TDK-Lambda G20-250, GB80-65, G100-50, GB20-250, GB100-50 Safety & Installation Instruction

...Page 1

Series

Programmable DC Power Supplies

5kW in 1U 0-600V/ 0-500A

Built in LAN, USB, RS-232 & RS-485 Interface

Optional Interface: IEEE488.2 (GPIB)

SAFETY & INSTALLATION MANUAL

This Manual Covers Models:

G10-500

G80-65

GB10-500

GB80-65

G20-250

G100-50

GB20-250

GB100-50

G30-170

G150-34

GB30-170

GB150-34

G40-125

G300-17

GB40-125

GB300-17

G60-85

G600-8.5

GB60-85

GB600-8.5

Manual Supplements

The full user manual is available on TDK-Lambda website or can be ordered, refer to User manual IA761-04-02_.

IA761-04-01

Page 2

This page intentionally left blank

Page 3

TABLE OF CONTENTS

WARRANTY ................................................................................................................................................................... 1

SAFETY & EMC APPROVALS ........................................................................................................................................... 2

GENERAL SAFETY INSTRUCTIONS ................................................................................................................................... 4

ALLGEMEINE SICHERHEITSVORSCHRIFTEN ..................................................................................................................... 6

INSTRUCCIONES DE SEGURIDAD GENERALES ................................................................................................................. 8

CONSIGNES GÉNÉRALES DE SÉCURITÉ .......................................................................................................................... 10

ISTRUZIONI GENERALI DI SICUREZZA ........................................................................................................................... 12

INSTRUÇÕES GERAIS DE SEGURANÇA .......................................................................................................................... 14

PRODUCT SAFETY INSTRUCTIONS ................................................................................................................................ 16

CHAPTER 1: GENERAL INFORMATION .......................................................................................................................... 22

1.1 User Manual Content ................................................................................................. 22

1.2 Introduction ................................................................................................................ 22

1.2.1 General Description ....................................................................................... 22

1.2.2 Multiple Output Power System ..................................................................... 22

1.2.3 Control via LAN, USB or RS232/485 Communication Ports .......................... 22

1.2.4 Analog Voltage Programming and Monitoring ............................................. 23

1.2.5 Parallel Operation.......................................................................................... 23

1.2.6 Output Connections ...................................................................................... 23

1.2.7 Cooling and Mechanical Construction........................................................... 23

1.3 Accessories ................................................................................................................. 23

1.3.1 Accessories provided with the power supply ................................................ 23

1.3.1.1 Input connector protection, includes 3 parts: ............................................................ 23

1.3.1.2 AC Input Plug P/N: PC 5/ 4-STCL1-7, 62 (Phoenix contact) ......................................... 23

1.3.1.3 Output connector/ Bus bars protection ...................................................................... 23

1.3.1.4 Serial link cable ............................................................................................................ 23

1.3.1.5 Misc. Hardware ........................................................................................................... 24

1.3.1.6 Bus bars Screws kits .................................................................................................... 24

1.3.2

Optional accessories

.................................................................................. 24

1.3.2.1 Printed User Manuals

.............................................................................................. 24

1.3.2.2 Serial Port Cables

..................................................................................................... 24

1.3.2.3 Paralleling Cable .......................................................................................................... 24

1.3.2.4 AC Cables

................................................................................................................... 24

CHAPTER 2: FRONT/REAR PANEL CONTROLS AND CONNECTORS ................................................................................ 25

2.1 Introduction ................................................................................................................ 25

2.2 Front Panel Display and Controls

......................................................................... 25

2.3 Rear Panel Connectors

.......................................................................................... 27

CHAPTER 3: INSTALLATION .......................................................................................................................................... 29

3.1 General ....................................................................................................................... 29

3.2 Preparation for Use ..................................................................................................... 29

3.3 Initial Inspection ......................................................................................................... 30

3.4 Rack Mounting............................................................................................................ 30

3.4.1 Install the Power Supply in a Rack ................................................................. 30

3.4.2 Rack Mount Slides (Optional) ........................................................................ 31

3.5 Location, Mounting and Cooling ................................................................................ 31

3.6 AC Input Power Connection ....................................................................................... 32

3.6.1 AC Input Connector ....................................................................................... 34

Page 4

3.6.2 AC Input Wire Connection ............................................................................. 35

3.7 Turn-On Checkout Procedure

.............................................................................. 38

3.7.1 General .......................................................................................................... 38

3.7.2 Prior to Operation .......................................................................................... 38

3.7.3 Constant Voltage Check ................................................................................ 38

3.7.4 Constant Current Check ................................................................................ 39

3.8 Connecting the Load

.............................................................................................. 39

3.8.1 Load Wiring ................................................................................................... 40

3.8.2 Current Carrying Capacity ............................................................................. 40

3.8.3 Wire Termination .......................................................................................... 41

3.8.4

Noise and Impedance Effects

.................................................................... 41

3.8.5

Inductive Loads

........................................................................................... 42

3.8.6 Making the Load Connections ....................................................................... 42

3.8.7

Grounding Outputs

..................................................................................... 49

3.9 Local and Remote Sensing .......................................................................................... 50

3.9.1 Sense Wiring .................................................................................................. 50

3.9.2 Local Sensing ................................................................................................. 50

3.9.3 Remote Sensing ............................................................................................. 50

3.9.4 J8 Sense Connector Technical Information ................................................... 51

3.9.5 Repackaging for Shipment............................................................................. 51

Page 5

1

WARRANTY

This TDK-Lambda product is warranted against defects in materials and workmanship for a period of five years

from date of shipment. During the warranty period, TDK-Lambda will, at its option, either repair or replace

products, which prove to be defective.

Limitation of Warranty

The warranty shall not apply to defects resulting from improper or inadequate usage or maintenance by the buyer,

buyer supplied products or interfacing. The warranty shall not apply to defects resulting from unauthorized

modifications or from operation exceeding the environmental specifications of the product or if the QA seal has

been removed or altered by anyone other than TDK-Lambda authorised personnel. TDK-Lambda does not

warrant the buyers circuitry or malfunctions of TDK-Lambda products resulting from the buyer's circuitry.

Furthermore, TDK-Lambda does not warrant any damage occurring as a result of the buyer's circuitry or the

buyer's - supplied products. No other warranty is expressed or implied.

Warranty Service

This product must be returned to an authorized TDK-Lambda service facility for repairs or other warranty service.

For products returned to TDK-Lambda for warranty service, the buyer shall prepay shipping charges to TDKLambda and TDK-Lambda shall pay the shipping charges to return the product to the buyer. Refer section 3.9.5

for Repackaging for Shipment.

Disclaimer

The information contained in this document is subject to change without notice. TDK-Lambda shall not be liable

for errors contained in this document or for incidental or consequential damages in connection with the furnishing,

performance or use of this material. No part of this document may be photocopied, reproduced or translated into

another language without the prior written consent of TDK-Lambda.

Page 6

2

SAFETY & EMC APPROVALS

SAFETY

UL 60950-1 and CSA22.2 No.60950-1 - UL Listed. C-UL for Canada.

IEC 60950-1 - CB Report and Certificate.

EN 60950-1 - CE mark.

EMC

IEC 61204-3, EN 61204-3, FCC Part 15-A, VCCI-A

Marking by the CE Symbol indicates compliance to the LVD and EMC Directives of the European Union.

A “Declaration of Conformity” in accordance with the preceding directives and standards has been made and is

on file at our EU representative TDK LAMBDA UK, located at Kingsley Avenue, Ilfracombe, Devon EX34 8ES,

UK.

A “Declaration of Conformity” may be accessed via company web site www.uk.tdk-lambda.com/technical-data/

NOTE

EMC tests are applicable only to output signals and communication ports up to 3m length

and DC output ports up to 30m length.

REGULATORY NOTICES

FCC Notice

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) this

device may not cause harmful interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation.

Page 7

3

NOTE

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction manual,

may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in

which case the user will be required to correct the interference at his own expense.

WARNING

Modifications not expressly approved by the party responsible for compliance could void

the users authority to operate the equipment under FCC Rules.

CE Notice (European Union)

Marking of the CE symbol indicates compliance to the EMC Directive and the Low Voltage

Directive of the European Union. Such marking is indicative that the ™ series meets the following

technical standards:

• EN 60950-1: Information technology equipment - Safety - Part 1: General requirements.

• EN 61204-3: Low-Voltage switch mode power supplies – Part 3: Electromagnetic compatibility (EMC).

WARNING

This is a Class A product. On a domestic environment, this product may cause radio

interference in which case user may be required to take adequate measures.

WARNING

This is a product designed for an industrial environment. In a residential, commercial or

light industrial environment it may cause radio interference. The user may be required to

take adequate measures to reduce interference.

Page 8

4

GENERAL SAFETY INSTRUCTIONS

READ SAFETY INSTRUCTIONS

The following safety precaution must be observed during all phases of operation, service and repair of this

equipment. Failure to comply with the safety precautions or warnings in this document violates safety

standards of design, manufacture and intended use of this equipment and may impair the built-in

protections within. TDK-Lambda shall not be liable for user’s failure to comply with these requirements.

SERVICING:

These products are not customer serviceable. Parts substitutions and modifications are by authorized

TDK-Lambda service personnel only. For repairs or modifications, the product must be returned to TDKLambda service facility.

CRITICAL COMPONENTS:

These products are not authorised for use as critical components in nuclear control systems, life support

systems or equipment for use in hazardous environments without the express written approval of the

Managing Director of TDK-Lambda Ltd.

PRODUCT USAGE:

These products are designed for use as standalone equipment within a limits described in product Manual.

ENVIRONMENTAL:

These products are IP20, and therefore chemicals/solvents, cleaning agents and other liquids must not be

used.

ENVIRONMENT:

These products are designed for use within a Pollution Degree 2, Overvoltage Category II environment.

OUTPUT LOADING:

The output power taken from the products must not exceed the rating stated on the product label, except

as stated in the product Manual.

INPUT PARAMETERS:

These products must be operated within the input parameters stated in the product Manual.

END OF LIFE DISPOSAL:

The products contains components that require special disposal. Make sure that the unit is properly

disposed of at the end of its service life and in accordance with local regulations.

Page 9

5

RISK OF ELECTRIC SHOCK

High Voltage Warning: Dangerous voltages are present within the power supply. To avoid injuries,

always disconnect power, discharge circuits and remove external voltage sources before touching

components.

Class I Warning: The unit is Class I product. To minimize electrical shock hazard, the unit must be reliably

earthed and professionally installed. Any interruption of the protective ground conductor or disconnection

of the protective earth terminal will cause a potential shock hazard that might cause personal injury.

Energy Hazards Warning: The main output of the unit is hazardous energy (240VA) and must not be

user accessible in the end application.

Hazardous output Warning: There is a potential shock hazard when using a power supply with an output

voltage greater than 60VDC. Do not turn ON power supply when output voltage is above 60VDC without

output bus-bars/or output connectors protection assembled. Turn OFF power supply or disconnect power

supply from AC mains before making or changing any rear panel connection.

Internal fuse Caution: Internal fuse protect the unit and must not be replaced by the user. In case of

internal defect, the unit must be returned to TDK-Lambda Ltd. or one of their authorised agents.

OTHER

The ventilation openings on these products must not be impeded. Ensure that there is at least 50mm

spacing between any obstruction and the ventilation openings.

Page 10

6

ALLGEMEINE SICHERHEITSVORSCHRIFTEN

LESEN SIE DIE SICHERHEITSVORSCHRIFTEN

Die folgenden Sicherheitsvorschriften müssen in allen Phasen des Betriebs, der Wartung und der

Reparatur der Anlage eingehalten werden. Eine Missachtung der Sicherheitsvorschriften und

Warnhinweise aus diesem Handbuch führt zur Verletzung der bestehenden Sicherheitsstandards für

Design, Produktion und der zweckbestimmten Verwendung der Anlage und kann die integrierten

Schutzvorrichtungen beschädigen.

TDK-Lambda ist nicht für Schäden haftbar, die durch Missachtung dieser Sicherheitsvorschriften

durch den Benutzer entstehen können.

WARTUNG:

Diese Produkte können nicht durch den Kunden gewartet werden. Ersatzteilaustausch und Modifikationen

dürfen nur durch von TDK-Lambda zugelassenes Personal durchgeführt werden. Für Reparaturen oder

Modifikationen muss das Gerät an einen Vertriebspartner von TDK- Lambda geschickt werden.

KRITISCHE KOMPONENTEN:

Diese Produkte sind nicht für die Verwendung als kritische Komponenten in nuklearen Kontrollsystemen,

Lebenserhaltungssystemen oder Geräten in gefährlichen Umgebungen geeignet, sofern dies nicht

ausdrücklich und in Schriftform durch den Geschäftsführer von TDK- Lambda Ltd. genehmigt wurde.

PRODUKTVERWENDUNG:

Diese Produkte sind für den Einsatz als Standalone-Geräte innerhalb der im Produkthandbuch

beschriebenen Grenzen konzipiert.

UMWELT:

Diese Produkte besitzen die Schutzklasse IP20. Aus diesem Grund dürfen keine

Chemikalien/Lösungsmittel, Reinigungsmittel und andere Flüssigkeiten verwendet werden.

UMGEBUNG:

Diese Produkte sind für den Einsatz in einer Umgebung mit Verschmutzungsgrad 2,

Überspannungskategorie II, konzipiert.

AUSGANGSSTROM:

Der Ausgangsstrom des Produktes darf die Leistung, die auf dem Label des Produktes vermerkt ist, nur

dann überschreiten, wenn dies in den Produktgrenzen dieses Handbuches ausgezeichnet ist.

EINGANGSPARAMETER:

Dieses Produkt muss innerhalb der Eingangsparameter betrieben werden, die im Produkthandbuch

angegeben sind.

ENTSORGUNG AM ENDE DER BETRIEBSZEIT:

Die Produkte enthalten Komponenten, die unter Sondermüll fallen. Das Gerät muss am Ende der

Betriebszeit ordnungsgemäß und in Übereinstimmung mit den regionalen Bestimmungen entsorgt werden.

Page 11

7

GEFAHR VON ELEKTRISCHEM SCHLAG

Hochspannungswarnung: Innerhalb des Netzteiles gibt es gefährliche Spannungen. Um

Personenschäden zu vermeiden, muss vor dem Kontakt mit dem Gerät immer die Stromversorgung

unterbrochen, die Stromkreise entladen und externe Spannungsquellen entfernt werden.

Schutzklasse I Warnung: Das Gerät ist ein Produkt der Schutzklasse 1. Zur Vermeidung gefährlicher

Energieinhalte und Spannungen, ist das Gerät an eine zuverlässige Schutzerde anzuschließen und durch

Fachleute zu installieren. Jede Unterbrechung des PE-Leiters oder die Trennung der PE-Verbindung kann

einen möglichen elektrischen Schlag hervorrufen, der Personenschäden zur Folge haben kann.

Warnung vor Stromschlaggefahr: Der Hauptausgang dieses Gerätes steht unter gefährlicher Spannung

(240 V) und darf im Endgerät, in das es installiert wird, nicht für den Benutzer zugänglich sein.

Warnung vor gefährlichem Ausgang: Es besteht Stromschlaggefahr, wenn eine Stromversorgung mit

einer Ausgangsspannung von mehr als 60 V Gleichspannung verwendet wird. Schalten Sie die

Stromversorgung nicht EIN, falls die Ausgangsspannung über 60 V Gleichspannung liegt, wenn die

Schutzabdeckungen der Stromschienen oder Ausgangsklemmen nicht montiert sind. Schalten Sie die

Stromversorgung AUS oder trennen Sie diese von der Netzversorgung, bevor Sie den rückwärtigen

Anschluss verbinden oder verändern.

Warnung - Interne Sicherung: Interne Sicherungen schützen das Gerät und dürfen durch den Benutzer

nicht ausgetauscht werden. Im Fall von internen Defekten muss das Gerät an TDK- Lambda Ltd. oder

einen der autorisierten Vertriebshändler zurückgeschickt werden.

WEITERES

Die Belüftungsöffnungen an diesem Produkt dürfen nicht blockiert werden. Achten Sie darauf, dass

mindestens 50 mm Abstand zwischen Hindernissen und den Belüftungsöffnungen bleibt.

Page 12

8

INSTRUCCIONES DE SEGURIDAD GENERALES

LEER LAS INSTRUCCIONES DE SEGURIDAD

La siguiente precaución de seguridad debe ser respetada durante todas las fases de funcionamiento,

mantenimiento y reparación de este equipo. El incumplimiento de las precauciones o advertencias de

seguridad recogidas en este documento infringe las normativas de seguridad de diseño, fabricación y uso

previsto de este equipo y puede afectar a las protecciones incorporadas en el mismo. TDK-Lambda no

asumirá responsabilidad alguna si el usuario no cumple estos requisitos.

MANTENIMIENTO:

El cliente no debe realizar el mantenimiento de estos productos. Solo el personal de servicio autorizado

de TDK-Lambda sustituirá y modificará las piezas. Para cualquier reparación o modificación del producto,

este debe ser enviado a un centro de servicio de TDK-Lambda.

COMPONENTES FUNDAMENTALES:

El uso de estos productos como componentes fundamentales en sistemas de control nuclear, sistemas de

soporte vital o equipos para el uso en entornos peligrosos queda prohibido sin el consentimiento expreso

por escrito del Director General de TDK-Lambda Ltd.

USO DE PRODUCTOS:

Estos productos han sido diseñados para utilizarse como equipo individual dentro de los límites descritos

en el manual del producto.

ECOLÓGICOS:

Estos productos son IP20, por lo que no deben utilizarse productos químicos/disolventes, productos de

limpieza ni otros líquidos.

MEDIO AMBIENTE:

Estos productos han sido diseñados para utilizarse dentro de un entorno con un nivel de contaminación 2

y categoría de sobretensión II.

CARGA DE SALIDA:

La potencia de salida extraída de los productos no debe exceder la potencia de servicio indicada en la

etiqueta del producto, con excepción de lo indicado en el manual del producto.

PARÁMETROS DE ENTRADA:

Estos productos deben utilizarse dentro de los parámetros de entrada indicados en el manual del

producto.

ELIMINACIÓN AL FINAL DE LA VIDA ÚTIL:

Los productos contienen componentes que deben eliminarse de forma especial. Asegurarse de que la

unidad se elimina de forma adecuada al final de su vida útil y de conformidad con las normas locales.

Page 13

9

RIESGO DE DESCARGAS ELÉCTRICAS

Advertencia sobre la alta tensión: existen tensiones peligrosas dentro de la fuente de alimentación.

Para evitar lesiones, desenchufe siempre el cable de alimentación, descargue los circuitos y desconecte

las fuentes de tensión externas antes de tocar los componentes.

Advertencia sobre la Clase I: la unidad es un producto de Clase I. Para minimizar el riesgo de

descargas eléctricas, la unidad debe conectarse a tierra de forma fiable e instalarse de forma profesional.

Cualquier interrupción del conductor de tierra de protección o desconexión del borne de tierra de

protección supondrá un riesgo potencial de descarga eléctrica que puede llegar a causar daños

personales.

Advertencia sobre los peligros de la energía: la salida principal de la unidad es energía peligrosa (240

VA) y no debe ser accesible a los usuarios en el equipo final.

Advertencia sobre la salida peligrosa: existe un peligro de descargas potencial cuando se utiliza una

fuente de alimentación con una tensión de salida superior a 60 V CC. No ENCENDER la fuente de

alimentación cuando la tensión de salida supere los 60 V CC sin tener montados tubos de conducción de

corriente de salida o conectores de salida. APAGAR la fuente de alimentación o desconectar la fuente de

alimentación de la red eléctrica CA antes de realizar o cambiar cualquier conexión del panel posterior.

Precaución sobre el fusible interno: el fusible interno protege la unidad y no debe ser sustituido por el

usuario. En caso de defecto interno, la unidad deberá enviarse a TDK-Lambda Ltd. o a alguno de sus

agentes autorizados.

INFORMACIÓN ADICIONAL

No deben obstruirse las aberturas de estos productos. Asegurarse de que hay un mínimo de 50 mm de

espacio entre cualquier obstrucción y las aberturas de ventilación.

Page 14

10

CONSIGNES GÉNÉRALES DE SÉCURITÉ

LISEZ LES CONSIGNES DE SÉCURITÉ

Respectez les consignes de sécurité suivantes pendant toutes les phases d'utilisation, d'entretien et de

réparation de cet équipement. Le non-respect des consignes de sécurité et des avertissements figurant

dans ce document enfreindrait les normes de sécurité relatives à la conception, à la fabrication et à l'usage

prévu de cet équipement. Il risquerait également d'en compromettre les protections incorporées. TDKLambda décline toute responsabilité en cas de non-respect de ces impératifs de sécurité.

ENTRETIEN:

ces produits n'ont pas été conçus pour être entretenus par le client. Les substitutions et modifications de

pièces doivent impérativement être réalisées par un technicien d'entretien agréé par TDK Lambda. Pour

les réparations ou les modifications, renvoyez le produit au centre d'entretien TDK Lambda.

COMPOSANTS CRITIQUES:

ces produits n'ont pas été conçus pour être utilisés comme composants critiques de systèmes de

commande nucléaire, de survie ou d’équipements utilisés dans des environnements dangereux, sans

l'autorisation écrite expresse du directeur général de TDK-Lambda Ltd.

UTILISATION DU PRODUIT:

ces produits ont été conçus pour être utilisés de manière autonome, conformément aux limites indiquées

dans le Manuel y afférent.

CONSIDÉRATIONS ENVIRONNEMENTALES:

ces produits étant conformes à la norme de protection IP20, ils ne doivent pas être utilisés avec les

produits chimiques/solvants, agents de nettoyage et autres liquides.

ENVIRONNEMENT:

ces produits sont compatibles avec une utilisation dans un milieu soumis à un Degré 2 de pollution,

Catégorie de surtension II.

CHARGE DE SORTIE:

la puissance de sortie de ces produits ne doit pas dépasser la valeur indiquée sur leur étiquette, autrement

que dans les conditions rappelées dans le Manuel y afférent.

PARAMÈTRES D'ENTRÉE:

ces produits doivent être utilisés avec les paramètres d'entrée indiqués dans leurs Manuels.

MISE AU REBUT EN FIN DE VIE:

ces produits contiennent des composants à soumettre à une procédure de mise au rebut particulière.

Veillez à ce que la mise au rebut de ces appareils en fin de vie utile s'effectue en bonne et due forme,

conformément à la réglementation en vigueur sur place.

Page 15

11

RISQUE DE CHOC ÉLECTRIQUE

Avertissement de haute tension: l'alimentation de ces appareils est parcourue par des tensions

dangereuses. Pour éviter les blessures, débranchez toujours l'alimentation, déchargez les circuits et

retirez les sources de tension extérieures avant de toucher les composants.

Avertissement de Classe I: l'appareil est un produit de Classe I. Pour réduire au minimum le risque de

choc électrique, l'appareil doit être relié à la terre et installé par un professionnel. Toute rupture du

conducteur de terre ou de la borne de raccordement à la terre de l'appareil, présenterait un risque de choc

électrique susceptible de provoquer des blessures.

Avertissement de danger électrique: l'appareil servant principalement à la production d'électricité

dangereuse (240 VA), il ne doit pas être accessible par l'utilisateur dans son application finale.

Avertissement de sortie dangereuse: l'utilisation d'une alimentation dont la tension de sortie dépasse 60

V c.c. présente un risque de choc électrique. Ne mettez pas l'alimentation sous tension lorsque la tension

de sortie est supérieure à 60 V c.c., avant d'avoir monté des bus- barres ou des connecteurs de sortie.

Éteignez l'alimentation ou débranchez-la de l'alimentation secteur avant d'effectuer ou de changer les

branchements au panneau arrière.

Précaution relative au coupe-circuit interne: un fusible interne protège l'appareil et ne doit pas être

remplacé par l'utilisateur. En cas de défaut interne, renvoyez l'appareil à TDK-Lambda Ltd. ou à l'un de

ses agents agréés.

AUTRE

Les ouïes d'aération de ces produits doivent être libres de toute entrave. Veuillez à prévoir au moins 50

mm d'espace libre entre une obstruction quelconque et les ouïes d'aération de ces appareils.

Page 16

12

ISTRUZIONI GENERALI DI SICUREZZA

LEGGERE LE ISTRUZIONI DI SICUREZZA

È necessario attenersi alle seguenti precauzioni di sicurezza, a tutti gli stadi del funzionamento, della

manutenzione e della riparazione dell’apparecchiatura. Il mancato rispetto delle precauzioni di sicurezza o

delle avvertenze contenute nel presente documento costituisce una violazione degli standard di sicurezza

relativi alla progettazione, fabbricazione e uso previsto dell’apparecchiatura, e potrebbe compromettere le

protezioni interne di quest’ultima. TDK-Lambda non sarà responsabile per l’inosservanza di tali requisiti da

parte dell’utente.

MANUTENZIONE:

Questi prodotti non possono essere sottoposti a manutenzione da parte del cliente. Qualunque

sostituzione o modifica dei componenti deve essere affidata esclusivamente al personale di manutenzione

di TDK-Lambda. Per eventuali riparazioni o modifiche, il prodotto deve essere inviato al centro assistenza

di TDK-Lambda.

COMPONENTI CRITICI:

L’uso di questi prodotti come componenti critici non è autorizzato all’interno di sistemi di controllo nucleari,

sistemi salvavita o apparecchiature destinate all’impiego in ambienti pericolosi, senza l’esplicito consenso

scritto dell’Amministratore delegato di TDK-Lambda Ltd.

USO DEI PRODOTTI:

Questi prodotti sono destinati all’uso come apparecchiature autonome, entro i limiti indicati nel loro

Manuale.

PRECAUZIONI AMBIENTALI:

Questi sono prodotti IP20, pertanto l’utente non deve utilizzare agenti chimici/solventi, agenti per la pulizia

e altri liquidi.

CONDIZIONI AMBIENTE:

Questi prodotti sono concepiti per l’uso in ambienti con Grado di inquinamento 2, Categoria di

sovratensione II.

CARICO DI USCITA:

La potenza di uscita dai prodotti non deve superare il livello nominale riportato sulla loro etichetta, salvo

quanto specificato nel Manuale dei prodotti.

PARAMETRI D’INGRESSO:

Il funzionamento di questi prodotti deve rientrare nei parametri d’ingresso riportati nel loro Manuale.

SMALTIMENTO AL TERMINE DELLA VITA UTILE:

I prodotti contengono componenti che è necessario smaltire in modo speciale. Accertarsi di smaltirli

correttamente al termine della loro vita utile e nel rispetto delle norme locali vigenti.

Page 17

13

RISCHIO DI SCOSSA ELETTRICA

Avvertenza - alta tensione: All’interno dell’alimentatore sono presenti tensioni pericolose. A prevenzione

del rischio di infortuni, scollegare sempre le unità dalla rete elettrica, scaricare i circuiti ed eliminare le fonti

esterne di tensione prima di toccare i componenti.

Avvertenza - prodotto di Classe I: L’unità è un prodotto di Classe I. Per ridurre al minimo il rischio di

scossa elettrica, l’unità deve essere messa a terra e installata in modo professionale e affidabile. In caso

di interruzione del conduttore protettivo di terra, o scollegamento del terminale protettivo di terra, vi sarà un

rischio di scossa elettrica e conseguenti infortuni alla persona.

Avvertenza - rischi elettrici: L’uscita principale di questa unità è energia pericolosa (240 VA) e non deve

essere accessibile da parte dell’utente nell’ambito dell’applicazione finale.

Avvertenza - uscita pericolosa: Vi è un potenziale rischio di scossa elettrica con l’uso di alimentatori la

cui tensione in uscita superi 60 V CC. Non ACCENDERE l’alimentatore quando la tensione in uscita è

superiore a 60 V CC in assenza di protezioni con sbarre collettrici o connettori di uscita. SPEGNERE

l’alimentatore o staccarlo dalla presa elettrica a CA prima di eseguire o modificare qualsiasi collegamento

sul pannello posteriore.

Precauzione - fusibile interno: Il fusibile interno protegge l’unità e non deve essere sostituito dall’utente.

Nell’eventualità di un difetto interno, l’unità deve essere inviata a TDK-Lambda Ltd. o a un suo agente

autorizzato.

ALTRO

Le aperture di ventilazione su questi prodotti non devono essere ostruite. Controllare che vi sia una

distanza minima di 50 mm fra le aperture di ventilazione e qualsiasi eventuale ostruzione.

Page 18

14

INSTRUÇÕES GERAIS DE SEGURANÇA

LEIA AS INSTRUÇÕES DE SEGURANÇA

As seguintes precauções de segurança devem ser respeitadas em todas as fases de funcionamento,

manutenção e reparação deste equipamento. A não observância dos avisos e precauções de segurança

constantes neste documento viola os padrões de segurança da concepção, fabrico e utilização pretendida

deste equipamento, podendo danificar as protecções integradas no seu interior. A TDK-Lambda não

poderá ser responsabilizada pelo não cumprimento destes requisitos por parte do utilizador.

MANUTENÇÃO:

Estes produtos não são podem ser submetidos a manutenção por parte do cliente. As modificações e

substituições de peças devem ser realizadas apenas pelo pessoal de assistência autorizado da TDKLambda. Para a realização de reparações ou modificações, é necessário devolver o produto a uma

unidade de serviço da TDK-Lambda.

COMPONENTES ESSENCIAIS:

Não é autorizada a utilização destes produtos como componentes essenciais de sistemas de controlo

nuclear, sistemas de suporte de vida ou equipamento para utilização em ambientes perigosos sem a

expressa autorização por escrito do Director-Geral da TDK-Lambda Ltd.

UTILIZAÇÃO DO PRODUTO:

Estes produtos foram concebidos para utilização como equipamento autónomo, dentro dos limites

descritos no manual do produto.

AMBIENTAL:

Estes produtos são IP20 e, como tal, não se devem utilizar químicos/solventes, agentes de limpeza e

outros líquidos.

AMBIENTE:

Estes produtos foram concebidos para utilização em ambientes da categoria de sobretensão II, com um

Nível de Poluição 2.

CARGA DE SAÍDA:

A potência de saída extraída dos produtos não deve exceder a classificação assinalada na etiqueta do

produto, excepto quando indicado no manual do produto.

PARÂMETROS DE ENTRADA:

Estes produtos devem ser utilizados dentro dos parâmetros de entrada indicados no manual do produto.

ELIMINAÇÃO NO FIM DE VIDA:

Os produtos contêm componentes que necessitam de procedimentos especiais de eliminação. Certifiquese de que a unidade é devidamente eliminada no fim da sua vida útil e que tal é feito em conformidade

com os regulamentos locais.

Page 19

15

RISCO DE CHOQUE ELÉCTRICO

Aviso de alta tensão: Estão presentes tensões perigosas dentro da fonte de alimentação. Para evitar

ferimentos, desligue sempre a energia, descarregue os circuitos e retire as fontes de tensão externas

antes de tocar nos componentes.

Aviso de classe I: A unidade é um produto de Classe I. Para reduzir o risco de choque eléctrico, a

unidade deve ser ligada à terra de forma fiável e instalada por um profissional. Qualquer interrupção do

condutor de terra de protecção ou corte do terminal de terra de protecção poderá originar um risco de

choque passível de provocar ferimentos.

Aviso de perigos de energia: A saída principal da unidade constitui energia perigosa (240 V AC) e não

deve estar acessível ao utilizador na aplicação final.

Aviso de saída perigosa: Há a possibilidade de existir risco de choque ao utilizar uma fonte de

alimentação com tensão de saída superior a 60 V CC. Não LIGUE a fonte de alimentação quando a

tensão de saída for superior a 60 V CC e não existir protecção para as barras do bus de saída/conectores

de saída. DESLIGUE a fonte de alimentação ou interrompa a ligação entre a fonte de alimentação e a

corrente alternada antes de realizar ou alterar qualquer ligação no painel traseiro.

Cuidados com o fusível interno: O fusível interno protege a unidade e não deve ser substituído pelo

utilizador. Em caso de defeito interno, a unidade deve ser devolvida à TDK-Lambda Ltd. ou a um dos seus

agentes autorizados.

OUTROS

As aberturas de ventilação destes produtos não devem ser obstruídas. Certifique-se de que existe um

espaçamento de pelo menos 50 mm entre qualquer obstrução e as aberturas de ventilação.

Page 20

16

PRODUCT SAFETY INSTRUCTIONS

CAUTION

The following safety precautions must be followed during all phases of operation, service,

and repair of this equipment. Failure to comply with the safety precautions or warnings in

this document violates safety standards of design, manufacture and intended use of this

equipment and may impair the built-in protections within. TDK-Lambda shall not be liable

for user’s failure to comply with these requirements.

VORSICHT

Die folgenden Sicherheitsvorschriften müssen vor Inbetriebnahme und in jeglichem

Betriebszustand bei Wartungsarbeiten oder Reparatur dieses Geräts beachtet werden.

Eine Missachtung der Sicherheitsvorschriften und Warnhinweise aus diesem Handbuch

stellt eine Verletzung der Sicherheitsstandards für Design, Herstellung und vorgesehene

Benutzung dieses Geräts dar und kann die im Gerät integrierten Schutzfunktionen

beeinträchtigen. TDK-Lambda ist nicht haftbar, wenn der Benutzer diese Anforderungen

missachtet.

OVERVOLTAGE CATEGORY AND ENVIRONMENTAL CONDITIONS

The ™ series units have been assigned to Overvoltage category II.

The ™ series units are intended for use in the following operation conditions:

• Indoor use

• Pollution degree 2

• Max. operational altitude: 3000m above sea level (Refer to product Spec. for operating

conditions).

• Ambient temperature: 0°C-50°C.

ÜBERSPANNUNGSKATEGORIE UND UMWELTBEDINGUNGEN

Die Geräte der

™ Serie wurden der Überspannungskategorie II zugeordnet.

Die Geräte der

™ Serie sind zur Benutzung unter folgenden Betriebsbedingungen

vorgesehen:

•

Benutzung in Innenräumen

•

Verschmutzungsgrad 2

• Maximale Einsatzhöhe: 3000 m über Null (siehe Produktspezifikationen für Betriebsbedingungen).

• Umgebungstemperatur: 0 °C – 50 °C.

Page 21

17

GROUNDING

This product is a Safety Class1 instrument. To minimize shock hazard, the instrument chassis must be

connected to an electrical ground. The instrument must be connected to the AC power supply mains

through a four conductor power cable with the ground wire firmly connected to an electrical ground

(safety ground) at the power outlet.

For instruments designed to be hard-wired to the supply mains, the protective earth terminal must be

connected to the safety electrical ground before another connection is made. Any interruption of the

protective ground conductor, or disconnection of the protective earth terminal will cause a potential

shock hazard. That might cause personal injury.

ERDUNG

Bei diesem Produkt handelt es sich um ein Gerät der Schutzklasse 1. Damit gefährliche Energieinhalte

und Spannungen vermieden werden, ist das Gehäuse des Gerätes an eine Schutzerde

anzuschliessen. Das Gerät muss mit Hilfe eines genormten 4-adrigen Kabels (L1, L2,L3, PE) fest an

eine 3-Phasige AC-Versorgung angeschlossen werden. Der PE-Anschluss ist an die vorgesehene

Schutzerde anzuschliessen.

Bei der Festverdrahtung des Gerätes ist sicherzustellen, dass der PE-Anschluss als erstes verbunden

wird.

Jede mögliche Unterbrechung des PE-Leiters oder Trennung der PE-Masse kann einen möglichen

elektrischen Schlag hervorrufen, der einen Personenschaden zur Folge hätte.

LIVE CIRCUITS

Operating personnel must not remove the instrument cover.

No internal adjustment or component replacement is allowed by non-TDK-Lambda qualified service

personnel. Never replace components with a power cable connected. To avoid injuries, always

disconnect power, discharge circuits, and remove external voltage sources before touching

components.

SPANNUNGSFÜHRENDE TEILE

Die Geräteabdeckung darf nicht vom Bedienungspersonal abgenommen werden.

Nur von TDK-Lambda zugelassene Servicekräfte dürfen interne Anpassungen vornehmen oder

Komponenten austauschen. Tauschen Sie niemals Komponenten aus, wenn das Versorgungskabel

noch mit der Steckdose verbunden ist. Um Verletzungen vorzubeugen, schalten Sie das Netzgerät

stromlos, entladen die Schaltkreise und entfernen externe Spannungsquellen, bevor Sie jegliche

Komponenten berühren.

Page 22

18

PARTS SUBSTITUTIONS & MODIFICATIONS

Parts substitutions and modifications are allowed by authorized TDK-Lambda Ltd. service personnel

only. For repairs or modifications, the instrument must be returned to TDK-Lambda Ltd. service facility.

AUSWECHSELN UND VERÄNDERUNG VON BAUTEILEN

Das Auswechseln sowie die Abänderung von Teilen darf nur von autorisierten TDK-Lambda Ltd.

Servicekräften vorgenommen werden. Für Reparaturen oder Abänderungen muss das Gerät an die

Servicestelle der TDK-Lambda Ltd. zurückgeschickt werden.

AC INPUT

The ™ series is designed for use in TN and TT power distribution systems.

Do not use AC supply, which exceeds the input voltage and frequency rating of this instrument. The

input voltage and frequency rating of the ™ power supply series are: 190-240V~, 47/63Hz

for Three Phase 200V models, 380-415V~, 47/63Hz for Three Phase 400V models, and 380-

480V~, 47/63Hz for Three Phase 480V models. For safety reasons, the mains supply voltage

fluctuations should not exceed +/-10% of the nominal voltage. Ensure that under heavy load, the AC

voltage supplied to the power supply does not fall below the specifications.

NETZEINGANG

Die

™ Serie ist für den Einsatz in TN und TT Energieverteilungssystemen vorgesehen.

Benutzen Sie keine AC-Versorgung, die dem Eingangsspannungs- und Frequenzwert dieses

Geräts nicht entspricht oder ihn überschreitet. Die Eingangsspannungs- und Frequenzwerte der

™

Netzgeräte Serie betragen: 190-240V~, 47/63Hz für dreiphasige 200V Modelle, 380415V~, 47/63Hz für dreiphasige 400V Modelle und 380-480V~, 47/63Hz für dreiphasige 480V

Modelle. Aus Sicherheitsgründen sollten die Netzspannungsschwankungen +/-10% der

Nennspannung nicht überschritten werden. Stellen Sie sicher, dass die am Netzgerät anliegende

Wechselstromspannung im Vollast-Betrieb nicht unter den Vorgaben liegt.

ENERGY HAZARD

The output of ™ series units is capable of providing the hazardous energy. Therefore, the

output and connections must not be user accessible. Customer's final equipment needs to provide

adequate protection for service personnel against inadvertent contact with output wires.

Page 23

19

GEFÄHRLICHE ENERGIEINHALTE

Am Ausgang der Geräte der ™ Serie können gefährliche Energieinhalte anliegen. Deshalb

müssen die Ausgangs-Anschlüsse berührungssicher durch den Benutzer ausgeführt sein. Die

Endkundenanlagen müssen so aufgebaut sein, dass Servicekräfte nicht versehentlich in Kontakt mit

den Ausgangsleitungen kommen können.

FUSES

CAUTION

MULTI-POLE FUSING

The ™ power supply units have fuses in all supply conductors. To prevent

potential risk of hazard during servicing, the unit shall be fully disconnected from the

supply.

Fuses must be changed by authorized TDK-Lambda Ltd. service personnel only. For continued

protection against risk of fire, replace only with the same type and rating of the fuse.

SICHERUNGEN

VORSICHT

MEHRFACH ABSICHERUNG

In den Netzgeräten der ™ Serie sind Sicherungen in allen Zuleitungen

vorgesehen. Die Geräte sollten während der Ausführung von Wartungsarbeiten vollständig

vom Versorgungsnetz getrennt werden, um Stromschläge zu vermeiden.

Nur von TDK-Lambda Ltd. autorisierte Servicekräfte dürfen Sicherungen austauschen. Sicherungen

dürfen nur durch Sicherungen des angegebenen Typs mit der angegebenen Nennstromstärke ersetzt

werden, um weiterhin die angemessenen Brandschutzfunktion zu gewähren.

FUSE RATING

There are no user replaceable fuses in the power supply. Internal fuses are sized for fault protection,

and if a fuse was opened, it will indicate that service is required. Fuse replacement should be made by

qualified technical personnel. Refer to Table 1-1 for a listing of the fuses.

Models rated 190-240Vac Input AC fuses F1, F2, F3 250VAC, 30A, Fast acting

Models rated 380-415Vac and 380-480Vac Input AC fuses F1, F2, F3 500VAC, 16A, Fast acting

Table 1-1: Internal Fuse

Page 24

20

SICHERUNGSWERTE

Im Gerät befinden sich keine Sicherungen, die durch den Anwender ersetzt werden können. Die

internen Netzsicherungen dienen als Fehlerschutz. Wenn eine solche Sicherung ausgelöst hatte, ist

dies ein eindeutiger Hinweis, dass das Gerät gewartet werden muss. Ein Sicherungstausch sollte nur

von qualifiziertem technischen Personal ausgewechselt werden. In Tabelle 1-1 sind die Sicherungen

aufgelistet.

Modelle Nennspannung 190-240Vac Netzsicherung F1, F2, F3 250VAC, 30A, Flinke Sicherung

Modelle Nennspannung 380-415Vac und

380- 480Vac.

Netzsicherung F1, F2, F3 500VAC, 16A, Flinke Sicherung

Tabelle 1-1: Interne Sicherungen

WARNING

There is an electric shock hazard when the power supply output is adjusted above 60VDC.

Ensure it is not possible to touch simultaneously one of the output terminals and earth

(including the power supply’s metal enclosure). Ensure it is not possible to touch

simultaneously one of the output terminals and metal parts of any external products

supplied by the power supply when the output is adjusted above 60VDC.

WARNUNG

Bei einer eingestellten Ausgangsspannung von über 60 VDC besteht die potentielle Gefahr

eines elektrischen Stromschlages.

Stellen Sie sicher, dass keine der Ausgangsklemmen und die Erdung (einschließlich des

Metallgehäuses des Netzgeräts) gleichzeitig berührt werden können. Dies gilt ebenfalls

für Ausgangsklemmen und andere leitfähige Komponenten externer Produkte, die von

dem Netzgerät versorgt werden, wenn deren Ausgangsspannung auf über 60 VDC

eingestellt ist.

WARNING

There is a potential electrical shock hazard when using a power supply with output voltage

greater than 60VDC. Do not turn ON power supply when output voltage is above 60VDC

without output protection assembled. Turn OFF power supply or disconnect power supply

from AC mains before making or changing any rear panel connection.

WARNUNG

Es besteht die Gefahr eines Stromschlags, wenn eine Stromversorgung mit einer

Ausgangsspannung von mehr als 60 VDC benutzt wird. Schalten Sie die Stromversorgung

nicht AN, wenn die Ausgangsspannung über 60 VDC liegt und kein Berührungsschutz

angebracht ist. Schalten Sie die Stromversorgung AUS oder trennen Sie das Netzkabel

vom Versorgungsnetz, bevor Sie irgendwelche Anschlüsse an der Geräterückseite

vornehmen oder ändern.

Page 25

21

GERÄUSCHPEGEL

Maschinenlärm - Verordnung - 3. GPSGV, der höchste Schalldruckpegel beträgt weniger als 70 dB(A) gemäss

EN ISO7779.

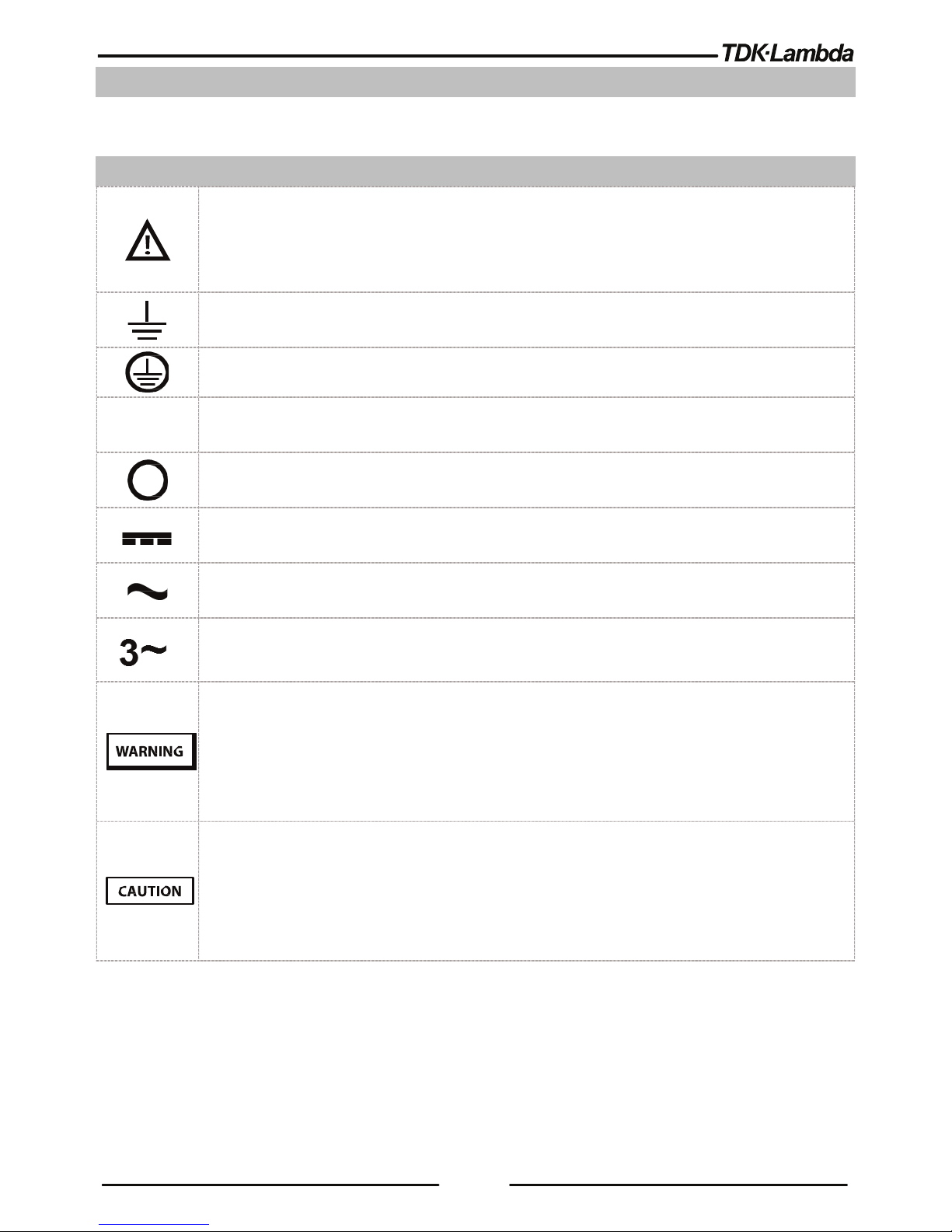

SYMBOLS/ ZEICHEN

Caution, risk of danger. Instruction manual symbol. The instrument will be marked with this symbol

when it is necessary for the user to refer to the Safety & Installation or Instruction manual.

Achtung Gefahr. Symbol im Benutzerhandbuch. Das Gerät wird mit diesem Symbol gekennzeichnet,

wenn der Benutzer auf das Sicherheits- & Installationshandbuch oder die Bedienungsanleitung

verwiesen wird.

Indicates ground terminal.

Zeigt einen Erdungsanschluss an.

Protective Ground Conductor Terminal.

Schutzleiterklemme.

ON (Supply).

EIN (Netzversorgung).

OFF (Supply).

AUS (Netzversorgung).

Direct current (DC).

Gleichstrom (DC).

Alternate current (AC).

Wechselstrom (AC).

Three-Phase Alternating Current (AC)

Drei-phasiger Wechselstrom (AC)

Denotes hazard. A procedure requires specific attention. Not following the procedure correctly

could result in a personal injury. A WARNING sign should not be skipped and all indicated

conditions must be fully understood and met.

Weist auf Gefahren hin, die eine besondere Aufmerksamkeit erfordern. Eine Nichteinhaltung

dieser Vorgehensweise, kann zu Körperverletzungen führen. Ein WARN-Hinweis sollte nicht

übergangen und alle angeführten Bedingungen müssen eindeutig verstanden und umgesetzt

werden.

Denotes hazard. A procedure requires specific attention. Not following the procedure correctly

could result in damage to the equipment. Do not proceed beyond a CAUTION sign until all indicated

conditions are fully understood and met.

Weist auf Gefahren hin, die eine besondere Aufmerksamkeit erfordern. Wenn die beschriebene

Vorgehensweise nicht korrekt durchgeführt wird, kann dadurch das Gerät beschädigt werden. Führen

Sie einem VORSICHTS-Hinweis erst durch, wenn Sie alle angezeigten Handlungen eindeutig verstanden

und umgesetzt haben.

I

Page 26

22

CHAPTER 1: GENERAL INFORMATION

1.1

User Manual Content

This safety & installation manual contains the operating instructions, installation instructions of the

™ 5000W power supply series. The instructions refer to the standard & Blank power

supplies, including the built-in USB, LAN and RS232/485 serial communication. For information related

to operation with the optional GPIB communication interface, refer to User manual (Chapter 8) in the

CD-ROM.

1.2

Introduction

1.2.1 General Description

™ Series power supplies are wide output range, high performance switching power supplies.

The ™ Series is power factor corrected and operates from worldwide AC voltage range

continuously. Output voltage and current are continuously displayed and indicators show the complete

operating status of the power supply (in the standard units). The Front Panel controls allow the user to

set the output parameters, the protection levels (Over-Voltage protection, Under-Voltage protection

and Foldback) and preview the settings (in the standard units). The rear panel includes the necessary

connectors to control and monitor the power supply operation by remote analog signals or by the builtin serial communication USB, RS232/485, and LAN.

IEEE is optional.

1.2.2 Multiple Output Power System

The ™ power supplies series can be configured into a programmable power system of up to

31 units using the built-in LAN, USB, or RS232/RS485 communication port in the power supply and

the RS485 linking cable provided with each power supply.

For further information regarding LAN interface, refer to the User manual (Chapter 5) in the CD-ROM.

For further information regarding optional IEEE interface, refer to the User manual (Chapter 8) in the

CD-ROM.

1.2.3 Control via LAN, USB or RS232/485 Communication Ports

The following basic functional parameters can be programmed via communication ports:

• Output voltage setting.

• Output current setting.

• Output voltage measurement.

• Output current measurement.

• Output on/off control.

• Foldback protection setting.

• Over-voltage protection setting and readback.

• Under-Voltage protection setting and readback.

Page 27

23

• Under-Voltage limit setting and read back.

• Power-supply start up mode (last setting or safe mode).

1.2.4 Analog Voltage Programming and Monitoring

Analog inputs and outputs are provided at the rear panel for analog control of the power supply. The

output voltage and the current limit can be programmed by analog voltage or by resistor,

and can

be monitored by analog voltage. The power supply output can be remotely set to On or Off and

analog signals monitor the proper operation of the power supply and the mode of

operation

(CV/CC).

1.2.5 Parallel Operation

Up to four

™ Series power supplies of the same output voltage and current rating can be

paralleled

in master-slave configuration with automatic current sharing to increase available power.

1.2.6 Output Connections

Output connections are made to rear panel Connector. Either the positive or negative terminal may

be grounded or the output may be floated. Models up to 100VDC rated output shall not float outputs

more than +/- 200VDC above/below chassis ground. Models up to 600VDC rated output shall not

float outputs more than +/- 600VDC above/below chassis ground. Contact factory for assistance with

higher float voltage applications. Local or remote sense may be used.

1.2.7 Cooling and Mechanical Construction

The ™ Series is cooled by an internal fan. At installation, care must be taken to allow free air

flow into the power supply via the front panel, and out of the power supply via the rear panel.

1.3

Accessories

1.3.1 Accessories provided with the power supply

1.3.1.1 Input connector protection, includes 3 parts:

•

Strain relief bracket assembly.

•

Strain relief P/N: 5301 5440 (LAPP GROUP).

•

Lock nut P/N: 8216 (AGRO).

1.3.1.2 AC Input Plug P/N: PC 5/ 4-STCL1-7, 62 (Phoenix contact)

1.3.1.3 Output connector/ Bus bars protection

•

Output protection assembly.

• Output Plug P/N: PC 5/ 4-STCL1-7, 62 (Phoenix contact), for output voltage including and above

150VDC.Serial Link Cable

1.3.1.4 Serial link cable

Serial link cable, for linking power supplies by RS485 communication.

Cable description: 0.5m length, shielded, RJ-45 type plugs, 8 contacts (P/N: GEN/RJ45).

Page 28

24

1.3.1.5 Misc. Hardware

•

DB-26 Connector P/N: 10090769-P264ALF

(FCI)

•

DB-15 Backshell P/N: 86303638BLF (FCI)

• CD-ROM

• SEMS Screw M3X6 Fe Ni, 2 Pcs.

• Flat head screw M3X8 Fe Ni, 2 Pcs.

1.3.1.6 Bus bars Screws kits

10V~40V Models

• Hex. Screw M10X25 St. St., Type DIN933, 4 Pcs.

• Hex. Nut M10 St. St., Type DIN493B, 4 Pcs.

• Flat washer M10 St. St., Type DIN125A, 8 Pcs.

• Spring washer M10 St. St., Type DIN127B, 4 Pcs.

60V~100V Models

• Hex. Screw M8X25 St. St., Type DIN933, 2 Pcs.

• Hex. Nut M8 St. St., Type DIN493B, 2 Pcs.

• Flat washer M8 St. St., Type DIN125A, 4 Pcs.

• Spring washer M8 St. St., Type DIN127A, 2 Pcs.

1.3.2 Optional accessories

1.3.2.1 Printed User Manuals

For ordering printed User manual, the P/N is: G/M

1.3.2.2 Serial Port Cables

• For ordering serial port cables refer to the User manual in the CD-ROM.

• USB/LAN cables are not provided with the power supply.

1.3.2.3 Paralleling Cable

• For ordering paralleling cables refer to the User manual in the CD-ROM.

1.3.2.4 AC Cables

AC Cables are not provided with the power supply. Refer to

Table 1-1

for recommended AC

input cables (customer applied).

AC Input Range

AC Input Cable

190~240~, Three phase Min. 4 X 12AWG (Three wires plus Safety ground), stranded copper,

300V, 60°C minimum, 3m max. length, outer diameter 10~14mm.

380~480~, Three phase Min. 4 X 16AWG (Three wires plus Safety ground), stranded copper,

600V, 60°C minimum, 3m max. length, outer diameter 10~14mm.

Table 1-1: Recommended AC Input Cables

Page 29

25

CHAPTER 2: FRONT/REAR PANEL CONTROLS AND CONNECTORS

2.1

Introduction

The

™ Power Supply series has a full set of controls, indicators

(in the standard units)

and connectors that allow the

user to set up and operate the unit. Before starting to operate the unit,

please read the following

sections for an explanation of the functions, controls and connector

terminals.

• Section 2.2: Front Panel Display and Controls.

• Section 2.3: Rear Panel Controls and Connectors.

2.2

Front Panel Display and Controls

Refer to Figure 2-1and Table 2-1 for description of the Front panel controls.

Figure 2-1: Front panel controls and indicators

No.

Control/Indicator

Description

Section

1 Power Switch POWER ON/OFF control

2 Power Supply Model Model, Voltage & Current Identifier

3 Voltage Encoder and

button

Encoder: High-resolution detent rotary Encoder for adjusting the

output voltage. Button: Auxiliary function to accept voltage-setting

value.

4 Voltage Display 4-digit 16-segment voltage display. Normally displays the output

voltage. In preview mode, the display indicates the program setting

of output voltage. In menu navigation, the display indicates the

selected function.

5 Operation mode indicator CV/CC/CP operation mode indicator.

6 Current Display 4-digit 16-segment current display. Normally displays the output

current. In preview mode, the display indicates the program setting

of output current. In menu navigation, the display indicates the

selected parameter.

7 Indicators bar

Refer to Fig 2.2 and Table 2.2 in the User manual for description of

the front panel indicators bar.

8 Current Encoder and

button

Encoder: High-resolution detent rotary Encoder for adjusting the

output current. Button: Auxiliary function to accept current-setting

value, select menu level & accept set parameter value.

9 BACK button Return one-step back in menu navigation mode.

10 PROG button / Indicator

Activates Program / Sequencer menu. Program menu provides

Sequencer function control, Trigger function control and load a

sequence stored inside Power Supply memory.

Green LED lights when Program menu is active. If Program menu is

active, PROG button press exits to main display.

9

1

3

6 7 8

2

4 5 10

11

12

13

14

15

16

17

9

Page 30

26

No.

Control/Indicator

Description

Section

11 SYST / Lock Front Panel

button / Indicator

Activates System menu. System menu provides output sensing

point selection (Local / Remote sense), Interlock function control,

Enable function control, Power Supply OK signal control,

SAVE/RECALL Power Supply configuration, Programmable Signals

control, Preload function control, Display brightness & dimming

function control & reset power Supply settings.

Green LED lights when System menu is active. If System menu is

active, SYST button press exits to main menu. Lock / Un-Lock front

panel buttons by pressing SYST button and accept by Current

Encoder button.

12 CONF button / Indicator

Activates Configuration menu. Configuration menu provides POWER

Supply start mode control, Voltage & Current source control,

Analog Programming / Monitoring range selection, Internal

Resistance function, Constant power limit function & Slew-Rate

control function. Green LED lights when Configuration menu is

active. If Configuration menu is active, CONF button press exits to

main menu.

13 PROT button / Indicator

Activates Protection menu. Protection menu provides OVP setting,

UVL setting, UVP function control, Foldback function control and

OCL function ON/OFF control. Green LED lights when Protection

menu is active. If Protection menu is active, PROT button press

exits to main menu.

14 COMM button / Indicator

Activates Communication menu. Communication menu provides

communication interface selection, Power Supply address selection,

LAN settings control, communication baud-rate selection,

communication language selection and software revision

information. Green LED lights when Communication menu is active.

If Communication menu is active, COMM button press exits to main

menu.

15 FINE button / Indicator

Voltage/Current Fine/Coarse adjustment control. Operates as a

toggle switch. In Fine mode, VOLTAGE and Current encoders

operate in high-resolution mode. In Coarse mode, Voltage and

Current encoders operate in standard-resolution (approx. 3 turns

for full voltage/current rated scale). Green LED, lights when the

unit is in Fine mode.

16 PREV button / indicator Press PREV to display output voltage and current limit settings. The

display will show the settings for 15 seconds, it will return back to

show actual output voltage and current if buttons are not pressed

for 15 seconds. Green LED, lights when PREV mode is active.

17 OUT button / indicator

Output ON/OFF control. Press OUTPUT to set the output ON or

OFF. Green LED, lights when DC Output is enabled.

Table 2-1: Front panel controls and indicators

Page 31

27

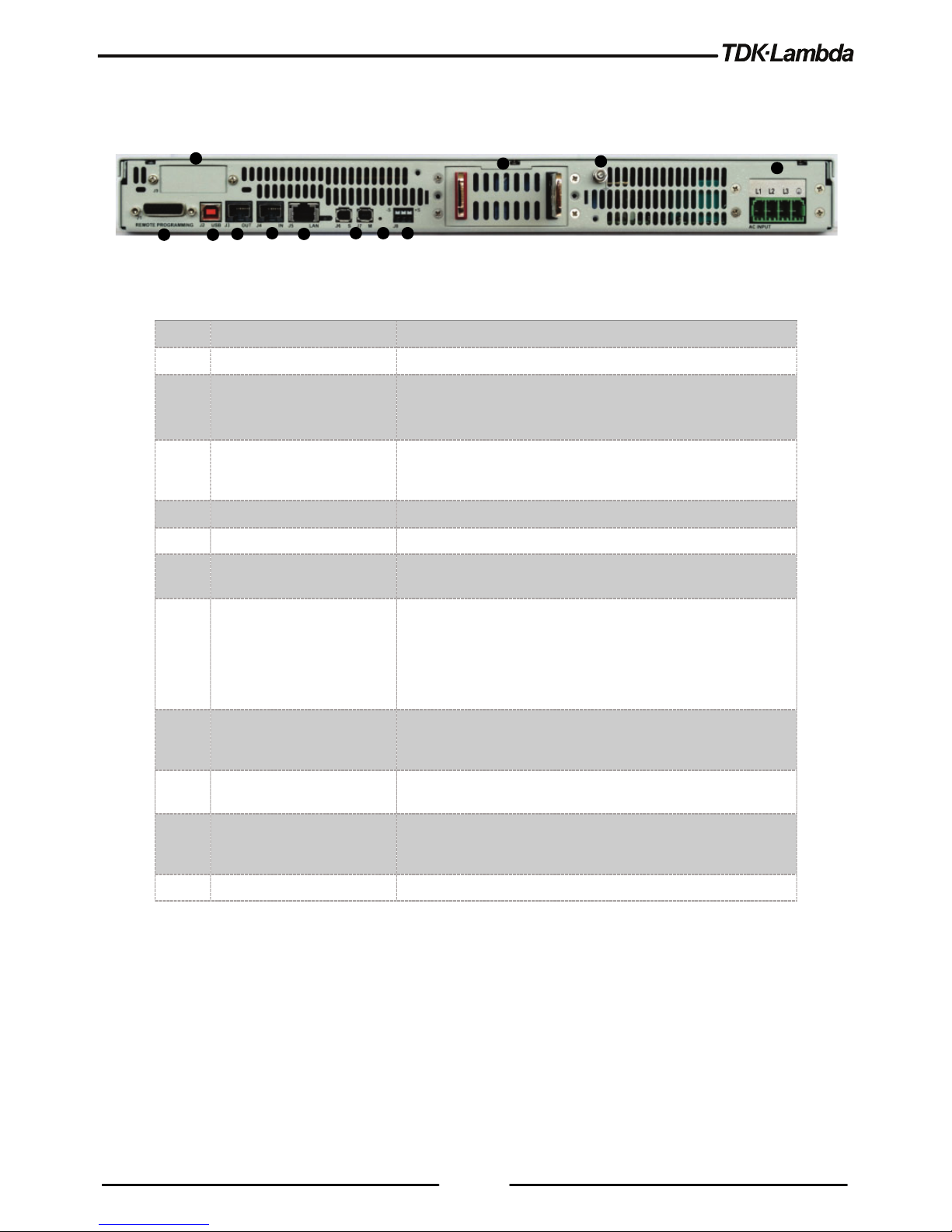

2.3

Rear Panel Connectors

Refer to Figure 2-2 and Table 2-2 for description of the Rear Panel connectors.

Figure 2-2: Rear panel connectors

No.

Connection

Description

1 AC Input Connector Connector type: Phoenix contact P/N: PC 5/ 4-G-7,62

2 Ground Stud Functional Ground connection M4x8 Stud

3

DC output bus-bar /

Connector

Bus-bars for 10V to 100V models.

Phoenix contact P/N: IPC 5/ 4-GF-7,62 for 150V to 600V

models.

4 Remote sense connector Connector for remote sensing connections. Connect to the

load for regulation of the load voltage and compensation of

load wire drop.

5 Reset button Set default Power Supply settings.

6 Paralleling Connectors Master/Slave connectors, mini I/O type.

7

LAN Connector +

Indicators

LAN interface connector, RJ-45 type + LXI indicators.

Connector type: UDE P/N: 26-31024KB91-1.

8 Serial In connector

RJ-45 type connector, used for connecting power supplies to

RS232 or RS485 port of a computer for remote control

purposes. When using several power supplies in a power

system, the first unit Remote-In is connected to the computer

and the remaining units are chained, Remote-In to RemoteOut. Connector type: Molex 95540-2881.

9 Serial Out connector RJ-45 type connector, used for chaining power supplies

to/from a serial communication bus. Connector type: Molex

95540-2881.

10 USB Connector

USB interface connector, type B. Connector type: SAMTEC

P/N: USBR-B-S-F-O-TH.

11 Isolated control and signals Isolated analog Control and monitoring signals, isolated from

the output potential. Connector type: WE P/N:

618026325223.

12 Optional Interface Position for optional communication interface.

Table 2-2: Front panel controls and indicators

2

3

4 5 6 7 8

11

10

9

1

12

Page 32

28

CAUTION

To prevent ground loops and to maintain the isolation of the power supply when programming from

J1, use an ungrounded programming source.

VORSICHT

Um Erdschleifen zu verhindern und die Isolierung auf dem Netzgerät aufrecht zu erhalten, wenn

Sie von J1 programmieren, müssen Sie eine ungeerdete Programmierquelle benutzen.

WARNING

There is a potential shock hazard at the output when using a power supply with an output greater

than 60VDC. Use wires with minimum insulation rating equivalent to the maximum output voltage of

the power supply.

WARNUNG

Bei Einsatz einer Stromversorgung mit einer Ausgangsspannung von über 60VDC besteht die

Gefahr eines elektrischen Schlags. Verwenden Sie nur Leitungen mit Isolationsklassen, die

mindestens für die maximale Ausgangsspannung der Stromversorgung geeignet sind.

Page 33

29

CHAPTER 3: INSTALLATION

CAUTION

Observe all torque guidelines within this manual. Over torque may damage unit or accessories.

Such damage is not covered under manufacturer’s warranty

.

VORSICHT

Beachten Sie alle Drehmoment-Richtlinien in diesem Handbuch. Wird ein zu großes

Drehmoment eingestellt bzw.verwendet, können dadurch das Gerät oder die Zubehörteile

beschädigt werden. Solche Schäden sind nicht von der Hersteller-Garantie abgedeckt.

3.1

General

This chapter contains instructions for initial inspection, preparation for use and repackaging for

shipment. Connection to PC, setting the communication port and linking ™ power supplies

are described in the User manual.

NOTE:

™ power supplies generate magnetic fields, which might affect the operation of

other instruments. If your equipment is susceptible to magnetic fields, do not position it

adjacent to the power supply.

NOTIZ:

Die ™ Netzgeräte können magnetische Felder erzeugen, die den Betrieb

anderer Geräte möglicherweise beeinträchtigen. Wenn Ihr Gerät empfindlich gegenüber

magnetischen Feldern ist, positionieren Sie diese nicht in der Nähe des Netzgeräts.

3.2

Preparation for Use

In order to be operational, the power supply must be connected to an appropriate AC source. The AC

source voltage should be within the power supply specification. Do not apply power before reading, the

safety instructions and Section 3.6.

Table 3-1 below, describes the basic setup procedure. Follow the instructions in Table 3-1 in the

sequence given to prepare the power supply for use.

Page 34

30

Step no.

Item

Description

Reference

1 Inspection Initial physical inspection of the power supply Section 3.3

2 Installation

Installing the power supply, Ensuring adequate

ventilation.

Section 3.4

Section 3.5

3 AC source AC source requirements

Connecting the power supply to the AC source.

Safety instructions

Section 3.6

4 Test Turn-on checkout procedure. Section 3.7

5 Load connection Wire size selection. Local /Remote sensing. Single or

multiple loads.

Section 3.8

6 Default setting The power supply setting at shipment. User Manual

Table 3-1: Basic Setup Procedure

3.3

Initial Inspection

Prior to shipment this power supply was inspected and found free of mechanical or electrical defects.

Upon unpacking of the power supply, inspect for any damage which may have occurred in transit. The

inspection should confirm that there is no exterior damage to the power supply such as broken knobs

or connectors and that the front panel and meter faces are not scratched or cracked. Keep all packing

material until the inspection has been completed. If damage is detected, file a claim with carrier

immediately and notify the TDK-Lambda sales or service facility nearest you.

3.4

Rack Mounting

The ™ power supply series is designed to fit in a standard 19” equipment rack.

3.4.1 Install the Power Supply in a Rack

1. Use the front panel rack-mount brackets to install the power supply in the rack.

2. Use a support bar to provide adequate support for the rear of the power supply. Do not obstruct

the air exhaust at the rear panel of the Unit.

Page 35

31

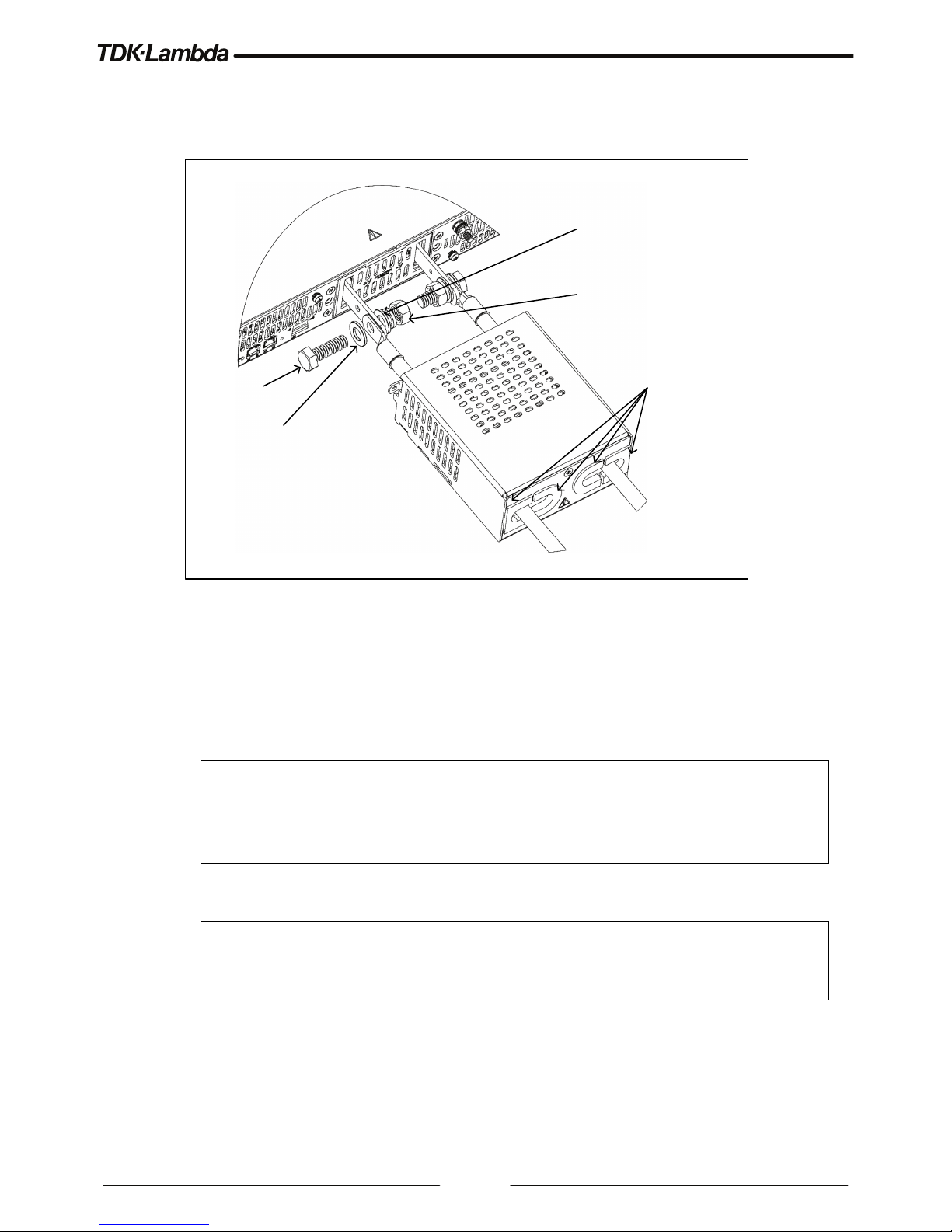

3.4.2 Rack Mount Slides (Optional)

Use rack mount slides: General Devices Catalog Number: C-300-S-116. Part/Drawing Number:

CC3001-00-0160 or equivalent to install the unit in a standard 19" equipment rack. Refer to Figure 3-1

for slides assembly instructions. Use three #10-32x0.38"(max.) screws at each side. To prevent

internal damage, use the specified screw length only.

#1032x0.38"(max.)

screws

Tightening torque:

25.4~31.7Lbf -i nch

Figure 3-1: Rack – Mount Slides Assembly

3.5

Location, Mounting and Cooling

This power supply is fan cooled. The air intake is at the front panel and the exhaust is at the rear

panel. Upon installation allow cooling air to reach the front panel ventilation inlets.

CAUTION

Allow minimum 10cm (4”) of unrestricted air space at the front and the rear of the unit. The

power supply should be used in an area where the ambient temperature does not exceed

+50°C.

VORSICHT

Halten Sie vor und hinter dem Gerät einen lichten Mindestabstand von 10 cm ein. Das

Netzgerät sollte nur in Arbeitsbereichen benutzt werden, in denen die

Umgebungstemperatur +50 °C nicht übersteigt.

Page 36

32

3.6

AC Input Power Connection

This Power supply shall be connected to the AC source via protective device

(Circuit breaker, fuses…etc.), rated for 30A.

WARNING

There is a potential electrical shock hazard when using a power supply without input

protection. Do not connect power supply to AC supply line without input protection properly

assembled.

WARNUNG

Es besteht die Gefahr eines Stromschlags, wenn ein Netzgerät ohne Berührungsschutz in

Betrieb genommen wird. Schließen Sie das Netzgerät nicht an Ihren Versorgungskreis an,

wenn der Berührungsschutz nicht ordnungsgemäß angebracht wurde.

CAUTION

Connection of this power supply to an AC source should be made by an electrician or other

qualified personnel.

VORSICHT

Nur Elektriker oder anderes Fachpersonal sollten dieses Netzgerät an die

Wechselstromquelle anschließen.

CAUTION

There is a potential shock hazard if the power supply chassis (with cover in place) is not

connected to an electrical safety ground via the safety ground terminal in the AC input

connector.

VORSICHT

Es besteht die Gefahr eines möglichen Stromschlages, wenn das Gehäuse des

Netzgeräts (auch mit aufgesetzter Abdeckung) nicht über den vorgesehenen

Schutzleiteranschluss an dem Wechselstrom-Eingangsanschluss mit der elektrischen

Schutzerde verbunden ist.

Page 37

33

WARNING

Some components inside the power supply are at AC voltage even when the On/Off

switch is in the”Off” position. To avoid electric shock hazard, disconnect the AC cord

and load, and wait two minutes before removing cover. Cover removal is allowed

only

by TDK-Lambda qualified service personnel.

WARNUNG

An einigen Komponenten im Innern des Netzgeräts liegt auch dann noch

Wechselspannung an, wenn der Netzschalter bereits auf AUS steht. Um die Gefahr eines

Stromschlags zu verhindern, trennen Sie das Netzkabel vom Versorgungsnetz und warten

dann zwei Minuten, bevor Sie die Schutzabdeckung abnehmen. Nur qualifizierte

Servicekräfte von TDK-Lambda dürfen die Gehäuse-Abdeckung abnehmen.

CAUTION

AC Input Wires No Conductor Pretreatment: All kinds of copper conductors can be

clamped without pretreatment (Solid, Flexible, with ferrule, with/without plastic sleeve). It is

forbidden to solder the conductors. The solder tin yields and fractures under high pressure.

The result is an increased contact resistance and an excessive temperature rise. In

addition, corrosion caused by pickling or fluxes has been observed on soldered conductor

ends. Notch fractures at the transition point from the rigid to the flexible conductor area are

also possible.

VORSICHT

Wechselstrom- Zuleitungen - Der Innenleiter muss nicht vorbereitet werden:

Alle Arten von Kupferleitungen können ohne Vorbehandlung fest geklemmt werden (feste,

flexible Leiter, mit Aderendhülse, mit/ohne Kunststoffhülse). Es ist verboten, die Leiter

vorab zu verlöten. Das Lötzinn gibt unter Druck nach und bricht. Dies führt zu einem

erhöhten Kontaktwiderstand und erzeugt dadurch einen übermäßigen Temperaturanstieg.

Zusätzlich wurde auf gelöteten Leiterenden Korrosion durch Einsatz von Beiz- oder

Flussmitteln beobachtet. Kerbenbrüche am Übergangspunkt vom starren zum flexiblen

Leiterbereich sind ebenfalls möglich.

Page 38

34

CAUTION

The power supply ON/OFF switch is not the main "disconnect device" and does not

completely disconnect all the circuits from the AC source. An appropriately rated

"disconnect device" such as circuit breaker, type B plug on power cord, etc., shall be

provided in the final installation. The "disconnect device" shall disconnect all supply lines

simultaneously. The "disconnect device" must be easily accessible.

VORSICHT

Der eingebaute EIN- / AUS-Schalter des Netzgeräts ist nicht die Haupt-„Trennvorrichtung“

und trennt somit nicht alle Schaltkreise vollständig von der Wechselstromquelle. Eine

entsprechend bemessene „Trennvorrichtung“ wie ein Sicherungsautomat der Typ B Klasse

in der Netzversorgung usw. sollen in der endgültigen System-Installation vorhanden sein.

Diese „Trennvorrichtung“ sollte alle Versorgungsleitungen gleichzeitig unterbrechen und

muss für das Service-Personal einfach zugänglich sein.

3.6.1 AC Input Connector

1. Ensure that the AC cable is disconnected from any electrical potential before making any

connection to the power supply.

The AC input connector is a header (Phoenix Contact P/N: PC 5/ 4-G-7, 62), located in the rear

panel. The mating plug has screws connections (Phoenix Contact P/N: PC 5/ 4-STCL1-7, 62),

and is provided in the accessories kit.

2. Use suitable wires and tightening torque to connect the mating plug:

• Wire diameter: 12AWG (2.5mm²) for three-phase 200Vac models and

• 16AWG for three-phase 400Vac, 480Vac models.

• Tightening torque: 4.5-5.3 Lbf-inch. (0.5-0.6Nm).

AC Input Cord

WARNING

AC input cord is not provided with the power supply.

Refer to section 1.3.2.4 for details for the recommended AC input cables and to section 3.6 for

disconnect device requirement.

WARNUNG

Die Netzzuleitung ist nicht im Lieferumfang bei der Auslieferung des Netzgerätes.

Page 39

35

3.6.2 AC Input Wire Connection

1. Strip the outside insulation of the AC cable approx. 10cm. Trim the wires so that the ground wire

is 10mm longer than the other wires. Strip 10mm at the end of each of the wires.

2. Insert the Cable gland into the Strain relief bracket Assembly as shown in Figure 3-2.

3. Tighten the plastic nut (supplied in the accessories box), from the inside part of the bracket by

using manual force only.

Cable gland

Strain relief

brack et

Nut

Figure 3-2: Insertion of the Plastic Nut into Strain Relief Bracket

4. Unscrew the conical cable entry part, until it will not apply any stress to the AC cable.

5. Insert the AC cable through the conic cable gland entry and the strain relief bracket as shown in

Figure 3-3.

AC Cable

Conical cable

gland entry

AC wires to

connect

Figure 3-3: Stripped Wires Inserted Through

6. Insert the AC wires into the AC input connector (as shown in Figure 3-4).

Page 40

36

7. Tighten the screws, tightening torque: 4.5-5.3 Lbf-inch. (0.5-0.6Nm).