Teaberry НР - 141 T Service Manual

TECHNICAL MANUAL

OPERATOR’S ORGANIZATIONAL, DIRECT SUPPORT, AND

GENERAL SUPPORT MAINTENANCE MANUAL

INCLUDING REPAIR PARTS AND SPECIAL TOOLS LISTS

FOR

SPECTRUM ANALYZER IP-1 21 6(P)/GR

(HEWLETT-PACKARD MODEL 141T)

(NSN 6625-00 424 4370)

This copy is a reprint which Includes current

pages from Change 1.

HEADQUARTERS, DEPARTMENT OF THE ARMY

TM 11-6625-2781-14&P

JUNE 1977

WARNNG NOTICE

A SHOCK HAZARD MAY EXIST ON THE FAN HOUSING OR ANY METAL PART COMMON TO IT . IF ANY OF THE

SERIES REGULATORS, THE TERMINAL SWITCH, OR THE FAN MOTOR ITSELF SHOULD SHORT T O TIHE FAN

HOUSING, A SHOCK HAZARD WOULD EXIST. TO ELIMINATE THE POTENTIAL SHOCK HAZARD, IT IS

NECESSARY TO INSTALL A GROUND WIRE FROM THE FAN HO USING TO T HE CHASSIS OF THE INST RUMENT;

PROCEED AS FOLLOWS:

a. Solder one end of ground wire to the chassis side of R11, as shown at point A of the figure below.

b. Install a starred washer and a ground lug ’under existing hardware, as shown at point B.

c. Solder other end of ground wire to ground lug.

AFTER INSTALLATION OF THE GROUND WIRE, INSURE THE FAN ASSEMBY HAS GOOD CONTINUITY TO

GROUND.

Parts required /one each)

Wire, black, 18 awg, 8 inches

Solder lug

External starred washer

TM 11-6625-2781-14&P

CHANGE

HEADQUARTERS

DEPARTMENT OF THE ARIMY

NO. 1 WASHINGTON, DC, 11

Operator’s, Organizational, Direct Support, And

General Support Maintenance Manual

(Including Repair Parts And Special Tools Lists)

For

SPECTRUM ANALYZER IP- 1216(P)/GR

(HEWLETT-PACKARD MODEL 141T)

(NSN 6625-00-424-4370)

TM 11-6625-2781-14&P, 1 June 1977, is changed as follows:

1. New or changed material is indicated by a vertical bar in the margin of the page.

2. Remove and insert pages as indicated below:

Remove Insert

i through 0-2..................i through 0-2

6-1 through 6-18............None

B-1.................................B- through B-28

C-l through C-5..............C- through C-4

3. File this change sheet in front of the publication for reference purposes.

C1

August 1978,

By Order of the Secretary of the Army:

Official:

J. C. PENNINGTON

Brigadier General, United States Arm

y

The Adjutant General

DISTRI BUTION:

Active Army:

TSG (1) Army Dep (1) except

USAARENBD (1) Fort Carson (5)

USAINSCOM (2) Fort Gillem (10)

TRADOC (2) Fort Huachuca (5)

DARCOM (1) Ft Richardson (CERCOM Ofc) (1)

TECOM (2) LBAD (10)

OS Maj Comd (2) SAAD (30)

USACC (2) TOAD (14)

HISA (Ft Monmouth)(33) SHAD (3)

Armies (I) Sig See USA Dep (1)

USASIGS (10) Units org under fol TOE’

Svc Colleges (1) 29-134 (1)

WSMR (1) 29-136 (1)

USAERDAA (1) 29-207 (2)

USAERDAW (1) 29-610 (2)

USA Dep (1)

NG.

None

USAR

For explanation of abbreviations used see, AR 310-50

None

BERNARD W. ROGERS

General, United States Army

Chief of Staff

TM 11-6625-2781-14&P

This manual contains copyright material reproduced by permission of the Hewlett-Packard Company.

TECHNICAL MANUAL, HEADQTUARTERS

DEPARTMIENT OF THE AR MY

} WASHINGTON ,

NO 11-6625-2781-14&P

OPERATOR’S, ORGANIZATIONAL, DIRECT SUPPORT, AND

GENERAL SUPPORT MAINTENANCE MANUAL

(INCLUDING REPAIR PARTS AND SPECIAL TOOLS LISTS)

FOR

SPECTRUM ANALYZER IP- 1216(P)/GR

(HEWLETT-PACKARD MODEL 141T)

(NSN 6625-00-424-4370)

REPORTING OF ERRORS

You can improve this manual by recommending improvements using DA Form 2028-2 (Test)

located in the back of the m anual. Simply tear out the self-addressed form , fill it out as shown on the

sample, fold it where shown, and drop it in the mail.

If there are no blank DA Forms 2028-2 (T est) in the back of your manual, use the standard DA

Form 2028 (Recomm ended Changes to Publications and Blank Forms) and forward to the Com mander,

US Army Communications and Electronics Materiel Readiness Command, ATTN: DRSEL-MA-Q, Fort

Monmouth, New Jersey 07703.

1JUNE 1977

In either case a reply will be furnished direct to you.

Change 1 i

TM 11-6625-2781-14&P

SAFETY SUMMARY

The following general safety precautions must be observed during all phases of operation, service, and repair of this

instrument. Failure to comply with these precautions or with specific warnings els ewhere in his manual violates safety

standards of design, manufacture, and intended use of the instrument. Hewlett-Pac kard Company assumes no liability for

the customer’s failure to comply with these requirements.

GROUND THE INSTRUMENT.

To minimize shock hazard, the instrument chassis and cabinet must be connected to an electrical gr ound. The instrument

is equipped with a three-conductor ac power cable. The power cable must either be plugged into an approved threecontact electrical outlet or used with a three-contact to two-contact adapter with the grounding wire (green) firmly

connected to an electrical ground (safety ground) at the power outlet. The power jack and mating plug of the power cable

meet International Electrotechnical Commissioned (IEC) safety standards.

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE.

Do not operate the instrument in the presence of flammable gases or fumes. Operation of any electric al instrument in

such an environment constitutes a definite safety hazard.

KEEP AWAY FROM LIVE CIRCUITS.

Operating personnel must not remove instrument covers. Component replacement and internal adjustments must be

made by qualified maintenance personnel. Do not replace components with power cable connected. Under certain

conditions, dangerous voltages may exis t even with the power c able removed. To av oid injuries always dis connect power

and discharge circuits before touching them.

DO NOT SERVICE OR ADJUST ALONE.

Do not attempt internal service or adjustment unless another person, cable of rendering first aid and resuscitation, is

present.

USE CAUTION WHEN EXPOSING OR HANDLING THE CRT.

Breakage of the cathode-ray tube (CRT) causes a high velocity scattering of glass fr agments ( implosion) . To pr event CRT

implosion, avoid rough handling or jarring of the instrument. Handling of the CRT shall be done only by qualified

maintenance personnel using approved safety mask and gloves.

DO NOT SUBSTITUTE PARTS OR MODIFY INSTRUMENT.

Because of the danger of introducing additional hazards, do not install substitute parts or perform any unauthorized

modification to the instrument. Return the instrument to a Hewlett-Packard Sales and Service Officer for service and

repair to ensure that safety features are maintained.

DANGEROUS PROCEDURE WARNINGS.

Warnings, such as the example below, precede potentially dangerous procedures throughout this manual. Instructions

contained in the warnings must be followed.

Dangerous voltages, capable of causing death, are present in this instrum ent. Use ex trem e caution when

handling, testing, and adjusting.

Change 1 ii

Model 141T

TM 11-6625-2781-14&P

TABLE OF CONTENTS

Section Title Page

0 GENERAL..................................................................... 0-1

I GENERAL INFORMATION........................................... 1-1

1-1 Introduction.........................................................1-1

1-4 Description..........................................................1-1

1-9 Cathode Ray Tube..............................................1-1

1-11Warranty.............................................................1-1

1-13Associated Equipment........................................1-1

1-15Instrument and Manual Identification..................1-3

1-19Inquiries.................................................................1 - 1-3

II INSTALLATION.................................................. 2-1

2-1 Introduction........................................................ 2-1

2-3 Initial Inspection................................................. 2-1

2-6 Preparation for Use............................................ 2-1

2-9 Three-conductor Ac Power Cable..................... 2-2

2-11Instrument Mounting.......................................... 2-2

2-14Instrument Cooling............................................. 2-3

2-17Claims......................................................... 2-3/’2-4

2-19Repacking for Shipment.............................. 2-3/2-4

III OPERATION...................................................... 3-1

3-1 Introduction........................................................ 3-1

3-3 Controls and Connectors................................... 3-1

3-5 Trace Align......................................................... 3-1

3-7 Beam Finder...................................................... 3-1

3-9 Focus and Astigmatism..................................... 3-1

3-11Z-axis Input........................................................ 3-1

3-13Plug-in Units...................................................... 3-1

3-19Operating Considerations.................................. 3-4

3-20Definitions.......................................................... 3-4

3-22Control Functions............................................... 3-4

3-30Operating Procedures........................................ 3-5

3-32Single-shot Operation........................................ 3-6

SectionTitle Page

V PERFORMANCE CHECK AND AD-

JUSTMENTS.................................................................5-1

5-1 Introduction...................................................... 5-1

5-3 Test Equipment.................................................5-1

5-5 Performance Check......................................... 5-1

5-8 Preliminary Setup............................................ 5-1

5-9 Beam Finder.....................................................5-2

5-11 Focus and Astig............................................... 5-2

5-13 Trace Align.................................................... 5-5-2

5-14 Calibrator......................................................... 5-2

5-15 Variable Persistence.........................................5-2

5-16 Writing Speed, Fast..........................................5-2

5-17 Store Time, Fast.............................................. 5-3

5-18 Writing Speed, Standard....................................53

5-19 Store Time, Standard....................................... 5-3

5-21 Adjustments.................................................... 5-3

5-24 Preliminary Setup........................................... 5-3

5-25 Low Voltage Power Supply

Adjustment....................................................... 5-3

5-26 High Voltage Power Supply

Adjustment....................................................... 5-3

5-27 Intensity Limit Adjust........................................ 5-4

5-28 -Geometry--..................................................... 5-5

5-29 Calibrator Adjustment...................................... 5-5

5-30 Pulse Circuit Adjustments................................ 5-5

VI REPILACEABILE PARTS DELETED

VII MANUAL CHANGES AND OPTIONS.............. 7-1

7-1 Introduction.......................................................7-1

7-3 Manual Changes...............................................7-1

7-5 Special Options.................................................7-4

7-9 Standard Options..............................................7-4

7-14. Additional Manual Changes................................7-4

IV PRINCIPI,ES OF OPERATION.......................... 4-1

4-1 Introduction........................................................ 4-1

4-3 Overall Functional Description........................... 4-1

4-5 Low-voltage Power Supply................................. 4-1

4-7 Calibrator.......................................................... 4-1

4-9 High-voltage Power Supply................................ 4-1

4-11Pulse Circuit....................................................... 4-2

4-13Horizontal Driver Circuit..................................... 4-2

4-15Circuit Description.............................................. 4-2

4-16Low-voltage Power Supply................................. 4-2

4-24Calibrator........................................................... 4-3

4-28High-voltage Supply........................................... 4-3

4-34Storage CRT...................................................... 4-4

4-41lPulse Circuit....................................................... 4-4

4-41 STD and Fast Modes......................................... 4-4

1-5,3 Pulse Circuit’ Store Mode............................... 4-6

4-57 Pulse Circuit: Conventional Mode.................. 4-6

4-60 Trace Align............................................... 4-7/4-8

4-62 Plug-in Kit Fabrication.............................. 4-7/4-8

Change 1 iii

VIII SCHEMATICS AND TROUBLE-

SHOOTING...................................................... 8-1

8-1 Introduction.......................................................8-1

8-3 Schematics.......................................................8-1

8-8 Reference Designations...................................8-1

8-12 Component Locations...................................... 8-1

8-14 Preventive Maintenance.................................. 8-1

8-15 DELETED.

8-17 Filter Maintenance............................................8-2

8-19 Electrical Maintenance......................................8-2

8-21 Repair and Replacement................................. 8-2

8-23 Instrument Repair.............................................8-2

8-26 CRT Removal and Replacement......................8-2

8-29 Fan Removal and Replacement...................... 8-2

8-31 Semiconductor Replacement........................... 8-2

List of Illustrations

TM 11-6625-2781-14&P

TABLE OF CONTENTS

Section Title Page

8-33.Servicing Circuit Boards..................................... 8-3

8-36. Overall Troubleshooting..................................... 8-3

8-39.Front Panel Controls.......................................... 8-4

8-41.Visual Checks.................................................... 8-4

8-43.Waveforms and Voltages..................................... 8-4

8-45.Final Checks...................................................... 8-4

8-47Detailed Troubleshooting................................... 8-4

8-48.Low-Voltage Supply........................................... 8-4

8-55.High-Voltage Supply.......................................... 8-6

8-60Pulse Circuit....................................................... 8-6

APPENDIX A References............................................. A-1

APPENDIX B Organizational, Direct Sup-

port, and General Support

’Maintenance Repair Parts

and Special Tools List (Including Depot Maintenance

Repair Parts and Special

Tools)

I INTRODUCTION.......................................................... B-1

II REPAIR PARTS LIST................................................... B-9

LIST OF ILLUSTRATIONS

Figure Title Page

1-1 Model 141T Display Section.............................. 1-0

1-2 Instrument Serial Number -................................ 1-3

2-1 Voltage Selection............................................... 2-1

2-2 Rear Mounting Procedure.................................. 2-2

3-1. Mode(141T Controls and Connectors................ 3-2

3-2 Intensity Adjustment.......................................... 3-3

3-3 Background Illumination immediately

after- erasing with ’RITING SPEED

in FAST and PERSISTENCE to

MAX S................................................................ 3-5

3-4 Persistence with a Slow Repetitive

Sweep............................................................... 3-5

3-5 Single-shot Trace Bloom caused by

INTENSITY and/or PERSISTENCE

set too high........................................................ 3-5

.3-6.Single-shot Display With INTENSITY

and PERSISTENCE set the same as

figure 3-5 and Increased Amplitude................... 3-5

3-7. Fade Positive after 2 to 4 minutes

in STD mode...................................................... 3-6

3-8 Single-shot 20 usec/div display......................... 3-6

3-9 Same Display as figure :3-S after

three minutes in STD mode............................... 3-6

Model 1llT

Section Title Page

Group OOSpectrum Analyzer IP-1216(P)/

GR (Hewlett-Packard Model

141T)....................................................... B-9

01 Circuit Card Assembly, Al..................... B-13

02 Circuit Card Assembly, Power

Supply, A2............................................. B-17

03 Circuit Card Assembly, Pulse, A.5........ B-21

04 Circuit Card Assembly, Horizon

tal Drive, A6.......................................... B-25

III SPECIAL TOOLS LIST (Not applicable)

IV NATIONAL STOCK NUMNBER AND

PART NUMBER INDEX........................ B-26

APPENDIX C Maintenance Allocation

I INTRODTUCTION.................................. C-1

II MAINTENANCE ALLOCATION

CHART.................................................... C-3

III TOOL AND TEST EQIUIPMENT

REQUIREMENTS................................... C-4

IV REMARKS (Not applicable)

Figure Title Page

3-10.Small Bright Spots caused by Minute

Imperfections in Storage Mesh.......................... 3-6

4-1. Model 141T Block Diagram ---........................... 4-1

4-2. Regulated Power Supply- Block

Diagram-............................................................ 4-2

4-3. High-voltage Power Supply Block

Diagram............................................................. 4-3

4-4. Pulse Circuit Block Diagram.............................. 4-5

4-5. Erase Functional Waveform.............................. 4-6

5-1ASpectrum Analyzer Intensity Limit

adjust-................................................................ 5-4

5-1. Adjustment Location...................................... 5-7/5-8

6-1

thru

6-5DELETED...........................................................................I

7-1A.Effect of Change 11........................................... 7-3

7-1. Component Identification Pulse

Circuit A5........................................................... 7-5

7-2 Pulse Circuit Schematic..................................... 7-5

7-3 Line Voltage Schematic..................................... 7-6

7-4. Option 009 Schematic Diagram......................... 7-6

7-5. Pulse Circuit Schematic..................................... 7-7

7-6 Line Voltage Schematic..................................... 7-8

Change 1 iv

Model 141T

TM 11-6625-2781-14&P

LIST OF ILLUUSTRATIONS

Figure Title Page

8-1 Semiconductor Terminal Identi-

fication............................................................ 8-3

8-2 Component Location, Top View..................... 8-8

8-3 Component Location, Bottom View................ 8-9

8-4 Component Location, Front View................. 8-10

8-5 Component Location, Rear View -............... 8-12

8-6 Plug-in Jack Connections............................. 8-13

8-7 Auxiliary A and Auxiliary B Wiring

Diagram........................................................ 8-13

8-8 Component Identification, Power

Supply A2..................................................... 8-14

8-9. Component Identification, Diode

Assy A1........................................................ 8-15

8-10. Low Voltage Schematic................................ 8-15

8-11. Component Identification, Power

Supply A2..................................................... 8-16

8-12. Component Identification, Horizontal

Driver A6...................................................... 8-17

8-13. High Voltage Schematic............................... 8-17

8-14. Component Identification, Pulse

Circuit A5...................................................... 8-18

8-15. Waveforms................................................... 8-19

8-16 Pulse Circuit Schematics............................ 8-19

LIST OF TABLES

Figure Title Page

B-1 Spectrum Analyzer IP-1216(P)/GR

(Hewlett-Packard Model 141T)

(Sheet 1 of 5)................................................. B-4

B-1 Spectrum Analyzer IP-1216(P)/GR

(Hewlett-Packard Model 141T)

(Sheet 2 of 5)................................................. B-4

B-1 Spectrum Analyzer IP-1216(P)/GR

(Hewlett-Packard Model 141T)

(Sheet 3 or 5)................................................. B-6

B-1 Spectrum Analyzer IP-1216(P)/GR

(Hewlett-Packard Model 141T)

(Sheet 3 or 5)................................................. B-6

B-1 Spectrum Analyzer IP-1216(P)/GR

(Hewlett-Packard Model 141T)

(Sheet 5 of 5)................................................. B-8

B-2 Circuit Card Assembly, Diode...................... B-12

B-3 Circuit Card Assembly, Power Supply

(Sheet 1 of 2)............................................... B-15

B-3 Circuit Card Assembly, Power Supply

(Sheet 2 of 2)............................................... B-16

B-4 Circuit Card Assembly, Pulse...................... B-20

B-5 Circuit Card Assembly, Horizontal

Drive............................................................. B-24

Table Title Page

1-1 Specifications..................................................... 1-2

1-2. Reference Designators and Abbre-

viations-............................................................. 1-3

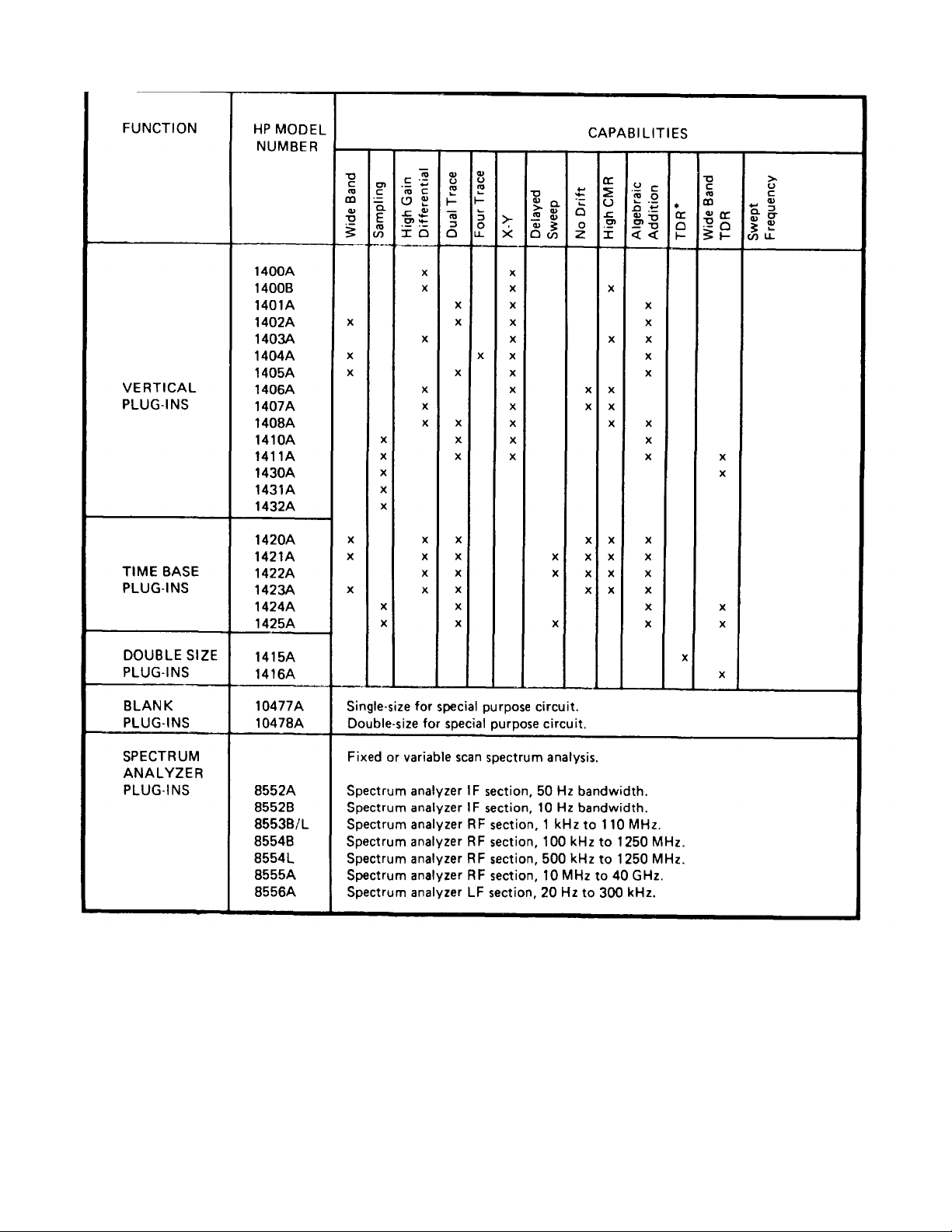

1-3. Plug-ins for Model 141T Display

Section................................................................1-4 -1-

4-1. Current Capability........................................ 4-7/4-8

5-1 Recommended Test Equipment........................ 5-1

Performance Check Record............................. 5-4a

5-2 Low Voltage Power Supply Adjustment............. 5-4

Change 1 v

Table Title Page

6-1

thru

6-4 DELETED

7-1 Manual Changes................................................7-1

7-2 DELETED

7-3 Option 009, Replaceable Parts...........................7-4

8-1 Troubleshooting High-voltage Supply,

No Voltage..........................................................8-5

8-2. Troubleshooting Hligh-voltage Supply,

Incorrect Voltage............................................... 8-5

8-3. Schematic Diagram Notes................................. 8-7

TM 11-6625-2781-14&P

General Information Model 141T

141T-R-14 1

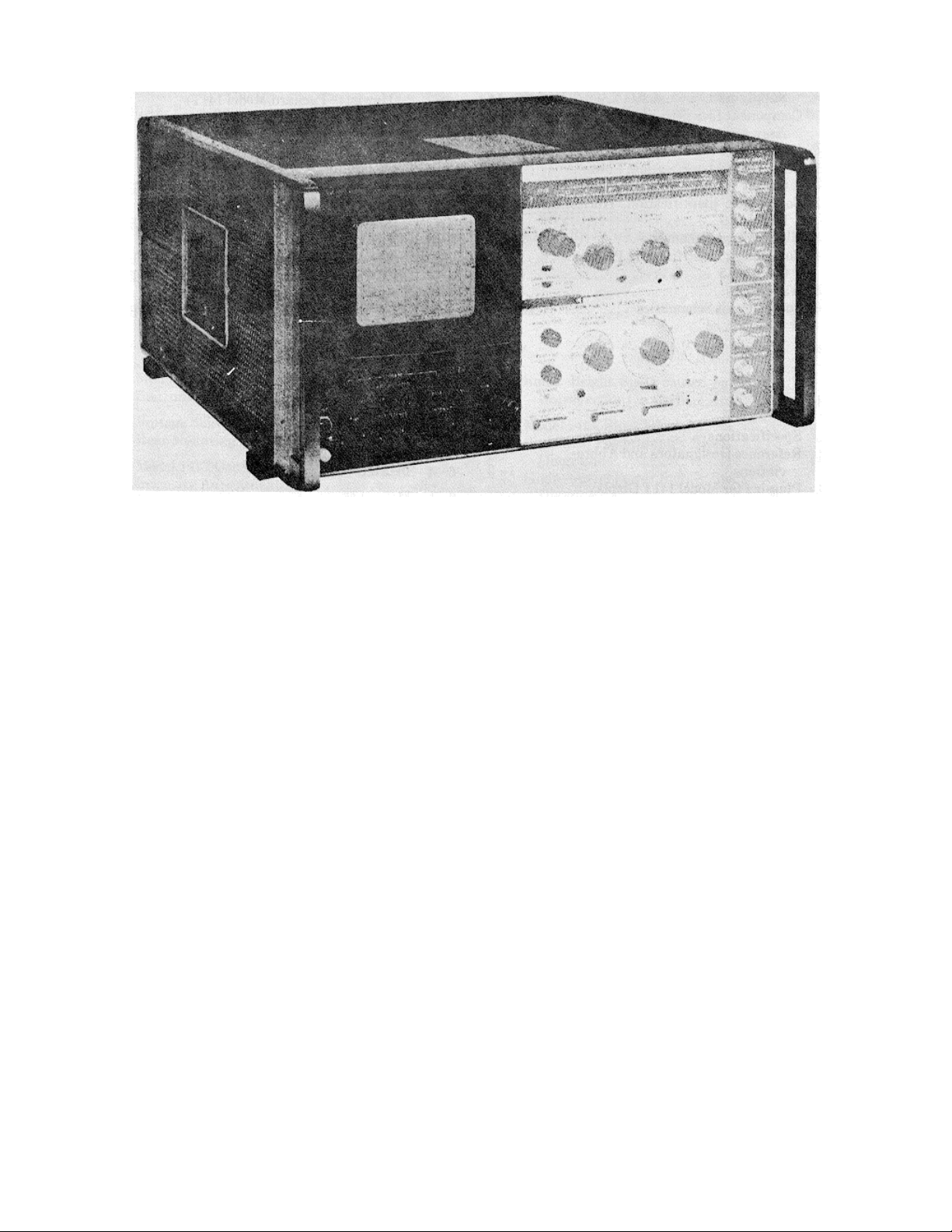

Figure 1-1. Model 141T Display Section

1-0

TM 11-6625-2781-14&P

SECTION 0

GENERAL

0-1. SCOPE.

This manual describes Spectrum Analyzer IP-1216(P)/GR (fig. 1-1) and provides instructions for operation and

maintenance. Through- out this manual, the IP-a216(P)/GR is referred to as the Hewlett-Packard Model lh1T.

0-2. INDEXES OF PUBLICATIONS.

a. DA Pam 310-4. Refer to the latest issue of DA Pam 310-4 to determine whether there are new editions,

changes, or additional publications pertaining to the equipment.

b. DA Pam 310-7. Refer to DA Pam 310-7 to determine whether there are modification work orders (MW O’s)

pertaining to the equipment.

0-3. FORMS AND RECORDS.

a. Reports of Maintenance and Unsatisfac tory Equipment. Maintenance forms, recor ds, and reports which are to

be used by maintenance personnel at all maintenance levels are listed in and prescribed by TM 38-750.

b. Report of Packaging and Handling Deficiencies. Fill out and forward DD Form 6 (Packaging Improvement

Report) as prescribed in AR700-58/NAVSUPINST 4030.29/AFR 71-13/MCO P4030.29A and DSAR 4145.8.

c. Discrepancy in Shipment Report (DISREP) (SF 361). Fill out and forward Discrepancy in Shipment Report

(DISREP) (SF 361) as prescribed in AR 55-38/NAVSUPINST 4610.33A/AFR 75-18/MCO P4610.19B and

DSAR 4500.15.

0-4. REPORTING EQUIPMENT IMPROVEMENT RECOMMENDATIONS (EIR).

EIR’s will be prepared using DA Form 2407, Maintenance Request. Instructions for preparing EIR’s are provided in

TM 38-750, The Army Maintenance Management System. EIR’s should be mailed directly to Commander, US Army

Communications and Electronics Materiel Readiness Command, AT TN: DRSEL-MA,-Q, Fort Monmouth, NJ 07703. A

reply will be furnished directly to you.

Change 1 0-1

TM 11-6625-2781-14&P

0-5. ADMINISTRATIVE STORAGE.

Administrative storage of equipment issued to and used by Army activities shall be in accordance with TM 740-90-1.

0-6. DESTRUCTION OF ARMY ELECTRONICS MATERIEL.

Destruction of Army electronics materiel to prevent enemy use shall be in accordance with TM 750-244-2.

0-2

TM 11-6625-2781-14&P

Model 141T General Information

SECTION I

GENERARAL INFORMATION

1-1. INTRODUCTION.

1-2. This manual provides operating and service

information for the Hewlett-Pack ard Model 141T Display

Section (figure 1-1). The manual is divided into eight

sections, each covering a specific topic or as pect of the

instrument. All schematics are located at the rear of the

manual and can be unfolded and used for reference

while reading any part of the manual.

1-3. This section contains a description of the Model

141T. The instrum ent s pecific ations ar e listed in table 1-

1. Table 1-2 lists and describes the abbreviations used

in this manual except Section VI. The parts list is a

computer printout and uses computer supplied

abbreviations. Table 1-3 contains a list of current plugins available for use with the Model 141T.

1-4. DESCRIPTION.

1-5. The Model 141T is designed for use as a display

section for the HP Model 141T/8550-series plug-in

spectrum analyzer and as an oscilloscope when used

with HP Model 1400-series plug-ins. The instrum ent has

variable persistence (duration of trace afterglow) and

storage of CRT displays. Persistence is variable from

0.2 second to more than 60 seconds . A display can be

stored (at reduced intensity) for more than hours or

displayed at normal intensity for up to 1 minute. Stored

displays can be erased in 350 milliseconds.

20 MHz and sensitivities to 100 microvolts per division

are available as well as time domain reflectometry and

swept frequency indicator units.

1-9. CATHODE RAY TUBE.

1-10. The Model 141T uses a post- ac celer ator CRT with

a non-glare rectangular faceplate. An internal graticule is

located on the same plane as the display to eliminate

parallax errors. The tube has a 9-kV accelerating

potential, and 8 vertical by 10 horizontal divisions. A type

P31 phosphor is used in the standard CRT.

CAUTION

The warranty may be void for

instruments having a mutilated serial

number tag.

1-11. WARRANTY.

1-12. The instrument ( except the CRT) is certified and

warranted as stated on the inside front cover of this

manual. The CRT is covered by a separate warranty.

The CRT warranty and a warranty claim form are located

at the rear of this manual. Should the CRT fail within the

time specified on the CRT warranty page, complete the

warranty claim form and return it with the defective CRT.

The procedure for returning a defective CRT is described

on the CRT warranty page.

1-6. Variable persistence is especially useful for viewing

slow-sweep signals. The persistence of the signals f rom

electrocardiograms or other bio-chemical phenomena

can be adjusted to provide a complete trace, yet to fade

fast enough to prevent interference with the next trac e..

Display persistence of swept frequency and time domain

reflectometry measurem ent readouts can be adj usted to

eliminate flicker and still provide high resolution.

1-7. The storage feature of the instrum ent can be used

to store single-shot waveforms and to later view or

photograph the phenomena. Comparis on of wave form s

can be accomplished by storing several display

separately and then viewing them simultaneously.

1-8. The instrument ac cepts all HP Model 1400 series

plug-in units. Amplifiers with bandwidths to

1-13. ASSOCIATED EQUIPMENT.

1-14. Plug-ins available for use with the instrument are

listed in table 1-3 and in the Hewlett-Packard

Instrumentation Catalog. The instrument is normally

operated with an IF section plug-in in the lower

compartment and an RF section plug-in in the upper

compartment. T he instrument can also be used as an

oscilloscope with a vertical plug-in in the lower

compartment and a time-base plug-in in the upper

compartment. Both plug-in com partments are the sam e

size, and the plug-in instruments may be interchanged

for any special application. The divider shield that

separates the two compartments can be removed and

one double sized plug-in installed. Blank plug-in kits,

both single and double sized, are available for fabrication

of special circuits. See table 4-1 for power supply

current limitations.

1-1

TM 11-6625-2781-14&P

General Information Model 141T

Table 1-1. Specifications

PLUG-INS

Accepts Model 8050-series IF and RF Section spectr um

analyzer plug-ins without the use of a center divider

shield

Also, accepts all HP Model 1100-series plug-ins. All

plug-ins operate directly into the horizontal and vertical

deflection plates. Centaur shield may be removed to

provide double-sized compartment f or use with a single,

dual axis Model 1400-series unit.

CATHODE-RAY TUBE

Type:

Post-accelerator storage tube; 9000s V accelerating

potential; aluminized P31 phosphor; etched safety glass

face plate.

Graticule:

8 x 10 divisions (approx. 7.1 .: 8.9 cm) parallax-free

internal graticule. Subdivisions of 0 2 div per major

division on major horizontal and vertical axes.

Intensity Modulation:

AC coupled, -20 volt pulse will blank trace of normal

intensity, input terminals on rear panel.

PERSISTENCE

Conventional:

Natural persistence of P31 phosphor (about 40 usec).

Variable:

STANDARD W riting Speed Mode: Continuously variable

from less than 0.2 second to more than one minute.

STORAGE TIME

Standard Writing Speed: more than two hours at

reduced brightness (typically four hours). Traces may be

viewed at maximum brightness for more than one

minute.

Fast Writing Speed. traces may be stored at reduced

brightness for more than 15 minutes (typically 30

minutes) or stored at m axim um br ightness for more than

15 seconds.

Brightness:

100 foot-lamberts in standard mode.

CALIBRATOR

Type:

Line-frequency rectangular signal, approximately 0.5

usec rise time.

Voltage.

Two outputs. 1 volt and 10 volts peak-to-peak ±1% from

15°C to 35°C, t3%, from 0°C to 55°C.

BEAM FINDER

Pressing BEAM FINDER pushbutton brings trace on

screen regardless of setting of horizontal, or vertical

position controls.

GENERAL

Power Requirements:

100, 120, 220 or 240 volts (+5 to --10%), 48 to 66 Hz

(Option H16 48 to 440 Hz), normally less than 285 watts

(varies with plug-in units).

ERASE

Manual or optional remote (see Section VII options):

Erasure takes approximately 350 msec ; scope ready to

record immediately after erasure.

WRITING SPEED PHOTOGRAPHIC

Conventional operation (using a HP Model 197A camera

with f/1.9 lens and Polaroid’ 3000 speed-film): 100 div

’usec.

WRITING SPEED

Storage:

Standard Mode: greater than 20 div/ms. Fast Mode:

greater than I div/usec.

Weight:

Net, 40 lbs (18 kg) (without plug-ins). Shipping,

51 lbs. (23 kg).

1-2

Model 141t

TM 11-6625-2781-14&P

1-15. INSTRUMENT AND MANUAL IDENTIFICATION.

1-16. This manual applies directly to Model 141T

instruments with a serial prefix num ber as listed on the

manual title page, The serial prefix number is the first

group of digits in the instrument serial number (f igure 1-

2). The instrument serial number is

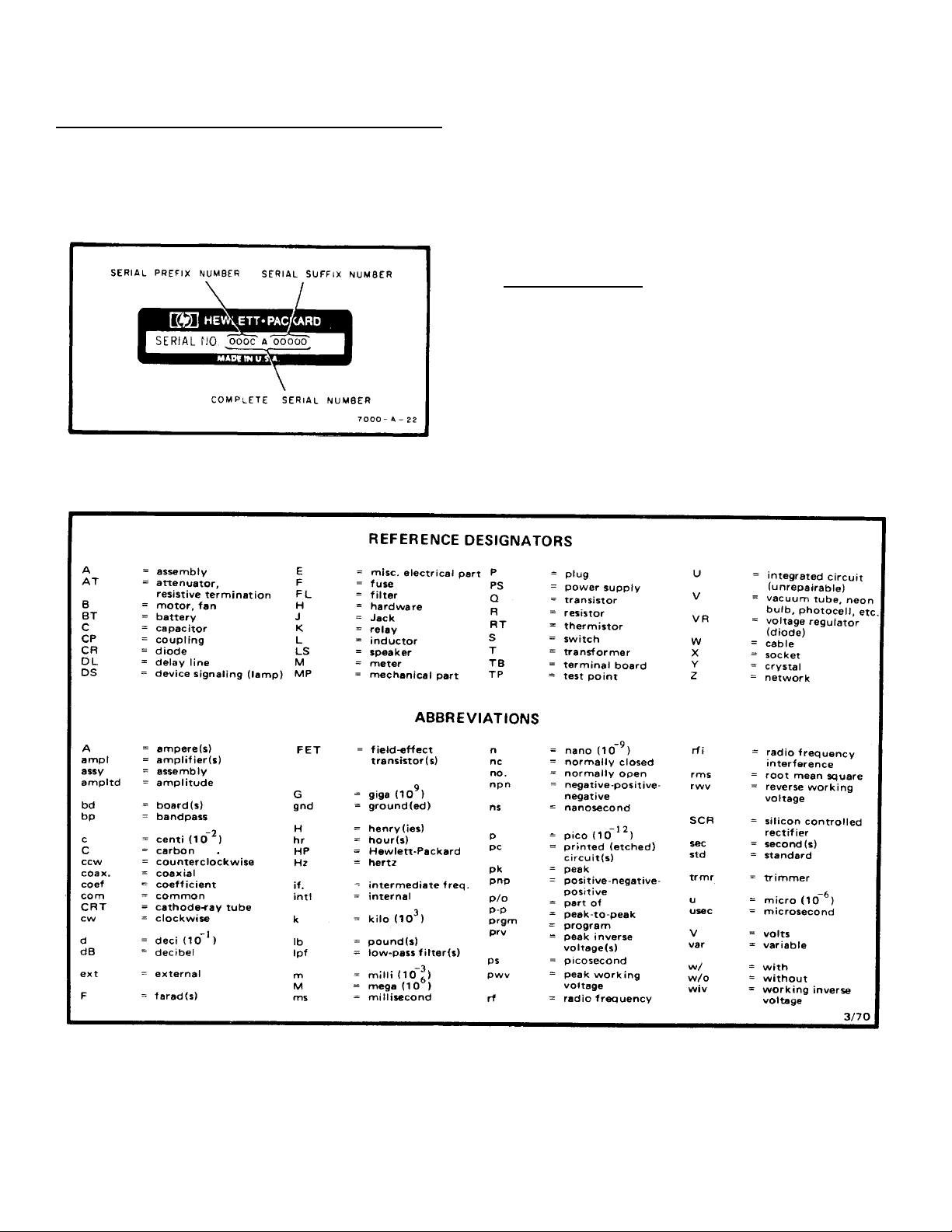

Figure 1-2. Instrument Serial Number

Table 1-2. Reference Designators and Abbreviations

1-17 Check the serial prefix number of the instr ument.

If the serial prefix num ber is diff erent from that listed on

the title page of this manual, refer to Section VII for

instructions to adapt this manual for proper instrument

coverage.

1-18. Errors in the manual are listed under errata on an

enclosed MANIUAL CHANGES sheet (if any).

1-19. INQUIRIES.

1-20) Refer any questions regarding the manual, the

change sheet, or the instrument to the nearest HP Sales

/Service Office. Always identify the instrum ent by model

number, complete nam e, and complete serial num ber in

all correspondence. Refer to the inside r ear c over of this

manual for a world-wide listing of HP Sales/Service

Offices

1-3

TM 11-6625-2781-14&P

Time Domain Reflectometry.

1-4

TM 11-6625-2781-14&P

Model 141T Installation

SECTION II

INSTALLATION

2-1. INTRODUCTION.

2-2. This section contains instructions for perf orming an

initial inspection of the Model 141T. Installation

procedures and precautions are presented in step-bystep order. The procedures for making a claim for

warranty repairs and for repacking the instrument for

shipment are also described in this section.

2-3. INITIAL INSPECTION.

2-4. The instrument was inspected mechanically and

electrically before shipment. Upon receipt, inspect it f or

damage that may have occurred in transit. Check for

broken knobs, bent or brok en connectors, and dents or

scratches. If damage is found, refer to the claims

paragraph in this section. Retain the packing material for

possible future use.

2-5. Check the electrical perf ormance of the instrument

immediately after receipt. Refer to Section V for the

performance chec k procedure. The performance chec k

will determine whether or not the instrument is operating

within the specifications listed in table 1-1. Initial

performance and acc uracy of the instrum ent are certif ied

as stated on the inside front cover of this manual. If the

instrument does not operate as specified, refer to the

claims paragraph in this section.

2-6. PREPARATION FOR USE.

2-7. The instrument requires a power source of 100-,

120-, 220-, or 240-volt +5 - 10o, single phase, 48 to 440

Hz, that can deliver approximately 400 volt-amperes. A

removable jumper board in power module A7, provides

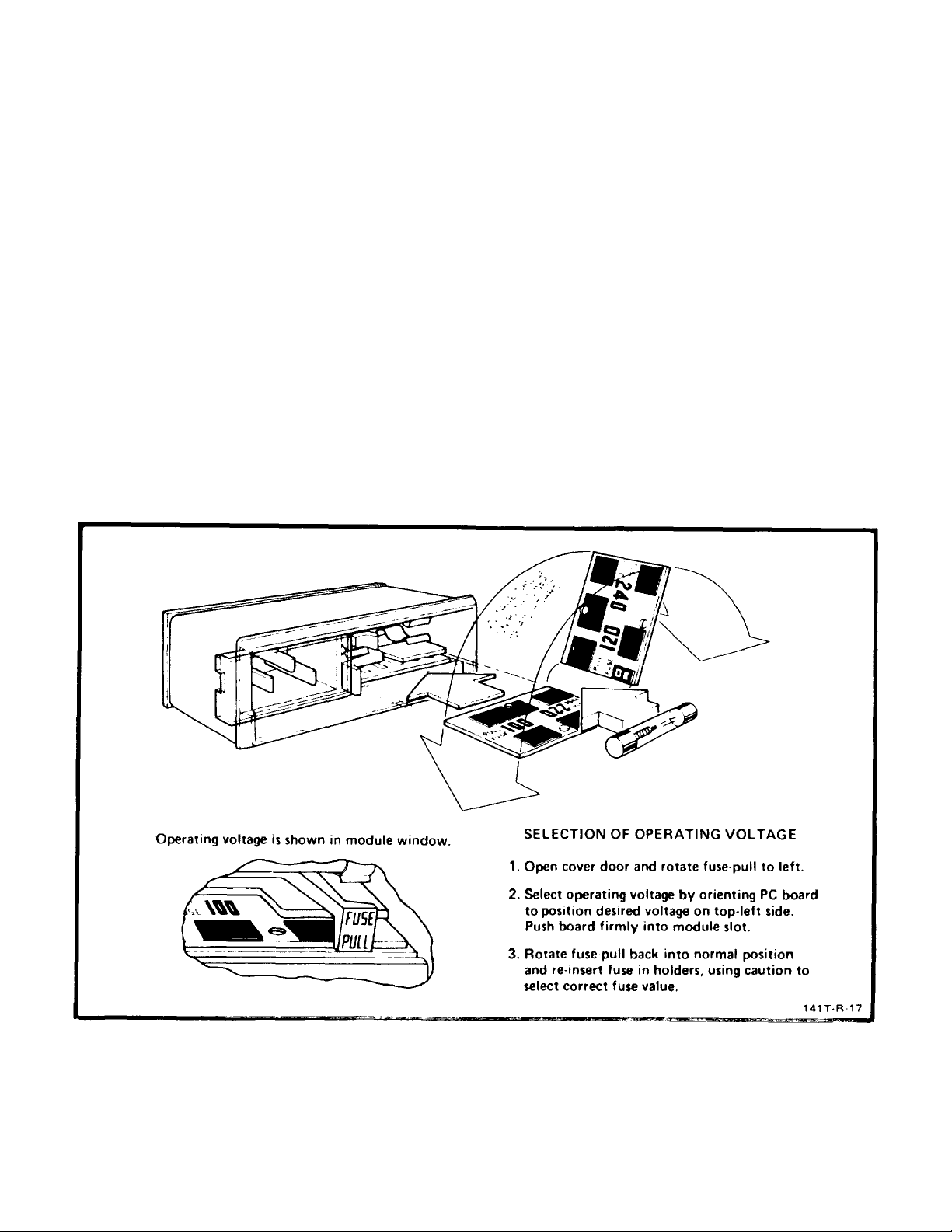

selection of the line voltage to be used (figure 2-1).

Figure 2-1. Voltage Selection

2-1

TM 11-6625-2781-14&P

Installation Model 141T

CAUTION

Before placing the Model 141T in operation, ensure that

the operating voltage indicated in the power module

window (figure 2-1) agrees with the line voltage being

used.

To avoid damaging CRT perform Intensity adjustment

(figure 3-2).

2-8. When oper ating the Model 141T from a 1OOV or

125V source, replace line fuse with a 4A slow-blow f use

When operating from a 220V or 240V source, replace

line fuse with a 2A slow-blow fuse.

2-9. THREE-CONDUCTOR AC POWER CABLE.

2-10. For the protection of operating personnel HewlettPackard Company recommends that the instrument

panel and cabinet be grounded. This instrument is

equipped with a three-conductor, ac power cable that,

when connected to an appropriate receptacle. grounds

the instrument through the offset pin. The power jack

and mating plug of the power cord meet International

Electro-technical Commission (IEC) safety standards.

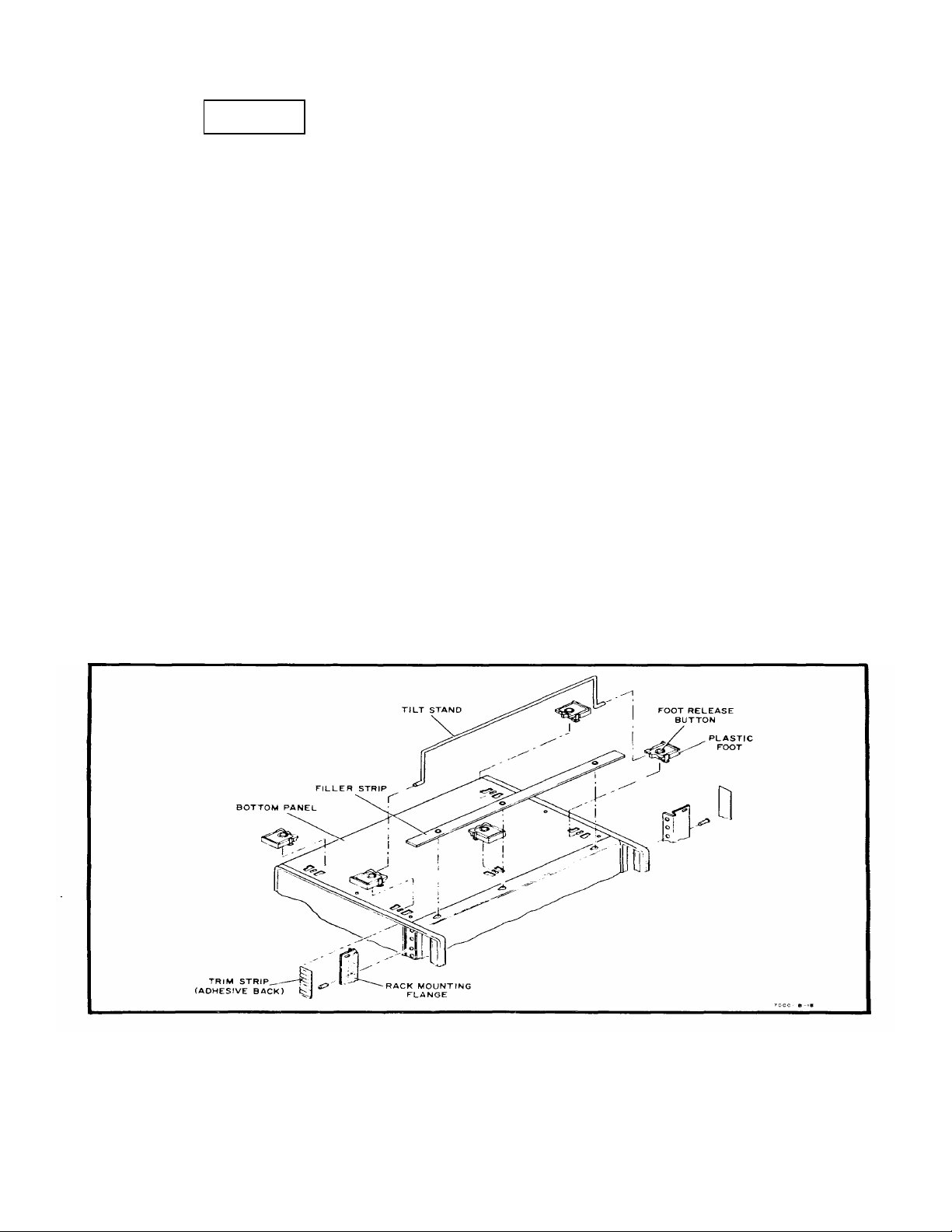

plastic trim in place Four supports are mounted on the

rear panel of the instrument for operation in a vertical

position. Top, left side, and bottom panel covers can he

removed, giving access to components and

adjustments. Allow suff ic ient spac e around the c abinet

for air circulation.

2-1:1. A kit for converting the modular cabinet to a

rack mount is included Instructions for making the

conversion are given Below figure 2-2).

a Detach tilt stand by pressing away from front feet

A.

b. Remove plastic feet by pressing metal button

and sliding each foot free.

c. Using thin-bladed tool, remove aluminum trim

strips. These strips have adhesive backing, and are

located on sides behind front handles.

d. Attach rack mounting flange, using screws

provided in kit, in each space where trip strip was

removed. Position large notch of flange at instrument

bottom.

2-11. INSTRUMENT MOUNTING.

?-12. The instrument is shipped from the factory as

a bench instrument with the tilt stand, feet, and

e. Rack mounting kit contains filler strips that s hould

be used as spacers between Model 141t and other

equipment mounted in same rack.

Figure 2-2. Rack Mounting Procedure

2-2

TM 11-6625-2781-14&P

Installation Model 141T

2-14. INSTRUMENT COOLING.

2-15. Forced-air cooling is used to m aintain the required

operating temperatures within the instrument The air

intake and filter are located on the r ear of the instrument.

Warm air is exhausted through the side-panel

perforations. Allow at least 3 inches of clearanc e around

the top, rear, and both sides of the instrument for

cooling.

2-16. The cooling fan does not require lubrication, but

the filter should be cleaned often enough to ensure

sufficient air flow. A thermal switch is mounted on the

fan to protect against over-heating.

2-17. CLAIMS.

2-18. The warranty statement applicable to this

instrument is printed inside the front cover of this

manual. Refer to the rear of this manual for the CRT

warranty statement. If physical damage is found

or if operation is not as specified when the instrum ent is

received, notify the carrier and nearest HP Sales/Service

Office im mediately (refer to the list in back of this manual

for addresses). The HP Sales/ Service Office will

arrange for repair or replacement without waiting for

settlement of the claim with the carrier.

2-19. REPACKING FOR SHIPMENT.

2-20. If the instrument is to be shipped to a HewlettPackard Sales/Service Off ice f or ser vice or r epair, attach

a tag showing owner (with address), complete instrument

serial number, and a description of the service required.

2-21. Use the original shipping carton and packing

material. If the original pack ing m aterial is not available,

the Hewlett-Packard Sales/Service Office will provide

information and recommendations on materials to be

used.

2-3/2-4

TM 11-6625-2781-14&P

Operation Model 141T

SECTION III

OPERATION

To externally modulate the trace intensity, set the switch

3-1. INTRODUCTION.

3-2. This section contains front panel c ontrol inf orm ation

and considerations for operating the instrument.

Controls for operation of power supplies and c athode-ray

tube are located on the instrument fr ont panel. All other

controls are located on the plug-in units. T he inst rument

includes high and low-voltage power supplies, a

calibrator circuit, a CRT, and a pulse circuit for variable

persistence and storage operation.

3-3. CONTROLS AND CONNECTORS.

3-4. figure 3-1 identifies the front panel controls and

gives a brief functional description of each. The

following paragraphs provide detailed descriptions of

controls with multiple or complex functions.

3-5. TRACE ALIGN.

3-6. The TRACE ALIGN adjustment compensates for

external magnetic fields that affect alignment of the

horizontal trace with the graticule. The alignment should

be checked when the instrument is moved to a new

location and adjustment made when necessary.

3-7. BEAM FINDER.

3-8. A high dc input signal may drive the trace off the

CRT screen. When the BEAM FINDER push-button is

pressed, the trace will be returned to the screen

regardless of the setting of horizontal or vertical

POSITION controls. If pressing the BEAM FINDER

pushbutton does not return a beam to the viewing area

press and hold the BEAM FINDER and gradually adjust

the INTENSITY control until a visible trace is obtained

and release BEAM FINDER. When used with 8550series frequency domain plug-ins, the BEAM FINDER

has no function.

to EXT, and connect the modulation signal to the

terminals. The am plitude of the pulse required to blank

the trace depends on the front panel INTENSITY control

setting, and is approximately 20 volts positive for normal

intensity settings. When not using ex ternal modulation,

set the switch to INT.

3-13. PLUG-IN UNITS.

3-14. Available plug-ins for the Model 141T ar e listed in

table 1-2. This instrument is norm ally operated with an

RF section plug-in in the upper compartment and IF

section plug-in in the lower compartment. The Operating

and Service Manuals for the plug-in units contain

detailed information for installing plug-ins.

3-’5. Arrangement of plug-ins can be selected to suit

special applications. For example, a vertical amplifier

and time base plug-in can be reversed s o that sweep is

vertical and signal deflection is horizontal. A vertical

plug-in can be used in each compartment to take X-Y

measurements.

3-16. Double-sized plug-ins, such as the Model 1415A

and Model 1416A, can be inserted into the instrument

after removal of the divider shield between lower and

upper compartments. Blank plug-ins, both single and

double size, are available for customer fabrication of

specialized vertical amplifier and time base plug-ins.

Refer to table 4-1 for power supply current limitations.

NOTE

For proper operation, the divider

shield must be in place when using

standard size plug-ins (does not apply to

spectrum analyzer plug-ins).

3-9. FOCUS AND ASTIGMATISM.

3-10. These controls provide uniform focus of the trace

over the entire CRT screen. Adjustment is m ade in the

STD W RITING SPEED with a low intensity spot on the

CRT screen. FOCUS and ASTIG are adjusted for a

round, sharply focused spot.

3-11. Z-AXIS INPUT.

3-12. The Z-AXIS INPUT jack and selector switch are

on the rear panel of the instrument (figure 6-3).

3-17. The Model 141T also accepts Model 1400-ser ies

plug-ins for standard oscilloscope use. W hen standard

1400-series oscilloscope plug-ins are used, plug-in

shield (HP Part No. 00140-0601) must also be-used.

Order the shield from the nearest HP Sales/Service

Office.

CAUTION

Do not operate instrument above 450C,

when using real time plug-ins.

3-1

TM 11-6625-2781-14&P

Operation Model 141T

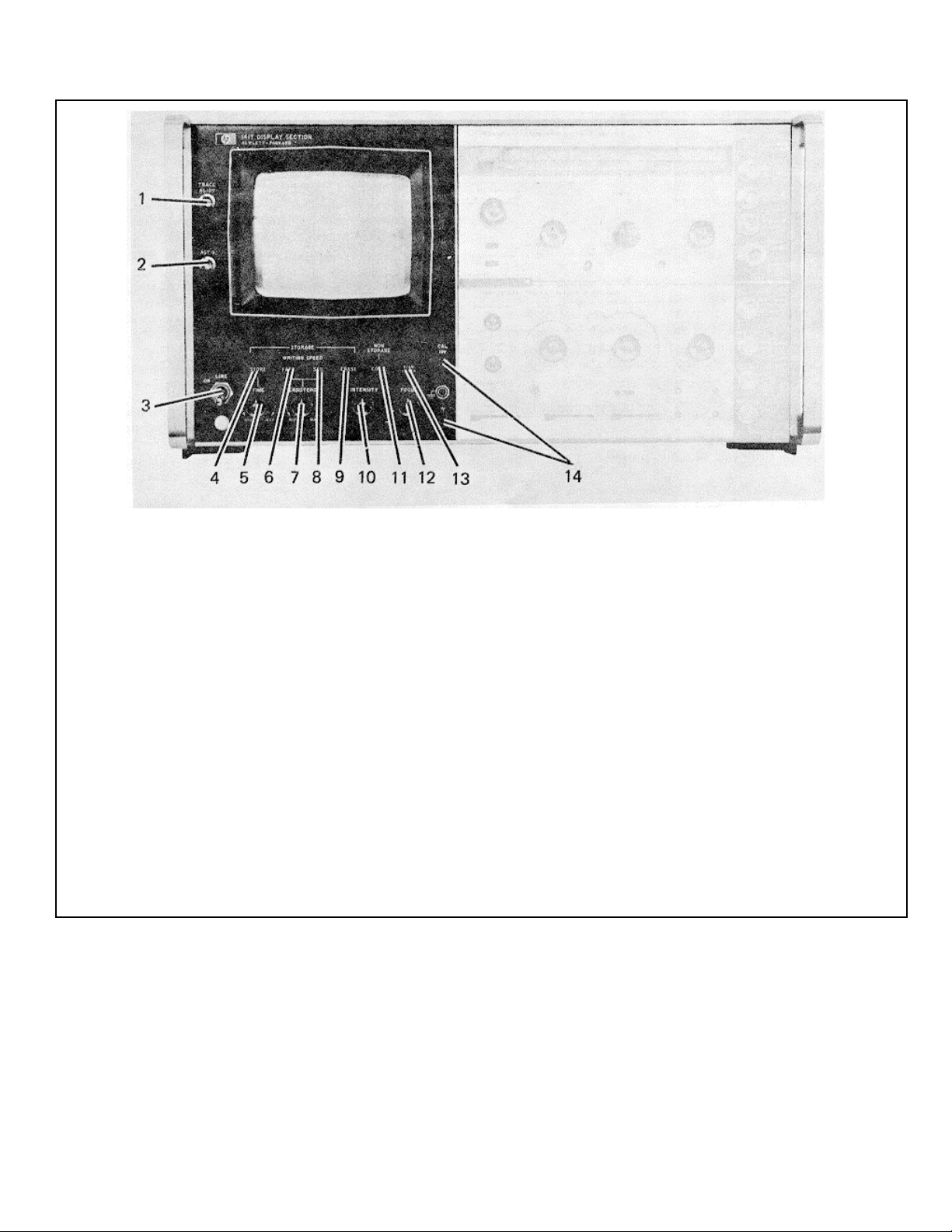

1. TRACE ALIGN: Adjustment to set trace parallel to

horizontal graticule lines.

2. ASTIG. Adjustment to set roundness of CRT

beam.

3. LINE: ON position connects ac power to

oscilloscope and lights indicator.

4. STORE. Retains displayed signal at reduced

intensity for viewing at a later time.

5. TIME. Control for setting storage time length.

6. FAST. Operates CRT at maximum writing s peed

with variable persistence.

7. PERSISTENCE: Controls endurance time of

displayed signal.

Figure 3-1. Model 141T Controls and Connectors

8 STD: Operates CRT at norm al writing speed with

variable persistence.

9. ERASE’: Removes stored or written displays.

10. INTENSITY. Control for setting intensity of CRT

display.

11. CON: Selects operation as standard oscilloscope.

12. FOCU’S: Control for focusing beam on CRT.

13. BEAM FINDER: Returns beam to CRT screen

regardless of deflection potentials when used with

400-series time-dom ain plug-ins. When used with

8550-series frequency-domain plug-ins , the BEAM

FINDER pushbutton has no function.

11. CAI: I-volt and 10-volt p-p, calibrated square wave

outputs.

3-2

TM 11-6625-2781-14&P

Operation Model 141T

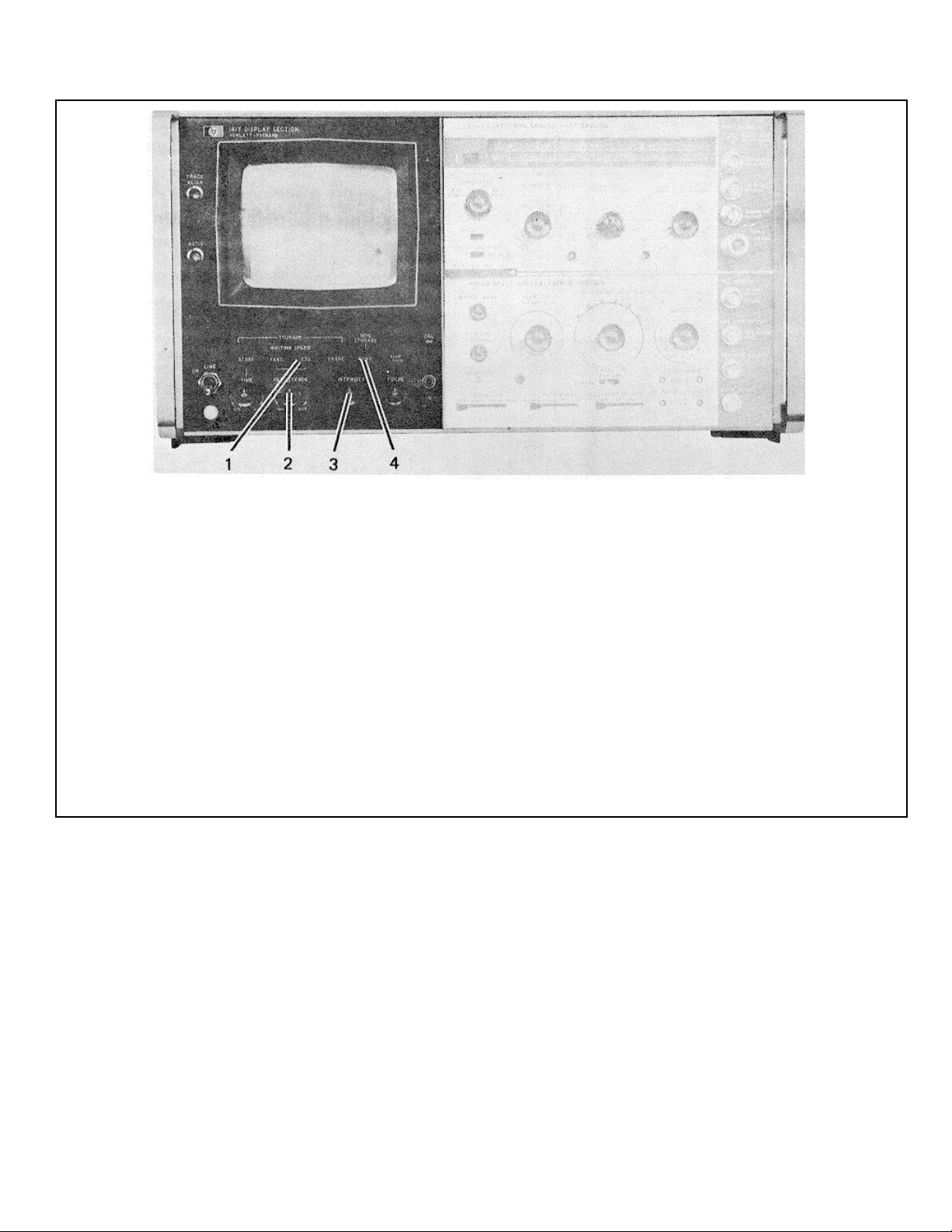

VARIABLE PERSISTENCE MODE

1. Press STD pushbutton.

2. Rotate PERSISTENCE control fully ccw.

3. Adjust INTENSITY to less than that intensity which

just eliminates trace blooming.

Trace blooming (figure 3-5) indicates ex cessive INTENSITY that can damage the CRT. Bloom ing does

not occur in the CONV mode. Do not increase intensity when in CONV mode. Always repeat above

procedure each time sweep speed or input signals change.

Figure 3-2. Intensity Adjustment

CONVENTIONAL

1. Press STD pushbutton.

2. Rotate PERSISTENCE control fully ccw.

3. Adjust INTENSITY to less than that intensity which

eliminates trace blooming.

4. Press CONV pushbutton. Do not increase

INTENSITY.

CAUTION

3-3

TM 11-6625-2781-14&P

Operation Model 141T

3-18. Slight differences in CRT sens itivities, m ay require

readjusting the sensitivity calibration of plug-ins installed

in the instrument for the f irst time, or when moved from

one display section mainframe to another. Ref er to the

Operating and Service Manual of the plug-in for the

required adjustment procedure.

3-19. OPERATING CONSIDERATIONS.

3-20. DEFINITIONS.

3-21. The definition of som e words and phrases used in

this manual may vary slightly from com mon usage. The

definitions of these words and phrase are as follows:

a. Write. To transform an input signal into visible

display on the CRT screen.

b. Persistence. The length of time a s ingle sweepwritten display remains visible on the CR’T screen

(intensity and sweep time constant).

c. Store. To retain, at reduced intensity, a display

which has been written on the CRT.

d. Erase. To rem ove all displays and blooms that

have been stored or written with persistence on the CRT.

e. Intensity. The brightness of a display as it is

written on the CRT screen (persistenc e and sweep time

constant).

f. Bloom. A visible, non-symm etrical expans ion of a

display written on the CRT screen, figure 3-5.

g. Fade positive. Appears as random green areas

on a dark background in MAX PERSISTENCE mode,

figure 3-7.

h. Background illumination. A green cloud of

illumination visible on the CRT screen, figure 3-7.

i. Sweep time. The time (in seconds, m illiseconds,

or microseconds) required for the beam to move

horizontally one unit of distance (division) across the

CRT screen, when writing a display.

j. Fadenegative. A condition in which a portion of

the trace or screen begins to dim.

k. Burn. A burn is permanent dam age to the CRT

phosphor or mesh resulting from excessive intensity

being maintained for too long a period. Phosphor bur ns

appear as a discolored area on the CRT scr een. Mesh

burns appear as spots or traces that are darker than the

background illumination in the MAX PERSISTENCE,

FAST WRITING SPEED modes.

which just eliminates any trace blooming with

minimum PERSISTENCE setting.

3-23. Persistence and intensity determine the duration of

display afterglow. Always set PERSISTENCE and

INTENSITY as shown in figure 3-2. The PERSISTENCE

control sets the rate that a display is erased; INTENSITY

sets the brightness of the trace as it is written. With a

given PERSISTENCE setting, the actual duration of trace

afterglow may be increased by increasing the

INTENSITY. The PERSISTENCE control sets the rate of

erasing a written display. The brighter a trace the more

time required to erase the display. Conversely, a display

of low intensity will erase more rapidly. The same

principle applies to a stored display of high and low

intensity.

3-24. Pressing STORE pushbutton permits a written

display to be stored at reduced intensity in the

oscilloscope for comparison, measurement, or

photography at a later time. Selection of the STORE

configuration disconnects STD, FAST, ERASE,

INTENSITY, PERSISTENCE, and CONV functions.

3-25. The TIME control varies the length of time a

display is stored. The time ranges from 15 seconds,

minimum TIME control setting when writing in FAST

speed and transferring to STORE; to over 2 hours,

maximum TIME control setting when writing STD speed

and transferring to STORE. Light output is inversely

proportional to storage time.

3-26. When the STD WRITING SPEED is used,

pressing ERASE pushbutton establishes the CRT in a

condition for variable persistenc e display of a signal that

later can be stored. Use the m inimum INT ENSITY and

maximum PERSISTENCE required to obtain the desired

display. The STD and FAST writing speeds are the only

configurations that a variable persistence dis play can be

written.

3-27. When FAST W RITING SPEED is used, pres sing

ERASE primes the CRT stor age surface to allow faster

writing on the storage surface. The display however, has

reduced contrast and fades positive more rapidly.

Contrast and storage time are also reduced.

3-22. CONTROL FUNCTIONS.

CAUTION

Excessive intensity may damage the CRT

storage mesh. The INTENSITY setting for any

sweep speed should be less than that intensity

3-28. Pressing ERASE pushbutton removes stored or

written displays from the CRT in either FAST or STD

modes. A display that has been stored or written at a

high level of INTENSITY may remain

3-4

TM 11-6625-2781-14&P

Operation Model 141T

visible after ERASE pushbutton has been released It

may be necessary to press and release ERASE

pushbutton more than once to com plete erasure of high

intensity displays.

3-29. Selection of CONV operating mode, dis ables the

variable persistence and storage functions and the

instrument operates as a c onventional, general purpose,

oscilloscope. Always adjust INTENSITY in STD mode

with minimum PERSISTENCE so the display does not

bloom, then switch to CONV. The PERSISTENCE

control does not function in CONV mode.

3-30. OPERATING PROCEDURES.

NOTE

After applying power, allow instrument

15 minutes warm up before attempting

to make measurements.

3-31. These operating procedures will familiarize the

operator with instrument controls and aid in obtaining

desired CRT display.

a. To improve persistence unif ormity in STD mode

adjust A5R45, STD collimator adjust. This will reduce

size of useable display area.

b. For variable persistence operation, use minim um

INTENSITY and maximum PERSISTENCE compatible

with desired display (figure 34).

c. Use WRITING SPEED in FAST mode only for

fast sweep time, single-shot displays, or to improve

uniformity of trace intensity. FAST WRITING SPEED

mode causes more rapid positive fading on CRT and

reduced persistence or storage time.

d. To store a display, press STD pushbutton and

adjust INTENSITY and PERSISTENCE for desired

display and press STORE.

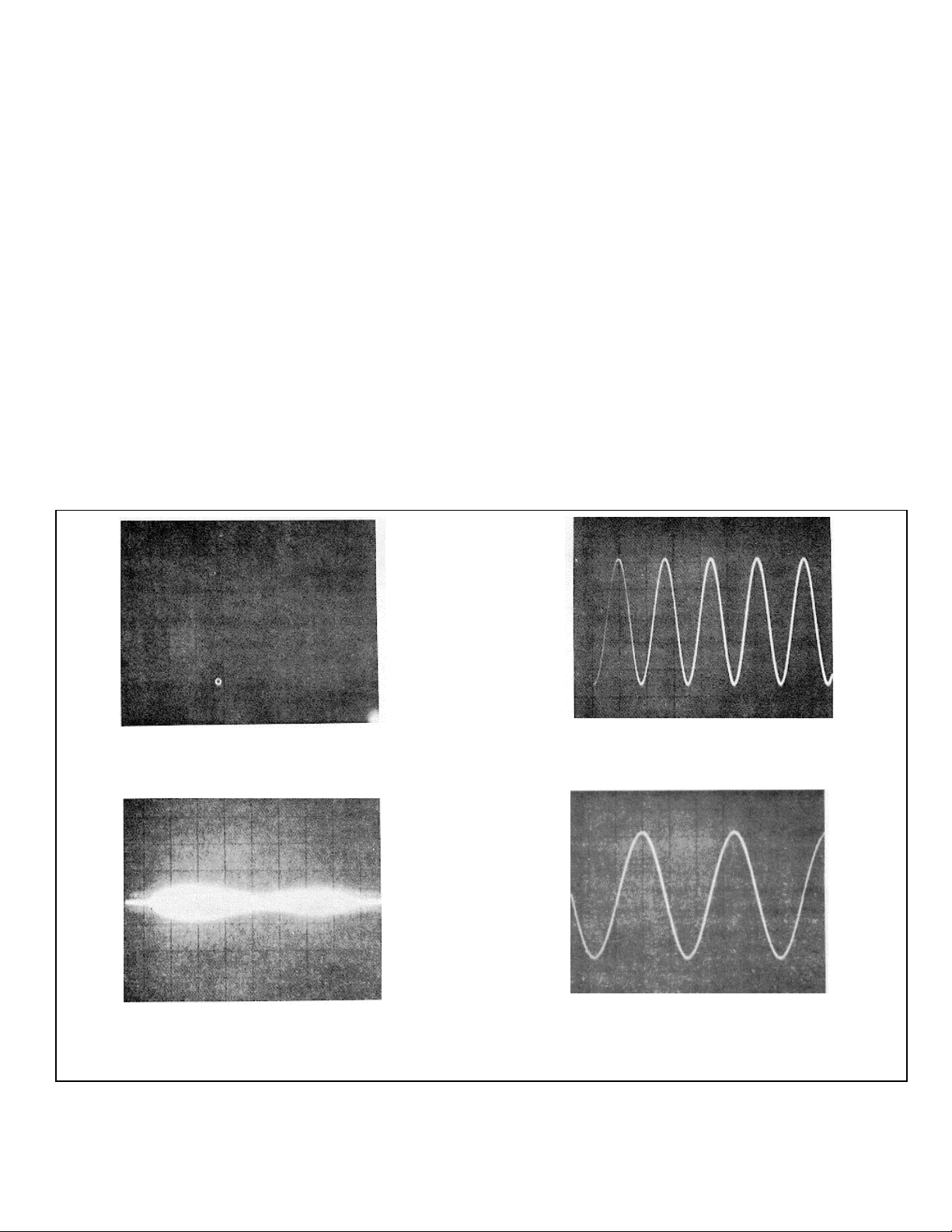

Figure 3-3. Background illumination immediately after

erasing with WRITING SPEED in FAST and

P’ERSISTENCE to MAX

Figure 3-5. Single-shot trace bloom caused by

INTENSITY and/or PERSISTENCE set too high

Figure 3-4. Variable persistence with a slow, repetitive

sweep

Figure 3-6. Single-shot display with INTENSITY and

PERSISTENCE set the same as figure 3-5 and

increased amplitude

3-5

TM 11-6625-2781-14&P

Operation Model 141T

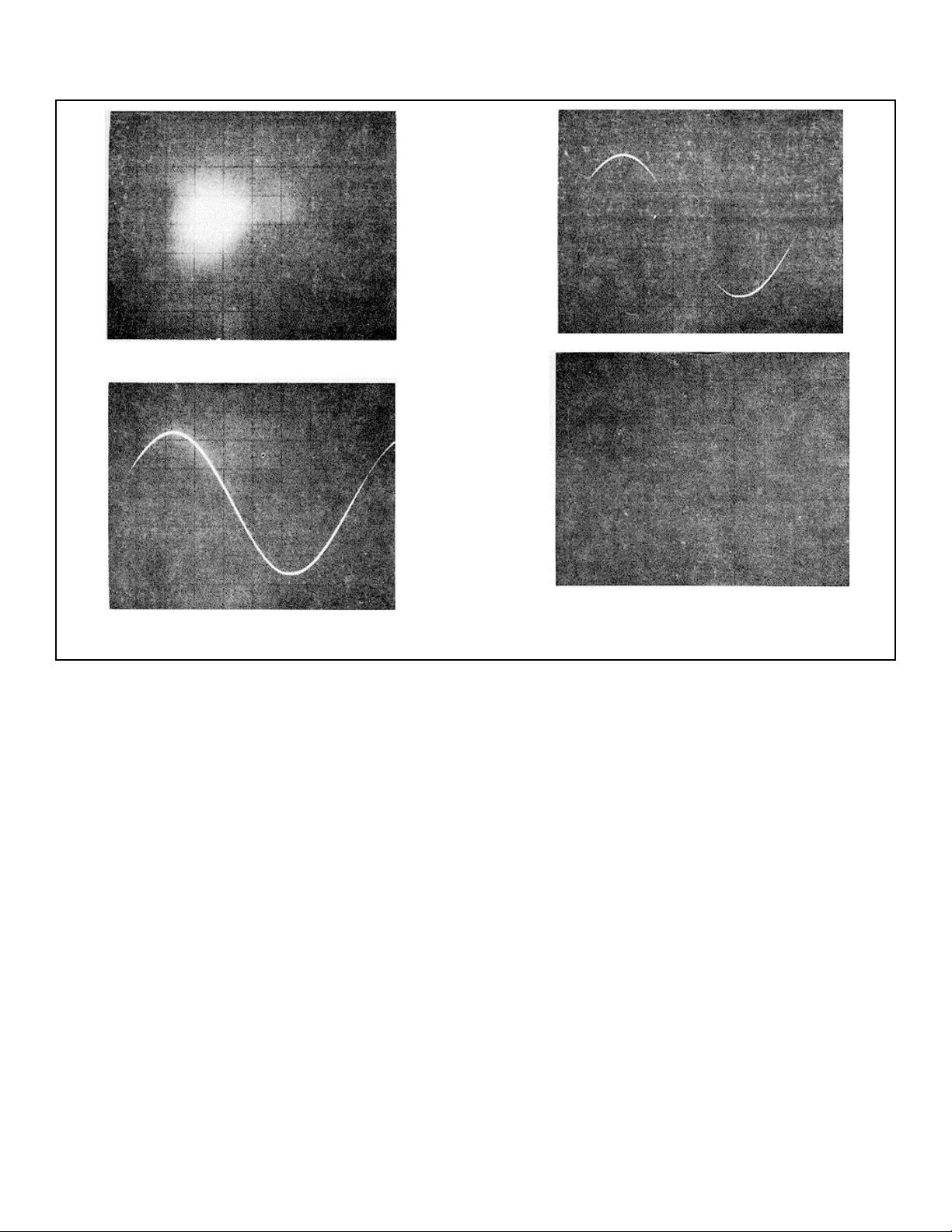

Figure 3-7. Fade positive after 2 to 4 minutes in STD

mode.

Figure 3-9. Same display as figure 3-8 after three

minutes in STD mode

e. To view a stored display, adjust TI ME contr ol until

stored display has desired brightness

f. To store more than one display, press STD

pushbutton, set PERSISTENCE fully cw and INT ENSITY

as required; allow first display to be written on CRT. Set

INTENSITY fully ccw, and connect second signal to be

stored. Reset vertical POSIT ION if s econd display is not

to be superimposed on first Slowly rotate INTENSITY

clockwise until second display appears. Press STORE

pushbutton and both displays will be stored.

g. A display stored when instrument power is turned

off will remain stored for several days. To observe a

stored display, press STORE, set the verti-

Figure 3-8. Single-shot 20 usec/div display

Figure 3-10. Small bright spots caused by minute

imperfections in storage mesh

cal position control ccw before turning on the instrum ent.

Then adjust the TIME control until the stored display is

visible.

h. To erase stored displays, press STD or FAST

and rotate the PERSISTENCE control fully ccw, or press

ERASE for approximately one second, then release.

(First method is not ef fective when W RITING SPEED is

set to FAST).

3-32. SINGLE-SHOT OPERATION.

3-33. To write with persistence or store a single-shot

phenomena, trial setting of INTENSITY is the best

approach. The amplitude of the phenomena and the

sweep-time required to display it will affect the

3-6

TM 11-6625-2781-14&P

Operation Model 141T

persistence. For example, with maximum

PERSISTENCE and some settings of INTENSITY, a

single -shot straight-line trace may bloom as shown in

figure 3-5, while a single-shot signal with amplitude

variations of several divisions may not cause blooming

(figure 3-6). To determ ine the best INTENSIT Y setting,

connect a signal which approximates the sweep time and

amplitude of the single-shot signal to be written. Set

PERSISTENCE fully cw and trigger a single sweep of the

test signal. Set the INTENSITY as far cw as possible

without causing blooming. Repeat the single sweep

signal, erasing the display and setting the INTENSITY

after each trace until the desired display is obtained.

This setup should give maximum persistence to the

single-shot display. After the single-shot signal has been

written, the display may be retained by pressing STORE

and setting the TIME control to MAX.

3-34. Single-shot signals which require a beam speed

faster than 50 microseconds per division can be

written with more brightness by setting the WRITING

SPEED to FAST. The screen will be unevenly

illuminated after erasing when WRITING SPEED is in

FAST, however, the INTENSITY can be set high enough

to make the display visible through the illumination. A

display, written with WRITING SPEED set to FAST, will

be obscured by positive fading more rapidly than a

display written with WRITING SPEED set to STD.

3-35. Single-shot signals which require a beam speed

between 20 and 200 microseconds per division may

have low brightness at some location on the screen. Fire

a single-shot test signal with INTENSITY and

PERSISTENCE fully cw and WRIT ING SPEED in STD,

and if the center brightness is low, wait for one to three

minutes for the low-brightness area to become brighter.

Likewise, if the entire display brightness appear s below a

usable level, or the display is not visible at all, wait for

one to five minutes for the display to appear (figures 3- 8

and 3-9).

3-7/3-8

TM 11-6625-2781-14&P

Theory Model 141T

SECTION IV

PRINCIPALS OF OPERATION

4-1. INTRODUCTION.

4-2. This section contains f unctional descriptions keyed

to an overall block diagram of the instrum ent, and circuit

descriptions keyed to simplif ied block diagram s of circ uit

groups. The schematics are located in Section VIII.

4-3. OVERALL FUNCTIONAL DESCRIPTION.

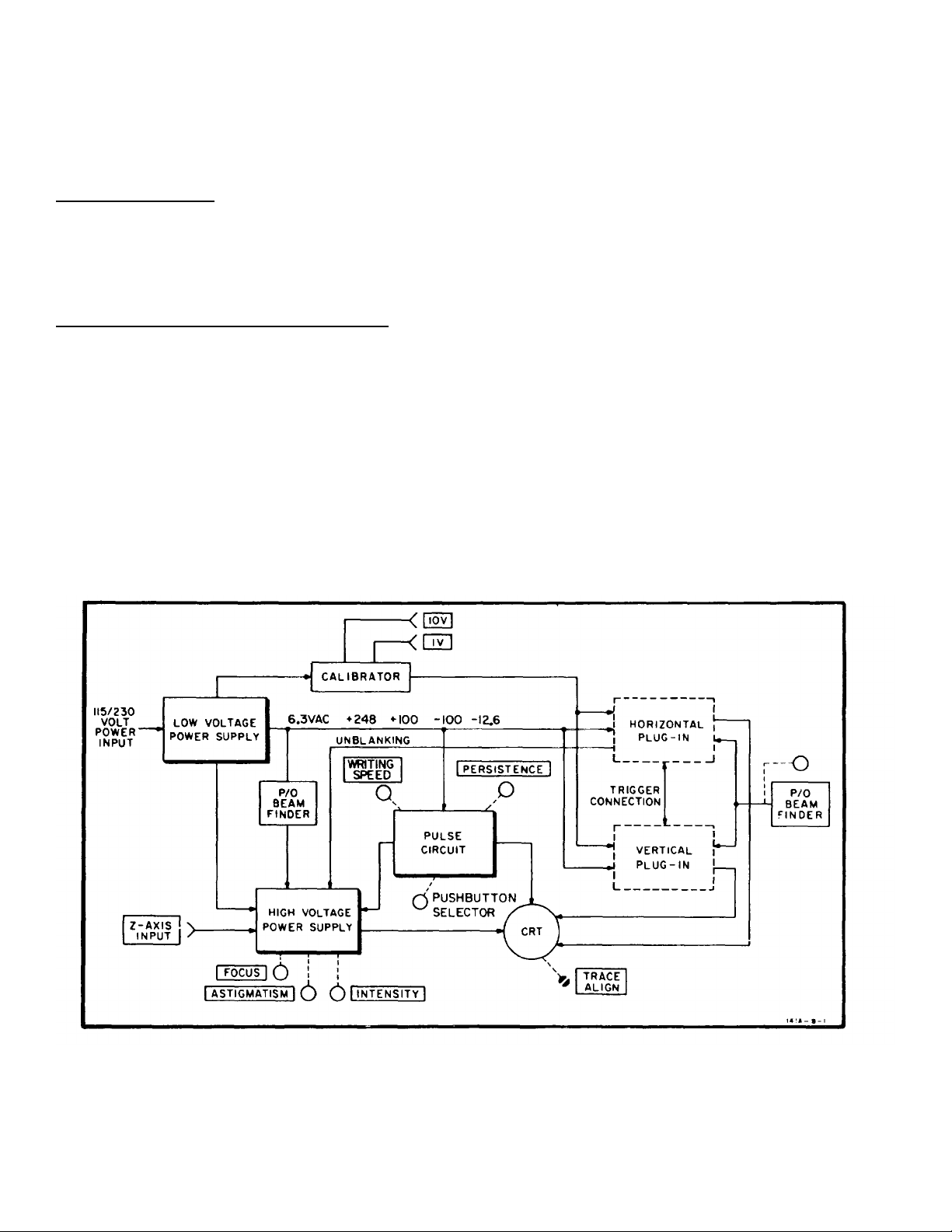

4-4. The Model 141T Display Section has five main

circuits (figure 4-1): low-voltage power supply, highvoltage power supply, calibrator circuit, pulse circ uit, and

horizontal driver circuit. The horizontal and vertical

amplifier circuits are in the plug-in units.

4-5. LOW-VOLTAGE POWER SUPPLY.

4-6. The low-voltage power supply operates on 100,120-, 220- or 240-volts, single phase, 48-440 Hz.

Output voltages are -12.6-, -100-, +100- and +248-volts

dc. All outputs are fused and electronically regulated.

Voltages are distributed to the high-voltage power

supply, calibrator, pulse circuits, and horizontal and

vertical plug-ins. The low voltage transformer supplies

6.3 Vac to the main filament of the CRT and to the

calibrator circuit.

4-7. CALIBRATOR.

4-8. The 6.3 Vac is applied to the calibrator circuit where

it is shaped into a square wave (of line frequency) and

applied to two front-panel connectors, 1V and 10V pk-pk.

The 1-volt output is also applied to the vertical and

horizontal plug-ins for sensitivity calibration. Accurac y of

the calibrating signals is 1%.

4-9. HIGH-VOLTAGE POWER SUPPLY.

4-10. A transistorized oscillator and a step-up

transformer are used to generate negative and positive

high voltages for the CRT. The negative 2350-volt

supply is electronically regulated.

Figure 4-1. Model 141T Block Diagram

4-1

TM 11-6625-2781-14&P

Theory Model 141T

4-11. PULSE CIRCUIT.

4-12. This circuit generates pulses of variable level and

rate. These pulses and other dc voltages from the circuit

are applied to the storage and persistence elements in

the CRT. The low-voltage power supply provides all

operating power for the pulse circuit.

4-13. HORIZONTAL DRIVER CIRCUIT.

4-14. The horizontal driver is an impedance converter

circuit. The output from the horizontal am plifier circuit in

the plug-in unit is applied to the input of the horizontal

driver circuit, which in turn drives the horizontal plates of

the CRT.

4-15. CIRCUIT DESCRIPTION.

4-16. LOW-VOLTAGE POWER SUPPLY.

4-17. The low-voltage power supply consists of +100volt supply, -100-volt supply, +248-volt supply and -12.6volt supply. The +100-volt supply is independent and

provides a reference voltage for the -100-volt supply.

The +248-volt and -12.6-volt supplies are dependent on

the -100-volt supply for reference voltages.

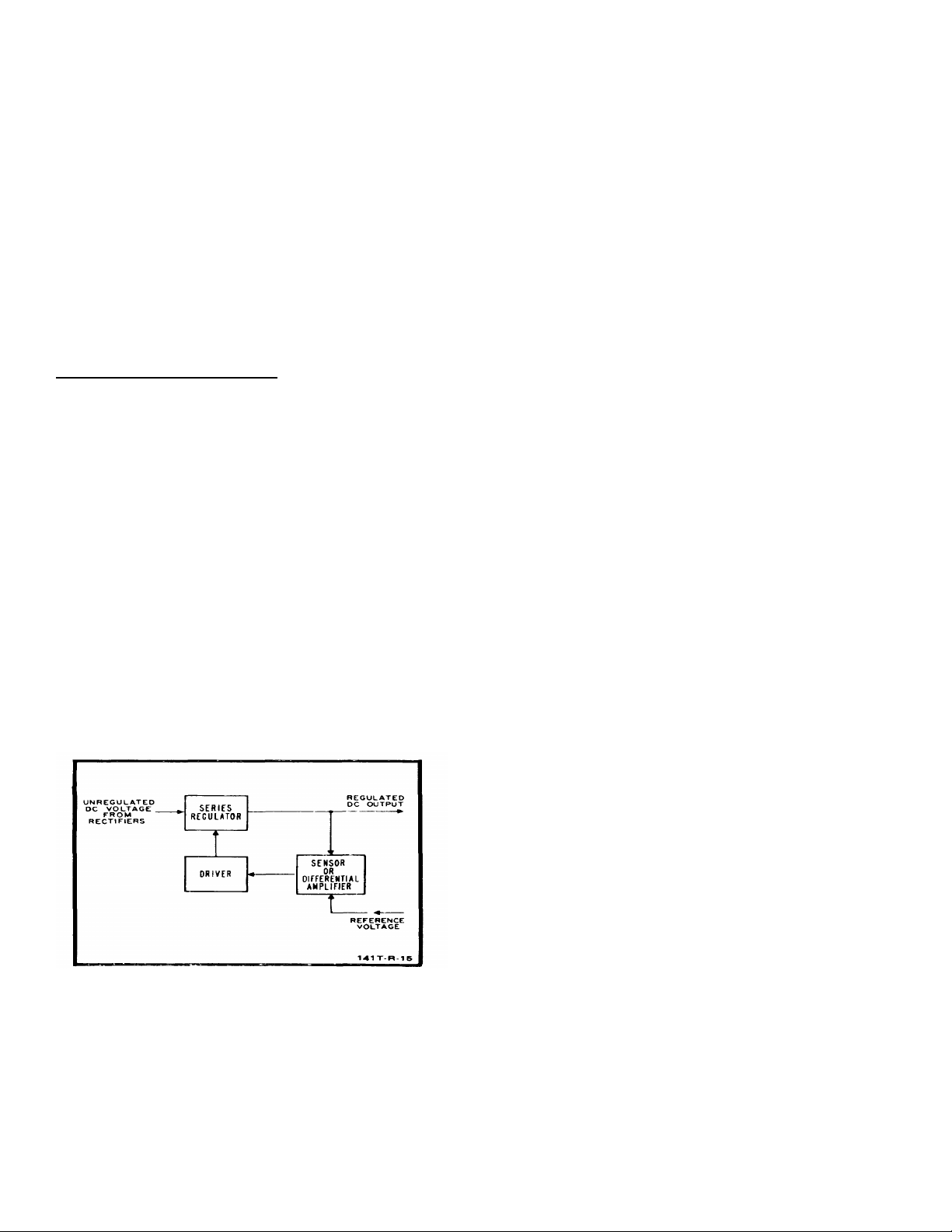

4-18. figure 4-2 is a simplified block diagram of the

regulator used in the low-voltage supply. The series

regulator acts as a variable resistance in the regulated

output. A sensor (or diff erential amplifier) c ompares the

output voltage with a reference voltage. The driver

(emitter follower or amplifier) controls the bias on the

series regulator, which effectively controls the series

resistance. Any change in output voltage is fed bac k to

the series regulator. The change in series resistance

and the resulting voltage drop is opposite to the output

voltage change, maintaining the output voltage at a

constant level.

applied to the primary of TI through an on-off switch, a

fuse and a thermal switch. Pilot lam p DS1, lights when

power is applied to T1. Two shunt resistors are

connected to the +248-volt supply to reduce series

regulator power dissipation when high-current plug-ins

are used. Each shunt is wired to a rear panel connector.

The internal wiring of the plug-in determines whether the

shunt is in the circuit or not.

4-20. +100-Volt Supply.

secondary ofT1 is rectified by A1CR5-AICR8 and

partially filtered by C3 and A2R17. The resulting dc

voltage is applied through the series regulator Q2, to the

output. Differential amplifier A2Q4/A2Q5, com pares the

voltage across A2V1 with a sample of the output voltage.

Any change in output voltage is applied to the base of

driver A2Q3, which controls the bias on regulator Q2.

Series regulator Q2, compensates for the change in

output voltage by changing resistance and restores the

output level to normal. The +100-volt output is adjusted

by A2RllB and fuse A2F2 provides overload protection.

4-21. -100-Volt Supply.

volt supply is taken from the output of the +100-volt

supply. The reference voltage across A2R31 is

compared with a sample of--100-volt output across

A2R35. The error voltage sensed by differential amplifier

A2Q7/A2Q8 is applied through driver A2Q6, and series

regulator Q3. The series regulator brings the -100 volt

supply back into proper balance with respect to the

+100-volt supply. Ac voltage from T1 is rectified by

A1CR9-A1CR12, partially filtered by C4/C5/A2R27, and

the resulting dc voltage is applied by the series regulator

Q3, to the -100-volt output. Regulation is obtained as in

the +100-volt supply. A2R11C adjusts the -100-volt

output, and fuse A2F3 provides overload protection.

4-22. +248-Volt Supply.

+248-volt supply senses any variation in the output

voltage with respect to -100 volts. The err or voltage is

amplified by driver A2Q1, which applies corrective bias to

series regulator Q1. A2RllA adjusts the +248-volt output

and fuse A2F1 provides overload protection. A2CR4

provides temperature compensation for A2Q2, and is

normally forward-biased.

The ac voltage from the

Reference voltage for the -100-

Sensor amplifier A2Q 2, in the

Figure 4-2. Regulated Power Supply Block Diagram

4-19. figure 8-10 is a schematic diagram of the low

voltage power supply. The primary winding is wired

through a rear panel power module for conversion to

100-, 120-, 220- or 240-Vac operation. Line voltage is

4-23. -12.6-Volt Supply.

senses any variation of output voltage with respect to 100 volts and applies the error voltage to driver am plifier

A2Q9. The driver increases signal current to the level

required to control series regulator Q4. The -12.6-volt

output is adjusted by A2R47A. Current limiter A2Q10 is

a protective circuit for the series regulator and is

normally biased off. If an overload occurs across the -

12.6-volt output, the base of

4-2

Sensor amplifier A2 Q11

TM 11-6625-2781-14&P

Theory Model 141T

A2(Q10 goes positive by the voltage drop across R11,

minus the forward voltage drop acros s A2CR16, turning

A2Q(10 on. The collector of A2Q10 is applied through

A2Q9 to the base of series regulator Q4, reducing the

current flowing through Q4. The current flows through

an external overload which limits the c urrent required to

keep A2QIO on. Additional over-load protection is

provided by fuse, A12F4.

4-24. CALIBRATOR.

4-25. The calibrator circuit ( f igure 8- 10) cons is ts of three

parts: a tunnel diode (square wave generator), ;1

transistor switch, and a calibration network.

4-26. Input to tunnel diode A2CRI9, is applied through

A2R5.0. The tunnel diode generates a square wave at

line frequency. Transistor switch A2Q12, is off during

the time of the positive half-cycle of the square wave

(when the voltage at the base is close to zero), and the

collector voltage is at a level set by breakdown diode

A2VR6 and resistor A2R47B. W hen the negative-going

portion of the square wave is applied to the base of

A2Q12, the transistor increases conduction, effectively

shorting the collector to ground. The output of the

calibrator becomes zero. At the end of the negative input

half-cycle (bias of A2Q12 returns to zero) the transistor is

turned off, and the output returns to its previous value.

4-27. Tunnel diode bias current is supplied through

A2R51. The bias current sets an operating level for the

diode which ,affects the symmetry of the square wave

output. Cal adj A2R47R, is used to set the dc

voltage at the collector of A2Q12 to -10 volts when the

transistor is off Breakdown diode A2VR6 reduces the

output impedance, and provides the temperature

compensation for the circuit. Voltage divider

A2R55, reduces the 10-volt output to 1 . Roth 10- and I volt outputs are available at the front panel of the

instrument, and the 1-volt output is available to both

plug-ins.

4-28. HIGH-VOLTAGE SUPPLY.

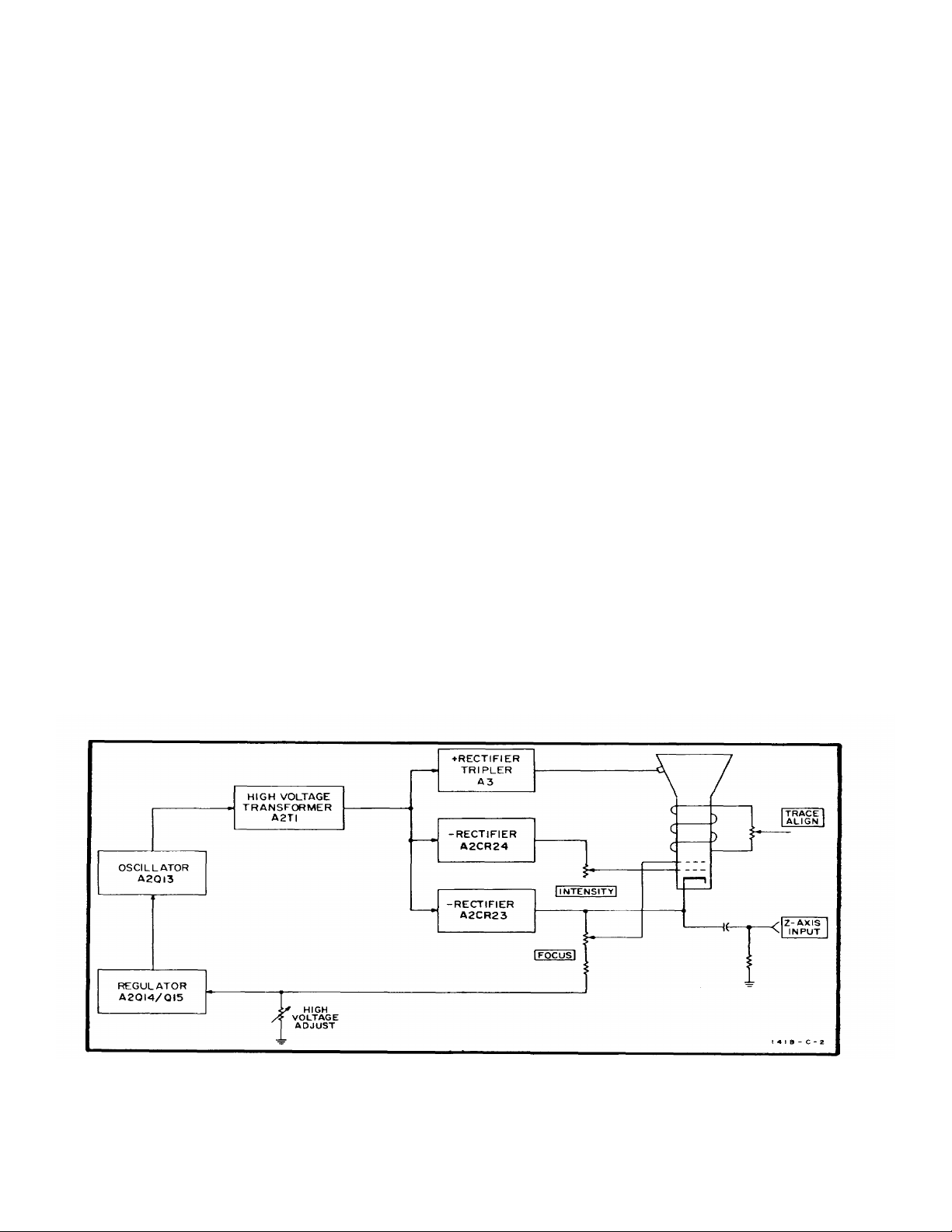

4-29. figure 4-3 is a block diagram of the high-voltage

power supply. The output of a regulated transistor

oscillator is stepped-up in voltage and applied to a ser ies

of high voltage rectifiers. The positive output of the

voltage tripler is connected to the post-ac celerator of the

CRT. The negative output voltages are used in the gun

assembly of the CRT and its associated controls . T he Zaxis input can be used to apply intensity modulating

signals to the CRT.

4-30. figure 8-13 is a schematic diagram of the highvoltage supply and the CRT. Oscillator A2Q12 operates

at a frequency of approximately 32 kHz. Any change in

the output voltage is applied to A2Q15, which converts

the voltage change to a current change. This current

change is applied, by emitter follower A2Q14, to the base

of the oscillator transistor . The amplitude of oscillations

is changed in such a direction as to oppose the original

output voltage change. high-voltage adjust A2R6:3 sets

the amplitude of oscillation to produce the cor rect output

voltage.

A2R;54

,’

Figure 4-3. High-Voltage Power Supply Block Diagram

4-3

TM 11-6625-2781-14&P

Theory Model 141T

4-31. Two separate negative supplies are used, one for

the control grid of the CRT, and one to provide the CRT

cathode and focusing voltages. Both supplies use half wave rectifiers (A2CR23 and A2CR24). T he unblanking

gate from the horizontal plug-in (pin 1, J2) is applied to

the return side of the grid supply, and changes the

negative grid voltage by about +50 volts to unblank the

trace. A positive pulse of about 20 volts will blank the

trace when applied to Z-axis input. When Z-axis input is

not used, S4 is set to INT to rec eive chopped blanking

from a dual-trace plug-in.

4-32. The voltage tripler circuit provides the 6.6 kV postaccelerating voltage applies to the CRT.

4-33. The ASTIG adjustment, R8, adj us ts the roundnes s

of the spot, and the geometry adjustment, A2-R72, is

used to optimize pattern shape.

4-34. STORAGE CRT.

4-35. Refer to figure 8-13 for the schematic diagram of

the storage CRT, VI. The CRT contains the conventional

electron (writing) gun, deflection plates, post-acc elerator,

and phosphor screen. In addition, there are two

floodguns, a collimator, a collec tor mesh, and a storage

mesh. These added elements make possible the

variable persistence and storage functions of the

instrument.

4-36. Flood Guns.

electron gun, outside of the horizontal deflection plates.

Horizontal drivers, A6QI and A6Q2, prevent flood gun

electrons from flowing through the deflection plates to

the output stage of the plug-in. The guns operate

continuously when the power switch is ON. An electron

cloud, that is emitted by the flood guns, is accelerated

toward the CRT screen by collimator and collector m esh

voltages. These electrons make stored or persisting

display visible. They are also used to erase stored and

persisting displays.

4-37 Collimator.

along the tapered portion of the CRT. A positive voltage

applied to the collimator focus es the f lood-gun electr ons.

The flood-gun electrons are formed into a column

perpendicular to, and approximately equal to the width of

the CRT screen.

4-38. Collector Mesh.

the flood guns and the storage mesh (closer to the

storage mesh). It is always positive with respect to the

storage mesh except in the ERASE mode of operation;

both are then at the same potential. In addition to

accelerating flood gun electrons, the collector m esh also

repels positive ions generated by the flood guns.

4-39. Storage Mesh.

the CRT screen and is coated with non-conducting

material. It is statically held at a slightly positive potential

(approximately +3 volts). W hen the electron beam from

the writing gun strikes the mesh coating, secondary

electrons are emitted. T his secondary emission creates

Two flood guns are located on the

The collimator is an internal coating

The collector mesh is between

The storage mes h is just behind

a pattern of positive potential identical to the m ovement

of the beam. Flood gun electrons are accelerated by this

positive potential pattern and strike the phosphor scr een,

creating a visible display.

4-40. The storage mesh is pulsed with pulses of

approximately 10 microseconds duration. T hese pulses

erase the positive pattern on the storage mesh by

discharging the mesh coating. Time required for this

erasing operation is determined by the pulse repetition

rate. The positive pattern on the mesh may also be

neutralized manually by connecting the collector and

storage meshes (erase). The high positive potential

(approximately +156 volts) allows more uniform

discharging of the surface. When the storage mesh is

disconnected from the collector m esh and r eturned to +3

volts, the coated surface is at a uniform ly equal potential

of--9 volts. In both cases, the screen has no illumination.

The pattern may be lost by the storage mesh fading

positive and allowing the entire screen to be illum inated.

This occurs when positive ions from the flood gun raise

the surface potential of the storage mesh in random

areas sufficiently to allow flood gun electrons to strike the

screen.

4-41. PULSE CIRCUIT.

4-42. figure 4-4 is a simplified block diagram of the

pulse circuit. The pulse circuit supplies pulses of

variable repetition rate to control the operation of the

CRT. The pulse timer generates a pulse which trigger s

the monostable multivibrator. The two outputs of the

monostable multivibrator are applied to the flood gun

driver and output pulser. The flood gun driver applies

pulses to the accelerator of the CRT to control storage

time of the display.

4-43. The output pulser applies a positive voltage to the

storage mesh of the CRT . The erase timer provides a

signal to the monostable multivibr ator and output pulser

to generate an erase pulse and also triggers the blanking

circuit. The blanking cir cuit energizes a relay in the high

voltage supply which applies a blanking voltage to the

CRT. The CRT collimator voltage is supplied by a linear

amplifier and is controlled by the selection of the writing

speed at the front panel.

4-44. STD AND FAST MODES.

S-E.S. Pulse Timer. figure

of the pulse circuit. Setting the front panel

PERSISTENCE control, R10, determines the amount of

current available from the pulse timer current source,

A5QI . A5C1 charges to a potential which tur ns A’5Q2

on. A5CI discharges through A5Q2, A5-Q2 turns off,

and A5Cl again begins to build a ramp voltage. The

repetition rate of this action is controlled by the setting of

the front panel PERSISTENCE con-

4-4

8-16 is a schematic diagram

Loading...

Loading...