User manual 1

User Manual Version 3.0

Plasma Power source

Plasma CUT 65

Item number:

294-005000-00000

(CUT 65 with torch length 8m)

Plasma CUT 85

Item number:

294-005010-00000

(CUT 85 with torch length 8m)

Plasma CUT 105

Item number:

294-005020-00000

(CUT 105 with torch length 8m)

Plasma CUT 125

Item number:

294-005030-00000

(CUT 125 with torch length 8m)

THIS MACHINE IS TO BE USED ONLY FOR METAL CUTTING OPERATIONS

and determined for professional use only!

User manual 2

Table of Contents

GENERAL INSTRUCTIONS 4

WARNING! 4

FOR YOUR SAFETY. READ THE INSTRUCTIONS! 5

DANGER 5

WARNING 5

CAUTION 5

IMPORTANT WARNING 6

ELECTRIC SHOCK CAN KILL 6

NOISE CAN DAMAGE HEARING 6

CUTTING CAN CAUSE FIRE OR 6

EXPLOSION 6

SMOKE AND GASES CAN BE 6

HAZARDOUS 6

HOT PARTS CAN CAUSE SEVERE BURNS 7

MAGNETIC FIELD CAN AFFECT PACEMAKERS 7

FLYING SPARKS CAN INJURE 7

PLASMA ARC CAN INJURE 7

PLASMA CUTTING CAN CAUSE INTERFERENCE 7

OVERUSE CAN CAUSE OVERHEATING IN THE EQUIPMENT 7

CAUTION WHEN CUTTING AROUND GAS CYLINDERS 7

LIGHTNING ARC CUTTING CAN BURN EYES AND SKIN 8

SPECIFICATIONS 9

Specifications – plasma power source 9

Spezifikation – Plasmastromquellen 65 -125 (Continuation) 10

Duty Cycle 11

Dimensions and weight of the power source 11

Specifications – torches AP 65 -125 12

Torches dimensions / Hand torch dimensions 13

Mechanized torch dimensions (with or without rail) 13

SYMBOLS AND MARKING 14

Marking S 14

IEC symbols 14

INSTALLATION 15

The acquisition time of 15

Claims 15

Box contents 15

Power source location 17

Mains power connection 17

Connecting to autonomous generator 18

Connecting to ground 18

Power cable 19

Three phase power cable 19

Installation power cable 19

Installation the plug 20

The mass grip area 20

Installation the torch 21

Feeding the plasma gas 23

Additional gas filtration 23

Installation of the gas supply 24

Alignment of the torch AP 65 -125 Auto 24

Connection “ON/OFF” (Turn ON/Turn OFF) on the remote control 25

Connecting the machine interface CNC 25

CNC - Arc voltage connection 26

CNC - Activating external DC coil with an external power supply. 29

User manual 3

CNC - Activating an external AC coil with an external power supply. 30

CNC - Activating an industrial isolated module with an external power supply. 31

OPERATIONS 32

Controls and indicators 32

Control panel 33

Torch consumables installation 34

Torch consumables configuration 34

Torch parts 35

Torch consumables configuration (continued) 36

Torch parts 37

Mode selection 38

Check and adjust the gas pressure and current ( power ) 39

Operating the manual torch 40

Fix the mass clamp 41

Cutting start from the edge of the piece 41

Hand torch cutting technique 42

Piercings 43

Gouging 44

CUTTING CHART 45

Mechanized unshielded consumables for 45 Amps 45

Mechanized unshielded consumables for 65 Amps 46

Mechanized unshielded consumables for 85 Amps 47

Mechanized unshielded consumables for 105 Amps 48

Mechanized unshielded consumables for 125 Amps 49

MAINTENANCE 50

Routine maintenance 50

Consumables inspection 51

Replace the gas filter element 52

Disconnect electrical power and gas supply. Remove the filter bowl. 52

Remove the filter element from the filter housing.

52

Install the filter bowl. 52

Controls and indicators 53

Lighting indicators 53

Solution to basic problems 54

Electric system circuits draw 57

PARTS 58

Configuration of the torch consumables 58

Configuration of the torch consumables (continuation) 59

DECLARATION OF CONFORMITY 60

DOC TW CUT 65 60

DOC TW CUT 85 61

DOC TW CUT 105 62

DOC TW CUT 125 63

MANUFACTOR AND DISTRIBUTOR INFORMATION 64

User manual 4

GENERAL INSTRUCTIONS

Read the operating instructions before to switch on the machine and start to work!

The operating instructions provide an introduction to the safe use of the products.

• Read and observe the operating instructions for all system components, especially

the safety instructions and warning notices!

• Observe the accident prevention regulations and any regional regulations!

• The operating instructions must be kept at the location where the machine is ope-

rated.

• Safety and warning labels on the machine indicate any possible risks.

• Keep these labels clean and legible at all times.

• The machine has been constructed to state-of-the-art standards in line with any

applicable regulations and industrial standards. Only trained personnel may operate, service and repair the machine.

• Technical changes due to further development in machine technology may lead to

a differing cutting behaviour.

WARNING!

In the event of queries on installation, commissioning, operation or special conditions

at the installation site, or on usage, please contact your sales partner or our customer

service department on +49 2623 9276400.

A list of authorised sales partners can be found at www.teamwelder.com.

Liability relating to the operation of this equipment is restricted solely to the function of the equipment. No other form of liability, regardless of type, shall be accepted.

This exclusion of liability shall be deemed accepted by the user on commissioning the

equipment.

The manufacturer is unable to monitor whether or not these instructions or the conditions and methods are observed during installation, operation, usage and maintenance

of the equipment.

An incorrectly performed installation can result in material damage and injure persons

as a result. For this reason, we do not accept any responsibility or liability for losses,

damages or costs arising from incorrect installation, improper operation or incorrect

usage and maintenance or any actions connected to this in any way.

TEAMWELDER Germany GmbH

Sälzerstraße 20a

D-56235 Ransbach-Baumbach

Deutschland / Germany

The copyright to this document remains the property of the manufacturer.

Reprinting, including extracts, only permitted with written approval.

The content of this document has been prepared and reviewed with all reasonable

care. The information provided is subject to change; errors excepted.

User manual 5

DANGER

Working or operating procedures which must be closely observed to prevent imminent serious and even fatal injuries.

• Safety notes include the „DANGER“ keyword in the heading with a general warning symbol.

• The hazard is also highlighted using a symbol on the edge of the page.

WARNING

Working or operating procedures which must be closely observed to prevent serious and even fatal injuries.

• Safety notes include the „WARNING“ keyword in the heading with a general warning symbol.

• The hazard is also highlighted using a symbol in the page margin.

CAUTION

Working or operating procedures which must be closely observed to prevent possible minor personal injury.

• The safety information includes the „CAUTION“ keyword in its heading with a general war-

ning symbol.

• The risk is explained using a symbol on the edge of the page.

Technical aspects which the user must observe to avoid material or equipment damage.

Instructions and lists detailing step-by-step actions for given situations can be recognised via

bullet points, e.g.:

• Insert the welding current lead socket into the relevant socket and lock.

FOR YOUR SAFETY. READ THE INSTRUCTIONS!

User manual 6

IMPORTANT WARNING

According to the European standard EN61000-312, which entered into force in December 2010, this

equipment is suitable for use with self-generating

power and private power networks. Its use in electric networks of public character does not conform

to the limits prescribed in the standard.

ELECTRIC SHOCK CAN KILL

Touching electrical parts could cause a

fatal shock or severe burns.

• Don’t touch the life electric parts.

• Wear dry insulated gloves, shoes and

protective clothing.

• Insulate yourself from work and ground using

dry insulating material and

non-flammable.

• The working area should be clean and dry.

• Switch OFF the machine for cleaning and

maintenance operations.

• Do not rape cables around your body.

• Turn OFF the machine when remain not used.

• Periodically check the supply hose, the

insulation must be intact. Replace the

hose immediately if damaged. Use the

machine with bare wires, uncoated, is

very dangerous.

• Before handling the cutting power

source must wait five minutes to ensure

complete discharge of the capacitors of

the machine.

• Keep your unit in good condition; repair

or replace damaged parts immediately.

Maintain unit according to manual.

CUTTING CAN CAUSE FIRE OR

EXPLOSION

Fire prevention

• Keep flammable items away from the

work area.

• Make sure the work area is a fire extinguisher,

and that it is in top condition for use.

• Ventilate the work area before using the slicer

when working in areas of potential fire risk.

Explosion prevention

• Do not cut in areas containing explosives,

flammable gases or vapours.

• Do not locate unit on, over, or near combustible

surfaces.

• Do not operate the machine in areas with an

atmosphere containing high concentrations of

dust, flammable gases or vapours.

• Never use the machine for cutting container of

flammable materials that

are not completely empty and clean, or

are under pressure.

SMOKE AND GASES CAN BE

HAZARDOUS

Induction heating of certain materials,

adhesives, and fluxes may cause fumes or

smoke.

Breathing these fumes and gases can be

hazardous to your health.

• Keep your head out of the smoke, do not

breathe the fumes.

• If inside, ventilate the area and / or us

an exhaust system near the cutting arc

to remove the smoke and gas cutting.

• If ventilation is poor, wear an approved

air-supplied respirator.

• Work in a confined space only if it is

well ventilated, or while wearing an

air-supplied respirator. The smoke and

gases from the heating process can

displace air and lower the oxygen level

causing injury or death. Be sure the

breathing air is safe.

NOISE CAN DAMAGE HEARING

Prolonged noise from some applications can

cause hearing damage.

• Use hearing protection or ear muffs if

nose level is high.

• Warn others about the dangers of noise.

User manual 7

HOT PARTS CAN CAUSE SEVERE

BURNS

• Do not touch hot parts bare handed.

• Allow cooling time before handling.

PLASMA CUTTING CAN CAUSE INTERFERENCE

• Electromagnetic energy can interfere with sen-

sitive electronic equipment such as computers,

or computer-driven equipment.

• Ensure that all equipment in the cutting area is

electromagnetically compatible.

• Ensure that the cutting machine is installed

and positioned according to this manual.

MAGNETIC FIELD CAN AFFECT PACEMAKERS

Prolonged noise from some applications can cause

hearing damage.

• Use hearing protection or ear muffs if

nose level is high.

• Warn others about the dangers of noise.

OVERUSE CAN CAUSE OVERHEATING IN THE EQUIPMENT

Prolonged noise from some applications can

cause hearing damage.

• Use hearing protection or ear muffs if

nose level is high.

• Warn others about the dangers of noise.

FLYING SPARKS CAN INJURE

During the cutting process, there can be

landslides incandescent material. Itching

can cause flying metal.

• Use face shield and safety glasses with

side shields.

• Use proper body protection to protect

your skin.

• Use earplugs and ears that are re-

sistant to flames to prevent sparks

from entering your ears.

PLASMA ARC CAN INJURE

The arc plasma is turned on immediately after

the torch switch is activated.

• Keep away from the torch tip, because it

can cut quickly gloves and skin.

• Do not place hands near the cutting path.

• Do not point gun toward oneself or to

another.

CAUTION WHEN CUTTING

AROUND GAS CYLINDERS

Gas cylinders containing gas under high

pressure, if damaged, there is a possibility of

explosion.

• Handle and use compressed gas cylin-

ders in accordance with local or national

codes.

• Never allow electrical contact between

the plasma arc and a bottle.

• Never expose cylinders to excessive heat,

sparks, slag or flames.

• Do not point gun toward oneself or to

another.

User manual 8

LIGHTNING ARC CUTTING CAN

BURN EYES AND SKIN

Arc rays from the cutting process produce intense

visible and invisible rays that can burn eyes and

skin.

• Use protective clothing made from durable,

flame-resistant material and foot protection.

• Use face protection (helmet or shield) with

filter lenses to protect your eyes right color and

face (see Table).

• Warn people you are close to the point of wor-

king them not to watch the arc cutting.

User manual 9

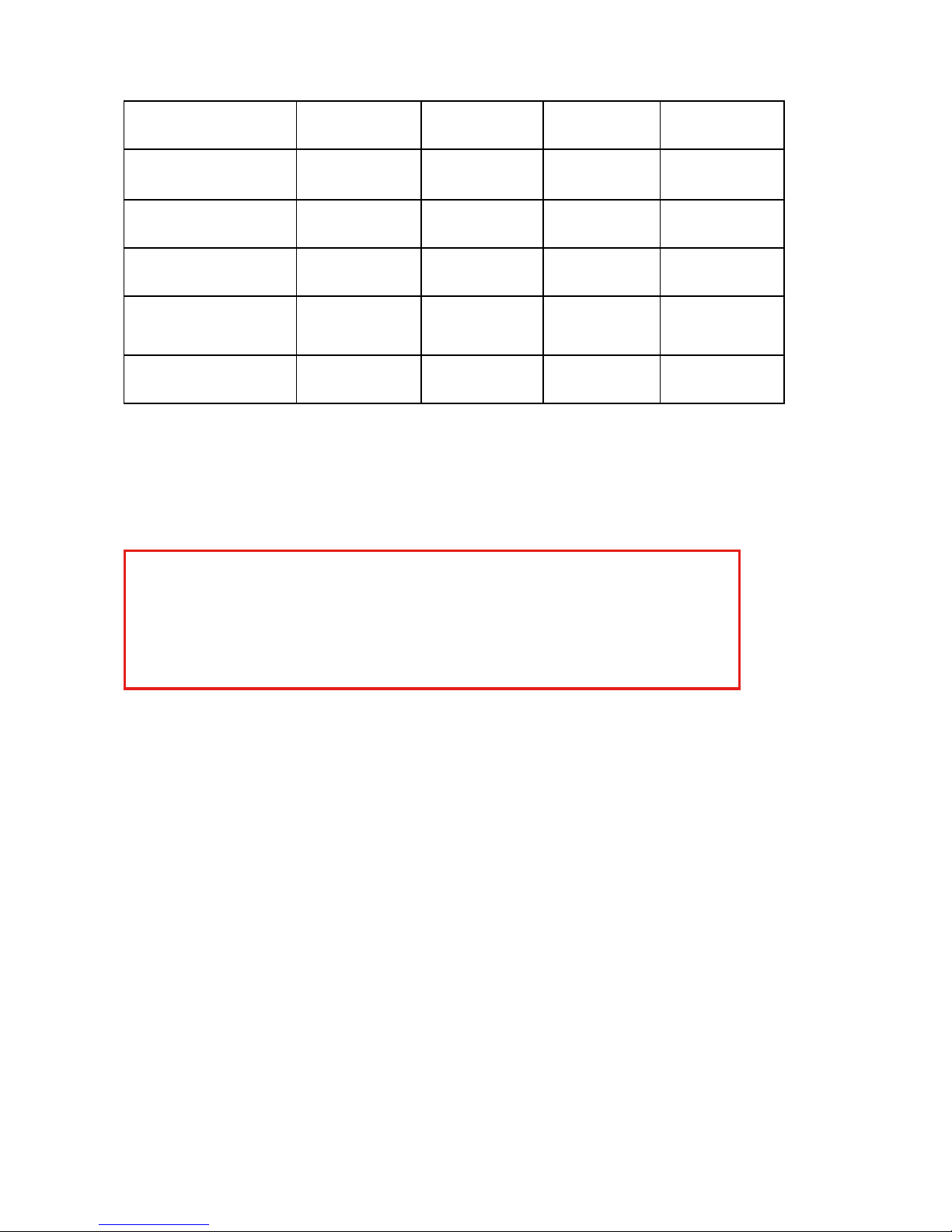

SPECIFICATIONS

Specifications – plasma power source

Model CUT 125 CUT 105 CUT 85 CUT 65

Voltage Supply 3x400+-15%Vac 3x400+-15%Vac 3x400+-15%Vac 3x400+-15%Vac

Frequency 50-60Hz 50-60Hz 50-60Hz 50-60Hz

Current Consumption 38A-30A 29A-27A 25A-22A 20A-17A

Maximum Power 26kVA-21kVA 20kVA-18kVA 17kVA-15kVA 13kVA-11kVA

No Load Voltage 300 Vdc 300 Vdc 300 Vdc 300 Vdc

Load Voltage 160Vdc 160Vdc 145Vdc 145Vdc

Power Performance 125A-110A 105A-95A 85A-70A 65A-50A

Maximum Cutting

Thickness

*FE/SS/AL

60/55/45 mm

*FE/SS/AL

50/45/35 mm

*FE/SS/AL

40/35/25 mm

*FE/SS/AL

30/25/15 mm

Recommended CuttingThickness

*FE/SS/AL

50/45/40 mm

*FE/SS/AL

40/35/30 mm

*FE/SS/AL

35/30/25 mm

*FE/SS/AL

25/20/15 mm

Optimum Cutting

Thickness

*FE/SS/AL

40/35/30 mm

*FE/SS/AL

35/30/25mm

*FE/SS/AL

30/25/20 mm

*FE/SS/AL

20/15/10 mm

Air Flow 200 L/min 200 L/min 180 L/min 180 L/min

Recommended Air

Pressure

5,5/6,5 Bar 5,5/6,5 Bar 5,5/6,5 Bar 5,5/6,5 Bar

Arc Ignition System Without HF Without HF Without HF Without HF

Recommended Compressor

7,5 CV/300L/

min.

7,5 CV/300L/

min.

5,5 CV/200L/

min.

7,5 CV/200L/

min.

Recom. Power Generator Group

30 KVA 25 KVA 20 KVA 15 KVA

Power Range 5-125A 5-105A 5-85A 5-65A

Protection Level IP 23 S IP 23 S IP 23 S IP 23 S

Insulation Class H H H H

Dimensions 270x810x500

mm

270x810x500

mm

230x655x450 mm230x655x450

mm

Weight Torch included 44 kg 42 kg 36 kg 32 kg

*Steel (FE), Stainless Steel (SS), Aluminum (AL)

User manual 10

Model CUT 125 CUT 105 CUT 85 CUT 65

Operating temperature -10 °C a +40 °C -10 °C a +40 °C -10 °C a +40 °C -10 °C a +40 °C

Norm IEC 61000-3-12 EC 61000-3-12 EC 61000-3-12 EC 61000-3-12

Gas type Air / Nitrogen Air / Nitrogen Air / Nitrogen Air / Nitrogen

Gas quality Clean, mois

ture-free,

without oil

Clean, mois

ture-free,

without oil

Clean, mois

ture-free,

without oil

Clean, mois

ture-free,

without oil

Gas inlet pressure and

flow

6,1 bar 200 l/

mm

6,1 bar 200 l/

mm

6,1 bar 200 l/mm6,1 bar 200 l/

mm

Spezifikation – Plasmastromquellen 65 -125 (Continuation)

*Steel (FE), Stainless Steel (SS), Aluminum (AL)

**IP - International Protection, 2 - No penetration of foreign bodies >12,5 mm, 3 - No penetration of

harmful spray water, S - Fan is during the water test

WARNING - Do not operate when it rains!

User manual 11

Duty Cycle

The duty cycle is the percentage of time, over a period of 10 minutes, the power source can

continuously cutting. The following diagram represents a duty cycle of 80%.

Dimensions and weight of the power source

8 minutes cutting

2 minutes resting

Weight power source

without torch.

Model CUT 65/85

32 kg - 36 kg

Model CUT 105/125

42 kg – 44 kg

High: 450 mm

Length: 655 mm

Width: 230 mm

High: 500 mm

Length: 810 mm

Width: 270 mm

Model CUT 65/85 Model CUT 105/125

User manual 12

Specifications – torches AP 65 -125

Cutting capacity CUT 65 CUT 85 CUT 105 CUT 125

Recommended capaci

-

ty [mm]

15 25 35 40

Maximum capacity 20 30 40 50

Severance capacity 30 40 50 60

Gouging capability

( metal removal rate

on Mild Steel )

6 kg/h 8 kg/h 10 kg/h 12 kg/h

Weight

Hand Lead 5m - 2,03 kg without consumables

Lead 8m - 2,85 kg without consumables

Lead 15m - 4,74kg without consumables

Lead 23m - 6,85 kg without consumables

Auto Lead 5m - 2,50 kg without consumables

Lead 8m - 3,40 kg without consumables

Lead 15m - 5,30 kg without consumables

Lead 23m - 7,30 kg without consumables

User manual 13

Torches dimensions / Hand torch dimensions

Mechanized torch dimensions (with or without rail)

User manual 14

SYMBOLS AND MARKING

Marking S

The mark S indicates that the power source and torch are suitable for use in environment with

danger of electrocution. The hand torches consumable parts must be protected to meet the

mark

S

IEC symbols

It is possible that the following symbols are present in the data plate plasma generator, control

labels and switches.

User manual 15

INSTALLATION

The acquisition time of

1. Verify that all items in your order have been received. Contact the supplier / manufacturer

of original equipment, if any item is damaged or has not arrived.

2. If there is evidence of damage, see Claims, below. All communications about this power

source should include the model number and serial number located on the back of the

generator.

3. Read safety section in this manual before installing and operating this equipment.

Claims

Claims for shipping damage – If the unit has been damaged in transit, you should complain to

the carrier. TEAMWELDER given a copy of the invoice packing upon request. If you need

additional assistance, please call Customer Service at the phone number listed at the end

of this guide or your authorized dealer TEAMWELDER.

Claims for defective merchandise or missing – All units shipped from TEAMWELDER have been

subjected to rigorous quality control. If any of the parts is defective or is not included, call your

dealer. If you need additional assistance, please call Customer Service at the phone number

listed at the end of this guide or your authorized dealer TEAMWELDER.

Box contents

Check the items that appears in the illustration shown. (CUT 65 - 125)

(Consumables starting kit / Air male and female connector)

User manual 16

f

f

f

Lift with crane.

Use an approved harness.

Keep the power source as

horizontal as possible.

Keep in place the cover.

User manual 17

Power source location

Place the plasma power source CUT 65 -125 with a minimum distance of 0.5m of space (both

front and back) to receive of the fan, for good ventilation.

Mains power connection

The CUT 65 -125 is a plasma generator capable of cutting at 380-400 Vac three phase. Use a

line disconnect breaker for each power input so that the operator can turn off the power supply

quickly in an emergency. Place the back of the machine with the switch so that it is easily

accessible to the operator. For a continious working, the operator must connect the machine

to a „Wall power breaker“ which is equal or over the level of consumption of the plasma power

source.

User manual 18

Connecting to ground

To that personnel safety, proper operation and to reduce electromagnetic interference (supply hose),

CUT 65 -125 must be properly grounded through the cable according to national or local electrical

codes. The three-phase service must be of the 4-wire cord with a protective, grounding, green or

green / yellow and must comply with national and local electrical requirements.

Connecting to autonomous generator

When using a generator to power the CUT 65 -125:

• Operating with the generator:

1. Set the output AC generator in three-phase.

2. Plug the power cord into the receptacle 65-125 CUT group.

3. Set the generator at maximum output (see chart below).

Model CE

Three-phase, 50/60 Hz, 380 – 400 Vac (Recommended 400 Vac for better performances)

User manual 19

Power cable

Use an extension line that national or local codes to be certified. The extension must be installed

by a licensed electrician. See the length requirements listed below.

Note: the unit was tested with a power cable 3 m for compliance with EMC standard EN50199.

Three phase power cable

CE models CUT 65 -105 come with power cord 4 mm2, 4 wires (3 phases plus ground).

CE models CUT 125 come with power cord 6 mm2, 4 wires (3 phases plus ground).

To operate the CUT 65 -125, use a plug that complies with national and local codes. A licensed

and qualified electrician should connect the power cord to the plug.

Installation power cable

1. Strip and prepare the power cables as shown below:

Unit CE

L1 Black(U) R

L2 Brown(V) S

L3 Grey(W) T

Hearth Green-Yellow

User manual 20

Green-Yellow

Brown

Grey

Black

Installation the plug

A licensed and qualified electrician should connect the power cord to the plug.

The mass grip area

Important:

Place dough in an area where no, or primer or paint. You have to go subject directly touching

clean metal.

User manual 21

Installation the torch

1. TURN OFF the power source

OFF (0) / Turn OFF

ON (I) /Turn ON

2. Unplug the socket from the power net.

3. Torch connector.

Safety Pin for connection of

plasma torches only, in

accordance with European

standards.

User manual 22

4. Addressing the key torch with key and dock connector.

Torch key

Female machine key

5. Once faced and well coupled to the

connector screw torch.

User manual 23

Feeding the plasma gas

The feed gas CUT 65 -125 can be shop air or compressed air cylinder. It should use a high-pressure regulator in any of the two types of power supply and should be capable of delivering gas to

the filter from the power supply to 200 l / min at a pressure of 6.0 bar.

Note: If the gas supply is not good, the cutting speed decrease, cut quality will deteriorate,

diminish the ability to cut the required thickness, and the life of the consumables will be shortened.

WARNING

Do not allow the gas pressure exceeds 8.0 bar. The filter bowl

could explode if the pressure exceeds.

Additional gas filtration

(Not necessary, just recommended)

Use set TEAMWELDER filtration system or use 3-stage filtration that binds, as shown, when site

conditions introduce moisture, oil or other contaminants into the air line.

User manual 24

Installation of the gas supply

1. Air attach

• The CE model has an adapter G1/4

• The male attach/adapter is in the consu-

mables box, located on the back side of the

machine closed with a black plastic cover.

2. Air hose

• Use an inert gas hose with a minimum

internal diameter of 10 mm and one

attach of G1/4 or a female quick connection located also in the back side of

the machine.

Alignment of the torch AP 65 -125 Auto

Mount the machine torch perpendicular to a given work piece, in order to get a vertical cut. Use

a ruler to align the torch at 0 ° and 90 °

User manual 25

Connection “ON/OFF” (Turn ON/Turn OFF) on the remote control

Inputs for arc starting with the machine torch FHT-125M are available through the connection

interface of the machine in the back of the power supply. Plug the remote TEAMWELDER (see

Parts List for part numbers) into the connector on the back panel.

Connecting the machine interface CNC

Are available through the machine interface (see the

figure above), signals for arc transfer and start, on the

back of the plasma generator. Plug the machine interface ( TELEC95072 ) into the connector of the rear panel.

Look at the table below to connect the interface cable to

the

machine cutting CNC.

User manual 26

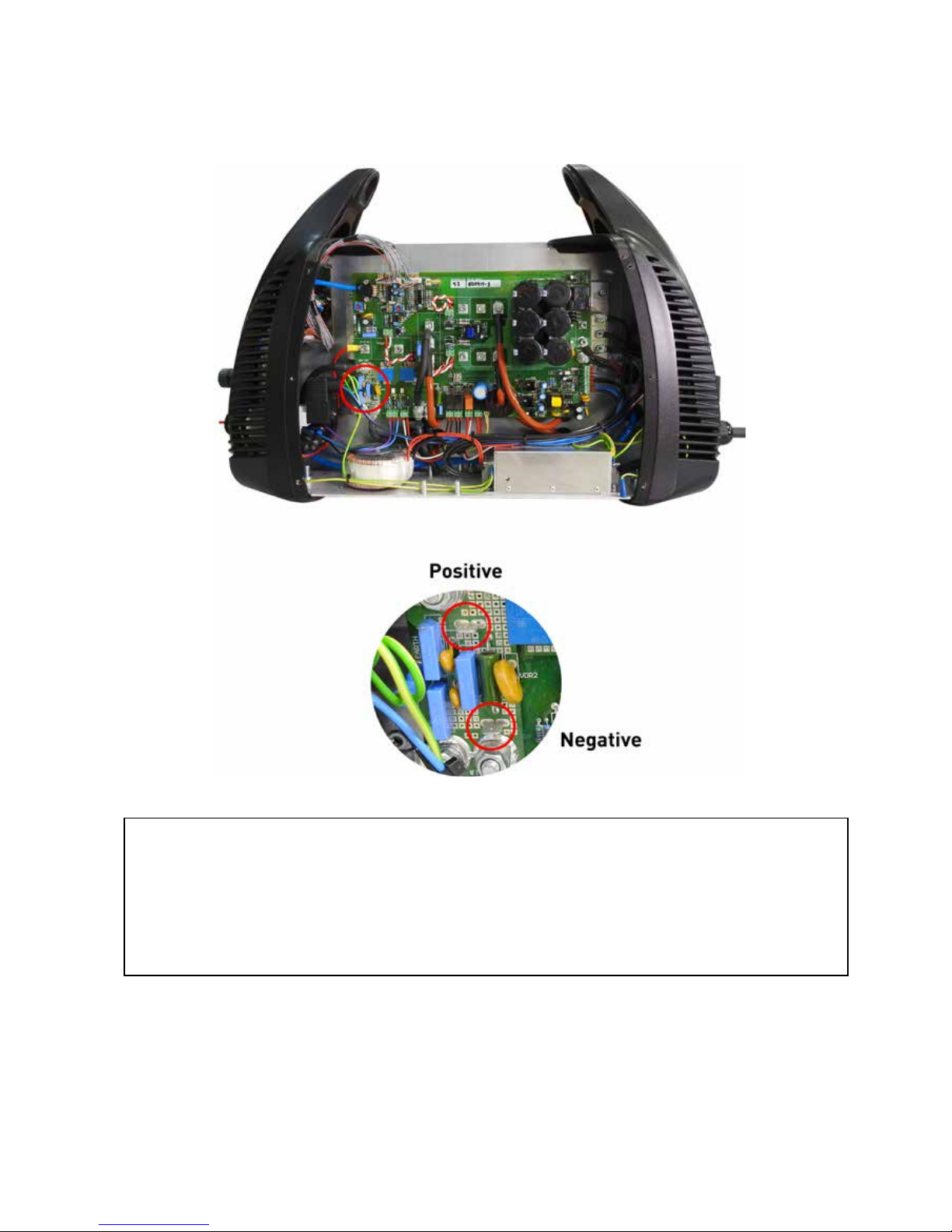

CNC - Arc voltage connection

If the arc voltage is necessary to enable the control of the height of the torch, the client must

obtain an isolated 1.0 mm2, single pair, 300V or higher. The arc voltage signal is accessible in the

interface card machine as follows:

1. Turn off the power of the plasma generator.

2. Remove the screws that joined the top of the power source to the chassis. Separate the cover.

3. Push the cable through the gland located in the back of the power supply. Look at the figure

below.

User manual 27

4. Arc voltage signal. See the below picture. Use insulated terminal ends of type “faston 6.35mm”

to connect to positive and negative.

Signal: Arc voltage ( to use in the torch height control )

Type: Output

Note: Full arc voltage. Without voltage divisor. 300Vdc maximum.

Positive + Vdc

Negative - Vdc

5. Tighten the cable gland.

6. Close the machine back.

User manual 28

1. Torch 2. Star-CNC 3. Arc. Trans 4. Solenoid

CNC - plasma cutting table is starting the movement of the exes X or Y.

User manual 29

CNC - Activating external DC coil with an external power supply.

User manual 30

CNC - Activating an external AC coil with an external power supply.

User manual 31

CNC - Activating an industrial isolated module with an external power supply.

User manual 32

OPERATIONS

Controls and indicators

User manual 33

Control panel

User manual 34

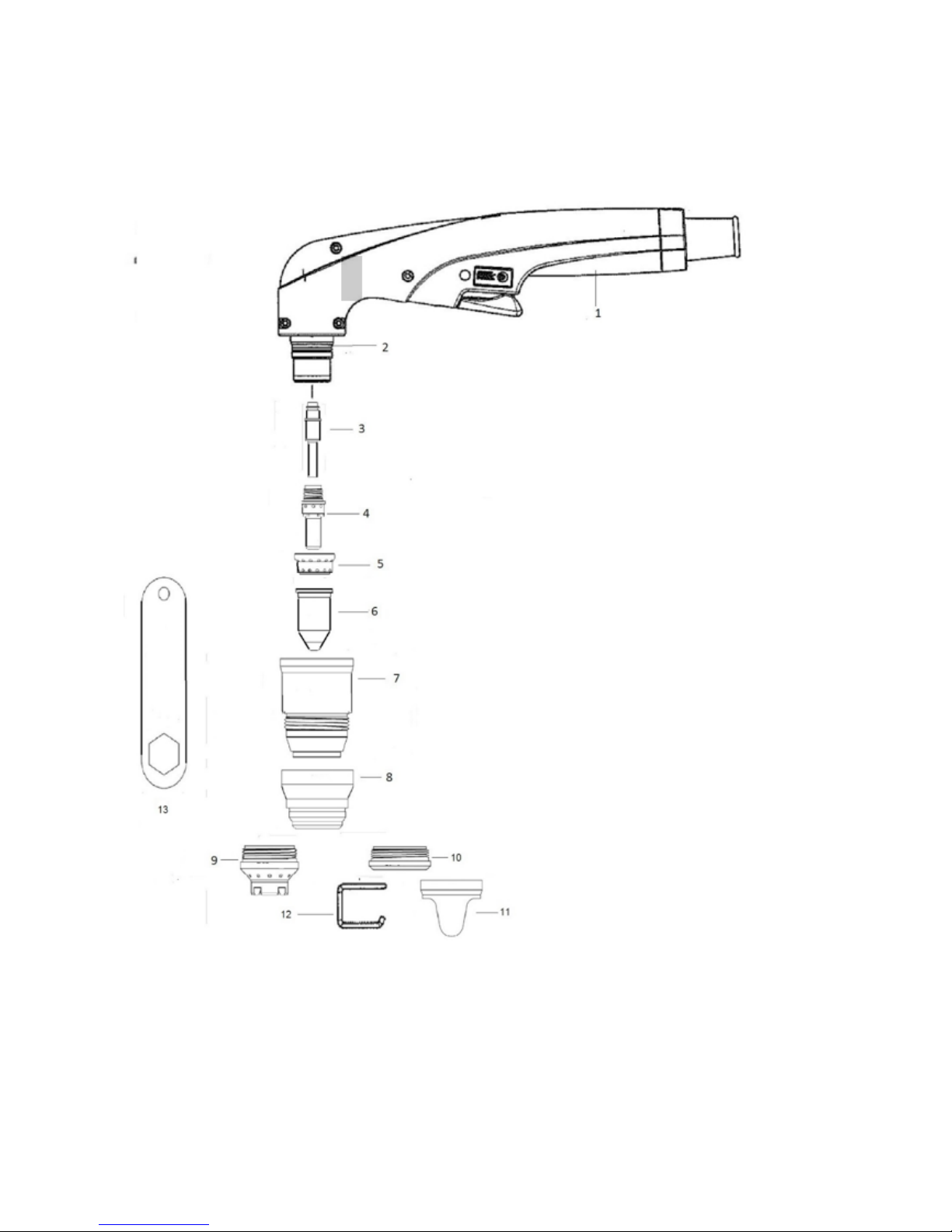

Torch consumables installation

Torch consumables configuration

User manual 35

Torch parts

User manual 36

Torch consumables configuration (continued)

User manual 37

Torch parts

User manual 38

Mode selection

Use it to cut metal into sheets / plates.

For optimal consumables duration.

Use it to cut the expanded metal.

Automatically re-start the pilot arc.

It is used to remove welding or gouging.

Switch ON (I) as shown.

Note: The cooling fan will only

work when the plasma needed.

Check that the gas pressure is above 3 bar in cutting and

grid mode and above 2 bar in gouging mode.

Check the lighting indicators

Check the indicator light ARE NOT illuminated. Safety indicator torch retaining cap.

Turn ON

User manual 39

Check and adjust the gas pressure and current ( power )

User manual 40

Operating the manual torch

Operating the safety torch trigger

User manual 41

Fix the mass clamp

Secure the clamp to the work piece that is going to work.

Hold the clamp as closed as possible to the cutting area to reduce exposure to

electromagnetic fields (EMC)

Do not hold the piece of piece to be release.

Cutting start from the edge of the piece

Keep the nozzle of the torch upright at the

edge of the piece.

Start cutting from the edge of the piece. Stop

at the edge until the arc has completely cut

through the part.

Then continue with the cut.

User manual 42

Hand torch cutting technique

Torch jogging without reducing the life of the

nozzle and the electrode.

When cutting, make sure the sparks out of the

bottom of the piece.

If sparks will jump up to the part, it is because

you are moving the torch too fast or without

enough energy.

Hold the torch vertically and watch the arc while cutting along the line.

Unshielded consumables. Keep away from the torch to the work of about 4.0 mm.

Shielded consumables. Please don`t tighten down the torch to the work piece

while cutting. Slide the torch carefully along the work piece to obtain a perfect cut.

• Put the torch along the cut, is easier to drive.

• For cutting thin material, reduce the amp to get a higher quality cut.

• For straight cuts, use a ruler as a guide. To cut circles, use a template ar circ-

le cutting attachment.

• Post flow – After the switch is released the gun trigger, the gas will continue

to flow for 30 seconds to cool the torch and consumables.

Note: The torch will restart if you enable the trigger during post flow. To stop post

flow activate and quickly release the gun trigger.

User manual 43

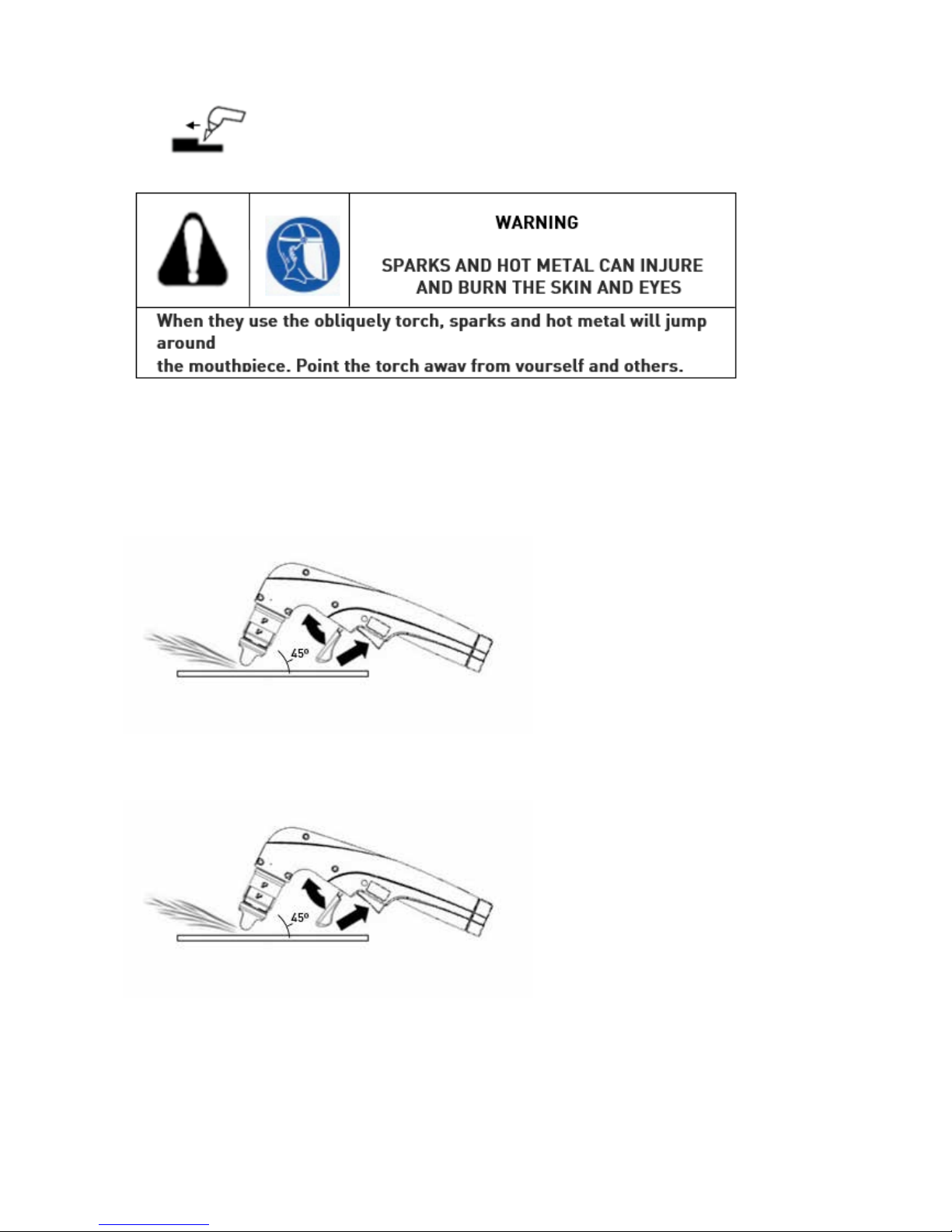

Piercings

Hold the gun so that the nozzle is within 3 mm of the piece before firing.

Trigger the torch obliquely to the piece, then

turn to the vertical position.

When sparks out the piece below, it indicates

that the arc has passed through the material.

After the pierce, proceed to court.

User manual 44

Gouging

Hold the gun so that the nozzle is within 1.5 mm of the piece before firing.

Hold the torch at an angle of 45 ° to

the work piece. Squeeze the trigger

to get a pilot arc. Transfer the plasma

arc to the work piece.

Maintain an approximately 45 ° angle,

of the work piece.

Lean into the slot.

NOTE: A shield is available for heat

for additional hand protection or the

torch.

User manual 45

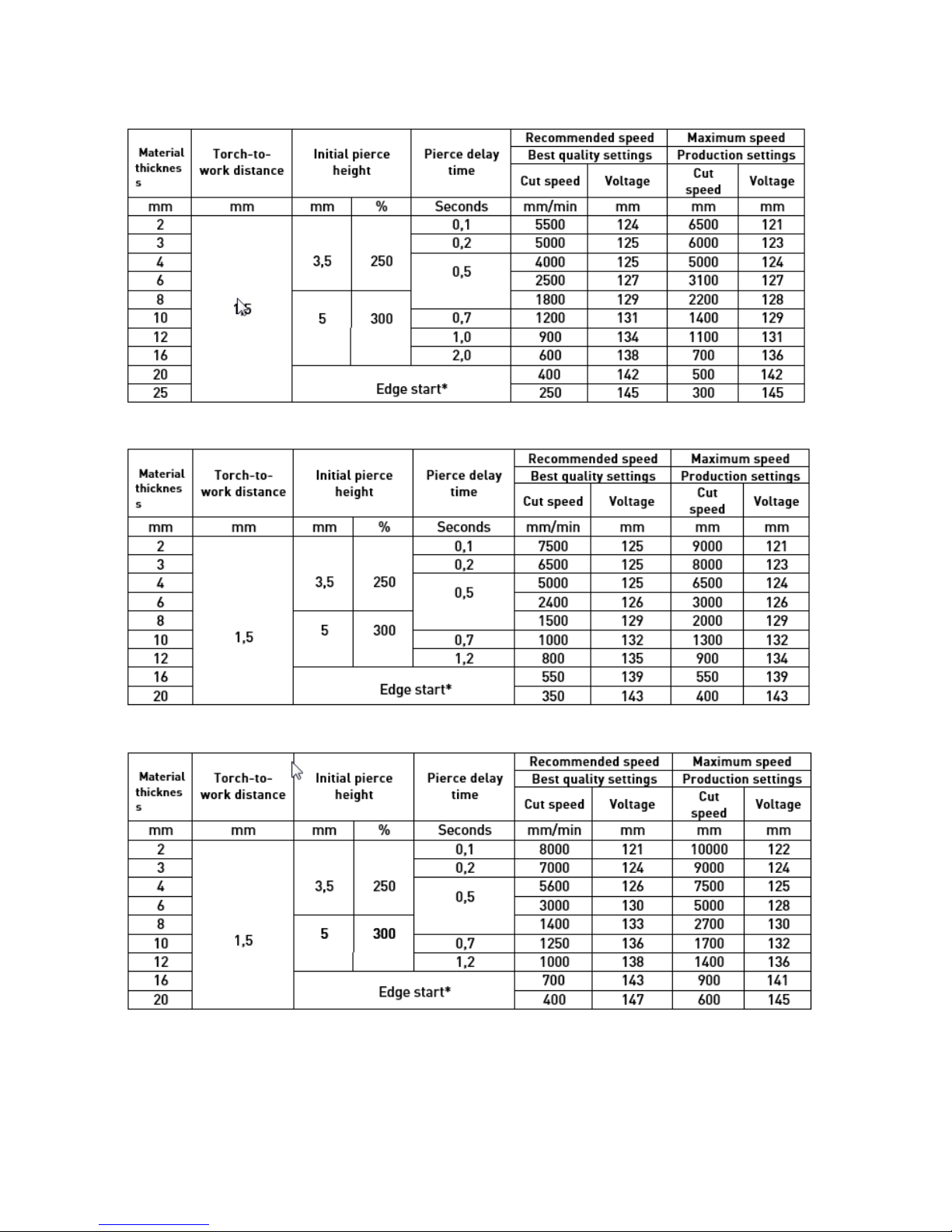

Mechanized unshielded consumables for 45 Amps

Mild steel

Stainless steel

Aluminum

* You can perform thicknesses up to 32 mm. If the CNC software and system control torch

height up provisionally allow the torch to pass over the pond scum that may form in the piercing.

CUTTING CHART

User manual 46

Mechanized unshielded consumables for 65 Amps

Mild steel

Stainless steel

Aluminum

User manual 47

Mechanized unshielded consumables for 85 Amps

Mild steel

Stainless steel

Aluminum

User manual 48

Mechanized unshielded consumables for 105 Amps

Mild steel

Stainless steel

Aluminum

User manual 49

Mechanized unshielded consumables for 125 Amps

Mild steel

Stainless steel

Aluminum

User manual 50

MAINTENANCE

WARNING

ELECTRIC SHOCK CAN KILL THE

Disconnect electrical power before servicing. A

trained technician should do any work that requires removing the cover of the power supply.

Each time it is used Check the gas pressure. Ensure that consumables are

installed properly and are not

worn.

Each week

Examine and check the safety switch for the cap: note the

red fault light and yellow light of the holding cap of the

torch, which illuminate when the cap is loose.

Every 3 months Replace damage labels Check pressure hose, filter

element, and connections for

leaks that.

Replace the cable or the

mains plug if they were

damaged.

Replace the torch cable if

damaged.

Replace damage labels

Every 6 months Clean the inside of the power

source with compressed air

or vacuuming.

Routine maintenance

User manual 51

Consumables inspection

User manual 52

Replace the gas filter element

Disconnect electrical power and gas supply. Remove the filter bowl.

A. Take out the metallic cover of the machine.

B. To release pull the black tab down and hold it.

C. Turn the filter bowl until it releases.

D. Pull the filter bowl down to remove.

Note: Do not discard the O-ring.

Remove the filter element from the filter housing.

Note: Do not allow the filter element turn when loosening the screw.

1.

2.

3. Install the filter bowl.

A. Slide the filter bowl on the filter element.

B. Align the marks on the filter bowl and filter body.

C. Turn the filter bowl until it clicks and locks into place.

User manual 53

Controls and indicators

Lighting indicators

Normal and bevel cutting.

Discontinuous material cutting (grid).

Gouging or remove welding.

Security indicator cap holding the torch.

On indicator signal START.

Indicator transferred arc and start cutting

(motion).

User manual 54

Solution to basic problems

Problems Cause/solution

Turn ON the main switch ON / OFF and the

control do not light

The line cord is not plugged into the socket.

Connect the line cord into the socket.

The power switch is not turned on or there is

no power switch on the power box.

Turn on power at the central panel or switch

box power.

Note: The fan turns ON and turns OFF

automatically. It is possible the fan is not

operating when the power is turned ON.

1. 1.1

1.2

1.3

2. On the display appears ”PHA”. 2.1 On of the three phases supply is not

connected. Check the installation by an

electrician.

3. The display leds, are flashing. 3.1 The voltage of one the phases, is very low.

Check the installation by an electrician.

4. On the display appears “HOT” message. 4.1 One of the internal switches thermostat

has ed due to overheating or low operation under extreme temperature.

Let the plasma generator on and allow

the fan to cool the generator (which is

over heated). Move the power source to a

colder place (extreme cold).

5. On the display appears “SEC”. 5.1 Check the pins or in the back side of the torch

(pins number 1-2-9) some of them could be

broken from outside or disconnected from its

place from inside of the central connector.

Check in the female central connector if

some of the pins (1-2-9) its been pushed back

into the power source and it is not touching

its corresponding male pin from the torch

side.

User manual 55

Problems Cause/solution

The arc does not jump to the part on which

you are working.

Work clamp is not connected to the work

piece, the work clamp is broken, or there

is a wrong connection inside the mass

cable. Connect or repair the mass

clamp/cable.

Work clamp does not make good contact

metal.

Clean the area where the work piece.

Connect the work piece.

The torch is too far from the piece.

Bring the torch to the workpiece and start

again.

6. 6.1

6.2

6.3

7. The arc goes out, but comes back on when

the gun trigger is pulled.

7.1 Consumable parts are worn or damaged.

Check and replace consumable parts if

they are need. Check the consumables in

this section.

The gas pressure is incorrect.

Adjust the gas pressure. See Setting and

check gas pressure, section 4.

Check that the gas pressure in the power

supply is not less than 6.0 bar with a flow

of 200 l / min

The internal filter gas element is

contaminated.

Change the element - See Change the

filter element, in this section.

7.2

7.3

8. The arc sputters and hisses. 8.1 The gas filter element out of the power

source is contaminated.

Replace the filter element.

There is water in the air line.

Drain the filter bowl. See additional

filtration gas in section 3.

Consumables worn or improperly

installed.

Inspect the consumables. Replace if

necessary.

8.2

8.3

9. The cut quality is not good. 9.1 The consumables are worn or not

properly used.

See Inspection of consumables in this

section.

See Operation Torch, section 4.

User manual 56

Solution to basic problems

Problems Cause/solution

On the display appears “VOO” message. The plasma arc is extinguished for lack of

material to be cut.

10. 10.1

11. 11.1

On the display appears“TOR” message.

Consumables are stuck or worn.

Turn the power OFF and check

consumables assembly line.

Technical questions

If you cannot solve a problem by following this basic troubleshooting guide or if you need further

assistance:

1. Call your dealer or authorized service center.

2. Call the nearest office listed at the beginning of this manual.

3. Seek the service manual for the CUT 65 - 125, where you will find wiring diagram,

troubleshooting and high level information lists more pieces.

User manual 57

Electric system circuits draw

User manual 58

PARTS

Configuration of the torch consumables

User manual 59

Configuration of the torch consumables (continuation)

User manual 60

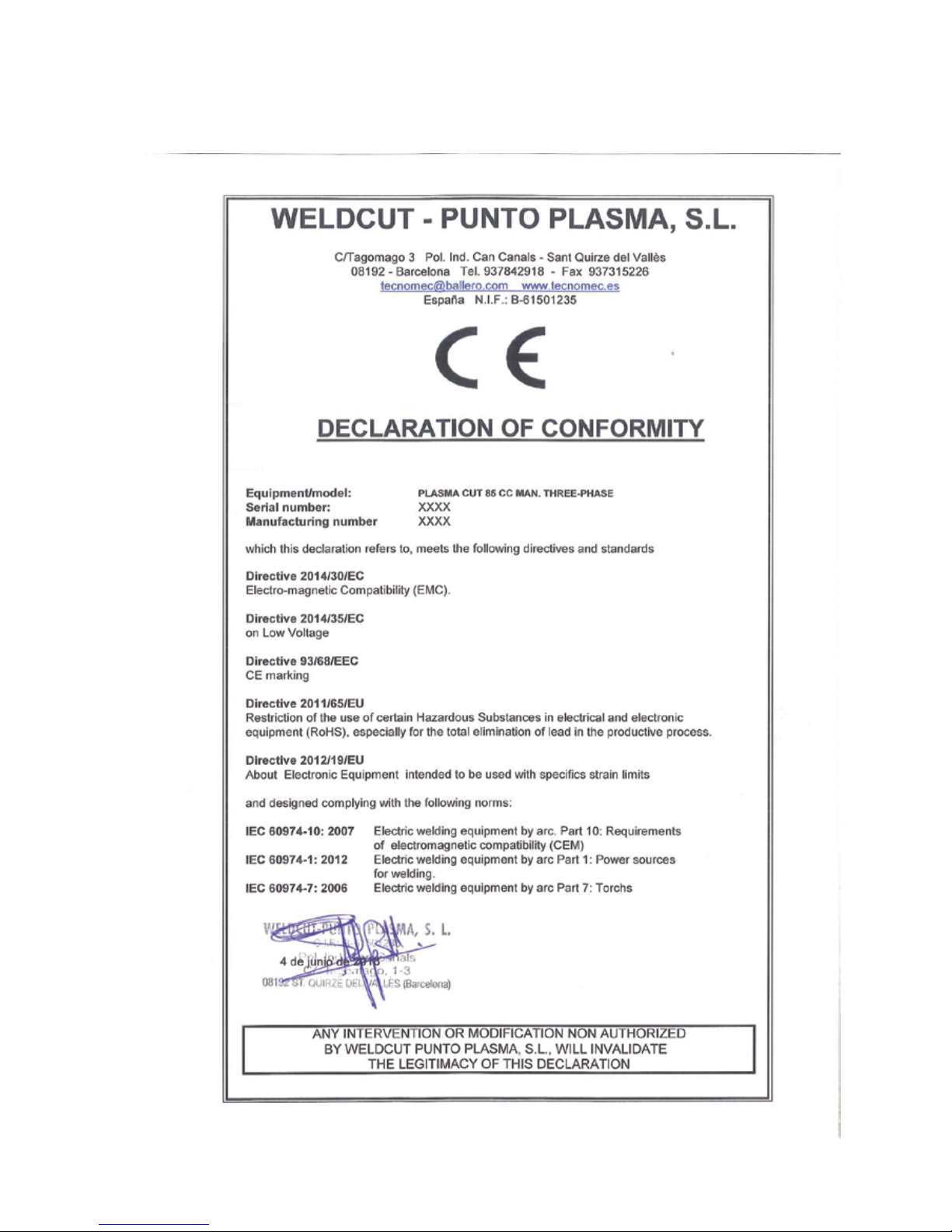

DECLARATION OF CONFORMITY

DOC TW CUT 65

User manual 61

DOC TW CUT 85

User manual 62

DOC TW CUT 105

User manual 63

DOC TW CUT 125

User manual 64

MANUFACTOR AND DISTRIBUTOR INFORMATION

Weldcut-Punto Plasma, S.L.

Pol. Ind. Can Canals Sector Sur-Oeste

C/Tagomago 3

08192 Sant Quirze del Vallés

(Barcelona) ESPAÑA

Tel.: 937842918

Fax: 937315226

http://www.tecnomec.es

tecnomec@ballero.com

Technical data subject to change without notice.

No liability for printing errors.

Text and Illustrations are protected by copyright.

TEAMWELDER Germany GmbH

Tel +49 2623 9276-400

Fax: +49 2623 9276-444

info@teamwelder.com

Sälzerstraße 20a

56235 Ransbach-Baumbach

Germany

Loading...

Loading...