Page 1

ZWS

-

B Series

Instruction Manual

CA790

-04-

01B

BEFORE USING THE POWER SUPPLY UNIT

Be sure to read this instruction manual thoroughly before using this product. Pay attention to all cautions and warnings before using this product.

Incorrect usage could lead to an electrical shock, damage to the unit or a fire hazard.

DANGER

1. Never use this product in locations where flammable gas or ignitable substances are present.

INSTALLATION WARNING

1. When installing, ensure that work is done in accordance with the instruction manual. When installation is improper, there is risk of electric

shock and fire.

2. Installation shall be done by Service personnel with necessary and appropriate technical training and experience. There is a risk of electric

shock and fire.

3. Do not cover the product with cloth or paper etc. Do not place anything flammable around. This might cause damage, electric shock or

fire.

WARNING ON USE

1. Do not touch this product or its internal components while circuit in operation, or shortly after shutdown. You may receive a burn.

2. While this product is operating, keep your hands and face away from it as you may be injured by an unexpected situation.

3. For products with no cover, do not touch them as there are high-voltage and high temperature parts inside. Touching them might cause

injury such as electric shock or burn.

4. There are cases where high voltage charge remains inside the product. Therefore, do not touch even if they are not in operation as you

might get injured due to high voltage and high temperature. You might also get electric shock or burn.

5. Do not make unauthorized changes to this product nor remove the cover as you might get an electric shock or might damage the product.

We will not be held responsible after the product has been modified, changed or dis-assembled.

6. Do not use this product under unusual condition such as emission of smoke or abnormal smell and sound etc. Please stop using it

immediately and shut off the product.

It might lead to fire and electric shock. In such cases, please contact us. Do not attempt repair by yourself, as it is dangerous for the user.

7. Do not operate and store these products in environments where condensation occurs due to moisture and humidity.

It might lead fire and electric shock.

8. Do not drop or apply shock to this product. It might cause failure. Do not operate these products mechanical stress is applied.

CAUTION ON MOUNTING

1. Confirm connections to input/output terminals are correct as indicated in the instruction manual before switching on.

2. Input voltage, Output current, Output power, ambient temperature and ambient humidity should be kept within specifications, otherwise

the product will be damaged.

3. Input line, please use the wires as short and thick as possible.

4. Do not use this product in special environment with strong electromagnetic field, corrosive gas or conductive substances and direct

sunlight, or places where product is exposed to water or rain.

5. Mount this product properly in accordance with the instruction manual, mounting direction and shall be properly be ventilated.

6. Please shut down the input when connecting input and output of the product.

7. When installing in environment where conductive foreign, dust and liquid may be present, please consider penetration of above foreign

material in the power supply by installing filter, to prevent trouble or malfunction.

8. This product contains a printed circuit board utilizing surface mounted devices. PCB stress such as bending, twisting etc. could cause damage.

Therefore, please handle with care.

9. When handling this product, hold the board edge and take care not to touch the component side. When installing this product in apparatus or

equipment, mount it on spacers.

ZWS10B・ZWS15B・ZWS30B

TDK-Lambda

ZWS10・15B・30B Series

Instruction Manual

- 1 -

Page 2

TDK-Lambda

ZWS10・15B・30B Series

Instruction Manual

CAUTION ON USE

1. Product individual notes are shown in the instruction manual. If there is any difference with common notes individual notes shall have

priority.

2. Before using this product, be sure to read the catalog and instruction manual. There is risk of electric shock or damage to the product or

fire due to improper use.

3. Input voltage, Output current, Output power, ambient temperature and ambient humidity should be kept within specifications, otherwise

the product will be damaged, or cause electric shock or fire.

4. If the built-in fuse is blown, do not use the product even after replacing the fuse, as there is risk of abnormality inside.

Be sure to request repair to our company.

5. For products without built-in protection circuit (element, fuse, etc.), insert fuse at the input to prevent smoke, fire during abnormal

operation.

As for products with built-in protection circuit, depending on usage conditions, built-in protection circuit might not work.

It is recommended to provide separate proper protection circuit.

6. For externally mounted fuse do not use other fuses aside from our specified and recommended fuse.

7. This product was made for general purpose electronic equipment use and is not designed for applications requiring high safety (such as

extremely high reliability and safety requirements. Even though high reliability and safety are not required, this product should not be

used directly for applications that have serious risk for life and physical safety.

Take sufficient consideration in fail-safe design (such as providing protective circuit or protective device inside the system, providing

redundant circuit to ensure no instability when single device failure occurs).

8. When used in environments with strong electromagnetic field, there is possibility of product damage due to malfunction.

9. When used in environment with corrosive gas (hydrogen sulfide, sulfur dioxide, etc.), there is possibility that they might penetrate the

product and lead to failure.

10. When used in environments where there is conductive foreign matter or dust, there is possibility of product failure or malfunction.

11. Provide countermeasure for prevention of lightning surge voltage as there is risk of damage due to abnormal voltage.

12. Connect together the frame ground terminal of the product and the ground terminal of the equipment for safety and noise reduction. If

these ground is not connected together, there is risk of electric shock.

13. Parts with lifetime specifications (built-in fan electrolytic capacitor) are required to be replaced periodically. Set the overhaul period

depending on the environment of usage and perform maintenance.

Also, note that there are cases when EOL products cannot be overhauled.

14. Take care not to apply external abnormal voltage to the output. Especially, applying reverse voltage or overvoltage more than the rated

voltage to the output might cause failure, electric shock or fire.

15. Never operate the product under over current or short-circuit conditions for more than 30 seconds, or outside its specified Input Voltage

Range. Insulation failure, smoking, burning or other damage may occur.

16. The outputs of this product may, under fault conditions, exceed SELV voltage limits. Therefore the outputs must be earthed in the end

equipment to maintain SELV. If the outputs are not earthed, they must be considered hazardous and must not be made user accessible.

17. This product has used Power Thermistor to protect the circuit from Inrush Current. Frequent repetition of input on/off might cause damage to

internal components because of generating surge current.

NOTE

1. Take note that traces of sheet metal processing be left in our power supplies.

2. When disposing product, follow disposal laws of each municipality.

3. Published EMI (CE, RE) or immunity is the result when measured in our standard measurement conditions and might not satisfy

specification when mounted and wired inside end-user equipment.

Use the product after sufficiently evaluating at actual end-user equipment.

4. When exporting our products, apply for necessary permissions as required by rules and regulations of Foreign Exchange and Foreign

Trade Control Act.

5. Catalogue, contents of the instruction manual may be changed without a prior notice. Refer to latest catalogue or instruction manual.

6. Reproduction or reprinting the instruction manual or its portion is forbidden without our permission.

STORAGE METHOD AND STORAGE PERIOD

1. Store in original package

2. Prevent excessive vibration, impact and external force from being applied during storage.

3. Store in an area out of direct sunlight

4. Temperature and humidity should be within range of product specification (with no condensation)

5. Storage period should be up to two years from receiving.

- 2 -

Page 3

Blank : Standard type.

1.Model name identification method

ZWS 10 B – 5 / □

2.Terminal Explanation

TDK-Lambda

ZWS10・15B・30B Series

Instruction Manual

Option (*1) (*1)

Rated Output Voltage /L : With chassis model.

/A : With chassis and cover model.

Output Power type

Series Name

① L : AC Input terminal Live line (Fuse in line.)

② N : AC Input terminal Neutral line

③ : Earth ( ) Terminal

④ Mounting hole (hole diameter : φ3.5mm)

This hole is connected to terminal of CN1.

Must be connected to electrically conductive spacer. The mounting surface of the spacer should be within Maxφ8mm.

⑤ Mounting hole (hole diameter : φ3.5mm)

This hole is not connected to terminal of CN1.

⑥ V.ADJ : Output voltage adjust trimmer. The output voltage rises when a trimmer is turned clockwise.

⑦ + : + Output Terminal

⑧ - : - Output Terminal

- 3 -

Page 4

3. Terminal Connection Method

Pay attention to the input wiring. If it is connected to wrong terminal, the power supply will be damaged.

Input must be off when making connections.

Connect terminal of input connector and mounting hole to protective earth of the equipment.

The output load line and input line shall be separated to improve noise sensitivity.

Do not apply stress to PCB, when connecting or removing connector.

Do not apply stress to other components (especially VR51 and C51), when connecting or removing connector.

Use input/output connector (housing) specified by the table below.

Use recommended crimping tool. Connector is not included with this product. (Refer to the following)

TDK-Lambda

ZWS10・15B・30B Series

Instruction Manual

Input/Output Connector

Model Connector Housing Terminal Pin Maker

Input ( CN1 ) Common B3P5-VH(LF)(SN) VHR-5N

Output ( CN51 ) ZWS10B, ZWS15B

Output ( CN51 ) ZWS30B

Hand Crimping Tool : YC-160R (J.S.T.)

B2P-VH(LF)(SN)

B4P-VH(LF)(SN)

VHR-2N

VHR-4N

SVH-21T-P1.1

BVH-21T-P1.1

J.S.T.

4.Explanation of Function and Precautions

4-1. Input Voltage Range

Input voltage range is single phase 85-265VAC (47-63Hz). Never operate the unit out of the specified input voltage range to avoid unit

failure.

For cases where conformance to various safeties required, input voltage range will be 100-240VAC (50/60Hz).

4-2. Output Voltage Range

Output voltage is set the rated value at shipment. V.ADJ trimmer (VR51) can adjust the output voltage within the range. Output voltage range

is within ±10% of nominal output voltage. To turn the trimmer clockwise, the output voltage will be increased. Take note when the output

voltage is increased excessively, over voltage protection (OVP) function may trigger and voltage will be shut down. Furthermore, when

increasing the output voltage reduce the output current so as not to exceed the maximum output power.

- 4 -

Page 5

TDK-Lambda

ZWS10・15B・30B Series

Instruction Manual

4-3. Inrush Current

This series equipped Power thermistor to limit the inrush current. Higher inrush current will flow at higher ambient temperature or re-input

condition. Please select input switch and fuse carefully with the high temperature and re-input the power condition. The Inrush Current value

is under cold start at 25℃ in the specification.

4-4. Over Voltage Protection (OVP)

The OVP function (Inverter shut down method, manual reset type) is provided. Please refer to its specification for OVP operating range.

When OVP trigger, the output will be shut down. To reset OVP, remove the input of power supply for a few minutes, and then re-input. In

addition, the setting value of OVP is fixed and not adjustable. Pay attention not to apply higher voltage externally to the output terminal to

avoid unit failure. In case of inductive load, put protective diode in series to the output power line.

4-5. Over Current Protection (OCP)

ZWS10B, ZWS15B, ZWS30B: Hiccup mode with automatic recovery.

OCP function operates when the output current exceeds 105% of maximum DC output current of specification. The outputs will be

automatically recovered when the overload condition is canceled. Never operate the unit under over current or shorted conditions for more

than 30seconds, which may leads damage or insulation failure. OCP setting is fixed and not to be adjusted externally.

4-6. Output Ripple & Noise

The standard specification for maximum ripple value is measured according to measurement circuit specified by JEITA-RC9131B. When

load lines are longer, ripple will becomes larger. In this case, electrolytic capacitor, film capacitor, etc. might be necessary to use across the

load terminal. The output ripple cannot be measured accurately if the probe ground lead of oscilloscope is too long. For start up at low

ambient temperature and low input voltage, output ripple noise might not meet specification. However, output ripple noise specification can

be met after one second.

A circuit reducing light load input power consumption is built in ZWS10B, ZWS15B, ZWS30B (Input power : 0.2W typ, 0.5W max at no

load). When output current is within 0-35% of rated load, the internal switch element is intermittent operated, and the switching loss is

decreased. The specification of the Ripple & Noise changes by this intermittent operation. The dynamic load response characteristic changes

by this intermittent operation too. Different input voltage and dynamic load condition has different dynamic load response characteristic.

Please contact us for details.

150mm

C1 : 0.1uF Film Cap.

C2 : 100uF Electric Cap.

C3 : 4700uF Ceramic Cap.

C3 : 4700pF Ceramic Cap.

R1 : 50Ω

Power

Supply

+

C1

C2

A

Load

‐

Oscilloscope

Coaxial Cable

1.5m 50Ω

R1

C3

4-7. Series Operation

For series operation, either method (A) or (B) is possible.

(A)

Power Supply

Output

Terminal

Load

Output

Terminal

(*1)

(*1)Please select a bypass diode with maximum forward current rating more than output load current. And maximum reverse voltage must

withstand each power supply output voltage.

(B)

Power Supply

Output

Terminal

Output

Terminal

Bandwidth : 100MHz

Load

Load

- 5 -

Page 6

TDK-Lambda

ZWS10・15B・30B Series

Instruction Manual

4-8. Parallel Operation

For parallel operation, method (B) is possible.

(A) To increase the output current is not possible.

Power Supply

Output

Terminal

Load

Output

Terminal

4-9. Isolation Test

Isolation resistance between Output and is more than 100MΩat 500VDC. For safety operation, voltage setting of DC isolation tester

must be done before the test. Ensure that the unit is fully discharged after the test.

Output - : 500VDC More than 100MΩ

(B) To use as Back-up Power Supply

1. Adjust the output voltage of each power supply to be the same.

2. Set power supply output voltage higher by the forward voltage

drop (Vf) of diode.

Use within the specification for output voltage and output power.

Power Supply

Output

Terminal

Load

Output

Terminal

AC(L)

AC(N)

+

‐

Isolation

Tester

4-10. Withstand Voltage

This series is designed to withstand 3.0kVAC between input and output, 2.0kVAC between input and and 500VAC between output and

each for 1 minute. When testing withstand voltage, set current limit of the withstand voltage test equipment to 10mA (output - : 20mA).

The applied voltage must be gradually increased from zero to the testing value and then gradually decreased for shut down. When timer is

used, the power supply may be damaged by high impulse voltage at timer switch on and off. Connect input and output as follows.

Input - Output (Dashed line) : 3.0kVAC 1min(10mA)

Input - (Solid line) : 2.0kVAC 1min(10mA) Output - : 500VAC 1min(20mA)

Withstand

Voltage Tester

Withstand

Voltage Tester

AC(L)

AC(N)

+

‐

Withstand

Voltage Tester

AC(L)

AC(N)

+

‐

- 6 -

Page 7

TDK-Lambda

ZWS10・15B・30B Series

5.Mounting Directions

5-1. Output Derating according to the Mounting Directions.

Recommended standard mounting method is (A). Method (B)-(F) are also possible. Refer to the output derating below.

Load(%) of derating curve indicates output power.

Instruction Manual

5-2. Output Derating vs Ambient temperature

Make sure that the specified temperature range is maintained. Operate the unit out of the specified derating curve may trigger OTP (IC

integrated). When OTP trigger, the output will be shut down. To reset OTP, remove the input of power supply for a few minutes, wait until

the unit cool down, and then re-input.

▥ CONVECTION COOLING

ZWS10B

ZWS15B

- 7 -

Page 8

Maximum Temperature of C51

ZWS30B

TDK-Lambda

ZWS10・15B・30B Series

Instruction Manual

▥ FORCED AIR COOLING

ZWS10B・ZWS15B・ZWS30B

*Recommended minimum air velocity : 0.7m/s. (Measured at component side of PCB, air must flow through component side)

As a reference for forced air cooling, let air flow so that the C51 temperature is lower than “Electrolytic capacitor allowable max

temperature” in the below table.

Electrolytic capacitor allowable Max temperature

MODEL

ZWS10B

ZWS15B

ZWS30B

Ta : -10℃ ~ +60℃ Ta : +60℃ ~ +70℃

65℃ Max. Ta + 5℃

70℃ Max. Ta + 10℃

70℃ Max. Ta + 10℃

- 8 -

Page 9

TDK-Lambda

ZWS10・15B・30B Series

Instruction Manual

ZWS10B

ZWS15B

CN1

(INPUT)

ZWS30B

CN1

(INPUT)

C51

CN1

(INPUT)

C51

5-3. Output Derating vs Input Voltage

Output derating is required when the power supply operate below 90VAC input. Refer to table below for details

C51

- 9 -

Page 10

TDK-Lambda

ZWS10・15B・30B Series

Instruction Manual

5-4. Mounting Method

Insert the spacer (Maxφ8) of height more than 8mm to lift the unit. And use all mounting holes for the unit installation. The vibration spec is

specified under this mounting condition.

▥ Mounting Holes size

Height more than

8mm spacer

ZWS10B,ZWS15B: 2 HOLES 3.5mm

ZWS30B: 4 HOLES 3.5mm

Allowable area by metal pieces is 8mm from each PCB corners. Refer to figure below.

8

8

ZWS10B,ZWS15B

8

8

8

8

8

8

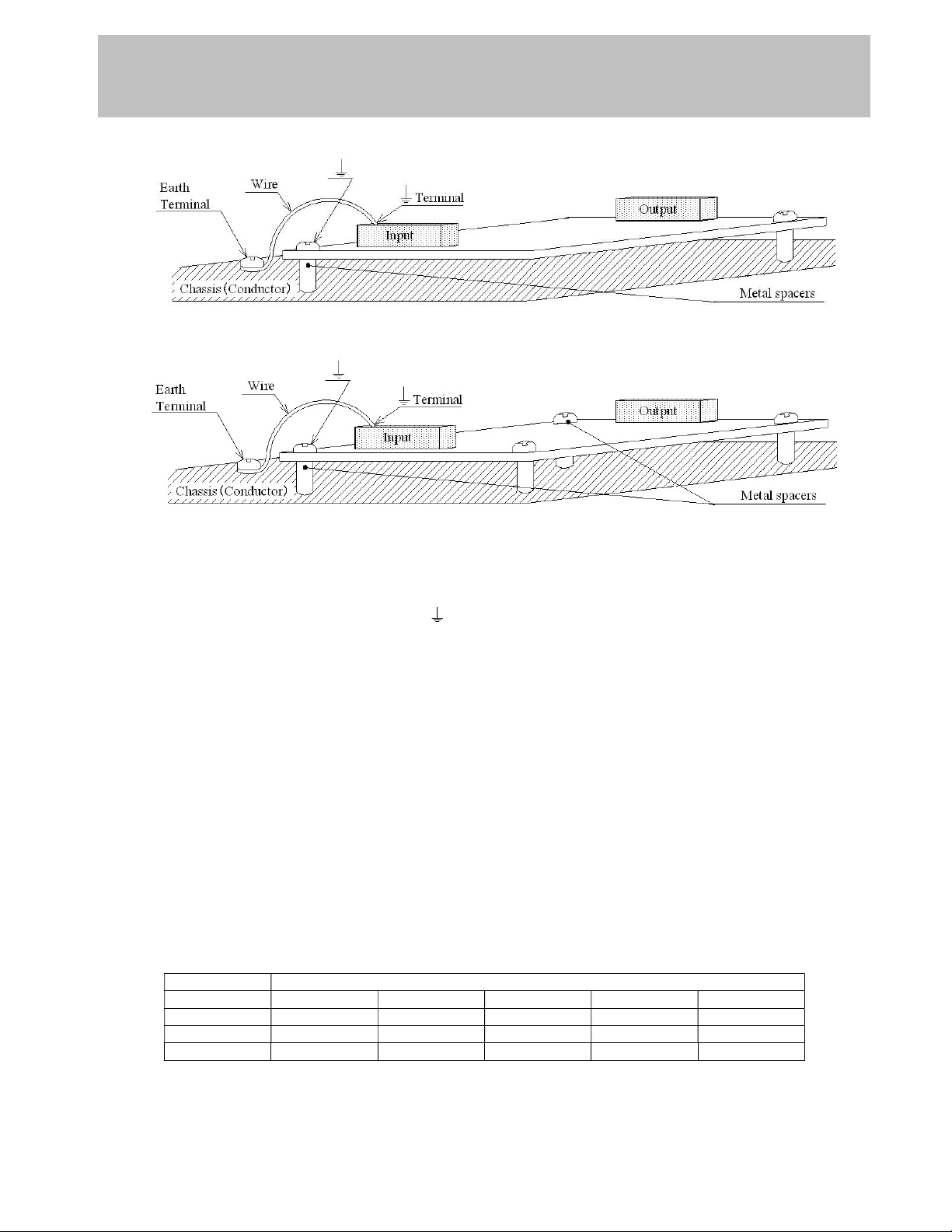

▥ Condition to meet Isolation & Withstand Voltage standard.

ZWS30B

More than

4mm

Height more than

8mm spacer

8

8

8

8

More than

4mm

More than

4mm

More than

8mm

More than

4mm

Keep 4mm space from the surfaces and sides of PCB. Especially, 8mm space is necessary from the solder surface.

More than

4mm

If the space is not enough, the specification of isolation and withstand will not be satisfied.

Keep enough space in the power supply surroundings and the upper area of components for convection cooling.

should be connected to the earth terminal of the equipment. Also the mounting hole are should be connected to the Chassis by metal

spacer. If not, the conducted noise, radiation noise and output noise will increase. Refer to figure below.

- 10 -

Page 11

Maximum external capacitance

MODEL

ZWS10B, ZWS15B

TDK-Lambda

ZWS10・15B・30B Series

Instruction Manual

ZWS30B

6. Wiring Method

(1) The output load line and input line shall be separated each other and twisted individually to improve noise.

(2) Use all lines as thick and short as possible to made lower impedance.

(3) Noise can be reduced by attaching a capacitor to the load terminals.

(4) For safety and EMI considerations, connect between terminal of input connector and Frame Ground terminal of equipment firmly.

7. External Fuse Rating

Refer to the following fuse rating when selecting the external fuses that are to be used on input line. Surge current flows when line turns on.

Have to use slow-blow or time-lag type fuse, not fast-blow fuse. Fuse rating is considered by in-rush current value at line turn-on. Do not

select the fuse according to input current (RMS.) values under the actual load condition

ZWS10B, ZWS15B: 2.0A

ZWS30B: 3.15A

8. Before concluding that the unit is at fault

(1) Check if the rated input voltage is connected.

(2) Check if the wiring of input and output is correct.

(3) Check if the wire thickness is enough.

(4) Check if the output current and output wattage dose not over specification.

(5) Check if the output voltage control (V.ADJ) is properly adjusted. OVP might be triggered and output is shut down.

(6) Audible noise can be heard when input voltage waveform is not sinusoidal wave.

(7) Audible noise can be heard during Dynamic-Load operation.

(8) Ensure that a large capacitor is not connected on the output side. Please use within maximum capacitance shown below.

ZWS10B 10,000uF 10,000uF 2,000uF 1,400uF 300uF

ZWS15B 10,000uF 10,000uF 2,500uF 1,000uF 500uF

ZWS30B 10,000uF 10,000uF 2,700uF 1,500uF 600uF

3.3V 5V 12V 15V 24V

9. Altitude

The clearance in power supply can meet 3000m altitude of IEC60664-1.

- 11 -

Page 12

10. Warranty Period

As for the breakdown under a normal use during warranty period, repair is at free of charge.

For mounting method aside from the following, inquire our company.

ZWS10B · ZWS30B

▥ CONVECTION COOLING

TDK-Lambda

ZWS10・15B・30B Series

Instruction Manual

ZWS15B

▥ CONVECTION COOLING

ZWS10B · ZWS15B· ZWS30B

▥ FORCED AIR COOLING

Following cases are not covered by warranty.

(1) Improper usage like dropping products, applying shock and defects from operation exceeding specification of the units.

(2) Defects resulting from natural disaster (fire, flood etc).

(3) Unauthorized modifications or repair by the buyers’ defects not cause by our company.

- 12 -

Loading...

Loading...