Page 1

1

10 11 341 - GB - 05

February 2003

CP(V) 188 - 268

SLIMLINE DUCTABLE SPLIT AIR CONDITIONER

CP 188 R

CP 268 R

CPV 188 L

CPV 268 X

INSTALLATION INSTRUCTIONS

Page 2

2

MARKING

This product marked conforms to the essential requirements of the Directives:

- Low voltage no. 73/23 EEC, modified 93/68 EEC,

- Electromagnetic Compatibility no. 89/336 EEC, modified 92/31 and 93/68 EEC.

SUMMARY

1-General.......................................................................................... 2

2-Presentation .................................................................................. 3

3-Positionning of the units ................................................................ 5

4-Connections................................................................................... 6

5-Indoor unit accessories ............................................................... 12

6-Outdoor unit accessories............................................................. 15

7-Connecting accessories .............................................................. 16

8-Control ......................................................................................... 16

9-Starting up ................................................................................... 20

10 - Maintenance instructions............................................................. 21

11 - Pressure curves........................................................................... 22

12 - Electrical connection diagrams.................................................... 24

13 - Wiring diagrams........................................................................... 28

To install the GR unit:

use these installation instructions.

NOTE

1 - GENERAL

• The equipment must be installed, started-up and maintained by authorised and qualified personnel, in accordance with local

rules and professional standards.

1.1 - GENERAL SUPPLY CONDITIONS

• Generally speaking, the material is transported at the consignee's risk.

• The consignee must immediately provide the carrier with written reserves if he finds any damage caused during transport.

1.2 - VOLTAGE

• Before carrying out any operation, check that the voltage indicated on the unit corresponds to the mains voltage.

1.3 - USE OF EQUIPMENT

• This equipment is intended for the air-conditioning of premises and to provide comfort for the personnel.

1.4 - REGULATIONS

• Check that the installation conforms to the relevant specific regulations, for example, the regulation covering areas designed

to receive people.

• PA units can be connected to the following types of condensing unit:

- Axial fan units (cooling only) : PA 188 C ➞ GRV 180 L (R 407 C)

PA 268 X ➞ GRV 265 X (R 407 C)

- Axial fan units (heat pump) : PA 188 R ➞ GR 188 R (R 22)

PA 268 R ➞ GR 268 R (R 22)

Page 3

3

269

25

202

24

445

305

233

934

870=

528

360

79

=40

909= =

Ø17

75

170

INDOOR UNIT - PA

4

2

1

3

PA 188 C

PA 268 X

2 - PRESENTATION

2.1 - DESCRIPTION

NOTE: - The PA-C and X models (cooling only) are supplied without regulation.

- The PA-R models (heat pump) come with specific electronic regulation with wired remote control.

OUTDOOR UNIT - GR(V)

2.2 - DIMENSIONS AND WEIGHTS OF THE UNITS

INDOOR UNIT - PA

Weight: 33 kg

PA 188 R

PA 268 R

6

5

3

1

8

4

7

2

GRV 180 L:

Low temperature version.

Use up to -15°C min. / 43°C max.

outdoor temperature.

GR 268 R

PA 188 C

PA 268 X

PA 188 R

PA 268 R

7

5

9

8

1 - Blowing

2 - Suction

3 - Electrical box

4 - Ventilation

Materials:

Sheet metal casing.

Polyethylene insulation M1.

Copper/aluminium evaporator.

Copper piping.

1 - Plate-fin exchanger.

2 - Compressor.

3 - Electrical box.

4 - Fan.

5 - Refrigerant connections.

6 - Holes for pipes and electric cables.

7 - Tapping points.

8 - Fan grille.

9 - Electrical box access panel.

Materials:

Painted sheet casing.

Plastic grille.

Copper/aluminium evaporator.

Copper piping.

Flare fitting,

gas 1/2" (PA 188)

5/8" (PA 268)

Flare fitting,

liquid 1/4" (PA 188)

3/8" (PA 268)

4 mounting

holes, 4 x 20

Condensate

tube

Electrical

box

Rear view

8

9

5

GRV 180 L

GR 188 R

GRV 265 X

Page 4

4

D

E

C

A

B

B

A

C

D

E

OUTDOOR UNIT - GR(V)

830

630

538 146

305

307

20

1060

697

543 258.5258.5 400

20

370

850

835

620

100

305

325

20

GR 268 R

A mm

B mm

C mm

D mm

E mm

Weight kg

934

54

258

886

213

2.5

2.3 - DIMENSIONS AND WEIGHTS OF THE ACCESSORIES OF THE PA

PA 188 C / R

PA 268 X / R

Accessories

AIR

A mm

B mm

C mm

D mm

E mm

Weight kg

Plenum with 160 mm dia. spiggots for

round ducts.

There is a plenum to install on the unit’s

delivery side (directly or on the electric

heater kit) and a plenum to install on the

airflow return side.

PLENUM WITH ROUND SPIGGOTS

A mm

B mm

C mm

D mm

Weight kg

A mm

B mm

C mm

Weight kg

874

174

80

3.5

874

210

36

75

2.5

A

B

C

D

A

B

C

Number of spiggots: PA 188 = 3, PA 268 = 4

1 070

215

310

870

170

12

Airflow

return side

887

255

35

75

2.5

The filter kit can be mounted on the back of

the unit or on the front panel.

This kit can also be used as a simple sleeve

by removing the filter.

FILTER WITH SPIGGOT

The electric heater is fitted onto the unit's

exhaust.

ELECTRIC HEATING

This grille can only be mounted on the

unit’s delivery side (directly or on the

electric heater kit).

DOUBLE DEFLECTOR GRILLE

Delivery

side

GRV 265 X

GRV 180 L

GR 188 R

Weight (kg)

52

54

65

70

GRV 180 L

GR 188 R

GRV265 X

GR 268 R

Page 5

5

150

500 200

A

21

21

10

3 - INSTALLATION OF THE UNITS

3.1 - INSTALLATION OF THE INDOOR UNIT

• The appliance can be installed vertically or horizontally.

3.1.1 - RECOMMENDATIONS

• Safety index: IP 20.

AVOID:

• Putting the unit in very damp places.

• Direct exposure to sunlight or the proximity of heat sources.

• Installing the unit above electric appliances.

MAKE SURE THAT:

• The position is the best one for providing good ventilation in the

room (do not place the blower and intake orifices too near each

other).

• That the solidity of the support is adequate for the weight of the unit

and does not cause vibrations.

• The position chosen complies with the recommended minimum

maintenance spaces (see drawing opposite), and that the distance

and difference in level between the units are as small as possible.

• The piping and the electric connections are easily accessible.

Dimension A:

If the filter kit is installed on the unit, dimension

A must be at least 250 mm (to facilitate filter

removal).

3.1.2 - POSSIBLE INSTALLATION CONFIGURATIONS

1 - Horizontal installation 2 - Vertical installation

Note:

The unit is supplied in configuration 1 as standard.

3.1.3 - CONFIGURATION MODIFICATION

• For suction at the front of the unit, remove the panel's 4 retaining

screws, turn the panel and secure it to the bottom of the unit.

3.1.4 - UNIT INSTALLATION

• Once the configuration has been selected, install any accessories

on the unit (see chapter entitled "Indoor unit accessories").

• Secure the unit to the wall or ceiling using the 4 mounting holes

provided at the back.

Secure the unit with either screws or M8 threaded lugs.

• In horizontal assembly, the appliance must be positioned as shown

in the drawing opposite to ensure that condensates flow toward the

outlet and that the appliance operates correctly.

Page 6

6

• Safety index: IP x 4.

3.2.1 - WALL MOUNTING

• Use the wall support (supplied as an accessory):

- reference K 70 U 001 Z for GRV 180 L,

GR 188 R and GR 268 R.

-reference K 60 U 035 Z for GRV 265 X.

3.2.2 - FLOOR MOUNTING

• Select the location for the unit on the basis of the following

criteria:

- the unit must be installed outside,

- it is necessary to make sure that the free space around

the unit is provided (see the minimum dimensions on

the drawing opposite),

- installation must be simple and make maintenance

work easy,

- the unit must be fixed on a hard base and must be

protected from risks of flooding. We recommend that

the GR 188 R and the GR 268 R be raised

approximately 100 mm off the ground to facilitate the

installation of condensate drainage tubing, as required,

-

use the anti-vibration mountings supplied (GRV 265 X),

making sure that they are not compressed too much

when the fastening screws are tightened,

- ensure that the exhaust is not directed toward

surrounding windows,

- ensure that noise and vibrations are not transmitted to

the building.

AVOID:

- Excessive exposure to salty air or sulfuric gas.

- Heat sources and extraction fans.

- Projections of mud (next to a roadway or path, for

example).

- Areas where there is strong wind blowing against the

unit's air exhaust.

DRAINAGE OF CONDENSATES

- For the GR 188 R and the GR 268 R, use the

condensate drainage connection accessory as

required.

(100)

20

100

50

(500)

50

(600)

250

400

0.15 m

0.50 m

1 m

0.17

Values in parentheses concern model GR 268 R

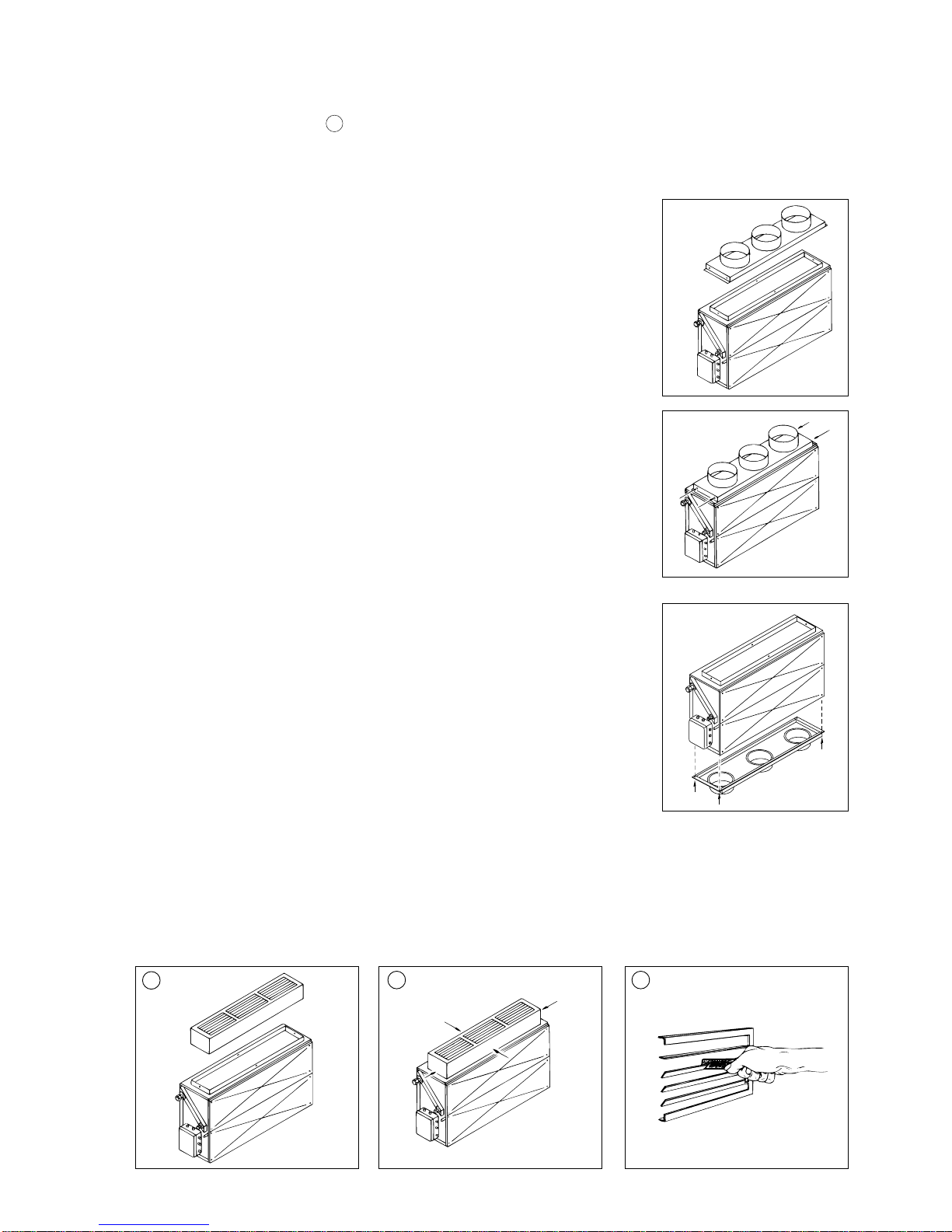

4 - CONNECTIONS

4

5

3

2

1

6

PA

GR(V)

3.2 - INSTALLATION OF THE OUTDOOR UNIT

Anti-vibration

mounting

Before installation,

screw in the bolts as shows.

1-Gas refrigerant connection.

2 - Liquid refrigerant connection.

3 - Electrical connection.

4 - Condensate drainage.

5 - Mains supply with isolating and protective device.

6 - Remote control:

- accessory for cooling only models,

- standard option for heat pump models.

4.1 - CONDENSATE CONNECTION

• The unit is fitted with a drainage tube on each side (O.D. 17 mm).

• Connect a drainage tube to the selected end fitting while respecting a slope in the liquid's flow direction.

• Be sure that the plastic cap is installed on the unused end fitting.

• All connections are made on the left-hand side of the unit (see page 3).

GRV 265 X

GRV 180 L

GR 188 R

GR 268 R

GRV 180 L - GR 188 R

Page 7

7

90

45

• First of all remove the top front panel by undoing the 2 clips

A a quarter of a turn.

Pull the front panel towards you and lift it.

• Then remove the bottom front panel by undoing the 2 clips

B a quarter of a turn.

Pull the front panel towards you and lift it.

Gas valve

Liquid valve

Hole for pipes and cables

HP tapping point

Hole for electric

cables

LP tapping point

Electrical equipment cabinet

• The pipes and cables are inserted through

the right-hand side of the unit.

Open the cap and use the rubber profiled

section supplied as protection.

Note:

To make it easier to install the pipes, the

stiffener can be removed. Make sure that it is

then re-fitted for good panel rigidity.

4.2 - PREPARING THE OUTDOOR UNIT - GRV 265 X

(to gain access to the refrigerant valves and electrical box)

Stiffener

4.3 - REFRIGERANT CONNECTION

* For lengths greater than 20 m, please consult us.

• If the difference in level is greater than 3 metres, do an oil trap.

NOTE:

The nominal capacity is given for a total length of 8 m.

Indoor unit

A

B

Oil trap

Outdoor unit

APPLIANCES FILLED WITH R 407 C

R 407 C

• Fluid R 407 C, as opposed to R22, is not a pure fluid but a blend

composed of:

- 23% R 32 + 25% R 125 + 52% R 134 A.

• The compressors approved for operation with this fluid are filled

beforehand with polyalcohol oil.

Contrary to mineral oil, it is very hygroscopic: it absorbs the

humidity of the ambient air very quickly. This can modify its

lubricant properties and lead in time to the destruction of the

compressor.

MAINTENANCE INSTRUCTIONS

1 - Never add oil to the appliance; the compressor is filled with

polyalcohol oil, a special oil which cannot tolerate the presence

of other oils.

2 - The instruments used for:

- filling,

- pressure measurements,

- emptying under vacuum,

- recovering the fluid,

must be compatible and only used for the R 407 C fluid.

3 - The weight of the refrigerant contained in the storage bottle must

be checked constantly. Do not use it from the moment the

remaining weight is less than 10% of the total weight.

4 - In the case of a new charge:

- do not use the charging cylinder,

- use a balance and a dip pipe type R 407 C cylinder,

- charge the weight of R 407 C as per the value indicated on the

unit’s identification plate (for "split systems", refer to the

installation instructions as the charge must consider the

length of the connecting lines),

- IMPORTANT: see paragraph 3.

5 - The charge must be undertaken in liquid phase.

6 - In case of leakage, do not complete the charge: recover the

remaining refrigerant for recycling and perform a total charge.

Recovery, recycling or the destruction of the fluid must be done

in compliance with the laws in force in the country concerned.

7 - If the refrigerant circuit is opened, you must:

- avoid the entry of air into the circuit as much as possible,

- replace the filter drier,

- perform the "vacuum operation" at a minimum level of 0.3

mbar (static).

Model

Dia.of pipes

Liquid

1/2"

5/8"

1/2"

5/8"

1/4"

3/8"

1/4"

3/8"

7

10

7

10

Gas

> 2 m 25 g/extra m

> 2 m 35 g/extra m

> 0 m 35 g/extra m

> 2 m 55 g/extra m

20

20

20

20

CPV 188 L

CPV 268 X

CP 188 R

CP 268 R

R 407 C = 1 670

1-phase

1 710 3-phase

R 407 C = 1 970

R 22 = 2 000

R 22 = 2 220

Maximum

difference in level

B (in m)

Max. length of

pipes

A (in m)

*

Additional charge

for extra length

Refrigerant load

in outdoor unit

(g)

Page 8

8

MAINS POWER CABLE A

•3 G 2.5 mm

2

to 230V/1/50Hz.

•5 G 1.5 mm

2

to 400 V/3N/50 Hz.

Note:

Power is supplied to the electric heater kit separately

(see Accessories chapter).

CONNECTION CABLE C between the units

• For cooling only models, use wiring of the same size as

that of the mains power supply cable.

•7 G 1.5 mm2 (6 conductors used) for heat pump models.

CONNECTION CABLE OF DE-FROSTING SENSOR D

of the outdoor unit (heat pump models only)

•2 x 1.5 mm

2

(maximum length: 50 m).

Caution: Do not lay this cable near power cables.

REMOTE CONTROL CONNECTION CABLE E

(heat pump models only)

• Number of conductors: 10.

• Min. section : 0.14 mm2 (copper).

• Max. section : 0.75 mm

2

(copper).

• Service voltage : 100 V mini.

• Max. diameter : 7 mm.

• Maximum length : 50 m.

Caution: Do not lay this cable near power cables

(including inside the PA).

3

1

1

2

4

4.3.4 - USING THE FLARE VALVE

• After completing the connection to the internal and external units, the

connections and internal unit must be bled.

• Proceed as indicated below:

1-Undo the plugs (1).

2-Remove the bleed plug (2).

3-Connect the vacuum pump (3).

4-We recommend that you fit a shut-off valve (4).

5-After bleeding, close the shut-off valve (4).

6-Open the two valves completely until they are right against the seat.

7-Remove the vacuum pump (3) and the shut-off valve (4).

8-Tighten the bleed plug (2).

9-Fully tighten the plugs (1).

10 - Add more charge if necessary (see paragraph 4.3).

Note: Refrigerant and electrical connections can be supplied as

accessories. See the "Accessories" section.

Liquide size

3-way valve

3-way

valve

Gas size

Indoor

unit

NOTE : The sections are given as an indication only.

They must be checked and adapted to suit the installation

conditions according to existing standards.

4.4 - ELECTRICAL CONNECTION

REMINDER:

• The PA-C and X models (cooling only) are supplied

without regulation.

• The PA-R models (heat pump) come with specific

electronic regulation with wired remote control.

NOTES:

• The acceptable voltage variation is ± 10% during

operation.

• The electrical connection conduits must be fixed.

• The electrical installation must be carried out in

compliance with the rules in force (especially NFC 15-100

CEI 364).

• The cables are not included in the supplies.

• Short circuit current: 6 kA (GR 268 R only).

MAINS SUPPLY:

• The power supply must come from an isolation and

electric protection device (not supplied) in accordance

with existing regulations.

Note:

In the case of the 3-phase GRV 265 X and GR 268 R,

check the correct phase rotation order. If this order is

not complied with, the SCROLL compressor "runs the

wrong way round" (and makes a strange noise).

To remedy this, simply invert 2 phases.

4.4.1 - CONNECTION CABLES

• See drawings in paragraph 12.

4.3.1 - INSULATION OF PIPES

• Insulate the 2 tubes separately.

• Use minimum 8 mm thick polyethylene sheathing.

• Pay particular attention to preventing water entering along the pipes via the hole in the wall.

Tightening torque

Dia. of pipes

1/4"

3/8"

1/2"

5/8"

2 kgf-m

3 kgf-m

5 kgf-m

6.5 kgf-m

4.3.2 - CONNECTION ON THE INDOOR UNIT

• Check that the connections are clean.

• Tighten the fittings by hand.

• Tighten using torque wrenches (see tightening torque in the table

opposite).

4.3.3 - CONNECTION ON THE OUTDOOR UNIT

• Connect the gas and liquid tubes on the corresponding Flare valves.

• Tighten by hand.

• Tighten using torque wrenches (see tightening torque in the table above).

Page 9

9

4.4.2 - TABLES OF CURRENT

CP 268 R

14

18.6

73

Nominal current A

Max. current A

Starting current A

Cooling only models

CP 188 R

Heat pump models

9.7

13.2

58

14.5

18.5

85

UNITS on 230V/1/50HZ

Cooling

Heating Cooling Heating

14.5

18.5

85

10.1

13.5

58

9.7

13.5

39

6

8.2

39

Nominal current A

Max. current A

Starting current A

Cooling only models

CP 268 R

Heat pump models

6.4

8.1

35

UNITS on 400V/3N/50HZ

Cooling

Heating

6.5

8.1

35

3.8

5.7

25

4.4.3 - CONNECTION TO THE INDOOR UNIT

• Electrical connections are made inside the plastic box located on the side of

the unit.

• Slide the cables through the cable glands on the side of the box and make

connections in accordance with the wiring diagram, paragraph 12.

4.4.4 - CONNECTION TO THE OUTDOOR UNIT

GRV 265 X

A - ACCESS TO THE ELECTRICAL BOX

• Remove the safety panel held by the 4 screws.

Note:

To improve access when working on the

components, the terminal board can be taken out

by removing the 2 thumb screws holding the sheet

metal support.

B - FEEDING IN THE CABLES

• Once the electrical wiring has been inserted into the unit, secure them with the cable clamps located under the electrical box.

• Connect the wires to the terminal board according to the connexion diagram, paragraph 12.

GR 268 R

• Remove the side panel.

• Connect the wires to the

terminal board according

to the connexion diagram,

paragraph 12.

GRV 180L - GR 188 R

• Remove the small cover.

• Connect the wires to the

terminal board according to

the connexion diagram,

paragraph 12.

4.4.5 - REMOTE CONTROL (heat pump models only)

A - PRECAUTIONS

• Only qualified personnel are authorised to open the packaging due to the presence of elements sensitive to static electricity.

1-Do not withdraw or position the base plate when powered up.

2-Do not place the printed circuit board on a conductive surface.

3-Avoid touching the circuit tracks, terminals or integrated circuits on the board.

4-Avoid exposing it to direct sunlight (store at -25°C to +70°C).

5-Use the original packaging for all shipments.

6-Discharge your body of any static electricity, by touching a conductive element connected with the ground, before handling

the printed circuit board.

Ambient conditions for carrying out electronic adjustments

- Operating temperature: 0°C to +60°C.

- Electric environment:

- control box protection class III,

- protection against interference according to CEI 801-4: N3.

CPV 188 L

CPV 268 X

CPV 188 L CPV 268 X

Page 10

10

Fastening:

- The base plate comprises

different openings for fastening to

the box if flush fitted or protruding.

Wall fitting:

- The box must be fitted in an accessible place approximately 1.5 m from the floor.

AVOID : Fitting on external walls, exposed to currents of air from windows or doors, to direct sunlight, or placing it

near heat sources (convectors, chimneys, lamps, etc.).

NOTE : Ambient air must be able to circulate freely around the box. This excludes its being fitted behind curtains,

between shelves, etc.

CAUTION: The box must not be placed in the path of a warm or cold air current from the air-conditioner. If this cannot

be avoided, use a remote sensor.

Make an opening of 7 mm for the lead-through of the connection cable to the left of the locking hook.

Use the main fastening holes to fasten the box.

Fitting a flush-fitted box:

- Holes are available for nearly all the existing flush-fitted boxes. The cable is fed through the hole in the centre of the box.

C - CONNECTION

• Connect the cable to the terminal fixed to the base plate.

Note: the power (5 V =) is supplied by the electronic power supply card of the PA.

Connecting the remote control cable to the PA:

- To be wired directly to the terminal strip of the electronic card located inside the electric box, in accordance with the wiring

diagram in paragraph 12.

CAUTION: To ensure against possible electromagnetic

interference, and if the connection cable is over 3 m

long, you must install an inductor on the cable.

This inductor, supplied with the PA, must be

installed in the appliance’s electric box near the

electronic card. The inductor is held firm on the

cable by 2 plastic clamps (supplied with the

inductor).

Installation in parallel

- For large premises, it is possible to control 3 PA’s using a single

control box.

Take care to comply with the wiring instructions to avoid incorrect

operation:

- connect terminals 1 to 10 of the control box to

corresponding terminals 1 to 10 of the nearest power

supply board,

- only connect terminals 3, 4 and 6 of this board to the next one.

CAUTION: Installation of the 10 wires in parallel leads to

defects.

• Remember to cut off power to all the air-conditioning units to switch off

the whole installation.

B - FITTING

Opening the box:

- Insert the screwdriver in the opening and turn it approximately 45°.

- Remove the cover.

D - CLOSING THE BOX

• After checking the cable connections and adjusting the differentials (see § Adjustment), the box can be closed.

• To do this, position the two upper rectangular spiggots in the corresponding recesses and push downwards.

The hook locks the cover automatically and the electric connection is ensured by pins.

CAUTION: Only close the cover after having carried out the complete installation.

Do not start the installation until the installation has been completed.

Locking hook

Connection terminal

Cable lead-through for fitting onto a wall

Fastening hole

Cable lead-through

Main fastenings

Cable

Inductor

Electronic card

Clamps

5 - 7 mm

Page 11

11

12

11

θ

KL1

CST1

KL2

SC1

P3

P2

P1

R26

IC1

KL3

269

64

30

170

528

54

21331

269

64

30

170

528

269

64

30

170

213

538

30

54

(CTN - 33k

ΩΩ

ΩΩ

Ω at 25°C)

Connection cable: 2 x 1.5 mm

2

Max. length: 50 m

4.4.6 - OTHER POSSIBILITIES OF CONNECTION (reversible models only)

A - REMOTE AMBIENT TEMPERATURE SENSOR

• The control box is ready equipped with an ambient temperature sensor

(marked R 26).

• In case of installation constraints, it may be necessary to off-set the

ambient temperature sensor.

• Two types of sensor exist as accessories:

- bare sensor K 60 D 028 Z,

- sensor in a wall unit K 60 D 033 Z.

• If a remote sensor is connected, sensor R 26 assembled in the

control box must be deactivated.

To do this, cut one of the fastening lugs of the R 26.

• This sensor must be connected to terminal strip KL3 of the electronic control card in

the PA.

CAUTION: Do not lay this cable near the power supply cables (including inside

the PA).

Internal sensor R 26

Bare

sensor

Sensor in a

wall unit

B - REMOTE STANDBY SWITCH

• The potential free contact must be connected to terminals 14 and 16 of terminal strip KL3 of the electronic power supply card

(inside the electric box of the PA).

• Closing this contact causes the control to switch to standby which stops the air-conditioner (the remote control lamps

extinguish).

CAUTION: When in "Standby", the appliance ignores all controls.

The internal functions are saved and the device switches to the configuration existing before being set at

standby as soon as the contact between terminals 14 and 16 is opened. Since the anti-short cycle time delay

can be deactivated, comply with the minimum standby time of 3 minutes.

CAUTION: Do not confuse "Standby" with cutting off the power. If in doubt test the corresponding wires.

CAUTION: Do not lay this cable near the power supply cables (including inside the PA).

• This contact may come from a time switch.

C - SIGNALLING CONTACT

• This potential free contact must be connected to terminals 17 and 18 of terminal strip KL3 on the power supply card (positioned

inside the PA electric box).

• Closing this contact causes a light to illuminate on the panel of the remote control box.

CAUTION: Do not lay this cable near the power supply cables (including inside the PA).

• This contact can be used, for example, to indicate a possible alarm.

4.5 - AERAULIC CONNECTION

• The PA units are intended for installations with or without

ductwork.

4.5.1 - WITH DUCTINGS

• The unit is delivered with a rectangular blower connecting

spiggot.

• For the suction side, a filter kit with a rectangular connecting

spiggot is available separately. See accessories chapter.

4.5.2 - WITHOUT DUCTINGS

• Suction and blowing are posible directly in the premises.

4.5.3 - NOTE

• If access to the filter is difficult or impossible, (especially

if the clearance below the device is insufficient, as

mentioned in chapter 3.1), we recommend displacing the

filter to the offset air intake grille.

• To ensure correct operation, it is important that the

rated output be respected and to never fall below the

minimum output value (see curves in the technical

documentation).

Minimum

flow rate

600 m

3

/h

900 m

3

/h

Nominal

flow rate

850 m

3

/h

1200 m

3

/h

PA 188 C or R

PA 268 X or R

Standard

factory

installation

Other

possible

installation

configurations

Duct spiggot

(standard)

Suction

Suction

spiggot

with filter

(accessory)

Suction

spiggot

with filter

(accessory)

Duct spiggot

(standard)

Page 12

12

5 - INDOOR UNIT ACCESSORIES

5.1 - FILTER WITH SPIGGOT - Code K 60 V 220 T

• This accessory is mounted on the air intake (front or rear panel).

• It is secured by means of 6 screws (supplied).

• It can also be used as a simple rectangular duct connecting spiggot when the filter is not

installed.

• Spiggot thickness: 30 mm with filter, and 55 mm without filter.

5.2 - ELECTRIC HEATING

Code K 60 C 653 T : 3 kW for PA 188 C or R

Code K 60 C 656 T : 6 kW for PA 268 X or R

• The kit is essentially a separate heating unit which fits onto the

unit's exhaust.

5.2.1 - FITTING

• Place flange A onto the unit's duct spiggot.

• If required, taper the spiggot with a hammer so that it fits fully and

snugly onto the sleeve so that no air passes in the angles.

• Using the mounting flange as a guide, drill four Ø3 mm holes in the

unit's spiggot (one on each side).

• Secure the flange by the 4 sheetmetal screws (supplied).

• With the electrical connection boxes on the same side (on the left),

position the heating unit B onto the flange.

• Secure the heating unit with the 4 M8 nuts and bolts in the angles,

as well as the 4 securing clamps on the long sides of the unit (2 on

each side).

• Affix the adhesive foam strip (supplied) to complete the anticondensation insulation.

• The air outlet must be ducted to avoid direct contact with the

heating elements.

IMPORTANT:

• The heater kit is fitted with an automatic reset safety thermostat

(located on the resistors) and a manual reset safety thermostat.

• The original position of the thermostat bulb is intended for units

installed horizontally.

• If the unit is installed vertically, the bulb must be moved.

- Cut the plastic ties holding the bulb in place.

- Place the bulb on the wire conduit for the safety device of the

resistor which is the closest to the kit's outlet.

- Use the two plastic ties provided to secure it.

400V/3+Earth

230V/1+Earth

4 G 1.5 mm

2

3 G 2.5 mm

2

Section

4 G 2.5 mm

2

3 G 4 mm

2

3 kW 6 kW

400V/3

230V/1

4.5 A

13 A

9 A

26 A

3 kW 6 kW

MAINS SUPPLY

• Power to the heater kit must be supplied separately from that of

the air conditioning unit.

The power supply must be protected by a protective device and cutoff device (not supplied) in compliance with the regulations in force.

Caution: High-temperature resistant ties must be used (150°C minimum rating).

• To reset this safety device, refer to the chapter entitled "Maintenance Instructions".

• The sections are given as an indication only.

They must be checked and adapted to suit the installation conditions according

to existing standards.

• Pass the cable (not supplied) from the heater's electrical box into units box

through the available cable gland.

• Connect the cable to the kit’s terminal strip as shown in the wiring diagram in paragraph 12 (cable F ).

Heating unit B

Nuts and bolts

(M8) in corners

Clamps

Flange A

Duct spiggot

Drill 4 holes Ø 3 mm

Adhesive strip

to be affixed

after assembly

New bulb position

Plastic ties

Initial bulb location (cut plastic ties)

Resistor

Automatic

safety device

5.2.2 - ELECTRICAL CONNECTION

• See general recommendations in paragraph 4.4.

CHARACTERISTICS

• Power : 1 model 3 kW, 1 model 6 kW.

• Power supply 400V/3+Earth or 230V/1+Earth

• Current:

Power cable

Control cable

Page 13

13

CONTROL

• The kit comes with the control cable 3 G 1.5 mm2.

• Route this cable through a cable gland of the air-conditioner’s electrical box to the next terminal strip as shown in the wiring

diagram in paragraph 12 (cable G ).

NOTE: For the reversible models, set the remote control’s SC1 program switch on "0" (see paragraph 8.3.6).

5.3 - DELIVERY SIDE PLENUM WITH ROUND SPIGOTS

• Code K 60 M 019 Z : 3 spiggots, for PA 188 C and R.

• Code K 60 M 020 Z : 4 spiggots, for PA 268 X and R.

NOTE:

It is recommended that these 2 plenums be placed as shown (for adequate power per

outlet and air speed), although they can be mounded on both units.

• The plenum is to be mounted on the delivery side of the unit (directly or on the electric

heater kit).

• Remove the seals in located in the angles of the unit’s delivery sleeve.

• Place the plenum on top of the unit’s sleeve (or heater kit).

• Drill four Ø 3 mm holes in the unit’s sleeve (or heater kit) using the holes in the plenum

as a guide.

• Secure the plenum using the 4 sheet-metal screws provided.

5.5 - DOUBLE DEFLECTOR GRILLE

• Code K 60 M 029 Z.

• The grille is mounted on the delivery side of the unit (directly or on the electric heater kit) (figure 1).

• Place the grille on top of the unit’s sleeve (or heater kit) (figure 2).

• Drill four Ø 3 mm holes in the unit’s sleeve (or heater kit) using the holes in the grille as a guide (figure 2).

• Secure the grille using the 4 sheet-metal screws provided.

• Adjust the orientation of the fins using the sheet-metal wrench included in the kit (figure 3).

5.4 - AIRFLOW RETURN SIDE PLENUM WITH ROUND SPIGOTS

• Code K 60 M 049 Z : 3 spiggots, for PA 188 C and R.

• Code K 60 M 050 Z : 4 spiggots, for PA 268 X and R.

NOTE:

It is recommended that these 2 plenums be placed as shown (for adequate power per

outlet and air speed), although they can be mounded on both units.

• The plenum is installed on the airflow return side of the unit.

Caution: in the case, the filter kit cannot be used.

• Secure the plenum using the 4 sheet-metal screws provided.

1

2 3

Page 14

14

62021 122 N2

T°

12

11

1 2 3 4 5 6 N

S3

B1

S2 S1

acc

0

N (neutral)

L (phase)

Fan

COOL

HEAT

HS MS

LS

S3

S2

S1

B1

Remote

sensor

N (neutral)

L (phase)

HS

MSLS

S2

COOL

HEAT

Fan

speed

S1

B1

5.5 - REMOTE CONTROL (exclusively for cooling only models)

5.5.1 - PRESENTATION

Manual remote control - K 60 D 016 Z

S1 On/Off switch.

S2 Ventilation speed selector switch.

S3 Function selector switch.

B1 Room thermostat.

Automatic remote control - K 60 D 025 Z

Optional: a remote temperature sensor K 60 D 028 Z (simple) or K 60 D 033 Z (box) may be connected (see documentation

supplied with the sensors).

S1 ON/Off switch.

S2 Ventilation speed selector switch.

B1 Room thermostat.

5.5.2 - INSTALLATION OF THE BOX

A - PLACEMENT

• Approximately 1.50 m above floor.

• The box must be:

- easily accessible,

- unobstructed (away from curtains, cabinet, shelving,...).

• Avoid:

- any direct sunlight on the box (for example, opposite a window),

- exposure to drafts,

- placing the unit directly in the path of air blown by the air conditioner,

- fixing it on a badly insulated external wall,

- fixing it on a lightweight partition which can vibrate.

B - MOUNTING

• To remove the cover from the box, remove the thermostat knob and unscrew the mounting screw located behind it.

• Attach the base to the wall.

• Route the wiring through the back or from underneath the unit.

5.5.3 - ELECTRICAL CONNECTION

• Make the electrical connection with cable at least 0.75 mm2 (cable not supplied).

• Make the connections onto the terminal strip as shown in the wiring diagram in paragraph 12 (cable H ).

NOTE:

The control circuit for CP 188 C and 268 X models is protected by a 5 x 20 - 4 A - 250 V fuse (rated breaking power: 63 A)

located in the PA (see schematic diagrams).

Page 15

15

50

mini

(GR 268 R = 100)

170

mini

6 - OUTDOOR UNIT ACCESSORIES

6.2 - WALL SUPPORT for GRV 265 X - Code K 60 U 035 Z

1-After making sure that the fixing system used is suitable for the wall, fix the 2 vertical brackets to the wall.

Make sure that measurement 543 is correct.

2-Fit the 2 arms using the M8 screws provided.

3 - Put the unit on the arms:

- Put the anti-vibration pads between the supports and the feet of the unit.

- Fit the unit on the supports using the M8 screws supplied, making sure that the pads are not compressed too much

when tightening.

Wall

support

543

100100

6.1 - WALL SUPPORT for GRV 180 L, GR 188 R, GR 268 R - Code K 70 U 001 Z

1-After making sure that the fixing system used is suitable for the wall, fix the 2 vertical brackets to the wall.

Make sure that measurement A is correct.

2-Fit the 2 arms using the M8 screws provided.

3 - Fix the unit on the support using the M8 screws provided.

Wall

support

1

2 3

1

2 3

6.3 - HP PRESSURE SWITCH KIT for GRV 265 X only - Code K 60 G 093 Z

Cut-off value: 29 bar. Non-adjustable. Manual reset.

• Install the pressure switch directly on the discharge piping pressure tapping (see drawing page 16).

• Remove the jumper between terminals 5 and 6 of the accessories terminal strip and connect the two pressure switch wires

in their place.

A

100100

GRV180 L

GR 188 R

GR 268 R

A (mm)

538

538

620

Page 16

16

REL 7

REL 1

REL 4

REL 2

REL 3

KL3

KL1

REL 6

REL 5

6.4 - LP PRESSURE SWITCH KIT for GRV 265 X only - Code K 60 G 094 Z

7 - CONNECTING ACCESSORIES

8 - STANDARD CONTROL TYPE 523

Cut-off value: 0.5 bar. Non-adjustable. Automatic reset.

• Install the pressure switch directly on the suction piping pressure

tapping (see drawing opposite).

• If no HP pressure switch is already connected, remove the jumper

between terminals 5 and 6 of the main terminal strip and connect the two

pressure switch wires in their place.

• If the HP pressure switch is already connected between terminals 5 and

6 of the main terminal strip, disconnect the wire of terminal 6 and connect

it to a wire of the LP pressure switch, by using the double male lug

supplied with the LP kit. Connect the second wire of the LP pressure

switch on the terminal 6, now free.

Important: This connection must be made inside the electrical box.

6.5 - "PROPORTIONAL" HEAD PRESSURE CONTROL

for GRV 265 X only - Code K 60 G 012 Z

• Fix the controller directly on the pressure tapping point provided (see drawing above).

• Insert the cable into the electric equipment cabinet through a cable gland.

• Remove the jumper between terminals 3 and 4 of the main terminal strip and connect the two wires of the controller in its place.

Main terminal strip

LP pressure switch

HP pressure switch

Condensing

pressure regulator

Accessories

terminal strip

• Heat pump models only

8.1 - PRINCIPLE

•The microprocessor manages the operation of the

air-conditioner.

• It constantly compares the ambient temperature with the

value displayed on the remote control. Each request for

operation processed by the controller is indicated by lights

7 and 8 (see paragraph 8.2.2).

These lights flash if a safety time delay is in progress.

It changes to a steady light when the unit is operating.

8.2 - PRESENTATION

8.2.1 - POWER SUPPLY CARD

• See wiring diagram for details on the

connections.

Remote

control

Electronic power

supply card

(in PA)

Actuators

Standby

contact

(possible)

Signalling

contact

(possible)

Remote ambient

thermoresistor

(option)

Defrosting sensor

(in GR-R)

Ambient

temperature

sensor

GR

fan control

PA

fan control

Cycle reverse

valve control

Compressor

control

Remote control

connection

Power supply 230 VAC

Defrosting sensor

Remote sensor

Make up

heating control

Standby

Signalling

7.1 - REFRIGERANT CONNECTIONS (for CP(V) 188 only)

Length CodeUnit

2 m

4 m

8 m

12 m

2 m

4 m

8 m

12 m

CPV 188 L

CP 188 R

CPV 188 L

CP 188 R

• These connections include the 2 insulated refrigeration lines.

7.2 - COMPLETE CONNECTION ASSEMBLIES

• These include: - the refrigeration lines,

- the electric cables,

-a condensate tube.

NOTE: The electric cables supplied in the connection assemblies cannot

be used for the reversible model.

K 70 A 02 BT

K 70 A 04 BT

K 70 A 08 BT

K 70 A 12 BT

K 70 A 02 BXT

K 70 A 04 BXT

K 70 A 08 BXT

K 70 A 12 BXT

Page 17

17

1

2

5678

13 12 11 10 9 3 15 14 4

KL1

KL2

SC1

P3

P2

P1

R26

IC1

1

00

0

0

1

0

1

0

1

0

1

0

1

0

1

0

111

Temperature °C

Rated ohmic value k

ΩΩ

ΩΩ

Ω

-10

-5

0

+5

+10

+15

+20

+25

+30

+35

187.034

142.602

109.587

85.279

66.785

52.330

41.272

33.000

26.281

21.137

Dimensions: Width : 130.5 mm

Height : 85 mm

Depth : 31 mm

8.2.2 - REMOTE CONTROL

A - FRONT PANEL

• Keys:

1 - Increase temperature set-point.

2 - Decrease temperature set-point.

3 - Air-conditioner operating mode selector.

4 - Ventilation operating mode selector.

• LED lights:

5 - Set-point temperature.

6 - Signalling (option).

7 - Operation in heating mode.

8 - Operation in cooling mode.

9 - "Standby" operating mode.

10 - "Automatic" operating mode (heating or cooling).

11 - "Ventilation only" operating mode.

12 - "Cooling only" operating mode.

13 - "Heating only" operating mode.

14 - "Automatic ventilation" mode.

15 - "Manual ventilation" mode (3 speeds).

B - INSIDE:

• Adjustment of differentials (see details in § 8-3):

- The neutral zone (between heating cut-off and cooling cutoff) is adjusted in the factory at 1K. P2 enables adjustment

up to 5 K.

-The difference between the triggering of the

thermodynamic heating and the possible make-up heating

is adjusted in the same way by P1.

- P3 is not used.

The adjustment of the potentiometers can only be done by

steps of 1 K. To do this, adjust the potentiometers on marks 1,

2, 3, 4 or 5.

For the intermediate positions, the electronics automatically

select the following whole value.

8.2.3 - TEMPERATURE SENSORS

Type CTN - 33 k

ΩΩ

ΩΩ

Ω (± 5%) at 25°C

8.3 - OPERATION

8.3.1 - TEMPERATURE ADJUSTMENT OPERATING

DIAGRAM

• Hysterisis of control signals: 0.6K to 1

K

• Set-point tolerance: ± 2.5

K

• Tolerance of neutral zone: ± 0.3

K

NOTE:

The cycle inversion valve is activated in heating mode.

Microprocessor

Connection pins

Temperature sensor

Potentiometer

Adjustment of differentials

BCD switch of programs

(for electric heating, set to position 0)

MS

MS

HS

HS

LS LS

Set-point

Valve

control

Compressor

control

in cooling

Compressor

control

in heating

Control of

possible

make-up

Ventilation control

in automatic mode

Boost

triggering differential

adjustable from

1 to 5K by P1

Neutral zone

adjustable from 1 to 5K by P2

Page 18

18

8.3.2 - OPERATING MODES

• The 5 available operating modes:

- Standby (indicated by yellow LED 9)

- Automatic (indicated by red LED 10)

- Ventilation only (indicated by red LED 11)

- Cooling only (indicated by red LED 12)

- Heating only (indicated by red LED 13)

• When powered up, the device is set at "Standby". In this mode, all the controller’s outputs are deactivated and the air-

conditioner is not is service. Only light 9 is lit.

• All mode selections on key 3 (by pressing it successively) are immediately indicated by a LED.

However, the device does not take into account the modification of the mode until after about 3 seconds.

Consequently, when rapidly going through the different modes, the device does not take into account the intermediate modes

and stays at its initial status.

A - AUTOMATIC MODE

• In this mode, the Cooling and Heating functions are selected automatically according to the difference between the set-point

and the ambient temperature (see preceding diagram).

• The set-point corresponds to the point where the compressor stops when in heating mode.

• The activated operating mode is indicated by light 7 for Heating and 8 for Cooling. These lights flash if a safety time delay

is in progress. They change to steady light when the unit is operating.

B - VENTILATION MODE ONLY

• In this mode, only the PA ventilator is in operation.

• The Heating/Cooling control is deactivated.

C - COOLING MODE ONLY

• In this mode, only the Cooling is in operation.

• The device does not heat.

• The cycle inversion valve is not activated.

D - HEATING MODE ONLY

• In this mode, only the Heating is in operation.

• The device does not cool.

• The cycle inversion valve is activated permanently.

8.3.3 - PA VENTILATION OPERATING MODES

• Two operating modes are available:

- Automatic (indicated by red LED 14)

- Manual (indicated by red LEDs 15)

A - AUTOMATIC VENTILATION MODE

• This mode is selected by the control as soon as it switches from "Standby" mode to "Automatic" mode, by pressing key 3.

• In this ventilation mode:

- ventilation speed is selected automatically according to the difference between the set-point and the ambiant temperature,

- ventilation stops when in the neutral zone between cold and hot,

- in HEATING and COOLING only modes, the ventilator is cut off at the point where these two functions are stopped,

- in VENTILATION ONLY, the operation is the same as for Cooling only, i.e. the ventilator is cut-off if the temperature falls

below the SET-POINT + NEUTRAL ZONE value.

B - MANUAL VENTILATION MODE

• This mode is selected by pressing key 4.

• In this mode, the ventilation operates continuously at the speed selected (3 speeds).

• It is possible to switch back to automatic ventilation mode by pressing on key 4 again.

NOTE: Stopping the ventilation of the PA is delayed by 1 minute after stopping in Heating mode to ensure the evacuation

of residual heat.

8.3.4 - SET-POINT ADJUSTMENT

• The set-point is adjusted by using the + and - keys (references 1 and 2). The adjustment range is from 16 to 30°C.

• At each press, the LED display shifts by one position to the right (increase temperature) when pressing the + key or to the

left (decrease temperature) when pressing the - key.

• In STANDBY mode all the LED’s of the scale are off. By selecting any mode by using the push-button on the left, the display

will light and correspond to the last value selected.

• When first powering up and after selecting the operating mode, the value displayed is automatically 22

°C.

• This is also the case after power has been cut-off for a period of 4 hours.

• As the control is equipped with a back-up accumulator, the display will indicate the last value selected after power

has been restored if the cut-off period is less then 4 hours.

Page 19

19

8.3.5 - ANTI-SHORT CYCLE COMPRESSOR

• To avoid over-frequent starting-up of the compressor and thus increase its lifetime, a 3 minute time delay is triggered every

time the compressor is activated.

• If the temperature varies suddenly during this time delay to the point of calling for heating or cooling, or if the set-point is

changed in the same proportions, the LED for the corresponding demand starts flashing, indicating that the anti-short cycle

has been activated.

It is only after this time delay has run-out that the control activates the corresponding output, after which the LED lights

normally.

8.3.6 - OUTDOOR UNIT DEFROSTING

• The De-frosting cycle starts when the external sensor

assembled on the unit detects a temperature ≤ -3°C and

stops when the temperature reaches +20°C or after a

maximum of 10 minutes.

• After de-frosting, a time delay prevents a new cycle for a

period of either 30 minutes, or 60 minutes. The selection

of the time delay is done by a jumper between terminals

2 and 6 of terminal strip KL1 (see above).

• During this time delay, the de-frosting cycle cannot restart

if the temperature falls below -3°C.

• The status of the relays during the defrosting can be

selected according to two variants:

- Air-conditioner without auxiliary heating (factory configuration)

(SC1 program switch set at position 1 on the remote control).

• If the temperature of the external sensor reaches

-3°C, the device switches to the de-frosting

function and the status of the relays will be as

follows (see table opposite).

• The PA ventilator stops, thus avoiding cold air

currents.

• To indicate that the device is in De-frosting mode,

the two cooling and heating demand LED’s 7 and

8 start flashing alternatively.

- Air-conditioner with auxiliary heating

(SC1 program switch on the remote control set at position 0).

8.3.7 - SAVING DURING POWER CUTS

• An accumulator installed on the power supply card permits saving the configuration during power cuts (operating mode,

ventilation mode, set-point).

• When restoring power, the control automatically returns to the previous configuration.

• However, to avoid incorrect switching, the outputs are activated only 20 seconds afterwards, permitting the device to measure

the current ambiance.

• The accumulator cannot save the data for a period longer than 4 hours after which they will be lost.

The device will be set at Standby after restoring power.

• The accumulator is fully charged when the device has been powered up for 3 days.

• If the temperature of the external sensor reaches

-3°C, the device triggers the defrosting cycle and

the status of the relays is therefore as follows (see

table opposite).

• Starting the auxiliary heating during the de-frosting

cycle prevents over-cooling the room.

• To indicate that the device is in De-frosting mode,

the two cooling and heating demand LED’s 7 and

8 start flashing alternatively.

Relay

REL 3

REL 2

REL 4/5/6

REL 1

REL 7

Status

energized

de-energized

de-energized

de-energized

de-energized

Function

Compressor in continuous operation

Reversal valve in Cooling position

Internal ventilator stopped

--External ventilator stopped

Relay

REL 3

REL 2

REL 4

REL 1

REL 7

REL 5/6

Status

energized

de-energized

energized

energized

de-energized

de-energized

Function

Compressor in continuous operation

Reversal valve in Cooling position

Internal fan on slow speed

Auxiliary heating activated

External fan stopped

MS and HS inhibited

Defrosting sensor

No jumper between 2 and 6: 30 mn

Jumper between 2 and 6: 60 mn

END OF DEFROSTING CYCLE

• If the temperature of the external sensor reaches +20°C or at maximum after 10 minutes, the device switches to normal

operation. The LED’s stop flashing and all the functions resume normal operation.

•A new de-frosting cycle cannot start until after a period of 30 or 60 minutes.

NOTE: During defrosting, if the operating mode is changed by pressing key 3, the defrosting stage stops before the appliance

starts in the required mode. If the appliance has been switched to standby remotely, the defrosting stage stops after

15 seconds.

To ensure smooth air-conditioner operation, we recommend against changing the operating mode and

stopping the appliance when in a defrosting stage.

Page 20

20

9 - STARTING

9.1 - PRELIMINARY CHECKS

• Make sure:

- that the refrigerant fittings are correctly tightened and that the two shut-off valves are open,

- that there are no leaks,

- that the indoor and outdoor unit are well fixed,

- that the power cables are well fixed to their connection terminals. Loose terminals can cause heat build-up on the terminal

board,

- that the electric cables are properly insulated from any pieces of sheet or metal parts which could damage them,

- that the unit is connected to earth,

- that no tools or any other objects have been left in the units,

- that the filter is correctly fitted,

- that the condensate discharge outlet is correctly connected.

IMPORTANT

Before doing any work on the installation, make sure it is switched off and put out of bounds;

Pay particular attention to the heater kit which is powered separately.

All operations must be carried out by personnel that are approved and qualified for this type of equipment.

8.4 - STARTING THE CONTROL

CHECKS TO BE CARRIED OUT

• This paragraph only concerns the control.

• For all measures and precautionary steps to be taken when starting up the air-conditioner, refer to § 9.

1 - Power-up the controller.

2 - Press mode selection key 3.

3 - Adjust the set-point by pressing keys +/- 1

and 2.

4 - Press mode selection key 3.

5 - Press ventilation selection key 4.

6 - Press ventilation selection key 4.

7 - Press ventilation selection key 4.

8 - Press mode selection key 3.

9 - Press mode selection key 3.

10 - Press mode selection key 3.

The STANDBY light 9 illuminates after 20 seconds.

The control switches to Automatic mode. Lights 10 and 14

illuminate.

If heating or cooling are called, the corresponding lights 7 and 8

illuminate.

The temperature scale light 5 illuminates at the desired value.

The control switches to Ventilation only mode.

The corresponding light 11 illuminates.

Heating and cooling do not function.

Ventilation shifts to continuous slow speed.

The corresponding light 15 illuminates.

Select medium then high speed.

The corresponding light illuminates.

The ventilation switches back to Automatic mode.

The corresponding 14 light illuminates.

The controller switches to Cooling only mode. The corresponding

light 12 illuminates.

If cooling is called light 8 illuminates (it flashes if a safety time delay

is in progress).

The controller switches to Heating only mode. The corresponding

light 13 illuminates.

If heating is called light 7 illuminates (it flashes if a safety time delay

is in progress).

The controller returns to Standby. The corresponding light 9

illuminates. The other lights extinguish.

Page 21

21

10 - MAINTENANCE INSTRUCTIONS

• Air filter:

- We recommend that the air filter be cleaned every 2 weeks by

compressed air or water.

See the "User's Manual".

- Remove the filter by pulling the cartridge as shown in the

diagram.

• External unit air exchanger:

- Cleaning recommended once a year.

• Electric connections:

- Once a year, check that the electric wires are well fastened to

their terminals.

• Electric boxes:

- Dusting is recommended once a year.

• Electric heating safety

- The heating kit is equipped with automatic resetting safety

thermostats (located on the resistors) and a manual reset safety

device.

- The manual reset is used in case of nonexistent or weak air flow.

Possible causes:

- faulty fan motor,

- turbines blocked or jammed,

- clogged filter,

- heat exchanger excessively dirty,

- air intake, outlet or ducts blocked.

- Correct the malfunction then reset the safety thermostat located

under the electrical box by removing the cap and pressing the

button as shown.

1 2

Resetting

button

IMPORTANT

Before doing any work on the installation, make sure it is switched off and put out of bounds.

Pay particular attention to the heater kit which is powered separately.

All operations must be carried out by personnel that are approved and qualified for this type of equipment.

Cap

9.2 - SWITCH ON THE UNIT

• Using the isolation and protection device.

9.3 - START THE UNIT

• Using the indoor unit's control panel (see paragraph 8.4 for reversible models).

9.4 - VENTILATION OF OUTDOOR UNIT

• All all-season usage, the GRV180 L is equipped with a condensation pressure control system as standard.

Ventilation motor speed varies according to the outside air temperature and the temperature of the outdoor exchanger.

Page 22

22

16

18

20

26

28

22

24

14

-824-6 -4 -2 0 2 4 6 8 10 12 14 16 18

20 22

-8

24

1

2

3

4

-6 -4 -2 0 2 4 6 8 10 12 14 16 18

20 22

5

14 16 18 20 22 24

11

13

15

17

19

21

23

25

14 16 18 20 22 24

0

1

2

3

4

5

6

7

14 16 18 20 22 24

11

13

15

17

19

21

23

25

14 16 18 20 22 24

0

1

2

3

4

5

6

7

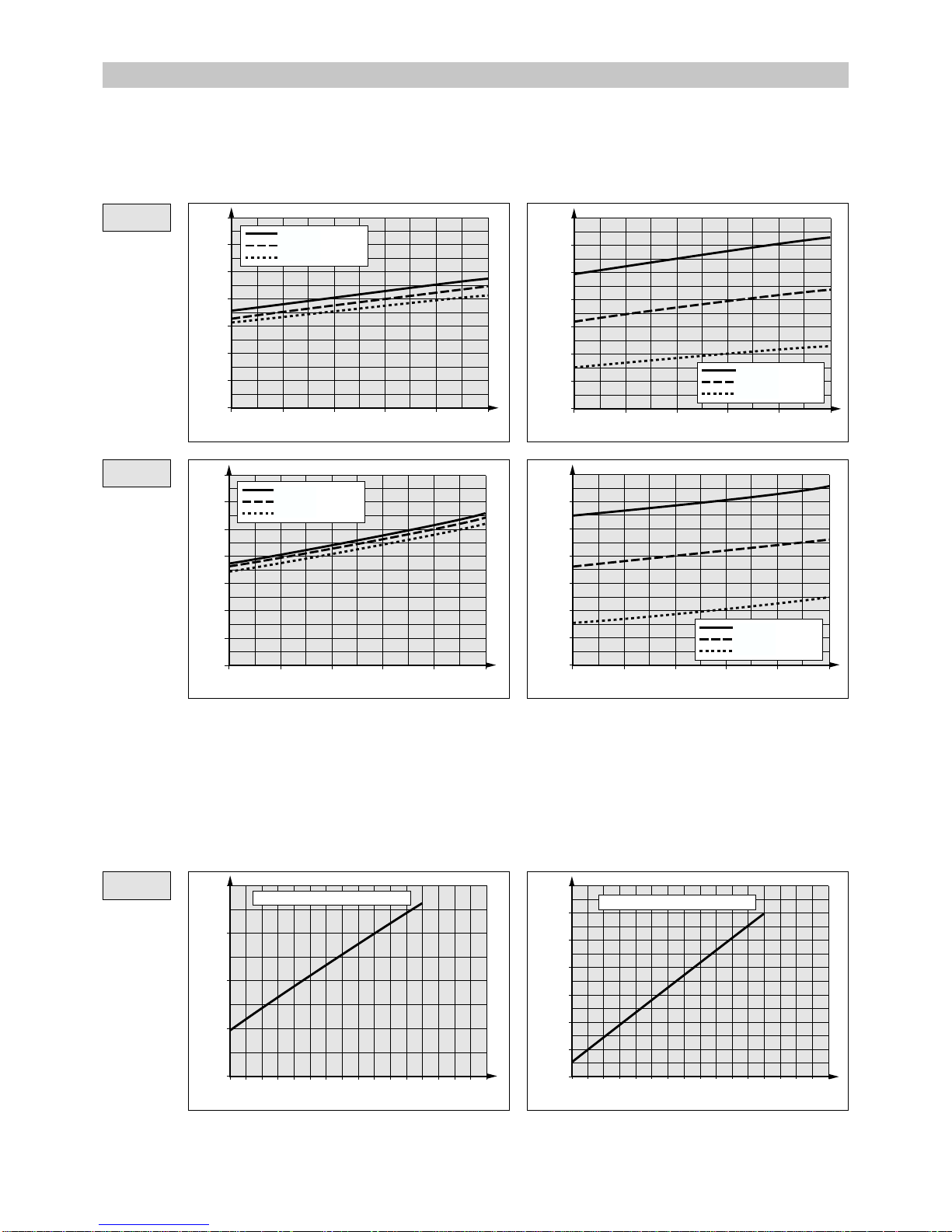

High pressure (relative bar)

Inside wet bulb temperature (°C)

Low pressure (relative bar)

Inside wet bulb temperature (°C)

High pressure (relative bar)

Inside wet bulb temperature (°C)

Low pressure (relative bar)

Inside wet bulb temperature (°C)

High pressure (relative bar)

Outside wet bulb temperature (°C)

Low pressure (relative bar)

Outside wet bulb temperature (°C)

11.1.2 - HEATING MODE

HIGH PRESSURE

LOW PRESSURE

Inside temperature = 20°C

CP 188 R

CP 268 R

CP 188 R

Inside temperature = 20°C

Out. temp. = 43°C

Out. temp. = 35°C

Out. temp. = 19°C

Out. temp. = 43°C

Out. temp. = 35°C

Out. temp. = 19°C

Out. temp. = 43°C

Out. temp. = 35°C

Out. temp. = 19°C

Out. temp. = 43°C

Out. temp. = 35°C

Out. temp. = 19°C

11 - PRESSURE CURVES

11.1.1 - COOLING MODE

11.1 - R 22 MODELS

HIGH PRESSURE

LOW PRESSURE

Page 23

23

12

14

16

22

28

18

20

24

26

10

30

-824-6 -4 -2 0 2 4 6 8 10 12 14 16 18

20 22

1

2

3

6

7

4

5

0

-824-6 -4 -2 0 2 4 6 8 10 12 14 16 18

20 22

HIGH PRESSURE

LOW PRESSURE

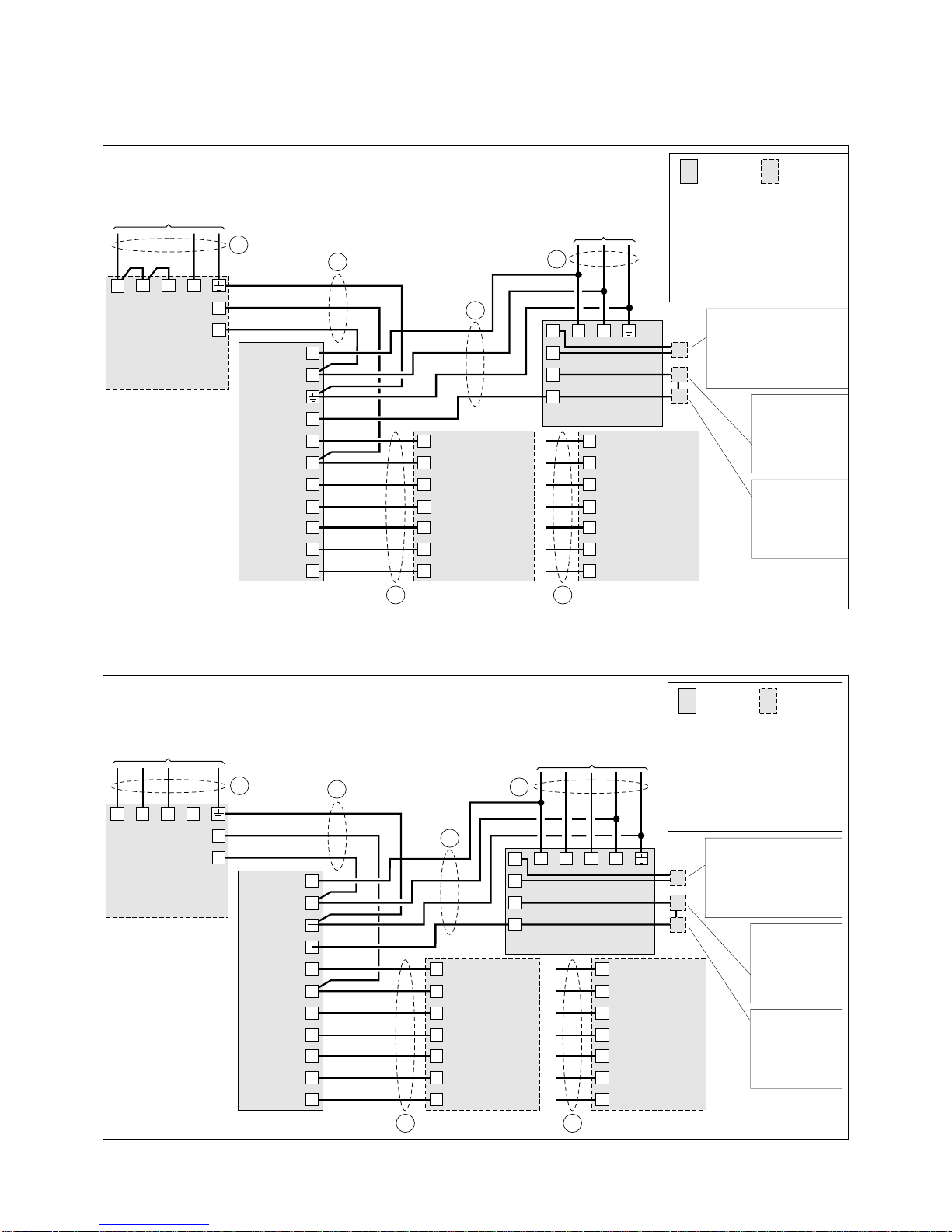

11.2 - R 407 C MODELS (cooling only)

HIGH PRESSURE

LOW PRESSURE

High pressure (relative bar)

Outside wet bulb temperature (°C)

Low pressure (relative bar)

Outside wet bulb temperature (°C)

CPV 268 X

CP 268 R

Inside temperature = 20°C

Inside temperature = 20°C

14 16 18 20 22 24

11

13

15

17

19

21

23

25

14 16 18 20 22 24

3

4

5

6

High pressure (relative bar)

Inside wet bulb temperature (°C)

Low pressure (relative bar)

Inside wet bulb temperature (°C)

Out. temp. = 43°C

Out. temp. = 35°C

Out. temp. = 19°C

Out. temp. = 43°C

Out. temp. = 35°C

Out. temp. = 19°C

CPV 188 L

14 16 18 20 22 24

11

13

15

17

19

21

23

25

14 16 18 20 22 24

3

3.5

4

4.5

5

5.5

6

6.5

7

High pressure (relative bar)

Inside wet bulb temperature (°C)

Low pressure (relative bar)

Inside wet bulb temperature (°C)

Out. temp. = 43°C

Out. temp. = 35°C

Out. temp. = 19°C

Out. temp. = 43°C

Out. temp. = 35°C

Out. temp. = 19°C

Page 24

24

B

Bleu

Blue

Blu

Azul

Blau

Standard

Standard

Standard

Estándar

Standard

Accessoire

Accessory

Accessorio

Accesorio

Zubehör

V/J

Vert/Jaune

Green/Yellow

Verde/Giallo

Verde/Amarillo

Grn/Gelb

M

Marron

Brown

Marrone

Marrn

Braun

C

5

1

2

11

12

31

32

33

PA 188 C

230/1/50

4

6

Commande à distance

Remote control

Comando a distanza

Mando a distancia

Fernsteuerung

K 60 D 016 Z

2

6

N

3

5

4

1

V/J

M

B

Alimentation kit chauffage

Power heater kit

limentazione kit riscaldamento

A

limentacin kit de calefaccin

Stromversorgung der Heizung

400 V / 3 / 50 Hz

26

22

Kit chauffage

Electric heater kit

Kit riscaldamento

Kit de calefacción

Elektrisch Heizung

N

3 kW = K 60 C 653 T

6 kW = K 60 C 656 T

U

V W

1

4

L3 L2

GRV 180 L

400/3N/50

A

Alimentation gnrale

Mains supply

Alimentazione generale

Alimentacin elctrica

Stromversorgung

400 V / 3 N / 50 Hz

2

L1

N

Commande à distance

Remote control

Comando a distanza

Mando a distancia

Fernsteuerung

K 60 D 025 Z

6

2

1

N

22

21

20

H H

G

F

Commande à distance

Remote control

Comando a distanza

Mando a distancia

Fernsteuerung

K 60 D 016 Z

2

6

N

3

5

4

Commande à distance

Remote control

Comando a distanza

Mando a distancia

Fernsteuerung

K 60 D 025 Z

6

2

1

N

22

21

20

1

4

L N

GRV 180 L

230/1/50

A

C

5

1

2

11

12

31

32

33

PA 188 C

230/1/50

4

6

Alimentation gnrale

Mains supply

Alimentazione generale

Alimentacin elctrica

Stromversorgung

230 V / 1 / 50 Hz

Monter le pont livr avec le kit.

Connect the bridge with the wire included in the kit.

Montare il ponte consegnato con il kit.

Montar el puente suministrado con el kit.

Die mit der elektrischen Heizung mitgelieferte Brcke installieren.

1

2

H H

Standard

Standard

Standard

Estándar

Standard

Accessoire

Accessory

Accessorio

Accesorio

Zubehör

V/J

Vert/Jaune

Green/Yellow

Verde/Giallo

Verde/Amarillo

Grn/Gelb

M

Marron

Brown

Marrone

Marrn

Braun

B

Bleu

Blue

Blu

Azul

Blau

V/J

M

B

Alimentation kit chauffage

Power heater kit

Alimentazione kit riscaldamento

Alimentacin kit de calefaccin

Stromversorgung der Heizung

230 V / 1 / 50 Hz

Kit chauffage

Electric heater kit

Kit riscaldamento

Kit de calefacción

Elektrisch Heizung

U

V W N

3 kW = K 60 C 653 T

6 kW = K 60 C 656 T

26

22

G

F

*

*

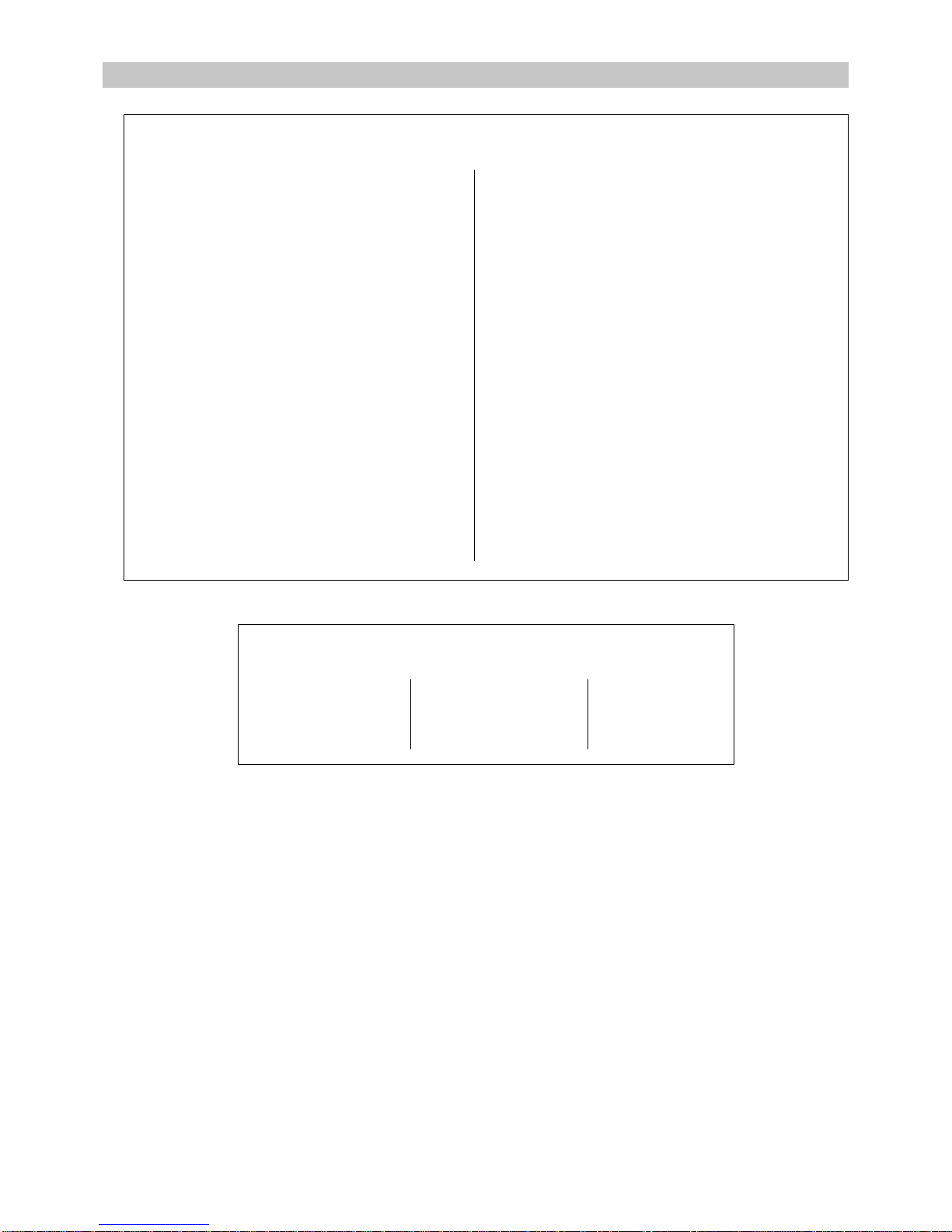

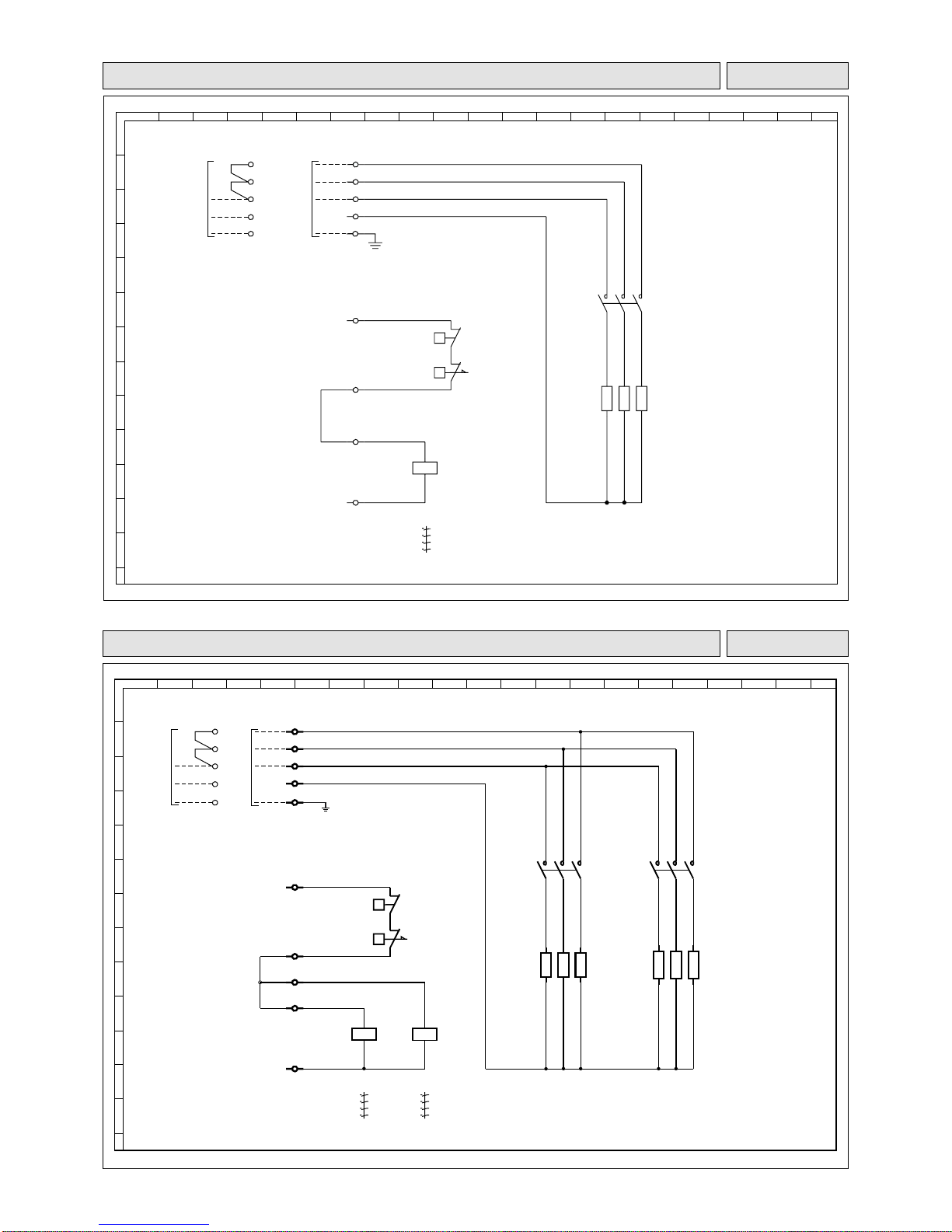

230V/1/50Hz to CONNECTION CPV 188 L

400V/3N/50Hz to CONNECTION CPV 188 L

12 - ELECTRICAL CONNECTION DIAGRAMS

Page 25

25

Standard

Standard

Standard

Estándar

Standard

Accessoire

Accessory

Accessorio

Accesorio

Zubehör

V/J

Vert/Jaune

Green/Yellow

Verde/Giallo

Verde/Amarillo

Grn/Gelb

M

Marron

Brown

Marrone

Marrn

Braun

B

Bleu

Blue

Blu

Azul

Blau

Commande à distance

Remote control

Comando a distanza

Mando a distancia

Fernsteuerung

K 60 D 016 Z

2

6

N

3

5

4

Commande à distance

Remote control

Comando a distanza

Mando a distancia

Fernsteuerung

K 60 D 025 Z

6

2

1

N

22

21

20

U V

GRV 265 X

400/3N/50

A

C

5

1

11

12

31

32

33

PA 268 X

230/1/50

4

6

Alimentation gnrale

Mains supply

Alimentazione generale

Alimentacin elctrica

Stromversorgung

400 V / 3N / 50 Hz

V/J

M

B

1

2

5

3

4

Alimentation kit chauffage

Power heater kit

limentazione kit riscaldamento

limentacin kit de calefaccin

Stromversorgung der Heizung

400 V / 3 / 50 Hz

26

22

3 kW = K 60 C 653 T

6 kW = K 60 C 656 T

Kit chauffage

Electric heater kit

Kit riscaldamento

Kit de calefacción

Elektrisch Heizung

N

6

Rgulation toutes saisons

Head pressure control

Regolazione tutte le stagioni

Regulacin todas estacione

s

Drehzahlgeregelt

K 60 G 012 Z

Pressostat BP

LP pressure switch

Pressostato BP

Presstato BP

ND-Pressostat

K 60 G 094 Z

Pressostat HP

HP pressure switc

h

Pressostato AP

Presstato AP

HD-Pressostat

K 60 G 093 Z

U

V W

N

W

HH

BP

HP

G

F

Commande à distance

Remote control

Comando a distanza

Mando a distancia

Fernsteuerung

K 60 D 016 Z

2

6

N

3

5

4

Commande à distance

Remote control

Comando a distanza

Mando a distancia

Fernsteuerung

K 60 D 025 Z

6

2

1

N

22

21

20

1 N

GRV 265 X

230/1/50

A

C

1

11

12

31

32

33

PA 268 X

230/1/50

4

6

Alimentation gnrale

Mains supply

Alimentazione generale

Alimentacin elctrica

Stromversorgung

230 V / 1 / 50 Hz

V/J

M

B

1

2

5

3

4

Alimentation kit chauffage

Power heater kit

limentazione kit riscaldamento

limentacin kit de calefaccin

Stromversorgung der Heizung

230 V / 1 / 50 Hz

26

22

3 kW = K 60 C 653 T

6 kW = K 60 C 656 T

Kit chauffage

Electric heater kit

Kit riscaldamento

Kit de calefacción

Elektrisch Heizung

U

V W N

6

Standard

Standard

Standard

Estándar

Standard

Accessoire

Accessory

Accessorio

Accesorio

Zubehör

V/J

Vert/Jaune

Green/Yellow

Verde/Giallo

Verde/Amarillo

Grn/Gelb

M

Marron

Brown

Marrone

Marrn

Braun

B

Bleu

Blue

Blu

Azul

Blau

Rgulation toutes saisons

Head pressure control

Regolazione tutte le stagioni

Regulacin todas estaciones

Drehzahlgeregelt

K 60 G 012 Z

Pressostat BP

LP pressure switch

Pressostato BP

Presstato BP

ND-Pressostat

K 60 G 094 Z

Pressostat HP

HP pressure switch

Pressostato AP

Presstato AP

HD-Pressostat

K 60 G 093 Z

H H

BP

HP

F

G

Monter le pont livr avec le kit.

Connect the bridge with the wire included in the kit.

Montare il ponte consegnato con il kit.

Montar el puente suministrado con el kit.

Die mit der elektrischen Heizung mitgelieferte Brcke installieren

.

5

*

*

230V/1/50Hz to CONNECTION CPV 268 X

400V/3N/50Hz to CONNECTION CPV 268 X

Page 26

26

Standard

Standard

Standard

Estándar

Standard

Accessoire

Accessory

Accessorio

Accesorio

Zubehör

V/J

Vert/Jaune

Green/Yellow

Verde/Giallo

Verde/Amarillo

Grün/Gelb

M

Marron

Brown

Marrone

Marrón

Braun

B

Bleu

Blue

Blu

Azul

Blau

Commande à distance

Remote control

Comando a distanza

Mando a distancia

Fernsteuerung

C

3

2

1

13

15

PA 188 R

PA 268 R

230/1/50

V/J

M

B

Alimentation kit chauffage

Power heater kit

Alimentazione kit riscaldamento

Alimentación kit de calefacción

Stromversorgung der Heizung

230 V / 1 / 50 Hz

26

22

3 kW = K 60 C 653 T

6 kW = K 60 C 656 T

Kit chauffage

Electric heater kit

Kit riscaldamento

Kit de calefacción

Elektrisch Heizung

U

V W N

A

Alimentation générale

Mains supply

Alimentazione generale

Alimentación eléctrica

Stromversorgung

230 V / 1 / 50 Hz

2

N L

GR 188 R

GR 268 R

230/1/50

1

6

4

5

8

7

D

Sonde dégivrage

Defrost sensor

Sonda sbrinamento

Sonda desescarche

Enteisungssonde

4

3

2

1

7

6

5

9

8

4

3

2

1

7

6

5

10

9

8

10

14

12

11

17

16

18

E

Sonde à distance

Remote sensor

Sonda a distanza

Sonda a distancia

Externe Temperatursonde

K 60 D 028 Z

ou / or / o / o / oder

K 60 D 033 Z

Marche/Arrêt à distance (hors fourniture)

Remote On/Off (not supplied)

Avviamento/Arresto a distanza (non fornito)

Funcionamiento/Parada a distancia (no suministro)

Ein/Aus Ferngesteuert (nicht mitgeliefert)

Alarme (hors fourniture)

Alarm (not supplied)

Allarme (non fornito)

Alarma (no suministro)

Alarm (nicht mitgeliefert)

Carte électronique placée dans le coffret électrique

Electronic card inserted in the electric box

Scheda elettronica posta nel cofano elettrico

Tarjeta electrónica colocada en el armarion eléctrico

Elektronikkarte im Schaltkasten

G

F

6

4

5

Monter le pont livré avec le kit.

Connect the bridge with the wire included in the kit.

Montare il ponte consegnato con il kit.

Montar el puente suministrado con el kit.

Die mit der elektrischen Heizung mitgelieferte Brücke installieren

.

*

*

ou, or, o, o, oder 3

230V/1/50Hz to CONNECTION CP 188 R / 268 R

Page 27

27

Commande à distance

Remote control

Comando a distanza

Mando a distancia

Fernsteuerung

C

3

2

1

13

15

PA 268 R

230/1/50

V/J

M

B

Alimentation kit chauffage

Power heater kit

Alimentazione kit riscaldamento

Alimentación kit de calefacción

Stromversorgung der Heizung

400 V / 3 / 50 Hz

26

22

3 kW = K 60 C 653 T

6 kW = K 60 C 656 T

Kit chauffage

Electric heater kit

Kit riscaldamento

Kit de calefacción

Elektrisch Heizung

U

N

A

Alimentation générale

Mains supply

Alimentazione generale

Alimentación eléctrica

Stromversorgung

400 V / 3N / 50 Hz

2

N

GR 268 R

400/3N/50

1

6

4

5

8

7

D

Sonde dégivrage

Defrost sensor

Sonda sbrinamento

Sonda desescarche

Enteisungssonde

4

3

2

1

7

6

5

9

8

4

3

2

1

7

6

5

10

9

8

10

14

12

11

17

16

18

E

Sonde à distance

Remote sensor

Sonda a distanza

Sonda a distancia

Externe Temperatursonde

K 60 D 028 Z

ou / or / o / o / oder

K 60 D 033 Z

Marche/Arrêt à distance (hors fourniture)

Remote On/Off (not supplied)

Avviamento/Arresto a distanza (non fornito)

Funcionamiento/Parada a distancia (no suministro)

Ein/Aus Ferngesteuert (nicht mitgeliefert)

Alarme (hors fourniture)

Alarm (not supplied)

Allarme (non fornito)

Alarma (no suministro)

Alarm (nicht mitgeliefert)

Carte électronique placée dans le coffret électrique

Electronic card inserted in the electric box

Scheda elettronica posta nel cofano elettrico

Tarjeta electrónica colocada en el armarion eléctrico

Elektronikkarte im Schaltkasten

V W

L

1

L3L

2

Standard

Standard

Standard

Estándar

Standard

Accessoire

Accessory

Accessorio

Accesorio

Zubehör

V/J

Vert/Jaune

Green/Yellow

Verde/Giallo

Verde/Amarillo

Grün/Gelb

M

Marron

Brown

Marrone

Marrón

Braun

B

Bleu

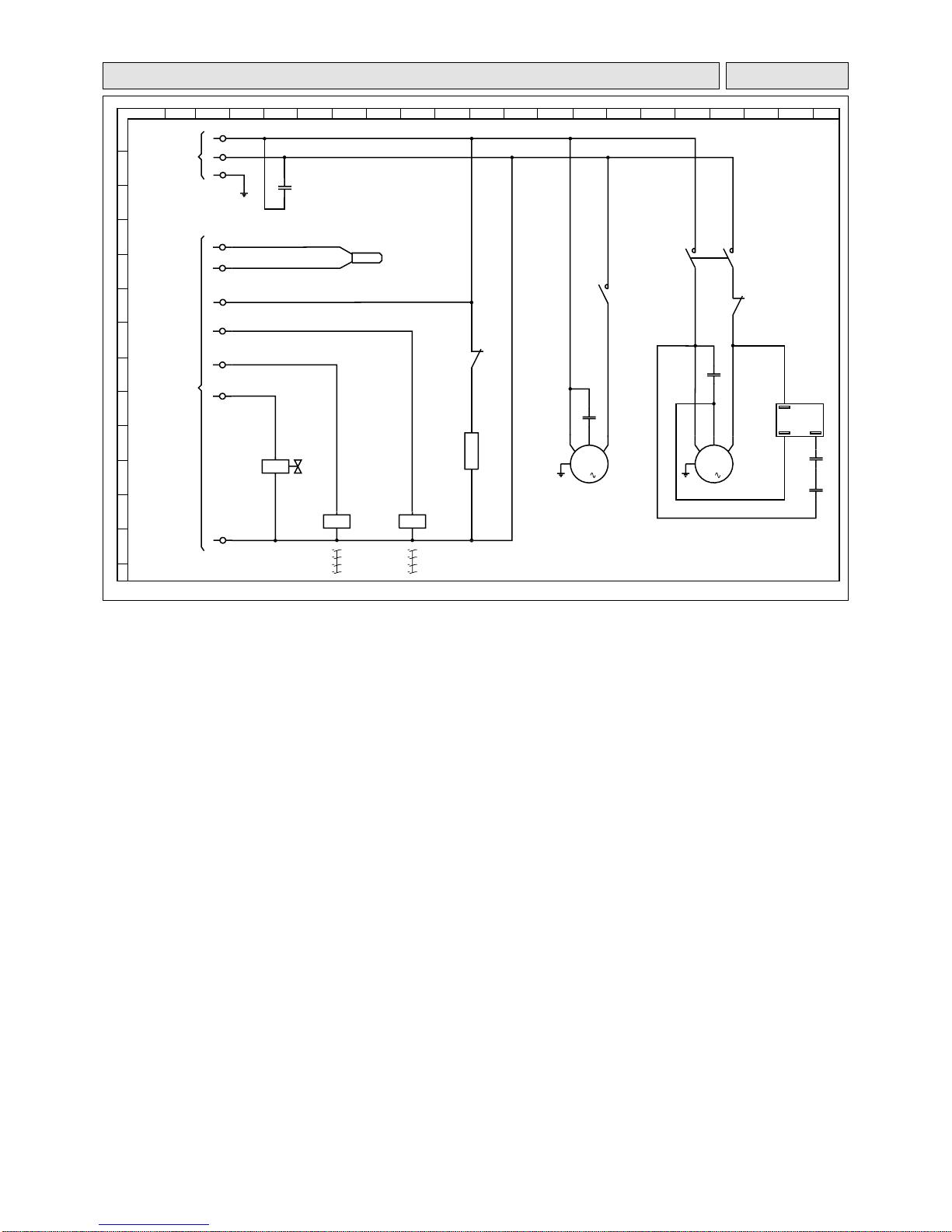

Blue