Page 1

TECHNICAL MANUAL FOR

GENESYS

750W HALF RACK

Programmable DC Power Supplies

Document: 83-507-5002 Rev B

TM

TDK-Lambda Americas Inc.

405 Essex Road, Neptune, NJ 07753

Tel: (732) 922-9300

Fax: (732) 922-9334

Web: www.US.TDK-Lambda.com/HP

Page 2

Page 3

Page 4

GENESYS™ Manual Supplement

FOR UNITS EQUIPPED WITH “IEMD” OPTION.

ALSO REFER TO MANUAL 83-030-200 IEMD.

83-507-5002 Rev. B

Page 5

TABLE OF CONTENTS

WARRANTY…………………………………………………………………………………………….

Pg. 1

SAFETY INSTRUCTIONS……………………………………………………………………………..

Pg. 2

GERMAN SAFETY INSTRUCTIONS…………………………………………………………………

Pg. 4

CHAPTER 1 GENERAL INFORMATION

…………………………………………………………...

Pg. 6

1.1 USER MANUAL CONTENT……………………………………………………………………….

Pg. 6

1.2 INTRODUCTION……………………………………………………………………………………

Pg. 6

1.

2.1 General description…………………………………………………………………………..

Pg. 6

1.2.2 Models covered ……………………………………………………………………………...

Pg. 6

1.2.3 Features and options ………………………………………………………………………..

Pg. 6

1.2.4 Multiple output power system ……………………………………………

…………………

Pg. 7

1.2.5 Control via the serial communication port…………………………………………………

Pg. 7

1.2.6 Analog voltage programming and monitoring…………………………………………….

Pg. 7

1.2.7 Parallel operation…………………………………………………………………………….

Pg. 7

1.2.8 Ou

tput connections………………………………………………………………………….

Pg. 7

1.2.9 Cooling and mechanical construction……………………………………………………..

Pg. 8

1.3 ACCESSORIES…………………………………………………………………………………….

Pg. 8

1.3.1 Included Accessories………………………………………………………………………..

Pg. 8

1.3.3 AC cables …………………………………………………………………………………….

Pg. 8

CHAPTER 2 SPECIFICATIONS

……………………………………………………………………...

Pg. 9

2.1 OUTPUT RATING………

………………………………………………………………………….

Pg. 9

2.2 INPUT CHARACTERISTICS……………………………………………………………………...

Pg. 9

2.3 CONSTANT VOLTAGE MODE…………………………………………………………………...

Pg. 9

2.4 CONSTANT CURRENT MODE…………………………………………………………………..

Pg. 9

2.5 ANALOG PROGRMAMING AND MONITORIN

G……………………………………………….

Pg. 9

2.6 PROGRAMMING AND READBACK……………………………………………………………..

Pg. 10

2.7 PROTECTIVE FUNCTIONS………………………………………………………………………

Pg. 10

2.8 FRONT PANEL…………………………………………………………………………………….

Pg. 10

2.9 ENVIRONMENTAL CONDITIONS………………………………………………………

……….

Pg. 10

2.10 MECHANICAL…………………………………………………………………………………….

Pg. 10

2.11 SAFETY/EMC……………………………………………………………………………………..

Pg. 10

2.12 SUPPLEMENTAL CHARACTERISTICS……………………………………………………….

Pg. 11

2.13 OUTLINE DRAWINGS…………………………………………………………………………...

Pg. 12

CHAPTER 3 INSTALLATION………………………………………………………………………..

Pg. 13

3.1 GENERAL…………………………………………………………………………………………...

Pg. 13

3.2 PREPARATION FOR USE………………………………………………………………………...

Pg. 13

3.3 INITIAL INSPECTION……………………………………………………………………………...

Pg. 13

3.4 RACK MOU

NTING…………………………………………………………………………………

Pg. 14

3.4.1 Single

-

unit installation………………………..……………………………………………..

Pg. 14

3.4.2 Dual unit install

a

tion………..……………………………………………………………….

Pg. 14

3.4.3 GENH/RM Rack Mounting outline drawings.………………………

…………………….

Pg. 15

3.5 LOCATION MOUNTING AND COOLING……………………………………………………….

Pg. 15

3.6 AC SOURCE REQUIREMENTS………………………………………………………………….

Pg. 15

3.7 AC INPUT POWER CONNECTION……………………………………………………………...

Pg. 15

3.7.1 AC input conne

c

tor………………….…………………………

……………………………

Pg. 16

3.7.2 AC input cord………………………………………………………………………………..

Pg. 16

3.8 TURN

-

ON CHECKOUT PROCEDURE………………………………………………………….

Pg. 16

3.8.1 General……………………………………………………………………………………….

Pg. 16

3.8.2 Prior to operation…………………………………

………………………………………….

Pg. 16

3.8.3 Constant voltage check……………………………………………………………………..

Pg. 17

3.8.4 Constant current check……………………………………………………………………..

Pg. 17

3.8.5 OVP check…………………………………………………………………………………...

Pg. 17

3.8.6 UVL chec

k……………………………………………………………………………………

Pg. 17

3.8.7 Foldback check……………………………………………………………………………...

Pg. 18

3.8.8 Address se

t

ting……………….……………………………………………………………..

Pg. 18

1.3.2 Optional Communication Cables……………………...…………………………………… Pg. 8

3.8.9 Baud rate setting……………………………………………………………………………. Pg. 18

83-507-5002 Rev. B

Page 6

3.9 CONNECTING THE LOAD………………………………………………………………………..

Pg. 18

3.9.1 Load Wiring…………………………………………………………………………………..

Pg. 18

3.9.2 Current Carrying Capa

c

ity………………………………………………………………….

Pg. 18

3.9.3 Wire termination………………………………………

……………………………….…….

Pg. 19

3.9.4 Noise and Impedance E

f

fects……………………………………………………………...

Pg. 20

3.9.5 Inductive loads……………………………………………………………………………….

Pg. 20

3.9.6 Making the load connections……………………………………………………………….

Pg. 20

3.9.7 C

onnecting single loads, local sensing (d

e

fault)…………………………………………

Pg. 23

3.9.8 Connecting single loads, remote sen

s

ing………………………………………………...

Pg. 23

3.9.9 Connecting multiple loads, radial distribution method…………...……………………...

Pg. 23

3.

9.10 Multiple loads connection with distribution terminals…………………………………..

Pg. 24

3.9.11 Grounding outputs…………………………………………………………………………

Pg. 24

3.10 LOCAL AND REMOTE SENSING………………………………………………………………

Pg. 25

3.10.1 Sensing wi

r

ing…………………………………………

…………………………………...

Pg. 25

3.10.2 Local sensing……………………………………………………………………………….

Pg. 25

3.10.3 Remote sensing……………………………………………………………………………

Pg. 26

3.10.4 J2 sense connector technical inform

a

tion………………………………………………

Pg. 26

3.11 REPACKAGING

FOR SHIPMENT………………………………………………………………

Pg. 26

CHAPTER 4 FRONT AND REAR PANEL CONTROLS AND CONNECTORS………...

………

Pg. 27

4.1 INTRODUCTION……………………………………………………………………………………

Pg. 27

4.4 REAR PANEL SW1 SETUP SWITCH……………………………………………………………

Pg. 30

4.4.1 SW1 positions fun

c

tions……………………………………………………………………

Pg. 30

4.4.2 Resetting the SW1 switch………………………………………………………………….

Pg. 31

4.5 REAR PANEL J1 PROGRAMMING AND MONITORING CONNECTOR……………………

Pg. 31

4.5.1 Making J1 connections……………………………………………………………………..

Pg. 31

CHAPTER 5 LOCAL OPERATION

………………………………………………………………….

Pg. 34

5.1 INTRODUCTION………………………………………………………………….

………………..

Pg. 34

5.2 STANDARD OPERATION…………………………………………………………………………

Pg. 34

5.2.1 Constant Voltage Mode…………………………………………………………………….

Pg. 34

5.2.2 Constant Current Operation………………………………………………………………..

Pg. 34

5.2.3 Automatic Crossover…………

……………………………………………………………..

Pg. 35

5.3 OVER VOLTAGE PROTECTION (OVP)………………………………………………………...

Pg. 35

5.3.1 Setting the OVP level……………………………………………………………………….

Pg. 35

5.3.2 Activated OVP protection indications……………………………………………………..

Pg. 35

5.4 UNDER VOLTAGE LIMIT (UVL)………………………………………………………………….

Pg. 36

5.4.1 Setting the UVL level………………………………………………………………………..

Pg. 36

5.5 FOLDBACK PROTECTION…………………………………………………………………

…….

Pg. 36

5.5.1 Setting the Foldback protection…………………………………………………………….

Pg. 36

5.5.2 Resetting activated Foldback protection…………………………………………………..

Pg. 36

5.6 OUTPUT ON/OFF CONTROL…………………………………………………………………….

Pg. 36

5.7 OUTPUT SHUT

-

OFF (SO) C

ONTROL VIA REAR PANEL J1 CONNECTOR………………

Pg. 36

5.8 ENABLE/DISABLE CONTROL VIA………………………………………………………………

Pg. 37

5.9 CV/CC SIGNAL……………………………………………………………………………………..

Pg. 37

5.10 PS OK SIGNAL……………………………………………………………………………………

Pg. 38

5.11 SAFE START AND AUTO

-RESTART MODES………………………………………………..

Pg. 38

5.11.1 Automatic start mode………………………………………………………………………

Pg. 38

5.11.2 Safe start mode……………………………………………………………………………..

Pg. 38

5.12 OVER TEMPERATURE PROTECTION (OTP)………………………………………………..

Pg. 38

5.13 LAST SE

TTING MEMORY………………………………………………………………………

Pg. 38

5.14 SERIES OPERATION…………………………………………………………………………….

Pg. 39

5.14.1 Series connection for increased output vol

t

age…………………………………………

Pg. 39

5.14.2 Series connection for positive and negative output

voltage……………………………

Pg. 40

TABLE OF CONTENTS

4.2 FRONT PANEL CONTROLS AND

4.3 REAR PANEL CONNECTIONS AND CONTROLS…………………………………...……….. Pg. 29

Pg. 27

5.3.3 Resetting the OVP circuit………………………………………………………………...... Pg. 35

83-507-5002 Rev. B

Page 7

TABLE OF CONTENTS

5.15 PARALLEL OPERATION………………………………………………………….………….….

Pg. 41

5.15.1 Basic parallel oper

a

tion…………………………………………………………………….

Pg. 41

5.15.2 Advanced parallel operation……………………………………………………………….

Pg. 42

5.16 DAISY

-

CHAIN SHUT

-

OFF CONNECTION…………………………………………………….

Pg. 44

5.17 FRONT PANEL LOCKING……………………………………………………………………….

Pg. 44

5.17.1 Unlocked front panel……………………………………………………………………….

Pg. 45

5.17.2 Locked front panel………………………………………………………

………………….

Pg. 45

CHAPTER 6 REMOTE ANALOG PROGRAMMING………………………………………………

Pg. 46

6.1 INTRODUCTION……………………………………………………………………………………

Pg. 46

6.2 LOCAL/REMOTE ANALOG CONTROL…………………………………………………………

Pg. 46

6.3 LOCAL/REMOTE ANALOG INDICATION……………………………………………………

…. Pg. 46

6.4 REMOTE VOLTAGE PROGRAMMING OF OUTPUT VOLTAGE AND CURRENT LIMIT

Pg. 47

6.5 RESISTIVE PROGRAMMING OF OUTPUT VOLTAGE AND CURRENT…………………..

Pg. 48

6.6 REMOTE MONITORING OF OUTPUT VOLTAGE AND CURRENT………………………...

Pg. 49

CHAPTER 7 RS232 & RS4

85 REMOTE CONTROL

……………………………………………...

Pg. 50

7.1 INTRODUCTION……………………………………………………………………………………

Pg. 50

7.2 CONFIGURATION………………………………………………………………………………….

Pg. 50

7.2.1 Default se

t

ting………………………………………………………………………………...

Pg. 50

7.2.2 Address settin

g……………………………………………………………………………….

Pg. 50

7.2.3 RS232 or RS485 sele

c

tion………………………………………………………………….

Pg. 50

7.2.4 Baud rate setting……………………………………………………………………………..

Pg. 50

7.2.5 Setting the unit into Remote or Local mode……………………………………………….

Pg. 50

7.2.6 RS232/458 port at Local mode……………………………………………………………..

Pg. 51

7.2.7 Front panel in Remote mode……………………………………………………………….

Pg. 51

7.3 REAR PANEL RS232/485 CONNECTOR……………………………………………………….

Pg. 51

7.4 MD MODE OPTION (Factory I

n

stalled)

………………………………………………………….

Pg. 52

7.4.1 MD Mode Description………………………………………………………………………..

Pg. 52

7.4.2 MD Mode enable

-

Serial communication mode………………………………………….

Pg. 52

7.4.3 MD Mode SRQ……………………………………………………………………………….

Pg. 52

7.4.4

Communication Collisions…………………………………………………………………..

Pg. 52

7.4.5 MD Mode SRQ Retransmission……………………………………………………………

Pg. 52

7.5 CONNECTING POWER SUPPLIES TO RS232 OR RS485 BUS…………………………….

Pg. 53

7.5.1 Single power supply……………………………………………………………

…………….

Pg. 53

7.5.2 Multi power supply connection to RS232 or RS485 BUS………………………………..

Pg. 54

7.6 COMMUNICATION INTERFACE PROTOCOL…………………………………………………

Pg. 54

7.6.1 Data fo

r

mat…………………………………………………………………………………...

Pg. 54

7.6.2 Addres

s

ing………

……………………………………………………………………………

Pg. 54

7.6.3 End of message……………………………………………………………………………..

Pg. 54

7.6.4 Command repeat…………………………………………………………………………….

Pg. 54

7.6.5 Checksum…………………………………………………………………………………….

Pg. 54

7.6.6 Acknowledge……

…………………………………………………………………………….

Pg. 54

7.6.7 Error message………………………………………………………………………………..

Pg. 55

7.6.8 Backspace…………………………………………………………………………………….

Pg. 55

7.7 ERROR MESSAGES………………………………………………………………………………

Pg. 55

7.8 COMMAND SET DESCRIPTION…………

………………………………………………………

Pg. 55

7.8.1 General guide.…………………………………………………………………………….….

Pg. 55

7.8.2 Command set categ

o

ries……………………………………………………………………

Pg. 55

7.8.3 Initialization control commands……………………………………………………………..

Pg. 56

7.8.4 I

D control co

m

mands………………………………………………………………………..

Pg. 56

7.8.5 Output control commands…………………………………………………………………..

Pg. 56

7.9 GLOBAL OUTPUT COMMANDS…………………………………………………………………

Pg. 58

7.9.1 General………………………………………………………………………………………..

Pg. 58

7.10 S

INGLE BYTE COMMANDS…………………………………………………………………….

Pg. 59

7.10.1 Ge

n

eral………………………………………………………………………………………

Pg. 59

7.10.2 Global commands without response……………………………………………………..

Pg. 59

7.10.3 Global commands with response………………………………………………………

… Pg. 60

83-507-5002 Rev. B

Page 8

TABLE OF CONTENTS

7.10.4 Addressed commands with response……………………………………………………

Pg. 60

7.10.5 Addressed commands without response………………………………………………..

Pg. 61

7.10.6 Status Control Commands………………………………………………………………..

Pg. 6

3

7.11 STATUS, ERROR AND SRQ REGISTERS……………………………………………….…..

Pg. 63

7.11.1 General Description………………………………………………………………….…….

Pg. 63

7.11.2 Conditional registers………………………………………………………………….……

Pg. 64

7.11.3 Service Request Enabled and Even

t Registers………………………………….……..

Pg. 65

7.12 SERIAL COMMUNICATION TEST SET

-

UP…………………………………………….…….

Pg. 68

CHAPTER 8 ISOLATED ANALOG PROGAMMING OPTION

……………………………..…….

Pg. 69

8.1 INTRODUCTION……………………………………………………………………………………

Pg. 69

8.2 SPECIFICATIONS…………

……………………………………………………………………….

Pg. 69

8.2.1 0

-

5V/0

-

10V o

p

tion (PN:IS510)………………………………………………………...……

Pg. 69

8.2.2 4

-

20mA option (PN: IS420)………………………………………………………….……..

Pg. 69

8.3 ISOLATED PROGRAMMING & MONITORING CONNECTOR………………………………

Pg. 70

8.4

SETUP AND OPERATING INSTRUCTIONS……………………………………………………

Pg. 71

8.4.1 Setting up the power supply for 0

-

5V/0

-

10V Isolated Programming and Monito

r

ing…

Pg. 71

8.4.2 Setting up the power supply for 4

-

20mA Isolated Programming and Monitoring……..

Pg.

71

CHAPTER 9 MAINTENANCE………………………………………………………………………...

Pg. 72

9.1 INTRODUCTION……………………………………………………………………………………

Pg. 72

9.2 UNITS UNDER WARRANTY……………………………………………………………………...

Pg. 72

9.3 PERIODIC MAINTENANCE……………………………………………………………………….

Pg. 72

9.4 ADJUSTMENT AND CALIBRATION……………………………………………………………..

Pg. 72

9.5 PARTS REPLACEMENT AND REPAIRS………………………………………………………..

Pg. 72

9.6 TROUBLESHOOTING……………………………………………………………………………..

Pg. 72

9.7 FUSE RATING……………………………………………………………………………………...

Pg. 74

83-507-5002 Rev. B

Page 9

1

WARRANTY

This TDK-Lambda Americas Inc. product is warranted against defects in materials and workmanship for

a period of five years from date of shipment. During the warranty period, TDK-Lambda Americas Inc.

will, at it’s option, either repair or replace products which prove to be defective.

LIMITATION OF WARRANTY

The warranty shall not apply to defects resulting from improper or inadequate usage or maintenance by

the buyer, buyer supplied products or interfacing. The warranty shall not apply to defects resulting from

unauthorized modifications, or from operation exceeding the environmental specifications of the

product, or if the QA seal has been removed or altered by anyone other than TDK-Lambda Americas

Inc. authorized personnel. TDK-Lambda Americas Inc. does not warrant the buyer’s circuitry or

malfunctions of TDK-Lambda Americas Inc. products resulting from the buyer’s circuitry. Furthermore,

TDK-Lambda Americas Inc. does not warrant any damage occurring as a result of the buyer’s circuitry

or the buyer’s - supplied products. THIS LIMITED WARRANTY IS IN LIEU OF, AND TDK-LAMBDA

AMERICAS INC DISCLAIMS AND EXCLUDES, ALL OTHER WARRANTIES, STATUTORY, EXPRESS

OR IMPLIED, INCLUDING, WITHOUT LIMITATION, ANY WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE, OR OF CONFORMITY TO MODELS OR SAMPLES.

WARRANTY SERVICE

This product must be returned to an authorized TDK-Lambda Americas Inc. service facility for repairs or

other warranty service. For products returned to TDK-Lambda Americas Inc. for warranty service, the

buyer shall prepay shipping charges to TDK-Lambda Americas Inc. If the unit is covered under the

foregoing warranty then TDK-Lambda Americas Inc. shall pay the shipping charges to return the

product to the buyer. Refer to Section 3.11 for repackaging for shipment.

DISCLAIMER

The information contained in this document is subject to change without notice. TDK-Lambda Americas

Inc. shall not be liable for errors contained in this document or for incidental or consequential damages

in connection with the furnishing, performance or use of this material. No part of this document may be

photocopied, reproduced or translated into another language without the prior written consent of TDKLambda Americas Inc.

TRADEMARK INFORMATION

Genesys™ power supply is a trademark of TDK-Lambda Americas Inc.

Microsoft™ and Windows™ are trademarks of Microsoft Corporation.

THE FCC WANTS YOU TO KNOW

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment.

This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference, in which case

the user will be required to correct the interference at his own expense.

FCC WARNING

Modifications not expressly approved by manufacturer could void the user authority to operate the

equipment under FCC Rules.

83-000-016 Rev. F

Page 10

SAFETY INSTRUCTIONS

grounded.

Do Not connect the Positive Output to ground when using the RS232/RS485 or IEEE.

CAUTION

The following safety precautions must be observed during all phases of operation, service and repair of

this equipment. Failure to comply with the safety precautions or warnings in this document violates

safety standards of design, manufacture and intended use of this equipment and may impair the builtin protections within.

TDK-Lambda Americas Inc. shall not be liable for user’s failure to comply with these requirements.

INSTALLATION CATEGORY

The GenesysTM power supply series has been evaluated to INSTALLATION CATEGORY II. Installation

category (over voltage category) II: local level, appliances, portable equipment etc. With smaller transient over voltage than Installation Category (over voltage category) III.

GROUNDING

This product is a Safety Class 1 instrument. To minimize shock hazard, the instrument chassis must be

connected to an electrical ground. The instrument must be connected to the AC power supply mains

through a three conductor power cable, with the ground wire firmly connected to an electrical ground

(safety ground) at the power outlet.

For instruments designed to be hard-wired to the supply mains, the protective earth terminal must be

connected to the safety electrical ground before another connection is made. Any interruption of the

protective ground conductor or disconnection of the protective earth terminal will cause a potential

shock hazard that might cause personal injury.

OUTPUT TERMINALS GROUNDING

There is a potential shock hazard at the RS232/RS485 and the IEEE ports when using power supplies

with rated or combined voltage greater than 400V and the Positive Output of the Power Supply is

WARNING

FUSES

Fuses must be changed by authorized TDK-Lambda Americas Inc. service personnel only. For continued protection against risk of fire, replace only with the same type and rating of fuse. Refer to Chapter

9 for fuse ratings.

INPUT RATINGS

Do not use AC supply, which exceeds the input voltage and frequency rating of this instrument. The

input voltage and frequency rating of the Genesys

safety reasons, the mains supply voltage fluctuations should not exceed +/-10% of nominal voltage.

TM

power supply series is: 100-240Vi, 50/60Hz. For

LIVE CIRCUITS

Operating personnel must not remove the instrument cover. No internal adjustment or component replacement is allowed by non-TDK-Lambda Americas Inc. qualified personnel. Never replace components with power cable connected. To avoid injuries, always disconnect power, discharge circuits and

remove external voltage source before touching components.

PARTS SUBSTITUTIONS & MODIFICATIONS

Parts substitutions and modifications are allowed by authorized TDK-Lambda Americas Inc. service

personnel only. For repairs or modifications, the instrument must be returned to an authorized TDKLambda Americas Inc. service facility.

2

83-507-5002 Rev. B

Page 11

83-507-5002 Rev. B

3

SAFETY INSTRUCTIONS

ENVIRONMENTAL CONDITIONS

The Genesys

TM

power supply series safety approval applies to the following operating cond

i

tions:

*Indoor use

*Ambien

t temperature: 0°C to 50°C

*Maximum relative humidity: 90% (no condensation)

*Altitude: up to 3000m

*Pollution degree 2

CAUTION Risk of Electrical Shock

Instruction manual symbol. The instrument will be marked with this symbol when it is

necessa

ry for the user to refer to the instruction manual.

Indicates hazardous voltage.

Indicates ground terminal.

Protective Ground Conductor Terminal

Off (Supply)

On (Supply)

The WARNING sign denotes a hazard. An attention to a procedure is

called. Not fo

l-low

ing procedure correctly could result in personal injury.

A WARNING sign should not be skipped and all indicated conditions must be

fully understood and met.

The CAUTION sign denotes a hazard. An atten

tion to a procedure is called. Not follo

w-

ing procedure correctly could result in damage to the equipment. Do not proceed b

e-

yond a CAUTION sign until all indicated conditions are fully understood and met.

FCC COMPLIANCE NOTICE:

Note: This equipment has be

en tested and found to comply with the limits for a Class A

digital device, pursuant to part 15 of the FCC Rules. These limits are designed to pr

o-

vide reasonable protection against harmful interference when the equipment is operated

in a commercial environ

ment. This equipment generates electro

-

magnetic field, and can

radiate radio frequency energy and, if not installed and used in accordance with the i

n-

struction manual, may cause harmful interference to radio communications. Operation

of this equipment in a

residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his own expense.

Page 12

SICHERHEITS-INSTALLATIONS ANWEISUNGEN

Vorsicht

Vor Anschluss an das Netz ist die Aufstellanleitung wie nachstehend beschrieben zu beachten. Die

nachstehenden Sicherheitsanweisugen mussen während aller Phasen des Betriebes, des Services

und der Reparatur dieser Ausrustung beachtet werden. Alle notwendigen Bedingungen die

sicherstellen, dass die Einrichtung zu keiner Gefahr im Sinne dieser Norm führen kann, sind in diesem

Handbuch beschrieben.

TDK-Lambda Americas Inc. ist nich verantwortlich fur Fehler, die bei der Inbetriebnahme des Gerates

auf Grundlage dieser Sicherheitsanweisungen durch den Betreiber entstehen können.

Betriebsbedingungen

Die Genesys

TM

Stromversorgungs-Reihe ist zur installation gemass Uberspannungs-Kategorie 2

entwickelt worden.

Installatios Kategorie (Uberspannungs-Kategories) 2 bedeutet: Kleinindustrie, Geräte, bewegliche

Ausrustung etc.. mit Uberspannungen kleiner als Installation Kategorie 3.

Erdungskonzept

Dieses Produkt ist ein Gerat mit Schutzklasse1. Damit gefahrliche Energieinhalte und Spannungen

vermieden werden, ist das Geratechassis an eine Schutzerde anzuschliessen. Das Gerat muss an die

AC-Wechselspannungsversorgung mit 3 Leitern (L, N, PE) angeschlossen werden. Der PEAnschluss ist an einen festen Erder anzuschliessen. Bei Festverdrahtung des Gerates ist

sicherzustellen, dass der PE Anschluss als erstes durchgefuhrt wird.

Jede mogliche Unterbrechung des PE-Leiters oder Trennung der PE Masses kann einen moglichen

elektrischen Schlag hervorrufen, der Personenschaden zur Folge hatte.

Vorsicht

Erdung des DC-Ausgangs

Es besteht Energiegefahr am RS232/RS485 und IEEE Anschluss, falls die Ausgangsspannung des

Gerates grosser ist als 400V und der positive Ausgangsanschluss des Netzteiles geerdet wird. Dies gilt

insbesondere auch bei Reihenschaltungen von unterschiedlichen Netzteilen. Wird die RS232/485 oder

IEEE Schnittstelle verwendet, ist darauf zu achten, dass der Plus-Ausgangsanschluss nicht geerdet

wird.

Absicherung

Sicherungen durfen nur durch autorisierte TDK-Lambda Americas Inc. Service Personen ausgetauscht

werden. Um Brandgefahr vorzubeugen, sind nur Sicherungen zu verwenden mit gleicher Bauart und

Auslosecharakteristik. Siehe hierzu Wartungsanweisungen in Kapitel 6 bezuglich Sicherungen.

Anschluss an Versorgungsstromkreis

Der Betrieb des Gerates ist nur fur den dafur spezifizierten Wechselspannungsbereich und der

angegebenen Frequenz erlaubt.

Der Nominaleingangsspannungsbereich der Genesys

einen sicheren Betrieb des Gerates ist eine Abweichung von max. +/-10% der Nominalspannung

erlaubt.

Spannungsfuhrende Teile

Die Gerateabdeckung darf nur im stromlosen Zustand geoffnet werden. Interne Modifikationen, sowie

Bauteileaustausch ist nur durch TDK-Lambda Americas Inc. qualifiziertes Personal erlaubt. Vor

Austausch von Bauteilen ist das Netzkabel bzw. Die Versorgungsspannung zu trennen.

Energieversorgungsanschlusse sind immer zu trennen um Personenverletzungen durch gefahrliche

Energieinhalte und Spannungen auszuschliessen. Die Stromkreise sind zu entladen, extreme

Spannunsquellen sind zu entfernen bevor Bauteile bzw. Komponenten getauscht werden.

TM

Serie liegt bei 100-240VAC mit 50/60Hz. Fur

4

83-507-5002 Rev. B

Page 13

Anderungen and Bauteileersatz

Handbuch zu beziehen.

Ersatzteilaustausch – und Anderungen durfen nur von autorisiertem TDK-Lambda Americas Inc.

SERVICE-PERSONEN durchgefuhrt werden. Fur Reparaturen oder Anderungen ist das

Gerat zur TDK-Lambda Americas Inc. Service-Niederlassung zu retournieren.

SICHERHEITS-HINWEISE

Umweltbedingungen

Die GenesysTM Stromversorgungs-Serie ist gemassden Sicherheitsabnahmen fur folgende

Betriebsbedingungen zugelassen.

*Stationare Einrichtungen in Gebauden.

*Umgebungstemperaturebereich: 0-50°C.

*Maximale Relative Luftfeuchtigkeit: 90% (nicht kondensierend).

*Betriebshohe: bis zu 3000m.

*Verschmutzungsgrad 2.

Sicherheits-und Warnsymbole

VORSICHT Spannungsfuhrende Teile-Gefahr durch elektrischen Schlag bzw.

Energieinhalte

Handbuch-Symbol. Das Gerat bzw. Gerateteile werden mit diesem Symbol

gekennzeichnet, wenn es fur den Benutzer notwendig ist, sich auf die Anweisungen im

Zeigt „spannungsfuhrende Teile“ mit gefahrlicher Spannung an.

Zeigt Masse-Anschluss an, keine Schutzerde. (z.B. Masseanschlussan einenVerbraucher).

Schutzleiter-Anschlussklemme.

Symbol fur Schalter oder Drucknopfe - Zeigt die "Ein" - Stellung hier an.

Symbol fur Schalter oder Drucknopfe - Zeigt die "Aus" - Stellung hier an.

Dieses Warnaufschrift weist auf eine Gefahr hin, die eine Uberprufunganweisung nach sich

ziecht. Nichteinhaltung kann zu Personenschaden fuhren. Dieser Warnhinweis darf nicht

ubersprungen werden und die beschriebene Vorgehensweise musstrikt verstanden werden

und dementsprechend umgesetzt werden.

Diese „Vorsichtswarnung“ weist auf eine Gefahr hin, die einer Vorkehrung bedarf.

Nichteinhaltung kann zur Zerstorung der Anlage oder des Gerates fuhren. Bitte

berucksichtigen Sie alle Anweisungen, die dort beschreiben sind, bevor Sie mit Benutzung

der Anlage bzw. des Gerates fortfahren.

5

83-507-5002 Rev. B

Page 14

GENH 6

-

100

0 - 6 0 -

100

GENH 60

-

12.5

0 -

60 0 - 12.5

GENH 8

-

90 0 - 8 0 - 90

GENH 80

-

9.5 0 - 80 0 - 9.5

GENH 12.5

-

60 0 - 12.5

0 -

60

GENH 100

-

7.5 0 - 100

0 -

7.5

GENH 20

-

38 0 - 20 0 - 38

GENH 150

- 5 0 - 150

0 - 5

GENH 30

-

25 0 - 30 0 - 25

GENH 300

-

2.5 0 - 300

0 -

2.5

GENH 40

-

19 0 - 40 0 - 19

GENH 600

-

1.3 0 - 600

0 -

1.3

CHAPTER 1 GENERAL INFORMATION

1.1 USER MANUAL CONTENT

This User’s Manual contains the operating instructions, installation instructions and specifications

of the GenesysTM GENH 750W power supply series. The instructions refer to the standard power

supplies, including the built-in RS232/RS485 serial communication. For information related to

operation with the optional IEEE programming, refer to User’s Manual for Power Supply IEEE

Programming Interface. (TDK-Lambda Americas Inc. P/N 83-030-200).

1.2 INTRODUCTION

1.2.1 General Description

GenesysTM power supplies are wide output range, high performance switching power supplies.

The GenesysTM series is power factor corrected and operates from worldwide AC voltage range

continuously. Output Voltage and Current are continuously displayed and LED indicators show

the complete operating status of the power supply. The Front panel controls allow the user to set

the output parameters, the protections levels (Over-Voltage protection, Under-Voltage limit and

Foldback) and preview the settings. The rear panel includes the necessary connectors to control

and monitor the power supply operation by remote analog signals or by the built-in serial communication (RS232/RS485). GPIB programming and Isolated-Analog programming/monitoring

are optional.

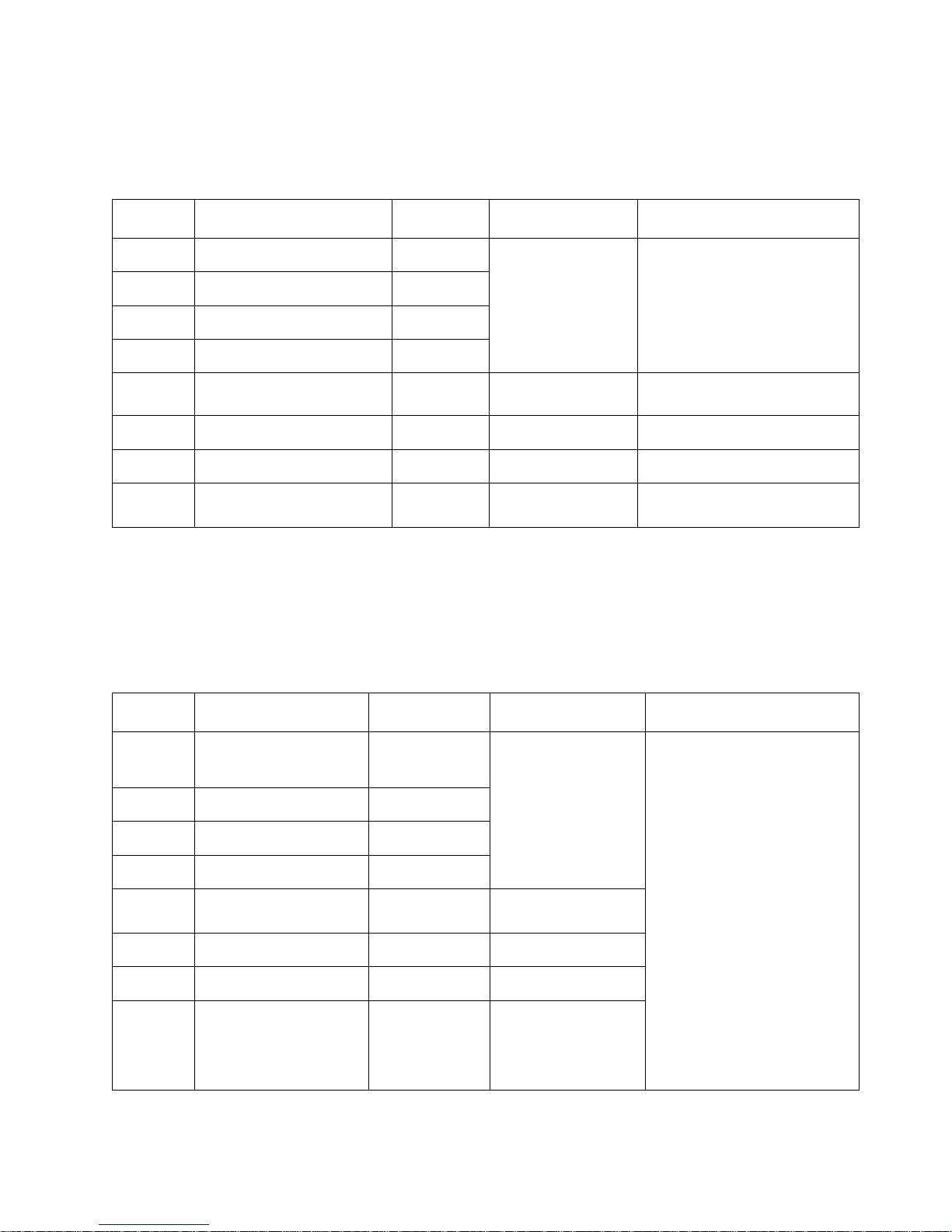

1.2.2 Models covered by this Manual

Model Voltage

range (V)

Current

range (A)

Model Voltage

range (V)

Table 1-1: Models covered by the Manual

1.2.3 Features and options

∗ Constant Voltage / Constant Current with automatic crossover.

∗ Active power factor correction.

∗ Universal Input Voltage (85i265Vac), continuous operation.

∗ Embedded Microprocessor Controller.

∗ Built-in RS-232/RS-485 Interface.

∗ Voltage & Current high resolution adjustment by digital encoders.

∗ High accuracy programming/readback.

∗ Software Calibration (no internal trimmers / potentiometers).

∗ Last Setting Memory.

∗ Independent Remote ON/OFF (opto-isolated) and remote Enable/Disable.

Current

range (A)

6

83-507-5002 Rev. B

Page 15

∗ Parallel operation (Master/Slave) with Active current sharing.

∗ Remote sensing to compensate for voltage drop of power leads.

∗ External Analog Programming and Monitoring standard (0-5V or 0-10V, user selectable).

∗ Cooling fan speed control for low noise and extended fan life.

∗ Zero stacking-no ventilation holes at the top and bottom surface of the power supply.

∗ Optional GPIB interface (SCPI compatible).

∗ Optional Isolated Analog programming/monitoring (0-5V or 0-10V, user selectable and 4-

20mA).

1.2.4 Multiple output power system

The GenesysTM power supplies series can be configured into a programmable power system of

up to 31 units using the built-in RS232/RS485 communication port and the RS485 linking cable

provided with each power supply.

In a GPIB system, each power supply can be controlled using the optional GPIB controller (factory installed).

1.2.5 Control via the serial communication port

The following parameters can be programmed / monitored via the serial communication port:

1. Output Voltage setting.

2. Output Current setting.

3. Output Voltage measurement.

4. Output On/Off control.

5. Output Current measurement.

6. Foldback protection setting

7. Over-voltage protection setting and readback.

8. Under-Voltage limit setting and readback.

9. Power-supply start up mode (Auto-restart or Safe-start mode).

1.2.6 Analog voltage programming and monitoring

Analog inputs and outputs are provided at the rear panel for analog control of the power supply.

The Output Voltage and the Current can be programmed by analog voltage or by resistor, and

can be monitored by analog voltage. The power supply output can be remotely set to On or Off

and analog signals monitor the proper operation of the power supply and the mode of operation

(CV/CC).

1.2.7 Parallel operation

GenesysTM power supplies of the same Output Voltage and Current rating can be paralleled in a

master-slave configuration with automatic current sharing to increase power available.

1.2.8 Output connections

Output connections are made to rear panel bus-bars for models up to 60V and to a 4-terminal

wire clamp connector for models above 60V rated output voltage. Either the positive or negative

terminal may be grounded or the output may be floated. Models up to 60VDC Rated Output shall

not float outputs more than +/- 60VDC above/below chassis ground. Models >60VDC Rated Output shall not float outputs more than +/-600VDC above/below chassis ground. Contact factory for

assistance with higher float voltage applications.

Local or remote sense may be used. In remote sense, the voltage drop on the load wires should

be minimized. Refer to the specifications for the maximum voltage drop value.

7

83-507-5002 Rev. B

Page 16

1.2.9 Cooling and mechanical construction

The GenesysTM series is cooled by internal fans. At the installation, care must be taken to allow

free airflow into the power supply via the front panel and out of the power supply via the rear

panel. The GenesysTM power supplies have a compact and lightweight package, which allows

easy installation and space saving in the application equipment.

CAUTION

Observe all torque guidelines within this manual. Applying more torque may

damage unit or accessories. Such damage is not covered under manufacturers

warranty.

1.3 ACCESSORIES

1.3.1 Included Accessories

The following accessories are delivered with the power supply:

1.3.1.1 Serial Link Cable

Serial link cable for linking power supplies by RS-485 communication.GEN/RJ45.

Cable description: 0.5m Length, shielded, RJ-45 type plugs, eight (8) contacts (P/N 15-507-201)

1.3.1.2 Hardware (delivered with power supply)

• Strain Relief for AC Cord

• Output terminal Shield

• DB25 Programming Plug kit (AMP 749809-9)

• Plastic legs for bench mounting.

• Power Cord - See Para 1.3.3.

1.3.2 Optional Communication Cables (See Para. 7.5)

• RS-232 Cables to connect GEN to Serial Port on PC

GEN to PC (DB9) GEN 232/9 P/N 15-507-203

GEN to PC (DB25) GEN 232/25 P/N 15-507-204

• RS-485 Cable to connect GEN to Serial Port on PC

GEN to PC (DB9) GEN/485-9 P/N 15-507-202)

1.3.3 AC cables

AC Cables are provided with 750W Model only, according to suffix in Model Number.

Part No. Market Description

NC301

(GEN/U)

NC302

(GEN/E)

NC303

(GEN/O)

NC305

(GEN/J)

NC306

(GEN/GB)

USA 13A 125V, unshielded, 2m typical length, with IEC320 connector on one end

and NEMA-5-15P connector on the other end.

Europe 10A 250V, unshielded, 2m typical length, with IEC320 connector on one end

and INT’L 7 standard VII, dual earthing.

General 10A 250V, unshielded, 2m typical length, with IEC320 connector on one end

and unterminated stripped wires on the other end. Use the cable only with

plug approved by the national safety standards of the country of usage.

Japan 13A 125V,unshielded, 2m typical length, with IEC320 connector on one end

and Japan type plug on the other end.

UK 10A 250V unshielded, 2m typical length, with IEC320 connector on one end

and UK type plug on the other end.

8

83-507-5002 Rev. B

Page 17

CHAPTER 2 SPECIFICATIONS

2.1 OUTPUT RATING

MODEL

GEN

6-100

8-90

12.5-60

20-38

30-25

40-19–60-12.5

80-9.5

100-7.5

150-5

300-2.5

600-1.3

1.Rated output voltage (*1)

V68

12.5203040–6080

100

150

300

600

2.Rated output current 750W (*2)

A

1009060382519–

12.5

8.5

7.552.5

1.3

3.Rated output power 750W

W

600

720

750

760

750

760–750

760

750

750

750

780

MODEL

GEN

6-200

8-180

12.5-120

20-76

30-50

40-38

50-30

60-25

80-19

100-15

150-10

300-5

600-2.6

1.Rated output voltage (*1)

V68

12.5203040506080

100

150

300

600

2.Rated Output Current 1500W (*2)

A

200

180

120765038302519151052.6

3.Rated output power 1500W

W

1200

1440

1500

1520

1500

1520

1500

1500

1520

1500

1500

1500

1560

2.2 INPUT CHARACTERISTICS

V68

12.5203040506080

100

150

300

600

1. Input voltage/freq. (*3)

–

2. Input current (at 100/200Vac)

A

3. Power Factor

–

4. 750W models Efficiency (*4)

%

76/78

77/80

81/84

82/85

82/85

83/87

83/87

83/87

83/87

83/87

83/87

83/87

83/87

5. 1500W models Efficiency (*4)

%

77/79

78/81

82/85

83/86

83/86

84/88

84/88

84/88

84/88

84/88

84/88

84/88

84/88

6. Inrush current at 100/200V

A

2.3 CONSTANT VOLTAGE MODE

V68

12.5203040506080

100

150

300

600

1. Max.Line regulation (*5)

–

2. Max.Load regulation (*6)

–

3. Ripple and noise (p-p,20MHz) (*10)

mV60606060606060608080

100

150

300

4. Ripple r.m.s., 5Hz~1MHz (*10)

mV88888888881025

60

5. Temperature coefficient

PPM/°C

100PPM/°C of rated output voltage, following 30 min utes warm up

6. Temperature drift

–

7. Rem. Sense compensation/wire

V1111

1.522345555

8. Up-prog. Response time 0~Vomax (*9)

mS

250

9. Down-prog. Response time: Full load

mS10250

No load

500

600

700

800

900

1000

1100

1100

1200

1500

2000

2500

4000

10. Transient response time

mS

11. Hold-up time

mS

2.4 CONSTANT CURRENT MODE

V68

12.5203040506080

100

150

300

600

1. Max.line regulation (*5)

–

2. Max.load regulation (*7)

–

3. Ripple r.m.s. 5Hz~1MHz.750W (*8)

mA

200

180

120766348–38292318138

1500W (*8)

mA

400

360

240

152

1259575755745352512

4. Temperature coefficient

PPM/°C

5. Temperature drift

–

2.5 ANALOG PROGRAMMING AND MONITORING

1.Vout voltage programming

–

2. Iout voltage programming

–

3. Vout resistor progrmming

–

4. Iout resistor programming

–

5. On/off control

–

6. Output current monitor

–

7. Output voltage monitor

–

8. Power supply OK signal

–

9. Parallel operation

–

10. Series operation

–

11. CV/CC inicator

–

12. Enable/Disable

–

13. Local/Remote analog control

–

14. Local/remote analog indicator

–

85~265Vac continuous, 47-63Hz, single phase.

10.5/5 for 750W model, 21/11 for 1500W models.

0.99@100/200Vac, rated output power.

Less than 25A for 750W models, 50A for 1500W models.

0.01% of rated output voltage +2mV

0.01% of rated output voltage +2mV

0.05% of rated Vout over 8hrs interval following 30 minutes warm-up. Constant line, load & temp.

80

150

5080150

Time for the output voltage to recover within 0.5% of its rated output for a load change 10~90% of rated

output current.

Output set-point: 10~100%.

Less than 1mS for models up to and including 100V; 2mS for models above 100V.

More than 20mS, 100Vac, rated output power.

0.01% of rated output voltage +2mA

0.02% of rated output current +5mA

100PPM/°C from rated output current, following 30 m inutes warm-up.

0.05% of rated lout over 8hrs interval following 30 minutes warm-up. Constant line, load & temp.

0~100%, 0~5V or 0~10V, user select. Accuracy and linearity; +/-0.5% of rated Vout.

0~100%, 0~5V or 0~10V, user select. Accuracy and linearity; +/-1% of rated Iout.

0~100%, 0~5/10Kohm full scale, user select. Accuracy and linearity: +/-1% of rated Vout.

0~100%, 0~5/10Kohm full scale, user select. Accuracy and linearity: +/-1.5% of rated Iout.

By electrical Voltage: 0~0.6V/2~15V or dry contact, user selectable logic.

0~5V or 0~10V, user selectable. Accuracy: 1%

0~5V or 0~10V, user selectable. Accuracy: 1%

4~5V-OK, 0V-Fail, 500ohm series resistance.

Possible, up to 4 units in master/slave mode with single wire current balance connection.

Possible (with external diodes), up to 2 units.

CV: TTL high (4~5V), source current: 10mA, CC: TTL low (0-0.6V). Sink current: 10mA .

Dry contact. Open: off, Short: on. Max. voltage at Enable/Disable in: 6V.

By electrical signal or Open/Short: 0~0.6V or short: Remote, 4~5V or open: Local.

Open collector. Local: Open, Remote: On. Maximum voltage: 30V, maximum sink current: 5mA.

9

83-507-5002 Rev. B

Page 18

1. Vout programming accuracy

–

2. Iout programming accuracy (*13)

–

3. Vout programming resolution.

–

4. Iout programming resolution

–

5. Vout readback accuracy

–

6. Iout readback accuracy (*13)

–

7. Vout readback resolution

–

8. Iout readback resolution

–

2.7 PROTECTIVE FUNCTIONS

V68

12.5203040506080

100

150

300

600

1. Foldback protection

2. Over-voltage protection

3. Over-voltage trip point

V

0.5-7.5

0.5-10

1-15

1-24

2-35

2-44.1

5-57

5-66

5-88

5-110

5-165

5-330

5-660

4. Output under voltage limit

5. Over temperature protection

2.8 FRONT PANEL

1. Control functions

–

–

–

–

–

–

–

–

–

–

–

2. Display

–

Vout:

–

Iout:

3. Indications

–

2.9 ENVIRONMENTAL CONDITIONS

1. Operating temperature

C

2. Storage temperature

C

3. Operating humidity

%

4. Storage humidity

%

5. Altitude

–

2.10 MECHANICAL

1. Cooling

–

2. Weight

Kg

3. Dimensions (W x H x D)

mm

4. Vibration

–

5. Shock

–

2.11 SAFETY/EMC

1. Applicable standards Safety

–

EMC

–

2. Withstand voltage

–

3. Insulation resistance

–

4. Conducted emission

–

5. Radiated emission

–

2.6 PROGRAMMING AND READBACK (RS232/485, Optional IEEE Interface)

0.05% + 0.05% of rated output voltage.

0.1% of actual output current + 0.1% of rated output current (for Iout >0.4% of rated Iout to 100% of rated Iout).

0.1% of actual output current +0.4% of rated output current (for Iout <0.4% of rated Iout to 0.4% of rated Iout).

0.012% of full scale.

0.012% of full scale.

0.1% + 0.1% of rated output voltage

0.1% + 0.3% of rated output current

0.012% of full scale

0.012% of full scale

Output shut-down when power supply changes from CV to CC. User presetable.

Inverter shut-down; manual reset by AC input recycle, OUT button.

Preset by front panel or communication port. Prevents adjusting Vout below limit. Raises the PS_OK signal in case

output voltage is below limit.

User selectable, latched or non latched.

Vout/Iout manual adjust by separate encoders. (Coarse and fine adjustment)

OVP/UVL manual adjust by Volt. Adjust encoder

Address selection by Voltage adjust encoder. No of addresses: 31

Go to local control

Output on/off

AC on/off

Front panel lock

Foldback control

Serial or IEEE display at power-up

Baud rate selection: 1200, 2400, 4800, 9600 and 19200

Re-start modes (Auto Restart, Safe Start)

4 digits, accuracy: 0.5% of rated voltage + 1 count

4 digits, accuracy: 0.5% of rated current + 1 count

VOLTAGE, CURRENT, ALARM FINE, PREVIEW, FOLDBACK, LOCAL, OUTPUT ON.

0~50 C, 100% load.

-20 to + 70

30~90% RH (no condensation).

10~95% RH (no condensation).

Maximum 3000m, Derate output current by 2%/100m above 2000m. Alternatively, derate maximum ambient

temperature by 1 degC/100m above 2000m.

Forced air cooled by internal fans.

Less than 4.5Kg

W: 214.0 H: 43.6 (57.0 Benchtop Version). D: 437.5 (Refer to Outline drawing).

MIL-810E, method 514.5 test condition l-3.3

Less than 20G, half sine, 11mS. Units unpacked

UL60950-1 listed, EN60950-1 Vout ≤ 40V: Output is SELV, IEEE/Isolated Analog are SELV.

60 < Vout < 400V: Output is hazardous, IEEE/Isolated analog are SELV

400 < Vout < 600V: Output is hazardous, IEEE/Isolated, Analog are not SELV

EN55024

Vout < 60V models: Input-Outputs (SELV): 3.0KVrms 1 min, Input-Ground: 2.0KVrms 1 min.

60 ≤ Vout ≤ 600V models: Input-Haz, output: 2.5KVrms 1 min, Input-SELV: 3KVrms 1 min, 1900VDC 1 min.

EN55022A, FCC part 15-A, VCCI-A

Hazardous Output - SELV: 1.9KVrms 1 min, Hazardous Output-Ground: 1.9KVrms 1 min.

Input-Ground: 2KVrms 1min

More than 100Mohm at 25°C, 70%RH

EN55022B, FCC part 15-B, VCCI-B

83-507-5002 Rev. B

10

Page 19

NOTES:

*1: Minimum voltage is guaranteed to maximum 0.2% of the rated output voltage.

*2: Minimum current is guaranteed to maximum 0.4% of the rated output current.

*3: For cases where conformance to various safety standards (UL, IEC etc.) is required, to be

described as 100-240Vac (50/60Hz).

*4: At 100/200V input voltage and maximum output power.

*5: From 85i132Vac or 170i265Vac, constant load.

*6: From No-load to Full-load, constant input voltage. Measured at the sensing point in Remote

Sense.

*7: For load voltage change, equal to the unit voltage rating, constant input voltage.

*8: For 6V models the ripple is measured at 2i6V output voltage and full output current. For other

models, the ripple is measured at 10i100% output voltage and full output current.

*9: With rated, resistive load.

*10. For 6i300V models: Measured with JEITA RC-9131A (1:1) probe

For 600V model: Measured with (10:1) probe.

2.12 SUPPLEMENTAL CHARACTERISTICS

The supplemental characteristics give typical but non-warranted performance characteristics.

The supplemental characteristics are useful in assessing applications for the power supply. Several kinds of supplemental characteristics are listed below.

1. Evaluation Data: Typical performance of the power supply.

2. Reliability Data: Reliability Performance of the power supply.

3. IEC1000 Data: Performance of the power supply under IEC1000 test conditions.

4. EMI Data: Typical EMI (conducted and radiated) performance of the power supply.

The supplemental characteristics data is held in each TDK-Lambda Americas Inc. sales and service facility. For further details please contact the TDK-Lambda Americas Inc. office nearest you.

11

83-507-5002 Rev. B

Page 20

83

-

507-5002 Re

v. B

12

2.13

GENES

YSTMGENH 750W POWER SUPPLIES OUTLINE DRAWINGS

Page 21

CHAPTER 3 INSTALLATION

3.1 GENERAL

This Chapter contains instructions for initial inspection, preparation for use and repackaging for

shipment. Connection to PC, setting the communication port and linking GenesysTM power supplies are described in Chapter 7.

NOTE

GenesysTM power supplies generate magnetic fields, which

might affect the operation of other instruments. If your

equipment is susceptible to magnetic fields, do not position it

adjacent to the power supply.

3.2 PREPARATION FOR USE

In order to be operational, the power supply must be connected to an appropriate AC source.

The AC source voltage should be within the power supply specification. Do not apply power before reading Section 3.6 and 3.7.

Table 3-1 below, describes the basic setup procedure. Follow the instructions in Table 3-1 in the

sequence given to prepare the power supply for use.

Step no. Item Description Reference

1 Inspection Initial physical inspection of the power supply Section 3.3

2 Installation Installing the power supply,

Ensuring adequate ventilation.

3 AC source

AC source requirements

Connecting the power supply to the AC source

Section 3.4

Section 3.5

Section 3.6

Section 3.7

4 Test Turn-on checkout procedure. Section 3.8

5 Load connection Wire size selection. Local/Remote sensing.

Section 3.9

Single or multiple loads.

6 Default setting The power supply setting at shipment. Section 7.2.1

Table 3-1: Basic setup procedure

3.3 INITIAL INSPECTIONS

Prior to shipment this power supply was inspected and found free of mechanical or electrical defects. Upon unpacking of the power supply, inspect for any damage, which may have occurred in

transit.

The inspection should confirm that there is no exterior damage to the power supply such as broken knobs or connectors and that the front panel and meters face are not scratched or cracked.

Keep all packing material until the inspection has been completed. If damage is detected, file a

claim with carrier immediately and notify the TDK-Lambda Americas Inc. sales or authorized service facility nearest you.

13

83-507-5002 Rev. B

Page 22

3.4 RACK MOUNTING

To install a GENH750W one unit or two units side-by-side in a standard 19” Rack in 1U (1.75”)

height, use option kit P/N: GENH/RM

The Rack Mount kit allows the units to be zero stacked for maximum system flexibility and power

density without increasing the 1U height of the units.

3.4.1 Single unit installation

To install a GENH750W power supply in a standard 19” Rack in 1U (1.75”) height, using a GENH

Rack Mount kit P/N: GENH/RM.

Fig. 3-1 Single unit installation

3.4.2 Dual unit installation

To install two GENH750W power supplies side-by-side in a standard 19” Rack in 1U (1.75”)

height, using a GENH Rack Mount kit P/N: GENH/RM.

14

83-507-5002 Rev. B

Page 23

ground via the safety ground in the AC input connector.

3.4.3 GENH/RM Rack Mounting outline drawings:

3.5 LOCATION, MOUNTING AND COOLING

This power supply is fan cooled. The air intake is at the front panel and the exhaust is at the rear

panel. Upon installation allow cooling air to each the front panel ventilation inlets. Allow minimum

10cm (4-inch) of unrestricted air space at the front and the rear of the unit.

The power supply should be used in an area that the ambient temperature does not exceed

+50°C.

3.6 AC SOURCE REQUIREMENTS

The GenesysTM series can be operated from a nominal 100V to 240V, single phase, 47i63 Hz.

The input voltage range and current required for each model is specified in Chapter 2. Ensure

that under heavy load, the AC voltage supplied to the power supply does not fall below the specifications described in Chapter 2.

3.7 AC INPUT POWER CONNECTION

CAUTION

Connection of this power supply to an AC power source

should be made by an electrician or other qualified personnel

WARNING

There is a potential shock hazard if the power supply chassis

(with cover in place) is not connected to an electrical safety

83-507-5002 Rev. B

15

Page 24

1 Remote (+) sense

5 Remote (-) sense

to the user. The AC input cord must be no longer than 3m.

WARNING

Some components inside the power supply area are at AC voltage

even when the On/Off switch is in the “Off” position. To avoid electric

shock hazard, disconnect the line cord and load and wait two minutes

before removing cover.

3.7.1 AC Input Connector

An IEC connector is provided on the rear panel for connecting the unit to the AC power source

with an AC cord. The IEC connector also provides the safety ground connection while the AC

cord is plugged into an appropriate AC receptacle.

3.7.2 AC Input Cord

Refer to Section 1.3.4 for details of the AC input cords recommended for the GENH750W models.

WARNING

The AC input cord is the disconnect device of the power

supply. The plug must be readily identifiable and accessible

3.8 TURN-ON CHECKOUT PROCEDURE

3.8.1 General

The following procedure ensures that the power supply is operational and may be used as a basic incoming inspection check. Refer to Fig.4-1 and Fig.4-2 for the location of the controls indicated in the procedure.

3.8.2 Prior to Operation

1. Ensure that the power supply is configured to the default setting:

– AC On/Off switch at Off position.

– Dip switch: All positions at Down (“Off”) position.

– Sense connector: Configured to Local Sense as shown in Fig.3-4:

– For units equipped with IEEE option, ensure that the IEEE_En switch is in Up (default)

position (Refer to Fig.4-2, Item 9 for location), if checkout is to be done in IEEE mode.

2 Local (+) sense

3 Not connected

4 Local (-) sense

Fig.3-4: Sense connector default connection

2. Connect the unit to an AC source as described in Section 3.7.

3. Connect a DVM with appropriate cables for the rated voltage to the output terminals.

4. Turn the front panel AC power switch to On.

83-507-5002 Rev. B

16

Page 25

3.8.3 Constant Voltage Check

1. Turn on the output by pressing the OUT pushbutton so the OUT LED illuminates.

2. Observe the power supply VOLT display and rotate the Voltage encoder. Ensure that the

Output Voltage varies while the VOLT encoder is rotated. The minimum control range is from

zero to the maximum rated output for the power supply model.

Compare the DVM reading with the front panel VOLT display to verify the accuracy of the

VOLT display. Ensure that the front panel VOLT LED is On.

3. Turn Off the front panel AC power switch.

3.8.4 Constant Current Check

1. Ensure that the front panel AC power switch is at the Off position and the DVM connected to

the output terminals shows zero voltage.

2. Connect a DC shunt across the output terminals. Ensure that the shunt and the wire current

ratings are higher than the power supply rating. Connect a DVM to the shunt.

3. Turn the front panel AC power switch to the On position,

4. Turn On the output by pressing OUT pushbutton so the OUT LED illuminates.

5. Observe the power supply CURRENT display and rotate the CURRENT encoder. Ensure that

the Output Current varies while the CURRENT encoder is rotated. The minimum control

range is from zero to the maximum rated output for the power supply model.

Compare the DVM reading with the front panel CURRENT display to verify the accuracy of

the CURRENT display. Ensure that the front panel CURRENT LED is On.

6. Turn Off the front panel AC power switch.

7. Remove the shunt from the power supply output terminals.

3.8.5 OVP Check

Refer to Section 5.3 for explanation of the OVP function prior to performing the procedure below.

1. Turn the front panel AC power switch to the On position and turn on the output by pressing

OUT pushbutton.

2. Using the VOLT encoder, adjust the Output Voltage to approx. 10% of the unit voltage rating.

3. Momentarily press the OVP/UVL button so that the CURRENT display shows “OUP”. The

VOLTAGE display will show the last setting of the OVP level.

4. Rotate the VOLT encoder CCW to adjust the OVP setting to 50% of the unit voltage rating.

5. Wait a few seconds until the VOLT display returns to show the Output Voltage.

6. Adjust the Output Voltage toward its maximum and check that the Output Voltage cannot be

increased more than the OVP setting.

7. Adjust OVP limit to the maximum by repeating Step 3 and rotating the VOLT encoder CW.

3.8.6 UVL Check

Refer to Section 5.4 for explanation of the UVL function prior to performing the procedure below.

1. Press the OVP/UVL button TWICE so that the CURRENT display shows “UUL”. The

VOLTAGE display will show the last setting of the UVL level.

2. Rotate the VOLT encoder to adjust the UVL level to approx. 10% of the unit voltage rating.

3. Wait a few seconds until the VOLT display returns to show the output voltage.

4. Adjust the output voltage toward its minimum and check that the output voltage cannot be

decreased below the UVL setting.

5. Adjust the UVL limit to the minimum by repeating step 1 and rotating the VOLT encoder CCW.

17

83-507-5002 Rev. B

Page 26

3.8.7 Foldback Check

WARNING

Shorting the output may expose the user to hazardous

voltages. Observe proper safety procedures.

Refer to Section 5.5 for explanation of the FOLD function prior to performing the procedure below.

1. Ensure that the Output Voltage is set to approx. 10% of the unit rating.

2. Adjust the CURRENT encoder to set the Output Current setting to approx. 10% of the unit

rating.

3. Momentarily press the FOLD button. Ensure that the FOLD LED illuminates. The Output

Voltage remains unchanged.

4. Short the output terminals momentarily (approx. 0.5 sec.). Ensure that the Output Voltage

falls to zero, the VOLT display shows “Fb” and the ALARM LED blinks.

5. Press the FOLD button again to cancel the protection. The Output Voltage remains zero.

6. Press the OUT button. Ensure that the Output Voltage returns to its last setting.

7. Turn the output off by pressing the OUT button. Ensure that the VOLT display shows “OFF”.

3.8.8 Address Setting

1. Press and hold the REM/LOC button for approx. 3 sec. The VOLT display will show the

communication port address.

2. Using the VOLT adjust encoder, check that the address can be set within the range of 0 to 30.

3.8.9 Baud Rate Setting (RS-232 and RS-485 only)

1. Press and hold the REM/LOC button for approx. 3 sec. The CURRENT display will show the

communication port Baud Rate.

2. Using The CURRENT adjust encoder, check that the Baud Rate can be set to 1200, 2400,

4800, 9600 and 19200.

3.9 CONNECTING THE LOAD

Turn Off the AC input power before making or changing any rear

panel connection. Ensure that all connections are securely tightened before applying power. There is a potential shock hazard

when using a power supply with a rated output greater than 40V.

3.9.1 Load Wiring

The following considerations should be made to select wiring for connecting the load to the

power supply:

∗ Current carrying capacity of the wire (refer to Section 3.9.2)

∗ Insulation rating of the wire should be at least equivalent to the maximum output voltage of

the power supply.

∗ Maximum wire length and voltage drop (refer to Section 3.9.2)

∗ Noise and impedance effects of the load wiring (refer to Section 3.9.4).

3.9.2 Current Carrying Capacity

Two factors must be considered when selecting the wire size:

1. Wires should be at least heavy enough not to overheat while carrying the power supply

load current at the rated load, or the current that would flow in the event the load wires

were shorted, whichever is greater.

WARNING

18

83-507-5002 Rev. B

Page 27

remote sensing. (Do not connect

-

S to +V or +S to

-

V).

2. Wire size should be selected to enable voltage drop per lead to be less than 1.0V at the

rated current. Although units will compensate for up to 5V in each load wire, it is recommended to minimize the voltage drop (1V typical maximum) to prevent excessive output

power consumption from the power supply and poor dynamic response to load changes.

Please refer to Tables 3-2 and 3-3 for minimum wire length (to limit voltage drop) in

American and European dimensions respectively.

Wire size

AWG

Resistivity

OHM/1000ft

5A 10A 20A 50A 150A

Maximum length in Feet to limit

voltage drop to 1V or less

14 2.526 80 40 20 8 2

12 1.589 120 60 30 12 3.4

10 0.9994 200 100 50 20 6

8 0.6285 320 160 80 32 10

6 0.3953 500 250 125 50 16

4 0.2486 800 400 200 80 26

2 0.1564 1200 600 300 125 40

0 0.0983 2000 1000 500 200 68

Table 3-2: Maximum wire length for 1V drop on lead (in feet)

Cross sect.

area

(mm²)

Resistivity

OHM/Km

Maximum length in meters to limit

voltage drop to 1V or less

5A 10A 20A 50A 150A

2.5 8.21 24.0 12.0 6.0 2.4 0.8

4 5.09 39.2 18.6 9.8 4.0 1.4

6 3.39 59.0 29.4 14.8 5.8 2.0

10 1.95 102.6 51.2 25.6 10.2 3.4

16 1.24 160.0 80.0 40.0 16.0 5.4

25 0.795 250.0 125.0 62.0 25.2 8.4

35 0.565 354.0 177.0 88.0 35.4 11.8

Table 3-3: Maximum wire length for 1 V drop on lead (in meters)

For currents not shown in Table 3-2 and 3-3, use the formula:

Where current is expressed in Amperes and resistivity in ohms/km or ohms/1000ft.

3.9.3 Wire termination

The wires should be properly terminated with terminals securely attached. DO NOT use unterminated wires for load connection at the power supply.

When local sensing, a short from +LS or +S to -V or -S or -LS,

will cause damage to the power supply. Reversing the sense

wires might cause damage to the power supply in local and

Maximum length=1000/(current x resistivity)

CAUTION

19

83-507-5002 Rev. B

Page 28

3.9.4 Noise and Impedance Effects

To minimize the noise pickup or radiation, the load wires and remote sense wires should be

twisted pairs to the shortest possible length. Shielding of sense leads may be necessary in high

noise environments. Where shielding is used, connect the shield to the chassis via a rear panel

Ground screw. Even if noise is not a concern, the load and remote sense wires should be

twisted-pairs to reduce coupling, which might impact the stability of power supply. The sense

leads should be separated from the power leads.

Twisting the load wires reduces the parasitic inductance of the cable, which could produce high

frequency voltage spikes at the load and the output of the power supply, because of current

variation in the load itself.

The impedance introduced between the power supply output and the load could make the ripple

and noise at the load worse than the noise at the power supply rear panel output. Additional filtering with bypass capacitors at the load terminals may be required to bypass the high frequency

load current.

3.9.5 Inductive loads

Inductive loads can produce voltage spikes that may be harmful to the power supply. A diode

should be connected across the output. The diode voltage and current rating should be greater

than the power supply maximum output voltage and current rating. Connect the cathode to the

positive output and the anode to the negative output of the power supply.

Where positive load transients such as back EMF from a motor may occur, connect a surge suppressor across the output to protect the power supply. The breakdown voltage rating of the suppressor must be approximately 10% higher than the maximum output voltage of the power supply.

3.9.6 Making the load connections

WARNING

Hazardous voltages may exist at the outputs and the load connections when using a power supply with a rated output greater than 40V.

To protect personnel against accidental contact with hazardous voltages, ensure that the load and its connections have no accessible live

parts. Ensure that the load wiring insulation rating is greater than or

equal to the maximum output voltage of the power supply.

CAUTION

Ensure that the load wiring mounting hardware does not short the output

terminals. Heavy connecting cables must have some form of strain relief

to prevent loosening the connections or bending the bus-bars.

6V to 60V Models

Refer to Fig.3-5 for connection of the load wires to the power supply bus-bars and to Fig.3-6 for

mounting the bus-bars shield to the chassis.

20

83-507-5002 Rev. B

Page 29

Fig. 3-6: bus-bars shield mounting

80V to 600V Models

Hazardous voltages exist at the outputs and the load connections. To

protect personnel against accidental contact with hazardous voltages,

ensure that the load and its connections have no accessible live parts.

Ensure that the load wiring insulation rating is greater than or equal to

the maximum output voltage of the power supply.

WARNING

21

83-507-5002 Rev. B

Page 30

The 80V to 600V models have a four terminal wire clamp output connector. The two left terminals

are the positive outputs and the two right terminals are the negative outputs. The connector requirements are as follows:

1. Wires: AWG18 to AWG10.

2. Tightening torque: 6.5-7.0 Lb-inch.

Follow the instructions below for connection of the load wires to the power supply:

1. Strip approx. 10mm (0.39 inches) at the end of each of the wires.

2. Loosen the connector terminal screws.

3. Insert the stripped wires into the terminal and tighten the terminal screw securely (see

Fig.3-7)

4. Loosen the two chassis screws marked “A” halfway as shown in Fig.3-8.

5. Assemble the protective shield to the chassis and tighten the two screws to fix the shield

to the chassis (see Fig.3-8). Screws tightening torque: 4.8-5.3 Lb-inch.

6. Tighten the wires to one of the shield sides using ty-wrap or equivalent. Refer to Fig.3-9.

Ensure that the wire length inside the shield is long enough to provide proper strain relief.

22

83-507-5002 Rev. B

Page 31

Load

Load

3.9.7 Connecting single loads, local sensing (default).

Fig.3-10 shows recommended load and sensing connections for a single load. The local sense

lines shown are default connections at the rear panel J2 sense connector. Local sensing is suitable for applications where load regulation is less critical.

Power

Supply

-

Rem.sense

-

Local sense

Local sense

+

Rem.sense

+

Fig.3-10: Single load connection, local sensing

+V

-V

+

Load lines, twisted

pair, shortest length

possible.

3.9.8 Connecting single loads, remote sensing

Fig.3-11 shows recommended remote sensing connection for single loads. Remote sensing is

used when, in Constant Voltage mode, the load regulation is important at the load terminals. Use

twisted or shielded wires to minimize noise pick-up. If shielded wires are used, the shield should

be connected to the ground at one point, either at the power supply chassis or the load ground.

The optimal point for the shield ground should be determined by experimentation.

Load lines. Twisted pair

shortest length possible.

Power

+V

-V

+

Supply

-

Rem.sense

-

Local sense

Local sense

+

Rem.sense

+

Sense lines. Twisted

pair or shielded.

Fig.3-11: Remote sensing, single load

3.9.9 Connecting multiple loads, radial distribution method

Fig.3-12 shows multiple loads connected to one supply. Each load should be connected to the

power supply’s output terminals using separate airs of wires. It is recommended that each pair of

wires will be as short as possible and twisted or shielded to minimize noise pick-up and radiation.

The sense wires should be connected to the power supply output terminals or to the load with the

most critical load regulation requirement.

23

83-507-5002 Rev. B

Page 32

Load#3

Load#2

Distribution terminal

Load#3

Load#2

Power

Supply

-

Rem.sense

-

Local sense

Local sense

+

Rem.sense

+

+V

-V

Fig.3-12: Multiple loads connection, radial distribution, local sense

Load lines, twisted pair,

shortest length possible.

+

Load#1

+

+

3.9.10 Multiple load connection with distribution terminals

If remotely located output distribution terminals are used, the power supply output terminals

should be connected to the distribution terminals by pair of twisted and/or shielded wires. Each

load should be separately connected to the remote distribution terminals (see Fig.3-13).

If remote sensing is required, the sensing wires should be connected to the distribution terminals

or at the most critical load.

Power

Supply

+V

-V

-

Rem.sense

-

Local sense

Local sense

+

Rem.sense

+

+V

-V

+

Load#1

+

+

Fig.3-13: Multiple loads connection with distribution terminal

3.9.11 Grounding outputs

Either the positive or negative output terminals can be grounded. To avoid noise probems

caused by common-mode current flowing from the load to ground, it is recommended to ground

the output terminal as close as possible to the power supply chassis ground.

Always use two wires to connect the load to the power supply regardless of how the system is

grounded.

WARNING

Models up to 60VDC Rated Output shall not float outputs more

than +/-60VDC above/below chassis ground. Models > 60VDC

Rated Output shall not float outputs more than +/-600VDC

above/below chassis ground.

24

83-507-5002 Rev. B

Page 33

Terminal

Function

J2-1 Remote positive sense (+S)

J2-2 Local positive sense. Connected intern

ally to the positive output terminal (+LS).

J2-3 Not connected (NC)

J2-4 Local negative sense. Connected internally to the negative output terminal (

-

LS).

J2-5 Remote negative sense (

-

S).

There is a potential shock hazard at the RS232/RS485 and the IEEE ports when

using power supplies with rated or combined voltage greater than 400V with the

Positive Output of the power supplies grounded. Do not connect the Positive output to ground when using the RS232/RS485 or IEEE under the above conditions.

OUTPUT TERMINAL GROUNDING

WARNING

3.10 LOCAL AND REMOTE SENSING

The rear panel J2 sense connector is used to configure the power supply for local or remote

sensing of the Output Voltage. Refer to Fig.3-14 for sense connector location.

3.10.1 Sense wiring

WARNING

There is a potential shock hazard at the sense connector when using a power

supply with a rated Output Voltage greater than 40V. Local sense and remote

sense wires should have a minimum insulation rating equivalent or greater than

the maximum Output Voltage of the power supply. Ensure that the connections at

the load end are shielded to prevent accidental contact with hazardous voltages.

3.10.2 Local sensing

The power supply is shipped with the rear panel J2 sense connector wired for local sensing of

the Output Voltage. See Table 3-4 for J2 terminals assignment. With local sensing, the Output

Voltage regulation is made at the output terminals. This method does not compensate for voltage

drop on the load wires, therefore it is recommended only for low load current applications or

where the load regulation is less critical.

Fig.3-14: Sense connector location

Table 3-4: J2 terminals

25

83-507-5002 Rev. B

Page 34

3.10.3 Remote sensing

WARNING

There is a potential shock hazard at the sense point when using a power supply

with a rated Output Voltage greater than 40V. Ensure that the connections at the

load end are shielded to prevent accidental contact with hazardous voltages.

CAUTION

When using shielded sense wires, ground the shield

in one place only. The location can be the power

supply chassis or one of the output terminals.

Use remote sense where the load regulation at the load end is critical. In remote sense, the

power supply will compensate for voltage drop on the load wires. Refer to the power supply

specifications for the maximum voltage drop on load wires. The voltage drop is subtracted from

the total voltage available at the output. Follow the instructions below to configure the power

supply for remote sensing:

1. Ensure that the AC On/Off is in the Off position.

2. Remove the local sense jumpers from J2.

3. Connect the negative sense lead to terminal J2-5 (S) and the positive sense lead to terminal

J2-1(+S) of the J2 mating connector. Ensure that the J2 mating connector is plugged securely into the rear panel sense connector, J2.

4. Turn On the power supply.

Notes:

1. If the power supply is operating in remote sense and either the positive or negative load wire

is not connected, an internal protection circuit will activate and shut down the power supply.

To resume operation, turn the AC On/Off to the Off position, connect the open load wire, and

turn On the power supply.

2. If the power supply is operated without the remote sense lines or local sense jumpers, it will

continue to work, but the output voltage regulation will be degraded. Also, the OVP circuit

may activate and shut down the power supply.

3.10.4 J2 sense connector technical information

- J2 connector type: MC 1.5/5-G-3.81, Phoenix.

- Plug type: MC 1.5/5-ST-3.81, Phoenix.

- Wire AWG; 28 up to 16.

- Stripping length: 7mm (0.28 inches).

- Tightening torque: 0.22-0.25Nm (1.95-2.21Lb-Inch.)

3.11 REPACKAGING FOR SHIPMENT

To ensure safe transportation of the instrument, contact the TDK-Lambda Americas Inc. sales or

service facility near you for Return Authorization and shipping information. Please attach a tag to

the power supply describing the problem and specifying the owner, model number and serial

number of the power supply. Refer to Warranty Information for further instructions.

26

83-507-5002 Rev. B

Page 35

10

4115

12

967