EXHAUST FAN FLOW METER

OVERVIEW AND MANUAL

THE ENERGY CONSERVATORY WARRANTY

EXPRESS LIMITED WARRANTY

Seller warrants that this product, under normal use and service as described in the operator’s manual, shall be free

from defects in workmanship and material for a period of 24 months, or such shorter length of time as may be specied

in the operator’s manual, from the date of shipment to the Customer.

LIMITATION OF WARRANTY AND LIABILITY

This limited warranty set forth above is subject to the following exclusions:

• With respect to any repair services rendered, Seller warrants that the parts repaired or replaced will be free from

defects in workmanship and material, under normal use, for a period of 90 days from the date of shipment to the

Purchaser.

• Seller does not provide any warranty on nished goods manufactured by others. Only the original manufacturer’s

warranty applies.

• Unless specically authorized in a separate writing, Seller makes no warranty with respect to, and shall have no

liability in connection with, any goods which are incorporated into other products or equipment by the Purchaser.

• All products returned under warranty shall be at the Purchaser’s risk of loss. The Purchaser is responsible for all

shipping charges to return the product to The Energy Conservatory. The Energy Conservatory will be responsible

for return standard ground shipping charges. The Customer may request and pay for the added cost of expedited

return shipping.

The foregoing warranty is in lieu of all other warranties and is subject to the conditions and limitations stated herein.

No other express or implied warranty IS PROVIDED, AND THE SELLER DISCLAIMS ANY IMPLIED WARRANTY OF

FITNESS for particular purpose or merchantability.

The exclusive remedy of the purchaser FOR ANY BREACH OF WARRANTY shall be the return of the product to the

factory or designated location for repair or replacement, or, at the option of The Energy Conservatory, refund of the

purchase price.

The Energy Conservatory’s maximum liability for any and all losses, injuries or damages (regardless of whether such

claims are based on contract, negligence, strict liability or other tort) shall be the purchase price paid for the products.

In no event shall the Seller be liable for any special, incidental or consequential damages. The Energy Conservatory

shall not be responsible for installation, dismantling, reassembly or reinstallation costs or charges. No action,

regardless of form, may be brought against the Seller more than one year after the cause of action has accrued.

The Customer is deemed to have accepted the terms of this Limitation of Warranty and Liability, which contains the

complete and exclusive limited warranty of the Seller. This Limitation of Warranty and Liability may not be amended or

modied, nor may any of its terms be waived except by a writing signed by an authorized representative of the Seller.

TO ARRANGE A REPAIR

Please call The Energy Conservatory at 612-827-1117 before sending any product back for repair or to inquire about

warranty coverage. All products returned for repair should include a return shipping address, name and phone number

of a contact person concerning this repair, and the purchase date of the equipment.

Kit components and parts of the Exhaust Fan Flow Meter

The Exhaust Fan Flow Meter kit includes

• Metering box

• Handle

• Overview booklet

Pressure tap

Velcro for handle

Snap pin position holes

Adjustable door

Overview

Short handle

Rubber gasket

Snap pin

Conversion chart

The Energy Conservatory’s (TEC) Exhaust Fan Flow Meter is designed to

make quick and accurate measurements of air ow through residential

exhaust fans. The effective air ow measurement range for the Exhaust Fan

Flow Meter is 10 to 124 cubic feet per minute (CFM). The device should be

used with a TEC pressure and ow gauge, such as the DG-1000.

During the measurement procedure, the Exhaust Fan Flow Meter is placed

directly over the exhaust fan grille and is pushed up against the wall or

ceiling so that the exible gasket on the end of the metering box creates an

air tight seal around the grill.

Overview continued

The pressure reading taken from the Exhaust Fan Flow Meter is easily converted to air ow in CFM using a ow table

attached to the side of the metering box. The DG-1000 and DG-700 digital pressure and ow gauges can also be set up to

display air ow readings directly in CFM.

The Exhaust Fan Flow Meter has three calibrated openings to provide an accurate measurement over the full range of the

device. A short handle is provided which can be attached to the metering box using Velcro strips. The handle is designed

to allow a standard painter’s pole or broom handle (not included) to be screwed into the open end of the handle to provide

access to exhaust fan grilles mounted high on walls, or on ceilings.

Connect tubing to the metering box

Connect one end of tubing to the pressure tap on the metering box (tubing is included with the

TEC pressure and ow gauge kit).

Connect tubing to the gauge

Connect the other end of the tubing to the T connector that is included with the TEC pressure

and ow gauge kit. Connect the two ends of the shorter tubing that is connected to the T

connector to the Channel A and Channel B input taps on the TEC gauge.

Set the door position on the metering box

The metering box comes with an adjustable opening which provides three ranges of

fan ow measurement.

The door position is determined by the position of the snap pin located on the top of

the metering box. The door position can be adjusted by pushing down on the snap

pin and sliding the door until the snap pin is in a new position hole.

Door Position Flow Range in CFM

E1 44 - 124

E2 21 - 59

E3 10 - 28

Attach the handle to the metering box

A short yellow handle is provided which can be attached to

the top of the metering box using the velcro strips. In addition,

a standard painters pole can be screwed into the end of the

yellow handle to make it easier to reach fan grills that are high

up on walls or on ceilings.

Snap pin position holes

Snap pin

Conducting the test

1. DG-1000: Turn on the DG-1000 gauge by pressing and holding the power button until the green light comes on.

DG-700: Power on the gauge by pressing the On/Off button.

DG-1000 power button

2. DG-1000: After the Home screen loads, touch Gauge to open the Gauge app.

3. DG-1000: Touch the mode area to open the Channel B Conguration menu.

Mode

1. DG-1000: Select Flow (CFM) from the Mode menu. Touch Device to open the Device menu and select Exhaust Fan

Flow Meter. Touch Conguration to open the Conguration menu and select which door position is being used. Touch

the arrow in the upper left of the screen to return to the Gauge app screen.

DG-700: Press the Mode button twice to put the gauge in PR/FL mode. Press the Device button until EXH appears in

the device section of the display. Press the Cong button until the setting on the gauge matches the door position on

the metering box.

Flow (CFM)

Exhaust Fan Flow Meter Door position

2. With the exhaust fan turned on, place the Exhaust Fan Flow Meter completely over the fan grill so that the exible

gasket on the end of the metering box creates an air tight seal around the grill. Hold the gauge steady for at least 10

seconds so that the gauge auto-zeros.

3. Acceptable metering box pressures

• When using the Exhaust Fan Flow Meter, the measured metering box pressure should never be greater than 8.0

Pa, and never lower than 1.0 Pa. Pressures above 8.0 Pa will commonly result in erroneous ow measurements

because the metering box will tend to restrict air ow through typical residential exhaust fans. Metering box

pressures below 1.0 Pa are too small to measure accurately.

4. Channel A pressure greater than 8.0

• If the Channel A pressure is above 8.0 Pa, rst check the door position. If the door position is set to E2 or E3,

adjust the position to create a larger opening in the metering box (e.g. E1 or E2). If the door position is set to

E1 (the largest opening) and the metering box pressure is still above 8.0 Pa, then the fan ow you are trying to

measure is outside the high range of the instrument (i.e. ow is greater than 124 CFM).

1. Channel A pressure less than 1.0 pascal

• If the Channel A pressure is below 1.0 Pa, rst check the door position. If the door position is set to E1 or E2,

adjust the position to create a smaller opening in the metering box (e.g. E2 or E3). If the door position is set to

E3 (the smallest opening) and the metering box pressure is still below 1.0 Pa, then the fan ow you are trying to

measure is outside the low range of the instrument (i.e. ow is less than 10 CFM).

2. Channel B will show the air ow reading from the exhaust fan. If the ow reading is uctuating, change the time

average setting on the gauge by touching TIME AVG.

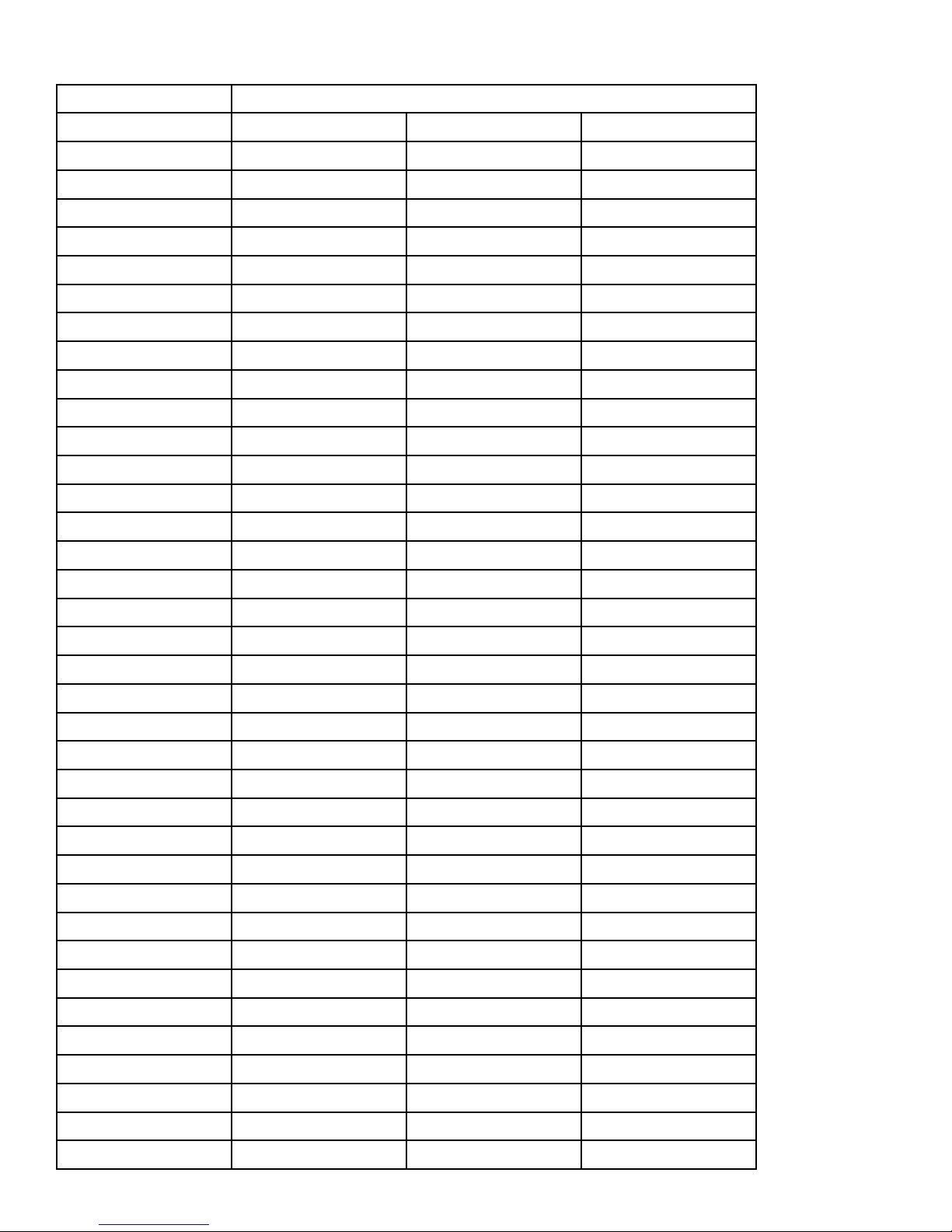

Flow Conversion Table

Meter Pressure (PA) Flow (CFM)

E1 E2 E3

1.0 44 21 10

1.2 48 23 11

1.4 52 25 12

1.6 55 26 13

1.8 59 28 14

2.0 62 29 14

2.2 65 31 15

2.4 68 32 16

2.6 71 33 16

2.8 73 35 17

3.0 76 36 17

3.2 78 37 18

3.4 81 38 19

3.6 83 39 19

3.8 85 40 20

4.0 87 41 20

4.2 90 42 21

4.4 92 43 21

4.6 94 44 22

4.8 96 45 22

5.0 98 46 23

5.2 100 47 23

5.4 102 48 23

5.6 103 49 24

5.8 105 50 24

6.0 107 51 25

6.2 109 52 25

6.4 111 52 25

6.6 112 53 26

6.8 114 54 26

7.0 116 55 27

7.2 117 56 27

7.4 119 56 27

7.6 121 57 28

7.8 122 58 28

8.0 124 59 28

Calibration and Measurement Accuracy

CALIBRATION FORMULA

Door Opening Formula

0.5

0.5

0.5

E1 Flow (CFM) = 43.73 x (Metering box pressure in pascals)

E2 Flow (CFM) = 20.72 x (Metering box pressure in pascals)

E3 Flow (CFM) = 10.07 x (Metering box pressure in pascals)

FLOW ACCURACY

±10% of reading when used with a 1% accurate pressure gauge (such as a DG-700) with a display resolution of 0.1 Pa (0.0004

inches of water)

FLOW RANGE

Door position E1: 44 - 124 CFM

Door position E2: 21 - 59 CFM

Door position E3: 10 - 28 CFM

DIMENSIONS (INSIDE)

16 in. L x 13 in. W x 8 in. D

WEIGHT

3 lbs. including handle

Software Information

The Energy Conservatory (TEC) offers a variety of Windows-based programs. These programs can be found and downloaded

for free at software.energyconservatory.com.

TEC also offers driver support for the DG-500, DG-700 and DG-1000. The drivers are designed to work with Windows-

based computers with the following operating systems:

• Windows 7

• Windows 8

• Windows 8.1

• Windows 10

The drivers are available through Windows Update, and the DG-500 and DG-700 drivers can be downloaded from TEC at

software.energyconservatory.com.

TEC also offers mobile apps for Apple and Android devices that can be found in the Apple App Store or the Google Play

Store.

Instructional Videos

The Energy Conservatory (TEC) offers a variety of online instructional videos, including

™

• Minneapolis Blower Door

• Minneapolis Duct Blaster

Quick Guide

®

Quick Guide

• Field Calibration Checks for Gauges

• Pressure and Airow Basics

• Exhaust Fan Flow Meter

• TECLOG3

• TECTITE 4.0

• And many more

Visit www.YouTube.com/EnergyConservatory to see all of TEC’s instructional videos.

®

© 201 7 The Energ y Conser vatory

Upda ted July 2017, V1

2801 21st Avenue South

Suite 160

Minneapolis, Minnesota 55407

Phone: (612) 827-1117

Fax: (612) 827-1051

info@energyconservatory.com

energyconservatory.com

Loading...

Loading...