INSTRUCTION MANUAL

Version

3305-10-03

04.12.2002 LK

26.1.2004 /LK

Instruction Manual

This instruction manual includes a spare parts list and instructions for setup for operation, operation and maintenance of the T-DRILL T-60 tee

forming machine. Type code of manual is 3305-10-03

Manufacturer: Subsidiary: Covering North

America

OY

P.O BOX 20

FIN-66401 Laihia, Finland

Tel. Int +358-6-4753 333

Telefax: (G3) +358-6-4753 300

www.t-drill.fi

INDUSTRIES INC.

1740 Corporate Drive, Suite 820,

N

orcross, Georgia 30093, USA

Phone: 800-554-2730

Fax: 770-925-3912

www.t-drill.com

Your local representative is:

Copyright © 2002 T-DRILL Oy. All rights reserved. This manual, or parts thereof, may

not be reproduced in any form or by any means, nor translated into any other language

without a written permission of T-DRILL Oy.

This manual has been produced with a great deal of care and attention. All information

has been checked for accuracy. No liability will be accepted for any incorrect or

incomplete information.

2

TEE FORMING MACHINE

T-6

0

Table of contents

1. Notes on the use of the instruction manual ......................................5

1.1 Symbols for warning used in this manual ....................................5

1.2 Symbolism...................................................................................6

2. General safety instructions.................................................................7

2.1 General safety instructions for work area ....................................7

2.2 Safety instructions for tool ........................................................... 8

2.3. Safety instructions for tee forming ............................................10

3. T-DRILL T-60, general........................................................................11

3.1 Introduction................................................................................11

3.2 The Parts of the T-60.................................................................11

3.3 Information about Accessories ..................................................12

3.4 Operating Range of the Machine............................................... 13

3.5 Technical specifications.............................................................13

4. Transport, Handling and Storage .....................................................14

4.1 T-60........................................................................................... 14

5. Preparing before use .........................................................................15

5.1 T-60, Detachment and attachment of the connecting cord........ 15

5.2 T-60:s start-up check................................................................. 15

6. The operation of the machine...........................................................16

6.1 Description of the control devices.............................................. 16

6.2 Selection and adjustment of the T-DRILL heads .......................18

6.3 Chucking the T-DRILL head ......................................................21

6.4 The tee forming process with the T-DRILL T-60........................ 23

6.5 Annealing of tube.......................................................................26

7. Maintenance .......................................................................................28

7.1 The maintenance of the T-DRILL T-60...................................... 28

7.2 The replacement of the forming pins ......................................... 29

8. Trouble-shooting................................................................................30

9. Disposing............................................................................................32

10. Warranty............................................................................................33

11. Supplement.......................................................................................34

12. Spare parts list.................................................................................38

12.1. T-60........................................................................................ 38

12.2. The T-60 Tee Forming Unit ....................................................40

12.3 T-DRILL Head..........................................................................42

12.4 Counterplate ........................................................................... 43

12.5 Optional Equipment.................................................................43

13. Ordering spare parts........................................................................45

3

INSTRUCTION MANUAL

4

TEE FORMING MACHINE

T-6

0

5

1. Notes on the use of the instruction manual

1.1 Symbols for warning used in this manual

IMPORTANT! Gray base color is used to emphasize an important detail

NOTE! May cause an accident or damage other property, if the right

precautionary measures have not been taken.

DANGER! Will or may cause a serious accident or death, if the right

precautionary measures have not been taken.

This instruction manual includes instructions for set-up, operation and

maintenance of the T-DRILL T-60 tee forming machine. This book also

includes instructions on how to use and select T-DRILL heads for hand

tools.

NOTE! Before carrying out any actions, read chapter 2 ”Safety

Instructions”.

Get acquainted with the instruction manuals of the MILWAUKEE DRILL

delivered with the machine before using the T-60 machine.

Acquaint yourself with the machine before using it. Read the

operation sequence described in the instruction manual thoroughly before

preparing, operating or maintenance of the machine.

IMPORTANT! Save these instructions for future use!

INSTRUCTION MANUAL

1.2 Symbolism

The following list defines the symbols on the tool.

Read the instruction manual carefully before using this

tool.

Double Insulated

130°

Thermally protected to 130°C)

Warning! Do not throw to trash. Please recycle

Warning! Watch your fingers. Rotating tool.

6

TEE FORMING MACHINE

T-6

0

2. General safety instructions

Read all the instructions before using the machine.

Know your power tool - Read the instruction manual carefully. Learn to

know your own skill and limitations as well as the specific potential

hazards peculiar to this tool.

DANGER! - The use of any accessory or attachment other than the ones

recommended in this operating instruction or T-DRILL catalogue may

create a risk of personal injury.

NOTE! Never detach the MILWAUKEE power unit from the

T-DRILL tee forming unit. Detaching the power unit will damage the

alignment made in factory.

NOTE! - The T-DRILL T-60 is designed for use with MILWAUKEE

power unit. Using any other power units with the T-DRILL

T-60 tee forming unit is not allowed.

IMPORTANT! Warranty is void if the power unit is detached from the

tee forming unit!

2.1 General safety instructions for work area

Keep work area clean – Cluttered areas and benches invite injuries.

Consider work area environment – Don’t use power tool in humid or wet

conditions. Keep work area well illuminated. Don’t use power tool in the

presence of flammable liquids or gases.

Keep children away – Do not let visitors touch the tool or it`s extension

cord. All visitors should be kept away from work area.

Stay alert – Be aware of what you are doing. Use common sense. Do not

operate tool when you are tired.

7

INSTRUCTION MANUAL

2.2 Safety instructions for tool

Store idle tools – when not in use, tools should be stored in dry, high, or

locked-up place, out of the reach of children.

Don’t force tool – It will do the job better and safer at the rate for which it

is intended.

Dress properly – Do not wear loose clothing or jewelry. They can be

caught in moving parts. Use appropriate gloves and footwear. Wear

protective hair covering to contain long hair.

Use safety glasses – Also use face or dust mask if cutting operation is

dusty.

Secure work – Use clamps or a vise to hold your work piece. It’s safer

than using your hand and it frees both hands to operate the tool.

Don’t overreach – Keep proper footing and balance at all times.

Maintain tools with care – Keep tools sharp and clean for better and

safer performance. Follow instructions for lubricating and changing

accessories. Inspect tool cords periodically and, if damaged, have them

repaired by authorised service workshop. Inspect extension cords

periodically and replace if damaged. Keep handles dry, clean and free

from oil and grease.

Don’t abuse cord – Never carry a tool by its cord or yank it to disconnect

it from receptacle. Keep cord from heat, oil and sharp edges.

Disconnect tools – When not in use, before servicing, and when

changing accessories such as blades, bits and cutters.

Remove adjusting keys and wrenches – Make it a rule to check that

keys and adjusting wrenches are removed from tool before turning it on.

Avoid accidental starting – Do not use a tool if the power switch does

not turn the tool on and off. Do not carry the tool with your finger on the

switch.

Outdoor use extension cords – When tool is used outdoors, use only

extension cords intended for use outdoors and so marked.

Check damaged parts – Before further use of tool, a guard or other part

that is damaged should be carefully checked to determinate that it will

operate properly and perform its intended function. Check for alignment of

8

TEE FORMING MACHINE

T-6

0

moving parts, binding of moving parts, breakage of parts, mounting, and

any other conditions that may affect its operation. A guard or other part

that is damaged should be properly repaired or replaced by an authorised

service unless otherwise indicated elsewhere in this instruction manual.

Have defective switches replaced by an authorised service. Do not use

tool if switch will not turn it on and off.

Have your tool repaired only by T-DRILL – This electric tool is in

accordance with the relevant safety requirements. Repairs should be

carried out only by certified persons using original spare parts; otherwise,

this may result in considerable danger to the user.

Keep tools away from items that may be damaged by magnets – The

motor contains a powerful magnet that may damage magnetic tape, credit

cards, computer disks and watches.

Use ear protectors. During operation the noise level of the collaring

machine may exceed 95dB(A).

The vibration excercised on the operator's hand is less than 2.5m/s.

9

INSTRUCTION MANUAL

2.3. Safety instructions for tee forming

Do not touch the rotating tool when the work cycle is on.

When fixing the machine to the tube, be careful not to leave your fingers

between the machine and the tube

When handling the tools, be careful with the cutting blades. Use protective

gloves.

A falling machine or tool may damage your feet. Use protective shoes.

The lubricating oil you use may cause irritation of the skin. Use protective

gloves.

The fumes emitted by the lubricant may irritate your eyes and hinder your

respiration. Pay attention to an adequate ventilation.

Make yourself familiar with the contents of the safetly data sheet regarding

the lubricants.

The loosening chips are hot and sharp. Provide adequate protection in

order not to get damaged.

Be careful to avoid accidental starting of the machine when handling it.

Never carry the tool with your finger on the trigger.

When cleaning the collar always use protecting gloves. The edges of the

collar use to be sharp.

Do not use inadequate protecting gloves, because they may get caught by

the rotating tool. Keep your hands off the dangerous area.

10

TEE FORMING MACHINE

T-6

0

3. T-DRILL T-60, general

3.1 Introduction

The T-DRILL T-60 is a special tool intended for mechanically forming tees

in copper tube typically found in domestic, commercial and industrial

tubing systems. The T-60 extrudes in the run tube an outlet, to which the

branch tube can be joined by brazing.

Before attempting to put the T-60 into service, make sure you have read

and fully understood the safety instructions which apply to all power tools

and capabilities of this special tool.

The T-DRILL T-60 includes an electric network driven power unit with

accessories. The power unit is grounded 120V /60Hz or double insulated

110V /50Hz and 230V /50Hz.

3.2 The Parts of the T-60

4 3

5 1 2

Main parts: 1. T-DRILL tee forming unit, 2. Power unit, 3. Connecting cord,

4. T-DRILL head, 5. Tube support.

11

INSTRUCTION MANUAL

3.3 Information about Accessories

For proper use of T-DRILL T-60 the following accessories are available:

Notcher ND-54

Tube end notcher forms the end of branch pipe to match inner curve of the

run tube. In this way maximum flow is achieved. The notcher also presses

two dimples simultaneously in the end of the branch tube, one acting as a

depth stop and the other one for inspection of the joint after brazing.

Gauge Block and rings

Correct size settings of the T-DRILL head for various tube sizes can easily

be checked with the gauge block. The range of size is NS 1/4"-1" with the

gauge block; 1¼”, 1½” and 2” with the rings).

Counter Plate

The counter plate assists forming of the outlet and improves the quality of

the outlet by supporting the tee forming machine against the run tube. The

counter plate is used for run tube sizes from NS 2 ½” (66.7 mm) to 4” (108

mm).

Lubrication for copper

A bottle of lubricant to be used for forming the outlet in copper tube, is

included.

12

TEE FORMING MACHINE

T-6

0

3.4 Operating Range of the Machine

The T-DRILL T-60 is intended for forming a tee in copper tube. The branch

tube is joined to the run tube by brazing.

The outlet size range of T-60 is NS 1/2" to 2" (10 – 54 mm).

The diameter of the run tube can be 1/2 " to 4" (15 – 108 mm). The

maximum wall thickness of the tube to be branched depends on the tube

diameter and the size of the T-DRILL head used.

Accurate capacity values: diameters and wall thicknesses of the tube are

specified in the capacity chart (chapter 11.1).

3.5 Technical specifications

T-60 Value NOTE!

Type Code 3305

Tee diameter NS 1/2” - 2” / 10– 54mm

Run tube NS 1/2” - 4” / 15– 108mm

Max. wall-thickness See Capacity chart (11.1)

Materials Copper (Cu)

Cycle 1 min. 45 s

Rotation speed of

spindle

500 / 50 RPM

A-accentuated

equivalent level of

sound pressure

82,5 dB (A) Use ear

protectors!

Vibration less than 2,5 m/s2

Dimensions of the unit 22.4”(l) x 4.9” (h) x 7.1” (d)

570 (l) x 125 (h) x 180 (d) mm

Weight of the unit 11,9 lbs /5,4 kg

Supply voltage of the

unit

120V / 60Hz / 7,0AMPS

230V / 50Hz / 4,0A

110V /50Hz 8,4AMPS

13

INSTRUCTION MANUAL

4. Transport, Handling and Storage

4.1 T-60

The T-60 is delivered in a transport box, dimensions 25.2” (640mm) x 6.5”

(165mm) x 14.2” (360mm) (w x h x d). The weight of the box is, depending

on the accessories, between 29 - 49 lbs (13 and 23 kg) .

Storage

Keep the T-60 stored in a cool, dry place, covered against dust etc.

14

TEE FORMING MACHINE

15

T-6

0

5. Preparing before use

5.1 T-60, Detachment and attachment of the connecting cord

When delivered the T-60 power unit is fitted with a connecting cord, which

allows quick changing in field conditions.

Detachment of the cord

Turn the nut of the cord 1/2 turn to the left in order to loosen the cord.

Draw the cord out of the power unit.

Attachment of the cord

Push the connector of the cord into the socket of the power unit, pushing

the connector as far as it will go.

In order to lock the cord, turn the nut 1/2 turn to the right.

5.2 T-60:s start-up check

NOTE! Carry out the start-up checks before using the machine.

Before using the machine, proceed as follows:

1. Check that the cord is connected to the machine

2. Check that the cord is connected to the mains.

INSTRUCTION MANUAL

6. The operation of the machine

6.1 Description of the control devices

6.1.1 T-DRILL T-60

2 1

3

Control devices: 1. Trigger, 2. Speed selector 3. Feed mechanism

engagement lever

NOTE! Use maximum speed of rotation when drilling and forming the

outlet - when working press the trigger completely down!

16

TEE FORMING MACHINE

17

T-6

0

T

h

e

s

p

e

e

d

s

1. Speed selector

2. The feed mechanism lever

The speed selector knob is on the top of the gearbox of the T-60. Slow

speed is marked “I” and fast speed is marked “II”. To shift from fast to slow

speed, turn the selector knob 180 degrees. Drilling is always done in fast

speed (II). The forming of the tee is done in either slow speed or fast

speed depending on the run tube and outlet sizes. See the chart in

chapter 11.

If the speed selector knob does not engage smoothly, rotate the

motor by “bumping” the trigger.

The feed mechanism lever is situated near the chuck-ring. The feed

mechanism is engaged (on) when the lever is turned downward, i.e. as

shown on the illustration.

If the feed mechanism lever does not engage smoothly, rotate the

motor by “bumping” the trigger.

Do not force lever.

INSTRUCTION MANUAL

6.2 Selection and adjustment of the T-DRILL heads

6.2.1 The identification of the T-DRILL head

The size of the T-DRILL head is stamped on the cover plate:

5310401

15 1/2

1

2

3

Identification: 1. Actual size in millimetres, 2. Nominal size in inches (NS),

3. The ordering and identification number of the T-DRILL head

18

TEE FORMING MACHINE

19

T-6

0

6.2.2 The fine adjustment of the outlet diameter

NOTE! When adjusting the outlet diameter, extend the forming pins first.

Each T-DRILL head is adjusted at the factory to correspond to the nominal

size stamped on the cover of each T-DRILL head. Changing the tube

sizes or the way of joining may require adjustment of the T-DRILL head in

order to achieve the right joint.

To extend the forming pins (1) press

the cover (2) in direction of the

shank. Twist the shank (3) at the

same time clockwise until a positive

stop is reached, and the forming pins

extend.

1

2

3

T

Check the forming pin span diameter T with an adjusting ring or slide

gage.

INSTRUCTION MANUAL

Depending on the size of the T-DRILL head, the forming pin span T should

be 0,020” – 0,055” (0,5 – 1,4mm) bigger than the branch pipe outer

diameter (O.D.)

1. Loosen the screws on the cover

plate by about one circle using a 3

mm hexagon wrench, that is

supplied with the T-DRILL

package.

2. To enlarge the outlet rotate the conical

cover with respect to the cover plate in

plus (+) direction. Hold the cover plate

stationary.

To make a smaller outlet rotate the

conical cover in minus (–) direction while

holding the cover plate stationary.

One

notc

h on the cover-plate equals to 0.01” or

0,25 mm on the forming pin span.

3. Tighten the two screws on the cover

plate and check the adjustment either by

measurement across the pins or by forming

a trial outlet.

20

TEE FORMING MACHINE

T-6

0

6.3 Chucking the T-DRILL head

6.3.1 Chucking

To insert the T-DRILL head into the chuck, rotate the locking ring (1)

clockwise and slide the T-DRILL head shaft into the chuck(2). Release the

locking ring. Rotate the T-DRILL head (3) in the chuck until it locks. Make

sure the T-DRILL head is tightly chucked.

6.3.2 Removal

To remove the T-DRILL head (2) from the chuck (1), rotate the locking ring

as far it will go. Turn the T-DRILL head to the same direction one quarter

of a turn (1/4) at the same time pulling it straight out. Release the lock ring.

2

3

1

Chucking the T-DRILL head and removing it.

21

INSTRUCTION MANUAL

6.3.3 Fitting the old T-DRILL heads to the T-60 –machine

If you have old 42/1½ or 54 /2 T-DRILL heads, you can use them in

T-DRILL T-60 after shortening the drill core as described below. Without

shortening the drill cores of old T-DRILL heads do not fit in the chuck of

the T-60.

6.3.3 Shortening the drill core. The distance between the center line of the

draft hole and the core end has to be 31/32” (25 mm).

22

TEE FORMING MACHINE

T-6

0

6.4 The tee forming process with the T-DRILL T-60

Since the process may be new to you, we recommend that you read the

following instructions carefully and then practice a few times on some

pieces of scrap tubing.

NOTE! Before forming any tee always make sure that the pipe is

completely drained and that it is not under pressure

1. Select the correct T-DRILL head.

2. Check the forming pin span (T). Adjust if necessary. (See chapter

6.2.2).

3. Chuck the T-DRILL head.

4. Lubricate the T-DRILL head

before every tee forming operation!

Extend the forming pins and

lubricate them as well as the

cutting edges of the T-DRILL head

as illustrated. Always use T-

DRILL lubricant.

5. Retract forming pins. Press

the conical cover towards the tool

and rotate it clockwise to retract

the forming pins.

23

INSTRUCTION MANUAL

6. Check that the speed selector knob is in position II and the feed

mechanism lever in “off”-position.

7. Pull the support legs out and place

the tube support firmly onto the point

where the tee is to be formed on the

tube, as shown on the illustration.

Press the tube support with the thumb

against the tube and twist the machine

counterclockwise at the handle of the

tool. This centers the T-DRILL head

onto the tube.

8. Start the tool by pressing the trigger

and drill until the bit has fully

penetrated into the tube. Release the

trigger - the machine will stop.

NOTE! If the tool does not have enough power to drill – select the low

speed I and continue drilling. This may be necessary if a long extension

cord is used.

9. Extend the forming pins on the TDRILL head by pressing the conical

cover towards the tool and rotating it

counterclockwise until the T-DRILL

head locks into the tee forming

position. Do not extend the forming

pins while the motor is running!

24

TEE FORMING MACHINE

T-6

0

10. Select low speed I by turning the

selector knob. (Always use low speed (I)

when forming the outlet, consult

capacity chart in section 11.1 for

options.) Engage the feed mechanism

as shown. If it does not engage

smoothly, rotate the motor by “bumping”

the trigger.

11. Start forming the outlet by pulling

the trigger and continue until the TDRILL head is completely out of the

tube. During the forming of the tee, keep

the tube support against the tube and

push the tool toward the tube. This

insures that you obtain a circular outlet.

12. Once the T-DRILL head has come

completely out of the outlet, release

the trigger.

IMPORTANT! Release the drill trigger as soon as the T-DRILL head

clears the rim of the outlet.

NOTE! Never attempt to “help” the tool by pulling it out of the tube. This

would result in an oval outlet!

NOTE! Wipe away any exess lubricant which may have remained inside

the outlet before brazing. Use sandcloth or Scotchbrite to clean the

inside of the rim of the outlet!

25

INSTRUCTION MANUAL

6.5 Annealing of tube

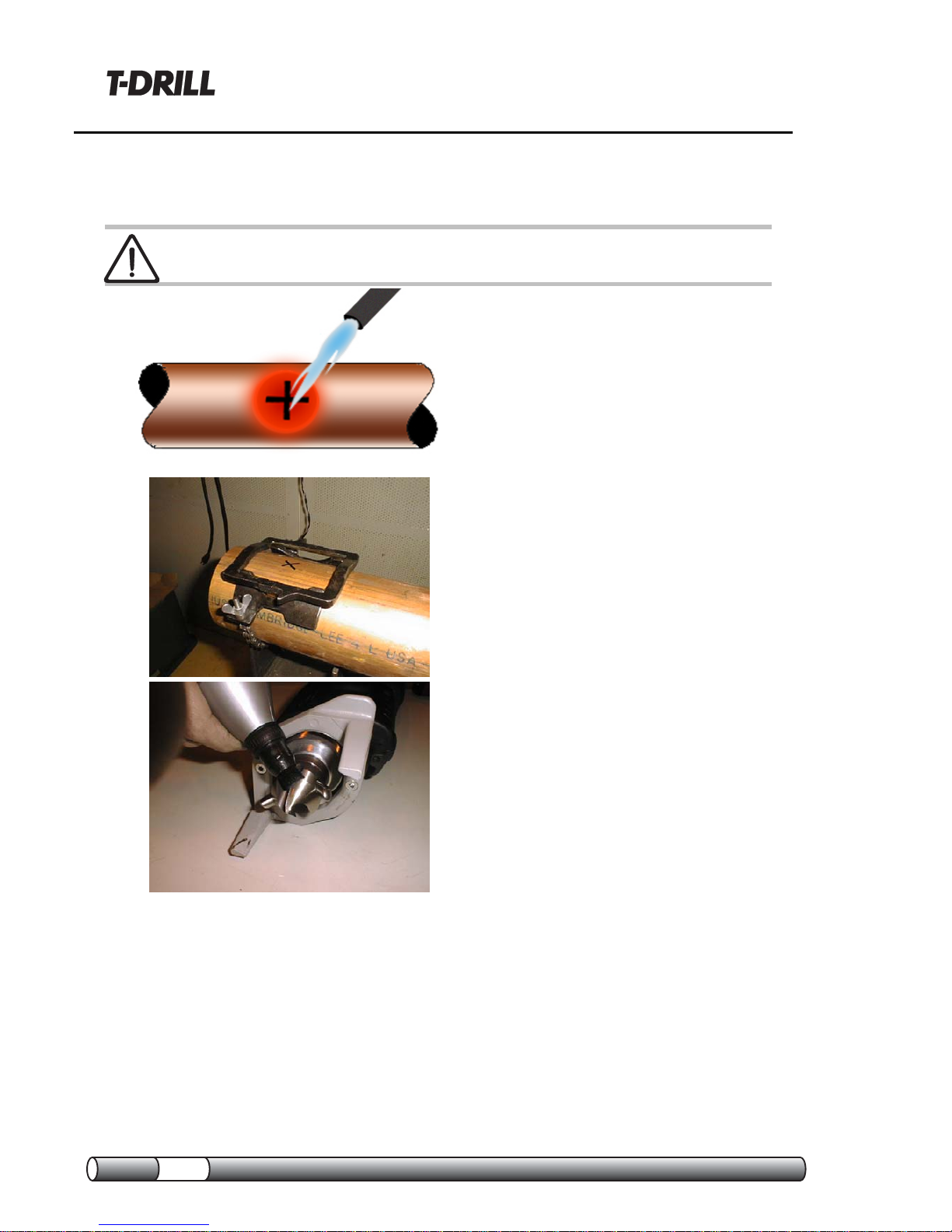

DANGER! The annealed work piece is extremely hot after annealing.

When working with the tube protective gloves should be used.

1. Anneal the area where outlet is to

be formed to a dull red.The area will

remain annealed even when cool. It

is not necessary to form the outlet on

hot tube!

2. Attach counterplate to the tube

where annealing has been done.

3. Lubricate forming pins and cutting

edges on T-DRILL head.

26

TEE FORMING MACHINE

T-6

0

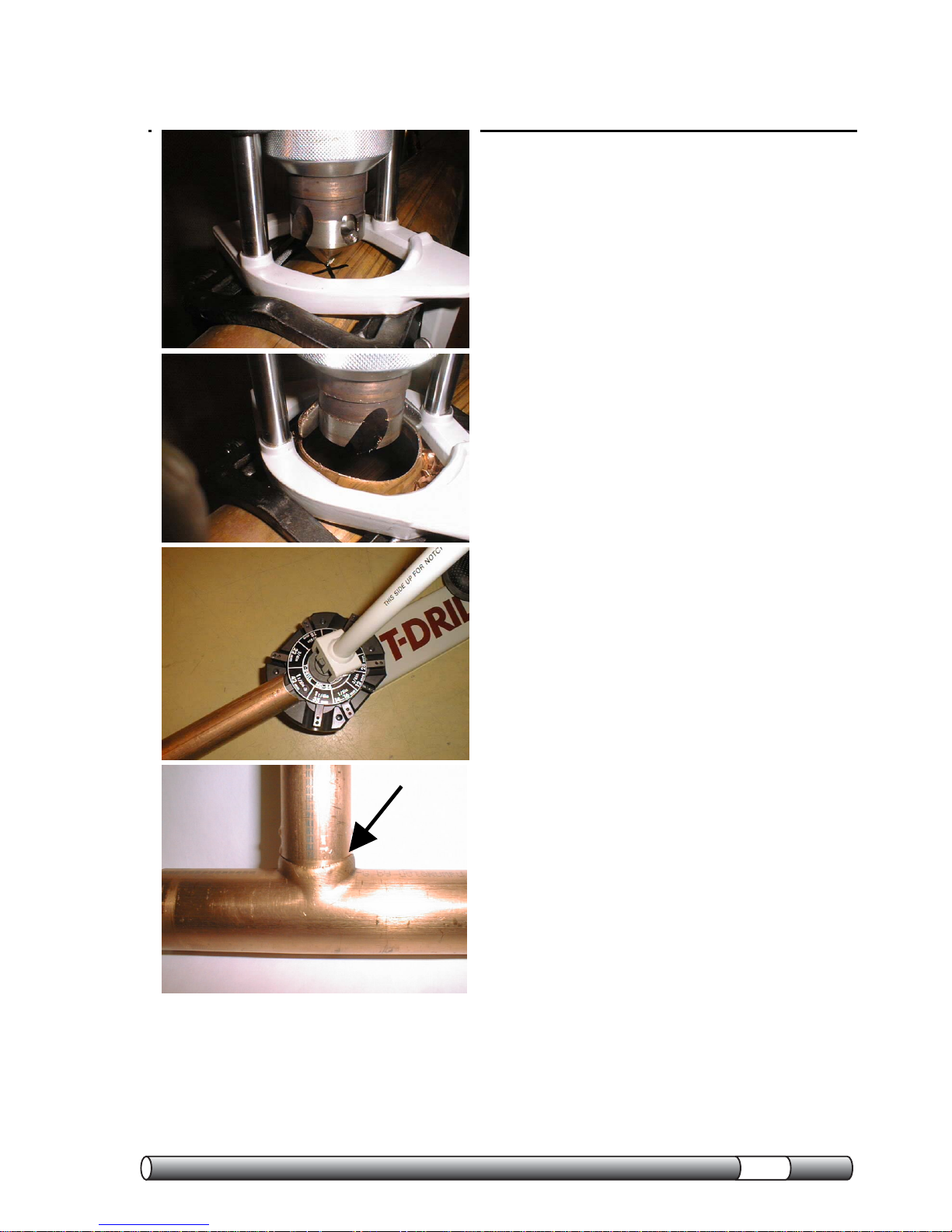

4. Retract forming pins on T-DRILL

Head and attach T-DRILL T-60 to

counterplate. Notches on tube

support fit on tabs of counterplate.

5. Drill pilot hole, extend forming

pins, reduce speed, engage feed

mechanism, pull trigger to form the

outlet. Release trigger when forming

pins clear the rim of the outlet.

6. Notch and dimple both sides of

branch tube.

7. Align dimples with the run of the

tube after insertion into the outlet.

Braze the joint.

27

INSTRUCTION MANUAL

7. Maintenance

7.1 The maintenance of the T-DRILL T-60

The T-DRILL T-60 is prelubricated and does not need special attention for

maintenance. Clean dust and dirt from tool vents.

NOTE! All maintenance operations for the T-DRILL T-60 and

MILWAUKEE power unit sold in North America are to be carried out

only by T-DRILL Industries, Inc. in Norcross, Georgia, USA.

28

TEE FORMING MACHINE

T-6

0

7.2 The replacement of the forming pins

1. Loosen the two screws on the

cover plate one turn and rotate

the conical cover with respect to

the cover plate so that the conical

cover can be removed. When the

conical cover is removed rotate

the cone so that the forming pins

will slide from the shank.

2. The forming pins can now

be changed.

3. Reassemble the T-DRILL

head using new forming pins and

adjust to the right outlet

diameter.

29

INSTRUCTION MANUAL

8. Trouble-shooting

Problem Cause Remedy

The power unit

doesn’t run.

The connection cord loose, or

the plugs do not make contact

with the wires inside the cord.

Trigger not fully pressed.

Insert the cord into the

bracket, or substitute the

cord with a new one.

Press the Trigger fully.

Burrs in the tee that

has been formed

Burrs in the pilot hole

- the drill bit is dull

- lubricant insufficient

- lubricant of bad quality

The forming pins are worn or

dirt stuck on their surface.

Insufficient lubricant during

forming of the outlet.

Lubricant not suitable to the

material

The wall thickness of the tube

exceeds the maximum

allowable thickness.

- Anneal Area to be

drilled

- Change drill bit

- Use more lubricant

- Only lubricant

recommended by

T-DRILL is to be used

Clean or change the

forming pins

Always lubricate the TDRILL head carefully

before every outlet forming

operation

Consult your local T-DRILL

representative

Consult the capacity charts

The size of the tee

varies.

Dirt stuck to the surface or the

holes of the forming pins.

Adjusting screws of the head

are too loose.

Clean the forming pins.

Tighten the screws

30

TEE FORMING MACHINE

T-6

0

Problem Cause Remedy

The forming pins break

off or the drill shank

breaks

Lack of annealling when

called for in instructions.

Burrs in the pilot hole

-drill bit dull

The wall-thickness of the

tube exceeds the max.

allowable thickness.

Not enough lubricant

during forming of the tee.

The lubricant is not

suitable for your

material

Tool is not straight

against the pipe.

Slow speed was not

used when referenced

on the capacity chart.

– Resharpen or change

the drill bit

See the capacity charts.

Lubricate the T-DRILL

head carefully before

forming the outlet.

Consult your local

T-DRILL representative.

Use counterplate. (extra

equipment)

Use slow speed when

indicated on the

capacity chart.

31

INSTRUCTION MANUAL

9. Disposing

Disposing of the T-DRILL machine

In the manufacturing of the T-DRILL machines various kinds of metals,

plastic and lubricants have been used. Dispose of your T-DRILL machine

according to federal, state and local regulations.

32

TEE FORMING MACHINE

T-6

0

10. Warranty

T-DRILL guarantees that every T-DRILL T-60 tee forming machine is free

from defects in materials and workmanship (other than normal wear and

tear) for a period of one (1) year from date of shipment. Should within this

period any T-60 be proved to T-DRILL's satisfaction to be defective, such

product shall be repaired or replaced. Such repair or replacement shall be

T-DRILL’s sole obligation; whereas the buyer's only obligation is to inform

T-DRILL of any such defect. T-DRILL must receive the reclamation in

writing within 10 days after a defect having been noticed and, at

T-DRILL’s option, buyer will have to return the complete tool to the

nearest T-DRILL Representative or Distribution Center. THIS

WARRANTY IS PRIMARY.

T-DRILL’s warranty shall be limited to the aforesaid warranty stipulations.

T-DRILL SHALL NOT BE SUBJECT TO ANY OTHER OBLIGATIONS OR

LIABILITIES, WHETHER ARISING OUT OF BREACH OF CONTRACT,

TORT (INCLUDING NEGLIGENCE) OR OTHER THEORIES OF LAW,

WITH RESPECT TO PRODUCTS SOLD OR SERVICES IMPLICATED,

OR ANY UNDERTAKINGS, ACTS OR OMISSIONS RELATING

THERETO. T-DRILL SHALL NOT BE LIABLE FOR AND DISCLAIMS ALL

CONSEQUENTIAL, INCIDENTIAL AND CONTIGENT DAMAGES

WHATSOEVER.

Please register your purchase by filling out and returning the

warranty registration card enclosed. Save your receipt.

33

INSTRUCTION MANUAL

11. Supplement

Capacity and instruction chart for T-DRILL T-60 on M, L, &

K tubing

Run Tube Size

1

/2” 3/4”

1”

1-1/4” 1-1/2”

2” 2-½” 3” 4”

Nominal

Outlet Size

Notch and dimple all branch tubes. Place dimples in line with the

run of the tube.Braze all joints

1

/2”

3 1 1 1 1 1 5

4

5 4 5

4

3

/4”

3 1 1 1 1 5

4

5

4

5

4

1”

3* 1* 1* 1* 5 5 5

1-1/4”

3 2 2 5 5 5

1-1/2”

3 2 5 5 5

2”

3 5 5 5

= Pre-anneal the area where tee is to be formed or anneal

pilot hole in this section. Form tee at slow speed. Use counter

plate

*

It may be necessary to use reduced speed to form the tee.

1. Apply T-DRILL lube to T-DRILL Head. Extend tube supports, place

tube supports on either side of tube. Drill pilot hole, extend forming

pins, engage feed mechanism, form outlet. Use high speed. Maintain

pressure towards tube as outlet is formed.

2. After drilling pilot hole, extend forming pins, form outlet at reduced

speed. maintain pressure towards tube as outlet is formed.

3. After drilling pilot hole, remove drill by engaging feed mechanism.

Anneal brieflty below each side of pilot hole. Reinsert drill, extend

forming pins and form outlet. It may be necessary to slightly oversize

forming pins to compensate for springback in copper tube wall.

Maintain pressure towards tube as outlet is formed.

4. When a ½“ or ¾“ outlet is needed on 2 ½” , 3” or 4” tube, follow the

directions in Legend 5 but form a 1” outlet and reduce with fitting by

copper reducer. Notch and dimple reducer. Align dimples with the run

of the tube – braze joint.

5. Anneal to a dull red area where outlet will be formed. Attach

counterplate to the tube. Apply T-DRILL lubricant to cutting edges and

forming pins of the T-DRILL Head. Retract forming pins on T-DRILL

Head and attach T-DRILL T-60 to the counterplate, drill pilot hole,

extend the forming pins, reduce speed using the speed selector dial,

34

TEE FORMING MACHINE

T-6

0

engage the feed mechanism, pull the trigger to form outlet. Notch and

dimple branch tube. Insert branch tube into outlet, align dimples with

the run of the tube – braze the joint.

** If motor slows during drilling of pilot hole, shift to slow speed.

NOTE: Lubricate drill bit and forming pins with T-DRILL lubrication on

every outlet. After outlet is formed clean lubricant from inside edge of the

rim with sand cloth or scotchbrite.

Have A Question?

Call Toll Free in USA 1-800-554-2730 Ext. 216

35

INSTRUCTION MANUAL

36

Capacity chart in millimeters

Use the capacity charts to determine the maximum wall-thickness of the

tube and to select the right T-DRILL head.

Instructions for the use of the capacity charts:

1. Use the unit of measure that is correct for you: the measures of the

charts are in both millimeters and in inches.

2. From the horizontal black row, find

the tee size you need (inner

diameter), and from the vertical black

column the outer diameter of your

run tube.

3. The intersection of the horizontal and

vertical rows will show you the

maximum wall-thickness of the tube.

This thickness is not to be exceeded.

Capacity charts for forming tees in copper tubes

Max wall-thicknesses (mm)

10 12 15 18 22 28 35 42 54

1/4” 3/8" 1/2" 5/8" 3/4" 1" 1¼" 1½" 2"

15 1/2" 1.0 1.2 1.2

18 5/8" 1.0 1.2 1.5 1.2

22 3/4" 1.0 1.2 1.5 1.5 1.5

28 1" 1.0 1.2 1.5 1.5 1.5 1.5

35 1¼" 1.0 1.2 1.5 1.5 1.5 1.5 1.5

42 1½" 1.0 1.2 1.5 1.5 1.5 1.5 2.0 2.0

54 2" 1.0 1.2 1.5 1.5 1.5 1.5 2.0 2.0 2.0

64 2½" 1.0 1.2 1.5 1.5 1.5 1.5 2.5 2.5 2.5

76,1 3" 1.0 1.2 1.5 1.5 1.5 1.5 2.5 2.5 2.5

88,9 3½" 1.0 1.2 1.5 1.5 1.5 1.5 2.5 2.5 2.5

108 4" 1.0 1.2 1.5 1.5 1.5 1.5 2.5 2.5 2.5

= Annealing before forming the tee is recommended!

TEE FORMING MACHINE

T-6

0

37

INSTRUCTION MANUAL

38

12. Spare parts list

12.1. T-60

1

6

7

3

2

4

5

8

TEE FORMING MACHINE

T-6

0

12.1. T-60

Part No. Complete Assembly

5330161 T-DRILL T-60 120V US

A

5330163 T-DRILL T-60 230V

Europe

5330110 T-DRILL T-60 110V U

K

5330209 T-DRILL T-60 110V

Item Part No. Description Qty

1 5330158

5330160

5330109

Power Unit 120V USA

Power Unit 230V Europe

Power Unit 110V UK

/Japan

1

2 5330154 T-60 Tee Forming Unit 1

3 2330111 Adapter PUR 1

4 3330032 Tube Support 1

5 9114027 Socket head cap screw 2

6 4330164

4330165

4330108

4330223

Name plate 120V USA

Name plate 230V Europe

Name plate 110V UK

Name plate 110V Japan

1

7 9146622 Sticker, read the instr. 1

8 9048335

9048320

9048342

9048331

Cord 120V USA

Cord 230V Europe

Cord 110V UK

Cord 110V Japan

1

39

INSTRUCTION MANUAL

12.2. The T-60 Tee Forming Unit

14

6

5

18

9

17

16

2

1

18

17

19

15

10

7

23

4

13

21

8

11

9

23

12

40

TEE FORMING MACHINE

T-6

0

Part No. Complete Assembly

5330154 T-60 Tee Forming Unit

Item Part No. Description Qty

1 5330156 Housing 1

2 5330117 Lead Screw 1

3 5330097 Nut Assy Complete 1

4 5540031 Reduction Gear 1

5 3330178 Gear Changer 1

6 5330115 Shift Knob 1

7 4330099 Push Rod 2

8 3330074 Lever 1

9 4540068 Pin 2

10 3330075 Drive Piece 1

11 4540056 Bar 1

12 3300056 Locking Ring 1

13 4300055 Chuck Ring Spring 1

14 4540069 Shaft 1

15 4300054 Chuck Drive Pin 2

16 3540045 Selector Gear 1

17 9026146 Spring 2

18 9018089 Parallel Pin 2

19 9012205 Spring Washer 1

20 9017033 Slot-headed screw 1

21 9018206 Spring Pin 3x8 1

23 9019007 Retaining Ring 2

24 9021006 Groove Ball Bearing

6005 2RS

1

41

INSTRUCTION MANUAL

12.3 T-DRILL Head

7

5

6

3

4

2

1

8

9

6

11

10

2

9

Tee Size ∅ mm

10 12 15 18 22 28 35 42 54

Nominal Tee Size ∅ inch

1/4 3/8 1/2 5/8 3/4 1 1/1/4 1/1/2 2

Order No. 5310399 5310400 5310401 5310402 5310403 5310404 5310411 5310412 5310413

Item Description Qty

Part No.

1 Drill Core 1

2310140 2310150 2310160 2310170 2310180 2310210 4310221 4050253 2050254

2 Forming Pin 2

3310240 3310245 3310250 3310250 4310466 4310467 3430033 3430033 3430034

3 Cone 1

2310283 2310283 2310283 2310283 2310283 2310283 2310451 2310451 2310451

4 Adjustment Plate 1

3310293 3310293 3310297 3310310 3310304 3310304 3310304 3050151 3050151

5 Cover Plate Assembl 1

4310323 4310329 4310335 4310341 4310347 4310359 4310362 4310364 4310365

6 Screw 2

4310372 4310372 4310372 4310372 4310372 4310372 4310372 4310372 4310372

7 Spring 1

4310376 4310376 4310376 4310376 4310376 4310376 4310376 4310376 4310376

8 Conical Cover 1

3310380 3310380 3310380 3310380 3310389 3310389 3050149 3050149 3050149

9 Circlip 2

9019003 9019003 9019003 9019003 9019003 9019003 9019003 9019003 9019003

10 Circlip 1

9019201 9019201 9019201 9019201 9019201 - - - -

11 Pin 1

9018038 9018038 9018038 9018038 9018038 9018038 9018038 9018038 9018038

42

TEE FORMING MACHINE

T-6

0

12.4 Counterplate 5540085

Item Part No. Name Size/Type Std./Manuf. Qty

1 3540011 Counterplate

1

2 3540012 Counter plate mask.

1

3 3540013 Counterplate fem.

1

5 5540201 Chain

1

6 9018038 Parallel pin

Ø3m6x20 DIN 6325 4

7 4540070 Pin

1

12.4.1 Chain 5540201

Item Part No. Name Size/Type Std./Manuf. Qty

1 4050090 Screw

1

2 4540015 Knob

1

3 9013201 Wing nut

M6 DIN 315 1

4 9024117 Coupler link

1/2" Wipperman

332

1

5 9024102 Roller chain

1/2" Wipperman

332 250

DIN 8187 1

43

INSTRUCTION MANUAL

12.5 Optional Equipment

Item Part No. Description Qty

1 5090294 Notcher ND-54 1

2 3310461 Gauge Block 1

3 5540085 Counter Plate 1

5 9010205 Lubricant for Copper

1L-bottle

1

44

TEE FORMING MACHINE

T-6

0

13. Ordering spare parts

When ordering spare parts, please state the following details:

-The type code of the machine

-Manufacturing code of the machine

-The part number

-A description of the part

-The quantity of the parts required

The type code and the manufacturing code of the machine are indicated

on the nameplate of the machine. The other information can be found from

parts list.

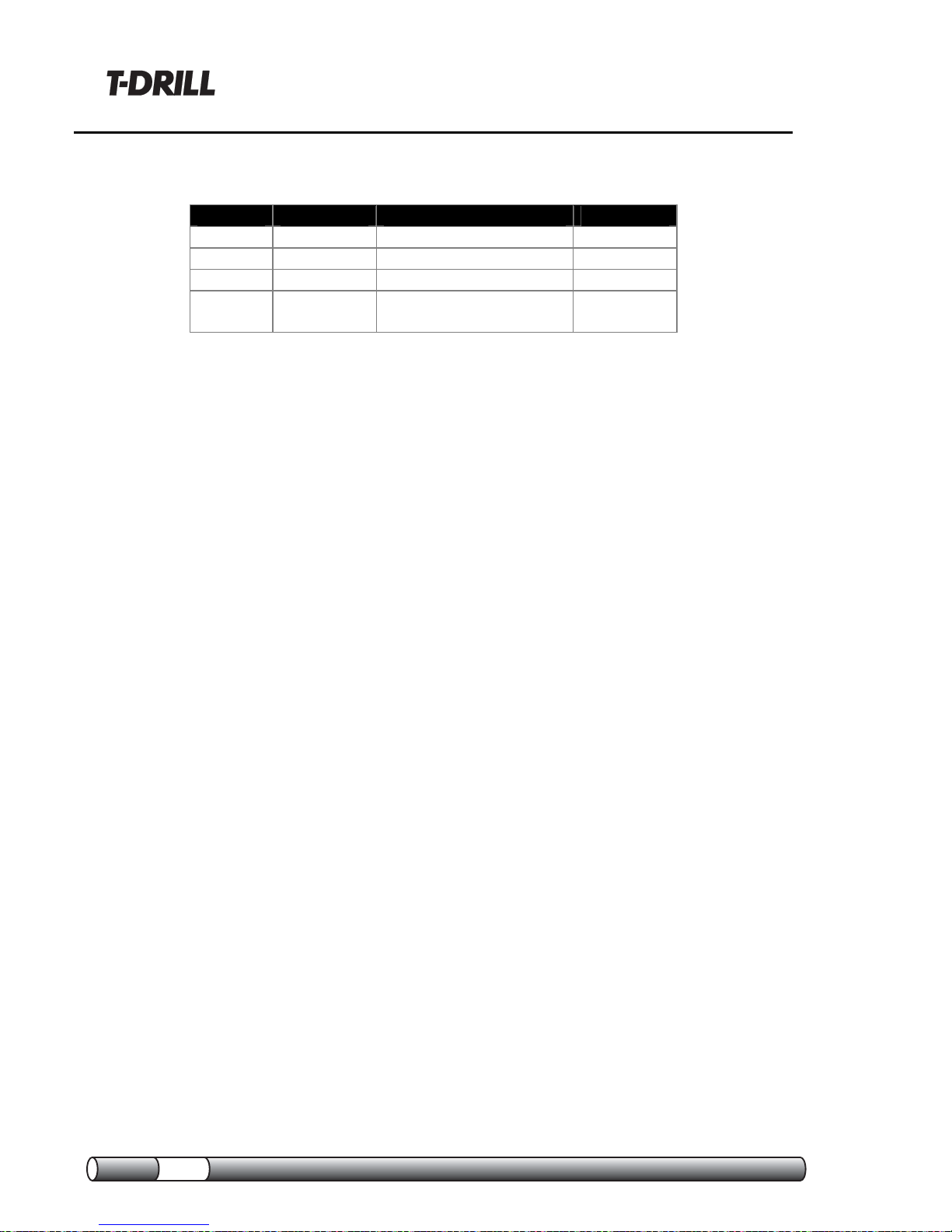

For example:

XX: Assembly name 5XXXXXX 2(4)

Item Part No. Designation Std. /Manuf. Qty

33 4800220 Left Hand Slide Gib

3

34 9014313 Flat Head Cap Screw M5x8

DIN7991

12

37 3801440 Lever

2

38 4800276 Rod Eye

1

39 4800299 Clamp Ring

4

1 2 3

1. Part number 2. Description 3. Quantity

When ordering spare parts, make a copy of the Service Sheet, fill it out

and fax or mail it.

To proceeding this way you will prevent misunderstandings and you make

sure to receive the correct spare parts and a prompt service.

45

INSTRUCTION MANUAL

INSTRUCTION MANUAL

46 46

Loading...

Loading...