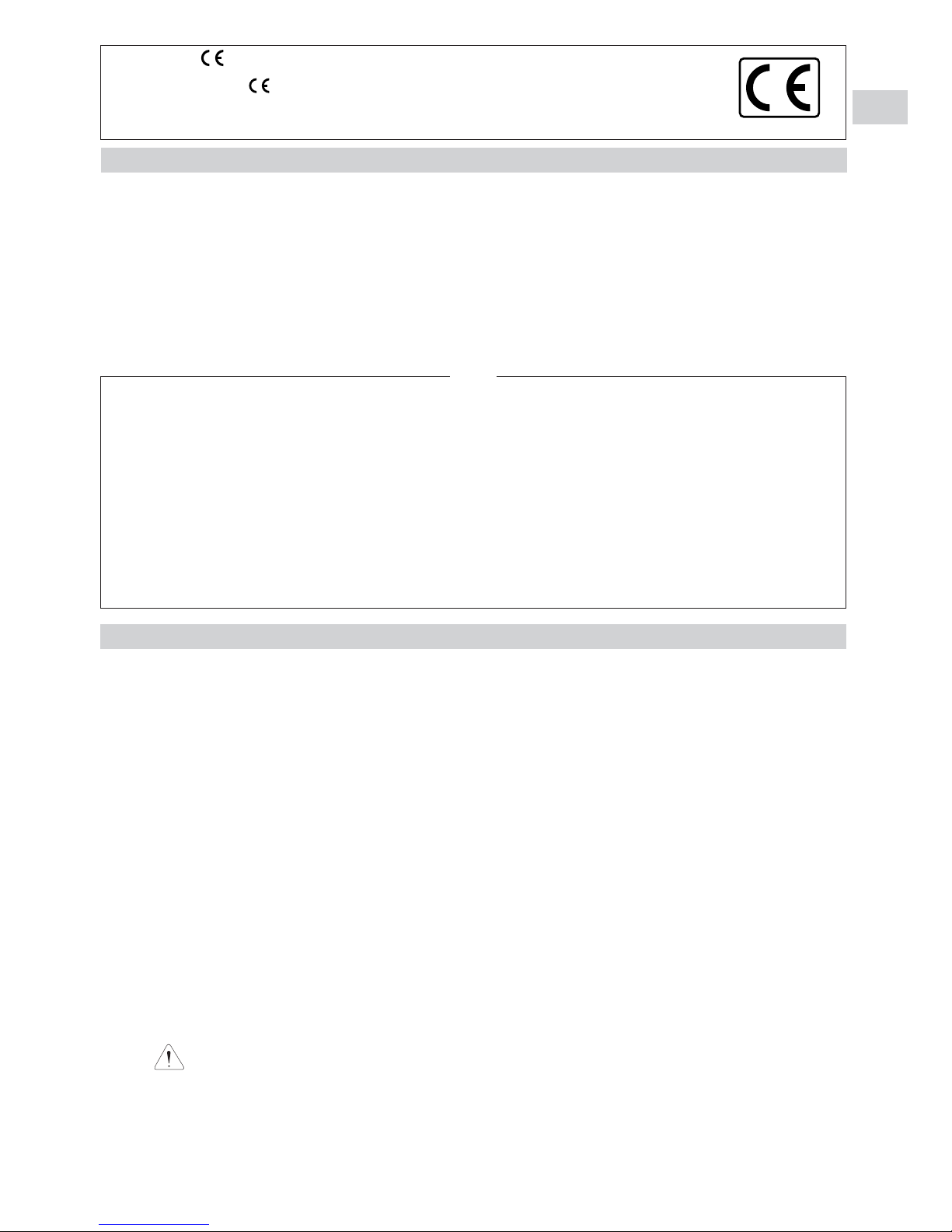

2.1.1 - GENERAL

• Reminder:

- Water system pressure: 2 bar.

- Operating limits:

1 - Plate type heat exchanger.

2 - Electric heater:

HKE 189R:

• 3 kW : 1

st

stage = 1.5 kW; 2ndstage = 1.5 kW.

• 4.5 kW : 1ststage = 3 kW; 2ndstage = 1.5 kW.

HKE 259R, 369R and 489R:

• 4 kW : 1

st

stage = 2 kW; 2ndstage = 2 kW.

• 6 kW : 1ststage = 4 kW; 2ndstage = 2 kW.

HKE 609R:

• 6 kW : 1

st

stage = 3 kW; 2ndstage = 3 kW.

• 9 kW : 1ststage = 6 kW; 2ndstage = 3 kW.

HKE 709R and 909R:

• 8 kW : 1

st

stage = 4 kW; 2ndstage = 4 kW.

• 12 kW : 1ststage = 8 kW; 2ndstage = 4 kW.

3 - Automatic air vent valve.

4 - Water pressostat.

5 - Automatic reset safety thermostat.

6 - Manual reset safety thermostat.

7 - Circulator pump.

8 - Surge tank.

9 - Manual air vent valve.

10 - Hydraulic system pressure gauge.

11 - Safety valve.

12 - Flow detector.

13 - Water inlet connection.

14 - Water outlet connection.

15 - Filling / drainage of the water

system.

16 - Safety valve drain connection.

17 - Flare gas connector.

18 - Flare liquid connector.

19 - Electrical cable passage.

20 - Water system pressure tap for flow

control.

21 - Cover.

22 - Communication module access window.

23 - Electrical box (see in paragraph 2.1.2).

HKE 189R

HKE 259R

HKE 369R

HKE 489R

HKE 609R

HKE 709R

HKE 909R

9

20

7

20

12

23

8

1

3

4

2

6

5

17 10 18 14 16 11 15 13 19

21

22

Materials:

- Copper piping.

- Stainless steel water heat exchanger.

- Painted sheet metal cabinet.

25

35

45

50

35

20-16 -10

5

18

20

35

4310

Outdoor dry air

temperature (°C)

Outdoor dry air

temperature (°C)

Water output

temperature (°C)

Water output

temperature (°C)

Heating mode Cooling mode

HKE 369R / 489R / 609R

25

35

50

35

-16 -10

Outdoor dry air

temperature (°C)

Water output

temperature (°C)

Heating mode

HKE 189R / 259R / 709R / 909R HKE 189R / 259R / 369R / 489R /

609R / 709R / 909R

Page 5

5

GB

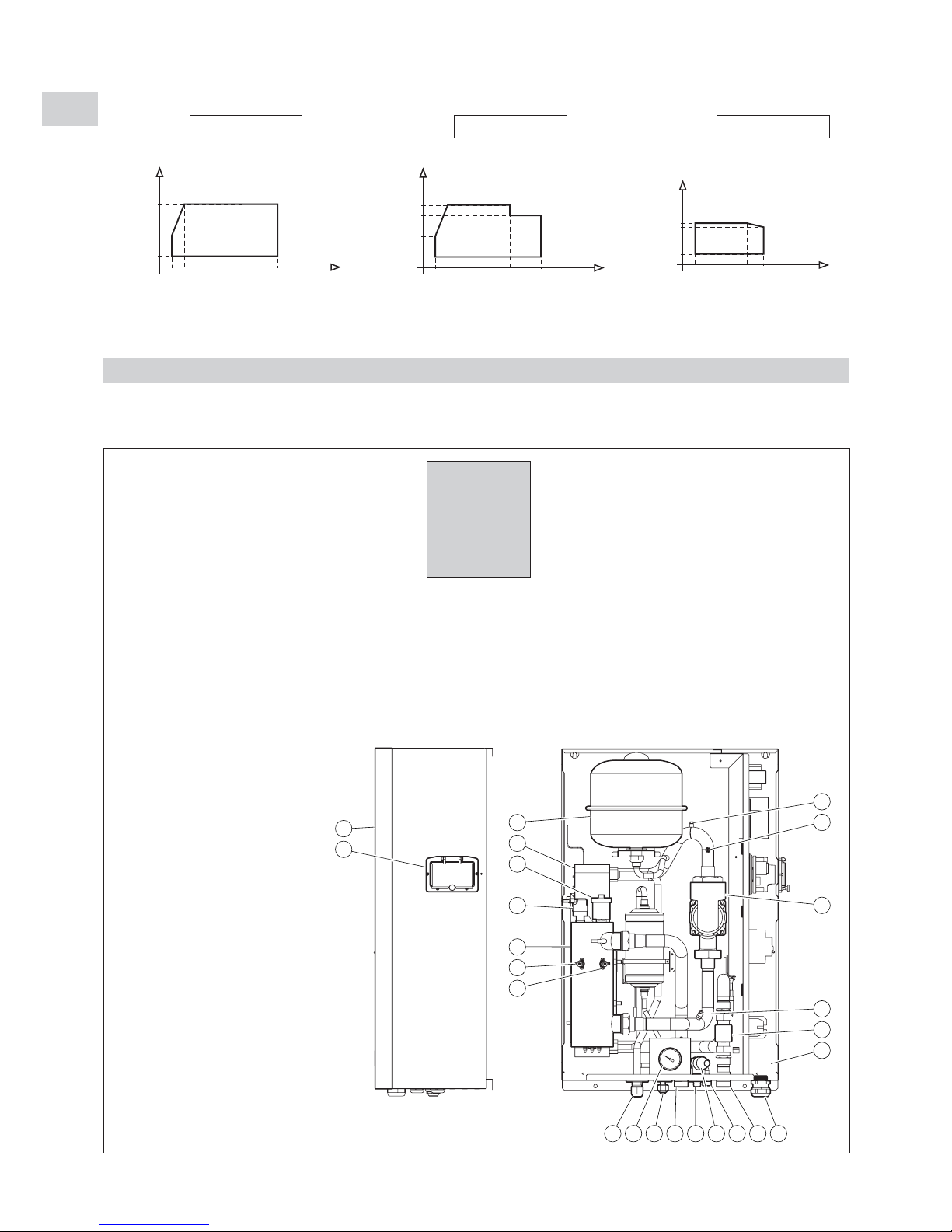

12

11

8

4

3

10

9

5

7

6

2

1

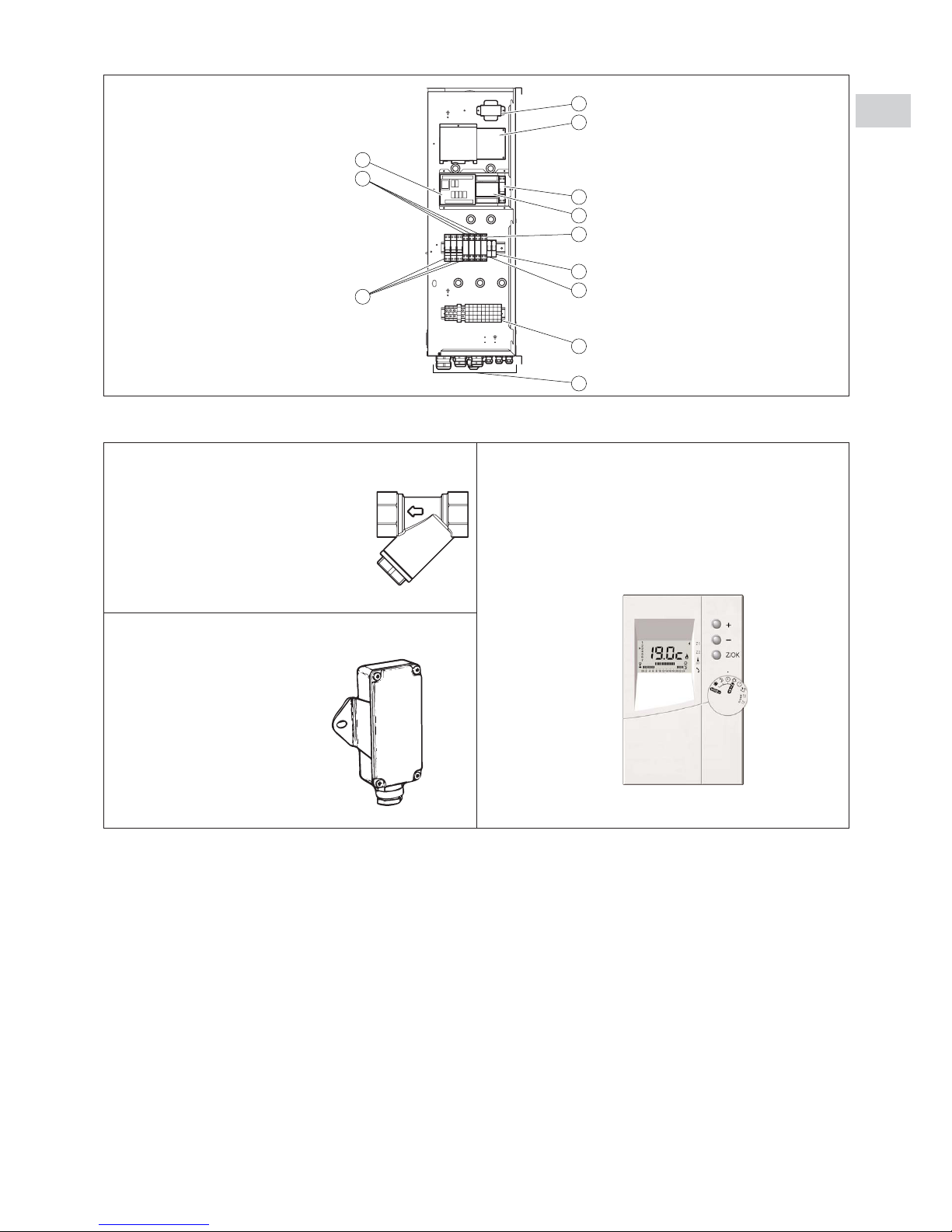

1 - Electrical cable passage.

2 - Terminal strip.

3 - Heating element circuit breakers.

4 - Heating element contactors.

5 - Circulator contactors.

6 - Fault relays.

7 - Water flow rate relay.

8 - Heating control board.

9 - Communication module CC1.

10 - Control circuit circuit-breaker.

11 - Indoor unit board.

12 - Transformer.

2.1.2 - ELECTRICAL BOX

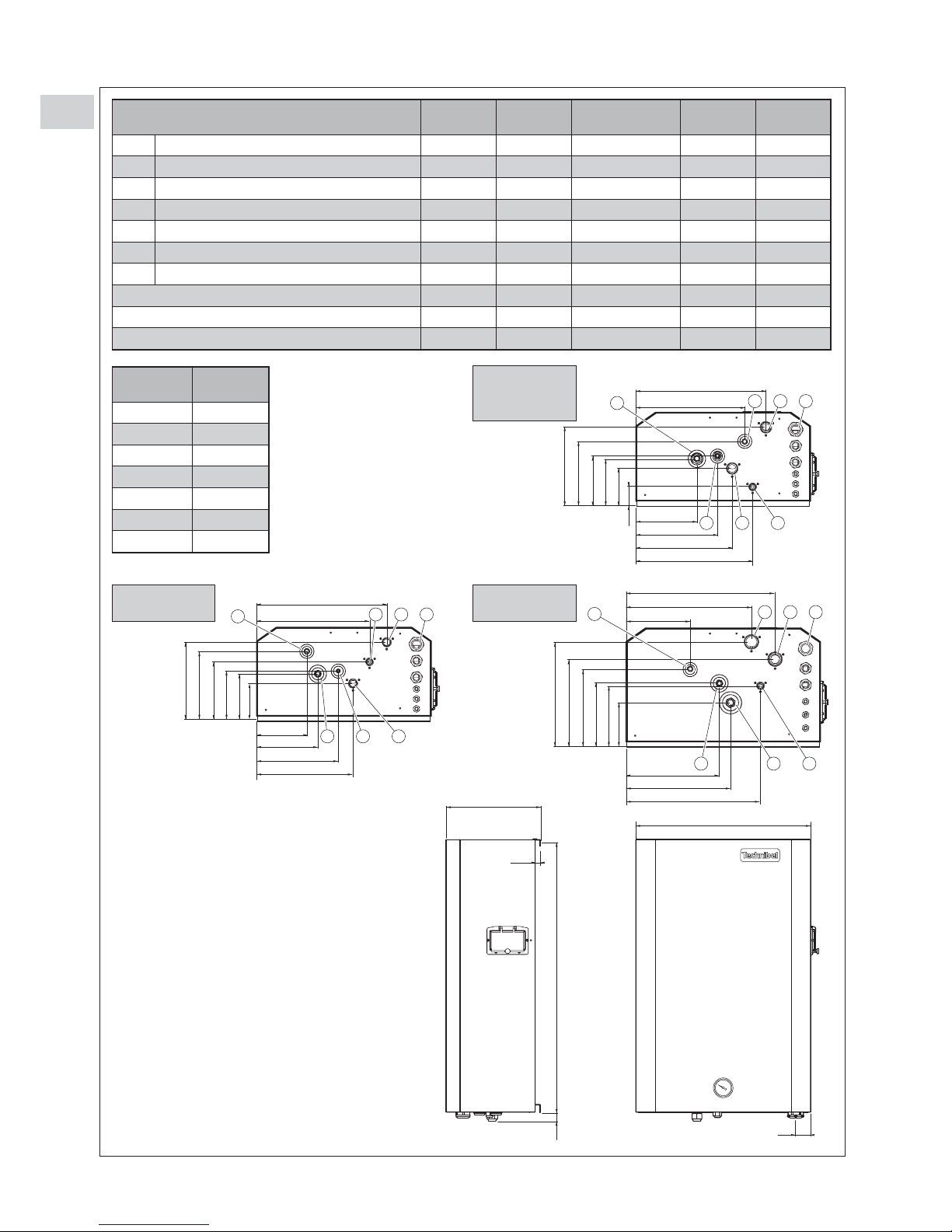

• Hydraulic filter:

- 3/4” FF for HKE 189R and 259R.

- 1” FF for HKE 369R, 489R and 609R.

- 1”1/4 for HKE 709R and 909R.

• Outside temperature sensor:

- Installed in a box with cable gland.

Note:

This sensor must be installed in

a location that is sheltered from

inclement weather.

See details in paragraph 3.4.

• Control unit:

- Plastic wall-mounted control unit.

- Dimensions: height = 128 mm

width = 86 mm

depth = 34 mm

- Colour: White

- Class lll

- IP 30

2.1.3 - ACCESSORIES INCLUDED WITH THE APPARATUS

Page 6

6

GB

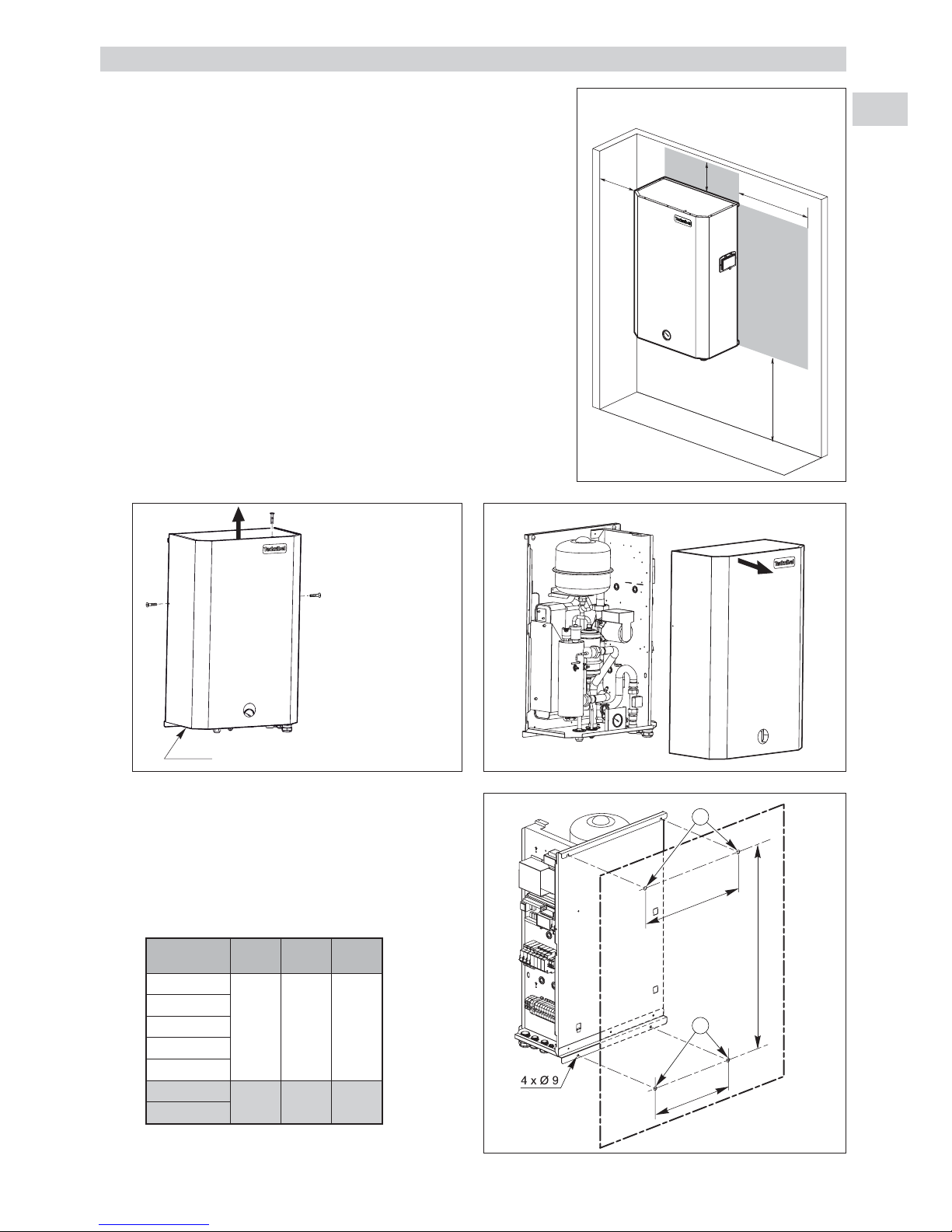

2.2 - DIMENSIONS AND WEIGHT

A

C

B

15.5

45

15.5

184

246

290.5

352

328

392

40.5

96

125

133.5

178

220.5

4 1 7

5

6 2 3

151

184

246

290.5

340

392

96

125

133.5

161

193

220.5

3 1 7

4

5 6 2

194

282

316

406

379

450

116

167

174

216

247

299.5

2 1 7

4

6 5 3

HKE

189R

HKE

259R

HKE

369R/489R/609R

HKE

709R

HKE 909R

1 Water inlet connection 3/4” male 3/4” male 1” male 1”1/4 male 1”1/4 male

2 Water outlet connection 3/4” male 3/4” male 1” male 1”1/4 male 1”1/4 male

3 Water circuit fill / drain 1/2” male 1/2” male 1/2” male 1/2” male 1/2” male

4 Safety valve connection and drainage - - - - -

5 Gas refrigerant connection 1/2” flare 5/8” flare 5/8” flare 3/4” flare 3/4” flare

6 Liquid refrigerant connection 1/4” flare 3/8” flare 3/8” flare 3/8” flare 1/2” flare

7 Holes for electric cables - - - - -

A (mm) 527 527 527 587 587

B (mm) 284 284 284 360 360

C (mm) 825.5 825.5 825.5 925.5 925.5

Weight

(Kg)

HKE 189R 40

HKE 259R 41

HKE 369R 42

HKE 489R 43

HKE 609R 44

HKE 709R 57

HKE 909R 60

HKE 369R

HKE 489R

HKE 609R

HKE 709R

HKE 909R

HKE 189R

HKE 259R

Page 7

7

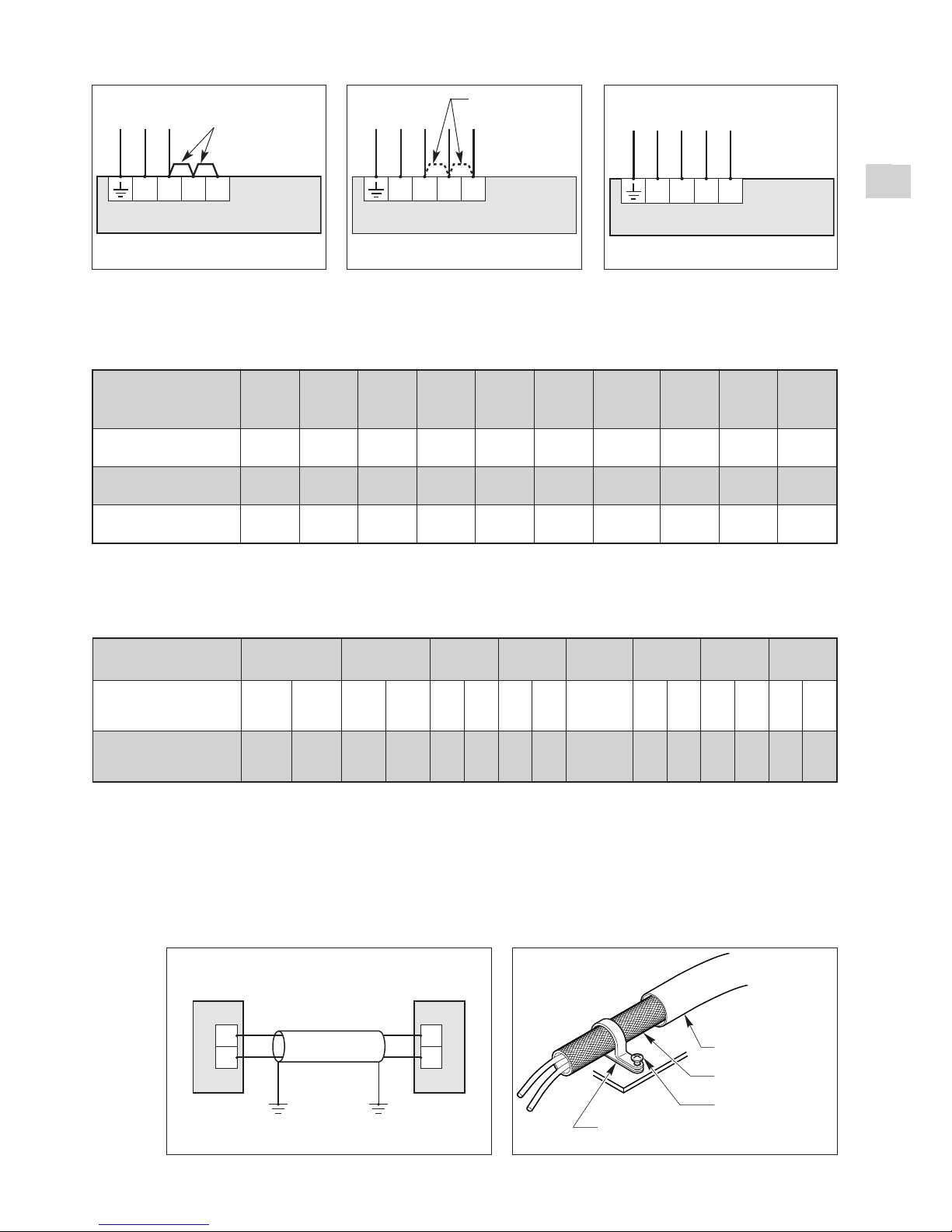

3 - INSTALLATION

3.1 - LOCATION

• Protection index of the unit: IP 21.

•

Select the location for the unit on the basis of the following criteria

:

- the unit must be installed in a sheltered location,

- the unit must not be installed near the following:

. sources of heat,

. combustible materials,

. return / air intake of an adjacent building.

- it is necessary to make sure that the free space around the unit is

provided (see the minimum dimensions on the drawing opposite),

- installation must be simple and make maintenance work easy,

- the unit must be secured to a wall able to support its weight.

3.2 - MOUNTING THE UNIT

• Remove the cover from the unit:

- remove the retaining screws (1 on each side and 1 on top) (1).

• Slide the cover upward (2), until the bottom edge of the covers is aligned

with the lower part of the rear support, then pull it towards you (3).

• Secure the unit to the wall. Refer to the position of the 4

mounting holes in the diagram opposite.

Use anchors and screws (not included) that are adapted

to the weight of the unit and the type of wall.

- Install the 2 screws in place in the upper holes (A) in

the wall.

- Hook the unit in place.

- Install the 2 screws in place in the lower holes (B).

0.80 m

0.20 m

0.20 m

1 m

3

A

B

Z

X

Y

Minimum clearance in front of the unit: 1 m

1

1

1

2

Align the bottom edge of the cover with the

lower part of the rear support

GB

X (mm) Y (mm) Z (mm)

HKE 189R

460 360 800

HKE 259R

HKE 369R

HKE 489R

HKE 609R

HKE 709R

520 420 900

HKE 909R

Page 8

8

GB

• Replacing the cover.

- Present the cover on the unit while aligning the lower

edge with the lower part of the rear support.

- Fit the cover against the rear support to engage the

hooks in the notches (1).

- Slide the cover downward fully into place (2).

- Replace the retaining screws.

. Note: the screw (T) on top of the unit ensures the

cover's ground continuity. This is a special screw

and only this model should be used.

. The screw on the left-hand side is used primarily

for transport. In the case of insufficient clearance

(too close to a wall), this screw need not be

replaced.

3.3 - CONTROL UNIT INSTALLATION

• As the control unit is equipped with a temperature sensor, it must be

installed in a location that is representative of the temperature in zone 1.

• Note: For 2-zone applications, an ambient temperature sensor (zone 1)

(accessory) can be connected on the 2-zone module thus doing away

with the need to install the control unit in zone 1.

• Wall mounting: the unit must not be installed in corners, on shelves or

behind curtains, near sources or heat or directly exposed to sunlight. The

unit should be installed approximately 1.5 m above the floor.

• Open the box by removing the lower screw and secure the base to the

wall (mounting holes, item (1)).

• Open the protective cover (screw (2)) and connect the

BUS link to the control board (see diagram in paragraph

4.3.4.).

• Fit the control unit back on its base.

3.4 - INSTALLATION OF THE OUTDOOR

TEMPERATURE SENSOR

•

This sensor must be located outside in a location that is

representative of the temperature to be measured (on a wall

facing North / North-west) and located away from parasitic

heat sources (chimney, thermal bridge, etc..) and sheltered

from inclement weather (under a roof overhand, for

example).

• Connection as per paragraph 4.3.4.

1

2

T

Bottom of cover

Lower part of

the rear

support

Align

1

2

Base

Rear view

1.50 m

Control unit

Mini. 20 cm

Page 9

9

GB

4 - CONNECTIONS

4.1 - REFRIGERATION CONNECTIONS

Outdoor unit

Indoor unit

Gas line

Liquid line

• For the connecting pipes, use the flare nuts provided with the unit or nuts intended for the R 410 A.

• Connect the units with the connecting tubes in accordance with the table below.

R 410 A

• R 410 A is a high-pressure refrigerant (+ 50% in relation to

R 22 and R 407 C).

• The compressors approved for operation with this fluid are

filled beforehand with polyalcohol oil.

Contrary to mineral oil, it is very hygroscopic: it absorbs the

humidity of the ambient air very quickly. This can modify its

lubricant properties and lead in time to the destruction of the

compressor.

MAINTENANCE INSTRUCTIONS

1 - Never add oil to the appliance; the compressor is filled

with polyalcohol oil, a special oil which cannot tolerate the

presence of other oils.

2 - The instruments used for:

- filling,

- pressure measurements,

- emptying under vacuum,

- recovering the fluid,

must be compatible and only used for the R 410 A fluid.

Note: the pressure taps of the refrigerating circuit are

5/16 SAE (1/2 - 20 - UNF).

3 - In the case of a new charge:

- the charge must be undertaken in liquid phase,

- use a balance and a dip pipe type R 410 A cylinder,

- charge the weight of R 410 A as per the value indicated

on the unit’s identification plate (for “split systems”, refer

to the installation instructions as the charge must

consider the length of the connecting lines).

4 - In case of leakage, do not complete the charge: recover

the remaining refrigerant for recycling and perform a total

charge.

Recovery, recycling or the destruction of the fluid must be

done in compliance with the laws in force in the country

concerned.

5 - If the refrigerant circuit is opened, you must:

- avoid the entry of air into the circuit as much as

possible,

- replace or install a drier,

- perform the “vacuum operation” at a minimum level of

0.3 mbar (static).

6 - Do not release R 410 A fluid into the atmosphere. This

fluid is a fluorinated greenhouse gases, covered by the

Kyoto Protocol with a Global Warming Potential (GWP) =

1975 - (CE Directive 842 / 2006).

APPLIANCES FILLED WITH R 410 A

Model 189R Model 259R Model 369R Model 489R Model 609R Model 709R Model 909R

ø Liquid tube

1/4”

(6.35 mm)

3/8”

(9.52 mm)

3/8”

(9.52 mm)

3/8”

(9.52 mm)

3/8”

(9.52 mm)

3/8”

(9.52 mm)

1/2”

(12.7 mm)

ø Gas tube

1/2”

(12.7 mm)

5/8”

(15.88 mm)

5/8”

(15.88 mm)

5/8”

(15.88 mm)

5/8”

(15.88 mm)

3/4”

(19.05 mm)

3/4”

(19.05 mm)

Minimum pipe length 3 m 3 m 3 m 3 m 3 m 5 m 5 m

Maximum pipe length without

addition of refrigerant load

10 m 10 m 10 m 10 m 10 m 10 m 10 m

Maximum pipe length with addition

of refrigerant load

30 m 30 m 30 m 30 m 30 m 30 m 30 m

Additional load per meter 20 g 40 g 40 g 40 g 40 g 40 g 80 g

Page 10

10

GB

• For the following information:

- Maximum height between units.

- Required tools.

- Advice concerning the piping installation.

- Connection to the outdoor unit.

- Leak testing.

- Vacuum operation.

- Additional refrigerant charge.

Refer to the installation instructions provided with the outdoor unit.

• For the connection to the indoor unit's flare couplings, use 2 wrenches to

maintain the coupling.

Tighten to the following tightening torque values:

- ø 1/4”: 14 - 18 N.m.

- ø 3/8”: 34 - 42 N.m.

- ø 1/2”: 49 - 61 N.m.

- ø 5/8”: 68 - 82 N.m.

- ø 3/4”: 100 - 120 N.m.

4.2 - HYDRAULIC CONNECTION

4.2.1 - WATER INLET AND OUTLET CONNECTION

• Connect the w ater inlet and outlet lines to the corresponding

couplings.

• Install the hydraulic filter (1) (supplied) on the water intake. Connect it

using 2 isolation valves (2) (not supplied) for cleaning purposes.

• "Water connection hose" accessories may be used (refer to the

accessories paragraph).

4.2.2 - FILLING / DRAINAGE CONNECTION

• A coupling is available for filling or draining water from the unit.

• To use this connection, install a shut-off valve with drain tap (3) (not

supplied).

4.2.3 - SAFETY VALVE CONNECTION

• The unit is equipped with a safety valve that opens if the pressure in

the hydraulic system exceeds 3 bar.

A flexible hose (4) (not supplied) can be connected to the coupling

insert (coupling OD: 18 mm).

• Note: use the safety valve tap to complete the draining of the unit.

4.3 - ELECTRICAL CONNECTION

4.3.1 - GENERAL:

• The acceptable voltage variation is: ± 10% during operation.

• The electrical connection conduits must be fixed.

• Use the cable clamps underneath the unit and route the wires into the electric panel, to the terminal strips.

• Class 1 unit.

• The electrical installation must comply with the standards and regulations applicable where the unit is being installed (in

particular NF C 15-100 ≈ IEC 364).

4.3.2 - POWER SUPPLY

• The power supply must come from an isolation and electric protection device (not supplied) in accordance with existing

regulations.

• A two-pole circuit breaker (not supplied) must be installed to protect single-phase equipment or a three-pole circuit

breaker (not supplied) for three-phase equipment. See the intensity ratings table.

Note 1

:

The unit is designed to be connected to a power supply having a TT neutral regime (neutral to ground) or TN.S regime

(to neutral) as per NF C 15-100.

1

2

3

4

Page 11

11

GB

POWER SUPPLY CABLE

- Section: see amperage table.

- The sections are given as an indication only. They have to be verified and adapted, if necessary, according to the

installation conditions and the standards in force.

CURRENTS AND CROSS-SECTIONS

(*) With 6 kW electric heating module only.

SELECTION OF ELECTRIC HEATING MODULE POWERS

- To obtain the maximum electric heating module power ratings, the jumper must be installed between 22 and 23 on

terminal strip XA (jumper included).

4.3.3 - CONNECTION WITH THE OUTDOOR UNIT

- The control connection between the indoor unit and the outdoor unit is made by a shielded 0.75 mm2cable

(AWG #18), with the shielding grounded at both the indoor unit and outdoor unit side.

- Maximum length 70 meters.

- The cable's shielding must be grounded at both ends by means of a metal clamp (not supplied) screwed onto the

terminal strip support plate.

- To avoid problems related to electromagnetic disturbances, do not route this cable near power cables.

1

2

U1

U2

Outdoor Unit Indoor Unit

Interconnect cable

between the indoor

unit and the outdoor

unit

Shielding

Screws (not supplied)

Metal clamp (not supplied) screwed to

the terminal strip's support plate

Grounding of the

cable shielding:

SPW-W706/906

N L1 L2 L3

Single-phase power supply

400V / 3+N+T / 50Hz

PE N

Ph1 Ph2 Ph3

Terminal

strip XA

SPW-W186/256/366/486/606

N L1 L2 L3

Single-phase power supply

230V / 1+T / 50Hz

PE N Ph

Jumper

Terminal

strip XA

SPW-W366/486/606

N L1 L2 L3

PE N Ph

Remove the

jumper

Terminal

strip XA

Model

SPWW186

230/1/50

SPW-

W256

230/1/50

SPWW366

230/1/50

SPWW366

400/3N/50

SPWW486

230/1/50

SPWW486

400/3N/50

SPWW606

230/1/50 (*)

SPWW606

400/3N/50

SPWW706

400/3N/50

SPWW906

400/3N/50

Rated input

amperage A

20.5 20.5 27 9.5 27 9.5 27 14 19 19

Protection rating A

25 25 32 12 32 12 32 16 25 25

Power supply cable

size

3G4mm23G4mm23G6mm25G2.5mm23G6mm25G2.5mm23G6mm25G2.5mm25G4mm25G4mm

2

Model

SPW-W186 SPW-W256

SPW-W366 SPW-W486

SPW-W606

single

SPW-W606

three

SPW-W706 SPW-W906

Jumper between

22 and 23 of terminal

strip XA

no yes no yes

no

yes no yes no no yes no yes no yes

Electric heating

module powers kW

3

(1.5+1.5)

4,5

(3+1.5)3(1.5+1.5)

4,5

(3+1.5)4(2+2)6(4+2)4(2+2)6(4+2)

6

only

(3+3)

6

(3+3)9(6+3)8(4+4)12(8+4)8(4+4)12(8+4)

Page 12

12

Note 2:

The sizing of the power supply cables is to be ensured by the installer in accordance with the installation conditions and

as per current standards.

Cable sizes, indicated below, are given for information purposes.

They are calculated in accordance with NFC 15-100 (≈ CEI 364) with the following hypotheses:

- Maximum current, see table below.

- Multi-pole copper cable with PR insulation.

- Installation in conduit (installation method No. 3 A / 4 A / 5 A). No other power cable.

- Ambient temperature 35°C.

Note 3

: Electromagnetic compatibility - Harmonic currents:

• The model 189R complies with the requirements of standard EN61000-3-2 defining the limits for harmonic current

emissions.

• Models 259R / 369R / 489R / 609R / 709R / 909R comply with the requirements of standard EN61000-3-12 defining the

limits for harmonic current emissions

In this case, for these models, the minimum short-circuit ratio “R

sce

” value to be respected is 250.

This value must be checked according to the characteristics of the network to which the installation is connected.

• Single-phase R

sce

=

• Three-phase R

sce

=

- Such that: Sc = Three-phase short-circuit power of the network.

Sc =

where: U

nominal

= nominal voltage between phases,

Z = impedence of the network at the main's frequency.

- Such that: Seq = Assigned apparent power of the unit,

single-phase Seq = Upx I

abs

(Up= single-phase voltage),

Three-phase Seq = x Uix I

abs(Ui

= voltage between phases).

4.3.2.1 - 230 V single-phase power supply

• Power is supplied separately on the indoor unit's power terminal. See diagram below.

Note

: consult the outdoor unit's installation manual regarding its power supply.

3

Sc

3 x Seq

Sc

Seq

U

2

nominal

Z

Power supply amperages and cable sizes

- The sections are given as an indication only. They have to be verified and adapted, if necessary, according to the

installation conditions and the standards in force.

(*) With 6 kW electric heating module power only.

HKE

N L1 L2 L3

Single-phase power supply

230 V / 1 + T / 50 Hz

N Ph

Bridge

Terminal

strip XA

Model

HKE 189R

230 / 1 / 50

HKE 259R

230 / 1 / 50

HKE 369R

230 / 1 / 50

HKE 489R

230 / 1 / 50

HKE 609R

230 / 1 / 50 (*)

Rated input

amperage (A)

20.5 27 27 27 27

Protection rating (A)

25 32 32 32 32

Power supply cable

size

3 G 4 mm

2

3 G 6 mm23 G 6 mm23 G 6 mm23 G 6 mm

2

GB

Page 13

13

1

2

U1

U2

Model

HKE

189R

HKE

259R

HKE

369R

HKE

489R

HKE

609R

single

HKE

609R

three

HKE

709R

HKE

909R

Bridge between

22 and 23 of terminal

strip XA

no yes no yes

no

yes no yes no no yes no yes no yes

Electric heating

module powers kW

3

(1.5+1.5)

4,5

(3+1.5)4(2+2)6(4+2)4(2+2)6(4+2)4(2+2)6(4+2)

6

only

(3+3)

6

(3+3)9(6+3)8(4+4)12(8+4)8(4+4)12(8+4)

Outdoor Unit Indoor Unit

Interconnect cable

between the indoor

unit and the outdoor

unit

Shielding

Screws (not supplied)

Metal clamp (not supplied) screwed

to the terminal strip's support plate

Grounding of the

cable shielding:

4.3.2.2 - 400 V three-phase power supply

• Provide a common power supply for both the outdoor unit and the indoor unit.

• The indoor unit power cable is connected to the outdoor unit's terminal strip. See diagram below.

Note

: the indoor unit's power cable must be the same size as the general power supply cable.

N L1 L2 L3

N L1 L2 L3

Single-phase power supply

400 V / 3 + N + T / 50 Hz

N Ph1 Ph2 Ph3

Remove the bridges

(for HKE 259R / 369R /

489R / 609R)

Terminal

strip XA

Terminal

strip XA

Outdoor unit GRFP

Indoor unit HKE

Power supply amperages and cable sizes

- The sections are given as an indication only. They have to be verified and adapted, if necessary, according to the

installation conditions and the standards in force.

(*) With maximum electric heating module power (see below).

4.3.2.3 - Selection of electric heating module powers

• To obtain the maximum electric heating module power ratings, the bridge must be installed between 22 and 23 on

terminal strip XA (bridge included).

Model 259R 369R 489R 609R 709R 909R

Maximum

input

amperage

(A)

Indoor unit HKE (*) 9.5 9.5 9.5 14 19 19

Outdoor unit GRFP 8.2 9 12.5 14 12.5 15

Total 17.7 18.5 22 28 31.5 34

Protection rating (A) 20 20 25 32 40 40

Power supply cable size 5 G 4 mm25 G 4 mm25 G 4 mm25 G 6 mm25 G 6 mm25 G 6 mm

2

4.3.3 - CONNECTION WITH THE OUTDOOR UNIT

• The control connection between the indoor unit and the outdoor unit is made by a shielded 0.75 mm2cable (AWG #18),

with the shielding grounded at both the indoor unit and outdoor unit side.

• Maximum length 70 meters.

• The cable's shielding must be grounded at both ends by means of a metal clamp (not supplied) screwed onto the

terminal strip support plate.

• To avoid problems related to electromagnetic disturbances, do not route this cable near power cables.

GB

Page 14

14

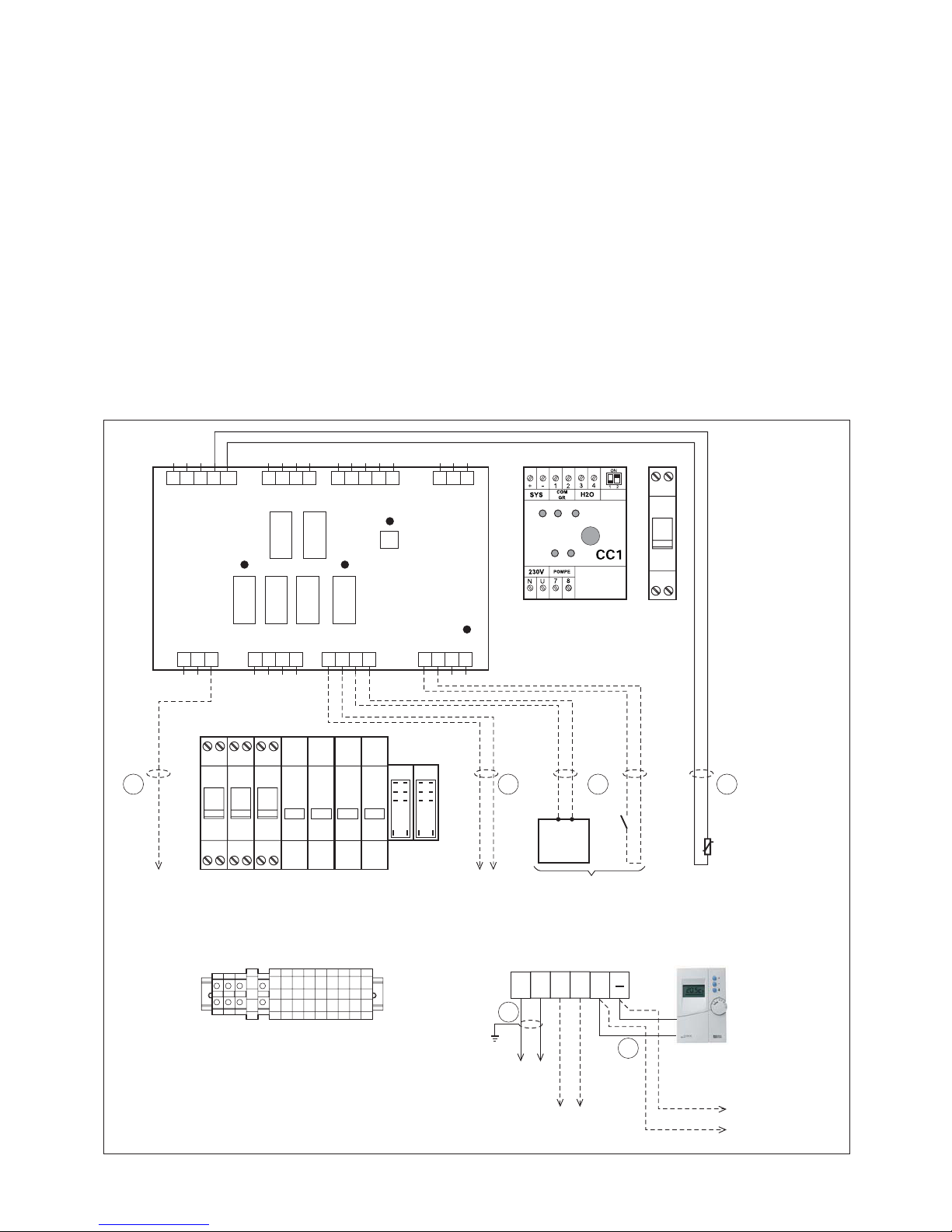

4.3.4 - OTHER CONTROL CONNECTIONS

Caution:

To avoid problems related to electromagnetic disturbances, do not route these cables near power cables.

B

D

C

A

A1

A2

CC1

Control unit

With built-in ambient temperature sensor.

To be installed in zone 1.

Load shedding

(if installed)

Outside air

temperature

Outdoor unit

Installation

water outlet

temperature

Installation

water return

temperature

A) BUS

- 2-conductor shielded cable, minimum size 1 mm2with shielding grounded on indoor unit side (*).

- Total length of the BUS connection: 40 meters (indoor unit / control box connection + indoor unit / 2-zone module

connection, if any or possible DHW tank).

- To be connected to the (+) and (-) terminals if terminal strip XB.

(*) Refer to the ground shielding principle in paragraph 4.3.3.

B) Outside temperature sensor

- 2-conductor cable, min. size 0.5 mm

2

.

- Maximum length 25 meters.

- To be connected to the heating board A1.

- Note:

This sensor must be located outside in a location that is representative of the temperature to be measured (on a wall facing

North / North-west) and located away from parasitic heat sources (chimney, thermal bridge, etc..) and sheltered from

inclement weather (under a roof overhand, for example)

.

C) Outdoor unit control connection

- 2-conductor shielded cable with shielding grounded on both the outdoor unit and indoor unit side.

- Minimum cable size: 0.75 mm

2

.

- Maximum length 70 meters.

- Connection as per paragraph 4.3.3.

D) Module additional heating load shedding signal (if installed)

- Two possibilities:

1) By a "remote info" signal coming from the electrical utility meter: 1 twisted pair (6/10) cable with shielding (shielding

grounded on module side).

2) By a good quality, potential-free external contact.

- Contact closed = load shedding of the additional electric heating.

- 2-conductor cable, min. size 0.5mm

2

.

- Maximum length 25 meters.

- To be connected to the heating board A1.

Indoor unit

GB

Page 15

15

GB

F) ECO signal for remote controls (if installed)

- In order to send reduced mode orders (Eco or standby) to the terminal unit remote control units in the case of

applications such as 1 terminal unit zone or 2 mixed zones.

- In the form of a potential-free contact which can used in VLV (Very Low Voltage), 2 A max.

- To be connected to the heating board A1.

- Note:

The contact can control up to 10 RCC10 (70250051) or RCC20 (70250052) type controls.

Consult the terminal unit and remote control documentation to connect this contact.

CONTROL PART CONNECTION DIAGRAM

- Route the control cables on the right side of the board.

- Pass the pilot wire (230 V) on the left side of the board.

1 2

CN1

230V

CN2 CN3 CN4

CN8 CN7 CN6 CN5

3

5 4 3 2 1 4 3 2 1 45 3 2 1 3 2 1

N U FP R1 R2 R3 C E1 E2 T+

H1A1 C A2 C4 3 2 1S1 C S2 C S3 A3 H2 H3

T- D1 D2 + -

1 2 3 4 1 2 3 4 1 2 3 4

F

D B

A

C

A1

Q4

N U

Q1

N UQ2N UQ3N U

KM1 KM2 KM3 KM4

KA1 KA2

U1 U2

1 2

R1 R2 +

E

Pilot wire

Electric

convectors

(if any)

ECO signal

(if any)

Electrical

utility

meter

Load shedding

(if installed)

Control unit

BUS connection to:

2-zone module

M2ZP or

M2ZM (if any) or

DHW tank KPECS

(if any)

OR

Outside

temperature

sensor

Heating

board

Power terminal strip XA

Control terminal strip XB

To Outdoor

Unit

Maintenance

keypad / display

unit

Page 16

16

GB

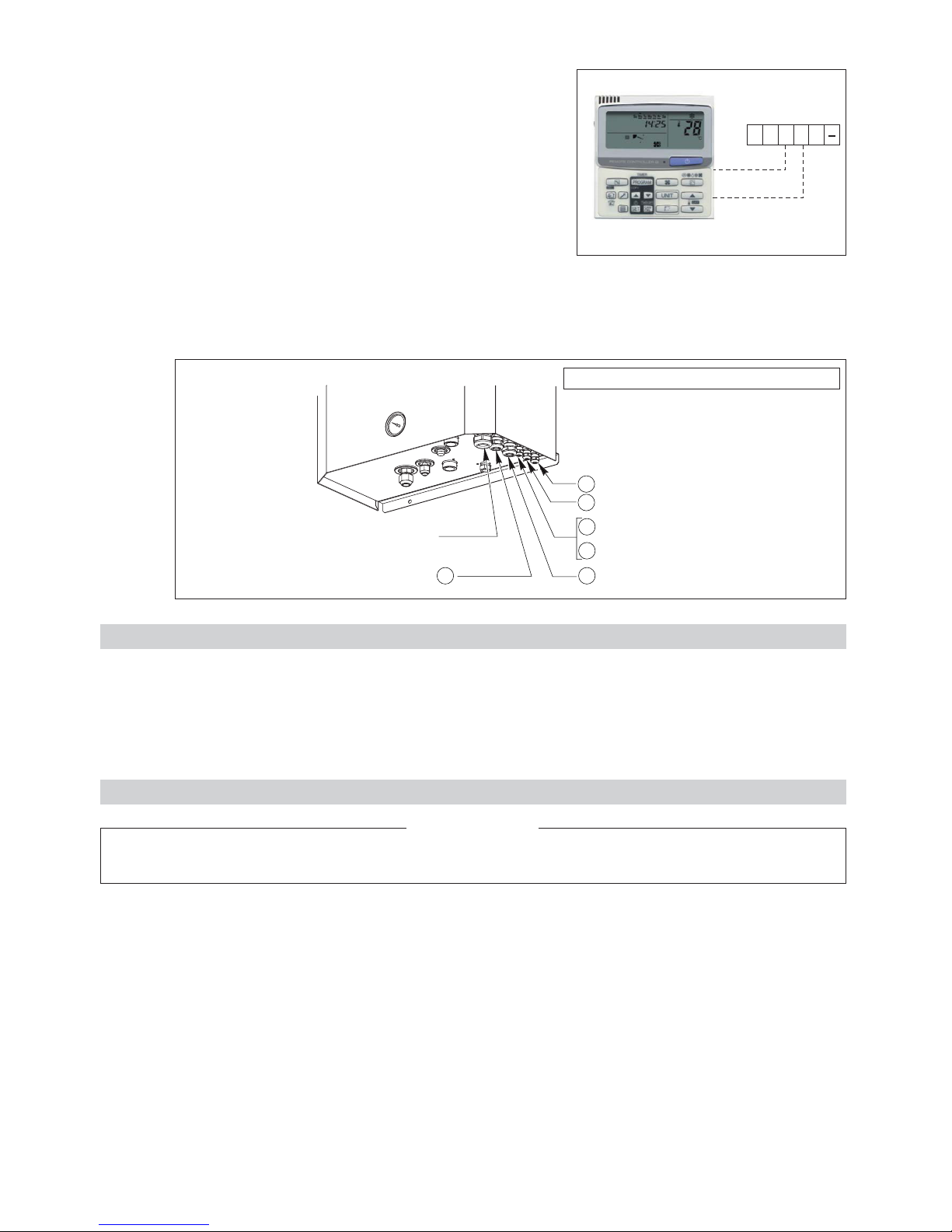

4.3.5 - MAINTENANCE KEYPAD / DISPLAY UNIT CONNECTION

• A specific keypad / display unit can be connected for maintenance

and troubleshooting operations. See maintenance manual.

Note:

This keypad / display unit must not be used for the installation's

normal operation.

4.3.6 - ROUTING OF CABLES

• To avoid problems related to electromagnetic disturbances, avoid routing control cables near power cables.

• Pass the cables through the cable glands.

• Route the control cables on the right side of the electric board.

• Pass the pilot wire (230 V), if used, on the left side of the electric board.

U1 U2 R1 R2 +

B

A

D

F

CE

Terminal XB

of the indoor unit

Black

White

BUS

Outside air temperature sensor

ECO signal for remote controls

+

Load shedding signal

Outdoor unit control connection

Pilot wire for electric convectors

Power supply

Bottom view of the indoor unit

5 - ACCESSORIES

5.1 - WATER CONNECTION HOSES

• Length 1 m, insulated, female:

- Ø 3/4” code 70600054 for HKE 189R and 259R.

- Ø 1” code 70600055 for HKE 369R, 489R and 609R.

- Ø 1”1/4 code 70600027 for HKE 709R and 909R.

6 - STARTING

Before carrying out any work on the installation, make sure that it is switched off and that access to it is prevented.

Any work must be carried out by personnel qualified and authorised to work on this type of machine.

IMPORTANT NOTE

Also refer to the installation instructions provided with the outdoor unit.

6.1 - PRELIMINARY CHECKS

6.1.1 - COOLING CIRCUIT

• Refrigeration couplings correctly tightened.

• Both of the outdoor unit's shutoff valves are open.

• integrity of the cooling circuit (per Decree of 7 May 2007).

• Also refer to the verifications indicated in the outdoor unit's installation instructions.

6.1.2 - HYDRAULIC CIRCUIT

• Hydraulic couplings correctly tightened.

• Hydraulic circuit operating correct:

- purge of circuits,

- position of valves,

- hydraulic pressure (2 bar),

• Integrity of the hydraulic circuit.

Page 17

17

GB

• Water quality:

- In order for the heat pump to operate under good conditions and provide optimum performance, it is essential to

ensure that the system’s water circuit is clean. If the water circuit becomes clogged, this will significantly affect the

machine’s performance. The circuit must therefore be cleaned with suitable products in compliance with current

standards as soon as it is installed, both for new and renovation work.

We recommend the use of products which are compatible with all metals and synthetic materials and approved by

official bodies.

Recommendations regarding water quality:

- PH: 6 to 9,

- TH: 10 to 20°F,

- Dry material in suspension: < 2 g/l,

- Granulometry: < 0.4 mm,

- Chloride: 50 mg/l maximum,

- Conductivity: 50 to 500 µS/cm2,

- Resistivity: 1 to 10 kΩ,

- Fibre: no fibres.

Any disorder which may occur on our machines due to the poor quality of the fluid in the installation will not be

covered by the warranty.

6.1.3 - ELECTRICAL SYSTEM

• The power cables are well fixed to their connection terminals. Terminals that are poorly tightened may cause overheating

and malfunctions.

• The electric cables are well insulated from any sections of sheet metal or metal parts which could damage them.

• The probe, control and power cables are properly separated.

• The machine is earthed.

6.1.4 - MISCELLANEOUS

• Overall good condition of the apparatus.

• No tools or other foreign objects inside the apparatus.

6.2 - CONFIGURATION AND PARAMETERISATION

6.2.1 - AUTO-ADDRESSING OF INDOOR AND OUTDOOR UNITS

• Set the control unit selector to “OFF”.

• Turn on the indoor and outdoor units. The unit cycles through an automatic addressing phase when the power is first

turned on. This phase may take 2 to 3 minutes and is indicated by the alternate blinking of LED1 and LED2 on the

outdoor unit card.

When these indicator lights cease blinking, addressing is completed and communication between the indoor and outdoor

unit is established.

Note 1:

The addressing phase is indicated on the screen of the keyboard / display unit (if installed) by the flashing “SETTING”

message.

Note 2:

Should a problem arise during this automatic addressing phase, a new phase can be restarted. To do this, simply

disconnect the power supply for at least 1 minute and when power is restored, press the black “AUTO ADD” button on

the outdoor unit's electronic board.

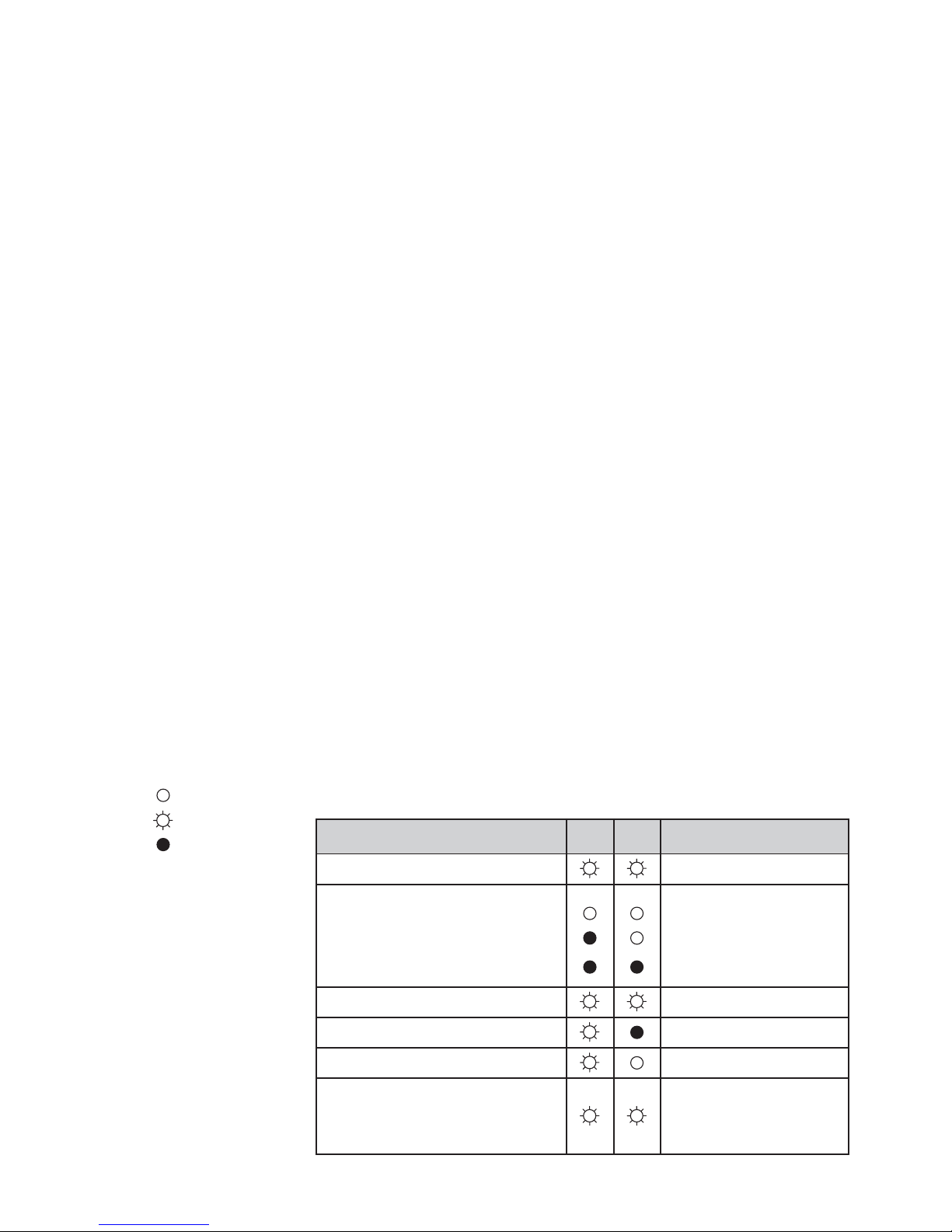

Meaning of LED1 and LED2 activity on the outdoor unit's board.

= ON steady

= ON blinking

= OFF

Meaning LED1 LED2

Auto-addressing in progress Alternating blinking

Power ON:

Step 1: no communication

Step 2: communication received from

the indoor unit

Step 3: normal communication

Alarm message Simultaneous blinking

No charge indicator

Refrigerant recovery mode

Alarms

(Refer to the details in the outdoor unit's

maintenance and troubleshooting

manual)

Repeated and alternating

blinking (of each indicator

light)

Page 18

18

GB

6.2.2 - MODULE CC1 CONFIGURATION

• The communication and control module manage the circulator and

the communication interface between the system and the generator.

It is equipped with 2 micro-switches, No. 1 and No. 2.

Micro-switch No. 1

:

In “ON” position, the circulator starts automatically if the outdoor

temperature is below 0°C to prevent the hydraulic circuit from

freezing. This position is recommended if the outdoor module is

installed in a location exposed to freezing temperatures (not

recommended).

The factory default setting for this micro-switch is “OFF”.

Micro-switch No. 2

:

Must be set to “ON” (activates the water flow safety on the

system).

6.2.3 - SYSTEM PARAMETERISATION

• Make sure that the control unit selector is “OFF”.

• Check the parameterisation and adapt it accordingly based on the

type of installation.

The parameters are set on the control box (refer to the system's installation manual).

6.3 - ADDITIONAL HYDRAULIC CIRCUIT VERIFICATIONS

6.3.1 - FORCED CIRCULATOR OPERATION

• In order to conduct the final verifications of the hydraulic circuit, force

the pump to start as follows (installation power ON):

- Set the system control unit to “OFF”.

- Press and hold the button for 5 seconds.

The circulator starts.

The circulator indicator light flashes.

- Check that the “H

2

O” flow indicator is illuminated.

6.3.2 - VERIFICATIONS

• Purging of circuits.

• Hydraulic pressure (2 bar).

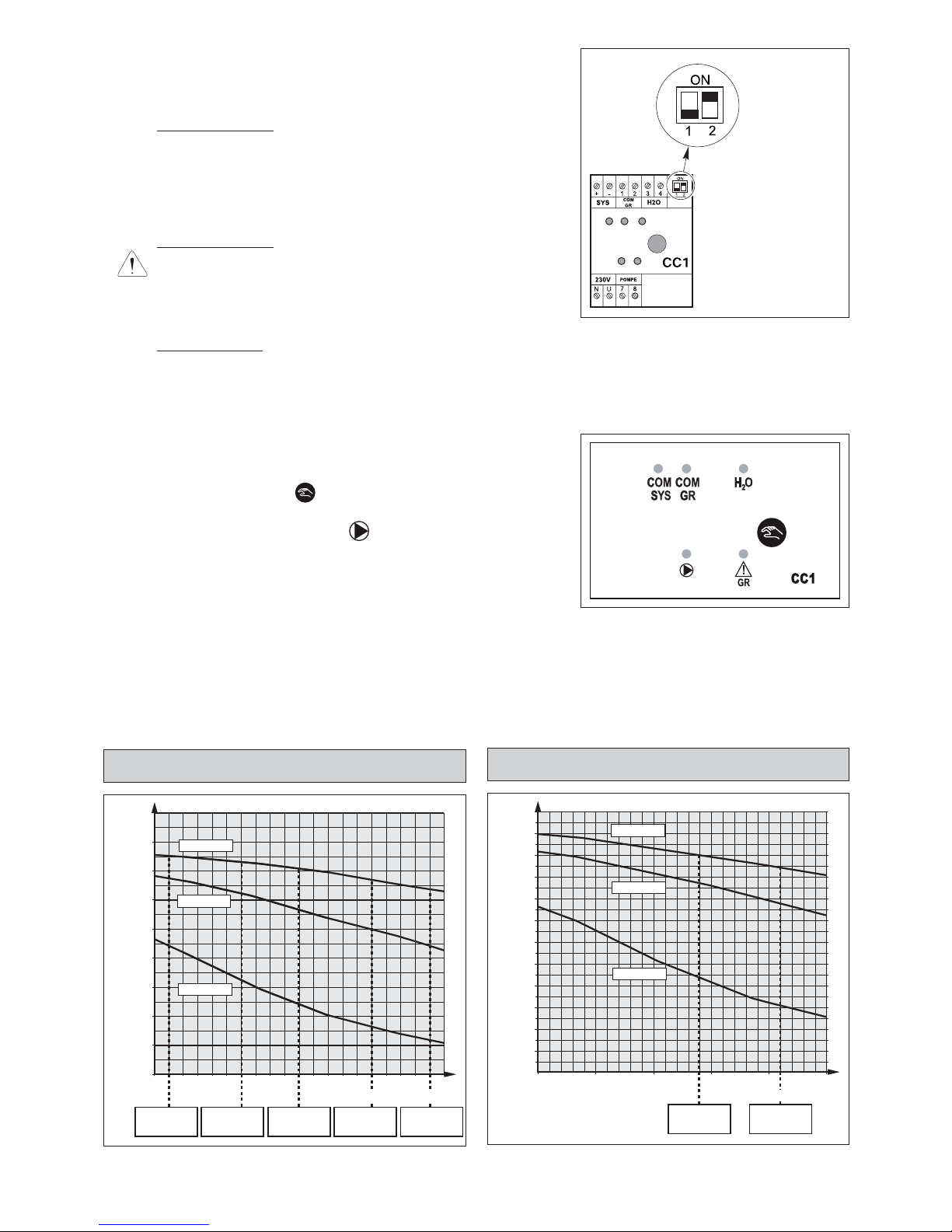

• Water flowrate: the unit is equipped with 1/4 SAE pressure taps at the circulator inlet and outlet (see paragraph 2.1.1),

so that the pressure loss can be measured using a hydraulic pressure gauge. Use the circulator curves below to

determine the water flow rate.

In order for the apparatus to work properly, the nominal flow rate must be respected.

6.3.3 - CIRCULATOR CURVES

Micro-switches

No. 1 and No. 2

0

10

20

30

40

50

60

70

80

90

1 1.5 2 2.5 2.8

HKE 369R

1.8

HKE 259R

1.4

HKE 189R

0.9

HKE 489R

2.3

HKE 609R

2.7

HKE 189R / 259R / 369R / 489R / 609R

Circulator SXM 32-55

Water flowrate (m3/h)

Manometric delivery head (kPa) of the circulator

Speed 1

Speed 2

Speed 3

0

10

20

30

40

50

60

70

80

90

100

110

120

2 2.5 4 4.53 3.5

HKE 709R

3.4

HKE 909R

4.1

HKE 709R / 909R

Circulator SXM 32-80 OEM

Water flowrate (m3/h)

Manometric delivery head (kPa) of the circulator

Speed 1

Speed 2

Speed 3

Page 19

19

GB

7 - MAINTENANCE INSTRUCTIONS

7.1 - GENERAL MAINTENANCE

All equipment must be properly maintained in order to provide optimum performance over time. Faulty maintenance can result in

the cancellation of the product guaranty. Depending on the products, maintenance operations consist in the cleaning of filters (air,

water), internal and external exchangers, casings, and the cleaning and protection of condensate tanks. Treating odours and the

disinfection of room surfaces and volumes also contributes to the cleanliness of the air breathed by users.

• Carry out the following operations at least once a year (the frequency depends on the installation and operating conditions):

- check for leaks on the refrigerating circuit (according to the order of 7th May 2007).

- check for traces of corrosion or oil stains around the refrigerating components,

- inspect the composition and the condition of the coolant and check that it does not contain traces of refrigerating fluid,

- cleaning the exchangers,

- checking the wear parts,

- checking the operating instructions and points,

- check the safety devices,

- de-dusting the electrical equipment cabinet,

- checking that the electrical connections are secure,

- checking the earth connection,

- check the hydraulic circuit (clean the filter, water quality, purge, flowrate, pressure, etc.).

7.2 - HEATER SAFETY

• The unit's heater is equipped with an automatic-reset and a manual-reset safety thermostat.

• These thermostats trip in case of excessive temperature on the heater wall.

• Possible causes:

- Excessively low or inexistent water flowrate.

- Improperly purged water system.

• If the manual thermostat trips, correct the fault then reset the thermostat as follows:

- T

urn off and lock out the unit.

- Remove the cover.

- The thermostats are located against the heater partition, on the front (see paragraph 2.1.1).

- Press the button in the centre of the manual thermostat.

7.3 - PROTECTION OF HEATER CIRCUITS

• The heater features three heating elements each supplied with 230 V between phases and neutral. Each of these circuits

are protected by a modular circuit breaker (Q1, Q2, Q3) located inside the electrical box.

7.4 - CONTROL CIRCUIT PROTECTION

• The indoor unit's control circuit is protected by a modular circuit breaker Q4 located next to module CC1. It is accessible

through the small window on the right-hand side of the unit (without removing the cover panel).

• Before doing any work on the installation, make sure it is switched off and all power supplies locked out.

• Also check that the capacitors are discharged.

• Any work must be carried out by personnel qualified and authorised to work on this type of machine.

• Prior to all maintenance and servicing on the refrigerating circuit, one must first shut down the unit then wait a

few minutes before installing temperature or pressure sensors. Certain equipment, such as the compressor and

piping, may reach temperatures above 100°C and high pressures may lead to serious burns.

IMPORTANT NOTE

6.3.4 - SHUTDOWN FORCED CIRCULATOR OPERATION

• Press and hold the button for 5 seconds.

The circulator stops.

The circulator indicator light and the “H

2

O” flow rate light do out.

6.4 - OPERATION

• Installation power is ON.

• Start the system in the desired operating mode using the control box button (consult the system control manual and the

control box user's guide).

Page 20

20

GB

• If tripped:

- Turn off and lock out the unit.

- Correct the fault.

- Reset the circuit breaker.

Note:

The opening of circuit breaker Q4 disconnects only the control part. In the event of maintenance / servicing, all circuits

must be disconnected by opening the main circuit breaker.

7.5 - TROUBLESHOOTING RECOMMENDATIONS

• All maintenance and servicing operations on the refrigerating circuit must be conducted in accordance with standard trade

practices and safety rules: recovery of the refrigerant, inert shielded (nitrogen) brazing, etc…

• All brazing operations must be conducted by qualified welders.

• For equipment charged with R 410 A, refer to the specific instructions in paragraph 4.1 and in the outdoor unit's manual.

• This unit is equipped with pressurised equipment, for example piping.

Use only genuine parts listed in the spare parts list for replacing defective refrigeration components.

• Pipes may only be replaced by copper tubing in compliance with standard NF EN 12735-1.

• Leak detection, in the case of pressure testing:

- Never use oxygen or dry air, as the risk of fire or explosion is present.

- Use dehydrated nitrogen or a nitrogen and refrigerant mix indicated on the manufacturer's plate.

- For units equipped with pressure gauges, the test pressure must not exceed the gauges' maximum allowable pressure

rating.

• All part replacement with other than genuine parts, all modifications of the refrigerating circuit, all replacement of refrigerant

by a fluid other than that indicated on the manufacturer's plate, all use of the unit outside the application limits defined in the

documentation, shall result in the cancellation of PED EC marking compliance which shall fall under the liability of the

individual who carried out these modifications.

• The technical information, relative to the safety requirements of the various applicable directives, is indicated on the

manufacturer's plate of the unit and mentioned on the 1

st

page of this manual.

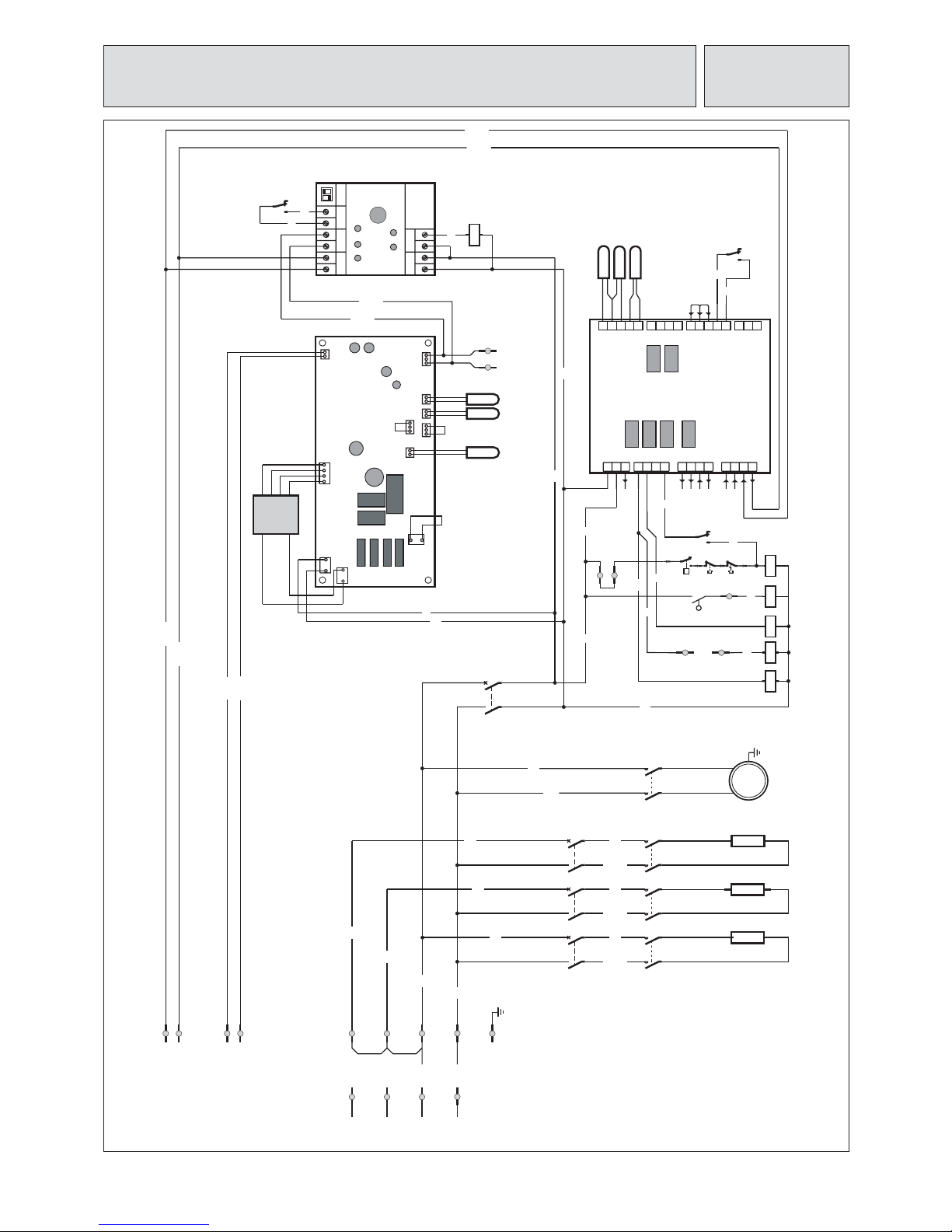

8 - WIRING DIAGRAM

A1 Heating control PCB

A2 Indoor unit PCB

CC1 Communication and control module

E1 Water pressostat

F1 Automatic - heater safety thermostat

F2 Manual - heater safety thermostat

J1 Water flow switch

KA1 Heater fault relay

KA2 Water flow relay

KM1 R1 contactor

KM2 R2 contactor

KM3 R3 contactor

KM4 M1 contactor

M1 Water circulator pump

Q1 R1 circuit breaker

Q2 R2 circuit breaker

Q3 R3 circuit breaker

Q4 Control circuit breaker

R1 Support heating element

R2 Support heating element

R3 Support heating element

S1 Water inlet temperature sensor (system)

S2 Water outlet temperature sensor

S3 Outdoor air temperature sensor

S4 Heat pump exchanger temperature sensor (E2)

S5 Liquid line temperature sensor (E1)

S6 Water return temperature sensor (Heat pump) (TA)

TR Indoor unit board power supply transformer

Symbols of the components

BU Blue

BK Black

PK Pink

RD Red

WT White

Colours of the wires

Page 21

21

GB

RD +

WH -

4

2

R2

WH-R2

BK-R1

5

L1

L2

L3

1

RD +

WH -

L4

BU - 4

L5

BU - 5

L6

BU - 6

BU

L1

2 1 - +

7

8

N U

R1

N

XA

L1

XA

L2

XA

L3

XA

3

7

6

CN80/PNL

TC/E2

CN041/RC

TA

AC IN / CN067

OC

CN040

TRANS-P

TRANS - S

CN076

T20

TCJ/E1

CN30/FS

BU

BU-1

BU-1

BU-1

1

1

R3

A1

A2

KM1

N U

CN8 CN7 CN6 CN5

CN1 CN2 CN3 CN4

5 4 3 2 1 4 13 2 12 3 435 2 1

1 2 3 1 2 3 4 1 2 3 4 21 3 4

S1 CC S2 S3 24 3 1 A1 CC A2

FP R1 R2 R3 C +D1 D2 -

A3 H1 H2 H3

E1 E2 T+ T-

230V

A1

A2

KM2

A1

A2

KM3

A1

A2

KA1

R3

Q4

1

2

3

4

KM3

Q3Q2Q1

KM2

PE

XA

F1

CX6

F2

E1

CX5/4 CX3/2

P

BUS

CX1

A1

A2

KA2

S1

S2

S3

11

KA1

12

14

J1

11

KA2

12

14

S4

S5

S6

TR

A1

M1

1

2

3

4

KM4

A2

A1

A2

KM4

U1

XBU2XB

PK-U1

L3

L2

-

XB

+

XB

L1

IU PCB

CC1

230V

POMPE

SYS

COM

GR

9

8

H2O

4 3

21

KA2

2224

R1

R2

N

XA

L1

XA

L2

XA

L3

XA

1

2

3

4

1

2

3

4

KM1

23

XA

22

XA

19

XA

20

XA21XA

BU-U2

ON

1

2

R2

1

R1

XB

R2

XB

ELECTRICAL DIAGRAM - HKE 189R / 259R / 369R / 489R / 609R /

709R / 909R - 230 / 1 / 50 - 400 / 3 N / 50

10 05 855 - 00

Power supply 400 / 3 N / 50 Hz

System

Outdoor

unit

230 / 1 / 50 Hz

Pilot

Eco

Inlet

Téléinfo

Load

shedding

Page 22

22

o18

310

13

27.5

(13)

(23.5)

336

285

608

85

(97)

46 100

12

50

5050

15

569

70790

249 32046

60

13

18

20

20

380

10

110660170

13

219 75 75105

26

290

940

780

18

20

942

296

150

219

13 13

21

18

20 10381

410

341

1313

171 660

111

How to Install the Outdoor Unit

Installing the Outdoor Unit

,esabehtekamotlairetamralimisaroetercnocesU

and ensure good drainage.

afI.eromromc5fothgiehesabaerusne,yliranidrO

drain pipe is used, or for use in cold-weather regions,

ensure a height of 15 cm or more at the feet on both

sides of the unit. (In this case, leave clearance below

the unit for the drain pipe, and to prevent freezing of

drainage water in cold weather regions.)

tlobrohcnaehtrof4-,3-,2-,1-41-1.giFotrefeR

dimensions.

.)01M(stlobrohcnahtiwteefehtrohcnaoteruseB

In addition, use anchoring washers on the top side.

(Use large square 32 ~ 32 SUS washers with JIS

nominal diameter of 10.) (Field supply)

Fig. 1-14-2

Fig. 1-14-1

Fig. 1-14-4

4- ø12 Anchor bolt hole

(Anchor bolt M8)

Air Intake

Air discharge

Drain port

For 2 HP unit

For 3 HP unit,259 (single-phase)

For 4, and 6 HP unit

Air

Intake

Drain port

Air

discharge

Piping direction

Drain port (2 locations)

Drain port

Anchor bolt (M10)

Drain port

Anchor bolt (M10)

4-R6.5 Anchor bolt hole

Air Intake

Air

Intake

For 3 HP unit (3-phase)

940

780

50

50

0 1 1170

340

15 10

380

405

660

13

13

18

75

75

70

220

38

256

Air

Intake

Air

discharge

Air Intake

4- ø32

Drain port

Anchor bolt (M10)

Fig. 1-14-3

=H 0331

Page 23

1

23

Electrical Wiring

General Precautions on Wiring

as shown on its nameplate, then carry out the

wiring closely following the wiring diagram.

(2) Provide a power outlet to be used exclusively for

each unit, and a power supply disconnect and

circuit breaker for overcurrent protection should be

provided in the exclusive line.

(3) To prevent possible hazards from insulation failure,

the unit must be grounded.

(4) Each wiring connection must be done in accordance

with the wiring system diagram. Wrong wiring may

cause the unit to misoperate or become damaged.

(5) Do not allow wiring to touch the refrigerant tubing,

compressor, or any moving parts of the fan.

(6) Unauthorized changes in the internal wiring can be

very dangerous. The manufacturer will accept no

responsibility for any damage or misoperation that

occurs as a result of such unauthorized changes.

(7) Regulations on wire diameters dier from locality to

LOCAL ELECTRICAL CODES before beginning.

You must ensure that installation complies with all

relevant rules and regulations.

(8) To prevent malfunction of the air conditioner caused

by electrical noise, care must be taken when wiring

as follows:

The remote control wiring and the inter-unit control

wiring should be wired apart from the inter-unit

power wiring.

Use shielded wires for inter-unit control wiring

between units and ground the shield on both sides.

(9) If the power supply cord of this appliance is damaged,

it must be replaced by a repair shop appointed by

the manufacture, because special-purpose tools are

required.

Recommended Wire Length and Wire Diameter for Power Supply System

Outdoor unit (Single-Phase)

(A) Power supply Tim

e delay

fuse or circuit

cap

acity

Wire size

Max. length

SPW-C186VEH 2.5 mm

2

19 m 16 A

SPW-C256VEH 2.5 mm

2

14 m 20 A

SPW-C366VEH (N) 2.5 mm

2

14 m 20 A

SPW-C486VEH (N) 4 mm

2

16 m 25 A

SPW-C606VEH (N) 6 mm

2

21 m 30 A

Outdoor unit (3-Phase)

(A) Power supply Tim

e delay

fuse or circuit

cap

acity

Wire size

Max. length

SPW-C256VEH8 2.5 mm

2

58 m 16 A

SPW-C366VEH8 2.5 mm

2

44 m 16 A

SPW-C486VEH8 2.5 mm

2

32 m 16 A

SPW-C606VEH8 2.5 mm

2

28 m 20 A

Page 24

24

Page 25

25

Page 26

26

Page 27

polarenergi.no

P.boks 117, 9450 Hamnvik

Loading...

Loading...