Page 1

CHGV

AIR COOLED WATER CHILLER

WITH HYDRAULIC EQUIPMENT

AIR / WATER

47 to 78 kW

CHGV 50

CHGV 64

CHGV 72

CHGV 80

November 2007

10 12 167 - GB - 02

TECHNICAL INSTRUCTIONS

PHRV heat pump model also available

Page 2

2

CONTENTS

1 - Application - Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 - Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3 - Technical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

4 - Physical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5 - Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

6 - Cooling performances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

7 - Corrections to be made when using anti-freeze . . . . . . . . . . . . . .8

8 - Curves of available pressures . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

9 - Sound levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

10 - Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

11 - "ECH" electronic control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

12 - Installation information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

MARKING

This product marked conforms to the essential requirements of the Directives:

- Low voltage no 2006/95/EC.

- Electromagnetic Compatibility no. 89/336 EEC, modified 92/31 EEC and 93/68 EEC.

- Pressure Equipment Directive No. 97/23/EC.

1 - APPLICATION - USE

• Air cooled type chilled water generator intended for climate control in buildings.

• Single package unit, factory assembled and tested.

•

Designed for outdoor installation.

• Supplied fully charged with R 407 C refrigerant.

• Convenient hydraulic and electrical connections.

• Practical service access via removable panels.

R 407 C

• Fluid R 407 C, as opposed to R22, is not a pure fluid but a

blend composed of:

- 23% R 32 + 25% R 125 + 52% R 134 A.

• The compressors approved for operation with this fluid are

filled beforehand with polyalcohol oil.

Contrary to mineral oil, it is very hygroscopic: it absorbs the

humidity of the ambient air very quickly. This can modify its

lubricant properties and lead in time to the destruction of the

compressor.

MAINTENANCE INSTRUCTIONS

1

- Never add oil to the appliance; the compressor is filled

with polyalcohol oil, a special oil which cannot tolerate the

presence of other oils.

2 - The instruments used for:

- filling,

-

pressure measurements,

- emptying under vacuum,

- recovering the fluid,

must be compatible and only used for the R 407 C fluid.

3 - The weight of the refrigerant contained in the storage

bottle must be checked constantly

. Do not use it from the

moment the remaining weight is less than 10% of the total

weight.

4 - In the case of a new charge:

- do not use the charging cylinder,

- use a balance and a dip pipe type R 407 C cylinder,

- charge the weight of R 407 C as per the value indicated

on the unit’s identification plate,

- IMPORTANT: see instruction 3 above.

5 - The charge must be undertaken in liquid phase.

6 - In case of leakage, do not complete the charge: recover

the remaining refrigerant for recycling and perform a total

charge.

Recovery, recycling or the destruction of the fluid must be

done in compliance with the laws in force in the country

concerned.

7 - If the refrigerant circuit is opened, you must:

- avoid the entry of air into the circuit as much as

possible,

- replace the filter drier,

- perform the "vacuum operation" at a minimum level of

0.3 mbar (static).

8 - Do not release R 407 C fluid into the atmosphere. This

fluid is a fluorinated greenhouse gases, covered by the

Kyoto Protocol with a Global W

arming Potential

(GWP) = 1653 - (CE Directive 842 / 2006).

APPLIANCES FILLED WITH R 407 C

Page 3

3

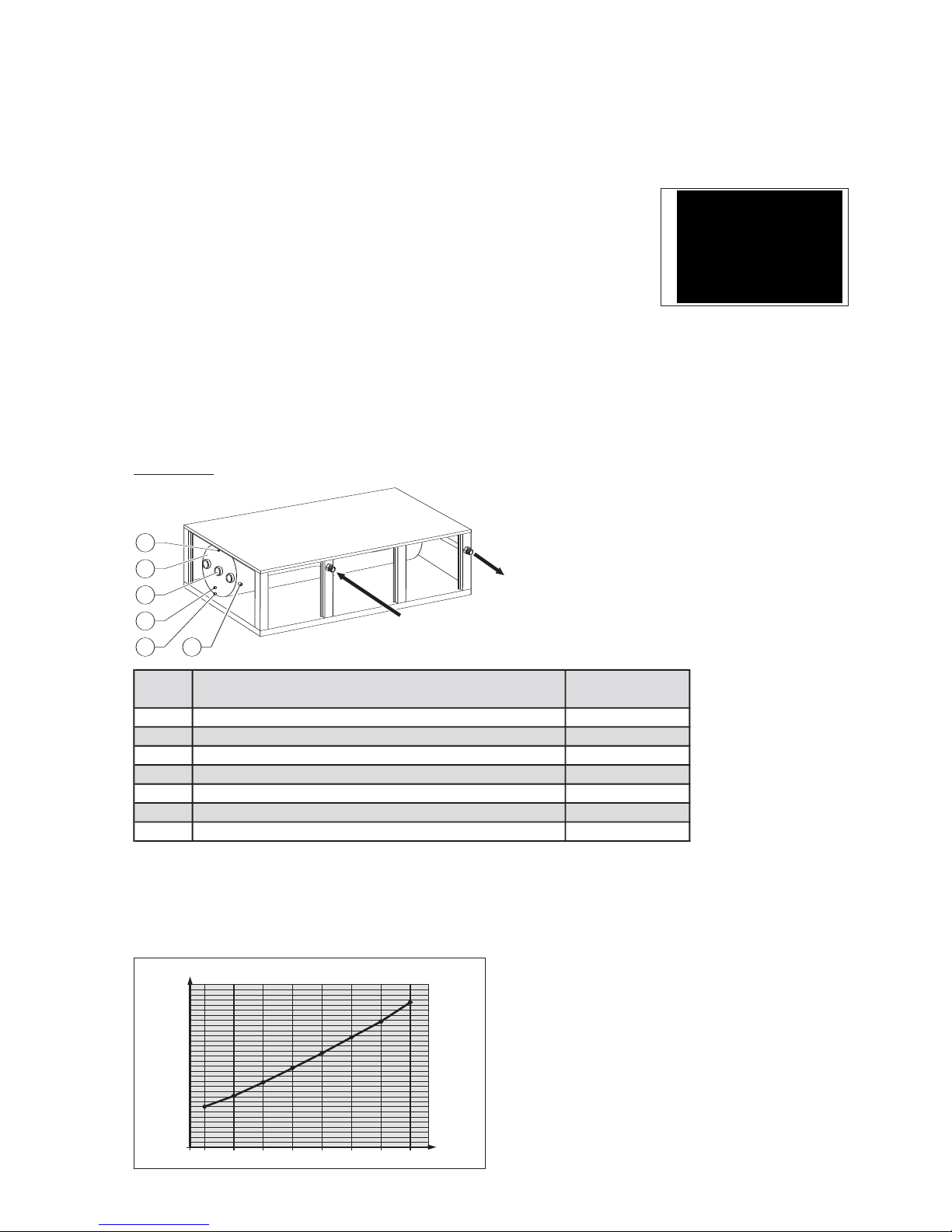

2 - PRESENTATION

• CHGV: An air cooled chilled water generator with built-in hydraulic

equipment.

Model

2 refrigerant circuits

R 407C 50 / 64 / 72 / 80

Refrigerant

b

a

5

9

7

4

3

2

1

6

8

Water inlet

Water outlet

SCROLL COMPRESSOR

• Mounted on vibration pads with sound insulation.

• 1 per circuit.

WATER EXCHANGER

• Plate water exchanger with heat insulation.

• 1 per circuit.

AIR EXCHANGER

• Thin plate air exchanger with protective grille.

• 1 per circuit.

ELECTRIC F

AN UNIT

•

E

lectric fan unit with protective grille.

• 1 per circuit.

SWITCH BOX

• “ECH” electronic control .

•

Main switch

.

• Phase-sequence tester.

• Power and control circuitry protected by magnetothermal

circuit breakers.

• Complies with standard EN 60 204-1.

• Short circuit current 10 kA, as per IEC 947-2.

CIRCULATING PUMP

• Circulating pump with heat insulation.

EXPANSION TANK

REFRIGERATION CIRCUITS

• R407C loads.

• Copper piping.

• Thermostatic regulator.

•

Filter-dryer.

• HP and LP safety pressure switches.

CHASSIS - BODYWORK

•

Galvanised sheet metal with light grey oven-baked

polyester powder paint (RAL 7035).

9

8

7

6

5

4

3

2

1

Page 4

4

3 - TECHNICAL CHARACTERISTICS

CHGV 50 CHGV 64 CHGV 72 CHGV 80

kW 47.60 62 67 78

kW 20.60 26.40 28.80 29.40

(EER) 2.31 2.35 2.33 2.65

kW 25 32 36 36.6

A 42.80 56.30 60.40 64.80

A 38.70 47.70 54 55.50

A 170 185 225 225

mm

2

16 16 25 25

m3/h 8.21 10.66 11.52 13.43

L/s 2.28 2.96 3.20 3.73

kPa 220 160 180 90

Electrical supply cable section

Nominal water flow

Available pressure

Model

Heating capacity

Nominal power consumption *

Effictuiveness heating *

Rated total input amperage

Total Max. power consumption **

Total Max. current consumption **

Starting current

(*) Gross value without hydraulic pump.

(**) In the operating range.

•

Power supply:

400V (±10%) / 3 Ph + Neutral + Earth / 50Hz

•

Nominal operating conditions:

- water inlet temperature : + 12°C

- water outlet temperature : + 7°C

- outdoor dry bulb temperature (dry) : + 35°C

•

Operating limits (pure water):

- temperature of inlet air to condenser : - 10°C to + 45°C

- water outlet temperature : + 4°C to + 20°C

•

Water system pressure: 1.5 to 3 bar.

Consult us for any special climatic conditions departing significantly from the nominal conditions.

Page 5

5

4 - PHYSICAL CHARACTERISTICS

Dimensions (in mm) are

given for standard units

without options.

General tolerance ±10 mm.

Condenser air discharge

Condenser air suction

a Chilled water inlet connection

b Chilled water outlet connection

c HP and LP hose entry

Electrical connections

Location of the 4 anti-vibration pads

(accessory) (100 x 100 x 25 mm) under

girders

G Centre of gravity (in the centre of the unit)

b

c

a

1

,955

x

G

1,175 (1,425 CHGV 80)

125

1,050

950

180

2 LP pressure

gauges (Accessory)

2 HP pressure

gauges (Accessory)

4 Ø 22.5 mm holes

for sling attachment

300

300

1000

300

(600 with tank)

• Clearances to be respected for unit

operation and maintenance.

• No obstacle less than 3 m above

the unit.

Front

Net Packed

weight weight Length 2,015 mm

50 500 kg 540 kg Depth 1,135 mm

64 534 kg 574 kg 1,370 mm

72 556 kg 596 kg 1,620 mm

80 606 kg 646 kg CHGV 80

Overall

packed

dimensions

Height

Net Packed

weight weight Length 1,990 mm

Tank Depth 1,110 mm

without heating Height 806 mm

185 kg

207 kg

Overall packed

dimensions

Access to switch box

CHGV

4.1 - CHGV

4.2 - 300-LITRE BUFFER TANK (ACCESSORY)

cba

1,955

315

1,050

1,300

611

40

160

4 Ø 22.5 mm holes

for passing slings for

handling the tank only

300

600

1000

300

•Clearances to be respected for

maintenance.

Front

Buf

fer tank

Hydraulic

connection

tube

Page 6

6

5 - DESCRIPTION

CHGV 50 CHGV 64 CHGV 72 CHGV 80

2 2 2 2

kg 2 x 7.25 2 x 8 2 x 9 2 x 12.5

• • • •

Number 2 2 2 2

Power supply 400V / 3 / 50Hz

Nominal current per compressor A 17.00 20.80 23.10 23.80

Nominal power consumed by the compressor kW 9.90 12.50 14.30 14.70

• • • •

Number 2 2 2 2

Air flow

m3/h 9,800 11,000 11,000 11,000

Diameter mm 760 760 760 760

Max. rotation speed (motor) rpm 620 660 660 660

Power consumption per motor kW 0.75 0.85 0.85 0.85

• • • •

Number 2 2 2 2

• • • •

Number 2 2 2 2

Water capacity liters 4 5 6 7

Male 1"1/2 coupling (40x49)

Minimum installation water volume * liters 120 160 170 200

Maximum installation water volume ** liters 1,500 1,500 1,500 1,500

Expansion tank (1.5 bar)

Tank capacity liters 18 18 18 18

Safety valve (3 bar) with pressure gauge

Differential water output pressure switch

Output control valve

Fill valve (ø 1/4" female)

Water filter supplied (not installed)

Circulating pump

Maximum power consumption (pump only) kW 1.40 1.40 1.90 1.90

Maximum current A 2.70 2.70 3.50 3.50

Power supply 400V / 3 / 50Hz

Electrical equipment IP 24 IP 24 IP 24 IP 24

Mechanical risks B B B B

Hermetic SCROLL compressor with soundproofing and internal

thermal protection

Model

Cooling circuit (number) with HP and LP pressure switches

R 407 C refrigerant charge

3.50

3.90

3.90

3.90

•••

•

Hydraulic circuit

Helicoidal electric fan, direct coupling, with internal thermal protector

General electrical power supply 400V / 3N + Earth / 50Hz

Equipment protection index

Water exchanger with stainless steel brazed plates AISI 316 L with

thermal insulation

Air exchanger with protective grille, copper tubes, aluminium fins

230V / 1 / 50Hz power supply with speed control for condensation

pressure control

Nominal current per motor (single-phase 230 VAC)

A

(*)

If the water volume of the system is below the minimum, a buf

fer tank must be installed.

(**)

If the water volume of the system is above the maximum, an additional expansion tank is required.

Page 7

7

6 - COOLING PERFORMANCES

4 6 8 10 12 14 16 18 20

10

20

30

40

50

4 6 8 10 12 14 16 18 20

22

24

26

28

30

32

34

36

38

4 6 8 10 12 14 16 18 20

17

19

21

23

25

27

29

31

33

4 6 8 10 12 14 16 18 20

12

14

16

18

20

22

24

4 6 8 10 12 14 16 18 20

50

60

70

80

90

100

110

120

130

4 6 8 10 12 14 16 18 20

40

50

60

70

80

90

100

110

4 6 8 10 12 14 16 18 20

40

50

60

70

80

90

100

110

4 6 8 10 12 14 16 18 20

38

42

46

50

54

58

62

66

70

74

78

TOTAL INPUT POWERCOOLING CAPACITY

CHGV 50

CHGV 64

CHGV 72

CHGV 80

Water outlet temperature (°C)

Cooling capacity (kW)

Water outlet temperature (°C)

Total input power (kW)

Water outlet temperature (°C)

Cooling capacity (kW)

Water outlet temperature (°C)

T

otal input power (kW)

Water outlet temperature (°C)

Cooling capacity (kW)

Water outlet temperature (°C)

Total input power (kW)

Water outlet temperature (°C)

Cooling capacity (kW)

Water outlet temperature (°C)

Total input power (kW)

∆ T (water) between 4 and 6°K.

Out. temp. = 15

°

C

Out. temp. = 25°C

Out. temp. = 35°C

Out. temp. = 45

°C

Out. temp. = 19

°

C

Out. temp. = 25°C

Out. temp. = 35°C

Out. temp. = 45°C

Out. temp. = 19

°C

Out. temp. = 25°C

Out. temp. = 35

°C

Out. temp. = 45°C

Out. temp. = 19°C

Out. temp. = 25°C

Out. temp. = 35°C

Out. temp. = 45°C

Out. temp. = 45°C

Out. temp. = 35°C

Out. temp. = 25°C

Out. temp. = 19°C

Out. temp. = 45°C

Out. temp. = 35°C

Out. temp. = 25°C

Out. temp. = 19°C

Out. temp. = 45°C

Out. temp. = 35°C

Out. temp. = 25°C

Out. temp. = 19°C

Out. temp. = 45°C

Out. temp. = 35°C

Out. temp. = 25°C

Out. temp. = 15

°

C

Page 8

8

9 - SOUND LEVELS

• Nominal operating conditions:

- Ambient temperature: 35°C.

• Sound-pressure level:

- Unit installed outdoors (free field) on a reflective surface.

- Measurement carried out at a distance of 10 m.

40

35

30

25

10 15 20 25 30

Distance in meters

dB to be

deducted from

the sound

power level

Power level Sound-pressure level

(dBA) (dBA)

50 78 50

64 82 54

72 87 59

80 87 59

CHGV

8 -

AVAILABLE PRESSURE CURVES ON THE HYDRAULIC SYSTEM

5 6 7 8 9 10 11 12 13 14 15

0

50

100

150

200

250

300

CHGV 80

CHGV 72

CHGV 64

CHGV 50

Water flow rate (m3/h)

Available head (kPa)

7 - CORRECTIONS TO BE MADE WHEN USING ANTI-FREEZE

•

V

alues at apparatus outlet without tank. (See § 10.5 for tank pressure losses).

10 - ACCESSORIES

10.1 - ANTI-VIBRATION KIT

•

Kit includes:

-

1 set of 4 anti-vibration plates, thickness 25 mm - code

70600035.

- 1 set of 2 flexible hoses: length 1.5 m, Ø 1" 1/2 - code 70600034.

• IMPORTANT:

Use monopropylene glycol; a minimum rate of 15% to 20% is needed to avoid any risk of corrosion.

PRINCIPLE OF USING THE CURVES

A- Choose the percentage of glycol according to the

minimum temperature to protect the hydraulic circuit

against frost.

B - Example:

Protection at an external temperature of -15

°C, which

gives 30% monopropylene glycol (freezing points

curve).

The loss of capacity is given on the "Reduction of

cooling capacity" curve (0.94).

The new flow is given by the coefficient on the water

flow curve (1.1

13).

Likewise, to determine the new pressure drop

coef

ficient in relation to the nominal flow, read the

pressure drop curve (1.19).

Valid curves for setting temperature at the water

inlet.

1.30

1.20

1.10

1.00

0.94

0 10 20 30 40

0

-5

-10

-15

-20

-25

1.19

1.113

% Glycol in weight

Outdoor temperature °C

Correction factors

Pressure drop

Water flow

Reduction of cooling capacity

Freezing points

Page 9

9

10.2 - HP AND LP PRESSURE GAUGES

• The accessory includes 1 set of 2 pressure gauges (HP and LP). Two per apparatus must be ordered.

• Code

70970007.

• These elements, mounted on the vertical members of the unit's front face, display the high and low pressure values for the

refrigeration circuit.

10.3 - REMOTE CONTROL

• Code 70250057.

• Enables reporting of the controller's display keypad functions up to a distance of 100

meters.

10.4 - SERIAL COMMUNICATIONS INTERFACE RS 485 (MODBUS

PROTOCOL)

• Code 70250056.

•

Interface module installed inside the unit's electrical box.

• MODBUS protocol. Please consult us for details concerning the protocol and addressing of data.

10.5 - 300-LITRE BUFFER TANK

• Code 70600120: model without supplementary heating with 800 W anti-freeze resistance (single-phase 230 VAC),

• Designed to be installed either underneath the unit, or separately.

For installation underneath the unit, the tank is supplied with mounting brackets and an insulated tube for connection

between the unit's water outlet and the tank's water inlet.

Composition:

5

1

2

3

4 6

70600120

without heating

1 Sheetmetal buffer tank - polyurethane insulation

2 800 W anti-freeze resistance

3 Fill valve

4 Drain valve

5 Purge

6 Safety valve (5 bar)

Galvanized steel chassis, painted RAL 7035

Mark

Water inlet (Male 1”1/2)

Water outlet (Male 1”1/2)

Anti-freeze resistance:

• Immersion heater mounted on the tank.

• Power: 800 W, single-phase 230 VAC.

• With limiting thermostat.

• The power supply and heating element control are to be done separately at the time of installation (not supplied).

2

4

6

8

10

12

14

16

0

7 8 9 10 11 12 13 14

Pressure losses in 300-litre tank:

Output m3/h

Kp

a

Page 10

10

11 - "ECH" ELECTRONIC CONTROL

• Microprocessor control module, including:

-

chilled water temperature control (water inlet),

- control of operating parameters,

-

self-adapting algorithm for water volume reduction,

- circulating pump control (frost protection and anti-sticking function),

- dynamic setpoints are possible according to the outside temperature (to be activated at the time of installation by means

of special parameterization).

- anti-short cycle system,

- hour counter compressor and circulating pump,

- alarm management,

- anti-freeze security (temperature probes at water exchanger outlet),

- digital display of:

.

water temperature,

. set-point,

.

alarm code (HP, LP, water output, probes, anti-freeze...).

- remote alarm reporting is possible via a potential-free contact,

-

integrated condensation pressure control (with pressure sensors),

- remote control with display unit (accessory),

- serial communications port (RS 485 interface, accessory) - MODBUS Protocol.

12 - INSTALLATION INFORMATION

• See details in the installation manual.

12.1 - INSTALLATION

• Protection index of the unit:

- IP 24 : for the electrical equipment,

(IPXXB : for the mechanical hazards).

• Before installation, verify the following points:

- the unit must be installed outside in an appropriate location and in compliance with environmental requirements (sound

level, integration, etc...),

- the water chiller’s installation location must be perfectly level and strong enough to support the weight of the unit and

must have adequate inundation protection,

- sufficient space around the unit should be provided in order to facilitate servicing and maintenance operations,

- air suction to the coil and fan discharge must not be obstructed,

- install the unit above the region’s average snowfall level,

- vibrations and noise must not be transmitted to adjacent buildings,

- install the machine on anti-vibration pads and fit hoses on piping elements, as required,

-

if necessary, consult an acoustics specialist concerning the unit’s optimum location,

-

4 holes Ø 22.5 enable to place hoisting hooks and lift the unit.

12.2 - ELECTRICAL CONNECTIONS

•

All required information is indicated on the electrical diagram provided with the unit and in the installation manual.

• Connections are to be made in compliance with the standard code of practice and as per the standards in force at the site

of installation.

12.3 - HYDRAULIC CONNECTIONS

• The hydraulic connections are to be made in compliance with the standard code of practice.

•

IMPERA

TIVE:

Install the filter supplied on the water inlet of the unit.

12.4 - STARTING - MAINTENANCE

•

Refer to the installation guide and the maintenance manual.

•

IMPORT

ANT

:

-

The unit's electronic control features a frost protection device that automatically starts the water circulating pump

depending on the outside temperature (adjustable threshold), even if the unit is turned off.

- In the event the unit may be taken out of service or in the case of a high risk of freezing:

- either drain the installation,

-

or add glycol to the circuit.

- Tank anti-freeze resistance:

its electrical power supply and control must be separate from those of the unit.

Page 11

11

Page 12

Due to our policy of continuous development, our products are liable to

modification without notice.

R.D. 28 Reyrieux BP

131 01601 Trévoux CEDEX France

Phone 33 4 74 00 92 92 - Fax 33 4 74 00 42 00

R.C.S. Bourg-en-Bresse B 759 200 728

Loading...

Loading...