Page 1

Programmable DC Power Supplies

Genesys

TM

Programmable DC Power Supplies

750W /1500W in 1U

750W /1500W in 1U

Built in RS-232 & RS-485 Interface

Built in RS-232 & RS-485 Interface

Parallel Current Summing

Parallel Current Summing

Optional Interfaces: USB

Optional Interfaces: USB

Compliant

Compliant

IEEE488.2 SCPI Multi-Drop

IEEE488.2 SCPI Multi-Drop

Isolated Analog Interface

Isolated Analog Interface

LAN

LAN

GenesysTM Family

GEN H 750W Half Rack

GEN 1U 750/1500W Full Rack

GEN 2U 3.3/5kW

GEN 3U 10/15kW

www.us.tdk-lambda.com/hp

Page 2

The Genesys™ family of programmable power supplies sets a new standard for flexible, reliable,

AC/DC power systems in Test & Measurement, Industrial and Laboratory applications.

Genesys™ power supplies are designed for demanding applications.

Common controls are shared across all platforms.

Test and Measurement

Last-Setting memory simplifies test design and requires no battery backup.

Built-in RS-232/RS-485 gives maximum system flexibility along with 0-5V and 0-10V, selectable analog programming.

Wide range of available outputs allows testing of many different devices.

Semiconductor Processing

Equipment designers appreciate the wide range Input (85-265Vac) and numerous Outputs from which to select

depending on application. Selectable Safe and Auto Re-start protects loads and process integrity.

Typical applications include Magnets, Filaments and Heaters.

Aerospace and Satellite Testing

Complex systems use the complete Genesys ™ Family: 1U 750W Half Rack, 1U 750W or 1500W Full-Rack, 2U 3.3kW

and 3U 10/15kW. All are identical in Front Panel, Rear Panel Analog and Digital Interface Commands. A wide variety of

outputs allows testing of many different devices.

Laser Diode

OVP is directly set on Voltage Display, assuring accurate protection settings.

Current Limit Fold Back assures load is protected from current surges.

Heater Supplies

Smooth, reliable encoders with selectable Fine and Coarse adjustment enhance Front Panel Control.

Remote Analog Programming is user selectable 0-5V or 0-10V and optional Isolated Programming/Monitoring Interfaces

are also available.

RF Amplifiers and Magnets

Robust design assures stable operation under a wide variety of loads.

High linearity in voltage and current mode.

1|

Genesys 750W/1500W-1U

TM

Page 3

Front Panel Description

1

2 4

3 6 5

8

1. AC ON/OFF Switch

2. Air Intake allows zero stacking for maximum system flexibility and power density.

3. Reliable encoder controls Output Voltage and sets Address.

4. Volt Display shows Output V P

5. Reliable encoder controls Output Current, sets baudrate, and Advanced Parallel Mode

6. Current Display shows Output Current and displays baudrate.

7. Function/Status LEDs:

Alarm

•

Fine Control

•

Preview Settings

•

8. Pushbuttons allow flexible user configuration

Coarse and fine Adjustment of Output Voltage/Current and Advanced Parallel Master or Slave select.

•

Preview settings and set Voltage/Current with Output OFF

•

Set OVP and UVL Limits

•

Set Current Foldback

•

Local/Remote Mode and select Address and Baudrate

•

Output ON/OFF and Auto-Start/Safe-Start Mode

•

oltage and directly displays OV L, UV and Address settings.

Foldback Mode

•

Remote Mode

•

Output On

•

7

Rear Panel Description

9

2 81 4 6 7 85

1. Remote/Local Output Voltage Sense Connections.

2. DIP Switches select 0-5V or 0-10V Programming and other functions.

3. DB25 (Female) connector allows (Non-isolated) Analog Program and Monitor and other functions.

4. RS-485 OUT to other Genesys™ Power Supplies.

5. RS-232/RS-485 IN Remote Serial Programming.

6. Output Connections: R

7. Exit air assures reliable operation when zero stacked.

8. Wide-Range Input 85-265VAC continuous, 47/63Hz with Active Power Factor Correction (0.99 typical)

AC Input Connector: 750W (IEC320), 1500W (screw terminal-shown).

9. Optional Interface Position for IEEE488.2 SCPI (shown), Isolated Analog Interface,

LAN Interface or USB Interface.

ged busbars for up to 60V Output; Terminal block for Outputs >60V.

ug

LAN Interface complies with Class C Specification

|2

Page 4

Genesys

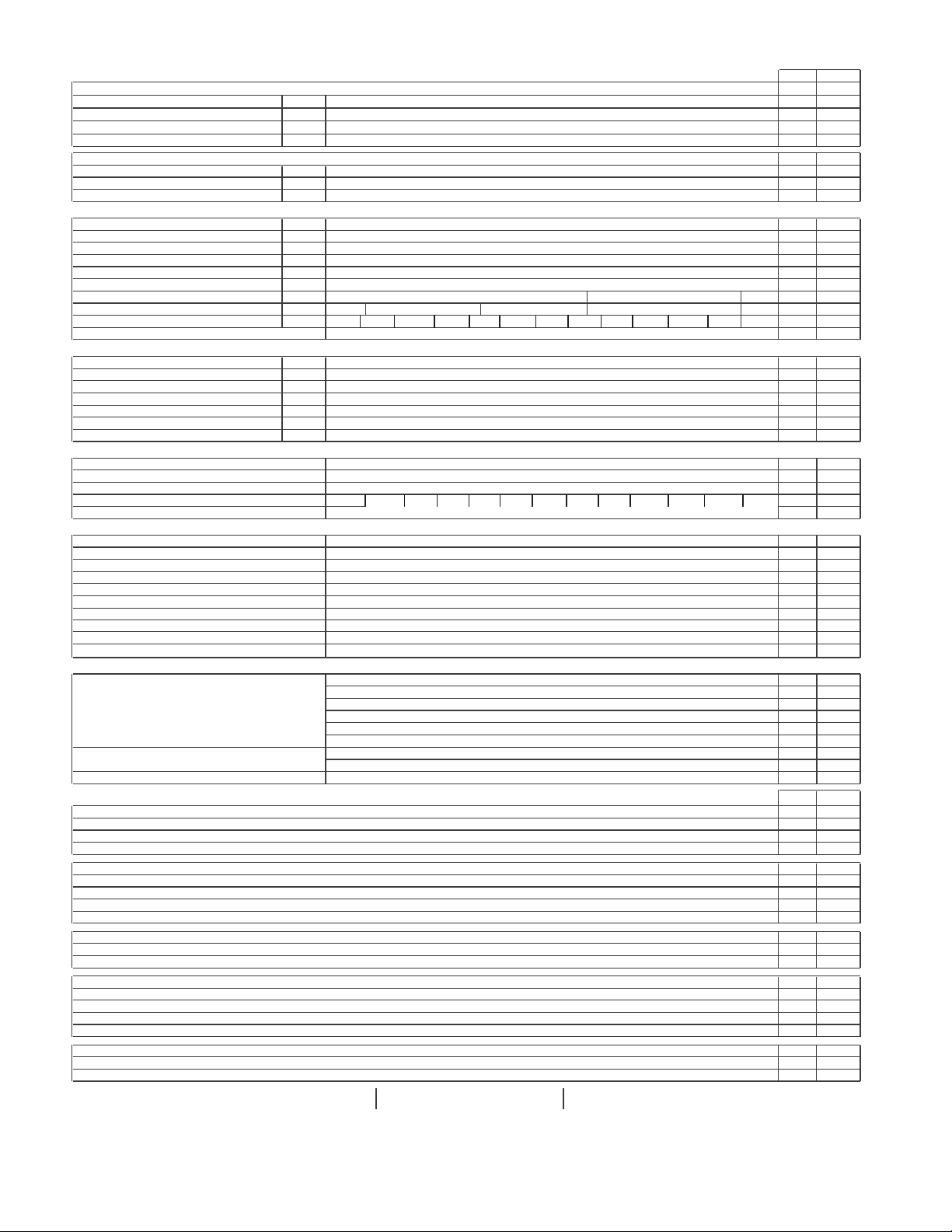

1.0 MODEL

1.Rated output voltage(*1)

2.Rated Output Current(*2)

3.Rated Output Power

4.Efficiency at 100/200Vac (*3)

1.0 MODEL

1.Rated output voltage (*1)

2.Rated Output Current (*2)

3.Rated Output Power

1.1 CONSTANT VOLTAGE MODE

1.Max.line regulation ( 0.01% of Vo+ 2mV )(*4)

2.Max load regulation ( 0.01% of Vo+2mV )(*5)

3.Ripple and noise p-p 20MHz

4.Ripple r.m.s 5Hz~1MHz

5.Remote sense compensation/line

6.Temp. coefficient

7.Up-prog. response time, 0~Vo Rated

8.Down-prog response time full-load

9.Down-prog response time no-load

10.Transient response time (*8)

1.2 CONSTANT CURRENT MODE

1.Max.line regulation (0.01% of Io+ 2mA)(*4)

2.Max.load regulation (0.02% of Io+5mA)(*6)

3.Ripple r.m.s 5Hz~1MHz . (*7)

4.Max.line regulation (0.01% of Io+ 2mA)(*4)

5.Max.load regulation (0.02% of Io+5mA)(*6)

6.Ripple r.m.s 5Hz~1MHz .(*7)

7.Temp. coefficient

1.3 PROTECTIVE FUNCTIONS

1. OCP

2. OCP Foldback

3. OVP type

4. OVP trip point

5. Over Temp. Protection

1.4 ANALOG PROGRAMMING AND MONITORING

1.Vout Voltage Programming

2.Iout Voltage Programming

3.Vout Resistor Programming

4.Iout Resistor Programming

5.On/Off control (rear panel)

6.Output Current monitor

7.Output Voltage monitor

8.Power Supply OK signal

9. CV/CC indicator

10. Enable/Disable

1.5 FRONT PANEL

1.Control functions

2.Display

3.Indications

750W/1500W Specifications

™

20-76

12.5-120

8-180

6-200

GEN

V

A

W

%

GEN

V

A

W

mV

mV

mV

mV

V

PPM/°CC

mS

mS

mS

Less than 1mSec for models up to and including 100V. 2msec for models above 100V

mA

mA

mA

mA

mA

mA

PPM/°CC 100PPM/°CC from rated output voltage,following 30 minutes warm up

0~105% Constant Current

Output shut down when power supply change from CV to CC. User selectable.

Inverter shut-down, manual reset by AC input recycle or by OUT button

User selectable , latched or non latched

0~100%, 0~5V or 0~10V, user select. Accuracy and linearity:+/-0.5% of rated Vout.

0~100%, 0~5V or 0~10V, user select. Accuracy and linearity:+/-1% of rated Iout.

0~100%, 0~5/10Kohm full scale,user select.,Accuracy and linearity:+/-1% of rated Vout.

0~100%, 0~5/10Kohm full scale,user select. Accuracy and linearity:+/-1.5% of rated Iout.

By electrical. Voltage: 0~0.6V/2~15V,or dry contact ,user selectable logic

0~5V or 0~10V , accuracy:1% , user selectable

0~5V or 0~10V ,accuracy:1% ,user selectable

TTL High=OK, 0V-Fail 500ohm impedance

CV: TTL high (4~5V) source: 10mA, CC: TTL low (0~0.4V):10mA

Dry contact. Open:off , Short: on. Max. voltage at Enable/Disable in: 6V

Vout/ Iout manual adjust by separate encoders (coarse and fine adjustment selectable)

OVP/UVL manual adjust by Volt. Adjust encoder

AC on/off, Output on/off, Re-start modes (auto, safe), Foldback control (CV to CC), Go to local control

Address selection by Voltage (or current) adjust encoder. Number of addresses:31

RS232/485 and IEEE488.2 selection by IEEE enable switch and DIP switch

Baudrate selection: 1200,2400,4800,9600 and 19,200

Voltage

Current

Voltage, Current, Alarm, Fine, Preview, Foldback, Local, Output On

8

6

180

200

1440

1200

78/81

77/80

8-90

6-100

8

6

90

100

720

600

2.8

2.6

2.8

2.6

60

60

8

8

1

1

100PPM/°CC of rated output voltage,following 30 minutes warm up

80mS , N.L/F.L , resistive load

10

600

500

11

12

23

25

180

200

20

22

41

45

360

400

5.5 70. ~ V

10.5~ 0V 1~15V 1~24V 2~36V 2~44V 5~66V 5~88V 5~110V 5~165V 5~330V 5~660V

4 digits , accuracy: 0.5%+/-1 count

4 digits, accuracy: 0.5%+/-1 count

12.5

120

1500

81/84

12.5-60

12.5

60

750

3.3

3.3

60

8

1

50

700

8.0

17

120

14

29

240

20

76

1520

83/86

20-38

20

38

760

60

800

5.8

12.6

76

9.6

20.2

152

50-30

1500

84/88

80

5~57V

60-25

80

60

50

30

---

---

---

---

7

7

60

8

2

1100

---

---

--5

11

85

1

19

25

1520

1500

84/88

84/88

80-9.5

60-12.5

80

60

9.5

12.5

760

750

10

8

10

8

80

60

8

8

4

3

150mS , N.L/F.L , resistive load

1200

100

2.95

3.25

6.9

7.5

29

38

3.9

4.5

8.8

10

57

75

100

15

1500

84/88

100-7.5

100

7.5

750

12

12

80

8

5

1500

2.75

6.5

23

3.5

8.0

45

150

1500

84/88

150-5

150

750

100

150

2000

2.5

6.0

3.0

7.0

600-2.6

300

600

5

10

5

17

17

10

5

18

35

1500

83/87

300-2.5

300

2.5

750

32

32

120

20

5

2500

2.25

5.5

13

2.5

6.0

25

2.6

1560

83/87

600-1.3

600

1.3

780

62

62

300

60

5

250

250

4000

2.13

5.26

8

2.26

5.52

12

40-38

30-50

40

30

38

50

1520

1500

84/88

83/86

40-19

30-25

40

30

19

25

760

750

6

5

4

4

8

1

60

1.5

900

4.5

10

63

7.0

15

125

6

5

60

8

8

2

1000

3.9

8.8

48

5.8

12.6

95

300-5

150-10

100-15

80-19

1.6 Interface RS232&RS485 or Optional GPIB Interface

80

6

8

0.96

6.0

8.0

10.8

12

180

24

21.6

360

0.96

16

12

12

10.8

360

400

24

21.6

720

800

6

8

60

80

*3: At maximum output power.

*4: 85~132Vac or 170~265Vac, constant load.

mV

mV

mA

mA

mA

mA

mV

mV

mA

mA

mA

mA

mV

mV

V

0.72

200

400

0.72

Model

1. Remote Voltage Programming (16 bit)

Resolution (0.012% of Vo Rated)

Accuracy (0.05%Vo Rated+0.05% of Vo Actual Output)

2. Remote Current Programming (16 bit)

Resolution (0.012% of Io Rated)

Accuracy (0.1% of Io Rated+0.1% of Io Actual Output)

Resolution (0.012% of Io Rated)

Accuracy (0.1% of Io Rated+0.1% of Io Actual Output)

3. Read back Voltage

Resolution (0.012% of Vo Rated)

Accuracy (0.1%Vo Rated+0.1% of Vo Actual Output)

4. Read back Current

Resolution (0.012% of Io Rated )

Accuracy (0.3% of Io Rated+0.1% of Io Actual Output)

Resolution (0.012% of Io Rated )

Accuracy (0.3% of Io Rated+0.1% of Io Actual Output)

5. OVP/UVL Programmi ng

Resolution (0.1% of Vo Rated)

Accuracy (1% of Vo Rated)

*1: Minimum voltage is guaranteed to maximum 0.2% of Vo Rated.

*2: Minimum current is guaranteed to maximum 0.4% of Io Rated

*7: For 6V models the ripple is measured at 2~6V output voltage and full output current. For other models, the ripple is measured at 10~100% output voltage and full output current.

*8: Time for the output voltage to recover within 0.5% of its rated for a load change 10~90% of rated output , Output set-point:10~100%.

Accuracy -Values have been calculated at Vo Rated & Io Rated

12.5

1.50

12.5

120

14.4

240

1.50

7.2

240

14.4

480

125

7.2

25

12

20

2.40

20

4.56

76

9.12

152

2.40

40

4.56

152

9.12

304

20

200

3.60

30

3.0

50

6.0

100

3.60

60

3.0

100

200

30

300

4.80

40

2.28

38

4.56

76

4.80

80

2.28

76

4.56

6

152

40

400

40

30

60

50

7.2

6

60

50

---

1.50

---

25

3.0

3.60

50

60

7.2

6.0

120

100

---

1.50

---

50

3.0

3.60

100

120

60

50

600

500

*5: From No-load to Full-load, constant input voltage.

*6: For load voltage change, equal to the unit voltage rating, constant input voltage.

9.6

80

1.14

19

2.28

38

9.6

160

1.14

38

2.28

76

80

800

100

12

100

0.90

15

1.80

30

12

200

0.90

30

1.80

60

100

1000

150

18

150

0.60

10

1.20

20

18

300

0.60

20

1.20

40

150

1500

300

36

300

0.30

5.0

0.60

10

36

600

0.30

10

0.60

20

300

3000

600

72

600

0.16

2.6

0.32

5.2

72

1200

0.16

5.2

0.32

10.4

600

6000

750W 1500W

750W

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

1500W

X X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

3|

Genesys 750W/1500W-1U

TM

Page 5

General Specifications Genesys™ 750W/1500W

2.1 INPUT CHARACTERISTICS

1. Input voltage/freq. (*1)

2. Power Factor 0.99 @100/200Vac, rated output power.

3. EN61000-3-2,3 compliance Complies with EN61000-3-2 class A and EN61000-3-3 at 20~100% output power.

4. Input current 100/200Vac

5. Inrush current 100/200Vac 750W :Less than 25A, 1500W :Less than 50A

6. Hold-up time

2.2 POWER SUPPLY CONFIGURATION

1. Parallel Operation

2. Series Operation

2.3 ENVIRONMENTAL CONDITIONS

1. Operating temp

2. Storage temp

3. Operating humidity

4. Storage humidity

5. Vibration

6. Shock

7. Altitude

2.4 EMC

1.Applicable Standards:

2.ESD

3.Fast transients IEC1000-4-4. 2KV

4.Surge immunity IEC1000-4-5. 1KV line to line, 2KV line to ground

5.Conducted immunity

6.Radiated immunity IEC1000-4-3, 3V/m

7.Conducted emission EN55022B,FCC part 15J-B,VCCI-2

8.Radiated emission

9.Voltage dips EN61000-4-11

10. Conducted emission

11. Radiated emission

2.5 SAFETY

1.Applicable standards:

2.Withstand voltage

3.Insulation resistance

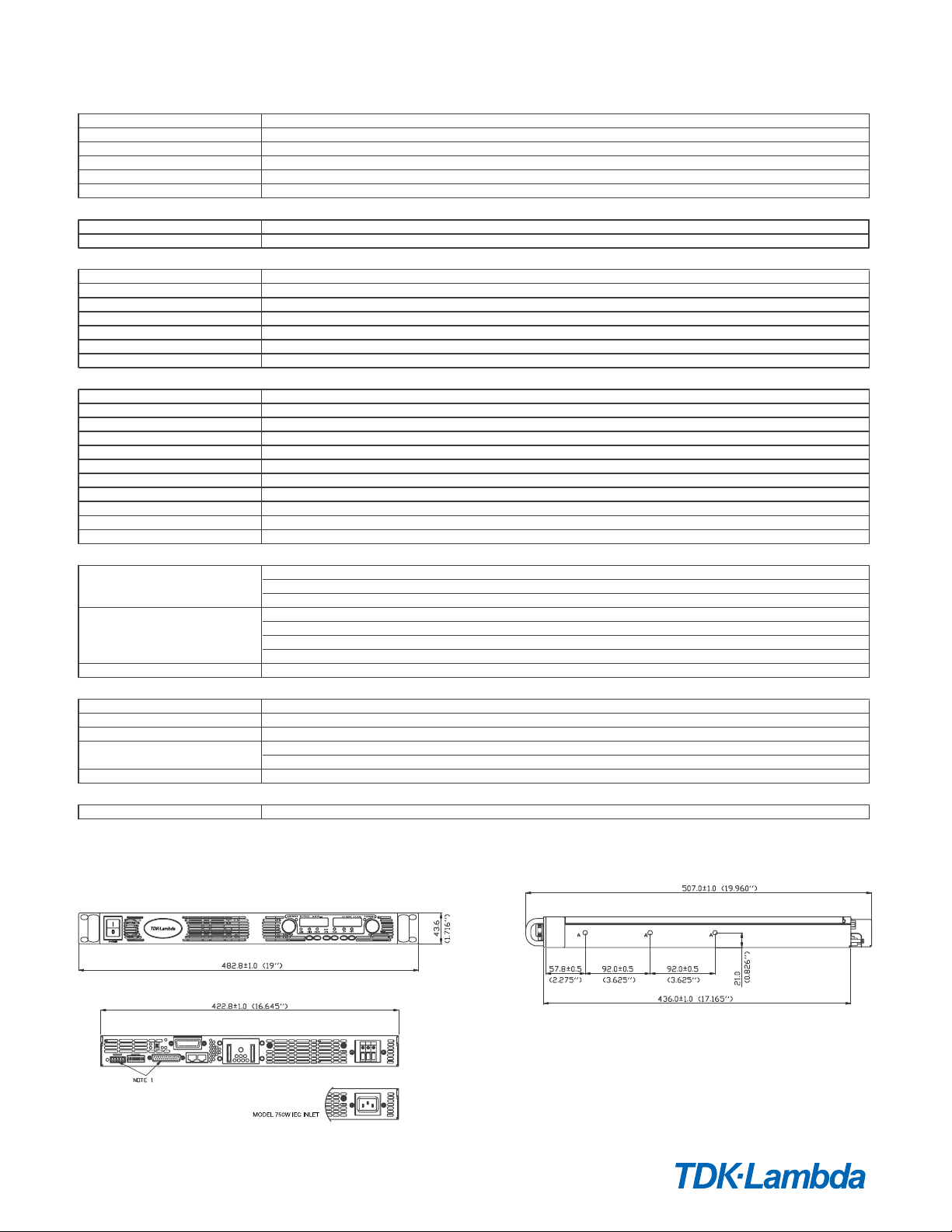

2.6 MECHANICAL CONSTRUCTION

1. Cooling

2. Dimensions (WxHxD) W: 16.64in, H: 1.72in, D: 17.04in (excluding connectors, encoders, handles, etc.)

3. Weight

4. AC Input connector 750W: IEC320 AC Inlet.

5.Output connectors

2.7 RELIABILITY SPECS

1. Warranty 5 years.

85~265Vac continuous, 47~63Hz, single phase

750W :10.5A / 5A, 1500W :21A / 11A

More than 20mS , 100Vac , at 100% load.

Up to 4 identical units in master/slave mode with parallel current summing (Advanced Parallel)

Up to 2 units. with external diodes. 600V Max to Chassis ground

0~50 °C, 100% load.

-20~70 °C

30~90% RH (non-condensing).

10~95% RH (non-condensing).

MIL-810E, method 514.4 , test cond. I-3.3.1. The EUT is fixed to the vibrating surface.

Less than 20G , half sine , 11mSec. Unit is unpacked.

Operating: 10000ft (3000m) , Non operating: 40000ft (12000m).

IEC1000-4-2. Air-disch.-8KV, contact disch.-4KV

IEC1000-4-6, 3V

EN55022A,FCC part 15-A,VCCI-1

EN55022B, FCC part 15-B, VCCI-2.

EN55022A, FCC part 15-A, VCCI-1.

CE Mark, UL60950,EN60950 listed. Vout<60V:Output is SELV , IEEE/Isolated analog are SELV.

60<Vout<400V: Output is hazardous, IEEE/Isolated analog are SELV.

400<Vout<600V:Output is hazardous, IEEE/Isolated analog are not SELV.

Vout<60V models :Input-Outputs (SELV): 3.0KVrms 1min, Input-Ground: 2.0KVrms 1min.

60<Vout<600V models: Input-Haz. Output: 2.5KVrms 1min, Input-SELV: 3KVrms 1min.

Hazardous Output.-SELV: 1.9KVrms 1min, Hazardous Output-Ground:1.9KVrms 1min.

Input-Ground: 2KVrms 1min.

More than 100Mohm at 25 C , 70% RH, 500Vdc

Forced air flow: from front to rear. No ventilation holes at the top or bottom of the chassis; Variable fan speed.

750W: 7Kg (15 Lbs) 1500W: 8.5Kg (18 Lbs)

1500W: Screw terminal block, Phoenix P/N: FRONT-4-H-7.62 , with strain relief

6V to 60V models: Bus-bars (hole Ø 8.5mm). 80V to 600V models: Terminal block, Phoenix P/N: FRONT-4-H-7.62

*1: For cases where conformance to various safety standards (UL, IEC etc.) is required, to be described as 100-240Vac (50/60Hz).

Outline Drawing Genesys™ 750W/1500W Units

NOTE

1. PLUG CONNECTORS INCLUDED WITH THE POWER SUPPLY

2. CHASSIS SLIDES MOUNTING HOLES #10-32 MARKED "A"

GENERAL DEVICES P/N: CC301-00-S160 OR EQUIVALENT

|4

Page 6

Genesys™ Power Parallel and Series Configurations

Parallel operation - Master/Slave:

Active current sharing allows up to four identical units to be connected

in an auto-parallel configuration for four times the output power.

In Advanced Parallel Master/Slave Mode, total current is

programmed and reported by the Master. Up to four supplies

act as one.

Series operation

Up to two units may be connected in series to increase the output

voltage or to provide bipolar output. (Max 600V to Chassis Ground).

Remote Programming via RS-232 & RS-485 Interface

Standard Serial Interface allows daisy-chain control of up to 31

power supplies on the same communication bus with built-in

RS-232 & RS-485 Interface with or without Multi-Drop option.

Programming Options (Factory installed)

New IEEE Multi-Drop Interface

• Allows IEEE Master to control up to 30 (Multi-Drop equipped) slaves over RS-485 daisy-chain

• Only the Master needs be equipped with IEEE Interface

• IEEE 488.2 SCPI Compliant

• Program Voltage • Program Current

• Measure Voltage • Measure Current

• Over Voltage setting and shutdown • Current Foldback shutdown

• Error and Status Messages

New Multi-Drop Slave Option

• Slaves need to be equipped with the MD Slave (RS-485) option

Isolated Analog Programming

• Four Channels to Program and Monitor Voltage and Current.

• Isolation allows operation with floating references in harsh electrical environments.

• Choose between programming with Voltage or Current.

• Connection via removable terminal block: Phoenix MC1,5/8-ST-3.81.

• Voltage Programming, user-selectable 0-5V or 0-10V signal.

Power supply Voltage and Current Programming Accuracy ±1%

Power supply Voltage and Current Monitoring Accuracy ±1.5%

• Current Programming with 4-20mA signal.

Power supply Voltage and Current Programming Accuracy ±1%

Power supply Voltage and Current Monitoring Accuracy ±1.5%

P/N: IEMD

P/N: MD

P/N: IS510

P/N: IS420

LAN Interface

• Meets all LXI-C Requirements

• Address Viewable on Front Panel

• Fixed and Dynamic Addressing

• Fast Startup

Compliant to Class C

• VISA & SCPI Compatible

• LAN Fault Indicators

• Auto-detects LAN Cross-over Cable

• Compatible with most standard Networks

USB Interface

• Allows Serial Connection to USB Port on computer

• Serial commands same as (standard) RS-232/RS-485 Interface

5|

Genesys 750W/1500W-1U

TM

P/N: LAN

P/N: USB

Page 7

Power Supply Identification / Accessories

How to order

GEN

Series

Name

Models 750/1500W

Model

GEN6-100

GEN6-200

GEN8-90

GEN8-180

GEN12.5-60

GEN12.5-120

GEN20-38

GEN20-76

GEN30-25

GEN30-50

GEN40-19

GEN40-38

Factory option P/N

RS-232/RS-485 Interface built-in Standard GPIB (Multi-Drop Master) Interface IEMD

Multi-Drop Slave Interface MD

Voltage Programming Isolated Analog Interface IS510

Current Programming Isolated Analog Interface IS420

LAN Interface (Complies with Class C) LAN

USB Interface USB

600

Output

Voltage

(0~600V)

Output

Voltage

VDC

0~6V

0~8V

0~12.5V

0~20V

0~30V

0~40V

Output

Current

( A )

0~100

0~200

0~90

0~180

0~60

0~120

0~38

0~76

0~25

0~50

0~19

0~38

2.6-

Output

Current

(0~2.6A)

Output

Power

( W )

600

1200

720

1440

750

1500

760

1520

750

1500

760

1520

-

Factory Options AC Cable option is 750W only

Option:

IEMD

MD

IS510

IS420

LAN

-

Region:

E - Europe

J - Japan

I - Middle East

U - North America

USB

Model

GEN50-30

GEN60-12.5

GEN60-25

GEN80-9.5

GEN80-19

GEN100~7.5

GEN100~15

GEN150~5

GEN150~10

GEN300~2.5

GEN300~5

GEN600~1.3

GEN600~2.6

Output

Voltage

VDC

0~50V

0~60V

0~80V

0~100V

0~150V

0~300V

0~600V

Output

Current

0~12.5

0~9.5

0~7.5

0~2.5

0~1.3

0~2.6

( A )

0~30

0~25

0~19

0~15

0~5

0~10

0~5

Output

Power

( W )

1500

750

1500

760

1520

750

1500

750

1500

750

1500

780

1560

AC Cords sets (750W only)

Region

Output Power

AC Cords

Wall Plug

Power Supply

Connector

Part Number

Europe

750W

10A/250 Vac L=2m

INT'L 7/VII

IEC320-C13

P/N: GEN/E

Japan

750W

13A/125 Vac L=2m

IEC320-C13

P/N: GEN/J

10A/250 Vac L=2m

Accessories

1. Communication cable

RS-232/RS-485 Cable is used to connect the power supply to the PC Controller.

Mode

PC Connector

Communication Cable

Power Supply Connector

DB-9F

Shield Ground L=2m

EIA/TIA-568A (RJ-45)

P/N

2. Serial link cable*

Daisy-chain up to 31 Genesys™ power supplies.

Mode

RS-485

* Included with power supply

RS485

GEN/485-9

Power Supply Connector

EIA/TIA-568A (RJ-45)

RS232

DB-9F

Shield Ground L=2m

EIA/TIA-568A (RJ-45)

GEN/232-9

Communication Cable

Shield Ground L=50cm

Middle East

750W

SI-32

IEC320-C13

P/N: GEN/I

North America

750W

13A/125 Vac L=2m

NEMA 5-15P

IEC320-C13

P/N : GEN/U

RS232

DB-25F

FShield Ground L=2m

EIA/TIA-568A (RJ-45)

GEN/232-25

P/N

GEN/RJ45

|6

Page 8

GLOBAL NETWORK

USA

TDK-Lambda Americas Inc.

405 Essex Rd. Neptune, NJ 07753

Tel: +1-732-922-9300 Fax: +1-732-922-1441

E-mail: sales@us.tdk-lambda.com

www.us.tdk-lambda.com/hp

CANADA

ACA TMetrix

5805 Kennedy Road, Mississauga, Ontario, L4Z 2G3

Tel: +1-800-665-7301 Fax: +1-905-890-1959

Email: lambda@aca.ca

tmetrix.com

MEXICO

AcMax de Mexico

39 Poniente 3515 Piso 5 Col. Las Animas

Puebla, Pue. C.P. 72400

Tel: 01-800-211-0060 / (222) 891-8484 Fax: 222-264-1445

Email: info@acmax.mx, Web: www.acmax.mx

BRAZIL

Supplitec

Rua Sena Madureira 455, Belo Hte - 31340-000

Tel: +55-31-3498 1177 Fax: +55-31-3441 0841

www.suplitec.com.br

UK IRELAND

TDK-Lambda UK

Kingsley Avenue

Ilfracombe, Devon EX 34 8ES

Tel: +44-1271-856666 Fax: +44-1271-864894

E-mail: powersolutions@uk.tdk-lambda.com

www.uk.tdk-lambda.com

FRANCE NETHERLANDS SPAIN

TDK-Lambda France

ZAC des Delaches, CS 41077

9 rue Thuillere, 91978 Villebon Courtaboeuf

Tel: +33 1 60 12 71 65 Fax: +33 1 60 12 71 66

www.fr.tdk-lambda.com

GERMANY AUSTRIA SWITZERLAND

TDK-Lambda Germany

Karl-Bold-Str.40, D-77855 Achern

Tel: +49-7841-666-0 Fax: +49-7841-500-0

E-mail: info.germany@de.tdk-lambda.com

www.de.tdk-lambda.com

ITALY

TDK-Lambda Italy

Via dei Lavoratori 128/130

IT 20092 Cinisello Balsamo (MI)

Tel: +39-02-6129-3863 Fax: +39-02-6129-0900

E-mail: info.italia@it.tdk-lambda.com

www.it.tdk-lambda.com

SCANDINAVIA BALTICS

TDK-Lambda Germany

Karl-Bold-Str.40, D-77855 Achern

Tel: +49-7841-666-0 Fax: +49-7841-500-0

E-mail: info.germany@de.tdk-lambda.com

www.de.tdk-lambda.com

JAPAN

TDK-Lambda Corporation

International Sales Division,

3-9-1, Shibaura, Minato-ku,

Tokyo 108-0023

Tel: +81 3-6852-7136 Fax: +81 3-6852-7148

E-mail: t.morimoto@jp.tdk-lambda.com

www.jp.tdk-lambda.com

CHINA

TDK-Lambda Shanghai Office

28F, Xingyuan Technology Building No.418, Guiping Road,

Shanghai, 200233 P.R. CHINA

Tel: +86-21-6485-0777 Fax: +86-21-6485-0666

www.cn.tdk-lambda.com

TDK-Lambda Beijing Office

Room 12B11-12B12, Unit 7 DACHENG SQUARE,

No.28 Xuanwumenxi Street, Xuanwu District Beijing,

100053, P.R. CHINA

Tel: +86-10-6310-4872 Fax: +86-10-6310-4874

www.cn.tdk-lambda.com

TDK-Lambda Hong Kong Office

1 / F. SAE Technology Centre, 6 science Park East Avenue,

HongKong Science Park, Shatin, NT.,

Tel: +852-23766658 Fax: +852-23172150

www.cn.tdk-lambda.com

KOREA

TDK-Lambda Corporation

6F Songok Bldg. 4-1 Soonae-Dong

Pundang-Gu, Songnam-Shi Kyonggi-Do, 463-020

Tel: +82-2-556-1171 Fax: +82-2-555-2706

www.tdk-lambda.co.kr

MALAYSIA

TDK-Lambda Malaysia

Lot 709, Nilai Industrial Estate

71800 Nilai, Negeri Sembilan

Tel: +60-6-799-1130 Fax: +60-6-799-3277

www.my.tdk-lambda.com

SINGAPORE PHILIPPINES

TDK-Lambda Singapore

1008 Toa Payoh North # 06-01/08

Singapore 318996

Tel: +65-6251-7211 Fax: +65-6250-9171

www.sg.tdk-lambda.com

INDIA

TDK-Lambda India

#526, Ground Floor, 10th Main, 7th Cross,

Jeevanbhimanagar, Bangalore 560 075,

Karnataka, India

Tel : +91-80-43550500 Fax :+91-80-43550501

www.in.tdk-lambda.com

ISRAEL

TDK-Lambda Ltd. Israel

Kibbutz Givat Hashlosha Tel-Aviv 48800

Tel: +972-3-9024-333 Fax: +972-3-9024-777

E-mail: info@tdk-lambda.co.il

www.tdk-lambda.co.il

RUSSIA

THAILAND

TDK-Lambda Americas Inc. 405 Essex Road, Neptune, NJ 07753 USA

Tel: +1 732 922 9300 Fax: +1 732 922 1441

www.us.tdk-lambda.com/hp

TDK Logo is a trademark or registered trademark of TDK Corporation

© Copyright 2013 TDK-Lambda Americas Inc.

Part No. 93-507-100 Rev E

Loading...

Loading...