Page 1

ST-44 USER’S MANUAL

Page 2

ST-45 User's Manual

Declaration of Conformity No. 27/2008

Hereby, we declare under sole responsibility that the ST-45

230V 50Hz thermoregulator manufactured by TECH, ul. St.

Batorego 14, 34-120 Andrychów, is compliant with the

Regulation by the Ministry of Economy. (Journal of Laws Dz.U.

155 Item 1089) of July 21, 2007 implementing provisions of the

Low Voltage Directive (LVD) 2006/95/EC of January 16, 2007.

The ST-45 controller has been tested for electromagnetic

compatibility (EMC) with optimal loads applied.

For compliance assessment, harmonized standards were

used:

PN-EN 60730-2-9:2006.

Co-owners:

Paweł Jura, Janusz Master

-2-

Page 3

TECH

ATTENTION!

HIGH VOLTAGE!

Make sure the regulator is unplugged before

working on the power supply (cable connections,

device installation, etc.)!

All mounting works must only be carried out by

qualified electricians.

Before activating the controller, measure the motor

resetting efficiency, check the boiler and inspect

wire insulation.

CAUTION

THE DEVICE MAY BE DAMAGED IF STRUCK BY A

LIGHTNING. MAKE SURE IT IS UNPLUGGED

DURING STORMS

-3-

Page 4

ST-45 User's Manual

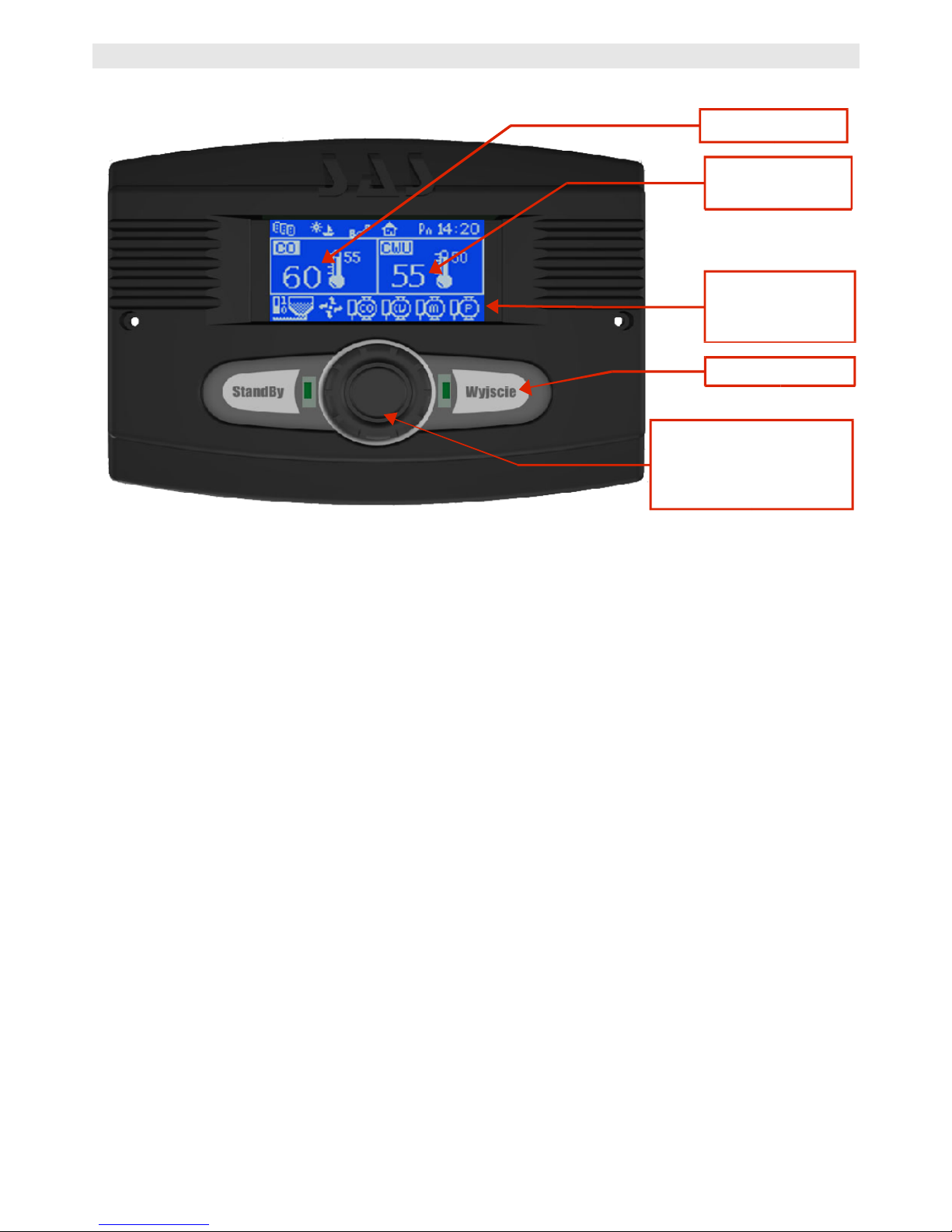

I.Description

The ST-45 temperature regulator is intended for use with central heating

boilers. It is used to control the water circulation pump, hot consumption

water pump, floor heating pump, mixing pump, blow (fan) and fuel

feeder. The ST-45 regulator features two modules: graphic display panel

and control panel.

The ST-45 can be used with two optional additional three-way or

four-way valve control modules. The regulator has been designed

and made for comfort.

It is very easy in use. All parameters are adjusted with a convenient

knob (encoder). The ST-45 regulator features also a graphic display that

shows the current status of the boiler.

If the furnace temperature is lower than the setpoint temperature, the

regulator is operated in its duty cycle, i.e. the blow is active and the

operation time of the fuel feeder is set by the user (both operation and

stand-by times are set).

If the furnace temperature is equal to or higher than the setpoint

-4-

Boiler Temp.

Water Heater

Temp.

Feeder; C.H.

Pump; H.C.W.

Pump; Fan

Button for accessing

submenus,

confirming settings

(encoder)

Exit

Page 5

TECH

temperature, the regulator is operated in its sustain cycle (both stand-

by and sustain mode times are to be set).

Please send all comments on the software to the boiler

manufacturer.

Your controller should be set according to your individual needs,

depending on the type of fuel and boiler used. TECH shall not be

held responsible for incorrect settings.

II.Regulator Functionality

This chapter describes regulator functionality, how to change settings

and navigate in the menu with the encoder (knob). Depending on the

mode the boiler is currently in, the display will show boiler operational

parameters. The given mode is selected by the user.

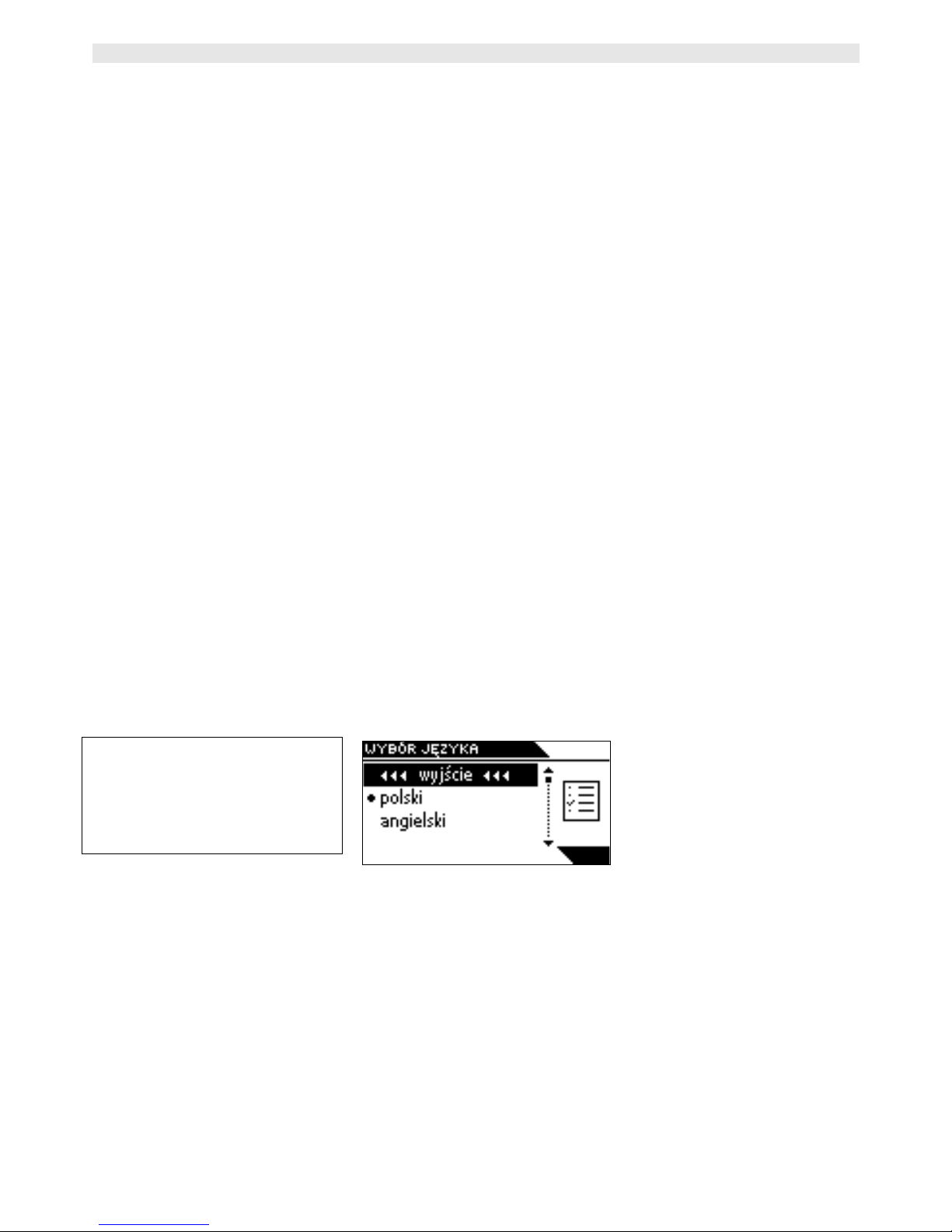

While the user is logging in, the display shows the manufacturer and the

software version.

After several seconds, you can select your language. With this function,

you can change the language version.

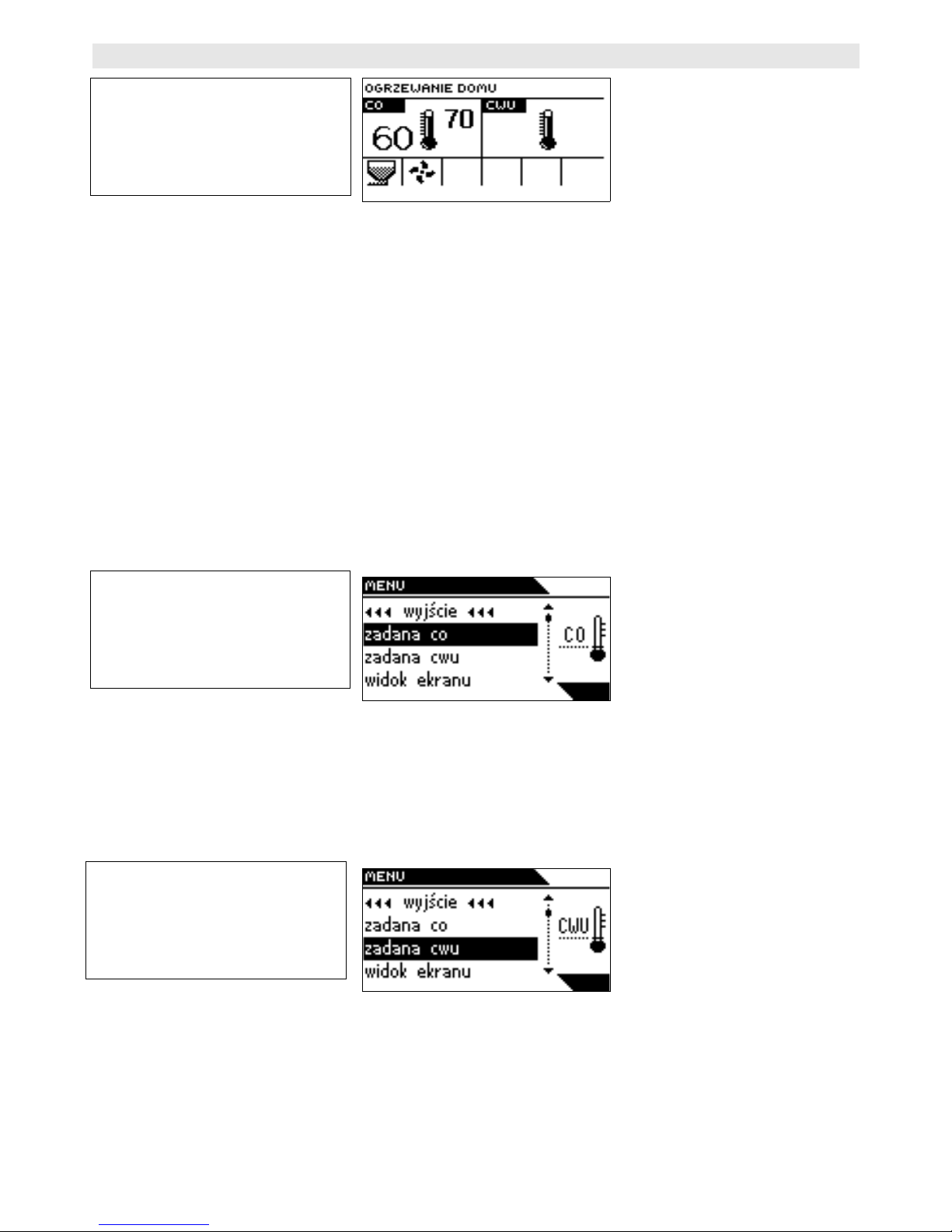

II.1.Main Page

During normal operation, the graphic display shows the main page with

the following data:

-5-

LANGUAGE VERSION

Exit

Polish

English

Page 6

ST-45 User's Manual

Boiler temperature (actual to the left; setpoint to the right)

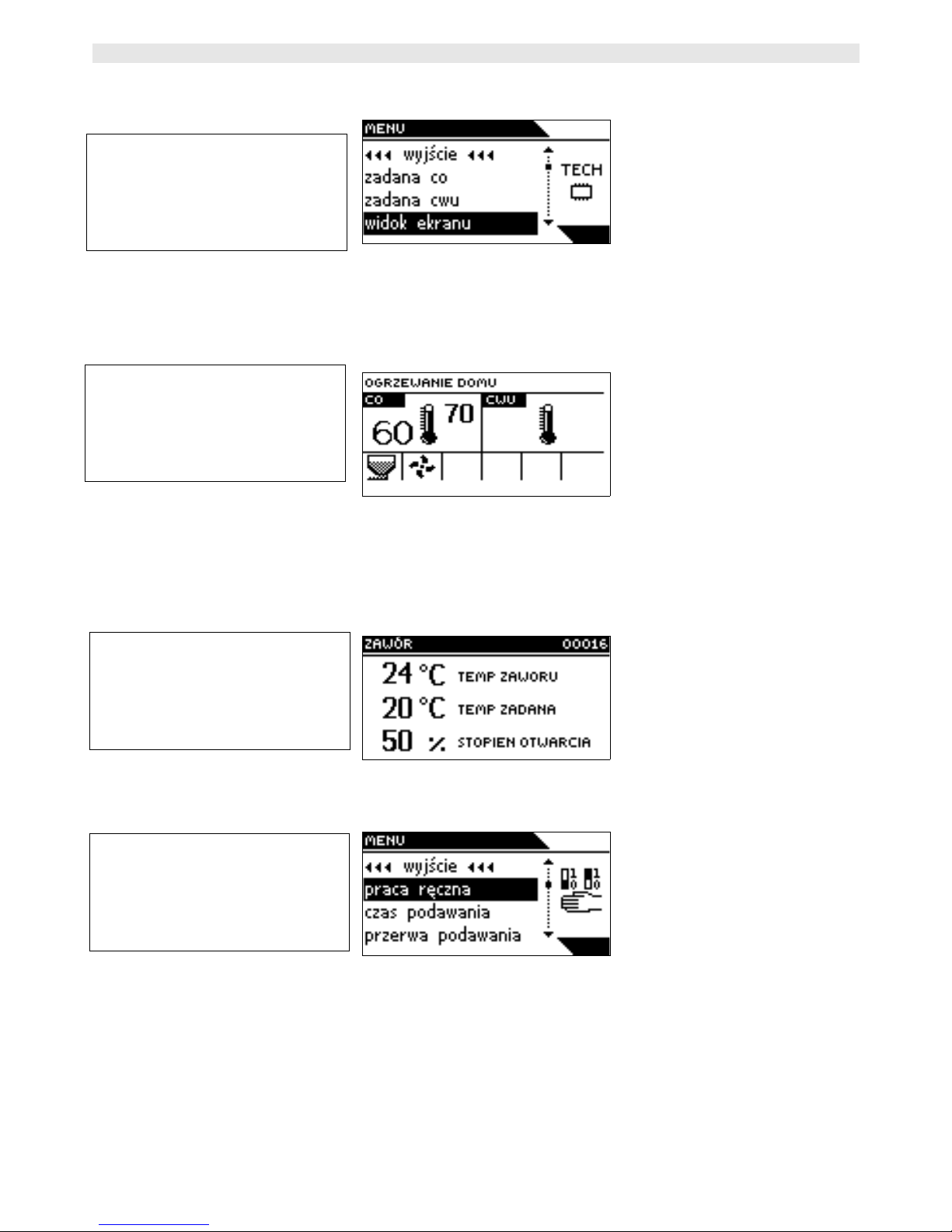

Pressing the encoder will move you to the first level. The display shows

three options of the menu. To move to next options, turn the knob

clockwise. In order to exit the menu, select EXIT (only in the edit mode)

In order to apply any changes, they need to be confirmed by pressing the

encoder on the CONFIRM message. If you do not wish to make any

changes in a given function, press the encoder on the CANCEL message.

II.2.C.H. Setpoint Temperature

With this function, you can set the boiler temperature. You can change

the boiler temperature in a range between 45°C and 80°C.

II.3.H.C.W. Setpoint Temperature

With this function, you can set the hot consumption water temperature.

You can change the boiler temperature in a range between 40°C and

75°C.

-6-

HOUSE HEATING

C.H. H.C.W.

MENU

Exit

C.H. Setpoint

H.C.W. Setpoint

Screen Display

MENU

Exit

C.H. Setpoint

H.C.W. Setpoint

Screen Display

Page 7

TECH

II.4.Screen

With this function, you can select one of three main screens to control

the thermoregulator. The C.H. screen is used for displaying the current

boiler status.

The valve 1 screen is used for displaying parameters of the first valve.

The valve 2 screen is used for displaying parameters of the second

valve.

II.5.Manual Mode

For your convenience, the regulator features a manual mode module. In

this mode, each individual element is enabled and disabled independently

of the other.

Pressing the ENCODER will enable the fuel feeder. The feeder will

operate until the ENCODER is pressed again.

-7-

MENU

Exit

C.H. Setpoint

H.C.W. Setpoint

Screen Display

HOUSE HEATING

VALVE

VALVE TEMP

SETPOINT TEMP

OPENING

MENU

Exit

Manual Mode

Feed Time

Feed Pause

Page 8

ST-45 User's Manual

Press the ENCODER to enable / disable the blow.

Press the ENCODER to enable / disable the central heating pump.

Press the ENCODER to enable / disable the (water heater) hot

consumption water pump.

Press the ENCODER to enable / disable the floor heating pump.

Press the ENCODER to enable / disable the mixing pump.

Press the ENCODER to enable / disable the alarm.

II.6.Feed Time

With this function, you can set the operation time for the fuel feeder. Set

the operation time according to the type of fuel and boiler used.

II.7.Feed Interval

With this function, you can set the stand-by time for the feeder,

depending on the type of fuel used in the boiler. Incorrect operation and

stand-by times may cause the boiler to malfunction, i.e. inability to burn

all carbon and to reach the setpoint temperature. Setting correct times

will ensure correct boiler operation.

II.8.Blow Force

With this function, you can control the fan speed. The adjustment range

is from 10 to 100% (it can be assumed that the fan operates in gears).

-8-

MENU

Exit

Manual Mode

Feed Time

Feed Pause

MENU

Exit

Blow Force

Operation Mode

Sustain Mode

Page 9

TECH

The higher the gear, the higher the speed with 10% being the minimum

and the 100% being the maximum speed of the fan.

Initially, the fan runs always at full speed so that it is possible to start it

with the motor being slightly dusty.

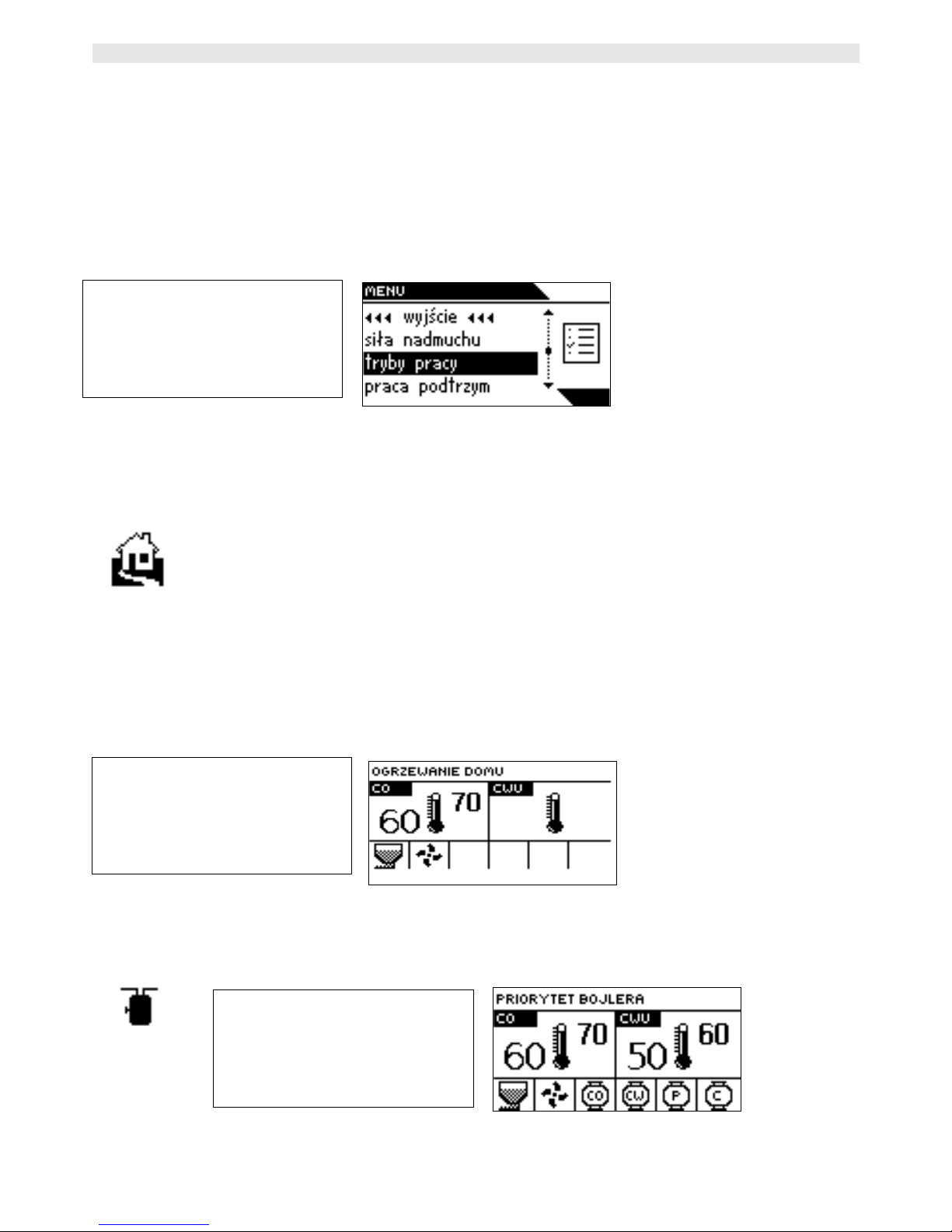

II.9.Operation Mode

With this function, you can select one out of four operation modes.

II.9.a)House Heating

If you select this option, the regulator will switch into the house heating

mode. The central heating pump starts to run above the pump activation

threshold (set to 40°C by default). Below this temperature, the pump is

shut off.

II.9.b) Water Heater Priority

-9-

MENU

Exit

Blow Force

Operation Mode

Sustain Mode

HOUSE HEATING

C.H. H.C.W.

WATER HEATER PRIORITY

C.H. H.C.W.

Page 10

ST-45 User's Manual

If you select this option, the regulator will switch into the water heater

priority mode. Activating the hot consumption water pump will cause the

regulator to switch into the water heater priority mode. In this mode, the

(hot consumption water) heater pump is activated until the set

temperature is reached. Then, the pump is shut off and the central

heating circulation pump is activated.

In order to activate the hot consumption water pump, it is necessary to

raise the setpoint temperature above the pump activation threshold (the

pump activation threshold to be adjusted in the service menu).

The temperature can be changed in the H.C.W Set function (see point

II 2).

In this mode, the fan and the feeder are operated as long as the

temperature is below 62°C to prevent the boiler from overheating. Such

condition will be maintained until the water heater setpoint temperature

is reached. When the temperature is reached, the hot consumption water

pump is shut off and the central heating pump is activated.

The central heating pump will run until the water heater temperature

drops below the setpoint value; then, the central heating pump is shut

off and the hot consumption water pump is activated.

The hot consumption water priority function consists in that the

consumption water is heated up before heating up water in radiators.

ATTENTION: the boiler should have non-return valves mounted on the

central heating pump and hot consumption water pump circuits. A valve

mounted on the pump will prevent the hot consumption water from being

discharged from the water heater. A valve mounted on the central

heating circuit will not let the hot consumption water move from the

water heater into the house circuit.

-10-

Page 11

TECH

II.9.c) Parallel Pumps

In this mode, the pumps run initially in parallel above the pump

activation threshold (set to 40°C by default). The central heating pump

continues to run and the hot consumption water pump is shut off after

the water heater setpoint temperature has been reached.

ATTENTION: in this mode, you should mount a three-way valve or a

mixing valve that will maintain different temperatures in the water heater

and in the house.

II.9.d) Summer Mode

When the function is enabled, the central heating pump is switched off

and the hot consumption water pump is activated above the pump

activation threshold (set to 40°C by default). In this mode, the hot

consumption water pump continues to run above the pump activation

threshold (set to 40°C by default). In the summer mode, the water

heater setpoint temperature is to be set. When the summer mode is

disabled, the actual temperature of the central heating and two

temperatures (actual and setpoint) of the hot consumption water are

displayed.

II.10.Sustain Mode Operation

With this function, you can set the operation time for the fuel feeder and

the fan.

-11-

SUMMER MODE

C.H. H.C.W.

Page 12

ST-45 User's Manual

II.11.Pause in Sustain Mode

With this function, you can set the pause of the feeder in the sustain

mode.

The function is used for regulating the furnace while in the sustain

mode. This is to prevent damping of the furnace when the boiler

temperature is over the setpoint value.

ATTENTION: incorrect settings may cause a continuous increase of the

temperature! Especially the Pause in Sustain Mode should not bee too

short.

II.12.Sustain Mode of Fan

In this function, you can set the operation time and the pause time for

the fan while in the burnout mode.

III.Fitter’s Menu

The fitter’s menu parameters are to be set by the boiler fitter or service

personnel provided by Sas.

-12-

MENU

Exit

Sustain Pause

Fan Sustain

Fitter’s Menu

MENU

Exit

Sustain Pause

Fan Sustain

Fitter’s Menu

MENU

Exit

Sustain Pause

Fan Sustain

Fitter’s Menu

Page 13

TECH

III.1.Factory Settings

The regulator has been pre-configured. However, it should be adjusted to

your individual needs. It is possible to return to the factory settings at

any time. By enabling factory settings, all boiler settings that you have

made will be replaced by settings made by the manufacturer. From then

on, you can again set your own operating parameters for the boiler.

III.2.Valves 1 and 2

With this function, you can set the operation time for the mixing (three-

or four-way) valve only with modules ST-61. For the valve to operate

properly and as required, it is necessary to set several parameters.

III.2.a) Registration

In this function, the fitter enters the serial number of the control module

used with the three-way valve actuator (ST-61, five-digit number

provided on the module housing). Without entering the number, the

function will be disabled.

-13-

FITTER’S MENU

Exit

Factory Settings

Valve 1

Valve 2

VALVE

Exit

Registration

Temp Monitor

Opening Time

FITTER’S MENU

Exit

Factory Settings

Valve 1

Valve 2

Page 14

ST-45 User's Manual

III.2.b) Temperature Monitoring

In this function, you can set the temperature monitoring time for water

that is delivered downstream of the valve to heat the house. This means

that the temperature downstream of the valve is checked periodically. If

decrease of the temperature is detected, the valve will be opened by a

defined amount in order to heat up the house. The above principle also

serves the opposite purpose when there is a need of decreasing the

temperature.

III.2.c) Opening Time

This function can be used for setting the opening time for the valve, i.e.

how long is it going to take for the valve to be fully opened.

-14-

REGISTRATION

Enter Module Number

C.H. VALVE

Calibrating valve

Please wait

VALVE

Exit

Registration

Temp Monitor

Opening Time

TEMP. MONITOR

seconds

OPENING TIME

seconds

Page 15

TECH

III.2.d) Single stroke

This function can be used for setting the opening stroke for the valve, i.e.

by what percent is the valve to be opened or closed.

III.2.e) Minimum opening

With this function, you can set the minimum value for closing of the

valve. The valve cannot be closed further than this value.

III.2.f) Valve Type

With this function, you can select the valve type, either the central

heating valve or the floor heating valve. By selecting the latter,

temperature rise is limited to 50°C in order to ensure safety in case of

floor heating.

III.3.Temperature Alarm

-15-

SINGLE STROKE

%

MINIMUM OPENING

%

FITTER’S MENU

Exit

Factory Settings

Valve 1

Valve 2

VALVE TYPE

Exit

C.H. Valve

Floor Valve

Page 16

ST-45 User's Manual

The function is enabled only in the duty mode (i.e. when the boiler

temperature is lower than the setpoint temperature). When the boiler

temperature fails to rise in the user-defined period, an alarm is

activated: the feeder and the fan are shut off (the water pump is

switched on and off independently) and the alarm is sounded. The

display shows the following message: C.H. Temperature Rise Failed. The

alarm can be reset with the encoder.

III.4.Room Regulator

The ST-45 regulator can be connected to a room regulator. In such case,

it has a higher priority, which does not apply to heating from the water

heater. The feeder, fan and central heating pup run until the temperature

set with the room regulator is reached. However, the boiler is limited in

its operation by the temperature set with the boiler controller.

CONNECTING THE ROOM REGULATOR: the room regulator features a

two-wire cable that should be connected to the controller's connection

strip, to a terminal labelled as room regulator.

ATTENTION: no external voltage can be applied to the room regulator

output.

III.5.Boiler Hysteresis

With this function, you can set the hysteresis of the setpoint

-16-

FITTER’S MENU

Exit

Temperature Alarm

Room Regulator

Boiler Hysteresis

FITTER’S MENU

Exit

Temperature Alarm

Room Regulator

Boiler Hysteresis

Page 17

TECH

temperature. This is a difference between the temperature of entering

into the sustain cycle and the temperature of returning to the duty cycle

(e.g.: when the setpoint temperature is set to 60°C, and the hysteresis is

set to 3°C, entering into the sustain cycle will be effected after the

temperature reaches 60°C, whereas return to the duty cycle will be

effected after the temperature drops to 57°C).

III.6.H.C.W. Hysteresis

With this function, you can set the hysteresis of the setpoint temperature

on the water heater.

This is a difference between the setpoint temperature (required by the

water heater) and the actual temperature on the water heater (e.g.:

when the setpoint temperature is set to 55oC and the hysteresis is set to

5oC). After reaching the setpoint temperature, i.e. 55°C, the hot

consumption water pump is shut off, causing the central heating pump to

be activated. The hot consumption water pump will be activated again

when the temperature drops to 50°C.

III.7.Floor Heating Pump

With this function, you can control the floor heating. You can set the floor

-17-

FITTER’S MENU

Exit

H.C.W. Hysteresis

Floor Pump

Circulation Pump

FITTER’S MENU

Exit

H.C.W. Hysteresis

Floor Pump

Circulation Pump

FLOOR PUMP

Exit

On

Off

Min Temperature

Page 18

ST-45 User's Manual

heating temperature in a range between 20°C and 55°C. You can also set

the pump switch-on and shut-off threshold, e.g. 25°C, meaning that

when the temperature drops below this value, the pump is shut off, and

when it rises above this value, the pump runs until the setpoint

temperature is reached. When the setpoint temperature has been

reached, e.g. 45°C, the floor heating pump is shut off. The floor heating

pump will be re-activated when the temperature drops to 2°C).

III.8.Circulation Pump

With this function, you can control the pump that is responsible for

mixing hot water between the boiler and hot consumption water

receivers. Operation and pause times are set by the user.

III.9.Automatic Mode of Feeder

With this function, you can disable or enable the automatic feed (e.g. in

order to damp the boiler).

-18-

FITTER’S MENU

Exit

H.C.W. Hysteresis

Floor Pump

Circulation Pump

CIRCULATION PUMP

Exit

On

Off

Operation Time

FITTER’S MENU

Exit

Feeder in Auto Mode

Language Version

Software Version

Page 19

TECH

III.10.Language Version

With this function, you can change the language version.

III.11.Software Version

With this function, you can check the software version for a given

thermoregulator.

IV.Service Menu

To be able access service functions of the ST-45 controller, you need to

enter a four-digit code. The code is available from Sas or Tech.

IV.1.Pump Switch-on Temperature

-19-

FITTER’S MENU

Exit

Feeder in Auto Mode

Language Version

Software Version

LANGUAGE VERSION

Exit

Polish

English

SERVICE MENU

Exit

Pump Activation Temp

Feeder Alarm Temp

Priority Temp

PUMP ACTIVATION TEMP

degrees

SERVICE MENU

Enter Access Code

Page 20

ST-45 User's Manual

With this function, you can set the temperature for central heating pump

and hot consumption water pump activation. (This is the temperature

measured on the boiler). Below the set temperature (-2°C), the pumps

are inoperative, and above the setpoint value, the pumps are activated

but they operate according to the selected mode.

IV.2.Feeder Alarm Temperature

With this protective function, you can set the alarm temperature for the

fuel feeder. If the feeder temperature rises unexpectedly, this can be due

to the presence of fire in the feeder. After the feeder alarm temperature

is reached, the feeder starts to run in order to discharge the burning

material into the furnace.

IV.3.Priority Temperature

With this function, you can set the temperature in the hot consumption

water heating priority. The temperature adjustment range is 50-75°C.

-20-

SERVICE MENU

Exit

Pump Activation Temp

Feeder Alarm Temp

Priority Temp

FEEDER ALARM TEMP

degrees

SERVICE MENU

Exit

Pump Activation Temp

Feeder Alarm Temp

Priority Temp

PRIORITY TEMP

degrees

Page 21

TECH

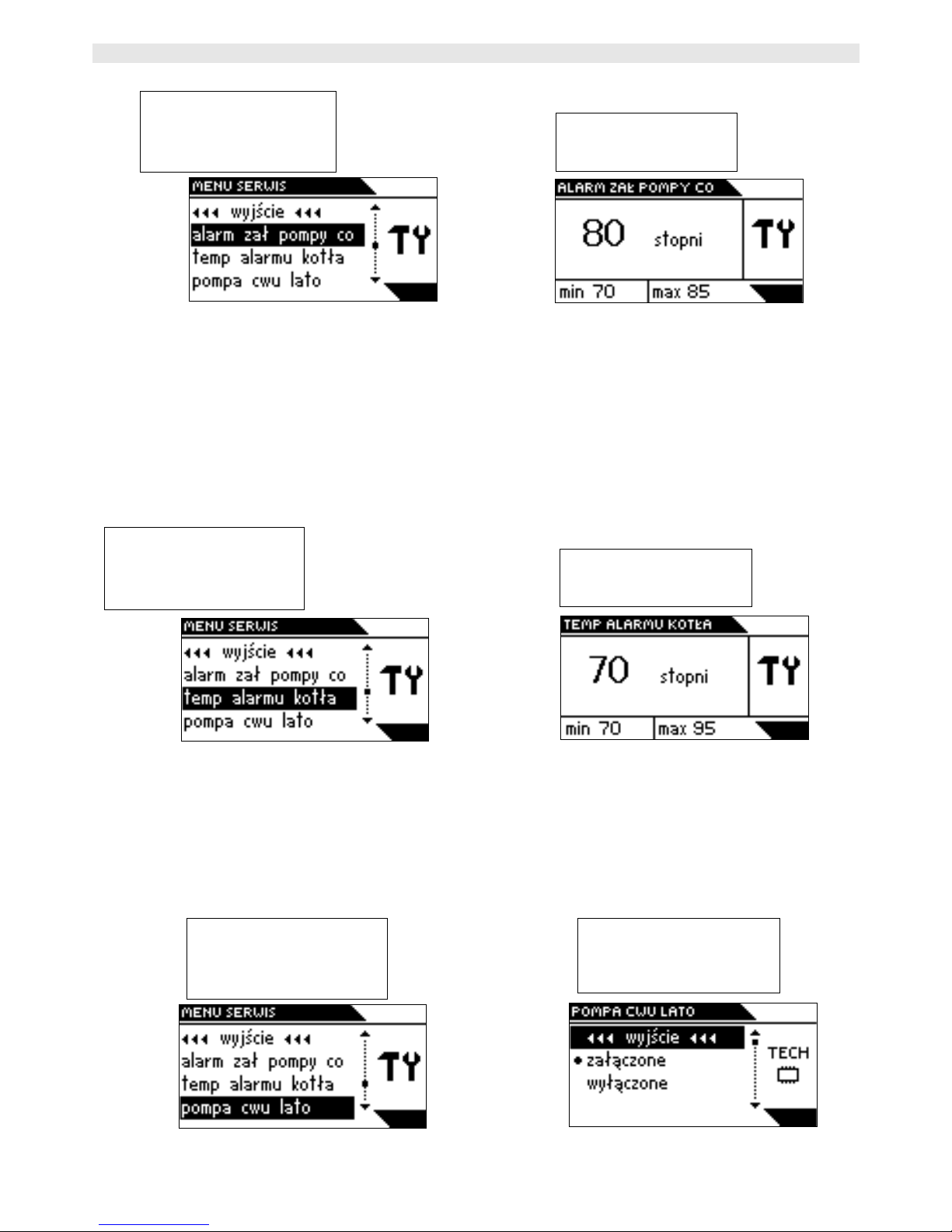

IV.4.C.H. Pump Activation Alarm

With this function, you can set the alarm temperature for central heating

pump activation. The central heating pump is to be activated in case the

boiler should be overheated, in the water heater priority mode. The

pump runs until the boiler temperature drops by 2°C. This protection is

applied when burnout functions are improperly set.

IV.5.Boiler Alarm Temperature

With this function, you can set the alarm temperature at which the feeder

and the fan will stop and the central heating pump will be activated in

order to distribute hot consumption water throughout the system.

IV.6.H.C.W. Summer Pump

-21-

SERVICE MENU

Exit

C.H. Pump On Alarm

Boiler Alarm Temp

H.C.W. Pump Summer

C.H. PUMP ON ALARM

degrees

SERVICE MENU

Exit

C.H. Pump On Alarm

Boiler Alarm Temp

H.C.W. Pump Summer

BOILER ALARM TEMP

degrees

SERVICE MENU

Exit

C.H. Pump On Alarm

Boiler Alarm Temp

H.C.W. Pump Summer

H.C.W. PUMP SUMMER

Exit

On

Off

Page 22

ST-45 User's Manual

With this function, you can switch on and off the hot consumption water

pump in the summer mode, i.e. specify whether the hot consumption

water pump is to run after the preset temperature has been reached or it

is to be shut off. If you enable the function, the hot consumption water

pump will run permanently in the summer mode, whereas if you disable

it, the pump will be shut off after the preset temperature has been

reached and activated again, depending on the boiler hysteresis applied.

IV.7.C.H. Pump Room Regulator

With this function, you can switch on or off the central heating pump

when the room regulator is active, i.e. you can decide whether the

central heating pump is to be shut off after the desired room temperature

has been reached.

B) Reed Relay Protection

With this function, you can set the duration of a complete feed cycle. If

the cycle is not completed within the set period, the following message is

displayed: Clean Feeder. In this function, data are obtained form the Hall

sensor that is located at the feeder.

V.Stand-by Mode

-22-

SERVICE MENU

Exit

C.H. Pump Room Reg.

C.H. PUMP ROOM REG.

Exit

On

Off

MENU

Exit

Service Menu

Stand-by Mode

Page 23

TECH

In this function, you can switch on or off the stand-by mode for the

thermoregulator. All motors of devices (e.g. fan) that are connected to

the thermoregulator are stopped.

ATTENTION: in the stand-by mode, the power is not cut off

completely.

Alternatively, you can switch the controller into the stand-by mode by

pressing and holding the encoder for several seconds.

VI.Protections

In order to ensure a safe and faultless operation, the regulator has

been provided with numerous protections. In the case of an alarm, an

acoustic warning is sounded and the display shows an appropriate

message.

Press the encoder to restore the controller to operation.

VI.1.Temperature Alarm

The protection is enabled only in the duty mode (i.e. when the

furnace temperature is lower than the setpoint temperature). When the

furnace temperature fails to rise in the user-defined period, an alarm is

activated: the feeder and the fan are shut off (the water pump is

activated regardless of the furnace temperature) and the alarm is

sounded. The display shows an appropriate message:

If you press the encoder, the regulator will deactivate the alarm.

The regulator will return to the previous working mode.

VI.2.Thermal Protection

The boiler is protected with an additional bimetal sensor (located at

the furnace sensor) that deactivates fan and feeder outputs when the

-23-

Page 24

ST-45 User's Manual

temperature exceeds the critical value, ranging from 85°C and 90°C. This

is to prevent water from boiling in the system when the boiler has been

overheated or the regulator damaged. With this type of safety

temperature protection, the system will return to the initial position

(automatically).

ATTENTION: in case the thermal relay is damaged, the fan and the

feeder are inoperative in both modes: manual and automatic.

VI.3.Automatic Sensor Check

When the temperature sensor of the central heating, hot

consumption water, screw or grate is damaged, an alarm is activated

with an additional indication shown in the display, e.g.: C.H. Sensor

Damaged:

the feeder and the fan are shut off. The pump is activated

regardless of the actual temperature. If you press the encoder (this

refers to the hot consumption water sensor), the regulator will deactivate

the alarm and the controller will return to its normal operation with a

single pump. If the central heating sensor or feeder sensor is damaged,

the alarm will remain active until the sensor is replaced.

VI.4.Anti-Boil Protection

This function is used for protecting the boiler against high

temperatures [only with the water heater priority function], e.g.

when the water heater setpoint temperature is 55°C and the boiler

temperature is 62°C, the controller shuts off the feeder and the fan.

When the temperature reaches 80°C, the central heating pump is

activated. When the temperature continues to rise, the alarm is sounded

at 85°C. Such condition may appear when the water heater or the pump

are damaged or when the sensor has been improperly mounted.

-24-

Page 25

TECH

However, if the temperature continues to drop, the controller will activate

the feeder and the fan at 60°C and it will continue to operate until the

water heater setpoint temperature is reached.

VI.5.Temperature Protection

The regulator features an additional protection in case the bimetal

sensor is damaged. After the temperature exceeds 95°C, the alarm is

sounded. The display shows: Temperature Too High

The current temperature is read from an electronic sensor and processed

by the thermoregulator. When the alarm temperature is exceeded, the

fan is shut off and both pumps begin to run in order to distribute hot

consumption water throughout the system.

VI.6.Fuel Container Protection

At the fuel container screw, an additional temperature sensor is

mounted. If the temperature rise is high (above 70°C), the alarm is

sounded: the feeder is activated for 3 minutes with the fuel being moved

into the combustion chamber. The screw sensor protects the fuel from

being combusted in the grate.

VI.7.Fuse

The regulator features two WT 6.3A tube fuses to protect the

network.

ATTENTION: it is not advisable to use fuses with higher current ratings.

Higher current ratings may cause damage to the controller.

-25-

Page 26

ST-45 User's Manual

VII.Maintenance

Before and during the heating season, the ST-45 controller should be

checked for any damages in its cables. You should also check if the

controller is properly mounted and clean it if dusty or dirty. It is

advisable to measure grounding parameters for the motors (central

heating pump, hot consumption water pump, fan, feeder, floor pump and

circulation pump).

We are committed to protecting the environment. Manufacturing electronic devices imposes an

obligation of providing for environmentally safe disposal of used electronic components and devices.

Hence, we have been entered into a register kept by the Inspection For Environmental Protection. The

crossed-out bin symbol on a product means that the product may not be disposed of to household

waste containers. Recycling of wastes helps to protect the environment. The user is obliged to transfer

their used equipment to a collection point where all electric and electronic components will be recycled.

-26-

Page 27

TECH

No. Specification Unit

1 Supply Voltage V 230V/50Hz +/-10%

2 Max. Power Consumption W 11

3 Ambient Temperature

O

C

10 - 50

4 Central Heating; Hot Consumption Water;

Floor; Circulation - Pump Outlet Load

A

,0 5

5 Fan Output Load A

,0 6

6 Feeder Output Load A

2

6

7

8

9

10

Temperature Measurement Range

Measurement Accuracy

Temperature Adjustment Range

Sensor Thermal Resistance

Fuse Insert

O

C

O

C

O

C

O

C

A

0 - 85

1

45 - 80

-25 - 100

6,3

VIII.Assembly

ATTENTION: all assembly works must only be carried out by qualified

persons. During assembly, the device must be disconnected (make sure

the power cord is unplugged)!

ATTENTION: improper cable connection may damage the regulator!

ATTENTION: the ST-45 controller must be built into the boiler so that

the cable connection strips are not accessible.

The regulator may not be operated in a closed-circuit central heating

system. It is necessary to provide for safety valves, pressure valves and

a surge tank in order to prevent water from boiling in the central heating

system.

-27-

Page 28

ST-45 User's Manual

VIII.1.Cable Connection Diagram for Controller

Particular attention should be paid when making cable connections with

the controller. Especially, the grounding conductor should be connected

properly.

PE-GROUND (YELLOW-GREEN)

N- NEUTRAL (BLUE)

L- PHASE (BROWN)

-28-

Figure 1: ST-45 cable connection diagram

Page 29

TECH

Table of Contents

I. Description.................................................................................. 4

II. Regulator Functionality................................................................ 5

II.1. Main Page............................................................................. 5

II.2. C.H. Setpoint Temperature.....................................................6

II.3. H.C.W. Setpoint Temperature..................................................6

II.4. Screen................................................................................. 7

II.5. Manual Mode.........................................................................7

II.6. Feed Interval........................................................................ 8

II.7. Blow Force............................................................................9

II.8. Operation Mode.....................................................................9

II.8.a) House Heating.................................................................9

II.8.b) Water Heater Priority.....................................................10

II.8.c) Parallel Pumps..............................................................11

II.8.d) Summer Mode..............................................................11

II.9. Sustain Mode Operation........................................................12

II.10. Pause in Sustain Mode........................................................12

II.11. Sustain Mode of Fan...........................................................12

III. Fitter’s Menu........................................................................... 13

III.1. Factory Settings.................................................................13

III.2. Valves 1 and 2................................................................... 13

III.2.a) Registration.................................................................14

III.2.b) Temperature Monitoring................................................14

III.2.c) Opening Time.............................................................. 15

III.2.d) Single stroke...............................................................15

III.2.e) Minimum opening.........................................................15

III.2.f) Valve Type...................................................................16

III.3. Temperature Alarm............................................................. 16

III.4. Room Regulator..................................................................16

III.5. Boiler Hysteresis.................................................................17

III.6. H.C.W. Hysteresis...............................................................17

III.7. Floor Heating Pump.............................................................18

III.8. Circulation Pump................................................................18

III.9. Automatic Mode of Feeder....................................................19

III.10. Language Version.............................................................19

III.11. Software Version...............................................................19

IV. Service Menu........................................................................... 20

IV.1. Pump Switch-on Temperature...............................................20

IV.2. Feeder Alarm Temperature...................................................20

IV.3. Priority Temperature............................................................21

IV.4. C.H. Pump Activation Alarm..................................................21

-29-

Page 30

ST-45 User's Manual

IV.5. Boiler Alarm Temperature....................................................22

IV.6. H.C.W. Summer Pump......................................................... 22

IV.7. C.H. Pump Room Regulator..................................................22

B) Reed Relay Protection............................................................. 23

V. Stand-by Mode..........................................................................23

VI. Protections..............................................................................24

VI.1. Temperature Alarm............................................................. 24

VI.2. Thermal Protection..............................................................24

VI.3. Automatic Sensor Check......................................................25

VI.4. Anti-Boil Protection.............................................................. 25

VI.5. Temperature Protection........................................................25

VI.6. Fuel Container Protection.....................................................26

A) Fuel Container Protection (Hall Sensor).....................................26

VI.7. Fuse..................................................................................26

VII. Maintenance........................................................................... 27

VIII. Assembly.............................................................................. 28

VIII.1. Cable Connection Diagram for Controller..............................29

-30-

Page 31

TECH

-31-

Page 32

ST-45 User's Manual

-32-

Loading...

Loading...