Page 1

HFE2500-S1U RACK INSTRUCTION MANUAL

HFE2500-S1U SERIES RACK SPECIFICATIONS

1

Number of power supply

modules to be inserted

(*1) --- Maximum of 4 x HFE2500 of the same model (output voltage rating and options).

2 Maximum output power W 9500W for 4 units inserted, refer to HFE2500 specifications for derating.

3 Maximum output current A 320A per output (Total 640A)

4 Input voltage / frequency range

(*2)

--- 85~265Vac continuous, 47~63Hz, Single phase, separate input for each PS module.

5

Maximum input current

(at 115/230Vac)

A 15/12 for each HFE2500 power supply module.

6 Maximum Line Regulation (*4) Less than 0.25% of rated output voltage

7 Maximum Load Regulation (*5) Less than 0.8% of rated output Current

8 AC input connector (*6) ---

Separate for each power supply. HFE2500-S1U: IEC inlet, type C20.

* HFE2500-S1U /TB: Terminal Block.

9 Output terminals ---

Two bus-bars outputs for each output terminal (two sides).

Refer to outline drawing.

10 Remote sensing

(*3)

V Possible. Refer to Fig 3.2.

11 Parallel operation --- Possible. Refer to Fig 3.9.

12 Series operation --- Possible. Refer to Fig 3.10.

13

Remote On/Off control

(INHIBIT)

---

Separate control for each PS unit, by electrical signal or dry contact.

"OFF": 0~0.6V or short. "ON": 2~15V or open. Refer to Fig 3.4.

14

Remote On/Off control

(ENABLE)

---

Common for all PS units, by electrical signal or dry contact.

"ON": 0~0.6V or short. "OFF": 2~15V or open. Refer to Fig 3.3.

15 DC OK signal ---

Separate signal for each PS unit, Open collector signal. Maximum sink current:

10mA. Tracking output setting, "LOW" when Vout>90+/-5% from output voltage

setting. Refer to Fig 3.5

16 AC fail signal ---

Separate signal for each PS unit. Open collector signal. Maximum sink current:

10mA "LOW" when input voltage is 85Vac<Vin<270Vac. Refer to Fig 3.5

17 Over Temperature alarm signal ---

Separate signal for each PS unit. Open collector signal. Maximum sink current 10mA

"LOW" when the internal temperature of the unit is within safe limit,

"HIGH" approximately 10°C below Thermal shut down. Refer to Fig 3.5

18 Output voltage trimming --- Common for all PS units, by built-in potentiometer. Refer to Sec 1.4.

19

Output voltage programming

by external voltage

--- Common for all PS units, by 0~5V signal. Refer to Fig 3.6.

20

OCP programming by external voltage

--- Common for all PS units, by 0~5V signal. Refer to Fig 3.6.1.

21

Output voltage programming

via PMbus interface

--- Common for all PS units. Refer to Instruction Manual Fig 3.7.

22

OCP programming via PMbus interface

--- Common for all PS units. Refer to Instruction Manual. Refer to Fig 3.7.1.

23 Auxiliary power supply 11.2~12.5VDC. Maximum output current: 0.5A.

24 Operating temperature ---

-10~+50°C -- 100% load.

+50°C to +60°C -- Derating 2%/°C.

+60°C to +70°C -- Derating 2.5%/°C.

25 Storage temperature --- -30~+85°C

26 Operating humidity --- 10~90% RH, no condensation.

27 Storage humidity --- 10~95% RH, no condensation.

28 Vibration --- Built to meet IEC60068-2-64 (Basic Transportation)

29 Shock --- Built to meet IEC60068-2-27 (Basic Transportation)

30 Applicable safety standards UL60950-1 Second Edition, EN60950-1 Second Edition

31 Withstand voltage ---

Input-Output: 3000Vrms, 1min. Input-Ground: 2000Vrms, 1min.

Output-Ground: 12V,24V models - 500Vrms, 1min.

Output-Ground: 48V model - 2250Vdc, 1min.

32 Insulation resistance --- More than 100Mohm at 25°C and 70% RH. Output-Ground: 500Vdc

33 Weight (Typ) (with accessories) kg 5.0

34 Size (W*H*D) mm 445x43.6x401 Refer to Outline Drawing.

Notes:

*1. Mixing of PMBus option units (HFE2500-xx/s) and standard units (HFE2500-xx) is not allowed.

The Output of all HFE2500 Modules are connected in parallel in the Rack.

*2. For cases where conformance to various safety standards (UL, EN etc.) is required, Input Voltage is to be described as 100-240Vac (50/60Hz).

*3. Maximum voltage drop on load connection: HFE2500-12: 0.25V/wire, HFE2500-24: 0.5V/wire, HFE2500-48: 1V/wire.

*4. From 85~132Vac or 170~265Vac constant load.

*5. From No-load to rated load, constant input voltage. Measured at the sensing point in remote sense.

*6 Use UL approved Insulated terminal lugs.

1

Page 2

SAFETY APPROVALS

UL 60950-1 and CSA22.2 No.60950-1 - UL Recognized. C-UL for Canada.

IEC 60950-1 - CB Report and Certificate.

EN 60950-1 - CE mark.

Marking by the CE Symbol indicates compliance to the Low Voltage Directive of the European Union.

A “Declaration of Conformity” in accordance with the preceding directives and standards has been made and is on file at our EU

representative TDK LAMBDA UK, located at Kingsley Avenue, Ilfracombe, Devon EX34 8ES, UK.

A “Declaration of Conformity” may be accessed via company website www.uk.tdk-lambda.com/technical-data

2

Page 3

SAFETY INSTRUCTIONS

CAUTION: The following safety precaution must be observed during all phases of operation, service and repair of this equipment.

Failure to comply with the safety precautions or warnings in this document violates safety standards of design, manufacture and

intended use of this equipment and may impair the built-in protections within. TDK Lambda shall not be liable for user’s failure to

comply with these requirements.

CAUTION: HFE2500-S1U rack is not authorized for use as critical component in nuclear control systems, life support systems or

equipment for use in hazardous environments without the express written approval of the managing director of TDK-Lambda.

INSTALLATION (OVERVOLTAGE) CATEGORY& ENVIRONMENTAL CONDITIONS

The HFE2500-S1U has been evaluated to Overvoltage category II.

The HFE2500-S1U intended for use in the following operation conditions:

* Indoor use * Pollution degree 2 * Max. operational altitude: 3000m above sea level

*Ambient temperature: -10°C-50°C at 100% load, up to 70°C with output de-rating applied (refer to Specification above).

GROUNDING

HFE2500-S1U rack is Class I product. To minimize shock hazard, the HFE2500-S1U rack must be connected to an electrical ground.

The instruments must be connected to the AC power supply mains through a three conductor power cable, with the ground wire

firmly connected to an electrical ground (safety ground) at the power outlet. For instruments designed to be hard-wired to the

supply mains, the protective earth terminal must be connected to the safety electrical ground before any other connection is made.

Any interruption of the protective ground conductor or disconnection of the protective earth terminal will cause a potential shock

hazard that might cause personal injury.

LIVE CIRCUITS

Operating personnel must not remove the HFE2500-S1U rack cover.

No internal adjustment or component replacement is allowed by non-TDK Lambda qualified service personnel. Never replace

components with power cable connected. To avoid injuries, always disconnect power, discharge circuits and remove external voltage

sources before touching components.

Restricted Access Area: HFE2500-S1U rack should only be installed in a Restricted Access Area. Access should be available to service

personnel only.

PARTS SUBSTITUTIONS & MODIFICATIONS

Parts substitutions and modifications are allowed by authorized TDK Lambda service personnel only. For repairs or modifications, the

instrument must be returned to TDK Lambda service facility.

AC INPUT, AC INPUT RATING, AC POWER CABLES

CAUTION

Risk of electrical shock and energy hazard. Disconnecting one

power supply line disconnects only one power supply module.

To isolate the unit completely, disconnect all power supply

lines. Terminal blocks should only be used by professional

workers to connect AC cables.

ACHTUNG

Spannungsführende Teile - Gefahr durch elektrischen Schlag

order hohe Energieinhalte. Alle Netzstecker der einzelnen

Komponenten bzw. der Einschübe müssen getrennt werden,

damit das System “spannungsfrei” ist.

Die Eingangsklemme der Stromversorgung ist nur innerhalb

eines Gesamtsystemes zu verwenden.

ATTENTION

Risque de choc et de danger e’lectriques. Le de’branchement

d’une seule alimenttation stabilise’e ne de’branche

uniquement qu’un module “Alimentation Stabilise’e”.

Pour isoler completement le module en cause, il faut

de’brancher toutes les alimentations stabilise’es.

Do not connect HFE2500-S1U to mains supply exceeding the input

voltage and frequency rating of HFE2500-S1U. The input voltage

and frequency rating is: 100-240V~, 50/60Hz. For safety reasons,

the mains supply voltage fluctuations should not exceed +/-10% of

nominal voltage.

AC Cables are not provided with unit. Refer to table below for recommended AC cables.

HEAT HAZARD

WARNING: Top, bottom and side surfaces may become hot when operating the unit continuously. To reduce the risk of injury from a

hot surface, allow the surface to cool before touching.

ENERGY HAZARD

The main output of HFE2500-S1U is capable of providing hazardous energy. Due to hazardous energy level the output bus bars and

connections therefore must not be user accessible. Manufacturer’s final equipment must provide protection to service personnel

against inadvertent contact with output bus bars.

HFE2500- S1U HFE2500- S1U/TB

Standard high temprature power cable with type C19

appliance plug rated: EU - 16A/250V; US/C - 20A/250V

Min. - 14AWG (1.5 mm2), rated Min. 300Vac,

80ºC for supply and ground connection.

Terminal Lug - Use UL approved Insulated terminal lugs.

3

Page 4

SYMBOLS

CAUTION Risk of Electrical Shock.

Instruction manual symbol. The instrument will be marked with this symbol when it is necessary for the user

to refer to the instruction manual.

Indicates hazardous voltage.

This symbol indicates the presence of a hot surface or component. Touching this surface could result in bodily injury.

Indicates ground terminal.

Protective Ground Conductor Terminal

L1 Indicates first Line supply terminal

L2/N Indicates second Line or Neutral supply terminal

Denotes hazard. An attention to a procedure is called. Not following the procedure correctly could result in

personal injury. A WARNING sign should not be skipped and all indicated conditions must be fully understood

and met.

Denotes hazard. An attention to a procedure is called. Not following the procedure correctly could result in

damage to the equipment.

FUSES

There are no fuses in the HFE2500-S1U rack.

OVERCURRENT PROTECTION:

A readily accessible branch circuit over current protective device rated 30A max. per each input must be incorporated in the building wiring.

The protective device must disconnect both supply line simultaneously.

4

Page 5

SICHERHEITS - HINWEISE

Vorsicht

Die folgenden Sicherheitsvorschriften müssen vor Inbetriebnahme und in jedem Betriebszustand bei Service oder Reparatur

beachtet werden. Missachtung der Sicherheitsvorschriften und Warnhinweise aus diesem Handbuch führen zur Verletzung der

bestehenden Sicherheitsstandards. Bei Betrieb des Gerätes ausserhalb dem bestimmungsgemässen Einsatz können die im Gerät

integrierten Schutzfunktionen beeinträchtigt werden. TDK-Lambda ist nicht haftbar für Schäden, die durch Missachtung dieser

Sicherheitsvorschriften entstehen können.

Vorsicht

Das HFE2500-S1U-Rack ist nicht für die Verwendung als kritische Komponente in nuklearen Steuerungssystemen, lebenserhaltenden

Systemen oder Geräte für den Einsatz in gefährlichen Umgebungen, ohne die ausdrückliche schriftliche Genehmigung durch TDKLambda zugelassen

Betriebsbedingungen und Umweltbedingungen

Das HFE2500-S1U-Rack ist zur Installation gemäss Überspannungs-Kategorie 2 evaluiert worden.

Das HFE2500-S1U-Rack ist gemäss den Sicherheitsabnahmen für folgende Betriebsbedingungen bestimmt.

* Stationäre Einrichtungen in Gebäuden.

* Verschmutzungsgrad 2.

* Erlaubte Betriebshöhe: bis zu 3000m.

* Umgebungstemperaturbereich: -10 bis +50° C, bis zu 70°C mit Derating (Details entnehmen Sie bitte dem Datenblatt)

Erdungskonzept

Dieses Produkt ist ein Gerät der Schutzklasse 1. Zur Vermeidung von gefährlichen Energieinhalten und Spannungen, ist das Gehäuse

an eine Schutzerde anzuschliessen. Der PE-Anschluss ist an einen festen Erder anzuschliessen. Bei Festverdrahtung des Gerätes ist

sicherzustellen, dass der PE Anschluss als erstes angeklemmt wird. Jede mögliche Unterbrechung des PE-Leiters oder Trennung der

PE Verbindung kann einen möglichen elektrischen Schlag hervorrufen, der Personenschäden zur Folge hätte.

Spannungsführende Teile

Die Geräteabdeckung darf nicht durch Endanwender geöffnet werden. Interne Modifikationen, sowie Bauteileaustausch ist nur

durch TDK-Lambda qualifiziertes Personal erlaubt. Vor Austausch von Bauteilen ist das Netzkabel bzw. die Versorgungsspannung

zu trennen. Energieversorgungsanschlüsse sind immer zu trennen, um Personenschäden durch gefährliche Energieinhalte und

Spannungen auszuschliessen. Die Stromkreise sind zu entladen, externe Spannungsquellen sind zu entfernen, bevor auf Bauteile

bzw. Komponenten Ebene gearbeitet wird.

Änderungen und Bauteileersatz

Ersatzteilaustausch - und Änderungen dürfen nur von autorisiertem TDK-Lambda SERVICE-PERSONAL durchgeführt werden. Für

Reparaturen oder Änderungen ist das Gerät zur TDK-Lambda Service-Niederlassung zu retournieren.

Anschluss an Versorgungsstromkreis

Der Betrieb des HFE2500-S1U ist nur für den dafür spezifizierten Wechselspannungsbereich und der angegebenen

Frequenz erlaubt. Die Eingangsspannung und Frequenz ist: 100-240V ~ bei 50/60Hz. Aus Gründen der Sicherheit sollten die

Netzspannungsschwankungen im Bereich von + / -10% der Nennspannung liegen.

Heisse Oberflächen

WARNUNG: Im Dauerbetrieb erwärmen sich die Gehäuseoberflächen. Um das Verletzungs-Risiko durch heisse Oberflächen zu

minimieren, sollte das Gerät einige Zeit abkühlen können, bevor weitere Arbeiten durchgeführt werden.

Gefährlicher Energieinhalt

Der Hauptausgang des HFE2500-S1U liefert gefährlich hohe Energieinhalte. Aufgrund der gefährlichen Energieinhalte müssen die

Stromschienen und die Ausgangsanschlüsse abgedeckt sein und dürfen für den Benutzer nicht zugänglich sein. Der Endgeräte

Lieferant hat für die Berührungssicherheit der Ausgänge und Stromschienen Sorge zu tragen.

Überstromschutz

Eine leicht zugängliche Vorsicherung mit 30A max.. pro Eingang muss in der Hausinstallation vorgesehen werden

SICHERUNGEN

Das HFE2500 S1U-Rack selbst verfügt über keine Absicherung

5

Page 6

VORSICHT Spannungsführende Teile-Gefahr durch elektrischen Schlag bzw. Energieinhalte.

Handbuch-Symbol. Das Gerät bzw. Geräteteile warden mit diesem Symbol gekennzeichnet, wenn es für den

Benutzer notwendig ist, sich auf die Anweisungen im Handbuch zu beziehen.

Zeigt “spannungsführende Teile” mit gefährlicher Spannung an.

Dieses Symbol weist auf das Vorhandensein einer heißen Oberfläche oder Komponente. Das Berühren dieser

Oberfläche kann zu Verletzungen führen.

Zeigt Masse-Anschluss an, keine Schutzerde. ( z.B .Masseanschluss an einen Verbraucher).

Schutzleiter-Anschlussklemme.

WARNUNG

Dieser Warnhinweis beschreibt Gefahren, deren Nichteinhaltung zu Personenschäden führen können. Die

Warnhinweise müssen daher zwingend wie im Handbuch beschrieben in der Applikation eingehalten

werden.

ACHTUNG

Diese Sicherheitsinformation weist auf Gefahren im täglichen Umgang mit dem Gerät hin, deren

Missachtung zu Fehlfunktionen oder Defekten in deer Applikation führen können. Bitte lesen Sie diese

Sicherheitsinformationen , bevor Sie das Gerät einbauen oder in Betrieb nehmen.

Sicherheits- und Warnsymbole

6

Page 7

1.1. J1 Connector for Control and Monitoring

Mating for J1 Control Plug (provided) or custom made plug/ cable should be inserted to J1 for proper operation of HFE2500 rack.

Refer to Chapter 3 for connection diagrams.

J1 Pin Allocation Chart see Table 1.1

J1 connector description: P/N IPLT1-120-01-L-D-RA (SAMTEC)

Mating Plug description: P/N IPD1-20-D (SAMTEC)

1. REAR PANEL CONNECTIONS AND CONTROLS

Fig 1.1 Rear view of HFE2500-S1U series

HFE2500-S1U

HFE2500-S1U/TB

AC Line Inputs

Output Bus Bars

+

+

-

-

J2

J1

AC Line Inputs

Output Bus Bars

++-

-

Control Mating Plug

J1

40

2

39

1

Adjustment trimmer

Address Selection

7

Page 8

Pin # Name Description Pos. #

Control

plug J1

Referenced to

1,10 -SENSE Negative sense Connected to –LS for local sensing, or –V on Load side. All

Short

2 -LS Connected to Negative Output bus bar through 3 Ohm resistor. All

3 +SENSE Positive sense Connected to +LS for local sensing, or +V on Load side. All

Short

4 +LS Connected to Positive Output bus bar through 3 Ohm resistor. All

5 V_PROG

Input (0~5V) referenced to –S. Provides Vout programming by Voltage.

Refer to Fig 3.6, 3.7.

All

Short

-SENSE

6 TRIM Output of Rear Panel potentiometer, for manual adjustment of Output Voltage. All -SENSE

7 I_PROG

Input (0-5V) referenced to -S. Provided current limit programming by external voltage.

Refer to Fig 3.6.1 and 3.7.1

All Short -SENSE

8,9 +5V/V_REF

5V fix output for standard option unit.

V_REF for Voltage and Current programming when PMBus option is being used.

All -SENSE

11 TEMP_ALM_A

Output signal of PS in position A.

"LOW" when the internal temperature is within safe limit,

"HIGH" approximately 10°C below Thermal shut down.

Open Collector (15V Max, sink Current 10mA max)

A SIGNAL RETURN

12 TEMP_ALM_B Output signal of PS in position B. Same as 11. B SIGNAL RETURN

13 TEMP_ALM_C Output signal of PS in position C. Same as 11. C SIGNAL RETURN

14 TEMP_ALM_D Output signal of PS in position D. Same as 11. D SIGNAL RETURN

15 NOT CONNECTED

16 AC_FAIL_A

Output signal of PS in position A.

"LOW" when the input voltage is 85Vac<Vin<270Vac,

"HIGH" when the input voltage is 85Vac>Vin or Vin>270Vac.

Open Collector (15V Max, sink Current 10mA max)

A SIGNAL RETURN

17 AC_FAIL_B Output signal of PS in position B. Same as 16. B SIGNAL RETURN

18 AC_FAIL_C Output signal of PS in position C. Same as 16. C SIGNAL RETURN

19 AC_FAIL_D Output signal of PS in position D. Same as 16. D SIGNAL RETURN

20 NOT CONNECTED

21 DC_OK_A

Output signal of PS in position A.

"LOW" when the output voltage is higher than 85~95% of Vout setting.

Open Collector (15V Max, sink Current 10mA max)

A SIGNAL RETURN

22 DC_OK_B Output signal of PS in position B. Same as 21. B SIGNAL RETURN

23 DC_OK_C Output signal of PS in position C. Same as 21. C SIGNAL RETURN

24 DC_OK_D Output signal of PS in position D. Same as 21. D SIGNAL RETURN

25 NOT CONNECTED

26

37

40

SIGNAL

RETURN

Reference for: ENABLE, INHIBIT, TEMP ALARM, AC FAIL, DC OK, +12V AUX, SCL,

SDA, SMB ALERT.

The SIGNAL RETURN is isolated from the output.

All

27 INHIBIT_A

Input for PS in position A.

Turns OFF the Main Output by electrical signal or dry contact.

"SHORT" or 0~0.6V – Output OFF. "OPEN" or 2~15V – Output ON.

A SIGNAL RETURN

28 INHIBIT_B Input signal for PS in position B. Same as 27. B SIGNAL RETURN

29 INHIBIT_C Input signal for PS in position C. Same as 27. C SIGNAL RETURN

30 INHIBIT_D Input signal for PS in position D. Same as 27. D SIGNAL RETURN

31 NOT USED NOT CONNECTED

32 PS_EXIST_A

Output signal of PS in position A.

SHORT to Signal Return when PS is inserted into the Rack.

A SIGNAL RETURN

33 PS_EXIST_B Output signal of PS in position B. Same as 32. B SIGNAL RETURN

34 PS_EXIST_C Output signal of PS in position C. Same as 32. C SIGNAL RETURN

35 PS_EXIST_D Output signal of PS in position D. Same as 32. D SIGNAL RETURN

36 NOT USED NOT CONNECTED

38 +12V_AUX Output. Auxiliary supply 11.2~12.5VDC. Not affected by any signal or fail state. SIGNAL RETURN

39 ENABLE

Input for entire rack. Turns ON the Main Output by electrical signal or dry

contact. "SHORT" or 0~0.6V – Output ON. "OPEN" or 2~15V – Output OFF.

All Short SIGNAL RETURN

Table 1.1 J1 Connector Pin Allocation Chart

8

Page 9

1.2. J2 Pin Allocation Chart

J2 connector (RJ45 type) is used for parallel connection of two Racks.

Table 1.2

1.3. Output Bus Bar Connections

The HFE2500-S1U has two identical Output Bus Bar connections on both sides of Rear Panel.

They are connected in parallel in the Rack.

Each or both of them can be used for output connections.

ATTENTION: Maximum allowable current for each pair of Output Bus Bars – 320A. Total Output Current: 640A

Fig 1.3a Output Bus-Bars.

Fig 1.3b Installation of Output Bus-Bars Protection Cover.

IN OUT

Pin # Name Pin # Name

1 CURRENT SHARE 1 CURRENT SHARE

2 I_PROG 2 I_PROG

3 V_PROG 3 V_PROG

4 -SENSE 4 -SENSE

5 SCL (PMBus) 5 SCL (PMBus)

6 SIGNAL_RETURN 6 SIGNAL_RETURN

7 SDA (PMBus) 7 SDA (PMBus)

8 SMB_ALERT 8 SMB_ALERT

Pin 1

Pin 1

Model HFE2500-12 HFE2500-24 HFE2500-48

Output voltage range (V) 9.6~13.2 19.2~29.0 38.4~58

Protection Cover

Canoe Clip

MAXIMUM 320A

MAXIMUM 320A

1.4. Output Voltage adjustment Trimmer

Output Voltage may be adjusted by the Rear Panel Trimmer.

+ -

+ -

Pin 1

“NOTE - manual trim setup not to be used with /S PMBus versions.

See section 3.7 Setup Output Voltage programming by PMBus

9

Page 10

1.5. PMBus address

Each slot in the Rack (see fig-2.2) has its own address for PMBus communication. Valid only if /S option power supply is being used. In

case parallel connection of two racks is used, SW1 located at the rear panel is used to differentiate between addresses for the same slots.

see Table 1.5.

2. RACK MECHANICAL FEATURES

2.1. Insertion and extraction of the PS

2.2. Definition of Power Supplies Position

Fig 2.2 Power supply positions

Position In Rack SW1-1 SW1-2 Address (Bin)

A ON ON 0010000

B 0010010

C 0010100

D 0010110

A OFF OFF 0010001

B 0010011

C 0010101

D 0010111

SW1

To insert the power supply, push unit into

the rack with extraction handle closed.

To extract power supply, elevate the

release knob and pull the extraction handle

simultaneously.

Position A Position B Position C Position D

Release Knob

Fig 2.1

CAUTION

When inserting a power supply into the rack, do not use unnecessary force;

slamming the power supply into the rack can damage the connectors on the rear of the supply and inside the rack.

10

Page 11

2.3 Keying Option to define the Rack’s Voltage

Keying Option can be installed to ensure that only the correct Power Supply can be inserted into the Rack.

The Key Option consists of two parts: Power Supply Key (one per unit Fig 2.3a) and Rack Keys (5 per Rack Fig 2.3b).

Power Supply Key and Rack Keys should be fixed (by Flat head screws M3x6) in position corresponding to Output Voltage.

Fig 2.3a

Assembly of PS Key

Fig 2.3c

Example 24V Model with assembled Key.

Fig 2.3d

Example Rack Key assembled

for 24V power supplies

Fig 2.3b

Assembly of Rack Key (Rack Top View)

2.4 Blank Panel

In case all positions of the Rack are not filled with supplies, Blank Panel should

be used to ensure proper Air Flow.

It is recommended to interleave supplies and Blank Panels wherever possible.

Fig 2.4

Blank Panel mounting

Position of voltage key slot

11

Page 12

140.0

140.0

IA706-32-06_ IA706-32-07_

433.0 MINIMUM

563.0 MAXIMUM

IA706-32-06_

IA706-32-07_

2.5 Rack mounting options

Rack can be mounted into 19” Rack Cabinet which suits both USA and European Standards:

OPTION BRACKET

IA706-32-06_

OPTION BRACKET

IA706-32-07_

SEMS SCREW M5x10

2 PLACES MARKED "A"

FIX OPTION BRACKET IA706-32-06_

TO THE RACK ASSEMBLY IA706-32-01-00_

A

A

SEMS SCREW M5x10

2 PLACES MARKED "A"

FIX OPTION BRACKET IA706-32-07_

TO THE RACK ASSEMBLY IA706-32-01-00_

A

A

Fig 2.5 Mounting options, brackets

and screws are included.

Mounting for 19” USA Rack

Mounting for 19” Euro Rack

12

Page 13

3. Typical applications

3.1 Basic connection

For basic connection, the supplied Control Plug should be inserted to J1.

Fig 3.1 Basic connection diagram.

3.2 Remote sensing

ATTENTION:

1. Maximum voltage drop on load wires: HFE2500-12: 0.25V/wire, HFE2500-24: 0.5V/wire, 48: 1V/wire.

2. Twisted wires should be used for Remote Sense connection.

3. If Remote Sensing is used, do not break Main Output connection.

Fig 3.2 Remote Sensing connection diagram

3.3 On/Off control for the entire Rack

Switch closed: Output ON

Switch open: Output OFF

Fig 3.3 Entire rack On/Off control diagram.

13

Page 14

3.4 Individual On/Off control for each PS

Switch closed: Output OFF

Switch open: Output ON

Fig 3.4 individual units On/Off diagram.

3.5 Supervisory signals.

Following signals are accessible from each power supply at J1:

DC OK

AC FAIL

PS EXIST

TEMP ALARM

These signals are Open Collector type (Max 15V, 10mA), isolated from Output and referenced to SIGNAL RETURN.

Fig 3.5 presents example of the typical connection for DC OK signal of power supply in position A.

Fig 3.5 “DC OK” signal connection diagram for Power Supply in Position A.

3.6 Output Voltage programming by External Voltage.

Fig 3.6 Output Voltage programming by External Voltage.

Voltage Programming

0

10

20

30

40

50

60

0 1 2 3 4 5

V PROG (V)

V OUT (V)

38.4

19.2

9.6

58

29

13.2

48V Model

24V Model

12V Model

14

Page 15

3.6.1 Output Current programming by External Voltage.

Fig 3.6.1 Output Current programming by External Voltage.

3.7 Output Voltage programming by PMBus.

Fig 3.7 Output Voltage programming by PMBus

3.8 PMBus Host connection

To connect the rack to the Host computer, connect communication cable

(refer to table 3.8 for cable connection) between J2 and computer:

Table 3.8 PMBus Cable.

RJ45 Shielded Male Connector should be used.

Cable must be shielded; only connector shield is connected to cable shield.

Signal Name From pin Wire (AWG) To Host Note

SCL

5 22~24 -

Twisted pair

SIGNAL_RETURN

6 22~24 -

SDA

7 22~24 -

Twisted pair

SMB_ALERT

8 22~24 -

3.7.1 Output Current programming by PMBus.

Fig 3.7.1 Output Current programming by PMBus

15

Page 16

OFF

On

OFF

On

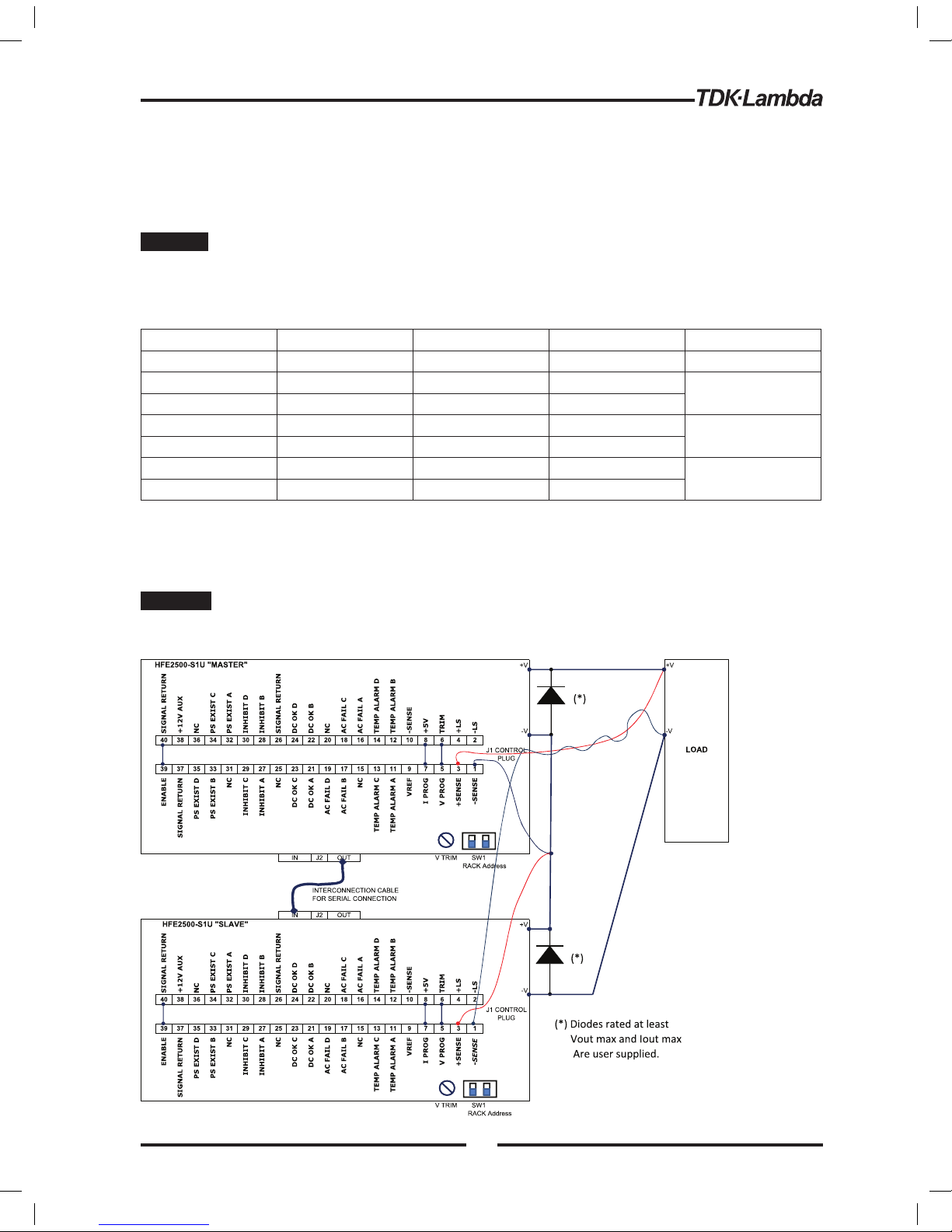

3.9 Parallel connection of two Racks

To connect two Racks in parallel for higher Output Current:

• Connect Main Output (Bus-Bars) in parallel. Make the connections as short as possible and with equal length.

• Connect Sense (twisted pairs) to Load point.

• Connect J2 connector of both Racks by Cable (for cable construction see Table 3.9).

• Slave - Disconnect connection between VPROG and TRIM (J1.5 and J1.6).

• Slave - Switch SW1 to “OFF” position (applicable for HFE2500-xx /S PMBus option). For addressing refer to Table 1.5.

• Output Voltage can be adjusted by the trimmer on Master Rack.

Table 3.9 Rack Interconnection Cable.

RJ45 Shielded Male Connectors should be used.

Cable must be shielded; only connector shields are connected to cable shield.

Fig 3.9 Racks parallel connection diagram.

*Note: For PMBUS OPTION in the master rack

1.Disconnect Pin 5&6

2. Connect Pin 5&9

Signal Name From pin Wire (AWG) To Pin Note

CURRENT SHARE

1 22~24 1 Twisted pair

V_PROG

3 22~24 3

Twisted pair

-SENSE

4 22~24 4

SCL

5 22~24 5

Twisted pair

SIGNAL_RETURN

6 22~24 6

SDA

7 22~24 7

Twisted pair

SMB_ALERT

8 22~24 8

16

Page 17

OFF

ON

OFF

ON

3.10 Series Rack connection

Up to 2 racks with the same number of power supplies and rating (voltage and current) can be used to increase the output voltage.

To connect two Racks in series:

• Connect Main Output (bus bars) in series;

• Connect Sense (twisted) to Load point (as shown in fig-3.10), or use Local Sensing using supplied Control Plugs.

• In case PMBus is used, Connect J2 connector of both Racks by Interconnect Cable for Serial connection (for cable construction see Table 3.10)

;

CAUTION

Do not use Cable as of Table 3.9.

• On one Rack put Switch SW1 to OFF position (only for HFE2500-xx /S PMBus option). For Addressing see Table 1.5;

• Output Voltage can be adjusted by potentiometers on both Racks.

RJ45 Shielded Male Connectors should be used. Cable must be shielded; only connector shields are connected to cable shield.

Diodes should be connected in parallel with each unit output to prevent reverse voltage. Each diode should be rated to at least the

power supply rated output voltage and output current.

WARNING

Do not connect -SENSE and any signals referenced to -SENSE between two Racks. Only signals referenced to SIGNAL RETURN

can be connected between Racks.

Table 3.10 Rack Interconnection Cable for Serial connection.

Fig 3.10 Serial connection diagram (remote sense).

Signal Name From pin Wire (AWG) To Pin Note

CURRENT SHARE

1 Open 1 Do not connect!

V_PROG

3 Open 3

Do not connect!

-SENSE

4 Open 4

SCL

5 22~24 5

Twisted pair

SIGNAL_RETURN

6 22~24 6

SDA

7 22~24 7

Twisted pair

SMB_ALERT

8 22~24 8

17

Page 18

426.5 ±1.0

1.2

409.0

1.0

10.0

2.0

445.0 ±1.0

11.0

A A A

A

HOLES FOR BLANK

PANEL MOUNTING.

USE FLAT HEAD SCREW

M3x6 8 PLACES

MARKED "A"

SEE NOTE 2.

MODEL KEY

FOR DIFFERENT

OUTPUT VOLTAGE

MODELS.

333.0 TYP x2

15.0 TYP x2

13.0 TYPx2

13.0 TYP x2

M5 HOLES FOR

MOUNTING BRACKETS.

4 PLACES

SEE NOTE 3.

483.0 ±1.0

24.5

43.6

+ 0.4

0.0

6.0

31.7

466.2 ±1.0

SEE NOTE 1.

14.0 TYPx2

16.0 TYPx2

17.0 TYPx2

22.0 TYP x2

125.8

82.5 61.0

214.5

10.7

88.5 273.6

14.0

24.6 TYP

MODULE "A"

MODULE "C"

MODULE "D"

OUTPUT

BUS BAR "-V"

OUTPUT

BUS BAR "+V"

OUTPUT

BUS BAR "-V"

OUTPUT

BUS BAR "+V"

PMBUS ADRESS

SEE NOTE 4.

MODULE "B"

AIR FLOW

DIRECTION

SEE NOTE 5.

MODULE "A"

MODULE "B"

MODULE "C"

MODULE "D"

CONNECTOR DESCRIPTION: IPLT1-120-01-L-D-RA(SAMTEC)

SIGNALS & CONTROL CONNECTOR PINS ASSIGNMENT

MATING CONNECTOR: IPD1-20-D (SAMTEC)

1402

39

4. REFER TO INSTRUCTION MANUAL FOR SETTING DETAILS.

5. MODEL NAME, VOLTAGE AND CURRENT RATING AND

SAFETY APPROVALS SYMBOLS WILL BE SHOWN HERE

ACCORDING TO THE SPECIFICATION.

6. THE HFE-S1U RACK IS SHOWN WITH 4 HFE2500

UNITS INSTALLED.

NOTES

1. MOUNTING HOLES FOR RACK 19". USE M6x12 SCREWS TO FIX THE

UNIT TO A RACK.

2. USE NUT,FLAT WASHER AND SPRING WASHER FOR LOAD WIRES

FIXING. USE LUG STUD M6 FOR LOAD WIRES.RECOMMENDED

TORQUE: 42-56 Kgf.cm

3. TO FIX THE MOUNTING BRACKET TO THE CHASSIS USE M5x10 SEMS

SCREWS .RECOMMENDED TIGHTENING TORQUE 27~31Kgf.cm.

SCREWS MUST NOT PENETRATE THE CHASSIS MORE THAN 6.0 mm.

HFE2500 - S1U Outline Drawing

18

Page 19

426.5 ±1.0

1.2

409.0

1.0

10.0

2.0

445.0 ±1.0

11.0

A A A

A

HOLES FOR BLANK

PANEL MOUNTING.

USE FLAT HEAD SCREW

M3x6 8 PLACES

MARKED "A"

SEE NOTE 2.

MODEL KEY

FOR DIFFERENT

OUTPUT VOLTAGE

MODELS.

333.0 TYP x2

15.0 TYP x2

13.0 TYPx2

13.0 TYP x2

M5 HOLES FOR

MOUNTING BRACKETS.

4 PLACES

SEE NOTE 3.

483.0 ±1.0

24.5

43.6

+

0.4

0.0

6.0

31.7

466.2 ±1.0

SEE NOTE 1.

14.0 TYPx2

16.0 TYPx2

17.0 TYPx2

22.0 TYP x2

82.7 60.8

214.5

10.7

88.5 273.8

14.0

15.5 TYP

125.8

MODULE "A"

MODULE "C"

MODULE "D"

OUTPUT

BUS BAR "-V"

OUTPUT

BUS BAR "+V"

OUTPUT

BUS BAR "-V"

OUTPUT

BUS BAR "+V"

PMBUS ADRESS

SEE NOTE 4.

MODULE "B"

AIR FLOW

DIRECTION

SEE NOTE 5.

MODULE "A"

MODULE "B"

MODULE "C"

MODULE "D"

CONNECTOR DESCRIPTION: IPLT1-120-01-L-D-RA-K(SAMTEC)

MATING CONNECTOR: IPD1-20-D-K (SAMTEC)

1402

39

SIGNALS & CONTROL CONNECTOR PINS ASSIGNMENT

10.0 10.0

TB CONNECTOR

SEMS SCREW M4

RECOMMENDED TORQUE

14~16Kgf.cm

SEE NOTE 6.

4. REFER TO INSTRUCTION MANUAL FOR SETTING DETAILS.

5. MODEL NAME, VOLTAGE AND CURRENT RATING AND

SAFETY APPROVALS SYMBOLS WILL BE SHOWN HERE

ACCORDING TO THE SPECIFICATION.

6. USE UL APPROVED INSULATED TERMINAL LUGS.

7. THE HFE-S1U RACK IS SHOWN WITH 4 HFE2500

UNITS INSTALLED.

NOTES

1. MOUNTING HOLES FOR RACK 19". USE M6x12 SCREWS TO FIX THE

UNIT TO A RACK.

2. USE NUT,FLAT WASHER AND SPRING WASHER FOR LOAD WIRES

FIXING. USE LUG STUD M6 FOR LOAD WIRES.RECOMMENDED

TORQUE: 42-56 Kgf.cm

3. TO FIX THE MOUNTING BRACKET TO THE CHASSIS USE M5x10 SEMS

SCREWS .RECOMMENDED TIGHTENING TORQUE 27~31Kgf.cm.

SCREWS MUST NOT PENETRATE THE CHASSIS MORE THAN 6.0 mm.

HFE2500 - S1U-TB Outline Drawing

19

Page 20

IA706-04-01G

20

Loading...

Loading...