Page 1

TECHNICAL DATA

& SERVICE MANUAL

OUTDOOR UNIT: GRV72L5TA-

GRV92L5TAGRV122L5TA-

SPLIT SYSTEM AIR CONDITIONER

0.8180.274.0 05/2002

Model No. Product Code No.

GRV72L5TA- 387107050

GRV92L5TA- 387107051

GRV122L5TA- 387107052

Page 2

IMPORTANT!

Please read before installation

This air conditioning system meets strict safety and operating

standards.

For the installer or service person, it is important to install or

service the system so that it operates safely and efficiently.

For safe installation and trouble-free operation, you must:

• Carefully read this instruction booklet before beginning.

• Follow each installation or repair step exactly as shown.

• Observe all local, state and national electrical codes.

• Pay close attention to all warning and caution notices given in

this manual.

•The unit must be supplied with a dedicated electrical line.

This symbol refers to a hazard or unsafe practice which can result

in severe personal injury or death.

This symbol refers to a hazard or unsafe practice which can result

in personal injury or product or property damage.

If necessary, get help

These instructions are all you need for most installation sites and

maintenance conditions.

If you require help for a special problem, contact our sale/service

outlet or your certified dealer for additional instructions.

In case of improper installation

The manufacturer shall in no way be responsible for improper

installation or maintenance service, including failure to follow the

instructions in this document.

SPECIAL PRECAUTIONS

• During installation, connect before the refrigerant system and

then the wiring one; proceed in the reverse orden when removing

the units.

When wiring

ELECTRICAL SHOCK CAN CAUSE SEVERE

PERSONAL INJURY OR DEATH. ONLY A QUALIFIED,

EXPERIENCED ELECTRICIANS SHOULD ATTEMPT

TO WIRE THIS SYSTEM.

• Do not supply power to the unit until all wiring and tubing are

completed or reconnected and checked, to ensure the grounding.

• Highly dangerous electrical voltages are used in this system.

Carefully refer to the wiring diagram and these instructions when

wiring.

Improper connections and inadequate grounding can cause

accidental injury and death.

• Ground the unit following local electrical codes.

• The Yellow/Green wire cannot be used for any connection

different from the ground connection.

• Connect all wiring tightly. Loose wiring may cause overheating

at connection points and a possible fire hazard.

• Do not allow wiring to touch the refrigerant tubing, compressor,

or any moving parts of the fan.

• Do not use multi-core cable when wiring the power supply and

control lines. Use separate cables for each type of line.

When transporting

Be careful when picking up and moving the indoor and outdoor

units. Get a partner to help, and bend your knees when lifting to

reduce strain on your back. Sharp edges or thin aluminium fins on

the air conditioner can cut your fingers.

When installing...

... In a ceiling or wall

Make sure the ceiling/wall is strong enough to hold the unit-weight.

It may be necessary to build a strong wooden or metal frame to

provide added support.

... In a room

Properly insulate any tubing run inside a room to prevent

"sweating", which can cause dripping and water damage to walls

and floors.

... In moist or uneven locations

Use a raised concrete base to provide a solid level foundation for

the outdoor unit.

This prevents damage and abnormal vibrations.

... In area with strong winds

Securely anchor the outdoor unit down with bolts and a metal

frame. Provide a suitable air baffle.

... In a snowy area (for heat pump-type systems)

Install the outdoor unit on a raised platform that is higher than

drifting snow. Provide snow vents.

When connecting refrigerant tubing

• Keep all tubing runs as short as possible.

• Use the flare method for connecting tubing.

• Apply refrigerant lubricant to the matching surfaces of the flare

and union tubes before connecting them; screw by hand and

then tighten the nut with a torque wrench for a leak-free

connection.

• Check carefully for leaks before starting the test run.

NOTE:

Depending on the system type, liquid and gas lines may be either

narrow or wide. Therefore, to avoid confusion, the refrigerant

tubing for your particular model is specified as narrow tube for

liquid, wide tube for gas.

When servicing

• Turn the power OFF at the main power board before opening

the unit to check or repair electrical parts and wiring.

• Keep your fingers and clothing away from any moving parts.

• Clean up the site after the work, remembering to check that no

metal scraps or bits of wiring have been left inside the unit being

serviced.

• Ventilate the room during the installation or testng the refrigeration

system; make sure that, after the installation, no gas leaks are

present, because this could produce toxic gas and dangerous

if in contact with flames or heat-sources.

WARNING

CAUTION

WARNING

2

Page 3

Page

1. OPERATING RANGE

4

2. SPECIFICATIONS

5

2-1 Unit specifications 5

2-2 Major Component specifications 8

2-3 Other Component specifications 11

3. DIMENSIONAL DATA

12

4. REFRIGERANT FLOW DIAGRAM

13

5. PERFORMANCE DATA

14

5-1 Performance Charts 14

5-2 Cooling Capacity 17

6. ELECTRICAL DATA

20

6-1 Electrical characteristics 20

6-2 Electric Wiring Diagram 21

6-3 System Wiring Diagram 21

Table of Contents

3

Page 4

1. OPERATING RANGE

Temperature Indoor Air Intake Temp. Outdoor Air Intake Temp.

Cooling

Maximum

Minimum

43°C D.B.

-15°C D.B.

32°C D.B. / 23°C W.B.

19°C D.B. / 14°C W.B.

4

Page 5

2. SPECIFICATIONS

2-1 Unit Specifications

GRV72L5TA-

Power source

V

oltage ratin

g

Performance * MCAV72C5TA

-

Capacity

kW

BTU/h

Air circulation (High) m³/h

Moisture removal (High) Liters/h

Electrical Ratin

g

Available voltage range V

Running amperes A

Power input W

Power factor %

C.O.P. W/W

Compressor locked rotor amperes A

Features

Fan speed

Compressor

Refrigerant / Amount charged at shipment g

Refrigerant control

Operation Sound Hi dB-A

Refrigerant tubing connections

Max. allowable tubing length at shipment m

Refrigerant Narrow tube mm(in.)

tube diameter Wide tube mm(in.)

Dimensions & Wei

g

ht

Unit dimensions Height mm

Width mm

Depth mm

Package dimensions Height mm

Width mm

Depth mm

Weight Net kg

Shipping kg

Shipping volume

m

3

DATA SUBJECT TO CHANGE WITHOUT NOTICE

Remarks:

Rating conditions are:

Cooling: Indoor air temperature 27°C D.B. / 19°C W.B.

Outdoor air temperature 35°C D.B. / 24°C W.B.

*

For other INDOOR UNITS' MODELS, please refer to catalogue

92

2,8

17

57

1(Hi)

198 ~ 264

Cooling

3,20

1,90

6485

430

0,40

0,16

230 V

815

343

34

37

6,35 (1/4)

700

265

568

220 - 240 V ~ 50 H

z

Cooling

540

Rotary (Hermetic)

R407C / 730

9,52 (3/8)

Flare type

Capillary tub

e

7.5

680

5

Page 6

GRV92L5TA-

Power source

V

oltage ratin

g

Performance * MCAV92C5TA

-

Capacity

kW

BTU/h

Air circulation (High) m³/h

Moisture removal (High) Liters/h

Electrical Ratin

g

Available voltage range V

Running amperes A

Power input W

Power factor %

C.O.P. W/W

Compressor locked rotor amperes A

Features

Fan speed

Compressor

Refrigerant / Amount charged at shipment g

Refrigerant control

Operation Sound Hi dB-A

Refrigerant tubing connections

Max. allowable tubing length at shipment m

Refrigerant Narrow tube mm(in.)

tube diameter Wide tube mm(in.)

Dimensions & Wei

g

ht

Unit dimensions Height mm

Width mm

Depth mm

Package dimensions Height mm

Width mm

Depth mm

Weight Net kg

Shipping kg

Shipping volume

m

3

DATA SUBJECT TO CHANGE WITHOUT NOTICE

Remarks:

Rating conditions are:

Cooling: Indoor air temperature 27°C D.B. / 19°C W.B.

Outdoor air temperature 35°C D.B. / 24°C W.B.

*

For other INDOOR UNITS' MODELS, please refer to catalogue

23

57

540

700

6,35 (1/4)

9,52 (3/8)

Flare type

7.5

1(Hi)

Rotary (Hermetic)

R407C / 800

Capillary tub

e

198 ~ 264

450

0,80

Cooling

4,40

990

98

2,6

36

39

0,16

265

568

815

343

8874

220 - 240 V ~ 50 H

z

230 V

Cooling

2,60

6

Page 7

GRV122L5TA-

Power source

V

oltage ratin

g

Performance * MCAV122C5TA

-

Capacity

kW

BTU/h

Air circulation (High) m³/h

Moisture removal (High) Liters/h

Electrical Ratin

g

Available voltage range V

Running amperes A

Power input W

Power factor %

C.O.P. W/W

Compressor locked rotor amperes A

Features

Fan speed

Compressor

Refrigerant / Amount charged at shipment g

Refrigerant control

Operation Sound Hi dB-A

Refrigerant tubing connections

Max. allowable tubing length at shipment m

Refrigerant Narrow tube mm(in.)

tube diameter Wide tube mm(in.)

Dimensions & Wei

g

ht

Unit dimensions Height mm

Width mm

Depth mm

Package dimensions Height mm

Width mm

Depth mm

Weight Net kg

Shipping kg

Shipping volume

m

3

DATA SUBJECT TO CHANGE WITHOUT NOTICE

Remarks:

Rating conditions are:

Cooling: Indoor air temperature 27°C D.B. / 19°C W.B.

Outdoor air temperature 35°C D.B. / 24°C W.B.

*

For other INDOOR UNITS' MODELS, please refer to catalogue

6,30

1380

95

2,5

11604

470

1,50

Cooling

6,35 (1/4)

12,7 (1/2)

540

700

0,16

198 ~ 264

815

343

37

40

Flare type

7.5

59

1(Hi)

220 - 240 V ~ 50 H

z

230 V

265

568

33

Cooling

3,40

Rotary (Hermetic)

R407C / 750

Capillary tub

e

7

Page 8

2-2 Major Component Specifications

Outdoor Unit: GRV72L5TA-

Controller PCB

Part No.

Control circuit fuse

Compressor

Type

Compressor model

Nominal output W

Compressor oil…Amount cc

Coil resistance (Ambient temp. 25°C)

Ω

Overload relay

Safety devices Type

Operating Temp. Open °C

Close °C

Operating amp. (Ambient temp. 25°C)

Run capacitor µF

VAC

Fan & Fan Motor

Type

Q'ty ……. Dia.

Fan motor model…Q'ty

No. Of poles…rpm (230 V, High)

Nominal output W

Coil resistance (Ambient temp. 25 °C )

Ω

Safety devices Type

Operating temp. Open °C

Close °C

Run capacitor µF

VAC

Heat Exch. Coil

Coil

Rows

Fin pitch mm

Face area

m

2

External Finish

DATA SUBJECT TO CHANGE WITHOUT NOTICE

4…782

C-R: 4,66

145 ± 5

69 ± 11

CS-7C115

450

//

1…. Ø 370

115 ± 3

802 060 35B C-1RN60H5C

600

95 ± 5

17,5

FV68S…350

C-S: 8,89

A

crylic baked-on enamel finish

Thermal protector

150 ± 10

1

1,3

0,353

1,5

A

luminium plate fin / Copper tube

450

A

utomatic

WHT-VLT: 244÷281

BLK-WHT: 211÷242

VLT-YEL: 83,5÷96,1

BLK-PNK: 41,7÷48,0

POW-CL128E

250 V 3,15

A

19

Rotary (Hermetic)

Propelle

r

K35410-M01846…1

External (OLR T)External (OLR A)

MRA 38072-3229

Trip in 6 to 16 s at 13

A

8

Page 9

Outdoor Unit: GRV92L5TA-

Controller PCB

Part No.

Control circuit fuse

Compressor

Type

Compressor model

Nominal output W

Compressor oil…Amount cc.

Coil resistance (Ambient temp. 25°C)

Ω

Overload relay

Safety devices Type

Operating Temp. Open °C

Close °C

Run capacitor µF

VAC

Fan & Fan Motor

Type

Q'ty ……. Dia.

Fan motor model…Q'ty

No. Of poles…rpm (230 V, High)

Nominal output W

Coil resistance (Ambient temp. 25 °C )

Ω

Safety devices Type

Operating temp. Open °C

Close °C

Run capacitor µF

VAC

Heat Exch. Coil

Coil

Rows

Fin pitch mm

Face area

m

2

External Finish

145 ± 5

MRA 38066-3229 CS-7C115

Trip in 6 to 16 s at 18

A

//

69 ± 11 95 ± 5

C-R: 3,07

C-S: 7,97

External (OLR A) External (OLR T)

WHT-VLT: 244÷281

BLK-PNK: 41,7÷48,0

4…782

K35410-M01846…1

A

crylic baked-on enamel finish

A

luminium plate fin / Copper tube

1

1,3

0,353

450

19

BLK-WHT: 211÷242

Thermal protector

A

utomatic

1,5

150 ± 10

VLT-YEL: 83,5÷96,1

POW-CL128E

250 V 3,15

A

Rotary (Hermetic)

115 ± 3

Propelle

r

1…. Ø 370

450

802 282 45G C-RN80H5

A

22,5

800

FV68S…470

9

Page 10

Outdoor Unit: GRV122L5TA-

Controller PCB

Part No.

Control circuit fuse

Compressor

Type

Compressor model

Nominal output W

Compressor oil…Amount cc.

Coil resistance (Ambient temp. 25°C)

Ω

Overload relay

Safety devices Type

Operating Temp. Open °C

Close °C

Run capacitor µF

VAC

Fan & Fan Motor

Type

Q'ty ……. Dia.

Fan motor model…Q'ty

No. Of poles…rpm (230 V, High)

Nominal output W

Coil resistance (Ambient temp. 25 °C )

Ω

Safety devices Type

Operating temp. Open °C

Close °C

Run capacitor µF

VAC

Heat Exch. Coil

Coil

Rows

Fin pitch mm

Face area

m

2

External Finish

A

crylic baked-on enamel finish

A

luminium plate fin / Copper tube

1

1,3

0,353

145 ± 5 115 ± 3

69 ± 11 95 ± 5

External (OLR A) External (OLR T)

MRA 38065-3229 CS-7C115

1100

FV68S…520

C-R: 1,962

C-S: 5,38

Rotary (Hermetic)

802 356 45B C-RN110H5B

Propelle

r

1…. Ø 370

K35410-M01846…1

4…819

22

BLK-WHT: 211÷242

BLK-PNK: 41,7÷48,0

WHT-VLT: 244÷281

VLT-YEL: 83,5÷96,1

450

Thermal protector

150 ± 10

A

utomatic

2

Trip in 6 to 16 s at 21

A

//

25

450

POW-CL128E

250 V 3,15

A

10

Page 11

2-3 Other Component Specifications

Outdoor Unit: GRV72L5TA-

GRV92L5TAGRV122L5TA-

Transformer

Type

Rating Primary

Secondary

Capacity

Coil resistance (at 21°C)

Ω

Thermal cut-off temp. °C

Thermistor

Type

Resistance

kΩ

A

TR-J105

PBC-41E-S14 or PBC-41E-S4

230 V ~ 50/60 H

z

19 V 0,526

A

10 V

A

Secondary (BRN-BRN): 2,0 ± 10%

Primary (WHT-WHT): 205 ± 10%

150

20 °C 6,5 ± 5%-20 °C 40,1 ± 5%

-10 °C 24,4 ± 5% 30 °C 4,4 ± 5%

0 °C 15,3 ± 5%

10 °C 9,9 ± 5%

40 °C 3,0 ± 5%

50 °C 2,1 ± 5%

11

Page 12

3. DIMENSIONAL DATA

700

540

15

470

4 – ø12 holes

116

320

294

Air intake

Air discharge

25510

170

103 57

Narrow tube service valve

ø6.35 (1/4")

Wide tube service valve

ø9.52 (3/8")

ø12.7 (1/2")

7000/9000 BTU/h

12000 BTU/h

Unit : mm

12

Page 13

4. REFRIGERANT FLOW DIAGRAM

Indoor Unit: Outdoor Unit: GRV72L5TA-

GRV92L5TA-

Indoor Unit: Outdoor Unit: GRV122L5TA-

Compressor

Accumulator

Wide tube

service

valve

Wide tube

O.D.

ø9.52 mm

(3/8 ")

Narrow

tube

service

valve

Narrow tube

O.D.

ø6.35 mm

(1/4")

Condenser

Capillary tube

Indoor Unit Outdoor Unit

Evaporator

Muffler

Compressor

Accumulator

Wide tube

service

valve

Wide tube

Narrow

tube

service

valve

Narrow tube

O.D.

ø6.35 mm

(1/4")

Condenser

Capillary tube

Indoor Unit Outdoor Unit

Evaporator

Muffler

O.D.

ø12.7 mm

(1/2 ")

Insulation of Refrigerant Tubing

Because capillary tubing is used in the outdoor unit, both the

wide and narrow tubes of this air conditioner become cold. To

prevent heat loss and wet floors due to dripping of

condensation, both tubes must be well insulated with a

proper insulation material. The thickness of the insulation

should be a min. 8 mm.

After a tube has been insulated,

never try to bend it into a narrow

curve because it can cause the tube

to break or crack.

IMPORTANT

CAUTION

Wide tube

Thickness:

Min. 8 mm

Insulation

Narrow tube

Thickness:

Min. 8 mm

13

Page 14

5. PERFORMANCE DATA

5-1 Performance charts

GRV72L5TA-

Coolin

g

Characteristics

Notes:

Points of Rating condition

Data referred to indoor unit

MCAV72C5TA-

0,00

0,10

0,20

0,30

0,40

0,50

0,60

0,70

0,80

0,90

20 25 30 35 40 45

Outdoor inlet air D.B. (°C)

Low pressure at wide tube service valve MPa

1

2

3

4

5

6

20 25 30 35 40 45

Outdoor inlet air D.B. temp. (°C)

Operating current (A)

Indoor inlet air

D.B. (°C)

Indoor inlet air

D.B. (°C)

27

1

9

32

27

19

3

2

14

Page 15

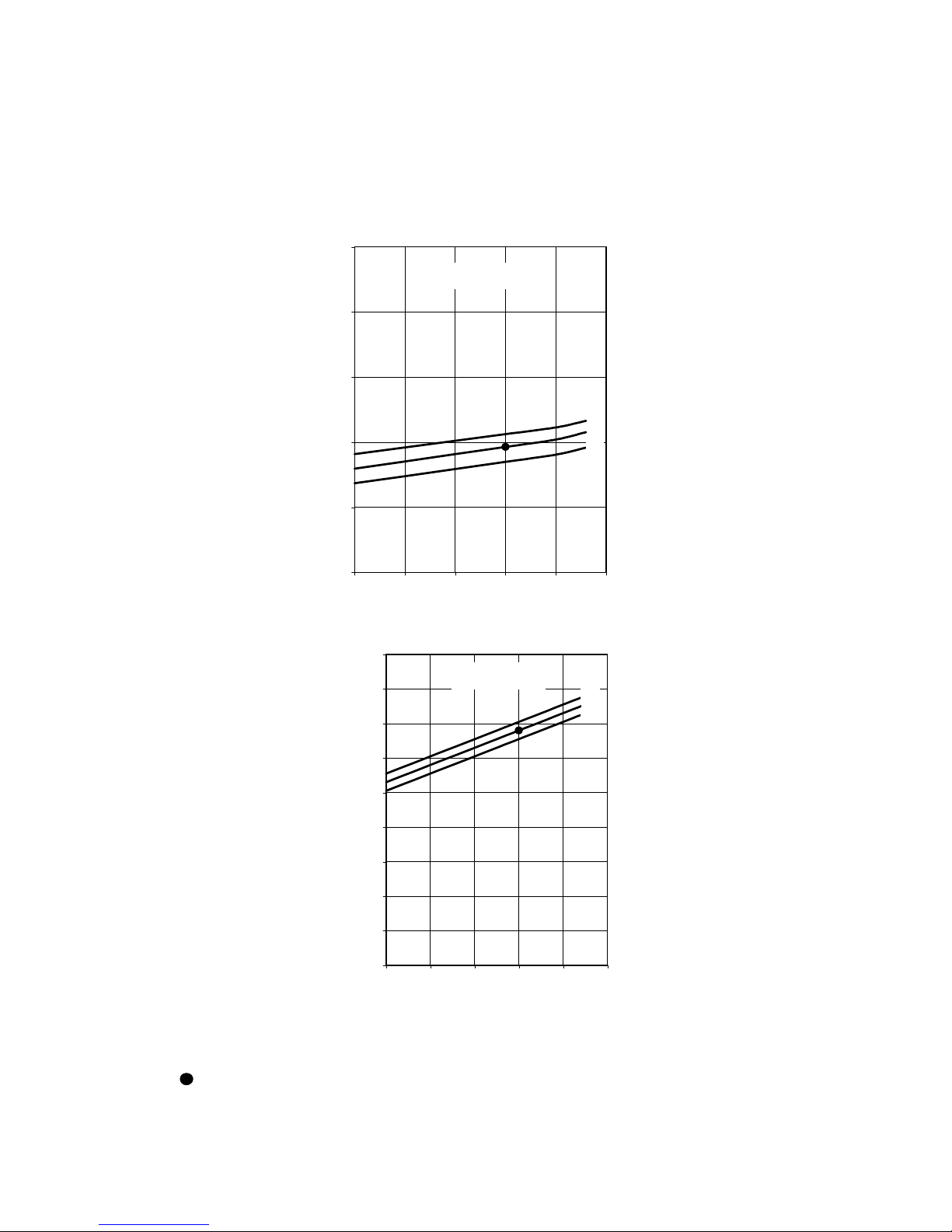

GRV92L5TA-

Coolin

g

Characteristics

Notes:

Points of Rating condition

Data referred to indoor unit

MCAV92C5TA-

0,00

0,10

0,20

0,30

0,40

0,50

0,60

0,70

0,80

0,90

20 25 30 35 40 45

Outdoor inlet air D.B. (°C)

Low pressure at wide tube service valve MPa

1

2

3

4

5

6

20 25 30 35 40 45

Outdoor inlet air D.B. temp. (°C)

Operating current (A)

Indoor inlet air

D.B.

(°C)

Indoor inlet air

D.B. (°C)

27

1

9

32

27

19

3

2

15

Page 16

GRV122L5TA-

Coolin

g

Characteristics

Notes:

Points of Rating condition

Data referred to indoor unit

MCAV122C5TA-

1

2

3

4

5

6

7

8

9

10

20 25 30 35 40 45

Outdoor inlet air D.B. temp. (°C)

Operating current (A)

Indoor inlet air

D.B.

(°C)

0,00

0,10

0,20

0,30

0,40

0,50

0,60

0,70

0,80

0,90

20 25 30 35 40 45

Outdoor inlet air D.B. (°C)

Low pressure at wide tube service valve MPa

Indoor inlet air

D.B. (°C)

27

1

9

32

27

19

3

2

16

Page 17

5-2 Cooling Capacity

OUTDOOR UNIT: GRV72L5TA-

220 - 240 V ~ 50 Hz

RATING CAPACITY 1,90 kW moisture removal 0,4 l/h

COMP. POWER INPUT 0,586 kW max comp input 0,666 kW

AIR FLOW RATE m³/h

EVAPORATOR

ENT.TEMP. °C

W.B. D.B. 20 25 30 35 40 43

TC 1,92 1,80 1,75 1,66 1,56 1,44

CM 0,48 0,51 0,53 0,55 0,57 0,60

21 SHC 1,33 1,23 1,21 1,17 1,12 1,06

23 SHC 1,51 1,40 1,37 1,33 1,28 1,22

15 25 SHC 1,67 1,56 1,53 1,49 1,44 1,38

27 SHC 1,84 1,72 1,69 1,65 1,56 1,44

29 SHC 1,92 1,80 1,75 1,66 1,56 1,44

31 SHC 1,92 1,80 1,75 1,66 1,56 1,44

TC 2,06 1,95 1,88 1,78 1,68 1,54

CM 0,50 0,52 0,55 0,57 0,59 0,61

21 SHC 1,15 1,08 1,05 1,01 0,96 0,90

23 SHC 1,32 1,24 1,21 1,16 1,12 1,06

17 25 SHC 1,49 1,41 1,37 1,33 1,28 1,21

27 SHC 1,67 1,57 1,52 1,48 1,43 1,38

29 SHC 1,84 1,73 1,69 1,64 1,59 1,53

31 SHC 2,01 1,90 1,84 1,78 1,68 1,54

TC 2,19 2,07 2,00 1,90 1,78 1,64

CM 0,52 0,54 0,56 0,59 0,61 0,63

21 SHC 0,96 0,90 0,88 0,83 0,78 0,73

23 SHC 1,14 1,06 1,04 1,00 0,95 0,89

19 25 SHC 1,31 1,22 1,19 1,15 1,11 1,05

27 SHC 1,48 1,38 1,35 1,62 1,26 1,21

29 SHC 1,65 1,53 1,51 1,47 1,43 1,36

31 SHC 1,82 1,69 1,67 1,63 1,58 1,52

TC 2,30 2,19 2,11 2,02 1,89 1,74

CM 0,54 0,56 0,58 0,61 0,63 0,65

23 SHC 0,94 0,89 0,86 0,82 0,77 0,71

21 25 SHC 1,12 1,05 1,02 0,98 0,93 0,88

27 SHC 1,29 1,20 1,18 1,14 1,09 1,03

29 SHC 1,46 1,36 1,34 1,30 1,25 1,19

31 SHC 1,63 1,52 1,50 1,46 1,41 1,35

TC 2,45 2,31 2,24 2,11 1,98 1,84

CM 0,56 0,58 0,60 0,62 0,65 0,67

23 25 SHC 0,92 0,87 0,84 0,79 0,74 0,69

27 SHC 1,09 1,02 1,00 0,95 0,90 0,85

29 SHC 1,27 1,17 1,16 1,11 1,06 1,01

31 SHC 1,44 1,33 1,32 1,27 1,22 1,17

TC: TOTAL COOLING CAPACITY kW

SHC: SENSIBLE HEAT CAPACITY kW

CM: COMPRESSOR INPUT kW

RATING CONDITIONS

Cooling: Indoor air temperature 27°C D.B. / 19°C W.B.

Outdoor air temperature 35°C D.B. / 24°C W.B.

NOTE: Data referred to indoor unit MCAV72C5TA-

CONDENSER

OUTDOOR AMBIENT TEMP. °C

430

17

Page 18

OUTDOOR UNIT: GRV92L5TA-

220 - 240 V ~ 50 Hz

RATING CAPACITY 2,60 kW moisture removal 0,8 l/h

COMP. POWER INPUT 0,89 kW max comp input 1,02 kW

AIR FLOW RATE m³/h

EVAPORATOR

ENT.TEMP. °C

W.B. D.B. 20 25 30 35 40 43

TC 2,63 2,46 2,39 2,28 2,14 1,97

CM 0,73 0,76 0,80 0,83 0,86 0,89

21 SHC 1,82 1,69 1,66 1,60 1,53 1,45

23 SHC 2,06 1,91 1,88 1,82 1,75 1,67

15 25 SHC 2,29 2,13 2,09 2,03 1,97 1,89

27 SHC 2,52 2,36 2,31 2,26 2,14 1,97

29 SHC 2,63 2,46 2,39 2,28 2,14 1,97

31 SHC 2,63 2,46 2,39 2,28 2,14 1,97

TC 2,81 2,67 2,57 2,44 2,29 2,11

CM 0,76 0,80 0,83 0,86 0,89 0,93

21 SHC 1,57 1,48 1,44 1,38 1,31 1,23

23 SHC 1,81 1,70 1,65 1,59 1,53 1,45

17 25 SHC 2,04 1,93 1,87 1,81 1,75 1,66

27 SHC 2,28 2,15 2,09 2,03 1,96 1,88

29 SHC 2,52 2,37 2,31 2,25 2,18 2,10

31 SHC 2,75 2,59 2,52 2,44 2,29 2,11

TC 2,99 2,83 2,73 2,60 2,44 2,25

CM 0,80 0,83 0,86 0,89 0,93 0,96

21 SHC 1,32 1,24 1,20 1,14 1,07 0,99

23 SHC 1,56 1,46 1,42 1,36 1,29 1,22

19 25 SHC 1,79 1,67 1,63 1,58 1,51 1,43

27 SHC 2,02 1,88 1,85 2,04 1,73 1,65

29 SHC 2,26 2,09 2,07 2,01 1,95 1,87

31 SHC 2,49 2,31 2,29 2,23 2,16 2,09

TC 3,15 3,00 2,89 2,76 2,59 2,39

CM 0,83 0,86 0,89 0,93 0,96 0,99

23 SHC 1,29 1,22 1,18 1,12 1,06 0,98

21 25 SHC 1,53 1,43 1,40 1,35 1,28 1,20

27 SHC 1,76 1,65 1,62 1,56 1,50 1,41

29 SHC 2,00 1,86 1,83 1,78 1,71 1,63

31 SHC 2,22 2,08 2,05 2,00 1,93 1,85

TC 3,35 3,16 3,06 2,89 2,71 2,52

CM 0,86 0,89 0,93 0,96 0,99 1,02

23 25 SHC 1,26 1,19 1,15 1,09 1,02 0,95

27 SHC 1,50 1,39 1,36 1,30 1,23 1,16

29 SHC 1,73 1,60 1,58 1,52 1,45 1,38

31 SHC 1,97 1,83 1,80 1,74 1,67 1,61

TC: TOTAL COOLING CAPACITY kW

SHC: SENSIBLE HEAT CAPACITY kW

CM: COMPRESSOR INPUT kW

RATING CONDITIONS

Cooling: Indoor air temperature 27°C D.B. / 19°C W.B.

Outdoor air temperature 35°C D.B. / 24°C W.B.

NOTE: Data referred to indoor unit MCAV92C5TA-

CONDENSER

OUTDOOR AMBIENT TEMP. °C

450

18

Page 19

OUTDOOR UNIT: GRV122L5TA-

220 - 240 V ~ 50 Hz

RATING CAPACITY 3,40 kW moisture removal 1,5 l/h

COMP. POWER INPUT 1,271 kW max comp input 1,491 kW

AIR FLOW RATE m³/h

EVAPORATOR

ENT.TEMP. °C

W.B. D.B. 20 25 30 35 40 43

TC 3,43 3,22 3,13 2,98 2,79 2,58

CM 0,98 1,05 1,12 1,19 1,27 1,34

21 SHC 2,38 2,21 2,17 2,09 2,00 1,90

23 SHC 2,69 2,50 2,45 2,38 2,29 2,19

15 25 SHC 2,99 2,79 2,73 2,66 2,57 2,47

27 SHC 3,30 3,08 3,02 2,95 2,79 2,58

29 SHC 3,43 3,22 3,13 2,98 2,79 2,58

31 SHC 3,43 3,22 3,13 2,98 2,79 2,58

TC 3,68 3,49 3,36 3,19 3,00 2,76

CM 1,02 1,09 1,16 1,23 1,30 1,38

21 SHC 2,05 1,93 1,88 1,80 1,71 1,60

23 SHC 2,36 2,22 2,16 2,08 2,00 1,89

17 25 SHC 2,67 2,52 2,45 2,37 2,28 2,17

27 SHC 2,98 2,81 2,73 2,65 2,56 2,46

29 SHC 3,29 3,10 3,02 2,94 2,85 2,74

31 SHC 3,59 3,39 3,30 3,19 3,00 2,76

TC 3,91 3,70 3,57 3,40 3,19 2,94

CM 1,06 1,13 1,20 1,27 1,34 1,41

21 SHC 1,73 1,62 1,57 1,49 1,40 1,30

23 SHC 2,04 1,90 1,86 1,78 1,69 1,59

19 25 SHC 2,35 2,18 2,14 2,06 1,98 1,87

27 SHC 2,64 2,46 2,42 2,35 2,26 2,16

29 SHC 2,95 2,73 2,71 2,63 2,55 2,44

31 SHC 3,26 3,02 2,99 2,92 2,83 2,73

TC 4,11 3,92 3,78 3,61 3,39 3,12

CM 1,08 1,16 1,23 1,30 1,38 1,45

23 SHC 1,69 1,60 1,54 1,47 1,38 1,28

21 25 SHC 2,00 1,87 1,83 1,76 1,67 1,57

27 SHC 2,31 2,15 2,11 2,04 1,96 1,85

29 SHC 2,62 2,43 2,39 2,33 2,24 2,14

31 SHC 2,91 2,71 2,68 2,61 2,53 2,42

TC 4,39 4,14 4,01 3,78 3,54 3,30

CM 1,11 1,19 1,26 1,34 1,41 1,49

23 25 SHC 1,65 1,55 1,50 1,42 1,33 1,24

27 SHC 1,96 1,82 1,78 1,70 1,61 1,52

29 SHC 2,27 2,09 2,07 1,99 1,90 1,81

31 SHC 2,58 2,39 2,36 2,27 2,18 2,10

TC: TOTAL COOLING CAPACITY kW

SHC: SENSIBLE HEAT CAPACITY kW

CM: COMPRESSOR INPUT kW

RATING CONDITIONS

Cooling: Indoor air temperature 27°C D.B. / 19°C W.B.

Outdoor air temperature 35°C D.B. / 24°C W.B.

NOTE: Data referred to indoor unit MCAV122C5TA-

CONDENSER

OUTDOOR AMBIENT TEMP. °C

470

19

Page 20

6. ELECTRICAL DATA

6-1 Electrical characteristics

OUTDOOR UNIT:

GRV72L5TA-

Indoor Unit Complete Unit

Fan Motor Fan Motor Compressor

Performance at

Rating conditions Running Amps. A 0,110 0,316 2,774 3,200

Power input kW 0,025 0,069 0,586 0,680

Full load conditions Running Amps. A 0,110 0,316 3,074 3,500

Power input kW 0,025 0,069 0,666 0,760

NOTE: Data referred to indoor unit MCAV72C5TA For other indoor unit models there could be some differences.

OUTDOOR UNIT:

GRV92L5TA-

Indoor Unit Complete Unit

Fan Motor Fan Motor Compressor

Performance at

Rating conditions Running Amps. A 0,120 0,316 3,964 4,400

Power input kW 0,027 0,069 0,894 0,990

Full load conditions Running Amps. A 0,120 0,316 4,464 4,900

Power input kW 0,027 0,069 1,024 1,120

NOTE: Data referred to indoor unit MCAV92C5TA For other indoor unit models there could be some differences.

OUTDOOR UNIT:

GRV122L5TA-

Indoor Unit Complete Unit

Fan Motor Fan Motor Compressor

Performance at

Rating conditions Running Amps. A 0,130 0,357 5,813 6,300

Power input kW 0,031 0,078 1,271 1,380

Full load conditions Running Amps. A 0,130 0,357 7,013 7,500

Power input kW 0,031 0,078 1,491 1,600

NOTE: Data referred to indoor unit MCAV122C5TA For other indoor unit models there could be some differences.

Rating Conditions: Indoor Air Temperature 27°C D.B. / 19°C W.B.

Outdoor Air Temperature 35°C D.B.

Full Load Conditions: Indoor Air Temperature 32°C D.B. / 23°C W.B.

Outdoor Air Temperature 43°C D.B.

Outdoor uni

t

230 V 1-Phase 50 H

z

Outdoor uni

t

230 V 1-Phase 50 H

z

Outdoor uni

t

230 V 1-Phase 50 H

z

20

Page 21

6-2 Electric Wiring Diagram

6-3 System Wiring Diagram

21

Page 22

R.D. 28 Reyrieux BP 131 - 01601 Trévoux CEDEX France

Tél. 04.74.00.92.92 - Fax 04.74.00.42.00

R.C.S. Bourg-en-Bresse B 759 200 728

Loading...

Loading...