Page 1

L-6 User’s manual

1

User’s manual

L-6

Page 2

TECH

2

I. Safety

Before using the device for the first time the user should read the following regulations

carefully. Not obeying the rules included in this manual may lead to personal injuries or

controller damage. The user’s manual should be stored in a safe place for further

reference. In order to avoid accidents and errors it should be ensured that every person

using the device has familiarized themselves with the principle of operation as well as

security functions of the controller. If the device is to be sold or put in a different place,

make sure that the user’s manual is there with the device so that any potential user has

access to essential information about the device.

The manufacturer does not accept responsibility for any injuries or damage resulting

from negligence; therefore, users are obliged to take the necessary safety measures

listed in this manual to protect their lives and property.

WARNING

High voltage! Make sure the regulator is disconnected from the mains before

performing any activities involving the power supply (plugging cables, installing

the device etc.)

The device should be installed by a qualified electrician.

Before starting the controller, the user shoud measure earthing resistance of the

electric motors as well as the insulation resistance of the cables.

The regulator should not be operated by children.

WARNING

The device may be damaged if struck by a lightning. Make sure the plug is

disconnected from the power supply during storm.

Any use other than specified by the manufacturer is forbidden.

Before and during the heating season, the controller should be checked for

condition of its cables. The user should also check if the controller is properly

mounted and clean it if dusty or dirty.

!

!

Page 3

L-6 User’s manual

3

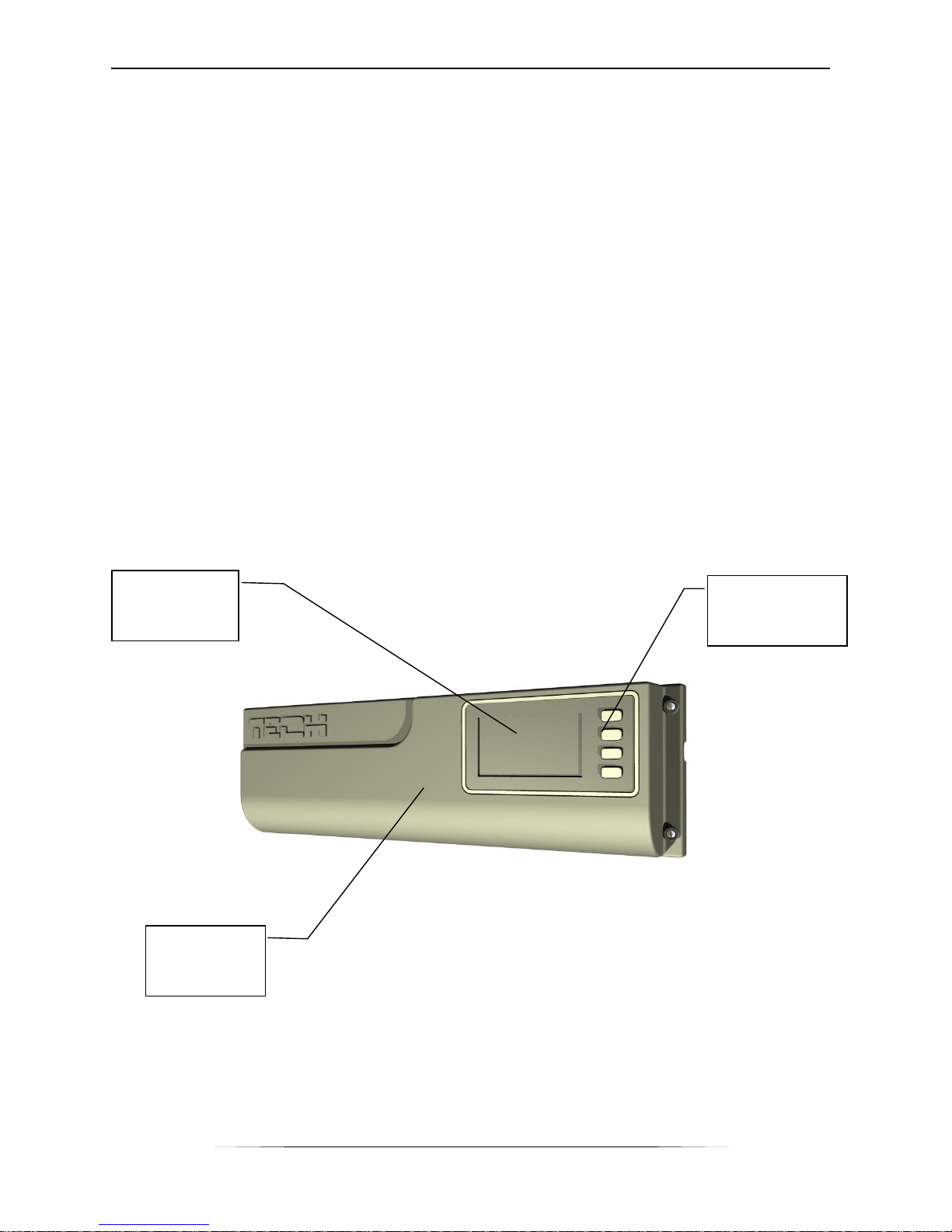

II. Description of the device

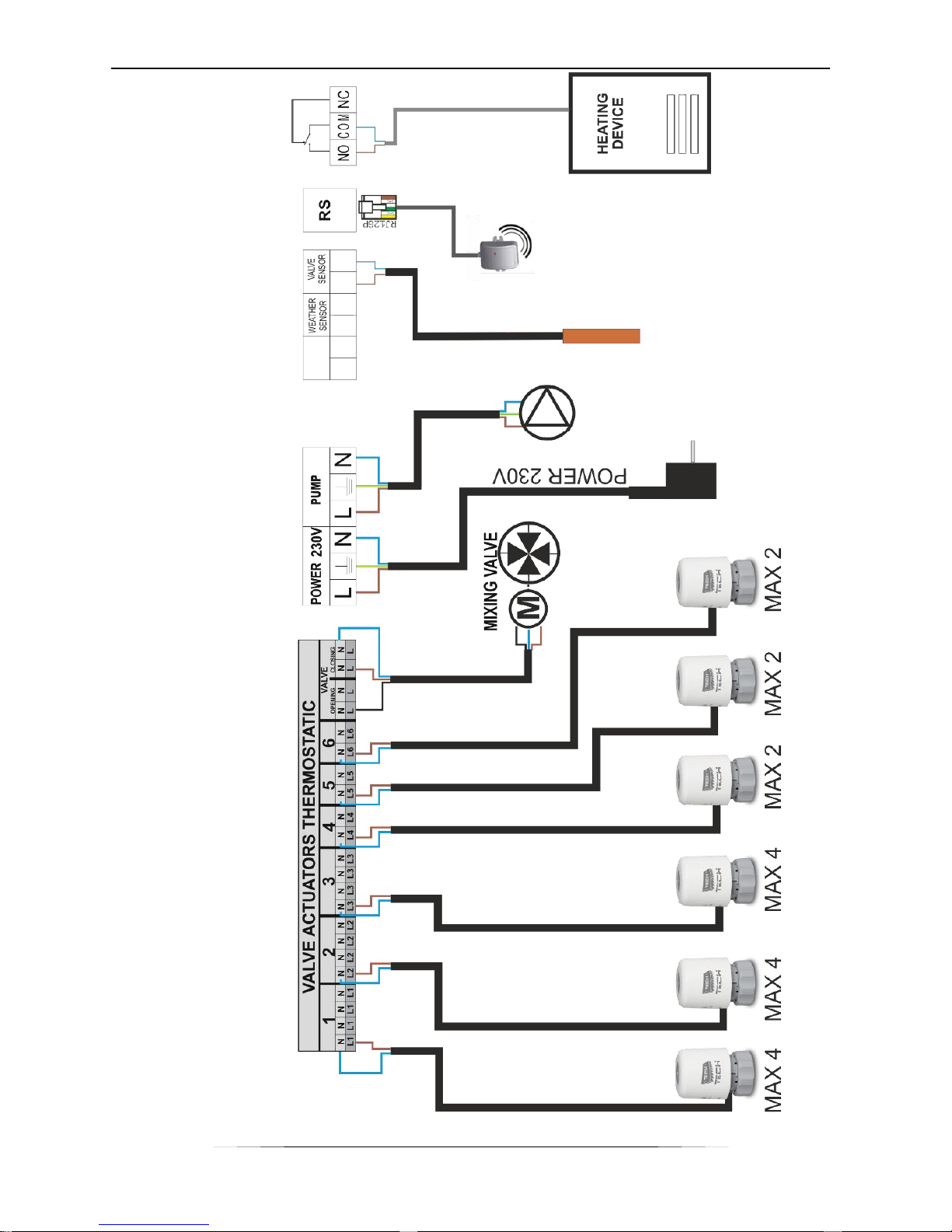

L-6 external controller is intended for both wired and wireless control of the valves. It

allows the user to limit considerably the power consumption due to precise control of the

room temperature. Thanks to advanced software, the device offers a wide range of

functions:

control of the mixing valve

control of up to 18 thermostatic valves via 6 room regulators (wired connection)

o 3 room regulators may support 12 actuators (the maximum of 4 actuators per one

regulator)

o 3 room regulators may support up to 6 actuators (the maximum of 2 actuators per

one regulator)

possibility of controlling thermostatic valves via radio signal

one 230V pump output

supporting pump with speed control (via PWM signal)

voltage-free contact

possibility of connecting ST-65 GSM module allowing the user to control some of

the functions via a mobile phone.

possibility of connecting ST-500 Ethernet module allowing the user to control some

of the functions and view certain parameters via the Internet

possibility of connecting an external control panel with RS communication

Buttons used

to navigate

the menu

Display

Controller

cover

Page 4

TECH

4

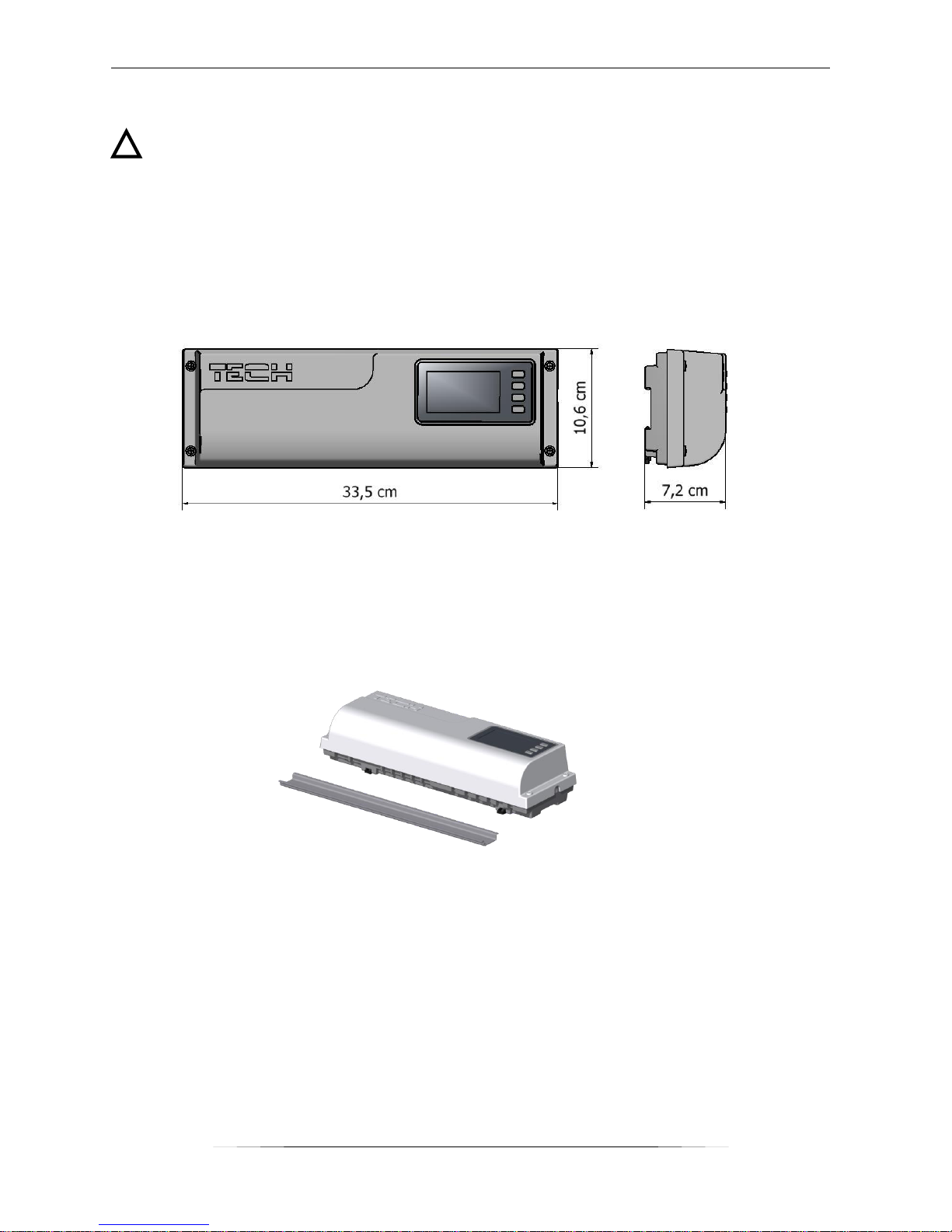

III. Controller installation

The controller should be installed by a qualified person.

WARNING

Risk of fatal electric shock from touching live connections. Before working on the

controller switch off the power supply and prevent it from being switched on again.

L-6 regulator may be installed as a free-standing device or as a panel mountable on a

wall.

The controller may be installed on a DIN strip.

In order to wire up the controller, the cover should be removed.

!

Page 5

L-6 User’s manual

5

Page 6

TECH

6

IV. Wireless communication

L-6 controller enables wireless communication with the following devices:

Function

Configuration

ST-290v4

ST-292v4

two-state

room

regulators

Sending information

about

sufficient/insufficient

temperature in a given

zone

- the room regulator needs

to be assigned to a

selected area in the room

regulator menu

- the current

communication channel

must be the same as in L-6

ST-286

two-state

room

regulators

(colour)

Sending information

about

sufficient/insufficient

temperature in a given

zone.

- the room regulator needs

to be assigned to a

selected area in the room

regulator menu

- the current

communication channel

must be the same as in L-6

ST-285

master room

regulator

Enabling the user to

view and change

certain parameters of

the room regulators

assigned to the zones

- an appropriate option

should be selected in ST-L6 menu (Main menu/

Fitter’s menu/ Room

regulator/ TECH regulator)

- ST-260 module is

necessary

ST-291

external

temperature

sensor

Enabling the user to

view the external

temperature and use

weather-based control

of the built-in valve

module

- the current

communication channel

must be the same as in L-6

ST-500

Internet

module

Enabling the user to

view and change

certain operation

parameters of L-6 via

the Internet

- additional ST-260 module

is necessary

STT-868

wireless

thermostatic

actuator

Helping to maintain the

pre-set temperature

- it needs to be registered

in L-6 controller.

Page 7

L-6 User’s manual

7

V. First start-up

In order for the controller to operate correctly, the following steps must be followed when

starting the device for the first time:

1. Wire up the controller

2. Switch on the controller.

3. If the set includes the master room regulator (ST-285), it needs to be activated

in the controller menu: Main Menu/ Fitter’s menu/ Room regulator/ TECH

regulator.

4. If the set includes ST-500 Internet module, it needs to be activated in the

controller menu: Main menu/ Fitter’s menu/ Internet module/ ON.

5. Define the type of external sensor by selecting one of the options in the controller

menu: OFF, Standard or Wireless (ST-291) in the controller menu: Main Menu /

External sensor.

6. Configuration of room regulators sending information about sufficient/insufficient

temperature in a given zone.

a. The user should check if the selected communication channel in the room

regulators is the same as in L-6. ‘0’ is the default channel in all devices. If

there is a conflict with other devices using radio communication, the user

needs to select a different channel.

Channel change in ST-286 controller:

In order to change the channel, press Controller settings in

the main menu and go to Channel selection. After a channel

is selected, confirm the change by pressing OK.

Channel change in ST-290v4 or ST-292v4:

ST-290v4

Screenshot

ST-292v4

- Press and hold MENU

button to view the controller

functions.

- Using arrows and

go to channel change

(see: screenshot)

- Select a desired channel by

using PLUS and MINUS

buttons.

- Confirm the change by

pressing MENU and holding it

for a few seconds.

- Press MENU to view the

controller functions

- Press MENU button until the

channel change panel appears

on the screen. (see:

screenshot)

- Using and

buttons select a desired

channel.

- Confirm the change by

pressing MENU and holding it

for a few seconds or by

pressing EXIT.

b. Each room regulator should be assigned to a zone.

NOTE

Each room regulator should be assigned to only one zone. If there are more room

regulators assigned to the same zone, L-6 controller will not work properly.

!

Page 8

TECH

8

How to assign ST-286room regulator to a selected zone:

Press Controller settings in the main menu and go to

Regulator number (zone number). Select a zone number and

confirm by pressing OK icon.

How to assign ST-290v4 or ST-292v4 to a selected zone:

ST-290v4

Screenshot

ST-292v4

- Press and hold MENU

button to view the controller

functions

- Using and

go to zone selection (see:

screenshot)

- Zone change function is

secured with 215 code – use

PLUS and MINUS buttons to

enter the first digit of the

code (‘2’). Press MENU to

confirm. Follow the same

procedure with ‘1’ and ‘5’.

- Press MENU to view the

controller functions

- Press MENU button until the

zone selection panel appears

on the screen. (see:

screenshot)

- Zone change function is

secured with 215 code - use

and buttons to

enter the first digit of the

code (‘2’). Confirm by

pressing and holding MENU

button. Follow the same

procedure with ‘1’ and ‘5’.

- Choose a desired zone

number using PLUS and

MINUS buttons.

- Press and hold MENU to

confirm the change.

- Choose a desired zone

number using

buttons.

- Confirm the change by

pressing MENU and holding it

for a few seconds or by

pressing EXIT.

7. If wireless thermostatic actuators are used, they need to be registered in the

zones.

VI. How to use the controller

V.a) Principle of operation

L-6 controls the CH pump switching it on when the temperature in any of the six zones

or the built-in valve is too low. The controller receives temperature information from the

subordinate room regulators assigned to particular zones. If the temperature in any of

the zones is too low, the controller opens the valves in this particular zone.

L-6 receives temperature information from different zones via room regulators e.g. ST292v4, ST-290v4 or ST-286. Room regulators use wireless communication to send

information to the L-6 controller.

It is possible to connect a master room regulator (ST-285) which controls the operation

of the room regulators in all zones via wireless communication.

To each zone the user may assign wired valve actuators and the maximum of 9 wireless

actuators communicating with L-6 via radio signal (registration is required).

Page 9

L-6 User’s manual

9

V.b) Main screen view and description

The user operates the controller using buttons located next to the display.

1. Information about active master room regulator (ST-285)

2. Current time

3. Buttons used to navigate

4. Current communication channel

5. Information about the zones:

A digit displayed on the screen refers to the room regulator which reports

insufficient/sufficient room temperature. If the digit is flashing, the room temperature is

too low – the valves are open. If a digit is not displayed, there is no signal from the room

regulator assigned to this number.

6. Information about active built-in valve

V.c) Controller functions – main menu.

Due to a great number of functions offered by the controller, the menu is divided into

Main menu and Fitter’s menu.

3

1

2

3

4 5 6

7

Page 10

TECH

10

V.c.1) Block diagram – Main menu

V.c.2) Manual operation

This function enables the user to control operation of

particular devices. Each of the following devices may be

switched on manually: main valve, pump, voltage-free

contact and particular valve actuators.

Main menu

Manual mode

Main valve

Pump

Voltage-free contact

Valve 1-6

Channel 0 Channel; range: 0÷20

Main valve

Valve status

Pre-set valve temperature

Opening time

Valve type

Weather-based control

Factory settings

External sensor

OFF

Standard

Wireless

Pump Delay

Language selection

Display contrast

Fitter's menu

Registration

Room regulator

Internet module

Clock

Page 11

L-6 User’s manual

11

V.c.3) Channel

This function is used to select the channel for wireless

communication with the room regulators and the external

sensor. The user needs to select the same channel in all

devices communicating with the L-6 controller. The range

of channels is 0-20.

‘0’ is the default channel in the devices cooperating

with L-6. The channel must be changed only if there

is a conflict with other devices using radio

communication. In such a case the user must

remember to change the channel in all the devices

communicating with L-6.

V.c.4) Main valve

L-6 controller is equipped with a built-in module

controlling the mixing valve. There is a range of

parameters regulating the valve operation and allowing

the user to customize it to individual needs.

Valve status

In order to activate the valve select ON.

Pre-set valve temperature

This function is used to define the pre-set temperature of

the valve. It is measured by the valve sensor.

Opening time

This parameter defines the time needed for the valve to

open from 0% to 100%. The value should be adjusted to

the valve actuator used (information on the rating plate).

Valve type

This function is used to select the type of valve to be

controlled:

CH VALVE – this option is selected when the user

wants to control the CH circuit temperature

FLOOR VALVE - this option is selected when the

user wants to control the temperature in the

underfloor heating circuit. This function protects

the underfloor heating system against hazardous temperature. If CH valve type is

Page 12

TECH

12

selected when the valve is connected to the underfloor heating system, the fragile

installation may be damaged.

Weather-based control

For the function of weather control to be active, the

external sensor mustn't be exposed to sunlight or

influenced by the weather conditions. After it is installed

in an appropriate place and wired up, weather control

function needs to be activated in the controller menu.

For the valve to operate correctly, the user defines the

pre-set temperature (behind the valve) for 4 intermediate

external temperatures:

-20ºC, -10ºC, 0ºC and 10ºC.

The user selects external temperature value using LEFT

and RIGHT arrows and defines a corresponding pre-set

temperature value using DOWN and UP arrows.

Subsequently, the display shows the heating curve.

Heating curve – it is a curve according to which the pre-

set controller temperature is determined, on the basis of

external temperature. In our controller, this curve is

constructed on the basis of four pre-set temperatures for

respective values of external temperatures.

The more points constructing the curve, the greater its

accuracy, which allows its flexible shaping. In our opinion,

four points seem a very good compromise ensuring decent

accuracy and easiness of setting the course of this curve.

NOTE

After weather-based control is switched on, pre-set valve temperature parameter is

not available. (Main menu-valve settings)

Factory settings

This function enables the user to restore the factory

settings for a particular valve. Restoring factory settings

does not change the selected valve type (CH or floor).

V.c.5) External sensor

The controller may be connected to a standard or wireless

external temperature sensor which enables weatherbased control of the built-in valve. Current external

temperature is displayed on the main screen. After the

external sensor is installed, the user needs to

define its type: standard or wireless.

!

Page 13

L-6 User’s manual

13

WARNING

If a wireless external sensor is used, the user needs to check if the same communication

channel is selected in L-6 controller. ‘0’ is the default channel in the external sensor.

Channel change in the external sensor:

Press and hold the channel change button in order to change the communication channel.

When the control light flashes twice, the process of channel change has been initiated.

Hold the button and wait until the light starts flashing again. The number of flashes

corresponds to the channel number (1 flash – channel 1; 5 flashes – channel 5). After

the desired channel has been selected, release the button. In order to return to channel

0, repeat the procedure releasing the button after the first two flashes.

V.c.6) Pump

L-6 controls the pump operation switching it on when

necessary.

The pump is activated when the temperature in any of the

zones is too low or if the pre-set temperature of the builtin valve has not been reached (the built-in valve needs to

be active). If all room regulators report sufficient

temperature and the pre-set temperature of the built-in

valve has been reached (if the valve is active), the

controller switches off the pump.

Delay function allows the user to define the

time of pump activation delay after the

temperature in any of the zones is too low or

after the valve temperature drops below the

pre-set value.

V.c.9) Language selection

This function is used to choose the language version.

!

Control light

Channel

change button

Page 14

TECH

14

V.c.10) Display contrast

This function enables adjustment of display contrast.

V.c.11) Fitter’s menu

Fitter’s menu should be accessed by a qualified person.

It is intended mostly for adjusting additional functions of

the controller.

1) Registration

Wireless thermostatic actuators must be registered in

particular zones. The user may choose from 6 zones

(Valve 1-6). The maximum of 9 actuators may be

registered in one zone.

Registration procedure:

1. Install the thermostatic actuator on the radiator.

2. Go to Registration in the Fitter’s menu of L-6

controller.

3. Choose the zone number in which the actuator

will be registered and select Registration.

4. Press registration button on the controller. It

must be done within 30 seconds from selecting

Registration option in the menu – after this time

the registration process is considered unsuccessful.

5. If the registration process has been successfully completed,

the display shows the message confirming the registration

as well as the number of registered valves. If an error

occurs during the registration process, the display shows an

appropriate message. There are three possible causes of

errors:

o an attempt to register more than 9 actuators

o an attempt to register an actuator which has

already been registered

o no signal from the valve actuator within 30

seconds

2) Room regulator

L-6 controller may cooperate with a master room regulator

(ST-285) which enables the user to:

view the status of particular valves

change the pre-set temperature of a given zone – in

the case of using subordinate room regulators with

RS communication (ST-286)

view the external temperature

Registration button on

the wireless

thermostatic actuator

Page 15

L-6 User’s manual

15

view the status of an additional contact (ON/OFF)

Regulator TECH option needs to be selected in order for

the communication between L-6 and the room regulator

to be active.

3) Internet module

L-6 controller may cooperate with the Internet module

allowing the user to view and change some of the

parameters via the Internet. This type of control is

available only after purchasing and connecting an

additional controlling module ST-500 which is not included

in the standard controller set.

The Internet module may be connected to L-6 controller

with RS cable. Wireless communication is possible if an

additional module - ST-260 is used.

Internet module is a device enabling the user remote

control of the CH boiler via the Internet or local network.

The user controls the status of all valves on the home

computer screen.

If two-state room regulators are used, the user may check

if the temperature is sufficient/insufficient. Room

regulators with RS communication enable the user to view

the current room temperature as well as change its preset value.

After switching the module on and selecting DHCP option,

the controller automatically downloads such parameters

as IP address, IP mask, gateway address and DNS

address from the local network. If any problems arise

when downloading the network parameters, they may be

set manually. The procedure of obtaining these parameters is described in detail in the

instruction manual of the Internet module.

Module password reset function may be used when the user has changed the default

password on the login page. If the user's new password is lost, the default password may

be restored by resetting the module password.

4) Clock

This function is used to set current time and day of the

week.

Page 16

TECH

16

VII. Protections and alarms

In order to ensure safe and failure-free operation, the regulator has been equipped with

a range of safeguards. In case of alarm, a sound signal is activated and the display shows

an appropriate message.

Automatic sensor control

If the valve temperature sensor or the external sensor is damaged, an alarm sound is

activated and the display message informs about the failure

e.g. 'Sensor damaged'. The pump is active regardless of the current

temperature.

The alarm is active until a new sensor is installed.

Fuse

The regulator has a WT 6,3A tube fuse-link (5x20mm) protecting the network.

CAUTION: Higher amperage fuse should not be used as it may damage the controller.

VIII. Technical data

No.

Specification

Unit

1

Supply voltage

V

230V/50Hz +/-10%

2

Maximum power consumption

W

7

3

Ambient temperature

O

C

5÷50

4

CH pump output load

A

0,5

5

Range of CH temperature measurement

O

C

0÷90

6

Accuracy of measurement

O

C

1

7

Thermal resistance of the sensor

O

C

-25÷90

8

Fuse link

A

6,3

Page 17

L-6 User’s manual

17

Table of contents

I. Safety .......................................................................................................... 2

II. Description of the device .............................................................................. 3

III. Controller installation ................................................................................... 4

IV. Wireless communication ............................................................................... 6

V. First start-up .............................................................................................. 7

VI. How to use the controller ............................................................................. 8

V.a) Principle of operation .................................................................................. 8

V.b) Main screen view and description ................................................................. 9

V.c) Controller functions – main menu. ................................................................ 9

V.c.1) Block diagram – Main menu ................................................................. 10

V.c.2) Manual operation ................................................................................ 10

V.c.3) Channel ............................................................................................. 11

V.c.4) Main valve ......................................................................................... 11

V.c.5) External sensor .................................................................................. 12

V.c.6) Pump ................................................................................................ 13

V.c.9) Language selection ............................................................................. 13

V.c.10) Display contrast ................................................................................ 14

V.c.11) Fitter’s menu .................................................................................... 14

1) Registration .......................................................................................... 14

2) Room regulator ..................................................................................... 14

3) Internet module .................................................................................... 15

4) Clock .................................................................................................... 15

VII. Protections and alarms ............................................................................... 16

Fuse .............................................................................................................. 16

VIII. Technical data ........................................................................................ 16

Page 18

TECH

18

We are committed to protecting the environment. Manufacturing

electronic devices imposes an obligation of providing for

environmentally safe disposal of used electronic components and

devices. Hence, we have been entered into a register kept by the

Inspection For Environmental Protection. The crossed-out bin

symbol on a product means that the product may not be disposed

of to household waste containers. Recycling of wastes helps to

protect the environment. The user is obliged to transfer their

used equipment to a collection point where all electric and

electronic components will be recycled.

Page 19

L-6 User’s manual

19

EU Declaration of conformity

Hereby, we declare under our sole responsibility that L-6 manufactured by TECH,

headquartered in Wieprz Biała Droga 31, 34-122 Wieprz, is compliant with:

Directive 1999/5/EC of the European Parliament and of the Council of 9 March 1999 on radio

equipment and telecommunications terminal equipment and the mutual recognition of their

conformity,

Directive 2014/35/EU of the European Parliament and of the Council of February 26, 2014 on

the harmonisation of the laws of Member States relating to the making available on the market

of electrical equipment designed for use within certain voltage limits (EU Journal of Laws L 96,

of 29.03.2014, p. 357),

Directive 2014/30/EU of the European Parliament and of the Council of February 26, 2014 on

the harmonisation of the laws of Member States relating to electromagnetic compatibility (EU

Journal of Laws L 96 of 29.03.2014, p.79),

Directive 2009/125/EC establishing a framework for the setting of ecodesign requirements for

energy-related products, the regulation by the Ministry of Economy of May 8, 2013 concerning

the essential requirements as regards the restriction of the use of certain hazard-ous

substances in electrical and electronic equip-ment, implementing provisions of RoHS directive

2011/65/EU.

For compliance assessment, harmonized standards were used:

PN-ETSI EN 301 489-1 V1.9.2:2012

PN-ETSI EN 301 489-3 V1.6.1:2014-03

PN-ETSI EN 300 220-1 V2.4.1:2013-02

PN-ETSI EN 300 220-2 V2.4.1:2013-02

PN-EN 60730-2-9:2011, PN-EN 60730-1:2012

Wieprz, 12. 10. 2015

Page 20

TECH

20

Loading...

Loading...