Page 1

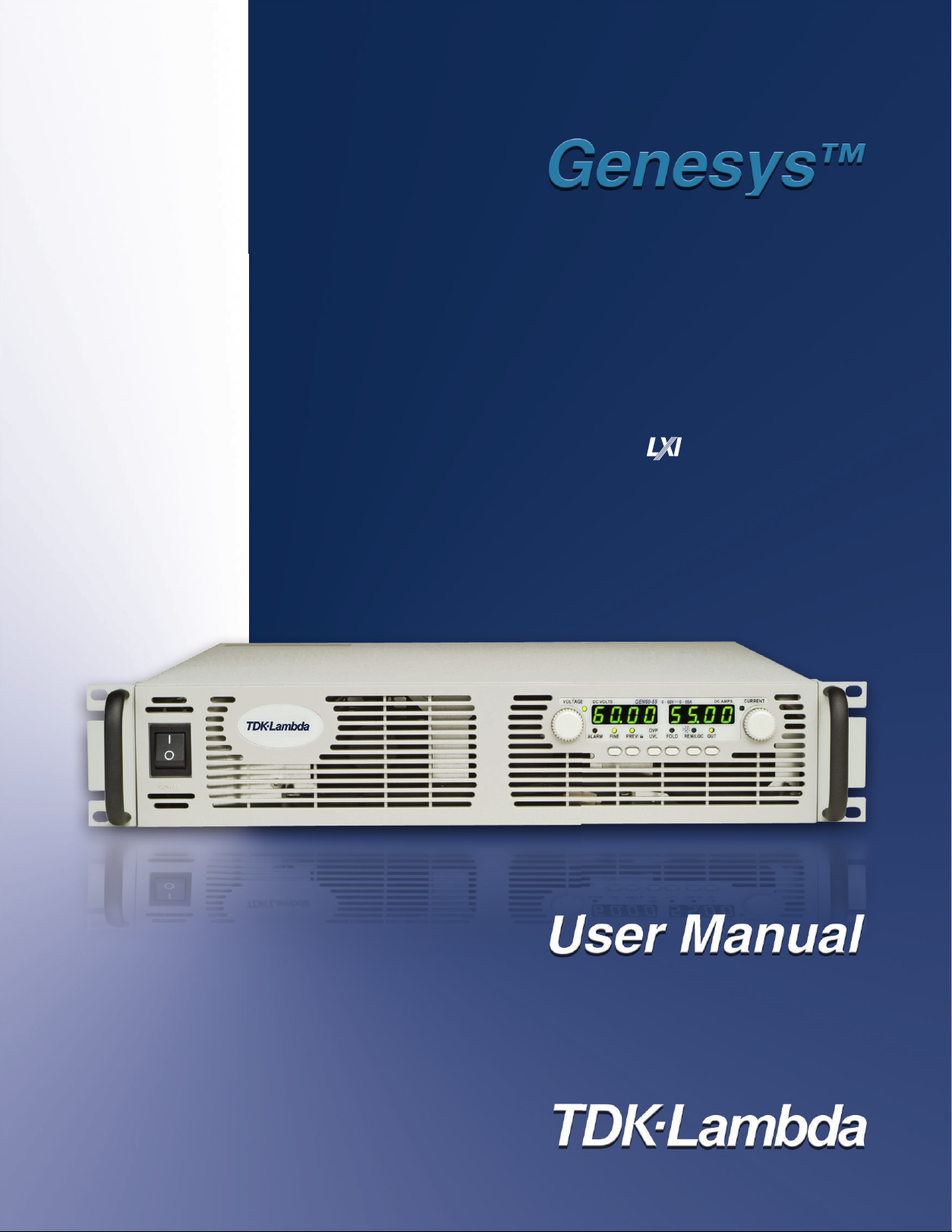

Programmable DC Power Supplies

3.3kW in 2U

Built in RS-232 & RS-485 Interface

Advanced Parallel Operation

Optional Interface:

Compliant LAN

IEEE488.2 SCPI (GPIB) Multi-Drop

Isolated Analog Programming

Page 2

GENESYS

TM

GEN 3.3kW SERIES POWER

SUPPLIES

USER MANUAL

GEN 3.3kW SERIES POWER

GEN8-400

TM

GENESYS

SUPPLIES

USER MANUAL

This Manual Covers Models:

GEN40-85

GEN200-16.5

GEN10-330

GEN15-220

GEN20-165

GEN30-110

GEN60-55

GEN80-42

GEN100-33

GEN150-22

GEN300-11

GEN600-5.5

Manual Supplement

For units equipped with IEEE488.2 (GPIB) Interface option,

refer to Manual IA586-04-01_.

For units equipped with LAN Interface option,

refer to Manual IA672-04-01_.

IA626-04-01-Rev. Q

Page 3

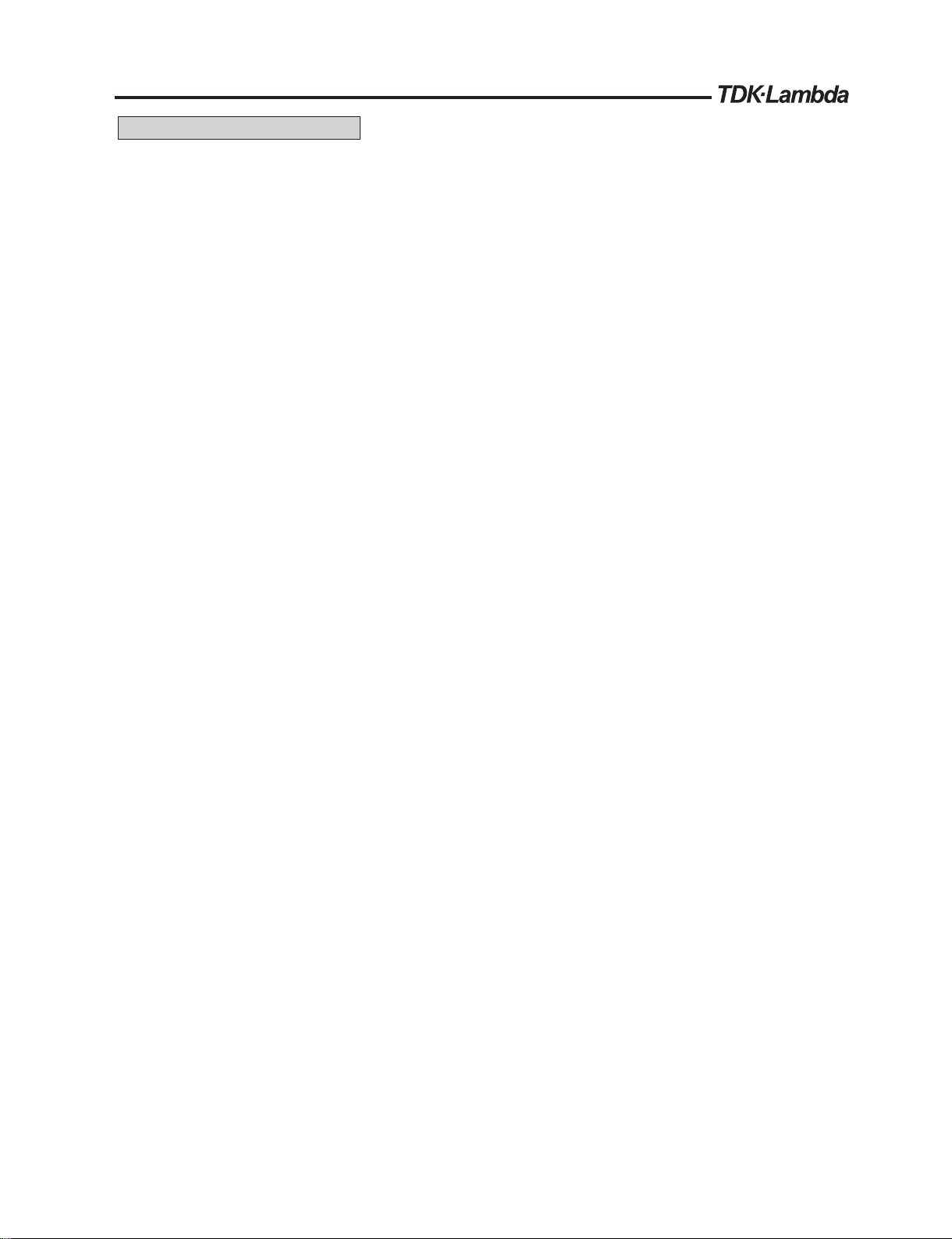

This information sheet was prepared based on People's Republic of China "Management Methods for Controlling Pollution Caused by

"SJ/T 11364—2006 Marking for Control of Pollution Caused by Electronic Information Products

As People's Republic of China "Management Methods for Controlling Pollution Caused by Electronic Information Products Regulatio

2002/95/EC

, inquiries concerning EU RoHS Directive

The date of manufacture

Part Name

GENESYS, GEN3.3KW POWER SUPPLY SERIES Product Weight

13Kg

Lead (Pb) Mercury (Hg) Cadmium (Cd) Hexavalent

Chromium (Cr6+)

Polybrominated

Biphenyls (PBB)

Polybrominated Diphenyl

Ethers(PBDE)

0.1wt% 0.1wt% 0.01wt% 0.1wt% 0.1wt% 0.1wt%

Case

OOOO O O

Plastic panel

OOOO O O

PCB's assembly XOOO O O

Inner metal parts OOOO O O

Inner cables OOOO O O

Accessories OOOO O OProvided in the package

○ : Indicates that the concentration values of toxic and hazardous substances in all "homogeneous materials" of respective parts and materials does not exceed the concentration limits

regulated by "SJ/T 11363-2006 Requirements for Concentration Limits for Certain Hazardous Substances in Electronic Information Products".

× : Indicates that the concentration value of a toxic or hazardous substance included in a "homogeneous part" of a respective part ot material exceeds the concentration limit regulated by

"SJ/T 11363-2006 Requirements for Concentration Limits for Certain Hazardous Substances in Electronic Information Products".

Information Concerning Inclusion of Toxic and Hazardous Substances

NotesConcentration Values of Toxic and Hazardous Substances/Elements (wt%)

Subpart Name

(2002/95/EC), inquiries concerning EU RoHS Directive (2002/95/EC) information should be done separately.

GENESYS, GEN3.3KW POWER SUPPLY SERIES Product Weight

13Kg

Lead (Pb) Mercury (Hg) Cadmium (Cd) Hexavalent

0.1wt% 0.1wt% 0.01wt% 0.1wt% 0.1wt% 0.1wt%

OOOO O O

Plastic panel

OOOO O O

PCB's assembly XOOO O O

Inner metal parts OOOO O O

Inner cables OOOO O O

Accessories OOOO O O

: Indicates that the concentration values of toxic and hazardous substances in all "homogeneous materials" of respective parts

regulated by "SJ/T 11363-2006 Requirements for Concentration Limits for Certain Hazardous Substances in Electronic Infor

: Indicates that the concentration value of a toxic or hazardous substance included in a "homogeneous part" of a respective p

"SJ/T 11363-2006 Requirements for Concentration Limits for Certain Hazardous Substances in Electronic Information Product

NotesConcentration Values of Toxic and Hazardous Substances/Elements (wt%)

n"is a different legislation from EU RoHS Directive

Electronic Information Products Regulation"and

Ethers(PBDE)

The date of manufacture

Polybrominated Diphenyl

Polybrominated

Biphenyls (PBB)

".

Provided in the package

and materials does not exceed the concentration limits

mation Products".

s".

art ot material exceeds the concentration limit regulated by

(2002/95/EC) information should be done separately.

)

Part Name

Chromium (Cr6+)

Subpart Name

(

Case

○

×

Page 4

DECLARATION OF CONFORMITY

GEN3300W SERIES

We, TDK-Lambda Ltd., located at Haharoshet St. 56 Industrial Zone P.O.B. 500 Karmiel, Israel declare under our sole

responsibility that the GEN3300W series as detailed on the products covered sheet comply with the provisions of

the following European Directive and are eligible to bear the CE mark:

Restriction Of the use of certain Hazardous Substances Directive 2011/65/EU (RoHS2)

Low Voltage Directive 2006/95/EC

EMC Directive 2004/108/EC

Assurance of conformance of the described product with the provisions of the stated EC Directive is given

through compliance to the following standard:

Electrical Safety EN 60950-1:2006+A11+A1+A12

Electromagnetic Compatibility (EMC): EN 55022:1998+A1:2000+A2:2003

EN 55024:1998+A1:2001+A2:2003

EN 61000-3-3:1995+A2:2005

which cover testing to the following standards:

EN 55022:1998+A1:2000+A2:2003 Conducted Emissions Class A

Radiated Emissions Class A

EN 61000-3-3 :1995+A2:2005 Voltage Fluctuations

EN 61000-4-2 :1995+A1:1998+A2:2001 ESD AD: 8KV, CD:4KV

EN 61000-4-3 :2006 Radiated Immunity 3V/m

EN 61000-4-4 :2004 EFT/B Power leads: 2KV

Signal leads: 0.5KV

EN 61000-4-5 :2006 Conductive Surges Common mode: 2KV

Dierential mode: 1KV

EN 61000-4-6 :2007 Conducted Disturbances 3Vrms

EN 61000-4-8 :1993+A1:2001 Immunity to Mag. Field 1A/m

EN 61000-4-11:2004 Voltage Dips

Our European Representative in the EU is TDK-Lambda UK Limited, located at Kingsley Avenue, llfracombe,

Devon, EX34 8ES UK. Further, all products covered by this declaration are manufactured in accordance with

ISO9000:2008 which ensure continued compliance of the products with the requirements of the Low Voltage

Directive and EMC Directive.

Name of Authorized Signatory Martin Southam

Signature of Authorized Signatory

Position of Authorized Signatory Marketing Director EMEA

Date 3

rd

April 2013

Date Series rst CE marked 22 February 2006

Place where signed Ilfracombe, Devon, England

PRODUCTS COVERED SHEET FOR:

GEN3300W series

1. GEN3300W with one phase input 190-240VAC

2. GEN3300W with three phase input 190-240VAC

3. GEN3300W with three phase input 380-415VAC

with rated output 0-8VDC/0-400A up to 0-600VDC/0-5.5A and total output power equial or less 3300W

Optional modules:

1. IEEE (GPIB) module

2. Isolated analog (V/I) module

3. LAN module

4. USB module

TDK-Lambda Ltd., Industrial Zone P.O.B 500 Karmiel, IsraelTDK-Lambda Ltd., Industrial Zone P.O.B 500 Karmiel, IsraelTDK-Lambda Ltd., Industrial Zone P.O.B 500 Karmiel, Israel

Page 5

This page intentionally left blank

Page 6

TABLEOF CONTENTS

WARRANTY ..........................................................................................................................................

SAFETY INSTRUCTIONS.....................................................................................................................

GERMAN SAFETY INSTRUCTIONS ...................................................................................................

CHAPTER 1 GENERAL INFORMATION

....................................................................................

1.1 OPERATION MANUAL CONTENT .................................................................................................

1.2 INTRODUCTION .............................................................................................................................

1.2.1 General description ................................................................................................................

1.2.2 Models covered ......................................................................................................................

1.2.3 Features and options .............................................................................................................

1.2.4 Multiple output power system .................................................................................................

1.2.5 Control via the serial communication port ..............................................................................

1.2.6 Analog voltage programming and monitoring .................................................................. ......

1.2.7 Parallel operation ...................................................................................................................

1.2.8 Output connections ................................................................................................................

1.2.9 Cooling and mechanical construction ....................................................................................

1.3 ACCESSORIES ...............................................................................................................................

1.3.1 General ..................................................................................................................................

1.3.2 Serial link cable ......................................................................................................................

1.3.3 Misc. hardware .......................................................................................................................

1.3.4 AC cables ...............................................................................................................................

CHAPTER 2 SPECIFICATIONS

...................................................................................................

2.1 OUTPUT RATING ...........................................................................................................................

2.2 INPUT CHARACTERISTICS ..........................................................................................................

2.3 CONSTANT VOLTAGE MODE .......................................................................................................

2.4 CONSTANT CURRENT MODE ......................................................................................................

2.5 ANALOG PROGRAMMING AND MONITORING ............................................................................

2.6 PROGRAMMING AND READBACK ...............................................................................................

2.7 PROTECTIVE FUNCTIONS ...........................................................................................................

2.8 FRONT PANEL ................................................................................................................................

2.9 ENVIRONMENTAL CONDITIONS ..................................................................................................

2.10 MECHANICAL ..............................................................................................................................

2.11 SAFETY/EMC ...............................................................................................................................

2.12 SUPPLEMENTAL CHARACTERISTICS .......................................................................................

2.13 OUTLINE DRAWINGS .................................................................................................................

Pg.1

Pg.2

Pg.4

Pg.6

Pg.6

Pg.6

Pg.6

Pg.6

Pg.6

Pg.7

Pg.7

Pg.7

Pg.7

Pg.7

Pg.8

Pg.8

Pg.8

Pg.8

Pg.8

Pg.8

Pg.9

Pg.9

Pg.9

Pg.9

Pg.9

Pg.9

Pg.10

Pg.10

Pg.10

Pg.10

Pg.10

Pg.10

Pg.11

Pg.12

CHAPTER 3 INSTALLATION

.......................................................................................................

3.1 GENERAL .......................................................................................................................................

3.2 PREPARATION FOR USE ..............................................................................................................

3.3 INITIAL INSPECTION .....................................................................................................................

3.4 RACK MOUNTING ..........................................................................................................................

3.4.1 To install the power supply inarack .......................................................................................

3.4.2 Rack mount slides ..................................................................................................................

3.5 LOCATION MOUNTING AND COOLING .......................................................................................

3.6 AC SOURCE REQUIREMENTS .....................................................................................................

3.7 AC INPUT POWER CONNECTION ................................................................................................

3.7.1 AC input connector..................................................................................................................

3.7.2 AC input cord ..........................................................................................................................

3.7.3 AC input wire connection.........................................................................................................

3.8 TURN-ON CHECKOUT PROCEDURE ...........................................................................................

3.8.1 General ...................................................................................................................................

3.8.2 Prior to operation ...................................................................................................................

3.8.3 Constant voltage check ..........................................................................................................

3.8.4 Constant current check ..........................................................................................................

3.8.5 OVP check .............................................................................................................................

3.8.6 UVL check ..............................................................................................................................

3.8.7 Foldback check ......................................................................................................................

3.8.8 Address setting ......................................................................................................................

3.8.9 Baud rate setting ....................................................................................................................

Pg.13

Pg.13

Pg.13

Pg.13

Pg.13

Pg.13

Pg.14

Pg.14

Pg.14

Pg.14

Pg.15

Pg.15

Pg.15

Pg.16

Pg.16

Pg.16

Pg.17

Pg.17

Pg.17

Pg.17

Pg.18

Pg.18

Pg.18

Page 7

TABLEOF CONTENTS

3.9 CONNECTING THE LOAD ..........................................................................................................

3.9.1 Load Wiring ..........................................................................................................................

3.9.2 Current Carrying Capacity ...................................................................................................

3.9.3 Wire termination .................................................................................................................

3.9.4 Noise and Impedance Effects ..............................................................................................

3.9.5 Inductive loads .....................................................................................................................

3.9.6 Making the load connections ................................................................................................

3.9.7 Connecting single loads, local sensing (default) ..................................................................

3.9.8 Connecting single loads, remote sensing ............................................................................

3.9.9 Connecting multiple loads, radial distribution method ..........................................................

3.9.10 Multiple loads connection with distribution terminals .........................................................

3.9.11 Grounding outputs .............................................................................................................

3.10 LOCAL AND REMOTE SENSING .............................................................................................

3.10.1 Sensing wiring ...................................................................................................................

3.10.2 Local sensing .....................................................................................................................

3.10.3 Remote sensing .................................................................................................................

3.10.4 J2 sense connector technical information ..........................................................................

3.11 REPACKAGING FOR SHIPMENT .............................................................................................

CHAPTER 4FRONT AND REAR PANEL CONTROLS AND CONNECT

4.1 INTRODUCTION ..........................................................................................................................

4.2 FRONT PANEL CONTROLS AND INDICATORS ........................................................................

4.3 REAR PANEL ...............................................................................................................................

4.4 REAR PANEL SW1 SETUP SWITCH .........................................................................................

4.4.1 SW1 positions functions ......................................................................................................

4.4.2 Resetting the switch .............................................................................................................

4.5 REAR PANEL J1 PROGRAMMING AND MONITORING CONNECTOR ....................................

4.5.1 Making J1 connections ........................................................................................................

ORS

...............

Pg.18

Pg.18

Pg.18

Pg.19

Pg.20

Pg.20

Pg.20

Pg.23

Pg.23

Pg.23

Pg.24

Pg.24

Pg.25

Pg.25

Pg.25

Pg.26

Pg.26

Pg.26

Pg.27

Pg.27

Pg.27

Pg.29

Pg.30

Pg.31

Pg.31

Pg.32

Pg.32

CHAPTER 5LOCAL OPERATION

5.1 INTRODUCTION ..........................................................................................................................

5.2 STANDARD OPERATION ............................................................................................................

5.2.1 Constant Voltage Mode .......................................................................................................

5.2.2 Constant Current Operation .................................................................................................

5.2.3 Automatic Crossover ............................................................................................................

5.3 OVER VOLTAGE PROTECTION (OVP) ......................................................................................

5.3.1 Setting the OVP level ..........................................................................................................

5.3.2 Activated OVP protection indications ...................................................................................

5.3.3 Resetting the OVP circuit .....................................................................................................

5.4 UNDER VOLTAGE LIMIT (UVL) ..................................................................................................

5.4.1 Setting the UVL level ...........................................................................................................

5.5 FOLDBACK PROTECTION ..........................................................................................................

5.5.1 Setting the Foldback protection ...........................................................................................

5.5.2. Resetting activated Foldback protection ............................................................................

5.6 OUTPUT ON/OFF CONTROL ......................................................................................................

5.7 OUTPUT SHUT-OFF (SO) CONTROL VIA REAR PANEL J1 CONNECTOR ..............................

5.8 ENABLE/DISABLE CONTROL VIA REAR PANEL J1 CONNECTOR ..........................................

5.9 CV/CC SIGNAL .............................................................................................................................

5.10 PS_OK SIGNAL ..........................................................................................................................

5.11 SAFE START AND AUTO-RESTART MODES ............................................................................

5.11.1 Automatic start mode .........................................................................................................

5.11.2 Safe start mode ..................................................................................................................

5.12 OVER TEMPERATURE PROTECTION (OTP) ..........................................................................

5.13 LAST SETTING MEMORY .........................................................................................................

5.14 SERIES OPERATION .................................................................................................................

5.14.1 Series connection for increased output voltage .................................................................

5.14.2 Series connection for positive and negative output voltage ...............................................

5.15 PARALLEL OPERATION ............................................................................................................

5.16 DAISY-CHAIN CONNECTION ....................................................................................................

5.17 FRONT PANEL LOCKING ..........................................................................................................

.............................................................................................

Pg.34

Pg.34

Pg.34

Pg.34

Pg.34

Pg.35

Pg.35

Pg.35

Pg.35

Pg.35

Pg.36

Pg.36

Pg.36

Pg.36

Pg.36

Pg.36

Pg.36

Pg.37

Pg.37

Pg.37

Pg.38

Pg.38

Pg.38

Pg.38

Pg.38

Pg.38

Pg.39

Pg.40

Pg.41

Pg.43

Pg.43

Page 8

TABLE OF CONTENTS

Pg.68

8.5

CHAPTER 6 REMOTE ANALOG PROGRAMMING

6.1INTRODUCTION ...........................................................................................................................

6.2 LOCAL/REMOTE ANALOG CONTROLL.......................................................................................

6.3 LOCAL/REMOTE ANALOG INDICATION......................................................................................

6.4 REMOTE VOLTAGE PROGRAMMING OF OUTPUT VOLTAGE AND CURRENT LIMIT .............

6.5 RESISTIVE PROGRAMMING OF OUTPUT VOLTAGE AND CURRENT LIMIT ...........................

6.6 REMOTE MONITORING OF OUTPUT VOLTAGE AND CURRENT .............................................

CHAPTER7RS232 & RS485 REMOTE CONTROL

7.1INTRODUCTION ...........................................................................................................................

7.2 CONFIGURATION .........................................................................................................................

7.2.1 Default setting .......................................................................................................................

7.2.2 Address setting .....................................................................................................................

7.2.3 RS232 or RS485 selection ...................................................................................................

7.2.4 Baud rate setting ...................................................................................................................

7.2.5 Settingthe unitinto Remoteor Local mode ..........................................................................

7.2.6 RS232/458 portat Local mode .............................................................................................

7.2.7Front panel in Remote mode ................................................................................................

7.3 REAR PANEL RS232/485 CONNECTOR ......................................................................................

7.4 CONNECTING POWER SUPPLIES TO RS232 OR RS485 BUS .................................................

7.4.1Single power supply ..............................................................................................................

7.4.2 Multi power supplies connectionto RS232 or RS485 bus ....................................................

7.5 COMMUNICATION INTERFACE PROTOCOL ..............................................................................

7.5.1 Dataformat ...........................................................................................................................

7.5.2 Addressing ............................................................................................................................

7.5.3 End of message ....................................................................................................................

7.5.4 Command repeat .................................................................................................................

7.5.5 Checksum .............................................................................................................................

7.5.6 Acknowledge .........................................................................................................................

7.5.7Error message ......................................................................................................................

7.5.8 Backspace ............................................................................................................................

7.6 ERROR MESSAGES .....................................................................................................................

7.7 COMMAND SET DESCRIPTION ..................................................................................................

7.7.1 General guides .....................................................................................................................

7.7.2 Command set categories ......................................................................................................

7.7.3Initialization control commands .............................................................................................

7.7.4ID control commands ............................................................................................................

7.7.5 Output control commands .....................................................................................................

7.7.6Global output commands.......................................................................................................

7.7.7Status control commands .....................................................................................................

7.8STATUS, ERROR AND SRQ REGISTERS ...................................................................................

7.8.1 General .................................................................................................................................

7.8.2 Conditional registers .............................................................................................................

7.8.3 Service Request: Enabled and Event Registers ...................................................................

7.9 SERIAL COMMUNICATION TEST SET-UP ..................................................................................

CHAPTER8ISOLATED ANALOG PROGRAMMING OPTION

8.1INTRODUCTION ...........................................................................................................................

8.2 SPECIFICATIONS .........................................................................................................................

8.2.10-5V/0-10V option .................................................................................................................

8.2.24-20mA option .......................................................................................................................

8.3ISOLATED PROGRAMMING&MONITORING CONNECTOR ....................................................

8.4 SETUP AND OPERATING INSTRUCTIONS .................................................................................

8.4.1 Settingupthe power supplyfor 0-5/0-10V Isolated Programming and Monitoring ...............

8.4.2 Settingupthe power supplyfor 4-20mA Isolated Programming and Monitoring ..................

PARALLEL OPERATION WITH ISOLATED ANALOG OPTION................................................................Pg.

.................................................................

...............................................................

..............................................

Pg.44

Pg.44

Pg.44

Pg.44

Pg.45

Pg.46

Pg.47

Pg.48

Pg.48

Pg.48

Pg.48

Pg.48

Pg.48

Pg.48

Pg.48

Pg.49

Pg.49

Pg.49

Pg.50

Pg.50

Pg.51

Pg.51

Pg.51

Pg.51

Pg.51

Pg.51

Pg.51

Pg.51

Pg.52

Pg.52

Pg.52

Pg.52

Pg.52

Pg.52

Pg.53

Pg.53

Pg.53

Pg.55

Pg.56

Pg.57

Pg.57

Pg.57

Pg.58

Pg.61

Pg.62

Pg.62

Pg.62

Pg.62

Pg.62

Pg.63

Pg.64

Pg.64

Pg.64

65

CHAPTER 9 MAINTENANCE

9.1INTRODUCTION ...........................................................................................................................

9.2 UNITS UNDER WARRANTY .........................................................................................................

9.3 PERIODIC MAINTENANCE ..........................................................................................................

9.4 ADJUSTMENT AND CALIBRATION .............................................................................................

9.5PARTS REPLACEMENT AND REPAIRS .......................................................................................

9.6 TROUBLESHOOTING ...................................................................................................................

9.7 FUSE RATING ...............................................................................................................................

USER MANUAL INDEX ........................................................................................................................

......................................................................................................

Pg.66

Pg.66

Pg.66

Pg.66

Pg.66

Pg.66

Pg.66

Pg.67

Page 9

This page intentionally left blank

Page 10

WARRANTY

This TDK-Lambda Ltd. product is warranted against defects in materials and workmanship for a period of

ve years from date of shipment. During the warranty period, TDK-Lambda Ltd. will, at it's option, either

repair or replace products which prove to be defective.

LIMITATION OF WARRANTY

The warranty shall not apply to defects resulting from improper or inadequate usage or maintenance

by the buyer, buyer supplied products or interfacing. The warranty shall not apply to defects resulting

from unauthorized modications or from operation exceeding the environmental specications of the

product or if the QA seal has been removed or altered by anyone other than TDK-Lambda Ltd. authorized

personnel. TDK-Lambda Ltd. does not warrant the buyers circuitry or malfunctions of TDK-Lambda

Ltd. products resulting from the buyer's circuitry. Furthermore, TDK-Lambda Ltd. does not warrant any

damage occurring as a result ofthe buyer's circuitry or the buyer's - supplied products. No other warranty

is expressed or implied.

WARRANTY SERVICE

This product must be returned to an authorized TDK-Lambda Ltd. service facility for repairs or other

warranty service. For products returned to TDK-Lambda Ltd. for warranty service, the buyer shall prepay

shipping charges to TDK-Lambda Ltd. and TDK-Lambda Ltd. shall pay the shipping charges to return the

product to the buyer. Refer to section 3.11 for repackaging for shipment.

DISCLAIMER

The information contained in this document is subject to change without notice. TDK-Lambda Ltd. shall not

be liable for errors contained in this document or for incidental or consequential damages in connection

with the furnishing, performance or use of this material. No part of this document may be photocopied,

reproduced or translated into another language without the prior written consent of TDK-Lambda Ltd..

TRADEMARK INFORMATION

Genesys™ power supply is a trademark of TDK-Lambda Ltd. & TDK- Lambda Americas Inc.

Microsoft™ and Windows™ are trademarks of Microsoft Corporation.

1

Page 11

REGULATORY NOTICES

FCC Notice

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) this device may not cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause undesired operation.

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful interference to

radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own expense.

WARNING: Modifications not expressly approved by the party responsible for compliance could

void the user’s authority to operate the equipment under FCC Rules.

CE Notice (European Union)

Marking by the CE Symbol indicates compliance to the EMC Directive and the Low Voltage

Directive of the European Union. Such marking is indicative that the Genesys series GEN3300W

meets the following technical standards:

TM

A “Declaration of Conformity” in accordance with the preceding directives and standards has been

made and is on file at our EU representative TDK-Lambda Limited, located at Kingsley Avenue,

Ilfracombe, Devon EX34 8ES, UK.

EN 55022:2010 Information technology equipment - Radio disturbance characteristics Limits and methods of measurement.

EN 55024:2010 Information thecnology equipment - Immunity characteristics - Limits and

methods of measurement.

EN 60950-1:2006+A11:2009 + A1:2010 + A12:2011 Information technology equipment Safety - Part 1: General requirements.

WARNING: This is a Class A product. On a domestic environment this product may cause radio

interference in which case user may be required to takeadequate measures.

SAFETY APPROVALS:

UL 60950-1 Second Edition, UL Listed, C-UL for Canada, IEC 60950-1 Second Edition, CE

marking, when applied to the GEN3300W product, indicates compliance with the Low Voltage

Directive 2006/95/EC in that it complies with EN 60950-1 Second Edition.

2

Page 12

SAFETY INSTRUCTIONS.

ENVIRONMENTAL CONDITIONS

The Genesys power supply series safety approval applies to the following operating conditions:

*Indoor use *Ambient temperature: 0Cto 50 C

*Maximum relative humidity: 90% (no condensation) *Altitude: up to 3000m

*Pollution degree 2

CAUTION

!

TM

oo

Do not use this product in environmentswith strong Electromagnetic field, corrosive

gas and conductive materials.

CAUTIONRiskof Electrical Shock.

Instruction manual symbol. The

instrument will be marked with this

symbol when it is necessary for the

user to referto the instruction

manual.

Indicates hazardous voltage.

-

-

On (Supply)

Direct Current (DC)

-

Alternative Current (AC)

~

Indicates ground terminal.

3

~

Three-PhaseAlternating Current

Protective Ground Conductor Terminal

Off (Supply)

WARNING

CAUTION

Standby (Supply)

The WARNING sign denotes a hazard. An attention toaprocedure is called.

Not following procedure correctly could result in personal injury.

AWARNING sign should not be skipped and all indicated conditions must be

fully understood and met.

The CAUTION sign denotes a hazard. An attention toaprocedure is called. Not

following procedure correctly could result in damage to the equipment. Do not proceed

beyond aCAUTION sign until all indicated conditions are fully understood and met.

FCC COMPLIANCE NOTICE:

Note: This equipment has been tested and found to comply with the limits for aClass A

digital device, pursuant to part 15 of the FCCRules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated inacommercial environment. This equipment generates uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications.

Operation of this equipment inaresidential area is likely to cause harmful interference

in which case the user will be required to correct the interference at his own expense.

345

Page 13

Page 14

Page 15

CHAPTER 1 GENERAL INFORMATION

1.1 USER MANUAL CONTENT

This user’s manual contains the operating instructions, installation instructions and specifications of

the Genesys 3300W power supply series. The instructions refer to the standard power supplies,

including the built-in RS232/485 serial communication. For information related to operation with the

optional IEEE programming, refer to User Manual for Power Supply IEEE Programming Interface.

1.2 INTRODUCTION

TM

1.2.1 General description

Genesys power supplies are wide output range, high performance switching power supplies. The

Genesys series is power factor corrected and operates from worldwide AC voltage range. Output

TM

TM

voltage and current are continuously displayed and LED indicators show the complete operating

status of the power supply. The Front panel controls allow the user to set the output parameters, the

protection levels (Over-Voltage protection, Under-Voltage limit and Foldback) and preview the

settings. The rear panel includes the necessary connectors to control and monitor the power supply

operation by remote analog signals or by the built-in serial communication (RS232/485). GPIB

programming and Isolated-Analog programming/monitoring are optional.

1.2.2 Models covered by this manual

Model Voltage Current

range(V) range(A)

GEN8-400 0-8 0-400

GEN10-330 0-10 0-330

GEN15-220 0-15 0-220

GEN20-165 0-20 0-165

GEN30-110 0-30 0-110

GEN40-85 0-40 0-85

GEN60-55 0-60 0-55

GEN80-42 0-80 0-42

GEN100-33 0-100 0-33

GEN150-22 0-150 0-22

GEN200-16.5 0-200 0-16.5

GEN300-11 0-300 0-11

GEN600-5.5 0-600 0-5.5

Table1-1: Models covered by the manual

1.2.3 Features and options

Constant Voltage /Constant Current with automatic crossover.

*

* Active Power Factor correction.

* Single Phase or Three Phase options.

*Embedded Microprocessor Controller.

* Built in RS232/485 Interface.

*Voltage&Current high resolution adjustment by digital encoders.

*High accuracy programming/readback-16 bit.

* Software Calibration (no internal trimmers / potentiometers).

* Last Setting Memory.

* Independent Remote ON/OFF (opto-isolated) and Remote Enable/Disable.

6

Page 16

* Parallel operation (Master/Slave) with Active current sharing.

* Remote sensing to compensate for voltage drop of power leads.

* External Analog Programming and Monitoring standard (0-5V or 0-10V, user selectable).

* Cooling fan speed control for low noise and extended fan life.

* Zero stacking- no ventillation holes at the top and bottom surface of the power supply.

*Optional GPIB interface (SCPI compatible).

*Optional Isolated Analog programming/monitoring (0-5V or 0-10V, user selectable

and 4-20mA).

1.2.4 Multiple output power system

The Genesys power supplies series can be configured intoaprogrammable power

TM

system of up to 31 units using the built-in RS232/RS485 communication port in the power

supply and the RS485 linking cable provided with each power supply.

InaGPIB system, each power supply can be controlled using the optional GPIB controller

(factory installed).

1.2.5 Control via the serial communication port

The following parameters can be programmed via the serial communication port:

1. Output voltage setting.

2. Output current setting.

3. Output voltage measurement.

4. Output on/off control.

5. Output current measurement.

6. Foldback protection setting.

7. Over-voltage protection setting and readback.

8. Under-Voltage limit setting and readback.

9. Power-supply start up mode (last setting or safe mode)

1.2.6 Analog voltage programming and monitoring

Analog inputs and outputs are provided at the rear panel for analog control of the power

supply. The output voltage and the current limit can be programmedby analog voltage or by

resistor, and can be monitored by analog voltage. The power supply output can be remotely

set to On or Off and analog signals monitor the proper operation of the power supply and the

mode of operation (CV/CC).

1.2.7 Parallel operation

Genesys power supplies of the same output voltage and current rating can be paralleled in

TM

master-slave configuration with automatic current sharing to increase power available.

1.2.8 Output connections

Output connections are made to rear panel bus-bars for models up to 100V and toa4terminal wire clamp connector for models above 100V rated output voltage. Either the

positive or negative terminal maybe grounded or the output maybe floated. Models up to

60VDC Rated Output shall not float outputsmore than +/- 60VDC above/below chassis

ground. Models >60VDC Rated Output shall not float outputsmore than +/-600VDC

above/below chassis ground. Contact factory for assistance with higher float voltage

applications.

Local or remote sense maybe used.

In remote sense, the voltage drop on the load wires

should be minimized. Refer to the specifications for the maximum voltage drop value.

7

Page 17

1.2.9 Cooling and mechanical construction

The Genesys series is cooled by internal fans. At the installation, care must be taken to

allow free air flow into the power supply via the front panel and out of the power supply via

the rear panel. The Genesys power supplies have a compact and lightweight package

TM

TM

which allows easy installation and space saving in the application equipment.

CAUTION

Observe all torque guidelines within this manual. Over torqueing may damage

unit or accessories. Such damage is not covered under manufacturers warranty.

1.3 ACCESSORIES

1.3.1 General

Accessories are delivered with the power supply or separately upon ordering. The list below

shows the possible accessories and ordering numbers.

1.3.2 Serial link cable

S

erial link cable, for linking power supplies by RS485 communication is provided with the

power supply.

Cable description: 0.5m length, shielded, RJ-45 type plugs, 8 contacts (P/N: GEN/RJ45).

1.3.3 Misc. hardware

* DB25 plug kit (AMP, 749809-9).

*Strain relief for AC cord

* Output terminal shield

* Plastic legs for bench mounting.

1.3.4 AC cables

AC cables are not provided with the power supply.

Refer to Table1-2 for recommended AC input cables (customer supplied). Add a non-locking

plug approved by the national safety standards of the country of usage.

AC Input Range

190-240V~ ,Single Phase

3x 12AWG (2 wire plus safety graund), stranded

copper, 300V,60Cminimum, rated for 25A. 3m

AC Input Cable

O

max. length, outer diameter: 9~11mm.

190-240V~ , Three Phase

4x14AWG (3 wire plus safety ground), standed

copper, 300V,60cminimum, rated for 15A. 3m

O

max. length, outer diameter: 9~11mm.

380-415V~ , Three Phase

4x16AWG (3 wire plus safety ground), standed

copper, 600V,60cminimum, rated for 10A. 3m

O

max. length, outer diameter: 9~11mm.

Table 1-2: Recommended AC input cable

8

Page 18

CHAPTER 2 SPECIFICATIONS

1.Vout voltage programming

2.Iout voltage programming (*13)

3.Vout resistor programming

4.Iout resistor programming (*13

5.On/off control

6.Output current monitor (*13)

7.Output voltage monitor

8.Power supply OK signal

9.Parallel operation

10.Series operation

11.CV/CC indicator

12.Enable/Disable

13.Local/Remote analog control

14.Local/Remote analog indicator

)

2.5 ANALOG PROGRAMMING AND MONITORING

---

---

---

---

---

---

---

---

---

---

---

---

---

---

0~100%, 0~5V or 0~10V, user selectable. Accuracy and linearity: +/-0.5% of rated Vout.

0~100%, 0~5V or 0~10V, user selectable. Accuracy and linearity: +/-1% of rated Iout.

0~100%, 0~5/10Kohm full scale, user selectable. Accuracy and linearity: +/-1% of rated Vout.

0~100%, 0~5/10Kohm full scale, user selectable. Accuracy and linearity: +/-1.5% of rated Iout.

By electrical Voltage: 0~0.6V/2~15V or dry contact, user selectable logic.

0~5V or 0~10V, user selectable. Accuracy: +/-1%.

0~5V or 0~10V, user selectable. Accuracy : +/-1%.

4~5V-OK, 0V-Fail. 500ohm series resistance.

Possible , up to 4 units in master/slave mode with two wires current balance connection.

Possible (with external diodes), up to 2 units.

Open collector. CC mode: On, CV mode: Off. Maximum voltage: 30V, maximum sink current: 10mA.

Dry contact. Open: Off, Short: On. Max. voltage at Enable/Disable in: 6V.

By electrical signal or Open/Short: 0~0.6V or short: Remote, 2~15V or open: Local.

Open collector. Local: Open, Remote: On. Maximum voltage: 30V, maximum sink current: 10mA.

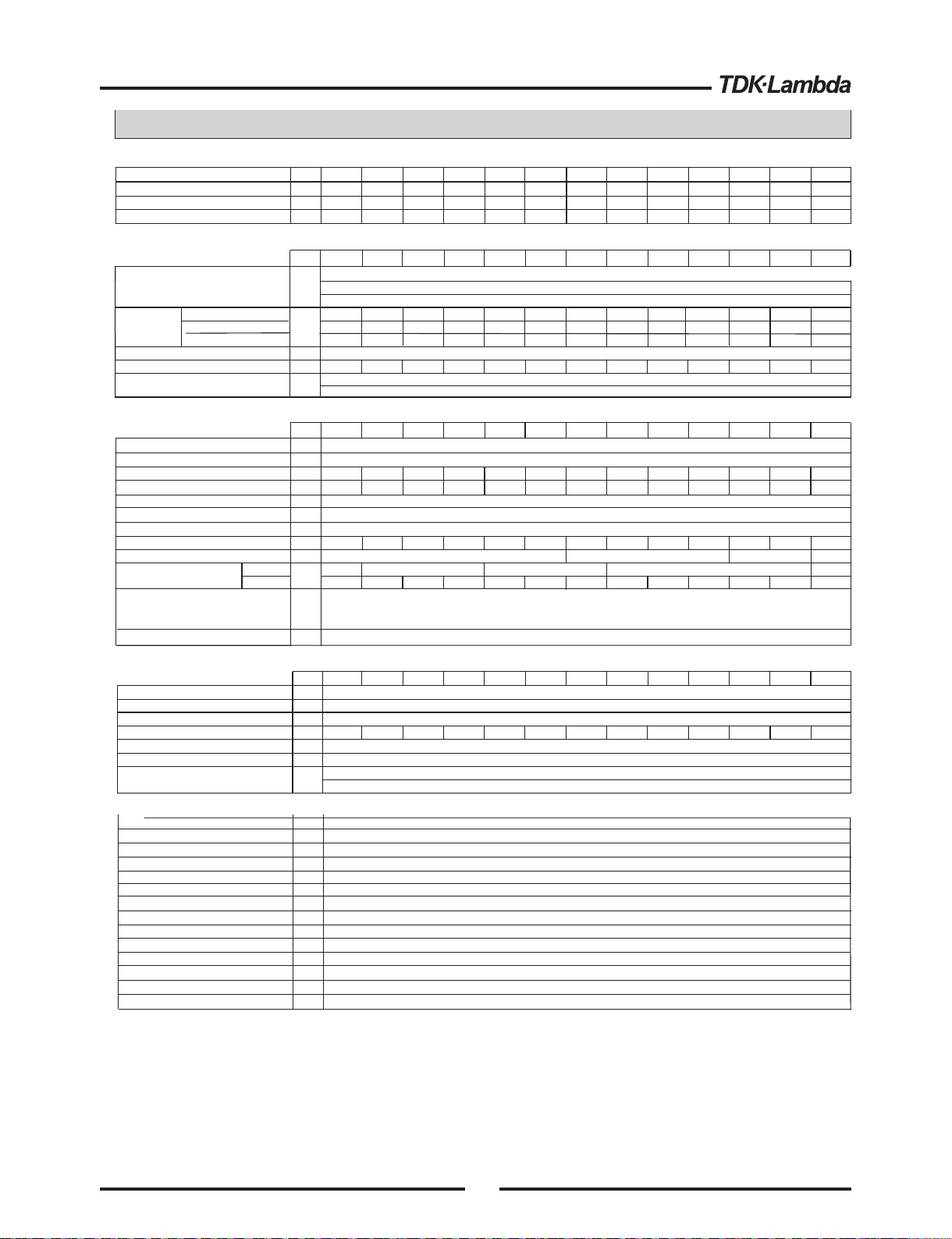

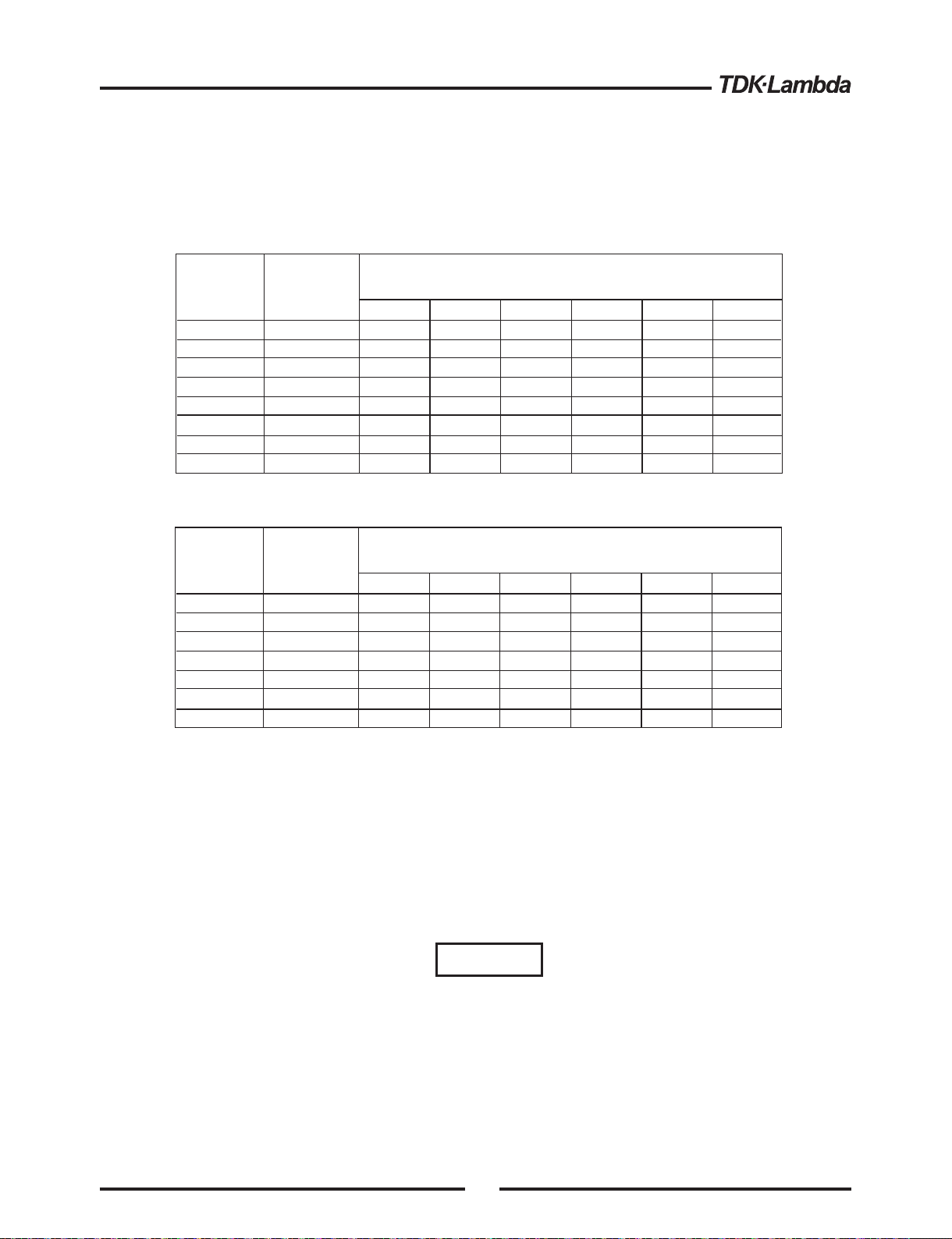

2.1 OUTPUT RATING

1.Rated output voltage(1*)

2.Rated output current (*2)

3.Rated output power

V

A

W

MODEL

GEN

8-400

8

400

3200

10-330

10

330

3300

15-220

15

220

3300

20-165

20

165

3300

30-110

30

110

3300

40-85

40

85

3400

60-55

60

55

3300

80-42

80

42

3360

100-33

100

33

3300

150-22

150

22

3300

200-16.5

200

16.5

3300

300-11

300

11

3300

600-5.5

600

5.5

3300

2.2 INPUT CHARACTERISTICS

Single Phase models:

3-Phase, 200V models:

3-Phase, 400V models:

---

--%

Single Phase models: 170~265V, 47~63Hz

Single Phase models: 0.99@200Vac, rated output power. 3-Phase models: 0.95@200/380Vac, rated output power.

3-Phase, 200V models: 170~265Vac, 47~63Hz

3-Phase, 400V models: 342~460Vac, 47~63Hz

Single-Phase and 3-Phase 200V models: Less than 50A

3-Phase 400V models: Less than 20A

V

8

10

15

20

30

60

40 150

100

80

600

200

300

24.0

14.5

7.2

24.0

14.5

7.2

24.0

14.5

7.2

24.0

14.5

7.2

23.0

14.0

7.0

24.0

14.5

7.2

23.0

13.6

6.8

23.5

14.0

7.0

23.0

13.7

6.8

23.0

13.7

6.8

23.0

13.7

6.8

23.0

13.9

7.0

23.0

13.8

6.9

3.Power Factor (Typ)

4.Efficiency (*4)

5.Inrush current (*5)

2.Maximum

Input current

at 100% load

1.Input voltage/freg. (*3)

---

A

82

83

83

83

86

86

87

88

88

88

87

87

87

8

10

15

30

20

40

60

80

150

100

200

300

600

2.3 CONSTANT VOLTAGE MODE

1.Max. Line regulation (*6)

2.Max. Load regulation (*7)

3.Ripple and noise (p-p , 20MHz) (*8)

4.Ripple r.m.s., 5Hz~1MHz

5.Temperature coefficient

6.Temperature stability

7.Warm-up drift

8.Remote sense compensation/wire

9.

11.Transient response time

12.Hold-up time (Typ)

Up-prog. response time, 0~Vomax.(*9)

10.Down-prog. response time

Full load(*9)

No load(*10)

V

---

--mV

mV

---

---

V

mS

PPM/ C

o

mS

mS

mS

0.01% of rated output voltage +2mV

0.015% of rated output voltage +5mV

55

8

55

7

55

8

55

7

55

7

70

20

100

20

350

80

55

7

60

7

100

25

275

70

300

80

50PPM/ C from rated output voltage, following 30 minutes warm-up.

O

0.01% of rated Vout over 8 hrs interval following 30 minutes warm-up. Constant line, load & temp.

Less than 0.05% of rated output voltage +2mV over 30 minutes following power on.

2

2

2

2

5

5

5

5

5

5

5

5

200

5

80

250

20

100

500

600

700

800

160

900

1000

300

150

1100

1200

1500

2000

500

3000

3500

4000

Time for output voltage to recover within 0.5% of its rated output for a load change 10~90% of rated output

current. Output set-point: 10~100%, Local sense.

Less than 1mS, for models up to and including 100V. 2mS, for models above 100V.

10mSec for Single-Phase and 3-Phase 200V models, 6mSec for 3-Phase 400V models. Rated output power.

V

8

10

15

20

40

30

60

80

100

150

200

600

300

2.4 CONSTANT CURRENT MODE

1.Max. Line regulation (*6)

2.Max. Load regulation (*11)

3.Load regulation thermal drift

4.Ripple r.m.s. 5Hz~1MHz (*12)

5.Temperature coefficient

6.Temperature stability

7.Warm-up drift

---

---

---

---

---

mA

PPM/ C

o

0.01% of rated output current +2mA

0.02% of rated output current +5mA

70PPM/ C from rated output current, following 30 minutes warm-up.

0.01% of rated Iout over 8hrs interval following 30 minutes warm-up. Constant line, load & temperature.

O

Less than 0.1% of rated output current over 30 minutes following load change.

650

400

300

1000

150

250

20

50

70

60

30

15

8

8~20V model: Less than +/-0.5% of rated output current over 30 minutes following power on.

30V~600V model: Less than +/-0.25% of rated output current over 30 minutes following power on.

9

Page 19

2.6 PROGRAMMING AND READBACK (RS232/485, Optional LAN/IEEE Interface)

1.Vout programming accuracy (*14)

2.Iout programming accuracy (*13)

3.Vout programming resolution

4.Iout programming resolution

5.Vout readback accuracy

6.Iout readback accuracy (*13)

7.Vout readback resolution

8.Iout readback resolution

---

---

---

---

---

---

0.05% of rated output voltage

0.1% of actual output current +0.2% of rated output current

0.002% of rated output voltage

0.002% of rated output current

0.05% of rated output voltage

0.3% of rated output current

2.7 PROTECTIVE FUNCTIONS

1.Foldback protection

2.Over-voltage protection

3.Over-voltage trip point

4.Output under voltage limit

5.Over temperature protection

---

---

---

---

V

Output shut-down when power supply change from CV to CC User presetable.

Inverter shut-down, manual reset by AC input recycle or by OUT button or by communication port command.

Preset by front panel or communication port. Prevents from adjusting Vout below limit. Does not affect analog

programming.

User selectable, latched or non latched.

0.5~10

0.5~12

2~36

1~24

1~18

2~44

5~66

5~165

5~110

5~88

5~220

5~330

5~660

V

8

15

2010

30

40

60

80

100

150

200

300

600

V

8

15

2010

30

40

60

80

100

150

200

300

600

2.8 FRONT PANEL

---

---

---

---

---

---

---

---

---

---

---

---

---

Vout/Iout manual adjust by separate encoders (coarse and fine adjustment).

OVP/UVL manual adjust by Vout. Adjust encoder.

Address selection by Voltage Adjust encoder. No of addresses:31.

Go to local control.

Output on/off

AC on/off

Front panel Lock

Foldback control

Baud rate selection: 1200, 2400, 4800, 9600 and 19200.

Re-start modes (automatic restart, safe mode).

Vout: 4 digits, accuracy: 0.05% of rated output voltage +/-1count.

Iout: 4 digits, accuracy: 0.2% of rated output current +/-1count.

VOLTAGE, CURRENT, ALARM, FINE, PREVIEW, FOLDBACK, LOCAL, OUTPUT ON, FRONT PANEL LOCK.

1.Control functions

2.Display

3.Indications

2.9 ENVIRONMENTAL CONDITIONS

1.Operating temperature

2.Storage temperature

3.Operating humidity

4.Storage humidity

5.Altitude

---

--%

%

---

0~50 C, 100% load.

-20~85 C

20~90% RH (no condensation).

10~95% RH (no condensation).

Maximum 3000m. Derate output current by 2%/100m above 2000m. Alternatively, derate maximum

ambient temperature by 1 C/100m above 2000m.

o

o

O

2.10 MECHANICAL

1.Cooling

2.Weight

3.Dimensions (WxHxD)

4.Vibration

5.Shock

---

Kg

mm

---

---

Forced air cooling by internal fans.

Less than 13Kg.

W: 423, H: 88, D: 442.5 (Refer to Outline drawing).

MIL-810F, method 514.5

Less than 20G, half sine, 11mS. Unit is unpacked.

Models with Vout 50V: Output is SELV, all communication/control interfaces (RS232/485, IEEE, Isolated Analog,

LAN, Sense, Remote Programming and Monitoring) are SELV.

Models with 60V Vout 400V: Output is Hazardous, communication/control interfaces: RS232/485, IEEE,

Isolated Analog, LAN, Remote Programing and Monitoring (pins 1-3, pins14-16) are SELV, Sense, Remote

Programming and Monitoring (pins 8-13, pins 21-25) are Hazardous.

Models with 400V<Vout 600V: Output is Hazardous, all communication/control interfaces (RS232/485, IEEE,

Isolated Analog, LAN, Sense, Remote Programming and Monitoring) are Hazardous.

Vout 50V models : Input-Output (SELV): 4242VDC 1min, Input-communication/control (SELV): 4242VDC 1min,

Input-Ground: 2828VDC 1min,

60V<Vout 100V models: Input-Output (Hazardous): 2600VDC 1min, Input-communication/control (SELV):

4242VDC 1min, Output(Hazardous)-SELV: 1900VDC 1min, Output(Hazardous)-Ground: 1200VDC 1min,

Input-Ground: 2828VDC 1min.

100V< Vout 600V models: Input-Output(Hazardous): 3550VDC 1min, Input-communication/control (SELV):

4242VDC 1min, Hazardous. Output-communication/control(SELV): 4242VDC 1min,

Output(Hazardous)-Ground: 2670VDC 1min, Input-Ground: 2828VDC 1min.

More than 100Mohm at 25 C, 70%RH.

O

2.11 SAFETY/EMC

2.Interface classification

4.Insulation resistance

3.Withstand voltage

1.Applicable standards: Safety

---

---

---

---

---

EMC

UL 60950-1, CSA22.2 No.60950-1, IEC 60950-1, EN 60950-1

EN55022, EN55024, EN61000-3-3, FCC part 15, VCCI.

Conducted emmision - EN55022 class A, FCC part 15 class A, VCCI class A.

Radiated emmision - EN55022 class A, FCC part 15 class A, VCCI class A.

Immunity - EN55024

% of rated

output voltage

% of rated

output current

0.002%

0.003%

0.007%

0.006%0.011%

0.004%

0.003%

0.002%

0.002%

0.011%

0.007%

0.006%

0.004%

0.002%

0.005%

0.007%0.004%

0.01%

0.002%

0.002%

0.003%

0.004%

0.005%

0.007%

0.01%

0.002%

10

Page 20

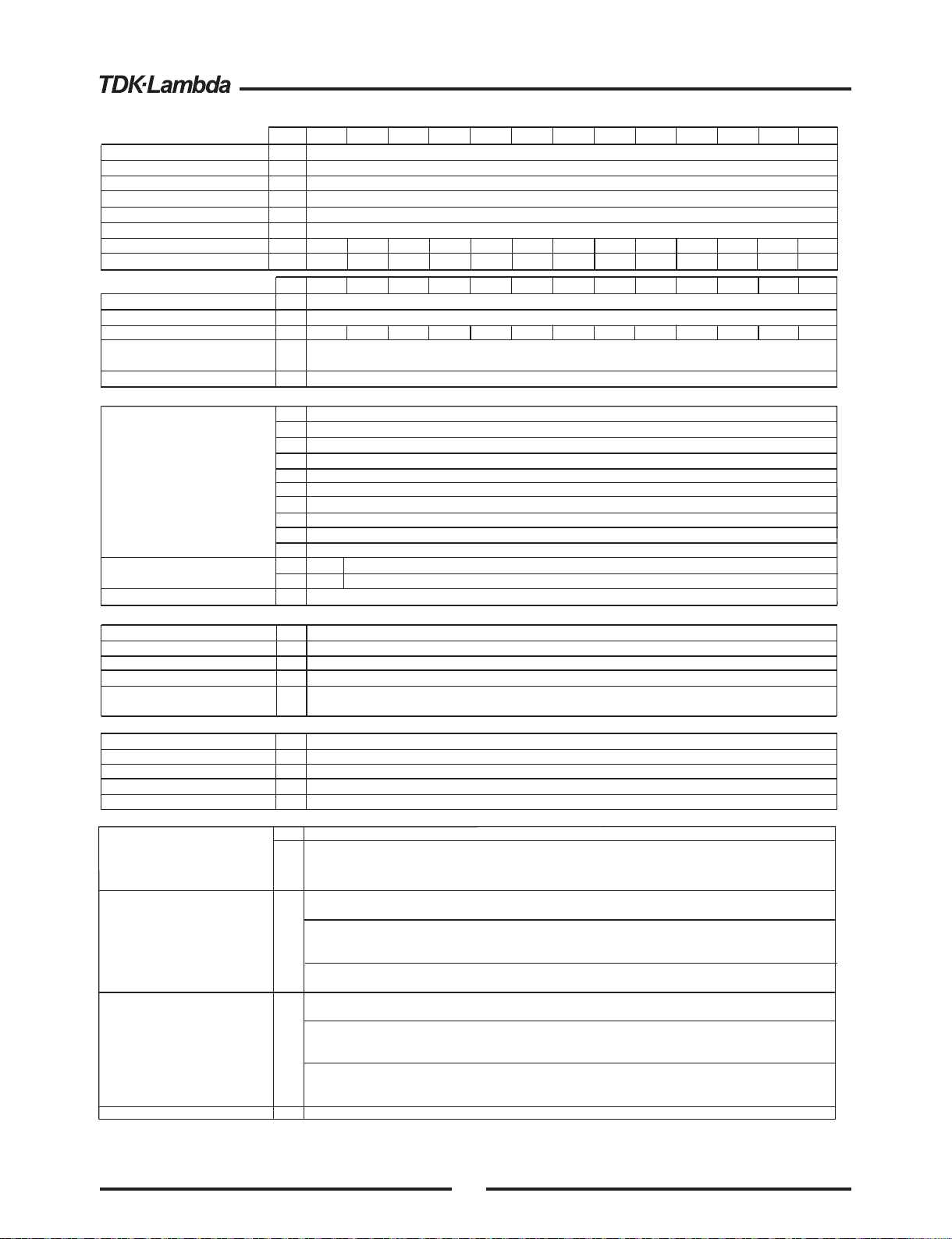

NOTES:

*1: Minimum voltage is guaranteed to maximum 0.2% of the rated output voltage.

*2: Minimum current is guaranteed to maximum 0.4% of the rated output current.

*3: For cases where conformance to various safety standards (UL, IEC etc.) is required, to be

described as 190~240Vac (50/60Hz) for Single-Phase and 3-Phase 200V models, and

380~415Vac (50/60Hz) for 3-Phase 400V models.

*4: Single-Phase and 3-Phase 200V models: at 200Vac input voltage.

3-Phase 400V: at 380Vac input voltage. With rated output power.

*5: Not including EMI filter inrush current, less than 0.2mSec.

*6: Single-Phase and 3-Phase 200V models: 170~265Vac, constant load.

3-Phase 400V models: 342~460Vac, constant load.

*7: From No-load to Full-load, constant input voltage. Measured at the sensing point in Remote

Sense.

*8: For 8V~300V models: measured with JEITA RC-9131A (1:1) probe.

For 600V model: measured with 10:1probe.

*9: From10% to 90% or 90% to 10% of rated output voltage, with rated , resistive load.

*10: From 90% to 10% of rated output voltage.

*11: For load voltage change, equal to the unit voltage rating, constant input voltage.

*12: For 8V~15V models the ripple is measured at 2V rated output voltage and rated output

current. For other models, the ripple is measured at 10~100% of rated output voltage and

rated output current.

*13: The Constant Current programming readback and monitoring accuracy does not include the

warm-up and Load regulation thermal drift.

*14: Measured at the sensing point.

2.12 SUPPLEMENTAL CHARACTERISTICS

The supplemental characteristics give typical but non-warranted performance characteristics.

The supplemental characteristics are useful in assessing applications for the power supply.

Several kinds of supplemental characteristics are listed below.

1.Evaluation Data: Typical performance of the power supply.

2.Reliability Data: Reliability performance of the power supply.

3.EN61000 Data: Performance of the power supply under EN61000 test conditions.

4.EMI Data: Typical EMI (conducted and radiated) performance of the power supply.

The supplemental characteristics data is held in each Lambda sales and service facility. For further

details please contact the Lambda office nearest you.

11

Page 21

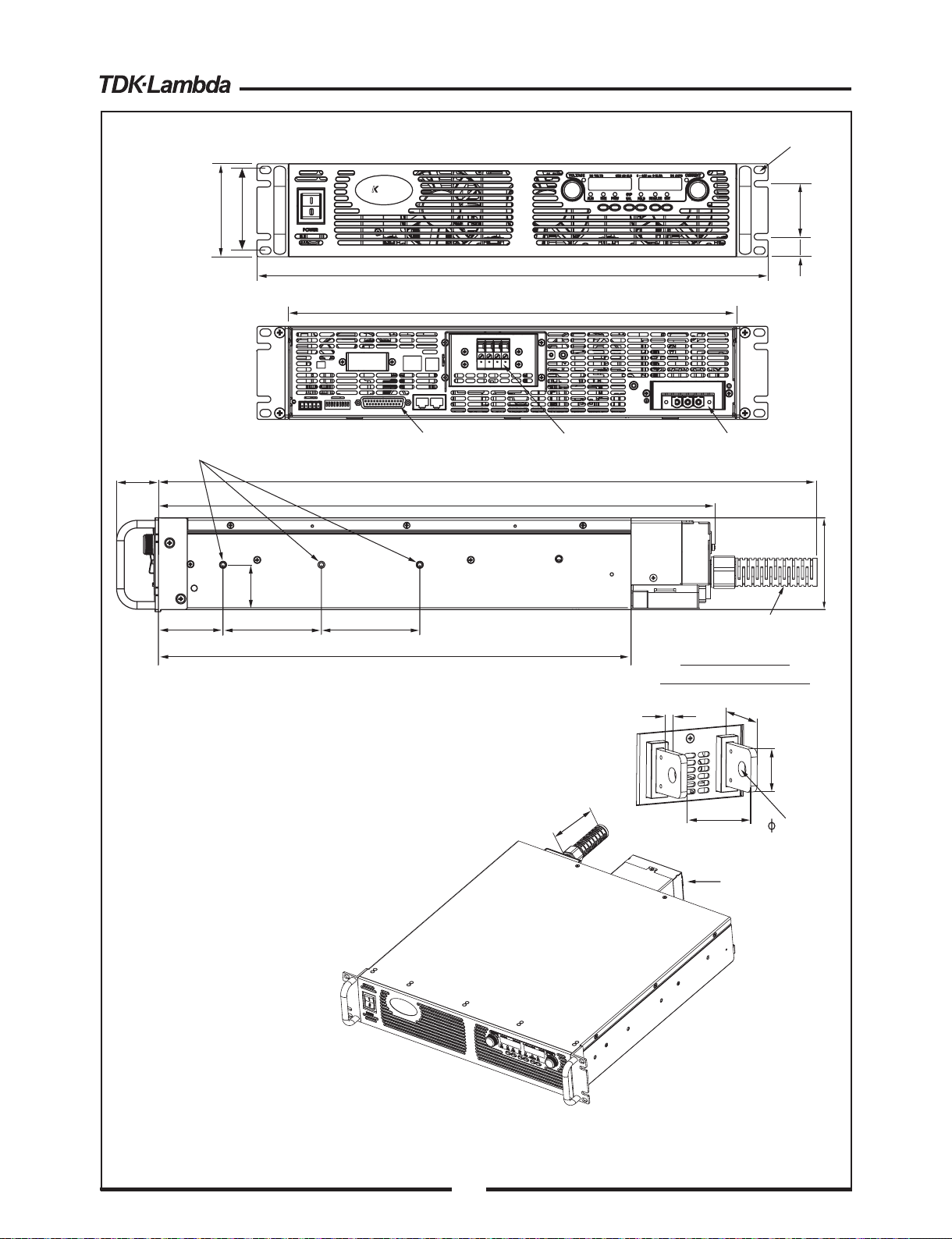

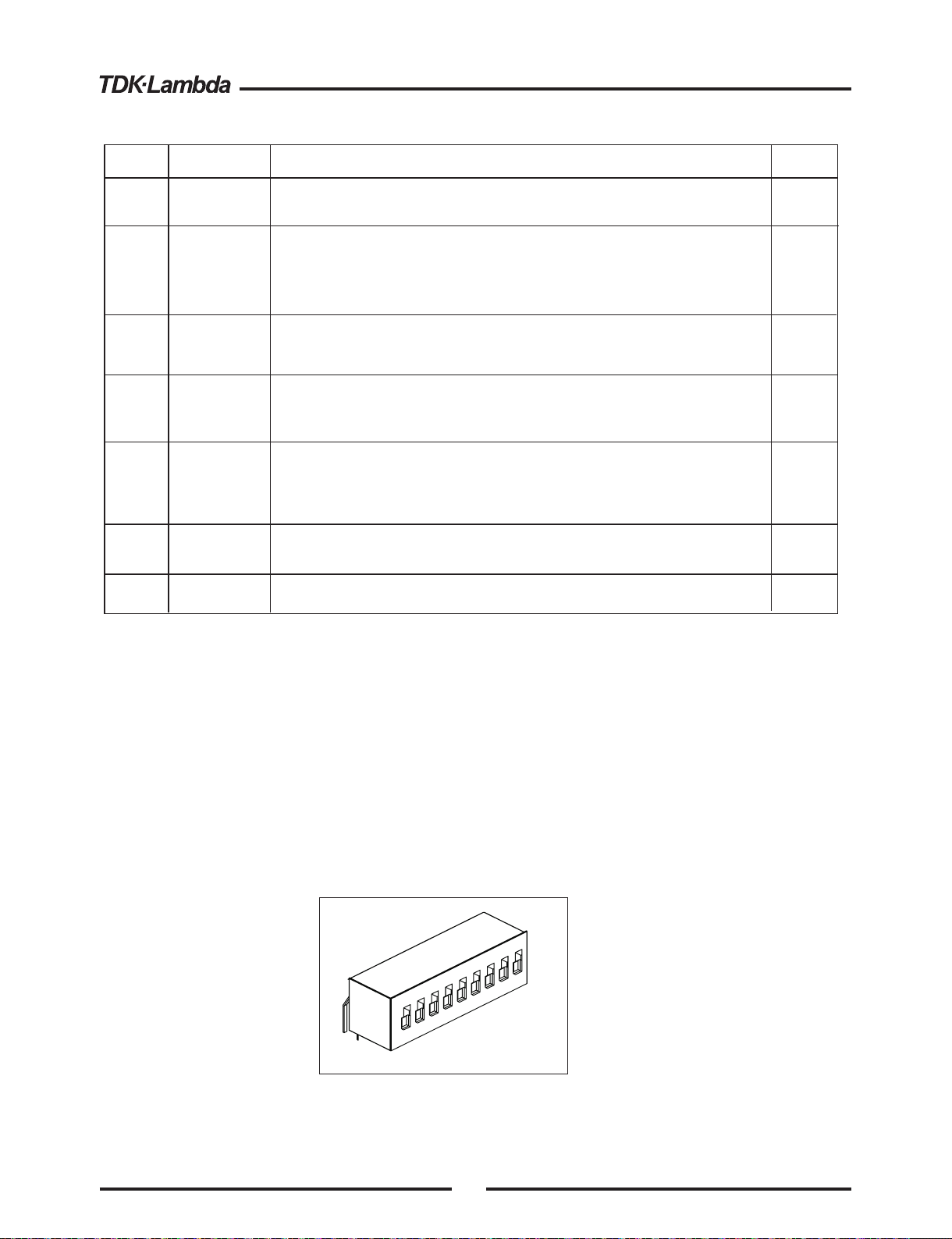

2.13 GENESYS 3300W POWER SUPPLIES

OUTLINE DRAWINGS

TM

NOTES:

1.Analog programming connector. Matingplug suppliedwith

power supply.

2.Bus-barsfor 8V to 100V models. See detail.

Wire clamp connector for 150V to 600V models(shown).

3. AC cablestrain relief(suppliedwith power supply).

4. AC input connector (single phase shown).

5. Chassisslides, GENERAL DEVICES P/N: CC3001-00-S160

or equivalent, mounting holes #10-32 marked "A".

6. Bus Bars enclosurefor 60V to 600V.

7. Mounting holes for 19” rack. Use M6x16

screws to fix the unittothe rack.

423.0±1.0mm

Note1

Note2(150V~600V)

Note4

Note7

88.0mm±0.3

50.0

19.0

482.0±1.0mm

Bus-Bar Detail

8V to 100V Models

40.0m

m

30.0mm

5.0mm

50.0mm

10.5mm

60.5

92.0

92.0

442.5±1.0mm

642.5±1.0mm

517.0±1.0mm

35.5±1.0mm

Note5

Note3

Note2

Note6

42.0

A

A

A

86±0.3

T

D

L

amb

da

-

I

10

4

±

2.0m

m

76.2

12

Page 22

CHAPTER 3 INSTALLATION

3.1 GENERAL

This chapter contains instructions for initial inspection, preparation for use and repackaging for

shipment. Connection to PC, setting the communication port and linking Genesys power supplies

are described in Chapter 7.

WARNING

The Genesys series is intended only for installation in

Restricted Access Location (RAL). Access to Hazardous

parts (rear side of the power supply) shall be prevented after

installation.

Genesys power supplies generate magnetic fields which

might affect the operation of other instruments. If your

equipment is susceptible to magnetic fields, do not position

it adjacent to the power supply

TM

TM

NOTE

WARNING

TM

.

through the front panel slits.

3.2 PREPARATIONFOR USE

To avoid electric shock hazard, do not insert conductive parts

I

n order to be operational the power supply must be connected to an appropriate AC source. The

AC source voltage should be within the power supply specification. Do not apply power before

reading, Section 3.6 and 3.7.

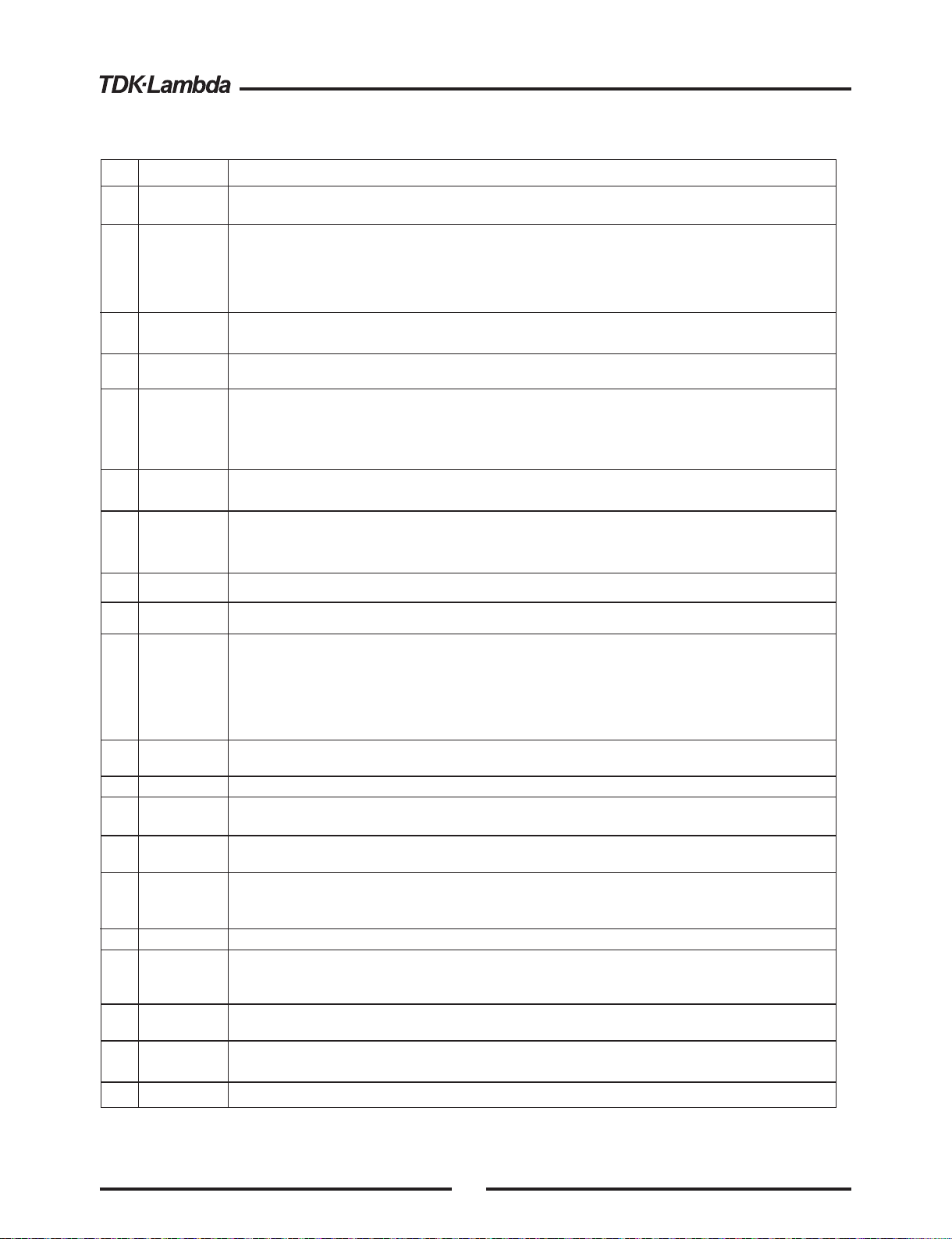

Table 3-1 below, describes the basic setup procedure. Follow the instructions in Table 3-1 in the

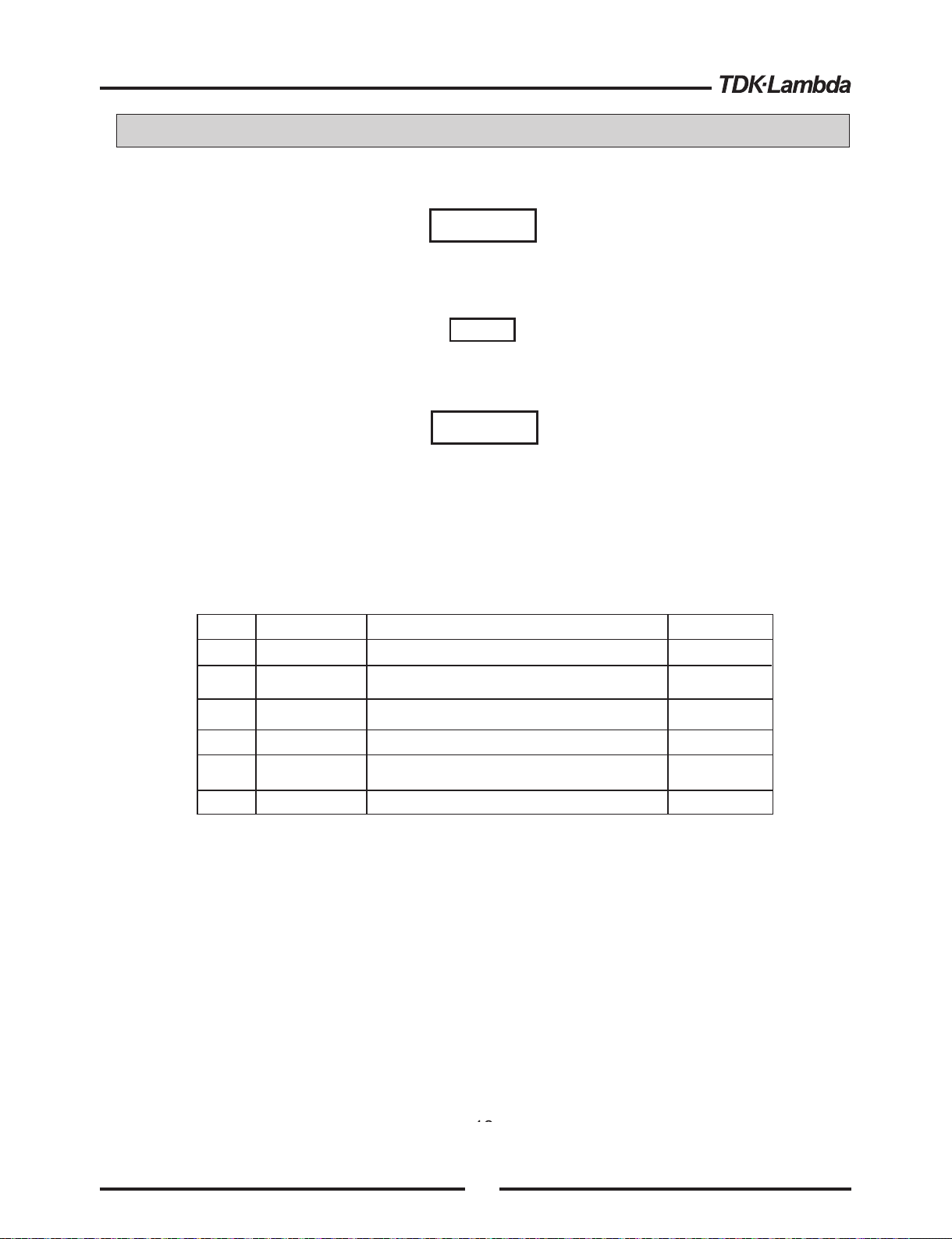

sequence given to prepare the power supply for use.

Step no.

1

2

3

4

5

6

Item Description Reference

Inspection

Installation

AC source

Test

Load connection

Default setting

Initial physical inspection of the power supply

Installing the power supply,

Ensuring adequate ventillation.

AC source requirements

Connecting the power supply to the AC source.

Turn-on checkout procedure.

Wire size selection. Local /Remote sensing.

Single or multiple loads.

The power supply setting at shipment.

Section 3.3

Section 3.4

Section 3.5

Section 3.6

Section 3.7

Section 3.8

Section 3.9

Section 7.2.1

Table 3-1: Basic setup procedure

3.3 INITIALINSPECTION

Prior to shipment this power supply was inspected and found free of mechanical or electrical

defects. Upon unpacking of the power supply, inspect for any damage which may have occured in

transit.

The inspection should confirm that there is no exterior damage to the power supply such as broken

knobs or connectors and that the front panel and meters face are not scratched or cracked. Keep all

packing material until the inspection has been completed. If damage is detected, fileaclaim with

carrier immediately and notify the Lambda sales or service facility nearest you.

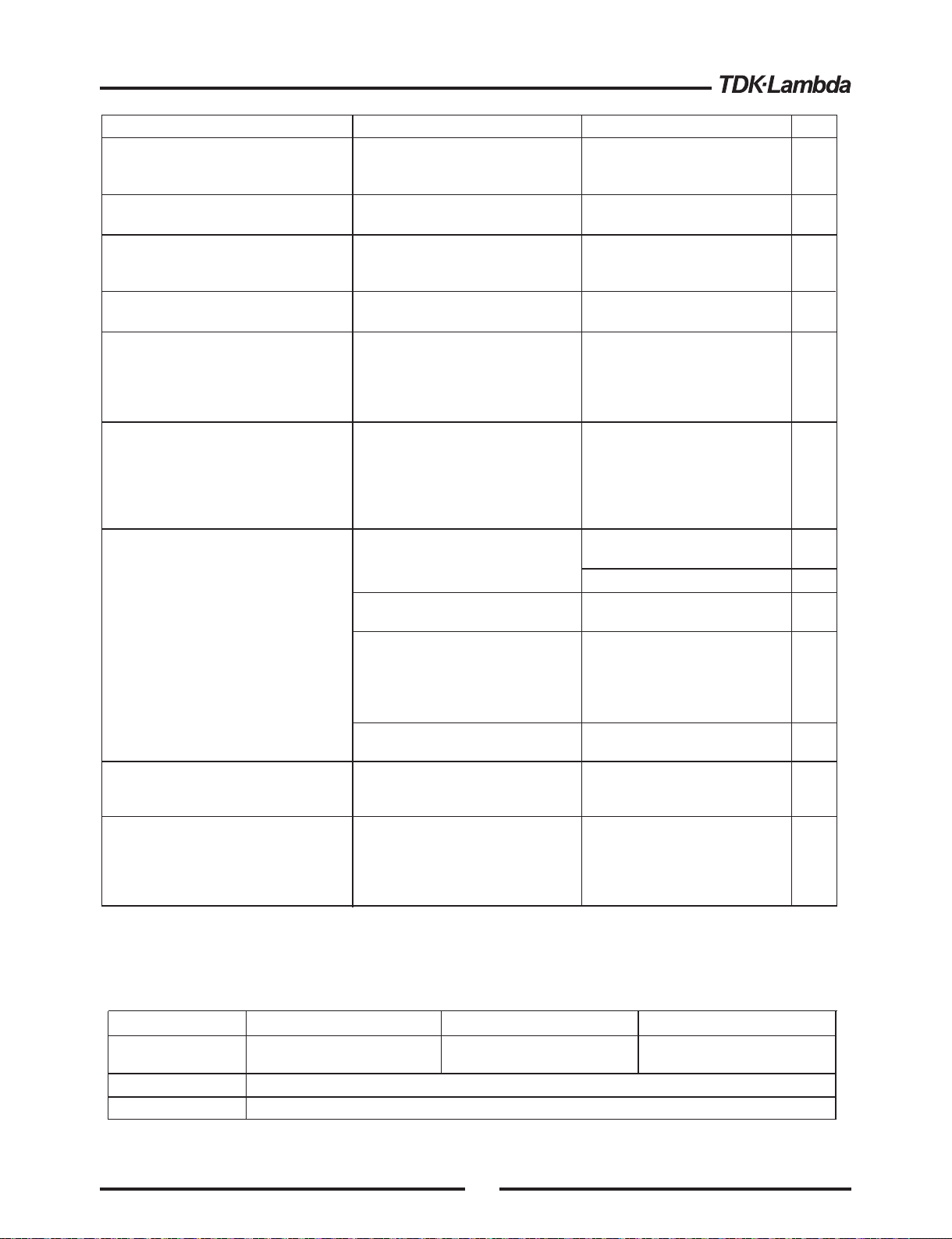

3.4 RACK MOUNTING

The Genesys power supply series is designed to fit inastandard 19” equipment rack.

TM

3.4.1 To install the Power Supply inarack:

1. Use the front panel rack-mount bracketsto install the power supply in the rack.

2. Useasupport bar to provide adequate support for the rear of the power supply.Do not obstruct

the air exhaust at the rear panel of the unit.

13

Page 23

14

Page 24

r

WARNING

so

The

n

the

Some componentsinsidethe power supplyare at AC voltage even whenthe On/Offswitch is in the

“Off”position.Toavoid electric shock hazard, disconnect the line cord and load and waittwo

minutes beforeremovingcover.

CAUTION

AC Input WiresNo Conductor Pretreatment:PhoenixContact clamping parts are designed

that all kinds of copper conductors canbe clamped without pretreatment.

It is forbidden to solder theconductors. The solder tin yieldsand fractures under high pressure.

result is increased contact resistance and an excessive temperature rise.Inaddition, corrosio

caused by picklingor fluxeshas been observedonsoldered conductor ends. Notch fractures at

transition point fromthe rigid to the flexible conductorareaare also possible.

The power supply ON/OFF switch is not themain “disconnectdevice”and does not completely

disconnectall the circuits fromthe AC source.

An appropriately rated“disconnect device”suchas circuit breaker, typeBplugonpower cord, ...etc.,

shallbeprovided in the final installation. The “disconnectdevice” for onephaseunits shall

disconnect bothsupply lines simultaneously.The “disconnected device”must be easily accessible.

3.7.1ACInput Connector

TheAC input connector is:for single phase: Phoenix ContactP/N: PC6/3-STF-10,16

forthree phase: Phoenix ContactP/N: PC6/4-STF-10,16

Header :for single-phase: Phoenix Contact P/N: PC6-16/3-GF-10,16

forthree-phase: Phoenix Contact P/N: PC6-16/4-GF-10,16

Use suitablewires and tightening torque as follows:

1. Wire diameter: 12AWG forsingle-phase models,

14AWG forthree-phase 200V models and

16AWG forthree-phase 400V models. Refer to Table1-2 for details.

2. Tightening torque: 10.7-13.4Lb-inch. (1.2 -1.5Nm).

3.7.2ACInput Cord

WARNING

AC input cordis not provided with power supply.

Refer to section1.3.4 for details of therecommended AC input cords and to section3.7 fo

disconnected device requirement.

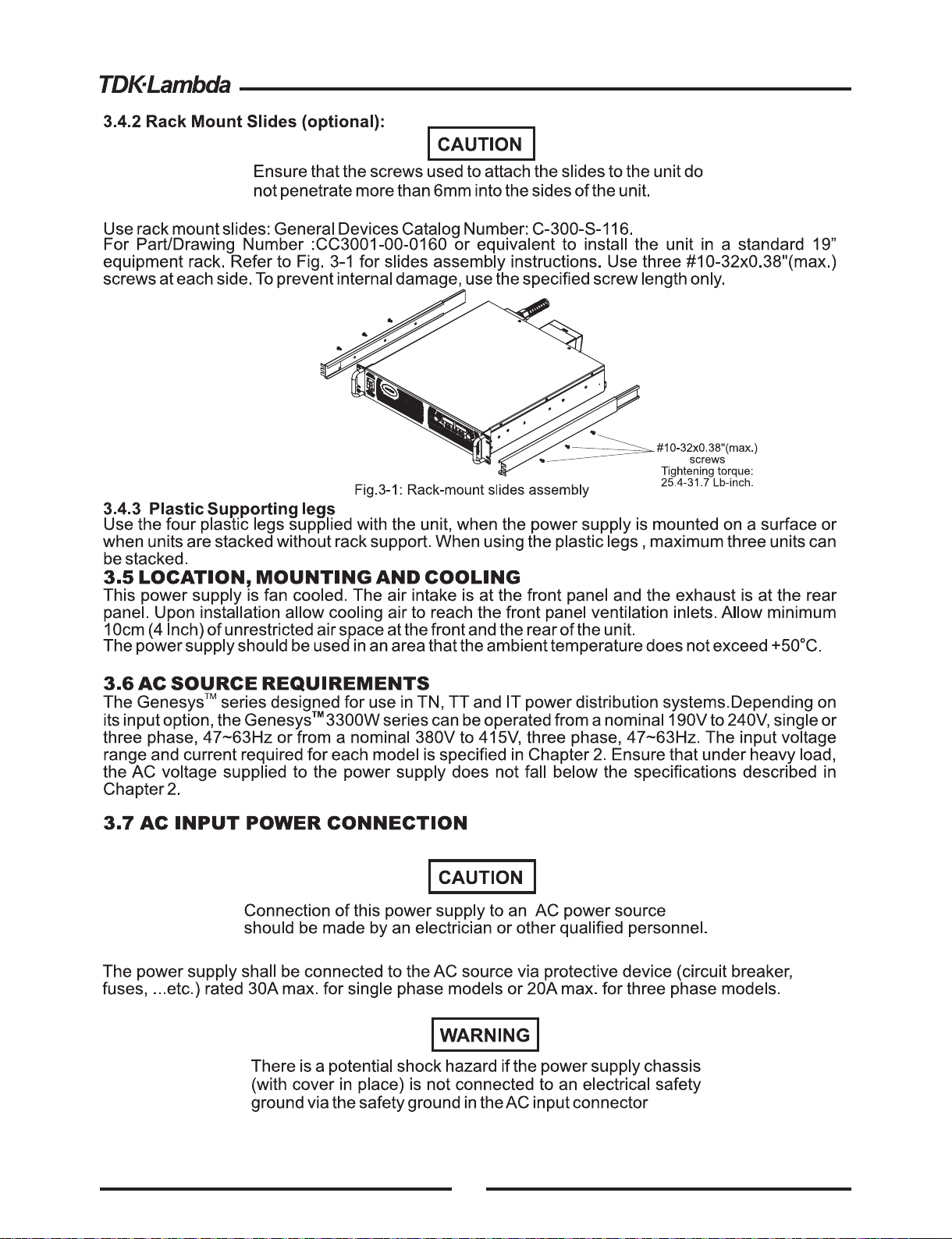

3.7.3ACInput Wire Connection

1.Stripthe outside insulationofthe AC cable approx. 10cm. Trim thewiressothat theground wire is

10mm longer than theother wires. Strip 10mm at the end of each of thewires.

2.Unscrew the base of thestrain relief fromthe helix-shaped body.Insertthe base through the

outside opening in theACinput cover and screw thelocknut securely(11-14 Lb-inch.)intothe

base, fromthe inside.

3.Slidethe helix-shaped body ontothe AC cable. Insertthe stripped wiresthrough thestrain relief

Screw-on

Locknut

Fig.3-2: Stripped WiresinstalledinStrain Relief

15

Page 25

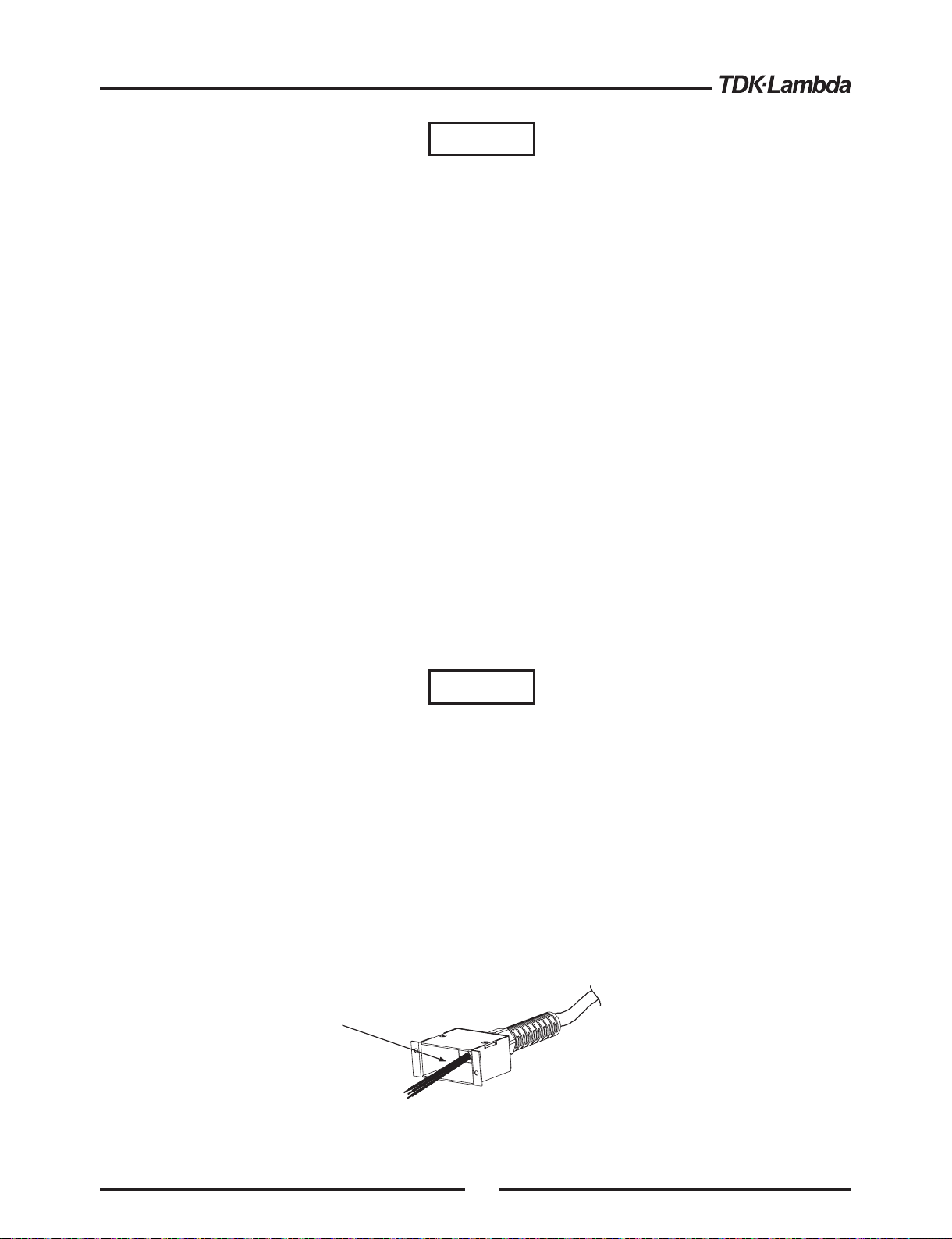

4.Connect

5.

position

Fig.3-4: AC input cover and strain relief

Removable cover. Remove only

to inspect AC Input wires

connection. Reinstall cover after

inspection.

Assembled Strain Relief

M3x8

Flat Head screws

(2 places)

L1

L2

L3

the AC wires to the terminals of the input plug supplied with the unit. To connect the

wires, loosen the terminal screw, insert the stripped wire into the terminal and tighten the

screw securely (4.4-5.3 Lb-inch.). Refer to Fig. 3-3 for details. Pay attention to connect the

wires according to the polarity marking on the plug.

AC Input Plug :

Single Phase: P/N: PC6/3-STF-10,16

Wire clamp screws

tightening torque: 10.7- 13.4 Lb-inch.

3-Phase: P/N: PC6/4-STF-10,16:

Protective Ground wire

t

AC Line wires

Fig.3-3: AC Input plug (3-Phase shown)

Connect the AC input plug to the AC input connector at the power supply rear panel. Fasten

the plug to the connector using the two screwsat each side of the plug.

(Tightening torque:10.7-13.4Lb inch)

Route the wires inside the cover to prevent pinching. Fasten the cover to the unit using the

M3x8 Flat Head screws are provided. Refer to Fig.3-4 for details.

3.8 TURN-ON CHECKOUT PROCEDURE

3.8.1 General

The following procedure ensures that the power supply is operational and may be used asabasic

incoming inspection check. Refer to Fig.4-1 and Fig.4-2 for the location of the controls indicated in

the procedure.

3.8.2 Prior to Operation

1. Ensure that the power supply is configured to the default setting:

-AC On/Off switch at Off position.

-Dip switch : All positions at Down (”Off”) position.

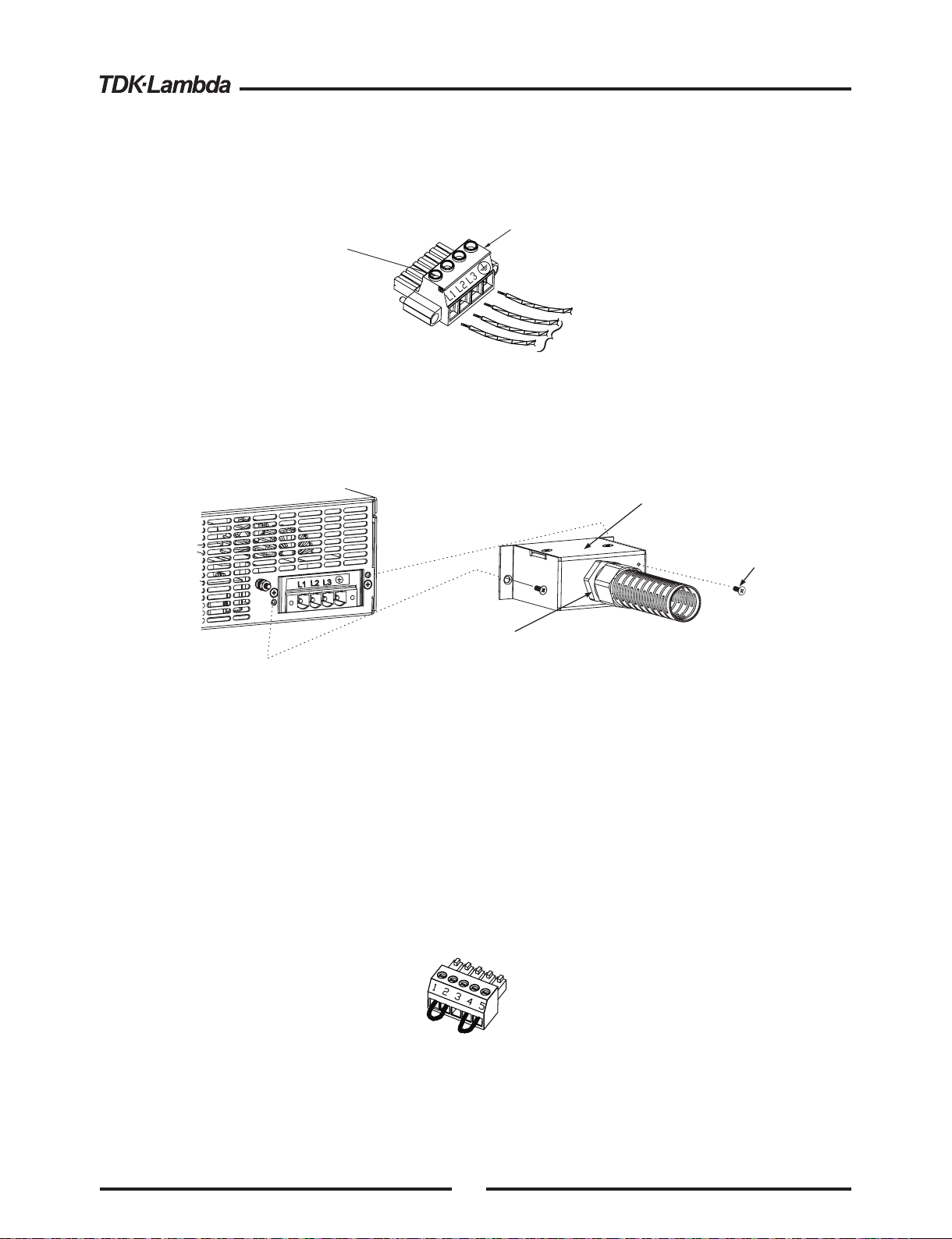

-Sense connector : Configured to Local Sense as shown in Fig.3-5:

1 Remote (+) sense

2 Local (+) sense

3 Not connected

4 Local (-) sense

5 Remote (-) sense

Fig.3-5: Sense connector default connection

Plug P/N: MC 1.5/5-ST-3.81

(Phoenix)

-For units equipped with IEEE option, ensure that the IEEE_En switch is in Up (default)

(Refer to Fig.4-2, item8for location), if checkout is to be done in IEEE mode.

16

Page 26

2. Connect the unit to anAC source as described in section 3.7.

3. Connect aDVM with appropriate cables for the rated voltage to the output terminals.

4. Turn the front panel AC power switch to On.

3.8.3 Constant Voltage Check

1. Turn on the output by pressing OUT pushbutton so the OUT LED illuminates.

2. Observe the power supply VOLT display and rotatethe Voltage encoder. Ensure that the

output voltage varies while the VOLT encoder is rotated. The minimum control range is from

zero to the maximum rated output for the power supply model.

Compare the DVM reading with the front panel VOLT display to verify the accuracy of the

VOLT display. Ensure that the front panel VOLT LED is on.

3. Turn off the front panelAC power switch.

3.8.4 Constant Current Check

1. Ensure that the front panelAC power switch is at Off position and the DVM connected to the

output terminals shows zero voltage.

2. Connect aDC shunt across the output terminals. Ensure that the shunt and the wires' current

ratings are higher than the power supply rating. Connect a DVM to the shunt.

3. Turn the front panel AC power switch to On position.

4. Turn on the output by pressing OUT pushbutton so the OUT LED illuminates.

5. Observe the power supply CURRENTdisplay and rotate the CURRENT encoder. Ensure that

the output current varies while the CURRENT encoder is rotated. The minimum control range

is from zero to the maximum rated output for the power supply model.

Compare the DVM reading with the front panel CURRENT display to verify the accuracy of

the CURRENT display. Ensure that the front panel CURRENT LED is on.

6. Turn off the front panel AC power switch.

7. Remove the shunt from the power supply output terminals.

3.8.5 OVPCheck

Refer to Section 5.3 for explanation of the OVP function prior to performing the procedure below.

1. Turn the front panel AC power switch to On position and turn on the output by pressing OUT

pushbutton.

2. Using the VOLT encoder, adjust the output voltage to approx. 10% of the unit voltagerating.

3. Momentarily press

VOLTAGE display will show the last setting of the OVPlevel.

4. Rotate the VOLT encoder CCW to adjust the OVPsetting to 50% of the unit voltage rating.

5. Wait a few seconds until the VOLT display returns to show the output voltage.

6. Adjust the output voltagetoward it’smaximum and check that the output voltagecannot be

increased more than the OVP setting.

7. Adjust OVPlimit to the maximum by repeating step 3 and rotatingthe VOLT encoder CW.

3.8.6 UVLCheck

Refer to Section 5.4 for explanation of the UVLfunction prior to performing the procedure below.

1. Press the OVP/UVLbutton TWICEso that the CURRENT display shows"UUL". The VOLTAGE

display will show the last setting of the UVL level.

2. Rotate the VOLT encoder to adjust the UVL level to approx. 10% of the unit voltage rating.

3. Wait a few seconds until the VOLT display returns to show the output voltage.

4. Adjust the output voltagetoward it’sminimum and check that the output voltagecannot be

decreased below the UVL setting.

5. Adjust the UVL limit to the minimum by repeating step1 and rotating the VOLT encoder CCW.

the OVP/UVL button so that the CURRENT display shows“OUP”. The

17

Page 27

3.8.7 Foldback Check

WARNING

Shorting the output may expose the user to hazardous

voltages. Observe proper safety procedures.

Refer to Section 5.5 for explanation of the FOLD function prior to performing the procedure

below.

1. Ensure that the output voltage is set to approx. 10% of the unit rating.

2. Adjust the CURRENT encoder to set the current limit to approx. 10% of the unit rating.

3. Momentarily press the FOLD button. Ensure that the FOLD LED illuminates. The output

voltage remains unchanged.

4. Short the output terminals momentarily (approx. 0.5 sec.). Ensure that the output voltage falls

to zero, the VOLT display shows “Fb” and the ALARM LED blinks.

5. Press the FOLD button again to cancel the protection. The output voltage remains zero.

6. Press OUT button. Ensure that the output voltage returns to it’s last setting.

7. Turn the output offby pressing OUT button. Ensure that the VOLT display shows“OFF”.

3.8.8 Address Setting

1. Press and hold the REM/LOC button for approx. 3sec. The VOLT display will show the

communication port address.

2. Using the VOLT adjust encoder, check that the address can be set within the range of0to 30.

3.8.9 Baud Rate Setting

1. Press and hold the REM/LOC button for approx. 3sec. The CURRENT display will show the

communication port Baud Rate.

2. Using The CURRENT adjust encoder, check that the Baud Rate can be set to 1200, 2400,

4800, 9600 and 19200.

3.9 CONNECTINGTHE LOAD

WARNING

Turn off the AC input power before making or changing any

rear panel connection. Ensure that all connections are

securely tightened before applying power.There isapotential

shock hazard when using a power supply with a rated output

greater than 40V.

3.9.1 Load Wiring

The following considerations should be made to select wiring for connecting the load to the power

supply:

* Current carrying capacity of the wire (refer to 3.9.2)

* Insulation rating of the wire should be at least equivalent to the maximum output voltage of

the power supply.

* Maximum wire length and voltage drop (refer to 3.9.2)

* Noise and impedance effectsof the load wiring (refer to 3.9.4).

3.9.2 Current Carrying Capacity

Two factors must be considered when selecting the wire size:

1. Wires should be heavy enough not to overheat while carrying the power supply load

current at the rated load, or the current that would flow in the event the load wires were

shorted, whichever is greater.

at least

18

Page 28