Page 1

TECHNICAL DATA & SERVICE MANUAL

Outdoor Unit Indoor Unit

GR360M4R5TAA MCA90MR5TAA (x4)

MULTI-SPLIT SYSTEM AIR CONDITIONER

0.8180.212.4 06/2002

MCA90MR5TAA

GR360M4R5TAA

Page 2

Important!

Please Read Before Starting

This air conditioning system meets strict safety and

operating standards. As the installer or service person,

it is an important part of your job to install or service the

system so it operates safely and efficiently.

For safe installation and trouble-free operation, you

must:

●Carefully read this instruction booklet before

beginning.

●Follow each installation or repair step exactly as

shown.

●Observe all local, state, and national electrical codes.

●Pay close attention to all warning and caution notices

given in this manual.

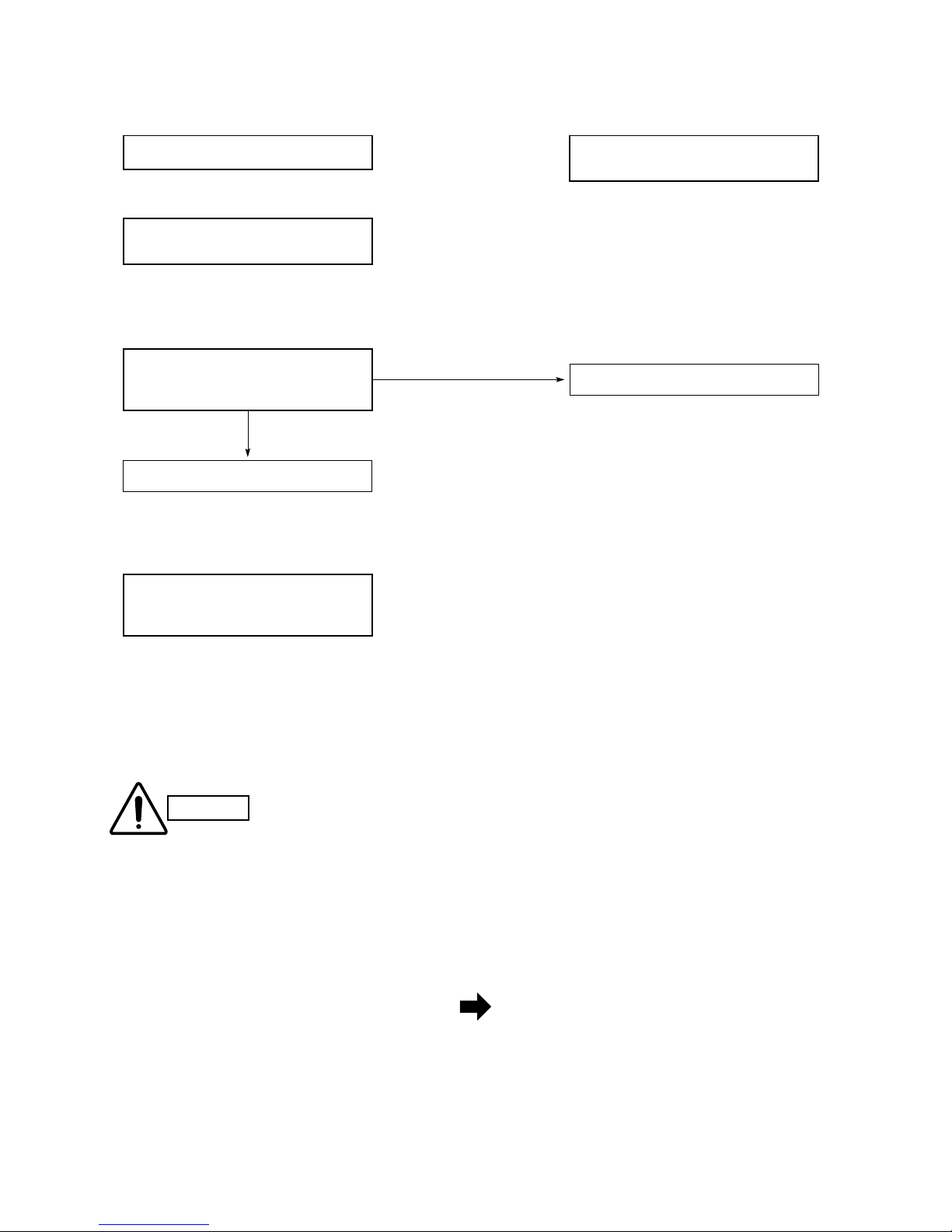

This symbol refers to a hazard or

unsafe practice which can result

in severe personal injury or

death.

This symbol refers to a hazard or

unsafe practice which can result

in personal injury or product or

property damage.

If Necessary, Get Help

These instructions are all you need for most installation

sites and maintenance conditions. If you require help

for a special problem, contact our sales/service outlet

or your certified dealer for additional instructions.

In Case of Improper Installation

The manufacturer shall in no way be responsible for

improper installation or maintenance service, including

failure to follow the instructions in this document.

Special Precautions

When Wiring

ELECTRICAL SHOCK CAN CAUSE

SEVERE PERSONAL INJURY OR

DEATH. ONLY A QUALIFIED,

EXPERIENCED ELECTRICIAN SHOULD

ATTEMPT TO WIRE THIS SYSTEM.

• Do not supply power to the unit until all wiring and

tubing are completed or reconnected and checked.

• Highly dangerous electrical voltages are used in this

system. Carefully refer to the wiring diagram and

these instructions when wiring. Improper connections

and inadequate grounding can cause accidental

injury or death.

• Ground the unit following local electrical codes.

• Connect all wiring tightly. Loose wiring may cause

overheating at connection points and a possible fire

hazard.

WARNING

CAUTION

WARNING

When Transporting

Be careful when picking up and moving the indoor and

outdoor units. Get a partner to help, and bend your

knees when lifting to reduce strain on your back. Sharp

edges or thin aluminum fins on the air conditioner can

cut your fingers.

When Installing…

…In a Ceiling or Wall

Make sure the ceiling/wall is strong enough to hold the

unit’s weight. It may be necessary to construct a strong

wood or metal frame to provide added support.

…In a Room

Properly insulate any tubing run inside a room to

prevent “sweating” that can cause dripping and water

damage to walls and floors.

…In Moist or Uneven Locations

Use a raised concrete pad or concrete blocks to

provide a solid, level foundation for the outdoor unit.

This prevents water damage and abnormal vibration.

…In an Area with High Winds

Securely anchor the outdoor unit down with bolts and a

metal frame. Provide a suitable air baffle.

…In a Snowy Area (for Heat Pump-type Systems)

Install the outdoor unit on a raised platform that is

higher than drifting snow. Provide snow vents.

When Connecting Refrigerant Tubing

• Use the flare method for connecting tubing.

• Apply refrigerant lubricant to the matching surfaces

of the flare and union tubes before connecting them,

then tighten the nut with a torque wrench for a leakfree connection.

• Check carefully for leaks before starting the test run.

When Servicing

• Turn the power off at the main power box (mains)

before opening the unit to check or repair electrical

parts and wiring.

• Keep your fingers and clothing away from any

moving parts.

• Clean up the site after you finish, remembering to

check that no metal scraps or bits of wiring have

been left inside the unit being serviced.

Others

• Ventilate any enclosed areas when installing or

testing the refrigeration system. Escaped refrigerant

gas, on contact with fire or heat, can produce

dangerously toxic gas.

• Confirm upon completing installation that no

refrigerant gas is leaking. If escaped gas comes in

contact with a stove, gas water heater, electric room

heater or other heat source, it can produce

dangerously toxic gas.

CAUTION

i

Page 3

Table of Contents

Page

Unit combination iv

1 OPERATING RANGE 1

2 SPECIFICATIONS

2-1 Unit Specification 2

2-2 Major Component Specifications 5

2-3 Other Component Specifications 7

3 DIMENSIONAL DATA 8

4 COOLING CAPACITY 10

5 HEATING CAPACITY 11

6 AIR THROW DISTANCE CHART 12

7 REFRIGERANT FLOW DIAGRAM 13

8 ELECTRICAL DATA

8-1 Electrical Characteristic 15

8-2 Electric Wiring Diagrams 16

10 TROUBLESHOOTING

10-1 Check before and after troubleshooting 33

10-2 Air Conditioner Does not operate 34

10-3 Some Part of Air Conditioner does not operate 38

10-4 Air Conditioner operates, but abnormalities are observed 40

10-5 If a sensor is defective 42

9 FUNCTION

9-1 Cool Mode Operation 17

9-2 Heat Mode Operation 18

9-3 Dry mode operation 19

9-4 Fan Operation 20

9-5 Protection Operations in Cool and Dry Mode 21

9-6 Protection Operation in Heat Mode 23

9-7 Cool Draft Prevention (Heating) 26

9-8 Others Features 27

11 ARRANGEMENT OF ELECTRICAL COMPONENTS 43

13 CHECKING ELECTRICAL COMPONENTS

13-1 Measurement of insulation Resistance 50

13-2 Checking Continuity of Fuse on PCB Ass’y 51

13-3 Checking Motor Capacitor 51

ii

12 SPECIAL PRECAUTIONS WHEN SERVICING THE UNIT

12-1 Solenoid valves opening for servicing 45

12-2 Refrigerant recovery 46

12-3 Service on outdoor unit 46

12-4 Evacuation using vacuum pump 46

12-5 Refrigerant charging 47

12-6 Reset the unit for normal operation 48

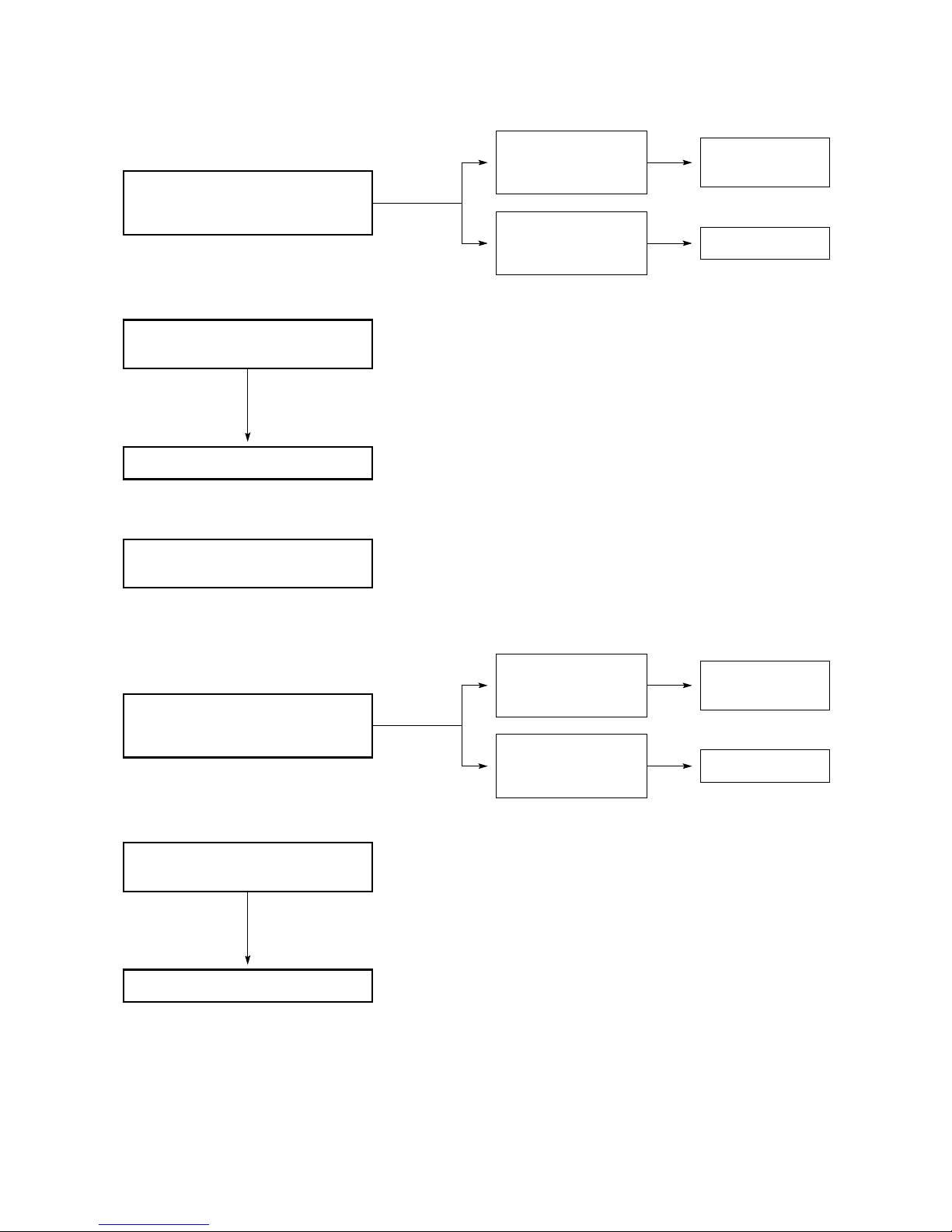

Page 4

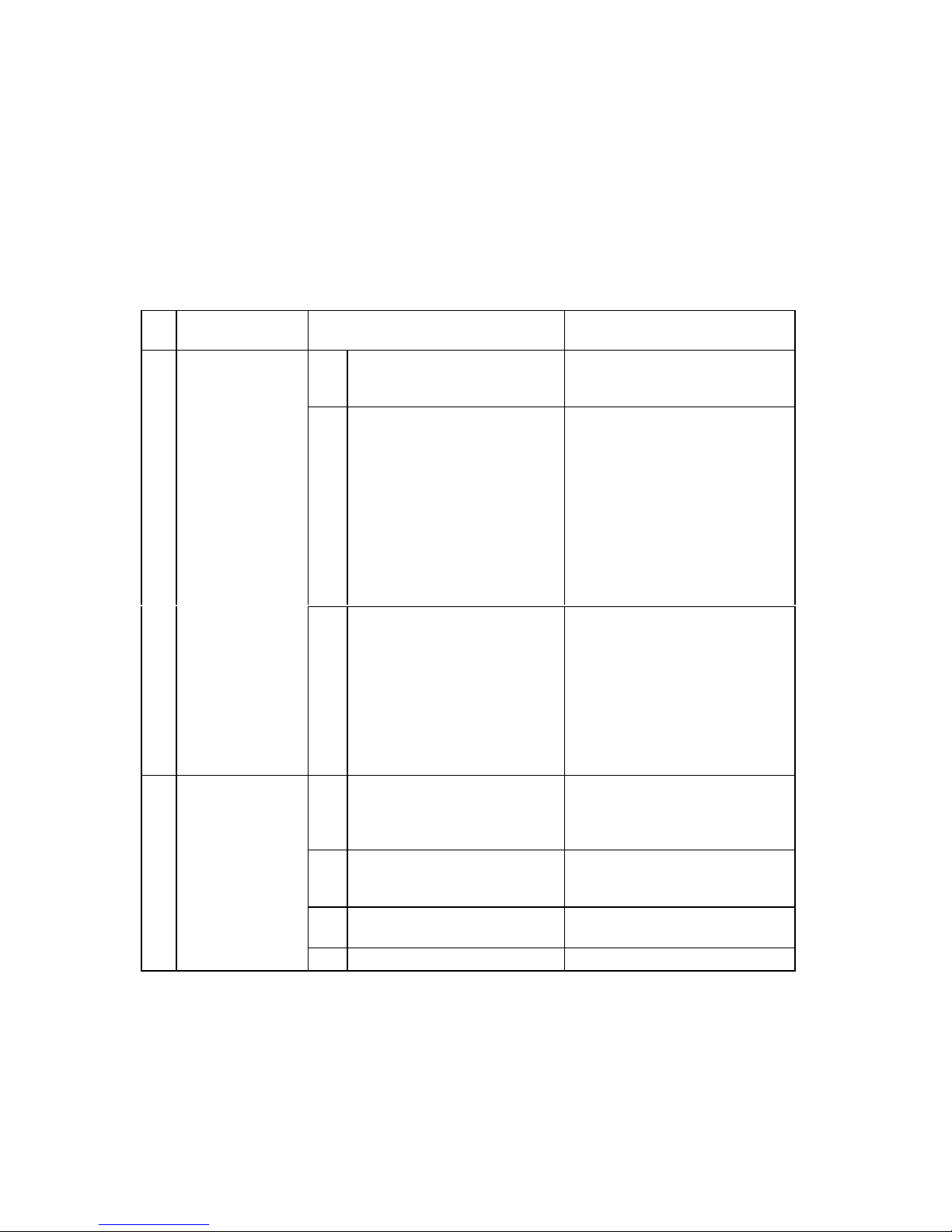

■

Unit Combination

Combine indoor and outdoor units only as listed below.

Symbol of

Indoor Unit

Outdoor Unit Indoor Unit

AE036QH

Refer to

MCA90MR5 A1

Fig.1

A2

B1

B2

Fig.1

SYSTEM

A

B

iii

MCA90MR5

MCA90MR5

MCA90MR5

Page 5

1. OPERATING RANGE

Temperature Indoor Air Intake Temp. Outdoor Air Intake Temp.

Cooling

Maximum 32°C DB / 23°C WB 46°C DB

Minimum 19°C DB / 14°C WB 19°C DB

Heating

Maximum 27°C DB 24°C DB / 18°C WB

Minimum - –5°C DB / –6°C WB

1

Page 6

2. SPECIFICATIONS

2-1. Unit Specifications

DATA SUBJECT TO CHANGE WITHOUT NOTICE.

Remarks: Rating conditions are:

Cooling: Indoor air temperature 27°C DB/19°C WB

Outdoor air temperature 35°C DB/24°C WB

Heating: Indoor air temperature 20°C DB

Outdoor air temperature 7°C DB/6°C WB

No. of indoor units. 1 indoor unit (A1 or A2, B1 or B2)

Power Source 220 – 240 V ~ 50 Hz

Cooling Heating

Capacity

kW 2.55 3.05

BTU/h 8,700 10,400

Air circulation (High) m

3

/h 470

Moisture removal (High) Liters/h 0.91 —

Voltage rating V 230

Available voltage range V 198 to 264

Running amperes A 9.8 10.2

Power input W 2200 2300

Power factor % 98 98

C.O.P. W/W 1.16 1.33

Compressor locked rotor amperes A 54

Controls / Temperature control Microprocessor / I.C. thermostat

Control unit Wireless remote control unit

Timer 24 hr ON / OFF

Fan speeds Indoor / Outdoor 3 and Auto / 1

Airflow direction (Indoor)

Horizontal Manual

Vertical Auto

Air filter Washable, Anti–Mold

Compressor Rotary (Hermetic)

Refrigerant / Amount charged at shipment g R22 / 1900 (each system)

Refrigerant control Capillary tube

Power sound level

Indoor – Hi dB-A 51

Outdoor – Hi dB-A 70

Refrigerant tubing connections Flare type

Max. allowable tubing length at shipment m 7.5

Refrigerant tube

Narrow tube mm (in.) 6.35 (1/4)

diameter

Wide tube mm (in.) 9.52 (3/8)

Indoor Unit Outdoor Unit

Unit dimensions Height mm

Width mm see page 8 see page 9

Depth mm

package dimensions Height mm 243 1390

Width mm 855 1141

Depth mm 332 418

Weight

Net kg 8.0 128

Shipping kg 10.0 138

Shipping volume m

3

0.07 0.59

Dimensions & Weight Features Electrical Rating Performance

Indoor Unit MCA90MR5TAA

Outdoor Unit GR360M4R5TAA

2

Page 7

DATA SUBJECT TO CHANGE WITHOUT NOTICE.

Remarks: Rating conditions are:

Cooling: Indoor air temperature 27°C DB/19°C WB

Outdoor air temperature 35°C DB/24°C WB

Heating: Indoor air temperature 20°C DB

Outdoor air temperature 7°C DB/6°C WB

No. of indoor units. 1 SYSTEM (A or B)

Power Source 220 – 240 V ~ 50 Hz

Cooling Heating

Capacity

kW 5.6 5.8

BTU/h 19,300 19,800

Air circulation (High) m

3

/h 470

Moisture removal (High) Liters/h 2.2 —

Voltage rating V 230

Available voltage range V 198 to 264

Running amperes A 9.8 10.2

Power input W 2200 2300

Power factor % 98 98

C.O.P. W/W 2.54 2.52

Compressor locked rotor amperes A 54

Controls / Temperature control Microprocessor / I.C. thermostat

Control unit Wireless remote control unit

Timer 24 hr ON / OFF

Fan speeds Indoor / Outdoor 3 and Auto / 1

Airflow direction (Indoor)

Horizontal Manual

Vertical Auto

Air filter Washable, Anti–Mold

Compressor Rotary (Hermetic)

Refrigerant / Amount charged at shipment g R22 / 1900 (each system)

Refrigerant control Capillary tube

Power sound level

Indoor – Hi dB-A 54

Outdoor – Hi dB-A 70

Refrigerant tubing connections Flare type

Max. allowable tubing length at shipment m 7.5

Refrigerant tube

Narrow tube mm (in.) 6.35 (1/4)

diameter

Wide tube mm (in.) 9.52 (3/8)

Indoor Unit Outdoor Unit

Unit dimensions Height mm

Width mm see page 8 see page 9

Depth mm

package dimensions Height mm 243 1390

Width mm 855 1141

Depth mm 332 418

Weight

Net kg 8.0 128

Shipping kg 10.0 138

Shipping volume m

3

0.07 0.59

Dimensions & Weight Features Electrical Rating Performance

Indoor Unit MCA90MR5TAA

Outdoor Unit GR360M4R5TAA

3

Page 8

DATA SUBJECT TO CHANGE WITHOUT NOTICE.

Remarks: Rating conditions are:

Cooling: Indoor air temperature 27°C DB/19°C WB

Outdoor air temperature 35°C DB/24°C WB

Heating: Indoor air temperature 20°C DB

Outdoor air temperature 7°C DB/6°C WB

No. of indoor units. 2 SYSTEMS (A + B)

Power Source 220 – 240 V ~ 50 Hz

Cooling Heating

Capacity

kW 11.2 11.6

BTU/h 38,300 39,600

Air circulation (High) m

3

/h 470

Moisture removal (High) Liters/h 4.4 —

Voltage rating V 230

Available voltage range V 198 to 264

Running amperes A 19.6 20.4

Power input W 4400 4600

Power factor % 98 98

C.O.P. W/W 2.54 2.52

Compressor locked rotor amperes A 54

Controls / Temperature control Microprocessor / I.C. thermostat

Control unit Wireless remote control unit

Timer 24 hr ON / OFF

Fan speeds Indoor / Outdoor 3 and Auto / 1

Airflow direction (Indoor)

Horizontal Manual

Vertical Auto

Air filter Washable, Anti–Mold

Compressor Rotary (Hermetic)

Refrigerant / Amount charged at shipment g R22 / 1900 (each system)

Refrigerant control Capillary tube

Power sound level

Indoor – Hi dB-A 54

Outdoor – Hi dB-A 73

Refrigerant tubing connections Flare type

Max. allowable tubing length at shipment m 7.5

Refrigerant tube

Narrow tube mm (in.) 6.35 (1/4)

diameter

Wide tube mm (in.) 9.52 (3/8)

Indoor Unit Outdoor Unit

Unit dimensions Height mm

Width mm see page 8 see page 9

Depth mm

package dimensions Height mm 243 1390

Width mm 855 1141

Depth mm 332 418

Weight

Net kg 8.0 128

Shipping kg 10.0 138

Shipping volume m

3

0.07 0.59

Dimensions & Weight Features Electrical Rating Performance

Indoor Unit MCA90MR5TAA

Outdoor Unit GR360M4R5TAA

4

Page 9

2-2. Major Component Specifications

DATA SUBJECT TO CHANGE WITHOUT NOTICE.

Part No. WSA –LTR

Controls Microprocessor

Control circuit fuse 250 V – 3.15 A

Remote Control Unit RC–2(WOA)

Type Cross–flow

Number ... Dia. and length mm 1 ... ø95 / L617

Fan motor model ... Number KFV4Q–11H5P -S... 1

No. of poles ... rpm (230 V, High) 4 ... 1190

Nominal output W 10

Coil resistance (Ambient temp. 20°C) Ω WHT – BRN : 561.8

WHT – VLT : 197.4

VLT – ORG : 63.4

ORG – YEL : 155.7

YEL – PNK : 115.9

Safety

Type Internal thermal fuse

devices

Operating temp.

Open °C 145 ± 2

Close —

Run capacitor

µF 0.8

VAC 440

Type Stepping motor

Model MP24GA1

Rating DC 12 V

Coil resistance (Ambient temp. 25°C) Ω WHT – BLU (respectively 4 wires) : 380 ± 7%

Coil Aluminum plate fin / Copper tube

Rows 2

Fin pitch mm 1.4

Face area m

2

0.130

Heat

Exch. Coil

Flap Motor Fan & Fan Motor

Controller

PCB

Indoor Unit MCA90MR5TAA

5

Page 10

6

Controller PCB MSC1V1 (40V1-D)

Control circuit fuse 250 V– 3.15 A

Type Rotary (Hermetic)

Compressor model ... Number PH36VTRT ... 2

Nominal output W 1600 x 2

Compressor oil ... Amount cc DIAMOND MS32(N-1) ... 900 x 2

Coil resistance (Ambient temp. 25°C) Ω C – R : 1.08

C – S : 6.36

Type Internal

Overload relay ... Number UP3RE0302 ... 2

Safety

Operating

Open °C 155 ± 5

devices

temp.

Close °C 90 ± 10

Operating amp.(Ambient temp. 25°C) Trip in 3 to 10 sec. at 54 A

Run capacitor µF 55 ... 2

... Number VAC 450 ... 2

Type Propeller

Number ... Dia. mm 2 ... ø460

Fan motor model ... Number KFC-6T-91C5P ... 2

No. of poles ... rpm (230 V,High) 6 ... 868

Nominal output W 100

Coil resistance (Ambient temp. 20°C) Ω WHT – BRN : 61 YEL - PNK: 17.7

WHT – YEL: 64.3

Safety Type Internal protector

devices

Operating

Open °C 130 ± 8

temp.

Close 79 ± 15

Run capacitor

µF 5.0

VAC 480

Coil Aluminum plate fin / Copper tube

Rows 2

Fin pitch mm 2

Face area m

2

0.45 (each system)

External Finish Acrylic baked-on enamel finish

Heat

Exch. Coil

CompressorFan & Fan Motor

DATA SUBJECT TO CHANGE WITHOUT NOTICE.

outdoor Unit GR360M4R5TAA

Page 11

2-3. Other Component Specifications

Indoor Unit MCA90MR5TAA

Thermistor (Coil sensor ) NTC - SENSOR

Resistance kΩ 25°C 10 ± 5%

Outdoor Unit GR360M4R5TAA

Power Relay (PRa, PRb)

DFU24D1-F (M)

Coil rating DC 24V

Coil resistance Ω (at 20°C) 650 ± 10%

Contact rating AC 250V, 20A

Thermistor (TOA, TCa, TCb) NTC - SENSOR

Resistance kΩ

Solenoid Coil - 4 way Valve (RVa1/a2, RVb1/b2) CHV-01AI506B1 (Coil), CHV-0101 (Valve)

Coil rating

AC 230V, 50Hz, 6W

Coil resistance Ω (at 20°C) 1400 ± 7%

Thermistor (Room sensor ) NTC - SENSOR

Resistance kΩ 25°C 10 ± 5%

Solenoid Coil - Bypass (SVa3, SVb3) NEV-MOAJ503B0 (Coil), NEV-202DXF (Valve)

Coil rating

AC 230V, 50Hz, 5W

Coil resistance Ω (at 20°C) 1450 ± 7%

Solenoid Coil - Indoor units (SVa1/a2, SVb1/b2) HM2-9100/RA6 (Coil), CASTEL (Valve)

Coil rating

AC 230V, 50Hz, 8W

Coil resistance Ω (at 20°C) 1000 ± 7%

7

25°C 10 ± 5%

Page 12

3. DIMENSIONAL DATA

Indoor Unit MCA90MR5TAA

58.599.5

805 177

41.0

41.0 270

Narrow tube ø6.35 (1/4")

Wide tube ø9.52 (3/8")

Center of tubing

hole (2 places)

Drain hose ø18

Remote control unit

18.5

61

172.5

Unit : mm

8

Page 13

Outdoor Unit GR360M4R5TAA

9

Page 14

4. COOLING CAPACITY (System A or B)

Indoor Unit MCA90MR5TAA

Outdoor Unit GR360M4R5TAA

230V 50 Hz

RATING CAPACITY 5,6 kW

AIR FLOW RATE 470 x 2 m³/h

EVAPORATOR CONDENSER

ENT.TEMP. °C OUTDOOR AMBIENT TEMP. °C

W.B. D.B. 25 30 35 40 43

TC 5,31 5,15 4,91 4,60 4,25

CM 1,81 1,93 2,08 2,28 2,48

21 SHC 3,64 3,57 3,45 3,30 3,13

23 SHC 4,12 4,04 3,92 3,77 3,60

15 25 SHC 4,60 4,50 4,38 4,24 4,07

27 SHC 5,08 4,98 4,86 4,60 4,25

29 SHC 5,31 5,15 4,91 4,60 4,25

31 SHC 5,31 5,15 4,91 4,60 4,25

TC 5,75 5,53 5,26 4,94 4,55

CM 1,85 1,99 2,13 2,35 2,55

21 SHC 3,18 3,09 2,97 2,82 2,64

23 SHC 3,66 3,55 3,43 3,29 3,12

17 25 SHC 4,15 4,03 3,91 3,76 3,58

27 SHC 4,62 4,49 4,37 4,22 4,05

29 SHC 5,11 4,97 4,85 4,70 4,52

31 SHC 5,59 5,43 5,26 4,94 4,55

TC 6,09 5,88 5,60 5,26 4,85

CM 1,95 2,05 2,20 2,41 2,62

21 SHC 2,67 2,58 2,46 2,31 2,14

23 SHC 3,13 3,06 2,93 2,79 2,62

19 25 SHC 3,59 3,52 3,40 3,26 3,08

27 SHC 4,05 3,99 3,87 3,73 3,55

29 SHC 4,50 4,46 4,33 4,20 4,02

31 SHC 4,98 4,93 4,81 4,66 4,49

TC 6,45 6,23 5,94 5,58 5,14

CM 1,99 2,11 2,27 2,48 2,70

23 SHC 2,63 2,54 2,42 2,28 2,11

21 25 SHC 3,08 3,01 2,90 2,75 2,58

27 SHC 3,55 3,48 3,36 3,23 3,04

29 SHC 4,00 3,94 3,83 3,69 3,52

31 SHC 4,47 4,42 4,30 4,16 3,99

TC 6,89 6,60 6,23 5,83 5,43

CM 2,03 2,16 2,32 2,54 2,76

23 25 SHC 2,58 2,47 2,34 2,19 2,05

27 SHC 3,02 2,93 2,80 2,65 2,51

29 SHC 3,48 3,41 3,27 3,13 2,98

31 SHC 3,98 3,88 3,74 3,59 3,46

TC: TOTAL COOLING CAPACITY kW

SHC: SENSIBLE HEAT CAPACITY kW

CM: COMPRESSOR INPUT kW

RATING CONDITIONS

OUTDOOR AMBIENT TEMPERATURE 35°C D.B.

INDOOR UNIT ENTERING AIR TEMP. 27°C D.B./19°C W.B.

10

Page 15

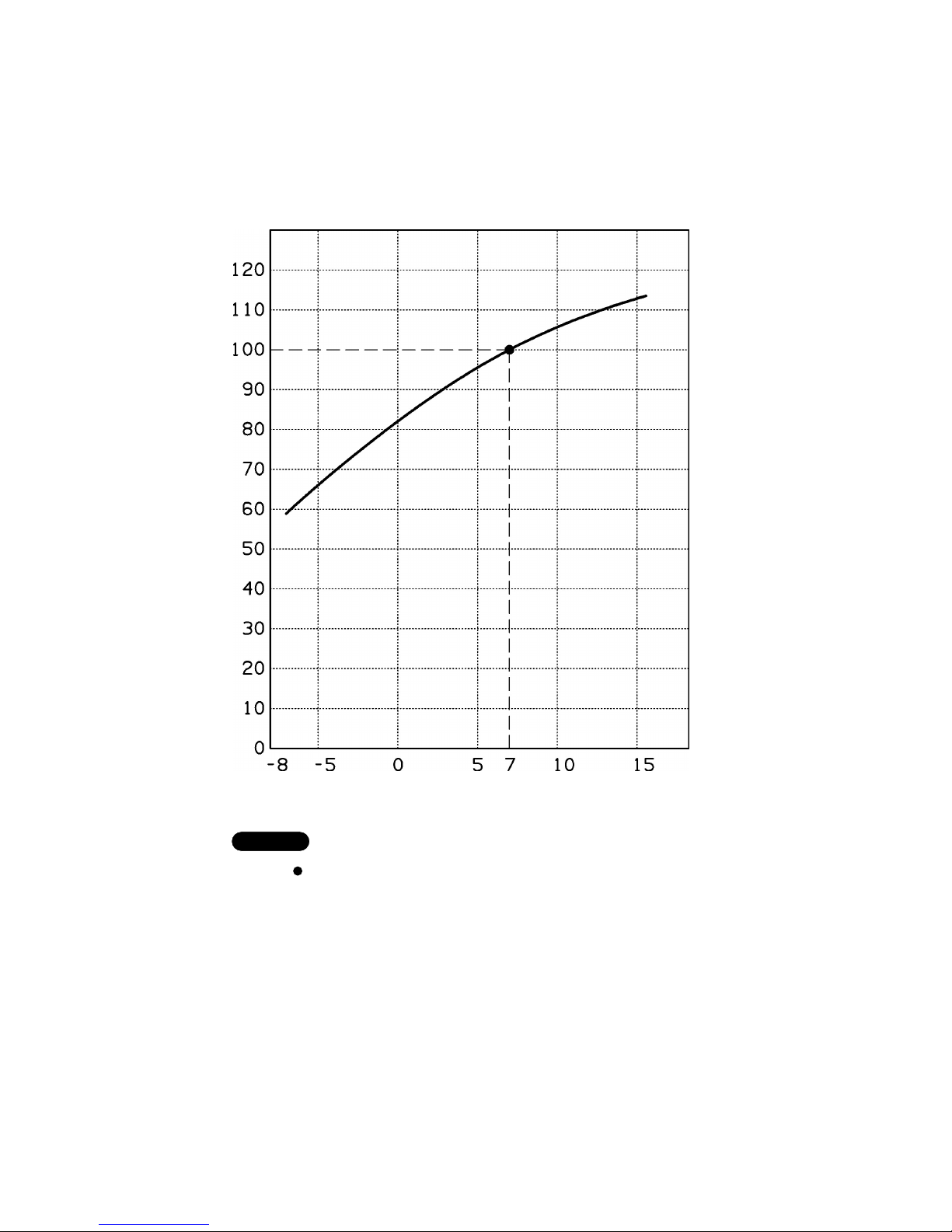

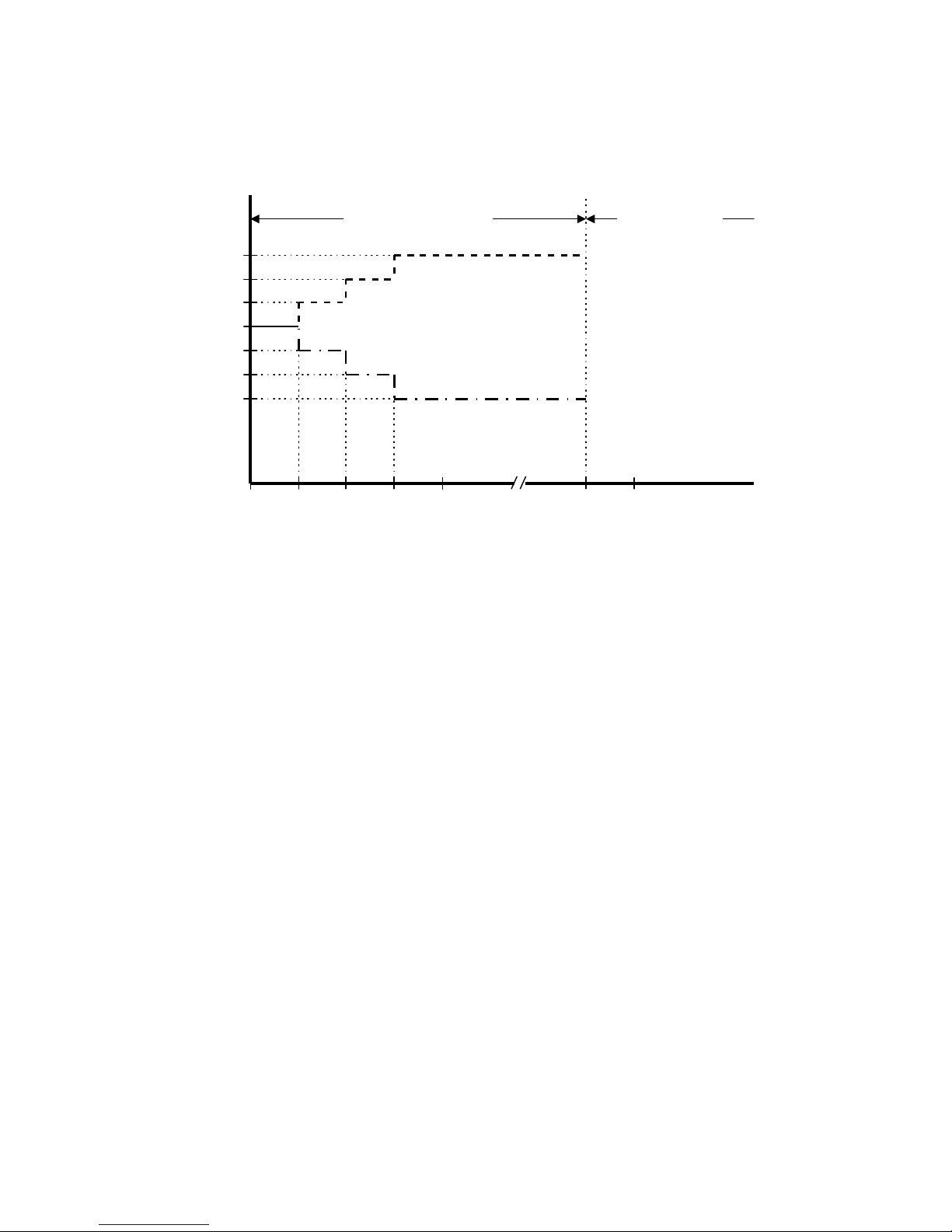

5. HEATING CAPACITY (System A, B or A+B)

Indoor Unit MCA90MR5TAA

Outdoor Unit GR360M4R5TAA

Outdoor temperature (°C DB)

Heating capacity ratio (%)

NOTE

1) … Point of Rating condition

Black dot in the chart indicate the following rating condition.

Indoor : 20°C DB

Outdoor : 7°C DB / 6°C WB

2) Above characteristics take into consideration defrost operation.

3) Fan speed : High

11

Page 16

Indoor Unit MCA90MR5TAA

0

123456789

1

2

3

4

Horizontal distance (m)

Axis air velocity (m/s)

Vertical distance (m)

Axis air velocity

Flap angle

45°

60°

Room air temp. : 20°C

Fan speed : High

Heating

0

123456789

1

2

3

4

Horizontal distance (m)

Axis air velocity (m/s)

Vertical distance (m)

Axis air velocity

Flap angle

0°

30°

Room air temp. : 27°C

Fan speed : High

Cooling

6. AIR THROW DISTANCE CHART

12

Page 17

Wide tube service valve

Narrow tube service valve

Indoor Unit MCA90MR5TAA

Outdoor Unit GR360M4R5TAA

7. REFRIGERANT FLOW DIAGRAM

CIRCUIT A

13

Page 18

Wide tube service valve

Narrow tube service valve

Indoor Unit MCA90MR5TAA

Outdoor Unit GR360M4R5TAA

CIRCUIT B

14

Page 19

8. ELECTRICAL DATA

8-1. Electrical Characteristics

The values in the table below indicate the sum of indoor

units which are in running condition.

NOTE

230V Single phase 50 Hz

Number of indoor unit

1 System 2 Systems

(A1+A2 or B1+B2) (A + B)

Rating Conditions

Running amp. A 9.8 19.6

Power input kW 2.2 4.4

Full Load Conditions

Running amp. A 11.2 22.5

Power input kW 2.55 5.1

230V Single phase 50 Hz

Cooling

Heating

Rating Conditions: Indoor Air Temperature 20°C DB

Outdoor Air Temperature 7°C DB / 6°C WB

Full Load Conditions: Indoor Air Temperature 27°C DB

Outdoor Air Temperature 24°C DB / 18°C WB

Cooling

Heating

Number of indoor unit

1 System 2 Systems

(A1+A2 or B1+B2) (A + B)

Rating Conditions

Running amp. A 10.2 20.4

Power input kW 2.3 4.6

Full Load Conditions

Running amp. A 11.2 22.5

Power input kW 2.55 5.1

15

Indoor Unit MCA90MR5TAA

Outdoor Unit GR360M4R5TAA

Rating Conditions: Indoor Air Temperature 27°C DB / 19°C WB

Outdoor Air Temperature 35°C DB

Full Load Conditions: Indoor Air Temperature 32°C DB / 23°C WB

Outdoor Air Temperature 46°C DB

Page 20

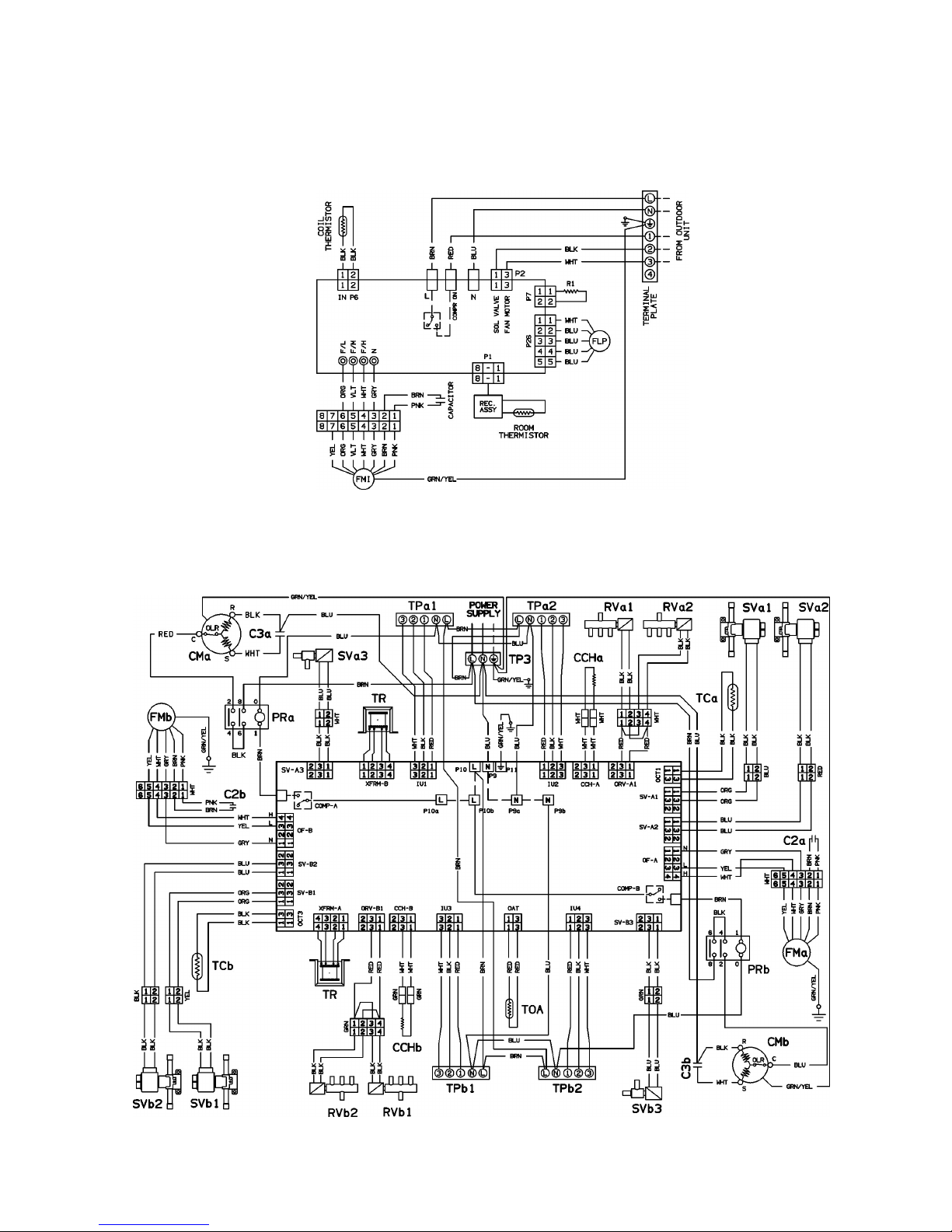

8-2. Electric Wiring Diagrams

Outdoor Unit GR360M4R5TAA

Indoor Unit MCA90MR5TAAA

16

Page 21

9. FUNCTION

9-1 Cool Mode Operation

(RT - SPT) [oc]

+3

+2

+1

0

-1

ON

OFF

ON

OFF

H

L

M

ON

OFF

COMP

OFAN

IFAN

RV

over 3 min over 5 min

over 30 sec

In Cool Mode, the operation of the Compressor (COMP), Outdoor Fan (OFAN) and Indoor Fan (IFAN) are

determined by the difference between the Room Temperature (RT) and the Set Point Temperature (SPT)

as in the graph above.

Notes:

1. In this graph, the IFAN is operating in the “Auto Fan Speed” setting. If the user has selected the low,

medium or high fan speed, the IFAN will run constantly at that speed only.

2. In addition to the value of (RT-SPT), the operations of the relays are also controlled by protection

delays. For example, (a) the minimum On/Off time of the COMP is 5 min and 3 min respectively, and

(b) the IFAN can change speed only after it has operated at the same speed for 30 sec.

17

Page 22

9-2 Heat Mode Operation

(RT - SPT) [oc]

+1

0

-1

-2

-3

H

OFF

L

M

ON

OFF

Note 1 Note 2

COMP

IFAN

RV

ON

OFF

30 sec

The Heat Mode operation is similar to the Cool Mode operation. The COMP, OFAN and IFAN are mainly

controlled by the value of (RT – SPT). In the graph above, the IFAN is operating in Auto Fan speed mode.

Therefore, the IFAN speed changes automatically according to the (RT - SPT).

Note 1: The 30s IFAN operation is for purging the heat from the in-coil after COMP has stopped.

Note 2: The IFAN will not be turned on until the in-coil temperature is high enough (as shown in the graph

below) to prevent the unit from supplying cool air.

In Auto Mode, the unit switches between the

IFAN Speed

Any

Low

Stop

30 35 40

ICT [oc]

ICT = In-coil Temperature

Any = Hi, Med or Low fan speed which is

selected by the user. In Auto Fan Speed

Mode, the fan speed is selected by the

unit automatically instead.

Low = The indoor fan is forced to operate at low

speed

18

Page 23

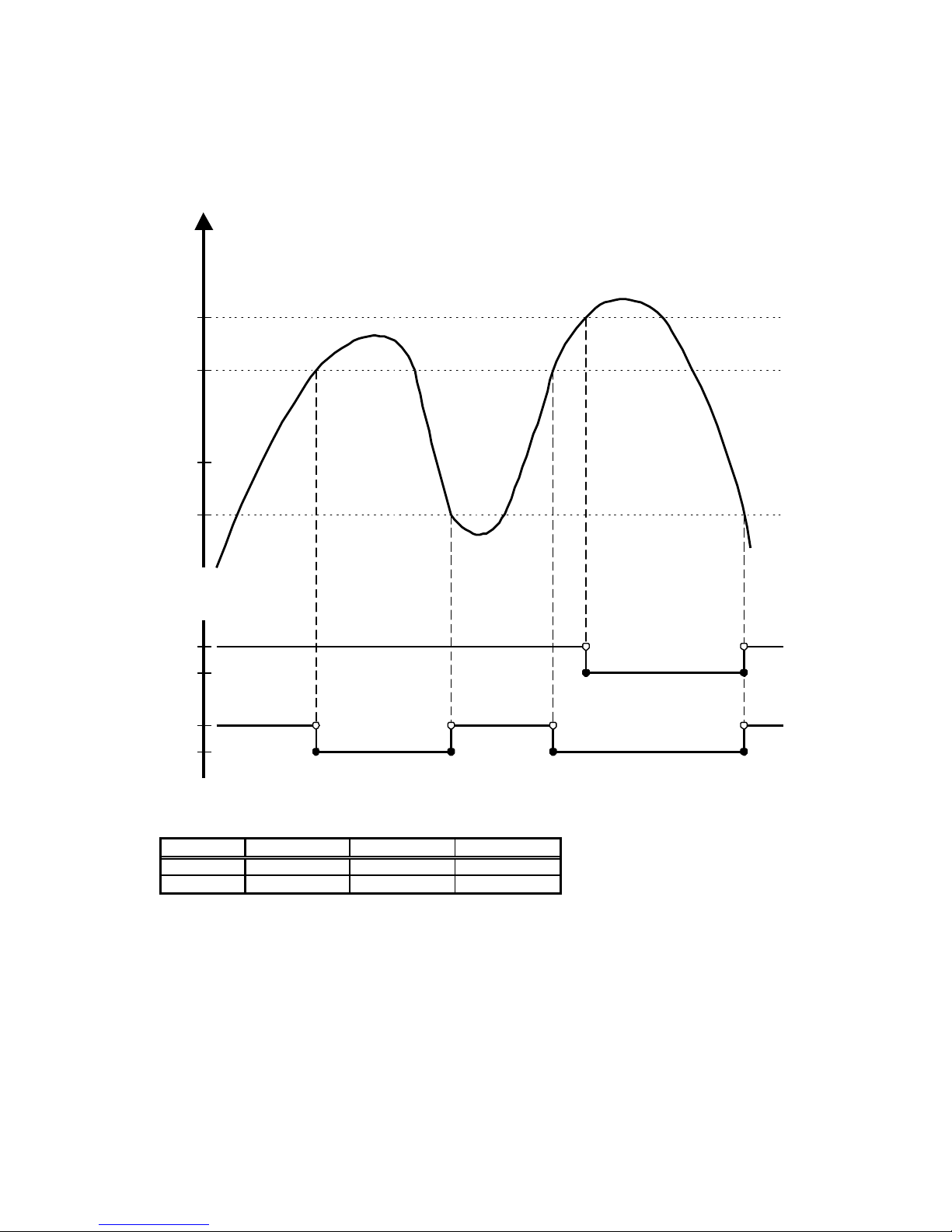

9-3 Dry Mode Operation

DRY

(RT - SPT) [oc]

+2

+1

0

-1

-2

ON

OFF

LOW

OFF

DRY-ON

DRY-OFF

Time [min]

10

20

30

40 50

COMP

& OFAN

IFAN

5 minutes COMP

ON time

Max 15 minutes Max 15 minutes 6 min

(Note 2)

3.5 min

(Note 1)

In Dry Mode, the unit operates in a mild cool mode to lower the humidity of the room. In order to maintain

a high efficiency in the drying operation without over lowering the room temperature excessively, the Dry

Mode is different from the Cool Mode in two ways.

1. The IFAN is forced to operate at low speed only. And, the IFAN is turned off with the COMP.

2. The unit operates in either the “Dry-on” state or the “Dry-off” state. If RT = SPT, the unit will operate in

“Dry-off” state. The COMP is forced to operate for 6 min after it has stopped working for 15 min. If RT

> SPT, the unit will operate in “Dry-on” state. The COMP is forced off for 3.5 min after it has been

working for 15 min.

Note 1: COMP is forced off in Dry-on state.

Note 2: COMP is forced to operate in Dry-off state.

19

Page 24

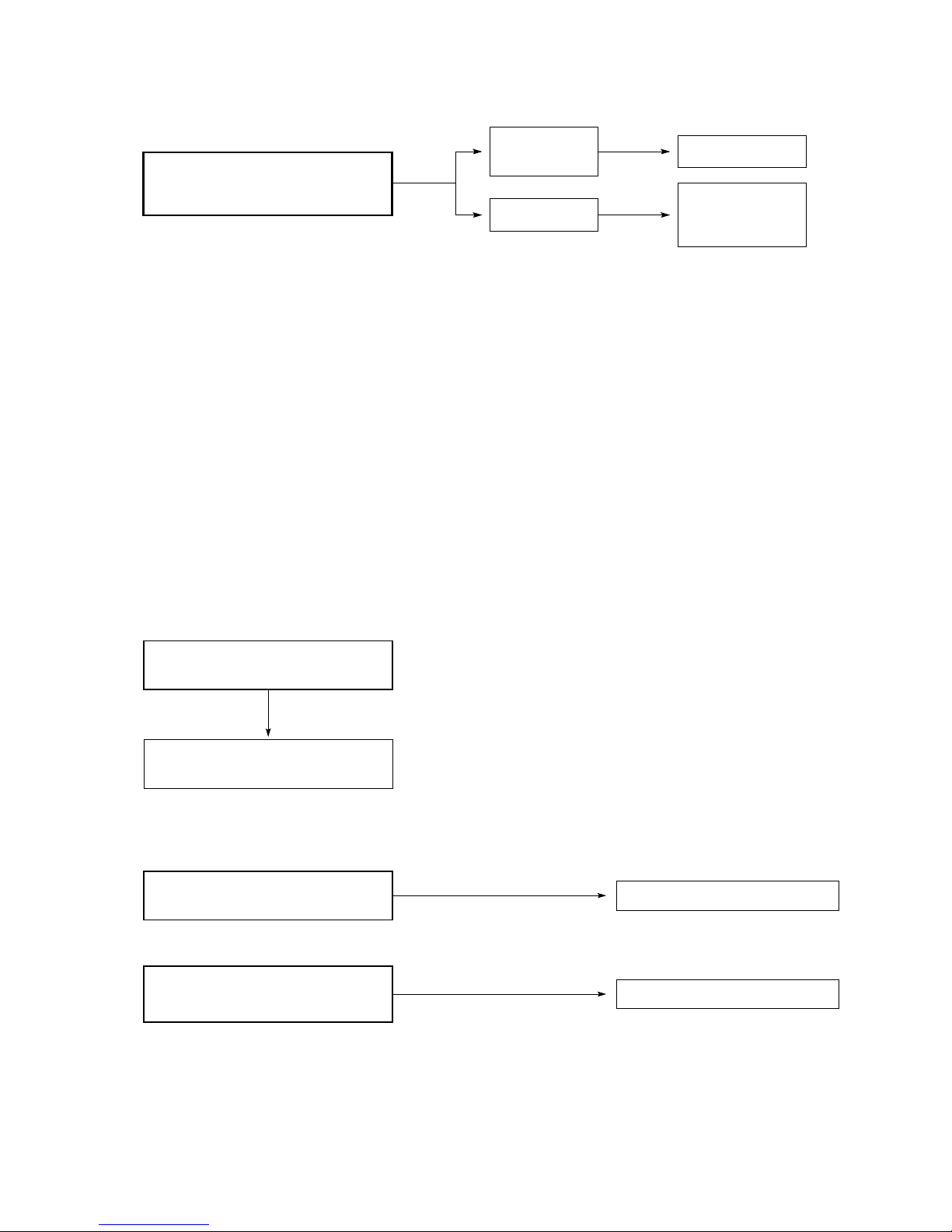

9-4 Fan Operation

1. Indoor unit

In Fan Mode the indoor fan is turned on to improve the air circulation in the room. Compressor and

outdoor fan remain OFF all the time.

Note: if the user has selected the Auto Fan Speed setting, the indoor fan speed would be selected by

the unit automatically according to the difference between RT and SPT, as in Cool Mode.

2. Outdoor unit

a. The speed of the Outdoor fans (OFH-A & OFL-A for system A and OFH-B & OFL-B for system B)

can be

• High - OFH is ON, OFL is OFF

• Low - OFH is OFF, OFL is ON

• OFF - both OFH and OFL are OFF

b. The OFH and OFL will never be turned ON at the same time.

c. When the compressor starts working, the speed of the corresponding OFAN is high during the

first 10 min., provided the OFAN is turned ON.

Note:

This rule is not applied at the first compressor starting after an High Pressure Protection (section 9-5).

In this case, the OFAN speed will be determined by the outdoor air thermistor (OAT) as in normal

operation (see below) instead of forced high for 10 minutes. This rule also does not apply when

the outdoor air thermistor is < 21

o

C in cool mode.

d. When compressor is OFF, the corresponding OFAN is forced OFF except during High Pressure

Protection. The OFAN will run at high speed under High Pressure Protection.

e. In general cases, when OFAN is turned ON, its speed (High or Low) is determined by the OAT as

below.

Heat Mode

f. The output of OFAN is low (fan stopped) when -2°C<OCT<8°C provided the HP protection operates

and that the OFAN is turned on (see section 9.6).

Cool Mode

20

Page 25

9-5 Protection Operations in Cool and Dry Modes

1. Indoor Coil Defrost Protection

The in-coil defrost protection can prevent the ice formation at the in-coil when the ambient temperature

is low.

ICT [oc]

+2

ON

OFF

ON

OFF

t1 t2 t3

COMP

OFAN

+1

+5

0

-1

ON

OFF

IFAN

t1 = 5 min minimum for each COMP starting

t2 = OFAN cycling (alternate between ON and OFF every 30 sec) for 20 min maximum

t3 = COMP and OFAN stop for 10 min minimum

21

Page 26

2. Outdoor coil High Pressure Protection

The outdoor coil High Pressure protection prevents the rising of pressure in the outdoor coil

during cool mode operation

Protection INPUTS (from indoor units) OUTPUTS

Condition A

Condition B

RV1

(RV3)

RV2

(RV4)

CO1

(CO3)

CO2

(CO4)

OCT-A

(OCT-B)

ORV-A

(ORV-B)

CO-A

(CO-B)

OF-A

(OF-B)

SV-A1

(SV-B1)

SV-A2

(SV-B2)

SV-A3

(SV-B3)

High Pressure

Protection

Any Any Any Any > 55 RV1

(RV3)

X Hi X X X

Off Off On On = 50 X ON Hi / Lo ON ON X

Termination of Off Off On Off = 50 X ON Hi / Lo ON X ON

HP Protection Off Off Off On = 50 X ON Hi / Lo X ON ON

Notes:

1. Protection Mode is activated when any of the condition A or condition B is satisfied.

• In OCT high pressure protection, only the system that start the protection is under the

control of the protection routine. The other system will continue to work in normal

mode.

2. The OCT HP protection is triggered by the measured OCT-A (or OCT-B) only. The status of the

RV & CO inputs from the indoor units are not checked. This way, the protection can also handle

the abnormal situation caused by hardware failure, such as RV or COM output relay is defective

and

3. If the OF speed is marked as “Hi/Lo”, its speed is governed by the outdoor air thermistor as

explained before.

22

Page 27

9-6 Protection Operations In Heat Mode

1. Outdoor coil De-ice Protection

Protection INPUTS OUTPUTS

Condition A

(Condition B)

RV1

(RV3)

RV2

(RV4)

CO1

(CO3)

CO2

(CO4)

OCT-A

(OCT-B)

ORV-A

(ORV-B)

CO-A

(CO-B)

OF-A

(OF-B)

SV-A1

(SV-B1)

SV-A2

(SV-B2)

SV-A3

(SV-B3)

On Any On On = -2 X ON X ON ON X

Any On On On = -2 X ON X ON ON X

De-icing On Off On Off = -2 X ON X ON X ON

Off On Off On = -2 X ON X X ON ON

On On On On > 12 ON ON Hi / Lo ON ON X

Termination of On Off On Off > 12 ON ON Hi / Lo ON X ON

De-icing Off On Off On > 12 X ON Hi / Lo X ON ON

Notes:

1. Protection Mode is activated when any of the condition A or condition B is satisfied.

• In De-icing mode, both systems (A & B) will always perform De-icing at the same time.

2. In the de-icing process:

(i) The de-icing process can be triggered by any one of the OCT which is < -2

o

C with the

corresponding COMP, RV are both ON and de-icing timer counts to zero.

(ii) The de-icing timer is stopped (the count is reserved) when both COM-A and COM-B

are OFF.

(iii) The de-icing timer counts down when any of the compressor turn on.

(iv) The de-icing timer is reset (to maximum count) when the condition “RV output of the

IDU are all Off or all OCT > -2

o

C” .

3. If the OF speed is marked as “Hi/Lo”, its speed is governed by the outdoor air thermistor as

explained before.

23

Page 28

2. Outdoor Coil High Pressure Protection in Heat Mode

The outdoor coil high pressure protection prevent the rising of pressure in the circuit during heating

operation at high evaporating temperatures.

24

Page 29

3. Indoor Coil High Pressure Protection in Heat Mode

The in-coil high pressure protection prevent the build up of high pressure at the in-coil during heating

operation.

Note:

The operation temperatures shown as A and B in the chart differ by models.

MCA90MR5

A 54 - B 45 - -

ICT [oc]

ANY

OFF

ANY

COMP

OFAN

B

A

64

OFF

COMP is forced OFF

25

Page 30

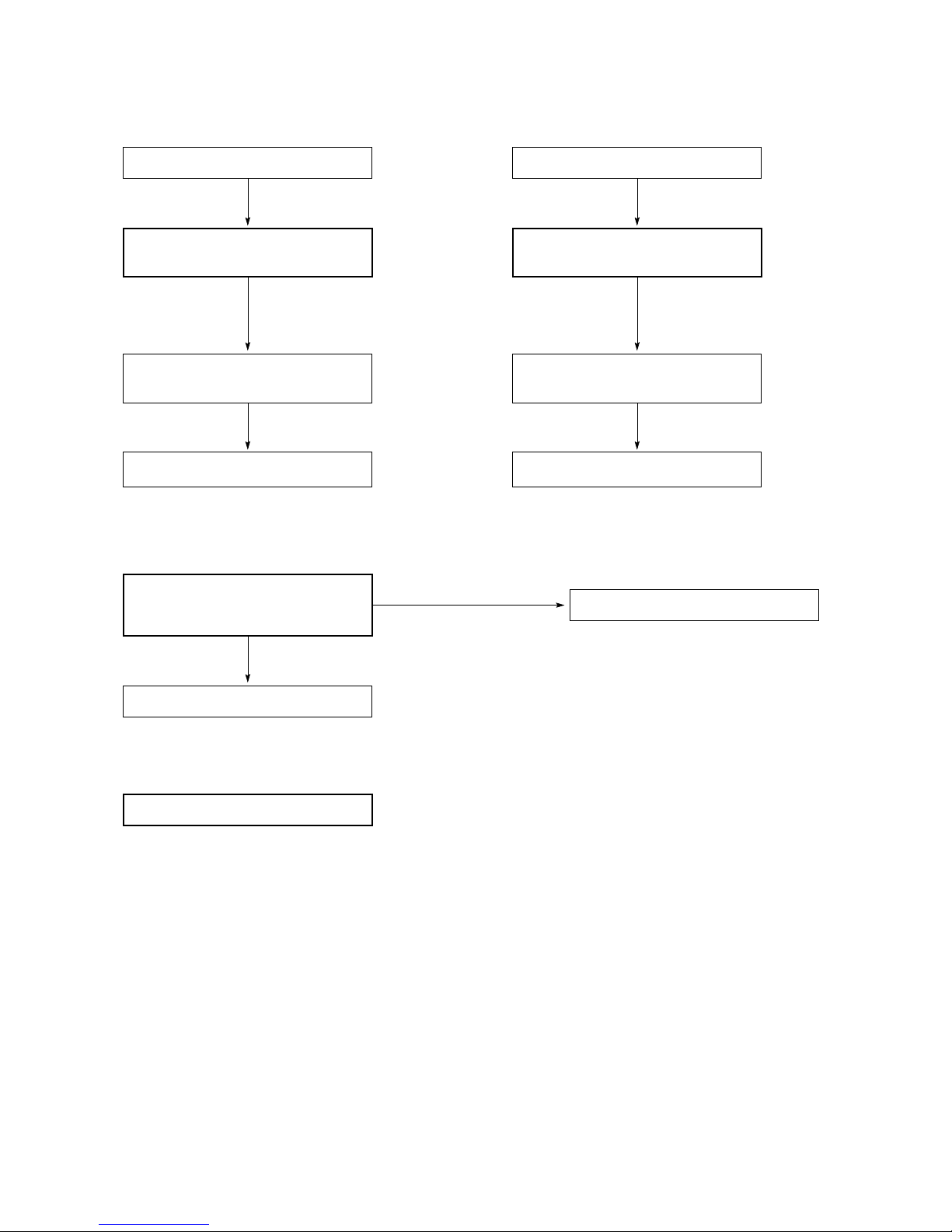

9-7 Cold Draft Prevention (Heating)

• This function controls indoor fan speed so a strong draft of cold air will not blow out before the indoor heat

exchange coil have sufficiently warmed up.

• When 10 minutes has elapsed, the fan speed is automatically switched to set speed regardless of indoor heat

exchange coil temperature.

Indoor heat exchange

coil temp. (°C)

Max.10 minutes

Tc

Indoor Fan OFF Set Speed

NOTE

• The operation temperature shown as Tc in the chart differ by models.

MCA90MR5

Tc 32

26

Page 31

9-8.1 Sleep Function

Room temperature is automatically controlled to compensate for body temperature variations while

sleeping. This mode of operation is designed for maximal comfort in both COOL and HEAT modes.

SPT

Time [Hr]

432

Start

Sleep

7 - 12

RT

SPT-1

SPT-2

SPT-3

SPT+2

SPT+1

SPT+3

1

7-12 Hours Sleep operation

Unit is turned to SB

after Sleep

Cool, Dry modes

Heat mode

9-8.2 Daily Timer Function

Unit can be programmed to be ON and OFF automatically at preset time everyday, by using a remote

controller. The resolutions of the ON/OFF timers are 10 min.

9-8.3 IFEEL Function

This feature is provided if the unit is used together with a remote controller with the I-FEEL function. When

this function is selected, the remote controller sends the room temperature measured by its build-in

thermistor to the air con for more accurate temperature control.

9-8.4 Louver Control

The airflow louver can be driven by either a 12V DC stepping motor or an AC motor. The louver can be

set to operate at auto swing mode or fix position mode.

Three additional features are provided if the louver is controlled by a DC stepping motor.

• Different swing positions (range) for Heat Mode and Cool Mode operation

• Last louver position in fix position mode is stored in the EEPROM, and is restored when the unit is

turned on.

• The louver is closed automatically when the unit is switched to standby mode.

27

Page 32

The push button switch and the LED indicators on the display panel let the user to control the unit

operation without a remote controller. Their operations are provided below.

STAND BY

INDICATOR

1. Lights up when the Air Conditioner is connected to power and

ready to receive the R/C commands

2. Blinks continuously in case of any thermistor failure.

OPERATION

INDICATOR

1. Lights up in operation mode (Note: OFF in standby mode).

2. Blinks for 0.5 sec., to announce that a R/C infrared signal has

been received and stored.

3. Blinks continuously during

• OCT High Pressure Protection Mode

• Deicing in Heating Mode

TIMER INDICATOR

1. Lights up during Timer and Sleep operation.

2. Active On/Off timer setting will become invalid after a power

failure. When this happens, the unit is forced to restart in STBY

mode, and the Timer Indicator is blinked continuously until (i) the

unit is switched to OPER Mode again, or (ii) any message from

the R/C is received.

Push Button switches:

MODE BUTTON

(Cool, Heat, SB)

Use to cycle the operation mode of the A/C unit among COOL,

HEAT and SB modes, without using the R/C.

Every time this switch is pressed, the next operation mode is

selected, in the order :

SB => Cool Mode => Heat Mode => SB => ...

28

9-8.5 Manual Unit Control and LED indicators

1. Indoor Unit PCB

2. Outdoor Unit PCB

The status of the Multi Split Controller system (MSC) is indicated by a system Status LED and a Power

LED on the control board of the outdoor unit. The Power LED will be ON whenever there is +5V

supply voltage in the system, otherwise it is OFF. In addition, only the Status LED will be

controlled by the microprocessor (MCU) to indicate its internal operational status. The leds’ operation

details can be described by the following table.

Conditions Power LED L3 (Green) Status LED L2 (Red)

Normal Operation ON OFF

Self test in progress ON ON

Self test completed w/o

error

ON Blink at 10Hz for 3sec,

then OFF

Fault Detected

(in operation or test mode)

ON Blinking

(see note below)

Power OFF / no power OFF OFF

Notes:

1. When any fault is detected, the most significant digit of the error code is shown by

using the blinking Status LED. For example, when one of the thermistors is not

operating properly, the Status LED will be blinking with the pattern “Blink 5 times ->

OFF for 2 sec -> Blink 5 times -> …” so as to indicate that an error code of 5 has

been detected (see section related to fault detection for more information).

Page 33

9-8.6. Fault Operations and Indications (Outdoor Unit PCB)

The MCU of the MSC system will monitor all input continuously. Then update the status of the inputs

every second. To prevent temporary input error from interfering with normal operation, the MCU will

not take immediately action when an error is detected. In general, the MCU will regard an input as

defective only if four successive invalid data are received at that input. As a result, there will be a 2

seconds delay between the occurrence of an error and the MCU makes proper response to this error.

1. Fault Conditions in Operating Mode

Fault operations can be one or more of the following:

• The zero crossing circuit is not working at the frequency of 90-132 Hz

• The OAT thermistor is not functional (Temp < -30oC or Temp > 75oC)

• Any of the OCT thermistor is not functional, that is:

measured OCT is out of operational range: Temp < -30

o

C or Temp > 95oC

• Any of the +12V DC supply voltage is under 8V DC.

• Any photo-coupler output of an enabled indoor unit is invalid

2. Fault Handling

Beside blinking the system Status LED, the MSC MCU will also response to the system faults by

taking different preventive actions to protect the system hardware.

(1) The MSC MCU will turn OFF all outputs of both systems in case of critical fault condition, one

example is:

• the zero crossing circuit is not working at the frequency 90-132 Hz.

(2) The MSC MCU will turn OFF the outputs of a system in case of local fault

• the +12V DC supply voltage of that system is under 8V DC

Note : If the +12V DC supply voltage of both systems is under 8V DC, the MCU will turn OFF

all relays, and suspend all relay operations. When one or both DC supply voltage is

back to normal, the MCU will perform a “System Reset” function.

(3) The MSC unit will disable a specific indoor unit, when

• the OCT thermistor of this unit is not functional

• any photo-coupler output of this unit is faulty

(4) The MSC unit will always select the High OFAN speed if the OFAN is turned ON, when

• OAT failure occurs

Note:

A failed input, such as thermistor or photo-coupler, can be recovered whenever 4 successive valid

inputs (2 sec) are received.

29

Page 34

3. Self Test

Self test is initiated by connecting J1 jumper and 3 fixed resistors of 10k 1/4W, 5% or thermistors at

OCT1, OCT3 and OAT satisfying conditions in note1, then H/W reset the unit. The J1 must be

connected throughout the test operations. Otherwise, the system will go back to normal operation

mode. Moreover, all Indoor Units must be in STBY mode to prevent the Indoor Unit operations from

interfering with the test procedure.

3.1 Self Test Procedure

No Step

Task Description / Work

Element

Observations on UUT

1 Initiate the Self

Test under

internal loop-back

1.1 Power up the UUT by

connecting Line-In on P10 and

Neutral P9

-

1.2 The following tests is

proceeded automatically:

- Relay Walk Test

- Zerocrossing frequency test

- 12VDC supply test

- EEPROM test

- Watchdog Reset timing test

- Thermistors test

- Auto Input Test

Wait for 8-10 seconds.

Each output of UUT is turned ON

for 2 sec with a 0.5 sec

separation in the order below:

CCH-A,ORV-A,COM-A,SVA1,SV-A2,SV-A3,OFH-A,OFL-A

CCH-B, ORV-B,COM-B,SVB1,SV-B2,SV-B3,OFH-B,OFLB,HE

1.3 Self test completed All relays are turned OFF.

If no error is detected, the Red

LED on UUT is blinked at 10 Hz

frequency for 3 sec and then

turned OFF.

If error is detected, the error

code is shown in the Red LED by

a flash pattern as indicated on

section 7.2

2 Initiate the Self

test under

external loop

back

2.1 Disconnect the power to the

UUT

2.2 Connect the Testplug at TP1,

which is also linked to IU1,

IU2, IU3 and IU4, on the UUT

2.3 Provide 220VAC signal inputs

to all photo-coupler

2.4 Repeat procedure 1.1 to 1.3

Note1: 1.The 3 thermistors must be within operation range.

2.The difference among the 2 OCTs must be less than 5°C.

3

.The maximum difference between the OAT and any OCT must be less than 5°C.

30

Page 35

4. Error Code Message

Display of Error Code: Indicated by the Status LED (Red color), a flash pattern consists of 1 to 6

flashes with 0.5sec separation, which is corresponding to the error code 1 to 6. The flash pattern is

repeated continuously with 2sec separation.

No of Flashes

(Error Code)

Error Message

1 Zero Crossing Test Fails

The frequency of the zero-crossing input is measured. To pass this test,

the frequency must be in the range of [90, 132] Hz.

2 12V DC Supplies Test Fails

The output levels of the two 12V DC supplies are measured. To pass this

test, the supply voltages must be over 8V.

3 EEPROM Test Fails

All locations in the EEPROM is tested by non-destructive Read, Write

and Verify.

4

Watchdog Reset Timing Test Fails

The Watchdog output from the MCU is stopped. And the time taken by

the external reset circuit to generate a Hardware Reset is measured.

Criteria to pass: the reset must be generated between 1 to 4 sec after the

Watchdog signal is stopped.

5 Thermistors Test Fails

The temperature detected by the 2 thermistors are compared with each

other.

Criteria to pass: the thermistor outputs must be within operational range

and the maximum difference between the OAT and any OCT must be

less than 5

o

C

6 Auto Input Test Fails

Each input from the photo-coupler is tested with Testplug or without

Testplug

- With Testplug, all input should provide 220VAC

- Without Testplug, all input should have no 220VAC

5. Jumper Settings

5.1 Self-test jumper - J1 (Factory test)

The J1 is used to switch the Outdoor unit to self-test mode. To do so, J1 must be closed before

switching ON the power of the unit. The J1 must be closed during the tests. Whenever J1 is

disconnected, the unit will go back to normal operation mode.

Operation Mode J1 setting

Self Test Closed

Normal Operation Open

31

Page 36

5.2 Quick Test jumper – J2 (Assembly test)

The jumper J2 is used to speed up the operation mode by 60.

Operation Mode J2 setting

Quick Test Closed

Normal Operation Open

9-8.7 Recovery from Power Failure (Indoor Unit PCB)

Last unit settings (SPT, operation mode, louver settings, etc) are saved in the EEPROM in the unit. In

case of power failure, these settings are restored automatically.

32

Page 37

10. TROUBLESHOOTING

10-1. Check before and after troubleshooting.

10-1-1. Check power supply wiring.

●

Check that power supply wires are correctly connected to terminals No. 1 and No. 2 on the 3P terminal plate in

the outdoor unit.

10-1-2. Check inter-unit wiring.

●

Check that inter-unit wiring is correctly connected to the indoor units from the outdoor unit.

10-1-3. Check power supply.

●

Check that voltage is in specified range (±10% of the rating).

●

Check that power is being supplied.

10-1-4. Check lead wires and connectors.

●

Check that coating of lead wires is not damaged.

●

Check that lead wires and connectors are firmly connected.

●

Check that wiring is correct.

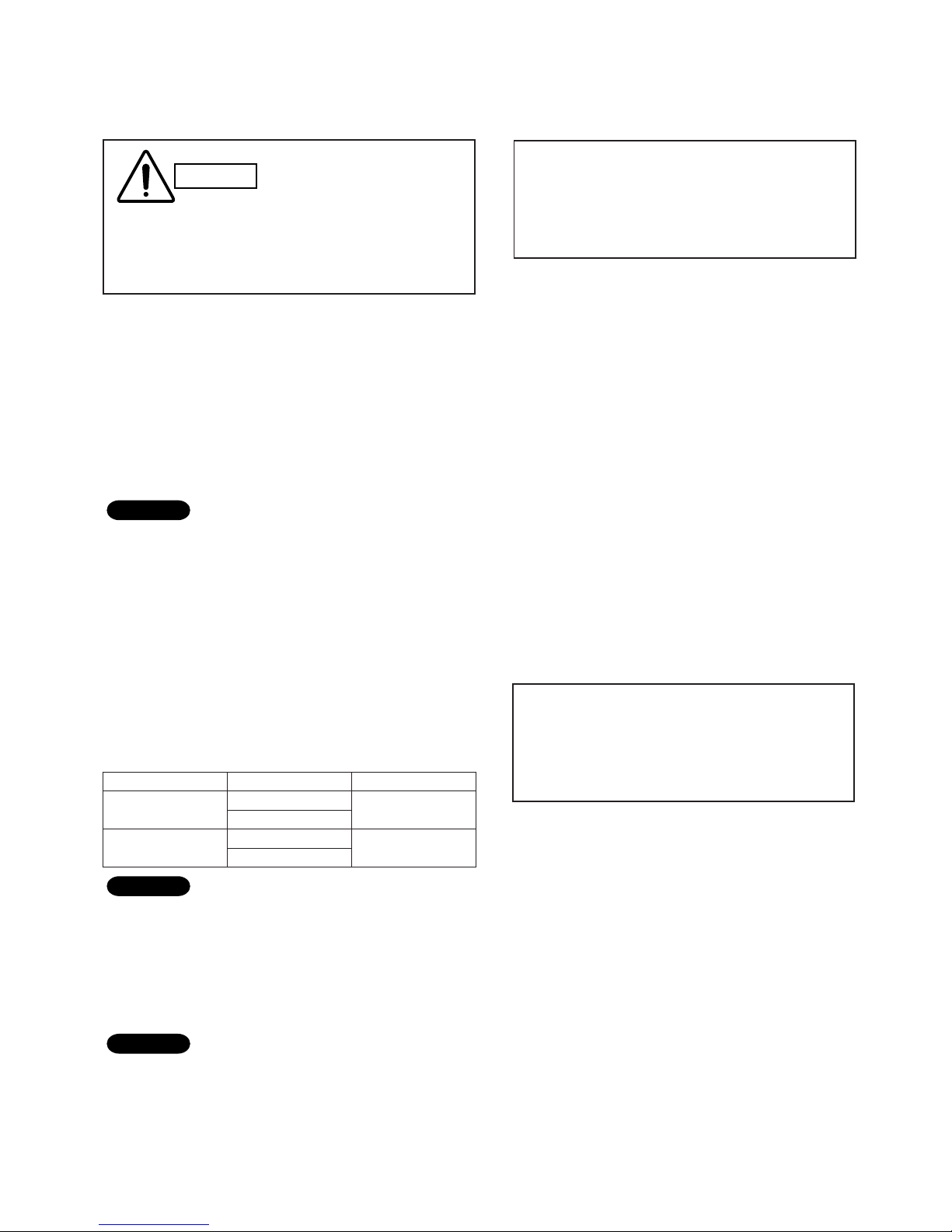

WARNING

Hazardous voltage can cause ELECTRIC SHOCK or DEATH.

Disconnect power or turn off circuit breaker before you start

checking or servicing.

33

Page 38

10-2. Air conditioner does not operate.

10-2-1. Circuit breaker trips (or fuse blows).

A. When the circuit breaker is set to ON, it is tripped soon. (Resetting is not possible.)

●

There is a possibility of ground fault.

●

Check insulation resistance.

If resistance value is 1MΩ or less, insulation is defective (“NO”).

B. Circuit breaker trips in several minutes after turning the air conditioner on.

●

There is a possibility of short circuit.

Measure insulation

resistance of electrical

parts in outdoor unit.

NO

NO

Set circuit breaker to OFF.

*

Measure insulation

resistance of electrical

parts in indoor unit.

1

Remove both power supply wires

and inter-unit wires from terminal

plate in outdoor unit.

Measure insulation resistance

of outdoor unit.

•

2

Remove inter-unit wires from

terminal plate in indoor unit.

Measure insulation resistance

of indoor unit.

•

•

•

Insulation of

outdoor unit

is defective.

Insulation of

indoor unit

is defective.

Check capacity of circuit breaker.

Capacity of circuit breaker is

suitable.

Replace with suitable

one (larger capacity).

•

Measure resistance of compressor

motor winding. (CMa, CMb)

•

Measure resistance of outdoor fan

motor winding. (FM)

•

NO

34

Page 39

10 -2-2.Neither indoor nor outdoor unit runs.

A. Power is not supplied.

B. Check remote control unit.

NO

•

Check power supply.

Power is being supplied to the

outdoor unit.

Circuit breaker

is tripped.

Power failure

Reset breaker.

Wait for recovery

or contact power

company.

OK

•

Try to run with another remote

control unit.

First remote control unit is defective.

•

Check for residue buildup on

transmitter of remote control unit.

•

Check for residue buildup on remote

control receiver on front of indoor

unit.

Clean transmitter.

Clean receiver.

35

Page 40

C. Check fuse on the indoor PCB Ass'y.

OK

Replace the fuse.

OK

OK

•

Check fuse on indoor PCB Ass'y

for continuity.

•

Check operation lamp to see

if light is ON.

Light is OFF

•

Measure resistance of primary and

secondary winding of transformer.

(TR)

Indoor PCB Ass'y or switch Ass'y is

defective.

OK

•

Measure resistance of indoor fan

motor winding.

(FMI)

•

Measure resistance of flap motor

winding. (FLP)

If fuse has been blown,

E. Check TIMER button on the remote control unit.

•

Timer is turned ON. Check to see

if "ON" is displayed on remote

control

YES

Press CLEAR button to cancel

the timer mode.

D. Check fuse on the outdoor PCB Ass'y.

OK

OK

OK

•

Check fuse on outdoor PCB Ass'y

for continuity.

•

Check operation led (L3 green) to see

if light is ON.

Light is OFF

•

Measure resistance of primary and

secondary winding of transformer.

(TR)

Indoor PCB Ass'y is defective.

OK

•

Measure resistance of outdoor fan

motor winding.

(FMa, FMb)

•

Measure resistance of solenoid valves

(SVa/b, RVa/b)

If fuse has been blown,

•

Measure resistance of crank case

heaters and power relays.

(CCHa, CCHb, PRa, PRb)

OK

Replace the fuse.

36

Page 41

10-2-3.Only outdoor unit does not run.

A. Check setting temperature.

B. Check PCB Ass'y in either indoor or outdoor unit.

12-2-4.Only indoor unit does not run.

OK

NO

Is room temperature too low ?

Try to lower setting temperature by

temperature setting button cooler.

Outdoor unit still does

not run.

Remote control unit is defective.

•

Try to run using another remote

control unit.

COOL

OK

NO

Is room temperature too high ?

Try to raise setting temperature by

temperature setting button warmer.

Outdoor unit still does

not run.

Remote control unit is defective.

•

Try to run using another remote

control unit.

HEAT

•

Indoor PCB Ass'y is defective.

•

Check voltage between terminals No.1

and N at terminal plate of indoor unit.

(AC 220V)

No voltage appears.

•

Outdoor PCB Ass'y is defective.

OK

•

Indoor PCB Ass'y is defective.

37

Page 42

10 -3. Some part of air conditioner does not operate.

10-3-1.Only indoor fan does not run.

10-3-2.Only flap motor does not run.

10-3-3.Only outdoor fan does not run.

Fan cannot

be turned.

OK

•

Check fan rotation.

Turn fan gently once or twice by

hand.

•

Check fan casing

foreign matter on

inside.

Fan motor burnout

or foreign matter in

bearings.

Remove foreign

matter or repair.

Repair or replace.

•

Measure resistance of indoor fan

motor winding.

•

Check fan motor capacitor.

Fan cannot

be turned.

Check fan casing

for foreign matter

on inside.

Check fan rotation.

Turn fan gently once or twice

by hand.

•

Measure resistance of outdoor fan

motor winding.

•

OK

•

Fan motor burnout

or foreign matter

in bearings.

Repair or replace.

Remove foreign

matter or repair.

Check fan motor capacitor.

•

•

Measure resistance of flap motor

winding.

38

Page 43

10-3-4.Only compressor does not run.

Measure resistance of

compressor motor winding.

•

NO

Check compressor motor

capacitor.

•

YES

YES

YES

Overload relay is working.

Refrigerant gas shortage. Charge refrigerant gas (R22).

Temperature of compressor is

abnormally high.

Rotor may be locked up.

(OLR)(C3a,C3b)

Measure coil resistance of

power relay. (PRa,PRb)

39

Page 44

10 -4. Air conditioner operates, but abnormalities are observed.

12-4-1.Operation does not switch from HEAT to COOL (or COOL to HEAT).

•

Indoor PCB Ass'y is defective.

•

Check voltage between terminals

No. 2 and N at terminal plate.

(AC 220V)

No voltage appears.

Outdoor PCB Ass'y is defective.

OK

•

Remote control unit may be defective.

•

Measure resistance of 4–way valve's

winding.

Receiver in switch Ass'y may be

defective.

COOL ➞ HEAT

•

Check voltage between terminals

No. 2 and N at terminal plate.

(0V)

HEAT ➞ COOL

When unit a1 stops unit a2 will switch to cooling or drying operation.

Unit a1 in heating mode (first unit switched)

Unit a2 in cooling or drying mode

Unit a1 in heating mode.

Heating operation has precedence so unit a2 is

in stand-by mode.

• If, in one system ( A for example), the units tried to be operated in different modes (unit a1 in heating while unit a2

in cooling), the results are as follows:

Units of one system (A or B) cannot operate in different modes simultaneously (for

example unit a1 operating in the heating mode while unit a2 is in the cooling one).

When operating two units of the same system, set them both to the same mode.

Different system instead, can operate in different mode that is system A can be in

cooling mode while B in the heating one.

CAUTION

40

Page 45

10-4-2.Poor cooling or heating.

10-4-3.Excessive cooling or heating.

Air filter is clogged.

NO

YES

Temperature

difference

is small.

YES

Temperature difference between

suction and discharge air is

large enough (approx. 10 deg. or more).

Possibility of

gas shortage.

YES

•

Check position of remote control unit.

Cool or warm air from air conditioner

reaches position directly.

•

Change position of remote

control unit.

•

Wide and narrow tubes between

indoor unit and outdoor unit are

insulated.

Insulate both wide and narrow

tubes separately and then

tape together.

•

Measure temperature of suction and

discharge air of air conditioner.

Charge refrigerant

gas (R22).

Check for clogging of air filter.

•

Fan speed is set to LOW.

Clean filter.

Set fan speed to either

HIGH or MEDIUM.

•

Review cooling load estimate,

if performance of air conditioner is

normal.

Reduce cooling or heating

load or replace the air

conditioner with larger

capacity.

NOTE

NO

NO

•

Set temperature is suitable.

Set temperature to higher or

lower value using temperature

setting buttons of the remote

control unit.

•

Remote control unit is placed where

it can detect room temperature

properly.

Change position of remote

control unit.

41

Page 46

10-5. If a sensor is defective.

10-5-1.Indoor coil / room temperature thermistor is defective.

•

Stand-by lamp on front side of

indoor unit is flashing on and off.

YES

•

Replace thermistor(s).

•

At least one of the thermistors is

defective (that is, SHORT or OPEN.)

Temperature

sensor

Lead

wires

Thermistor Structure

10-5-2.Outdoor coil / outdoor air temperature thermistor is defective.

•

Status led (RED) on outdoor PCB

blinks 5 times then off (repeat)

YES

•

Replace thermistor(s).

•

At least one of the thermistors is

defective (that is, SHORT or OPEN.)

Definition of Open or Short Circuit of Sensor (Thermistor)

Open...A lead wire is broken or disconnected or the circuit inside the temperature sensor is open .

Short...The protective cover of a lead wire has been damaged, and the exposed wire is touching another metal

part, or both lead wires have become exposed and are touching each other. Alternatively, the circuit inside

the temperature sensor is closed.

NOTE

42

Page 47

11.ARRANGEMENT OF ELECTRICAL COMPONENTS

Terminal Plate

Outdoor Unit GR360M4R5TAA

43

Page 48

Outdoor Unit GR360M4R5TAA

Parts Layout in Unit

44

Page 49

IMPORTANT!

For your personal safety, be sure to read

and understand the following precautions

before servicing.

●

To avoid risk of injury when servicing the outdoor unit

(for instance, when replacing the compressor or

repairing a refrigerant leak), follow the procedure

12-1-1. Confirm mains power is switched OFF, then

open the electrical box in order to access to

the Power Control Board (PCB).

IMPORTANT!

Always check for fan running during the

servicing. This ensure you that the solenoid

valves SVa1 and SVa3 are open.

12. SPECIAL PRECAUTIONS WHEN SERVICING THE UNIT

Injuries can occur from burns or inhalation of

toxic gas if servicing is performed while

refrigerant remains in the refrigeration circuit.

This servicing includes disassembling brazed

tubing connections and removing any

refrigeration parts or components.

WARNING

Fig.12-1

Fig.12-2

The following procedures are outlined as if SYSTEM A

has to be serviced. The same steps, obviously, applies

in case of SYSTEM B servicing.

NOTE

12-1-2. Disconnect the brown wire from the terminal

of PCB's compressor relay. (Fig.12-1)

12-1-3. Connect two wires between poles L, 1, and 3

of the terminal plate (Fig.12-2)

Supply power to the outdoor unit. After 3 minutes

the outdoor fan A will start running and the solenoid

valves SVa1 and Sva3 will open.

In some cases it is required to have solenoid valves opened

during servicing. When so, perform the following steps:

45

Page 50

12-2. Refrigerant recovery

12-2-1. Open the service valve to recover refrigerant into

refrigerant recovery unit.

12-3. Service on outdoor unit

12-3-1. After making sure that the refrigerant in the

circuit has been completely discharged, perform

the required servicing, such as replacing the

compressor or repairing refrigerant leaks.

12-3-2. Before going on to the next step, leak test all

joints where welding has been done.

Nitrogen gas is best when pressurizing the system

for a leak test. However, if it is necessary to instead

test with refrigerant gas, be sure to recover all gas

into the refrigerant recovery unit after completing

the leak test.

12-4. Evacuation using vacuum pump

12-4-1. Using a hex wrench, set the valve stems of both

the narrow and wide tube service valves as

indicated in table below.

Refer to " Service Valve Construction "shown later

12-4-2. Connect the vacuum pump and a manifold valve

as shown in Fig.12-3.

Confirm that all connections are correctly made.

In order to withstand negative suction pressure

during evacuation, the manifold valve should be

equipped with a Hi/ Lo compound gauge with a

minimum scale reading of -76

cmHg.

NOTE

NOTE

NOTE

Refrigerant released into the air contributes to

destruction of our planet's ozone layer. You

should always use the refrigerant recovery unit

to help protect the environment.

CAUTION

Service Valve Valve Position

Unit A 1

Narrow

Wide

Unit A2

Narrow

position -a-

Wide

IMPORTANT!

This procedure requires solenoid valves

opening during the operation. Follow the

steps of 12.1 before starting.

position -c-

IMPORTANT!

This procedure requires solenoid valves

opening during the operation. Follow the

steps of 12.1 before starting.

46

Page 51

12-4-3. Install (first by hand-tightening, then securely with

a wrench) flare nuts and bonnets at all service

valves in the refrigeration circuit where evacuation

will take place. This process is highly important

to completely evacuate the system.

12-4-4. With the " Lo " and "Hi" knobs of the manifold valve

open run the vacuum pump. The operation time

varies with the capacity of the pump.

Evacuation is successful if the vacuum gauge

reading remains –75 cmHg or more for at least 10

seconds after closing the " Lo " and "Hi" knobs of

the manifold valve.

12-4-5. With the vacuum pump still running, turn the wide

and narrow service valves all the way in order to close

them (position -a-).

Stop the pump.

12-4-6. After removing the vacuum hoses from the service

valves, replace the flare nuts and bonnets on the

valves. The refrigerant circuit is now ready for

charging.

12-5. Refrigerant charging

12-5-1. After evacuation is completed, charge the circuit

with the proper amount of refrigerant.

The proper amount of refrigerant is specified on

the nameplate of the outdoor unit and in Section

"2-1. Unit Specifications" in the service manual.

12-5-2. Use a hose to connect the narrow tube service

valve to the liquid port of the charging cylinder.

(Fig.12-4 )

12-5-3. Purge air from the hose. Do this by opening the

charging cylinder valve, then slightly loosening the

connection to the narrow tube service valve. Wait

a few moments, then retighten the connection.

NOTE

Fig. 12-3

Fig. 12-4

47

Page 52

12-5-4. With a hex wrench, open the service valve little

by little to let refrigerant enter the circuit.

(Figs.12-4 )

●

Write down the gradation levels on the charging

cylinder before and after the charging. This allows

you to calculate the charging volume.

12-5-5. If it is not possible to completely charge the unit

with the proper amount of refrigerant, an additional

charging can be made after installing the units.

In this case after re-setting the outdoor unit to the

normal state (see 12-6), the charge is done using the

wide valve port with the system running in COOLING

12-6. Reset the unit for normal operation

12-6-1. Turn off the power source.

12-6-2. Connect the brown wire to the relay terminal as

it was before servicing. (Fig.12-5 )

NOTE

Charging

volume

Gradation

level before

charging

Gradation

level after

charging

=

–

NOTE

Reset always the unit as it was before servicing.

Otherwise the system will not perform correctly

and damage may occur.

CAUTION

12-6-3. Remove the servicing wires from the terminal

plate. (Fig.12-6 )

Fig.12-5

Fig.12-6

When servicing has finished, the outdoor unit must be set to

the normal operation state. In this case do the following:

mode.

Charging the unit with a large amount of

refrigerant at once may damage the compressor.

Always charge the unit at a constant charging rate

of about 100g.

48

Page 53

■

Service Valve Construction

●

Valve Position -a-

The valve stems of both the wide and narrow tubes

are turned all the way in. The unit is shipped from the

factory in this position. (Fig.12-7a)

●

Valve Position -b-

The valve stems of both the wide and narrow tubes

are turned all the way out ("BACK SEAT" position).

This is the normal operating position. (Fig.12-7b)

●

Valve Position -c-

With the narrow tube valve kept at BACK SEAT, only

the wide tube valve stem is turned to the halfwaydown position. This position is used when refrigerant

circuit evacuation is required from both narrow and

wide tube valves at the same time. This position is

also used when additional refrigerant charging is

required in the field with both the indoor and outdoor

units installed.(Fig.12-7c)

●

Valve Position -d-

With the valve stem of the wide tube turned all the way

in, only the narrow tube valve stem is turned to the

halfway-down position. This position is used for

refrigerant charging for only the outdoor unit.

(Fig.12-7d).

When opening or closing the

service valve stem, use the

supplied accessory hex

wrench. Be sure to fully seat

the wrench before turning the

valve.

CAUTION

• Condition at Evacuation

• Condition at Charging

in the Field.(-c-)

• Condition at Charging

with Only Outdoor Unit (-d-)

• Condition at Operation (-b-)

• Condition at Shipping (-a-)

Valve cap

Stem

O-ring

Fig.12-7d

Fig.12-7c

Fig.12-7b

Fig.12-7a

Wide Tube Narrow Tube

Close

Hex

wrench

Open

49

Page 54

13-1. Measurement of Insulation

Resistance

●

The insulation is in good condition if the resistance

exceeds 2MΩ.

13-1-1. Power Supply Wires

Clamp the ground wire of the power supply wires with

the lead clip of the insulation resistance tester and measure the resistance by placing a probe on either of the

power wires. (Fig. 1)

Then measure the resistance between the ground wire

and the other power wire. (Fig. 1)

13-1-2. Indoor Unit

Clamp an aluminum plate fin or copper tube with the lead

clip of the insulation resistance tester and measure the

resistance by placing a probe on each terminal screw

except where the ground line is connected on the terminal plate. (Fig. 2)

13-1-3. Outdoor Unit

Clamp a metallic part of the unit with the lead clip of the

insulation resistance tester and measure the resistance

by placing a probe on each terminal screw where power

supply lines are connected on the terminal plate. (Fig. 2)

13-1-4. Measurement of Insulation

Resistance for Electrical Parts

Disconnect the lead wires of the desired electric part

from terminal plate, capacitor, etc. Similarly disconnect

the connector. Then measure the insulation resistance.

(Figs. 1 to 4)

Refer to Electric Wiring Diagram.

If the probe cannot enter the poles because the hole is

too narrow then use a probe with a thinner pin.

Insulation

tester

Probe

Clip

Ground wire

Fig. 1

Terminal plate

Copper

tube or

metallic part

Clip

Insulation

tester

Probe

Fig. 2

Copper

tube or

metallic part

Clip

Insulation

tester

Probe

Fig. 3

Clip

Insulation

tester

Probe

Metallic

part

From fan motor,

compressor and

other parts

Fig. 4

13. CHECKING ELECTRICAL COMPONENTS

NOTE

50

Page 55

13-2. Checking continuity of Fuse on

PCB Ass'y

●

Check for continuity using a multimeter as shown in

Fig. 6.

Method Used to Replace Fuse on PCB Ass'y

— Indoor PCB Ass'y —

1. Remove the PCB Ass'y from the electrical compo

nent box

2. Then pull out the fuse from the PCB Ass'y.(Fig.5a)

— Outdoor PCB Ass'y —

1. Remove the PCB Ass’y from the electrical component

box.

2. Pull out the fuse at the metal clasp using pliers while

heating the soldered leads on the back side of the

PCB Ass'y with a soldering iron

(30W or 60W).(Fig.5b)

3. Remove the fuse ends one by one. For replacement

insert a fuse of the same rating and solder it. (Allow

time to radiate heat during soldering so that the fuse

does not melt.)

13-3. Checking Motor Capacitor

Remove the lead wires from the capacitor terminals, and

then place a probe on the capacitor terminals as shown

in Fig. 7. Observe the deflection of the pointer, setting

the resistance measuring range of the multimeter to the

maximum value.

The capacitor is “good” if the pointer bounces to a great

extent and then gradually returns to its original position.

The range of deflection and deflection time differ according to the capacity of the capacitor.

Multimeter

Ω

Compressor motor

capacitor

Fan motor

capacitor

Fuse

PCB Ass’y

Indoor

Fig. 5a

Fuse

Fig. 6

Fig. 7

Soldering iron

PCB Ass’y

Outdoor

Fuse

Pliers

Fig. 5b

NOTE

51

Page 56

S.A.C. - olgiate olona - printed in italy

R.D. 28 Reyrieux BP 131 - 01601 Trévoux CEDEX France

Tél. 04.74.00.92.92 - Fax 04.74.00.42.00

R.C.S. Bourg-en-Bresse B 759 200 728

Loading...

Loading...