Page 1

1

April 2004 10 11 220 - GB - 12

INSTALLATION INSTRUCTIONS

CSCV - L

CONSOLE TYPE SPLIT SYSTEM

R 407 C refrigerant

CSCV 175 L

CSCV 225 L

Page 2

2

• TAV 175 C and 225 C can be connected to the following condensing units

- Axial fan unit : TAV 175 C ➞ GRV 180 L (R 407 C)

TAV 225 C ➞ GRV 220 L (R 407 C)

NOTE

To install the GRV unit:

use these installation instructions.

MARKING

This product marked conforms to the essential requirements of the Directives :

- Low voltage no. 73/23 EEC, modified 93/68 EEC,

- Electromagnetic Compatibility no. 89/336 EEC, modified 92/31 and 93/68 EEC.

1-General ................................................................................................................. 2

2-Presentation.......................................................................................................... 3

3-Positionning of the units........................................................................................ 4

4-Connections .......................................................................................................... 6

5-Indoor unit accessories ......................................................................................... 9

6-Outdoor unit accessories .................................................................................... 11

7-Connecting accessories...................................................................................... 11

8-Starting................................................................................................................ 12

9-Maintenance instructions .................................................................................... 12

10 - Wiring diagrams .................................................................................................. 13

SUMMARY

• The equipment must be installed, started-up and maintained by authorised and qualified personnel, in accordance with local

rules and professional standards.

1.1 - GENERAL SUPPLY CONDITIONS

• Generally speaking, the material is transported at the consignee's risk.

• The consignee must immediately provide the carrier with written reserves if he finds any damage caused during transport.

1.2 - VOLTAGE

• Prior to any operation, check that the voltage specified nameplate agrees with the supply voltage.

1.3 - USE OF EQUIPMENT

• This equipment is intended for the air-conditioning of premises and to provide comfort for the personnel.

1- GENERAL

Page 3

3

80 C 80

55

4-60 x 110

235

A

B

101310189

55

80 80C

600

15

30

110

50

1

2

4

3

5

3

4

2

1

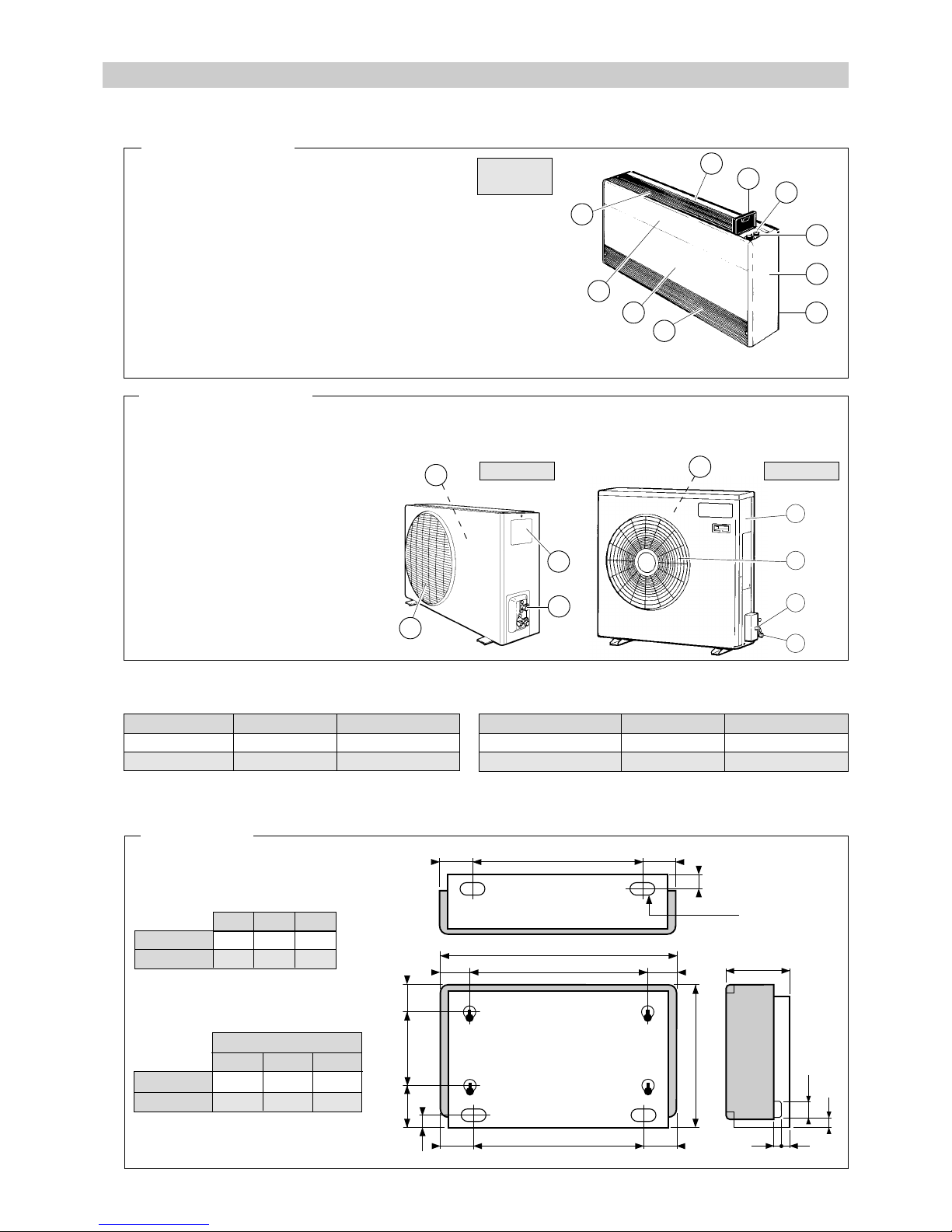

2 - PRESENTATION

INDOOR UNIT - TAV

1 - Outlet grille.

2 - Removable panel.

3 - Front panel.

4 - Inlet grille.

5 - Rear support.

6 - Side.

7 - Control panel.

8 - Control buttons.

9 - Door.

10 - Fixed panel.

2.1 - DESCRIPTION

TAV 175 C

TAV 225 C

OUTDOOR UNIT - GRV

1 - Air inlet (suction).

2 - Fan grille.

3 - Refrigerant connection.

4 - Electrical box access panel.

5 - Tapping point.

GRV 180 L and 220 L : Low temperature version. Use up to -15°C min. / 43°C max. outdoor temperature. extérieure.

Materials:

Painted sheet casing.

Plastic grille.

Copper piping.

Copper/aluminium heat exchanger.

10

9

7

8

6

5

4

3

2

1

Materials:

Plastic coated sheet casing.

Metal grilles.

Polyethylene insulation M1.

Copper/aluminium heat exchanger.

Copper piping.

GR 180 C

2.2 - WEIGHT

Unit

Packed weight

57 kg

76 kg

Net weight

52 kg

67 kg

Unit

TAV 175 C

TAV 225 C

Packed weight

43 kg

49 kg

Net weight

37 kg

42 kg

2.3 - DIMENSIONS

INDOOR UNIT

Under view

Right side

TAV 175 C

TAV 225 C

B

C

790

980

850

1 040

A

950

1 140

Length Height

650

650

Depth

295

295

Packed unit

1 010

1 200

TAV 175 C

TAV 225 C

GR 220 C

NOTE: The refrigerant connections are on the left of the unit, inside the housing.

GRV 180 L

GRV 220 L

Page 4

4

B

A

1

C

B

C

4

8

A

A

A

OUTDOOR UNIT

Length Height

700

900

Depth

400

400

Packed unit

GRV 180 L

GRV 220 L

990

1 000

307

305

20

850

835

620

100

305

325

20

GRV 180 L

GRV 220 L

538

830

146

630

3 - INSTALLATION OF THE UNITS

3.1 - INSTALLATION OF THE INTERNAL UNIT

• It is preferable to handle the air handler without its cabinet, when

installing it.

• If necessary, remove the fan assembly too.

3.1.1 - REMOVING THE CABINET

• Undo the 2 knurled screws (B) and the 2 tinsmith's screws (C).

• Remove the 2 control buttons (8).

• Remove the cabinet by lifting it slightly and pulling it forwards.

NOTE : To make the cabinet easier to handle, the outlet grille (1)

and the inlet grille (4) can be removed beforehand. To do this,

undo the clips (A) by turning them a quarter of a turn using a

screwdriver or a coin.

IMPORTANT : When refitting the grilles, take care to lock the clips

(A) by turning them a quarter of a turn.

3.1.2 - REMOVING THE FAN ASSEMBLY

• Remove the fastening screws.

• Disconnect the loom at connector (D).

• Pull the fan assembly.

3.1.3 - CHOOSING THE LOCATION

AVOID:

• Putting the unit in very damp places. This unit is designed to be installed in sheltered

rooms (IP 20).

• Direct exposure to sunlight or the proximity of heat sources.

• Installing the unit behind curtains or furniture which could prevent air circulation.

• Installing the device near inflammable materials (as it can be equipped with an

electric heater).

MAKE SURE THAT:

• The position is the best one for providing good ventilation in the room.

• That the solidity of the support is adequate for the weight of the unit and does not

cause vibrations.

0.30m

1 m

D

• The position chosen complies with the recommended minimum maintenance spaces (see drawing opposite), and that the

distance and difference in level between the units are as small as possible.

• The piping and the electric connections are easily accessible.

A

Page 5

5

FORWARD

BLOWING

BACKWARD

BLOWING

3

6

7

5

2

4

1

B

B

B

1

9

A

A

7

C

C

7

C

D

D

2

B

9

2

DD

1

A

A

8

9

3.1.4 - MOUNTING

• The system can be placed on the floor or fixed to the wall or ceiling.

• It must be fitted flush against a wall in all cases.

• For wall or ceiling mounting, refer to the Accessories section for the supports which can be used.

3.1.5 - CHOOSING THE BLOWING DIRECTION

A - STANDARD DELIVERY

• Vertical backward blowing.

B - FORWARD BLOWING:

• Turn the grille 180° (see "Removal" below).

3.1.6 - HORIZONTAL BLOWING

• Remove the cabinet (see page 4).

1-Remove the outlet grille (1): undo the two clips (A) by turning them a quarter of a turn (using a screw driver or a coin).

2 - Remove the door (9) by pressing on the side to release the hinge pin (B).

3 - Remove the control panel (7) by taking out the two fastening screws (C).

4 - Remove the removable panel (2) by taking out the four fastening screws (D).

5 - Refit the removable panel (2) on the top and fix it with the four screws (D).

6 - Refit the control panel (7) on the front part and fix it with the two screws (C).

7 - Refit the door (9) by pressing on the side to engage the hinge pin (B) in the hole.

Refit the outlet grille (1) and lock the two clips (A) by turning them a quarter of a turn.

8 - Take out the control panel held by two screws.

9 - Remove the ceiling tray held by 4 screws.

10 - Position the control panel by turning it 90° towards the front.

Fix with the 2 screws.

10

Page 6

6

4 - CONNECTING

1 - Gas refrigerant connection.

2 - Liquid refrigerant connection.

3 - Electrical connection.

4 - Condensate drainage.

5 - Mains supply with isolating and protective

device.

6 - Remote control (accessory).

End piece

Copper pipe

Hose

4.1 -

CONNECTING THE CONDENSATE LINES

4.1.1 - VERTICAL MOUNTING

• Use the 12 mm dia. x 16 mm hose supplied.

• Pass it with refrigerant pipes through one of the covers

and connect it to a pipe of minimum internal diameter

12 mm, respecting a slope in the liquid's flow direction.

4.1.2 - CEILING MOUNTING

• Use the copper pipe and the end piece supplied.

Ceiling mounting

1

23

5

6

GRV

TAV

4

3.2 - INSTALLATION OF OUTDOOR UNIT

• Safety index : IP x 4.

3.2.1 - WALL MOUNTING

• Use the wall support available as an accessory:

- code K 70 U 001 Z.

3.2.2 - FLOOR MOUNTING

• Select the location for the unit on the basis of the following

criteria:

- the unit must be installed outside,

- it is necessary to make sure that the free space around

the unit is provided (see the minimum dimensions on

the drawing opposite),

- installation must be simple and make maintenance

work easy,

- the unit must be fixed on a hard base and must be

protected from risks of flooding,

- the blown air must not be directed towards

surrounding windows,

- vibrations and noise must not be transmitted to a

nearby building.

AVOID:

- Excessive exposure to salty air or sulfuric gas.

- Heat sources and extraction fans.

- Projections of mud (next to a roadway or path, for

example).

- Areas where there is strong wind blowing against the

unit's air exhaust.

GRV 180 L

GRV 220 L

100

20

100

600

50 500

GRV 220 L

Before installation

remove the protective

spacer for

transportation

45°

Page 7

7

4.2 - REFRIGERANT CONNECTIONS

A

B

Outdoor unit

Internal unit

Oil trap

4.2.2 - CONNECTION TO THE INDOOR UNIT

• According to the direction of the outlet chosen, break one of the covers. Protect the point where the pipes go through the sheet

section with the rubber membrane supplied or the rubber profile supplied. For the side outlets, the membrane has to be cut

in two.

Tightening torque

1.5 to 2 kgf-m

3 kgf-m

5 kgf-m

6.5 kgf-m

Dia. of pipes

1/4"

3/8"

1/2"

5/8"

4.2.1 - INSULATION OF PIPES

• Insulate the 2 pipes separately.

• Use polyethylene sheathing at least 8 mm thick.

• Pay particular attention to water entering along the pipes through the wall.

• Connect the gas and liquid pipes on the corresponding Flare connectors.

• Tighten by hand.

• Tighten using torque wrenches (see tightening torque in the table opposite).

• IMPORTANT NOTE: hold the FLARE fitting with a counter-key.

Addition of

refrigerant

above

(m)

Maxaximum

permissible

difference in

level B (m)

Maximum

permissible

length

A (m)

LiquidGas

Dia. of pipes

Quantity of

refrigerant to

be added

(g/m)

Refrigerant

load

in the GRV

(g)

• For connecting lengths greater than 20 m, please contact us.

• If the difference in level is greater than 3 metres, make an oil trap.

NOTE:

The nominal capacity of the units is given for a total length of 8 m.

APPLIANCES FILLED WITH R 407 C

R 407 C

• Fluid R 407 C, as opposed to R22, is not a pure fluid

but a blend composed of:

- 23% R 32 + 25% R 125 + 52% R 134 A.

• The compressors approved for operation with this

fluid are filled beforehand with polyalcohol oil.

Contrary to mineral oil, it is very hygroscopic: it

absorbs the humidity of the ambient air very quickly.

This can modify its lubricant properties and lead in

time to the destruction of the compressor.

MAINTENANCE INSTRUCTIONS

1 - Never add oil to the appliance; the compressor is

filled with polyalcohol oil, a special oil which cannot

tolerate the presence of other oils.

2 - The instruments used for:

- filling,

- pressure measurements,

- emptying under vacuum,

- recovering the fluid,

must be compatible and only used for the R 407 C

fluid.

3 - The weight of the refrigerant contained in the

storage bottle must be checked constantly. Do not

use it from the moment the remaining weight is less

than 10% of the total weight.

4 - In the case of a new charge:

- do not use the charging cylinder,

- use a balance and a dip pipe type R 407 C cylinder,

- charge the weight of R 407 C as per the value

indicated on the unit’s identification plate (for “split

systems”, refer to the installation instructions as the

charge must consider the length of the connecting

lines),

- IMPORTANT: see paragraph 3.

5 - The charge must be undertaken in liquid phase.

6 -

In case of leakage, do not complete the charge:

recover the remaining refrigerant for recycling and

perform a total charge.

Recovery, recycling or the destruction of the fluid must

be done in compliance with the laws in force in the

country concerned.

7 -

If the refrigerant circuit is opened, you must

:

- avoid the entry of air into the circuit as much as

possible,

- replace the filter drier,

- perform the “vacuum operation” at a minimum level

of 0.3 mbar (static).

1/2"

5/8"

CSCV 175 L

CSCV 225 L

1/4"

1/4"

25

25

20

30

7

7

1 660 1-phase

1 680 3-phase

1 620 3-phase

8

8

Page 8

8

Refrigerant valves

Refrigerant valves

GRV 220 L

4.2.4 - USING THE FLARE VALVE

Liquid side

3-way valve

3-waay

valve

Gas side

Indoor

unit

4.3.2 - TABLES OF CURRENT

* The indoor unit

is connected to

230/1/50.

• After completing the connection to the internal and external units, the

connections and internal unit must be bled.

• Proceed as indicated below:

1 - Undo the plugs (1).

2 - Remove the bleed plug (2).

3 - Connect the vacuum pump (3).

4 - We recommend that you fit a shut-off valve (4).

5 - After bleeding, close the shut-off valve (4).

6 - Open the two valves completely until they are right against the seat.

7 - Remove the vacuum pump (3) and the shut-off valve (4).

8 - Tighten the bleed plug (2).

9 - Fully tighten the plugs (1).

10 - Add more charge if necessary (see § 4.2).

Note: Refrigerant and electrical connections can be supplied as accessories. See the "Accessories" section.

Cooling mode

Heating mode

CSCV 175 L

Unit on 400V/3N/50Hz *

Nominal current A

Max. current A

Starting current A

Max. current with heating 2 kW A

3 kW A

4.2

7

21

9.5

14

5.2

8

38

9.5

14

CSCV 225 L

GRV 180 L

Cooling mode

Heating mode

CSCV 175 L

Unit on 230V/1/50Hz

Nominal current A

Max. current A

Starting current A

Max. current with heating 2 kW A

3 kW A

11.2

13.4

52

9.5

14

4.2.3 - CONNECTION TO THE OUTDOOR UNIT

• Connect the gas and liquid pipes on the corresponding Flare

valves.

• Tighten by hand.

• Tighten using torque wrenches (see tightening torque in the table

page 7).

4.3 - ELECTRICAL CONNECTIONS

NOTES :

• Class 1 appliance.

• The electrical connection conduits must be fixed.

• The electrical installation must be carried out in compliance with the rules in force (especially NFC 15-100

CEI 364).

• The cables are not included in the supplies.

MAINS SUPPLY

• The power supply must come from an isolation and electric protection device (not supplied) in accordance with existing

regulations. It is connected to the outdoor unit. See the connection diagram below.

• The acceptable voltage variation is ± 10% during operation.

CAUTION:

In the case of a three-phase power supply, prior to commissioning the unit, make sure that the phase

rotation order is correct.

The phase-sequence controller restricts the unit from operating if the 3 supply phases are

not in order or if a phase is absent.

4.3.1 - CONNECTION CABLES

MAINS POWER CABLE

• on 230V/1/50Hz : 3 G 2.5 mm

2

• on 400V/3N/50Hz : 5 G 1.5 mm2 without electrical heating,

5 G 2.5 mm2 with electrical heating.

C

ONNECTION CABLE BETWEEN THE UNITS

• Use a cable of section equivalent to that of the mains power cable.

NOTE

The sections are given as an

indication only.

They must be checked and

adapted to suit the installation

conditions according to existing

standards.

Page 9

9

4.3.4 - CONNECTION TO THE OUTDOOR UNIT

A - To the GRV 180 L

• Remove the small cover.

• Pass the cables through one

of the covers.

• Connect them to the terminal

board according to the

connection diagrams.

B - To the GRV 220 L

• Remove the side panel.

•Connect them to the

terminal board according to

the connection diagrams.

4.3.5 - CONNECTION DIAGRAMS

L1

1

TAV 175 C

GRV 180 L

230/1//50

5

2

4

230/1/50

LNN

Mains supply 230/1/50

Mains supply 400/3N/50

Connection

cable

5 - INDOOR UNIT ACCESSORIES

adjustment wheels

with threaded rods

Eight 10 mm dia.

holes in the ceiling

60 60

B

D

C

A

A

=

=

50

50

B

13

A

L1

1

5

2

4

L2

L3 NL1

N

TAV 175 C

TAV 225 C

GRV 180 L

GRV 220 L

400/3N//50230/1/50

Connection

cable

5.1 - CEILING SUPPORT

• To make the unit easier to handle, we recommend that you

remove the cabinet as well as the fan assembly (see page 4).

FIXING:

• Drill eight 10 mm dia. holes in the places indicated.

• Insert the 8 S 10 plugs (supplied).

• Fix the 2 bars with the 8 screws (supplied).

• Fix the indoor unit, complying with the minimum and maximum

dimensions. The distance between the bar and the indoor unit

must be a maximum of 20 mm.

IMPORTANT :

Level it, using the adjustment wheels, or with a backward slope

(up to 5 mm).

Type

TAV 175 C

TAV 225 C

A

800

990

B

465

465

C

880

1 070

D

415

415

Accessory code

K 60 U 020 Z

K 60 U 020 Z

Type

TAV 175 C

TAV 225 C

Accessory code

K 60 U 023 Z

K 60 U 024 Z

A

870

1 060

B

850

1 040

5.2 - WALL SUPPORT

• Fix the support to the wall using the screws and plugs supplied.

• Level it using the M6 hex. head screws item A.

5.3 - CROSS DEFLECTION GRILLE

TAV 175 C : Code K 60 N 014 Z TAV 225 C : Code K 60 N 015 Z

• Remove the outlet grille (see page 4).

• The deflection grille is fixed under the outlet grille using plastic clips which are fixed on

the deflection grille and lock onto the outlet grille's pins.

4.3.3 - CONNECTION TO THE INDOOR UNIT

• Pass the cables through one of the covers.

• Connect them to the terminal board according to the connection diagrams.

Page 10

10

5.4 - ELECTRIC HEATING

2 kW : Code K 60 C 842 Z 3 kW : Code K 60 C 843 Z

• See installation instructions supplied with the accessory.

Operating switch

with fan speed selection

Temperature setting knob

Heating / cooling selector switch

K 60 D 076 Z

L

Y1

Q3

Q2

Q1

SR2

SR1

SR

Auto

Y2

TAV

L1

2

1

N

3

4

6

Phase

Neutral

HS

MS

LS

Cooling

Heating

5.5.3 - CONNECTIONS WITH AUTOMATIC REMOTE CONTROL - Code K 60 D 025 Z

On/Off switch

Fan speed selector

Temperature setting knob

K 60 D 025 Z

1

N

2

22

21

20

6

TAV

11

12

L1

2

1

N

3

4

6

Phase

Neutral

HS

MS

LS

Cooling

Heating

Air temperature sensor

(if used)

K 60 D 028 Z or K 60 D 033 Z

5.5 - REMOTE CONTROL

5.5.1 - MONTAGE / INSTALLATION

• See the main characteristics in the Technical Instructions.

• Consult the "Installation instructions" supplied with the control.

• The unit is connected using 0.75mm

2

cable (minimum) (1.5mm2 max.).

The cables used must comply with the insulation requirements for the voltage used (230V).

This information relates above all to the sensor input of the automatic control connected to the 230V supply.

• The temperature adjustment range can be limited by means of the mechanical limit stops located on the control knob.

• Wall mounting:

- Secure the unit at a height of approximately 1.5 m from the floor in a location representative of normal convection

currents, while avoiding:

- wall which are poorly insulated or liable to vibrate,

- the proximity of parasitic heat sources (sunshine, heating appliances, lamps, fireplaces, televisions, etc.),

- currents of air from doors or windows,

- sheltered locations such as shelves or behind curtains,

- near electrical outlets.

- For manual control K 60 D 076 Z, check and modify as required the ventilation selection jumper connection SR

depending on the appliance (see below).

- For the K 60 D 025 Z automatic control, if necessary, adjust the neutral zone using the potentiometer located inside

the control.

• Caution:

If a remote control is used, remove the wire between terminal L1 and switch S1 on the air processor terminal

board.

5.5.2 - CONNECTIONS WITH "RAB 30" MANUAL REMOTE CONTROL - Code K 60 D 076 Z

Position of the SR bridge located inside the controller:

- on SR1 = Permanent ventilation.

- on SR2 (Auto) = Ventilation activated when the thermostat

is in demand.

This position is not accessible with a

heating kit.

Page 11

11

5.5.4 - TEMPERATURE SENSOR ACCESSORIES

• For automatic remote control K 60 D 025 Z

• Temperature sensor K 60 D 028 Z

- CTN 33 kΩ type - IP 67

• Air temperature sensor in box K 60 D 033 Z

- CTN 33 kΩ type - IP 30

• See the specific installation guide.

6 - ACCESSORIES OF THE OUTDOOR UNIT

Wall

support

A

100100

31

2

GRV 180 L

GRV 220 L

A (mm)

538

620

50

mini

6.1 - WALL MOUNTING - Code K 70 U 001 Z

1-After making sure that the fixing system used is suitable for the wall, fix the 2 vertical brackets to the wall.

Make sure that measurement A is correct.

2-Fit the 2 arms using the M8 screws provided.

3 - Fit the unit on the supports using the M8 screws supplied.

7 - CONNECTING ACCESSORIES

Length Code

K 70 A 02 BT

K 70 A 04 BT

K 70 A 08 BT

K 70 A 12 BT

K 70 A 15 BT

K 70 A 20 BT

Unit

CSCV 175 L

7.1 - REFRIGERANT CONNECTIONS

• These connections include 2 insulated refrigeration lines.

2 m

4 m

8 m

12 m

15 m

20 m

Length Code

K 70 A 04 CT

K 70 A 08 CT

K 70 A 12 CT

K 70 A 15 CT

K 70 A 20 CT

Unit

CSCV 225 L

4 m

8 m

12 m

15 m

20 m

7.2 - COMPLETE CONNECTION ASSEMBLIES

• These include: - the refrigeration lines,

- the electric cables,

-a condensate tube.

Length Code

Unit

CSCV 175 L

2 m

4 m

8 m

12 m

15 m

20 m

Length Code

Unit

CSCV 225 L

4 m

8 m

12 m

15 m

20 m

K 70 A 02 BT

+ K 70 A 02 XT

K 70 A 04 BT

+ K 70 A 04 XT

K 70 A 08 BT

+ K 70 A 08 XT

K 70 A 12 BT

+ K 70 A 12 XT

K 70 A 15 BT

+ K 70 A 15 XT

K 70 A 20 BT

+ K 70 A 20 XT

K 70 A 04 CT

+ K 70 A 04 XT

K 70 A 08 CT

+ K 70 A 08 XT

K 70 A 12 CT

+ K 70 A 12 XT

K 70 A 15 CT

+ K 70 A 15 XT

K 70 A 20 CT

+ K 70 A 20 XT

Page 12

12

8.1 - PRELIMINARY CHECKS

• Make sure:

- that the refrigerant fittings are correctly tightened and that the two shut-off valves are open.

- that there are no leaks.

- that the air handler and the condenser unit are well fixed.

- that the power cables are well fixed to their connection terminals. Loose terminals can cause heat build-up on the terminal

board.

- that the electric cables are properly insulated from any pieces of sheet or metal parts which could damage them.

- that the unit is connected to earth.

- that no tools or any other objects have been left in the units.

- that the filter is correctly fitted.

- that the condensate discharge outlet is correctly connected.

8.2 - SWITCH ON THE UNIT

• Using the isolation and protection device.

8.3 - START THE UNIT

• Using the indoor unit's control panel.

- Turn the switch to the required position.

- Set the temperature using the thermostat (see "User manual").

8.4 - EXTERNAL UNIT FAN

• The GRV 180 L and 220 L units are an all-season adjustable fan speed system standard equipment.

Fan motor speed varies according to the pressure of condensation and the outside temperature.

8 - STARTING

9 - MAINTENANCE INSTRUCTIONS

IMPORTANT

Before doing any work on the installation, make sure it is switched off and put out of bounds.

All operations must be carried out by personnel that are approved and qualified for this type of equipment.

• Air filter: Clean every 15 days. See "Operating Manual".

• External unit air exchanger: Cleaning recommended once a year.

• Electric connections: Once a year, check that the electric wires are well fastened to their terminals.

• Electric box: Dusting is recommended once a year.

IMPORTANT

Before doing any work on the installation, make sure it is switched off and put out of bounds.

All operations must be carried out by personnel that are approved and qualified for this type of equipment.

Page 13

13

N

6

JV

BW

B

R

L1

RW

NW LW

B

1234567

M1

RW

NW LW

B

1234567

W

M1

M1

N

L1L1

BN

S1

θ

SA

NL

NL

B1

NG

SF

4

3

SB SBSB SE

0

2

S6

S2 S4S3 S5

6123

G

RW

4

5

θ

B3

G

4

3

GW

C1

N

B

B

NWLWR

RWNWLW

JV

L1

N

N

B

R

6

W

C3

TAV 175 C - TAV 225 C - 230/1/50 10 05 443 - 02

Electric heating

connection

K 60 C 842 Z 2 kW

Electric heating

as accessory

K 60 C 843 Z 3 kW

Outdoor

unit control

TAV 225 CTAV 175 C

Speed connection

S

1

2

3

4

5

6

7

8

S1

0

1

1

1

1

1

1

1

S2

0

1

0

0

1

0

1

0

S3

0

0

1

0

0

1

0

1

S4

0

0

0

1

0

0

0

0

S5

0

0

0

0

0

0

1

1

S6

0

1

1

1

0

0

0

0

B1 Room thermostat

B3 Anti-frost thermostat

C1 M1 capacitor

C3 Filtration capacitor

M1 Fan

S Switch

B Blue

BW Blue/White

G Grey

GW Grey/White

JV Yellow/

Green

LW Purple/White

N Black

NG Black/Grey

NL Black/Purple

NW Black/White

R Red

RW Red/White

W White

10 - WIRING DIAGRAMS

GRV 180 L - 230/1/50

L

N

1

2

3

4

TP

FM

P

M

W

CM

W

N

R

JV

JV

JV

W

N

N

N

B

B

J

R

G

M

B

J

W

R

R

O

JV

S

R

C

CCH

N

W

1

0

KM2

A1

HPS

T

284

6

3

2

1

LOAD

N2

N1

LINE

3

C

H

L

2

1

C1 C2

Power supply

230/1/50

t7

B Blue

G Grey

J Yellow

JV Yellow/Green

L Purple

M Brown

N Black

O Orange

P Pink

R Red

W White

A1 Speed controller

C1 Fan capacitor

C2 Capacitor compressor

CCH Crankcase resistor

CM Compressor

FM Fan

HPS High pressure sensor

KM2 Compressor contactor

T Thermostat

TP Terminal board

Page 14

14

GRV 220 L - 400/3N/50

B Blue

G Grey

J Yellow

JV Yellow/Green

M Brown

N Black

O Orange

A1 Speed controller

C1 Fan capacitor

CCH Crankcase resistor

CM Compressor

FM Fan

HPS High pressure sensor

KM2 Compressor contactor

NPR Phase sequence controller

OLR Protection relay

T Thermostat

TP Terminal board

P Pink

R Red

W White

GRV 180 L - 400/3N/50

Power supply

400/3N/50

Indoor unit

L1

L2

L3

TP

N

1

2

4

A1

NPR

1

2

3

R

U

U/2

8/95

7/96

W/6

VW

14

R

R

T

S

a/A1

b/A2

ST

13

S

T

LOAD

N1

N2

LINE

1

2

3

HPS

CCH

T

C

LH

R

G

G

B

B

G

JV

G

R

R

R

R

W

W

JV

M

G

B

N

J

R

B

G

M

B

B

J

CM

W

B

N

G

W

P

M

R

R

J

JV

KM2

F2

JV

FM

C1

B

C

A

A1 Speed controller

C1 Fan capacitor

CCH Crankcase resistor

CM Compressor

F2 Compressor internal protection

FM Fan

HPS High pressure sensor

KM2 Compressor contactor

NPR Phase sequence controller

T Thermostat

TP Terminal board

B Blue

G Grey

J Yellow

JV Yellow/Green

L Purple

M Brown

N Black

O Orange

P Pink

R Red

W White

Power supply 400/3N/50

Indoor unit

N

4

2

1

L3

L2

L1

U

R

B

A

KM2

A

B

C

R

S

T

SVTW13

14

WU

8

7

CM

R

S

T

1

2

3

LOAD

LINE

N2

N1

3

2

1

CCH

FM

L

H

C

NPR

OLR

TP

C1

T

A1 HPS

JV

G

R

M

G

G

G

G

B

R

R

R

W

W

JV

R

B

N

R

G

O

G

R

B

N

P

M

G

W

J

P

M

G

W

J

JV

JV

R

W

B

N

J

G

Page 15

15

R.D. 28 Reyrieux BP 131 01601 Trévoux CEDEX France

Tel. 33 4 74 00 92 92 - Fax 33 4 74 00 42 00

R.C.S. Bourg-en-Bresse B 759 200 728

Due to our policy of continuous development, our products are liable to modification without notice.

Loading...

Loading...