TEC POS Terminal

ST-6400 SERIES

Owner’s Manual

CE Compliance (For EU only)

This product complies with the requirements of EMC and Low Voltage Directives including their

amendments.

WARNING

This is a Class A product. In a domestic environment this product may cause radio interference in which

case the user may be required to take adequate measures.

Warnung

Dies ist ein Klasse A Produkt. In einer örtlichen Umgebung kann dieses Gerät Funkstörungen verursachen.

ATTENTION

Ce produit est de classe A. Dans un environnement domestique, il peut causer des interférences radio.

Auquel cas, I’utilisateur sera amené à prendre les mesures adéquates.

Atención

Este es un producto de la clase A. En ambientes domésticos éste producto puede causar radio

interferencias en cuyo caso el usuario deberá tomar las medldas oportunas.

VERWITTIGING

Dit is een klasse A produkt. Het gebruik hiervan kan radio interferenties veroorzaken die de gebruiker

ertoe kunnen dwingen sommige maatregelen te moeten treffen.

Schallemission : unter 70 dB (A) nach DIN 45635 (ISO 7779).........Thermodrucker-Type

Schallemission : 71 dB (A) nach DIN 45635 (ISO 7779)..........Matrixdrucker-Type

FCC Notice

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct

the interference at his own expense.

Changes or modifications not expressly approved by manufacturer for compliance could void the user’s

authority to operate the equipment.

CAUTION

The connectors, DRW1/2, are exclusive for TOSHIBA TEC Drawer Unit.

Do not connect the equipment which is not specified by the manufacturer's instructions.

Copyright © 2001

by TOSHIBA TEC CORPORATION

All Rights Reserved

570 Ohito, Ohito-cho, Tagata-gun, Shizuoka-ken, JAPAN

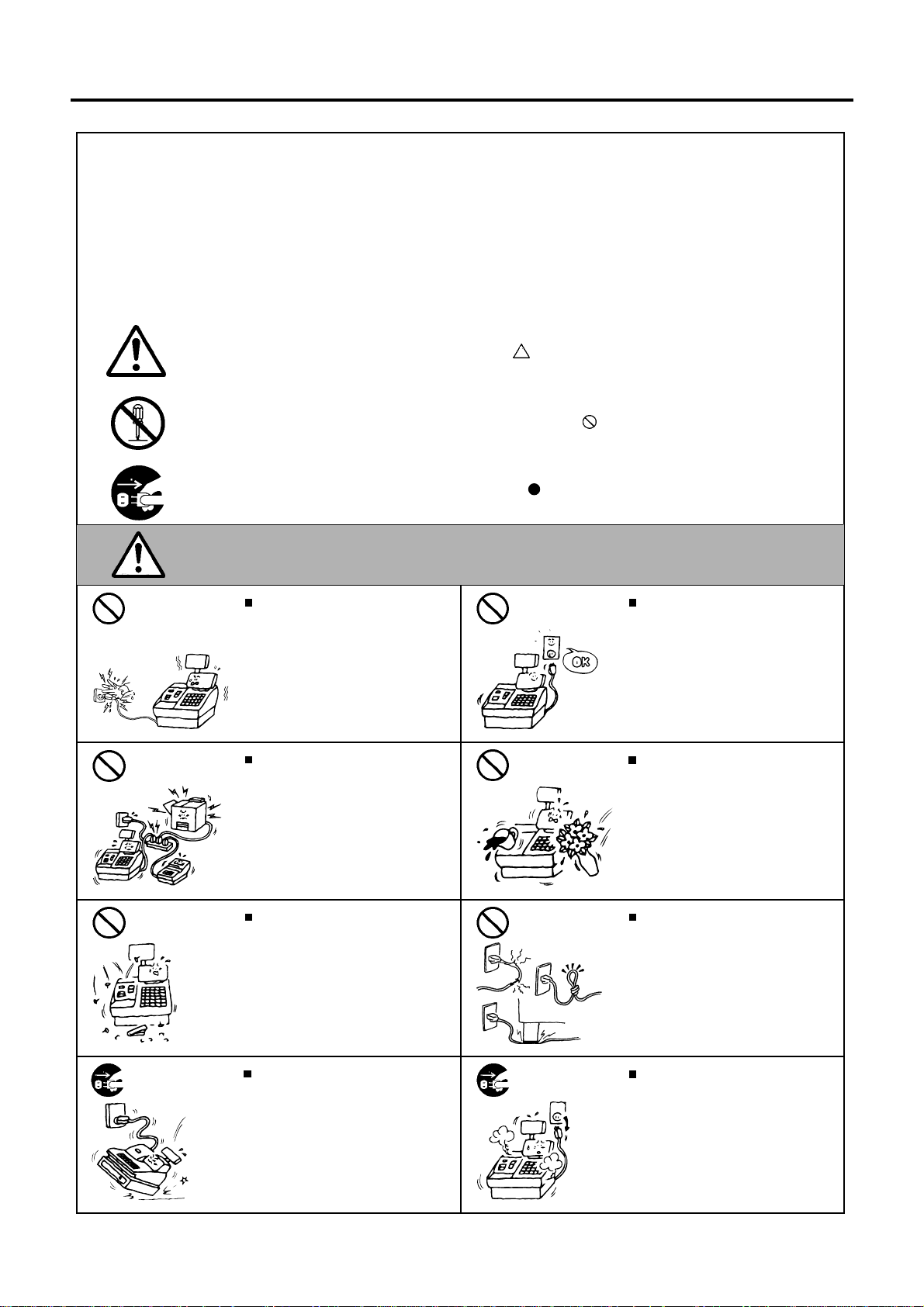

Safety Summary

Safety Summary

Personal safety in handling or maintaining the equipment is extremely important. Warnings and Cautions

necessary for safe handling are included in this manual. All warnings and cautions contained in this

manual should be read and understood before handling or maintaining the equipment.

Do not attempt to effect repairs or modifications to this equipment. If a fault occurs that cannot be rectified

using the procedures described in this manual, turn off the power, unplug the machine, then contact your

authorized TOSHIBA TEC representative for assistance.

Meanings of Each Symbol

This symbol indicates warning items (including cautions).

Specific warning contents are drawn inside the symbol.

(The symbol on the left indicates a general caution.)

This symbol indicates prohibited actions (prohibited items).

Specific prohibited contents are drawn inside or near the symbol.

(The symbol on the left indicates “no disassembling”.)

This symbol indicates actions which must be performed.

Specific instructions are drawn inside or near the symbol.

(The symbol on the left indicates “disconnect the power cord plug from the outlet”.)

EO1-11099

This indicates that there is the risk of death or serious injury if the

WARNING

Prohibited

Prohibited

Prohibited Prohibited

Do not plug in or unplug the power

cord plug with wet hands as this may

cause electric shock.

If the machines share the same

outlet with any other electrical

appliances which consume large

amounts of power, the voltage will

fluctuate widely each time these

appliances operate. Be sure to

provide an exclusive outlet for the

machine as this may cause fire or

electric shock.

Do not insert or drop metal,

flammable or other foreign objects into

the machines through the ventilation

slits, as this may cause fire or electric

shock.

machines are improperly handled contrary to this indication.

Any other than the

specified AC voltage

is prohibited.

Prohibited

Do not use voltages other than the

voltage (AC) specified on the rating

plate, as this may cause fire or

electric shock.

Do not place metal objects or

water-filled containers such as flower

vases, flower pots or mugs, etc. on

top of the machines. If metal objects

or spilled liquid enter the machines,

this may cause fire or electric

shock.

Do not scratch, damage or modify

the power cords. Also, do not place

heavy objects on, pull on, or excessively bend the cords, as this may

cause fire or electric shock.

Disconnect

the plug.

If the machines are dropped or their

cabinets damaged, first turn off the

power switches and disconnect the

power cord plugs from the outlet, and

then contact your authorized

TOSHIBA TEC representative for

assistance. Continued use of the

machine in that condition may cause

fire or electric shock.

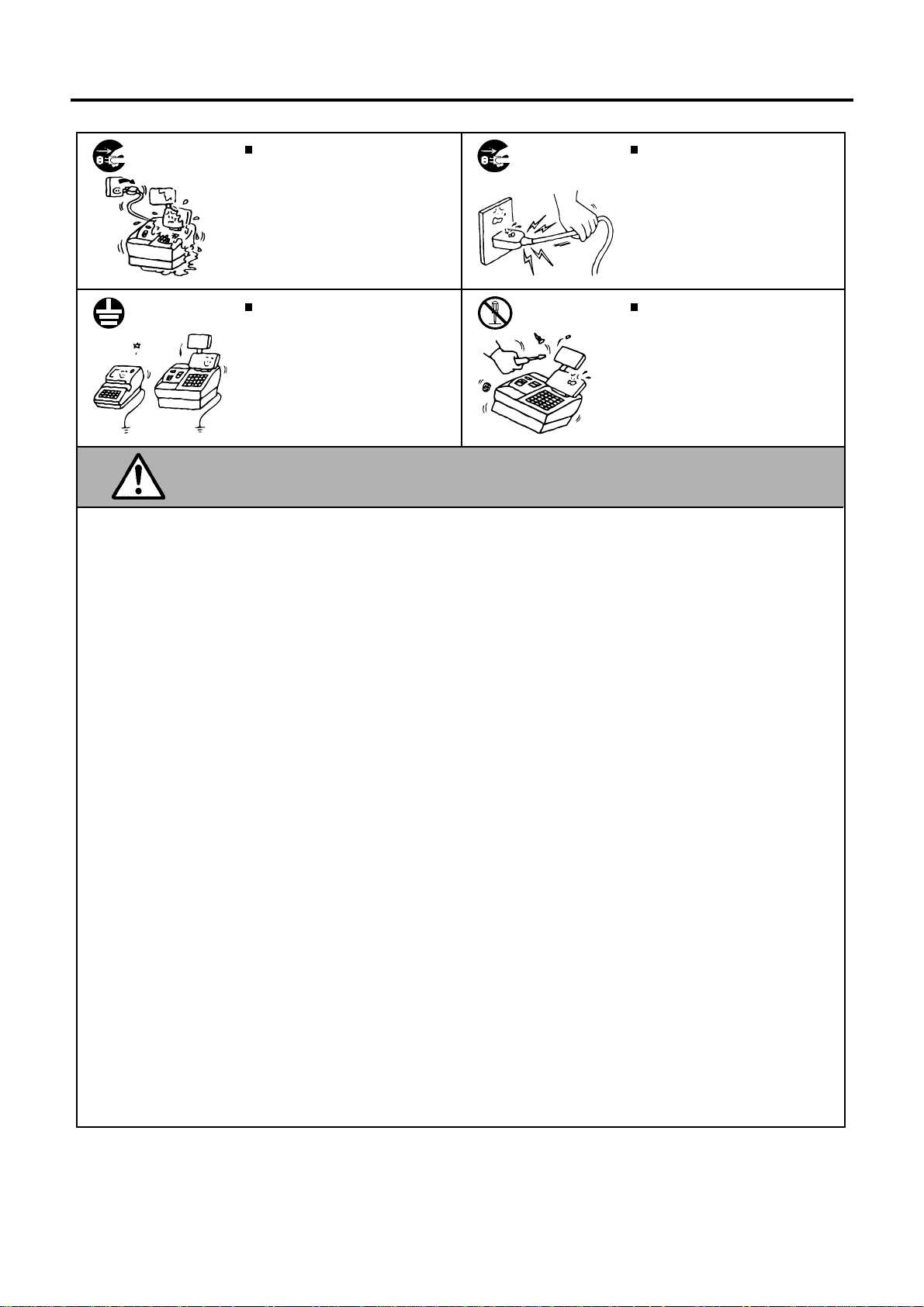

(i)

Disconnect

the plug.

Continued use of the machines in an

abnormal condition such as when the

machines are producing smoke or

strange smells may cause fire or elec-

tric shock. In these cases, immediately turn off the power switches and

disconnect the power cord plugs from

the outlet. Then, contact your authorized TOSHIBA TEC representative for

assistance.

Safety Summary

EO1-11099

Disconnect

the plug.

Connect a

grounding

wire.

If foreign objects (metal fragments,

water, liquids) enter the machines,

first turn off the power switches and

disconnect the power cord plugs from

the outlet, and then contact your

authorized TOSHIBA TEC representative for assistance. Continued

use of the machine in that condition

may cause fire or electric shock.

Ensure that the equipment is

properly grounded. Extension cables

should also be grounded. Fire or

electric shock can occur on improperly grounded equipment.

Disconnect

the plug.

No

disassembling.

When unplugging the power

cords, be sure to hold and pull on

the plug portion. Pulling on the cord

portion may cut or expose the internal wires and cause fire or electric

shock.

Do not remove covers, repair or

modify the machine by yourself. You

may be injured by high voltage, very

hot parts or sharp edges inside the

machine.

Unauthorized modification is prohibited.

This indicates that there is the risk of personal Injury or damage to

CAUTION

objects if the machines are improperly handled contrary to this indication.

Precaution

The following precautions will help to ensure that this machine will continue to function correctly.

• Try to avoid locations that have the following adverse conditions:

* Temperatures out of the specification * Direct sunlight * High humidity

* Shared power socket * Excessive vibration * Dust/Gas

• Do not subject the machine to sudden shocks.

• Do not press the keys too hard. Keys will operate correctly if they are touched lightly.

• Clean the cover and keyboard, etc. by wiping with a dry cloth or a cloth soaked with detergent and wrung out

thoroughly. Never use thinner or other volatile solvent for cleaning.

• At the end of the day, turn the power OFF, then clean and inspect the exterior of the machine.

• Try to avoid using this equipment on the same power supply as high voltage equipment or equipment likely to

cause mains interference.

• USE ONLY TOSHIBA TEC SPECIFIED consumables.

• DO NOT STORE the consumables where they might be exposed to direct sunlight, high temperatures, high

humidity, dust, or gas.

• When moving the machine, take hold of the drawer and lift the machine.

• Do not place heavy objects on top of the machines, as these items may become unbalanced and fall causing

injury.

• Do not block the ventilation slits of the machines, as this will cause heat to build up inside the machines and

may cause fire.

• Do not lean against the machine. It may fall on you and could cause injury.

Request Regarding Maintenance

• Utilize our maintenance services.

After purchasing the machines, contact your authorized TOSHIBA TEC representative for assistance once per year or

so to have the inside of the machines cleaned. Otherwise, dust will build up inside the machines and may cause fire or

malfunction. Cleaning is particularly effective before humid rainy seasons.

• Our maintenance service performs the periodic checks and other work required to maintain the quality and

performance of the machines, preventing accidents beforehand.

For details, please consult your authorized TOSHIBA TEC representative for assistance.

• Using insecticides and other chemicals

Do not expose the machines to insecticides or other volatile solvents, as this will deteriorate the cabinet or other parts

or cause the paint to peel.

(ii)

EO1-12027

TABLE OF CONTENTS

Page

1. INTRODUCTION ......................................................................................................................... 1-1

1.1 Applicable Model ................................................................................................................ 1-1

1.2 Accessor ies ........................................................................................................................ 1-2

2. SPECIFICATIONS ....................................................................................................................... 2-1

2.1 Basic Specifications............................................................................................................ 2-1

2.2 Option ................................................................................................................................. 2-2

2.3 Receipt/Journal Paper Roll for the Dot Printer.................................................................... 2-3

2.4 Thermal Paper Roll for the Thermal Printer ........................................................................ 2-4

3. OVERVIEW.................................................................................................................................. 3-1

3.1 Front/Rear View .................................................................................................................. 3-1

3.2 Control Lock and Mode Selector Keys................................................................................ 3-3

3.3 Operation Panel.................................................................................................................. 3-3

4. FLOPPY DISK AND FLOPPY DISK DRIVE (with FDD Model) ................................................. 4-1

4.1 Floppy Disk Write Protection .............................................................................................. 4-1

4.2 Handling the Floppy Disk Drive .......................................................................................... 4-1

5. HANDLING OF THE PRINTER (2-station Dot Printer Type) ..................................................... 5-1

5-1 Removing the Receipt Cover.............................................................................................. 5-1

5.2 Removing the Ribbon Cover............................................................................................... 5-2

5.3 Installing/Replacing the Receipt Roll .................................................................................. 5-3

5.4 Installing/Replacing the Journal Roll .................................................................................. 5-5

5.5 Setting/Replacing the Ribbon Cassette .............................................................................. 5-7

5.6 Replacing the Store Name/Message Stamp with Ink ......................................................... 5-8

6. HANDLING OF THE PRINTER (Single Station Thermal Printer Type)..................................... 6-1

6.1 When using the Auto Loading Function.............................................................................. 6-1

6.2 When using the Manual Loading Function ......................................................................... 6-3

7. DISPLAY (LIUST-51) ................................................................................................................... 7-1

8. DRAWER..................................................................................................................................... 8-1

8.1 Manual Drawer Release and Lock...................................................................................... 8-1

8.2 Removing the Drawer ......................................................................................................... 8-2

8.3 Locking the Cash Drawer Cover (CDC).............................................................................. 8-2

8.4 Changing the Layout of the Money Case............................................................................ 8-2

8.5 Media Slot........................................................................................................................... 8-4

9. GENERAL MAINTENANCE........................................................................................................ 9-1

9.1 Cleaning ............................................................................................................................. 9-1

10. TROUBLESHOOTING .............................................................................................................. 10-1

1. INTRODUCTION

1.1 Applicable Model

EO1-12027

1. INTRODUCTION

Thank you for purchasing the TOSHIBA TEC ST-6400 Series POS Terminal.

This POS Terminal contains all the high performance register functions necessary for a specialty store POS terminal

and enables the user oriented system configuration. By adopting a high-speed CPU (CeleronTM 566MHz), memory with

large capacity, and magnetic device, this POS Terminal flexibly accepts the modification corresponding to the future

system environment as the user expects.

This manual describes the functions and handling of this POS terminal and should be read carefully to help gain

maximum performance and life from your POS terminal.

For most queries please refer to this manual and keep it safe for future reference.

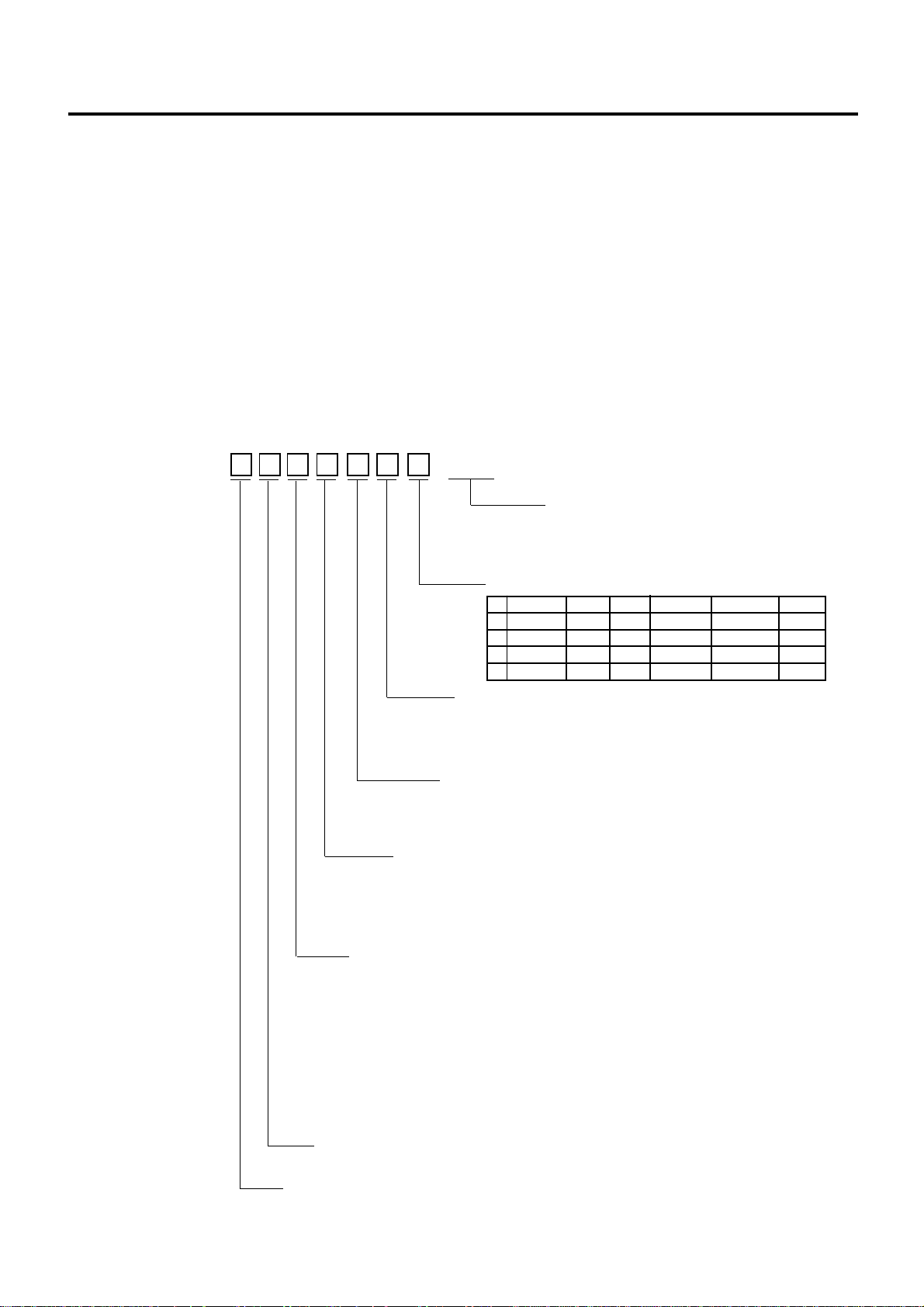

1.1 Applicable Model

Model Name Description

ST-6401- -QM

Printer Type

1: 2-station dot printer (58 mm)

S: Single station thermal printer (80 mm)

4: 2-station dot printer (58 mm)

7: 2-station dot printer (58 mm)

A: 2-station dot printer (45 mm)

CPU Frequency

5: 566 MHz

CPU Type

C: Celeron

TM

Destination Code (Country/Region)

QM: Standard for worldwide

Internal Construction

Memory HDD FDD SIO1,2 NVRAM USB

1 64MB No No No No Yes

5 64MB No No Yes No Yes

A 64MB No Yes No 128KB Yes

B 64MB No Yes No No Yes

Packing (Drawer)

N: None

4: With ESP Drawer (MC-4 type)

8: With ESP Drawer (MC-8 type)

Packing (Display)

N: None

P: With Pole

R: With Remote Indicator Unit + Pole

Keyboard Type

0: Normal keyboard (1x1 keys only)

1: Flat keyboard

2: Combination keyboard

3: Normal Keyboard (12 double keys)

Single validation/full cut

Multi validation/full cut

Multi validation/full & stub cut

Multi validation/full & stub cut

1-1

1. INTRODUCTION

EO1-12027

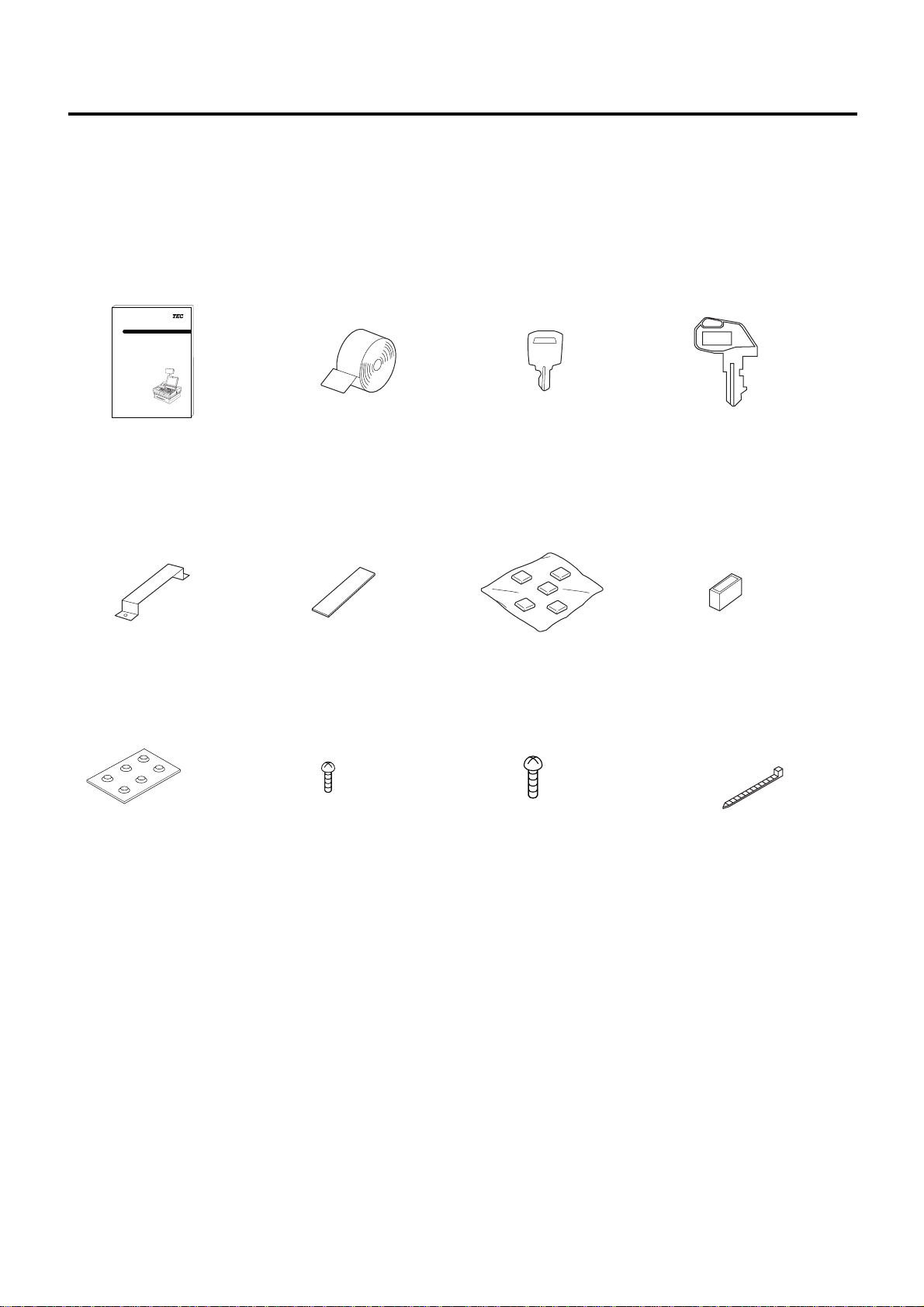

1.2 Accessories

1.2 Accessories

Confirm that all the following Accessories are contained in the carton. If any accessories are missing or damaged,

contact your nearest TOSHIBA TEC service representative.

• Accessories common to the all models

TEC POS Terminal

ST-6400 SERIES

Owner's Manual

TEC

TOSHIBA TEC CORPORATION

TEC

Owner’s Manual (1 pc.)

MCR Stay (1 pc.)

Rubber Foot (6 pcs.)

Paper Roll

2 pcs. : Dot Printer

(

1 pc. : Thermal Printer

Top Dummy Cover (4 pcs.)

Bind Screw M3x6

(4 pcs.)

(Used to secure the FDD)

FDD Cover Key

(1 set: 2 keys)

)

Key Cap Set

(1x1: 66 caps/Keyboard type :0)

(1x1:42 caps,1x2:12 caps/Key-

board type :3)

Bind Unify Screw No.6x4.5

(8 pcs.)

(Used to secure the HDDs)

Mode Selector Key Set (1 set)

REG, X, MA, S keys;

2 keys respectively

Short Plug (1 pc.)

Fasten Band (1 pc.)

(Used to secure the

Display Cable)

1-2

1. INTRODUCTION

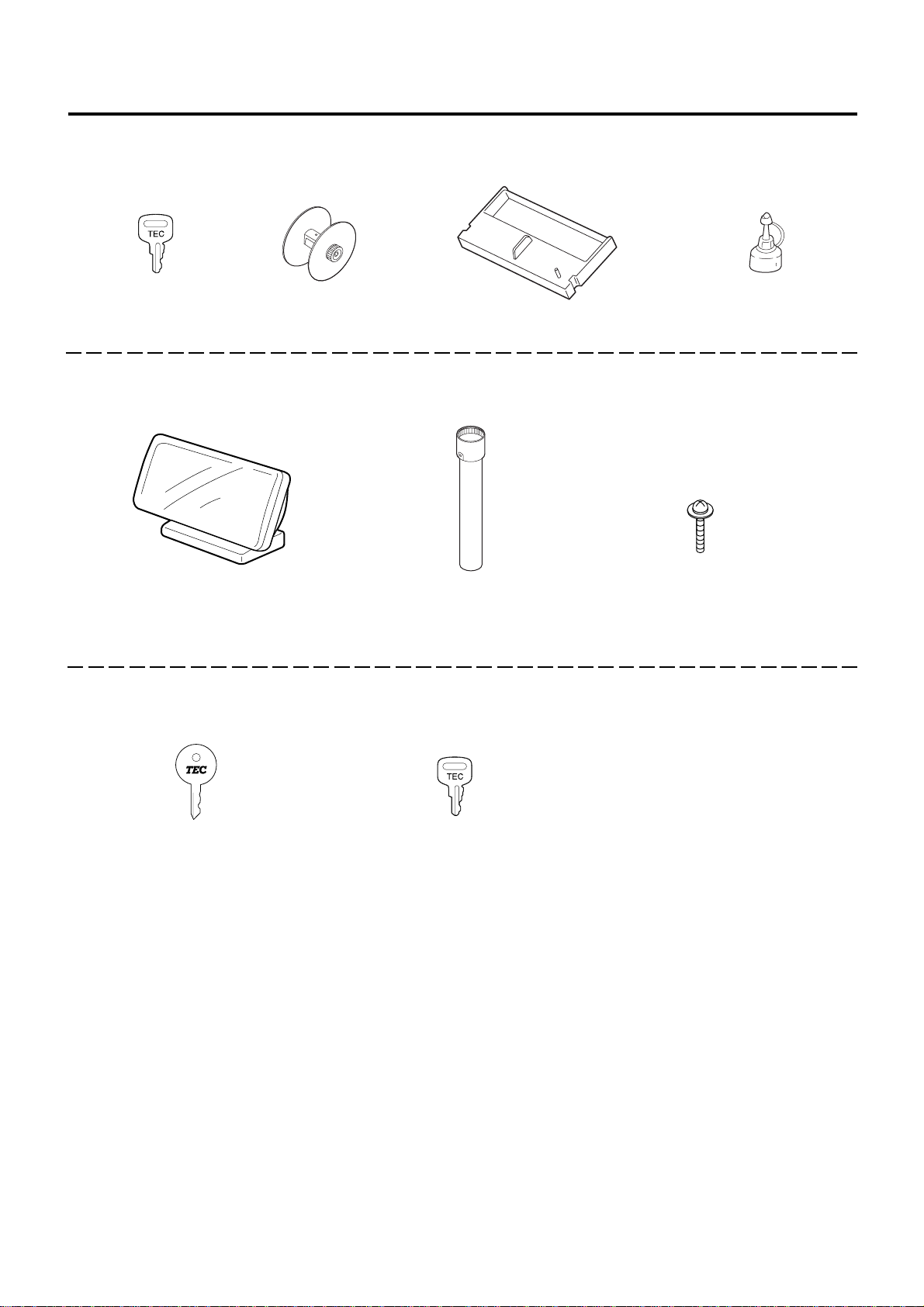

• Only for the model including the Dot Printer

EO1-12027

1.2 Accessories

Receipt Cover Key

Take-up Reel (1 pc.)

Ribbon Cassette (1 pc.)

(1 set: 2 keys)

• Only for the model including the Display Unit as standard

Display Unit (1 pc.)

Pole Unit (1 pc.)

• Only for the model including the Drawer Unit as standard

Stamp Ink (1 pc.)

Double Sems Screw M3x45

(2 pcs.)

(Used to secure the Pole Unit

to the Drawer)

Drawer Release Key

(1 set: 2 keys)

Cash Drawer Cover Key

(1 set: 2 keys)

1-3

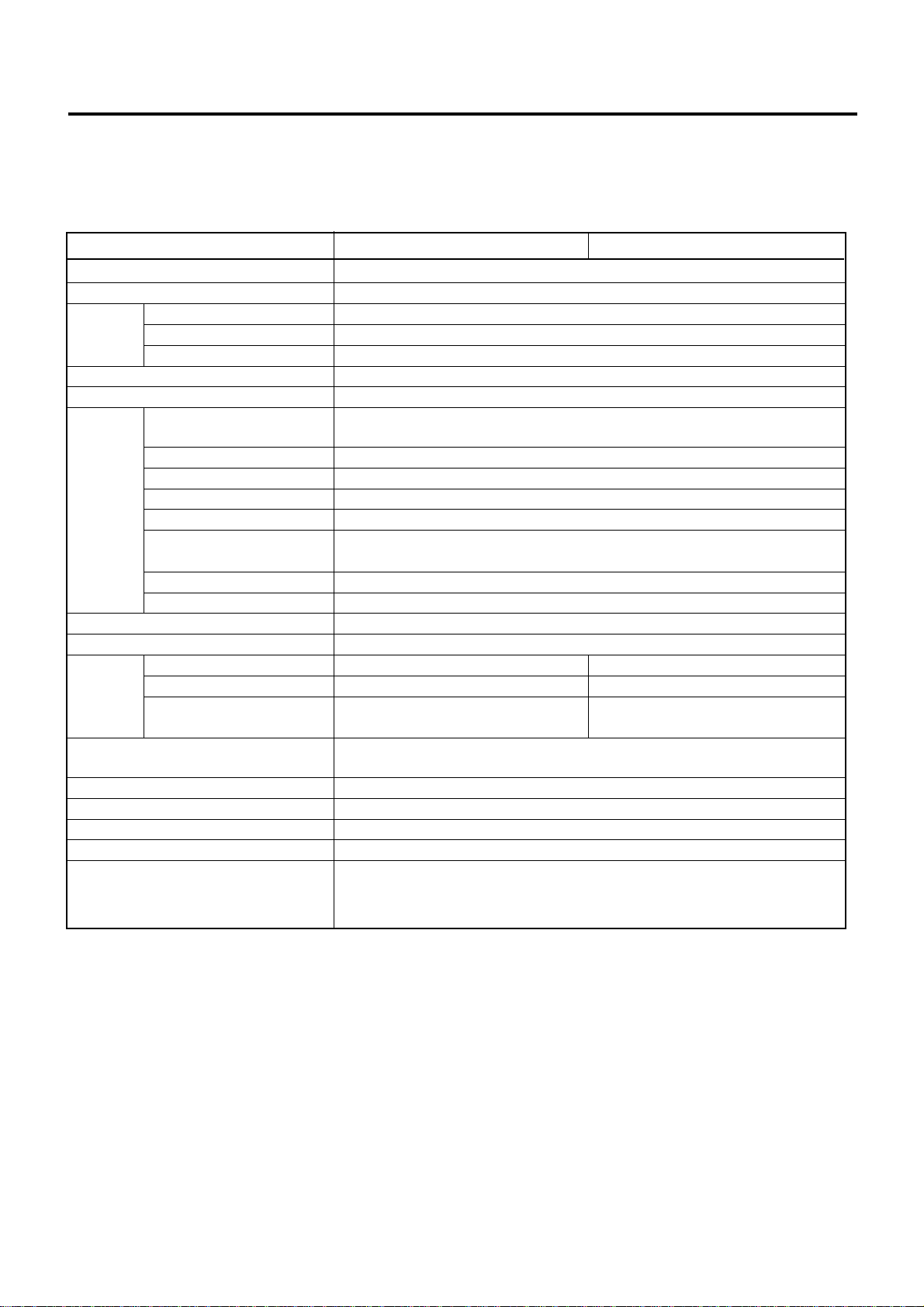

2. SPECIFICATIONS

2.1 Basic Specifications

EO1-12027

2. SPECIFICATIONS

2.1 Basic Specifications

ST-6401-C51/4/7/AXXXX-QM ST-6401-C5SXXXX-QM

CPU Celeron™ 566MHz

BIOS ROM 512KB Flash ROM

Capacity 64MB as standard, expandable up to 512MB

RAM Type SDRAM, non parity bit, without ECC, PC100 or more

Socket 168-pin DIMM connector x 2 slots

Secondary Cache 128KB (CPU on die)

PCI Bus Up to two PCI standard boards can be installed

Interface Serial I/F

Parallel I/F LPT: D-sub 25-pin female connector

Keyboard I/F PS-2 interface: 1 channel

Mouse I/F PS-2 interface: 1 channel

Drawer I/F TEC standard 24V drawer: 2 channels

VGA I/F (Analogue RGB) VGA Controller: Intel® 82810E built-in (Directly AGP connection)

LAN I/F IEEE802.3 10BASE-T/100BASE-TX

USB I/F USB1 and USB2: 2 channels

Floppy Disk Drive One 3.5-inch FDD (1.44MB/720KB format)

Hard Disk Drive 3.5-inch, IDE I/F ( Dealer option)

Printer Printer Model DPR-245A or 258A series LT-380

Printing Method 2-station dot matrix Line Thermal Direct

Roll Paper Width 45mm (DPR-245A) 80mm

Input Voltage AC: 100 - 127V +5%/-10%, 50/60 Hz

Power Consumed 180W

Ambient Temperature 5°C to 35°C

Relative Humidity 20% to 80% (no condensation)

Weight 12Kg (excluding options)

Dimension Dot Printer Model : 493(W) x 469(D) x 199.5(H) mm without Drawer

(NOTE 3)

COM1, COM2 : D-sub 9-pin male connector

COM3, COM4, SIO1, SIO2 : D-sub 9-pin female connector

Video Memory: The system memory used

58mm (DPR-258A)

220 - 240V +10%/-10%, 50/60 Hz

Dot Printer Model : 493(W) x 469(D) x 305 (H) mm with Drawer

Thermal Printer Model : 493(W) x 469(D) x 192.5(H) mm without Drawer

(NOTE 2)

(NOTE 4)

NOTES: 1 ) Celeron™ is a registered trade mark of Intel Corporation.

2) Board size (Lower Slot): 140mm (One board)

Board size (Upper Slot): 185mm (One board)

3) Some models are provided with the SIO1 and SIO2 as standard.

4) Some models are provided with the 3.5" FDD as standard.

2-1

2. SPECIFICATIONS

2.2 Option

Option Name Type Description

Drawer Unit DRWST-64 Series 24V-drive ESP type drawer

Size and Weight: 460(W) x 400(D) x 115(H) mm 8.6Kg

Remote LIUST-51 Series 20 characters x 2 lines dot display

Display Unit LIUST-53 Series 256 x 64 dot display

Scanner HS-530-RS Series Touch scanner (RS-232C Interface Type)

Unit LS-770 Series Vertical laser slot scanner

LS-770-H Series Horizontal laser slot scanner

LS-780 Series Vertical laser slot scanner

LS-780-H Series Horizontal laser slot scanner

FDD FDDST-51 3.5-inch 1.44MB FDD Unit

NV-RAM NVMST-50-32 32KB NV-RAM

NVMST-50-128 128KB NV-RAM

Pole Option POLST-51 Pole type mounting kit for the LIUST-51/53

MCR MCRST-50 Magnetic Card Reader for Normal keyboard type

Display TFTST-52T 10.4-inch TFT Display with touch panel (without VGA board)

TFTST-56T 12.1-inch TFT Display with touch panel (with VGA board)

VGA Board VGAST-52-12 VGA board for the TFTST-52T

Plate KITST-65-1 VGA board attachment plate for the TFTST-52T

KITST-65-2 VGA board attachment plate for the TFTST-56T

EO1-12027

2.2 Option

2-2

2. SPECIFICATIONS

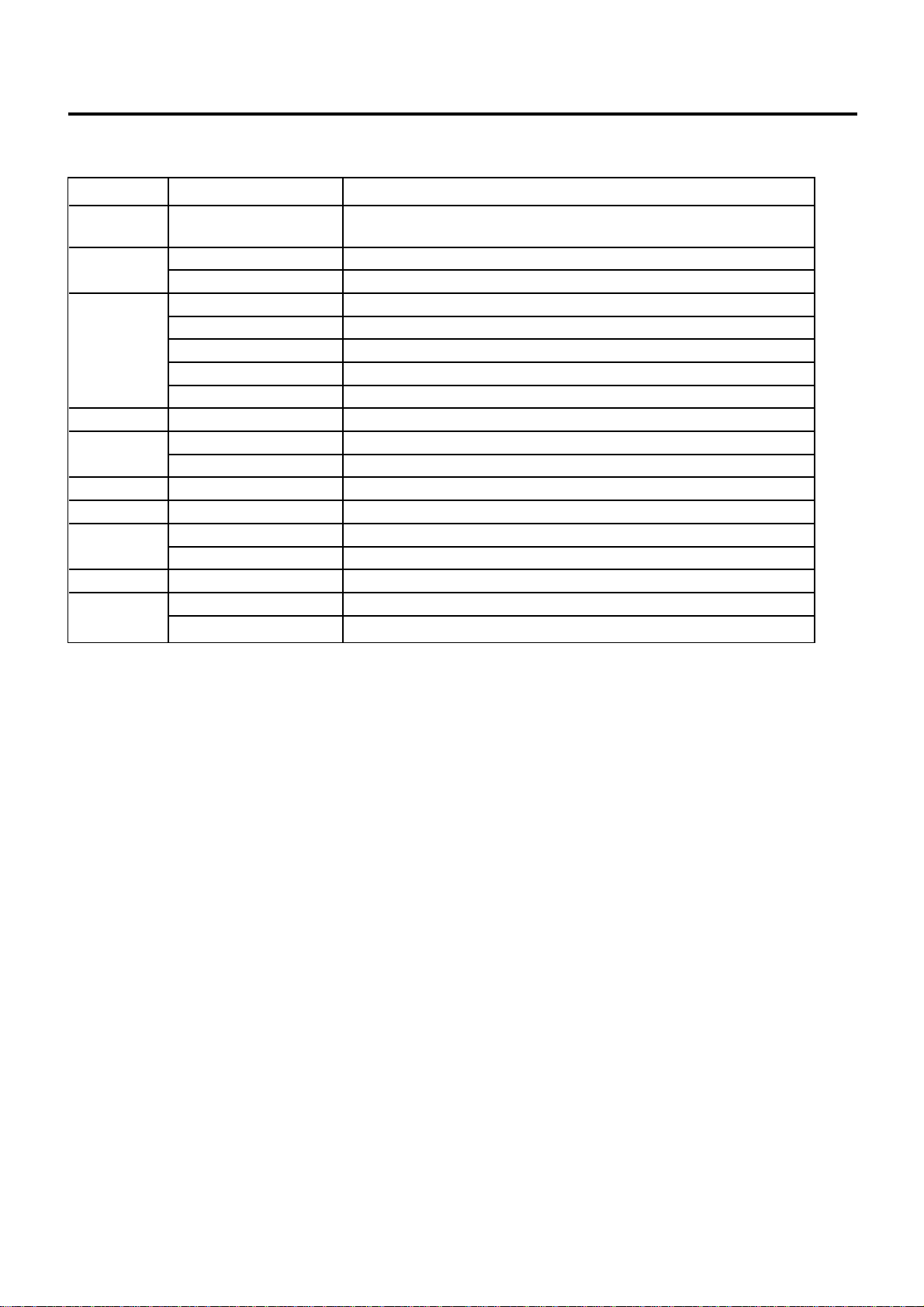

2.3 Receipt/Journal Paper Roll for the Dot Printer

Width (W)

Paper

thickness (T)

EO1-12027

2.3 Receipt/Journal Paper Roll for the Dot Printer

Inner core

diameter (ID)

Outer

diameter (D)

Outer core

diameter (OD)

Paper Type Paper rolled with the print side facing outside.

Width (W) 45 +0/-1 mm (DPR-245A Series) 58 +0/-1 mm (DPR-258A Series)

Outer diameter (D) 80 mm

Paper thickness (T) 0.083 ±0.005 mm

Weight 54.3±2g/m

2

Outer core diameter (OD) 25 mm

Inner core diameter (ID) 18 +0/-0.5 mm

Recommended paper 45R-80 (MHG01-00105/06) TOSHIBA TEC (DPR-245A Series)

58R-80 (MHG01-00109/10) TOSHIBA TEC (DPR-258A Series)

CAUTION!

Use only paper which meet specified requirements. Use of non-specified paper may shorten the head life of printer,

result in problems with print quality, or cause a paper feed failure.

All paper should be handled with care to avoid any damage to the paper. Read the following guideline carefully.

• Do not store the paper for longer than the manufacture’s recommended shelf life.

• Store the paper in a cool, dry place. Avoid areas where they would be exposed to direct sunlight, high temperature,

high humidity, dust or gas.

For further information please contact your authorised TOSHIBA TEC represrntative or authorised paper manufacturer.

2-3

2. SPECIFICATIONS

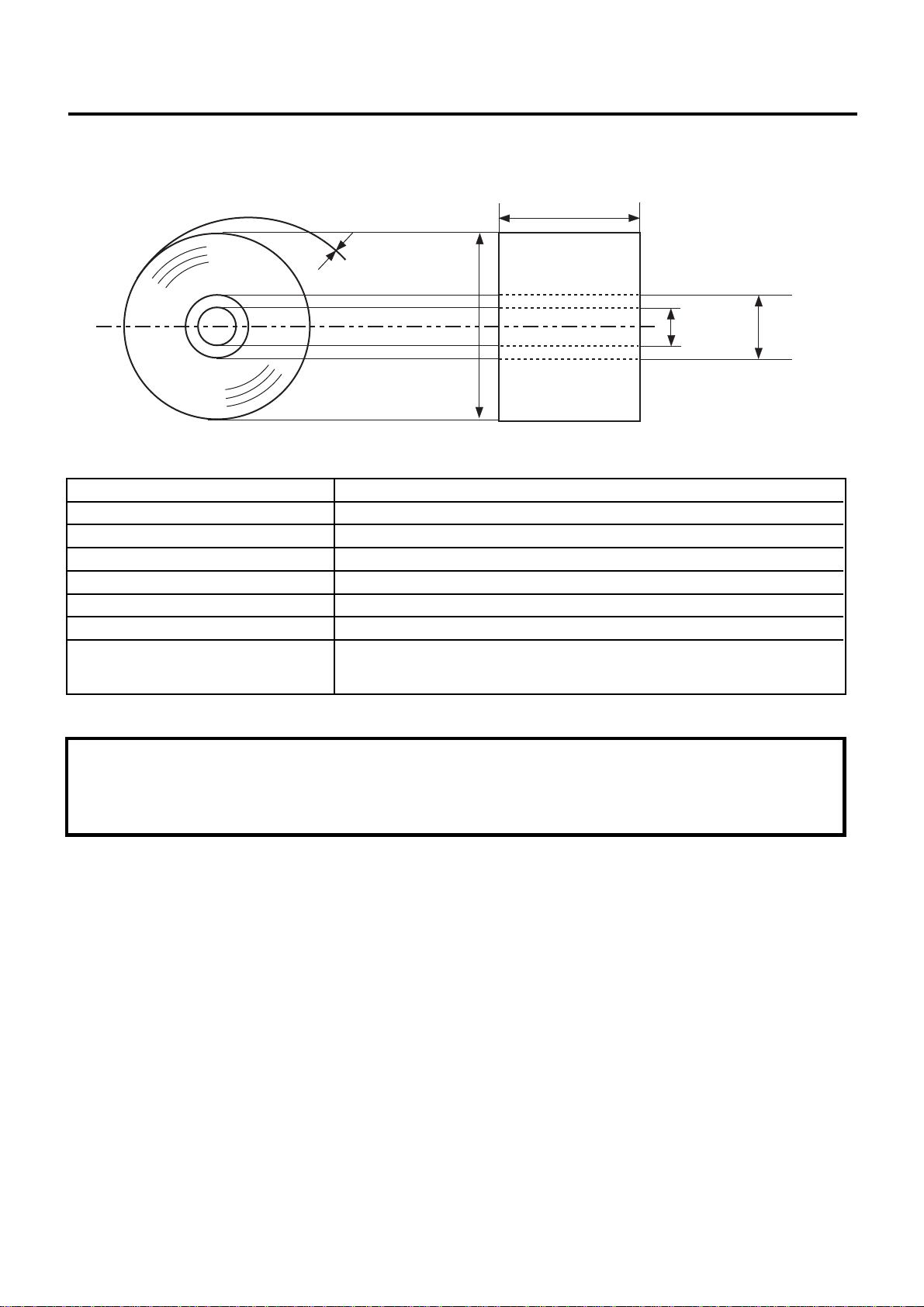

2.4 Thermal Paper Roll for the Thermal Printer

Width (W)

Paper

thickness (T)

EO1-12027

2.4 Thermal Paper Roll for the Thermal Printer

Inner core

diameter (ID)

Outer

diameter (D)

Outer core

diameter (OD)

Paper Type Thermal paper rolled with the print side facing outside.

Width (W) 80 +0/-1 mm

Outer diameter (D) 80 +0.5/-1 mm

Paper thickness (T) 0.075 ±0.005 mm

Weight 69±3g/m

2

Outer core diameter (OD) 18 mm

Inner core diameter (ID) 12 mm

Recommended Thermal paper Paper rolled onto a core are acceptable, however, the paper end should

not be pasted to the core.

Normal paper: PD150R OHJI PAPER (Japan)

Highly storable paper: PD152R OHJI PAPER (Japan)

CAUTION!

Use only paper which meet specified requirements. Use of non-specified paper may shorten the head life of printer,

result in problems with print quality, or cause a paper feed failure.

All paper should be handled with care to avoid any damage to the paper. Read the following guideline carefully.

• Do not store the paper for longer than the manufacture’s recommended shelf life.

• Store the paper in a cool, dry place. Avoid areas where they would be exposed to direct sunlight, high temperature,

high humidity, dust or gas.

• A contact of chemical or oil may discolor or erase the record.

• Rubbing the paper hard with nail or hard metal may discolor the paper.

For further information please contact your authorised TOSHIBA TEC represrntative or authorised paper manufacturer.

2-4

3. OVERVIEW

3. OVERVIEW

3.1 Front/Rear View

EO1-12027

3.1 Front/Rear View

<Front View>

Journal Window

Receipt Outlet

Validation Slot

Ribbon Cover

Receipt Cover

Remote Indicator Unit

TFT Display (option)

Operation Panel

Control Lock

PC Keyboard Connector

Magnetic Card Reader (option)

(see NOTE 2 below)

Drawer

(see NOTE 3 Below)

HDD Active LED

Power Switch

3.5" FDD

Keyboard

(see NOTE 4 below)

NOTES: 1) The above figure shows 2-station dot printer type.

2) Some models are provided with the Remote Indicator Unit as standard.

3) Some models are provided with the Drawer as standard.

4) Some models are provided with the 3.5" FDD as standard.

5) As the power cord is not provided for this product, please purchase it locally. For detail specifications,

please contact your nearest authorised TOSHIBA TEC representative.

6) A 3.5-inch hard disk drive is optional part for the ST-6400 standard models.

Power Cord

(see NOTE 5 below)

3-1

3. OVERVIEW

<Rear View>

EO1-12027

3.1 Front/Rear View

AC Outlet

Cable Clamp for LAN Cable

DRW2 DRW1

LAN LAN LED

Reset Switch

AC IN

P24V

SIO2

MOUSE LPT1

KB COM1COM3COM4

USB 1

USB 2

SIO1

PCI Slot

PCI Slot

VGA

COM2

Speaker Volume

AC Outlet Connector for the AC outlet, used for the CRT power supply.

AC Inlet Connector for the AC inlet.

P24V To this DC24V line connector, the power cable of the printer installed in the ST-6400

is connected.

DRW1·2 A 24V type drawer (DRWST-64, etc) is connectable. The drawer included in the ST-

6400 as standard is connected to the DRW1.

MOUSE Connector for the PS-2 type mouse.

KB To this connector, the PS-2 type keyboard installed in the ST-6400 is connected.

COM1 D-sub 9-pin male type connector (without power supply). The LS-770/780 slot scanner,

modem, serial Interface type scale, EFT, etc. are connectable.

COM2 D-sub 9-pin male type connector (without power supply). The LS-770/780 slot scanner,

modem, serial Interface type scale, EFT, etc. are connectable.

COM3 D-sub 9-pin female type connector (with +5V, +12V output). The LIUST-51/53, RS-

232C type hand scanner (HS-530) are connectable.

COM4 D-sub 9-pin female type connector (with +5V, +12V output). The LIUST-51/53, RS-

232C type hand scanner (HS-530) are connectable.

SIO1·2 Equivalent to COM3 and COM4 (D-Sub 9-pin female).

VGA Connector for the CRT.

LPT1 This is a Centronics interface connector, to which the printer cable of the PC standard

printer installed in the ST-6400 is connected.

USB 1, 2 Connector for the USB(Universal Serial Bus) I/F. USB Mouse, USB Keyboard, etc. can

be connected to these connectors.

LAN Modular type connector for the 10BASE-T/100BASE-TX LAN interface.

Speaker Volume Used to adjust the speaker volume. When turned to left, the sound volume decreases.

When turned to right, the sound volume increases.

Reset Switch Pressing this switch while the ST-6400 is hung-up resets the unit.

PCI Slot Slots for installing the PCI board. Maximum of 2 boards can be installed.

Installable board size: Lower slot (PCI1) 140 mm 1 board

Upper slot (PCI2) 185 mm 1 board

Cable Clamp for The LAN cable is fixed with this cable clamp to prevent the cable being caught in the

LAN Cable Rear Cover.

3-2

3. OVERVIEW

3.2 Control Lock and Mode Selector Keys

Control Lock Mode Selector Keys

S

MA

EO1-12027

3.2 Control Lock and Mode Selector Keys

X

REG

1

(8) (7)

4

3

2

5

6

3.3 Operation Panel

3.3.1 2-station Dot Printer Type

ST-6400

* The key can be inserted or removed at Position 1 or 2.

JOURNAL

RECEIPT

PAPER OUT VALI

MA Key S Key

MA

RECEIPT

FEED

JOURNAL

S

REG Key

PRINTER

REG

POWER

X Key

X

POWER LED: Green

Lights: The power is supplied.

Extinguished: The power is not supplied.

PRINTER LED: Green

Lights: The printer is ready to print. (on-line mode)

Extinguished: The printer is not ready to print. (off-line mode)

VALI LED: Green

Lights: Validation mode

Extinguished: Receipt/journal mode

Blinks: Waiting for validation paper.

RECEIPT/JOURNAL PAPER OUT LED: Red

Lights: Detects that receipt/journal paper has almost run out.

Extinguished: Not detect that receipt/journal paper has almost run out. (Usual status)

PRINTER Switch

This switch is used to select on-line or off-line. In on-line mode, printing is performed in usual mode.

When off-line mode is selected, the printer stops printing after printing the line being printed.

RECEIPT/JOURNAL FEED Switch

This switch is used to feed receipt/journal paper. This switch is effective only when the PRINTER LED is turned

off (off-line mode).

3-3

3. OVERVIEW

3.3.2 Single Station Thermal Printer Type

EO1-12027

3.3 Operation Panel

ST-6400

ERROR

PAPER OUT

PRINTER

PAPER

FEED

POWER

POWER LED: Green

Lights: The power is supplied.

Extinguished: The power is not supplied.

PAPER FEED Switch

Pressing this switch for a short time feeds the paper by one line. Holding it down feeds the paper continuously.

ERROR LED: Red

Indicates different errors by lighting or blinking.

Error Display Pattern Resetting Method

Printer cover open Illuminated Close the cover.

Head up Illuminated CLose the printing head.

Memory check Disabled

Head overheat Automatically reset by temperature

Macro execution wait Press the PAPER FEED switch.

Cutter motorlock Remove jammed paper.

PAPER OUT LED: Red

Illuminated when the paper nearly runs out. (Stops after printing the set length)

drop.

3-4

4. FLOPPY DISK AND FLOPPY DISK DRIVE (with FDD Model)

4.1 Floppy Disk Write Protection

EO1-12027

4. FLOPPY DISK AND FLOPPY DISK DRIVE (with FDD Model)

CAUTION!

When handling a floppy disk, care should be taken as follows:

• Do not place the floppy disk close to any magnetic product.

• Do not use a damaged floppy disk.

• Do not bend the floppy disk.

• Keep the floppy disk away from water.

• Do not expose the floppy disk to direct sunlight.

4.1 Floppy Disk Write Protection

The Floppy Disk contains the program to run the ST-6400. Before using this disk, make absolutely sure to write

protect the disk to prevent accidental overwrite.

• How to Write Protect the Floppy Disk

Slide the Write Protect Tab on the reverse side of the Floppy Disk downward to open the Write Protection Hole.

Write Protection Hole

Write Enable

Wite Protect

Write Protect Tab

• How to cancel the Write Protect

Slide the Write Protect Tab upward to close the Write Protection Hole.

4.2 Handling the Floppy Disk Drive

The Floppy Disk drive reads and writes data via the Floppy Disk by rotating the disk at a high speed.

There are two read/write heads (multiple) in the drive. The heads touch both sides of the disk to perform read or write

function.

3.5-inch Floppy Disk Drive

FDD Active LED

FDD Active LED: Lit when the Floppy Disk drive reads or writes data in the Floppy Disk.

4-1

Eject Button

4. FLOPPY DISK AND FLOPPY DISK DRIVE (with FDD Model)

4.2.1. Loading the Floppy Disk

1) Unlock the FDD Cover to open by pressing the left side of the FDD Lock.

FDD Cover Key

FDD Cover

2) Insert the Floppy Disk gently with the label side up until it clicks.

EO1-12027

4.2 Handling the Floppy Disk Drive

4.2.2. Ejecting the Floppy Disk

CAUTION!

Do not press the eject button while the active LED is lit. Doing so may destroy the data in the floppy disk.

Press the Eject Button on the Floppy Disk Drive. The Floppy Disk pops out to the position where it can be

removed by hand.

Eject Button

4-2

5. HANDLING OF THE PRINTER (2-station Dot Printer Type)

5.1 Removing the Reciept Cover

EO1-12027

5. HANDLING OF THE PRINTER (2-station Dot Printer Type)

5.1 Removing the Reciept Cover

Remove the Receipt Cover when the Receipt or Journal Paper Roll is replaced with a new one or when the Store

Name/Message Stamp must be replenished with the Ink.

5.1.1 Removing the Receipt Cover

1) Insert the Cover Lock Key into the Cover Lock and turn it 90 degrees clockwise to unlock.

Receipt Cover

Cover Lock Key

2) Remove the Receipt Cover by lifting both edges of the Receipt Cover.

Receipt Cover

5.1.2 Attaching the Receipt Cover

1) Align the hooks on the rear of the Receipt Cover with the notches in the lower cover. Then, push down the front

side of the Receipt Cover until it clicks, and lock the receipt cover with the key.

Receipt Cover

5-1

Hook

5. HANDLING OF THE PRINTER (2-station Dot Printer Type)

5.2 Removing the Ribbon Cover

Remove the Ribbon Cover when the Ribbon Cassette must be replaced.

5.2.1 Removing the Ribbon Cover

1) Remove the Receipt Cover. (Refer to "Removing the Receipt Cover.")

2) Remove the Ribbon Cover by lifting the left edge of the Ribbon Cover.

Ribbon Cover

EO1-12027

5.2 Removing the Ribbon Cover

5.2.2 Attaching the Ribbon Cover

1) Align the tabs on the front of the Ribbon Cover with the holes in the Top Cover. Then, push down the rear

side of the Ribbon Cover until it clicks.

Ribbon Cover

5-2

5. HANDLING OF THE PRINTER (2-station Dot Printer Type)

5.3 Installing/Replacing the Reciept Roll

5.3.1 Installing the Receipt Roll

1) Remove the Receipt Cover. (Refer to "Removing the Receipt Cover.")

2) Cut the paper end to make it straight.

EO1-12027

5.3 Installing/Replacing the Reciept Roll

3) Put the Receipt Roll in the left holder so that the paper will be fed from the bottom of the Paper Roll.

4) Insert the paper end into the paper slot until it stops, then feed the paper by pressing the [RECEIPT FEED] Switch.

5) Attach the Receipt Cover with the paper end coming out of the receipt outlet. (Refer to "Attaching the Receipt

Cover.")

5-3

5. HANDLING OF THE PRINTER (2-station Dot Printer Type)

5.3.2 Replacing the Receipt Roll

1) Remove the Receipt Cover. (Refer to "Removing the Receipt Cover.")

2) Pull up the Green Lever on the receipt side.

Green Lever

EO1-12027

5.3 Installing/Replacing the Reciept Roll

3) Remove the remaining paper roll from the rear of the printer.

4) Press down the green lever on receipt side.

Green Lever

5) Install a new paper roll according to steps 2) to 5) of the procedure "Installing the Receipt Roll."

5-4

5. HANDLING OF THE PRINTER (2-station Dot Printer Type)

5.4 Installing/Replacing the Journal Roll

5.4 Installing/Replacing the Journal Roll

5.4.1 Installing the Journal Roll

1) Follow Steps 1) and 2) for "Installing the Receipt Roll" in the preceding section.

2) Put the Journal Roll in the right holder so that the paper will be fed from the bottom of the Paper Roll.

EO1-12027

3) Insert the paper end into the paper slot until it stops, then feed the paper by pressing the [JOURNAL FEED]

Switch until the leading edge of the journal comes out about 25 cm.

4) Insert the paper end into the slit in the Take-up Reel and wind it around the reel two or three times. Then, place

the Take-up Reel on the Take-up Holder.

Take-up Reel

Take-up Reel

Take-up Holder

5) Turn the Take-up Reel rearward until slack in paper is taken out.

6) Attach the Receipt Cover. (Refer to "Attaching the Receipt Cover.")

5-5

5. HANDLING OF THE PRINTER (2-station Dot Printer Type)

5.4 Installing/Replacing the Journal Roll

5.4.2 Replacing the Journal Roll

1) Remove the Receipt Cover. (Refer to "Removing the Receipt Cover.")

2) Cut the Journal Paper as shown in the figure.

3) Pull up the Green Lever on the journal side ( 1 ). Lift the Take-up Reel to remove paper ( 2 ).

EO1-12027

4) Press down the Green Lever on journal side.

Take-up Reel

Green Lever

2

1

Green Lever

5) Install a new paper roll according to steps 1) to 6) of the procedure "Installing the Journal Roll."

5-6

5. HANDLING OF THE PRINTER (2-station Dot Printer Type)

5.5 Setting/Replacing the Ribbon Cassette

EO1-12027

5.5 Setting/Replacing the Ribbon Cassette

5.5.1 Setting the Ribbon Cassette

1) Remove the Receipt Cover and the Ribbon Cover. (Refer to "Removing the Receipt Cover." and "Removing the

Ribbon Cover.")

2) Push down the Ribbon Cassette until it clicks.

Ribbon Cassette

3) Turn the knob of the Ribbon Cassette in the direction of the arrow several times to remove any slack in the ribbon.

Ribbon Cassette

Knob

4) Attach the Ribbon Cover and the Receipt Cover. (Refer to "Attaching the Ribbon Cover." and "Attaching the

Receipt Cover.")

5.5.2 Replacing the Ribbon Cassette

1) Remove the Receipt Cover and the Ribbon Cover. (Refer to "Removing the receipt cover." and "Removing the

Ribbon Cover.")

2) Remove the old Ribbon Cassette by lifting if from the right front side so that it does not make contact with the Top

Cover.

Ribbon Cassette

3) Set a new Ribbon Cassette according to steps 2) to 4) of the procedure "Setting the Ribbon Cassette."

5-7

5. HANDLING OF THE PRINTER (2-station Dot Printer Type)

5.6 Replenishing the Store Name/Message Stamp with Ink

EO1-12027

5.6 Replenishing the Store Name/Message Stamp with Ink

When the Store Name/Message Stamp is installe and printing appears too light, replenish the ink in the following

procedure.

1) Remove the Receipt Cover. (Refer to "Removing the Receipt Cover.")

2) Remove the Store Name/Message Stamp by pulling it as shown in the figure.

Store Name/Message Stamp

3) Apply only two or three drops of ink. The stamp may not print dark immediately. Allow time for ink to saturate

the stamp.

Stamp Ink

Store Name/Message Stamp

4) Install the stamp by inserting it in the direction of the arrow until it clicks.

Store Name/Message Stamp

5-8

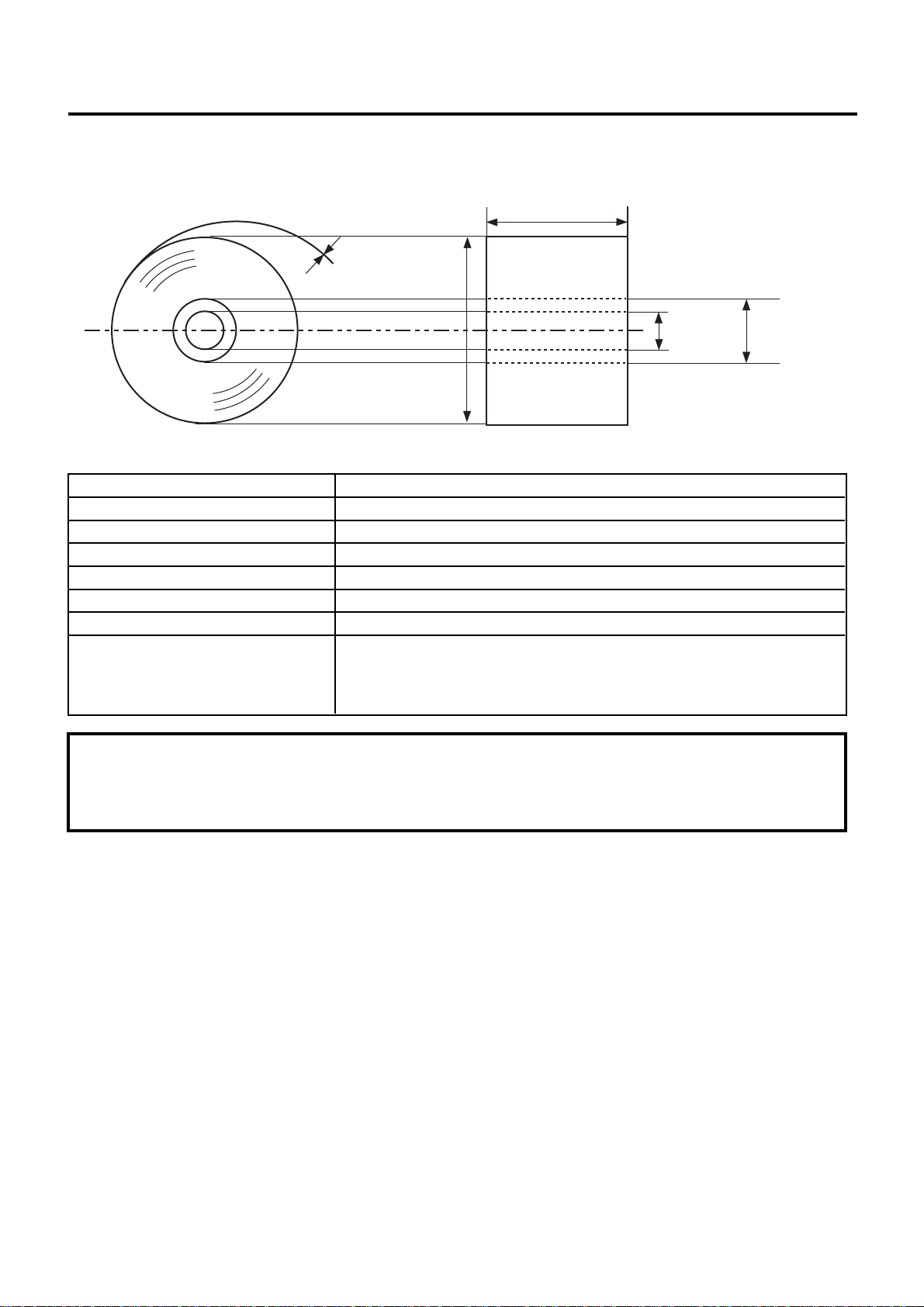

6. HANDLING OF THE PRINTER (Single Station Thermal Printer Type)

6.1 When using the Auto Loading Function

EO1-12027

6. HANDLING OF THE PRINTER

(Single Station Thermal Printer T ype)

A thermal receipt printer is provided on this unit. (A thermal printer prints thermal receipt paper by applying heat to

the paper to react with the chemicals on the paper surface.)

WARNING!

1. There is a Cutter Blade inside. Do not touch and disassemble this cutter block.

2. After printing, the thermal head may become very hot. Do not touch the thermal head to

avoid burning your fingers.

CAUTION!

1. Do not subject the thermal receipt paper to water, oil, or heat source as this will darken the paper.

2. Do not open the printer cover during printing.

6.1 When using the Auto Loading Function

1) Open the Printer Cover.

2) Move the Head-up Lever in the direction of the arrow to raise the Printing Head.

Printer Cover

Head-up Lever

Auto Cutter

3) Cut the end of the paper straight with a pair of scissors. Do not insert the paper into the printer with its end

fluffed or bent.

Good NG

6-1

NG

NG

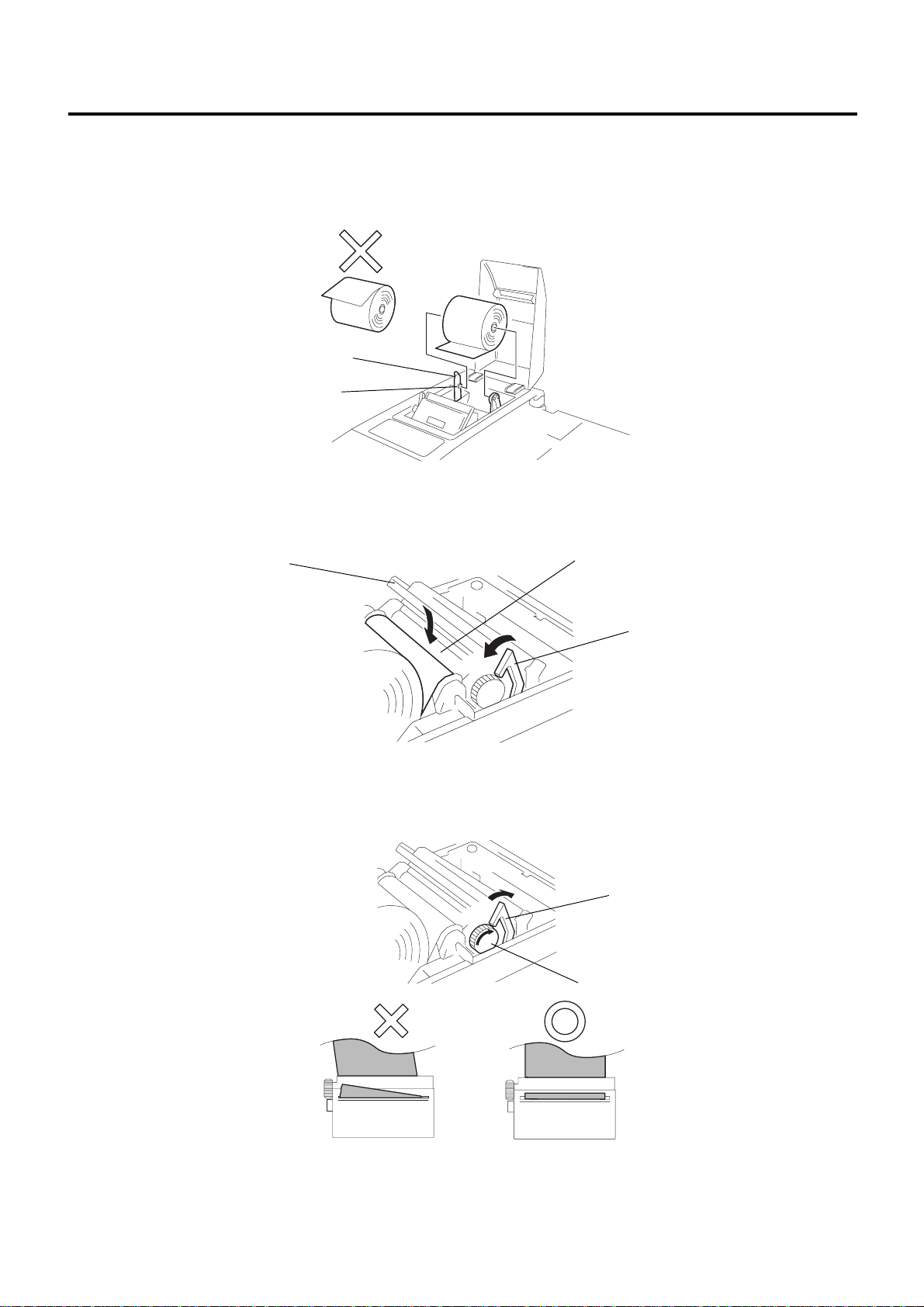

6. HANDLING OF THE PRINTER (Single Station Thermal Printer Type)

6.1 When using the Auto Loading Function

4) Confirm the winding direction of the Paper Roll. Spread the Paper Holder and fit the protrusions into the

paper core properly.

Paper Holder

Protrusion

EO1-12027

5) Insert the end of the paper straight into the paper slot of the printer and close the Printing Head. The paper

is automatically pulled in by a constant length.

Printing Head

Paper Slot

Head-up Lever

NOTE: When the inserted paper skews, remove the paper by pulling up the Head-up Lever, raising the

Printing Head, and rotating the Paper Feed Knob. Then, reinsert the paper.

Head-up Lever

6) Close the Printer Cover to finish setting of the Paper Roll.

6-2

Paper Feed Knob

6. HANDLING OF THE PRINTER (Single Station Thermal Printer Type)

6.2 When using the Manual Loading Function

6.2 When using the Manual Loading Function

CAUTION!

Auto Loading is selected as default. If you want to change it to the manual set, please contact your nearest

TOSHIBA TEC service representative.

1) Open the Printer Cover.

2) Move the Head-up Lever in the direction of the arrow to raise the Printing Head.

Printer Cover

Head-up Lever

Auto Cutter

EO1-12027

3) Insert the end of the paper into the Paper Slot, turn the Paper Feed Knob in the direction of the arrow until

the paper end comes out of the auto cutter's paper outlet for about 5cm.

Paper Slot

Paper Feed Knob

Auto Cutter

Paper Outlet

4) When the paper is tilting, correct it and close the Printing Head.

6-3

6. HANDLING OF THE PRINTER (Single Station Thermal Printer Type)

6.2 When using the Manual Loading Function

5) Move the Head-up Lever in the direction of the arrow to close the Printing Head. Cut off the surplus paper

at the edge of the paper outlet of the auto cutter.

Head-up Lever

Paper Outlet

Auto Cutter

6) Close the Printer Cover. The Paper Roll loading has been completed.

EO1-12027

7) To take out the end of the paper, pull it out straight while the Printing Head is opened.

6-4

7. DISPLAY (LIUST-51)

7. DISPLAY (LIUST-51)

EO1-12027

7. DISPLAY (LIUST-51)

This LIUST-51 is a dot fliorescent display for ANK indication with 20 digits in 2 lines, connected to the ST-6400 POS

Terminal. It has a built-in controller and connects to the Control Unit of the ST-6400 with the I/O serial interface (RS232C or equivalent). It is normally supplied as a stand type, but can be modified to a pole type which are integrated

into the ST-6400 terminal.

Stand Type

Display Section

Base

<Overview of Display Section>

Cable

Display Section

Pole Type

Neck (Ø 34mm)

POLST-51

<Display Angle Adjustment>

This line display can be adjusted in vertical (tilt) and horizontal (swivel) direction so that the operator or

customer can see it easily.

Tilt direction

10 to 42 degrees above the horizontal

level (8° x 4 steps)

Swivel direction

165 degrees on either side from the

center (15° x 22 steps)

7-1

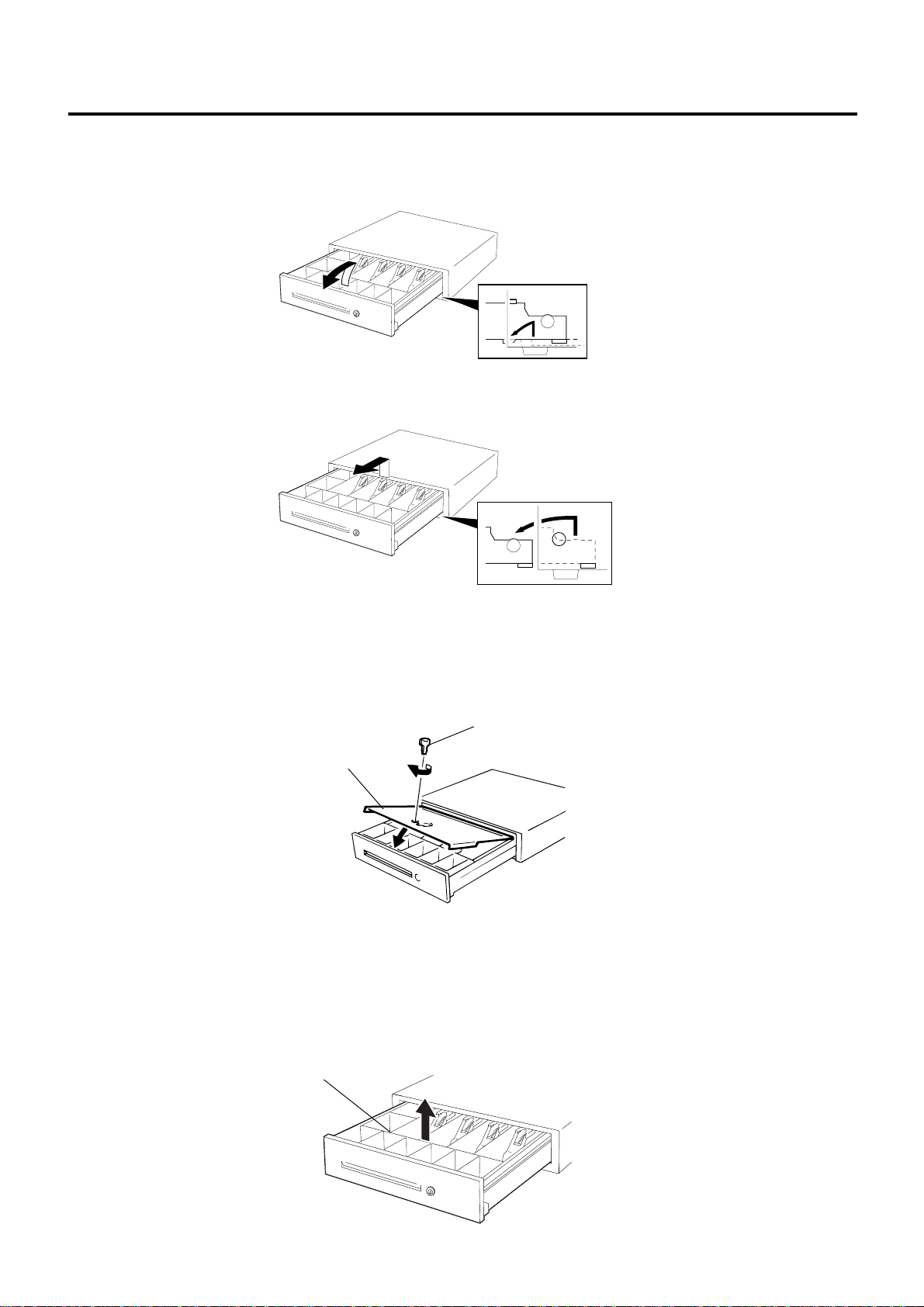

8. DRAWER

8.1 Manual Drawer Release and Lock

EO1-12027

8. DRAWER

WARNING!

When opening the drawer, be careful not to let the drawer hit any person.

This drawer can be used both as an integrated drawer into the ST-6400 terminal, and as a separate remote drawer.

Drawer Cable

Media Slot

Drawer Release Lock

8.1 Manual Drawer Release and Lock

The drawer opens automatically when a registration is performed. In the event of a power failure or other trouble, the

drawer can be opened manually in the following manner.

8.1.1 Releasing

Insert the Drawer Release Key into the Drawer Release Lock, then turn the key clockwise. The drawer will now

open. The Drawer Release Key can be taken out by returning it to the original position.

Drawer Release Key

Drawer Release Lock

8.1.2 Locking

When the drawer is closed, it is automatically locked and will not open without the Drawer Release Key or

transaction entries.

8-1

8. DRAWER

8.2 Removing the Drawer

1) Pull the drawer out, and when it stops by the stopper, lift the drawer up and pull it again.

2) When it stops again by the roller fixed in the drawer case, lift it and pull it again.

EO1-12027

8.2 Removing the Drawer

8.3 Locking the Cash Drawer Cover (CDC)

8.3.1 Locking

Push the Cash Drawer Cover to the back of the drawer. Then, press the cover lightly, insert the key into the

key hole in the cover, and turn it to lock.

Cash Drawer Cover Key

Cash Drawer Cover

8.3.2 Unlocking

Unlock the cover using the key, and lift the front end.

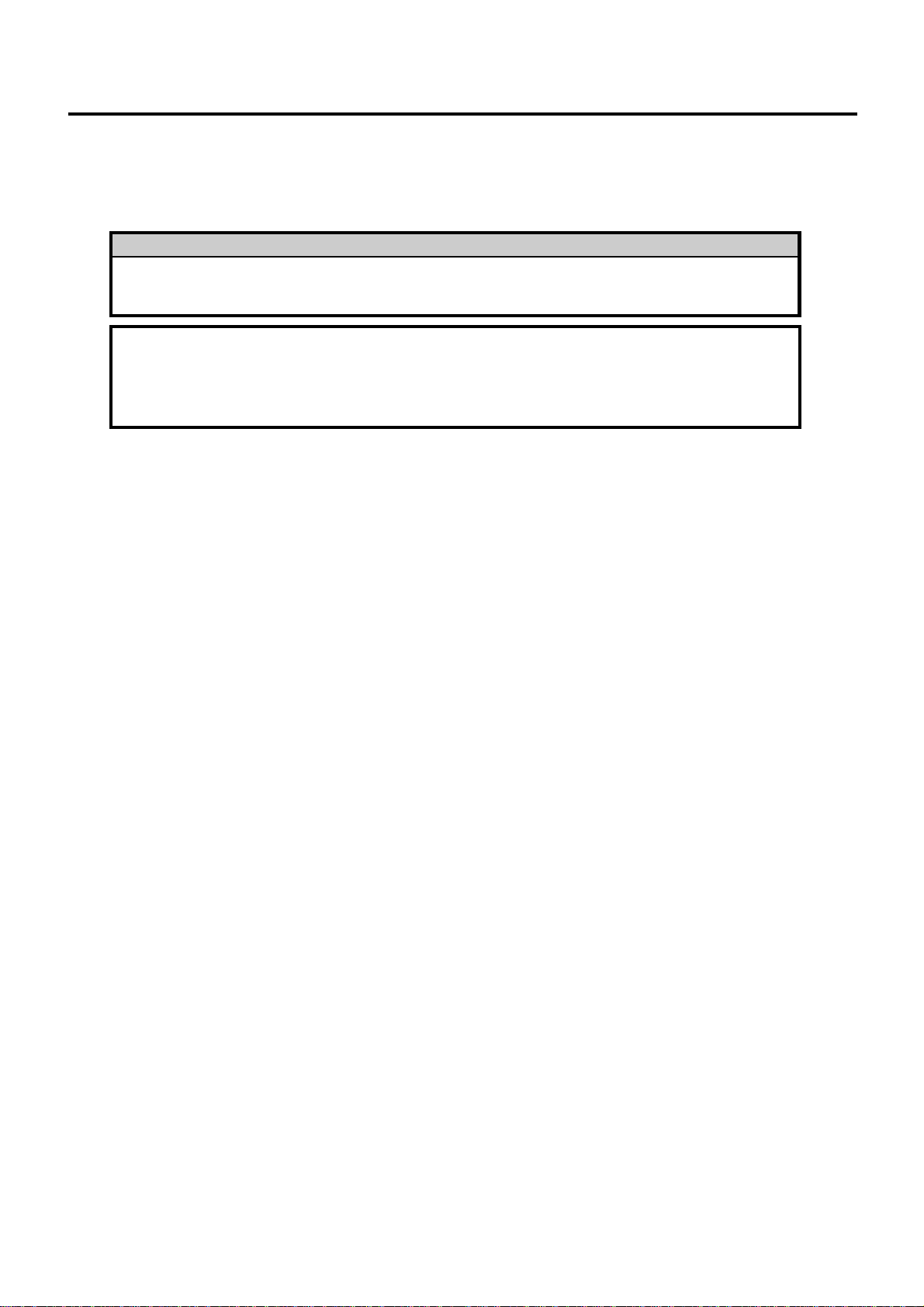

8.4 Changing the Layout of the Money Case

1) Open the drawer, then take the Money Case out.

Money Case

8-2

8. DRAWER

8.4 Changing the Layout of the Money Case

2) Remove the Coin Case from the Money Case.

Coin Case

Money Case

3) To remove the Partition from the Coin Case, pull the Partition upward while pushing the Coin Case outward.

Partition

EO1-12027

Coin Case

4) Set the Partition in the groove of the place where you like to set, then push the Partition downward.

Partition

Coin Case

5) To change the layout of the Bill Case, it is necessary to remove the Bill Holder. To remove the Bill Holder,

insert the tip of the phillips screwdriver in the back of the Bill Holder, then push the phillips screwdriver

downward. To remove the Partition, pull the front of the Partition upward.

Bill Holder

Phillips Screwdriver

8-3

Bill Holder

8. DRAWER

8.5 Media Slot

The Media Slot provided at the front of the drawer is used to put non-cash media such as check in the drawer

without opening it. The non-cash media put from this slot are kept under the Money Case, therefore you can

keep them in secret.

EO1-12027

8.5 Media Slot

Media Slot

Money Case

Non-cash media are kept here.

8-4

9. GENERAL MAINTENANCE

EO1-12027

9.1 Cleaning

9. GENERAL MAINTENANCE

9.1 Cleaning

WARNING!

1. Be sure to disconnect the power cord prior to performing any maintenance.

2. Do not pour water directly on or wipe the operator’s/Customer's display with a soaked cloth,

as this may cause fire, electric shock, or machine failure.

CAUTION!

1. Never use an organic solvent like thinners or benzene for cleaning. Using such solvents may

discolor the covers.

2. Do not use any sharp object to clean the operator’s/Customer's display. Doing so may cause

an operator’s/Customer's display failure.

To help retain the high quality and performance of your POS Terminal, it should be cleaned regularly.

The greater the usage on the POS Terminal, the more frequent the cleaning. (i.e. low usage = weekly: high usage

= daily)

• Cleaning the Operator’s Display

Clean the surface of the operator’s display with a soft dry cloth or with an electrostatic free cleaner for automated office equipment.

• Cleaning the Covers

Wipe the covers with a soft dry cloth or soft cloth slightly moistened with mild detergent. After using detergent

for cleaning, be sure to wipe it off with a slightly moistened cloth.

9-1

10. TROUBLESHOOTING

10. TROUBLESHOOTING

10. TROUBLESHOOTING

WARNING!

If you cannot solve a problem with the following solutions, do not attempt to repair it yourself.

Turn the power off, unplug the POS Terminal, then contact your TOSHIBA TEC representative for

assistance.

Symptom Check Point Solution

The power does not turn on. • Is the power cord plugged in • Plug in correctly.

correctly?

• Is the power supplied to the AC • If it is not a power failure, check

outlet? for the power supply to the AC

outlet with another electric

appliance. When the power is

not supplied, contact your

nearest power company.

• Has the fuse or circuit breaker • Check the fuse or circuit breaker.

blown?

Registration cannot be performed. • Is the key position set correctly? • Set the key position correctly.

EO1-12027

Receipt paper is not issued. • Is the receipt roll loaded • Refer to page 5-3 (Dot Printer

properly? Type) or 6-1 (Thermal Printer

Type) and load the receipt roll

properly.

• Is the printer jammed with the • Remove the jammed receipt, and

receipt? reload the receipt roll.

Journal paper is not taken up. • Is the journal roll loaded • Refer to page 5-5 and load the

properly? journal roll oroperly.

10-1

PRINTED IN JAPAN

E

EO1-12027 0106500 D

Loading...

Loading...