Technibel CA250X5TAA, CA360X5TAA, GR250X5TAA, GR360X7TAA, GR250X7TAA Technical & Service Manual

...Page 1

TECHNICAL & SERVICE MANUAL

SPLIT SYSTEM AIR CONDITIONER

CA250X5TAA - GR250X5TAA

CA250X5TAA - GR250X7TAA

CA360X5TAA - GR360X7TAA

CA480X5TAA - GR480X7TAA

0.8180.112.1 05/01

Page 2

−

2

−

Table of Contents

1.SPECIFICATIONS…………………………………………………………………………… 3

1-1 Unit Specifications…………………………………………………………………….. 3

1-2 Major Component Specifications……………………………………………………. 7

(A) Indoor Unit……………………………………………………………………….... 7

(B) Outdoor Unit………………………………………………………………………. 9

1-3 Other Component Specifications……………………………………………………. 12

(A) Indoor Unit……………………………………………………………………….... 12

(B) Outdoor Unit………………………………………………………………………. 13

1-4 Dimensional Data……………………………………………………………………... 14

(A) Indoor Unit……………………………………………………………………….... 14

(B) Outdoor Unit………………………………………………………………………. 16

1-5 Refrigerant Flow Diagram……………………………………………………………. 18

1-6 Operating Range……………………………………………………………………… 20

1-7 Cooling Capacity………………………………………………………………………. 21

1-8 Noise Criterion Curves……………………………………………………………….. 25

1-9 Air Throw Distance Chart…………………………………………………………….. 27

2. PROCESSES AND FUNCTIONS……………………………………………………….… 28

2-1 Room Temperature Control………………………………………………………….. 28

2-2 Freeze Prevention (Cooling)……………………………………………………….… 29

2-3 Drain Pump Control…………………………………………………………………… 29

2-4 Outdoor Fan Control………………………………………………………………….. 30

3. ELECTRICAL DATA………………………………………………………………………... 31

3-1 Electrical Characteristics……………………………………………………………... 31

3-2 Electric Wiring Diagrams / Schematic Diagrams…………………………………... 33

(A) Indoor Unit……………………………………………………………………….... 33

(B) Outdoor Unit………………………………………………………………………. 35

4. SERVICE PROCEDURES………………………………………………………………….. 43

4-1 Troubleshooting……………………………………………………………………….. 43

4-2 A Sensor is Defective…………………………………………………………………. 54

4-3 Operation of Major Electrical parts………………………………………………….. 54

4-4 Checking the Electrical Components……………………………………………….. 55

Page 3

– 3 –

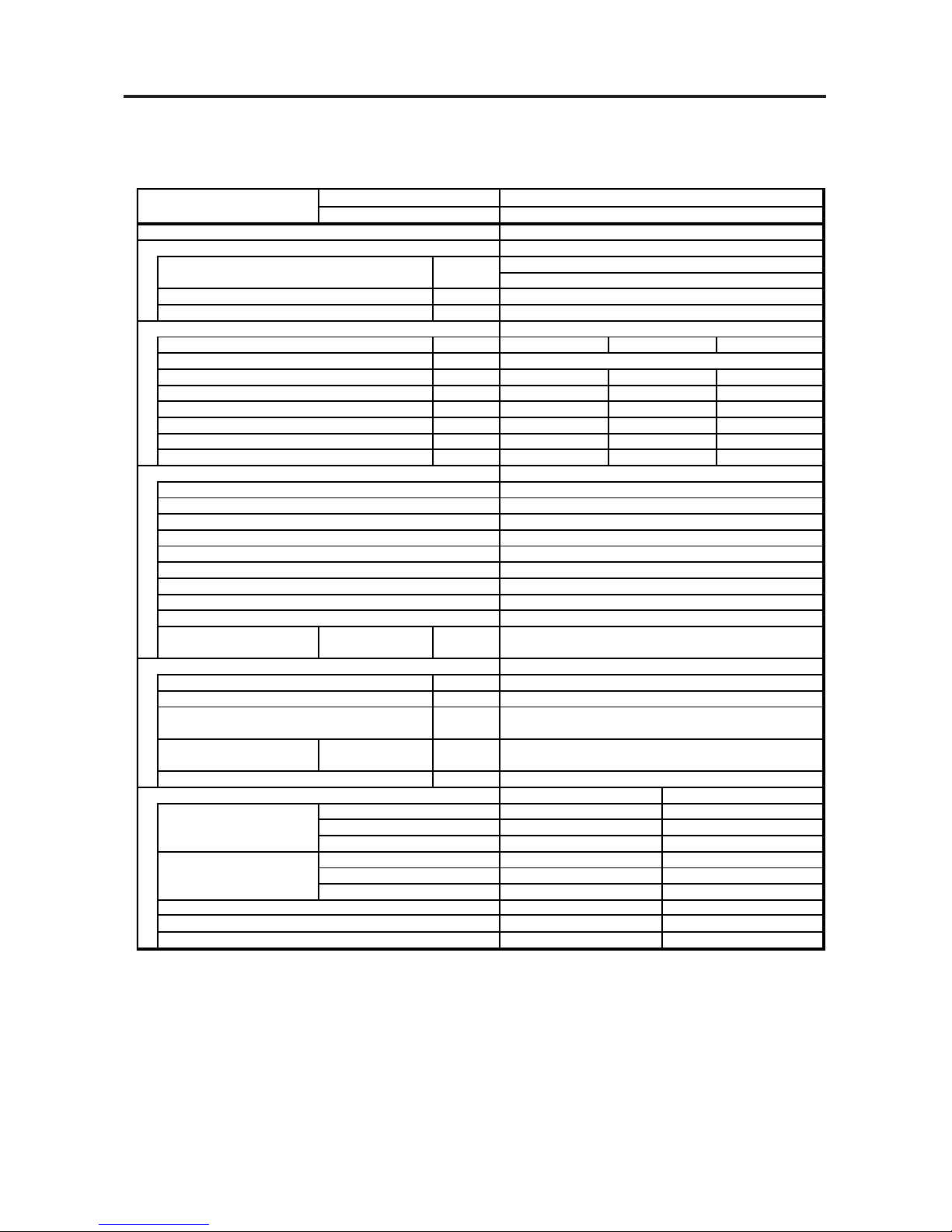

1.SPECIFICATIONS

MODEL No. Indoor Unit CA250X5TAA

Outdoor Unit GR250X5TAA

POWER SOURCE 220 - 230 - 240 V / 1 Phase / 50 Hz

PERFORMANCE Cooling

Capacity kW 7.3

BTU / h 25,000

Air circulation (Hi/Me/Lo) m3 / h 1,140/1,020/840

Moisture removal(High) Liters/ h 3.6

ELECTRICAL RATINGS

Voltage rating V 220 230 240

Available voltage range V 198 - 264

Running amperes* A 14.5 14.6 14.7

Max. running amperes** A 20.2 19.6 19.4

Power input kW 3.01 3.07 3.16

Power factor % 94.4 91.4 89.6

C.O.P W / W 2.43 2.38 2.31

Max. starting amperes A 69 72 75

FEATURES

Controls Microprocessor

Timer ON/OFF 24-hours & Program

Fan speeds Indoor/Outdoor 3 and Automatic control/ 2 (Auto)

Airflow direction (Indoor) Automatic (Remote control)

Air filter Washable, easy access

Remote controller (Accessory) RCS-5PN3E

Refrigerant control Capillary tube

Drain pump (drain connection) Max. head 25cm above drain connection (25A,OD32mm)

Compressor Rotary

Operation sound Indoor - Hi/Me/Lo dB - A 37 / 35 / 31

Outdoor - Hi dB - A 53

REFRIGERANT TUBING

Limit of tubing length m (ft.) 40 (131)

Limit of tubing length at shipment m (ft.) 15 (49)

Limit of elevation difference m (ft.) Outdoor unit is higher than indoor unit: 40 (131)

between the two units Outdoor unit is lower than indoor unit: 25 (82)

Refrigerant tube Narrow tube mm (in) 6.35 (1 / 4)

outer diameter Wide tube mm (in) 15.88 (5 / 8)

Refrigerant amount at shipment kg R22 - 2.4

DIMENSIONS & WEIGHT Indoor unit Outdoor unit

Unit dimensions Height mm (in) 328(12-29/32) 735(28-30/32)

Width mm (in) 860(33-27/32) 940(37)

Depth mm (in) 860(33-27/32) 340(13-12/32)

Package dimensions Height mm (in) 410(16-5/32) 826(32-17/32)

Width mm (in) 988(38-29/32) 1,016(40)

Depth mm (in) 988(38-29/32) 416(16-12/32)

Net weight kg (lb) 30(66) 68(150)

Shipping weight kg (lb) 47(104) 74(163)

Shipping volume m3 (Cu. ft.) 0.4(14.1) 0.349(12.3)

DATA SUBJECT TO CHANGE WITHOUT NOTICE

Cooling :

Rating conditions(*) : Indoor air temperature 27 °C DB / 19 °C WB, Outdoor air temperature 35 °C DB

1-1 Unit Specifications

Page 4

– 4 –

1.SPECIFICATIONS

MODEL No. Indoor Unit CA250X5TAA

Outdoor Unit GR250X7TAA

POWER SOURCE 380 - 400 - 415 V / 3N / 50 Hz

PERFORMANCE Cooling

Capacity kW 7.3

BTU / h 25,000

Air circulation (Hi/Me/Lo) m3 / h 1,140/1,020/840

Moisture removal(High) Liters/ h 3.6

ELECTRICAL RATINGS

Voltage rating V 380 400 415

Available voltage range V 342- 456

Running amperes* A 4.7 4.7 4.6

Max. running amperes** A 6 5.8 5.7

Power input kW 2.76 2.8 2.81

Power factor % 89.2 86 85

C.O.P W / W 2.64 2.61 2.6

Max. starting amperes A 27 29 30

FEATURES

Controls Microprocessor

Timer ON/OFF 24-hours & Program

Fan speeds Indoor/Outdoor 3 and Automatic control/ 2 (Auto)

Airflow direction (Indoor) Automatic (Remote control)

Air filter Washable, easy access

Remote controller (Accessory) RCS-5PN3E

Refrigerant control Capillary tube

Drain pump (drain connection) Max. head 25cm above drain connection (25A,OD32mm)

Compressor Rotary

Operation sound Indoor - Hi/Me/Lo dB - A 37 / 35 / 31

Outdoor - Hi dB - A 53

REFRIGERANT TUBING

Limit of tubing length m (ft.) 40 (131)

Limit of tubing length at shipment m (ft.) 15 (49)

Limit of elevation difference m (ft.) Outdoor unit is higher than indoor unit: 40 (131)

between the two units Outdoor unit is lower than indoor unit: 25 (82)

Refrigerant tube Narrow tube mm (in) 6.35 (1 / 4)

outer diameter Wide tube mm (in) 15.88 (5 / 8)

Refrigerant amount at shipment kg R22 - 2.4

DIMENSIONS & WEIGHT Indoor unit Outdoor unit

Unit dimensions Height mm (in) 328(12-29/32) 735(28-30/32)

Width mm (in) 860(33-27/32) 940(37)

Depth mm (in) 860(33-27/32) 340(13-12/32)

Package dimensions Height mm (in) 410(16-5/32) 826(32-17/32)

Width mm (in) 988(38-29/32) 1,016(40)

Depth mm (in) 988(38-29/32) 416(16-12/32)

Net weight kg (lb) 30(66) 68(150)

Shipping weight kg (lb) 47(104) 74(163)

Shipping volume m3 (Cu. ft.) 0.4(14.1) 0.349(12.3)

DATA SUBJECT TO CHANGE WITHOUT NOTICE

Cooling :

Rating conditions(*) : Indoor air temperature 27 °C DB / 19 °C WB, Outdoor air temperature 35 °C DB

1-1 Unit Specifications

Page 5

– 5 –

1.SPECIFICATIONS

MODEL No. Indoor Unit CA360X5TAA

Outdoor Unit GR360X7TAA

POWER SOURCE 380 - 400 - 415 V / 3N / 50 Hz

PERFORMANCE Cooling

Capacity kW 10.6

BTU / h 36,000

Air circulation (Hi/Me/Lo) m3 / h 1,920/1,680/1,320

Moisture removal(High) Liters/ h 4.7

ELECTRICAL RATINGS

Voltage rating V 380 400 415

Available voltage range V 342 - 456

Running amperes* A 5.2 5.1 5.1

Max. running amperes** A 6.7 6.5 6.4

Power input kW 3.07 3.11 3.15

Power factor % 89.7 88 85.9

C.O.P W / W 3.45 3.41 3.37

Max. starting amperes A 31 33 34

FEATURES

Controls Microprocessor

Timer ON/OFF 24-hours & Program

Fan speeds Indoor/Outdoor 3 and Automatic control/ 2 (Auto)

Airflow direction (Indoor) Automatic (Remote control)

Air filter Washable, easy access

Remote controller (Accessory) RCS-5PN3E

Refrigerant control Capillary tube

Drain pump (drain connection) Max. head 25cm above drain connection (25A,OD32mm)

Compressor Rotary

Operation sound Indoor - Hi/Me/Lo dB - A 43 / 40 / 36

Outdoor - Hi dB - A 54

REFRIGERANT TUBING

Limit of tubing length m (ft.) 50 (164)

Limit of tubing length at shipment m (ft.) 15 (49)

Limit of elevation difference m (ft.) Outdoor unit is higher than indoor unit: 50 (164)

between the two units Outdoor unit is lower than indoor unit: 30 (98)

Refrigerant tube Narrow tube mm (in) 9.52 (3 / 8)

outer diameter Wide tube mm (in) 19.05 (3 / 4)

Refrigerant amount at shipment kg R22 - 4.0

DIMENSIONS & WEIGHT Indoor unit Outdoor unit

Unit dimensions Height mm (in) 358(14-3/32) 1,235(48-20/32)

Width mm (in) 1,150(45-9/32) 940(37)

Depth mm (in) 860(33-27/32) 340(13-12/32)

Package dimensions Height mm (in) 440(17-10/32) 1,326(52-7/32)

Width mm (in) 1,278(50-10/32) 1,016(40)

Depth mm (in) 988(38-29/32) 416(16-12/32)

Net weight kg (lb) 38(84) 94(207)

Shipping weight kg (lb) 62(137) 101(223)

Shipping volume m

3

(Cu. ft.) 0.556(19.6) 0.56(19.8)

DATA SUBJECT TO CHANGE WITHOUT NOTICE

Cooling :

Rating conditions(*) : Indoor air temperature 27 °C DB / 19 °C WB, Outdoor air temperature 35 °C DB

1-1 Unit Specifications

Page 6

– 6 –

1.SPECIFICATIONS

MODEL No. Indoor Unit CA480X5TAA

Outdoor Unit GR480X7TAA

POWER SOURCE 380 - 400 - 415 V / 3N / 50 Hz

PERFORMANCE Cooling

Capacity kW 14

BTU / h 47,800

Air circulation (Hi/Me/Lo) m3 / h 1,920/1,680/1,320

Moisture removal(High) Liters/ h 7.4

ELECTRICAL RATINGS

Voltage rating V 380 400 415

Available voltage range V 342 - 456

Running amperes* A 8.4 8.5 8.9

Max. running amperes** A 10.3 9.9 9.5

Power input kW 4.7 4.76 4.86

Power factor % 85 80.8 76

C.O.P W / W 2.98 2.94 2.88

Max. starting amperes A 71 73 75

FEATURES

Controls Microprocessor

Timer ON/OFF 24-hours & Program

Fan speeds Indoor/Outdoor 3 and Automatic control/ 2 (Auto)

Airflow direction (Indoor) Automatic (Remote control)

Air filter Washable, easy access

Remote controller (Accessory) RCS-5PN3E

Refrigerant control Capillary tube

Drain pump (drain connection) Max. head 25cm above drain connection (25A,OD32mm)

Compressor Rotary

Operation sound Indoor - Hi/Me/Lo dB - A 43 / 40 / 36

Outdoor - Hi dB - A 56

REFRIGERANT TUBING

Limit of tubing length m (ft.) 50 (164)

Limit of tubing length at shipment m (ft.) 15 (49)

Limit of elevation difference m (ft.) Outdoor unit is higher than indoor unit: 50 (164)

between the two units Outdoor unit is lower than indoor unit: 30 (98)

Refrigerant tube Narrow tube mm (in) 9.52 (3 / 8)

outer diameter Wide tube mm (in) 19.05 (3 / 4)

Refrigerant amount at shipment kg R22 - 4.3

DIMENSIONS & WEIGHT Indoor unit Outdoor unit

Unit dimensions Height mm (in) 358(14-3/32) 1,235(48-20/32)

Width mm (in) 1,150(45-9/32) 940(37)

Depth mm (in) 860(33-27/32) 340(13-12/32)

Package dimensions Height mm (in) 440(17-10/32) 1,326(52-7/32)

Width mm (in) 1,278(50-10/32) 1,016(40)

Depth mm (in) 988(38-29/32) 416(16-12/32)

Net weight kg (lb) 38(84) 106(234)

Shipping weight kg (lb) 62(137) 113(249)

Shipping volume m3 (Cu. ft.) 0.556(19.6) 0.56(19.8)

DATA SUBJECT TO CHANGE WITHOUT NOTICE

Cooling :

Rating conditions(*) : Indoor air temperature 27 °C DB / 19 °C WB, Outdoor air temperature 35 °C DB

1-1 Unit Specifications

Page 7

– 7 –

1.SPECIFICATIONS

(A)Indoor Unit

MODEL No. CA250X5TAA

Source 220 - 230 - 240 V / 1 phase / 50 Hz

Remote controller (Accessory) RCS- 5PN3E

Controller P. C. B Ass'y CR - X363GS

Switch Ass'y SW - X363GS

Fan (Number … diameter) mm Turbo (1… ø 490)

Fan motor

Model … Nominal output W SFG6X - 41A5P … 40 W

Source 220 - 230 - 240 V / 1 phase / 50 Hz

No. of pole … r.p.m. (230 V, High) rpm 6 … 470

Coil resistance Ω BRN – WHT :114.0 , ORG–YEL : 66.4

(Ambient temperature 20 °C) WHT–VLT : 23.9 , WHT–PNK : 77.4

VLT –ORG : 12.4 , YEL–BLK : 82.1

Safety device

Operating temperature Open°C130±8 °C

Close°C79±15 °C

Run capacitor VAC , µF 440 V , 4 µF

Heat exchanger

Coil Aluminum plate fin / Copper tube

Rows … fin pitch mm 2 … 1.7

Face area m

2

0.295

Panel

Model No. PNR - X253GS

Indicator Lamp Ass'y IND - X253GS

Dew proof heater 240 V , 26 W

Auto louver motor M2LB24ZA12

Auto louver motor … Rated V, W, rpm. 240 VAC , 3 W , 2.5 rpm

Coil resistance (at 25 °C) Ω 15,620 Ω ± 15 %

1-2 Major Component Specifications

Page 8

– 8 –

1.SPECIFICATIONS

(A) Indoor Unit

MODEL No. CA360X5TAA CA480X5TAA

Source 220 - 230 - 240 V / 1 phase / 50 Hz

Remote controller (Accessory) RCS - 5PN3E

Controller P. C. B Ass'y CR - X363GS

Switch ass'y SW - X363GS

Fan (Number … diameter) mm Turbo (1… ø 490)

Fan motor

Model … Nominal output W SFG6X - 61A3P … 60 W

Source 220 - 230 - 240 V / 1 phase / 50 Hz

No. of pole … r.p.m. (230 V, High) rpm 6 … 530

Coil resistance Ω BRN – WHT : 71.1 , ORG–YEL : 22.7

(Ambient temperature 20 °C) WHT–VLT : 8.7 , VLT –PNK : 43.2

VLT –ORG : 13.3 , YEL–BLK : 54.32

Safety device

Operating temperature Open°C130±8 °C

Close°C79±15 °C

Run capacitor VAC , µF 440 V , 6 µF

Heat exchanger

Coil Aluminum plate fin / Copper tube

Rows … fin pitch mm 2 … 1.7

Face area m

2

0.479

Panel

Model No. PNR - X483GS

Indicator Lamp ass'y IND - X483GS

Dew proof heater 240 V , 31 W

Auto louver motor M2LB24ZA12

Auto louver motor … Rated V, W, rpm 240 VAC , 3 W , 2.5 rpm

Coil resistance (at 25 °C) Ω 15,620 Ω ± 15 %

Page 9

– 9 –

1.SPECIFICATIONS

(B) Outdoor Unit

MODEL No. GR250X5TAA

Source 220 - 230 - 240 V / 1 phase / 50 Hz

Compressor Rotary (Hermetic)

Model ... Code No. C - R221H5V

Nominal output W 2,200

Compressor oil cc 1,350

Coil resistance (at 25°C) Ω

C - R : 0.76, C - S :2.76

Refrigerant amount at shipment kg R22 - 2.4

Safety device Internal/OL - D24

Operating temperature Open °C 160±5/150±10

Close °C 87±9/63±10

Run capacitor V,µF 400V, 40

High pressure switch ACB - 1TB07

Set pressure OFF kg/cm

2

30

ON kg/cm

2

24 ± 2.0

Fan (Number…diameter (mm)) Propeller (1…ø 460)

Fan motor

Model…Nominal output W KFC6S - 91C5P…100 W

No. of pole ... rpm (230V, High) rpm 6...868

Coil resistance Ω BRN – WHT : 61.0

(Ambient temperature 20°C) YEL–PNK : 17.7

WHT–YEL : 64.3

Safety device Internal type

Operating temperature Open °C 130±8

Close °C 79±15

Run capacitor VAC, µF 440 V, 5 µF

Heat exchanger

Coil Aluminium plate fin / Copper tube

Rows ... fin pitch mm 2...2.0

Face area m

2

0.616

+ 2.0

+ 0.5

1-2 Major Component Specifications

Page 10

– 10 –

1.SPECIFICATIONS

(B) Outdoor Unit

MODEL No. GR250X7TAA

Source 380 - 400 - 415 V / 3 phase / 50 Hz

Compressor Rotary (Hermetic)

Model … Code No. C - R224H8S

Nominal output W 2,200

Compressor oil CC 1,350

Coil resistance (at 25°C) Ω R - S:5.54,S - T:5.54,T - R: 5.54

Refrigerant amount at shipment kg R22 - 2.4

Safety device Internal type External type

Overload relay models — FMSA - 1SZ607A

Operating temperature Open °C120±5—

Close °C98±11 —

Operating ampere (at 25°C) A — 6A, 110 %

Run capacitor V, µF—

High pressure switch ACB - 1TB07

Set pressure OFFkg/cm

2

30

ON kg/cm

2

24 ± 2.0

Fan Number … diameter mm Propeller (1 … ø 460)

Fan motor

Model … Nominal output W KFC6S - 91C5P … 100 W

No. of pole … rpm (230 V, High) rpm 6 … 868

Coil resistance Ω BRN – WHT : 61.0 , YEL–PNK : 17.7

(Ambient temperature 20°C)

WHT–YEL : 64.3

Safety device

Operating temperature Open °C130±8

Close °C79±15

Run capacitor VAC, µF 440V, 5 µF

Heat exchanger

Coil Aluminum plate fin / Copper tube

Rows … fin pitch mm 2 … 2.0

Face area m

2

0.616

+ 2.0

+ 0.5

Page 11

– 11 –

1.SPECIFICATIONS

(B) Outdoor Unit

MODEL No. GR360X7TAA GR480X7TAA

Source 380-400- 415 V / 3 phase / 50 Hz

Compressor Rotary (Hermetic) Scroll (Hermetic)

Model...Code No. C - R243H8T ZR61KC - TFD - 522

Nominal output W 2,400 3,750

Compressor oil cc 1,350 2,130

Coil resistance Ω T – R:5.54,R – S:5.54 T1 – T2:2.72,T2 – T3:2.72

(Ambient temperature 25°C ) S – T:5.54 T3 – T1:2.72

Refrigerant amount at shipment kg R 22 - 4.0 R 22 - 4.3

Safety devices Internal type External type Internal type External type

Overload relay models —

FMSA -1SZ607A

—

FMSA -1SZ607A

Operating temperature Open °C 120 ±5— 130—

Close °C 98 ± 11 — 61 —

Operating ampere (at 25°C) A — 6 A, 110 % — 10 A, 110 %

Run capacitor V, µF—

High pressure switch ACB - 1TB07

Set pressure OFF kg/cm

2

30

ON kg/cm

2

24 ± 2.0

Fan (Number...diameter) mm Propeller (2...ø460)

Fan motor

Model...Nominal output W KFC6S - 91C5PX2...100WX2

No. of pole...rpm (230 V, High) rpm 6...871

Coil resistance Ω BRN–WHT : 61.0

(Ambient temperature 20°C) WHT–YEL : 64.3

YEL–PNK : 17.7

Safety device

Operating temperature Open °C130±8

Close °C79±15

Run capacitor VAC, µF 440V,5 µF/440 V,5 µF

Heat exchanger

Coil Aluminum plate fin / Copper tube

Rows...fin pitch mm

2

2...2.0

Face area m

2

1.08

+ 2.0

+ 0.5

Page 12

– 12 –

1

1-3 Other Component Specifications

(A) Indoor Unit

CA250X5TAA CA360X5TAA CA480X5TAA

Power Transformer ATR – I75A

Rated Primary AC 230 V, 50 Hz

Secondary 10.6 V, 0.93 A

Capacity 9.85 VAC

Coil resistance WHT - WHT : 96.5 , BRN - BRN : 0.8 (at 20 °C)

Thermistor cut off temperature °C 150

Thermistor (Coil sensor) PBC - 41E - S26 PBC - 41E - S36

Coil resistance k –10 °C : 23.7 , 5 °C : 12.1

–5 °C : 18.8 , 10 °C : 9.7

0 °C : 15.0 , 15 °C : 8.0

Thermistor (Room or coil sensor) KTEC - 35 - S6

Coil resistance k 0 °C : 16.5 , 40 °C : 2.7

5 °C : 12.8 , 45 °C : 2.2

10 °C : 10.0 , 50 °C : 1.8

20 °C : 6.3 , 55 °C : 1.5

30 °C : 4.0 ,

Drain pump WP20SL - 21

Rated AC 230 V, 14.7 W

Float switch FS - 0218 - 103

Rated (Contact rated) AC 230 V, 50 W

Switch Ass'y SW - X363GS

Indicator Lamp Ass' IND - X253GS

Synchronized Motor M2LB24ZA12

1.SPECIFICATIONS

Page 13

– 13 –

1

(B) Outdoor Unit

MODEL No GR250X7TAA GR360X7TAA GR480X7TAA

Compressor Motor Magnetic Contactor FMSA - 1SZ607A

Coil rated AC 220 - 240 V, 50 Hz

Coil resistance (at 20°C) 828 (at 20 °C)

Contact rated V, A AC 440 V, 13 A

Thermal Relay

Contact rated V, A AC 220 V, 2.25 A

Rated ampere (90 / 120%) A 6 A, 110 % 6 A, 110 % 10 A, 110 %

Auxiliary relay HH62S / 085

Coil rated A AC 240 V, 50 Hz

Coil resistance kW 15.5 ± 20 %

Contact rated A AC 250 V, 10A

Relay RDR - S400

Rated voltage V AC 380 - 415 V, 3 phase, 50 Hz

Resistance (at 20°C) k R - T : 76.3

Thermostat (Coil sensor) YTB - S377

Operating Temperature °C 27.5 ± 1.5 OFF (High)

25.5 ON (Low)

Contact ratedAC 250 V, 1 A

MODEL No GR250X5TAA

Compressor Motor Mgnetic ContactorFMCA - 1SZ607

Coil rated AC 220 - 240 V, 50 Hz

Coil resistance (at 20°C) 828 ± 15 %

Contact rated V, A AC 440 V, 13 A

Auxiliary relay HH62S / 085

Coil rated AC 240 V, 50 Hz

Coil resistance (at 20°C) k 17.2

Contact rated V, A AC 220 V, 5 A

Thermostat (Coil sensor) YTB - S377

Operating Temperature °C 27.5 ± 1.5 OFF (High)

25.5 ON (Low)

Contact rated A AC 250 V, 1 A

+ 1.5

– 0.5

+ 1.5

– 0.5

1.SPECIFICATIONS

Page 14

– 14 –

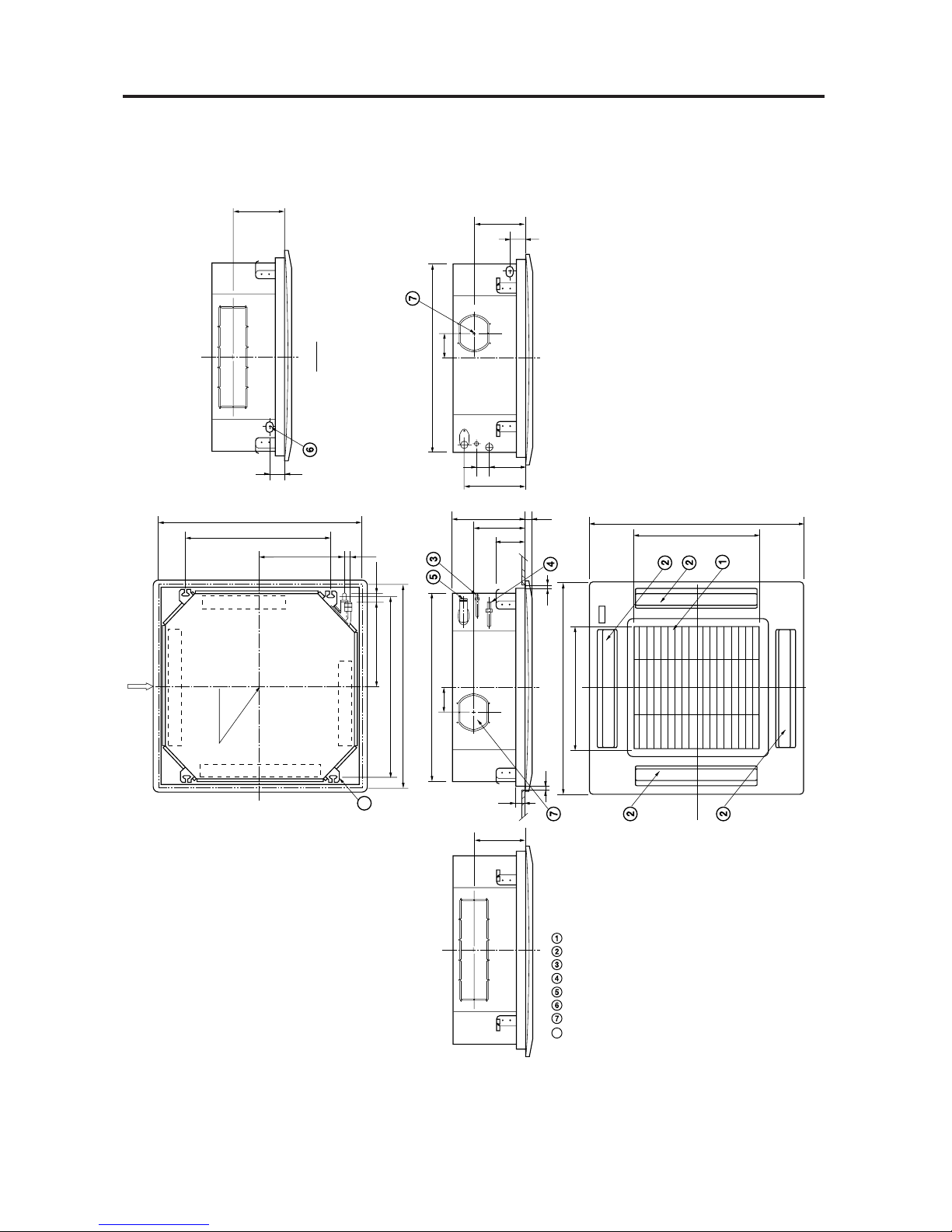

(A)Indoor Unit:CA250X5TAA

860

100

760

500

500

298 30

205

125

12

12

48

860

820 (Ceiling opening)

820 (Ceiling opening)

61

730 (Suspention bolt pitch)

Panel center

590 (Suspention bolt pitch)

345 35

Air intake grille

Air outlet

Refrigerant liquid line (ø 6.35)

Refrigerant gas line (ø 15.88)

Drain connection

Power supply entry

For discharge duct

Suspention bolt mounting

342 15

X-view

0410_X_S

207

100

205

61

760

50 150

255

207

8

8

1.SPECIFICATIONS

1-4Dimensional Data

Page 15

– 15 –

(A)Indoor Unit:CA360X5TAA, CA480X5TAA

1150

1050

790

500

328

30

218

125

860

1110 (Ceiling opening)

820 (Ceiling opening)

61

1020 (Suspention bolt pitch)

Panel center

590 (Suspention bolt pitch)

490 40

Air intake grille

Air outlet

Refrigerant liquid line (ø9.52)

(SPW-X303G56, SPW-X303GS56 ø6.35)

Refrigerant gas line (ø19.05)

(SPW-X303G56, SPW-X303GS56 ø15.88)

Drain connection

Power supply entry

For discharge duct

Suspension bolt mounting

X-view

0603_X_S

218

14535

210

60

760

70 165

285

210

100 100

8

8

342 15

12

48

12

1.SPECIFICATIONS

Page 16

– 16 –

(B) Outdoor Unit :GR250X5TAA

GR250X7TAA

400

380

20

340

20

110660170

735

280

307

940

Dimension : mm

Hole for anchor bolt (4-ø13)

Refrigerant tube joint (narrow tube)

Flare connection 1/4 in (6.35 mm)

Refrigerant tube joint (wide tube)

Flare connection 5/8 in (15.88 mm)

Refrigerant tubing inlet

Power supply inlet

0411_C_S

1.SPECIFICATIONS

1-4Dimensional Data

Page 17

– 17 –

(B) Outdoor Unit :GR360X7TAA

GR480X7TAA

400

380

20

340

20

110660170

1235

580

607

940

Dimension : mm

Hole for anchor bolt (4-ø13)

Refrigerant tube joint (narrow tube)

Flare connection 3/8 in (9.52 mm)

Refrigerant tube joint (wide tube)

Flare connection 3/4 in (19.05 mm)

Refrigerant tubing inlet

Power supply inlet

0412_C_S

1.SPECIFICATIONS

Page 18

– 18 –

Indoor Unit :CA250X5TAA

Outdoor Unit:GR250X5TAA

GR250X7TAA

Indoor Unit :CA360X5TAA Outdoor Unit:GR360X7TAA

O. D.

15.88 mm

(5/8")

Evaporator

Capillary

O. D.

6.35 mm

(1/4")

Condenser

Compressor

Accumulator

Capillary

Sub-condenser

Wide tube

service valve

Narrow tube

service valve

0664_X_S

Strainer

Strainer

HP

High

pressure

switch

O. D.

19.05 mm

(3/4")

Evaporator

Capillary

O. D.

9.52 mm

(3/8")

Condenser

HP

High

pressure

switch

Compressor

Accumulator

Capillary

Sub-condenser

Wide tube

service valve

0605_X_S

Narrow tube

service valve

Strainer

Strainer

1.SPECIFICATIONS

1-5Refrigerant Flow Diagram

Page 19

– 19 –

Indoor Unit :CA480X5TAA

Outdoor Unit:GR480X7TAA

Insulation of Regrigerant Tubing

IMPORTANT

To prevent heat loss and wet floors due to

dripping of condensation, both the wide and

narrow tubes must be well insulated with a

proper insulation material. The thickness of

the insulation should be a min. 8 mm.

After a tube has been

insulated, never try to bend

it into a narrow curve

because it can casue the

tube to break or crack.

Insulator

Thickness:

Min. 8mm

Narrow tube

Wide tube

0133_C_I

O. D.

19.05 mm

(3/4")

Evaporator

Capillary

O. D.

9.52 mm

(3/8")

Condenser

HP

High

pressure

switch

Compressor

Accumulator

Sub-condenser

Wide tube

service valve

0606_X_S

Narrow tube

service valve

Strainer

1.SPECIFICATIONS

Page 20

– 20–

Temperature Indoor air intake temp. Outdoor air intake temp.

Maximum 35°C DB / 22.5°C WB 52°C DB

Minimum 18°C DB / 14°C WB 19°C DB

1.SPECIFICATIONS

1-6Operating Range

Page 21

– 21 –

Indoor Unit :CA250X5TAA Outdoor Unit : GR250X7TAA

TC :Total Cooling Capacity (kW)

SHC:Sensible Heat Capacity (kW)

CI :Compressor Input (kW)

Rating conditions are

:Outdoor Ambient Temp. 35 °C DB

:Indoor Unit Entering Air Temp. 27 °C DB / 19 °C WB

RATING CAPACITY : 7.3 kW AIR FLOW RATE : 1140 m3/h

EVAPORATOR CONDENSER

ENT. TEMP. °C AMBIENT TEMP. C

WB DB 25 30 35 40 45 50

TC 7.37 7.03 6.67 6.26 5.81 5.34

CI 2.32 2.48 2.66 2.92 3.19 3.45

21 SHC 4.9 4.7 4.5 4.3 4.1 3.8

23 SHC 5.4 5.2 5 4.8 4.6 4.4

15 25 SHC 6 5.8 5.6 5.4 5.2 4.9

27 SHC 6.5 6.3 6.2 5.9 5.7 5.34

29 SHC 7.1 6.9 6.67 6.26 5.81 5.34

31 SHC 7.37 7.03 6.67 6.26 5.81 5.34

TC 7.61 7.31 6.96 6.59 6.18 5.75

CI 2.38 2.55 2.74 3 3.27 3.53

21 SHC 4.1 4 3.8 3.7 3.5 3.3

23 SHC 4.7 4.6 4.4 4.2 4 3.8

17 25 SHC 5.3 5.1 4.9 4.8 4.6 4.4

27 SHC 5.8 5.7 5.5 5.3 5.1 4.9

29 SHC 6.4 6.2 6.1 5.9 5.7 5.5

31 SHC 6.9 6.8 6.6 6.4 6.18 5.75

TC 7.88 7.6 #7.3 6.94 6.54 6.1

CI 2.45 2.63 2.82 3.09 3.36 3.63

21 SHC 3.4 3.3 3.2 3 2.8 2.7

23 SHC 4 3.9 3.7 3.6 3.4 3.2

19 25 SHC 4.6 4.4 4.3 4.1 4 3.8

27 SHC 5.1 5 4.9 4.7 4.5 4.3

29 SHC 5.7 5.5 5.4 5.3 5.1 4.9

31 SHC 6.2 6.1 6 5.8 5.6 5.4

TC 8.14 7.85 7.56 7.21 6.86 6.46

CI 2.52 2.7 2.9 3.18 3.45 3.73

23 SHC 3.3 3.2 3 2.9 2.8 2.6

21 25 SHC 3.8 3.7 3.6 3.5 3.3 3.2

27 SHC 4.4 4.3 4.2 4 3.9 3.7

29 SHC 5 4.8 4.7 4.6 4.4 4.3

31 SHC 5.5 5.4 5.3 5.1 5 4.8

TC 8.42 8.17 7.88 7.59 7.24 6.88

CI 2.59 2.77 2.98 3.26 3.54 3.82

23 25 SHC 3.1 3 2.9 2.8 2.7 2.6

27 SHC 3.7 3.6 3.5 3.4 3.2 3.1

29 SHC 4.2 4.2 4 3.9 3.8 3.7

31 SHC 4.8 4.7 4.6 4.5 4.4 4.2

TC 8.76 8.45 8.2 7.91 7.61 7.27

CI 2.67 2.86 3.03 3.34 3.64 3.93

25 27 SHC 3 2.9 2.8 2.7 2.6 2.5

29 SHC 3.6 3.4 3.4 3.3 3.2 3

31 SHC 4.1 4 3.9 3.8 3.7 3.6

1.SPECIFICATIONS

1-7Cooling Capacity

Page 22

– 22 –

Indoor Unit :CA250X5TAA Outdoor Unit : GR250X7TAA

TC :Total Cooling Capacity (kW)

SHC:Sensible Heat Capacity (kW)

CI :Compressor Input (kW)

Rating conditions are

:Outdoor Ambient Temp. 35 °C DB

:Indoor Unit Entering Air Temp. 27 °C DB / 19 °C WB

RATING CAPACITY : 7.3 kW AIR FLOW RATE : 1140 m3/h

EVAPORATOR CONDENSER

ENT. TEMP. °C AMBIENT TEMP. C

WB DB 25 30 35 40 45 50

TC 7.37 7.03 6.67 6.26 5.81 5.34

CI 2.03 2.17 2.33 2.5 2.67 2.84

21 SHC 4.9 4.7 4.5 4.3 4.1 3.8

23 SHC 5.4 5.2 5 4.8 4.6 4.4

15 25 SHC 6 5.8 5.6 5.4 5.2 4.9

27 SHC 6.5 6.3 6.2 5.9 5.7 5.34

29 SHC 7.1 6.9 6.67 6.26 5.81 5.34

31 SHC 7.37 7.03 6.67 6.26 5.81 5.34

TC 7.61 7.31 6.96 6.59 6.18 5.75

CI 2.08 2.23 2.4 2.57 2.74 2.91

21 SHC 4.1 4 3.8 3.7 3.5 3.3

23 SHC 4.7 4.6 4.4 4.2 4 3.8

17 25 SHC 5.3 5.1 4.9 4.8 4.6 4.4

27 SHC 5.8 5.7 5.5 5.3 5.1 4.9

29 SHC 6.4 6.2 6.1 5.9 5.7 5.5

31 SHC 6.9 6.8 6.6 6.4 6.18 5.75

TC 7.88 7.6 #7.3 6.94 6.54 6.1

CI 2.15 2.3 2.47 2.65 2.82 3

21 SHC 3.4 3.3 3.2 3 2.8 2.7

23 SHC 4 3.9 3.7 3.6 3.4 3.2

19 25 SHC 4.6 4.4 4.3 4.1 4 3.8

27 SHC 5.1 5 4.9 4.7 4.5 4.3

29 SHC 5.7 5.5 5.4 5.3 5.1 4.9

31 SHC 6.2 6.1 6 5.8 5.6 5.4

TC 8.14 7.85 7.56 7.21 6.86 6.46

CI 2.21 2.37 2.54 2.72 2.9 3.08

23 SHC 3.3 3.2 3 2.9 2.8 2.6

21 25 SHC 3.8 3.7 3.6 3.5 3.3 3.2

27 SHC 4.4 4.3 4.2 4 3.9 3.7

29 SHC 5 4.8 4.7 4.6 4.4 4.3

31 SHC 5.5 5.4 5.3 5.1 5 4.8

TC 8.42 8.17 7.88 7.59 7.24 6.88

CI 2.27 2.43 2.61 2.79 2.98 3.16

23 25 SHC 3.1 3 2.9 2.8 2.7 2.6

27 SHC 3.7 3.6 3.5 3.4 3.2 3.1

29 SHC 4.2 4.2 4 3.9 3.8 3.7

31 SHC 4.8 4.7 4.6 4.5 4.4 4.2

TC 8.76 8.45 8.2 7.91 7.61 7.27

CI 2.34 2.51 2.66 2.86 3.07 3.26

25 27 SHC 3 2.9 2.8 2.7 2.6 2.5

29 SHC 3.6 3.4 3.4 3.3 3.2 3

31 SHC 4.1 4 3.9 3.8 3.7 3.6

1.SPECIFICATIONS

Page 23

– 23 –

Indoor Unit :CA360X5TAA Outdoor Unit : GR360X7TAA

TC :Total Cooling Capacity (kW)

SHC:Sensible Heat Capacity (kW)

CI :Compressor Input (kW)

Rating conditions are

:Outdoor Ambient Temp. 35 °C DB

:Indoor Unit Entering Air Temp. 27 °C DB / 19 °C WB

RATING CAPACITY : 10.6 kW AIR FLOW RATE : 1920 m3/h

EVAPORATOR CONDENSER

ENT. TEMP. °C AMBIENT TEMP. C

WB DB 25 30 35 40 45 50

TC 10.7 10.21 9.69 9.08 8.44 7.76

CI 2.11 2.25 2.42 2.63 2.86 3.07

21 SHC 7.3 7 6.8 6.5 6.2 5.9

23 SHC 8.2 8 7.7 7.4 7.1 6.8

15 25 SHC 9.1 8.9 8.6 8.3 8 7.7

27 SHC 10.1 9.8 9.6 9.08 8.44 7.76

29 SHC 10.7 10.21 9.69 9.08 8.44 7.76

31 SHC 10.7 10.21 9.69 9.08 8.44 7.76

TC 11.06 10.61 10.11 9.57 8.98 8.34

CI 2.16 2.31 2.48 2.71 2.93 3.15

21 SHC 6.1 5.9 5.7 5.5 5.2 4.9

23 SHC 7.1 6.9 6.6 6.4 6.1 5.8

17 25 SHC 8 7.8 7.6 7.3 7.1 6.8

27 SHC 8.9 8.7 8.5 8.3 8 7.7

29 SHC 9.9 9.7 9.4 9.2 8.9 8.34

31 SHC 10.8 10.6 10.11 9.57 8.98 8.34

TC 11.45 11.03 #10.6 10.07 9.5 8.85

CI 2.23 2.39 2.56 2.79 3.01 3.24

21 SHC 5 4.8 4.6 4.4 4.2 3.9

23 SHC 5.9 5.7 5.6 5.3 5.1 4.8

19 25 SHC 6.9 6.7 6.5 6.3 6 5.8

27 SHC 7.8 7.6 7.4 7.2 7 6.7

29 SHC 8.7 8.5 8.4 8.1 7.9 7.6

31 SHC 9.7 9.5 9.3 9.1 8.8 8.6

TC 11.82 11.41 10.97 10.47 9.96 9.38

CI 2.29 2.45 2.63 2.86 3.1 3.33

23 SHC 4.8 4.6 4.4 4.2 4.1 3.8

21 25 SHC 5.7 5.5 5.4 5.2 5 4.8

27 SHC 6.6 6.5 6.3 6.1 5.9 5.7

29 SHC 7.6 7.4 7.2 7 6.8 6.6

31 SHC 8.5 8.3 8.2 8 7.8 7.6

TC 12.22 11.86 11.45 11.02 10.52 9.99

CI 2.35 2.52 2.7 2.94 3.17 3.41

23 25 SHC 4.6 4.4 4.3 4.1 3.9 3.8

27 SHC 5.5 5.4 5.2 5.1 4.9 4.7

29 SHC 6.4 6.3 6.1 6 5.8 5.6

31 SHC 7.4 7.2 7.1 6.9 6.7 6.6

TC 12.72 12.27 11.9 11.49 11.05 10.56

CI 2.43 2.6 2.75 3.01 3.27 3.51

25 27 SHC 4.4 4.2 4.1 4 3.8 3.7

29 SHC 5.3 5.1 5 4.9 4.7 4.6

31 SHC 6.2 6.1 6 5.8 5.7 5.5

1.SPECIFICATIONS

Page 24

– 24 –

Indoor Unit :CA480X5TAA Outdoor Unit : GR480X7TAA

TC :Total Cooling Capacity (kW)

SHC:Sensible Heat Capacity (kW)

CI :Compressor Input (kW)

Rating conditions are

:Outdoor Ambient Temp. 35 °C DB

:Indoor Unit Entering Air Temp. 27 °C DB / 19 °C WB

RATING CAPACITY : 14 kW AIR FLOW RATE : 1920 m3/h

EVAPORATOR CONDENSER

ENT. TEMP. °C AMBIENT TEMP. C

WB DB 25 30 35 40 45 50

TC 14.13 13.48 12.8 12 11.14 10.25

CI 3.43 3.67 3.94 4.34 4.76 5.17

21 SHC 9.1 8.8 8.4 8 7.5 7

23 SHC 10.1 9.7 9.3 8.9 8.4 8

15 25 SHC 11 10.6 10.2 9.8 9.4 8.9

27 SHC 11.9 11.6 11.2 10.8 10.3 9.8

29 SHC 12.9 12.5 12.1 11.7 11.14 10.25

31 SHC 13.8 13.4 12.8 12 11.14 10.25

TC 14.6 14.01 13.36 12.64 11.86 11.02

CI 3.52 3.77 4.04 4.46 4.88 5.29

21 SHC 7.9 7.6 7.3 6.9 6.5 6.1

23 SHC 8.8 8.5 8.2 7.8 7.5 7.1

17 25 SHC 9.8 9.5 9.1 8.8 8.4 8

27 SHC 10.7 10.4 10.1 9.7 9.3 8.9

29 SHC 11.6 11.3 11 10.6 10.3 9.9

31 SHC 12.6 12.3 11.9 11.6 11.2 10.8

TC 15.12 14.57 #14 13.3 12.54 11.69

CI 3.63 3.89 4.17 4.59 5.02 5.44

21 SHC 6.7 6.4 6.2 5.8 5.5 5.1

23 SHC 7.6 7.4 7.1 6.8 6.4 6

19 25 SHC 8.6 8.3 8 7.7 7.3 7

27 SHC 9.5 9.2 8.9 8.6 8.3 7.9

29 SHC 10.4 10.2 9.9 9.6 9.2 8.8

31 SHC 11.4 11.1 10.8 10.5 10.1 9.8

TC 15.61 15.06 14.49 13.83 13.16 12.39

CI 3.73 3.99 4.29 4.72 5.15 5.58

23 SHC 6.4 6.1 5.9 5.6 5.3 5

21 25 SHC 7.3 7.1 6.8 6.5 6.3 5.9

27 SHC 8.2 8 7.7 7.5 7.2 6.9

29 SHC 9.2 8.9 8.7 8.4 8.1 7.8

31 SHC 10.1 9.9 9.6 9.3 9 8.7

TC 16.14 15.67 15.12 14.56 13.89 13.19

CI 3.83 4.1 4.4 4.84 5.28 5.72

23 25 SHC 6.1 5.9 5.7 5.4 5.2 4.9

27 SHC 7 6.8 6.6 6.4 6.1 5.8

29 SHC 7.9 7.7 7.5 7.3 7 6.8

31 SHC 8.9 8.7 8.5 8.2 8 7.7

TC 16.8 16.21 15.72 15.18 14.59 13.94

CI 3.95 4.23 4.49 4.96 5.43 5.88

25 27 SHC 5.8 5.6 5.4 5.2 5 4.8

29 SHC 6.7 6.5 6.3 6.1 5.9 5.7

31 SHC 7.7 7.4 7.3 7.1 6.9 6.6

1.SPECIFICATIONS

Page 25

– 25 –

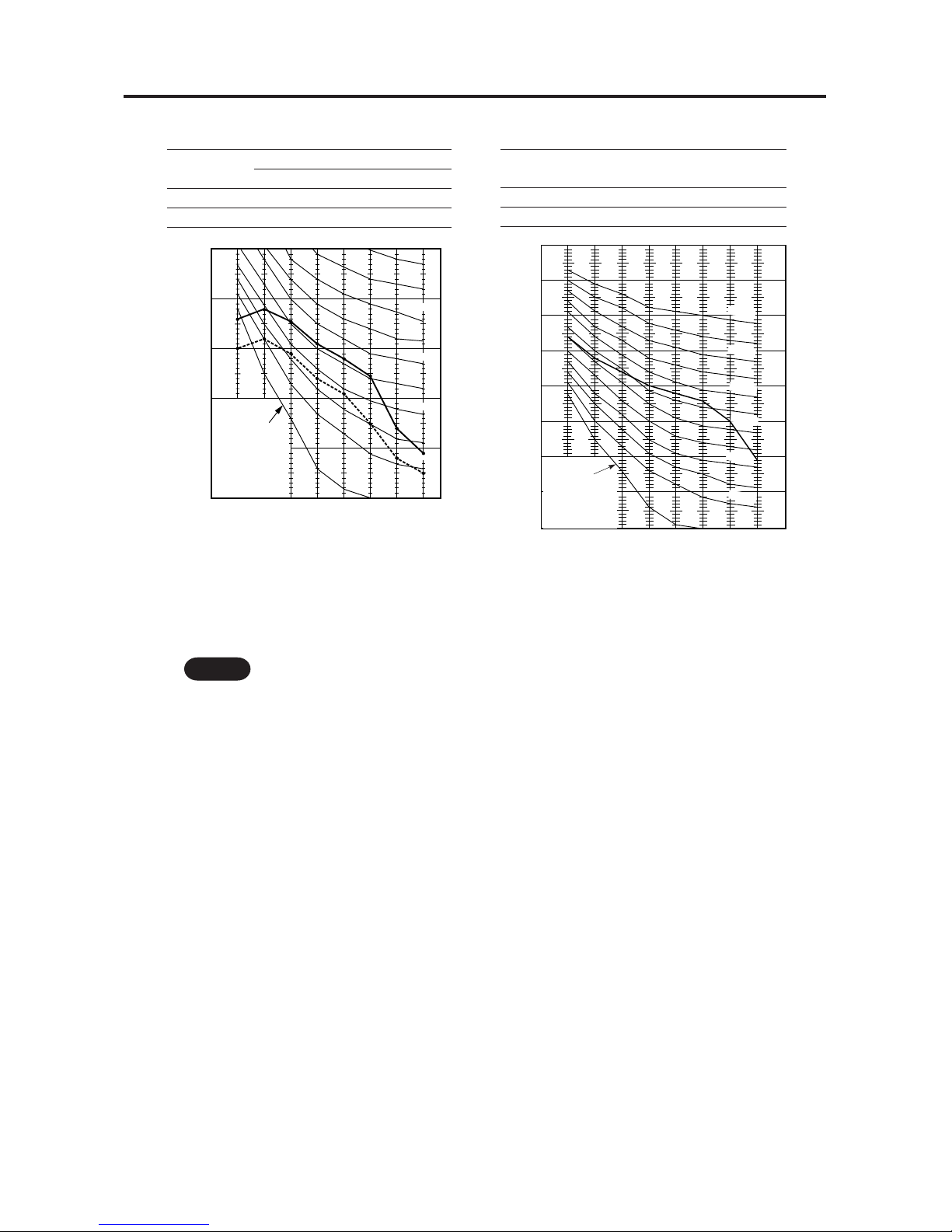

60

50

40

30

20

10

OCTAVE BAND SOUND PRESSURE LEVEL, dB

(0 dB = 0.0002 µbar)

63 125 250 500 1000200040008000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

BAND CENTER FREQUENCIES, Hz

NC-20

NC-40

NC-50

NC-30

MODEL :GR250X5TAA

:GR250X7TAA

SOUND LEVEL:53dB(A), NC45

CONDITION :Distance1m,Height1m

SOURCE :220 - 230 - 240 V, 1Phase, 50Hz

: 380 - 400 - 415 V, 3Phase, 50Hz

MODEL :CA250X5TAA

SOUND LEVEL:HIGH37dB(A),NC30

LOW 31dB(A),NC22

CONDITION :Distance1 m,Under the unit1.5 m

SOURCE :220 - 230 - 240V,1Phase,50Hz

REMARKS:1.Value obtained in the actual place where the unit is installed may be slightly higher than

the values shown in this graph because of the conditions of operation, the structure of

the building, the background noise and other factors.

2.The test results were obtained from an anechoic room.

NOTE To evaluate “Noise level” the maximum number of the measured OCTAVE BAND

SOUND PRESSURE LEVEL is used. Read the number on each BAND CENTER

FREQUENCIES (horizontal axis) ranging from 63Hz to 8000Hz and select the maximum

value (vertical axis) among them.

90

80

70

60

50

40

30

20

10

60 125

250

500

100020004000

8000

APPROXIMATE

THRESHOLD OF

CONTINUOUS

NOISE

NC-70

NC-50

NC-60

NC-40

NC-30

NC-20

OCTAVE BAND SOUND PRESSURE LEVEL, dB

(0dB=0.0002 µbar)

BAND CENTER FREQUENCIES, Hz

60

50

40

30

20

10

OCTAVE BAND SOUND PRESSURE LEVEL, dB

(0dB=0.0002 µbar)

63 125 250 500 1000200040008000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

BAND CENTER FREQUENCIES, Hz

NC-20

NC-40

NC-50

NC-30

MODEL :CA360X5TAA

SOUND LEVEL:HIGH43dB(A),NC36

LOW 36dB(A), NC24

CONDITION :Distance1 m,Under the unit1.5 m

SOURCE :220 - 230 - 240V,1Phase,50Hz

90

80

70

60

50

40

30

20

10

60 125

250

500

100020004000

8000

APPROXIMATE

THRESHOLD OF

CONTINUOUS

NOISE

NC-70

NC-50

NC-60

NC-40

NC-30

NC-20

OCTAVE BAND SOUND PRESSURE LEVEL, dB

(0dB=0.0002 µbar)

BAND CENTER FREQUENCIES, Hz

MODEL : GR360X7TAA

SOUND LEVEL:54dB(A), NC45

CONDITION :Distance1 m,Height1 m

SOURCE : 380 - 400 - 415 V, 3Phase, 50Hz

1.SPECIFICATIONS

1-8Noise Criterion Curves

Page 26

– 26 –

REMARKS:1.Value obtained in the actual place where the unit is installed may be slightly higher than

the values shown in this graph because of the conditions of operation, the structure of

the building, the background noise and other factors.

2.The test results were obtained from an anechoic room.

NOTE To evaluate “Noise level” the maximum number of the measured OCTAVE BAND

SOUND PRESSURE LEVEL is used. Read the number on each BAND CENTER

FREQUENCIES (horizontal axis) ranging from 63Hz to 8000Hz and select the maximum

value (vertical axis) among them.

MODEL :CA480X5TAA

SOUND LEVEL:HIGH43dB(A),NC36

LOW 36dB(A),NC24

CONDITION :Distance1m,Under the unit1.5 m

SOURCE :220 - 230 - 240V,1Phase, 50Hz

MODEL :GR480X7TAA

SOUND LEVEL:56dB(A), NC47

CONDITION :Distance1 m,Height1 m

SOURCE :380 - 400 - 415 V,3Phase, 50Hz

60

50

40

30

20

10

OCTAVE BAND SOUND PRESSURE LEVEL, dB

(0dB=0.0002 µbar)

63 125 250 500 1000200040008000

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

BAND CENTER FREQUENCIES, Hz

NC-20

NC-40

NC-50

NC-30

90

80

70

60

50

40

30

20

10

63 125 250 500 1000200040008000

BAND CENTER FREQUENCIES, Hz

APPROXIMATE

THRESHOLD OF

HEARING FOR

CONTINUOUS

NOISE

NC-70

NC-50

NC-20

NC-60

NC-40

NC-30

OCTAVE BAND SOUND PRESSURE LEVEL, dB

(0dB=0.0002 µbar)

1.SPECIFICATIONS

Page 27

– 27 –

MODEL : CA250X5TAA

0123456

0

1

2

3

4

HORIZONTAL DISTANCE (m)

AXIS AIR VELOCITY (m/s)

VERTICAL DISTANCE (m)

AXIS AIR VELOCITY

FAN SPEED

COOLING

ROOM AIR TEMP.

LOUVER ANGLE

HIGH

27˚

30˚

: COOLING

: 0.3 m/s

0659_X_S

MODEL : CA360X5TAA

CA480X5TAA

0123456

0

1

2

3

4

HORIZONTAL DISTANCE (m)

AXIS AIR VELOCITY (m/s)

VERTICAL DISTANCE (m)

AXIS AIR VELOCITY

FAN SPEED

COOLING

ROOM AIR TEMP.

LOUVER ANGLE

HIGH

27˚

30˚

: COOLING

: 0.3 m/s

0661_X_S

1.SPECIFICATIONS

1-9 Air Throw Distance Chart

Page 28

– 28 –

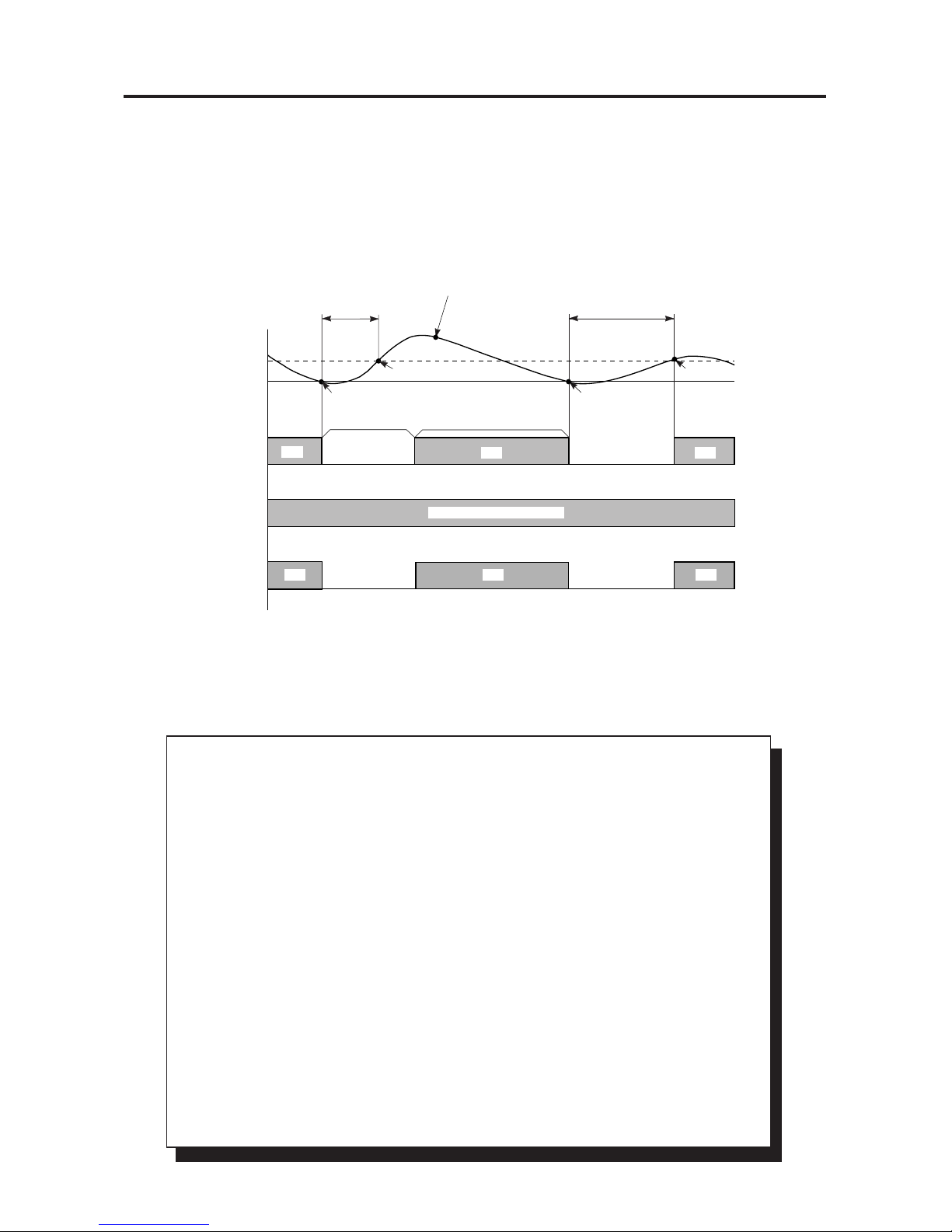

2

2-1 Room T emperature Control

The Unit adjusts room temperature by turning the outdoor unit’s compressor ON and OFF.

This process is controlled by the thermostat located in the remote control unit.

The figures on this and the next pages show how each part of the system performs when

the room temperature changes and the thermostat activates the compressor to start

(thermo ON) or stop (thermo OFF). Fig. 6 shows about the cooling cycle.

Fig. 6

THERMO ON

ROOM TEMPERATURE

THERMO ON

S. T.+0.5°C

SET TEMP. T°C

(S.T.)

COMPRESSOR

OFF

OFF

WITHIN 3 MINUTE

MORE THAN

5 MINUTES

ON

ON ON

0607_X_S

OFF OFF

INDOOR FAN

OUTDOOR FAN

SET SPEED (MANUAL)

THERMO OFF

3 MINUTES

THERMO OFF

MORE THAN 3 MINUTES

ON ON

ON

Chart Summary and Explanations

❑ Once the compressor starts, it keeps running for 5 minutes.

❑ Once the compressor stops, it will not start running again for 3 minutes.

❑ If you change the operation mode during the cooling cycle, the control circuit stops the

compressor for 3 minutes.

❑ For 5 minutes after the compressor is first turned on, and for 3 minutes after it is turned off,

the compressor is not controlled by the room sensor.

❑ Thermo ON: When room temperature rises 0.5°C above the set temperature T˚,

(T˚+0.5 °C):

Compressor ➞ ON

❑ Thermo OFF: When the room temperature is equal to or below the set temperature T˚:

Compressor ➞ OFF

❑ In case of wireless remote control model (GS type).

• The remote control unit sends the temperature signal to the air conditioner regularly at 3

minute intervals. If the signal from the remote control unit stops for more than 10 minutes

due to the damage of the remote control unit or other trouble, the air conditioner will

switch to the temperature sensor which is built in the indoor unit and control the room

temperature. In these cases, the temperature around the remote contorl unit may differ

from the temperature detected at the air conditioner’s position.

• If the remote control is located near a heat source, such as a space heater or in direct

sunlight, press the A/C SENSOR button to switch to the sensor in the indoor unit.

2.PROCESSES AND FUNCTIONS

Page 29

– 29 –

2

2-2 Freeze Prevention

Freeze Prevention keeps the indoor heat exchange coil from freezing. Freezing reduces

the efficiency of the unit, and frost buildup on the coil blocks cool air circulation from the

indoor unit’s fan.

Fig. 7

2-3 Drain Pump Control

Drain pump operates when compressor starts to operate or when Float Switch turns off.

COMPRESSOR

OUTDOOR FAN

INDOOR FAN

OFF

OFF OFF

OFF

INDOOR COIL

TEMPERATURE

MORE THAN 10 MINUTES

FREEZE

PREVENTION

6 MINUTES 10 MINUTES

FREEZE

PREVENTION

6 MINUTES

(THERMO OFF)

(THERMO ON)

–1°C

ON

ON

ON

ON

ON

ON

0608_X_S

SET SPEED

Fig. 8

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

SET SPEED

OFF

OFF

OFF

OFF

OFF

OFF

FLOAT SWITCH

ON: low water level

OFF: high water level

COMPRESSOR

DRAIN PUMP

OUTDOOR FAN

INDOOR FAN

20 MINUTES

0609_X_S

2.PROCESSES AND FUNCTIONS

Page 30

– 30 –

2

2-4 Outdoor Fan Control

• In low outdoor temperature, the outdoor fan is set automatically from HIGH to LOW to

prevent the indoor heat exchanger from freezing.

• When the outdoor temperature falls below 25.5°C, the outdoor fan is set from HIGH to

LOW automatically. When the outdoor temperature rises to 27.5°C, the outdoor fan is

set from LOW to HIGH automatically.

2.PROCESSES AND FUNCTIONS

Page 31

– 31 –

3.ELECTRICAL DATA

Indoor Unit Outdoor Unit

Complete Unit

Fan Motor Fan Motor Compressor

Performance at 220 - 240 V / 1 phase / 50 Hz 220 - 240 V / 1 phase / 50 Hz

Rating conditions

A 0.60 / 0.63 0.75 / 0.78 13.32 / 13.74 14.67 / 15.15

kW 0.13 / 0.15 0.17 / 0.19 2.76 / 2.82 3.06/ 3.16

Full load conditions

A 0.60 / 0.63 0.75 / 0.78 18.87/18.03 20.22 / 19.44

kW 0.13 / 0.15 0.17 / 0.19 3.92/ 3.93 4.22 / 4.27

Starting amperes A 1 / 1 1 / 1 67 / 73 69 / 75

Rating Conditions :Indoor Air Temperature 27 °C DB / 19 °C WB

Outdoor Air Temperature35 °C DB

Full Load Conditions:Indoor Air Temperature 35 °C DB / 22.5 °C WB

Outdoor Air Temperature52 °C DB

Indoor model : CA250X5TAA /Outdoor model : GR250X5TAA

Indoor model : CA250X5TAA /Outdoor model : GR250X7TAA

Indoor Unit Outdoor Unit

Complete Unit

Fan Motor Fan Motor Compressor

Performance at 220 - 240 V / 1 phase / 50 Hz 380 - 415 V / 3 phase / 50 Hz

Rating conditions

A 0.60 / 0.63 0.75 / 0.78 4.32 / 4.20 4.74 / 4.62

kW 0.13 / 0.15 0.17 / 0.19 2.46 / 2.47 2.76/ 2.81

Full load conditions

A 0.60 / 0.63 0.75 / 0.78 5.52/5.22 5.95 / 5.65

kW 0.13 / 0.15 0.17 / 0.19 3.27/ 3.26 3.56 / 3.59

Starting amperes A 1 / 1 1 / 1 25 / 28 27 / 30

Indoor model : CA360X5TAA /Outdoor model : GR360X7TAA

Indoor Unit Outdoor Unit

Complete Unit

Fan Motor Fan Motor Compressor

Performance at 220 - 240 V / 1 phase / 50 Hz 380 - 415 V / 3 phase / 50 Hz

Rating conditions

A 0.92 / 0.93 1.51 / 1.56 4.46 / 4.37 5.21 / 5.11

kW 0.20 / 0.22 0.33 / 0.37 2.54 / 2.56 3.07 / 3.15

Full load conditions

A 0.92 / 0.93 1.51 / 1.56 5.96 / 5.64 6.72 / 6.41

kW 0.20 / 0.22 0.33 / 0.37 3.53 / 3.51 4.06 / 4.10

Starting amperes A 2 / 2 3 / 3 27 / 30 31 / 34

3-1 Electrical characteristics

Page 32

– 32 –

3.ELECTRICAL DATA

Indoor model : CA480X5TAA /Outdoor model : GR480X7TAA

Indoor Unit Outdoor Unit

Complete Unit

Fan Motor Fan Motor Compressor

Performance at 220 - 240 V / 1 phase / 50 Hz 380 - 415 V / 3 phase / 50 Hz

Rating conditions

A 0.92 / 0.93 1.51 / 1.56 7.66 / 8.19 8.37 / 8.86

kW 0.20 / 0.22 0.33 / 0.37 4.17 / 4.27 4.70 / 4.86

Full load conditions

A 0.92 / 0.93 1.51 / 1.56 10.18 / 10.07 10.93 / 10.81

kW 0.20 / 0.22 0.33 / 0.37 5.87 / 5.88 6.40 / 6.48

Starting amperes A 2 / 2 3 / 3 66 / 70 71 / 75

Rating Conditions :Indoor Air Temperature 27 °C DB / 19 °C WB

Outdoor Air Temperature35 °C DB

Full Load Conditions:Indoor Air Temperature 35 °C DB / 22.5 °C WB

Outdoor Air Temperature52 °C DB

Page 33

– 33 –

TH1 (Coil)

31

DP

DPH

Connector

9P(WHT)

31

FS

21

31

31

31

3175315

213

213

1234

1SP234

123456789

1

P

S

23456789

1

To Outdoor Unit

Power Supply

Terminal Plate(4P)

Connector

4P(WHT)

• Electric Wiring Diagram

2 3 4

GRN/YEL

GRN/YEL

GRN/YEL

GRN/YEL

Earth

Terminal

Earth

Terminal

Earth

Terminal

YEL

ORG

VLT

WHT

GRY

GRY

PNK

BRN

BLK

YEL

WHT

GRY

BLK

BLK

GRY

WHT

YEL

BLK

BLK

FMI

LM

Controller (CR-X363GS)

E

2P(RED)

TH1

TH2 (Room)

21

BLK

BLK

2P(YEL)

TH2 DPH

3P(RED)LM3P(GRN)

21

TR

PS

21

2P(WHT)

PRY

2P(WHT)

SEC

3P(BLU)DP3P(RED)

FS

3P(WHT)

49FMI

FM

COM

5P(WHT)

SUP

BLK

BLK

BLK

BLK

WHT

WHT

RED

WHT

BRN

BRN

BRN

7P(WHT)

MHL

7P(WHT)3P(WHT)

71

71

IND Lamp

Assy

Switch

Assy

RED

ORG

BRN

C

ORG

VLT

WHT

GRY

GRY

PNK

BRN

BRN

(A) Indoor Unit

CA250X5TAA, CA360X5TAA, CA480X5TAA

3.ELECTRICAL DATA

3-2 Electric Wiring Diagrams / Schematic Diagrams

Page 34

– 34 –

• Schematic Diagram

2

1

3

1

3

1

2

IND

3

1

2

717

1

SW

TR

Coil

TH1

2

1

Room

TH2

FS

CR-X363GS

Controller

1

3

5

F

2

1

2

1

3

DP

DPH

RY2

RY1

RY3

RY4

RY5

3

4

LM

1

3

RY3

4P-1

4P-4

1

4P-2

RY5

FMI

C

12

1

735

456

RY1

RY2 RY2

HLM

3

2

1

1

18

3

49FMI

9

RY4

RY4

Symbols Description

FMI

49FMI

C

F

DP

DPH

LM

TR

RY1-RY5

FS

TH1

TH2

Indoor Fan Motor

Indoor Motor Thermal Protector

Capacitor

Fuse

Drain Pump

Dew Proof Heater

Auto Louver Motor

Power Transformer

Auxiliary Relay

Float Switch

Thermistor (Indoor Coil)

Room Thermistor

Symbols Description

CR-X363GS

IND

SW

Indoor Controller

Indicator Lamp Assy

Switch Assy

Terminal Plate

Connector

Terminal

CA250X5TAA, CA360X5TAA, CA480X5TAA

3.ELECTRICAL DATA

Page 35

– 35 –

CM

FM

C1

C2

YEL

WHT

GRY

BRN

PNK

45

452323

1

1

Connector

6P (WHT)

Connector 2P (WHT) 63PH

313213

14

TWSVR

UAB

OLR

PS

Earth

Terminal

C

R

S

GRN/YEL GRN/YEL

GRN/YEL

52C

5

7

8

13

Relay

121

2

6

24

1Y

Power Supply

50Hz 1ø 220 V To Indoor Unit

Terminal

Plate

1

2

4

L

N

WHT

PNK

WHT

PNK

WHT

WHT

RED

BRN

RED

WHT

BLK

WHT

BLU

RED

RED

WHT

• Electric Wiring Diagram

W 854-2-5268-461-00-1 (AE425SCE)

P

S

C

HL

23S

YEL

WHT

GRY

BRN

PNK

RED

RED

(B) Outdoor Unit

GR250X5TAA

3.ELECTRICAL DATA

3-2 Electric Wiring Diagrams / Schematic Diagrams

Page 36

– 36 –

1

2

1Y 52C

4

1

2

N

L

S

V

R

U

1Y

C1

63PH

C2

52C

OLR

23S

FM

CM

LH

C

45

123

W

T

52C

• Schematic Diagram

Symbols Description

CM

FM

52C

63PH

23S

C1, 2

OLR

1Y

Compressor motor

Fan Motor

Compressor Motor Magnetic Contactor

High Pressure Switch

Fan Speedcontrol Thermostat

Capacitor

Overload relay

Auxiliary Relay

Connector

Terminal Plate

GR250X5TAA

3.ELECTRICAL DATA

Page 37

– 37 –

CM

FM

C

YEL

WHT

GRY

BRN

PNK

YEL

WHT

GRY

BRN

PNK

45

45

23

23

1

1

Connector

6P (WHT)

P

S

Connector 2P (WHT) 63PH

313213

14

TWSVR

U

642

A

B

95

9651C

C

PS

HL

23S

49C

Earth

Terminal

R

S

T

GRN/YEL GRN/YEL

GRN/YEL

52C

46

35

8

Relay

S

BATR

C

7

121

2

1Y

47C

Power Supply

50Hz 3ø 380 V / 415 V To Indoor Unit

Terminal

Plate

1

2

4

5

6

7

8

L1

L2

L3

N

PNK

BRN

ORG

WHT

WHT

PNK

PNK

BLU

RED

PNK

YEL

RED

WHT

BLU

ORG

RED

WHT

WHT

BLU

RED

RED

GRY

WHT

ORG

• Electric Wiring Diagram

GR250X7TAA

3.ELECTRICAL DATA

Page 38

– 38 –

1

2

1

AB

S

T

R

C

47C

49C

2

4

52C

1Y

47C

5

6

7

8

L1

L2

L3

N

C

FM

LH

63PH

C

23S

45

123

52C

51C

• Schematic Diagram

Symbols Description

CM

FM

52C

51C

49C

47C

63PH

23S

C

1Y

Compressor motor

Fan Motor

Compressor Motor Magnetic Contactor

Compressor Motor Overcurrent Relay

Compressor Motor Thermal Protector

Negative Phase Relay

High Pressure Switch

Fan Speedcontrol Thermostat

Capacitor

Auxiliary Relay

Connector

Terminal Plate

13

14

5

95

96

51C

52C

1Y

3

CM

GR250X7TAA

3.ELECTRICAL DATA

Page 39

– 39 –

CM

FM1

C1

YEL

WHT

GRY

BRN

PNK

YEL

WHT

GRY

BRN

PNK

45

452323

1

1

Connector

6P (WHT)

Connector 2P (WHT) 63PH

313213

14

TWSVR

U

642

A

B

95

9651C

PS

49C

Earth

Terminal

R

S

T

GRN/YEL GRN/YEL

GRN/YEL

GRN/YEL

52C

46

35

8

Relay

Relay

S

BATR

C

7

121

2

2Y

47C

Power Supply

50Hz 3ø 380 V / 415 V To Indoor Unit

Terminal

Plate

1

2

4

5

6

7

8

L1

L2

L3

N

PNK

BRN

ORG

WHT

WHT

PNK

PNK

BLU

RED

PNK

YEL

RED

WHT

BLU

ORG

GRY

RED

WHT

BLU

RED

RED

GRY

WHT

ORG

ORG

• Electric Wiring Diagram

P

S

FM2

C2

YEL

WHT

GRY

BRN

PNK

YEL

WHT

GRY

BRN

PNK

45

452323

1

1

Connector

6P (WHT)

P

S

3

8

7

14

5

1Y

2

6

C

H

L

23S

WHT

ORG

WHT

VLT

WHT

WHT

GR360X7TAA

3.ELECTRICAL DATA

Page 40

– 40 –

1

2

1

C1

FM1

31

5

54

123

AB

S

T

R

C

47C

49C

H

2

4

52C

1Y

2Y

47C

5

6

7

8

L1

L2

L3

N

C2

FM2

42

L

23S

63PH

C

6

54

123

52C

51C

• Schematic Diagram

Symbols Description

CM

FM1, 2

52C

51C

49C

47C

63PH

23S

C1, 2

1Y, 2Y

Compressor motor

Fan Motor

Compressor Motor Magnetic Contactor

Compressor Motor Overcurrent Relay

Compressor Motor Thermal Protector

Negative Phase Relay

High Pressure Switch

Fan Speedcontrol Thermostat

Capacitor

Auxiliary Relay

Connector

Terminal Plate

13

14

5

95

96

51C

52C

2Y

3

CM

GR360X7TAA

3.ELECTRICAL DATA

Page 41

– 41 –

CM

FM1

C1

YEL

WHT

GRY

BRN

PNK

YEL

WHT

GRY

BRN

PNK

45

452323

1

1

Connector

6P (WHT)

Connector 2P (WHT) 63PH

313213

14

TWSVR

U

642

A

B

95

9651C

PS

Earth

Terminal

T1

T2

T3

GRN/YEL GRN/YEL

GRN/YEL

GRN/YEL

52C

46

35

8

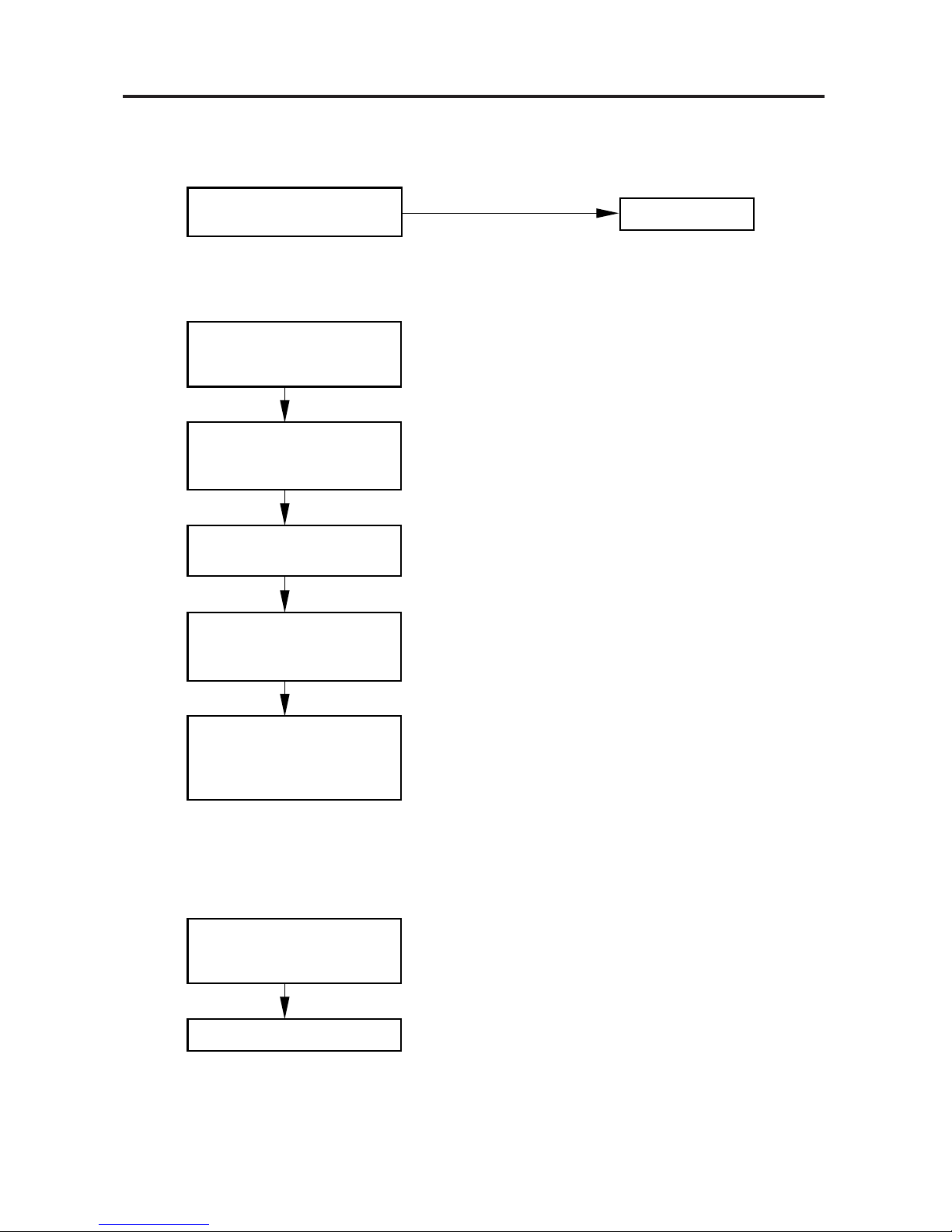

Relay

Relay

S

BATR

C

7

121

2

2Y

47C

Power Supply

50Hz 3ø 380 V / 415 V To Indoor Unit

Terminal

Plate

1

2

4

5

6

7

8

L1

L2

L3

N

PNK

PNK

BRN

ORG

WHT

WHT

PNK

PNK

BLU

RED

PNK

RED

WHT

BLU

GRY

RED

WHT

BLU

RED

RED

GRY

WHT

ORG

ORG

YEL

• Electric Wiring Diagram

P

S

FM2

C2

YEL

WHT

GRY

BRN

PNK

YEL

WHT

GRY

BRN

PNK

45

452323

1

1

Connector

6P (WHT)

P

S

3

8

7

14

5

1Y

2

6

C

H

L

23S

WHT

ORG

WHT

VLT

WHT

WHT

GR480X7TAA

3.ELECTRICAL DATA

Page 42

– 42 –

1

2

1

C1

FM1

31

5

54

123

AB

S

T

R

C

47C

H

2

4

52C

1Y

2Y

47C

5

6

7

8

L1

L2

L3

N

C2

FM2

42

L

23S

63PH

C

6

54

123

52C

51C

• Schematic Diagram

Symbols Description

CM

FM1, 2

52C

51C

47C

63PH

23S

C1, 2

1Y, 2Y

Compressor motor

Fan Motor

Compressor Motor Magnetic Contactor

Compressor Motor Overcurrent Relay

Negative Phase Relay

High Pressure Switch

Fan Speedcontrol Thermostat

Capacitor

Auxiliary Relay

Connector

Terminal Plate

13

14

5

95

96

51C

52C

2Y

3

CM

GR480X7TAA

3.ELECTRICAL DATA

Page 43

– 43 –

4

4-1 Trobleshooting

(1) Check before and after Troubleshooting

Many problems may happen because of wiring or power supply problems, so you should

check these areas first. Problems here can cause false results in some of the other tests,

and so should be corrected first.

11

11

1. Check power supply wiring

(a) Single-phase

❑ Check that power supply wires are correctly connected to terminal No.

1 through No. 4 on the 4P terminal plate in the indoor unit and L and N

on the 6P terminal in the outdoor unit.

(b) 3-phase

❑ Check that power supply wires are correctly connected to terminal No.

1 through No. 4 on the 4P terminal plate in the indoor unit and L1

through L3 and N on the 8P terminal in the outdoor unit.

22

22

2. Check inter-unit wiring

❑ Check that inter-unit control wiring (AC 220 - 240 V Line voltage) is

correctly connected between the indoor unit and outdoor unit.

33

33

3. Check power supply

❑ Check that voltage is within the specified range (±10% of the rating).

❑ Check that power is being supplied.

If the following troubleshooting must be done with power being supplied,

be careful not to thouch any uninsulated live part that can cause

ELECTRIC SHOCK.

44

44

4. Check the lead wires and connectors in indoor and outdoor units.

❑ Check that the sheath of lead wires is not damaged.

❑ Check that the lead wires are firmly connected at the terminal plate.

❑ Check that the wiring is correct.

55

55

5 Reference

• Condition of general cooling operation (Thermo. ON)

SWEEP..................ON

Indoor fan speed....HIGH

Single-phase outdoor unit

3-phase outdoor unit

1

2

4

1

2

4

L

N

Indoor Unit Outdoor Unit

Ground

Ground

B

A

0611_X_S

L

N

Power supply

Inter-Unit

Wiring

(Line voltage)

Fig. 16

1

2

4

1

2

4

L1

N

Indoor Unit Outdoor Unit

Power supply

Inter-Unit

Wiring

(Line voltage)

Ground

Ground

B

A

0612_X_S

L1

L2

L2

L3

L3

N

4.SERVICE PROCEDURES

Page 44

– 44 –

4

(2) Air conditioner does not operate

11

11

1 Circuit breaker trips (or fuse blows).

(a) When the circuit breaker is set to ON, it is tripped soon.

• There is a possibility of ground fault.

• Check insulation resistance.

If resistance value is 1MΩ or less, it is a defect of insulation.

1

2

3

(Example)

*Set the circuit breaker to OFF.

Remove power supply cords

from the terminal plate in

the outdoor unit.

• Check insulation resistance

of power supply cords.

OK

NO

NO Insulation of

outdoor unit

is defective.

Execute

rewiring.

Remove interunit power line

from the terminal plate in

the outdoor unit.

• Check insulation resistance

of outdoor unit.

OK

Remove interunit power line

from the terminal plate in

the indoor unit.

• Check insulation resistance

of indoor unit.

OK

Interunit power lines are

defective.

NO

Insulation of

outdoor unit

is defective.

• Check insulation

resistance of

electrical parts

in the outdoor unit.

• Check insulation

resistance of

electrical parts

in the outdoor unit.

Execute

rewiring.

0613_X_S

+

+

+

+

+

+

1

3

2

Circuit

breaker

Outdoor

unit

5 1

6 2

3

4

Indoor

unit

1

2

3

4

Power

supply

cords

Interunit

power line

L

N

Earth

+

+

+

+

+

+

+

+

1

3

2

Circuit

breaker

Indoor

unit

1

2

Power

supply

cords

Interunit

power line

L1

L2

L3

N

Earth

4

+

+

+

+

4

Outdoor

unit

5 1

6

7 2

4

3

84

3

4.SERVICE PROCEDURES

Page 45

– 45 –

4

(b)

Circuit breaker trips in several minutes after turning the air conditioner on.

• There is a possibility of short circuit.

22

22

2 Neither indoor unit nor outdoor unit runs.

A. Power is not supplied

0615_X_S

• Check power supply.

Is power being supplied

to outdoor unit ?

Circuit breaker

is tripped.

Power failure.

Reset the breaker.

Wait for recovery

or consult power

supply company.

NO

B. Check remote control unit.

0616_X_S

• Try to run both indoor and

outdoor units with another

remote control unit.

Refer to item C.

NO

The other remote control

unit is defective.

OK

• Check capacity of circuit

breaker.

NO

• Check resistance of

outdoor fan motor winding.

0614_X_S

Is capacity of circuit

breaker sufficient ?

• Check resistance of

compressor motor winding.

Replace it with a

suitable one.

(= larger capacity)

4.SERVICE PROCEDURES

Page 46

– 46 –

4

C. Check “Operation selector” switch in the indoor unit.

: In case of wireless remote control unit

D. Check compressor motor protectors.

a) High pressure switch (63PH)

b)Compressor motor overcurrent relay (51C)

0618_X_S

• Check high pressure switch.

Does high pressure switch

actuate ? (63PH)

YES

YES

Clean heat exchanger coil

or remove obstacles.

• Is outdoor heat exchanger

coil dirty or are there

obstacles near air suction

inlet of outdoor unit ?

• Check if outdoor fan rotates.

Refer to “Only outdoor fan

does not run.”

NO

Disconnect the socket from 2P (WHT) connector.

Check the continuity between No.1 and No.2 poles

of the socket.

0617_X_S

• Has “Operation selector”

switch been set to ON

position ?

YES

Set “Operation selector”

switch to ON.

NO

But neither unit runs.

Switch Ass’y or P.C.B.

Ass’y in the indoor unit

is defective.

IND. LAMP Ass’y or P.C.B.

Ass’y in the indoor unit

is defective.

0619_X_S

• Check compressor motor

overcurrent relay. (51C)

Does it actuate ?

YES

NO

YES

Consult power supply company

and restore voltage to

normal value.

• Check power supply voltage.

Is voltage 90% or less of

rated voltage ?

• Following causes may be considered.

Locked rotor of compressor.

Overcharged refrigerant.

Air shortage of outdoor unit ventilation.

Obstacles in front of outdoor unit.

NO

Refer to “CHECKING ELECTRICAL COMPONENTS

(Electro magnetic contactor)”.

90% or more of

rated voltage.

4.SERVICE PROCEDURES

Page 47

– 47 –

4

E. Check. auxiliary relay. (1Y or 2Y)

0620_X_S

• Check coil resistance of

auxiliary relay.

(1Y or 2Y)

F. Check indoor fan motor thermal protector (49FMI)

• Disconnect the socket from 9P (WHT) connector.

• Check the continuity

between No. 8 and No.9

poles of the 9P socket.

The thermal protector (49FMI)

is operated.

No continuity.

0621_X_S

• Check fan rotation.

Rotate the fan gently once

or twice by hand.

Check fan casing

for foreign matter

on the inside.

Remove foreign

matter or repair.

Repair or replace.

Fan cannot

be rotated.

OK

• Check fan motor capacitor.

Fan motor burnout

or foreign matter

in bearing.

G. Check fuse on the P.C.B. Ass’y in the indoor unit.

0622_X_S

• Check fuse on the P.C.B.

Ass'y in the indoor unit

for continuity.

• Check transformer. (TR)

• Check resistance of indoor

fan motor winding.

(FMI)

• Check resistance of louver

motor winding. (LM)

When the fuse blows.

OK

OK

OK

• Check resistance of drain

pump winding. (DP)

• Check coil of compressor

motor magnetic contactor.

(52C)

• P.C.B. Ass'y is defective.

OK

OK

OK

• Check resistance of dew

proof heater. (DPH)

4.SERVICE PROCEDURES

Page 48

– 48 –

4

(3) Outdoor unit does not run.

A. Check COOL/FAN selector switch in the remote control unit.

0623_X_S

• Is COOL/FAN selector switch

set to COOL ?

NO

Set to COOL.

B. Check set temperature.

0624_X_S

Try to lower set

temperature by Temperature

setting button “COOLER”.

• Set “Operation selector”

switch to TEST in the

indoor unit.

YES

Outdoor unit runs.

Is room temperature too

low ?

NO

• Try to run both indoor and

outdoor units with another

remote control unit.

OK

The other remote control

unit is defective.

(Room sensor in the remote

control unit is defective.)

C. Outdoor unit is abnormal.

a) Check power supply wiring

0625_X_S

• Check negative phase relay.

(47C)

Dose it operate ?

Rewire power supply cords.

NO

4.SERVICE PROCEDURES

Page 49

– 49 –

4

b) Check compressor motor thermal protector (49C)

0628_X_S

• Check voltage between

terminals No.2 and No.4 at

terminal plate.

• Check P.C.B. Ass’y.

No voltage appears.

P.C.B. Ass’y is defective.

D. Check indoor unit P.C.B.

E. Check float switch.

• Refer to “2-3 Drain Pump Control”

0629_X_S

Is drainage prevented from

flowing ?

• Check drain hose.

YES

• Check float switch (FS).

NO (Wait for 20 minutes.)

0626_X_S

Is temperature of compressor

abnormally high ?

Refrigerant gas shortage.

YES

NO

Compressor is defective.

Charge refrigerant gas.

• Check compressor motor

thermal protector. (49C)

0627_X_S

• Check compressor motor

magnetic contactor.

(52C)

(Only outdoor fan does not run.)

4.SERVICE PROCEDURES

Page 50

– 50 –

4

(4) Indoor unit does not run.

(Indoor fan and louver motor do not run.

0630_X_S

P.C.B. Ass’y is defective.

(5) Some part does not operate.

(1) Indoor fan does not run.

• Check resistance of fan

motor winding.

• Check fan motor capacitor.

OK

Relay RY1 or RY2 on the

P.C.B. Ass’y is defective.

• Check fan rotation.

Rotate the fan gently once

or twice by hand.

0631_X_S

Check fan casing

for foreign matter

on the inside.

Remove foreign

matter or repair.

Repair or replace.

Fan cannot

be rotated.

Fan motor burnout

or foreign matter

in bearing.

OK

(2) Louver motor does not run.

• Check resistance of

louver motor winding.

P.C.B. Ass’y or remote

control unit is defective.

OK

0632_X_S

4.SERVICE PROCEDURES

Page 51

– 51 –

4

(6) Outdoor fan does not run.

• Check resistance of fan

motor winding.

• Check fan motor capacitor

OK

• Check continuity between

terminals on the compressor

motor magnetic contactor.

• Check fan rotation.

Rotate the fan gently once

or twice by hand.

0633_X_S

• Check fan casing

for foreign matter

on the inside.

Remove foreign

matter or repair.

Repair or replace.

Fan cannot

be rotated.

• Fan motor burnout

or foreign matter

in bearing.

GR360X7TAA and GR480X7TAA

(8) Compressor does not run.

• Check compressor motor capacitor.

Refer to

4-4

0635_X_S

• Check resistance of compressor motor winding.

• Check compressor motor overload relay.

(Only SPW-C253G5, SPW-C253G5/M)

OK

OK

OK

NG

NG

NG

Refer to

4-4

Refer to

4-4

Refer to 4-4

NG

Replace magnetic

contactor.

• Check continuity between terminals R-U, and

then S-V on the magnetic contactor.

OK

(7) Outdoor fan speed is not switched from High to Low even when the outdoor

temperature falls below 25.5°C.

• Check the thermostat (23S).

• Check coil resistance of

the auxiliary relay.

(1Y)

0634_X_S

4.SERVICE PROCEDURES

Page 52

– 52 –

4

(9) Poor cooling

Check installation position

of remote control unit.

• Does cool air from air condi tioner reach remote control

unit directly ?

• Is wide tube between indoor unit

and outdoor unit insulated ?

0636_X_S

• Measure temperatures of suction

and discharge air of indoor unit.

Change installation

position of remote

control unit.

Insulate wide tube and

then execute taping with

narrow tube.

YES

NO

Possibility of

refrigerant

shortage.

Charge

refrigerant

(R22).

Temperature

difference

is small.

YES

• Check clogging of air

filter.

Temperature difference between

suction and discharge air is

large enough (Approx. 10 deg. or more).

Clean filter.

Air filter is clogged.

Set fan speed to either

HIGH or MEDIUM.

• Is fan speed set to LOW ?

Reduce cooling load or

replace the unit with

higher cooling capacity.

• Review cooling load estimate,

if performance of air conditioner

is normal.

YES

4.SERVICE PROCEDURES

Page 53

– 53 –

4

(10) Excessive cooling.

• The set temperature is too low.

• Is the remote control unit installed

at a place where it can

detect the room temperature

properly ?

0637_X_S

Set the temperature to

higher value using

temperature setting

button of the remote

control unit.

Change installation

position of the remote

control unit.

YES

NO

4.SERVICE PROCEDURES

Page 54

– 54 –

4

4-2 A Sensor is Defective.

11

11

1 Indoor (heat exchanger) coil temp. Sensor is defective.

(a) Open (=No continuity in sensor)

Compressor and outdoor fan repeat ON for 10 minutes and OFF for 6 minutes

when sensor opens.

(b) Short

“Freeze Prevention” does not operate when dehumidified water is frozen on the

indoor coil.

22

22

2 Room temp. Sensor (in the remote control unit) is defective.

(a) Open (=No continuity in sensor)

Neither outdoor fan nor compressor runs.

(b) Short

Outdoor fan and compressor do not stop. — Excessive cooling.

4-3 Operation of Major Electrical Parts

(Function)

Operation

Indoor unit and Remote Control unit

Oudoor unit

Freeze prevention

Manual

Energy

saver

Night

setback

Timer

(set)

Fan

Operation Mode

Sweep

Stop

Indicator lamps

Thermo. ON VV V V V

Thermo. OFF VV V

Thermo. ON VV V VV V

Thermo. OFF VV V

Thermo. ON VV V VV V

Thermo. OFF VV V

ON Timer V

OFF Timer VVV VV V

VV V

VV

Cool VV* V* VV* V*

Fan VV

Cool VV* V* VV* V*

Fan VV

NOTE V* Refer to Cooling Mode.

Cool

Timer

Sweep

Cool

-ing

Fan

Flap

Night setback

Energy saver

Room

Temp.

Fan Compressor

4.SERVICE PROCEDURES

Page 55

– 55 –

4

4-4 Checking the Electrical Components

(1) Measurement of Insulation

Resistance

• The electrical insulation is acceptable when the

resistance exceeds 1 MΩ.

1 Power Supply Wires

Clamp the earthed wire of the Power Supply wires

with a lead clip of the insulation resistance tester and

measure the resistance by placing a probe on either

of the power wires. (Fig. 42)

Then measure the resistance between the earthed

wire and the other power wires. (Fig. 42)

2 Indoor Unit

Clamp an aluminum plate fin or copper tube with the

lead clip of the insulation resistance tester and

measure the resistance by placing a probe on the

terminal plate (Fig. 43)

3 Outdoor Unit

Measure the resistance by placing a probe on the

terminal plate in the same manner as explained

above 2. (Fig. 43)

4 Measurement of Insulation Resistance for

Electrical parts

• Disconnect the connector of the desired electric

part from terminal plate, P.C.B. Ass’y, etc. (Fig. 44)

• Similarly, disconnect the lead wires from

compressor, capacitor, etc. (Fig. 45)

• Measure the resistance in the same manner as

illustrated on the right.

Refer to Electrical Wiring Diagram.

NOTE

If the probe does not enter the hole because the

hole is too narrow, use a probe with a thinner pin.

Fig. 42

Fig. 43

Fig. 44

Fig. 45

Copper

tube or

metallic part

Clip

Insulation

tester

Probe

Terminal plate

0639_X_S

Copper

tube or

metallic part

Clip

Insulation

tester

Probe

0640_X_S

From fan motor,

compressor and other

parts.

Clip

Probe

Insulation

tester

Metallic

part

0641_X_S

Earthed wire

Clip

Probe

Insulation

tester

0638_X_S

4.SERVICE PROCEDURES

Page 56

– 56 –

4

(2) Checking the Protective Devices

• Disconnect the connector, which consists of P (plug) and S (socket) when you want to

check the protective device.

• Then check continuity among plug’s (and/or socket’s) terminal as in Fig. 46.

• Normality of the protective device can be judged by the following table.

The Protective Device is proved normal if there is a continuity between terminals.

1 Indoor fan motor thermal protector (49FI) . . . . . . Indoor unit

• Disconnect the connector which leads to the indoor fan motor (FMI).

• Check the socket’s terminals.

2 Compressor motor thermal protector (49C) . . . . . . Outdoor unit

• Disconnect both the connectors in the outdoor unit.

• Check terminal between the plug and socket.

3 Outdoor fan motor thermal protector (49FO) . . . . . . Outdoor unit

• Disconnect both the connector which leads to the outdoor fan motor (FMO).

• Check socket’s terminal.

Fig. 46

Ω

socket

Multimeter

0642_X_S

4.SERVICE PROCEDURES

Page 57

– 57 –

4

Fig. 47

Multimeter

Fan motor

Capacitor

0643_X_S

(3) Checking the Electrical Parts

1 Power transformer (TR1) ................. Indoor unit *Measure the coil resistance.

• Primary 220-240 V; Measure the resistance between two WHT lead wire

terminals of socket connected to power transformer.