Thyristor

Product

Catalog

Teccor Electronics

1800 Hurd Drive

Irving, Texas 75038

United States of America

Phone: +1 972-580-7777

Fax: +1 972-550-1309

Website: http://www.teccor.com

E-mail: power.techsales@teccor.com

©2002 Teccor Electronics i http://www.teccor.com

Thyristor Product Catalog +1 972-580-7777

Teccor Electronics reserves the right to make changes at any time in order to improve designs and to supply the best products possible.

The information in this catalog has been carefully checked and is believed to be accurate and reliable; however, no liability of any type

shall be incurred by Teccor for the use of the circuits or devices described in this publication. Furthermore, no license of any patent

rights is implied or given to any purchaser.

Teccor Electronics is the proprietor of the QUADRAC® trademark. is a registered trademark of Underwriters Laboratories, Inc. All other brand names may be trademarks of their respective companies. To conserve space in this catalog, the

trademark sign (®) is omitted.

http://www.teccor.com ii ©2002 Teccor Electronics

+1 972-580-7777 Thyristor Product Catalog

Contents

Product Selection Guide

Product Descriptions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - vi

Circuit Requirement Diagram - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - vii

Product Packages - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - viii

Description of Part Numbers- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - x

Quality and Reliability Assurance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -xii

Standard Terms and Conditions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - xiv

Data Sheets

V-I Characteristics of Thyristor Devices - - - - - - - - - - - - - - - - - - - - - - - - E0-2

Electrical Parameter Terminology - - - - - - - - - - - - - - - - - - - - - - - - - - - - E0-3

Electrical Specifications

Sensitive Triacs- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E1

Triacs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E2

QUADRACs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E3

Alternistor Triacs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E4

Sensitive SCRs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E5

SCRs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E6

Rectifiers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E7

Diacs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E8

SIDAC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E9

Mechanical Specifications

Package Dimensions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - M1

Lead Form Dimensions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - M2

Packing Options - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - M3

Application Notes

Fundamental Characteristics of Thyristors - - - - - - - - - - - - - - - - - - - AN1001

Gating, Latching, and Holding of SCRs and Triacs - - - - - - - - - - - - - AN1002

Phase Control Using Thyristors- - - - - - - - - - - - - - - - - - - - - - - - - - - AN1003

Mounting and Handling of Semiconductor Devices - - - - - - - - - - - - - AN1004

Surface Mount Soldering Recommendations - - - - - - - - - - - - - - - - - AN1005

Testing Teccor Semiconductor Devices

Using Curve Tracers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - AN1006

Thyristors Used As AC Static Switches and Relays - - - - - - - - - - - - AN1007

Explanation of Maximum Ratings and Characteristics for Thyristors - AN1008

Miscellaneous Design Tips and Facts - - - - - - - - - - - - - - - - - - - - - - AN1009

Thyristors for Ignition of Fluorescent Lamps - - - - - - - - - - - - - - - - - - AN1010

Appendix

Cross Reference Guide - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A1

Part Numbers Index- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A27

©2002 Teccor Electronics iii http://www.teccor.com

Thyristor Product Catalog +1 972-580-7777

http://www.teccor.com iv ©2002 Teccor Electronics

+1 972-580-7777 Thyristor Product Catalog

Product Selection Guide

Product Descriptions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - P 2

Circuit Requirement Diagram - - - - - - - - - - - - - - - - - - - - - - - - - - - - - P 3

Product Packages - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - P 4

Description of Part Numbers- - - - - - - - - - - - - - - - - - - - - - - - - - - - - P 6

Quality and Reliability Assurance - - - - - - - - - - - - - - - - - - - - - - - - - P 8

Standard Terms and Conditions - - - - - - - - - - - - - - - - - - - - - - - - - P 10

©2002 Teccor Electronics P - 1 http://www.teccor.com

Thyristor Product Catalog +1 972-580-7777

Product Descriptions

Thyristors

A thyristor is any semiconductor switch with a bi-stable action

depending on p-n-p-n regenerative feedback. Thyristors are normally two- or three-terminal devices for either unidirectional or bidirectional circuit configurations. Thyristors can have many forms,

but they have certain commonalities. All thyristors are solid state

switches that are normally open circuits (very high impedance),

capable of withstanding rated blocking/off-state voltage until triggered to on state. When triggered to on state, thyristors become a

low-impedance current path until principle current either stops or

drops below a minimum holding level. After a thyristor is triggered

to on-state condition, the trigger current can be removed without

turning off the device. Thyristors are used to control the flow of

electrical currents in applications including:

• Home appliances (lighting, heating, temperature control, alarm

activation, fan speed)

• Electrical tools (for controlled actions such as motor speed, stapling event, battery charging)

• Outdoor equipment (water sprinklers, gas engine ignition, electronic displays, area lighting, sports equipment, physical fitness)

Sensitive Triacs

Teccor's sensitive gate triacs are AC bidirectional silicon

switches that provide guaranteed gate trigger current levels in

Quadrants I, II, III, and IV. Interfacing to microprocessors or other

equipment with single polarity gate triggering is made possible with

sensitive gate triacs. Gate triggering currents of 3 mA, 5 mA,

10 mA, or 20 mA may be specified.

Sensitive gate triacs are capable of controlling AC load currents

from 0.8 A to 8 A rms and can withstand operating voltages from

200 V to 600 V.

Triacs

Teccor's triac products are bidirectional AC switches, capable of

controlling loads from 0.8 A to 35 A rms with 10 mA, 25 mA, and

50 mA I

Triacs are useful in full-wave AC applications to control AC power

either through full-cycle switching or phase control of current to the

load element. These triacs are rated to block voltage in the “OFF”

condition from 200 V minimum with selected products capable of

1000 V operation. Typical applications include motor speed controls, heater controls, and incandescent light controls.

in operating Quadrants I, II and III.

GT

Quadrac

Quadrac devices, originally developed by Teccor, are triacs and

alternistor triacs with a diac trigger mounted inside the same package. These devices save the user the expense and assembly time

of buying a discrete diac and assembling in conjunction with a

gated triac.

The Quadrac is offered in capacities from 4 A to 15 A rms and voltages from 200 V ac to 600 V ac.

Alternistor Triacs

The Teccor alternistor is specifically designed for applications

required to switch highly inductive loads. The design of this special

chip effectively offers the same performance as two thyristors

(SCRs) wired inverse parallel (back-to-back).

This new chip construction provides the equivalent of two electrically-separate SCR structures, providing enhanced dv/dt characteristics while retaining the advantages of a single-chip device.

Teccor manufactures 6 A to 40 A alternistors with blocking voltage

rating from 200 V to 1000 V. Alternistors are offered in TO-220,

TO-218, and TO-218X packages with isolated and non-isolated

versions.

http://www.teccor.com P - 2 ©2002 Teccor Electronics

+1 972-580-7777 Thyristor Product Catalog(972) 580-7777

Sensitive SCRs

Teccor's sensitive gate SCRs are silicon-controlled rectifiers representing the best in design, performance, and packaging techniques

for low- and medium-current applications.

Anode currents of 0.8 A to 10 A rms can be controlled by sensitive

gate SCRs with gate drive currents ranging from 12 µA to 500 µA.

Sensitive gate SCRs are ideally suited for interfacing to integrated

circuits or in applications where high current load requirements and

limited gate drive current capabilities exist. Examples include ignition circuits, motor controls, and DC latching for alarms in smoke

detectors. Sensitive gate SCRs are available in voltage ratings to

600 V ac.

SCRs

Teccor's SCR products are half-wave, silicon-controlled rectifiers

that represent the state of the art in design and performance.

Load current capabilities range from 1 A to 70 A rms, and voltages

from 200 V to 1000 V may be specified to meet a variety of application needs.

Because of its unidirectional switching capability, the SCR is used

in circuits where high surge currents or latching action is required.

It may also be used for half-wave-type circuits where gate-controlled rectification action is required. Applications include crowbars in power supplies, camera flash units, smoke alarms, motor

controls, battery chargers, and engine ignition.

Surge current ratings are available from 30 A in the TO-92 packaging to 950 A in the TO-218X package.

Rectifiers

Teccor manufactures 15 A to 25 A rms rectifiers with voltages

rated from 200 V to 1000 V. Due to the electrically isolated TO-220

package, these rectifiers may be used in common anode or common cathode circuits using only one part type, thereby simplifying

stock requirements.

Diacs

Diacs are trigger devices used in phase control circuits to provide

gate pulses to a triac or SCR. They are voltage-triggered bidirectional silicon devices housed in DO-35 glass axial lead packages

and DO-214 surface mount packages.

Diac voltage selections from 27 V to 45 V provide trigger pulses

closely matched in symmetry at the positive and negative breakover points to minimize DC component in the load circuit.

Some applications include gate triggers for light controls, dimmers,

power pulse circuits, voltage references in AC power circuits, and

triac triggers in motor speed controls.

Sidacs

Sidacs represent a unique set of thyristor qualities. The sidac is a

bidirectional voltage triggered switch. Some characteristics of this

device include a normal 95 V to 330 V switching point, negative

resistance range, latching characteristics at turn-on, and a low onstate voltage drop.

One-cycle surge current capability up to 20 A makes the sidac an

ideal product for dumping charged capacitors through an inductor

in order to generate high-voltage pulses. Applications include light

controls, high-pressure sodium lamp starters, power oscillators,

and high-voltage power supplies.

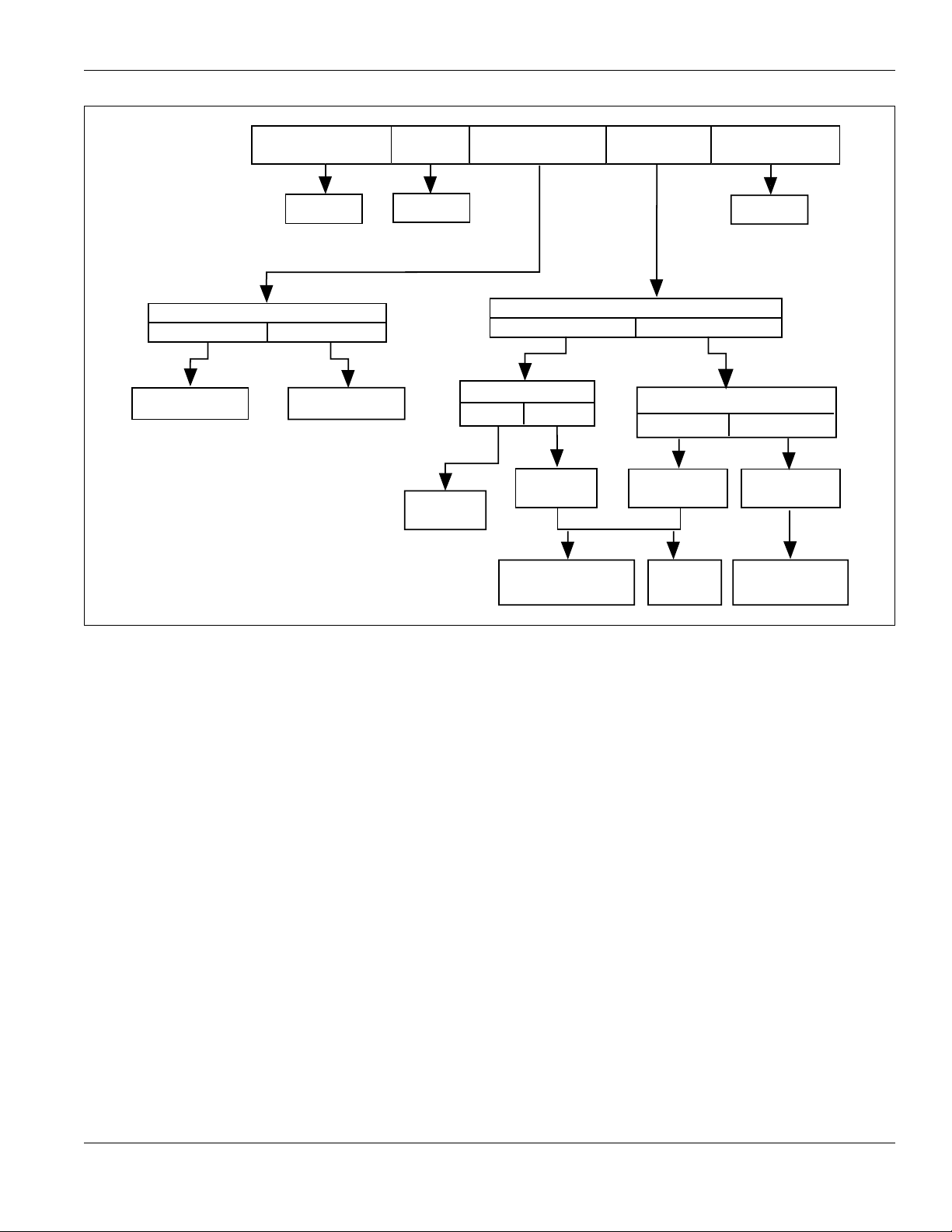

Circuit Requirement Diagram

BILATERAL VOLTAGE

SWITCH

SIDAC *

GATE CURRENT

12-500 µA 10-50 mA

SCR *SCR (Sensitive) *

* For detailed information, see specific data sheet in product catalog.

RECTIFIER REVERSE BLOCKING

RECTIFIER *

QUADRAC *

THYRISTOR

DIAC TRIGGER DIRECT

OPTIONS

INTERNAL EXTERNAL

DIACS *

ALTERNISTOR TRIAC *

BIDIRECTIONAL

THYRISTOR

GATE CONTROL

(See Quadrant Chart on Data Sheet)

I I I I I I I I I I I I I V

GATE CURRENT

10-100 mA

TRIAC *

BILATERAL

VOLTAGE TRIGGER

DIAC *

QUADRANT OPERATION

GATE CURRENT

3-20 mA

SENSITIVE TRIAC *

©2002 Teccor Electronics P - 3 http://www.teccor.com

Thyristor Product Catalog +1 972-580-7777

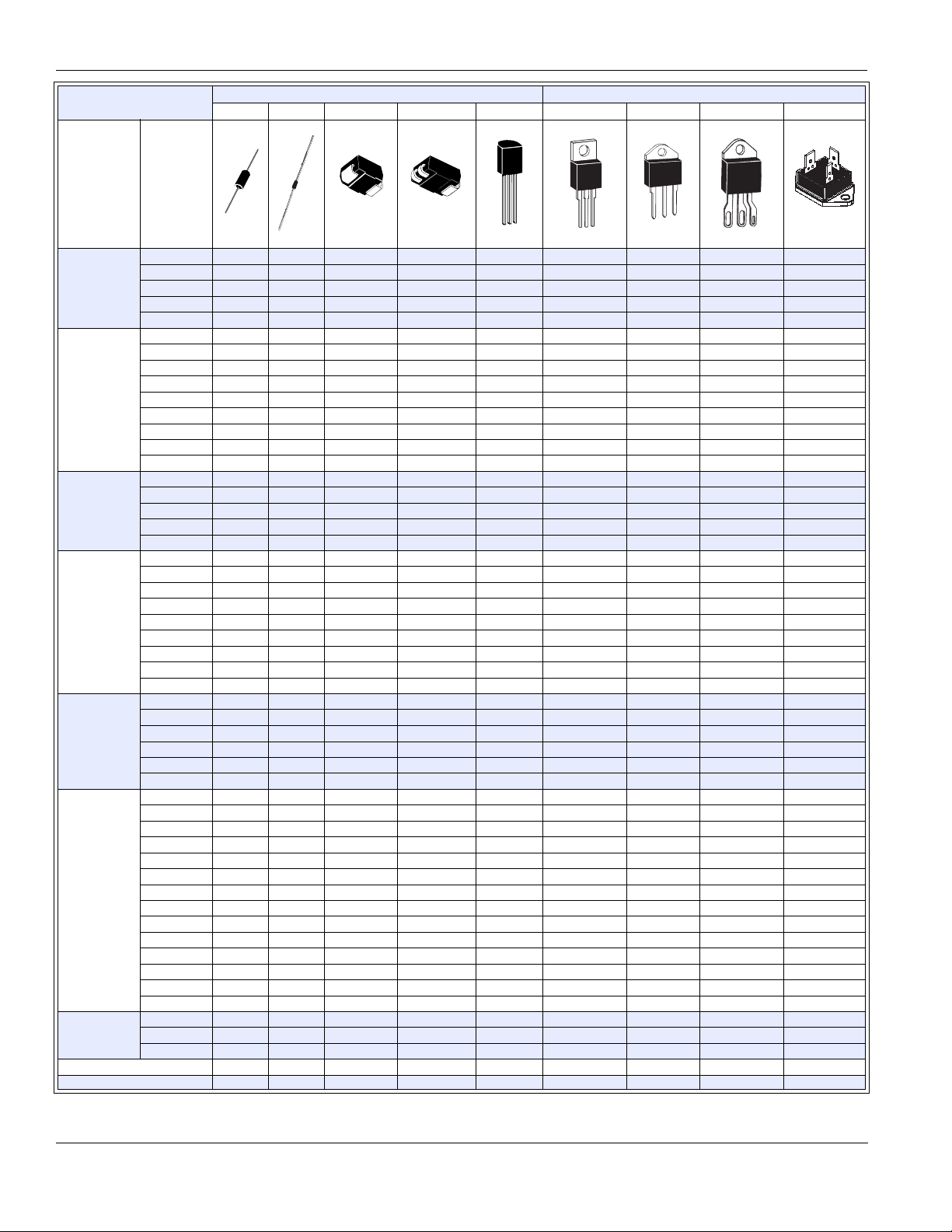

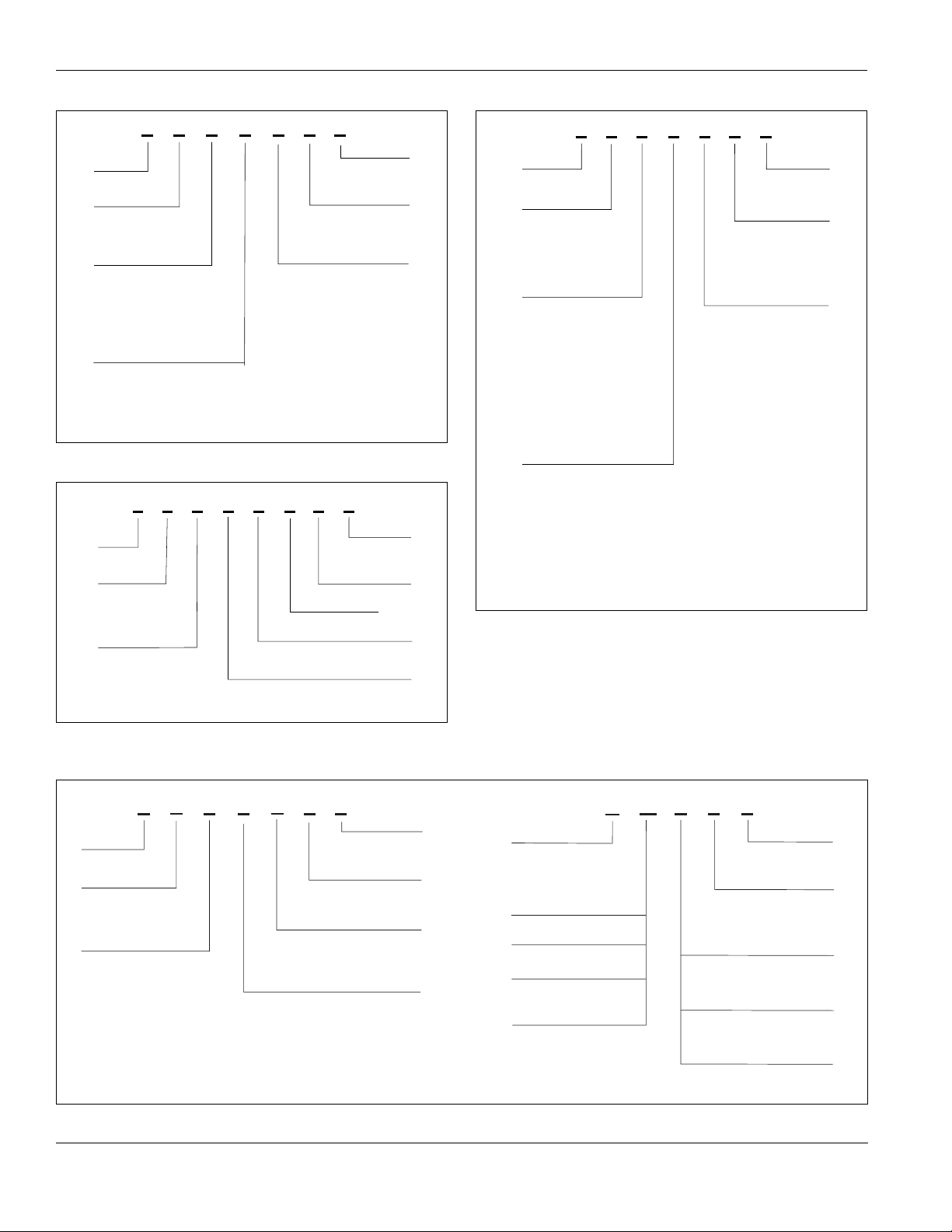

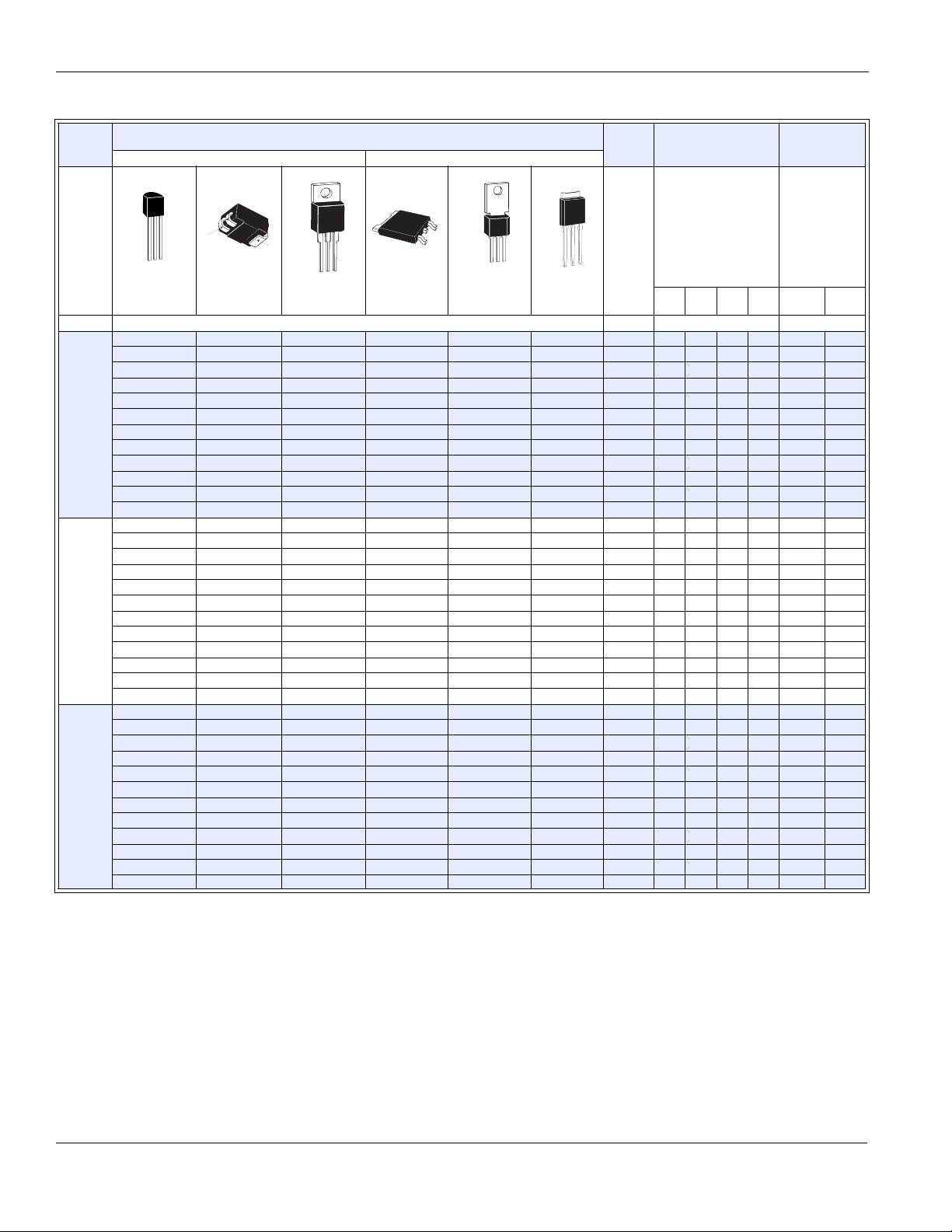

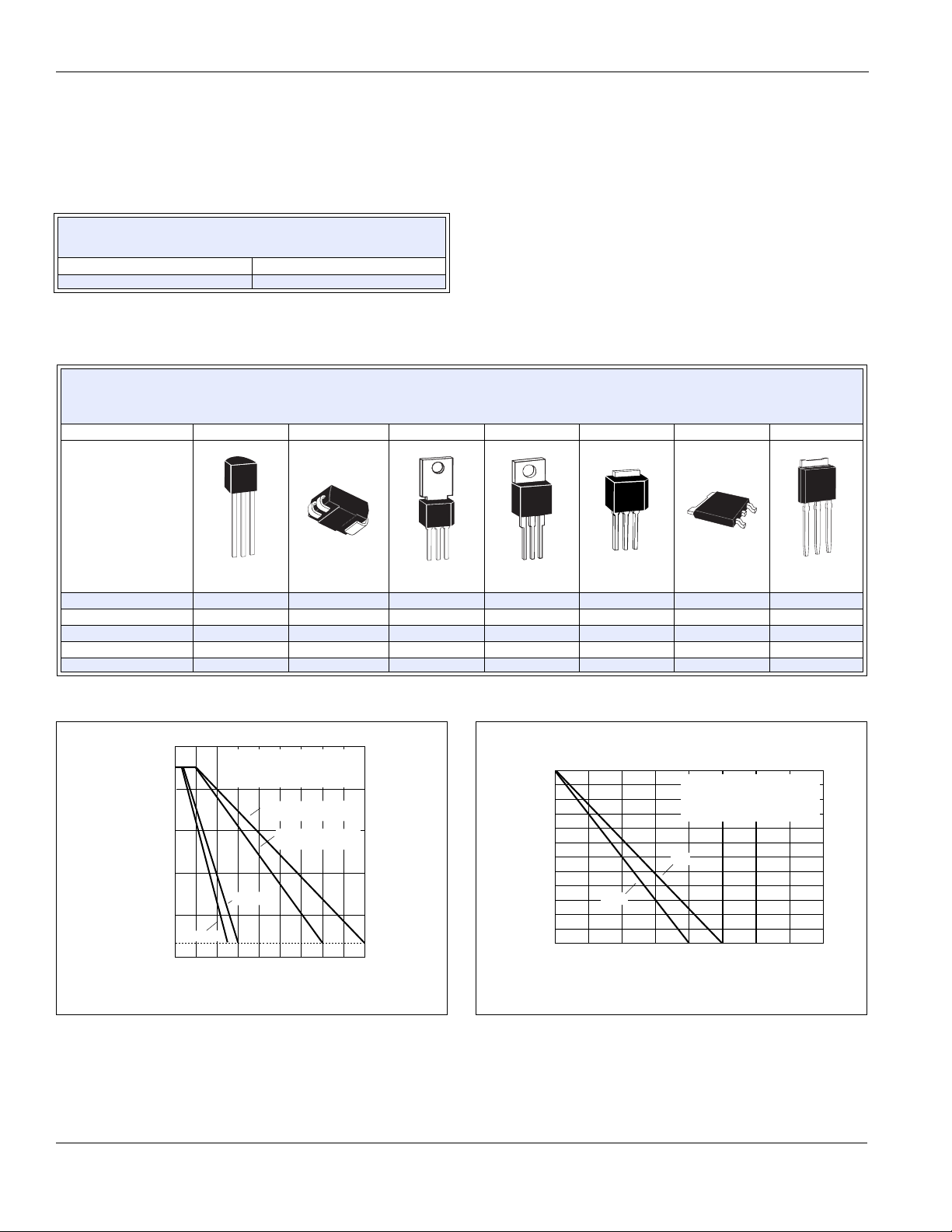

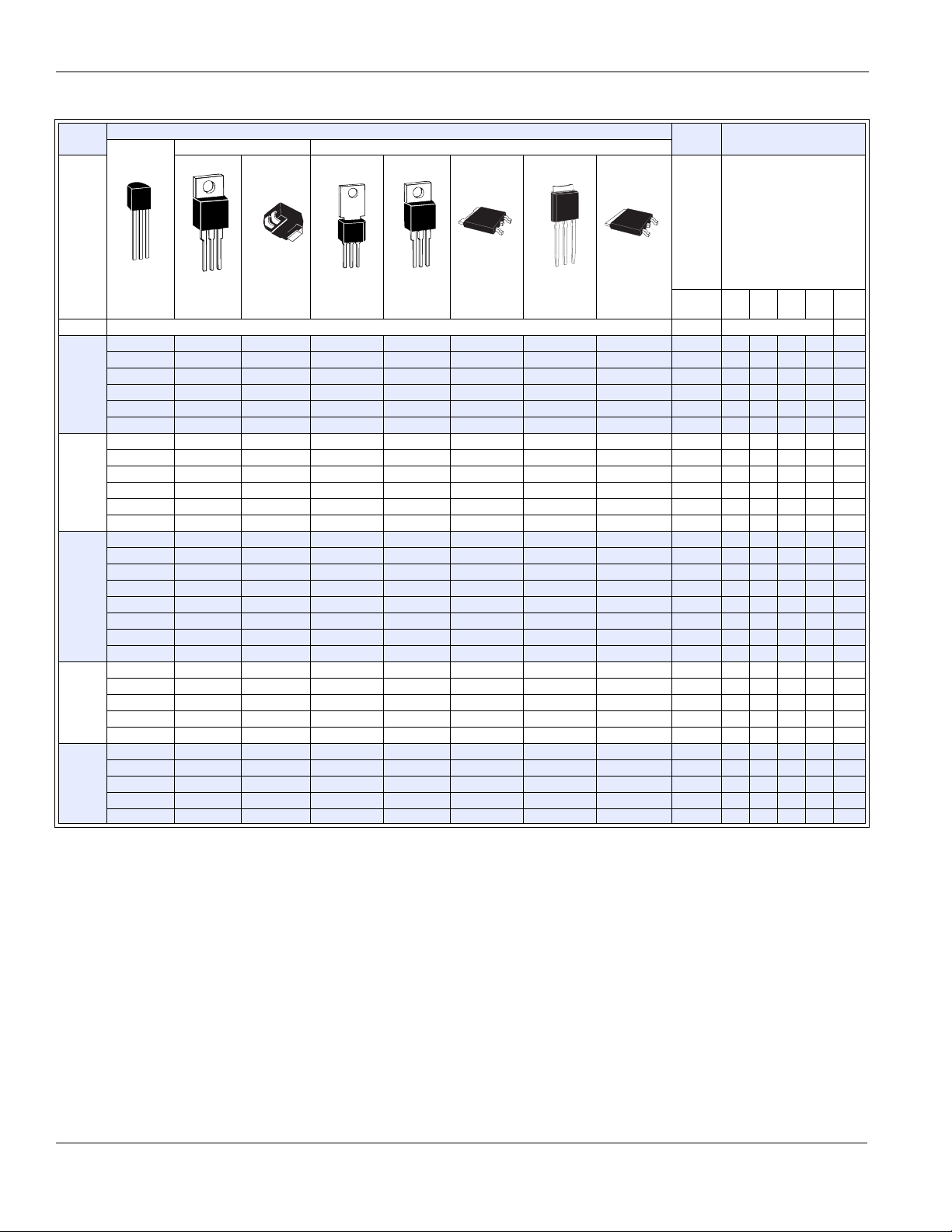

Product Packages

Package Code

GY S C E L K J P

Isolated Mounting Tab

Product

Type

Sensitive

Triac

Triac

Quadrac

Alternistor

Sensitive

SCR

SCR

Rectifier

Current

(Amps)

0.8 ✔ ✔

1 ✔ ✔

4 ✔

6 ✔

8 ✔

0.8 ✔✔

1 ✔✔

4 ✔

6 ✔

8 ✔

10 ✔

15 ✔

25 ✔

35 ✔

4 ✔

6 ✔

8 ✔

10 ✔

15 ✔

6 ✔

8 ✔

10 ✔

12 ✔

16 ✔

25 ✔✔✔

30 ✔

35

40

0.8 ✔ ✔

1.5 ✔

4

6 ✔

8 ✔

10 ✔

1 ✔✔

6 ✔

8 ✔

10 ✔

12

15

16

20

25 ✔

35 ✔✔

40

55

65

70

15 ✔

20 ✔

25 ✔

DO-15 DO-35 DO-214 Compak TO-92 * TO-220 TO-218 TO-218X

Diac

Sidac

* No center lead on TO-92 Sidacs.

TO-3

Fastpak

✔✔

✔

✔

✔✔

✔✔

✔ ✔ ✔ *

http://www.teccor.com P - 4 ©2002 Teccor Electronics

+1 972-580-7777 Thyristor Product Catalog(972) 580-7777

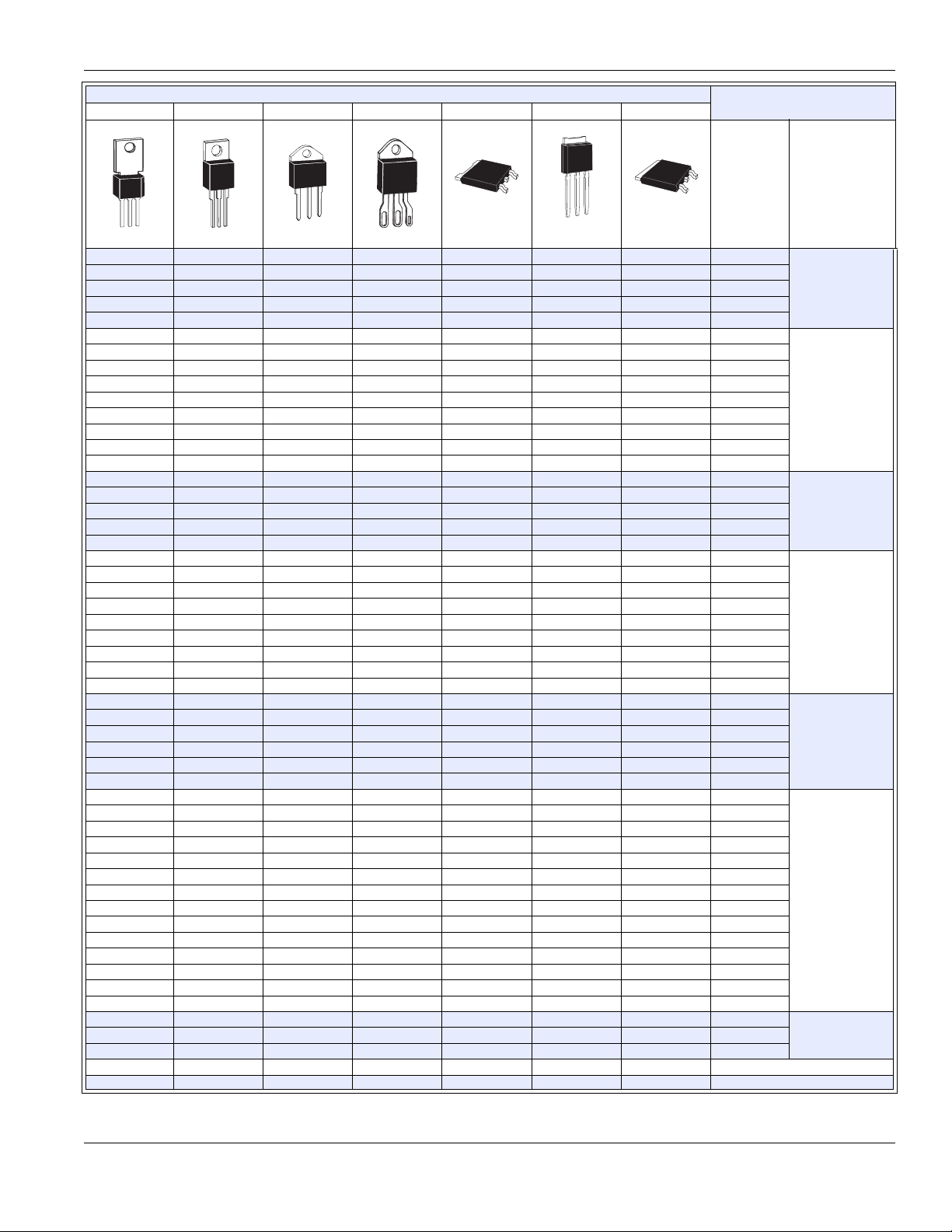

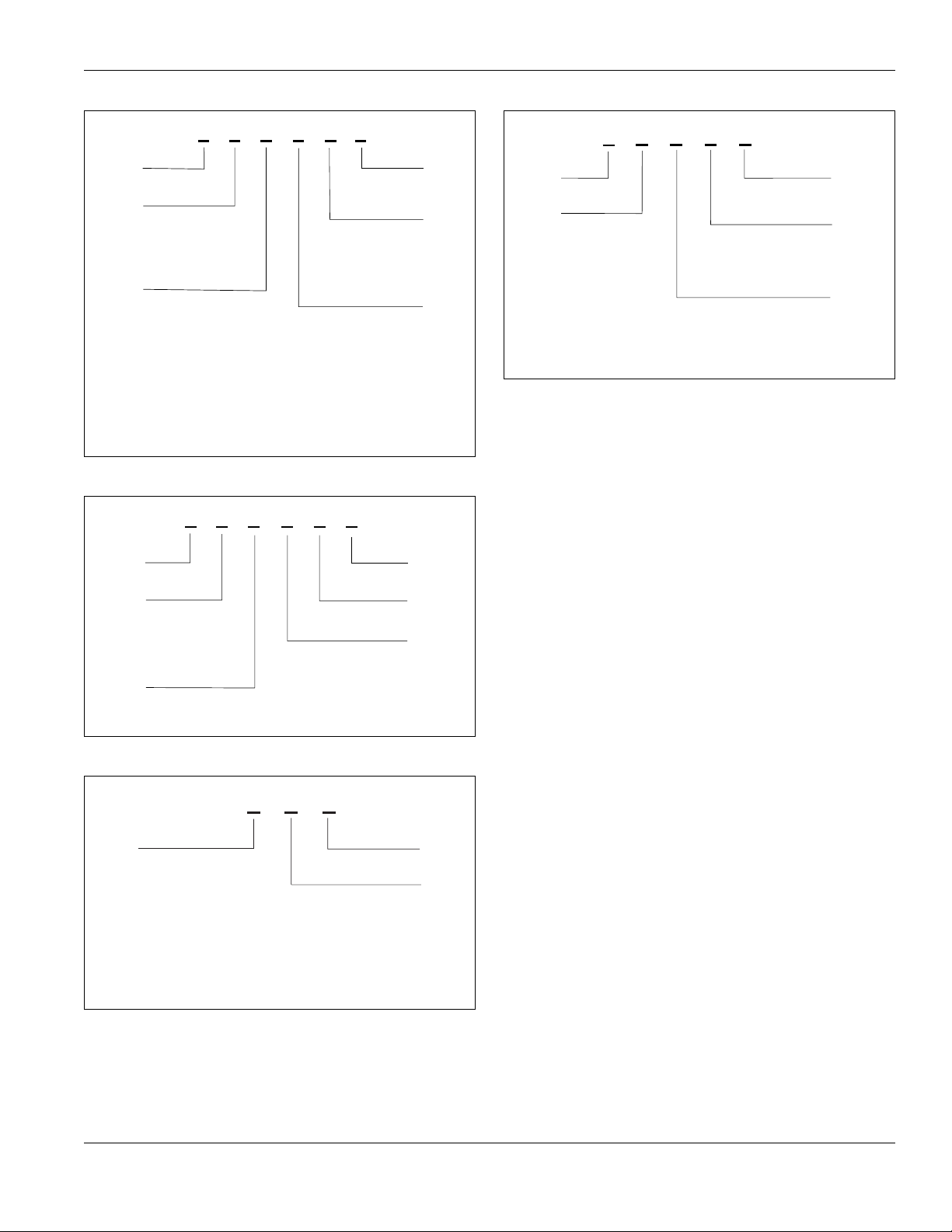

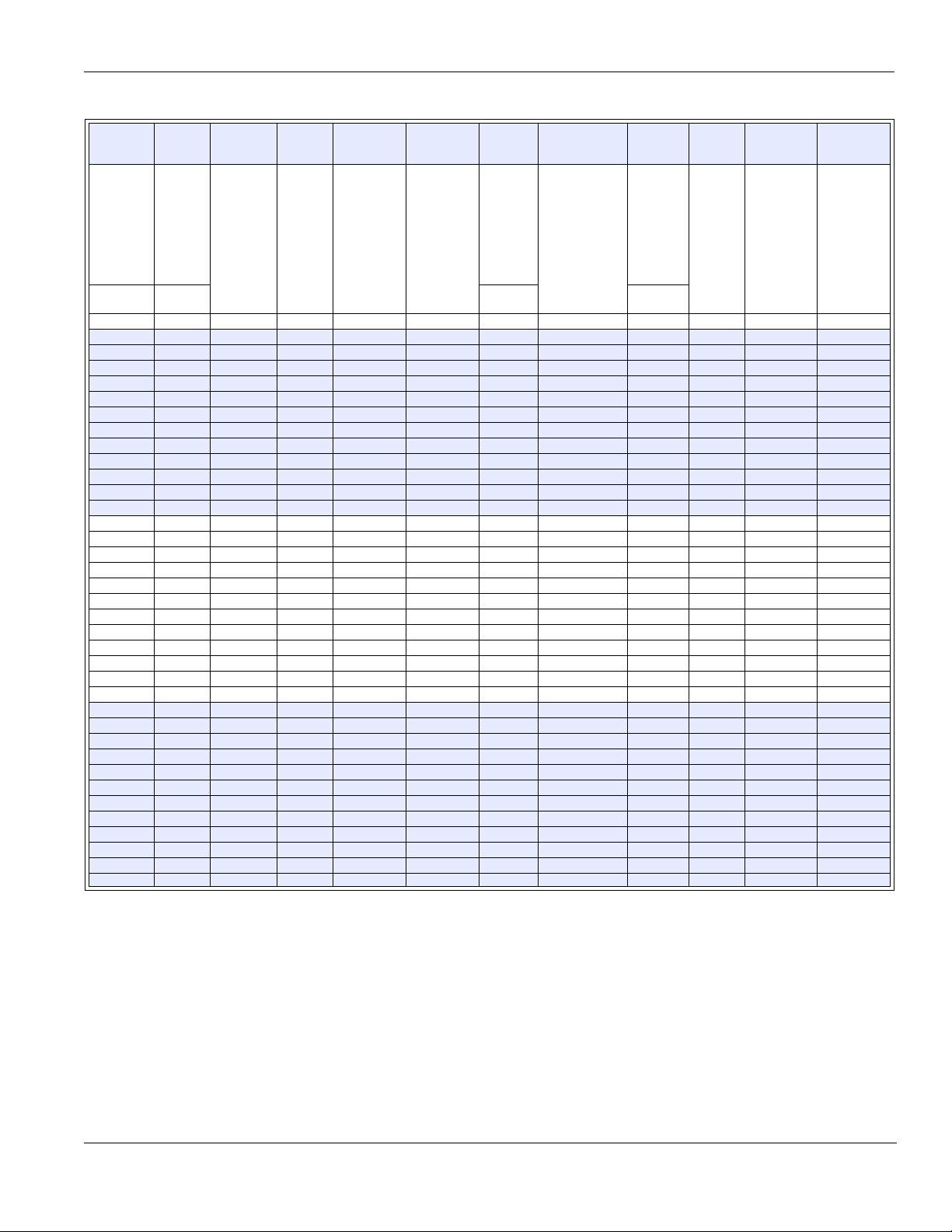

Product Packages

Non-isolated Mounting Tab

FRMWDVN

Package Code

TO-202 TO-220 TO-218 TO-218X

✔ ✔ ✔ 4

✔ ✔✔ 4

✔✔ ✔ 6

✔✔ ✔ 8

✔✔ ✔ 10

✔ ✔ 15

✔ ✔ 25

✔ ✔✔✔ 6

✔ ✔✔✔ 8

✔ ✔ 10

✔ ✔ 12

✔ ✔ 16

✔ ✔ 25

✔ 35

✔ 0.8

✔ 1.5

✔ ✔ ✔ ✔ 4

✔ ✔ ✔ ✔ 6

✔ ✔ ✔ ✔ 8

✔ ✔ ✔ ✔ 10

✔ ✔✔ 6

✔✔ ✔✔ 8

✔✔ ✔✔ 10

✔✔✔12

✔ ✔ 16

✔ ✔ 25

✔ ✔ 40

✔✔✔ ✔55

✔ 70

✔

TO-252

D-Pak

✔ ✔ 6

✔ ✔ 8

TO-251

V-Pa k

TO-263

2

D

Pak

Current

(Amps)

0.8

1

0.8

1

35

4

6

8

10

15

30

40

1

15

20

35

65

15

20

25

Product

Typ e

Sensitive

Triac

Triac

Quadrac

Alternistor

Sensitive SCR

SCR

Rectifier

Diac

Sidac

©2002 Teccor Electronics P - 5 http://www.teccor.com

Thyristor Product Catalog +1 972-580-7777

Description of Part Numbers

Sensitive Triac

L

Device Type

L = Sensitive Triac

Voltage Rating

20 = 200 V

40 = 400 V

60 = 600 V

Current Rating

X8 = 0.8 A

N = 1 A

01 = 1 A

04 = 4 A

06 = 6 A

08 = 8 A

Package Type

Blank =

Compak

D = TO-252 (Surface Mount)

E = TO-92 (Isolated)

F = TO-202 (Non-islolated)

L = TO-220 (Isolated)

V = TO-251 (Non-islolated)

(Surface Mount)

Quadrac

Q2004 L T 52

Device Type

Q =

Quadrac

Voltage Rating

20 = 200 V

40 = 400 V

60 = 600 V

Current Rating

04 = 4 A

06 = 6 A

08 = 8 A

10 = 10 A

15 = 15 A

20

04

F5

12

H

X

Special Options

V = 4000 V Isolation

(TO-220 Package Only)

Lead Form Dimensions

3 = 3 mA (Q I, II, III, IV)

5 = 5 mA (Q I, II, III, IV)

TO-202

TO-220

TO-92

Gate Variations

6 = 5 mA (Q I, II, III)

6 = 10 mA (Q IV)

8 = 10 mA (Q I, II, III)

8 = 20 mA (Q IV)

X

Special Options

V = 4000 V Isolation

(TO-220 Package Only)

Lead Form Dimensions

TO-220

Alternistor

Gate Variation

T = Internal Diac Trigger

Package Type

L = TO-220 (Isolated)

Triac and Alternistor

Q

20

Device Type

Q = Triac or Alternistor

Voltage Rating

20 = 200 V

40 = 400 V

60 = 600 V

80 = 800 V

K0 = 1000 V

Current Rating

X8 = 0.8 A

01 = 1 A

04 = 4 A

06 = 6 A

08 = 8 A

10 = 10 A

12 = 12 A

15 = 15 A

25 = 25 A

30 = 30 A

35 = 35 A

40 = 40 A

Package Type

D = TO-252 (Surface Mount)

E = TO-92 (Isolated)

F = TO-202 (Non-isolated)

J = TO-218X (Isolated)

K = TO-218 (Isolated)

L = TO-220 (Isolated)

N = TO-263 (Surface Mount)

P =

Fastpak

(Isolated)

R = TO-220 (Non-isolated)

V = TO-251 (Non-isolated)

W = TO-218X (Non-isolated)

04

X

F3

1

Special Options

V = 4000 V Isolation

(TO-220 Package Only)

Lead Form Dimensions

DH3 and VH3 = 10mA (Q I, II, III)

H4 = 35 mA (Q I, II, III) *

H5 = 50 mA (Q I, II, III) *

6 = 80 mA (Q I, II, III) *

7 = 100 mA (Q I, II, III) *

* NOTE:

Alternistor device; no Quadrant IV operation

TO-202

TO-220

TO-92

TO-218X

TO-218

Gate Variation

3 = 10 mA (Q I, II, III)

H3 = 20mA (Q I, II, III)

4 = 25 mA (Q I, II, III)

5 = 50 mA (Q I, II, III)

Sensitive SCR

20

06

FS2

21

X

Special Options

V = 4000 V Isolated

(TO-220 Package Only)

Lead Form Dimensions

Blank = Compak (Surface Mount)

D = TO-252 (Surface Mount)

F = TO-202 (Non-islolated)

V = TO-251 (Non-islolated)

TO-202

TO-220

Gate Variations

S1 = 50 µA

S2 = 200 µA

S3 = 500 µA

Package Type

L = TO-220 (Isolated)

Device Type

TCR = TO-92 (Isolated)

EC = TO-92 (Isolated)

T = TO-202 (Non-isolated)

2N = JEDEC (Isolated)

Current Rating for TCR

22 = 1.5 A

Current Rating for EC

103 = 0.8 A

Current Rating for T

106 = 4 A (I

107 = 4 A (I

Current Rating for 2N

5xxx = 0.8 A

= 200 µA)

GT

= 500 µA)

GT

EC

103

D

75

1

Gate Current (for EC series only)

Voltage Rating for EC and T

Lead Form Dimensions

Voltage Rating for TCR

Voltage Rating for 2N

TO-92

TO-202

None = 200 µA

1 = 12 µA

2 = 50 µA

3 = 500 µA

-4 = 200 V

-6 = 400 V

-8 = 600 V

B = 200 V

D = 400 V

M = 600 V

5064 = 200 V

6565 = 400 V

S

Device Type

S = Sensitive SCR

Voltage Rating

20 = 200 V

40 = 400 V

60 = 600 V

Current Rating

X8 = 0.8 A

N = 1 A

06 = 6 A

08 = 8 A

10 = 10 A

http://www.teccor.com P - 6 ©2002 Teccor Electronics

+1 972-580-7777 Thyristor Product Catalog(972) 580-7777

Description of Part Numbers

SCR

Rectifier

S

Device Type

S = Non-sensitive SCR

Voltage Rating

20 = 200 V

40 = 400 V

60 = 600 V

80 = 800 V

K0 = 1000 V

Current Rating

01 = 1 A

06 = 6 A

08 = 8 A

10 = 10 A

12 = 12 A

15 = 15 A

16 = 16 A

20 = 20 A

25 = 25 A

35 = 35 A

55 = 55 A

65 = 65 A

70 = 70 A

D

20

20

08

15

F12

D = TO

F = TO-202 (Non-isolated)

M = TO-218 (Non-isolated)

N = TO-263 (Surface Mount)

R = TO-220 (Non-isolated)

V = TO-251 (Non-isolated)

W = TO-218X (Non-isolated)

L55

X

Special Options

V = 4000 V Isolation

(TO-220 Package Only)

Lead Form Dimensions

-

252 (Surface Mount)

E = TO

J = TO-218X (Isolated)

K = TO-218 (Isolated)

L = TO-220 (Isolated)

-

TO

202

-

TO

220

-

TO

92

-

218X

TO

-

TO

218

Package Type

-

92 (Isolated)

V

Sidac

K

Device Type

K = Sidac

Voltage Rating

105 = 95 V to 113 V

110 = 104 V to 118 V

120 = 110 V to 125 V

130 = 120 V to 138 V

140 = 130 V to 146 V

150 = 140 V to 170 V

200 = 190 V to 215 V

220 = 205 V to 230 V

240 = 220 V to 250 V

250 = 240 V to 280 V

300 = 270 V to 330 V

105

0

E70

Lead Form Dimensions

E = TO-92 (Isolated)

F = TO-202 (Non-islolated)

G = DO-15X (Isolated)

S = DO-214 (Surface Mount)

TO-202

TO-92

Package Type

Current Rating

0 = 1 A

Diac

Device Type

D = Rectifier

Voltage Rating

20 = 200 V

40 = 400 V

60 = 600 V

80 = 800 V

K0 = 1000 V

Current Rating

15 = 15 A

20 = 20 A

25 = 25 A

Device Type

HT = Diac Trigger in DO-35

ST = Diac Trigger in DO-214

HT

Lead Form Dimensions

L = TO-220 (Isolated)

32

91

Lead Form Dimensions

32A / 5761 = 28 V to 36 V

32B / 5761A = 30 V to 34 V

36A / 5762 = 32 V to 40 V

Special Options

V = 4000 V Isolation

TO-220

Package Type

DO-35

Voltage Rating

32 = 27 V to 37 V

35 = 30 V to 40 V

40 = 35 V to 45 V

34B = 32 V to 36 V

36B = 34 V to 38 V

©2002 Teccor Electronics P - 7 http://www.teccor.com

Thyristor Product Catalog +1 972-580-7777

Quality and Reliability

It is Teccor’s policy to ship quality products on time. We accomplish this through Total Quality Management based on the fundamentals of customer focus, continuous improvement, and people

involvement.

In support of this commitment, Teccor applies the following principles:

• Employees shall be respected, involved, informed, and qualified

for their job with appropriate education, training, and experience.

• Customer expectations shall be met or exceeded by consistently

shipping products that meet the agreed specifications, quality

levels, quantities, schedules, and test and reliability parameters.

• Suppliers shall be selected by considering quality, service, delivery, and cost of ownership.

• Design of products and processes will be driven by customer

needs, reliability, and manufacturability.

It is the responsibility of management to incorporate these

principles into policies and systems.

It is the responsibility of those in leadership roles to coach their

people and to reinforce these principles.

It is the responsibility of each individual employee to follow the

spirit of this statement to ensure that we meet the primary policy

— to ship quality products on time.

Quality Assurance

All products must first undergo rigid quality design reviews and

pass extensive environmental life testing. Teccor uses Statistical

Process Control (SPC) with associated control charts throughout

to monitor the manufacturing processes.

Only those products which pass tests designed to assure Teccor's high quality and reliability standards, while economically

satisfying customer requirements, are approved for shipment. All

new products and materials must receive approval of QRA prior

to being released to production.

The combination of reliability testing, process controls, and lot

tracking assures the quality and reliability of Teccor's devices.

Since even the best control systems cannot overcome measurement limitations, Teccor designs and manufactures its own computerized test equipment.

Teccor's Reliability Engineering Group conducts ongoing product

reliability testing to further confirm the design and manufacturing

parameters.

Incoming Material Quality

Teccor “Vendor Analysis” programs provide stringent requirements before components are delivered to Teccor. In addition,

purchased materials are tested rigidly at incoming inspection for

specification compliance prior to acceptance for use.

Process Controls

From silicon slice input through final testing, we use statistical

methods to control all critical processes. Process audits and lot

inspections are performed routinely at all stages of the manufacturing cycle.

Parametric Testing

All devices are 100% computer tested for specific electrical characteristics at critical processing points.

Final Inspection

Each completed manufacturing lot is sampled and tested for

compliance with electrical and mechanical requirements.

Reliability Testing

Random samples are taken from various product families for

ongoing reliability testing.

Finished Goods Inspection

Product assurance inspection is performed immediately prior to

shipping.

Design Assurance

The design and production of Teccor devices is a demanding and

challenging task. Disciplined skills coupled with advanced computer-aided design, production techniques, and test equipment

are essential elements in Teccor's ability to meet your demands

for the very highest levels of quality.

http://www.teccor.com P - 8 ©2002 Teccor Electronics

+1 972-580-7777 Thyristor Product Catalog(972) 580-7777

Quality and Reliability

Reliability Stress Tests

The following table contains brief descriptions of the reliability tests commonly used in evaluating Teccor product reliability on a periodic basis. These tests are applied across product lines depending on product availability and test equipment capacities. Other tests

may be performed when appropriate.

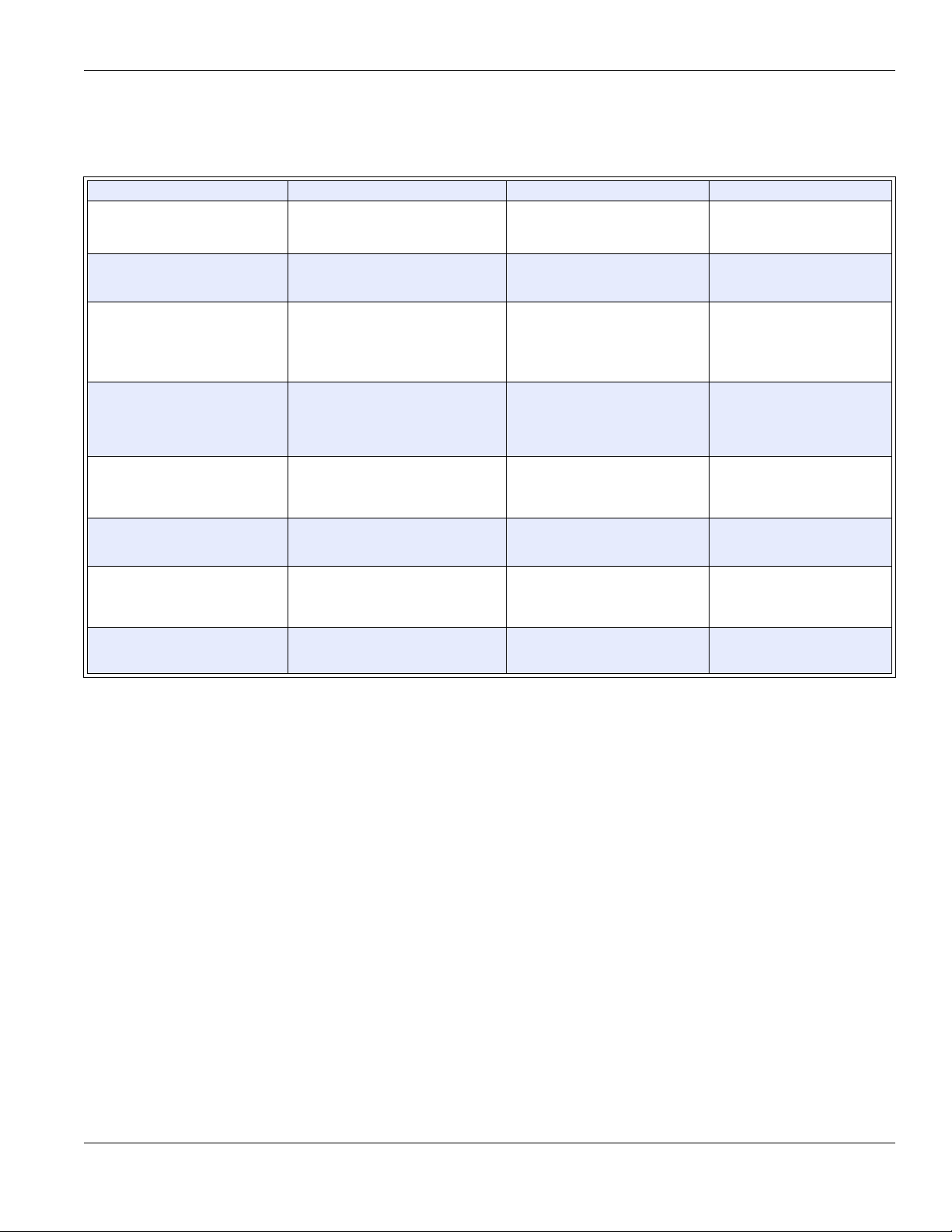

Test Ty p e Typical Conditions Test Description Standards

High Temperature

AC Blocking

High Temperature

Storage Life

Temperature and Humidity

Bias Life

Temperature Cycle

[Air to Air]

Thermal Shock

[Liquid to Liquid]

Autoclave

Resistance to

Solder Heat

Solderability

TA = 100 °C to 150 °C, Bias @

100%

Rated V

T

A

, t = 24 hrs to 1000 hrs

DRM

= 150 °C, t = 250 to 1000 hrs Evaluation of the effects on

Evaluation of the reliability of

product under bias conditions

and elevated temperature

devices after long periods of

storage at high temperature

T

= 85 °C to 95 °C, rh = 85% to

A

95%

Bias @ 80% Rated V

DRM

Evaluation of the reliability of nonhermetic packaged devices in

humid environments

(320 VDC max)

t = 168 to 1008 hrs

T

= -65°C to 150°C,

A

cycles = 10 to 500

Evaluation of the device’s ability

to withstand the exposure to

extreme temperatures and the

forces of TCE during transitions

between temperatures

T

= 0 °C to 100 °C, t

A

cycled = 10 to 20

= ≤10 s,

txfr

Evaluation of the device’s ability

to withstand the sudden changes

in temperature and exposure to

extreme temperatures

T

= 121 °C, rh = 100%, P = 15 psig,

A

t = 24 hrs to 168 hrs

T

= 260 °C, t = 10 s Evaluation of the device’s ability

A

Accelerated environmental test to

evaluate the moisture resistance

of plastic packages

to withstand the temperatures as

seen in wave soldering

operations

Steam aging = 1 hr to 8 hrs,

= 245 °C, Flux = R

T

solder

Evaluation of the solderability of

device terminals after an

extended period

MIL-STD-750, M-1040

MIL-STD-750, M-1031

EIA / JEDEC, JESD22-A101

MIL-STD-750, M-1051,

EIA / JEDEC, JESD22-A104

MIL-STD-750, M-1056

EIA / JEDEC, JESD22-A102

MIL-STD-750, M-2031

MIL-STD-750, M-2026,

ANSI-J-STD-002

Flammability Test

For the UL 94V0 flammability test, all expoxies used in Teccor encapsulated devices are recognized by Underwriters Laboratories

©2002 Teccor Electronics P - 9 http://www.teccor.com

Thyristor Product Catalog +1 972-580-7777

Standard Terms and Conditions

Supplier shall not be bound by any term proposed by Buyer in the

absence of written agreement to such term signed by an authorized officer of Supplier.

(1) PRICE:

(A) Supplier reserves the right to change product prices at

any time but, whenever practicable, Supplier will give

Buyer at least thirty (30) days written notice before the

effective date of any price change. Unless Supplier has

specifically agreed in writing, signed by an authorized

officer of Supplier, that a quoted price shall not be subject to change for a certain time, all products shipped on

or after the effective date of a price change may be

billed at the new price level.

(B) Whenever Supplier agrees to a modification of Buyer's

order (which modification must be in writing and signed

by an authorized officer of Supplier), Supplier reserves

the right to alter its price, whether or not such price was

quoted as “firm.”

(C) Prices do not include federal, state or local taxes, now or

hereafter enacted, applicable to the goods sold. Taxes

will be added by Supplier to the sales prices whenever

Supplier has legal obligation to collect them and will be

paid by Buyer as invoiced unless Buyer provides Supplier with a proper tax exemption certificate.

(2) PRODUCTION: Supplier may, at its sole discretion and at

any time, withdraw any catalog item from further production

without notice or liability to Buyer.

(3) INTEREST:

(A) All late payments shall bear interest thirty (30) days after

the due date stated on the invoice until paid at the lower

of one and one-half percent per month or the maximum

rate permitted by law. All interest becoming due shall, if

not paid when due, be added to principal and bear interest from the due date. At Supplier's option, any payment

shall be applied first to interest and then to principal.

(B) It is the intention of the parties to comply with the laws of

the jurisdiction governing any agreement between the

parties relating to interest. If any construction of the

agreement between the parties indicates a different

right given to Supplier to demand or receive any sum

greater than that permissible by law as interest, such as

a mistake in calculation or wording, this paragraph shall

override. In any contingency which will cause the interest paid or agreed to be paid to exceed the maximum

rate permitted by law, such excess will be applied to the

reduction of any principal amount due, or if there is no

principal amount due, shall be refunded.

(4) TITLE AND DELIVERY: Title to goods ordered by Buyer and

risk of loss or damage in transit or thereafter shall pass to

Buyer upon Supplier's delivery of the goods at Supplier's

plant or to a common carrier for shipment to Buyer.

(5) CONTINGENCIES: Supplier shall not be responsible for any

failure to perform due to causes reasonably beyond its control. These causes shall include, but not be restricted to, fire,

storm, flood, earthquake, explosion, accident, acts of public

enemy, war rebellion, insurrection, sabotage, epidemic,

quarantine restrictions, labor disputes, labor shortages, labor

slow downs and sit downs, transportation embargoes, failure

or delays in transportation, inability to secure raw materials

or machinery for the manufacture of its devices, acts of God,

acts of the Federal Government or any agency thereof, acts

of any state or local government or agency thereof, and judicial action. Similar causes shall excuse Buyer for failure to

take goods ordered by Buyer, from the time Supplier

receives written notice from Buyer and for as long as the disabling cause continues, other than for goods already in transit or specially fabricated and not readily saleable to other

buyers.

Supplier assumes no responsibility for any tools, dies, and

other equipment furnished Supplier by Buyer.

(6) LIMITED WARRANTY AND EXCLUSIVE REMEDY: Supplier

warrants all catalog products to be free from defects in materials and workmanship under normal and proper use and

application for a period of twelve (12) months from the date

code on the product in question (or if none, from the date of

delivery to Buyer.) With respect to products assembled, prepared, or manufactured to Buyer's specifications, Supplier

warrants only that such products will meet Buyer's specifications upon delivery. As the party responsible for the specifications, Buyer shall be responsible for testing and inspecting

the products for adherence to specifications, and Supplier

shall have no liability in the absence of such testing and

inspection or if the product passes such testing or inspection. THE ABOVE WARRANTY IS THE ONLY WARRANTY

EXTENDED BY SUPPLIER, AND IS IN LIEU OF AND

EXCLUDES ALL OTHER WARRANTIES AND CONDITIONS, EXPRESSED OR IMPLIED (EXCEPT AS PROVIDED HEREIN AS TO TITLE), ON ANY GOODS OR

SERVICES SOLD OR RENDERED BY SUPPLIER, INCLUDING ANY IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE. THIS

WARRANTY WILL NOT CREATE WARRANTY COVERAGE

FOR ANY ITEM INTO WHICH ANY PRODUCT SOLD BY

SUPPLIER MAY HAVE BEEN INCORPORATED OR

ADDED.

http://www.teccor.com P - 10 ©2002 Teccor Electronics

+1 972-580-7777 Thyristor Product Catalog(972) 580-7777

Standard Terms and Conditions

SUPPLIER'S ENTIRE LIABILITY AND BUYER'S EXCLUSIVE REMEDY UNDER THIS WARRANTY SHALL BE, AT

SUPPLIER'S OPTION, EITHER THE REPLACEMENT OF,

REPAIR OF, OR ISSUANCE OF CREDIT TO BUYER'S

ACCOUNT WITH SUPPLIER FOR ANY PRODUCTS

WHICH ARE PROPERLY RETURNED BY BUYER DURING

THE WARRANTY PERIOD. All returns must comply with the

following conditions:

(A) Supplier is to be promptly notified in writing upon discov-

ery of defects by Buyer.

(B) Buyer must obtain a Return Material Authorization

(RMA) number from the Supplier prior to returning product.

(C) The defective product is returned to Supplier, transporta-

tion charges prepaid by Buyer.

(D) Supplier's examination of such product discloses, to its

satisfaction, that such defects have not been caused by

misuse, neglect, improper installation, repair, alteration,

or accident.

(E) The product is returned in the form it was delivered with

any necessary disassembly carried out by Buyer at

Buyer's expense.

IN NO EVENT SHALL SUPPLIER, OR ANYONE ELSE

ASSOCIATED IN THE CREATION OF ANY OF SUPPLIER'S

PRODUCTS OR SERVICES, BE LIABLE TO BUYER FOR

INCIDENTAL OR CONSEQUENTIAL DAMAGES OF ANY

NATURE INCLUDING LOSS OF PROFITS, LOSS OF USE,

BUSINESS INTERUPTION, AND THE LIKE. BUYER

ACKNOWLEDGES THAT THE ABOVE WARRANTIES AND

LIMITATIONS THEREON ARE APPROPRIATE AND REASONABLE IN EFFECTUATING SUPPLIER'S AND BUYER'S

MUTUAL INTENTION TO CONDUCT AN EFFICIENT

TRANSACTION AT PRICES MORE ADVANTAGEOUS TO

BUYER THAN WOULD BE AVAILABLE IN THE PRESENCE

OF OTHER WARRANTIES AND ASSURANCES.

(7) PATENTS: Buyer shall notify Supplier in writing of any claim

that any product or any part of use thereof furnished under

this agreement constitutes an infringement of any U.S.

patent, copyright, trade secret, or other proprietary rights of a

third party. Notice shall be given within a reasonable period

of time which should in most cases be within ten (10) days of

receipt by Buyer of any letter, summons, or complaint pertaining to such a claim. At its option, Supplier may defend at

its expense any action brought against Buyer to the extent

that it is based on such a claim. Should Supplier choose to

defend any such claim, Supplier may fully participate in the

defense, settlement, or appeal of any action based on such

claim.

Should any product become, or in Supplier's opinion be likely

to become, the subject of an action based on any such claim,

Supplier may, at its option, as the Buyer's exclusive remedy,

either procure for the Buyer the right to continue using the

product, replace the product or modify the product to make it

noninfringing. IN NO EVENT SHALL SUPPLIER BE LIABLE

FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES

BASED ON ANY CLAIM OF INFRINGEMENT.

Supplier shall have no liability for any claim based on modifications of a product made by any person or entity other than

Supplier, or based on use of a product in conjunction with

any other item, unless expressly approved by Supplier. Supplier does not warrant goods against claims of infringement

which are assembled, prepared, or manufactured to Buyer's

specifications.

(8) NON-WAIVER OF DEFAULT: Each shipment made under

any order shall be treated as a separate transaction, but in

the event of any default by Buyer, Supplier may decline to

make further shipments without in any way affecting its rights

under such order. If, despite any default by Buyer, Supplier

elects to continue to make shipments, its action shall not

constitute a waiver of that or any default by Buyer or in any

way affect Supplier's legal remedies for any such default. At

any time, Supplier's failure to exercise any right to remedy

available to it shall not constitute a waiver of that right or

remedy.

(9) TERMINATION: If the products to be furnished under this

order are to be used in the performance of a Government

contract or subcontract, and the Government terminates

such contract in whole or part, this order may be canceled to

the extent it was to be used in the canceled portion of said

Government contract and the liability of Buyer for termination

allowances shall be determined by the then applicable regulations of the Government regarding termination of contracts.

Supplier may cancel any unfilled orders unless Buyer shall,

upon written notice, immediately pay for all goods delivered

or shall pay in advance for all goods ordered but not delivered, or both, at Supplier's option.

(10) LAW: The validity, performance and construction of these

terms and conditions and any sale made hereunder shall be

governed by the laws of the state of Texas.

(11) ASSIGNS: This agreement shall not be assignable by

either Supplier or Buyer. However, should either Supplier or

Buyer be sold or transferred in its entirety and as an ongoing

business, or should Supplier or Buyer sell or transfer in its

entirety and as an ongoing concern, any division, department, or subsidiary responsible in whole or in part for the

performance of this Agreement, this Agreement shall be

binding upon and inure to the benefit of those successors

and assigns of Supplier, Buyer, or such division, department,

or subsidiary.

(12) MODIFICATION OF STANDARD TERMS AND CONDI-

TIONS: No attempted or suggested modification of or addition to any of the provisions upon the face or reverse of this

form, whether contained or arising in correspondence and/or

documents passing between Supplier and Buyer, in any

course of dealing between Supplier or Buyer, or in any customary usage prevalent among businesses comparable to

those of Supplier and/or Buyer, shall be binding upon Supplier unless made and agreed to in writing and signed by an

officer of Supplier.

(13) QUANTITIES: Any variation in quantities of electronic com-

ponents, or other goods shipped over or under the quantities

ordered (not to exceed 5%) shall constitute compliance with

Buyer's order and the unit price will continue to apply.

©2002 Teccor Electronics P - 11 http://www.teccor.com

Thyristor Product Catalog +1 972-580-7777

Notes

E0

Data Sheets

V-I Characteristics of Thyristor Devices - - - - - - - - - - - - - - - - - - - - - E0-2

Electrical Parameter Terminology - - - - - - - - - - - - - - - - - - - - - - - - - E0-3

Sensitive Triacs- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E1

Triacs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E2

QUADRACs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E3

Alternistor Triacs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E4

Sensitive SCRs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E5

SCRs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E6

Rectifiers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E7

Diacs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E8

SIDAC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E9

©2002 Teccor Electronics http://www.teccor.com

Thyristor Product Catalog +1 972-580-7777

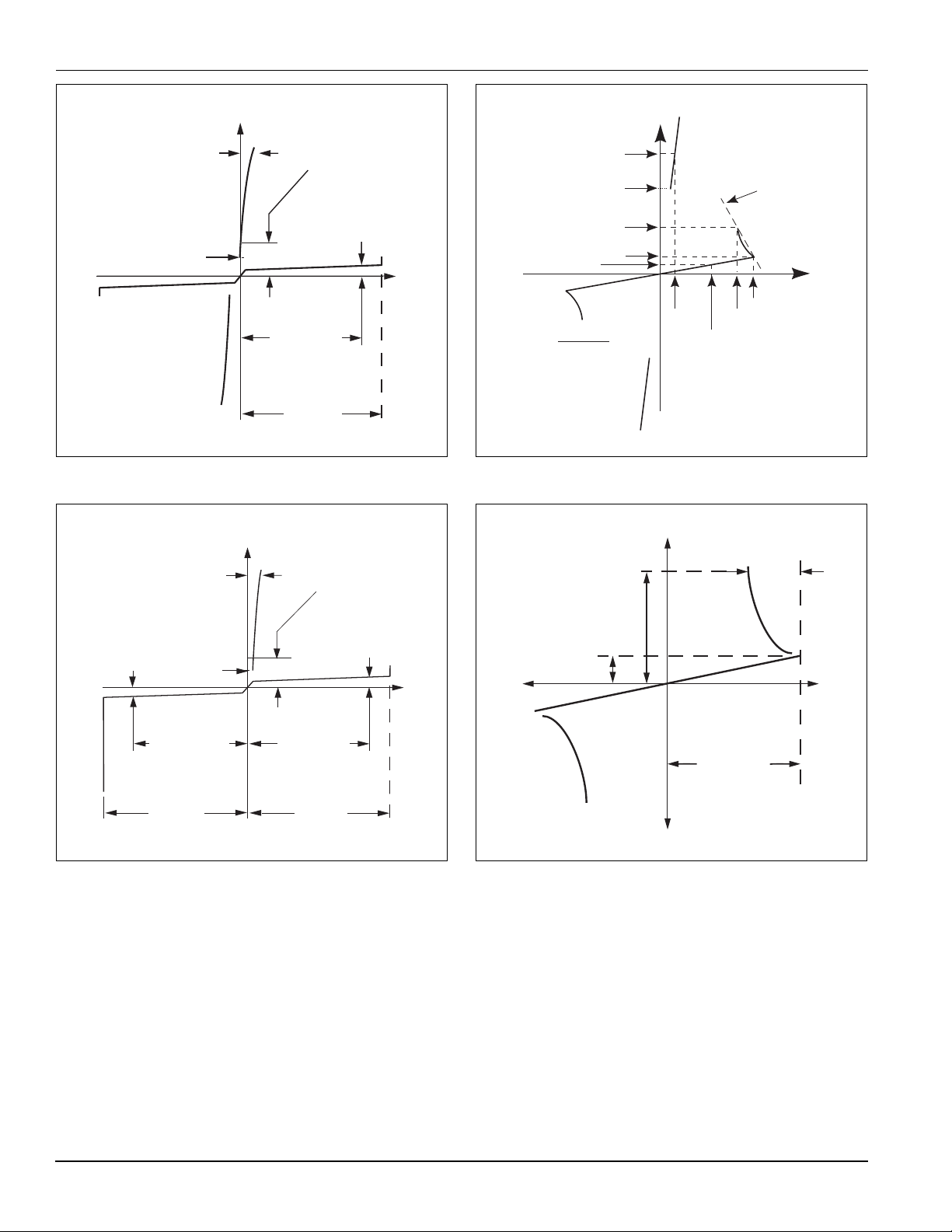

V-I Characteristics of Thyristor Devices

Voltage Drop (V

Specified Current (i

) at

T

)

T

Minimum Holding

Current (I

)

H

-V

V-I Characteristics of Triac Device

+I

Specified Minimum

Off-state

Blocking

Voltage (V

Breakover

-I

+I

Latching Current (I

Off-state Leakage

Current – (I

Specified V

)

DRM

Voltage

DRM

DRM

L

+V

+I

I

T

)

I

H

)

at

-V

(V

=

R

S

(IS - IBO)

I

BO

DRM

- VS)

I

S

I

BO

V

T

V

DRM

R

S

+V

V

BO

V

S

-I

V-I Characteristics of Sidac Device with Negative Resistance

+I

Reverse Leakage

Current - (I

RRM

Specified V

RRM

-V

Voltage Drop (VT) at

Specified Current (i

) at

Minimum Holding

Current (I

Specified Minimum

Reverse Blocking

Voltage (V

Reverse

Breakdown

Voltage

RRM

)

T

)

H

)

V-I Characteristics of SCR Device

-I

Latching Current (IL)

Specified Minimum

Off - State

Blocking

Voltage (V

DRM

Forward

Breakover

Voltage

Off - State Leakage

Current - (I

Specified V

)

DRM

DRM

10 mA

∆V

Breakover

) at

+V

Current

I

BO

+V-V

Breakover

Voltage

V

BO

-I

V-I Characteristics of Bilateral Trigger Diac

http://www.teccor.com E0 - 2 ©2002 Teccor Electronics

+1 972-580-7777 Thyristor Product Catalog

Electrical Parameter Terminology

Thyristor

di/dt (Critical Rate-of-rise of On-state Current) – Maximum

value of the rate-of-rise of on-state current which a thyristor can

withstand without deleterious effect

dv/dt (Critical Rate-of-rise of Off-state Voltage or Static

dv/dt) –

which will cause switching from the off state to the on state

dv/dt(c) Critical Rate-of-rise of Commutation Voltage of a

Triac (Commutating dv/dt) –

of principal voltage which will cause switching from the off state

to the on state immediately following on-state current conduction

in the opposite quadrant

I2t (RMS Surge (Non-repetitive) On-state Fusing Current) –

Measure of let-through energy in terms of current and time for

fusing purposes

I

BO

point

I

DRM

current that may occur under the conditions of V

IGT (Gate Trigger Current) – Minimum gate current required to

switch a thyristor from the off state to the on state

IH (Holding Current) – Minimum principal current required to

maintain the thyristor in the on state

IPP (Peak Pulse Current) – Peak pulse current at a short time

duration and specified waveshape

I

RRM

current that may occur under the conditions of V

IS (Switching Current) – Current at V

from the clamping state to on state

I

T(RMS)

that may be allowed under stated conditions, usually the fullcycle RMS current

I

TSM

cycle AC current pulse allowed

P

power which may be dissipated between the gate and main terminal 1 (or cathode) average over a full cycle

PGM (Peak Gate Power Dissipation) – Maximum power which

may be dissipated between the gate and main terminal 1 (or

cathode) for a specified time duration

R

ture difference between the thyristor junction and ambient divided

by the power dissipation causing the temperature difference

under conditions of thermal equilibrium

Note: Ambient is defined as the point where temperature does

not change as a result of the dissipation.

R

difference between the thyristor junction and the thyristor case

divided by the power dissipation causing the temperature difference under conditions of thermal equilibrium

Minimum value of the rate-of-rise of principal voltage

Minimum value of the rate-of-rise

(Breakover Current) – Principal current at the breakover

(Repetitive Peak Off-state Current) – Maximum leakage

DRM

(Repetitive Peak Reverse Current) – Maximum leakage

RRM

when a sidac switches

S

(On-state Current) – Anode cathode principal current

(Surge (Non-repetitive) On-state Current) – Peak single

(Average Gate Power Dissipation) – Value of gate

G(AV)

(Thermal Resistance, Junction-to-ambient) – Tempera-

θJA

(Thermal Resistance, Junction-to-case) – Temperature

θJC

tgt (Gate-controlled Turn-on Time) – Time interval between

the 10% rise of the gate pulse and the 90% rise of the principal

current pulse during switching of a thyristor from the off state to

the on state

tq (Circuit-commutated Turn-off Time) – Time interval

between the instant when the principal current has decreased to

zero after external switching of the principal voltage circuit and

the instant when the SCR is capable of supporting a specified

principal voltage without turning on

VBO (Breakover Voltage) – Principal voltage at the breakover

point

V

(Repetitive Peak Off-state Voltage) – Maximum allow-

DRM

able instantaneous value of repetitive off-state voltage that may

be applied across a bidirectional thyristor (forward or reverse

direction) or SCR (forward direction only)

V

(Gate Trigger Voltage) – Minimum gate voltage required to

GT

produce the gate trigger current

V

(Repetitive Peak Reverse Voltage) – Maximum allow-

RRM

able instantaneous value of a repetitive reverse voltage that may

be applied across an SCR without causing reverse current avalanche

VS (Switching Voltage) – Voltage point after V

switches from a clamping state to on state

when a sidac

BO

VT (On-state Voltage) – Principal voltage when the thyristor is in

the on state

Diode Rectifiers

I

(Average Forward Current) – Average forward conduc-

F(AV)

tion current

IFM (Maximum (Peak) Reverse Current) – Maximum reverse

leakage current that may occur at rated V

I

(RMS Forward Current) – RMS forward conduction cur-

F(RMS)

rent

I

(Maximum (Peak) Forward (Non-repetitive) Surge

FSM

Current) –

rent allowed for specified duration

Maximum (peak) forward single cycle AC surge cur-

VFM (Maximum (Peak) Forward Voltage Drop) – Maximum

(peak) forward voltage drop from the anode to cathode at stated

conditions

VR (Reverse Blocking Voltage) – Maximum allowable DC

reverse blocking voltage that may be applied to the rectifier

V

(Maximum (Peak) Repetitive Reverse Voltage) – Maxi-

RRM

mum peak allowable value of a repetitive reverse voltage that

may be applied to the rectifier

RRM

©2002 Teccor Electronics E0 - 3 http://www.teccor.com

Thyristor Product Catalog +1 972-580-7777

Notes

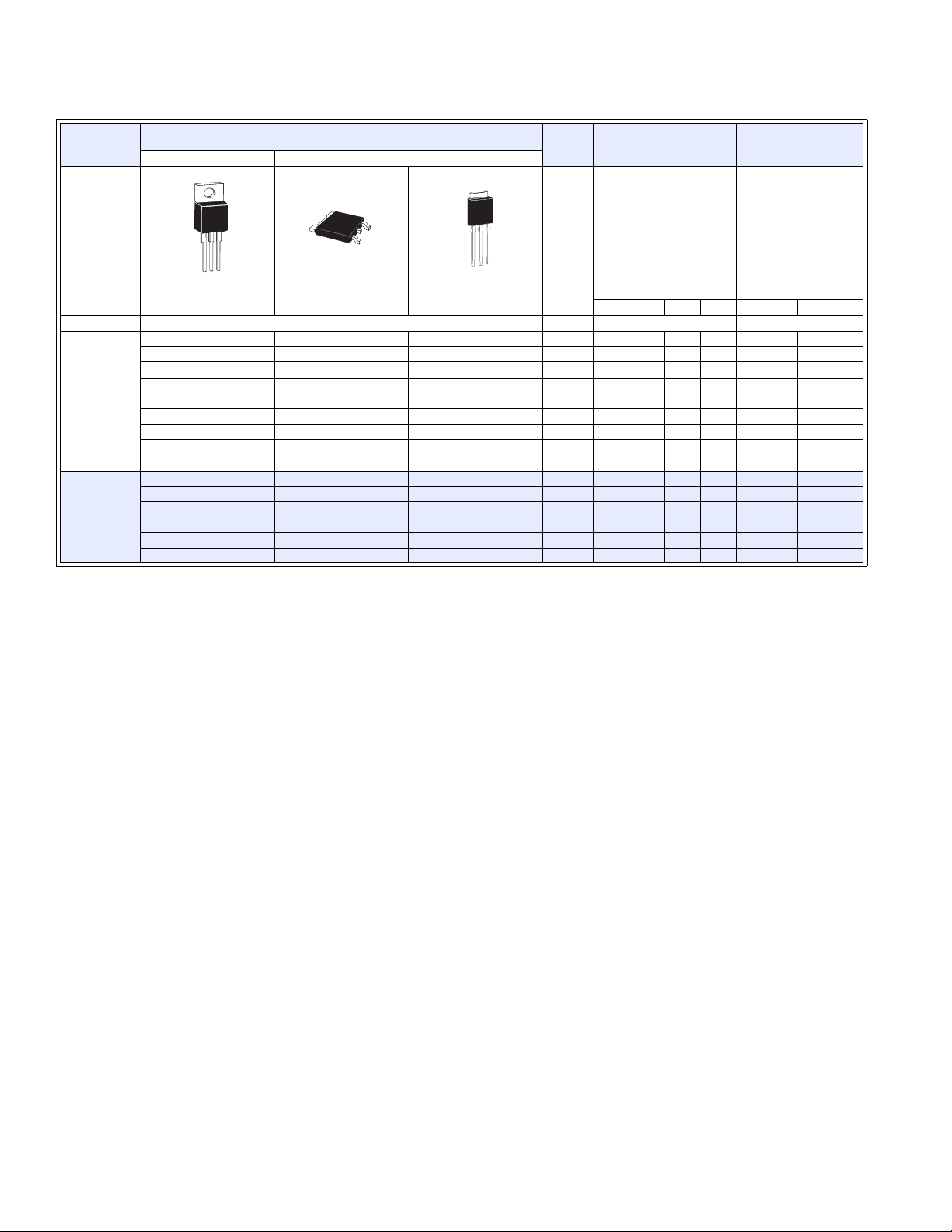

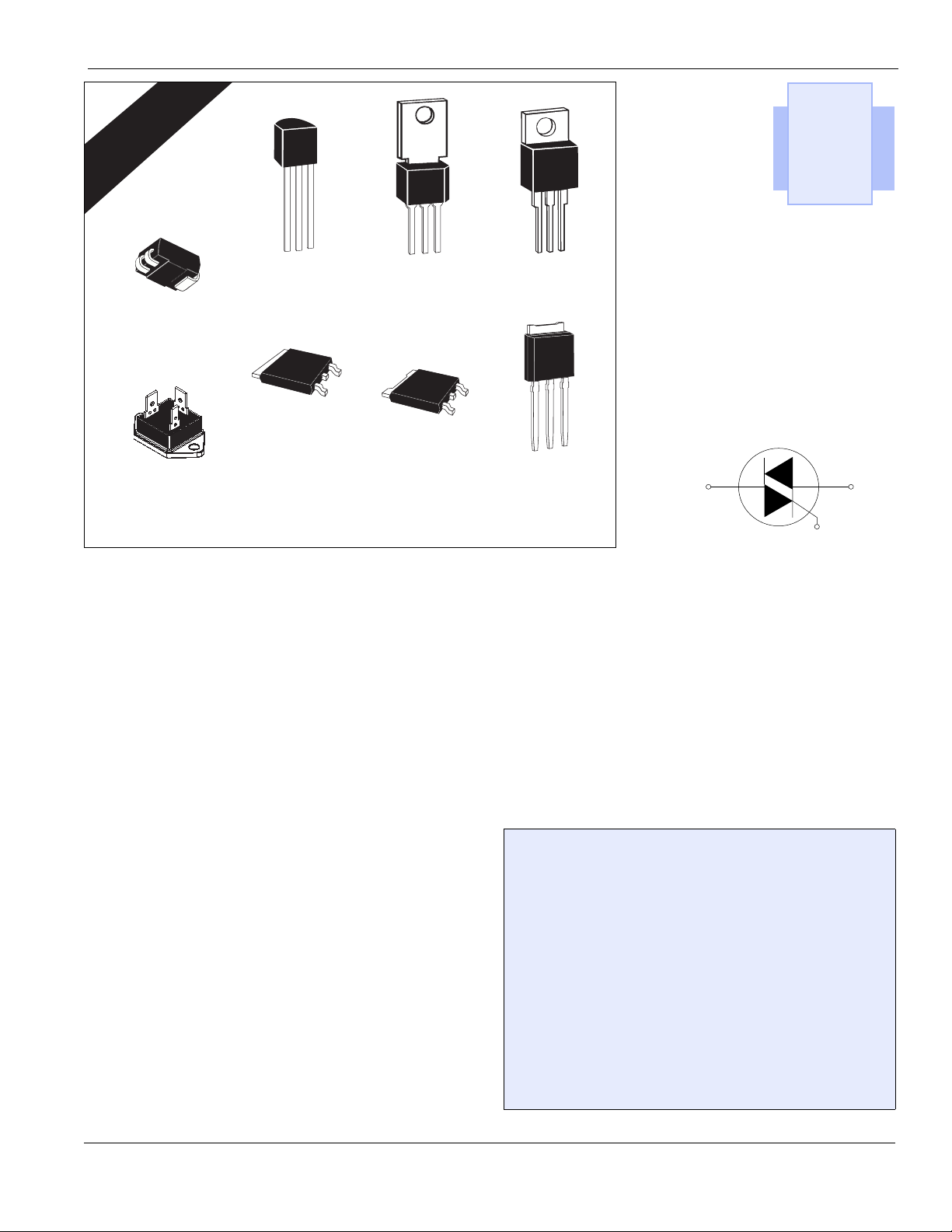

Selected Packages*

File #E71639

U.L. RECOGNIZED

TO-202

E1

TO-92

*TO-220

Isolated

3-lead

Compak

TO-252

D-Pak

MT2 MT1

TO-251

V-P ak

G

Sensitive Triacs

E1

General Description

Teccor's line of sensitive gate triacs includes devices with current

capabilities through 8 A. Voltage ranges are available from 200 V

to 600 V. This line features devices with guaranteed gate control

in Quadrants II and IV as well as control in the commonly used

Quadrants I and III. Four-quadrant control devices require

sensitive gate triacs. They can be controlled by digital circuitry

where positive-only or negative-only pulses must control AC

current in both directions through the device. Note that triacs with

low I

values in Quadrants II and IV will have lower dv/dt

GT

characteristics.

The sensitive gate triac is a bidirectional AC switch and is gate

controlled for either polarity of main terminal voltage. It is used

primarily for AC switching and phase control applications such as

motor speed controls, temperature modulation controls, and

lighting controls.

The epoxy TO-92 and TO-220 configurations feature Teccor's

electrically-isolated construction where the case or mounting tab

is internally isolated from the semiconductor chip and lead

attachments. Non-isolated epoxy TO-202 packages are available

as well as TO-251 and surface mount TO-252 (D-Pak). Tapeand-reel capability and tube packing also are available. See

“Packing Options” section of this catalog.

(0.8 A to 8 A)

All Teccor triacs have glass-passivated junctions. This glassing

process prevents migration of contaminants and ensures longterm device reliability with parameter stability.

Variations of devices covered in this data sheet are available for

custom design applications. Consult factory for more information.

Features

• Electrically-isolated packages

• Glass-passivated junctions ensure long device

reliability and parameter stability

• Voltage capability — up to 600 V

• Surge capability — up to 80 A

• Four-quadrant gating guaranteed

Compak Sensitive Gate Triac

• Surface mount package — 0.8 A and 1 A series

• New small profile three-leaded Compak package

• Packaged in embossed carrier tape with 2,500

devices per reel

• Can replace SOT-223

©2002 Teccor Electronics E1 - 1 http://www.teccor.com

Thyristor Product Catalog +1 972-580-7777

Sensitive Triacs Data Sheets

I

T(RMS)

(11)

MT2

MT1

G

TO-92 Compak TO-220

Isolated Non-isolated

MT2

G

MT2

MT1

G

MT2

MT1

MT2

MT2

MT1

G

TO-252

D-Pak TO-202

MT1

MT2

MT2

G

MT1

TO-251

V-Pa k

MAX See “Package Dimensions” section for variations. (12) MIN MAX MAX

L2X8E3 L2X3 200 3 3 3 3 0.01 0.1

L4X8E3 L4X3 400 3 3 3 3 0.01 0.1

L6X8E3 L6X3 600 3 3 3 3 0.01 0.1

L2X8E5 L2X5 200 5 5 5 5 0.01 0.1

L4X8E5 L4X5 400 5 5 5 5 0.01 0.1

0.8 A

L6X8E5 L6X5 600 5 5 5 5 0.01 0.1

L2X8E6 200 5 5 5 10 0.01 0.1

L4X8E6 400 5 5 5 10 0.01 0.1

L6X8E6 600 5 5 5 10 0.01 0.1

L2X8E8 200 10 10 10 20 0.01 0.1

L4X8E8 400 10 10 10 20 0.01 0.1

L6X8E8 600 10 10 10 20 0.01 0.1

L201E3 L2N3 200 33330.01 0.1

L401E3 L4N3 400 33330.01 0.1

L601E3 L6N3 600 33330.01 0.1

L201E5 L2N5 200 55550.01 0.1

L401E5 L4N5 400 55550.01 0.1

1A

L601E5 L6N5 600 55550.01 0.1

L201E6 200 5 5 5 10 0.01 0.1

L401E6 400 5 5 5 10 0.01 0.1

L601E6 600 5 5 5 10 0.01 0.1

L201E8 200 10101020 0.01 0.1

L401E8 400 10101020 0.01 0.1

L601E8 600 10101020 0.01 0.1

L2004L3 L2004D3 L2004F31 L2004V3 200 3 3 3 3 0.01 0.2

L4004L3 L4004D3 L4004F31 L4004V3 400 3 3 3 3 0.01 0.2

L6004L3 L6004D3 L6004F31 L6004V3 600 3 3 3 3 0.01 0.2

L2004L5 L2004D5 L2004F51 L2004V5 200 5 5 5 5 0.01 0.2

L4004L5 L4004D5 L4004F51 L4004V5 400 5 5 5 5 0.01 0.2

4A

L6004L5 L6004D5 L6004F51 L6004V5 600 5 5 5 5 0.01 0.2

L2004L6 L2004D6 L2004F61 L2004V6 200 5 5 5 10 0.01 0.2

L4004L6 L4004D6 L4004F61 L4004V6 400 5 5 5 10 0.01 0.2

L6004L6 L6004D6 L6004F61 L6004V6 600 5 5 5 10 0.01 0.2

L2004L8 L2004D8 L2004F81 L2004V8 200 10 10 10 20 0.01 0.2

L4004L8 L4004D8 L4004F81 L4004V8 400 10 10 10 20 0.01 0.2

L6004L8 L6004D8 L6004F81 L6004V8 600 10 10 10 20 0.01 0.2

MT2

V

DRM

(1)

G

I

GT

(3) (6) (9)

mAmps

Volts

QI QII QIII QIV

25 °C

See “General Notes” on page E1 - 4 and “Electrical Specification Notes” on page E1 - 5.

Part No.

T

C

I

DRM

(1) (14)

mAmps

=

TC =

110 °C

http://www.teccor.com E1 - 2 ©2002 Teccor Electronics

+1 972-580-7777 Thyristor Product Catalog

Data Sheets Sensitive Triacs

V

TM

(1) (4)

Volt s

=

T

C

25 °C

MAX MAX MAX TYP TYP TYP

1.6 2 5 1 10 0.2 10/8.3 0.5 20 2.8 0.41 20

1.6 2 5 1 10 0.2 10/8.3 0.5 15 2.8 0.41 20

1.6 2 5 1 10 0.2 10/8.3 0.5 10 2.8 0.41 20

1.6 2 10 1 10 0.2 10/8.3 1 20 3 0.41 20

1.6 2 10 1 10 0.2 10/8.3 1 15 3 0.41 20

1.6 2 10 1 10 0.2 10/8.3 1 10 3 0.41 20

1.6 2 10 1 10 0.2 10/8.3 1 30 3 0.41 20

1.6 2 10 1 10 0.2 10/8.3 1 25 3 0.41 20

1.6 2 10 1 10 0.2 10/8.3 1 20 3 0.41 20

1.6 2 15 1 10 0.2 10/8.3 2 35 3.2 0.41 20

1.6 2 15 1 10 0.2 10/8.3 2 30 3.2 0.41 20

1.6 2 15 1 10 0.2 10/8.3 2 25 3.2 0.41 20

1.625110 0.220/16.70.5 202.81.6 20

1.625110 0.220/16.70.5 202.81.6 20

1.625110 0.220/16.70.5 102.81.6 20

1.6 2 10 1 10 0.2 20/16.7 1 20 3 1.6 20

1.6 2 10 1 10 0.2 20/16.7 1 20 3 1.6 20

1.6 2 10 1 10 0.2 20/16.7 1 10 3 1.6 20

1.6 2 10 1 10 0.2 20/16.7 1 30 3 1.6 20

1.6 2 10 1 10 0.2 20/16.7 1 30 3 1.6 20

1.6 2 10 1 10 0.2 20/16.7 1 20 3 1.6 20

1.6 2 15 1 10 0.2 20/16.7 1 35 3.2 1.6 20

1.6 2 15 1 10 0.2 20/16.7 1 35 3.2 1.6 20

1.6 2 15 1 10 0.2 20/16.7 1 25 3.2 1.6 20

1.6 2 5 1.2 15 0.3 40/33 0.5 25 2.8 6.6 50

1.6 2 5 1.2 15 0.3 40/33 0.5 25 2.8 6.6 50

1.6 2 5 1.2 15 0.3 40/33 0.5 15 2.8 6.6 50

1.6 2 10 1.2 15 0.3 40/33 1 25 3 6.6 50

1.6 2 10 1.2 15 0.3 40/33 1 25 3 6.6 50

1.6 2 10 1.2 15 0.3 40/33 1 15 3 6.6 50

1.6 2 10 1.2 15 0.3 40/33 1 30 3 6.6 50

1.6 2 10 1.2 15 0.3 40/33 1 30 3 6.6 50

1.6 2 10 1.2 15 0.3 40/33 1 20 3 6.6 50

1.6 2 15 1.2 15 0.3 40/33 2 35 3.2 6.6 50

1.6 2 15 1.2 15 0.3 40/33 2 35 3.2 6.6 50

1.6 2 15 1.2 15 0.3 40/33 2 25 3.2 6.6 50

V

GT

(2) (5) (15)

Volt s

TC =

25 °C60/50Hz

I

H

(1) (7)

mAmps

I

GTM

(13)

Amps

P

GM

(13)

Watts Watts

P

G(AV)

I

TSM

(8) (10)

Amps

dv/dt(c) dv/dt

(1) (10)

Volt s/ µSec

(1)

Vol ts/µSec

TC =

100 °C

t

gt

(9)

µSec Amps

I2t di/dt

2

Sec Amps/µSec

See “General Notes” on page E1 - 4 and “Electrical Specification Notes” on page E1 - 5.

©2002 Teccor Electronics E1 - 3 http://www.teccor.com

Thyristor Product Catalog +1 972-580-7777

Sensitive Triacs Data Sheets

I

T(RMS)

(11)

MAX See “Package Dimensions” section for variations. (12) MIN MAX MAX

6A

8A

Isolated Non-isolated

MT2

MT2

G

MT1

MT2

TO-220

L2006L5 L2006D5 L2006V5 2005555 0.02 0.5

L4006L5 L4006D5 L4006V5 4005555 0.02 0.5

L6006L5 L6006D5 L6006V5 6005555 0.02 0.5

L2006L6 L2006D6 L2006V6 200 5 5 5 10 0.02 0.5

L4006L6 L4006D6 L4006V6 400 5 5 5 10 0.02 0.5

L6006L6 L6006D6 L6006V6 600 5 5 5 10 0.02 0.5

L2006L8 L2006D8 L2006V8 200 10 10 10 20 0.02 0.5

L4006L8 L4006D8 L4006V8 400 10 10 10 20 0.02 0.5

L6006L8 L6006D8 L6006V8 600 10 10 10 20 0.02 0.5

L2008L6 L2008D6 L2008V6 200 5 5 5 10 0.02 0.5

L4008L6 L4008D6 L4008V6 400 5 5 5 10 0.02 0.5

L6008L6 L6008D6 L6008V6 600 5 5 5 10 0.02 0.5

L2008L8 L2008D8 L2008V8 200 10 10 10 20 0.02 0.5

L4008L8 L4008D8 L4008V8 400 10 10 10 20 0.02 0.5

L6008L8 L6008D8 L6008V8 600 10 10 10 20 0.02 0.5

TO-252

D-Pak

MT1

MT2

G

G

MT1

MT2

TO-251

V-Pa k

V

Volt s

DRM

(1)

mAmps

QI QII QIII QIV T

I

GT

(3) (6)

(1) (14)

mAmps

= 25 °C TC = 110 °C

C

Part No.

I

DRM

Specified Test Conditions

di/dt — Maximum rate-of-change of on-state current; IGT = 50 mA with

µs rise time

0.1

dv/dt — Critical rate-of-rise of off-state voltage at rated V

dv/dt(c) — Critical rate-of-rise of commutation voltage at rated V

and I

commutating di/dt = 0.54 rated I

T(RMS)

T(RMS)

unenergized

2

t — RMS surge (non-repetitive) on-state current for period of 8.3 ms

I

for fusing

— Peak off-state current, gate open; V

I

DRM

— DC gate trigger current in specific operating quadrants;

I

GT

= 12 V dc; RL = 60 Ω

V

D

— Peak gate trigger current

I

GTM

I

— Holding current gate open; initial on-state current = 100 mA dc

H

— RMS on-state current conduction angle of 360°

I

T(RMS)

— Peak one-cycle surge

I

TSM

— Average gate power dissipation

P

G(AV)

— Peak gate power dissipation; I

P

GM

GT

= max rated value

DRM

≤ I

GTM

tgt — Gate controlled turn-on time; IGT = 50 mA with 0.1 µs rise time

— Repetitive peak off-state/blocking voltage

V

DRM

— DC gate trigger voltage; VD = 12 V dc; RL = 60 Ω

V

GT

— Peak on-state voltage at max rated RMS current

V

TM

DRM

/ms; gate

gate open

DRM

General Notes

• All measurements are made with 60 Hz resistive load and at an

ambient temperature of +25 °C unless otherwise specified.

• Operating temperature range (T

devices and -40 °C to 110 °C for all other devices.

• Storage temperature range (T

devices, -40 °C to +150 °C for TO-202 devices, and -40 °C to

+125 °C for TO-220 devices.

• Lead solder temperature is a maximum of 230 °C for 10 seconds

maximum at a minimum of 1/16” (1.59 mm) from case.

• The case or lead temperature (T

dimensional outline drawings. See “Package Dimensions” section

of this catalog.

) is -65 °C to +110 °C for TO-92

J

) is -65 °C to +150 °C for TO-92

S

or TL) is measured as shown on

C

http://www.teccor.com E1 - 4 ©2002 Teccor Electronics

+1 972-580-7777 Thyristor Product Catalog

Data Sheets Sensitive Triacs

V

TM

(1) (4)

Volts

T

= 25 °C TC = 25 °C 60/50 Hz TC = 100 °C

C

MAX MAX MAX TYP TYP TYP

1.6 2 10 1.6 18 0.4 60/50 1 40 3 15 70

1.6 2 10 1.6 18 0.4 60/50 1 30 3 15 70

1.6 2 10 1.6 18 0.4 60/50 1 20 3 15 70

1.6 2 10 1.6 18 0.4 60/50 2 40 3 15 70

1.6 2 10 1.6 18 0.4 60/50 2 30 3 15 70

1.6 2 10 1.6 18 0.4 60/50 2 20 3 15 70

1.6 2 20 1.6 18 0.4 60/50 2 45 3.2 15 70

1.6 2 20 1.6 18 0.4 60/50 2 40 3.2 15 70

1.6 2 20 1.6 18 0.4 60/50 2 30 3.2 15 70

1.6 2 10 1.6 18 0.4 80/65 2 40 3 26.5 70

1.6 2 10 1.6 18 0.4 80/65 2 30 3 26.5 70

1.6 2 10 1.6 18 0.4 80/65 2 20 3 26.5 70

1.6 2 20 1.6 18 0.4 80/65 2 45 3.2 26.5 70

1.6 2 20 1.6 18 0.4 80/65 2 40 3.2 26.5 70

1.6 2 20 1.6 18 0.4 80/65 2 30 3.2 26.5 70

Electrical Specification Notes

(1) For either polarity of MT2 with reference to MT1 terminal

(2) For either polarity of gate voltage V

terminal

(3) See Gate Characteristics and Definition of Quadrants.

(4) See Figure E1.4 for i

(5) See Figure E1.6 for V

(6) See Figure E1.7 for I

(7) See Figure E1.5 for I

(8) See Figure E1.9 for surge rating and specific duration.

(9) See Figure E1.8 for t

(10) See Figure E1.2 and Figure E1.3 for maximum allowable case

temperature at maximum rated current.

(11) See Figure E1.1, Figure E1.2, and Figure E1.3 for T

I

T(RMS)

(12) See package outlines for lead form configurations. When ordering

special lead forming, add type number as suffix to part number.

(13) Pulse width ≤10 µs

or T

(14) T

C

(15) Minimum non-trigger V

V

GT

(2) (5) (15)

Volts

I

H

(1) (7)

mAmps

versus vT.

T

versus TC.

GT

versus TC.

GT

versus TC.

H

versus IGT.

gt

I

GTM

(13)

Amps

GT

.

= TJ for test conditions in off state

L

at 110 °C is 0.2 V.

GT

P

GM

(13)

Watts Watts

P

G(AV)

with reference to MT1

or TC versus

A

I

TSM

(8) (10)

Amps

dv/dt(c) dv/dt

(1) (10)

Volts/ µSec

(1)

Volts/ µSec

t

gt

(9)

µSec Amps

I2t di/dt

2

Sec Amps/µSec

Gate Characteristics

Teccor triacs may be turned on between gate and MT1 terminals

in the following ways:

• In-phase signals (with standard AC line) using Quadrants I

and III

• Application of unipolar pulses (gate always positive or negative), using Quadrants II and III with negative gate pulses and

Quadrants I and IV with positive gate pulses

When maximum surge capability is required, pulses should be a

minimum of one magnitude above I

waveform (

≤1 µs rise time).

ALL POLARITIES ARE REFERENCED TO MT1

(-)

I

GT

GATE

I

-

GT

(-)

I

GT

GATE

MT2 POSITIVE

(Positive Half Cycle)

MT2

MT1

REF

MT2

REF

QIII

MT1

MT2 NEGATIVE

(Negative Half Cycle)

rating with a steep rising

GT

+

(+)

I

GT

GATE

QII

QI

QIV

(+)

I

GT

GATE

-

MT2

REF

MT2

REF

Definition of Quadrants

MT1

MT1

+

I

GT

©2002 Teccor Electronics E1 - 5 http://www.teccor.com

Thyristor Product Catalog +1 972-580-7777

Sensitive Triacs Data Sheets

Electrical Isolation

Teccor’s isolated triac packages withstand a minimum high

potential test of 2500 V ac rms from leads to mounting tab over

the device's operating temperature range. The following isolation

table shows standard isolation ratings.

Electrical Isolation

from Leads to Mounting Tab

VACRMS TO-220 *

2500 Standard

*UL Recognized File #E71639

Thermal Resistance (Steady State) Junction to Mounting Tab

and Junction to Ambient

[R

R

θJC

] °C/W (TYP)

θJA

Package Code ECFLF2DV

Typ e

TO-92

Plastic Compak

TO-202

Type 1

TO-220

Isolated

TO-202

Type 2

TO-252

D-Pak

TO-251

V-Pa k

0.8 A 60 [135] 60 *

1 A 50 [95] 40 *

4A 3.5 [45] 3.6 [50] 6.0 [70] 3.5 6.0 [70]

6A 3.3 3.2 3.2

8A 2.8 2.7 2.7

* Mounted on 1 cm

2

copper foil surface; two-ounce copper foil

120

) - ˚C

A

T

100

80

60

40

25

20

Maximum Allowable Ambient Temperature (

0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8

CURRENT WAVEFORM: Sinusoidal

LOAD: Resistive or Inductive

CONDUCTION ANGLE: 360

FREE AIR RATING – NO HEATSINK

1 A TO-92

0.8 A TO-92

RMS On-State Current [I

˚

TO-220 and

TYPE 1 and 3 TO-202

TYPE 2 and 4 TO-202

and TO-251

] - Amps

T(RMS)

110

) – ˚C

C

100

90

80

70

60

50

0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6

Maximum Allowable Case Temperature (T

0.8 A

RMS On-State Current [I

CURRENT WAVEFORM: Sinusoidal

LOAD: Resistive or Inductive

CONDUCTION ANGLE: 360˚

CASE TEMPERATURE: Measured as

shown on Dimensional Drawings

1 A

] – Amps

T(RMS)

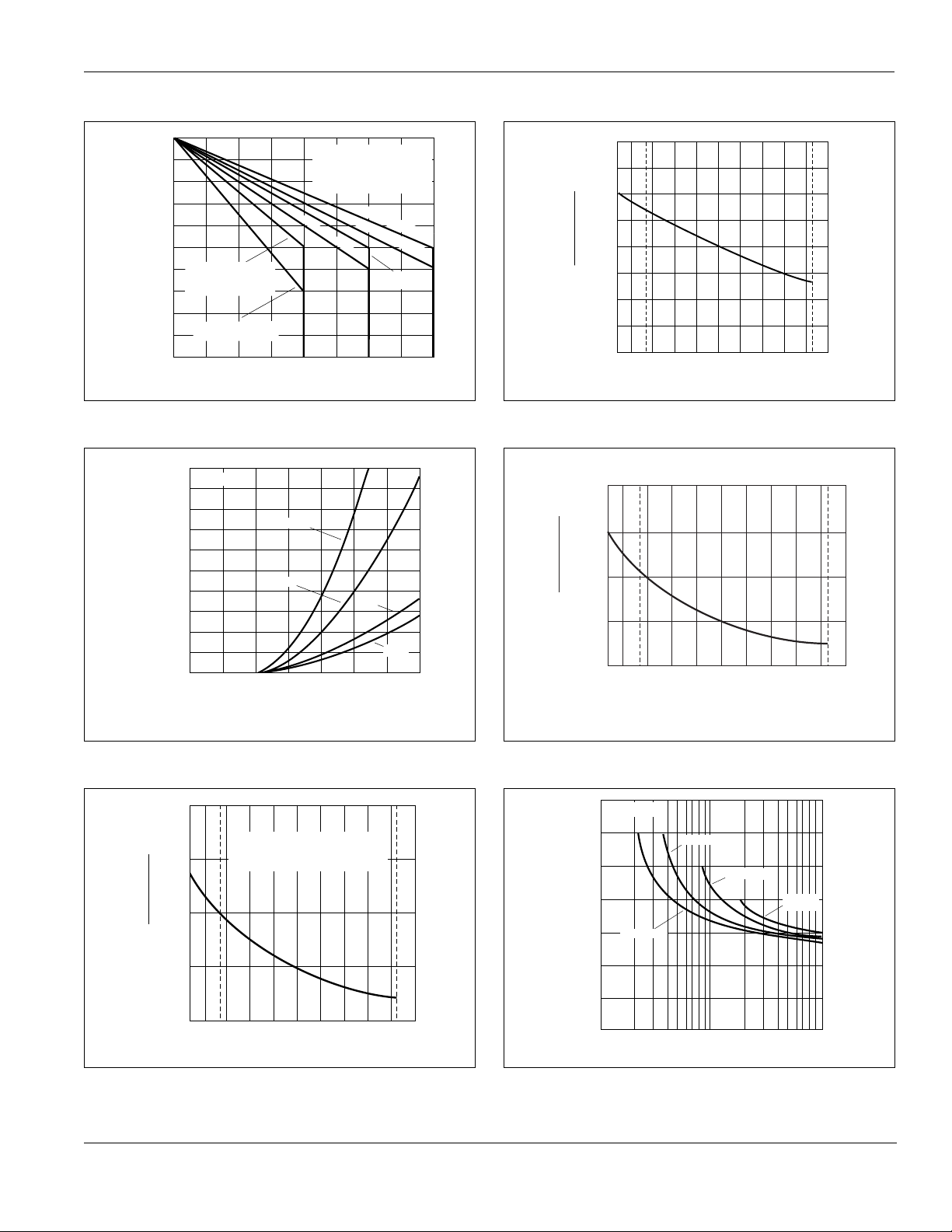

Figure E1.1 Maximum Allowable Ambient Temperature versus

On-state Current

Figure E1.2 Maximum Allowable Case Temperature versus

On-state Current (0.8 A and 1 A)

http://www.teccor.com E1 - 6 ©2002 Teccor Electronics

+1 972-580-7777 Thyristor Product Catalog

Data Sheets Sensitive Triacs

110

- ˚C

)

105

C

T

(

100

95

90

85

80

4 A TYPE 1 and 3 TO-202

4 A TO-220 (Isolated)

4 A TO-252

75

70

4 A TYPE 2 and 4 TO-202

65

4 A TO-251

Maximum Allowable Case Temperature

60

01 23 4 5 6 7 8

RMS On-State Current [I

CURRENT WAVEFORM: Sinusoidal

LOAD: Resistive or Inductive

CONDUCTION ANGLE: 360˚

CASE TEMPERATURE: Measured as

shown on Dimensional Drawings

6 A TO-220 (Isolated)

8 A TO-251 and TO-252

8 A TO-220 (Isolated)

T(RMS)

6 A TO-251

6 A TO-252

] - Amps

Figure E1.3 Maximum Allowable Case Temperature versus

On-state Current (4 A, 6 A, and 8 A)

20

TC = 25 ˚C

18

16

14

) - Amps

12

T

10

8

6

4

On-state Current (i

Positive or Negative Instantaneous

2

0

0 0.5 0.8 1.0 1.2 1.4 1.6 1.8

6 A and 8 A

4 A

1 A

Positive or Negative Instantaneous

On-state Voltage (v

) - Volts

T

0.8 A

2.0

1.5

= 25 ˚C)

GT

C

V

(T

1.0

GT

V

.5

Ratio of

0

-65 -40 -15 +65 +110 +125+25

Case Temperature (

) - ˚C

T

C

Figure E1.6 Normalized DC Gate Trigger Voltage for All Quadrants

versus Case Temperature

4.0

3.0

= 25 ˚C)

GT

I

C

(T

2.0

GT

I

1.0

Ratio of

0

-65 -40 -15 +65 +110 +125+25

Case Temperature (TC) - ˚C

Figure E1.4 On-state Current versus On-state Voltage (Typical)

Figure E1.7 Normalized DC Gate Trigger Current for All Quadrants

versus Case Temperature

4.0

INITIAL ON-STATE CURRENT

= 100 mA (DC) 0.8 - 4 A Devices

= 200 mA (DC) 6 - 8 A Devices

-40 -15 +25 +65

Case Temperature (

T

C

) - ˚C

+110

+125

H

I

3.0

C)

˚

= 25

C

2.0

(T

H

I

Ratio of

1.0

0

-65

Figure E1.5 Normalized DC Holding Current versus Case Temperature

Figure E1.8 Turn-on Time versus Gate Trigger Current (Typical)

7.0

TC = 25 ˚C

6.0

5.0

) - µSec

gt

4.0

3.0

IGT = 3 mA MAX

Turn-On Time (t

2.0

1.0

0

123465 8 10 20 30 40 60 80 100

IGT = 5 mA MAX

IGT = 10 mA MAX

DC Gate Trigger Current (IGT) - mA

IGT = 20 mA

MAX

©2002 Teccor Electronics E1 - 7 http://www.teccor.com

Thyristor Product Catalog +1 972-580-7777

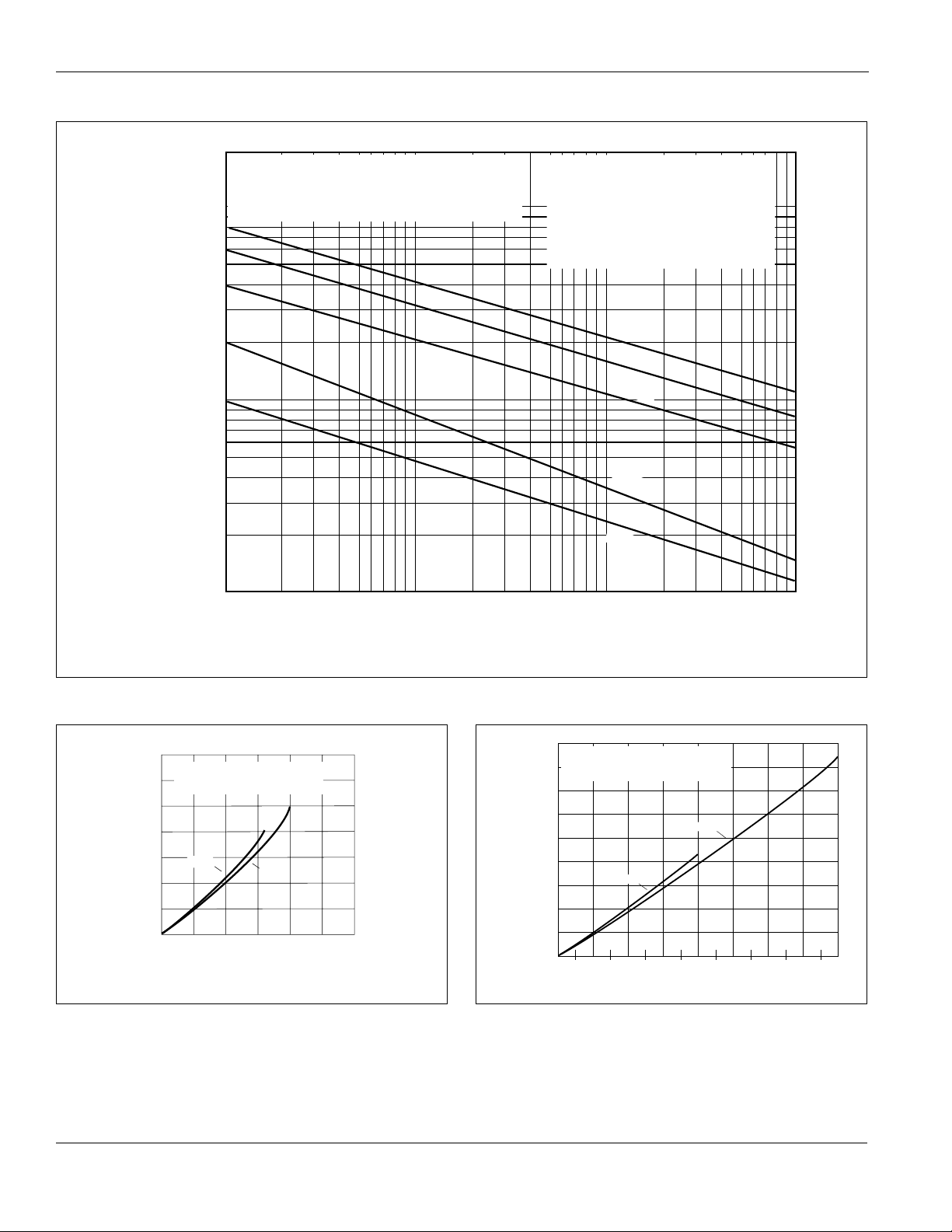

Sensitive Triacs Data Sheets

200

150

100

SUPPLY FREQUENCY: 60 Hz Sinusoidal

LOAD: Resistive

RMS On-state Current: [I

Rated Value at Specified Case Temperature

80

T(RMS)

60

40

) – Amps

30

TSM

20

10

8

6

4

Peak Surge (Non-Repetitive)

3

On-State Current (I

2

1

1 2436810204030 60 100 200 400 600 1000

]: Maximum

NOTES:

1) Gate control may be lost during

and immediately following surge

current interval.

2) Overload may not be repeated until

junction temperature has returned

to steady-state rated value.

8 A

6 A

4 A

1 A

0.8 A

Surge Current Duration – Full Cycles

Figure E1.9 Peak Surge Current versus Surge Current Duration

CURRENT WAVEFORM: Sinusoidal

LOAD: Resistive or Inductive

1.5

CONDUCTION ANGLE: 360˚

1.0

] – Watts

D(AV)

0.5

[P

Average On-state Power Dissipation

Figure E1.10 Power Dissipation (Typical) versus RMS On-state Current

(0.8 A and 1 A)

0.8 A

0

0 0.25 0.50 0.75 1.0 1.25 1.5

RMS On-state Current [I

1 A

T(RMS)

] – Amps

9.0

CURRENT WAVEFORM: Sinusoidal

8.0

LOAD: Resistive or Inductive

CONDUCTION ANGLE: 360

7.0

6.0

5.0

] – Watts

4.0

D(AV)

[P

3.0

2.0

Average On-state Power Dissipation

1.0

0

0 .5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0 7.5

Figure E1.11 Power Dissipation (Typical) versus RMS On-state Current

(4 A, 6 A, and 8 A)

4 A

RMS On-state Current [I

˚

6 A and 8 A

T(RMS)

] – Amps

8.0

http://www.teccor.com E1 - 8 ©2002 Teccor Electronics

+1 972-580-7777 Thyristor Product Catalog

Selected Packages*

File #E71639

U.L. RECOGNIZED

E2

3-lead

Compak

*TO-3

Fastpak

TO-92

TO-92

TO-263

2

D

Pak

TO-202 *TO-220

TO-252

D-Pak

TO-251

V-P ak

MT2 MT1

G

Triacs

(0.8 A to 35 A)

E2

General Description

These gated triacs from Teccor Electronics are part of a broad

line of bidirectional semiconductors. The devices range in current

ratings from 0.8 A to 35 A and in voltages from 200 V to 1000 V.

The triac may be gate triggered from a blocking to conduction

state for either polarity of applied voltage and is designed for AC

switching and phase control applications such as speed and temperature modulation controls, lighting controls, and static switching relays. The triggering signal is normally applied between the

gate and MT1.

Isolated packages are offered with internal construction, having

the case or mounting tab electrically isolated from the semiconductor chip. This feature facilitates the use of low-cost assembly

and convenient packaging techniques. Tape-and-reel capability

is available. See “Packing Options” section of this catalog.

All Teccor triacs have glass-passivated junctions to ensure longterm device reliability and parameter stability. Teccor's glass-passivated junctions offer a rugged, reliable barrier against junction

contamination.

©2002 Teccor Electronics E2 - 1 http://www.teccor.com

Thyristor Product Catalog +1 972-580-7777

Variations of devices covered in this data sheet are available for

custom design applications. Consult factory for more information.

Features

• Electrically-isolated packages

• Glass-passivated junctions

• Voltage capability — up to 1000 V

• Surge capability — up to 200 A

Compak Package

• Surface mount package — 0.8 A and 1 A series

• New small profile three-leaded Compak package

• Packaged in embossed carrier tape with 2,500

devices per reel

• Can replace SOT-223

Triacs Data Sheets

I

T(RMS)

(4)

MT2

MT1

G

TO-92 TO-220 Compak TO-202 TO-220

Isolated Non-isolated

MT1

MT2

MT2

G

MT1

MT2

G

G

MT1

MT2

MT1

MT2

MT2

G

MT2

TO-252

D-Pak

MT1

MT2

MT2

MT2

MT2

G

TO-263

2

D

Pak

G

MT1

TO-251

V-Pa k

MAX See “Package Dimensions” section for variations. (11) MIN MAX TYP

0.8 A

Q2X8E3 Q2X3 200 10 10 10 25

Q4X8E3 Q4X3 400 10 10 10 25

Q6X8E3 Q6X3 600 10 10 10 25

Q2X8E4 Q2X4 200 25 25 25 50

Q4X8E4 Q4X4 400 25 25 25 50

Q6X8E4 Q6X4 600 25 25 25 50

1A

Q201E3 Q2N3 200 101010 25

Q401E3 Q4N3 400 101010 25

Q601E3 Q6N3 600 101010 25

Q201E4 Q2N4 200 252525 50

Q401E4 Q4N4 400 252525 50

Q601E4 Q6N4 600 252525 50

4A

Q2004L3 Q2004F31 Q2004D3 Q2004V3 200 10 10 10 25

Q4004L3 Q4004F31 Q4004D3 Q4004V3 400 10 10 10 25

Q6004L3 Q6004F31 Q6004D3 Q6004V3 600 10 10 10 25

Q2004L4 Q2004F41 Q2004D4 Q2004V4 200 25 25 25 50

Q4004L4 Q4004F41 Q4004D4 Q4004V4 400 25 25 25 50

Q6004L4 Q6004F41 Q6004D4 Q6004V4 600 25 25 25 50

Q8004L4 Q8004D4 Q8004V4 800 25 25 25 50

QK004L4 QK004D4 QK004V4 1000 25 25 25 50

6A

Q2006L4 Q2006F41 Q2006R4 Q2006N4 200 25 25 25 50

Q4006L4 Q4006F41 Q4006R4 Q4006N4 400 25 25 25 50

Q6006L5 Q6006F51 Q6006R5 Q6006N5 600 50 50 50 75

Q8006L5 Q8006R5 Q8006N5 800 50 50 50 75

QK006L5 QK006R5 QK006N5 1000 50 50 50 75

8A

Q2008L4 Q2008F41 Q2008R4 Q2008N4 200 25 25 25 50

Q4008L4 Q4008F41 Q4008R4 Q4008N4 400 25 25 25 50

Q6008L5 Q6008F51 Q6008R5 Q6008N5 600 50 50 50 75

Q8008L5 Q8008R5 Q8008N5 800 50 50 50 75

QK008L5 QK008R5 QK008N5 1000 50 50 50 75

MT1

MT2

V

DRM

(1)

G

Volt s

I

GT

(3) (7) (15)

mAmps

QI QII QIII QIV QIV

See “General Notes” on page E2 - 4 and “Electrical Specification Notes” on page E2 - 5.

Part Number

http://www.teccor.com E2 - 2 ©2002 Teccor Electronics

+1 972-580-7777 Thyristor Product Catalog

Data Sheets Triacs

I

DRM

(1) (16)

mAmps

T

=

TC =

C

25 °C

100 °C

125 °C

MAX MAX MAX MAX TYP MIN TYP

0.02 0.5 1 1.6 2 15 1 10 0.2 10/8.3 1 40 30 2.5 0.41 20

0.02 0.5 1 1.6 2 15 1 10 0.2 10/8.3 1 35 25 2.5 0.41 20

0.02 0.5 1 1.6 2 15 1 10 0.2 10/8.3 1 25 15 2.5 0.41 20

0.02 0.5 1 1.6 2.5 25 1 10 0.2 10/8.3 1 50 40 3 0.41 20

0.02 0.5 1 1.6 2.5 25 1 10 0.2 10/8.3 1 45 35 3 0.41 20

0.02 0.5 1 1.6 2.5 25 1 10 0.2 10/8.3 1 35 25 3 0.41 20

0.02 0.5 1 1.6 2 15 1 10 0.2 20/16.7 1 40 30 2.5 1.6 30

0.02 0.5 1 1.6 2 15 1 10 0.2 20/16.7 1 40 30 2.5 1.6 30

0.02 0.5 1 1.6 2 15 1 10 0.2 20/16.7 1 30 20 2.5 1.6 30

0.02 0.5 1 1.6 2.5 25 1 10 0.2 20/16.7 1 50 40 3 1.6 30

0.02 0.5 1 1.6 2.5 25 1 10 0.2 20/16.7 1 50 40 3 1.6 30

0.02 0.5 1 1.6 2.5 25 1 10 0.2 20/16.7 1 40 30 3 1.6 30

0.05 0.5 2 1.6 2 20 1.2 15 0.3 55/46 2 50 40 2.5 12.5 50

0.05 0.5 2 1.6 2 20 1.2 15 0.3 55/46 2 50 40 2.5 12.5 50

0.05 0.5 2 1.6 2 20 1.2 15 0.3 55/46 2 40 30 2.5 12.5 50

0.05 0.5 2 1.6 2.5 30 1.2 15 0.3 55/46 2 100 75 3 12.5 50

0.05 0.5 2 1.6 2.5 30 1.2 15 0.3 55/46 2 100 75 3 12.5 50

0.05 0.5 2 1.6 2.5 30 1.2 15 0.3 55/46 2 75 50 3 12.5 50

0.05 0.5 2 1.6 2.5 30 1.2 15 0.3 55/46 2 60 40 3 12.5 50

0.05 3 1.6 2.5 30 1.2 15 0.3 55/46 2 50 3 12.5 50

0.05 0.5 2 1.6 2.5 50 1.6 18 0.5 80/65 4 200 120 3 26.5 70

0.05 0.5 2 1.6 2.5 50 1.6 18 0.5 80/65 4 200 120 3 26.5 70

0.05 0.5 2 1.6 2.5 50 1.6 18 0.5 80/65 4 150 100 3 26.5 70

0.05 0.5 2 1.6 2.5 50 1.6 18 0.5 80/65 4 125 85 3 26.5 70

0.05 3 1.6 2.5 50 1.6 18 0.5 80/65 4 100 3 26.5 70

0.05 0.5 2 1.6 2.5 50 1.8 20 0.5 100/83 4 250 150 3 41 70

0.05 0.5 2 1.6 2.5 50 1.8 20 0.5 100/83 4 250 150 3 41 70