Page 1

PICO-PI-IMX6UL

NXP i.MX6Ultralite

February 24, 2017

Page 2

PICO-PI-IMX6UL HARDWARE MANUAL – VER 1.00 – FEB 24 2017

Page 2 of 44

TABLE OF CONTENTS

1. PICO-PI-IMX6UL Product Overview ................................................................................................... 3

1.1. PICO-IMX6 System -on-Module Overview ................................................................................... 4

1.2. PICO-PI-IMX6UL Carrier Baseboard Overview ........................................................................... 5

2. Core Components ............................................................................................................................... 6

2.1. NXP i.MX6Ultralite Cortex-A7 Processor ..................................................................................... 6

2.2. NXP PF3000 Power Management IC (PMIC) .............................................................................. 7

2.3. Memory (SKHynix) ....................................................................................................................... 8

2.4. eMMC Storage (Kingston) ............................................................................................................ 8

2.5. Broadcom BCM4343W WiFi/Bluetooth SiP Module ..................................................................... 9

3. PICO-PI-IMX6UL Interfaces and Connectors ................................................................................... 12

3.1. Power Input Connector ............................................................................................................... 12

3.2. System RESET Button ............................................................................................................... 12

3.3. Fast Ethernet .............................................................................................................................. 13

3.4. Audio Interface ........................................................................................................................... 14

3.5. Universal Serial Bus (USB) Host Interface ................................................................................. 15

3.6. Universal Serial Bus (USB) OTG Interface ................................................................................ 15

3.7. Debug Interface .......................................................................................................................... 16

3.8. Serial Boot or eMMC Boot Control Pins ..................................................................................... 17

3.9. Expansion Header Pins .............................................................................................................. 18

3.10. Display and Touch Connector .................................................................................................. 21

4. Booting up the PICO-PI-IMX6UL ...................................................................................................... 24

4.1.1. Overview .................................................................................................................................. 24

4.1.2 i.MX6UL boot process details ................................................................................................... 24

4.1.3 Changing PICO-PI-IMX6UL boot mode ................................................................................... 24

4.1.4 Preparing a bootable software image ....................................................................................... 26

4.1.4.1 Procedure overview ........................................................................................................... 26

4.1.4.2 eMMC boot overview ......................................................................................................... 26

4.1.4.3 Preparing an OS image ..................................................................................................... 26

4.1.4.4 Creating the image file from a block device ....................................................................... 27

4.2. Programming PICO-PI-IMX6UL using a Windows host ............................................................. 28

4.2.1. Preparing the setup ............................................................................................................. 28

4.2.2. Using sb_loader ................................................................................................................... 29

4.2.3. Using WinDiskImager to flash the eMMC ............................................................................ 31

4.3. Programming PICO-PI-IMX6UL eMMC using a Linux host ....................................................... 32

4.3.1. Using imx_usb tool and flashing the eMMC ........................................................................ 32

4.3.2. Copying files to eMMC without an image file ....................................................................... 32

5. PICO-IMX6 Com pute Module Pin Assignm ent ................................................................................ 33

6. PICO-IMX6 Com pute Module Pinm ux Overview ............................................................................. 40

7. Disclaimer and Important Notice ....................................................................................................... 43

8. FCC Statement .... ............................................................................................................................. 44

Page 3

PICO-PI-IMX6UL HARDWARE MANUAL – VER 1.00 – FEB 24 2017

Page 3 of 44

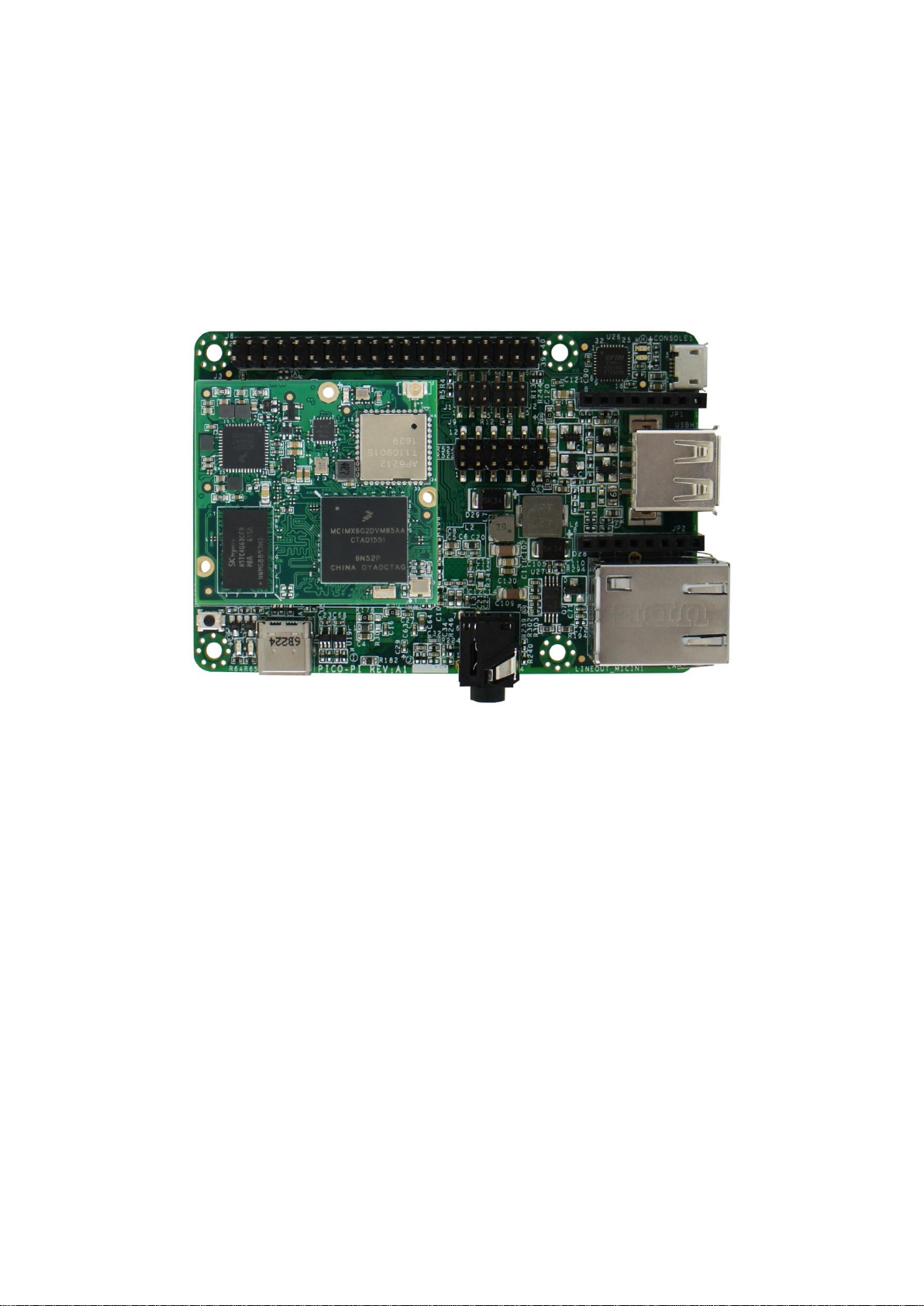

1. PICO-PI-IMX6UL Product Overview

The PICO-PI-IMX6UL is a 2 board developm ent board consisting of a System -on-Module and a

carrier baseboard and optim ized for the Internet-of-Things (IoT).

Product operating temperature 60 C.

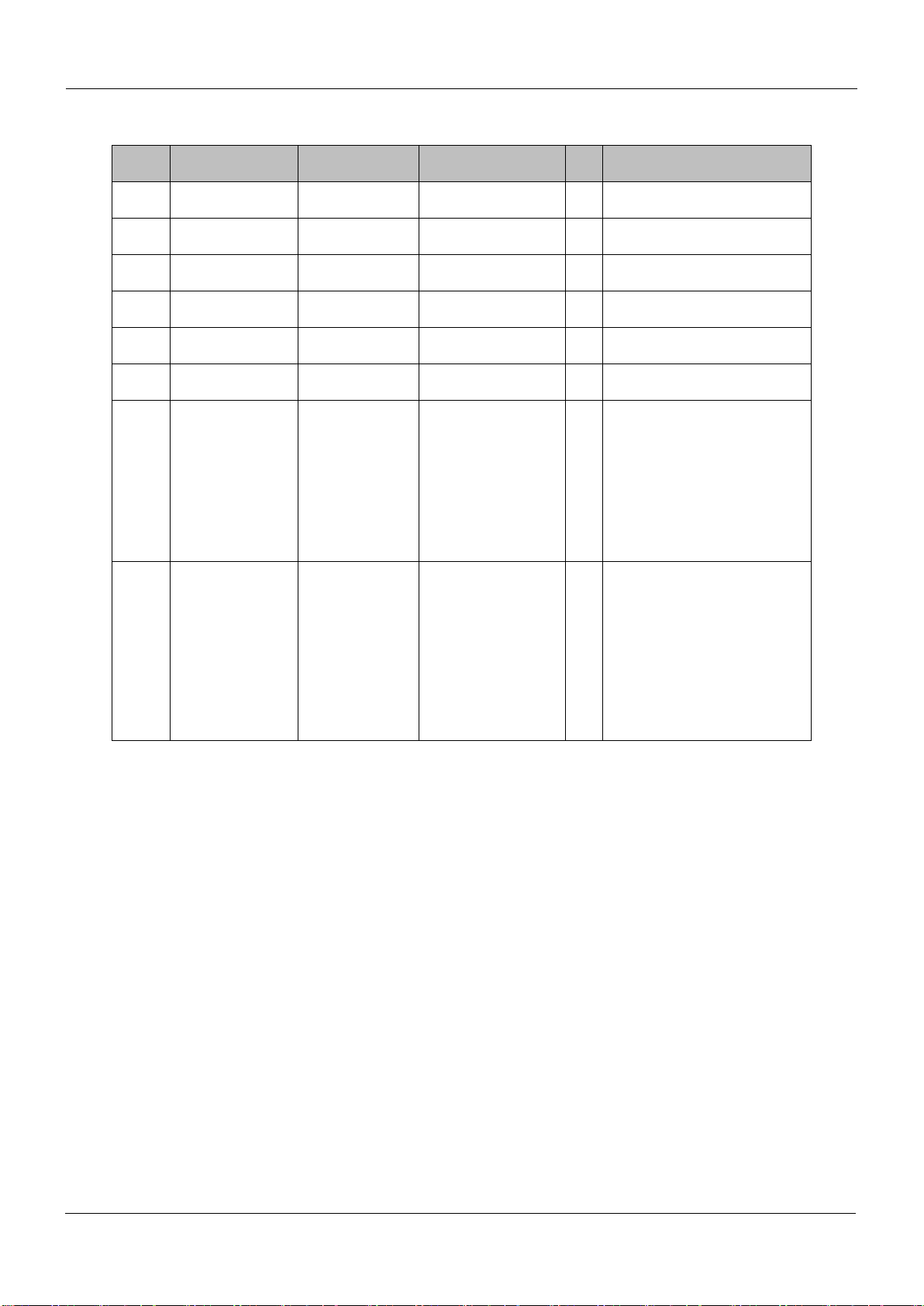

Figure 1 - PICO-PI-IM X6UL IC Identification and Overview

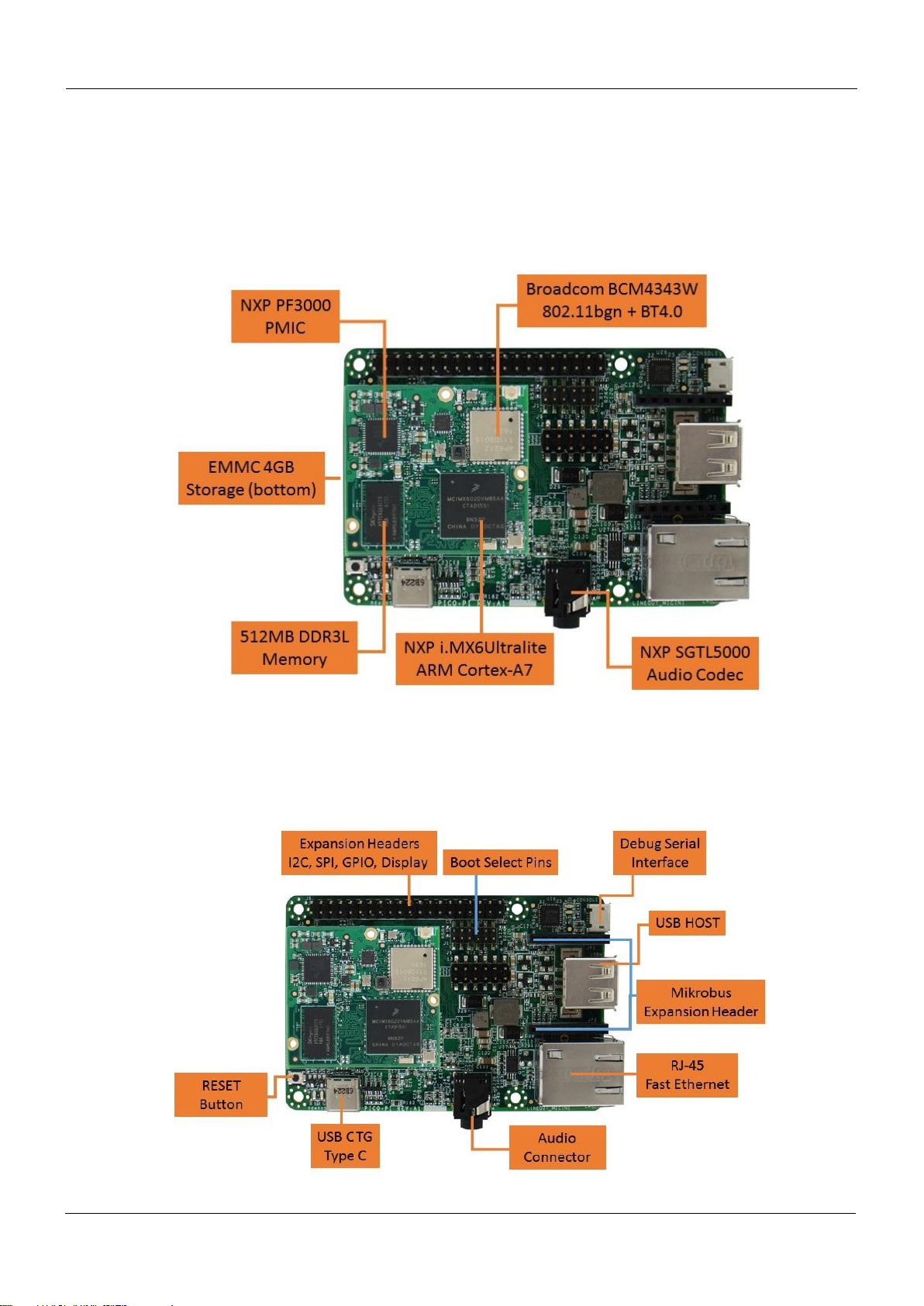

Figure 2 - PICO-PI-IMX6UL Connector Overview

Page 4

PICO-PI-IMX6UL HARDWARE MANUAL – VER 1.00 – FEB 24 2017

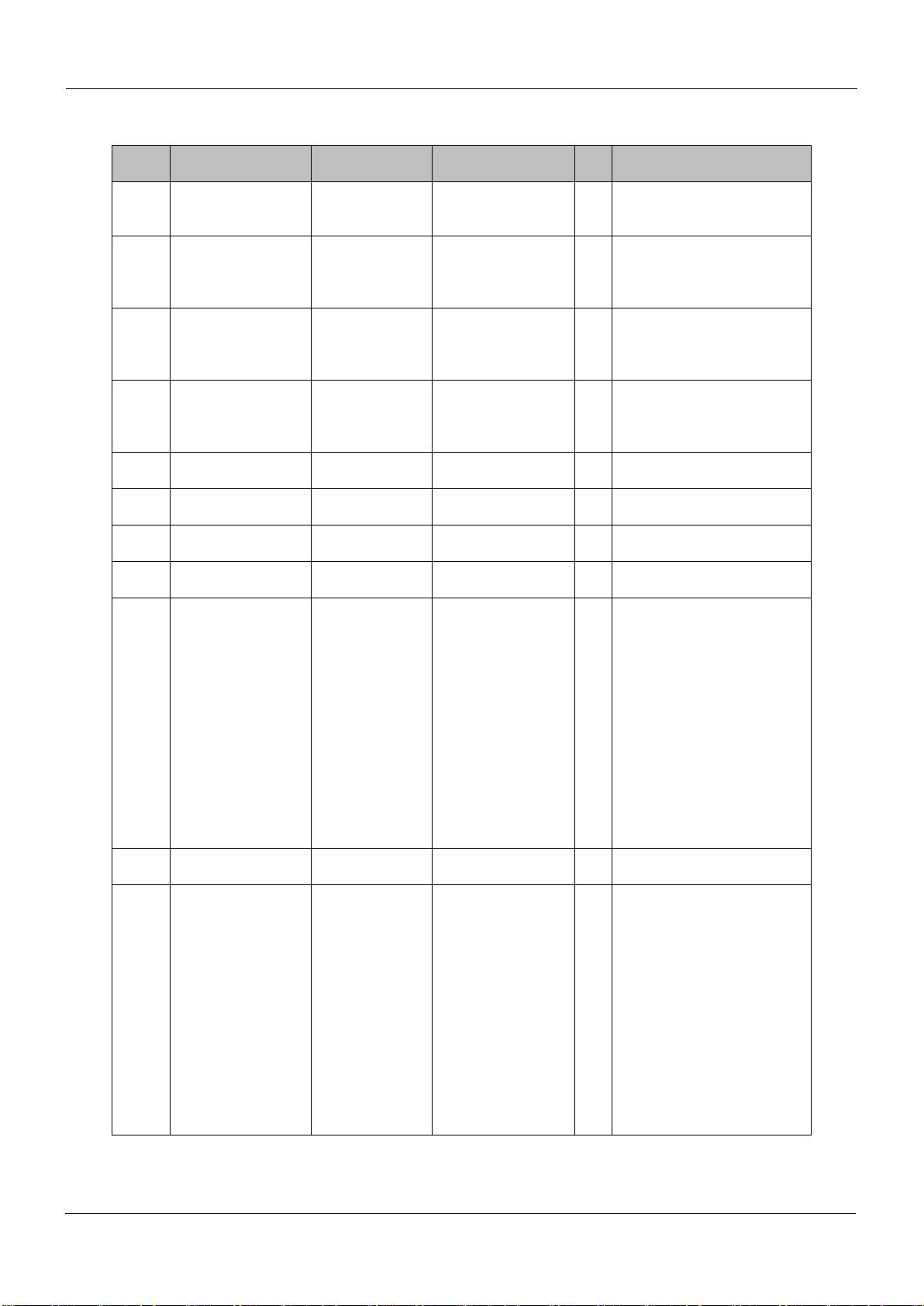

(PMIC) and WiFi / Bluetooth on the

module.

Figure 3 – PICO-PI-IMX6UL Bottom Side Connector Overview

1.1. PICO-IMX6 System-on-Module Overview

The PICO-IMX6 System-on-Module (PICO-IMX6UL-EMMC) has 3 Hirose high-speed 70 pin boardto-board connectors and integrates the NXP i.MX6Ultralite, Memory, eMMC, Power Management IC

Figure 4 - PICO-IMX6 System-on-Module

Page 4 of 44

Page 5

PICO-PI-IMX6UL HARDWARE MANUAL – VER 1.00 – FEB 24 2017

Page 5 of 44

Figure 5 - PICO-IM X6 System-on-M odule Signal Overview

1.2. PICO-PI-IMX6UL Carrier Baseboard Overview

The PICO-PI-IMX6UL Carrier Baseboard (PICO-PI-FL) has 3 Hirose high-speed 70 pin board-toboard connectors that connect to the System-on-Module and provides the real-world interfaces such

as audio, network, USB and a large number of signals on the various pin headers.

Figure 6 - PICO-PI-FL Carrier Board

Page 6

PICO-PI-IMX6UL HARDWARE MANUAL – VER 1.00 – FEB 24 2017

Page 6 of 44

2. Core Components

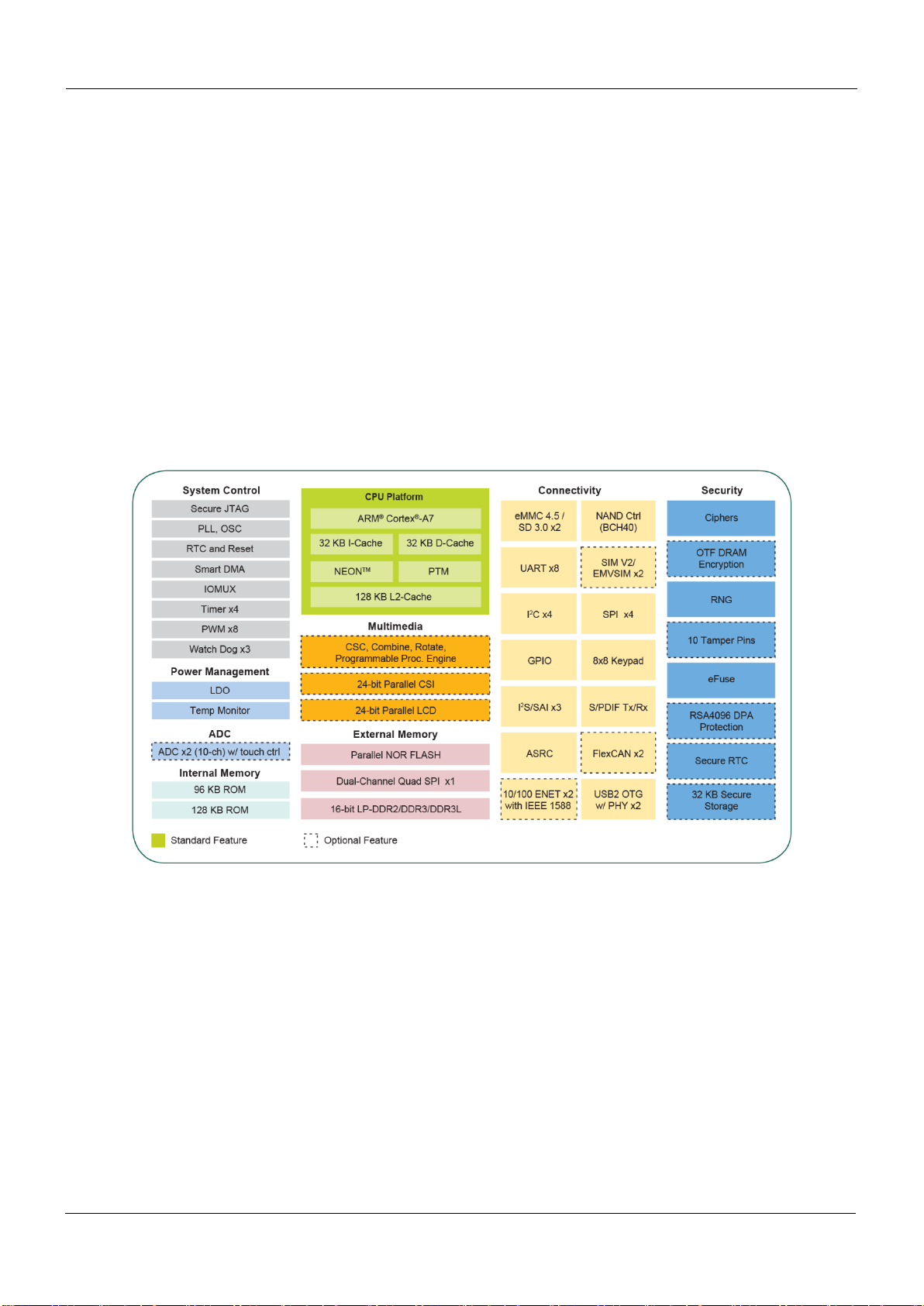

2.1. NXP i.MX6Ultralite Cortex-A7 Processor

The i.MX 6UltraLite is an ultra-efficient processor family with featuring Freescale’s advanced

implementation of the single ARM Cortex®-A7 core, which operates at speeds of up to 528 MHz.

The device is composed of the following major subsystems:

o Single-core ARM Cortex-A7 MPCore™ Platform

o 32 KBytes L1 Instruction Cache

o 32 KBytes L1 Data Cache

o Private Timer and Watchdog

o TrustZone support

o Cortex-A7 NEON MPE (Media Processing Engine) Co-processor

PXP—PiXel Processing Pipeline for imagine resize, rotation, overlay and CSC. Offloading key

pixel processing operations are required to support the LCD display applications.

Figure 7 - NXP i.MX6Ultralite Processor Blocks

Page 7

PICO-PI-IMX6UL HARDWARE MANUAL – VER 1.00 – FEB 24 2017

Page 7 of 44

2.2. NXP PF3000 Power Management IC (PMIC)

The PICO-IMX6 has on onboard NXP PF3000 power m anagem ent integrated circuit (PMIC) that

features a configurable architecture supporting the numerous outputs with various current ratings as

well as programm able voltage and sequencing required b y the com ponents on the PICO-IMX6Compute Module.

To perform a hard-reset of the PICO-IMX6 a software reset signal can be im plem ented.

CPU

BALL

CPU PAD

NAME

Pinmux (mode)

Signal

V

I/O

Description

E9

LCD_RESET

lcdif.RESET

(mode0)

RESET

3V3

I

Connected to the

PWRON signal of PMIC

The PICO-IMX6 Com pute Module as well has an RESET signal routed on connector E1_36 this

pin is connected to the RESET Button on the PICO-PI-IMX6UL. Simply pressing this button will

RESET the PICO-PI-IMX6.

Connector

Signal

V

I/O

Description

E1_36

RESET

3V3

I

Connected to the PWRON signal of PMIC on the PICO

Compute Module.

Connected to the RESET Button on the PICO-PIIMX6UL.

Figure 8 – PICO-PI-IMX6UL Reset Button Location

Page 8

PICO-PI-IMX6UL HARDWARE MANUAL – VER 1.00 – FEB 24 2017

Page 8 of 44

2.3. Memory (SKHynix)

The PICO-IMX6 integrates 512MB (4Gbit) Double Data Rate III (DDR3) S ynchronous DRAM in a

single (16 bit) channel configuration.

SK Hynix 4Gbit low power Double Data Rate III (DDR3L) Synchronous DRAM, ideally suited for the

main memory applications which requires large memory density, high bandwidth and low power

operation at 1.35V.

More information can be retrieved from SKHynix.

2.4. eMMC Storage (Kingston)

The PICO-IMX6 onboard 4GB eMMC device is connected on the SD1 pins of the i.MX6Ultralite

processor in an 8 bit width configuration.

Kingston e•MMC™ products follow the JEDEC e•MMC™ 4.5 standard. It is an ideal universal storage

solutions for many electronic devices, including smartphones, tablet PCs, PDAs, eBook readers,

digital cameras, recorders, MP3, MP4 players, electronic learning products, digital TVs and set-top

boxes. E•MMC™ encloses the MLC NAND and e•MMC™ controller inside as one JEDEC standard

package, providing a standard interface to the host. The e•MMC™ controller directly manages NAND

flash, including ECC, wear-leveling, IOPS optimization and read sensing.

The Kingston NAND Device is fully compatible with the JEDEC Standard Specification No.JESD84B45.

More information can be retrieved from Kingston.

Page 9

PICO-PI-IMX6UL HARDWARE MANUAL – VER 1.00 – FEB 24 2017

Page 9 of 44

2.5. Broadcom BCM4343W WiFi/Bluetooth SiP Module

The PICO-IMX6 com es with an onboard W iFI/Bluetooth SIP m odule. T he 802.11bgn + BT SiP

module is a small sized BGA mounted module that provides full function of 802.11bgn and Bluetooth

class 4.0 +HS

The small size & low profile physical design make it easier for system design to enable high

performance wireless connectivity without space constrain. The low power consumption and excellent

radio performance make it the best solution for OEM customers who require embedded Wi-Fi +

Bluetooth features.

The SIP module is based on Broadcom BCM4343W chipset which is a WiFi + BT SOC. The Radio

architecture & high integration MAC/BB chip provide excellent sensitivity with rich system

performance.

In addition to WEP 64/128, WPA and TKIP, AES, CCX is supported to provide the latest security

requirement on your network.

The SiP module is designed to operate with a single antenna for WiFi and Bluetooth to be connected

to the u.FL connector (separate purchase, SKU: “WBANTENNAKIT”)

Figure 9 - PICO-PI-IMX6UL WiFi / Bluetooth Module and Antenna Connector Location

Page 10

PICO-PI-IMX6UL HARDWARE MANUAL – VER 1.00 – FEB 24 2017

Page 10 of 44

Table 1 - WiFi Signal Description

CPU

BALL

PAD NAME

Pinmux

(mode)

Signal

I/O

Description

D7

NAND_DATA00

usdhc2.DATA0

(mode1)

SDIO_D0

I/O

MMC/SDIO Data bit 0

B7

NAND_DATA01

usdhc2.DATA1

(mode1)

SDIO_D1

I/O

MMC/SDIO Data bit 1

A7

NAND_DATA02

usdhc2.DATA2

(mode1)

SDIO_D2

I/O

MMC/SDIO Data bit 2

D6

NAND_DATA03

usdhc2.DATA3

(mode1)

SDIO_D3

I/O

MMC/SDIO Data bit 3

C8

NAND_WE_B

usdhc2.CMD

(mode1)

SDIO_CMD

I/O

MMC/SDIO Command

D8

NAND_RE_B

usdhc2.CLK

(mode1)

SDIO_CLK

I/O

MMC/SDIO Clock

C6

NAND_DATA04

gpio4.IO[6]

(mode5)

WL_HOST_WAKE

O

General purpose interface

pin. This pin is highimpedance on power up

and reset. Subsequently, it

becomes an input or output

through software control.

This pin has a

programmable weak pullup/down.

A6

NAND_DATA06

gpio4.IO[8]

(mode5)

WL_REG_ON

I

Used by PMU (OR-gated

with BT_REG_ON) to

power up or power down

internal BCM4339

regulators used by the

WLAN section. This pin is

also a low-asserting reset

for WLAN only

(Bluetooth is not affected

by this pin).

Page 11

PICO-PI-IMX6UL HARDWARE MANUAL – VER 1.00 – FEB 24 2017

Page 11 of 44

Table 2 - Bluetooth Signal Description

CPU

BALL

PAD NAME

Pinmux

(mode)

Signal

I/O

Description

M16

GPIO1_IO04

uart5.TX

(mode8)

BT_UART_RXD

I

Bluetooth UART Serial

Input. Serial data input for

the HCI UART Interface

M17

GPIO1_IO05

uart5.RX

(mode8)

BT_UART_TXD

O

Bluetooth UART Serial

Output. Serial data output

for the HCI UART

Interface.

M15

GPIO1_IO09

uart5.CTS_B

(mode8)

BT_UART_CTS

I/O

Bluetooth UART Clear to

Send. Active-low clear-tosend signal for the HCI

UART interface.

N17

GPIO1_IO08

uart5.RTS_B

(mode8)

BT_UART_RTS

I/O

Bluetooth UART Request

to Send. Active-low

request-to-send signal for

the HCI UART interface.

N14

JTAG_TRST_B

sai2.TX_DATA

(mode2)

BT_PCM_IN

I

PCM data input

M14

JTAG_TCK

sai2.RX_DATA

(mode2)

BT_PCM_OUT

O

PCM data output

N16

JTAG_TDI

sai2.TX_BCLK

(mode2)

BT_PCM_CLK

I/O

PCM clock

N15

JTAG_TDO

sai2.TX_SYNC

(mode2)

BT_PCB_SYNC

I/O

PCM sync signal

N9

SNVS_TAMPER8

gpio5.IO[8]

(mode5)

BT_WAKE

I

Bluetooth device wake-up:

Signal from the host to the

module indicating that the

host requires attention.

• Asserted: Bluetooth

device must wake-up or

remain awake.

• Deserted: Bluetooth

device may sleep when

sleep criteria are met.

The polarity of this signal

is software configurable

and can be asserted high

or low.

R6

SNVS_TAMPER9

gpio5.IO[9]

(mode5)

BT_RST_N

I

Low asserting reset for BT

core

B6

NAND_DATA05

gpio4.IO[7]

(mode5)

BT_HOST_WAKE

O

Host UART wake up.

Signal from the module to

the host indicating that the

module requires Attention.

• Asserted: Host device

must wake-up or remain

awake.

• Deserted: Host device

may sleep when sleep

criteria are met.

The polarity of this signal

is software configurable

and can be asserted high

or low.

Page 12

PICO-PI-IMX6UL HARDWARE MANUAL – VER 1.00 – FEB 24 2017

Page 12 of 44

3. PICO-PI-IMX6UL Interfaces and Connectors

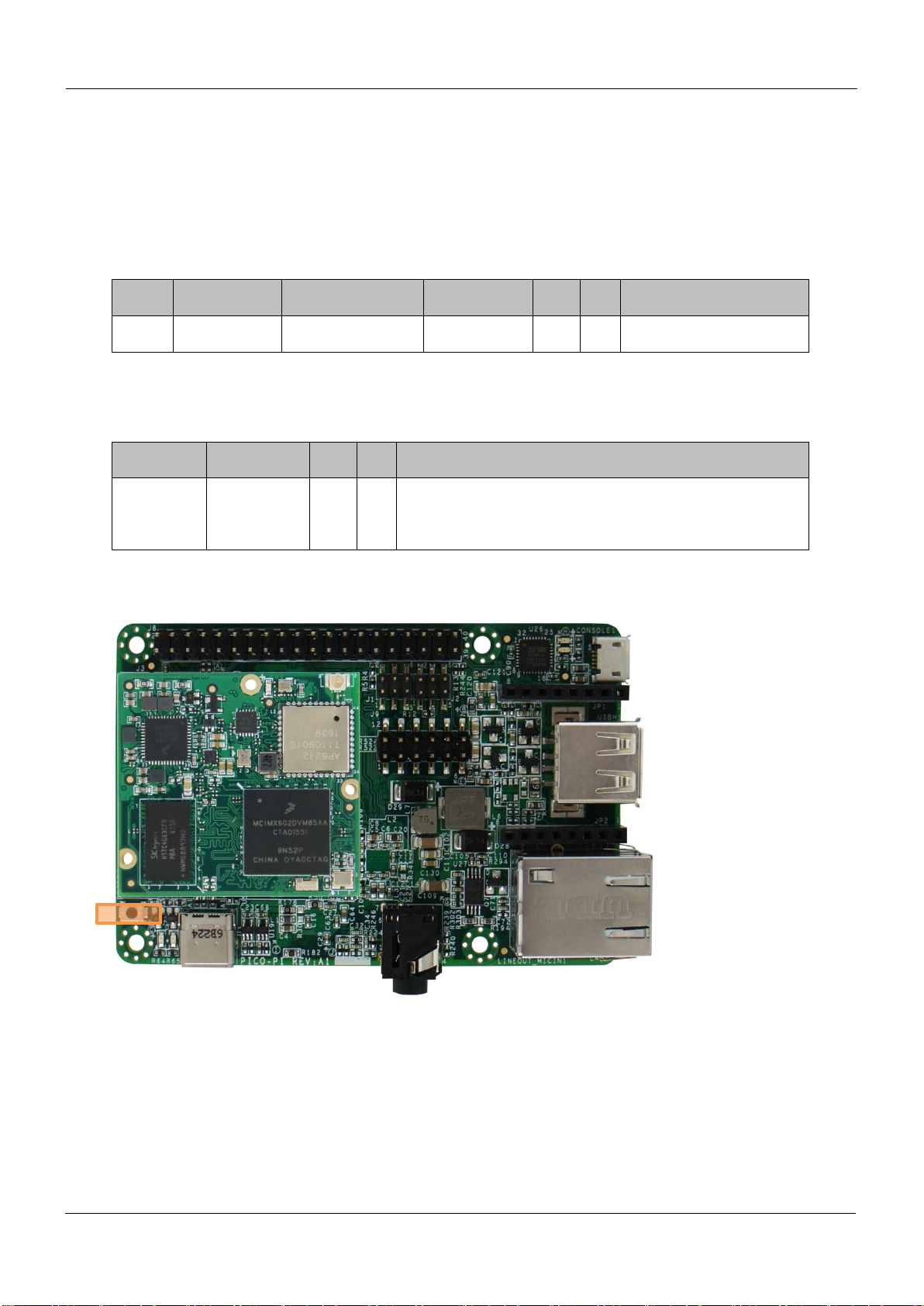

3.1. Power Input Connector

The PICO-PI-IMX6UL can be easil y powered over the USB T ype -C cable. Operating Voltage:5Vdc

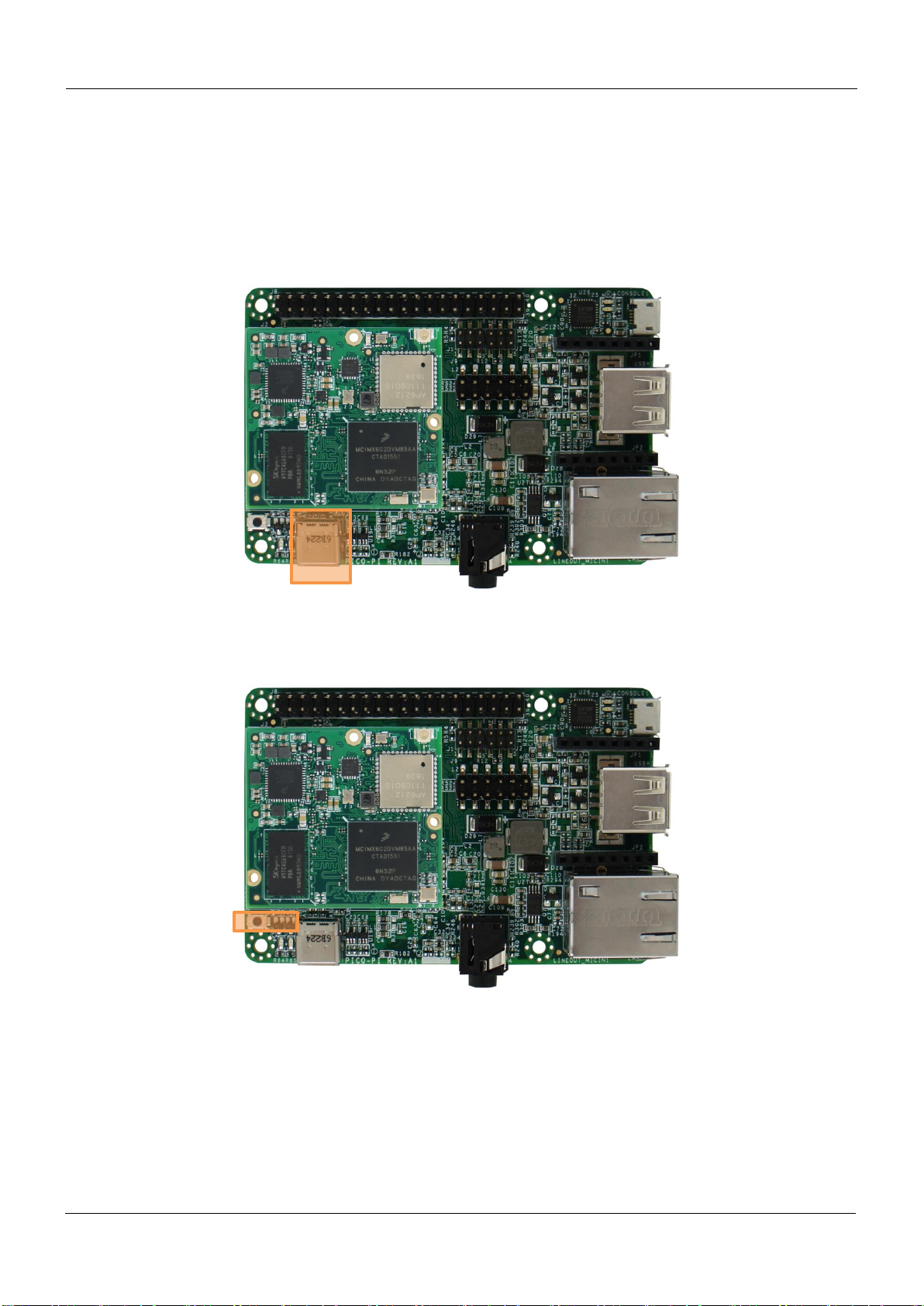

Figure 10 – PICO-PI-IMX6UL USB Type-C Location

3.2. System RESET Button

Figure 11 – PICO-PI-IMX6UL Reset Button Location

Page 13

PICO-PI-IMX6UL HARDWARE MANUAL – VER 1.00 – FEB 24 2017

Page 13 of 44

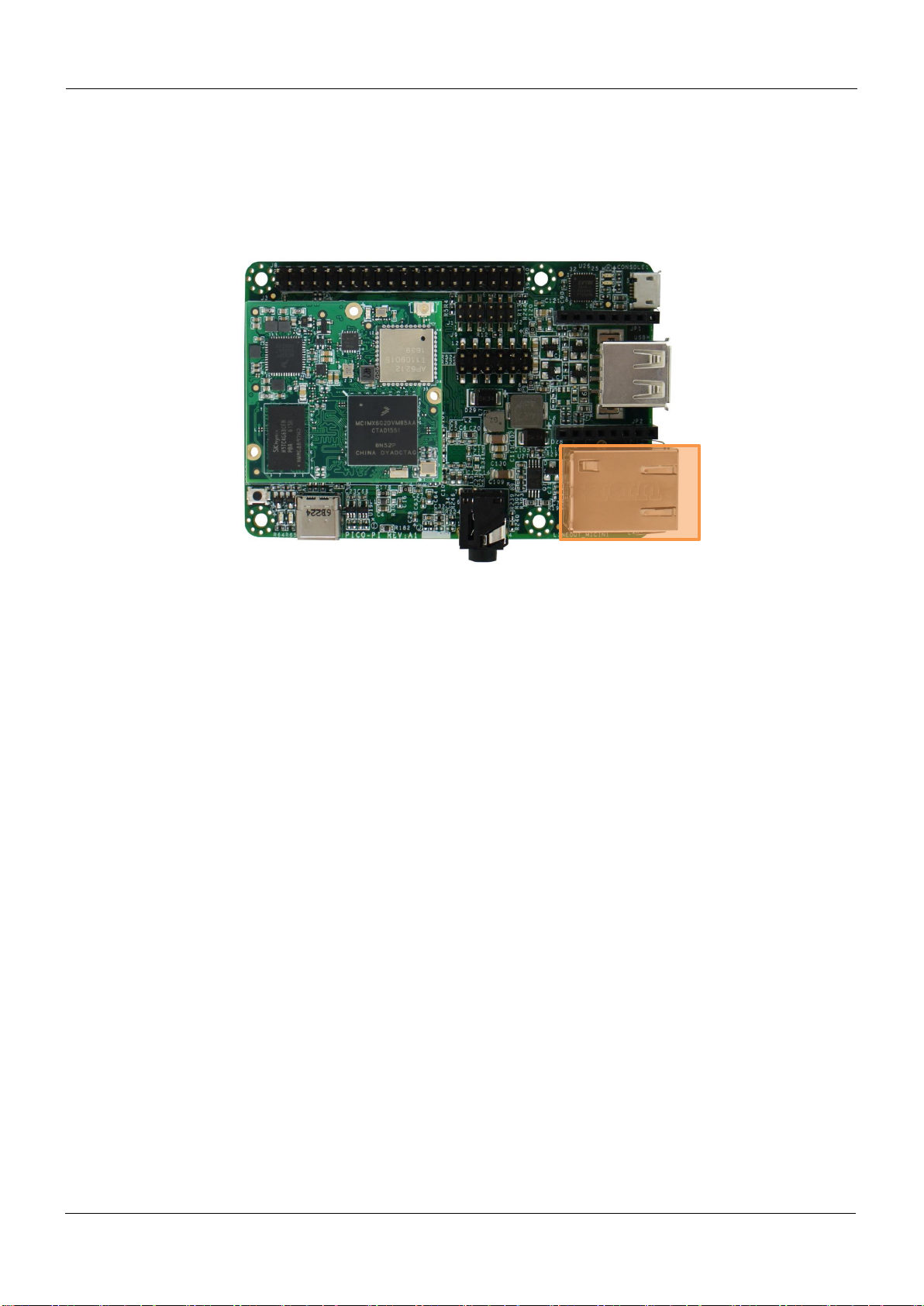

3.3. Fast Ethernet

The PICO-PI-IMX6UL features a 10/100 Mbit/s Fast Ethernet MAC compliant with the IEEE802.32002 standard. The MAC layer provides compatibility with half- or full-duplex 10/100 Mbit/s Ethernet

LANs.

Figure 12 - PICO-PI-IMX6UL RJ-45 Network Connector Location

Page 14

PICO-PI-IMX6UL HARDWARE MANUAL – VER 1.00 – FEB 24 2017

Page 14 of 44

3.4. Audio Interface

The PICO-PI-IMX6UL comes with an Audio jack which is compliant with the CTIA standard. A

standard mobile phone headset will work.

Figure 13 - PICO-PI-IMX6UL Audio Jack Location

Figure 14 - PICO-PI-IMX6UL Audio I2S Signal Location

Detail

Description

Since the PICO-PI-MX6UL only has a single I2S

channel.

Please select the jumpers as the picture.

Page 15

PICO-PI-IMX6UL HARDWARE MANUAL – VER 1.00 – FEB 24 2017

Page 15 of 44

3.5. Universal Serial Bus (USB) Host Interface

The PICO-PI-IMX6UL features a standard USB 2.0 Host Connector.

Figure 15 - PICO-PI-IMX6UL USB HOST Connector Location

3.6. Universal Serial Bus (USB) OTG Interface

The PICO-PI-IMX6UL incorporates a single USB Host/OTG controller which also function as the

system power input.

The signals are routed to a USB Type-C connector.

Figure 16- PICO-PI-IMX6UL USB OTG Type-C Connector Location

Page 16

PICO-PI-IMX6UL HARDWARE MANUAL – VER 1.00 – FEB 24 2017

Page 16 of 44

3.7. Debug Interface

The PICO-PI-IMX6UL serial debug interface can be easily connected with a micro-USB cable.

The debug interface can be found on the PICO-PI-IMX6UL at the following physical location and in

software can be accessed over UART6.

Figure 17 – PICO-PI-IMX6UL Serial Debug Location

Page 17

PICO-PI-IMX6UL HARDWARE MANUAL – VER 1.00 – FEB 24 2017

Page 17 of 44

3.8. Serial Boot or eMMC Boot Control Pins

The PICO-PI-IMX6UL has a number of pins to override the default boot media (eMMC) and enter in

Serial Boot Loader mode.

Figure 18 - PICO-PI-IMX6UL Boot Control Pins

Boot from eMMC

Serial Boot Loader

Page 18

PICO-PI-IMX6UL HARDWARE MANUAL – VER 1.00 – FEB 24 2017

Page 18 of 44

3.9. Expansion Header Pins

The PICO-PI-IMX6UL has a number of expansion headers that can be used to connect sensors,

motors, and external devices.

Figure 19 - PICO-PI-IMX6UL Mikrobus Header Location

PIN

i.MX6UL

CPU PAD NAME

Signal

V

I/O

Description

JP1_1

NC

Not Connected

JP1_2

PMIC

RESET

RESET

3V3

I

Reset power signal

JP1_3

NC

Not Connected

JP1_4

J16

UART2_RXD

ECSPI3_SCLK

3V3

O

Serial Peripheral

Interface clock signal

JP1_5

J15

UART2_RTS

ECSPI3_MISO

3V3

I

Serial Peripheral

Interface master input

slave output signal

JP1_6

H14

UART2_CTS

ECSPI3_MOSI

3V3

O

Serial Peripheral

Interface master output

slave input signal

JP1_7

3V3 Power

3V3

P

3V3 Power

JP1_8

GND

P Ground

PIN

i.MX6UL

CPU PAD NAME

Signal

V

I/O

Description

JP2_1

F14

ENET1_TX_CLK

PWM7_OUT

3V3

I/O

General Purpose Input

Output with PWM control

JP2_2

E4

CSI_DATA00

GPIO4_IO21

3V3

I/O

General Purpose Input

Output

JP2_3

H16

UART3_RXD

UART3_RX

3V3

I

Universal Asynchronous

Receive Transmit receive

data signal

JP2_4

H17

UART3_TXD

UART3_TXD

3V3

O

Universal Asynchronous

Receive Transmit

transmit data signal

JP2_5

F17

UART5_TXD

I2C2_SCL

3V3

I/O

I2C bus clock line

JP2_6

G13

UART5_RXD

I2C2_SDA

3V3

I/O

I2C bus data line

JP2_7

5V Power

5V

P

5V Power

JP2_8

GND

P Ground

Page 19

PICO-PI-IMX6UL HARDWARE MANUAL – VER 1.00 – FEB 24 2017

Page 19 of 44

Figure 20 - PICO-PI-IMX6UL Expansion Header Location

PIN

i.MX6UL

CPU PAD NAME

Signal

V

I/O

Description

JP8_1

3V3 Power

3V3

P

3V3 Power

JP8_2

5V Power

5V

P

5V Power

JP8_3

G13

UART5_RXD

I2C2_SDA

3V3

I/O

I2C bus data line

JP8_4

5V Power

5V

P

5V Power

JP8_5

F17

UART5_TXD

I2C2_SCL

3V3

I/O

I2C bus clock line

JP8_6

GND

P Ground

JP8_7

G14

UART3_RTS

UART3_RTS

3V3

O

Universal Asynchronous

Receive Transmit request

to send signal

JP8_8

H17

UART3_TXD

UART3_TXD

3V3

O

Universal Asynchronous

Receive Transmit

transmit data signal

JP8_9

GND

P Ground

JP8_10

H16

UART3_RXD

UART3_RXD

3V3

I

Universal Asynchronous

Receive Transmit receive

data signal

JP8_11

F14

ENET1_TX_CLK

PWM7_OUT

3V3

I/O

General Purpose Input

Output with PWM control

JP8_12

H15

UART3_CTS

UART3_CTS

3V3

O

Universal Asynchronous

Receive Transmit clear to

send signal

JP8_13

D15

ENET1_RX_ER

PWM8_OUT

3V3

I/O

General Purpose Input

Output with PWM control

JP8_14

GND

P Ground

JP8_15

NC

Not Connected

JP8_16

F16

ENET1_RXD0

CAN1_TX

3V3

I/O

CAN (controller Area

Network) transmit signal

JP8_17

3V3 Power

3V3

P

3V3 Power

JP8_18

E17

ENET1_RXD1

CAN1_RX

3V3

I/O

CAN (controller Area

Network) receive signal

JP8_19

H14

UART2_CTS

ECSPI3_MOSI

3V3

O

Serial Peripheral

Interface

master output slave input

signal

JP8_20

GND

P Ground

Page 20

PICO-PI-IMX6UL HARDWARE MANUAL – VER 1.00 – FEB 24 2017

Page 20 of 44

JP8_21

J15

UART2_RTS

ECSPI3_MISO

3V3

I

Serial Peripheral

Interface

master input slave output

signal

JP8_22

NC

Not Connected

JP8_23

J16

UART2_RXD

ECSPI3_SCLK

3V3

O

Serial Peripheral

Interface

clock signal

JP8_24

NC

Not Connected

JP8_25

GND

P Ground

JP8_26

J17

UART2_TXD

ECSPI3_SS0

3V3

I/O

Serial Peripheral

Interface

Chip Select 1 signal

JP8_27

K16

UART1_RXD

I2C3_SDA

3V3

I/O

I2C bus data line

JP8_28

K14

UART1_TXD

I2C3_SCL

3V3

I/O

I2C bus clock line

JP8_29

E4

CSI_DATA00

GPIO4_IO21

3V3

I/O

General Purpose Input

Output

JP8_30

GND

P Ground

JP8_31

E3

CSI_DATA01

GPIO4_IO22

3V3

I/O

General Purpose Input

Output

JP8_32

E1

CSI_DATA03

GPIO4_IO24

3V3

I/O

General Purpose Input

Output

JP8_33

E2

CSI_DATA02

GPIO4_IO23

3V3

I/O

General Purpose Input

Output

JP8_34

GND

P Ground

JP8_35

F2

CSI_VSYNC

GPIO4_IO19

3V3

I/O

General Purpose Input

Output

JP8_36

P11

SNVS_TAMPER2

GPIO5_IO02

3V3

I/O

General Purpose Input

Output

JP8_37

K15

UART1_CTS

GPIO4_IO18

3V3

I/O

General Purpose Input

Output

JP8_38

E16

ENET1_RX_EN

CAN2_TX

3V3

I/O

CAN (controller Area

Network) transmit signal

JP8_39

GND

P Ground

JP8_40

E15

ENET1_TXD0

CAN2_RX

3V3

I/O

CAN (controller Area

Network) receive signal

Page 21

PICO-PI-IMX6UL HARDWARE MANUAL – VER 1.00 – FEB 24 2017

Page 21 of 44

3.10. Display and Touch Connector

The PICO-PI-IMX6UL features a Touch and RGB TTL Display interface that can be connected directly

to a multi-touch 24-bit LCD panel.

The following LCD displays have been tested:

Manufacturer

Partnumber

Description

TechNexion

TDP0500T800480PCAP

5 INCH 800 x 480 PCAP MULTI TOUCH LCD

PANEL INCLUDING TOUCH CABLE

TechNexion

TDP0700T800480PCAP

7 INCH 800 x 480 PCAP MULTI TOUCH LCD

PANEL INCLUDING TOUCH CABLE

5 INCH

7 INCH

1 – 8 : ON

2 – 7 : OFF

3 – 6 : ON

4 – 5 : OFF

1 – 8 : ON

2 – 7 : ON

3 – 6 : ON

4 – 5 : OFF

Figure 21 - PICO-PI-IMX6UL LCD Display FPC Connector Location

Page 22

PICO-PI-IMX6UL HARDWARE MANUAL – VER 1.00 – FEB 24 2017

Page 22 of 44

PIN

i.MX6UL

CPU PAD NAME

Signal

V

I/O

Description

LCD1_1

VLED+

21V7

LED Backlight Voltage

LCD1_2

VLED+

21V7

LED Backlight Voltage

LCD1_3

VLED-

GND

P

Ground

LCD1_4

VLED-

GND

P

Ground

LCD1_5

GND

P Ground

LCD1_6

VCOM

4V09

Common Voltage

LCD1_7

DVDD

3V3

Power for Digital Circuit

LCD1_8

MODE

3V3

DE/SYNC mode select

LCD1_9

B8

LCD_ENABLE

LCDIF_ENABLE

3V3

O

LCD dot enable pin

signal

LCD1_10

C9

LCD_VSYNC

LCDIF_VSYNC

3V3

O

LCD Vertical

Synchronization

LCD1_11

D9

LCD_HSYNC

LCDIF_HSYNC

3V3

O

LCD Horizontal

Synchronization

LCD1_12

D11

LCD_DATA7

LCDIF_DATA7

3V3

O

LCD Pixel Data bit 7

LCD1_13

A10

LCD_DATA6

LCDIF_DATA6

3V3

O

LCD Pixel Data bit 6

LCD1_14

B10

LCD_DATA5

LCDIF_DATA5

3V3

O

LCD Pixel Data bit 5

LCD1_15

C10

LCD_DATA4

LCDIF_DATA4

3V3

O

LCD Pixel Data bit 4

LCD1_16

D10

LCD_DATA3

LCDIF_DATA3

3V3

O

LCD Pixel Data bit 3

LCD1_17

E10

LCD_DATA2

LCDIF_DATA2

3V3

O

LCD Pixel Data bit 2

LCD1_18

A9

LCD_DATA1

LCDIF_DATA1

3V3

O

LCD Pixel Data bit 1

LCD1_19

B9

LCD_DATA0

LCDIF_DATA0

3V3

O

LCD Pixel Data bit 0

LCD1_20

D13

LCD_DATA15

LCDIF_DATA15

3V3

O

LCD Pixel Data bit 15

LCD1_21

A12

LCD_DATA14

LCDIF_DATA14

3V3

O

LCD Pixel Data bit 14

LCD1_22

B12

LCD_DATA13

LCDIF_DATA13

3V3

O

LCD Pixel Data bit 13

LCD1_23

C12

LCD_DATA12

LCDIF_DATA12

3V3

O

LCD Pixel Data bit 12

LCD1_24

D12

LCD_DATA11

LCDIF_DATA11

3V3

O

LCD Pixel Data bit 11

LCD1_25

E12

LCD_DATA10

LCDIF_DATA10

3V3

O

LCD Pixel Data bit 10

LCD1_26

A11

LCD_DATA9

LCDIF_DATA9

3V3

O

LCD Pixel Data bit 9

LCD1_27

B11

LCD_DATA8

LCDIF_DATA8

3V3

O

LCD Pixel Data bit 8

LCD1_28

B16

LCD_DATA23

LCDIF_DATA23

3V3

O

LCD Pixel Data bit 23

LCD1_29

A14

LCD_DATA22

LCDIF_DATA22

3V3

O

LCD Pixel Data bit 22

LCD1_30

B14

LCD_DATA21

LCDIF_DATA21

3V3

O

LCD Pixel Data bit 21

LCD1_31

C14

LCD_DATA20

LCDIF_DATA20

3V3

O

LCD Pixel Data bit 20

LCD1_32

D14

LCD_DATA19

LCDIF_DATA19

3V3

O

LCD Pixel Data bit 19

LCD1_33

A13

LCD_DATA18

LCDIF_DATA18

3V3

O

LCD Pixel Data bit 18

LCD1_34

B13

LCD_DATA17

LCDIF_DATA17

3V3

O

LCD Pixel Data bit 17

LCD1_35

C13

LCD_DATA16

LCDIF_DATA16

3V3

O

LCD Pixel Data bit 16

LCD1_36

GND

P Ground

LCD1_37

A8

LCD_CLK

LCDIF_CLK

3V3

O

LCD Pixel Clock

LCD1_38

GND

P Ground

LCD1_39

L/R

3V3

I

Left / Right Selection

LCD1_40

U/D

3V3

I

Up / Down Selection

LCD1_41

VGH

16V0

P

Gate ON Voltage

LCD1_42

VGL

-6V0

P

Gate OFF Voltage

LCD1_43

AVDD

10V4

P

Power for Analog Circuit

LCD1_44

RESET

RESET

3V3

I

Reset power signal

LCD1_45

NC

Not Connected

LCD1_46

VCOM

3V3

I

Common voltage

LCD1_47

DITHB

3V3

I

Dithering function

LCD1_48

GND

P Ground

LCD1_49

NC

Not Connected

LCD1_50

NC

Not Connected

Page 23

PICO-PI-IMX6UL HARDWARE MANUAL – VER 1.00 – FEB 24 2017

Page 23 of 44

Figure 22 - PICO-PI-IMX6UL Touch Panel Connector Location

PIN

i.MX6UL

CPU PAD NAME

Signal

V

I/O

Description

TOUCH_1

L17

GPIO1_IO03

I2C1_SDA

3V3

I/O

I2C bus data line

TOUCH_2

L14

GPIO1_IO02

I2C1_SCL

3V3

I/O

I2C bus clock line

TOUCH_3

3V3 Power

3V3

P

3V3 Power

TOUCH_4

G16

UART4_RXD

GPIO4_IO29

3V3

I/O

General Purpose Input

Output

TOUCH_5

E1

CSI_DATA03

GPIO4_IO24

3V3

I/O

General Purpose Input

Output

TOUCH_6

GND

P Ground

Page 24

PICO-PI-IMX6UL HARDWARE MANUAL – VER 1.00 – FEB 24 2017

Page 24 of 44

4. Booting up the PICO-PI-IMX6UL

4.1.1. Overview

The boot mode for the PICO-PI-IMX6UL is controlled with jumpers on the baseboard. Normally, the

board is intended to boot from the on-board eMMC flash, but sometimes the board needs to be

booted from an external source. This can happen for example if the eMMC contains a faulty

bootloader. This document guides how the on-board eMMC flash of a PICO-PI-IMX6UL can be

flashed from a host PC.

4.1.2 i.MX6UL boot process details

When the boot jumpers are set to eMMC boot, the ROM code will attempt to boot from eMMC. If there

is no bootable software present, the board will revert to "serial download mode". The name "serial

download mode" is slighlty misleading, since the mode has grown past UART communication and

nowadays is a way to access the board over an USB OTG port, or in the case of PICO-PI-IMX6UL,

the USB type C port.

4.1.3 Changing PICO-PI-IMX6UL boot mode

To force the board into serial download mode using a PICO-PI-IMX6UL, change the boot mode

jumpers J1 to 1-2 and jumper J4 to 2-3, as pictured below.

With this jumper setting, the board will not even attempt to boot from eMMC, but always expect it to

be programmed over the USB type C connector.

To set the boot mode to eMMC, restore the jumpers J1 to 2-3 and jumper J4 to 1-2 (as pictured

below).

Page 25

PICO-PI-IMX6UL HARDWARE MANUAL – VER 1.00 – FEB 24 2017

Page 25 of 44

In this mode the board will attempt to boot from eMMC, but can in some circumstances revert to serial

download mode. This can happen for instance if the eMMC is not bootable. Note that "half-booting"

software, like a u-boot that does not initialize memory timings for correct operation, will be interpreted

as booting. More technically, if the ROM code finds the correct signature 1kB into the eMMC, it

considers the board bootable from eMMC. To verify your PICO-PI-IMX6UL is in serial download

mode, connect a USB cable between the host PC and the PICO-PI-IMX6UL. Power up the board. If a

USB device with name "Freescale Semiconductor in Recovery Mode" appears, the board is in serial

download mode.

Page 26

PICO-PI-IMX6UL HARDWARE MANUAL – VER 1.00 – FEB 24 2017

Page 26 of 44

4.1.4 Preparing a bootable software image

This section explains how software should be laid out inside the eMMC for a succesful boot. There

are also steps how to prepare software to be programmed into the PICO-PI-IMX6UL eMMC.

4.1.4.1 Procedure overview

The procedure recommended here for programming the board is:

1. Prepare a file containing a bit-by-bit copy of what should be in eMMC (an "image" file). The

layout of such files is described in sections 4.1.4.2 and 4.1.4.3.

2. Booting the board in serial download mode

3. Accessing the eMMC as a mass storage device (see chapters 4.2 and 4.3)

4. Copying the eMMC image file to the board

5. Booting the image

4.1.4.2 eMMC boot overview

This section describes how to use a Linux computer to prepare an image file of eMMC content. This

step can be omitted, but is useful for creating image files which are easily distributable (since it is a

all-in-one file).

A conventional Linux image consists of

u-boot bootloader

kernel

devicetree

root filesystem

and sometimes, an initial ramdisk

The usual set up is that the kernel, device tree and the optional RAM disk is placed in a FAT partition

as the first partition, and the OS filesystems occupies the remaining partitions. Linux systems usually

occupy just the second partition, and in case a swap partition, also the third partition, but other

operating systems can make use of more advanced partition schemes.

Convenient ways to prepare an image using a Linux computer is using a block device (like a USB

stick or an SD card) or a loopback device. It is also possible to access the eMMC as a mass storage

device and manually place the data in the right place. See section 4.3.x.

4.1.4.3 Preparing an OS image

This section describes how to prepare the eMMC contents so the system can boot. This is intended

for those wanting to prepare their own image, and not to use an image already provided by someone

else.

The device is assumed to be a block device (like USB stick or SD card), but can beneficially be the

eMMC itself (see chapter 4.2 and 4.3 on how to access the eMMC as a block device on a host PC).

Here the block device is denoted /dev/sdX; care must be taken that the right device is used.

First, partition your device. Leave the first 1MB (or so) unpartitioned so that the first partition starts

about 1MB into the device. The reason for this is that the u-boot bootloader needs to reside in

unpartitioned space in the beginning of the block device.

The first partition is usually a FAT partition containing the Linux kernel as a zImage and the device

tree blob (dtb) file. If an initial ramdisk is used, the initrd files can also reside in the FAT partition.

The second partition is usually the Linux root file system. Keep in mind when partitioning that the

eMMC is limited in size to approximately 4GB, and not let your image become too large to fit.

Page 27

PICO-PI-IMX6UL HARDWARE MANUAL – VER 1.00 – FEB 24 2017

Page 27 of 44

Then copy your bootloader (u-boot) 1kB into the image. On a Linux host, the following command can

be used. Remember to replace /dev/sdX with the appropriate device or image file.

# dd if=u-boot.imx of=/dev/sdX bs=1k seek=1 conv=notrunc oflag=dsync

Thereafter format the additional partitions, with the expected file systems, copy the files there.

4.1.4.4 Creating the image file from a block device

As a last step create the image file from your block device. This can be done using the following Linux

commands: First list the partitions in the block device:

# fdisk -lc /dev/sdX

The output looks something like:

Disk /dev/sdX: 3965 MB, 3965190144 bytes

122 heads, 62 sectors/track, 1023 cylinders

Units = cylinders of 7564 * 512 = 3872768 bytes

Sector size (logical/physical): 512 bytes / 512 bytes

I/O size (minimum/optimal): 512 bytes / 512 bytes

Disk identifier: 0x0005ffff

Device Boot Start End Blocks Id System

/dev/sdX1 2 4 8192+ 83 FAT12

/dev/sdX2 4 85 307200 83 Linux

/dev/sdX3 85 363 1048576 82 Linux swap

To extract the OS image from this issue the command

# dd if=/dev/sdX of=image.img bs=3872768 count=85

The blocksize (bs= parameter) is taken from the line "Units = cylinders of 7564 * 512 = 3872768

bytes" and the count parameter is the end of the last non-swap partition, /dev/sdX2.

Page 28

PICO-PI-IMX6UL HARDWARE MANUAL – VER 1.00 – FEB 24 2017

Page 28 of 44

4.2. Programming PICO-PI-IMX6UL using a Windows host

This section guides on how to use a Windows 7 computer to access the eMMC on a PICO-PIIMX6UL, and how to program an image file to the eMMC.

Tools needed:

sb_loader_imx6ul.exe (or similar)

a "bootbomb" file that can be dropped on the board, enabling it to be accessible as a USB

Mass Storage device

Windiskimager or similar tool that allows raw writing of block devices.

An eMMC image file to be programmed to the eMMC flash of the board.

And optionally, a serial terminal emulator program

For convenience, there is a downloadable tool package containing the three first items at:

http://www.wandboard.org/downloads/hobbit/hobbitboard_tools-20160322.zip

4.2.1. Preparing the setup

First attach a USB Type C peripheral cable to the board, and the other end to the host PC. Set the

boot jumpers to serial download mode, power up the board, and verify that a "SE Blank 6UL" device

appears (as below):

Next, download the tools package. Copy the folder inside the ZIP file to the Desktop.

Page 29

PICO-PI-IMX6UL HARDWARE MANUAL – VER 1.00 – FEB 24 2017

Page 29 of 44

4.2.2. Using sb_loader

Then start a command prompt by clicking on the start menu, and in the "Search programs and files"

box enter "cmd" (see below):

In the command line interface, navigate to the PICO-PI-IMX6UL tools package and the sb_loader

folder inside it by typing the following commands:

cd Desktop

cd hobbitboard_tools-20160322

cd windows

cd sb_loader

(see screenshot below)

Page 30

PICO-PI-IMX6UL HARDWARE MANUAL – VER 1.00 – FEB 24 2017

Page 30 of 44

Next run sb_loader to boot the image on the board. Issue the command:

sb_loader_imx6ul.exe -f ..\..\bootbomb-20160306.imx

The loader will push the image to the board, and a mass storage device will appear (in the example

below it gets the letter F:)

Page 31

PICO-PI-IMX6UL HARDWARE MANUAL – VER 1.00 – FEB 24 2017

Page 31 of 44

4.2.3. Using WinDiskImager to flash the eMMC

Start win32diskimager, and open the image file that is to be used. In the image below the file picoimx6ul-buildroot-2016030.img is used as an example.

NOTE: It is important that you use the mass storage device that appeared when using sb_loader,

using the wrong device might corrupt your hard drive!

After WinDiskImager finishes, power off the board, set the boot jumpers back to eMMC boot and

power up the board.

Page 32

PICO-PI-IMX6UL HARDWARE MANUAL – VER 1.00 – FEB 24 2017

Page 32 of 44

4.3. Programming PICO-PI-IMX6UL eMMC using a Linux host

This section describes how to program the eMMC using a Linux computer. The description below is

less verbose as the one for Windows systems.

Tools needed are:

imx_usb loader

a "bootbomb" file that can be dropped on the board, enabling it to be accessible as a USB

Mass Storage device

And, preferrably, an eMMC image file to be programmed to the eMMC flash of the board.

As above, the two first items are included in the tools package at:

http://www.wandboard.org/downloads/hobbit/hobbitboard_tools-20160322.zip

4.3.1. Using imx_usb tool and flashing the eMMC

Boot the board in serial download mode. Connect the USB type C cable to the board and the other

end to the host PC.

It is possible to use the command 'lsusb' to verify that the board really is in serial download mode. If

so, then there is a "Freescale Semiconductor" device present in the list:

Bus 002 Device 033: ID 15a2:007d Freescale Semiconductor, Inc.

Then drop the boot image on the board with the command

# ./imx_usb bootbomb.imx

After a few seconds a USB Mass Storage Device appears.

Now it is possilble to use commands like 'dd' to program the eMMC on the board, for instance copying

an operating system image file to the board can be done with:

# dd if=image.img of=/dev/sdX bs=1M oflag=dsync

where sdX is the mass storage device corresponding to the PICO-PI-IMX6UL EMMC.

After this, change the jumpers back to eMMC boot and reboot the board.

4.3.2. Copying files to eMMC without an image file

It is also possible to assemble an image directly in the eMMC of the PICO-PI-IMX6UL. To do so,

perform the steps in chapter 4.1.4.3 using the Mass Storage block device presented after running the

imx_usb tool.

Page 33

PICO-PI-IMX6UL HARDWARE MANUAL – VER 1.00 – FEB 24 2017

Page 33 of 44

5. PICO-IMX6 Compute M odule Pin Assignment

W ant to m ak e your own carrier baseboard and want t o use the PICO-IMX6 Com pute Module.

Here is the complete pinout.

PIN

CPU

BALL

CPU PAD NAME

Signal

V

I/O

Description

E1_1

GND

P Ground

E1_2

VSYS

P

System input power (4.0

to 5.25V)

E1_3

K13

GPIO1_IO00

USB_OTG1_PWR

3V3

I

USB OTG ID Pin

E1_4

VSYS

P

System input power (4.0

to 5.25V)

E1_5

GND

P Ground

E1_6

VSYS

P

System input power (4.0

to 5.25V)

E1_7

NC

Not Connected

E1_8

3V3 P

System 3.3V Output

E1_9

GND

P Ground

E1_10

3V3 P

System 3.3V Output

E1_11

GND

P Ground

E1_12

1V8 P

System 1.8V Output

(same as E1 connector

I/O voltage levels)

E1_13

GND

P Ground

E1_14

VSYS

P

System input power (4.0

to 5.25V)

E1_15

GND

P Ground

E1_16

U15

USB_OTG1_DP

USB_OTG_DP

USB

I/O

Universal Serial Bus

differential pair positive

signal

E1

X1

X2

Page 34

PICO-PI-IMX6UL HARDWARE MANUAL – VER 1.00 – FEB 24 2017

Page 34 of 44

PIN

CPU

BALL

CPU PAD NAME

Signal

V

I/O

Description

E1_17

R8

ONOFF

SRC_RESET_B

3V3

I

Power ON button input

signal

E1_18

T15

USB_OTG1_DN

USB_OTG1_DN

USB

I/O

Universal Serial Bus

differential pair negative

signal

E1_19

L15

GPIO1_IO01

GPIO1_IO01

1V8

I

Over current detect input

pin to monitor USB power

over current

E1_20

T12

USB_OTG1_VBUS

USB_OTG1_VBUS

5V

I/O

Universal Serial Bus

power

E1_21

K17

GPIO1_IO06

USB_OTG_

PWR_WAKE

USB

I

Universal Serial Bus

power enable

E1_22

E5

CSI_PIXCLK

UART6_RX

1V8

I

Universal Asynchronous

Receive Transmit receive

data signal

E1_23

NC

Not Connected

E1_24

F2

CSI_VSYNC

GPIO4_IO19

1V8

I/O

General Purpose Input

Output

E1_25

F3

CSI_HSYNC

GPIO4_IO20

1V8

I/O

General Purpose Input

Output

E1_26

E4

CSI_DATA00

GPIO4_IO21

1V8

I/O

General Purpose Input

Output

E1_27

F5

CSI_MCLK

UART6_TX

1V8

O

Universal Asynchronous

Receive Transmit transmit

data signal

E1_28

E3

CSI_DATA01

GPIO4_IO22

1V8

I/O

General Purpose Input

Output

E1_29

NC

Not Connected

E1_30

E2

CSI_DATA02

GPIO4_IO23

1V8

I/O

General Purpose Input

Output

E1_31

NC

Not Connected

E1_32

E1

CSI_DATA03

GPIO4_IO24

1V8

I/O

General Purpose Input

Output

E1_33

D15

ENET1_RX_ER

PWM8_OUT

1V8

I/O

General Purpose Input

Output with PWM control

E1_34

K15

UART1_CTS

GPIO4_IO18

1V8

I/O

General Purpose Input

Output

E1_35

F14

ENET1_TX_CLK

PWM7_OUT

1V8

I/O

General Purpose Input

Output with PWM control

E1_36

PMIC

RESET

RESET

1V8

I

Reset power signal

E1_37

NC

Not Connected

E1_38

NC

Not Connected

E1_39

NC

Not Connected

E1_40

NC

Not Connected

E1_41

F17

UART5_TXD

I2C2_SCL

1V8

I/O

I2C bus clock line

E1_42

G17

UART4_TXD

GPIO4_IO28

1V8

I/O

General Purpose Input

Output

E1_43

G13

UART5_RXD

I2C2_SDA

1V8

I/O

I2C bus data line

E1_44

G16

UART4_RXD

GPIO4_IO29

1V8

I/O

General Purpose Input

Output

E1_45

K14

UART1_TXD

I2C3_SCL

1V8

I/O

I2C bus clock line

Page 35

PICO-PI-IMX6UL HARDWARE MANUAL – VER 1.00 – FEB 24 2017

Page 35 of 44

PIN

CPU

BALL

CPU PAD NAME

Signal

V

I/O

Description

E1_46

H17

UART3_TXD

UART3_TXD

1V8

O

Universal Asynchronous

Receive Transmit transmit

data signal

E1_47

K16

UART1_RXD

I2C3_SDA

1V8

I/O

I2C bus data line

E1_48

P11

SNVS_TAMPER2

GPIO5_IO02

1V8

I/O

General Purpose Input

Output

E1_49

NC

Not Connected

E1_50

D2

CSI_DATA06

SAI1_RX_DATA

1V8

I

Integrated Interchip

Sound (I2S) channel

receive data line

E1_51

NC

Not Connected

E1_52

D3

CSI_DATA05

SAI1_TX_BCLK

1V8

O

Integrated Interchip

Sound (I2S) channel word

clock signal

E1_53

J17

UART2_TXD

ECSPI3_SS0

1V8

Serial Peripheral Interface

Chip Select 1 signal

E1_54

D4

CSI_DATA04

SAI1_TX_SYNC

1V8

O

Integrated Interchip

Sound (I2S) channel

frame synchronization

signal

E1_55

J16

UART2_RXD

ECSPI3_SCLK

1V8

O

Serial Peripheral Interface

clock signal

E1_56

D1

CSI_DATA07

SAI1_TX_DATA

1V8

O

Integrated Interchip

Sound (I2S) channel

transmit data line

E1_57

H14

UART2_CTS

ECSPI3_MOSI

1V8

O

Serial Peripheral Interface

master output slave input

signal

E1_58

NC

Not Connected

E1_59

J15

UART2_RTS

ECSPI3_MISO

1V8

I

Serial Peripheral Interface

master input slave output

signal

E1_60

NC

Not Connected

E1_61

H16

UART3_RXD

UART3_RX

1V8

I

Universal Asynchronous

Receive Transmit receive

data signal

E1_62

NC

Not Connected

E1_63

G14

UART3_RTS

UART3_RTS

1V8

O

Universal Asynchronous

Receive Transmit request

to send signal

E1_64

NC

Not Connected

E1_65

H15

UART3_CTS

UART3_CTS

1V8

O

Universal Asynchronous

Receive Transmit clear to

send signal

E1_66

NC

Not Connected

E1_67

NC

Not Connected

E1_68

NC

Not Connected

E1_69

NC

Not Connected

E1_70

NC

Not Connected

Page 36

PICO-PI-IMX6UL HARDWARE MANUAL – VER 1.00 – FEB 24 2017

Page 36 of 44

PIN

CPU

BALL

CPU PAD NAME

Signal

V

I/O

Description

X1_1

GND

P Ground

X1_2

GND

P Ground

X1_3

NC

Not Connected

X1_4

NC

Not Connected

X1_5

NC

Not Connected

X1_6

NC

Not Connected

X1_7

GND

P Ground

X1_8

B16

LCD_DATA23

LCDIF_DATA23

3V3

O

LCD Pixel Data bit 23

X1_9

NC

Not Connected

X1_10

A14

LCD_DATA22

LCDIF_DATA22

3V3

O

LCD Pixel Data bit 22

X1_11

NC

Not Connected

X1_12

B14

LCD_DATA21

LCDIF_DATA21

3V3

O

LCD Pixel Data bit 21

X1_13

GND

P Ground

X1_14

C14

LCD_DATA20

LCDIF_DATA20

3V3

O

LCD Pixel Data bit 20

X1_15

NC

Not Connected

X1_16

D14

LCD_DATA19

LCDIF_DATA19

3V3

O

LCD Pixel Data bit 19

X1_17

NC

Not Connected

X1_18

A13

LCD_DATA18

LCDIF_DATA18

3V3

O

LCD Pixel Data bit 18

X1_19

GND

P Ground

X1_20

B13

LCD_DATA17

LCDIF_DATA17

3V3

O

LCD Pixel Data bit 17

X1_21

NC

Not Connected

X1_22

C13

LCD_DATA16

LCDIF_DATA16

3V3

O

LCD Pixel Data bit 16

X1_23

NC

Not Connected

X1_24

D13

LCD_DATA15

LCDIF_DATA15

3V3

O

LCD Pixel Data bit 15

X1_25

GND

P Ground

X1_26

A12

LCD_DATA14

LCDIF_DATA14

3V3

O

LCD Pixel Data bit 14

X1_27

NC

Not Connected

X1_28

B12

LCD_DATA13

LCDIF_DATA13

3V3

O

LCD Pixel Data bit 13

X1_29

NC

Not Connected

X1_30

C12

LCD_DATA12

LCDIF_DATA12

3V3

O

LCD Pixel Data bit 12

X1_31

GND

P Ground

X1_32

D12

LCD_DATA11

LCDIF_DATA11

3V3

O

LCD Pixel Data bit 11

X1_33

F15

ENET1_TXEN

ENET2_MDIC

3V3

Management data clock

reference

X1_34

E12

LCD_DATA10

LCDIF_DATA10

3V3

O

LCD Pixel Data bit 10

X1_35

E14

ENET1_TXD1

ENET2_MDIO

3V3

Management data

X1_36

A11

LCD_DATA9

LCDIF_DATA9

3V3

O

LCD Pixel Data bit 9

X1_37

D16

ENET2_RXER

GPIO2_IO15

3V3

Ethernet reset

X1_38

B11

LCD_DATA8

LCDIF_DATA8

3V3

O

LCD Pixel Data bit 8

X1_39

N11

SNVS_TAMPER6

GPIO5_IO06

3V3

Ethernet interrupt output

X1_40

D11

LCD_DATA7

LCDIF_DATA7

3V3

O

LCD Pixel Data bit 7

X1_41

L16

GPIO1_IO07

ANATOP_ENET_

REF_CLK2

3V3

Synchronous Ethernet

recovered clock

X1_42

A10

LCD_DATA6

LCDIF_DATA6

3V3

O

LCD Pixel Data bit 6

X1_43

B15

ENET2_TXEN

ENET2_TX_EN

3V3

RMII transmit enable

X1_44

B10

LCD_DATA5

LCDIF_DATA5

3V3

O

LCD Pixel Data bit 5

X1_45

B17

ENET2_CRS_DV

ENET2_RX_EN

3V3

RMII receive data valid

X1_46

C10

LCD_DATA4

LCDIF_DATA4

3V3

O

LCD Pixel Data bit 4

Page 37

PICO-PI-IMX6UL HARDWARE MANUAL – VER 1.00 – FEB 24 2017

Page 37 of 44

PIN

CPU

BALL

CPU PAD NAME

Signal

V

I/O

Description

X1_47

GND

P Ground

X1_48

D10

LCD_DATA3

LCDIF_DATA3

3V3

O

LCD Pixel Data bit 3

X1_49

D17

ENET2_TXCLK

ENET2_TX_CLK

3V3

O

RMII transmit clock

X1_50

E10

LCD_DATA2

LCDIF_DATA2

3V3

O

LCD Pixel Data bit 2

X1_51

A15

ENET2_TXD0

ENET2_TX_DATA0

3V3

O

RMII transmit data 0

X1_52

A9

LCD_DATA1

LCDIF_DATA1

3V3

O

LCD Pixel Data bit 1

X1_53

A16

ENET2_TXD1

ENET2_TX_DATA1

3V3

O

RMII transmit data 1

X1_54

B9

LCD_DATA0

LCDIF_DATA0

3V3

O

LCD Pixel Data bit 0

X1_55

NC

Not Connected

X1_56

N8

SNVS_TAMPER5

GPIO5_IO05

3V3

O

LCD backlight

enable/disable

X1_57

NC

Not Connected

X1_58

D9

LCD_HSYNC

LCDIF_HSYNC

3V3

O

LCD Horizontal

Synchronization

X1_59

GND

P Ground

X1_60

B8

LCD_ENABLE

LCDIF_ENABLE

3V3

O

LCD dot enable pin

signal

X1_61

NC

Not Connected

X1_62

C9

LCD_VSYNC

LCDIF_VSYNC

3V3

O

LCD Vertical

Synchronization

X1_63

C17

ENET2_RXD0

ENET2_RX_DATA0

3V3

I

RMII receive data 0

X1_64

A8

LCD_CLK

LCDIF_CLK

3V3

O

LCD Pixel Clock

X1_65

C16

ENET2_RXD1

ENET2_RX_DATA1

3V3

I

RMII receive data 1

X1_66

B4

NAND_ALE

PWM3_OUT

3V3

O

LCD Backlight brightness

Control

X1_67

NC

Not Connected

X1_68

P14

JTAG_TMS

GPIO1_IO11

3V3

O

LCD Voltage On

X1_69

NC

Not Connected

X1_70

GND

P Ground

Page 38

PICO-PI-IMX6UL HARDWARE MANUAL – VER 1.00 – FEB 24 2017

Page 38 of 44

PIN

CPU

BALL

CPU PAD NAME

Signal

V

I/O

Description

X2_1

GND

P Ground

X2_2

GND

P Ground

X2_3

T10

BOOT_MODE0

BOOT_MODE0

1V8

I

Boot Select pin

X2_4

NC

Not Connected

X2_5

U10

BOOT_MODE1

BOOT_MODE1

1V8

I

Boot Select pin

X2_6

NC

Not Connected

X2_7

B12

LCD_DATA13

BT_CFG13

1V8

I

Boot Select pin

X2_8

GND

P Ground

X2_9

A12

LCD_DATA14

BT_CFG14

1V8

I

Boot Select pin

X2_10

NC

Not Connected

X2_11

GND

P Ground

X2_12

NC

Not Connected

X2_13

L14

GPIO1_IO02

I2C1_SCL

3V3

I/O

I2C bus clock line

X2_14

GND

P Ground

X2_15

L17

GPIO1_IO03

I2C1_SDA

3V3

I/O

I2C bus data line

X2_16

NC

Not Connected

X2_17

GND

P Ground

X2_18

NC

Not Connected

X2_19

F16

ENET1_RXD0

CAN1_TX

3V3

I/O

CAN (controller Area

Network) transmit signal

X2_20

GND

P Ground

X2_21

E17

ENET1_RXD1

CAN1_RX

3V3

I/O

CAN (controller Area

Network) receive signal

X2_22

NC

Not Connected

X2_23

GND

P Ground

X2_24

NC

Not Connected

X2_25

E16

ENET1_RX_EN

CAN2_TX

3V3

I/O

CAN (controller Area

Network) transmit signal

X2_26

GND

P Ground

X2_27

E15

ENET1_TXD0

CAN2_RX

3V3

I/O

CAN (controller Area

Network) receive signal

X2_28

NC

Not Connected

X2_29

GND

P Ground

X2_30

NC

Not Connected

X2_31

NC

Not Connected

X2_32

GND

P Ground

X2_33

NC

Not Connected

X2_34

NC

Not Connected

X2_35

NC

Not Connected

X2_36

NC

Not Connected

X2_37

NC

Not Connected

X2_38

GND

P Ground

X2_39

NC

Not Connected

X2_40

NC

Not Connected

X2_41

NC

Not Connected

X2_42

NC

Not Connected

X2_43

NC

Not Connected

X2_44

GND

P Ground

X2_45

NC

Not Connected

Page 39

PICO-PI-IMX6UL HARDWARE MANUAL – VER 1.00 – FEB 24 2017

Page 39 of 44

PIN

CPU

BALL

CPU PAD NAME

Signal

V

I/O

Description

X2_46

T13

USB_OTG2_DN

USB_OTG2_DN

3V3

I/O

Universal Serial Bus

differential pair negative

signal

X2_47

NC

Not Connected

X2_48

U13

USB_OTG2_DP

USB_OTG2_DP

3V3

I/O

Universal Serial Bus

differential pair positive

signal

X2_49

NC

Not Connected

X2_50

U12

USB_OTG2_VBUS

USB_OTG2_VBUS

5V

I/O

Universal Serial Bus

power

X2_51

GND

P Ground

X2_52

R10

SNVS_TAMPER0

GPIO5_IO00

3V3

I

Active low input, to inform

USB overcurrent condition

(low = overcurrent

detected)

X2_53

NC

Not Connected

X2_54

GND

P Ground

X2_55

NC

Not Connected

X2_56

NC

Not Connected

X2_57

NC

Not Connected

X2_58

NC

Not Connected

X2_59

NC

Not Connected

X2_60

GND

P Ground

X2_61

NC

Not Connected

X2_62

NC

Not Connected

X2_63

NC

Not Connected

X2_64

NC

Not Connected

X2_65

NC

Not Connected

X2_66

GND

P Ground

X2_67

NC

Not Connected

X2_68

NC

Not Connected

X2_69

NC

Not Connected

X2_70

NC

Not Connected

Page 40

PICO-PI-IMX6UL HARDWARE MANUAL – VER 1.00 – FEB 24 2017

Page 40 of 44

6. PICO-IMX6 Compute M odule Pinmux Overview

Man y signals on the PICO-IMX6 can be configured to support other interfaces. The table below

gives an overview of all pins that can be modified.

The default operation mode which is compatible with other PICO Compute Modules has been

highlighted.

PIN

CPU BALL

PADNAME

MODE0

MODE1

MODE2

MODE3

MODE4

MODE5

MODE6

MODE8

E1_3

K13

GPIO1_IO00

i2c2.SCL

gpt1.CAPTU

RE1

usb.OTG1_P

WR

anatop.ENET

_REF_CLK1

mqs.RIGHT

gpio1.IO[0]

enet1.1588_

EVENT0_IN

wdog3.WDO

G_B

E1_17

R8

ONOFF

src.RESET_

B

E1_19

L15

GPIO1_IO01

i2c2.SDA

gpt1.COMPA

RE1

usb.OTG1_O

C

anatop.ENET

_REF_CLK2

mqs.LEFT

gpio1.IO[1]

enet1.1588_

EVENT0_OU

T

wdog2.WDO

G_B

E1_21

K17

GPIO1_IO06

enet1.MDIO

anatop.ENET

_REF_CLK1

usb.OTG_P

WR_WAKE

csi.MCLK

usdhc2.WP

gpio1.IO[6]

enet2.1588_

EVENT1_IN

uart1.CTS_B

E1_22

E5

CSI_PIXCLK

csi.PIXCLK

usdhc2.WP

rawnand.CE

3_B

i2c1.SCL

weim.OE

gpio4.IO[18]

enet1.MDC

uart6.RX

E1_24

F2

CSI_VSYNC

csi.VSYNC

usdhc2.CLK

sim1.PORT1

_CLK

i2c2.SDA

weim.RW

gpio4.IO[19]

enet2.MDIO

uart6.RTS_B

E1_25

F3

CSI_HSYNC

csi.HSYNC

usdhc2.CMD

sim1.PORT1

_PD

i2c2.SCL

weim.LBA_B

gpio4.IO[20]

enet2.MDC

uart6.CTS_B

E1_26

E4

CSI_DATA00

csi.DATA[2]

usdhc2.DAT

A0

sim1.PORT1

_RST_B

ecspi2.SCLK

weim.AD[0]

gpio4.IO[21]

wdog3.WDO

G_B

uart5.TX

E1_27

F5

CSI_MCLK

csi.MCLK

usdhc2.CD_

B

rawnand.CE

2_B

i2c1.SDA

weim.CS0_B

gpio4.IO[17]

enet1.MDIO

uart6.TX

E1_28

E3

CSI_DATA01

csi.DATA[3]

usdhc2.DAT

A1

sim1.PORT1

_SVEN

ecspi2.SS0

weim.AD[1]

gpio4.IO[22]

sai1.MCLK

uart5.RX

E1_30

E2

CSI_DATA02

csi.DATA[4]

usdhc2.DAT

A2

sim1.PORT1

_TRXD

ecspi2.MOSI

weim.AD[2]

gpio4.IO[23]

sai1.RX_SY

NC

uart5.RTS_B

E1_32

E1

CSI_DATA03

csi.DATA[5]

usdhc2.DAT

A3

sim2.PORT1

_PD

ecspi2.MISO

weim.AD[3]

gpio4.IO[24]

sai1.RX_BCL

K

uart5.CTS_B

E1_33

D15

ENET1_RXE

R

enet1.RX_E

R

uart7.RTS_B

pwm8.OUT

csi.DATA[23]

weim.CRE

gpio2.IO[7]

global wdog

E1_34

K15

UART1_CTS

uart1.CTS_B

enet1.RX_CL

K

usdhc1.WP

csi.DATA[4]

kpp.ROW[1]

gpio1.IO[18]

src.INT_BOO

T

usdhc2.WP

E1_35

F14

ENET1_TXC

LK

enet1.TX_CL

K

uart7.CTS_B

pwm7.OUT

csi.DATA[22]

anatop.ENET

_REF_CLK2

gpio2.IO[6]

gpt1.CLK

E1_41

F17

UART5_TXD

uart5.TX

enet2.CRS

i2c2.SCL

csi.DATA[14]

kpp.ROW[7]

gpio1.IO[30]

csu.CSU_AL

ARM_AUT[0]

ecspi2.MOSI

E1_42

G17

UART4_TXD

uart4.TX

enet2.TDAT

A[2]

i2c1.SCL

csi.DATA[12]

kpp.ROW[6]

gpio1.IO[28]

csu.CSU_AL

ARM_AUT[2]

ecspi2.SCLK

E1_43

G13

UART5_RXD

uart5.RX

enet2.COL

i2c2.SDA

csi.DATA[15]

kpp.COL[7]

gpio1.IO[31]

csu.CSU_IN

T_DEB

ecspi2.MISO

E1_44

G16

UART4_RXD

uart4.RX

enet2.TDAT

A[3]

i2c1.SDA

csi.DATA[13]

kpp.COL[6]

gpio1.IO[29]

csu.CSU_AL

ARM_AUT[1]

ecspi2.SS0

E1_45

K14

UART1_TXD

uart1.TX

enet1.RDAT

A[2]

i2c3.SCL

csi.DATA[2]

kpp.ROW[0]

gpio1.IO[16]

snvs_hp_wra

pper.VIO_5_

CTL

spdif.OUT

E1_46

H17

UART3_TXD

uart3.TX

enet2.RDAT

A[2]

uart2.RTS_B

csi.DATA[1]

kpp.ROW[4]

gpio1.IO[24]

gpt1.COMPA

RE3

anatop.OTG

1_ID

E1_47

K16

UART1_RXD

uart1.RX

enet1.RDAT

A[3]

i2c3.SDA

csi.DATA[3]

kpp.COL[0]

gpio1.IO[17]

snvs_hp_wra

pper.VIO_5

spdif.IN

E1_48

P11

SNVS_TAM

PER2

snvs_lp_wra

pper.TAMPE

R[2]

gpio5.IO[2]

E1_50

D2

CSI_DATA06

csi.DATA[8]

usdhc2.DAT

A6

sim2.PORT1

_SVEN

ecspi1.MOSI

weim.AD[6]

gpio4.IO[27]

sai1.RX_DA

TA

usdhc1.RES

ET_B

E1_52

D3

CSI_DATA05

csi.DATA[7]

usdhc2.DAT

A5

sim2.PORT1

_RST_B

ecspi1.SS0

weim.AD[5]

gpio4.IO[26]

sai1.TX_BCL

K

usdhc1.CD_

B

E1_53

J17

UART2_TXD

uart2.TX

enet1.TDAT

A[2]

i2c4.SCL

csi.DATA[6]

kpp.ROW[2]

gpio1.IO[20]

gpt1.CAPTU

RE2

ecspi3.SS0

E1_54

D4

CSI_DATA04

csi.DATA[6]

usdhc2.DAT

A4

sim2.PORT1

_CLK

ecspi1.SCLK

weim.AD[4]

gpio4.IO[25]

sai1.TX_SYN

C

usdhc1.WP

E1_55

J16

UART2_RXD

uart2.RX

enet1.TDAT

A[3]

i2c4.SDA

csi.DATA[7]

kpp.COL[2]

gpio1.IO[21]

gpt1.COMPA

RE1

ecspi3.SCLK

E1_56

D1

CSI_DATA07

csi.DATA[9]

usdhc2.DAT

A7

sim2.PORT1

_TRXD

ecspi1.MISO

weim.AD[7]

gpio4.IO[28]

sai1.TX_DAT

A

usdhc1.VSE

LECT

E1_57

H14

UART2_CTS

uart2.CTS_B

enet1.CRS

can2.RX

csi.DATA[8]

kpp.ROW[3]

gpio1.IO[22]

gpt1.CLK

ecspi3.MOSI

E1_59

J15

UART2_RTS

uart2.RTS_B

enet1.COL

can2.TX

csi.DATA[9]

kpp.COL[3]

gpio1.IO[23]

gpt1.COMPA

RE2

ecspi3.MISO

E1_61

H16

UART3_RXD

uart3.RX

enet2.RDAT

A[3]

uart2.CTS_B

csi.DATA[0]

kpp.COL[4]

gpio1.IO[25]

caam_wrapp

er.RNG_OS

C_OBS

epit1.OUT

E1_63

G14

UART3_CTS

uart3.CTS_B

enet2.RX_CL

K

can1.RX

csi.DATA[10]

kpp.ROW[5]

gpio1.IO[26]

ccm.WAIT

epit2.OUT

E1_65

H15

UART3_RTS

uart3.RTS_B

enet2.TX_ER

can1.TX

csi.DATA[11]

kpp.COL[5]

gpio1.IO[27]

ccm.STOP

wdog1.WDO

G_B

Page 41

PICO-PI-IMX6UL HARDWARE MANUAL – VER 1.00 – FEB 24 2017

Page 41 of 44

PIN

CPU BALL

PADNAME

MODE0

MODE1

MODE2

MODE3

MODE4

MODE5

MODE6

MODE8

X1_8

B16

LCD_DATA2

3

lcdif.DATA[2

3]

uart8.RTS_B

ecspi1.MISO

csi.DATA[15]

weim.DATA[

15]

gpio3.IO[28]

src.BT_CFG[

31]

usdhc1.DAT

A3

X1_10

A14

LCD_DATA2

2

lcdif.DATA[2

2]

uart8.CTS_B

ecspi1.MOSI

csi.DATA[14]

weim.DATA[

14]

gpio3.IO[27]

src.BT_CFG[

30]

usdhc1.DAT

A2

X1_12

B14

LCD_DATA2

1

lcdif.DATA[2

1]

uart8.RX

ecspi1.SS0

csi.DATA[13]

weim.DATA[

13]

gpio3.IO[26]

src.BT_CFG[

29]

usdhc1.DAT

A1

X1_14

C14

LCD_DATA2

0

lcdif.DATA[2

0]

uart8.TX

ecspi1.SCLK

csi.DATA[12]

weim.DATA[

12]

gpio3.IO[25]

src.BT_CFG[

28]

usdhc1.DAT

A0

X1_16

D14

LCD_DATA1

9

lcdif.DATA[1

9]

uart7.RTS_B

global wdog

csi.DATA[11]

weim.DATA[

11]

gpio3.IO[24]

src.BT_CFG[

27]

usdhc1.CLK

X1_18

A13

LCD_DATA1

8

lcdif.DATA[1

8]

uart7.CTS_B

ca7_platform

.EVENTO

csi.DATA[10]

weim.DATA[

10]

gpio3.IO[23]

src.BT_CFG[

26]

usdhc1.CMD

X1_20

B13

LCD_DATA1

7

lcdif.DATA[1

7]

uart7.RX

ca7_platform

.TRACE_CT

L

csi.DATA[0]

weim.DATA[

9]

gpio3.IO[22]

src.BT_CFG[

25]

usdhc1.DAT

A7

X1_22

C13

LCD_DATA1

6

lcdif.DATA[1

6]

uart7.TX

ca7_platform

.TRACE_CL

K

csi.DATA[1]

weim.DATA[

8]

gpio3.IO[21]

src.BT_CFG[

24]

usdhc1.DAT

A6

X1_24

D13

LCD_DATA1

5

lcdif.DATA[1

5]

sai3.TX_DAT

A

ca7_platform

.TRACE[15]

csi.DATA[23]

weim.DATA[

7]

gpio3.IO[20]

src.BT_CFG[

15]

usdhc1.DAT

A5

X1_26*

A12

LCD_DATA1

4

lcdif.DATA[1

4]

sai3.RX_DA

TA

ca7_platform

.TRACE[14]

csi.DATA[22]

weim.DATA[

6]

gpio3.IO[19]

src.BT_CFG[

14]

usdhc1.DAT

A4

X1_28*

B12

LCD_DATA1

3

lcdif.DATA[1

3]

sai3.TX_BCL

K

ca7_platform

.TRACE[13]

csi.DATA[21]

weim.DATA[

5]

gpio3.IO[18]

src.BT_CFG[

13]

usdhc1.RES

ET_B

X1_30

C12

LCD_DATA1

2

lcdif.DATA[1

2]

sai3.TX_SYN

C

ca7_platform

.TRACE[12]

csi.DATA[20]

weim.DATA[

4]

gpio3.IO[17]

src.BT_CFG[

12]

ecspi1.RDY

X1_32

D12

LCD_DATA1

1

lcdif.DATA[1

1]

sai3.RX_BCL

K

ca7_platform

.TRACE[11]

csi.DATA[19]

weim.DATA[

3]

gpio3.IO[16]

src.BT_CFG[

11]

can2.RX

X1_33

F15

ENET1_TXE

N

enet1.TX_EN

uart6.RTS_B

pwm6.OUT

csi.DATA[21]

enet2.MDC

gpio2.IO[5]

mqs.LEFT

X1_34

E12

LCD_DATA1

0

lcdif.DATA[1

0]

sai3.RX_SY

NC

ca7_platform

.TRACE[10]

csi.DATA[18]

weim.DATA[

2]

gpio3.IO[15]

src.BT_CFG[

10]

can2.TX

X1_35

E14

ENET1_TXD

1

enet1.TDAT

A[1]

uart6.CTS_B

pwm5.OUT

csi.DATA[20]

enet2.MDIO

gpio2.IO[4]

GPIO1_IO04

X1_36

A11

LCD_DATA0

9

lcdif.DATA[9]

sai3.MCLK

ca7_platform

.TRACE[9]

csi.DATA[17]

weim.DATA[

1]

gpio3.IO[14]

src.BT_CFG[

9]

can1.RX

X1_37

D16

ENET2_RXE

R

enet2.RX_E

R

uart8.RTS_B

sim2.PORT0

_SVEN

ecspi4.SS0

weim.ADDR[

25]

gpio2.IO[15]

global wdog

X1_38

B11

LCD_DATA0

8

lcdif.DATA[8]

spdif.IN

ca7_platform

.TRACE[8]

csi.DATA[16]

weim.DATA[

0]

gpio3.IO[13]

src.BT_CFG[

8]

can1.TX

X1_39

N11

SNVS_TAM

PER6

snvs_lp_wra

pper.TAMPE

R[6]

gpio5.IO[6]

X1_40

D11

LCD_DATA0

7

lcdif.DATA[7]

pwm8.OUT

ca7_platform

.TRACE[7]

enet2.1588_

EVENT3_OU

T

spdif.EXT_C

LK

gpio3.IO[12]

src.BT_CFG[

7]

ecspi1.SS3

X1_41

L16

GPIO1_IO07

enet1.MDC

anatop.ENET

_REF_CLK2

usb.OTG_H

OST_MODE

csi.PIXCLK

usdhc2.CD_

B

gpio1.IO[7]

enet2.1588_

EVENT1_OU

T

uart1.RTS_B

X1_42

A10

LCD_DATA0

6

lcdif.DATA[6]

pwm7.OUT

ca7_platform

.TRACE[6]

enet2.1588_

EVENT3_IN

spdif.LOCK

gpio3.IO[11]

src.BT_CFG[

6]

ecspi1.SS2

X1_43

B15

ENET2_TXE

N

enet2.TX_EN

uart8.RX

sim2.PORT0

_CLK

ecspi4.MOSI

weim.ACLK_

FREERUN

gpio2.IO[13]

usb.OTG2_O

C

X1_44

B10

LCD_DATA0

5

lcdif.DATA[5]

pwm6.OUT

ca7_platform

.TRACE[5]

enet2.1588_

EVENT2_OU

T

spdif.OUT

gpio3.IO[10]

src.BT_CFG[

5]

ecspi1.SS1

X1_45

B17

ENET2_CRS

_DV

enet2.RX_E

N

uart7.TX

sim1.PORT0

_RST_B

i2c4.SCL

weim.ADDR[

26]

gpio2.IO[10]

usb.OTG1_P

WR

X1_46

C10

LCD_DATA0

4

lcdif.DATA[4]

pwm5.OUT

ca7_platform

.TRACE[4]

enet2.1588_

EVENT2_IN

spdif.SR_CL

K

gpio3.IO[9]

src.BT_CFG[

4]

sai1.TX_DAT

A

X1_48

D10

LCD_DATA0

3

lcdif.DATA[3]

pwm4.OUT

ca7_platform

.TRACE[3]

enet1.1588_

EVENT3_OU

T

i2c4.SCL

gpio3.IO[8]

src.BT_CFG[

3]

sai1.RX_DA

TA

X1_49

D17

ENET2_TXC

LK

enet2.TX_CL

K

uart8.CTS_B

sim2.PORT0

_RST_B

ecspi4.MISO

anatop.ENET

_REF_CLK1

gpio2.IO[14]

anatop.OTG

2_ID

X1_50

E10

LCD_DATA0

2

lcdif.DATA[2]

pwm3.OUT

ca7_platform

.TRACE[2]

enet1.1588_

EVENT3_IN

i2c4.SDA

gpio3.IO[7]

src.BT_CFG[

2]

sai1.TX_BCL

K

X1_51

A15

ENET2_TXD

0

enet2.TDAT

A[0]

uart7.RX

sim1.PORT0

_SVEN

i2c4.SDA

weim.EB_B[2

]

gpio2.IO[11]

usb.OTG1_O

C

X1_52

A9

LCD_DATA0

1

lcdif.DATA[1]

pwm2.OUT

ca7_platform

.TRACE[1]

enet1.1588_

EVENT2_OU

T

i2c3.SCL

gpio3.IO[6]

src.BT_CFG[

1]

sai1.TX_SYN

C

X1_53

A16

ENET2_TXD

1

enet2.TDAT

A[1]

uart8.TX

sim2.PORT0

_TRXD

ecspi4.SCLK

weim.EB_B[3

]

gpio2.IO[12]

usb.OTG2_P

WR

X1_54

B9

LCD_DATA0

0

lcdif.DATA[0]

pwm1.OUT

ca7_platform

.TRACE[0]

enet1.1588_

EVENT2_IN

i2c3.SDA

gpio3.IO[5]

src.BT_CFG[

0]

sai1.MCLK

X1_56

N8

SNVS_TAM

PER5

snvs_lp_wra

pper.TAMPE

R[5]

gpio5.IO[5]

X1_58

D9

LCD_HSYN

C

lcdif.HSYNC

lcdif.RS

uart4.CTS_B

sai3.TX_BCL

K

wdog3.WDO

G_RST_B_D

EB

gpio3.IO[2]

ecspi2.SS1

X1_60

B8

LCD_ENABL

E

lcdif.ENABLE

lcdif.RD_E

uart4.RX

sai3.TX_SYN

C

weim.CS3_B

gpio3.IO[1]

ecspi2.RDY

X1_62

C9

LCD_VSYNC

lcdif.VSYNC

lcdif.BUSY

uart4.RTS_B

sai3.RX_DA

TA

wdog2.WDO

G_B

gpio3.IO[3]

ecspi2.SS2

X1_63

C17

ENET2_RXD

0

enet2.RDAT

A[0]

uart6.TX

sim1.PORT0

_TRXD

i2c3.SCL

enet1.MDIO

gpio2.IO[8]

wdog1.WDO

G_RST_B_D

EB

X1_64

A8

LCD_CLK

lcdif.CLK

lcdif.WR_RW

N

uart4.TX

sai3.MCLK

weim.CS2_B

gpio3.IO[0]

wdog1.WDO

G_RST_B_D

EB

X1_65

C16

ENET2_RXD

1

enet2.RDAT

A[1]

uart6.RX

sim1.PORT0

_CLK

i2c3.SDA

enet1.MDC

gpio2.IO[9]

wdog2.WDO

G_RST_B_D

EB

X1_66

B4

NAND_ALE

rawnand.ALE

usdhc2.RES

ET_B

qspiA_DQS

pwm3.OUT

weim.ADDR[

17]

gpio4.IO[10]

ecspi3.SS1

X1_68

P14

JTAG_TMS

sjc.TMS

gpt2.CAPTU

RE1

sai2.MCLK

ccm.CLKO1

ccm.WAIT

gpio1.IO[11]

sdma.EXT_E

VENT[1]

epit1.OUT

Page 42

PICO-PI-IMX6UL HARDWARE MANUAL – VER 1.00 – FEB 24 2017

Page 42 of 44

PIN

CPU BALL