UV/VIS Spectrophotometer

UV 2600

Version: 1

INSTRUCTION

MANUAL

UV2600 UV/VIS Spectrophotometer

CONTENT

PREDACE ............................................................................................................................ 1

ABOUT THIS MANUAL ....................................................................................................... 1

PRECAUTIONS ON SAFETY ............................................................................................. 6

Chapter 1 Installation ......................................................................................................... 12

1.1 Unpacking ............................................................................................................. 12

1.2 Installation Conditions .......................................................................................... 13

1.2.1 Work Power Supply .................................................................................... 13

1.2.2 Work Table.................................................................................................. 13

1.3 Installation Environment ....................................................................................... 14

1.3.1 Operating Temperature .............................................................................. 14

1.3.2 Operating Humidity .................................................................................... 14

1.3.3 Storage Temperature .................................................................................. 14

1.3.4 Atmospheric Environment .......................................................................... 14

1.3.5 Sample Solvent .......................................................................................... 14

1.3.6 Other General Notes .................................................................................. 14

1.4 Check of Contents ................................................................................................ 15

1.5 Instrument Installation .......................................................................................... 16

1.6 Check of Voltage and Fuse .................................................................................. 16

1.7 Connection of Communication Cable................................................................... 17

1.7.1 PC Port ....................................................................................................... 17

1.7.2 Acc Port ...................................................................................................... 17

1.8 Connection of Power Cord and Grounding Wire.................................................. 17

1.9 Power On .............................................................................................................. 18

Chapter 2 Function .......................................................................................................... 19

2.1 Work Principle....................................................................................................... 19

2.2 Optical Path System ............................................................................................. 20

2.3 Circuit System ...................................................................................................... 21

2.4 Function Mode ...................................................................................................... 22

2.5 Sample Compartment........................................................................................... 23

2.6 Specifications ........................................................................................................ 24

Chapter 3 Operation .......................................................................................................... 25

3.1 Preparation ........................................................................................................... 25

3.1.1 Install Software & Connect UV2600 to PC ................................................ 25

3.1.2 Initialization ................................................................................................. 25

3.2 Basic Operation .................................................................................................... 26

3.2.1 Operation Method ...................................................................................... 26

Chapter 4 Maintenance ..................................................................................................... 28

4.1 Daily Maintenance ................................................................................................ 28

4.1.1 Cleaning of Sample Compartment ............................................................. 28

4.1.2 Clean of Spectrophotometer Cover ........................................................... 30

4.1.3 Cleaning and Storing of Cuvette ................................................................ 31

4.1.4 Add Lube .................................................................................................... 32

4.1.5 Clean of Window Frame and Lens of Sample Compartment ................. 32

4.2 Performance Verification ...................................................................................... 33

4.3 Troubleshooting .................................................................................................... 34

4.3.1 Error Information ........................................................................................ 34

4.3.2 Failure Cause and Countermeasure .......................................................... 35

4.3.3 Replacing fuses .......................................................................................... 35

4.4 Replacement of Consumable Parts ..................................................................... 36

4.4.1 Replacement of Light Source Lamp .......................................................... 36

4.4.2 Clear of Lamp Use Time ............................................................................ 41

4.4.3 Adjustment of Lamp ................................................................................... 41

4.5 Disassembly of Instrument Main Parts ................................................................. 45

4.5.1 Open Instrument Cover .............................................................................. 45

4.5.2 Removal Procedures of Power Switch ...................................................... 45

4.5.3 Removal of Control Board and Lamp Power Supply Board ...................... 46

4.5.4 Removal Procedures of Pre-amplifier ........................................................ 46

4.6 Storing of Instrument .......................................................................................... 47

4.6.1 After Test Is Finished .................................................................................. 47

4.6.2 Instrument Will Not Be Used for a Long Time ........................................... 47

PREFACE&SAFETY SUMMARY

PREFACE

Thank you very much for your purchase of Techcomp Model UV2600

UV/VIS Spectrophotometer.

The Model UV2600 Spectrophotometer is intended for the purpose of

spectral analysis. Do not use it for any other purpose.

The Model UV2600 is designed for use by persons having a basic

knowledge of chemical analysis. Other persons should operate the

instrument in the presence of someone who has such basic knowledge.

Remember that improper use of the instrument, chemicals or samples

would result not only in wrong analytical data but in consequences adverse

to safety.

Before using the instrument, be sure to read through this instruction

manual to enable correct use.

For installation/maintenance of the instrument, read the instruction manual

carefully to attain a full understanding of the instructions. Be sure to

observe cautionary instructions.

Keep this manual handy for easy reference when necessary.

Information contained in this manual is subject to change without notice for

product improvement.

ABOUT THIS MANUAL

Before using the instrument, be sure to read through this instruction

manual. First of all, read “SAFETY SUMMARY” included at the beginning

of this manual for ensuring safety in operation of the spectrophotometer

main unit.

1

PREFACE&SAFETY SUMMARY

Precautions on Electromagnetic Wave Interference

(1)Possible Electromagnetic Wave Interference Caused by This Instrument

When this instrument is used in a residential area or an adjacent area

thereto, it may cause interference to radio and television reception.

To prevent this, use the specified system connection cables in strict

accordance with the instruction manual. The instrument is designed to

minimize possible electromagnetic wave interference caused by it if the

specified cables are connected properly.

However, there is no guarantee that electromagnetic wave interference will

not be caused by the instrument. If the instrument does cause

interference to radio or television reception, which can be determined by

turning off and on the instrument, the user is encouraged to try to correct

the interference by one or more of the following measures:

Increase separation between the instrument and radio/TV receiver.

Connect the instrument to an outlet on a circuit different from that to

which the radio/TV receiver is connected.

(2)Possible Electromagnetic Wave Interference Affecting This Instrument

If this instrument is used near an intense electromagnetic source,

interference noise may be given to the instrument to incur an adverse effect

on its performance or functionality.This effect will be less than 1% and still

could be accepted.

To prevent this, use the specified system connection cables in strict

accordance with the instruction manual. The instrument is designed to

minimize possible electromagnetic wave interference affecting it if the

specified cables are connected properly.

However, there is no guarantee that electromagnetic wave interference will

not occur in this instrument. If the instrument does incur electromagnetic

wave interference, which can be determined by turning on and off possible

sources of electromagnetic wave interference nearby, the user is

encouraged to try to correct the interference by one or more of the following

measures:

Reorient the instrument.

Increase separation between the instrument and possible sources of

electromagnetic wave interference.

Increase separation between the power cable of the instrument and

possible sources of electromagnetic wave interference.

Connect the instrument to an outlet on a circuit different from that to

which possible sources of electromagnetic wave interference are

connected.

Confirm that any other device connected with the instrument is not

affected by electromagnetic wave interference.

2

PREFACE&SAFETY SUMMARY

Warranty on Product

The Model UV2600 Spectrophotometer is warranted to operate according

to the specifications given in the instruction manual, provided it is used in

accordance with the instructions described in the manual.

(1)Scope of Warranty

(a) Main unit of the instrument which prove to be defective in design or

workmanship during the warranty period will be repaired without charge.

(b) A substitute part may be used for repair, or replacement with an

equivalent product may be made instead of repair.

(c) Such system components as a personal computer and printer to be

updated frequently for improvement may not be available in original

versions at the time of replacement.

(d) The instrument can’t be provided repair for free in warranty period if it

was sold to other user.

(2)Warranty Period

One year from the date of initial installation or received by the customer (The

deadline refer to the fist one).

(3)Limitations and Exclusions on Warranty

Note that this warranty is void in the following cases, even if they occur

within the warranty period.

(a) Failure due to operation at a place not meeting the installation

requirements specified by us

(b) Failure due to power supply voltage/frequency other than specified by

us or due to abnormality in power supply

(c) Corrosion or deterioration of the tubing due to impurities contained in

reagent, gas, air or cooling water supplied by the user

(d) Corrosion of the electric circuits or deterioration of the optical elements

due to highly corrosive atmospheric gas

(e) Failure due to use of hardware, software or spare parts other than

supplied by us

(f) Failure due to improper handling or maintenance by the user

(g) Failure due to maintenance or repair by a service agent not approved

or authorized by us

3

PREFACE&SAFETY SUMMARY

(h) After disposal of this instrument, or after its resale without our approval

(i) Failure due to relocation or transport after initial installation

(j) Failure due to disassembly, modification or relocation not approved by

us

(k) Consumables, and failure of parts that have reached the end of

specified useful life

(l) Failure of parts excluded from the warranty in the instruction manual or

other documents

(m) Failure due to acts of God, including fire, earthquake, storm, lightning,

social disturbance, riot, crime, insurrection, war (declared or undeclared),

radioactive pollution, contamination with harmful substances, etc.

(n) Failure of the hardware, or damage to the system software, application

software, data or hard disk due to computer virus infection

(o) Failure of the personal computer connected with the instrument, or

damage to the system software, application software, data or hard disk

due to power interruption or momentary power voltage drop caused by

lightning or the like

(p) Failure of the personal computer connected with the instrument, or

damage to the system software, application software, data or hard disk

due to disconnection of main power to the personal computer without

taking the specified normal shutdown procedure

Warning: Class A equipments is intended for use in an industrial environment. In the

documentation for the user, a statement shall be included drawing attention to the fact that

there may be potential difficulties in ensuring electromagnetic compatibility in other

environments, due to conducted as well as radiated disturbances.

(4)Disclaimer of Warranty

(a) Any express warranties other than the explicit conditions indicated in

(1) are excluded from this warranty.

Any other implied warranties of merchantability and fitness for a particular

purpose are not included in this warranty. No liability is assumed for

direct or indirect damages arising out of explicit or implied warranties.

(b) Oral or written information or advice given by our dealers, distributors,

agents or employees without our express permission shall not create a

warranty or in any way increase the scope of this warranty.

Installation, Relocation and After-sale Technical Service

4

PREFACE&SAFETY SUMMARY

Installation of this instrument shall be carried out by or under supervision of

qualified service personnel of Techcomp Corporation or its authorized service

agent.

Before installation of the instrument, the user shall make preparations for

satisfying the installation requirements in accordance with the instruction

manual.

If relocation of the instrument becomes necessary after initial installation

(delivery), please notify your local sales representative or nearest service

office of Techcomp.

Technology Training for User

For using the instrument safely and correctly, technology training speeches are

held at Techcomp’s or user’s site. Contact Techcomp for attending procedures.

Technology training speeches are payable, it will charge fee.

Disposal of this Instrument

When you discard equipment, please check and confirm some related

statute, law and practices .or ask the service section of Techcomp.

Other Precautions

(1)Handling of Chemicals and Samples

(1) The user is responsible for following relevant legal standards and

regulations in handling, storage and discarding of chemicals and samples

used in analytical operations of this instrument.

(2) Reagents, standard solutions and accuracy-control samples shall be

handled, stored and discarded as instructed by the respective suppliers.

(2)Notice on Instruction Manuals

(1) Information contained in the instruction manuals furnished with the

instrument is subjected to change without notice for product improvement.

(2) This manual is copyrighted by Techcomp with all rights reserved.

(3) No part of this manual may be reproduced or transmitted in any form or

by any means without our express written permission.

5

PREFACE&SAFETY SUMMARY

SAFETY SUMMARY

PRECAUTIONS ON SAFETY

Before using the Model UV2600 Spectrophotometer, be sure to read the

following safety instructions carefully.

General Safety Guidelines

Follow all the operating procedures provided in this manual.

Installation and maintenance of the product shall be carried out by

service personnel qualified therefore.

Be sure to observe the warnings indicated on the product and in the

instruction manual. Failure to do so could result in personal injury or

damage to the product.

The hazard warnings which appear on the warning labels on the

product or in the manual have one of the following alert headings

consisting of an alert symbol and signal word DANGER, WARNING, or

CAUTION.

DANGER: Indicates an imminently hazardous situation which, if

not avoided, will result in death or serious injury.

(This warning does not apply to this product.)

WARNING: Indicates a potentially hazardous situation which, if

not avoided, can result in death or serious injury.

CAUTION: Indicates a hazardous situation which, if not avoided,

will or can result in minor or moderate injury, or

serious damage to the product.

: Precedes every signal word for hazard warnings, and

appears in safety-related descriptions in the manual.

“NOTICE” and “NOTE” are heading words which do not concern personal

safety directly.

NOTICE:Used to indicate an instruction for preventing damage to the

product.

NOTE: Used to indicate an instruction for ensuring correct use of the

product and accurate analysis therewith.

6

PREFACE&SAFETY SUMMARY

SAFETY SUMMARY

General Safety Guidelines

■ Do not modify the product, replace parts that are not user-

serviceable, use non-specified parts, nor remove safety devices, as it

could be hazardous.

■ Installation at delivery, maintenance and relocation should be referred

to our qualified service personnel.

■ Do not perform any operation or action other than described in the

instruction manual. When in doubt, please contact our sales

representative or service office nearest you.

■ When using a chemical for analytical operation, be sure to provide

proper ventilation in the laboratory room as per local requirements.

Inadequate ventilation could endanger human health.

Keep in mind that the hazard warnings in the manual or on the product

cannot cover every possible case, as it is impossible to predict and

evaluate circumstances beforehand.

Be alert and use your common sense.

7

PREFACE&SAFETY SUMMARY

SAFETY SUMMARY

This instruction manual contains the following cautious instructions.

DANGER

The warning “DANGER” does not apply to this product.

WARNING

Electric Shock in Contact with Dangerous High Voltage (500 V)

In contact with D2 lamp power supply voltage (500 V), you may receive an

electric shock to cause fatal or serious injury.

Before replacing the D2 lamp, make sure that the POWER switch of the

spectrophotometer main unit is turned off.

Electric Shock in Contact with Dangerous Voltage

In contact with power supply voltage (100-240V), you may receive an

electric shock to cause fatal or serious injury.

Before connecting the power cord, make sure that the POWER switch of

the spectrophotometer main unit is turned off.

CAUTION

Burn in Contact with High Temperature

The D2 lamp and WI lamp reach a high temperature.

They can burn you if touched.

Before replacing or adjusting the lamp, turn off the POWER switch and

wait until it cools down sufficiently.

Fatigue on Long Use

Watching the CRT screen in the same posture for a long time

accumulates fatigue in your eyes or body. For long use, take a 10 to

15-minute rest every hour for your health.

Oxygen Deficiency due to Presence of Nitrogen

■ If nitrogen purging is carried out for long hours in a narrow room without

operating an exhaust duct, the oxygen concentration in the room will

decrease and an oxygen deficiency could result.

Be sure to operate an exhaust duct or else open a window during the

purge for ventilation purposes.

8

PREFACE&SAFETY SUMMARY

SAFETY SUMMARY

Remarks on safety of spectrophotometer

Electricity

(a) Confirm the power supply to the spectrophotometer is AC100-240V.

(50Hz or 60Hz).Power is more than 1 KVA.

Fluctuation in voltage or noise on the power line would not only affect

the spectrophotometer main unit adversely but also cause an accident.

(b) Be sure to provide grounding connection along with power connection.

Make sure that the spectrophotometer is grounded at a grounding

resistance of 10 or less.

If grounding is improper, the spectrophotometer is easily affected by

external noise and floating voltage generated in it endangers physical

safety.

(c) High-voltage circuits are used inside the spectrophotometer.

Do not open any other cover than necessary for operation.

Fire

Avoid smoking and using a fire in the vicinity of the spectrophotometer.

Labels on spectrophotometer

There are warning labels of high pressure, high temperature on UV2600

Spectrophotometer. Pay attention to them during operation to avoid safety

accidents.

Back Up the Data

It is therefore recommended to back up the contents of the hard disk

beforehand.

To avoid misoperation, set space of more than 100 MB in computer

harddisk as work area for UV apllication software.

Computer Virus

If programs or data has suddenly been destroyed, if an unexpected

operation takes place or if an abnormal display appears on the screen,

your personal computer may have been infiltrated by a computer virus.

The computer virus is a rogue program that secretly invades a personal

computer and operates it willfully while destroying memorized data.

A program for eliminating the virus is called vaccine program.

There is a possibility of contamination with a computer virus by

downloading through communication a program including a computer

virus, or by using an exchangeable recording medium such as a floppy

disk that contains a computer virus. Also, it is possible to transmit the

9

PREFACE&SAFETY SUMMARY

virus from one personal computer to another via communication or

recording media. So avoid using a program or recording medium that

might include a virus.

Carry out check using a vaccine program if there is a possibility of

contamination with a virus. But depending on the type of vaccine

program, it may be impossible to eliminate the virus.

Personal Computer (PC)

Do not turn off the PC power supply alone. If the PC power supply is

turned off during access to the hard disk or floppy disk, the PC may

malfunction and the data or software stored in it may be destroyed. To

turn off the PC power supply, be sure to complete the spectrophotometer

control and data processing program (UV Analyst) before taking the

shutdown procedure for the system software.

Power Failure

A power failure or momentary voltage drop of the power supply due to

lightning, etc. may cause failure of the personal computer used with the

instrument and also damages the system software, application software

and other data.

To avoid such problems, it is recommended to use an AC uninterruptible

power source.

10

PREFACE&SAFETY SUMMARY

SAFETY SUMMARY

Warning Labels

The warning labels shown below are attached to the Model UV2600

Spectrophotometer.

(1) Dangerous Voltage(500V、100-240V)

The warning label above is attached to cover of lamp source compartment and power

supply socket.

(2)Attention to High Temperature

The warning label above is attached to cover of lamp source compartment.

11

CHAPTER 1 INSTALLATION

1.1 Unpacking

After opening the packing case, put the instrument onto work table with great

care. Avoid serious shock to packing case when unpacking it. Moreover, the

weight of UV2600 spectrophotometer is about 50kg. Care should be taken

when moving it.

Figure 1-1 UV2600 UV/VIS Spectrophotometer

△ Note:To avoid shock during transportation, sponge has been used for

fixing viewfinder in UV2600. Before powering on the instrument, first open

cover of light source compartment and take out sponge in viewfinder.

Otherwise, it may have influence on instrument initialization check and normal

use.

CHAPTER 1 INSTALLATION

12

CHAPTER 1 INSTALLATION

1.2 Installation Conditions

Before installing the instrument, please confirm the following installation

conditions.

1.2.1 Work Power Supply

The requirements for UV2600 work power supply are as follows:

1)Voltage:AC100-240V, fluctuation within ±10% is allowed.

2)Frequency:50Hz or 60Hz,fluctuation within ±4% is allowed.

3)Power:more than 600VA is required. If other devices share the same power

supply,it needs more than 1KVA.

4)Grounding wire:Grounding resistance must be less than10Ωinstalled as per

relative standards.

1.2.2 Work Table

The requirements for work table are as follows:

1)Work table for UV2600 spectrophotometer should be horizontal and reliable,

withstanding weight of more than 85kg, with a width of more than 800mm, a

depth of more than 750mm.

2)If other devices will be put on the work table as well, the area required

should be more.

3)Leave space of more than 200mm at both sides of the instrument. Avoid

instrument touching to the wall directly.

4)The height of UV2600 spectrophotometer is about 270mm. For easy

operation, select suitable height of work table.

13

CHAPTER 1 INSTALLATION

1.3 Installation Environment

Work environment will have great influence on instrument performance and life

time. Before installing UV2600, confirm the following environment conditions

at installation site.

1.3.1 Operating Temperature

Allowed environmental temperature range:5~35℃. However, it is suggested

to install air conditioner and set room temperature to 20~25℃ for instrument

under stable work status.

1.3.2 Operating Humidity

Allowed environmental humidity range:45%~85%。It is suggested to install

dehumidifying device and control the hunidity in room within 30%~70% for

instrument under stable work status.

1.3.3 Storage Temperature

Allowed temperature range for storage:-20~60℃。

1.3.4 Atmospheric Environment

1)Free from acid gas or alkaline gas and other gases which may corrode

metals significantly.

2)Free from gases which may dissolve paint such as from organic solvents

(particularly benzene, thinner etc).

1.3.5 Sample Solvent

1)Sample solvent and corrosive material should not to be put near instrument.

When using them, be careful to avoid drop or spill onto the cover or inside

sample compartment.

2) If organic solvent has been spilled on the cover or inside sample

compartment, please cleans it by soft cloth or paper at once.

3)If acid or alkali solution has been spilled inside sample compartment, please

take apart the compartment to wash and clean.

1.3.6 Other General Notes

a) Avoid direct sunlight (otherwise optical performance might deteriorate or the

housing might become discolored). Avoid installation by a window if at all

possible.

b) Vibrations or shocks strong enough to be felt by the human body must not

be transmitted to the instrument (otherwise the fine adjustment mechanism

might malfunction).

c) Avoid installation in near heat generating apparatus such as a gas burner,

electric heater or oven in order to prevent the mainframe cover being heated

beyond 70 Deg C.

d) Avoid installation near instruments which generate a strong electric field

14

CHAPTER 1 INSTALLATION

(such as an electric welding machine, high frequency furnace or pole

transformer).

e) Avoid a dusty environment (otherwise optical performance might

deteriorate).

f) The line voltage must be stable and free from a rapid fluctuation (otherwise

noise might increase).

g) Do not frequently turn on and off electric instruments (stirrer, vibrator, etc)

which are connected to the same power line as the UV2600 but are not fitted

with noise suppressors.

h) Height above sea level: ≤2000m.

I) Pollution degree: IP20.

J) Transient overvoltage is cagegory Ⅱ.

△ Note

The optical system is very delicate.In addition, the control unit incorporates

high-density electronic circuit components which function as a computer.

The above cautions should be strictly observed.

1.4 Check of Contents

After unpacking, check the contents of delivery against the packing list. If any

part is missing or damaged, or if you have a question, contact the nearest

Techcomp sales representative.

Figure 1-2 UV2600 Spectrophotometer Accessory

15

CHAPTER 1 INSTALLATION

1.5 Instrument Installation

WARMING

The Voltage is AC100~240V, which may cause electric shock. Please

connect instrument power cord after instrument installation has been

finished.

To avoid shock during transportation, sponge has been used for fixing

viewfinder in UV2600. Before powering on the instrument, first open cover of

light source compartment and take out sponge in viewfinder. Otherwise, it may

have influence on instrument initialization check and normal use. The

procedures for taking out sponge are as follows:

1)Unscrew fix Screw on cover of light source compartment and remove cover

of light source compartment.

2)Take out sponge inside viewfinder.

3)Install cover and tighten the screw.

1.6 Check of Voltage and Fuse

WARMING

The Voltage of instrument is AC100-240V, which may cause electric

shock. Before selecting and confirming the voltage used, first confirm

power cord has not been connected to the instrument.

According to the voltage of work power supply, select and confirm the voltage

level allowed besides UV2600 plug of power supply(POWER). Otherwise,

instrument failure or accident may occur.

Figure 1-3 Power supply of UV2600 Spectrophotometer

Fuse

16

CHAPTER 1 INSTALLATION

Select and confirm the suitable fuse according to voltage used.

Power supply voltage

Fuse Capacity

250V

F 3.15A

1.7 Connection of Communication Cable

Besides power supply plug(POWER), UV2600 has PC port and Acc port.

1.7.1 PC Port

UV2600 is controlled by UV Analyst software. Operation control and data

analysis are done by PC.

Using communication cable (standard accessory) provided by UV control

software, connect UV2600 PC port to computer COM port.

1.7.2 Acc Port

Many optional accessories can be configured on UV2600, including autosipper

controlled by PC.

Using communication cable provided by optional part, connect UV2600 Acc

port to the optional part.

△ NOTE

Pull in or pull out PC port and Acc port when main unit is turned off. Please

comply with the NOTE.

1.8 Connection of Power Cord and Grounding Wire

WARNING

Before plugging in the power cord, make sure the POWER switch is

turned off.

The procedures are as follows, shown in Figure 1-4.

1)Confirm power supply lines and ground connection are OK.

2)Confirm voltage of power supply is OK. (AC100-240V).

3)Plug the two sides of power cord into power supply output socket and

instrument power supply input socket respectively.

17

CHAPTER 1 INSTALLATION

Figure 1-4 Connection of power cord and grounding wire

1.9 Power On

After confirming that connection of power cord and ground wire is OK,

connection of PC and computer is OK, connection of optional part is OK, turn

on UV2600 spectrophotometer and run UV Analyst.

18

CHAPTER 2 FUNCTION

2.1 Work Principle

UV2600 Spectrophotmeter is used for sample spectral analysis in UV and

visible area according to the law below:

A=KLC

A(Abs)is the absorbency of material tested to homogeneous light.

K is absorption coefficient of material tested; L is thickness of material tested;

C is concentration of material tested.

We can see from above law, A is proportional to C.

In actual test, homogeneous light attain photoelectricity conversion part such

as photodiode through sample and its light energy signal will be converted to

photocurrent. So A can be expressed by photocurrent. Assume that

photocurrent not through sample to be tested is I0,and photocurrent throught

sample to be tested is It. So the ratio of the two is transmittance τ(T%).

τ=I

t/I0

×100%

A = -lgτ= -lg(It/I0)= KLC

K has relation to wavelength of incidence homogeneous light and material to

be tested, i.e. different materials under different wavelengthes of

homogeneous light have different absorbency, which is theory basic for

qualitative and quantitative analysis.

Figure 2-1 Work Principle

CHAPTER 2 FUNCTION

19

CHAPTER 2 FUNCTION

2.2 Optical Path System

Polychromatic light from light source lamp (WI\D2)enters monochromator

through filter and Slit after reflected by M1. Grating in monochromator will

change polychromatic light into homogeneous light, which will focus on M3.

Homogeneous light with corresponding wavelength will enter light split system

through emergence Slit by grating rotation. Half mirror M6 will split it into

measuring beam (transmittance) and reference beam (reflect). Measuring

beam will enter phtoelectricity convertor after relected by M7, through sample

cell and reflected by M10, M11, M12. And it will convert to electricity signal.

Reference beam will enter the same phtoelectricity convertor after reflected by

M8, through reference sample cell and reflected by M9, M13. The electricity

signal converted is basic signal. As half mirror is rotating, reference beam and

measuring beam enter the detector alternatively. The two beam

spectrophotometer with one light source and one detector can get stable test

data.

Figure 2-2 UV2600 Optical Path System

20

CHAPTER 2 FUNCTION

2.3 Circuit System

UV2600 circuit system can be seen in Figure 2-3.

The system can be controlled by PC.

Light signal is converted into electricity signal by Detector, then will be

amplified by pre-amplifier (AMP). Then it will processed by PC (main control

board) and data result will be sent to PC and displayed by software.

HV Board provides negative high-pressure power supply used by detector, and

control board will select suitable negative high-pressure value automatically to

obtain stable energy.

Work power supply of PC control part is controlled or provided by lamp power

supply.

RS232 Port is communication port; ACC port is communication port for

optional part.

Figure 2-3 UV2600 Circuit System

21

CHAPTER 2 FUNCTION

2.4 Function Mode

Function mode of UV2600 can be seen in Figure 2-4.

Nucleic acid

measurement

Protein

measurement

UV2600

PC control

Autozero

Wavelength

WL display

Wavelength

setting

Filter setting

Light source

setting

Measruing value display

Measuring value print

Sample No. print

Measuring value communication

Sample No. communication

Data

communication

Print

Result

Data saving

CONC mode

Time scan

Photometry

measurement

Wavelength range:190~900nm

Figure 2-4 UV2600 Function Mode

22

CHAPTER 2 FUNCTION

2.5 Sample Compartment

UV2600 sample compartment can be seen in Figure 2-5.(Single cell holder is

standard configuration).

UV2600 can configure options such as single cell holder, micro cuvette holder,

glass test holder, film holder, rectangle long holder, flow cell assembly, 6-port

positioner with temp control, manual 5-cell holder and autosipper etc. Thease

options are installed inside sample compartment and can be replaced easily.

As for installation and use of options, refer to option instruction manual

Figure 2-5 UV2600 Sample Compartment(Single cell holder)

Measurement

cell

Reference

cell

23

CHAPTER 2 FUNCTION

2.6 Specifications

Specifications of UV2600 can be seen as follows:

Wavelength range

190~900nm

Wavelength setting

0.01nm increment

Wavelength accuracy

±0.3nm

Wavelength repeatability

≤0.2nm

Test mode

Abs, %T, Conc,E(S),E(R)

Photometric range

Abs:-2.000~3.000

%T:0~300%T

Conc:0~9999

E(S) ,E(R):0~600

Photometric accuracy

±0.002Abs(0~0.5Abs)

±0.004Abs(0.5~1Abs)

±0.008Abs(1~2Abs)

±0.15%T(NIST930D standard filter); ±0.25%T(potassium

dichromate)

Photometric repeatability

±0.001Abs(0~0.5Abs)

±0.002Abs(0.5~1Abs)

±0.004Abs(1~2Abs)

±0.15%T(NIST930D standard filter); ±0.25%T(potassium

dichromate)

Baseline flatness

±0.001Abs(200~850nm);

Baseline stability

≤0.0004Abs/hr(at 500nm,2 hours after power on)

Spectrum bandwidth

0.2nm, 0.5nm, 1nm, 2nm, 5nm autoswitch

Stray light

≤0.010%T(at 220nm NaI,at 340nm,360nm NaNO2)

Wavelength scan speed

1 nm/min ,5nm/min ,20 nm/min ,120 nm/min ,

300 nm/min ,1000 nm/min ,1600 nm/min ,2000nm/min

(excluding switch time of filter and light source lamp)

Wavelength moving speed

3000nm/min

Light source

WI lamp,D2 lamp

Switch point of light source

Auto(325nm~370nm can be set)

Detector

Photomultiplier

Control method

PC computer

Optics

Dual beam, C-T Monochromator

Dimension of sample

compartment

124(W)×300(D)×142(H)mm

Dimension

710(W)×630(D)×268(H)mm

Weight

About 50kg

Power supply

AC100-240V±10%(50/60Hz)

Power consumed

300VA

24

CHAPTER 3 OPERATION

3.1 Preparation

3.1.1 Install Software & Connect UV2600 to PC

1.

2.

3.

4

Turn on PC,install “UV Analyst” software to PC.

Turn off UV2600,and connect UV2600 main unit to RS232 port of PC.

As for PC without RS232 port, user needs to buy “USB to RS232” convertor.

Confirm RS232 communication cable connecting to UV2600 main unit has

connected to any port of COM1~COM8. If port convertor is used, may need to

set the software, refer to port convertor instruction manual for detail.

3.1.2 Initialization

Turn off UV2600 main unit, and connect UV2600 main unit to PC. Turn on

UV2600, run the software in PC, and instrument will check the following items

automatically.

RAM

Check RAM

EPROM

Check EPROM

Wavelength drive

Check wavelength driving system

D2 Lamp

Check D2 lamp

WI Lamp

Check WI lamp

AD conversion

Check A/D conversion system

656.1nm

Check calibration at wavelength 656.1nm

Figure 3-3 UV2600 Initialization Interface

CHAPTER 3 OPERATION

25

CHAPTER 3 OPERATION

If items above are OK, it will enter normal work status, as shown below:

3.2 Basic Operation

3.2.1 Operation Method

The following figure is basic operation interface of software.

Refer to UV Analyst Instruction Manual for detail.

26

CHAPTER 3 OPERATION

△Note

1. When turning on the instrument, confirm that there is

not any sample or material blocking light inside sample

compartment.

2. Every time instrument is turned on, 1nm slit is used

automatically. Wavelength is calibrated using feature

peak of D2 lamp at 656.1nm.

3. To save initialization time, instrument will not calibrate

wavelength of other slits. Instrument saves wavelength

position of other slits using memory function.

4. If high precision measurement at certain slit level is

required, or wavelength correctness of each slit should

be improved, please set the slit level needed, and

perform wavelength calibration under this slit.

Instrument will save the wavelength position of this slit

level.

5. For D2 lamp and instrument pre-heating, it is suggested

that wavelength calibration should be done 30 minutes

after powering on.

6. As instrument has photomultiplier auto protection

function, correct reading will be obtained 3 seconds

after closing cover of sample compartment.

7. As instrument has photomultiplier auto protection

function, we still suggest that cover of sample

compartment should be closed usually.

27

CHAPTER 4 MAINTENANCE

4.1 Daily Maintenance

UV2600 instrument has high precision. The purpose of maintenance is to

make spectrophotometer work under good status.

4.1.1 Cleaning of Sample Compartment

Sample compartment is easy to be contaminated. If sample is spilled inside the

compartment, make sure to wash the compartment. The wash procedures are

as follows. Reassemble the sample compartment after it is dry. (Figure 1-4 to

Figure 4-5).

(1) Open cover of sample compartment.

(2) Unscrew the screw of cuvette holder (one screw).

(3) Hold front board of sample compartment, and take out cuvette holder

(Note:there is assigned bolt).

(4) Clean and dry cuvette holder and inner of sample compartment.

(5) Install cuvette holder back to sample compartment and tighten the screw.

Cuvette

Cover

Cuvette base

Front board

Screw

CHAPTER 4 MAINTENANCE

Figure 4-1 Open cover of sample compartment

28

CHAPTER 4 MAINTENANCE

Figure 4-2 move the screw of cuvette holder

Figure 4-3 Removal of cuvette holder

29

CHAPTER 4 MAINTENANCE

4.1.2 Clean of Spectrophotometer Cover

Please do not put chemical reagent, sample on the spectrophotometer.

Otherwise, optical system performance may be influenced.

In case chemical reagent, sample has been spilled on the cover, be sure to

clean the cover by soft cloth, water and scour and dry the cover.

Figure 4-4 Sample compartment after cuvette holder removed

Figure 4-5 Cuvette holder taken out

30

CHAPTER 4 MAINTENANCE

4.1.3 Cleaning and Storing of Cuvette

After sample test is finished, clean the cuvette by distilled water carefully. And

clean inner of cuvette using soft cloth or pledget.

When storing it, put cuvette into seal container and put dryer inside it as well.

Put the container in clean place.

If there is dirt on transmittance face of cuvette, can use mixed solution of

alcohol and aether 1:1 and soft cloth to clean the transmittance face of cuvette.

△Note

(1) The quality of cuvette will have influence the reading accuracy of

instrument. Please use cuvette with good quality.

(2) The cuvette of UV2600 instrument is optional part.

(3) There are two kinds of cuvettes: quartz cuvette can be used in whole

wavelength, and glass cuvette can only be used in visible area with

wavelength more than 400nm. They have the same appearance, so pay

attention to this when purchase.

(4) Cuvette bracket has been adjusted in factory. Do not put the cuvette

forcibly to avoid transmittance face of cuvette not vertical to optical path

which may cause reading error.

Instrument

cover

Cover of light source compartment

Cover of sample

compartment

Figure 4-6 UV2600 Spectrophotometer

31

CHAPTER 4 MAINTENANCE

4.1.4 Add Lube

Exclusive lube has been added on each movable part of instrument in factory.

If movable part is found abnormal after the instrument has been used for a long

time, please contact to our Service Department.

4.1.5 Clean of Window Frame and Lens of Sample Compartment

If window plate and lens of sample compartment has been contaminated,

clean them according to the following procedures after wash your hands.

(1)First confirm instrument has been turned off. And power cord of instrument

has been pulled out.

(2)Open cover of sample compartment and take out cuvette bracket.

(3)Clean window plate and lens using mixed solution of alcohol and aether

1:1 and soft cloth. Dry them.

(4)Install cuvette bracket back to the previous position.

△Note

(1) When cleaning lens, only need to clean the face towards sample

compartment, for the other face is sealed and need not to be cleaned.

(2) Try not to remove lens or lens assembly to avoid optical path deviation.

(3) When cleaning window plate, only need to clean the face towards sample

compartment, for the other face is sealed and need not to be cleaned.

(4) Window plate must be removed for clean, shown as Figure 4-8.

(5) During clean and removal process, do not leave fingerprint on widow plate

or lens.

Cuvette

Cuvette

bracket

Screw hole

Figure 4-7 Cuvette and cuvette bracket(Single cell holder)

32

CHAPTER 4 MAINTENANCE

4.2 Performance Verification

After powering on the instrument, wait for 30 minutes for stability. Then

performance verification can be done.

Item

Contents

(1)Wavelength Accuracy

Test peak value of D2 lamp feature spectrum and

get the error comparing with 656.1nm. At 1nm slit

after powering on.

Specification:±0.3nm

(2)Wavelength

Repeatability

For repeatability test of wavelength standard

value, do the test at 1nm slit after powering on.

Specification:±0.1nm

(3)Baseline Stability

Check stability using time scan.

Specification:≤0.0004Abs/h(500nm)

(◇Note: 2 hours after powering on)

(4)Baseline Flatness

Check baseline flatness using wavelength scan

(200nm~850nm,120nm/min)

Specification:≤±0.001Abs

△Note

1)Auto test basic performance and work status of main parts of instrument,

must wait for 30 minutes after powering on the instrument.

2)As for baseline stability test, it must be done 120 minutes after powering on

the instrument. And test time is about 60 minutes. Usually, it need not to test

this item.

3)If instrument performance has been tested too often, it may have bad effect

on instrument lifetime. It is suggested to select certain item for test.

Transparent Window

Window frame

Optical axis

Spring

Adhesive tape

Black window frame

(Pull it forward with tweezers)

Figure 4-8 Removal of Sample Compartment Window Plate

33

CHAPTER 4 MAINTENANCE

4.3 Troubleshooting

If there is an abnormality, correct it referring to the following table

4.3.1 Error Information

If failure occurs during operation, error information will be displayed on

instrument.

Symptom

Cause

Solution

ROM!

ROM broken

Contact to serviceman

RAM!

RAM broken

Contact to serviceman

656.1nm!

656.1nm not found

Check whether sponge in

viewfinder has been taken out,

whether any material in sample

compartment, and do

wavelength calibration again.

Wavelength

drive!

Wavelength drive error

Contact to serviceman

Baseline!

Current baseline parameter not

complied with setting parameter

Reset parameters for baseline

calibration.

D2!

When setting D2 lamp ON or need to

use D2 lamp, lamp is not ON.

Turn on D2 lamp

WI!

When setting WI lamp ON or need to

use WI lamp, lamp is not ON.

Turn on WI lamp

34

CHAPTER 4 MAINTENANCE

4.3.2 Failure Cause and Countermeasure

If instrument is abnormal, deal with it according to the following.

Symptom

Cause

Countermeasure

Turn on the instrument, but

no action

( Instrument unable to

operate)

(1) Power cord, fuse are

abnormal

(2) Work power supply

abnormal

(1) Replace power cord and

fuse.

(2) Replace work power

supply

After powering on, light

source is not ON,“D2 !”

or“WI!” displayed on status

display.

(1) Relevant light source

lamp is broken.

(2) Light source light has

been set under OFF status.

(1) Replace relevant light

source lamp.

(2) Confirm setting of light

source lamp again.

Data fluctuation is large

(1) There is sth blocking

optical path in sample

compartment.

(2) Lamp performance

decreases.

(3) Lamp or viewfinder

contaminated

(4) Misoperation during zero

calibration.

(1) Take out material

blocking optical path.

(2) Replace light source

lamp.

(3) Replace, clean lamp/

viewfinder.

(4) Adjusting zero correctly.

“656.1nm !” displayed on

status display

Wavelength value is not

correct

(1) Perform wavelength

calibration.

(2) Contact to our Service

Department.

“ ROM !” or“ RAM !”

displayed on status display

Micro control board fails

Replace micro control

board.

”Wavelength drive!”

displayed on status display

(1) Abnormal wavelength

driver

(2) Abnormal wavelength

resetting signal

(3) Micro control board fails

(1) Check wavelength

screw, slide, screw for

fixing, motor etc.

(2) Replace microswitch of

wavelength resetting.

(3) Replace micro control

board.

4.3.3 Replacing fuses

There are fuses(3.15A) installed in instrument input power supply, and power

supply board, circuit board inside instrument.

If fuse is found broken, first check and find the cause. Then replace the fuse.

35

CHAPTER 4 MAINTENANCE

4.4 Replacement of Consumable Parts

WI lamp, D2 lamp and fuse are consumable parts. When WI lamp and D2 lamp

exceed their lifetime, light energy may decrease or lamp may not be ON. So

WI lamp and D2 lamp need to be replaced. If user has no WI lamp or D2 lamp

for spare, contact our Service Department for purchase.

WI lamp(25-03-0001) lifetime:1000 hours

D2 lamp(25-02-0007) lifetime:1000 hours

WARNING

Accidents may occur due to electric shock by power supply voltage.

Before open the cover of light source compartment, first turn off the

instrument and pull out power cord to avoid accident.

4.4.1 Replacement of Light Source Lamp

The procedures are as follows(Refer to Figure 4-9~Figure 4-15)

(1)Turn off the power supply(switch to OFF position), then wait until light

source lamp cools.

(2) Unscrew the screw of light source compartment cover. Remove cover of

light source compartment.

(3)Replace WI lamp(Refer to Figure 4-10~Figure 4-13)

(a) Pull out the old WI lamp gently, and take out old WI lamp from lamp base.

(b) Put the new WI lamp inside lamp base and push to the bottom.

(c) Pay attention that spirality of WI lamp filament should face to light-entrance

slot (at right side).

(4)Replace D2 lamp:(Refer to Figure 4-14 ~Figure 4-15)

(a) Pull out plug of D2 lamp lead

(b) Hold metal part of base of old D2 lamp; rotate anticlockwise to take out old D2

lamp.

(c) Hold metal part of base of new D2 lamp, and rotate clockwise to fix the new D2

lamp.

(d) Plug the pin of D2 lamp lead.

(5) Install cover of lamp source compartment.

36

CHAPTER 4 MAINTENANCE

NOTE

(1) When power supply switch is ON, replacing lamp is forbidden.

(2) After turning off the power supply, wait until lamp cool. Then

replace the lamp.

(3) When installing new lamp, use clean gloves, cloth and paper to

hold lamp to avoid any fingerprint left on lamp.

(4) After lamp has been replaced, when confirming the lamp ON,

please close the cover of lamp source compartment to avoid eye

iInjury caused by lamp.

Screw

Figure 4-9 Removal of light source compartment cover

37

CHAPTER 4 MAINTENANCE

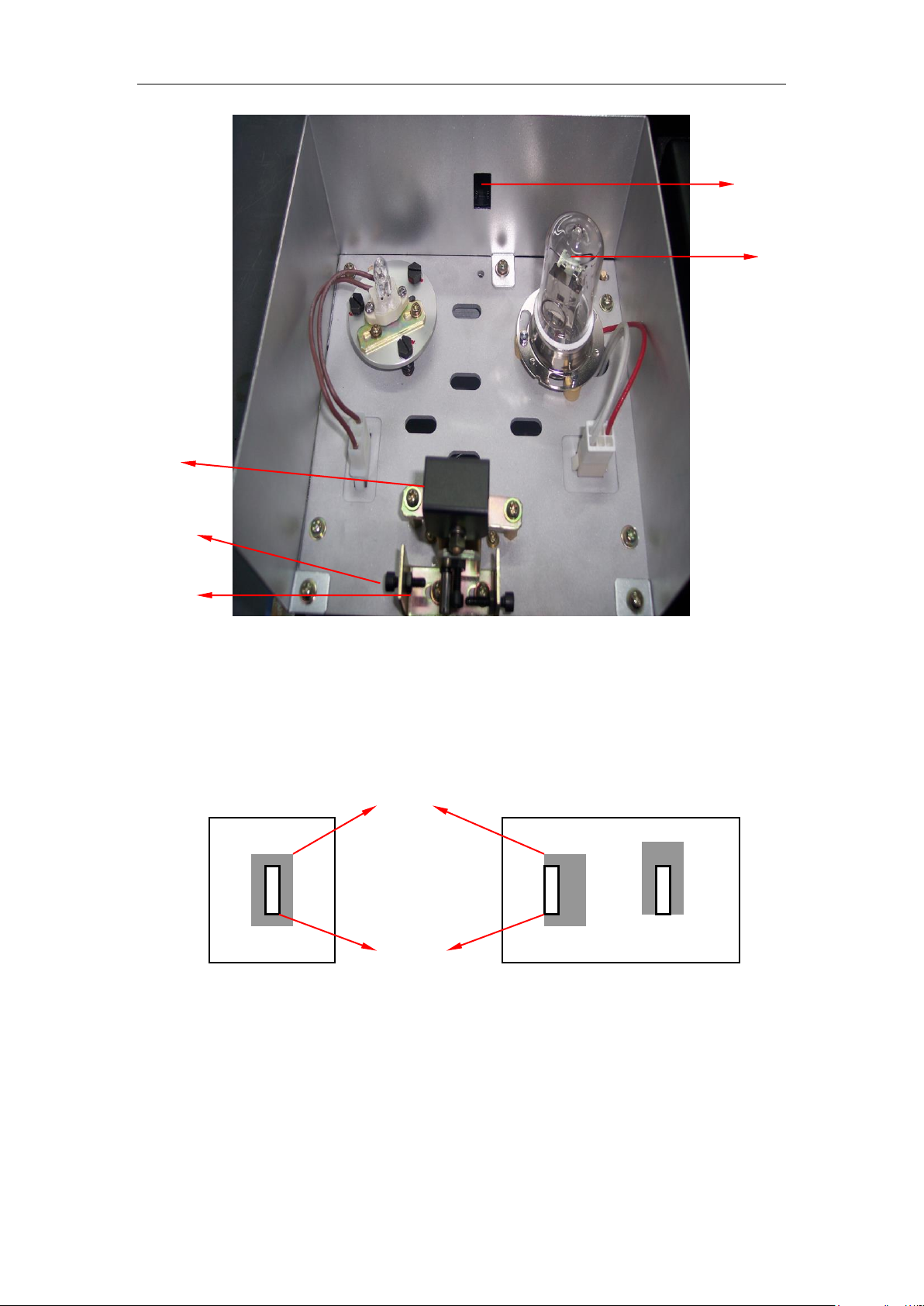

D2 lamp

Base

D2 plug

WI plug

WI lamp

WI base

Viewfinder

Figure 4-10 Structure of light source compartment

Figure 4-11 Removing WI lamp

38

CHAPTER 4 MAINTENANCE

Bow of fuse

Twist

Figure 4-12 Install WI lamp

Figure 4-13 Shape of WI lamp fuse

39

CHAPTER 4 MAINTENANCE

Figure 4-14 Pull out/install plug of D2 lamp lead

Figure 4-15 Remove/install D2 lamp

40

CHAPTER 4 MAINTENANCE

4.4.2 Clear of Lamp Use Time

After replacing the lamp, clear the use time of old lamp. The procedures can

refer to “UV Analyst Operation Manual” relevant section.

4.4.3 Adjustment of Lamp

WARNING

Usually, after replacing lamp, there is no need to do any adjustment. If

light source adjustment is required, warnings are as follows:

(1) When lamp is ON, WI lamp and D2 lamp have high voltage. So

touching lamp and its lead is forbidden to avoid electric shock.

(2) When lamp is ON, WI lamp and D2 lamp have high temperature.

So touching surface of the lamp is forbidden to avoid scald.

(3) When D2 lamp is ON, it will emit strong ultraviolet radiation. So

avoid seeing the lamp directly.

A)The adjustment of WI lamp position are as follows: (Refer to Figure 4-16~

Figure 4-17)

(1)Turn off D2 lamp.

(2) Set wavelength below 300nm, and set 2nm slit.

Aim the viewfinder of light source at WI lamp side to make WI lamp aim at

light-entrance slit. Cofirm relative position of WI lamp facula and light-entrance

slit is OK.

If relative position of WI lamp facula and light-entrance slit has deviation, adjust

Screw C of WI lamp and Screw A of viewfinder.

If WI lamp facula has horizontal deviation, adjust screw A of viewfinder.

If WI lamp has vertical deviation, adjust Screw C of WI lamp (three in all).

After adjustment, tighten Screw A.

(3) Set wavelength as 580nm.

Open the door of sample compartment under wavelength 580nm. Insert a

white paper in front of photodiode, aiming at the shape of WI lamp facula

(yellow at 580nm). If facula is dark or the shape is abnormal, adjust Screw C of

WI lamp and Screw of viewfinder.

A, Make the shape of WI lamp facula rectangle.

◇Note: As for turning on and turning off the lamp, setting of wavelength,

please refer to relevant section.

41

CHAPTER 4 MAINTENANCE

B)The adjustment of D2 lamp position are as follows:(Refer to Figure 4-18~

Figure 4-19)

(1) Turn off WI lamp.

Confirm WI

lamp facula at

this position.

Screw C

(Three)

Viewfinder

Screw A

Nut A

WI lamp

WI lamp facula

Light-entrance slit

Normal status

Horizontal deviation

Vertical deviation

Figure 4-16 replacement and adjustment of WI lamp

Figure 4-17 Relative position of WI lamp facula and light-entrance slit

42

CHAPTER 4 MAINTENANCE

(2) Set wavelength below 300nm, and set 2nm slit.

Aim the viewfinder of light source at D2 lamp side to make D2 lamp aim at

light-entrance slit. Cofirm relative position of WI lamp facula and light-entrance

slot is OK.

If relative position of D2 lamp facula and light-entrance slit has deviation,

adjust Screw B of viewfinder.

If D2 lamp facula has horizontal deviation, adjust screw B of viewfinder.

After adjustment, tighten Screw B.

◇Note:D2 lamp is UV light source lamp. D2 lamp facula can be observed at

light-entrance slit of lamp source compartment, which is polychromatic light.

But after polychromatic light of D2 lamp has been changed into homogeneous

light by monochromator, we cannot see facula by eye. So we cannot observe

the shape of D2 lamp facula inside sample compartment by eye and we cannot

adjust D2 lamp position.

◇Note: As for turning on and turning off the lamp, wavelength settings,

transmittance/ absorbency mode setting, refer to relevant section.

◇Note: When adjusting position of WI lamp and D2 lamp, if instrument is OK

by Step (2), there is no need to perform Step (3) and Step (4).

◇Note: If position of D2 lamp and WI lamp has serious deviation, light source

viewfinder may need to be adjusted. However, the method is very complex,

please contact to Service Department for help.

43

CHAPTER 4 MAINTENANCE

Confirm D2

lamp facula at

this position.

Viewfinder

Screw

Nut B

D2 lamp assembly

D2 lamp facula

Light-entrance

Normal status

Horizontal deviation

Vertical deviation

Figure 4-18 Replacement and adjustment of D2 Lamp

Figure 4-19 Relative position of D2 lamp facula and light-entrance slit

44

CHAPTER 4 MAINTENANCE

4.5 Disassembly of Instrument Main Parts

If failures occur, parts may need to be replaced. This section mainly introduce

the disassembly methods of main parts.

WARNING

Those who has not been trained are forbidden to disassemble the

instrument, otherwise instrument may be damaged or human may be

injured.

WARNING

Pay attention to the electric shock caused by power supply voltage.

Before open the cover or disassemble the circuit of instrument, please

first turn off the power supply and pull out the power cord.

4.5.1 Open Instrument Cover

(1) Open cover of sample compartment, and unscrew the screw of cuvette

holder. Take out holder.

(2) Unscrew the screw of sample compartment holder.

(3) Loosen the screw at side of instrument.

(4) Take out instrument cover. (Do not force to the motor at front of the cover

to avoid connection line broken).

(5) Install the cover.(Do not press the connection wire of motor by cover

during installation.)

△Note

When taking out or installing the case, pay attention to avoid the sponge fallen

down.

4.5.2 Removal Procedures of Power Switch

(1) Remove instrument cover.

(2) Pull out each pin of power supply.

(3) Unscrew the screws of power supply switch and take out power supply

switch.

(4) Install the power supply switch (pay attention to plug the pins correctly).

45

CHAPTER 4 MAINTENANCE

4.5.3 Removal of Control Board and Lamp Power Supply Board

(1) Remove instrument cover.

(2) Pull out each pin of lamp power supply.

(3) Unscrew the screws of lamp power supply and take out lamp power supply.

(4) Unscrew the screw of main control board or lamp power supply board.

Take out the board.

(5) When installing them, pay attention to plug the pins correctly.

△Note

When replacing circuit board, do not bend the board forcibly.

4.5.4 Removal Procedures of Pre-amplifier

(1) Remove instrument cover.

(2) Unscrew the screw on the cover of pre-amplifier, and remove the cover of

pre-amplifier.

(3) Pull out each pin of pre-amplifier.

(4) Unscrew the screw of pre-amplifier. And take out pre-amplifier.

(5) Install pre-amplifier (pay attention to plug the pins correctly).

△Note

(1) When removing and installing reference photoelectricity convertor and

pre-amplifier, avoid touching the high-ohmic resistor by hand.

(2) Pull out and plug the signal cable with great care to avoid signal cable and

its pin broken.

46

CHAPTER 4 MAINTENANCE

4.6 Storing of Instrument

4.6.1 After Test Is Finished

(1) Turn off the instrument. Pull out the plug of power cord.

(2) Cover the instrument with dustproof cover.

△Note

If there are corrosive, volatile organic solvent or venomous sample in the

sample compartment, be sure to take them out.

4.6.2 Instrument Will Not Be Used for a Long Time

(1) Please do not place the instrument in the place with high temperature

(more than 70℃), low temperature (less than -20℃), high hunidity (more than

80%), or vibrant source.

(2) Make sure to cover the dustproof cover on the instrument.

(3) Instrument cannot be touched to corrosive and venomous gases.

(4) When instrument is being transported to storage place, fix the viewfinder by

sponge.

(5) Do not keep the instrument in electromagnetism field place.

(6) Do not keep the instrument in dusty place.

(7) Avoid direct sunlight to the instrument.

47

No. 16, 201 Minyi Road, Songjiang District, Shanghai, China

+86-21-67687200

+86-21-67687190

sh-factory@techcomp.cn

www.techcomp.cn

Shanghai Techcomp Instrument Ltd.

48

Loading...

Loading...