Page 1

Programmable DC Power Supplies

200W/400W/600W/800W in 2U

Built-in USB, RS-232 & RS-485 Interface

Series

User Manual

Optional Interface:

IEEE488.2 SCPI (GPIB) Multi-Drop

Page 2

USER MANUAL FOR

IEEE Programming Interface

POWER SUPPLIES

Manual Supplement

Refer to the Z

+

Technical Manual for information on installing the power supply,

safety requirements, specifications, operating the front panel, using the serial

RS-232/485, USB programming and the analog programming.

IA710-04-03A

Page 3

Table of Contents

INTRODUCTION ...........................................................................................................3

SCOPE OF MANUAL .....................................................................................................3

CHAPTER 1: THE IEEE-488.2 INTERFACE ....................................................................3

CHAPTER 2: CONNECTION

2.1 Point to Point ...................................................................................................................................... 4

2.2 Multi Drop ............................................................................................................................................ 4

2.2.1 Selecting One Power Supply in a Multi Drop Chain ............................................................................4

2.3 Communication Cables ................................................................................................................... 4

CHAPTER 3: CONFIGURATION

3.1 Configuration the IEEE Controller ................................................................................................ 5

3.2 Configuration the Power Supply ................................................................................................. 5

3.2.1 To Select the Communication Interface .....................................................................................................5

3.2.2 To Select the Address .............................................................................................................................................6

3.2.3 To Select the Baud Rate 57600. (485 Interface only) ............................................................................6

3.2.4 To Select the Communication Language SCPI. (485 interface only) .........................................6

CHAPTER 4: PROGRAMMING COMMANDS

4.1 SCPI Protocol ...................................................................................................................................... 7

4.2 SCPI Common Commands ............................................................................................................. 7

4.3 SCPI Subsystem Commands .......................................................................................................... 8

4.4 Register Structure............................................................................................................................. 12

4.5 The Summary Registers ................................................................................................................. 12

4.6 Output Queue ................................................................................................................................... 12

4.7 Error Messages .................................................................................................................................. 12

4.8 Execution Time ................................................................................................................................. 12

CHAPTER 5: COMMUNICATION EXAMPLE ................................................................15

Page 4

3

INTRODUCTION

The internal factory installed General Purpose Interface Bus (GPIB) allows operation of the Z+ Power

Supply from a computer via IEEE-488.

The interface allows the user complete remote control of the Power Supply, including output

voltage and current setting and monitoring, protection setting, trigger, waveform list operation,

Power Supply status and SRQ reporting.

Communication over the GPIB interface meets IEEE 488.2 standards for Programmable Instrumentation

(SCPI) compliant.

SCOPE OF MANUAL

This manual contains the information needed to operate the optional embedded IEEE(GPIB)

Interface used in the Power Supply. It includes the following:

• A general description of the GPIB.

• Connection.

• Configuration.

• Listing and description of SCPI command.

• Communication Example.

CHAPTER 1: THE IEEE-488.2 INTERFACE

The IEEE-488 digital programming interface (also called the GPIB interface) is a popular way to

connect instruments to a computer. It uses a specialized 24-pin cable with connectors that allow

cables to be ‘stacked’ together. There are eight data wires; eight control wires and eight ground

wires. If the system runs from a personal computer, there are numerous vendors of IEEE controller

cards and software.

The IEEE-488 standard has gone through several upgrades. The IEEE-488.1 focused on the

handshaking of the eight control lines. The IEEE-488.2 added status registers inside each instrument

and it added common commands to make programming groups of instruments easier. The latest

specification, SCPI, adds guidelines for the command syntax so one vendor’s Power Supply will

use the same commands as another’s. The Interface follows all of these standards.

Because many instruments may be connected and independently controlled by a single IEEE

controller, each instrument must have a unique address. The IEEE controller automatically sets

its address equal to the Power Supply address.

For complete and specific information, refer to the following documents: ANSI/IEEE Std 488.1-1987

IEEE Standard Digital Interface for Programmable Instrumentation and ANSI/IEEE Std 488.2-1987

IEEE Standard Codes, Formats, Protocols and Common Commands.

Page 5

4

CHAPTER 2: CONNECTION

This section provides information on variable IEEE (GPIB) connection modes, communication

cables and selecting communication parameters for operation via IEEE (GPIB) interface.

It is possible connect to IEEE (GPIB) interface in two ways.

2.1 Point to Point

One IEEE Interface can control only one Z+ Power Supply. Refer to Fig.2-1. Each Power Supply must

be configured for IEEE communication interface. Each unit must have a unique address, ranging

from 01 to 31. Baud rate and address are automatically fixed to “57600" and "SCPI".

2.2 Multi Drop

One IEEE Interface can control more than one Z+ Power Supply. A maximum of 30 Z+ units can be

connected via RS485 interface to a Power Supply with the installed IEEE option. Refer to Fig.2-2.The

Power Supply connected to a PC via the GPIB cable must be configured for an IEEE communication

interface, the other must be configured for a RS485 interface. Each unit must have a unique address,

ranging from 01 to 31. IEEE module gets the address of the unit into which it is installed. For RS485

interface set Baud rate at “57600" bps and Communication Language to "SCPI".

2.2.1 Selecting One Power Supply in a Multi Drop Chain

All the SCPI commands may be sent to any one of the Power Supplies in an RS-485 chain by first

sending the INST:nSEL address command. All commands and queries will then apply only to

the selected Power Supply, until a new INST:nSEL is sent.

At power-up, the IEEE master Power Supply is automatically the one selected.

After sending INST:nSEL, it is recommended that you verify the command by sending INST:nSEL?,

otherwise the following commands may be sent to the wrong Power Supply.

Fig.2-1: Point To Point Connection Fig.2-2: Multi Drop Connection

2.3 Communication Cables

• GPIB cable - Use standard IEEE-488, 26 AWG GPIB cable up to 3 meters in length.

• RS485 link cable - Use serial link cable with RJ-45 shielded connectors (P/N: GEN/RJ45). Refer

to Z+ Series User Manual Fig.7-8.

Page 6

5

CHAPTER 3: CONFIGURATION

3.1 Configuration the IEEE Controller

A typical IEEE controller is a personal computer with an IEEE interface card. Each card vendor

supplies its own configuration instructions and interface software.

Each time the software is executed, the controller is configured as follows:

• Controller Address = Power Supply address.

• Serial bus Baud Rate = 57600

• SCPI protocol.

• EOI Flag = TRUE. The “End or Identify” is a control line in the IEEE cable that is initiated when

the last character of a message string is sent. It is not supported by this interface.

• EOS Flag = FALSE: The “End of String”, used in some instruments to indicate the last character

of a message. It is required for this interface.

Fig.3-1: Front Panel Fig.3-2: Rear Panel

1. AC ON/OFF Switch

2. REM LED/Buttom

3. Voltage Encoder

4. Voltage Display

5. Current Encoder

6. Current Display

7. RS-232/RS-485 INPUT Remote Serial Programming

8. RS-485 OUTPUT to other Z+ Power Supplies

3.2 Configuration the Power Supply

Refer to Fig.3-1.

3.2.1 To Select the Communication Interface

1. Press REM button. The LED is illuminated. “IN t F " appears on Voltage display.

2. Press Voltage Encoder. Existing communication mode appears on Current display.

3. Turn Current Encoder until desired message appears; "I" (for unit with IEEE option) or "5".

4. To select desired parameter press Current encoder.

Page 7

6

3.2.2 To Select the Address

1. Press REM button. The LED is illuminated. “Adr" appears on Current display.

2. Press Current Encoder. Existing address mode appears on Current display.

3. Turn Current Encoder until desired address appears.

4. To select desired address press Current encoder.

3.2.3 To Select the Baud Rate 57600. (485 Interface only)

1. Press REM button. The LED is illuminated. “IN t F " appears on Voltage display.

2. Turn Voltage Encoder until "baUd" message appears on Current display

3. Press Current Encoder. Existing Baud Rate appears on Current display.

4. Turn Current Encoder until "57600" appears.

5. To select desired Baud Rate press Current encoder.

3.2.4 To Select the Communication Language SCPI. (485 interface only)

1. Press REM button. The LED is illuminated. “IN t F " appears on Voltage display.

2. Turn Voltage Encoder until "La nG" message appears on Current display

3. Press Current Encoder. Existing Language appears on Current display.

4. Turn Current Encoder until "SCPI" appears.

5. To select desired Language press Current encoder.

For more information refer to section 4 of Z

+

series User Manual

Page 8

7

CHAPTER 4: PROGRAMMING COMMANDS

Communication over the GPIB interface meets IEEE 488.2 standards and is Standard Commands

for Programmable Instrumentation (SCPI) compliant.

4.1 SCPI Protocol

Refer to section 7.10 of Z+ series User Manual

4.2 SCPI Common Commands

Common commands are used to control instrument status registers, status reporting, synchronization,

data storage, and other common functions.

*CLS Clear Status command. Clears the entire status structure.

*ESE <NR1> Standard Event Status Enable command.

*ESR? Standard Event Status Register query.

*IDN? Identification query.

*OPC Operation Complete command.

*OPC? Operation Complete query.

*OPT? Returns a string identifying internal options.

*PSC <bool> Power-On Status Clear (PSC).

*RCL <NR1> Restores the Power Supply to a state previously stored in memory.

*RST Resets the Power Supply to a defined state.

*SAV <NR1> The SAV command saves all applied configuration setting.

*SRE <NR1> Service Request Enable command.

*STB? Status Byte query. Returns the contents of the Status Byte Register.

*TRG Command starts the waveform when the trigger source is set to BUS.

ABORt Resets the trigger system and places the Power Supply in an IDLE state.

For more information refer to section 7.11 of Z

+

series User Manual.

Page 9

8

4.3 SCPI Subsystem Commands

Subsystem commands control all Z+ functions. For a full command description refer to section

7.12 in Z+ series User Manual. Short list of Z+ series commands:

OUTPut

[:STATe] <bool>

Enable/Disable output

[:STATe]?

Enable/Disable output query

:PON

[:STATe] <bool>

Set power-on state in Safe or Auto start

[:STATe]?

Power-on state in Safe or Auto start query

:PROTection

:CLEar

Reset latched protection

:FOLDback

[:MODE] <CRD>

Protection at transition CC<->CV modes

[:MODE]?

Protection at transition CC<->CV modes query

:DELay <NR3>

Delay before protection activated

:DELay?

Delay before protection activated query

:ILC

:MODE <CRD>

Set remote inhibit input (ENAble|DISable)

:MODE?

Set remote inhibit input query

:TTLTrg

:MODE <CRD>

Set or disable Function Strobe Mode

:MODE?

Function Strobe Mode query

:RELay

[:STATe] <bool>

Set programming pin status

[:STATe]?

Programming pin status query

:MODE?

Replay operation mode CV/CC/OFF

INSTrument

:COUPle <CRD> Couple for all

Z

+

power supplies

:NSELect <NR1>

Select the Power Supply to remote operation

:NSELect?

Selected Power Supply

VOLTage

[:LEVel]

[:IMMediate]

[:AMPLitude] <NR3>

Set output voltage

[:AMPLitude]?

Set output voltage query

:TRIGger <NR3>

Set current value for trigger pending

:TRIGger?

Set current value for trigger pending query

Page 10

9

:PROTection

:LEVel <NR3>

Set OVP value

:LEVel?

Set OVP value query

: LOW

:STATe <CRD>

Set UVP or UVL mode

:STATe?

Set UVP or UVL mode query

:[LEVel] <NR3>

Set UVP|UVL value

:[LEVel]?

Set UVP|UVL value

:CLEar

:MODE <CRD>

Set arbitrary trigger control mode

:MODE?

Set arbitrary trigger control mode query

CURRent

[:LEVel]

[:IMMediate]

[:AMPLitude] <NR3>

Set output Current

[:AMPLitude]?

Set output Current query

:TRIGger <NR3>

Set current value for trigger pending

:TRIGger?

Set current value for trigger pending query

:MODE <CRD>

Select arbitrary trigger control mode

:MODE?

Select arbitrary trigger control mode query

MEASure

:CURRent[:DC]?

Reads the measured output current.

:VOLTage[:DC]?

Reads the measured output voltage.

:POWer[:DC]?

Reads the measured output power.

DISPlay

[:WINDow]:STAT <bool>

Display ON/OFF

[:WINDow]:FLASh <bool>

Display Flash ON/OFF

INITate

[:IMMediate]

Enables the trigger subsystem.

:CONTinuous <bool>

Trigger system is continuously enabled/disabled

:CONTinuous?

Trigger system is continuously enabled/disabled

Page 11

10

LIST

:COUN <NR3>

Set the number of times the list is executed before it is completed.

:COUN?

Set the number of times the list is executed query

:CURR <NR3>

Specifies the output current points in a list.

:CURR?

Specifies the output current points in a list query.

:DWEL <NR3>

Specifies the time interval that each point of a list is to remain in effect.

:DWEL?

Specifies the time interval that each point of a list is to remain query.

:LOAD <NR1>

Loads from memory LIST type.

:STEP <CRD>

Determines if a trigger causes to next point or through all points.

:STEP?

Determines if a trigger causes to next point or through all points query.

:STORe <NR1>

Saves data under specified numbers <1..4> of the last LIST typed

:VOLT <NR3>

Specifies the output voltage points in a list.

:VOLT ?

Specifies the output voltage points in a list query.

STATus

:OPERation

Returns the value of the event register

[:EVENt]

Returns the value of the condition register

:CONDition?

Set current value for trigger pending

:ENABle <NR1>

Enables specific bits in the Event register

:ENABle?

Enables specific bits in the Event register query

:QUEStionable

[:EVENt]

Returns the value of the event register

:CONDition?

Returns the value of the condition register

:ENABle <NR1>

Enable specific bits in the Event register

:ENABle?

Enables specific bits in the Event register query

SYSTem

:ERRor:ENABle

Enable Error Message

:ERRor? Read system error. Refer to table 9-6 of

Z

+

series User Manual

:LANGuage

Switch to GEN Language

:REMote

[:STATe] <CDR>

Set program communication mode

[:STATe]?

Set program communication mode query

:VERSion?

Z

+

Main software revision

:DATE?

Calibration date

:PON:TIME?

Operation time from first power on applied

Page 12

11

TRIGger

[:START] Run trigger

:DELay <NR3> Set trigger delay

:DELay? Set trigger delay query

:SOURce <CRD> Set trigger source

:SOURce ? Set trigger source query

WAVE

:COUN <NR1>

Set the number of times that waveform is executed before it is

completed.

:COUN?

Set the number of times that waveform is executed before it is

completed query.

:CURR <NR1> This command specifies the output current points in a list.

:CURR? This command specifies the output current points in a list query.

:LOAD <NR1> Loads from memory WAVE type.

:STEP <CRD> Determines if a trigger causes to next point or through all points.

:STEP? Determines if a trigger causes to next point or through all points.

:STORe <NR1> Saves data under specified numbers <1..4> of the last WAVE typed

:TIME <NR1> Set the slope time of the waveform.

:TIME? Set the slope time of the waveform query.

:VOLT <NR3> Specifies the output voltage points in a waveform list.

:VOLT? Specifies the output voltage points in a waveform list query.

GLOBal

:OUTPut

[:STATe] <bool> Set all Power Supply Output On /OFF

:VOLTage

[:AMPLitude] <NR3> Set all Power Supply output voltage

:CURRent

[:AMPLitude] <NR3> Set all Power Supply output current

:*SAV <NR1> Same as *SAV <NR1>

:*RCL <NR1> Same as *RCL <NR1>

:*RST Same as *RST

4.4 Register Structure

Refer to Fig.3-1.

Refer to section 9 of Z+ series User Manual.

Page 13

12

4.5 The Summary Registers

The INSTRUMENT SUMMARY EVENT REGISTER, ISUM1 through ISUM3 (Refer to Fig.3-2), will

record the address of the supply causing an SRQ. These are ‘EVENT’ registers and the bits will

remain set until read by the STAT:QUES:INST:ISUMn command. (Refer to Table 4-1)

Command Description

STATus:QUEStionable

:INSTrument:ISUMmary1?

Reads the source of the SRQ in Logical

Z+ Supplies 0 through 13

STATus:QUEStionable

:INSTrument:ISUMmary2?

Reads the source of the SRQ in Logical

Z+ Supplies 14 through 27

STATus:QUEStionable

:INSTrument:ISUMmary3?

Reads the source of the SRQ in Logical

Z+ Supplies 28 through 30

STATus:QUEStionable

:INSTrument:ISUMmary1:ENABle xx

Enable supplies to cause IEEE SRQ in Logical

Z+ Supplies 0 through 13

STATus:QUEStionable

:INSTrument:ISUMmary2:ENABle xx

Enable supplies to cause IEEE SRQ in Logical

Z+ Supplies 14 through

27

STATus:QUEStionable

:INSTrument:ISUMmary3:ENABle xx

Enable supplies to cause IEEE SRQ in Logical

Z+ Supplies 28 through

30

STATus:QUEStionable

:INSTrument:ISUMmary1:ENABle?

Read which supplies can cause IEEE SRQ in Logical

Z+ Supplies 0

through 13

STATus:QUEStionable

:INSTrument:ISUMmary2:ENABle?

Read which supplies can cause IEEE SRQ in Logical

Z+ Supplies 14

through 27

STATus:QUEStionable

:INSTrument:ISUMmary3:ENABle?

Read which supplies can cause IEEE SRQ in Logical

Z+ Supplies 28

through 30

Table 4-1: ISUM commands

4.6 Output Queue

Refer to section 9.6.16 of Z+ series User Manual.

4.7 Error Messages

Refer to section 9.6.17 of Z+ series User Manual.

4.8 Execution Time

Command execution time except for *CLS (150mS) is less than 15 milliseconds.

INST:NSEL 06 11 millisecond

OUTP:STAT ON 12 millisecond

:VOLT 15 10 millisecond

WAVE:TIME 1,1,1,1,1,1,1,1,1,1,1,1 14 millisecond

Query execution time is between 20-50 milliseconds. Response is dependent upon string length.

WAVE:VOLT? 45 millisecond

SYST:ERR? 22 millisecond

*IDN? 38 millisecond

INST:NSEL? 20 millisecond

It is required that the user adds a delay after a command before sending any further messages.

(Refer to Table 4-2)

Page 14

13

LSB

MSB

STAT:OPER:COND?

STAT?

STAT:OPER:ENAB nnnn

STAT:OPER:ENAB?

SENA nnnn

SENA?

STAT:OPER:EVEN?

SEVE?

Condition

Enable

Event

Operational Condition

LSB Condition Enable

Standard Event Status

*ESR? *ESE nn

*ESE?

PON

_ \_Power On

0

0User Request

CME

_ \_Command Error

EXE

_ \_Execution Error

DDE

_ \_Device Depandant Error

QYE

_ \_Query Error

OPC

_ \_Operation Complite

0

0Not Used

CV

_ \_ CV

Constant Voltage

CC

_ \_ CCConstant Current

NFLT

_ \_ NFLTNo Fault

TWI

0 0Trigger Wait

AST

0 0

Auto Start Enabled

FBE

_ \_ FBEFoldback Enable

LSC

_ \_ LSCList Step Complite

LOC

_ \_ LOCLockal / Remote

OR

UVPE _ \_ UPE

UVP enabled

ILCE

_ \_ ILCEInterlock enable

0

0 0Reserved

CFBM

_ \_ FBMCurrent Foldback mode

AVP

_ \_ AVP

Analog Voltage Channel

ACP

_ \_ ACPAnalog Current Channel

DWE

0 0List Step Active

0

0 0Reserved

OR

MSB

M E S S A G E

Output Queue

LSB

MSB

STAT:QUES:COND?

FLT?

STAT:QUES:ENAB nnnn

STAT:QUES:ENAB?

FENA nnnn

FENA?

STAT:QUES:EVEN?

FEVE?

Condition

Enable

Event

AC _ \_ ACAC Fail

OTP

_ \_ OTPOver Temperature

FLD

_ \_ FLDFoldback (tripped)

OVP

_ \_ OVP

Over Voltage Protection

SO

_ \_ SOShut Off

OFF

_ \_ OFFOutput Off

INT

_ \_ INTInterlock

OR

UVP _ \_ UVP

Under Voltage Protection

0

_ \_ 0Not used

INPO

_ \_ INPOInternal Input Overflow

INTO

_ \_ INTOInternal Overflow

ITMO

_ \_ ITMO

Internal Time Out

ICOM

_ \_ ICOMInternal Comm Error

0

_ \_ 0Not used

0

0 0Not used

NOR

*SRE?

OR

00

0BSY

_ \_SYS

_ \_QUE

_ \_MAV

_ \_ESB

0RQS

_ \_OPR

*SRE nn*STB?

Service Request Enable

Staus byte

Service Request

0 , N o E r r

1 0 2 , S y n t

2 2 2 , D a t a

1 4 1 , I n v a

r

t

e

a

Syst:Err Queue

Command Erroe "Cnn"

Execution Error "Enn"

OR

Language select

Positive Logic

0 = No Event

1 = Event Occured

OR

!nn(SRQ)

7

6

5

4

3

2

0

1

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Questionable Summary

Message Available

Standard Event Summary

Operation Summary

GEN

SYST ERR?

System Error

Busy

To Instrument Summary register

Fault Registers

Fig.4- 1: Status Register and SRQ Tree

ADDRESSED COMMAND/QUERY 10 milliseconds

GLOBAL COMMAND 20 milliseconds

Table 4-2: Addition of Delay

Page 15

14

Fig.4‐2: Instrument Summary Register Tree for Multi Drop Mode

Page 16

15

CHAPTER 5: COMMUNICATION EXAMPLE

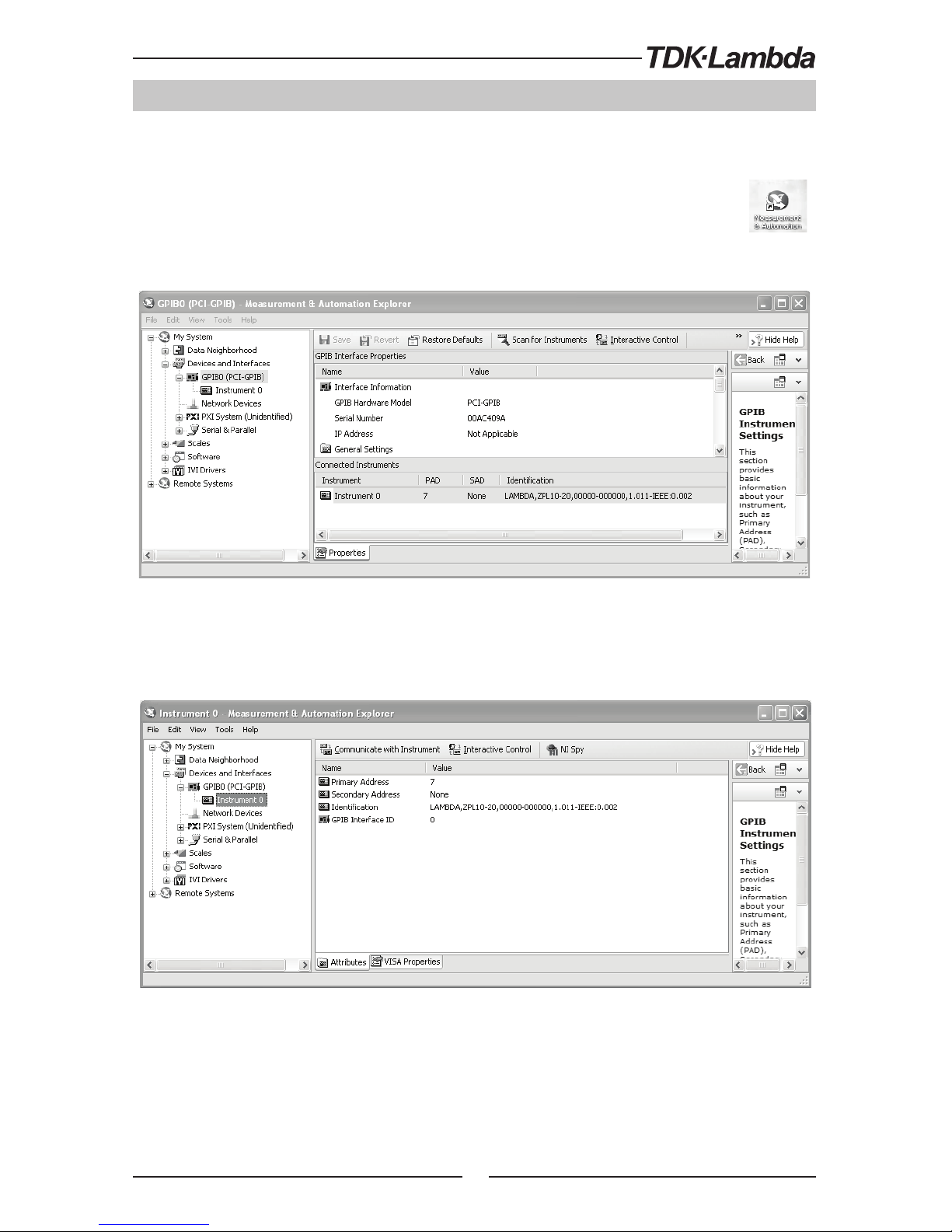

This section provides an example the National Instruments™ MAX program to communicate with

the Z+.

1. Run National Instruments™ MAX (Measurement & Automation Explorer) program

2. Select “Devices and Interfaces” -> “GPIB0” press Scan for Instruments. Refer to Fig.4-1

3. In the right window, click on Instrument0 and review the device properties. Refer to Fig.4-2

Fig.5-1: Scanning for Instrument

Fig.5-2: Instrument Properties

Page 17

16

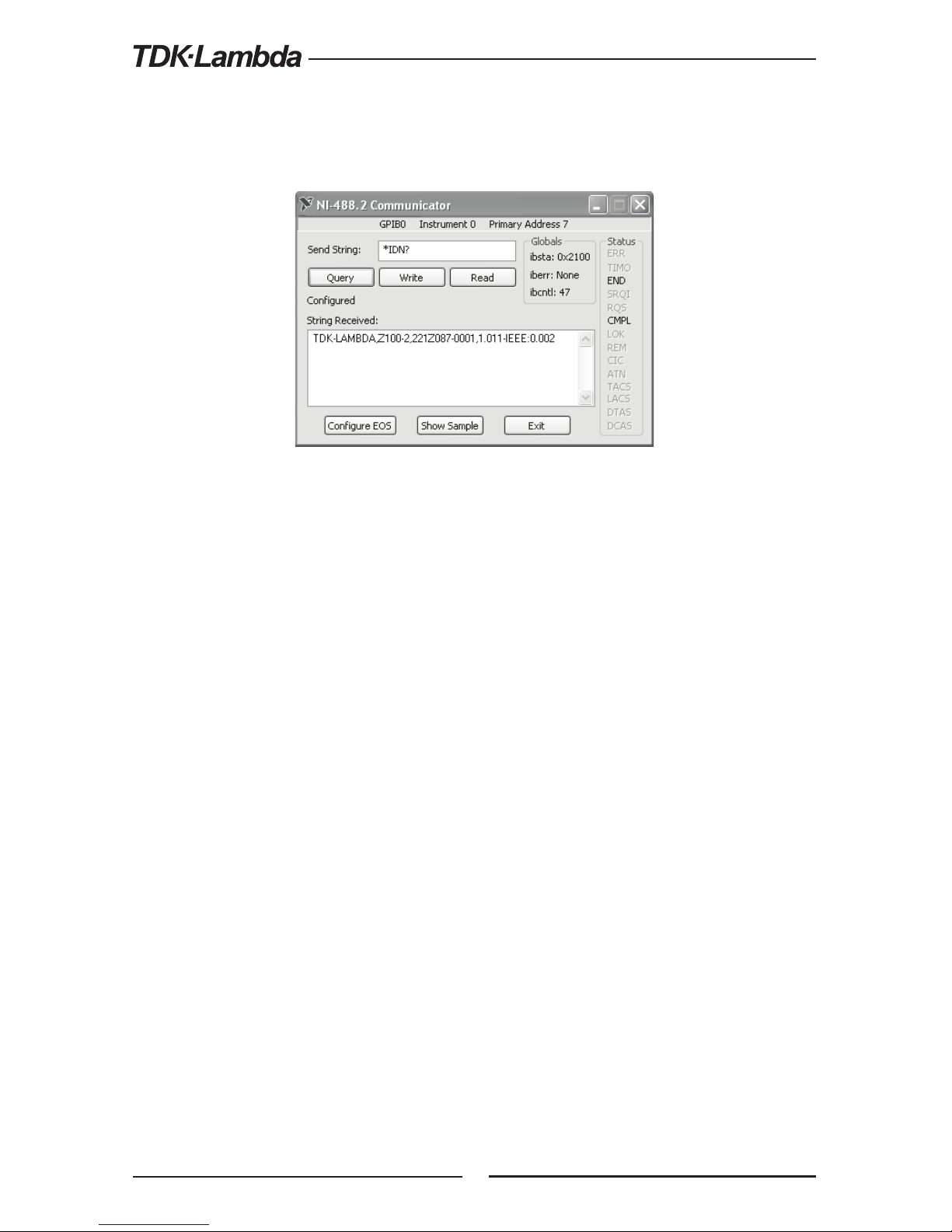

4. Click Communicate with Instrument in the GPIB Explorer toolbar. NI-488.2 Communicator

appears. Refer to Fig. 4-3

5. In the Send String box, *IDN? appears. Click Query. The ID string indicates the model, serial

number, firmware version and the GPIB card firmware version. This will be shown in the text

box below String Received. Refer to Fig.4-3.

Fig.5-3: ID String Query

IA710-04-03A

Page 18

TDK-Lambda EMEA

www.emea.tdk-lambda.com

Innovating Reliable Power

AD0412

IA710-04-03A

NORTH AMERICA

TDK-Lambda Americas Inc.

3055 Del Sol Boulevard San Diego, CA 92154 U.S.A.

Tel: +1-619-575-4400

Fax: +1-619-575-7185

www.us.tdk-lambda.com/lp

UK

TDK-Lambda UK Ltd.

Kingsley Avenue Ilfracombe, Devon

EX 34 8ES United Kingdom

Tel: +44-1271-856666 Fax: +44-1271-864894

E-mail: powersolutions@uk.tdk-lambda.com

www.uk.tdk-lambda.com

FRANCE

TDK-Lambda France SAS

ZAC des Delaches

BP 1077 - Gometz le Chatel

91940 LES ULIS

Tel: +33 1 60 12 71 65

Fax: +33 1 60 12 71 66

E-mail: france@fr.tdk-lambda.com

www.fr.tdk-lambda.com

GERMANY

TDK-Lambda Germany GmbH

Karl-Bold-Str.40,

D-77855 Achern, Germany

Tel: +49-7841-666-0 Fax: +49-7841-500-0

E-mail: info.germany@de.tdk-lambda.com

www.de.tdk-lambda.com

AUSTRIA

TDK-Lambda Austria Sales Office

Aredstrasse 22,

A - 2544 Leobersdorf, Austria

Tel: +43-2256-65584 Fax: +43-2256-64512

E-mail: info.germany@de.tdk-lambda.com

www.de.tdk-lambda.com

ITALY

TDK-Lambda Italy Sales Office

Via dei Lavoratori 128/130

IT20092 Cinisello Balsamo, Milano, Italy

Tel: +39-02-6129-3863 Fax: +39-02-6129-0900

E-mail: info.italia@it.tdk-lambda.com

www.it.tdk-lambda.com

ISRAEL

TDK-Lambda Ltd.

Sales Office: Kibbutz Givat Hashlosha Tel-Aviv

4880000, Israel

Tel: +972-3-9024-333 Fax: +972-3-9024-777

Plant: 56 Haharoshet St., POB 500

Karmiel Industrial Zone 2165158, Israel

Tel: +972-4-9887-491 Fax: +972- 4-9583-071

www.tdk-lambda.co.il E-mail: info@tdk-lambda.co.il

JAPA N

TDK-Lambda Corporation

International Sales Divison

Nittetsu Bldg. 6F, 1-13-1 Nihonbashi, Chuo-ku, Tokyo 103-0027, Japan

Tel: +81-3-5201-7175

Fax: +81-3-5201-7287

www.tdk-lambda.com

CHINA

Shanghai Branch of Wuxi TDK-Lambda Electronic Co. Ltd.

28F, Xingyuan Technology Building No.418, Guiping Road,

Shanghai, China 200233

Tel: +86-21-6485-0777 Fax: +86-21-6485-0666

www. cn.tdk-lambda.com

Beijing Branch of Wuxi TDK-Lambda Electronic Co. Ltd.

Room 12B11-12B12, Unit 7 DACHENG SQUARE, No.28

Xuanwumenxi Street, Xuanwu District Beijing, 100053, CHINA

Tel: +86-10-6310-4872 Fax: +86-10-6310-4874

www. cn.tdk-lambda.com

Shenzhen Branch of Wuxi TDK-Lambda Electronics Co.Ltd.

Room 4302, Excellence Times Square Building,

4068 Yi Tian Road, Futian District,

Shenzhen, China 518048

Tel: +86 -755-83588261 Fax: +86 -755-83588260

www. cn.tdk-lambda.com

KOREA

TDK-Lambda Corporation Seoul Office

8F Songnam Bldg, 1358-6, Seocho-Dong,

Seocho-Gu, Seoul, 137-862 KOREA

Tel: +82-2-3473-7051

Fax: +82-2-3472-9137

www.tdk-lambda.co.kr

www.tdk-lambda.co.kr

SINGAPORE

TDK-Lambda Singapore Pte.Ltd.

Blk 1008 Toa Payoh North # 07-01/03

Singapore 318996

Tel: +65-6251-7211 Fax: +65-6250-9171

www.tdk-lambda.com.sg

INDIA

TDK-Lambda Bangalore Office

#526, Ground Floor, 10th Main, 7th Cross,

Jeevanbhimanagar , Bangalore 560 075

Karnataka , India

Tel: +91-80-43550 550

Fax: +91-80-43550 501

www.tdk-lambda.com.sg

MALAYSIA

TDK-Lambda Malaysia Sdn. Bhd.

c/o TDK (Malaysia) Sdn Bhd

Lot 709, Nilai Industrial Estate 71800 Nilai

Negeri Sembilan, Malaysia

Tel: + 60 6-799 1130

Fax: + 60 6 799 3277

www.tdk-lambda.com.my

Loading...

Loading...