TDK-Lambda ZUP10-20, ZUP6-33,ZUP10-20,ZUP20-10,ZUP36-6,ZUP60-3.5,ZUP80-2.5,ZUP120-1.8,ZUP6-66,ZUP10-40,ZUP20-20,ZUP36-12,ZUP60-7,ZUP80-5,ZUP120-3.6,ZUP6-132,ZUP10-80,ZUP20-40,ZUP36-24,ZUP60-14, ZUP6-33, ZUP20-10, ZUP36-6 User Manual

...Page 1

ZERO-UP 200W/400W/800W

Programmable DC Power Supplies

Constant Voltage/Constant Current

Built-in RS-232 & RS-485 Interface

with GPIB option.

USER’S MANUAL

Page 2

We Nemic-Lambda Ltd., located at Karmiel Industrial Zone, Israel, declare under our sole

responsibility that the product:

Product name: Programmable Regulated Power Supplies, ZUP Series

Models:

conforms to the following product specifications:

Safety: EN61010-1:2001

Electromagnetic Emissions:EN61326:1997:A3:2003 which covers testing to the following standards:

EN55011:1998:A2:2002 Conducted Emissions: Class B

Radiated Emissions: ClassA

IEC61000-4-2:1995 4.0KV CD, 4.0KV AD Level 2

IEC61000-4-3:1995 3V/m Level 2

IEC61000-4-4:1995 1.0KVAC Power Lines Level 2

0.5KV Communication Lines

IEC61000-4-5:1995 2.0KVAC Power Lines Level 3

1.0KVAC to Ground

1.0KV Communication Lines

IEC61000-4-6:1996 3V Level 2

IEC61000-4-11:1994

IEC61000-3-2:2000 ClassA

IEC61000-3-3:1995:A1:2001

The product herewith complies with the requirements of the Low Voltage Directive 73/23/EEC, as

amended by 93/68/EEC, and the EMC directive 89/336/EEC, as amended by 92/31/EEC and

93/68/EEC for Electrical Equipment used in Information Technology environments, and carries the CE

mark accordingly.

Our authorized representative in the EU is Coutant Lambda Limited, located at Kingsley Avenue,

Ilfracombe, Devon EX34 8ES, UK. Further, all products covered by this declaration are manufactured

by processes which ensure continued compliance of the products with the requirements of the Low

voltage and the EMC directives.

Name ofAuthorized Signatory:

Signature ofAuthorized Signatory:

Position ofAuthorized Signatory:

Date:

Place where signed:

Martin Southam

Director of Marketing, Coutant Lambda

June 1, 2006

Ilfracombe, UK

ZUP6-33

ZUP10-20

ZUP20-10

ZUP36-6

ZUP60-3.5

ZUP80-2.5

ZUP120-1.8

ZUP6-66

ZUP10-40

ZUP20-20

ZUP36-12

ZUP60-7

ZUP80-5

ZUP120-3.6

ZUP6-132

ZUP10-80

ZUP20-40

ZUP36-24

ZUP60-14

KARMIEL INDUSTRIAL ZONE, POB 500, ZC-20101, ISRAEL.

TEL: 972-4-9887491 FAX:972-4-9887487

DECLARATION OF CONFORMITY

IA-549-04-01M

Page 3

This information sheet was prepared based on People's Republic of China "Management Methods for Controlling Pollution Caused by Electronic Information Products Regulation"and

"SJ/T 11364—2006 Marking for Control of Pollution Caused by Electronic Information Products".

As People's Republic of China "Management Methods for Controlling Pollution Caused by Electronic Information Products Regulation"is a different legislation from EU RoHS Directive

(2002/95/EC), inquiries concerning EU RoHS Directive (2002/95/EC) information should be done separately.

The date of manufacture

Part Name

ZUP200W/400W/800W POWER SUPPLY SERIES Product Weight ZUP200

2.9Kg

Product Weight ZUP400

3.2Kg

Product Weight ZUP800

5.8Kg

Lead (Pb) Mercury (Hg) Cadmium (Cd) Hexavalent

Chromium (Cr6+)

Polybrominated

Biphenyls(PBB)

Polybrominated Diphenyl

Ethers(PBDE)

0.1wt% 0.1wt% 0.01wt% 0.1wt% 0.1wt% 0.1wt%

Case

O O O O O O

Plastic panel

O O O O O O

PCB's assembly X O O O O O

Inner metal parts O O O O O O

Inner cables O O O O O O

Accessories O O O O O O Provided in the package

○ : Indicates that the concentration values of toxic and hazardous substances in all "homogeneous materials" of respective parts and materials does not exceed the concentration limits

regulated by "SJ/T 11363-2006 Requirements for Concentration Limits for Certain Hazardous Substances in Electronic Information Products".

× : Indicates that the concentration value of a toxic or hazardous substance included in a "homogeneous part" of a respective part ot material exceeds the concentration limit regulated by

"SJ/T 11363-2006 Requirements for Concentration Limits for Certain Hazardous Substances in Electronic Information Products".

Information Concerning Inclusion of Toxic and Hazardous Substances

NotesConcentration Values of Toxic and Hazardous Substances/Elements (wt%)

Subpart Name

(2002/95/EC), inquiries concerning EU RoHS Directive (2002/95/EC) information should be done separately.

The date of manufacture

Part Name

ZUP200W/400W/800W POWER SUPPLY SERIES Product Weight ZUP200

2.9Kg

Product Weight ZUP400

3.2Kg

Product Weight ZUP800

5.8Kg

Lead (Pb) Mercury (Hg) Cadmium (Cd) Hexavalent

Chromium (Cr6+)

Polybrominated

Biphenyls(PBB)

Polybrominated Diphenyl

Ethers(PBDE)

0.1wt% 0.1wt% 0.01wt% 0.1wt% 0.1wt% 0.1wt%

Case

O O O O O O

Plastic panel

O O O O O O

PCB's assembly X O O O O O

Inner metal parts O O O O O O

Inner cables O O O O O O

Accessories O O O O O O Provided in the package

○ : Indicates that the concentration values of toxic and hazardous substances in all "homogeneous materials" of respective parts and materials does not exceed the concentration limits

regulated by "SJ/T 11363-2006 Requirements for Concentration Limits for Certain Hazardous Substances in Electronic Information Products".

× : Indicates that the concentration value of a toxic or hazardous substance included in a "homogeneous part" of a respective part ot material exceeds the concentration limit regulated by

"SJ/T 11363-2006 Requirements for Concentration Limits for Certain Hazardous Substances in Electronic Information Products".

NotesConcentration Values of Toxic and Hazardous Substances/Elements (wt%)

Subpart Name

Page 4

TABLE OF CONTENTS: ZUP SERIES

SAFETY INSTRUCTIONS .....................................................................

WARRANTY ..........................................................................................

CHAPTER 1. General Information

CHAPTER 2. Specifications

CHAPTER 3. Installation

......................................................

1.1 User manual content

1.2 Introduction

1.2.1 General description

1.2.2 Configurations

1.2.3 Control via the serial communication port

1.2.4 Output connections

1.2.5 Analog voltage programming

1.2.6 Parallel operation

1.2.7 Cooling and mechanical construction .....................................

1.3 Accessories

1.3.1 General

1.3.2 Serial link cables

1.3.3 AC cables

1.3.4 Front panel outputs option

................................................................

2.1 200W/400W Series

800W Series...................................................................................

2.2 Supplemental characteristics .........................................................

.....................................................................

3.1 General

3.2 Initial inspection

3.2.1 Mechanical inspection

3.2.2 Preparation for use

3.3 AC source requirements

3.4 Cooling and placement

3.5 Rack mounting

3.6 Power connection

3.7 Connecting the load .......................................................................

3.7.1 Selecting wire size

3.7.2 Wire termination .....................................................................

3.7.3 Single load connection, local sense

3.7.4 Single load connection, remote sensing ................................

3.7.5 Multiple load connections, radial distribution method

3.7.6 Multiple load connections with distribution terminals .............

3.7.7 Grounding outputs

3.8 External control connector

3.8.1 General

3.8.2 Pin description .......................................................................

3.8.3 Technical description

3.8.4 Default connections................................................................

3.9 Repackaging for shipment

pg. 2

pg. 1

pg. 5

pg. 6

pg. 7

pg. 9

pg. 11

pg. 12

pg.13

pg.14

pg.15

pg.16

pg.17

pg.18

Page 5

Table 4-1: Front panel controls and indicators .......................................

4.2.2 Rear panel ............................................................................

4.2.3 Rear panel connections description .....................................

4.3 Turn-on Checkout Procedure

4.3.1 General

4.3.2 Prior to operation

4.3.3 Constant Voltage check

4.3.4 Constant Current check ........................................................

4.3.5 OVP check

4.3.6 UVP check

4.3.7 Foldback check

4.3.8 Output On/Off

4.3.9 Address setting

4.3.10 Local/Remote Operation

4.4 Local Operation ...............................................................................

4.4.1 Introduction

4.4.2 Constant Voltage Operation

4.4.3 Constant Current Operation

4.4.4 Automatic Crossover ..............................................................

4.4.5 Over Voltage protection (OVP)

4.4.6 Under Voltage Protection (UVP)

4.4.7 Foldback Protection ................................................................

4.4.8 Output On/Off Control

4.4.9 Last Setting memory ...............................................................

4.4.10 Output Voltage & Current programming by external resistor

4.4.11 Output Voltage Programming by external voltage .................

4.4.12 Output Current programming by external voltage

4.4.13 Auto Parallel operation...........................................................

4.4.14 Series Operation ....................................................................

4.4.15 Output good signal.................................................................

.....................................

5.1 Introduction

5.2 Configuration

5.2.1 Address setting

5.2.2 RS232 or RS485 selection

5.2.3 Baud rate setting

5.2.4 Local/remote selection

CHAPTER 5. RS232 & RS485 remote control

.................................................

4.1 Introduction

4.2 Controls and Indicators

4.2.1 Front Panel

CHAPTER 4. Operating Instructions.

pg.23

pg.22

pg.24

pg.25

pg.26

pg.27

pg.28

pg.29

pg.30

pg.32

pg.33

pg.37

pg.38

pg.35

TABLE OF CONTENTS: ZUP SERIES

3.10 Outline drawings: ZUP 200W & 400W series.................................

3.11 Outline drawing: ZUP 800W series...............................................

3.12 Outline drawing: front panel connector option ...............................

pg.19

pg.20

pg.21

Page 6

5.4.1 Introduction

5.4.2 RS485 cable

5.4.3 Linking power supplies

5.5 ZUP series command set description

5.5.1 ID control commands...............................................................

5.5.2 Initialization control

5.5.3 Output control..........................................................................

5.5.4 Status control ..........................................................................

5.5.4.1 Registers structure

5.5.4.2 Status control commands ....................................................

5.6 Communication Protocol..................................................................

5.6.1 General information

5.6.2 Accessing a ZUP unit

5.6.3 End of message

5.6.4 Communication Test set up.................................................... pg.48

5.7.Service Request................................................................................. pg.49

................................................................... pg.50

6.1 Introduction

6.2 Units under warranty

6.3 Periodic Maintenance

6.4 Adjustment and calibration

6.5 Part replacement and repairs

6.6 Fuse ratings

...................................................................... pg.51

CHAPTER 6. Maintenance

USER’S MANUAL INDEX

pg.45

pg.42

pg.46

pg.43

pg.47

5.7.1 Service Request (SRQ)

5.7.2 Service Request message

5.7.3 Service Request enable/disable commands

TABLE OF CONTENTS: ZUP SERIES

5.3 Remote programming via RS232.....................................................

5.3.1 Introduction

5.3.2 Rear panel connectors pinout

5.3.3 RS232 cable ............................................................................

5.3.4 Linking power supplies

5.4 Remote programming via RS485 .....................................................

pg.39

pg.40

pg.41

Page 7

WARRANTY SERVICE

WARRANTY

DISCLAIMER

LIMITATION OF WARRANTY

TRADEMARK INFORMATION

This product must be returned to an authorized Nemic-Lambda service facility for repairs or other

warranty service. For products returned to Nemic-Lambda for warranty service, the buyer shall prepay

shipping charges to Nemic-Lambda and Nemic-Lambda shall pay the shipping charges to return the

product to the buyer.

This Nemic-Lambda product is warranted against defects in materials and workmanship for a period of

three years from date of shipment .During the warranty period, Nemic-Lambda will, at it’s option, either

repair or replace products which prove to be defective.

The information contained in this document is subject to change without notice. Nemic-Lambda shall

not be liable for errors contained in this document or for incidental or consequential damages in

connection with the furnishing, performance or use of this material. No part of this document may be

photocopied, reproduced or translated into another language without the prior written consent of

Nemic-Lambda.

The warranty shall not apply to defects resulting from improper or inadequate usage or maintenance by

the buyer , buyer supplied products or interfacing. The warranty shall not apply to defects resulting

from unauthorized modifications or from operation exceeding the environmental specifications of the

product.

Nemic-Lambda does not warrant the buyers circuitry or malfunctions of Nemic-Lambda products

resulting from the buyer’s circuitry. Furthermore, Nemic-Lambda does not warrant any damage

occurring as a result of the buyer’s circuitry or the buyer’s - supplied products.

No other warranty is expressed or implied.

Microsoft and Windows are trademarks of Microsoft Corporation.

Page 8

SAFETY INSTRUCTIONS

CAUTION

INSTALLATION CATEGORY

GROUNDING

FUSES

LIVE CIRCUITS

PART SUBSTITUTIONS & MODIFICATIONS

ENVIRONMENTAL CONDITIONS

INPUT RATINGS

The following safety precaution must be observed during all phases of operation, service and repair of

this equipment. Failure to comply with the safety precautions or warnings in this document violates

safety standards of design, manufacture and intended use of this equipment and may impair the built-in

protections within.

Nemic-Lambda shall not be liable for user’s failure to comply with these requirements.

The ZUP Series has been evaluated to INSTALLATION CATEGORY II. Installation Category (over

voltage category) II: local level, appliances, portable equipment etc.. With smaller transient over

voltages than Installation Category (over voltage category) III.

This product is a Safety Class 1 instrument. To minimize shock hazard, the instrument chassis must be

connected to an electrical ground. The instrument must be connected to the AC power supply mains

through a three conductor power cable, with the ground wire firmly connected to an electrical ground

(safety ground) at the power outlet.

For instruments designed to be hard - wired to the supply mains, the protective earth terminal must be

connected to the safety electrical ground before an other connection is made. Any interruption of the

protective ground conductor, or disconnection of the protective earth terminal will cause a potential

shock hazard that might cause personal injury.

Fuse must be changed by authorized Nemic-Lambda service personnel only. For continued protection

against risk of fire, replace only with the same type and rating of fuse. Refer to maintenance instructions

in chapter 6 for fuse rating.

Operating personnel must not remove the instrument cover. No internal adjustment or component

replacement is allowed by non-Nemic-Lambda qualified service personnel. Never replace

components with power cable connected. To avoid injuries, always disconnect power, discharge

circuits and remove external voltage sources before touching components.

Part substitutions and modifications are allowed by authorized Nemic-Lambda service personnel only.

For repairs or modifications, the instrument must be returned to a Nemic-Lambda service facility.

The ZUP series safety approval applies to the following operating conditions:

* Indoor use * Ambient temperature: 0 C to 50 C

* Maximum relative humidity: 90% (no dew drop) * Altitude:

up to 3,000 m

* Pollution degree 2

O O

Do not use AC supply which exceeds the input voltage and frequency rating of this instrument. The

input voltage and frequency rating of the ZUP Series is; 100-240V~, 50/60Hz. For safety reasons, the

mains supply voltage fluctuations should not exceed +/- 10% of nominal voltage.

Page 9

SAFETY INSTRUCTIONS

SAFETY SYMBOLS

Instruction manual symbol. The instrument will be marked with this symbol when it is

necessary for the user to refer to the instruction manual.

Indicates hazardous voltage.

Indicates ground terminal.

The WARNING sign denotes a hazard.An attention to a procedure is called.

Not following procedure correctly could result in personal injury.

AWARNING sign should not be skipped and all indicated conditions must be

fully understood and met.

The CAUTION sign denotes a hazard. An attention to a procedure is called.

Not following procedure correctly could result in damage to the equipment.

Do not proceed beyond a CAUTION sign until all indicated conditions are

fully understood and met.

FCC COMPLIANCE NOTICE:

Note: This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is

likely to cause harmful interference in which case the user will be required to correct the

interference at his own expense.

!

WARNING

CAUTION

Page 10

OUTPUT TERMINALS COVER

Models up to 60V output voltage

After connection of the load wires ( refer to par. 3-7 ), attach the plastic cover to the rear panel of the

power supply, using two self tapping screws supplied with the unit. Refer to Fig. 1-1 for details.

Fig. 1-2: Output wires connection

OUTPUT CONNECTOR COVER

80V and 120V models

MALE CONNECTOR (PSC1.5/3-M-PE , Phoenix)

FEMALE PLUG (PSC 1.5/3-F)

PLASTIC PLUG COVER

Wires : Copper , AWG16-30

Tightening torque : 4lib-in

WARNING

Hazardous voltages may exist at the output terminals.

Attach the terminals cover, supplied with the unit, to the chassis after connecting the load wires as

described below.

Fig. 1-1: Terminals cover assembly

REAR PANEL

LOAD WIRES

PLASTIC COVER

SAFETY INSTRUCTIONS

+V

-V

Page 11

CHAPTER 1 GENERAL INFORMATION

1.1 USER’S MANUAL CONTENT

1.2 INTRODUCTION

1.2.1 General description

1.2.2 Configurations

1.2.4 Output connections

1.2.5 Analog voltage programming

1.2.6 Parallel operation

1.2.3 Control via the serial communication port

This user’s manual contains the operating instructions, installation instructions and specifications of

the ZUP series. For information related to operation with GPIB control, refer to Nemic-Lambda GP485

user’s manual.

The ZUP series are wide range output switching power supplies with laboratory performance. The ZUP

series is power factor corrected and operates from worldwide AC voltage range continuously. Output

voltage and current are continuously displayed and LED indicators show the complete operating status

of the power supply. The front panel controls allow the user to set the output parameters, the protection

levels (over-voltage / under-voltage)and arm the foldback protection to disable the output if the unit

switches from Constant-voltage mode to Constant-current mode.

The ZUP can be configured into a programmable power system of up to 31 DC outputs using the built-in

RS232 or RS485 communication port in the power supply. In a GPIB system the GP485 controller can

control up to 31 ZUP units in a single GPIB address.

Output connections are made to rear panel bus-bars for models up to 60V and connector for the 80V

and 120V models. Either the positive or negative terminal may be grounded or the output may be

floated. The maximum potential (including the output voltage) that either output terminal is from ground

must not exceed the rated output voltage. Local or remote sense may be used. In remote sense, the

maximum voltage drop on each wire is 0.5V for models up to 60V and 2V for the 80V and 120V models.

Analog inputs are provided at the rear panel for analog voltage programming of output voltage and

current, and On/Off control. Inputs are provided for resistive programming of the output voltage and

current.

Zup units of the same output voltage and current rating can be paralleled in master-slave configuration

with automatic current sharing for power-up purposes.

The following parameters can be programmed via the serial communication port:

1. Output voltage setting

2. Output current setting

3. Output On/Off

4.Arming or release of the

foldback protection

5. Over-voltage protection setting

6. ‘Soft’under-voltage limit

7. Output voltage measurement

8. Output current measurement

9. Power supply start-up mode

(last setting or safe mode)

10. Over-voltage protection setting read

11. Under-voltage limit read

12. Remote/Local Control

Page 12

1.3.1 General

1.3.4 Front Panel Outputs option

1.3.3 AC Cables

1.3.2 Serial link cables

1.3 ACCESSORIES

Accessories are delivered with the power supply or separately upon ordering.

Below are listed possible accessories and ordering numbers.

PART No. DESCRIPTION

NL 100 19” rack, 3U height

NL 200 Dual output packing

NL 101 Blank panel for 19” rack

NL 102 Additionalinstruction manual

PART No. MARKET DESCRIPTION

ZUP/U USA 13A, 125V, unshielded, 2m typ. length, with IEC320 connector on one

(NC301) side and NEMA-5-15P connector the on other side.

ZUP/E Europe 10A, 250V, unshielded, 2m typ. length, with IEC320 connector on one

(NC302) side and INT’L 7 standard VII, dual earthing on the other side.

ZUP/O General 10A, 250V, unshielded, 2m typ. length, with IEC320 connector on one

(NC303) side and unterminated stripped wires on the other side. Use the cable

only with plug approved by the national safety standards of the country

of usage.

ZUP/J Japan 13A, 125V unshielded, 2m typ. length, with IEC320 connector on one

(NC305) side and Japan type plug on other side.

In cases where load connection at the front panel is required, optional Front Panel output Jacks for a

load current of 20A maximum is available. Please note that the power supply height is increased with

this option. Refer to outline drawing (par. 3.12) for details.

ORDER No. DESCRIPTION

ZUP /L 20AFront Panel Output Jacks

Serial link cable, for linking power supplies by RS485 communication is provided with the power supply

according to order.Cable description: 0.5m typ. length, shielded, EIA-568A type plugs, 8 contacts.

Refer to par.5.3.4 , for details.

1.2.7 Cooling and mechanical construction

The Zup series is fan cooled. Upon installation take care to allow free air flow into the power supply via

the front panel and out of the power supply via the rear panel. The ZUP series is contained in a compact,

lightweight package which allows for easy installation and space saving in the application equipment.

Page 13

CHAPTER 2 SPECIFICATIONS

2.1 SPECIFICATIONS: 200W/400W Series

ZUP20-

20

ZUP20-

10

ZUP10-

40

ZUP10-

20

ZUP6-

66

ZUP6-

33

ZUP60-

7

0 ~ 7

0 ~ 12

ZUP60-

3.5

0 ~ 3.5

0 ~ 6

216 432 210 420

ZUP36-

12

ZUP36-

6

0 ~ 36

0 ~ 60

ZUP120-

3.6

ZUP120-

1.8

ZUP80-

5

ZUP80-

2.5

V

A

W

-

mV

mV

mS

-

mS

mS

mS

-

mA

-

-

-

-

-

-

V

-

-

-

-

-

-

A

-

-

%

A

MODEL

OUTPUT VOLTAGE (*1)

OUTPUT CURRENT (*2)

RATED OUTPUT POWER

LOAD REGULATION

LINE REGULATION

RMS RIPPLE

RIPPLE

RECOVERY TIME (*4)

TEMPERATURE COEFFICIENT

TEMPERATURE DRIFT

(5Hz-1MHz Bandwid

th)

(pk to pk 20MHz Bandwid

th)

LOAD REGULATION

LINE REGULATION

RMS RIPPLE

TEMPERATURE COEFFICIENT

TEMPERATURE DRIFT

(5Hz-1MHz Bandwid

th)

INPUT VOLTAGE (*8)

INPUT CURRENT (*6)

INPUT CURRENT HARMONICS

POWER FACTOR (TYP)

EFFICIENCY (*6)

INRUSH CURRENT (*7)

100/200V

VOLTAGE

CURRENT

STATUS

UP PROGRAMMING RESPONSE TIME

FULL LOAD

NO LOAD

RESOLUTION

ACCURACY

RESOLUTION

ACCURACY

VOLTAGE

CURRENT

CONSTANT

VOLTAGE

CONSTANT

CURRENT

DOWN

PROGRAMMING

RESPONSE TIME

PROGRA-

MING (*3)

DISPLAY

OVERVOLTAGE PROTECTION

(*5)

HOLD UP TIME

OUTPUT PROTECTIONS

INPUT

10

5.6 / 2.7

5.3/2.6

80 / 84

82 / 86

15

5.6 / 2.7

4.9/2.4

80 / 84

83 / 87

0 ~ 20

30

5.6 / 2.7

79 / 83

0 ~ 40

50

5.6 / 2.7

79 / 82

0 ~ 66

0.005% +2mV (*10)

0.005% +4mV

0.005% +1mV (*1

1)

0.005% +2mV

5

50

30ppm/ C from rated volt

age following 30-minute warm-up

O

0.01% +2mV change in output over 8-hour interval under const

ant line, load and ambient

temperature following 30-minute warm-up

50

50

100

5.6 / 2.7

74 / 77

15

15

15

15

15

15

15

5

5

5

5

5

2.9 / 1.4

2.9/1.4

75 / 79

78 / 82

7.5

2.9 / 1.4

2.6/1.3

76 / 80

78 / 82

0 ~ 10

15

2.9 / 1.4

74 / 78

0 ~ 20

25

2.9 / 1.4

73 / 77

0 ~ 33

198 396 200 400 200 400

50

3.0 / 1.5

69 / 72

15 / 30 15 / 30 15 / 30 15 / 30

15 / 30

15 / 30

15 / 30

250

0 - 7.5

1

350

0 -13

0.5

400

0 - 24

0.2

0.01% + 5mA for load voltage change equal to unit volt

age rating , constant input voltage.

0.01% +2mA from 85-132VAC or 170-265VAC, constant load

20mS at 100V/200VAC, rated output volt

age and output current

100ppm/ C from rated current following 30 minute warm-up

O

Better than 0.028% of rated output volt

age

0.02% + 5mV 0.02% + 8mV 0.02% + 12mV 0.02% + 26mV 0.02% + 35mV

0.4% + 40mA

Better than 0.03% of rated output current

0.02% +5mA change in output over 8-hour interval under const

ant line, load and ambient

temperature following 30 minute warm-up

3 digits (6V, 20V, 36V, 60V, 80V) 3.5 digits (10V, 120V) accuracy: 0.2% +/- 2 digit

s

3 digits accuracy: 0.5% +/- 3 digit

s

CV/CC, Alarm, Fold, Local/Remote, ON/OFF

Over Voltage, Over Temperature, Foldback

85 ~ 265VAC Continuous, 47 ~ 63Hz

Complies with EN61000-3-2, Class

A

0.99 at 100/200VAC, 100% Load

500

0 - 40

0.02%+50mV

0.4%+

0.4%+

0.4%+

0.4%+

15mA

30mA

10mA

20mA

0 - 88

0 - 132

0.02%+80mV

0.2

750

0 - 66

0.2

100

0 ~ 6

0 ~ 10

0 ~ 20

0 ~ 1.8

0 ~ 5

20

0 ~ 3.6

0 ~ 2.5

20

200

70

60

0.2

800

400

80

80

0.2

1000

216 432

0 ~ 80

0 ~ 120

Page 14

-

-

-

-

-

Kg

mm

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

OPERATING TEMPERATURE

OPERATING HUMIDITY

STORAGE TEMPERATURE

STORAGE HUMIDITY

VIBRATION (*9)

SHOCK

WEIGHT

SIZE (WxHxD)

OUTPUT ON/OFF

OUTPUT GOOD

OUTPUT VOLTAGE PROGR.

OUTPUT CURRENT PROGR.

REMOTE SENSING

COMMUNICATION INTERFACE

ENVIRON-

MENT

MECHANI-

CAL

EXTERNAL

FUNCTIONS

SAFETY STANDARDS

EMC STANDARDS

APPRO-

VALS

NOTES:

* 1 MINIMUM VOLTAGE IS GUARANTEED TO MAXIMUM 0.2% OF

THE RATED OUTPUT VOLTAGE.

* 2 MINIMUM CURRENT IS GUARANTEED TO MAXIMUM 0.4% OF

THE RATED OUTPUT CURRENT.

* 3 GIVEN FOR CONTROL

OF THE OUTPUT VIA THE SERIAL COMMUNICATION OR VIA FRONT PANEL CONTROLS.

* 4 TIME FOR RECOVERY TO WITHIN +/- 50mV AGAINST CURRENT CHANGE OF 50% TO 100%.

* 5 INVERTER SHUT DOWN METHOD, MANUAL

RESET BY AC INPUT RECYCLING.(OVP WILL SHUT DOWN OUTPUT).

* 6 AT 100V/200V AND MAXIMUM OUTPUT

POWER.

* 7 FOR 200W UNITS -

AT COLD START Ta = 25°C.

* 8 FOR CASES WHERE CONFORMANCE

TO VARIOUS SAFETY SPECS, (UL, IEC ETC.)

ARE REQUIRED TO BE DESCRIBED

AS 100-240VAC (50/60Hz) ON NAME PLA

TE.

* 9 WHEN MOUNTED WITH MOUNTING SCREWS.

*10 FROM NO LOAD TO FULL LOAD , CONSTANT INPUT VOLTAGE AT REMOTE SENSE.

*11 FROM 85~132VAC OR 170~265VAC , CONSTANT LOAD.

*12 FROM ZERO VOL

TS TO FULL SCALE , RESISTIVE LOAD , CURRENT

SETTING AT MAX.

CONDUCTED EMI

RADIATED EMI

SERIAL OPERATION

PARALLEL OPERATION

COOLING

ISOLATION RESISTANCE

WITHSTAND VOLTAGE

ZUP60-

7

3.2

3.2

3.2

ZUP60-

3.5

2.9

2.9

2.9

ZUP36-

12

ZUP36-

6

ZUP20-

20

ZUP20-

10

ZUP10-

40

ZUP10-

20

ZUP6-

66

0 ~ 50 C: 100% Load.

O

-20 ~ 70 C

O

30 ~ 90% RH ( No Dewdrop )

10 ~ 95% RH ( No Dewdrop )

Less than 20G

10 ~ 55Hz, Amplitude (sweep 1min) Less than 2G

, X,Y, Z, 1 hour each.

70 x 124 x 350.

By TTL Signal or Dry Contact - refer to instruction manual

Open collector - refer to instruction manual

By Voltage ( 0 ~ 4V ) or by Resist

ance ( 0 ~ 4K ) refer to instruction manual

By Voltage ( 0 ~ 4V ) or by Resist

ance ( 0 ~ 4K ) refer to instruction manual

Maximum possible drop on each load wire is 0.5 V for models up to 60V and 2V for the 80V and 120V models.

RS232 and RS485 Built-in, IEEE488 Optional

UL 3111-1, EN61010-1

EN 61326-1, IEC 61326 -1, FCC p

art 15 (class A)

Master - slave method: up to 5 unit

s, refer to instruction manual

Up to 2 units, refer to instruction manual

EN55022-B, FCC-B, VCCI-B

Forced air by blower fan, (blower fan is mounted within unit)

EN55022-A, FCC-A, VCCI-A

Input-Chassis: 2.0kVAC 1 min. Input-Output: 3.0kV

AC 1 min. Output-Chassis:

500V

AC 1min.

Input-Chassis: 2.0kVAC 1 min..

Input-output(HAZ

) : 2.0kV

AC 1min.

Input-Output(SELV):3.0kVAC 1min.

ZUP6-

33

3.2

3.2 2.9

2.9

3.2

3.2 2.9

2.9

2.1 SPECIFICATIONS: 200W/400W Series continued

ZUP120-

3.6

ZUP120-

1.8

ZUP80-

5

ZUP80-

2.5

More than 100MOhm at 25

C and 70% R.H.

O

Page 15

V

A

W

-

mV

mV

mS

-

mS

mS

mS

-

mA

-

-

-

-

-

-

V

-

-

-

-

-

-

A

-

%

A

MODEL

OUTPUT VOLTAGE (*1)

OUTPUT CURRENT (*2)

RATED OUTPUT POWER

LOAD REGULATION

LINE REGULATION

RMS RIPPLE

RIPPLE

RECOVERY TIME (*4)

TEMPERATURE COEFFICIENT

TEMPERATURE DRIFT

(5Hz-1MHz Bandwid

th)

(pk to pk 20MHz Bandwid

th)

LOAD REGULATION

LINE REGULATION

RMS RIPPLE

TEMPERATURE COEFFICIENT

TEMPERATURE DRIFT

(5Hz-1MHz Bandwid

th)

INPUT VOLTAGE (*7)

INPUT CURRENT (*6)

INPUT CURRENT HARMONICS

POWER FACTOR (TYP)

EFFICIENCY (*6)

INRUSH CURRENT

100/200V

VOLTAGE

CURRENT

STATUS

UP PROGRAMMING RESPONSE TIME

FULL LOAD

NO LOAD

RESOLUTION

ACCURACY

RESOLUTION

ACCURACY

VOLTAGE

CURRENT

CONSTANT

VOLTAGE

CONSTANT

CURRENT

DOWN

PROGRAMMING

RESPONSE TIME

PROGRAM-

MING

(*3)

DISPLAY

OVERVOLTAGE PROTECTION

(*5)

HOLD UP TIME

OUTPUT PROTECTIONS

INPUT

ZUP60-14

0 ~ 14

20

11.2 / 5.4

80 / 84

0 ~ 24

30

11.2 / 5.4

80 / 84

0 ~ 40

60

11.2 / 5.4

79 / 82

0 ~ 80

100

11.2 / 5.4

77 / 81

0 ~ 132

792

800

800

864

840

200

11.2 / 5.4

74 / 77

30

0.005% +2mV from no load to full load, const

ant input voltage

0.005% +1mV from 85-132V

AC or 170-265VAC, constant load

5

80

30ppm/ °C from rated volt

age following 30-minute warm-up

0.01% +2mV change in output over 8-hour interval under const

ant line, load and ambient

temperature following 30-minute warm-up

50

ZUP36-24

ZUP20-40

ZUP10-80

ZUP6-132

250

0-7.5

1

100

8

70

5

350

0-13

0.5

90

8

60

5

400

0-24

0.2

0.07% + 10mA for load voltage change equal to unit volt

age rating , constant input voltage.

0.01% +5mA from 85-132VAC or 170-265VAC, constant load

20mS at 100V/200VAC, rated output volt

age and output current

100ppm/ C from rated current following 30 minute warm-up

O

0.05% +10mA change in output over 8-hour interval under const

ant line, load and ambient

temperature following 30 minute warm-up

3 digits (6V, 20V, 36V, 60V) 3.5 digits (10V) accuracy: 0.2% +/- 2 digit

s

3.5 digits (132A), all others 3 digit

s accuracy: 0.5% +/- 3 digit

s

CV/CC, Alarm, Fold, Local/Remote, ON/OFF

Over Voltage, Over Temperature, Foldback

85 ~ 265VAC Continuous, 47 ~ 63Hz

Complies with EN61000-3-2, Class

A

0.99 at 100/200VAC, 100% Load

500

0-40

0.2

750

70

0-66

0.2

0 ~ 6

0 ~ 10

0 ~ 20

0 ~ 36 0 ~ 60

2.1 SPECIFICATIONS: 800W Series

Better than 0.028% of rated output volt

age

0.4% + 40mA

Better than 0.03% of rated output current

50mS (From zero volt

s to full scale, resistive load, current setting at max.)

0.02% + 5mV 0.02% + 8mV 0.02% + 12mV 0.02% + 26mV 0.02% + 35mV

Page 16

-

-

-

-

-

Kg

mm

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

OPERATING TEMPERATURE

OPERATING HUMIDITY

STORAGE TEMPERATURE

STORAGE HUMIDITY

VIBRATION (*8)

SHOCK

WEIGHT

SIZE (WxHxD)

OUTPUT ON/OFF

OUTPUT GOOD

OUTPUT VOLTAGE PROGR.

OUTPUT CURRENT PROGR.

REMOTE SENSING

COMMUNICATION INTERFACE

ENVIRON-

MENT

MECHANI-

CAL

EXTERNAL

FUNCTIONS

APPLICABLE SAFETY STANDARDS

APPLICABLE EMC ST

ANDARDS

CONDUCTED EMI

RADIATED EMI

SERIAL OPERATION

PARALLEL OPERATION

COOLING

WITHSTAND VOLTAGE

ISOLATION RESISTANCE

ZUP60-

14

5.8

ZUP36-

24

ZUP20-

40

ZUP10-

80

ZUP6-

132

0 ~ 50 C: 100% Load.

O

-20 ~ 70 C

O

30 ~ 90% RH ( No Dewdrop )

10 ~ 95% RH ( No Dewdrop )

Less than 20G

10 ~ 55Hz, Amplitude ( sweep 1min ) Less than 2G

, X,Y, Z, 1hour each.

140 x 124 x 350 refer to outline drawing

By TTL Signal or Dry Contact - refer to instruction manual

Open collector - refer to instruction manual

By Voltage ( 0 ~ 4V ) or by Resist

ance ( 0 ~ 4K ) refer to instruction manual

By Voltage ( 0 ~ 4V ) or by Resist

ance ( 0 ~ 4K ) refer to instruction manual

Possible, maximum 0.5V drop on each load wire

RS232 and RS485 Built-in, IEEE488 Optional

UL 3111-1, EN61010-1

EN 61326-1, IEC 61326 -1, FCC p

art 15 (class A)

Master - slave method: up to 5 unit

s, refer to instruction manual

Up to 2 units, refer to instruction manual

More than 100MOhm at 25°C and 70% R.H.

EN55022-B, FCC-B, VCCI-B

Forced air by blower fan, (blower fan is mounted within unit)

EN55022-A, FCC-A, VCCI-A

Input - Chassis: 2.0kV

AC 1 min. Input - Output: 3.0kV

AC 1 min. Output - Chassis: 500V

AC 1 min.

NOTES:

* 1 MINIMUM VOLTAGE IS GUARANTEED TO MAXIMUM 0.2% OF

THE RATED OUTPUT VOLTAGE.

* 2 MINIMUM CURRENT IS GUARANTEED TO MAXIMUM 0.4% OF

THE RATED OUTPUT CURRENT.

* 3 GIVEN FOR CONTROL

OF THE OUTPUT VIA THE SERIAL COMMUNICATION OR VIA FRONT PANEL CONTROLS.

* 4 TIME FOR RECOVERY TO WITHIN +/- 50mV AGAINST CURRENT CHANGE OF 50% TO 100%.

* 5 INVERTER SHUT DOWN METHOD, MANUAL

RESET BY AC INPUT RECYCLING. (OVP WILL SHUT DOWN OUTPUT).

* 6 AT 100V/200V AND MAXIMUM OUTPUT

POWER.

* 7 FOR CASES WHERE CONFORMANCE

TO VARIOUS SAFETY SPECS, (UL, IEC ETC.)

ARE REQUIRED TO BE DESCRIBED

AS 100-240VAC (50/60Hz) ON NAME PLA

TE.

*8 WHEN MOUNTED WITH MOUNTING SCREWS.

2.1 SPECIFICATIONS: 800W Series continued

Page 17

2.2 SUPPLEMENTAL CHARACTERISTICS

The supplemental characteristics give typical but non-warranted performance characteristics. The

supplemental characteristics are useful in accessing applications for the power supply. Several kinds

of supplemental characteristics are listed below.

1. EVALUATION DATA: Typical performance of the power supply.

2. RELIABILITY DATA: Reliability performance of the power supply.

3. IEC 1000 DATA: Performance of the power supply under IEC 1000 test conditions.

4. EMI DATA: TypicalEMI (conducted and radiated) performance of the power supply.

The supplemental characteristics data are held in each Nemic-Lambda sales and service facility. For

further details please contact the Nemic-Lambda office nearest you.

Page 18

CHAPTER 3 INSTALLATION

3.1 GENERAL

3.2 INITIAL INSPECTION

3.2.1 Mechanical inspection

3.2.2 Preparation for use

3.3 AC SOURCE REQUIREMENTS

3.4 COOLING & PLACEMENT

3.5 RACK MOUNTING

3.6 POWER CONNECTION

NOTE

CAUTION

This chapter contains instructions for initial inspection, preparation for use and repackaging for

shipment. Connection to PC, linking ZUP units and setting the address are described in chapter 5.

Prior to shipment this power supply was inspected and found free of mechanical or electrical defects.

Upon unpacking of the power supply, inspect for any damage which may have occurred in transit. Keep

all packing materials until inspection has been completed. If any damage is detected, file a claim with

the carrier immediately and notify the Nemic-Lambda sales or service facility nearest you.

The mechanical inspection should confirm that there is no exterior damage to the power supply such as

broken knobs or connectors and that the front panel and meter face are not scratched or cracked.

In order to be operational the power supply must be connected to an appropriate AC source. The line

voltage must be within the power supply specification. DO NOT apply power before reading paragraph

3.3.

The ZUP series can be operated from a nominal 100V to 240V, single phase, 47 ~ 63Hz. The input

voltage range and current required for each model is specified in chapter 2. Make sure that under

heavy load, theAC voltage supplied to the power supply does not fall below “low limit” specifications.

This power supply is fan cooled. Upon installation ensure sufficient space for air intake (front panel) and

exhaust (rear panel). The power supply should be used in an area where the ambient temperature

does not exceed +50 C

O

ZUP models can be mounted in a standard 19” rack (3U height). The 200W and 400W models occupy

1/6 rack length. The 800W model occupies 1/3 rack length. The power supplies should be fixed by M4

screws replacing the rubber feet on the bottom of the power supply.The screws must not protrude more

than 6mm into the power supply. Refer to the outline drawing in this chapter for mounting details.

Connection of this power supply to an AC power source should

be made by

an electrician or other qualified personnel.

ZUP series power supplies generate a magnetic field which might affect the

operation of other instruments. If your equipment is susceptible to magnetic fields,

do not position adjacent to the ZUP.

Page 19

This power supply is equipped with a three conductor power cable. The third conductor is the ground

conductor. When the cable is plugged-in to an appropriate receptacle, the power supply is grounded.

Under no circumstances should this power supply be operated without an adequate ground

connection. If a two contact receptacle is encountered, it must be replaced by a three contact

receptacle, properly grounded. This operation should be done by a qualified electrician. It is

recommended to keep the AC input wires separate from the DC output and signal wires to avoid

interference.

To meet radiated EMI specification, the EMI suppressor clamp should be attached to the AC cable as

close as possible to theAC inlet of the power supply.

WARNING

WARNING

Some components inside the power supply are at AC voltage even when the

On/Off switch is in the “Off” position. To avoid the hazard of electric shock,

disconnect line cord and load and wait 2 minutes before removing cover.

Turn off the AC input power before making or changing any rear panel connection.

Make sure that all connections are securely tightened before applying power.

There is a potential shock hazard when using a power supply with a rated output greater than 40V.

Use load wiring with a minimum insulation rating equivalent to the maximum output voltage of the

power supply.

3.7 CONNECTING THE LOAD

3.7.1 Selecting wire size

Twofactors must be considered in selecting wire size.

1. Wires should be at least heavy enough to avoid overheating while carrying the power supply load

current at the rated load, or the current that would flow in the event the load wire were shorted,

whichever is greater.

2. Wire size should be selected to enable voltage drop per lead to be less than 0.5V at the rated current.

It is recommended to minimize voltage drop on the wires to prevent excessive output power

consumption from the power supply.

Please refer to Tables 3-1 and 3-2 for maximum wire length to limit voltage drop by American and

European measurements respectively.

Table 3-1: Maximum wire length for

0.5V drop on lead (in feet)

wire size

AWG

5A

40 20 10 4 1

63 31 15 6 1.7

100 50 25 10 3

160 80 40 16 5

253 126 63 25 8

400 200 100 40 13

640 320 160 64 21

1016 508 254 102 34

14

12

10

8

6

4

2

0

2.526

1.589

0.9994

0.6285

0.3953

0.2486

0.1564

0.0983

Maximum length in feet to limit voltage drop to 0.5V or less

10A 20A 50A 150A

Resistivity

Ohm/kft

Page 20

13

For current not shown in tables 3-1 and 3-2 use formula: Maximum length=500/(current*resistivity)

Where current is expressed in ampers and resistivity in ohms/km or ohms/1000ft.

Table 3-2: Maximum wire length for 0.5V drop on lead (in meters)

cross sect.

area

(mm 2)

5A

12.2 6.1 3.0 1.2 0.4

19.6 9.8 4.9 2.0 0.7

29.5 14.7 7.4 2.9 1.0

51.3 25.6 12.8

5.1

1.7

80.6 40.3 20.2 8.1 2.7

125.8 62.9 31.4 12.6 4.2

177.0 88.5 44.2 17.7 5.9

2.5

4

6

10

16

25

35

8.21

5.09

3.39

1.95

1.24

0.795

0.565

Maximum length in meters to limit voltage drop to 0.5V or less

10A 20A 50A 150A

<

Resistivity

Ohm/km

3.7.2 Wire termination

3.7.3 Single load connection, Local Sensing

The wires should be properly terminated with terminals securely attached. DO NOT use non

terminated wires for load connection at the power supply.

Fig. 3-1 illustrates the connection of a single load to the power supply using local sensing. This

connection is made via the “External Control Connector” located on the rear panel of the power supply.

Local sensing is suitable for applications where load regulation is not critical.

Fig. 3-1: Single load connection, Local Sensing

14

2

- LS

+ S

- V

- S

+LS

+LS

- LS

+S

On/Off

+V

- S

COM

Output Good

P

VRFV

VCVP

VRFI

VCCP

RCVP

EXTERNAL CONTROL

CONNECTOR

(ZUP rear panel view)

LOAD

POWER

SUPPLY

+

_

RCCP

1

CAUTION

At local sensing, short between +LS or +S to -V or -S or -LS will cause damage to the

power supply. Reversing the sense wires might cause damage to the power supply

at local and remote sensing.

Page 21

3.7.4 Single load connection, Remote Sensing

3.7.5 Multiple load connections, radial distribution method

Remote Sensing is used in cases where, in Constant Voltage mode the load regulation is important at

the load terminals. Use twisted or shielded wires to minimize noise pick-up. If shielded wires are used,

the shield should be connected to the ground at one point, either the power supply chassis or the load

ground. The optimal point for the shield ground should be determined by experimentation. At Remote

Sensing, the maximum voltage drop allowed at the load wires is 0.5V per wire for 6V to 60V models and

2V per wire for 80V and 120V models.

In cases of multiple loads connected to one supply, each load should be connected to the power

supply’s output terminals using separate pairs of wires. It is recommended that each pair of wires will be

as short as possible and twisted or shielded to minimize noise pick-up and radiation. The sense wires

should be connected to the power supply output terminals or to the load with the most critical load

regulation requirement.

Fig. 3-2: Remote Sensing, single load.

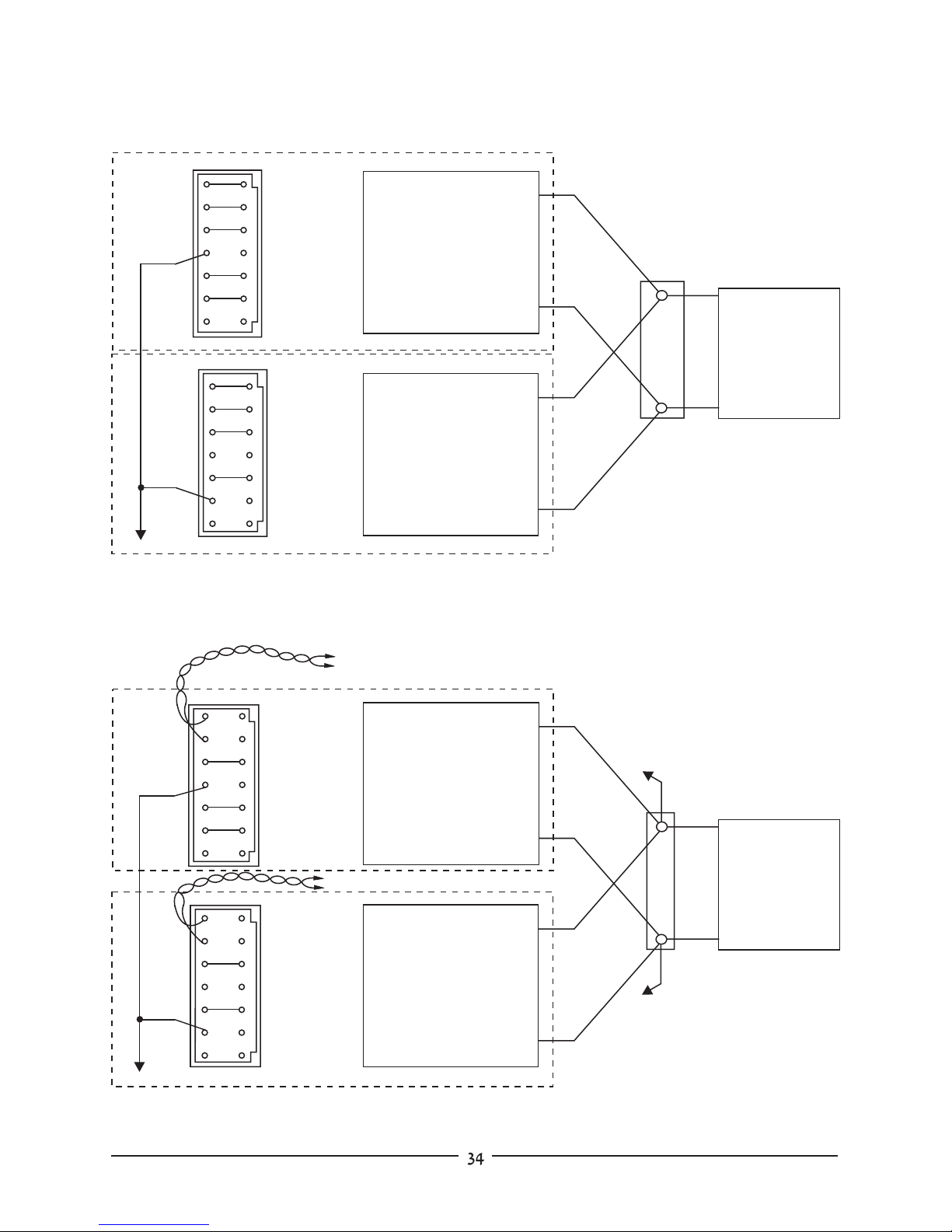

Fig. 3-3: Multiple load connections with distribution terminal

2

2

- LS

- LS

+ S

- V

- S

- S

+LS

+LS

+S

+S

On/Off

On/Off

+ V

- S

COM

COM

Output Good

Output Good

P

P

VRFV

VRFV

VCVP

VCVP

VRFI

VRFI

VCCP

VCCP

RCVP

RCVP

EXTERNAL CONTROL

CONNECTOR

(ZUP rear panel view)

EXTERNAL CONTROL

CONNECTOR

(ZUP rear panel view)

LOAD

LOAD #1

LOAD #2

LOAD #3

POWER

SUPPLY

POWER

SUPPLY

To Load Terminals

Shield

+

+

+

+

_

_

_

_

RCCP

RCCP

1

1

+S

- V

+LS

- LS

+V

- S

Page 22

Fig. 3-5:

3.7.6 Multiple load connections with distribution terminals

3.7.7 Grounding outputs

3.8 EXTERNAL CONTROL CONNECTOR

3.8.1 General

If remotely located output distribution terminals are used, the power supply output terminals should be

connected to the distribution terminals by a pair of twisted or shielded wires. Each load should be

separately connected to the remote distribution terminals. If Remote Sensing is required, the sensing

wires should be connected to the distribution terminals or at the most critical load.

Either the positive or negative output terminals can be grounded. To avoid noise problems caused by

common-mode current flowing from the load to ground, it is recommended to ground the output

terminal as close as possible to the power supply output.

Always use two wires to connect the load to the power supply regardless of how the system is

grounded.

The external control connector, used for analog programming of the power supply, is located on the

rear panel of the unit,(Fig. 4-2, item 4). The pin assignment is shown in Fig. 3-5 below.

The External Control Connector signals are connected to the

negative output terminal. If the negative output terminal is

floated with respect to chassis ground , those signals will also

float at the same potential. Use appropriate safety measures

to prevent a shock hazard.

Fig. 3-4: Multiple load connections with distribution terminal

DISTRIBUTION

TERMINAL

LOAD #1

LOAD #2

LOAD #3

POWER

SUPPLY

+

+

+

_

_

_

+S

- V

- V

+V

+V

- S

To Dristribution Terminals

WARNING

The maximum potential (including output voltage) that either output terminal

is from ground, must not exceed the specified voltage on the front panel.

WARNING

1

14

13

2

2

- LS

- S

+LS

+S

On/Off

COM

Output Good

P

VRFV

VCVP

VRFI

VCCP

RCVP

EXTERNAL CONTROL

CONNECTOR

(ZUP rear panel view)

RCCP

1

External Control Connector pin

assignment (ZUP rear panel view)

Page 23

3.8.2 Pin Description

3.8.3 External Control Connector - Technical description

1. Connector type : AMP, Part No: 5102617-5 14 contacts, double row.

2. Receptacle : AMP, Part No: 87631-9, Polarized, 14 contacts, double row.

3. Receptacle contacts : AMP, Part No: 87523-5 (strip form) or 87523-6 (loose piece).

4. Wires : AWG: 24 to 20.

5. Hand tool for wire connection : AMP, Part No: 90202-2.

6. Applicator for stripper/crimper machine : AMP, Part No: 466905-1

#

Name

1 RCVP

2 RCCP

3 VRFI

4 VCCP

5 VRFV

6 VCVP

7 OUTPUT

GOOD

8 P

9 ON/OFF

10 COM

11 + LS

12 + S

13 - LS

14 - S

Description

Resistive Constant Voltage programming

Resistive Constant Current programming

Reference voltage for Constant Current control. (connected to

VCCP pin except external voltage or resistive programming).

Input of the Constant Current control circuit.

Reference voltage for Constant Voltage control. (connected to

VCVP pin except external voltage or resistive programming).

Input of the Constant Voltage control circuit.

Open collector output. 0~0.8V during normal operation, open at

fault condition (OVP, FOLD and Over-Temp.).

Parallel connection pin.

On/Off control pin.

Common pin for programming, On/off control and Output Good

signal. Internally connected to - Sense.

Positive Local sensing pin.

Positive Sensing pin for remote sense operation.

Negative Local sensing pin.

Negative Sensing pin for remote sense operation.

4.4.10

4.4.10

4.4.10, 11, 12

4.4.10, 11, 12

4.4.10, 11, 12

4.4.10, 11, 12

4.4.15

4.4.13

4.4.8

4.4.10, 11, 12

4.4.8

3.7.3, 4, 5, 6

3.7.3, 4, 5, 6

3.7.3, 4, 5, 6

3.7.3, 4, 5, 6

Par.

Table 3-3: External Control connector pin description

CAUTION

COM pin (10) is connected internally to the - Sense potential. Connection of the COM to another

potential or other than shown in this manual may cause damage to the power supply.

Page 24

3.9 REPACKAGING FOR SHIPMENT

To ensure safe transportation of the instrument, it is recommended to use the original package. The

original packaging material is reusable. If the original package is not available, contact the NemicLambda Sales or service facility near you for details on obtaining suitable packaging and shipping

information. Please attach a tag to the power supply describing the problem and specifying the owner,

model number and serial number of the power supply.

3.8.4 External Control Connector -

Default configuration connections

The external control connector is configured for Local sensing and no external On/Off control. Refer to

Fig: 3-6 below for the default configuration description. The default configuration is: Local sensing,

Rear panel On/Off disabled (On/Off can be controlled by the Front panel or by the serial communication

port), and output voltage and current are controlled by the Front panel or by the serial communication

port. For other configurations, remove the contact that should be modified, and replace it with a new

one with a suitable connection. Replacement contacts are supplied in the packaging of the power

supply.

Fig. 3-6:

External Control connector - default configuration

(ZUP rear panel view)

1

14

13

2

- LS

- S

+LS

+S

On/Off

COM

Output Good

P

VRFV

VCVP

VRFI

VCCP

RCVP

RCCP

Page 25

3.10 OUTLINE DRAWINGS

ZUP 200W and ZUP 400W Series

DIMENSIONS: mm

200W /400W units:

70x124x350

WEIGHT: Kg

200W units: 2.9

400W units: 3.2

20.0

20.0

13.0

13.0

59.5

30.0

(Note4)

70.0

201.5

11.0

+

0.5

_

+

+

0.5

0.5

_

_

350.0

+

1

_

290.0

+

1

_

+

1

_

124.0

48.0

11.0

Mounting Holes

Tap M4 x 4 marked ‘A’

(See note 1)

Notes:

1. Mounting screws must not

protrude more than 6mm

into the power supply.

2. Use M6 or 1/4” screw for

load wires connection,

enclosed in the package

at time of shipment.

3. Receptacle: AMP, 87631-9,

14 contacts, double row.

Pin: 87523-5 or 87523-6

4. For 6V to 60V models.

5. Male connector (P.S. side) :PSC 1.5/3-M-PE , Phoenix

Accessories: Female connector (user side) :PSC 1.5/3-F , Phoenix

Strain relief plastic housing.

Rubber Bumpers

4 places marked ‘B’

(removable)

10.6

B

B

B

B

A

A

A

A

48.4

_

+

0.5

21.5

19.0

External

Control

Connector

(Note3)

IEC320

AC Inlet

RS232/RS485

communication

connectors

+

1

_

131.0

A

ALM

CC

CV

V

POWER SUPPLY

ADDR

OVP/UVP

V/A

FOLD

REM

OUT

POWER

NEMIC-LAMBDA

LTD.

H

25.0

17.5

(Note 5)

(Note 2)

131.0 1.0

6V TO 60V MODELS

80V AND 120V MODELS

Page 26

Rubber Bumpers:

4 places marked ‘B’ (removable)

3.11 OUTLINE DRAWINGS

ZUP 800W Series

DIMENSIONS:

140x124x350 mm.

WEIGHT:

5.8 kg.

20.0

22.0

22.0

30.0

46.3

47.0

External

Control

Connector

(Note3)

IEC320

AC Inlet

RS232/RS485

communication

connectors

REMOVABLE HANDLE

11.0

+

1.0

_

350.0

+

1

_

290.0

+

1

_

139.5

107.5

Mounting Holes: Tap M4 x 4 marked ‘A’

(See note 1)

Notes:

1. Mounting screws must not

protrude more than 6mm

into the power supply.

2. Use M8 or 5/16” screw for

load wires connection,

enclosed in the package

at time of shipment.

3. Receptacle: AMP, 87631-9,

14 contacts, double row.

Pin: 87523-5 or 87523-6.

140.0

+

0.5

_

+

0.5

_

124.0

+

1.0

_

99.6

201.50

+

0.5

_

59.5

10.4

B

B

B

A

A

A

A

118.90

_

+

0.5

B

18.5

POWER

20.0

+

1.0

_

131.0

Page 27

Physical Dimensions in mm.

392.0 Max.

153.0

+

1.0

_

70.0

+

0.5

_

Front Panel Output Jacks Option: available for ZUP200W , ZUP400W and ZUP800W series for 6V to 60V

models.

ZUP200/L and ZUP400/ L

Up to 20A output current via front panel jacks.

CAUTION:

ZUP800 front panel output is protected against overcurrent by 25A 125V Fast acting fuse.

For continued protection against risk of fire, replace only with same type and rating of fuse.

3.12 OUTLINE DRAWINGS

ZUP800/L

153.0

+

1.0

_

140.0

+

0.5

_

Page 28

This chapter describes the operating modes, controls and indicators of the ZUP power supply series.

Details of local operation via the front panel and various modes of operation are described in this

chapter, including remote analog control via the rear panel. For computer control via the Serial port

(RS232 or RS485), refer to chapter 5.

CHAPTER 4 OPERATING INSTRUCTIONS

4.1 INTRODUCTION

4.2 CONTROLS AND INDICATORS

4.2.1 Front panel

Fig. 4-1: Front panel controls and indicators

8

9

10

11

12

13

1

2

3

7

4

6

5

Page 29

Table 4-1: Front panel controls and indicators

#

Control/Indicator

1 AMPS Display

2 VOLTS Display

3 CV Indicator

4 CC Indicator

4.4.2

4.4.3

4.4.5

4.4.6

5.2.1

4.4.8

4.4.9

5.2.4

4.4.7

5 ADJUST knob

(Rotary pulse generator)

6 ALM Indicator

7 OUT Pushbutton

8 REM Pushbutton

9 FOLD Pushbutton

Description

Actual output current display at normal operation. While

adjusting the output current, the set value will be shown.

The display will automatically return to show the actual

current approx. 3sec from completion of adjustment.

Actual output voltage display at normal operation. The

measurement circuits monitor the voltage at the sensing

points, hence at remote sensing where there is voltage

drop on the load wires, the voltage at the power supply

output terminals will be higher than the displayed value.

Attention should be taken not to exceed the output power

rating. While adjusting the output voltage, the set value will

be shown. The display will automatically return to show the

actual voltage approx. 3sec after completion of adjustment.

CV LED indicates that the power supply is regulating it’s

output at a constant voltage.

CC LED indicates that the power supply is regulating it’s

output at a constant current.

The ADJUST knob functions to determine the following

output parameters:

1. Output voltage adjust - as determined by V/Apushbutton

2. Output current adjust - as determined by V/Apushbutton

3. Over voltage protection adjust - as determined by

OVP/UVP pushbutton

4. Under voltage soft limit adjust-as determined

by OVP/UVP pushbutton

5.Address selection

ALM indicates alarm caused by activation of one of the

following protections:

* Over voltage protection

* Over temperature protection

* Foldback protection

Main function: Enable or disable the power supply output.

Auxiliary function: Press and hold OUT pushbutton for

approx. 3sec to change function to select between safe

mode restart and automatic restart.

Main function: Select between local or remote operation.

Auxiliary function: Press and hold REM pushbutton for

approx. 3sec to change function to select between RS232

or RS485 communication.

Pressing FOLD pushbutton arms foldback protection

which shuts down output if supply transits from CV to CC.

Par.

Page 30

Table 4-1 contd.: Front panel controls and indicators

4.2.2 Rear Panel

6V to 60V models

80V and 120V models

#

Control/Indicator

10 AC ON/OFF

11 V/A Pushbutton

12 OVP / UVP

13 ADDR

Description

TurnsAC power On and Off.

Selects the voltage or current adjust mode. fast or slow

adjustment speed can be selected by pressing the

pushbutton consecutively. Adjustment is made by rotating

theAdjust knob.

Makes selection between Over-voltage or Under-voltage

adjust mode. Adjustment is made by rotating the Adjust

knob.

Main function: Selects the address for remote control. The

adjustment is made by rotating theAdjust knob.

Auxiliary function: Holding ADDR pressed for approx. 3sec.

changes the function to Baud-rate selection.

Par.

1

3

4

5

2

Fig. 4-2: Rear panel connections

4.4.2

4.4.5

4.4.3

4.4.6

5.2.1

5.2.3

6

6

Page 31

4.2.3 Rear Panel Connections description

#

Connection

1 AC Inlet

2 Remote In

3 Remote Out

4 External control

5 Output Bus Bars

7

(6V to 60V models)

6 Ground thread

O u t p u t c o n n e c t o r

(80V and 120V models)

Description

IEC type appliance inlet.

EIA/TIA-568A type connector, used for connecting power

supply to RS232 or RS485 port of computer for remote

control purposes. When using several power supply units

in a power system, the first unit Remote-in is connected to

the computer and the remaining units are chained,

Remote-In to Remote-Out.

EIA/TIA-568 type connector, used for chaining power

supplies to form a serial communication bus.

Connector containing control and signal lines for external

(remote) control of the power supply. +/- Sense, On/Off,

Output voltage and current programming by external

resistor and Output voltage and current programming by

external voltage and Output Good signal.

Bus bars for output connection. Use M6 or 1/4” screws for

load wire connections.

M4 thread for grounding either the positive or negative

output.

Male connector , PSC 1.5/3-M-PE , Phoenix.

Par.

4.3 TURN-ON CHECKOUT PROCEDURE

4.3.1 General

4.3.2 Prior to operation

4.3.3 Constant Voltage check

The following procedure ensures that the power supply is operational and may be used as a basic

incoming inspection check.

Check that the Rear panel external control receptacle is properly inserted into the connector and the

wires are connected as shown in Fig: 3-6. Connect the unit to an AC source as described in paragraph

3.6. Connect a DVM to the output terminals.

Turn-on the power supply. Turn on the output by pressing OUT pushbutton so the OUT LED illuminates.

Momentarily press V/A pushbutton, until the V LED illuminates and the VOLTS display shows FA_V.

The AMPS display will show the last setting of the output voltage. Rotate the Adjust knob at the front

panel and check that the output voltage can be varied throughout the entire range. Check that the

AMPS display shows the correct output voltage (within the display specifications). Momentarily press

V/A pushbutton again, so the A LED illuminates and the VOLTS display shows FA_A. The AMP display

will show the last setting of the output current. Rotate the Adjust knob and check that the AMP display

varies. Set theAMP display to

the rated output current.

3.6

3.8

5.3.4

5.3.4

3.7

Page 32

4.3.4 Constant Current check

4.3.5 OVP check

4.3.6 UVP check

4.3.7 Foldback check

4.3.8 Output On/Off

4.3.9 Address setting

4.3.10 Local/Remote operation

Turn off the power supply. Connect an electronic load with suitable voltage and current rating to the

output terminals, as explained in paragraph 3.7.3. Turn-on the power supply. Vary the load current and

check that the unit regulates the output voltage while the load current is smaller than the power supply

current rating. Further increase the load current and check that the power supply regulates the output

current.

Adjust the output voltage to zero using the front panel knob. Momentarily press OVP/UVP pushbutton

until the OVP LED illuminates and the VOLTS display shows OUP. The AMPS display will show the last

setting of the OVP level. Rotate the Adjust knob to 50% of the supply’s voltage rating. Adjust the output

voltage toward it’s maximum and check that the output voltage cannot be increased more than the OVP

setting.

Adjust the output voltage to the rated voltage using the front panel knob. Momentarily press OVP/UVP

pushbutton until the UVP LED illuminates and the VOLTS display shows UUP.. The AMPS display will

show the last setting of the UVP level. Rotate the ADJUST knob to 50% of the supply’s voltage rating.

Adjust the output voltage toward it’s minimum and check that the output voltage cannot be decreased

below the UVP setting.

Set the load current to 50% of the supply rating. Momentarily press FOLD pushbutton and check that

the FOLD LED illuminates. Increase the load current toward the supply current rating. Check that the

output voltage and current fall to zero when the load current reaches the Constant Current setting. The

FOLD LED should flash , theALM LED illuminates and the output is disabled in this condition.

Reduce the load current setting below the power supply current rating and momentarily press FOLD

pushbutton. Check that the output voltage and current recover and FOLD continuously illuminates.

Momentarily press the FOLD pushbutton and check that FOLD LED turns off.

Repeatedly press OUT pushbutton and check that the power supply output is turned On and Off. While

the output is On,

the OUT LED illuminates. While the output is Off, the LED is Off.

Momentarily pressADDR pushbutton so the ADDR LED illuminates and the AMPS display shows Addr.

The VOLTS display shows the last address setting. Rotate the ADJUST knob and check that the

VOLTS display varies between 0 and 31.

Repeatedly press REM pushbutton and check that REM LED turns on and off. While the power supply

is at Remote mode, the LED is on and while at Local mode, the LED is off. While the LED is off, turn off

the power supply, remove the DVM and the load wires.

Page 33

4.4 LOCAL OPERATION

4.4.1 Introduction

4.4.2 Constant Voltage Operation

This paragraph describes the operating modes not involved in programming the power supply via it’s

serial communication port. Operation utilizing the front and rear panel are described in this paragraph.

For information regarding serial port usage, please refer to chapter 5.

The REM LED on the front panel indicates whether the power supply is in Local or Remote mode. The

extinguished LED indicates Local operation. If the LED illuminates, the REM pushbutton (fig.4-1, item

8),should be pressed to change the operating mode to Local.

1. In constant voltage mode, the power supply maintains the output voltage at the selected value while

the load current varies as required by the load.

2. While the power supply is operating at constant voltage, the CV LED on the front panel illuminates.

3. For coarse output voltage adjustment, press V/A consecutively, until the V LED illuminates, and

the VOLTS display shows FA_V. The AMPS display will show the output voltage setting value.

Rotate the ADJUST knob to set the output voltage. At this mode, approx. 6 turns are required to

adjust the entire range. Approx. 3sec after the adjustment, the display returns to show the actual

voltage and current.

3. For coarse output current adjustment, press V/Aconsecutively, until theA LED illuminates, and

the VOLTS display shows FA_A. The AMPS display will show the output current setting value.

Rotate the ADJUST knob to set the output current. At this mode, approx. 6 turns are required to

adjust the entire range. Approx. 3sec after the adjustment, the display returns to show the actual

voltage and current.

4.4.3 Constant Current Operation

NOTE

NOTE

4. For fine adjustment of output voltage, press V/Aconsecutively until the V LED illuminates and the

VOLTS display shows SL_V. TheAMPS display will show the output voltage setting value. Rotate

theADJUST knob to set the output voltage. At this mode the adjustment resolution is maximal.

Approx 3sec. after the adjustment, the display returns to show the actual voltage and current.

4. For fine adjustment of output current, press V/Aconsecutively until the A LED illuminates and

the

VOLTS display shows SL_A. TheAMPS display will show the output current setting value. Rotate

theADJUST knob to set the output current. At this mode the adjustment resolution is maximal.

Approx 3sec. after the adjustment, the display returns to show the actual voltage and current.

1. In constant current mode the power supply maintains the output current at the selected value, while

the load voltage varies with the load requirement.

2. While the power supply is operating at constant current, the CC LED on the front panel illuminates.

If after completing the adjustment the display shows a different value than the setting, the power

supply may be at current limit. Check the load condition and the power supply current limit setting.

The maximum and minimum setting values of the output voltage are limited by the over voltage and

under voltage protection settings. Refer to par. 4.4.5 and 4.4.6 for details.

Page 34

4.4.4 Automatic Crossover

4.4.5 Over Voltage Protection (OVP)

If the power supply operates in Constant voltage mode while the load current is increased to greater

than the current limit setting, the power supply will automatically switch to Constant current mode. If the

load is decreased to less than the current limit setting, the power supply will automatically switch back

to Constant voltage mode.

MODEL (by output voltage) 6V

7.5V

10V

13V

20V

24V

36V

40V

60V

80V

120V

66V

88V

132V

Maximum OVP

1.The OVP circuit monitors the voltage at the power supply sensing points thus guaranteeing the

protection level at the load. Upon detection of Over Voltage condition, the power supply will shut

down. To resume operation, the power switch should be turned off for approx. 30sec. Prior to turn-on,

check carefully that the sense wires are connected correctly and secured.

2. OVP setting values are limited at the minimum and maximum levels.At minimum level, the OVP level

is limited by the Output Voltage setting, therefore the OVPlevel cannot be adjusted below the

Output Voltage.At maximum level, the OVP level is limited to the values shown in Table 4-1.

Table 4-1: Maximum OVP setting levels.

4.4.6 Under Voltage Protection (UVP)

3.For over voltage protection adjustment, press OVP/UVP consecutively, until the OVP LED

illuminates and the VOLTS display shows OUP. The AMPS display will show the over voltage

protection setting value. Rotate theADJUST knob to set the over voltage protection level.Approx.

3sec after the adjustment, the display returns to show the actual voltage and current.

4. In order to see the value of the OVP, press OVP/UVP pushbutton, so that the OVP LED illuminates.

At this time the display will show the OVP set value for approx. 3sec.

5. The minimum over voltage level is approx. 105% of the output voltage set value. Attempting to

adjust the over voltage protection below this value will result in no response to the adjustment

attempt.

6. In case the OVP is triggered, the front panel control is disabled unitl the AC input is recycled by

turning the AC ON/OFF switch to OFF and after approx. 30 sec. to ON.

1.The UVP prevents adjustment of the output voltage below a certain limit. The combination of UVP

and OVP functions allows the user to create a protection window for sensitive loads circuitry.

2. For under voltage protection adjustment, press OVP/UVP consecutively until the UVPLED

illuminates and the VOLTS display shows UUP. The AMPS display will show the under voltage

protection setting value. Rotate theADJUST knob to set the under voltage protection level.

3. In order to see the set value of the UVP, press OVP/UVP pushbutton, so that the UVP LED

illuminates.At this time the display will show the UVP set value for approx. 3sec.

4. The maximum under voltage level is approx. 95% of the output voltage set value. An attempt to

adjust the under voltage protection above this value will result in no response to the adjustment

attempt.

5.The under voltage protection is a software protection only.

Page 35

4.4.8 Output ON/OFF Control

4.4.7 Foldback Protection

The ON/OFF circuit has two controls; a front panel pushbutton and a rear panel connection. priority is

given to the rear panel connection.

1. Foldback protection will shut down the power supply output if the load current exceeds the current

limit setting level. This protection is useful when the load circuitry is sensitive to over current

condition.

2. To arm the Foldback protection, the FOLD pushbutton should be pressed so the FOLD LED

illuminates.At this condition transition from Constant Voltage to Constant Current mode will activate

the Foldback protection.

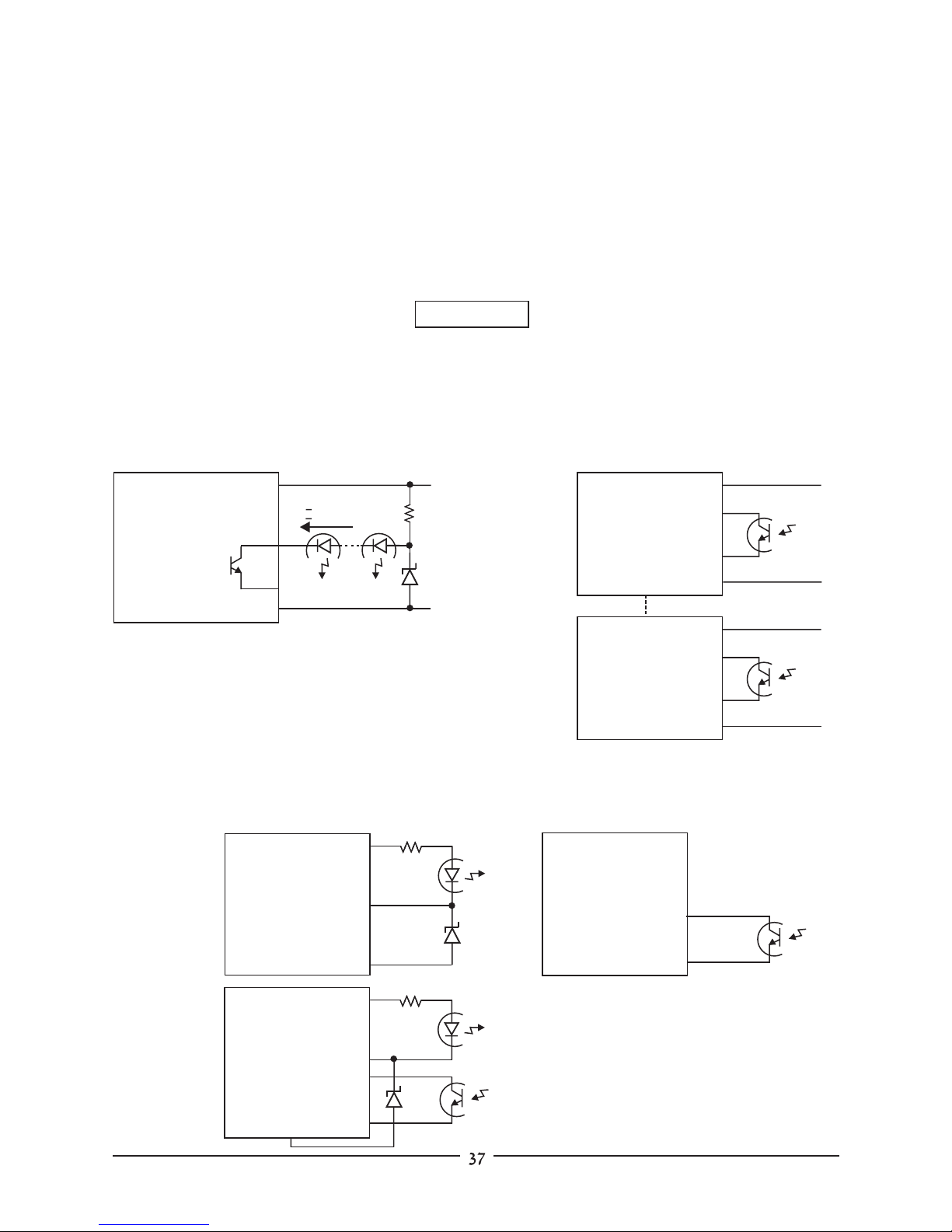

3. Activation of the Foldback protection disables the power supply’s output, turns on the ALM (alarm)