Page 1

TM-200 Broadcast Modulator

OPERATING MANUAL

Page 2

TABLE OF CONTENTS

1.0 S

AFEGUARDS

General Safeguards ........................................................................................................................... 2

Safety and First Aid............................................................................................................................ 3

WARRANTY

2.0

3.0

DESCRIPTION AND SPECIFICATIONS

General Description ........................................................................................................................... 5

Standard Features .............................................................................................................................. 5

Available Options ............................................................................................................................... 6

Block Diagram .................................................................................................................................... 7

Specifications ..................................................................................................................................... 9

Signal Conditioning Module............................................................................................................ 11

INSTALLATION

4.0

Building Recommendations............................................................................................................ 12

Heating and Cooling Requirements ............................................................................................... 12

Electrical Service Recommendations ............................................................................................ 13

Antenna and Tower Recommendations......................................................................................... 14

Shelter Security ................................................................................................................................ 15

Unpacking and Inspection .............................................................................................................. 16

Location and Function of Controls and Connectors.................................................................... 17

OPERATING PROCEDURE

5.0

Preliminary Hook-up ........................................................................................................................ 19

Setup of Output Level and Channel Selection .............................................................................. 20

Setup of Video Input Connection and Adjustment ....................................................................... 21

Setup of Baseband Audio Input Connection and Adjustment .................................................... 22

Setup of 4.5 MHz Sub-Carrier Audio Input Connection and Adjustment ................................... 23

Setup of IF Pre-Correction on Signal Conditioning PCB ............................................................. 24

Setup of Sync Level on Signal Conditioning PCB ........................................................................ 25

Automatic Shut Down ...................................................................................................................... 26

Transmitter Hookup ......................................................................................................................... 27

6.0

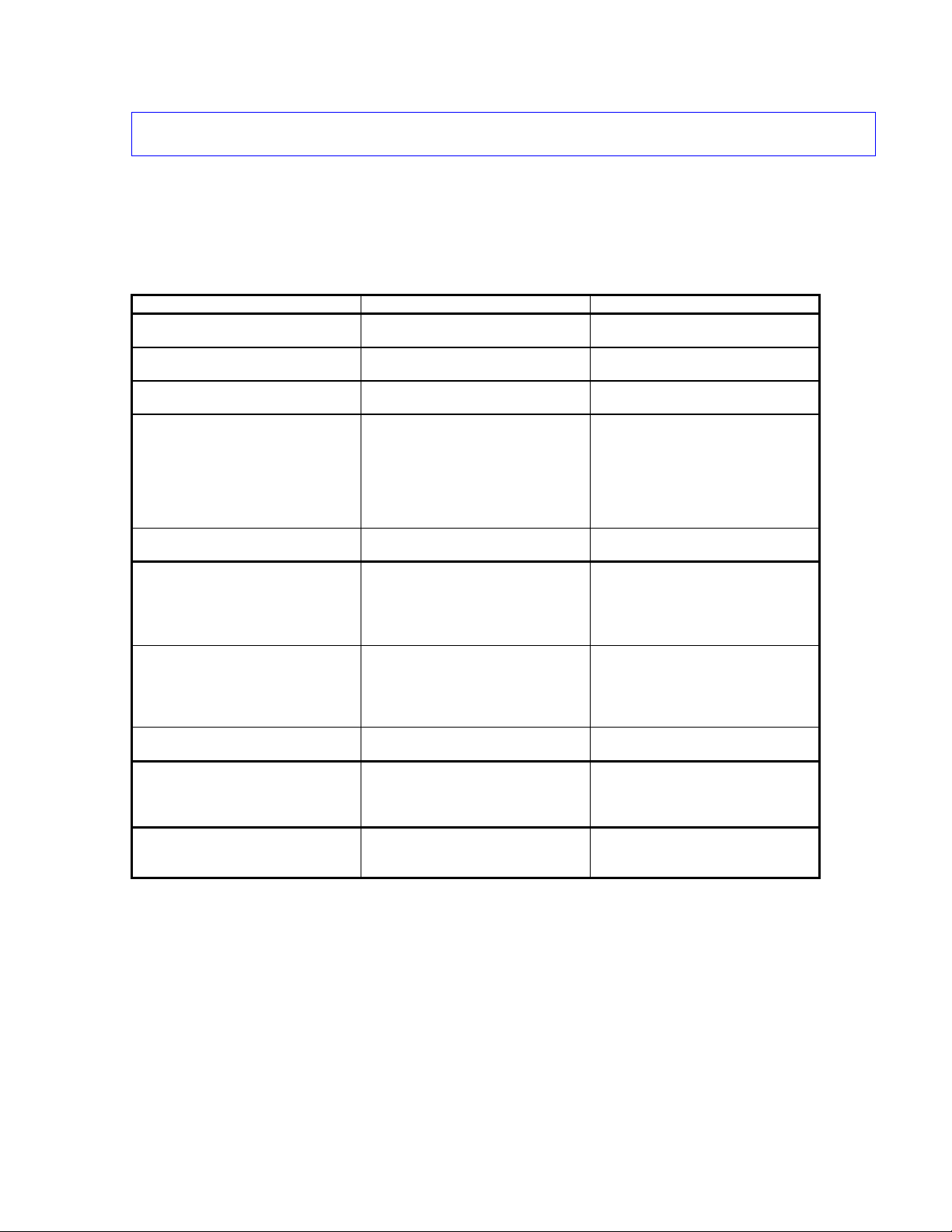

PROBLEM TROUBLESHOOTING GUIDE

BILL OF MATERIALS, SCHEMATICS, AND

7.0

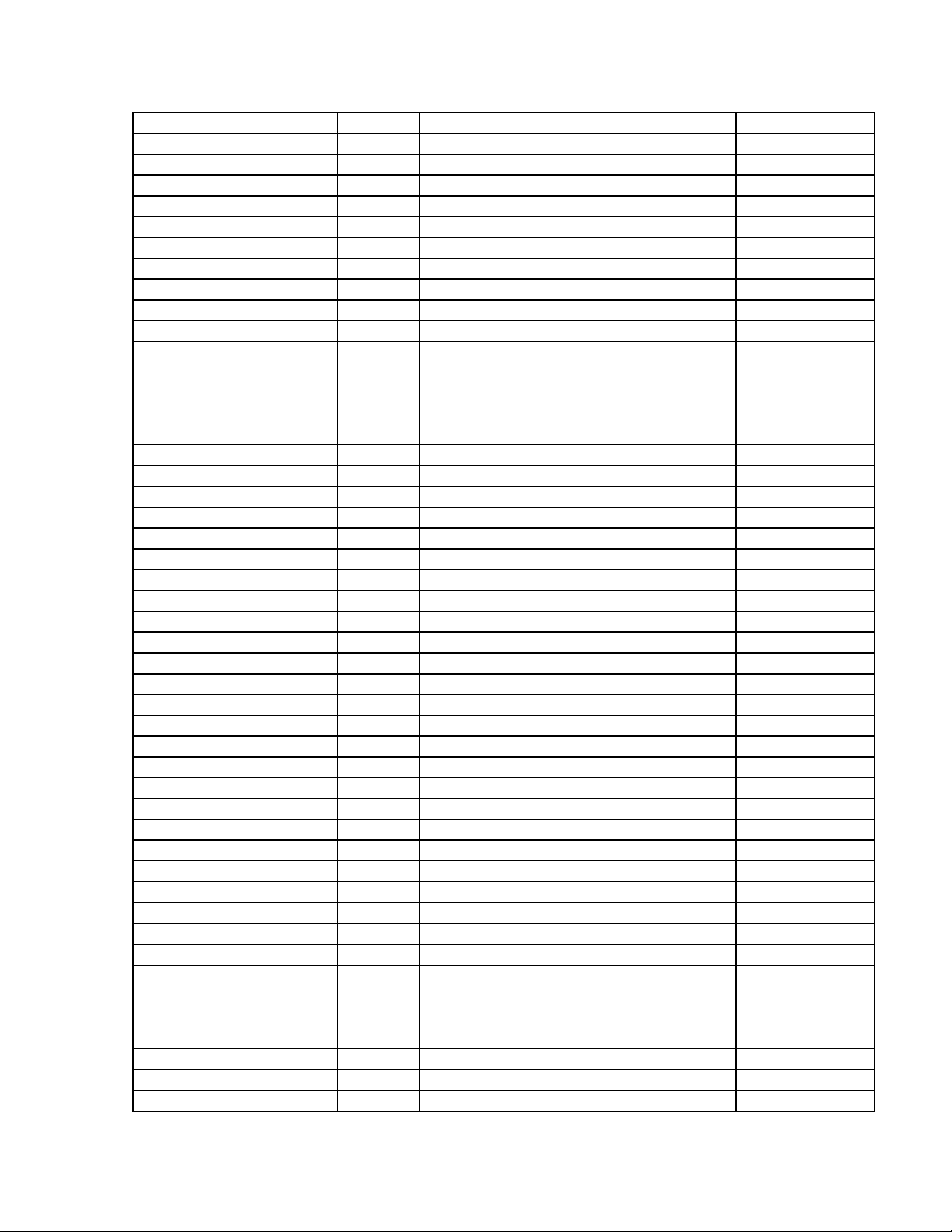

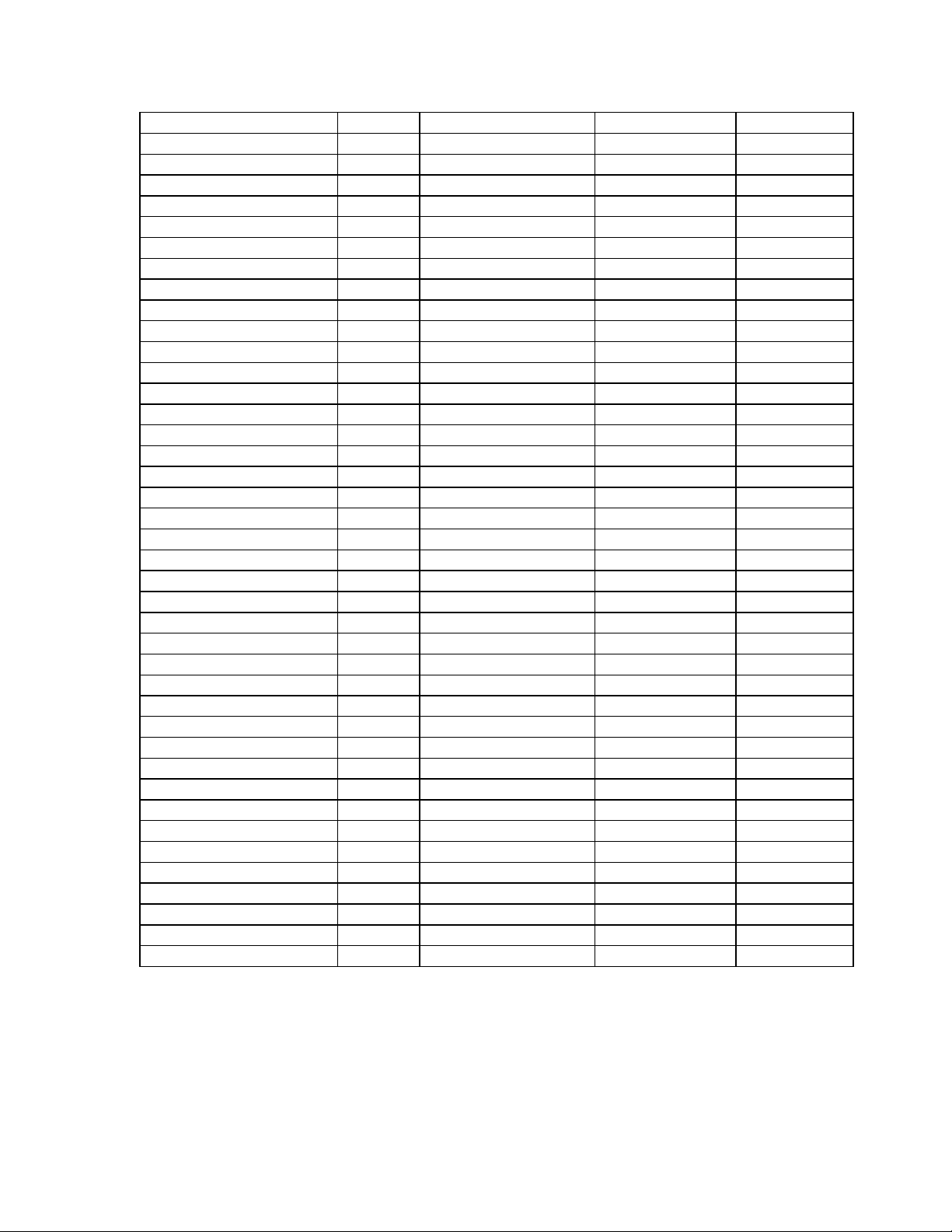

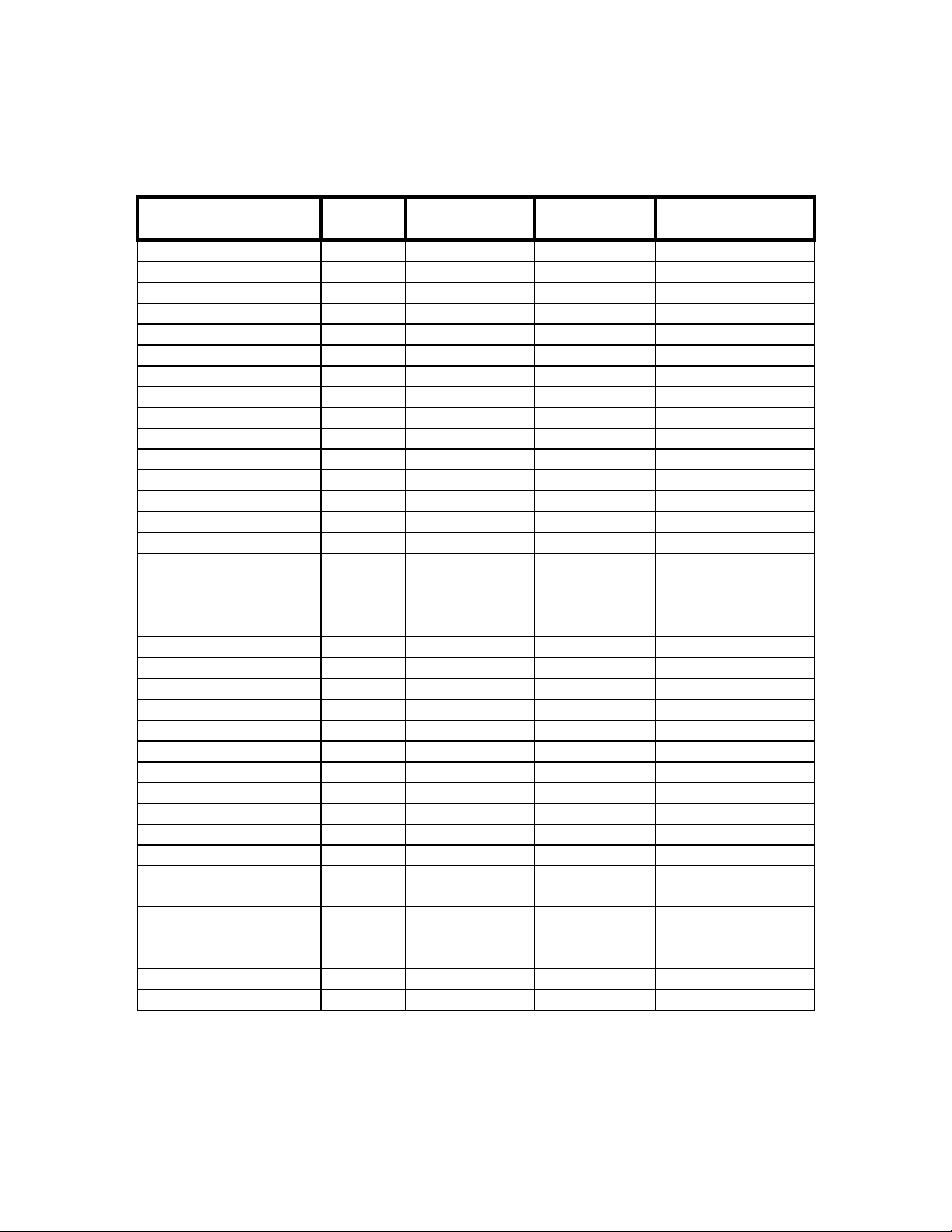

Agile Logic Board Bill of Materials................................................................................................. 29

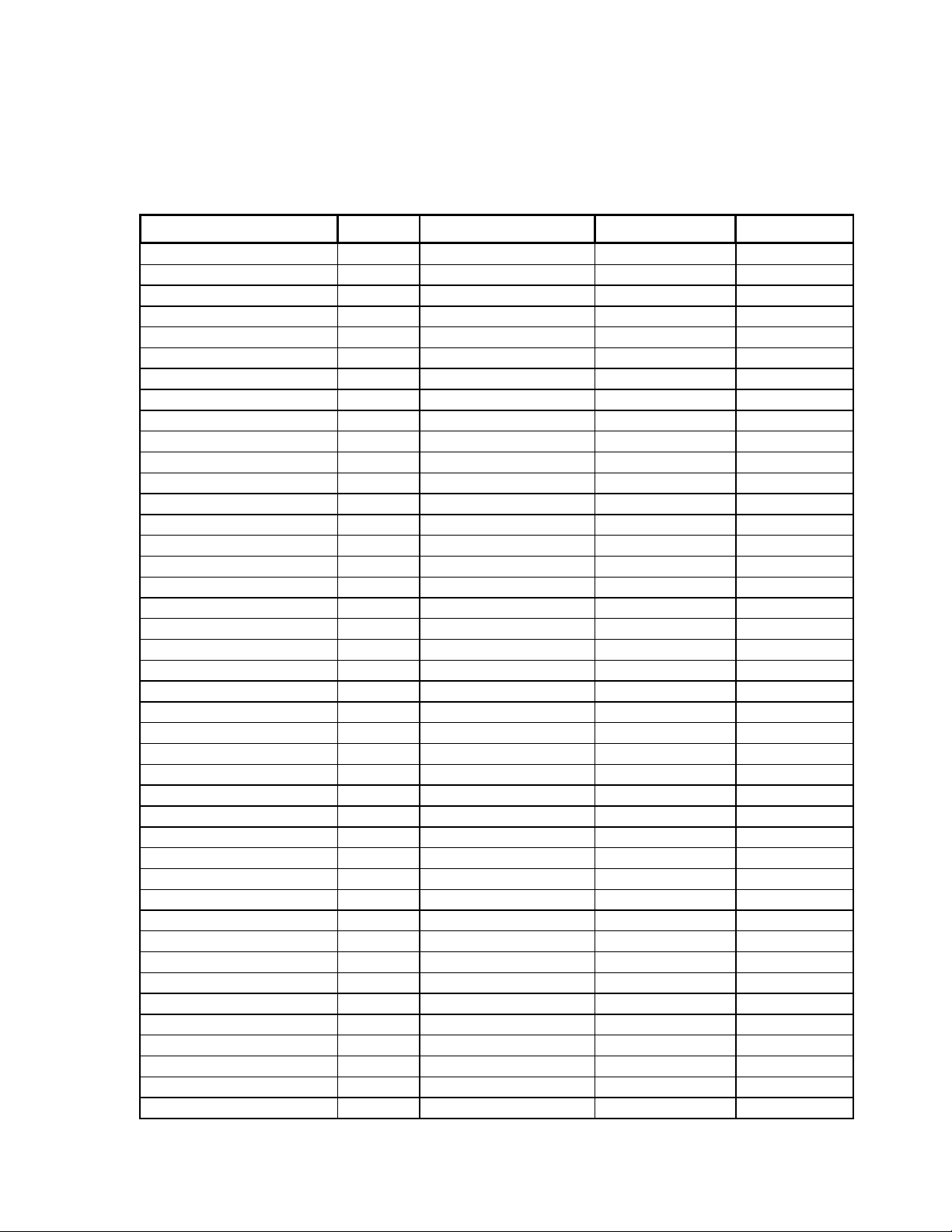

Agile Output Amplifier Bill of Materials ......................................................................................... 34

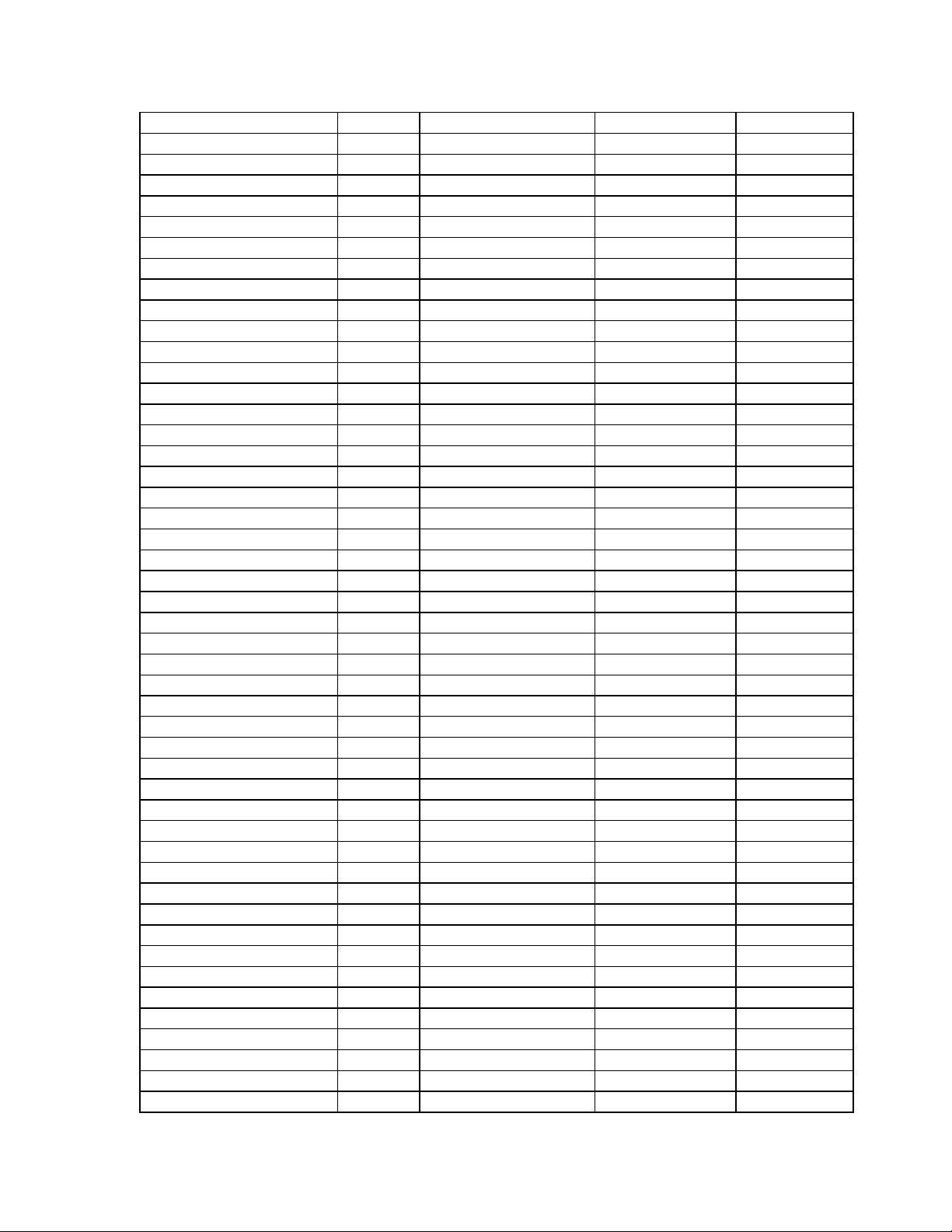

Audio Video Modulator Board Bill of Materials............................................................................. 37

Signal Conditioning Bill of Materials.............................................................................................. 46

Digital Up converter Bill of Materials ............................................................................................. 50

750 MHz Down Converter Bill of Materials .................................................................................... 56

Power Supply Bill of Materials........................................................................................................ 61

................................................................................................................................... 2

...................................................................................................................................... 4

................................................................................................... 5

................................................................................................................................ 12

................................................................................................................ 19

............................................................................................. 28

PCB O

VERLAYS

................................................................ 29

TM-200 Issue 1.02 November 2005 Page 1 of 64

Page 3

1.0 S

AFEGUARDS

General Safeguards

This section is written as a general guide for those having previous knowledge and

experience with these kinds of equipment. It is not intended to contain a complete

statement of all safety precautions, which should be observed by personnel using this or

other electronic equipment.

To reduce the risk of fire or electric shock, do not expose this equipment to rain or

moisture. Do not open the cabinet. Refer servicing to qualified personnel.

1. READ INSTRUCTIONS - All safety, installation, and operating instructions should be

read before the equipment is operated.

2. RETAIN INSTRUCTIONS - The safety and operating instructions should be retained

for future reference.

3. FOLLOW INSTRUCTIONS - All safety, installation, and operating instructions should

be followed.

4. GROUNDING AND POLARIZATION - The TM-200 Modulator is equipped with a

three prong grounded power plug. Do not remove the ground prong from the plug.

Do not use an AC receptacle where the plug blades cannot be fully inserted.

5. SERVICING - Do not attempt to service this equipment yourself as opening or

removing covers may expose you to dangerous voltage or other hazards and will

void the warranty. Refer all servicing to qualified service personnel.

6. DAMAGE REQUIRING SERVICE - Unplug this equipment and refer servicing to

qualified service personnel under the following conditions:

• if the power cord or plug is damaged.

• if liquid has been spilled or objects have fallen into the equipment.

• if the equipment has been exposed to rain or water.

• if the equipment does not operate normally by following the operating

instructions. Adjust only those controls covered by the operating instructions. An

improper adjustment may result in damage and will often require extensive work

by a qualified technician to restore the equipment to its normal operation.

• if the equipment has been dropped or the cabinet has been damaged.

• if the equipment exhibits a distinct change in performance.

TM-200 Issue 1.02 November 2005 Page 2 of 64

Page 4

Safety and First Aid

Personnel engaged in the installation, operation, maintenance, or servicing of electronic

equipment are exposed to the hazard of high voltage. It is imperative that all safety

regulations and precautions are consistently observed. Knowledge of first aid

procedures is recommended. The following information is presented as a reference

only.

• At all times, avoid placing any part of the body in series between ground and circuit

points, whether power is on or off.

• Dangerous voltage may be present in equipment even though power is off. Do not

open the cabinet. Refer servicing to qualified service personnel.

• It is the duty of all personnel to be prepared to give adequate emergency first aid

treatment and thereby prevent avoidable loss of life.

• There are three principle degrees of burns, recognizable as follows:

• a first-degree burn reddens the skin.

• a second-degree burn blisters the skin.

• a third degree burn chars the flesh and frequently places the victim in a state of

shock accompanied by respiratory paralysis.

• Respiratory paralysis can cause death by suffocation within seconds. It is imperative

that the approved methods of artificial respiration are initiated immediately and

continue until the victim’s breathing is normal.

• A muscular spasm of unconsciousness may render the victim unable to break free of

the electric power. If this is the case, turn the power off immediately.

DO NOT TOUCH THE VICTIM OR YOU MAY SHARE THE SAME

PREDICAMENT.

• If the power cannot be turned off immediately, very carefully loop a dry rope, article

of clothing, length of strong cloth or a rolled-up newspaper around the victim and pull

the victim free of the power source. Carefully avoid touching the victim or clothing.

• Once free of the power source, the victim must be placed in a reclining position and

covered with a blanket or newspapers to keep warm. At the first opportunity, enlist

help in summoning a doctor. If a doctor cannot be summoned, transport the victim to

the doctor or a hospital. Be sure the victim is kept well covered and warm while

awaiting professional treatment.

TM-200 Issue 1.02 November 2005 Page 3 of 64

Page 5

2.0 W

ARRANTY

Technalogix Ltd. products have been completely tested and found to meet specifications

and be in proper operating condition. They are warranted to be free from defects in

materials and workmanship for a period of one year from the date of shipment.

Technalogix Ltd. will not be liable for damages of whatever nature arising out of or in

connection with the equipment or its use thereof. Technalogix does not assume

responsibility for injury or damage resulting from the practices of untrained or unqualified

personnel in the handling of this equipment.

Technalogix Ltd. warranty does not include:

• misuse, neglect or accident.

• incorrect wiring and /or improper installation.

• unauthorized repairs, modifications or use in violation of instructions issued by

Technalogix.

• incidental or consequential damages as a result of any defect.

• reshipment cost or insurance of the unit or replacement units or parts.

• acts of God.

Technalogix agrees, at our option, to remedy warranted defects or furnish a new part in

exchange for any part of a unit which, under normal installation, use and service,

becomes defective. The user will pay for transportation costs to and from the repair

center.

To claim your rights under this warranty:

• Contact Technalogix and describe the problem in as much detail as possible. See

troubleshooting section in this manual. If a solution cannot be found at this time, it

may be determined that the unit will have to be returned to Technalogix for repair.

• Package equipment carefully for prepaid shipment to Technalogix. Include a written

description of the problem experienced and a copy of the original invoice establishing

warranty status.

Technalogix reserves the right to make revisions in current production of the equipment

and assumes no obligation to incorporate these changes in earlier models.

TM-200 Issue 1.02 November 2005 Page 4 of 64

Page 6

3.0 D

ESCRIPTION AND SPECIFICATIONS

General Description

The TM-200 is a high output modulator that eliminates the need for preamplifiers prior to

the power amplifier system. The modulator first processes baseband audio and video

information to provide an IF output consisting of a visual IF carrier at 45.75 MHz, using

amplitude modulation, and an aural IF carrier at 41.25 MHz, using frequency modulation.

Pre-correction is implemented at IF frequencies with a Signal Conditioning Board.

Frequency conversion circuitry then translates the modulator’s IF carriers to VHF and

UHF television frequencies. All operating controls are located on the front panel, and

will be discussed in later section, while input and output interfaces are on the back plate.

An aural loop through is provided to properly set transmitter power.

Standard Features

• Totally microprocessor controlled with self-diagnostic monitoring.

• Selectable output channels:

Standard Broadcast VHF 2 – 13, UHF 14 – 60, T7 – T13

HRC channels 1 through 118

±10 kHz offsets

• SAW filtered IF designed for adjacent channel operation.

• + 10 dBm (minimum) output using low distortion hybrid amplifiers.

• Synthesized oscillators – crystal referenced phase locked.

• Bar graph modulation and digital LED readout.

• Internal switch selects standard or HRC output.

• Surface mount technology construction.

• RF muted during tuning.

• Optional aural sub-carrier and baseband audio input

• Phase lock loop FM audio.

• BTSC stereo compatible.

• External separate audio/video and composite IF loop-through.

• RS-232 control option

• Sound carrier level adjustable –10 dB to –15 dB.

• Video delay pre-distortion network meets FCC 73.687.

• High stability TCXO, ± 250 Hz

• Non-volatile memory retains channel selection after power loss.

• Video Detection turns off carrier in event of loss of video.

• IF pre-correction allow slope/knee linearization of signal.

• Sync level adjustment to ensure sync tip at proper levels.

• White clip and DC restoration of baseband video signal.

• 50-ohm RF Output and tap-off

TM-200 Issue 1.02 November 2005 Page 5 of 64

Page 7

Available Options

• 4.5 MHz sub carrier and baseband audio inputs.

• Dual RS-232 control with daisy chain capabilities that allow for remote control by

PC workstation.

• HRC Output Frequency Set - This feature is controlled by an internal dip switch

assembly, DS-1. The switch is located near the right front corner (with the panel

facing you) between the test point and the output converter module. DS-1 is

clearly marked on the PCB. Switch #3 placed in the OFF position switches the

output frequency to HRC on all channels. The switch is normally set to ON at the

factory.

TM-200 Issue 1.02 November 2005 Page 6 of 64

Page 8

Block Diagram

The baseband input source enters through a Video In connector, and Baseband Audio In

or 4.5 Audio In connector on the back of the modulator. The connectors are mounted

directly on the A/V Modulation PCB where the IF output is generated. The baseband

video signal passes into the modulator, through a group delay filter, and onto the Signal

Conditioning PCB to the video detect/sync level adjust section. The IF signal from the IF

loop on the modulator is connected through the IF pre-correction portion of the same

Signal Conditioning PCB. The visual IF carrier and the aural IF carrier are then

combined before entering the Upconverter PCB. The outputs are at RF frequencies of

945.75 MHz for the visual carrier and 941.25 MHz for the aural carrier. Then, the signal

passes through a Downconverter section allowing a user selectable VHF or UHF

broadcast television channel. Finally, the signal passes through an output amplifier

which increases the RF signal level typically to 15 dBm.

TM-200 Issue 1.02 November 2005 Page 7 of 64

Page 9

VIDEO IN AUDIO IN

Baseband Audio 4.5 MHz Audio

Aural IF Carrier

Visual IF Carrier

A/V Modulation PCB

Combiner

Upconverter

Video Detect

Downconverter

In Out

Signal Conditioning Board Display and Control Board

Output

IF Pre-correction

Out In

RF Output

Amplifier

TM-200 Issue 1.02 November 2005 Page 8 of 64

Page 10

Specifications

RF Characteristics

Frequency range 7 to 750 MHz

Frequency Response (one channel) ±0.5 dB

Frequency Stability ±250 Hz

RF Output Level +60 dBmV max

Output Impedance 50 Ohms

Harmonics > 60 dB below rated power

Predominant Intermodulation Distortion dBc = decibels below visual carrier

+ 920 kHz

- 920 kHz

+ 2.66 MHz

- 2.66 MHz

+ 5.42 MHz

+ 7.16 MHz

> -53 dBc

> -53 dBc

> -53 dBc

> -53 dBc

> -53 dBc

> -53 dBc

3rd Order Intermodulation Distortion

+ 4.5 MHz

+ 9.0 MHz

All others

> -60 dBc

> -60 dBc

> -60 dBc

Spurious Emissions > -60 dBc

NTSC Video Characteristics

Input Level to modulator (for 87.5% modulation) 1.0 V

Differential Phase (at 87.5% modulation) ±2 Degrees

Differential Gain (at 87.5% modulation) 2%

Group Delay < ±40 nS

Video Group Delay Pre-emphasis Conforms to IC/FCC specifications

K-Factor 1.9% for 2T Pulse

Hum and Noise > 60 dB below rated power

Aural Characteristics

Input: 50 Hz – 15 KHz 0 dBm (0.8V)

Impedance 600 ohms, balanced

Frequency Response +/- 1.0 dB

Frequency Tolerance, +/- 500 Hz 4.5 MHz

Frequency Deviation +/- 25 KHz

Harmonic Distortion 1% max

Preemphasis (mono)

Internally Defeatable

PP

75 µs

TM-200 Issue 1.02 November 2005 Page 9 of 64

Page 11

IF Section

Output Impedance 75 ohms, unbalanced

Video IF level

+ 37 dBmV, +97 dBµV

Audio IF Level +22 dBmV

Adjustable

+82 dBµV

Return Loss > 14 dB

IF Frequency, Video Carrier 45.75 MHz

IF Frequency, Audio Carrier 41.25 MHz

Video Sound Spacing + 4.5 MHz

Vestigial side-band width 0.05 MHz

Second IF Frequency 945.75 MHz

Physical Characteristics

Power Requirements 100-130 Vac, 210-230 Vac, 50/60 Hz,

1 Aac at 110 Vac

Operating Temperature 0 - 50°C

Weight 12 lbs

Dimensions (modulator only) W-19", D-16" with connectors, H- 2U-

high

TM-200 Issue 1.02 November 2005 Page 10 of 64

Page 12

Signal Conditioning Module

The TM-200 modulator includes a separate circuit board called the Signal Conditioning

Module. The Signal Conditioning PCB contains the video detect/sync level adjust

section in addition to the IF pre-correction section. The baseband video signal passes

into the modulator, through a group delay filter, and onto the Signal Conditioning PCB to

the video detect/sync level adjust section. The IF signal from the IF loop on the

modulator are connected through the IF pre-correction portion of the same PCB. The

Signal Conditioning features are as follows:

1. Sync Level Adjust - Allows the user to adjust the sync level to maintain the

proper level. Adjustment is made via front panel.

2. Video Detect - Turns off the 24Vdc supply to the final amplifier stage in the TM200 in the event of missing video input. The power supply for the final amplifier

(+24Vdc) is routed through a relay on the Signal Conditioning PCB. In the event

of a missing video signal, the relay contact is opened and the +24Vdc is

disconnected from the final amplifier stage.

3. IF Pre-Correction – Allows the user to optimize the linearity of their power

amplifier using slope-knee adjustments available from front panel. Adjustment

will alter several RF performance parameters including in-band intermodulation

products, differential phase and gain, and others.

The input and output impedance of the Signal Conditioning PCB is 75-ohms. Baseband

video connections are made via RCA connectors for the sync level adjust and video

detect sections and the IF connections are made via F connectors. The Signal

Conditioning PCB can be bypassed, if necessary.

TM-200 Issue 1.02 November 2005 Page 11 of 64

Page 13

4.0 I

NSTALLATION

This section contains installation recommendations, unpacking, inspection, and

installation instructions for the Technalogix TM-200 Modulator. Carefully read all material

in this section prior to installation. Also read and review operating procedures later in this

section.

Building Recommendations

The quality of the building is of great importance if you are to expect long life and

continued performance from the modulator. The building must be clean, dry,

temperature controlled and secure. The modulator takes up a single 1-U high space on a

19” rack. Don’t forget to allow space in the building for any additional racks to house test

equipment, a workbench area, line regulating transformers, ladders, equipment and

parts storage, first aid kit, emergency generator if used, as well as heating and cooling

devices that may be unique to your installation. A sloping roof will tend to develop leaks

less rapidly. The building should be well roofed with good material. The cooling load will

be lowered with reflective or light colored roofing material.

Heating and Cooling Requirements

The environment’s temperature will contribute greatly to the length of the modulator’s

life. Technalogix recommends that the building’s filtered air intake must have capacity for

all air-flow in the building plus an additional 20%. Keep the intake below the roofline to

avoid intake of solar heated air. Please ensure that the intake and exhaust areas are on

the same side of the building to avoid pressure differentials during windy conditions.

Also, do not position intake near exhaust’s preheated air. If air conditioning is required to

cool the shelter, discuss the situation with a qualified HVAC technician. Under average

conditions, 12,000 BTUs will cool approximately 500 square feet to a comfortable level.

TM-200 Issue 1.02 November 2005 Page 12 of 64

Page 14

Electrical Service Recommendations

Technalogix recommends that a qualified, licensed local electrician be consulted for the

required electrical service. We suggest local electricians because:

• The personnel knows the local codes

• The personnel can be on site readily

• You are apt to get better overall support if you give what business you can to local

suppliers

Technalogix recommends that proper AC line conditioning and surge suppression be

provided on the primary AC input to the power amplifier. All electrical service should be

installed with your national electrical code in your area, any applicable provincial or state

codes, and good engineering practice. Special consideration should be given to lightning

protection of all systems in view of the vulnerability of most transmitter sites to lightning.

Lightning arrestors are recommended in the service entrance. Straight and short

grounds are recommended. The electrical serviced must be well grounded. Do not

connect the unit to an open delta primary power supply, as voltage fluctuations could

harm the unit. Branch your circuits. Do not allow your lights, your workbench plugs, and

your transmitting or translating equipment off of one circuit breaker. Each transmitter

should have its own circuit breaker, so a failure in one does not shut off the whole

installation.

TM-200 Issue 1.02 November 2005 Page 13 of 64

Page 15

Antenna and Tower Recommendations

Your preliminary engineering workgroup should establish your antenna and tower

requirements, both for receiving and transmitting antennas. Construction of sturdy, high

quality antenna/tower systems will pay off in terms of coverage of your service area, the

overall quality and saleability of your radiated signal, and reduced maintenance

expenses. Technalogix provides complete turnkey antenna systems if needed.

Transmitting antennas can enhance or seriously impair the transmitter output. It is

assumed that one has been selected prior to system installation, but the best-designed

antenna system will function poorly if shortcuts and compromises are used during

installation. Follow the manufacturer’s instructions exactly, along with any engineering

data prepared for the site.

The selection, routing, and length of coaxial cable is extremely important in the

installation. If there is a 3 dB line loss in the cable between your unit’s output and the

transmitting antenna, a 500 watt unit will only deliver 250 watts to the antenna. Buy the

best cable you can obtain, route it via the shortest way to the antenna, and keep it

straight. Do not form it into sharp bends on its way. Do not use any more cable fittings

for the installation than absolutely necessary. All cautions here apply equally to all

coaxial cables in the system - input and output. The better known tower manufacturers

offer complete technical and safety documentation with their towers. Be sure that you

have this information as it regards wind loading, guying, etc. Be absolutely safe and

certain about this aspect as human lives may be at stake.

TM-200 Issue 1.02 November 2005 Page 14 of 64

Page 16

Shelter Security

The FCC requires that the transmitter be secure from entry or control by unauthorized

persons, and that any hazardous voltages or other dangers (including most tower bases)

be protected by locks or fences as necessary to protect personnel and prevent

unauthorized tampering or operation. Security of the building further implies that it be

secure from wildlife. Use sturdy construction materials, including sheet metal if

necessary. Holes around conduit, cable, and other similar entry points should be stuffed

with steel wool and caulked to prevent entry of wildlife. Other features of security for your

shelter may include its location with respect to the prevailing wind conditions. A location

leeward of some natural topographical feature will prevent wind damage and snowdrifts.

Check the soil runoff conditions that may slow or hasten wind or water erosion and other

concerns that may be unique to your location.

TM-200 Issue 1.02 November 2005 Page 15 of 64

Page 17

Unpacking and Inspection

Check the outside of the container. Carefully open the container and remove the

modulator. Retain all packing material that can be reassembled in the event that the

equipment must be returned to the factory.

Exercise care in handling equipment during inspection to prevent

damage due to rough or careless handling.

Visually inspect the enclosure of the modulator for damage that may have occurred

during shipment. Check for evidence of water damage, bent or warped chassis, loose

screws or nuts, or extraneous packing material in connectors. Inspect all connectors for

bent connector pins. If the equipment is damaged, a claim should be filed with the carrier

once the extent of the damage is assessed. Technalogix cannot stress too strongly the

importance of immediate careful inspection of the equipment and subsequent immediate

filing of the necessary claims against the carrier if necessary. If possible, inspect the

equipment in the presence of the delivery person. If the equipment is damaged, the

carrier is your first area of recourse. If the equipment is damaged and must be returned

to the factory, phone for a return authorization. Claims for loss or damage may not be

withheld from any payment to Technalogix, nor may any payment due be withheld

pending the outcome thereof. Technalogix cannot guarantee the carrier’s performance.

TM-200 Issue 1.02 November 2005 Page 16 of 64

Page 18

Location and Function of Controls and Connectors

The following illustrations depict the location of the installation connectors when

installing the power amplifier with a modulator or processor.

FRONT

BACK

Audio Deviation – Allows user to control extent of audio deviation. Original factory

setting at 25 KHz deviation using standard pre-emphasis curve.

Audio/Video Display Select - Provides a graphical representation of audio deviation and

visual modulation levels on an LED bar graph. The switch selects between audio

deviation or visual modulation.

Video Modulation -- Allows user to control extent of video modulation. Original factory

setting at 87.5% video modulation with 1.0 Volt peak to peak baseband input video

signal.

Frequency Offset Select – Toggles between +10 KHz, 0KHz, and –10 KHz frequency

offset.

TM-200 Issue 1.02 November 2005 Page 17 of 64

Page 19

Aural Carrier Level - Allows user to set aural carrier level relative to visual carrier level.

Modulator is factory tested at –10 dBc (decibels below visual carrier).

Output Select – Selects the desired channel of operation. If you require a lower channel

than the one currently displayed, push the toggle switch down. The channels will

change one at a time as many times as you press the switch. Holding the select switch

in the up or down position will “scan” to the desired channel. It is normal for the

frequency lock LED to turn off during and for a few seconds after, changing channels.

The switch must be held up or down initially for three seconds. This helps to ensure that

no accidental channel changes will occur.

Output Level – Sets visual carrier output level.

RF Out Test Point – Provides a sample of the RF output level which is 20 dB below the

actual value. RF test point is only a relative indicator of the actual RF output level and

may vary. All RF operating measurements should be made at the RF output of the unit.

RF Output - Modulated Audio/ Video output capable of +60 dBmV levels using built in

low distortion hybrid amplifiers.

RS-232 Ports – Set up for optional RS-232 control option.

Combined IF Input/ Output – 45.75 MHz visual carrier and 41.25 MHz audio carrier

intermediate frequency signal loop.

Audio Input/ Ouput Loop – Available for baseband audio processing.

Video Input/ Output Loop - Available for baseband video processing.

IF Pre-Correction Loop – Allows pre-correction adjustment to improve linearity,

intermodulation performance, and other RF parameters. Internally connected to Signal

Conditioning PCB.

Video In – Connection for 1.0 Volt peak to peak video source.

Balanced Baseband Audio In – Used to connect a 1 Volt peak to peak baseband audio

signal. For balanced input connection, connect 1 audio input lead to the left terminal on

the connector and the other audio input lead to the right terminal. For an unbalanced

input connection, connect one audio input lead to the left terminal on the connector and

the other audio input lead to the centre terminal. The center terminal is chassis ground.

TM-200 Issue 1.02 November 2005 Page 18 of 64

Page 20

5.0 O

PERATING PROCEDURE

Preliminary Hook-up

1. Terminate modulator into a 50 ohm load before applying power.

2. Connect the power cord of the Technalogix TM-200 agile modulator to a proper

electrical source as indicated on the back of the unit.

3. Observe the front panel. If power is applied and present, the red power LED will

illuminate. Also, all the elements of the displays behind the display readout

window will illuminate momentarily as a display test.

4. Observe the numbers displayed behind the display readout window after the test.

They will indicate:

• Microprocessor software version;

• Internal option dipswitch settings;

• RS-232 unit ID (if so equipped); and

• Last tuned channel.

5. After a moment, the Lock Detect LED will illuminate.

TM-200 Issue 1.02 November 2005 Page 19 of 64

Page 21

Setup of Output Level and Channel Selection

1. Connect a spectrum analyzer, or a field strength meter tuned to the frequency of

the video RF carrier of the desired channel, to the RF OUTPUT jack on the rear

panel of the unit. Alternatively, connect a spectrum analyzer or a field strength

meter to the –20dB TEST POINT on the front panel of the unit.

2. Select the desired output channel using the CHANNEL SELECT paddle switch

on the front panel.

• Hold the CHANNEL SELECT switch in the up- or down-position for

approximately 3 seconds to activate the channel-select circuit;

• Toggle the CHANNEL SELECT switch up to select a higher channel

or toggle it down to select a lower channel. The switch may be held in

the up- or down-position for rapid channel switching.

3. Observe the output on the spectrum analyzer, or the field strength meter. If

measuring from the rear panel RF OUTPUT jack, adjust the front panel OUTPUT

LEVEL potentiometer for an output level between +55dBmV and +60dBmV. If

measuring from the front panel –20dB TEST POINT, ensure that the rear panel

RF OUTPUT jack is terminated into a 50Ω load, then adjust the front panel

OUTPUT LEVEL potentiometer for an output level between +35dBmV and

+40dBmV.

4. If using a field strength meter, retune the meter to the frequency of the audio RF

Carrier.

5. Still observing the output on the spectrum analyzer, or the field strength meter

(now tuned to the frequency of the audio RF carrier), adjust the front panel

AURAL CARRIER potentiometer for an output level 10-13dB lower than that at

which the video RF Carrier is set.

6. Remove the spectrum analyzer, or field strength meter from the unit. If available,

connect a television/monitor to the front panel –20dB TEST POINT, apply power

to the television/monitor and tune to the selected output channel of the

Technalogix TM-200 modulator.

TM-200 Issue 1.02 November 2005 Page 20 of 64

Page 22

Setup of Video Input Connection and Adjustment

1. Connect a 1.0V

video source to the VIDEO IN jack on the rear panel.

P-P

2. Adjust the front panel VIDEO MODULATION control for 87.5% modulation.

• Set the front panel DISPLAY SELECT switch to VIDEO (down)

position;

• Observe front panel LED bar graph behind front panel display readout

window.

• First RED LED will begin illumination at approximately 87.5%

modulation; or

• Observe TV monitor for good visual image.

TM-200 Issue 1.02 November 2005 Page 21 of 64

Page 23

Setup of Baseband Audio Input Connection and Adjustment

1. If your Technalogix TM-200 agile modulator is equipped with a 4.5MHz subcarrier input option, ensure that the rear-panel AUDIO SELECT switch is in the

BASEBAND position.

2. Connect a 1V

baseband audio signal to the rear panel baseband audio

P-P

connector as follows:

• For balanced input connection, connect one audio input lead to the

left terminal on the connector and the other audio input lead to the

right terminal.

• For unbalanced input connection, connect one audio input lead to the

left terminal on the connector and the other audio input lead to the

center terminal.

• Center terminal is chassis ground.

• Insert the terminal into the connector on the rear panel of the TM-200.

3. Adjust the front panel AUDIO MODULATION control for 100% modulation.

• Set the front panel DISPLAY SELECT switch to AUDIO (up) position.

• Observe front panel LED bar graph behind front panel display readout

window.

• First RED LED will begin illumination at approximately 95%

modulation; or

• Adjust for ±25KHz deviation using a spectrum analyzer; or

• Listen to the audio output from TV monitor and setting the loudness

equal to that of an off-air channel carried on your system.

TM-200 Issue 1.02 November 2005 Page 22 of 64

Page 24

Setup of 4.5 MHz Sub-Carrier Audio Input Connection and Adjustment

1. Set the rear panel AUDIO SELECT switch in the 4.5 position.

2. Connect a modulated 4.5MHz sub-carrier signal to the rear panel 4.5MHz input

F-connector jack.

3. Inject a minimum +36dBmV (-12.75dBm) 4.5MHz RF carrier into the unit.

4. Using the setup in Step 5, Setup of Output Level and Channel Selection,

measure the audio RF carrier output level at the rear panel RF OUTPUT jack.

Level should be within ±2dB of the measurement taken in Step 5, Setup of

Output Level and Channel Selection.

TM-200 Issue 1.02 November 2005 Page 23 of 64

Page 25

Setup of IF Pre-Correction on Signal Conditioning PCB

Varying these two pots can increase and dec

rease the

1. Install the modulator but do not apply power yet.

2. Ensure that the two IF pre-correction potentiometers on the front panel of the

modulator are turned fully counter clockwise.

3. With the transmitter and modulator fully installed, apply power and bring the

transmitter up to rated power.

4. Apply a red field test signal to the input of the modulator with the aural carrier

turned on.

5. Take a sample of the RF output and view it on a spectrum analyzer.

6. Looking at the +/- 920kHz intermodulation products, adjust the two IF pre-

correction potentiometers to obtain the lowest level on the intermodulation

products.

output power, so this should be carefully monitored.

TM-200 Issue 1.02 November 2005 Page 24 of 64

Page 26

Setup of Sync Level on Signal Conditioning PCB

Varying these two pots can increase and decrease the

1. With the transmitter at rated power and an NTC7 Composite signal applied

to the input of the modulator, view the demodulated waveform on a waveform

monitor.

2. Adjust the sync level potentiometer on the front panel clockwise for more sync or

counter clockwise for less sync to obtain 40 IRE of sync.

3. Maintain the white bar level at 100 IRE by adjusting the video modulation

potentiometer on the front panel.

output power, so this should be carefully monitored.

TM-200 Issue 1.02 November 2005 Page 25 of 64

Page 27

Automatic Shut Down

Technalogix power supplies are designed so that under certain power line or heat

buildup conditions, the unit shuts off. An indicator would be no RF output, but the

POWER LED remains on. If this occurs, unplug the power cord and wait two minutes

before re-powering. Upon applying power, you should again have RF output. If not, or

should the unit return to shutdown mode, please contact Technalogix for assistance.

Technalogix highly recommends a 1.75 inch air circulation space between any rack

mounted equipment.

TM-200 Issue 1.02 November 2005 Page 26 of 64

Page 28

Transmitter Hookup

1. Connect modulated video from TM-200 RF OUT to the Technalogix power amplifier.

2. Turn down RF level on TM-200 all the way.

3. Ensure that IF OUT is connected to IF IN on the TM-200 modulator using the loop F

to F cable supplied. If the IF pre-correction circuit is to be used, simply jumper 75ohm coaxial from the IF PRE-CORRECTION - IN to the OUTPUTS – VIDEO and

jumper from IF PRE-CORRECTION – OUT to the INPUTS – VIDEO connection.

4. Connect the transmitting antenna cable to the RF output connector on the power

amplifier. It is recommended that a quality through line wattmeter be installed in this

same line.

5. Verify that all signal and RF cables are connected properly.

6. After following proper installation procedures outlined in the power amplifier manual,

plug the power amplifier’s power cords into an appropriate electrical outlet.

Output power should be adjusted with a sync and blanking signal only with the aural

carrier removed. This is simply done by disconnecting one end of the audio carrier loop

found on the back panel of the TM-200.

TM-200 Issue 1.02 November 2005 Page 27 of 64

Page 29

6.0 P

ROBLEM TROUBLESHOOTING GUIDE

The guide below covers some typical symptoms, possible associated causes and

suggested actions to follow before returning the unit for repair. It is not meant to be allinclusive.

Symptom Possible Cause Suggested Action

No output or weak output Baseband input level too weak Ensure proper 1 Vp-p video signal

present on input

IF loop cable on rear of unit loose

or disconnected

Unit not plugged in or getting AC

power

Unit tuned to output channel

different from desired (this occurs

particularly on the units which

have green LED on the front

panel to indicate “T” channels and

channels above 99)

Loss of video on the input – video

detect turned off RF Output

Excessive noise or spurious

signals

IF level too high (most often

Input signal too strong or no input

Bad/noisy video Aural carrier interfering with video

Channels do not change Delay feature active Hold channel change switch in

Output level above rated

maximum (most often occurs

when changing from high-number

channel to low-number channel,

especially to the “T” channels)

occurs when routing IF through

scrambler or other external

device)

signal at all

carrier

Check IF loop cable is securely

attached

Check power cord and power source,

fuse

Ensure selected output channel is

desired channel

Ensure proper 1 Vp-p video signal

present on input

Measure RF output from rear

panel jack and adjust front panel

OUTPUT LEVEL control as

required

Measure normal IF output level

for applied CW/unmodulated input

carrier and ensure same level is

returned to unit after external

processing

Measure video level and pad to

within specified input levels.

Measure Aural Carrier level

and/or adjust AURAL CARRIER

LEVEL control on front panel

raised/lowered position for at least

three seconds

TM-200 Issue 1.02 November 2005 Page 28 of 64

Page 30

7.0 B

ILL OF MATERIALS, SCHEMATICS, AND

Agile Logic Board Bill of Materials

Last Revision: 09.12.00

Component Reference Quantity

C1 1 22pF CAP250D

C10 1 0.47uF CAP100RP

C11 1 10 uF CAP100RP

C12 1 22 uF CAP100RP

C13 1 22 uF CAP100RP

C14 1 22 uF CAP100RP

C15 1 22 uF CAP100RP

C16 1 0.01uF CAP250D

C17 1 0.01uF CAP250D

C18 1 47 uF CAP100RP

C19 1 47 uF CAP100RP

C2 1 22pF CAP250D

C20 1 CAP100RP

C21 1 0.01uF CAP250D

C22 1 0.01uF CAP250D

C23 1 0.01uF CAP250D

C24 1 0.01uF CAP250D

C3 1 22 uF CAP100RP

C4 1 10 uF CAP100RP

C5 1 0.47uF CAP100RP

C6 1 0.47uF CAP100RP

C7 1 0.01uF CAP250D

C8 1 0.01uF CAP250D

C9 1 470 uF CAP197R

D1 1 RED T1 LED T1-W/HLD

D2 1 T1 W/HLD LED

D3 1 RED T1 LED T1-W/HLD

DS1 1 8 POS DPS8W

JP1 1 4 POS HEADER

JP2 1 8 POS HEADER

JP3 1 JP-DUAL4

JP4 1 3PIN JP3IL

JP5 1 3PIN JP3IL

JP6 1 3PIN JP3IL

JP7 1 3 POS JP3IL

JP8 1 3 IL JP3IL

L1 1 6 T COIL 60

PCB O

VERLAYS

Identification Modifier Package

JP-DUAL4

JP-DUAL8

TM-200 Issue 1.02 November 2005 Page 29 of 64

Page 31

L2 1 6 T COIL 60

L3 1 6 T COIL 60

L4 1 6 T COIL 60

L5 1 6 T COIL 60

P1 1 4 PIN SMB

P10 1 10 POS DIPIL10

P11 1 4 PIN SMB

P12 1 8 POS CONNIL8

P2 1 RT ANG F FCONN

P3 1 12 POS CONN IL12

P4 1 12 POS CONN IL12

P5 1 ON DISPLAY

CONN IL19

BDS

P6 1 12 POS CONN IL12

P7 1 12 POS CONN IL12

P8 1 4 PIN SMB

P9 1 10 PIN CONN10IL

Q1 1 2222 TRANS2222

Q2 1 2907 TO18C

QP1 1 4-2222A DIP14C

R1 1 10 Mohm RES1-8

R10 1 1 kOhm RES1-8

R11 1 5 kOhm POT1

R12 1 10 Kohm RES1-8

R13 1 10 Kohm RES1-8

R14 1 1 kOhm RES1-8

R15 1 6.8 kOhm RES1-8

R16 1 1 kOhm RES1-8

R17 1 500 Ohm POT1

R18 1 10 Kohm RES1-8

R19 1 5.6 kOhm RES1-8

R2 1 4.7 Ohm RES1-8

R20 1 10 Kohm RES1-8

R21 1 91 Ohm RES1-8

R22 1 10 Ohm RES1-8

R23 1 5 kOhm POT1

R3 1 5 kOhm POT1

R4 1 10 Kohm RES1-8

R5 1 1 kOhm RES1-8

R6 1 68 kOhm RES1-8

R7 1 68 kOhm RES1-8

R8 1 68 kOhm RES1-8

R9 1 4.7 Ohm RES1-8

RP1 1 10 Kohm DIPIL11

RP2 1 10 Kohm DIPIL11

RP3 1 10 Kohm DIPIL11

RP4 1 150 Ohm DIP IL8

RP5 1 150 Ohm DIP IL8

TM-200 Issue 1.02 November 2005 Page 30 of 64

Page 32

SW1 1 PADDLE SW1

SW2 1 PADDLE SW1

SW3 1 ROCKER SW1

SW4 1 ROCKER SW1

U1 1 MC74HC165 DIP16C

U2 1 IC34064 REGTO92

U3 1 68705C8 DIP40C

U4 1 74H04 DIP14C

U5 1 74H04 DIP14C

U6 1 MC14499 DIP18C

U7 1 DS232 DIP16C

U8 1 X2402 DIP8C

Y1 1 4MHz XTAL

TM-200 Issue 1.02 November 2005 Page 31 of 64

Page 33

TM-200 Issue 1.02 November 2005 Page 32 of 64

Page 34

TM-200 Issue 1.02 November 2005 Page 33 of 64

Page 35

Agile Output Amplifier Bill of Materials

Last Revision: 09.12.00

Component Reference Quantity

Identification Modifier Package

C1 1 0.1uF 1206

C2 1 0.1uF 1206

C3 1 2.7 pF 1206

C4 1 3-10pF VCAP CGKG27

C5 1 3-10pF VCAP CGKG27

C6 1 3-10pF VCAP CGKG27

C7 1 2.7 pF 1206

E1 1 E-COAX

E2 1 12 V EPAD

E3 1 E-COAX

E5 1 GND EPAD

I1 1 1206

L1 1 IND400

L2 1 10 nH 1210

L3 1 12 nH 1210

L4 1 12 nH 1210

L5 1 10 nH 1210

P1 1 FCONN-S

U1 1 AMP6342

TM-200 Issue 1.02 November 2005 Page 34 of 64

Page 36

TM-200 Issue 1.02 November 2005 Page 35 of 64

Page 37

TM-200 Issue 1.02 November 2005 Page 36 of 64

Page 38

Audio Video Modulator Board Bill of Materials

Last Revision: 09.12.00

Component

Quantity

Identification Modifier Package

Reference

C1 1 0.1uF SMD1206

C10 1 0.1uF SMD1206

C100 1 4.7uF CAP100RP

C101 1 100pF SMD1206

C102 1 47uF CAP100RP

C103 1 0.1uF SMD1206

C104 1 470pF SMD1206

C105 1 0.1uF SMD1206

C106 1 470uF CAP200RP

C107 1 0.1uF SMD1206

C108 1 470uF CAP200RP

C109 1 0.0027uF SMD1206

C11 1 0.1uF SMD1206

C110 1 0.1uF SMD1206

C111 1 NI SMD1206

C112 1 470uF CAP200RP

C113 1 0.1uF SMD1206

C114 1 0.1uF SMD1206

C115 1 0.1uF SMD1206

C116 1 0.1uF SMD1206

C117 1 0.01uF SMD1206

C118 1 18pF SMD1206

C119 1 NI SMD1206

C12 1 0.01uF SMD1206

C120 1 0.1uF SMD1206

C121 1 470uF CAP200RP

C122 1 0.01uF SMD1206

C123 1 470uF CAP200RP

C124 1 10pF SMD1206

C125 1 27pF SMD1206

C126 1 82pF SMD1206

C127 1 0.001uF SMD1206

C128 1 0.01uF SMD1206

C129 1 0.01uF SMD1206

C13 1 0.1uF SMD1206

C130 1 0.1uF SMD1206

C131 1 NI SMD1206

C132 1 0.1uF SMD1206

C133 1 0.01uF SMD1206

C134 1 0.01uF SMD1206

TM-200 Issue 1.02 November 2005 Page 37 of 64

Page 39

C135 1 0.1uF SMD1206

C136 1 0.1uF SMD1206

C137 1 0.01uF SMD1206

C138 1 0.1uF SMD1206

C139 1 0.01uF SMD1206

C14 1 0.001uF SMD1206

C140 1 0.01uF SMD1206

C141 1 0.01uF SMD1206

C142 1 0.1uF SMD1206

C143 1 12pF SMD1206

C144 1 12pF SMD1206

C145 1 3-10pF CGKG27

C146 1 12pF SMD1206

C147 1 12pF SMD1206

C148 1 0.1uF SMD1206

C149 1 0.01uF SMD1206

C15 1 0.01uF SMD1206

C150 1 0.1uF SMD1206

C151 1 27pF SMD1206

C152 1 56pF SMD1206

C153 1 27pF SMD1206

C154 1 0.01uF SMD1206

C155 1 0.01uF SMD1206

C156 1 0.01uF SMD1206

C16 1 0.1uF SMD1206

C17 1 22pF SMD1206

C18 1 56pF SMD1206

C19 1 10pF SMD1206

C2 1 0.1uF SMD1206

C20 1 0.001uF SMD1206

C21 1 0.47uF SMD1206

C22 1 22pF SMD1206

C23 1 22pF SMD1206

C24 1 4.5-20pF CGKG27

C25 1 0.01uF SMD1206

C26 1 0.001uF SMD1206

C27 1 22pF SMD1206

C28 1 4.7uF CAP100RP

C29 1 100pF SMD1206

C3 1 4.7uF CAP100RP

C30 1 0.01uF SMD1206

C31 1 0.1uF SMD1206

C32 1 0.001uF SMD1206

C33 1 0.01uF SMD1206

C34 1 68pF SMD1206

C35 1 100pF SMD1206

C36 1 100pF SMD1206

C37 1 68pF SMD1206

TM-200 Issue 1.02 November 2005 Page 38 of 64

Page 40

C38 1 470uF CAP200RP

C39 1 0.01uF SMD1206

C4 1 0.1uF SMD1206

C40 1 0.01uF SMD1206

C41 1 0.1uF SMD1206

C42 1 0.01uF SMD1206

C43 1 0.01uF SMD1206

C44 1 0.1uF SMD1206

C45 1 470uF 25V CAP200RP

C46 1 1000uF CAP300RP

C5 1 4.7uF CAP100RP

C6 1 0.1uF SMD1206

C7 1 0.001uF SMD1206

C8 1 470uF CAP200RP

C9 1 47pF SMD1206

D1 1 5236 SOT23

D10 1 3800 SOT23

D100 1 2800 SOT23

D101 1 2800 SOT23

D11 1 3800 SOT23

D2 1 2800 SOT23

D3 1 2800 SOT23

D6 1 MMBV105GL SOT23

D7 1 10 V SOT23

D8 1 4.7V SOT23

D9 1 3800 SOT23

F1 1 SIP5L

F100 1 FILTER2219

F101 1 SF28S

J1 1 NI SMD1206

JP1 1 NI SMD1206

JP2 1 0 SMD1206

JP3 1 NI SMD1206

JP4 1 NI SMD1206

JP5 1 0 SMD1206

L1 1 10.5 T,26GA COIL

L100 1 12.5T 22GA COIL

L101 1 0.47uH SMD1812

L102 1 0.47uH SMD1812

L103 1 12.5T 22GA COIL-S

L104 1 12.5T 22GA COIL-S

L105 1 0.47uH SMD1812

L106 1 0.47uH SMD1812

L107 1 0.47uH SMD1812

L15 1 0.47uH IND400

L2 1 0.33uH SMD1812

L3 1 0.33uH SMD1812

L4 1 0.33uH SMD1812

TM-200 Issue 1.02 November 2005 Page 39 of 64

Page 41

L5 1 0.47uH SMD1812

MX100 1 MIXER

P1 1 FCONN-S

P100 1 FCONN-S

P101 1 RTARCA

P102 1 RTARCA

P103 1 FCONN-S

P2 1 CONN10IL

P7 1 CONHDR6

P8 1 CONHDR6

Q1 1 2369 SOT23

Q100 1 2222 SOT23

Q101 1 2907 SOT23

Q102 1 2222 SOT23

Q103 1 2222 SOT23

Q104 1 2907 SOT23

Q105 1 2222 SOT23

Q106 1 2222 SOT23

Q107 1 2222 SOT23

Q108 1 MRF559B2

Q109 1 MRF559B2

Q110 1 MRF559B2

Q2 1 2369 SOT23

R1 1 300kohm SMD1206

R10 1 220kohm SMD1206

R100 1 75ohm R1206A

R101 1 22kohm SMD1206

R102 1 270ohm SMD1206

R103 1 620ohm SMD1206

R104 1 2kohm SMD1206

R105 1 360ohm SMD1206

R106 1 2kohm SMD1206

R107 1 51ohm SMD1206

R108 1 330ohm SMD1206

R109 1 3.6kohm SMD1206

R11 1 100ohm SMD1206

R110 1 6.8kohm SMD1206

R111 1 680kohm SMD1206

R112 1 1kohm SMD1206

R113 1 910ohm SMD1206

R114 1 22ohm SMD1206

R115 1 330ohm SMD1206

R116 1 1.5kohm SMD1206

R117 1 560ohm SMD1206

R118 1 1kohm SMD1206

R119 1 330ohm SMD1206

R12 1 75kohm SMD1206

R120 1 1kohm POTENTIOMETER ST53YJ

TM-200 Issue 1.02 November 2005 Page 40 of 64

Page 42

R121 1 560ohm SMD1206

R122 1 1.5kohm SMD1206

R123 1 470kohm SMD1206

R124 1 51ohm SMD1206

R125 1 10kohm POTENTIOMETER ST53YJ

R126 1 1kohm SMD1206

R127 1 1kohm SMD1206

R128 1 NI SMD1206

R129 1 360ohm SMD1206

R13 1 1kohm SMD1206

R130 1 10kohm POTENTIOMETER ST53YJ

R131 1 180ohm SMD1206

R132 1 51ohm SMD1206

R133 1 150ohm SMD1206

R134 1 22ohm SMD1206

R135 1 10kohm SMD1206

R136 1 10kohm SMD1206

R137 1 1.5kohm SMD1206

R138 1 1kohm SMD1206

R139 1 10kohm SMD1206

R14 1 470kohm SMD1206

R140 1 20kohm 1% SMD1206

R141 1 27ohm SMD1206

R142 1 36ohms SMD1206

R143 1 27ohm SMD1206

R144 1 1kohm SMD1206

R145 1 4.7ohm SMD1206

R146 1 82ohm SMD1206

R147 1 2kohm SMD1206

R148 1 220ohm SMD1206

R149 1 75ohm SMD1206

R15 1 10kohm POTENTIOMETER ST53YJ

R150 1 1kohm SMD1206

R151 1 18ohm SMD1206

R152 1 1kohm SMD1206

R153 1 1kohm SMD1206

R154 1 2kohm SMD1206

R155 1 4.7ohm SMD1206

R156 1 82ohm SMD1206

R157 1 220ohm SMD1206

R158 1 75ohm SMD1206

R159 1 4.7ohm SMD1206

R16 1 100ohm SMD1206

R160 1 91ohm SMD1206

R161 1 4.7ohm SMD1206

R162 1 4.7ohm SMD1206

R163 1 75ohm SMD1206

R164 1 4.7ohm SMD1206

TM-200 Issue 1.02 November 2005 Page 41 of 64

Page 43

R165 1 1kohm SMD1206

R166 1 2kohm SMD1206

R167 1 4.7ohm SMD1206

R168 1 82ohm SMD1206

R169 1 75ohm SMD1206

R17 1 1kohm SMD1206

R170 1 220ohm SMD1206

R171 1 NI SMD1206

R172 1 NI SMD1206

R18 1 270ohm SMD1206

R19 1 10kohm SMD1206

R2 1 150kohm SMD1206

R20 1 560ohm SMD1206

R21 1 10kohm SMD1206

R22 1 1kohm SMD1206

R23 1 390ohm SMD1206

R24 1 100kohm SMD1206

R25 1 220kohm SMD1206

R26 1 1Mohm SMD1206

R27 1 2kohm SMD1206

R28 1 68ohm RES2010A

R29 1 220ohm 1/2 WATT RES2010A

R3 1 300kohm SMD1206

R30 1 75ohm SMD1206

R31 1 1kohm SMD1206

R32 1 1kohm SMD1206

R33 1 2kohm SMD1206

R34 1 1kohm SMD1206

R35 1 4.7kohm SMD1206

R36 1 2kohm SMD1206

R37 1 1kohm SMD1206

R38 1 430ohm SMD1206

R39 1 27ohm SMD1206

R4 1 150kohm SMD1206

R40 1 430ohm SMD1206

R5 1 1kohm SMD1206

R7 1 4.7kohm SMD1206

R8 1 10kohm SMD1206

R9 1 10kohm SMD1206

TB1 1 TERBLK

TP100 1 0 SMD1206

TP101 1 0 SMD1206

U1 1 LF353 DIP8SM

U100 1 NE592D DIP8SM

U101 1 2090 DIP16SM

U102 1 LM1881 DIP8SM

U103 1 LM358 DIP8SM

U2 1 145106 145106

TM-200 Issue 1.02 November 2005 Page 42 of 64

Page 44

U4 1 501 FPT-08-M01

Y1 1 XTL49

Y100 1 45.75Mhz XTL49

TM-200 Issue 1.02 November 2005 Page 43 of 64

Page 45

TM-200 Issue 1.02 November 2005 Page 44 of 64

Page 46

TM-200 Issue 1.02 November 2005 Page 45 of 64

Page 47

Signal Conditioning Bill of Materials

Last Revision: 11.07.05

Index

Qty

Designations Description Mfg. Part Number Package

1 1 C832 Capacitor, electrolytic, 10uF 35V ECE-V1VA100SR VS "C"

2 2 C839, C840 Capacitor, electrolytic, 100uF, 25V, SMD ECE-V1EA101UP VS 'E'

3 1 C817 Capacitor, electrolytic, 100uF, 10V, SMD ECE-V1AA101SP VS 'D'

4 4

5 1 C820 Capacitor, ceramic, 470pF 50V X7R CC0805KRX7R9BB471 SMD 0805

6 10

7 10

8 9

9 1 C838 Capacitor, ceramic, 0.33 uF, 25V, SMD ECJ-2YF1E334Z SMD 0805

10 1 C822 Capacitor, trim 5-50pF low power 9410-5SL-1 SMD

11 1 D801 Diode, 200mA, 100V, SMD SOT-23

12 1 D802 Diode Sil 2A 200V DO-214AA S2D SMBJ

13 2 D803, D804 Diode, If= 1A, Vbr= 100V SOT-23

14 1 D805 Diode, LED, 5mm, 1500mCd SSL-LX5093SRC/DV TH

15 1 J801 Connector, 4-position, 0.2" spacing, rt. angle ED120/4DS 0.2" THT

16 2 J802, J803 Connector, RCA, jack, vertical, PC mount, blue RCJ-021

J804, J805 Connector, F, PCB, strait RFF-1450-03 TH

17 1 K801 Relay, DPDT, 5Vdc coil TX2SA-5V SMD

18 5

19 1 L806 Inductor, 1.5uH, 5% KL32LTE1R5J SMD 1210

20 2 L807, L808 Inductor, 2.2uH, 5% KL32LTE2R2J SMD 1210

21 4

22 2 R830, R831 Resistor, 0.0Ω, 5% 9C12063A0R00JLHFT SMD 1206

23 2 R821, R822 Resistor, 39Ω, 1% MCR10EZHF39R0 SMD 0805

24 1 R826 Resistor, 56Ω, 1% MCR10EZHF56R0 SMD 0805

25 1 R819 Resistor, 68Ω, 1% MCR10EZHF68R0 SMD 0805

26 2 R808, R818 Resistor, 75 ohm, 1/4W CRCW1206-750JRT1 SMD 1206

27 1 R827 Resistor, 100Ω, 1% MCR10EZHF1000 SMD 0805

28 1 R820 Resistor, 100Ω, 5% ERJ-1TYJ101U SMD 2512

29 3

C803, C806,

C809, C815

C821, C824,

C825, C826,

C827, C828,

C829, C830,

C833, C834 Capacitor, ceramic, 1000pF 50V, X7R 10% ECJ-2VB1H102K SMD 0805

C802, C805,

C808, C814,

C818, C823,

C831, C835,

C836, C837 Capacitor, ceramic, 0.01uF 50V X7R C0805C103K5RACTU SMD 0805

C801, C804,

C807, C810,

C811, C812,

C813, C816,

C819 Capacitor, ceramic, 0.1 uF, 50V, SMD C0805C104K5RACTU SMD 0805

L801, L802,

L803, L804,

L805 Inductor, 0.01uH, 0.450A max NLV32T-010J-PF SMD 1210

Q801, Q802,

Q803, Q804 Transistor, general purpose SOT-23

R801, R824,

R825 Resistor, 120 ohm, 1/8W MCR10EZHF1210 SMD 0805

Capacitor, tantalum, 10uF, 16V, SMD T491B106K016AS SMD 3528

TM-200 Issue 1.02 November 2005 Page 46 of 64

Page 48

30 1 R823 Resistor, 120Ω, 5% MCR18EZHJ121 SMD 1206

31 2 R806,R807 Resistor, 402 ohm, 1/8W MCR10EZHF4020 SMD 0805

32 2 R803, R832 Resistor, 470 ohm, 1/8W MCR10EZHF4700 SMD 0805

33 1 R829 Resistor, 680Ω, 1% MCR10EZHF6800 SMD 0805

34 1 R813 Resistor, 1 kohm, 1/8W MCR10EZHF1001 SMD 0805

35 1 R828 Resistor, 1.8KΩ, 1% MCR10EZHF1801 SMD 0805

36 4

37 5

38 1 R809 Resistor, 47 kohm, 1/8W MCR10EZHF4702 SMD 0805

39 1 R805 Resistor, TBD, 1/8W ( Not stuffed) SMD 0805

40 1 S801 Square post header, 3 position, 0.1" breakaway 7000-1X25SG -

41 1 S802 Square post header, 2 position, 0.1" breakaway

42 1 U801 IC, video signal conditioner MAX7450 SOIC-8

43 2 U802, U803 IC, op-amp, voltage limiting OPA698ID SOIC-8

44 1 U804 IC, comparator, dual LM393M SOIC-8

45 1 U805 IC, voltage reference SOT-23

46 1 U806 Amplifier SMD

47 1 U807 IC, regulator, +5V, 500mA LM78M05CDT SMD

48 1 U808 IC, voltage converter, 100mA, 735mW LM2660M SOIC-8

49 1 VR801 Potentiometer, 10KΩ, 3/8" top adj. 3386P-1-103 TH

50 2 VR804, VR805 Potentiometer, 10KΩ, 4MM top adj. 3214W-1-103E SMD

51 2 VR802, VR803 Potentiometer, 500Ω, 3/8" top adj. 3386P-1-501 TH

52 1 PCB

53 3 Spacer, 1/4" Hex, Aluminum, M/F, 4-40 139213

54 1

R811, R812,

R816, R817 Resistor, 3 kohm, 1/8W MCR10EZHF3001 SMD 0805

R802, R804,

R810, R814,

R815 Resistor, 10 kohm, 1/8W MCR10EZHF1002 SMD 0805

Printed circuit board, double sided, FR4,

0.062", 3.359" (W) X 1.550" (H) -

Cable, RG-179/PP7.5", connects V.C.B. to

modulator 500-0010-045

TM-200 Issue 1.02 November 2005 Page 47 of 64

Page 49

TM-200 Issue 1.02 November 2005 Page 48 of 64

Page 50

TM-200 Issue 1.02 November 2005 Page 49 of 64

Page 51

Digital Up converter Bill of Materials

Last Revision: 09.12.00

Component Reference

Quantity Identification Modifier Package

C1 1 0.1uF 1206

C101 1 100 Pf 1206

C102 1 0.1uF 1206

C103 1 100uF 25V CAP100RP

C104 1 0.47uF 1812

C105 1 0.1uF 1206

C106 1 0.22uF 1206

C107 1 100 Pf 1206

C108 1 1pF 1206

C109 1 100 Pf 1206

C11 1 0.1uF 1206

C110 1 100 Pf 1206

C111 1 1pF 1206

C112 1 1pF 1206

C113 1 1pF 1206

C114 1 1pF 1206

C115 1 0.47uF 1812

C116 1 0.1uF 1206

C116A 1 100uF 25V CAP100RP

C117 1 0.1uF 1206

C118 1 0.1uF 1206

C119 1 0.1uF 1206

C12 1 0.01uF 1206

C120 1 100 Pf 1206

C126 1 0.1uF 1206

C127 1 0.1uF 1206

C128 1 100 Pf 1206

C129 1 0.1uF 1206

C13 1 0.1uF 1206

C130 1 2.2pF 1206

C131 1 100 Pf 1206

C132 1 0.1uF 1206

C133 1 0.47uF 1206

C134 1 100uF 25V CAP100RP

C135 1 10 Pf 1206

C136 1 10 Pf 1206

C137 1 10 Pf 1206

C138 1 10 Pf 1206

C139 1 10 Pf 1206

C14 1 0.01uF 1206

C140 1 10 Pf 1206

C141 1 NI 1206

TM-200 Issue 1.02 November 2005 Page 50 of 64

Page 52

C15 1 0.1uF 1206

C2 1 0.01uF 1206

C201 1 NI CGKG27

C204 1 0.1uF 1206

C205 1 0.1uF 1206

C206 1 100 Pf 1206

C207 1 0.1uF 1206

C208 1 2.2pF 1206

C209 1 0.1uF 1206

C21 1 0.1uF 1206

C210 1 0.1uF 1206

C3 1 0.01uF 1206

C300 1 0.1uF 1206

C301 1 100 Pf 1206

C303 1 470 uF 25 V CAP200RP

C4 1 0.01uF 1206

C5 1 0.1uF 1206

D1 1 3800 SOT-23

D100 1 9.1V DIODEZ DO214AC

D101 1 9V 914 SOT-23

D102 1 4.7V SOT-23

D103 1 10 V DIODEZ DO214AC

D2 1 3800 SOT-23

D3 1 3800 SOT-23

F2 1 F-LP-TOKO

F4 1 F-LP-TOKO

FT200 1 FIL-TOKO

J1 1 N/A THRU-HOLE

J10 1 N/A THRU-HOLE

J2 1 N/A THRU-HOLE

J3 1 N/A THRU-HOLE

J4 1 N/A THRU-HOLE

J5 1 N/A THRU-HOLE

J6 1 N/A THRU-HOLE

J7 1 N/A THRU-HOLE

J8 1 N/A THRU-HOLE

J9 1 N/A THRU-HOLE

L1 1 0.47uH 1812

L104 1 10nH 1812

L107 1 0.22uH 1210

L108 1 0.22uH 1210

L109 1 0.22uH 1210

L5 1 0.47uH 1812

L6 1 0.47uH 1812

M1 1 MIXER-RF2

P1 1 N/A FCONN-S

P2 1 N/A FCONN-S

R1 1 1k Ohm 1206

TM-200 Issue 1.02 November 2005 Page 51 of 64

Page 53

R101 1 1k Ohm 1206

R102 1 910 Ohm 1206

R103 1 910 Ohm 1206

R104 1 0 1206

R105 1 47 kOhm 1206

R106 1 220 Ohm 1/2 WATT RES2010A

R108 1 43 Ohm 1/2 WATTS RES2010A

R109 1 220 Ohm 1/2 WATT RES2010A

R111 1 33 Ohm 1206

R112 1 180 Ohm 1206

R113 1 180 Ohm 1206

R114 1 220 Ohm 1/2 WATT RES2010A

R115 1 75 Ohm 1206

R116 1 10 Ohm 1206

R117 1 36 Ohm 1206

R118 1 10 Ohm 1206

R119 1 75 Ohm 1206

R120 1 110 Ohm 1 WATT RES2010A

R121 1 4.7 Ohm 1206

R122 1 91 Ohm 1206

R123 1 4.7 Ohm 1206

R14 1 36 Ohm 1206

R15 1 62 Ohm 1206

R16 1 36 Ohm 1206

R17 1 1k Ohm 1206

R18 1 2k Ohm 1206

R19 1 75 Ohm 1206

R2 1 1k Ohm 1206

R20 1 8.2 Ohm 1206

R200 1 300 Ohm 1206

R201 1 18 Ohm 1206

R202 1 300 Ohm 1206

R203 1 100 Ohm 1206

R204 1 110 Ohm 1 WATT RES2010A

R205 1 4.7 Ohm 1206

R206 1 75 Ohm

1206

R207 1 4.7 Ohm 1206

R21 1 82 Ohm 1206

R22 1 220 Ohm 1206

R23 1 100 Ohm 1206

R24 1 4.7 Ohm 1206

R25 1 100 Ohm 1206

R3 1 2k Ohm 1206

R4 1 4.7k Ohm 1206

R5 1 2k Ohm 1206

R6 1 1k Ohm 1206

U100 1 145200 TSSOP20

U101 1 ERA5 WW107

TM-200 Issue 1.02 November 2005 Page 52 of 64

Page 54

U102 1 ERA5 WW107

U2 1 RF559B2

U200 1 ERA5 WW107

VC01 1 MINI14SL

TM-200 Issue 1.02 November 2005 Page 53 of 64

Page 55

TM-200 Issue 1.02 November 2005 Page 54 of 64

Page 56

TM-200 Issue 1.02 November 2005 Page 55 of 64

Page 57

750 MHz Down Converter Bill of Materials

Last Revision: 09.13.00

Component Reference

Quantity

Identification Modifier Package

C1 1 27 pF 1206

C10 1 100 pF 1206

C100 1 2.2 pF 1206

C101 1 2.2 pF 1206

C102 1 NI 1206

C11 1 0.1 uF 1206

C12 1 0.47 uF 1812

C13 1 100 uF 25 V CAP100RP

C14 1 NI 1206

C15 1 10 pF 1206

C16 1 10 pF 1206

C17 1 10 pF 1206

C18 1 10 pF 1206

C19 1 10 pF 1206

C2 1 27 pF 1206

C20 1 10 pF 1206

C200 1 NI 1206

C205 1 2.7 pF 1206

C206 1 3-10 pF CGKG27

C207 1 3-10 pF CGKG27

C208 1 3-10 pF CGKG27

C209 1 2.7 pF 1206

C21 1 0.1 uF 1206

C210 1 0.1 uF 1206

C211 1 0.1 uF 1206

C212 1 0.1 uF 1206

C213 1 100 pF 1206

C214 1 1 pF 1206

C215 1 10 pF 1206

C22 1 0.22 uF 1206

C23 1 100 pF 1206

C24 1 1 pF 1206

C25 1 100 pF 1206

C26 1 0.1 uF 1206

C27 1 100 uF 25 V CAP100RP

C28 1 0.1 uF 1206

C29 1 0.1 uF 1206

C3 1 4.5-20 pF CGKG27

C30 1 0.1 uF 1206

C301 1 0.1 uF 1206

C302 1 100 pF 1206

C303 1 470 uF 35 WV

CAP275RP650

TM-200 Issue 1.02 November 2005 Page 56 of 64

Page 58

C304 1 0.1 uF 1206

C31 1 1206

C33 1 1 pF 1206

C34 1 1 pF 1206

C35 1 1 pF 1206

C36 1 1 pF 1206

C37 1 0.1 uF 1206

C38 1 0.1 uF 1206

C39 1 NI 1206

C4 1 0.47 uF 1812

C40 1 NI 1206

C41 1 NI 1206

C44 1 0.1 uF 1206

C45 1 0.1 uF 1206

C46 1 100 pF 1206

C5 1 100 pF 1206

C6 1 0.1 uF 1206

C7 1 0.47 uF 1812

C8 1 100 uF 25 V CAP100RP

C9 1 100 pF 1206

D1 1 9 V D914 SOT23

D2 1 9.1 V DIODEZ D0214AC

D3 1 9 V SOT23

D4 1 DIODEZ D0214AC

FT100 1 FIL-TOKO

J1 1 THRU-HOLE

J2 1 THRU-HOLE

J3 1 THRU-HOLE

J4 1 THRU-HOLE

J5 1 THRU-HOLE

J6 1 THRU-HOLE

J7 1 THRU-HOLE

J8 1 THRU-HOLE

J9 1 THRU-HOLE

L1 1 0.22 uH 1210

L100 1 10 nH 1210

L2 1 0.22 uH 1210

L200 1 10 nH 1210

L201 1 12 nH 1210

L202 1 12 nH 1210

L203 1 10 nH 1210

L204 1 10 nH 1210

L3 1 0.22 uH 1210

L4 1 10 nH 1210

M1 1 PULSAR MIXER-RF2

OSC1 1 MA06 MINI14SL

P1 1 FCONN-S

P2 1 FCONN-S

TM-200 Issue 1.02 November 2005 Page 57 of 64

Page 59

R10 1 180 Ohm 1206

R100 1 33 Ohm 1206

R101 1 51 Ohm 1206

R102 1 4.7 Ohm 1206

R103 1 91 Ohm 1206

R104 1 4.7 Ohm 1206

R11 1 33 Ohm 1206

R12 1 180 Ohm 1206

R13 1 220 Ohm 1/2 WATT RES2010A

R14 1 0 Ohm 1206

R15 1 75 Ohm 1206

R16 1 10 Ohm 1206

R17 1 33 Ohm 1206

R18 1 NI 1206

R19 1 NI 1206

R2 1 10 kOhm 1206

R20 1 4.7 Ohm 1206

R200 1 NI 1206

R201 1 NI 1206

R202 1 0 Ohm 1206

R203 1 NI 1206

R204 1 0 Ohm 1206

R207 1 0 Ohm 1206

R208 1 110 Ohm 1 WATT RES2010A

R209 1 0 Ohm 1206

R21 1 110 Ohm 1 WATT RES2010A

R210 1 NI 1206

R211 1 0 Ohm 1206

R22 1 75 Ohm 1206

R3 1 220 Ohm 1/2 WATT RES2010A

R4 1 47 kOhm 1206

R5 1 RES2010A

R6 1 910 Ohm 1206

R7 1 910 Ohm 1206

R8 1 0 Ohm 1206

R9 1 43 Ohm 1/2 WATT RES2010A

U1 1 145200 TSSOP20

U2 1 ERA3 WW107

U201 1 ERA5 WW107

U3 1 ERA5 WW107

Y1 1 4000 MHz XTL49

TM-200 Issue 1.02 November 2005 Page 58 of 64

Page 60

TM-200 Issue 1.02 November 2005 Page 59 of 64

Page 61

TM-200 Issue 1.02 November 2005 Page 60 of 64

Page 62

Power Supply Bill of Materials

Last Revision: 09.12.00

Component

Quantity

Reference

C1 1 4700 35 V CAP400RPHORZ

C10 1 0.1 uF CAP250

C11 1 0.1 uF CAP250

C12 1 0.1 uF CAP250

C13 1 0.1 uF CAP250

C14 1 1000 50 V CAP275RP650

C15 1 0.1 uF CAP250

C16 1 4700 16 VDC CAP275RP650

C17 1 1000 50 V CAP275RP650

C18 1 0.1 uF CAP250

C19 1 0.1 uF CAP250

C2 1 4700 35 V CAP400RPHORZ

C3 1 0.1 uF CAP250

C4 1 0.1 uF CAP250

C5 1 0.1 uF CAP250

C6 1 0.1 uF CAP250

C7 1 2200 35 V CAP275RP650

C8 1 0.1 uF CAP250

C9 1 10000 25 VDC CAP400RPHORZ

P1 1 CONHDR6

P2 1 CONHDR6

P3 1 CONHDR6

P4 1 CONHDR6

P5 1 CONHDR6

P6 1 CONHDR6

P7 1 CONHDR8

R1 1 2 kOhm RES400

R2 1 240 Ohm RES400

R4 1 5.6 kOhm RES400

U1 1 BRIDGE

U2 1 RBRDG-RECT-

U3 1 LM317 T0-220-AB

U4 1 7824 T0-220-AB

U5 1 7812 T0-220-AB

U6 1 7805 T0-220-AB

U7 1 DIP6-2

Identification Modifier Package

403M

TM-200 Issue 1.02 November 2005 Page 61 of 64

Page 63

TM-200 Issue 1.02 November 2005 Page 62 of 64

Page 64

TM-200 Issue 1.02 November 2005 Page 63 of 64

Loading...

Loading...