INSTALLATION INSTRUCTIONS

Please follow these instructions to ensure the proper operation of your T & D MACHINE

PRODUCTS Chrysler B-1 Rocker Arm Assembly with 5/8" diameter rocker shafts.

1. CYLINDER HEAD INSPECTION AND PREPARATION

Inspect the cylinder heads to be sure they are clean and free of any burrs that may

interfere with the rocker stands. Inspect the tapped holes for proper thread depth.

Minimum thread depth is 3/4". This rocker system is designed to oil through the

pushrods, so the block and lifters must be modified accordingly. Also, the oil

supply holes in the cylinder head must be plugged to prevent leaking by tapping the

oil holes for a 12-24 set screw.

2. DETERMINE CORRECT STAND HEIGHT

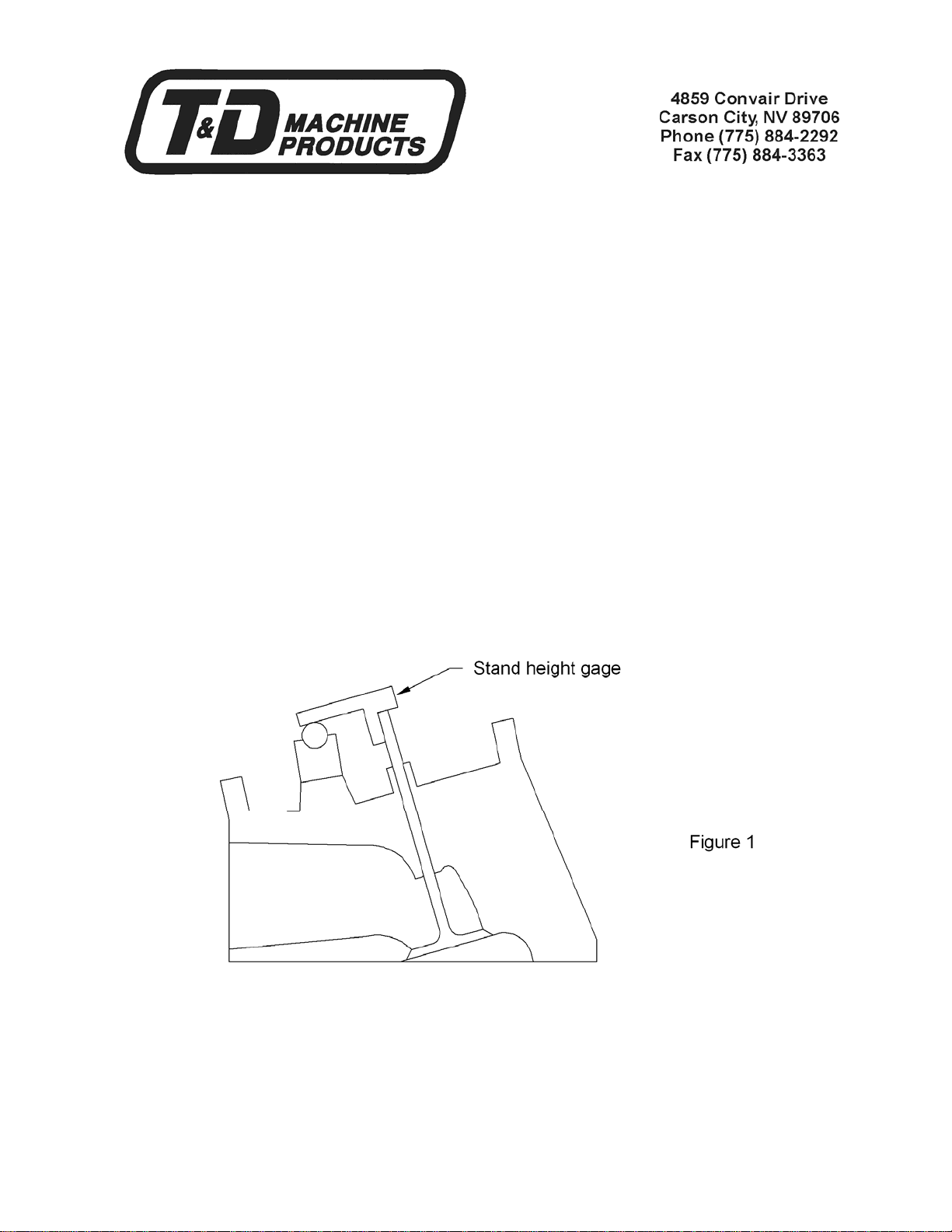

Install the rocker stands on the cylinder head using the 3/8-16, 12 point attaching

bolts. Remove a rocker arm from one of the shafts and place that shaft on a

stand. Take the shaft height gage supplied with the kit and place it on the valve

stem as shown in Figure 1.

The gage should contact the top of the valve and the rocker shaft as shown in

Figure 1.

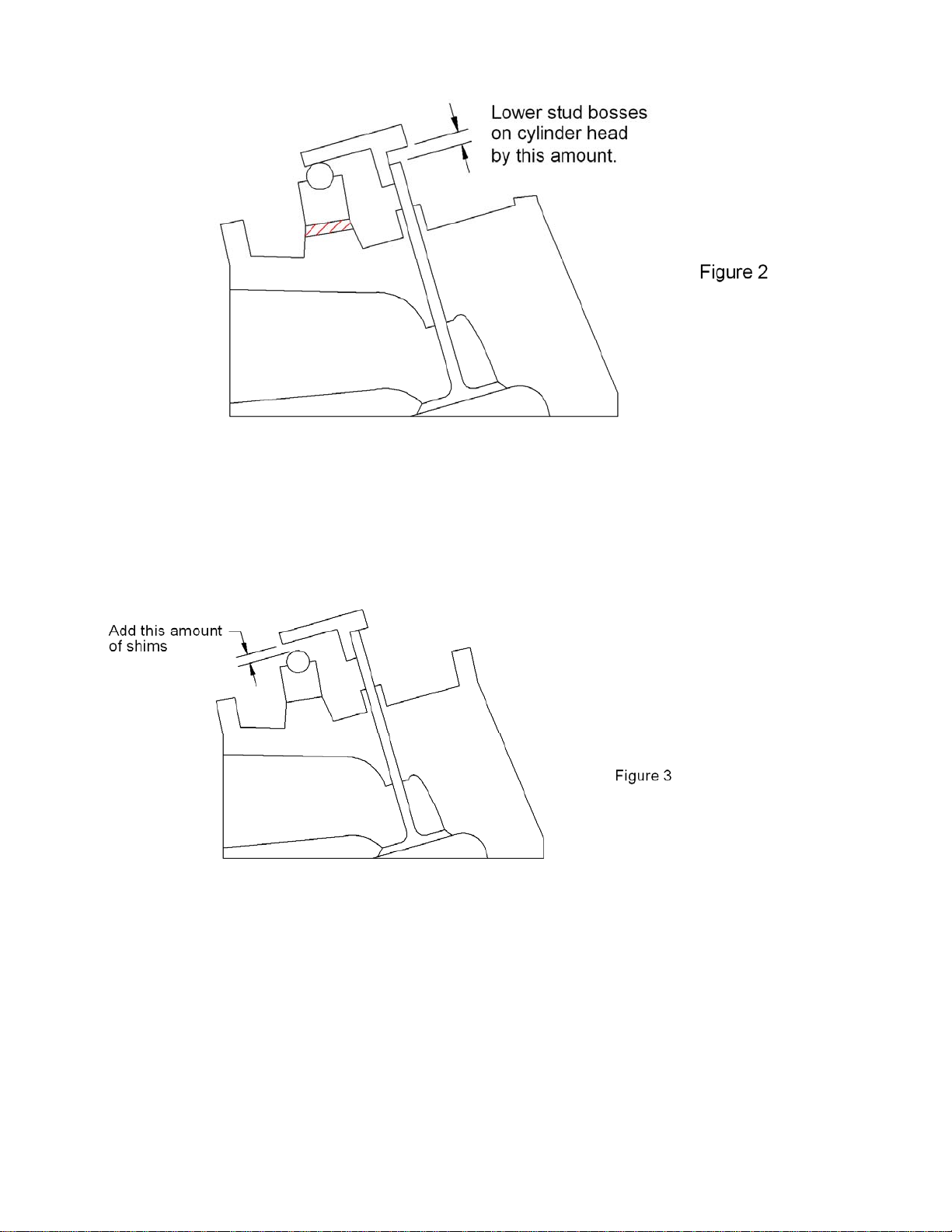

If the gage contacts the shaft before touching the top of the valve stem, as shown

in Figure 2, remove a corresponding amount of material from the stud bosses on

the cylinder head. This will lower the rocker stand on the cylinder head.

If the gage contacts the top of the valve stem and does not touch the rocker shaft,

as shown in Figure 3, add a corresponding amount of shims between the stand

and the cylinder head. This will raise the rocker stand and shaft to the correct

height.

4. DETERMINE CORRECT PUSHROD LENGTH

Place a pushrod length checker into the lifter and install the rocker arm assemblies.

Be sure the cam is rotated to the base circle. Seat the bottom of the adjuster screw

up against the recess in the rocker arm and turn the adjuster screw clockwise one

full turn down. This is the initial adjuster position. Adjust the pushrod length tool to

the proper length, remove from the engine, and measure its overall length.

The rocker arm should not be operated with the adjuster screw more than one turn

up or down, from the initial adjuster position. Doing so can cut off the flow of oil to

the rocker arm.

5. FINAL ASSEMBLY

After all of the stand heights have been set, place a rocker and shaft back on the

stand to assure good rocker to valve alignment and torque the stand attaching bolts

to 50/55 ft-lbs. Install the 5/16 studs and torque them to 50 inch-pounds. When the

stands are aligned and tightened down, place the rocker arm and shaft assemblies

on the stands and tighten the shaft hold down nuts to 25 ft-lbs. After all of the

rockers have been tightened down, set valve lash and torque the adjuster screw

jam nut to 5/20 ft-lbs.

Loading...

Loading...