Page 1

G10-500

G80-65

GB10-500

GB80-65

G20-250

G100-50

GB20-250

GB100-50

G30-170

G150-34

GB30-170

GB150-34

G40-125

G300-17

GB40-125

GB300-17

G60-85

G600-8.5

GB60-85

GB600-8.5

Series

Programmable DC Power Supplies

5kW in 1U 0-600V/ 0-500A

Built in LAN, USB, RS-232 & RS-485 Interface

Optional Interface: IEEE488.2 (GPIB)

This manual covers models

USER MANUAL

IA761-04-02

Page 2

TABLE OF CONTENTS

CHAPTER 1: SPECIFICATIONS ................................................................................................. 1

1.1

5000W Series Specifications ...................................................................................... 1

1.2

Standard Unit Low Voltage Outline............................................................................ 5

1.3

Standard Unit High Voltage Outline ........................................................................... 6

1.4

Blank Panel Unit Low Voltage Outline ....................................................................... 7

1.5

Blank Panel Unit High Voltage Outline ....................................................................... 8

1.6

Optional accessories .................................................................................................. 9

1.6.1 Printed User manual ..................................................................................... 9

1.6.2 Serial Port Cables .......................................................................................... 9

1.6.3 Paralleling Cable ........................................................................................... 9

CHAPTER 2: FRONT/REAR PANEL CONTROL & CONNECTORS ............................................... 10

2.1

Introduction ............................................................................................................. 10

2.2

Front Panel Controls................................................................................................. 10

2.3

Front Panel Display and Indicators .......................................................................... 13

2.4

Rear Panel Connections and Controls ...................................................................... 16

2.5

J1 Connector Terminal and Function ....................................................................... 17

2.6

Front Panel Display Messages .................................................................................. 19

2.7

Menu Navigation ...................................................................................................... 20

2.7.1 Introduction ................................................................................................ 20

2.7.2 Exiting a Menu ............................................................................................ 25

CHAPTER 3: LOCAL OPERATION ........................................................................................... 26

3.1

Introduction ............................................................................................................. 26

3.2

Load Connections Options ....................................................................................... 26

3.2.1 Connecting Single Loads, Local Sensing (Default) ...................................... 26

3.2.2 Connecting Single Loads, Remote Sensing ................................................. 26

3.2.3 Connecting Multiple Loads, Radial Distribution Method ........................... 28

3.2.4 Multiple Load Connection with Distribution Terminals ............................. 28

3.2.5 Constant Voltage Mode and Voltage Setting ............................................. 29

3.2.6 Constant Current Mode and Current Setting ............................................. 29

3.2.7 Automatic Crossover .................................................................................. 30

3.2.8 Output On/Off Control ............................................................................... 30

3.2.9 Safe-Start and Auto-Restart Modes............................................................ 31

3.2.10 Viewing Software Revision ......................................................................... 31

3.3

Alarms and Protective Functions ............................................................................. 31

3.3.1 Introduction ................................................................................................ 31

3.3.2 Over Voltage Protection ............................................................................. 32

3.3.2.1 Resetting the OVP Circuit ............................................................. 32

3.3.3 Under Voltage Protection and Under Voltage Limit ................................... 33

3.3.3.1 Activated UVP Alarm .................................................................... 33

3.3.4 Foldback Protection .................................................................................... 34

3.3.4.1 Activated FOLD Alarm .................................................................. 34

3.3.5 Protection Delay ......................................................................................... 35

3.3.6 Over Temperature Protection .................................................................... 35

3.3.7 AC Fail Alarm ............................................................................................... 35

Page 3

3.4

Series Operation ....................................................................................................... 36

3.4.1 Series Connection for Increased Output Voltage ....................................... 36

3.4.2 Series Connection for Positive and Negative Output Voltage .................... 37

3.4.3 Remote Programming in Series Operation ................................................. 37

3.5

Daisy-Chain Connection ........................................................................................... 38

3.5.1 Daisy In Function ........................................................................................ 38

3.6

Rear Panel (J1 Connector) Functions ....................................................................... 39

3.6.1 Interlock Function - Analog On/Off (Enable/Disable) ................................. 39

3.6.2 Enable In Function ...................................................................................... 40

3.6.3 Enable_In Polarity ....................................................................................... 40

3.6.4 Auxiliary Programmed Signals Prog_out_1 and Prog_out_2 ..................... 41

3.6.5 Power Supply OK Signal .............................................................................. 42

3.6.6 CV/CC Signal ................................................................................................ 42

3.7

Parameter Setting Memory ..................................................................................... 43

3.7.1 Default Setting ............................................................................................ 43

3.7.2 Reset ........................................................................................................... 43

3.7.3 Last Setting Memory ................................................................................... 43

3.7.4 Save <1..4> .................................................................................................. 43

3.7.5 Recall <1..4> ................................................................................................ 43

CHAPTER 4: REMOTE ANALOG PROGRAMMING .................................................................. 46

4.1

Introduction ............................................................................................................. 46

4.2

Local/Remote Analog Control .................................................................................. 46

4.3

Local/Remote Analog Indication .............................................................................. 46

4.4

Remote Voltage Programming of Output Voltage and Current .............................. 47

4.5

Remote Resistor Programming of Output Voltage and Output Current ................. 48

4.6

Monitoring of Output Voltage (V_MON) and Current (I_MON) .............................. 49

CHAPTER 5: SERIAL RS232/RS485, USB & LAN INTERFACES .................................................. 50

5.1

Introduction ............................................................................................................. 50

5.2

Configuration ........................................................................................................... 50

5.2.1 Default Setting ............................................................................................ 50

5.2.2 Communication Interface Selection ........................................................... 50

5.2.3 Address Setting ........................................................................................... 51

5.2.4 IP Address Setting ....................................................................................... 51

5.2.5 Baud Rate Setting ....................................................................................... 52

5.2.6 Language Selection (RS232/RS485, USB) .................................................... 52

5.2.7 Setting Unit in Remote, Local Lockout or Local Mode ............................... 53

5.3

Rear Panel RS232/RS485 IN Connector ................................................................... 54

5.4

Rear Panel RS485 OUT Connector............................................................................ 55

5.5

Connecting Power Supply to RS232 or RS485 BUS .................................................. 56

5.6

Rear Panel USB Connector ....................................................................................... 57

5.6.1 USB Getting Started .................................................................................... 57

5.7

Rear Panel LAN ......................................................................................................... 58

5.7.1 Introduction ................................................................................................ 58

5.7.1.1 Feature Summary ......................................................................... 58

5.7.2 Specifications .............................................................................................. 59

5.7.2.1 LAN Specifications ........................................................................ 59

Page 4

5.7.2.2 LAN Command Speed .................................................................. 61

5.7.3 Select the Control Method ......................................................................... 62

5.7.3.1 Control Method Options .............................................................. 62

5.7.3.2 Select LAN Remote Mode ............................................................ 62

5.7.3.3 LAN Status LEDs ........................................................................... 62

5.7.4 Connect to a Network ................................................................................. 63

5.7.4.1 LAN Cable ..................................................................................... 63

5.7.4.2 Types of Networks ....................................................................... 63

5.7.4.3 Power-up the LAN Power Supply ................................................. 64

5.7.4.4 IP Addresses ................................................................................. 65

5.7.4.5 Hostname ..................................................................................... 65

5.7.4.6 Description and DNS Service Names............................................ 66

5.7.5 LAN Setup ................................................................................................... 67

5.7.5.1 View the IP and MAC Addresses .................................................. 67

5.7.5.2 Change the IP Address ................................................................. 67

5.7.5.3 LAN Reset ..................................................................................... 68

5.7.6 Web Pages .................................................................................................. 69

5.7.6.1 Benefits of Web Pages ................................................................. 69

5.7.6.2 Opening the HOME Page ............................................................. 69

5.7.6.3 The Home Page ............................................................................ 70

5.7.6.4 Login Rules ................................................................................... 71

5.7.6.5 DC Power Page ............................................................................. 72

5.7.6.6 LAN Page ...................................................................................... 75

5.7.6.7 HELP Page .................................................................................... 79

5.7.7 Programming Using VISA Drivers ................................................................ 80

5.7.7.1 VISA Description ........................................................................... 80

5.7.7.2 VXI-11 Compatibility .................................................................... 80

5.7.7.3 Opening the VISA Connection ...................................................... 80

5.7.7.4 Communicating Using VISA .......................................................... 80

5.7.8 Programming Using Sockets ....................................................................... 81

5.7.8.1 Socket Description ....................................................................... 81

5.7.8.2 Communicating Using Sockets ..................................................... 81

5.7.8.3 Controller Access: Single and Multiple Clients ............................ 81

5.7.8.4 Input Buffer Requirements .......................................................... 82

5.7.8.5 Message Terminators .................................................................. 82

5.7.8.6 Using TCP Sockets ........................................................................ 82

5.7.8.7 Using UDP Sockets ....................................................................... 83

5.7.9 Connecting Over WAN ................................................................................ 83

5.7.9.1 View Web Pages Over WAN......................................................... 83

5.7.9.2 Use Sockets Over WAN ................................................................ 83

5.8

Multi Power Supply Connection (Daisy-Chain) to RS232, RS485, USB or LAN ......... 84

5.9

GEN Protocol (GEN series communication language) .............................................. 87

5.9.1 Data Format ................................................................................................ 87

5.9.2 End of Message ........................................................................................... 87

5.9.3 Command Repeat ....................................................................................... 87

5.9.4 Checksum .................................................................................................... 87

5.9.5 Acknowledge .............................................................................................. 87

5.9.6 Backspace ................................................................................................... 87

5.10

GEN Command Set Description ................................................................................ 87

5.10.1 General guides ............................................................................................ 87

Page 5

5.10.2 Numeric / Data Type Parameters ............................................................... 88

5.10.3 Command Set Categories ........................................................................... 88

5.10.4 Identification Commands ........................................................................... 89

5.10.5 Initialization Commands ............................................................................. 89

5.10.6 Output Commands ..................................................................................... 90

5.10.7 Global Output Commands .......................................................................... 93

5.10.8 Auxiliary Commands ................................................................................... 95

5.10.9 Status Commands ....................................................................................... 96

5.11

Serial Communication Test Set-Up .......................................................................... 98

5.12

SCPI Protocol ............................................................................................................ 99

5.12.1 Data Format ................................................................................................ 99

5.12.2 End of Message ........................................................................................... 99

5.12.3 End of Command ........................................................................................ 99

5.12.4 Checksum .................................................................................................... 99

5.12.5 SCPI Requirements ..................................................................................... 99

5.12.6 SCPI Command Hierarchy ......................................................................... 100

5.12.7 Header ...................................................................................................... 100

5.12.8 Data Formats ............................................................................................ 100

5.12.9 Commands Notes ..................................................................................... 101

5.13

SCPI Common Commands ...................................................................................... 101

5.14

SCPI Subsystem Commands ................................................................................... 106

5.14.1 Display Subsystem .................................................................................... 106

5.14.2 Initiate Subsystem .................................................................................... 107

5.14.3 Instrument Subsystem .............................................................................. 107

5.14.4 Global Subsystem ..................................................................................... 107

5.14.5 Measure Subsystem.................................................................................. 108

5.14.6 Output Subsystem .................................................................................... 109

5.14.7 Program Subsystem .................................................................................. 111

5.14.8 Source Subsystem ..................................................................................... 115

5.14.9 STATus Subsystem .................................................................................... 120

5.14.10 SYSTem Subsystem ................................................................................... 124

5.14.11 TRIGger Subsystem ................................................................................... 129

5.15

SCPI Commands Summary ..................................................................................... 130

CHAPTER 6: ADVANCED FUNCTIONS ................................................................................. 133

6.1

Sequencer............................................................................................................... 133

6.1.1 LIST Mode ................................................................................................. 133

6.1.2 WAVE Mode .............................................................................................. 134

6.1.3 Sequencer Functions ................................................................................ 135

6.1.3.1 Counter ...................................................................................... 135

6.1.3.2 Dwell .......................................................................................... 135

6.1.3.3 Time ........................................................................................... 135

6.1.3.4 Load ............................................................................................ 135

6.1.3.5 Store ........................................................................................... 135

6.1.3.6 Step ............................................................................................ 136

6.1.3.7 Abort .......................................................................................... 136

6.2

Trigger System ........................................................................................................ 137

6.2.1 Trigger Initialize ........................................................................................ 137

6.2.2 Trigger In ................................................................................................... 137

Page 6

6.2.3 Trigger Out ................................................................................................ 137

6.2.4 Trigger Delay ............................................................................................. 138

6.3

Sequencer + Trigger System Examples ................................................................... 138

6.3.1 WAVE Mode Voltage Programming via Communication Example ........... 138

6.3.2 WAVE Mode Execution via Communication Example .............................. 138

6.3.3 LIST Mode Example ................................................................................... 139

6.3.4 WAVE Mode Example ............................................................................... 140

6.4

Internal Resistance ................................................................................................. 141

6.5

Constant Power Limit ............................................................................................. 142

6.6

Preload Control ...................................................................................................... 143

6.7

OCL – Analog Programming Over Current Limit .................................................... 144

6.7.1 OCL Example (10Volts, 500Amperes supply) ............................................ 144

6.8

Slew-Rate Control .................................................................................................. 145

6.9

Advanced Parallel ................................................................................................... 146

6.9.1 Advanced Parallel Connection (System Assembly) ................................... 146

6.9.2 Load Connection ....................................................................................... 146

6.9.3 Advanced Parallel System Acknowledge .................................................. 147

6.9.3.1 Acknowledge via the front panel ............................................... 148

6.9.3.2 Acknowledge via communication .............................................. 148

6.9.3.3 Acknowledge via communication (Blank Panel master power

supply) 148

6.9.4 Advanced Parallel operation .................................................................... 148

6.9.5 Slave units operation in Advanced Parallel connection ........................... 149

6.9.6 Advanced Parallel fault system ................................................................. 149

6.9.7 Advanced Parallel system identification (*idn?) ...................................... 149

CHAPTER 7: STATUS, FAULT AND SRQ REGISTERS .............................................................. 150

7.1

General ................................................................................................................... 150

7.2

SCPI Language ........................................................................................................ 150

7.2.1 SCPI Register Tree ..................................................................................... 150

7.2.2 Questionable Condition (Fault Register) Group Structure ....................... 151

7.2.3 Operational Condition (Status Register) Group Structure ........................ 152

7.2.4 Standard Event Status Group Structure ................................................... 153

7.2.5 Output Queue ........................................................................................... 154

7.2.6 Error Queue .............................................................................................. 154

7.2.7 Service Request Enable Group Structure.................................................. 157

7.2.8 Determining the Cause of a Service Interrupt .......................................... 158

7.3

GEN Language ........................................................................................................ 159

7.3.1 GEN Register Tree ..................................................................................... 159

7.3.2 Questionable Group (Fault Register) Structure ........................................ 160

7.3.3 Operational Group (Status Register) Structure ........................................ 161

7.3.4 Command Error (“Cxx”) ............................................................................ 161

7.3.5 Execution Error (“Exx”) ............................................................................. 162

7.3.6 Service Request (SRQ) .............................................................................. 162

CHAPTER 8: IEEE OPTION .................................................................................................. 163

8.1

General ................................................................................................................... 163

8.2

IEEE-488.2 Interface ............................................................................................... 163

8.3

Point to Point Connection ...................................................................................... 163

Page 7

8.4

Multi Drop Connection ........................................................................................... 164

8.4.1 Selecting a Single Power Supply in a Multi Drop Chain ............................ 164

8.5

Communication Cables .......................................................................................... 165

8.6

IEEE Controller Configuration ................................................................................ 165

8.7

Power Supply Configuration .................................................................................. 165

8.8

Execution Time ....................................................................................................... 165

8.9

Communication Example ....................................................................................... 166

CHAPTER 9: AIR FILTER OPTION ......................................................................................... 168

9.1

General ................................................................................................................... 168

9.2

Specifications ......................................................................................................... 168

9.3

Maintenance .......................................................................................................... 168

9.3.1 Cleaning Instructions ................................................................................ 168

9.3.2 Assembly Instructions for Standard Power Supplies ................................ 169

9.3.3 Assembly Instructions for Blank Power Supplies (Without Display) ........ 171

CHAPTER 10: MAINTENANCE .............................................................................................. 173

10.1

Introduction ........................................................................................................... 173

10.2

Units under Warranty ............................................................................................ 173

10.3

Periodic Maintenance ............................................................................................ 173

10.4

Adjustments and Calibration .................................................................................. 173

10.5

Parts Replacement and Repairs ............................................................................. 174

10.6

Troubleshooting ..................................................................................................... 174

10.7

Fuse Rating ............................................................................................................. 175

10.1

Einleitung ............................................................................................................... 176

CHAPTER 11: INDEX ............................................................................................................ 179

Page 8

This page intentionally left blank

Page 9

CHAPTER 1: SPECIFICATIONS

1.1

5000W Series Specifications

1

Page 10

2

Page 11

3

Page 12

4

Page 13

1.2

Standard Unit Low Voltage Outline

5

Page 14

1.3

Standard Unit High Voltage Outline

6

Page 15

1.4

Blank Panel Unit Low Voltage Outline

7

Page 16

1.5

Blank Panel Unit High Voltage Outline

8

Page 17

1.6

Optional accessories

1.6.1 Printed User manual

• Printed User manual, order P/N: G/M

1.6.2 Serial Port Cables

• For ordering serial port cables refer to CHAPTER 5:

1.6.3 Paralleling Cable

• Paralleling cable: order P/N: G/P.

9

Page 18

CHAPTER 2: FRONT/REAR PANEL CONTROL & CONNECTORS

No.

Control/Indicator

Description

1

Power Switch

POWER ON/OFF control.

2

Power Supply Model

Model, Voltage & Current Identifier.

value in Preview mode.

function.

5

Operation Mode Indicator

CV/CC/CP Operation mode indicator.

2.1

Introduction

The Power Supply series has a full set of controls, indicators and connectors that allow

the user to setup and operate the unit. Before starting to operate the unit, please read the following

sections for an explanation of the functions, controls and connector terminals.

• Section 2.2: Front Panel Controls

• Section 2.3: Front Panel Display and Indicators.

• Section 2.4: Rear Panel Connections and Controls

•

Section 2.5: J1 Connector Terminal and Function

2.2

Front Panel Controls

Refer to Figure 2–1 and Table 2-1 for description of the Front Panel controls.

Figure 2–1: Front Panel Controls

3 Voltage Encoder and

Button

4 Voltage Display 4-digit 16-segment Voltage display.

Encoder: A high-resolution detent rotary Encoder adjusting

the output voltage and navigating menu.

Button: An auxiliary function to accept the voltage-setting

Normally displays the output voltage.

In Preview mode, the display indicates the program setting of

the output voltage.

In Menu navigation, the display indicates the selected

10

Page 19

No.

Control/Indicator

Description

parameter.

Indicators for description of the front panel Indicators bar.

value, select menu level, and set parameter value.

9

BACK Button

Return one step back in menu navigation mode.

display. *

button, followed by current encoder press. *

6 Current Display 4-digit 16-segment Current display.

Normally displays the output current.

In Preview mode, the display indicates the program setting of

the output current.

In menu navigation, the display indicates the selected

7 Indicators Bar Refer to Figure 2–2 and Table 2-2: Front Panel Display and

8 Current Encoder and

Button

10 PROG Button / Indicator Activates the Program / Sequencer menu.

11 SYST / Lock Front Panel

Button / Indicator

Encoder: A high-resolution detent rotary Encoder adjusting

the output current and navigating menu.

Button: An auxiliary function to accept the current-setting

The Program menu provides Sequencer function control,

Trigger function control, and loads a sequence stored inside

the power supply memory.

Green LED lights when Program menu is active. If Program

menu is active, press PROG button to exit to the main

Activates the System menu.

The System menu provides output sensing point selection

(Local / Remote sense), Interlock function control, Enable

function control, Power Supply OK signal control,

SAVE/RECALL power supply configuration, Programmable

Signals control, Preload function control, Display brightness &

dimming function control, and reset power supply settings.

11

Green LED lights when the System menu is active.

If the System menu is active, press the SYST button to exit

to the main menu.

Lock / Unlock Front Panel buttons by pressing the SYST

Page 20

No.

Control/Indicator

Description

12 CONF Button / Indicator Activates the Configuration menu.

exit to the main menu. *

exit to the main menu. *

to exit to the main menu. *

Green LED lights when the unit is in the Fine mode.

The Configuration menu provides power supply start mode

control, Voltage & Current source control, Analog

Programming / Monitoring range selection, Internal

Resistance function, Constant power limit function, and SlewRate control function.

Green LED lights when the Configuration menu is active.

If the Configuration menu is active, press the CONF button to

13 PROT Button / Indicator Activates the Protection menu.

The Protection menu provides OVP setting, UVL setting, UVP

function control, Foldback function control, and OCL function

ON/OFF control.

Green LED lights when the Protection menu is active.

If the Protection menu is active, press the PROT button to

14 COMM Button / Indicator Activates the Communication menu.

The Communication menu provides communication interface

selection, power supply address selection, LAN settings

control, communication baud-rate selection, communication

language selection, and software revision information.

Green LED lights when the Communication menu is active.

If the Communication menu is active, press the COMM button

15 FINE Button / Indicator Voltage/Current Fine/Coarse adjustment control.

Operates as a toggle switch.

In the Fine mode, Voltage and Current encoders operate in

high-resolution mode.

12

In the Coarse mode, Voltage and Current encoders operate in

standard-resolution (approx. 3 turns for full voltage/current

rated scale).

Page 21

No.

Control/Indicator

Description

Green LED lights when the PREV mode is active.

Green LED lights when the DC Output is enabled.

16 PREV Button / Indicator Press the PREV button to display the Output Voltage and

Current Limit settings.

The display shows the settings for 5 seconds.

If buttons are not pressed for 5 seconds, the display returns

back to show actual output voltage and current.

If Voltage or Current values are changed, and there is no

keypress for 15 seconds, the display returns back to show

actual output Voltage and Current.

17 OUT Button / Indicator Output ON/OFF control.

Press OUTPUT to set the output ON or OFF.

Table 2-1: Front Panel Controls

2.3

NOTE

* If a menu is active, and there is no key press within 15 seconds, power supply returns to the

main display (OFF or actual Voltage and Current display).

Front Panel Display and Indicators

Refer to Figure 2–2 and Table 2-2 for description of the Front Panel display and indicators.

Figure 2–2: Front Panel Display and Indicators

13

Page 22

No.

Control/Indicator

Description

Section

function.

2

Operation Mode Indicator

CV/CC/CP operation mode indicator.

parameter.

LFP is on if the Front Panel is locked.

AUTO is on if the Auto-Start mode is active.

SAFE is on, if the Safe-Start mode is active.

FOLD C is on if Foldback CC is active.

active, regardless of the power supply output state.

ext I is on if Analog Current Programming channel is active.

1 Voltage Display 4-digit 16-segment Voltage display.

Normally displays the output voltage.

In preview mode, the display indicates the program setting of

the output voltage.

In menu navigation, the display indicates the selected

3 Current Display 4-digit 16-segment Current display.

Normally displays the output current.

In preview mode, the display indicates the program setting of

the output current.

In menu navigation, the display indicates the selected

4 LFP Indicator Locked Front Panel indicator.

5 AUTO Indicator AUTO-Start indicator.

6 SAFE Indicator SAFE-Start indicator.

7 FOLD VI Indicator Foldback indicator.

FOLD V is on if Foldback CV is active.

8 Power / Address Indicator If power supply output is ON, actual output power is

displayed.

If power supply output is OFF, power supply address is

displayed.

* The address is displayed while Communication menu is

9 ext V / ext I Indicators External Voltage / External Current Analog Programming

Indicators.

ext V is on if Analog Voltage Programming channel is active.

14

Page 23

No.

Control/Indicator

Description

Section

communication (RS232/485, USB, LAN, OPTional).

RS232 or RS485 communication type is selected.

USB communication type is selected.

LAN communication type is selected.

Optional communication type is selected.

power supply is ready to receive trigger-in signal.

The Indicator is blinking if a sequence is running.

10 REM Indicator REMOTE indicator.

REM is on if power supply is controlled by a remote

11 RS Indicator Recommended Standard indicator.

12 USB Indicator Universal Serial Bus indicator.

13 LAN Indicator Local Area Network indicator.

14 OPT Indicator Optional communication type indicator.

15 TRIG Indicator Trigger Indicator.

TRIG is on if the trigger-in is enabled and initialized.

16 Active Memory-Cell

Indicator

Display active memory cell.

1,2,3,4 – A sequence is loaded from cells 1,2,3 or 4

_ - A sequence is loaded from a PC

Table 2-2: Front Panel Display and Indicators

15

Page 24

2.4

No.

Connection

Description

Section

2

Ground Stud

Functional Ground connection M4x8 Stud.

IPC 5/ 4-GF-7,62 for 150V to 600V models.

compensation of load wire drop.

Button between 5 to 10 sec. Refer to Table 3-5 & Table 3-6.

6

Paralleling Connectors

Master/Slave connectors, mini I/O type

Red status indicator (close to RJ45) – LAN fault / Not connected.

the remaining units are chained, Remote-Out to Remote-In.

a serial communication bus.

10

USB Connector

USB interface connector, type B.

signals

the output potential.

12

Optional Interface

Position for optional communication interface.

Rear Panel Connections and Controls

Refer to Figure 2–3 and Table 2-3 for description of the Rear Panel connections and controls.

Figure 2–3: Rear Panel Connection and Controls

1 AC Input Connector Connector type: PC 5/ 4-G-7,62.

3 DC Output Bus-Bar /

Connector

4 Remote Sense Connector A Connector for remote sensing connections.

5 Reset Button Set default power supply settings (Factory Reset). Press Reset

7 LAN Connector +

Indicators *

8 Serial In Connector RJ-45 type connector, used for connecting power supplies to

Bus-bars for 10V to 100V models,

Connect to the load for regulation of the load voltage and

LAN interface connector, RJ-45 type + LAN status indicators.

Green LED on RJ45 connector – Link / Activity.

Amber LED on RJ45 connector – Speed. Lit – 100Mbps,

otherwise 10Mbps.

Green status indicator (close to RJ45) – Connection active.

RS232 or RS485 port of a computer for remote control

purposes. When using several power supplies in a power

system, the first unit Serial-In is connected to the computer and

9 Serial Out Connector RJ-45 type connector, used for chaining power supplies to/from

11 Isolated control and

Isolated analog Control and monitoring signals, isolated from

Table 2-3: Rear Panel Connections and Controls

16

Page 25

No.

Connection

Description

Section

power supply output.

supply status. High level is OK.

type, low level is OK.

4

CV/CC

Output for Constant-Voltage / Constant-Current mode indication.

(analog) programming mode.

programming of the output Voltage and Current.

the Output Current.

9

18

26

1

10

19

2.5

NOTE

* LAN Connector LEDs (Green & Amber) and Red Status Indicators might lit in Power Switch OFF

state.

WARNING

Refer to the Safety & Installation Manual for any connect/disconnect of any connector on the rear

panel.

J1 Connector Terminal and Function

Control and monitoring signals are SELV.

Connector Technical Information:

Connector type: 618026325223, WURTH

DB26HD Receptacle type: 10090769-P264ALF, FCI

Wire: AWG 24-28

Figure 2–4: J1 Connector Terminals and Functions

1 Daisy In / SO Input for Series Operation / Input for Shut Off control of the

2 Daisy Out / PS_OK #2 Output for Series Operation / Output #2 for indication of power

3 PS_OK #1 Output #1 for indication of power supply status. Open Collector

5 LOC/REM MON Output for indicating if the unit is in Local (digital) or Remote

6 LOC/REM SELECT Input for selecting between Local (digital) or Remote (analog)

7 IPGM Input for Remote (analog) voltage/resistance programming of

17

Page 26

No.

Connection

Description

Section

the Output Voltage.

9

NOT USED

open) or voltage source. Selectable signal polarity.

11

COM

COMMON. Return for all signals.

12

COM

COMMON. Return for all signals.

13

COM

COMMON. Return for all signals.

14

COM

COMMON. Return for all signals.

15

NOT USED

16

NOT USED

17

COM

COMMON. Return for all signals.

18

COM

COMMON. Return for all signals.

open) or voltage source.

20

Programmed Signal 2

General Purpose Open Drain Port 2.

21

Programmed Signal 1

General Purpose Open Drain Port 1

edge triggered, pulse width: min. 10usec.

23

Trigger Out

Trigger output, positive edge, pulse width: min. 100usec.

24

NOT USED

25

I_MON

Output for monitoring the power supply output Current.

26

V_MON

Output for monitoring the power supply output Voltage.

8 VPGM Input for remote (analog) voltage/resistance programming of

10 ENA_IN Enable / Disable the power supply output by dry-contact (short /

19 ILC Enable / Disable the power supply output by dry-contact (short /

22 Trigger In Power supply trigger input for sequencer operations. Positive

Table 2-4: J1 Connector Terminals and Functions

18

Page 27

Display Text

Text Description

Display Text

Text Description

OUTPUT

LOCK

OFF

UNLOCK

Interface

SENSE

RS232

LOCAL

RS485

REMOTE

USB

INTERLOCK

LAN

ON

ADDRESS

ENABLE

IP

ENABLE POLARITY

MAC

NORMAL

BAUD RATE

REVERSE

LANGUAGE

POWER SUPPLY OK DELAY

SCPI

SAVE

GENESYS

RECALL

REVISION

FACTORY RESET

OVP

DEFAULT

UVL

SURE

UVP

YES

UVP DELAY

NO

FOLDBACK

PIN 1

FOLDBACK DELAY

PIN 2

CC

CURRENT

CV

VOLTAGE

OVER CURRENT LIMIT

PRELOAD

START

DISPLAY

SAFE

BRIGHTNESS

AUTO

DIMMING BRIGHTNESS

VOLTAGE SOURCE

DIMMING DELAY

2.6

Front Panel Display Messages

Table 2-5 shows the various messages shown on the display in different operating modes.

OUT

OFF

INTFC

RS232

RS485

USB

LAN

ADR

IP

MAC

BAUD

LANG

SCPI

GEN

REV.

ovp

uvl

UVP

UVP.DL

FOLD

FLD.DL

CC

CV

OCL

START

SAFE

AUTO

V.SRC

LOCK

ULOCK

SENSE

LOCAL

REM

ILC

ON

ENA

ENA.PL

NORM

REV

PSO.DL

SAVE

RECAL

FRST

DEFLT

SURE

YES

NO

PIN 1

PIN 2

CURR

VOLT

PREL

DISP

BRT

DM.BRT

DM.DL

19

Page 28

Display Text

Text Description

Display Text

Text Description

PANEL

TRIGGER

EXTERNAL VOLTAGE

INIT

EXTERNAL RESISTANCE

ABORT

CURRENT SOURCE

LOAD

RANGE

TRIGGER INPUT

INTERNAL RESISTANCE

EXTERNAL

CONSTANT POWER

BUS

POWER

CONTINUES

SLEW

TRIGGER DELAY

CURRENT SLEW UP

TRIGGER OUT

CURRENT SLEW DOWN

FUNCTION STROBE

VOLTAGE SLEW UP

OPTIONAL COMMUNICATION

VOLTAGE SLEW DOWN

RESISTANCE

PANEL

E.VOL

E.RES

C.SRC

RANGE

R.INT

C.PWR

POWER

SLEW

CSL.UP

CSL.DN

VSL.UP

VSL.DN

TRIG

INIT

ABORT

LOAD

TRG.IN

EXT

BUS

CONT

TRG.DL

TRG.OU

FSTR

OPT

RES

2.7

Menu Navigation

2.7.1 Introduction

Power Supply series contains the following five independent menus:

• COMMUNICATION

• PROTECTION

• CONFIGURATION

• SYSTEM

• PROGRAM

1. To enter a menu, press COMM, PROT, CONF, SYST or PROG button.

An appropriate LED lights indicating that a menu is active.

2. Navigate the menu by rotating the Voltage encoder to scroll through the selected Menu

functions.

Table 2-5: Front Panel Display Messages

3. Rotate the Current Encoder to select a parameter or a parameter value.

4. Press the Current Encoder to accept a desired parameter value.

5. If the parameter is accepted, the display blinks once indicating the parameter is accepted.

20

Page 29

RS232 RS485 USB LANINTFC

0ADR 1 31

9. 6 K 38.4 K 57. 6 K 115.2 K

BAUD

GENLANG SCPI

G: xx. xxx

REV.

Voltage encod er 1 step rotate

Current encod er 1 step rotate

OPT

--------------------- built_in --------------------- --- optional - --

IP1

0 255

IP4

RESET

1--4

IP

MAC 1

MAC 6

1--6

MAC

0 255

00 FF

00 FF

LAN

Function ( Voltage Disp lay)

Parameter (Current Display)

LAN Interface

Active

NO

COMM

ENTER

ENTER

CURRENT

ENCODER

VOLTAGE

ENCODER

6

COMMUNIC ATION MENU

ENTER

ENTER

Level down

YES

Note: Press Current enc oder to select required parameter. Current display b links - Parameter accepted

For LAN or OPT Interfaces, GE N lang uage is not av aila ble

19.2 K

SURE

ENTER

LAN

Interface

Not Active

Voltage encod er multiple steps rotate

Current encod er multiple step s rotate

Figure 2–5: COMMUNICATION Menu Diagram

21

Page 30

OVP

MIN

UVL

MAX

PROT

ENTER

CURRENT

ENCODER

VOLTAGE

ENCODER

0 MAX

OFF

UVP

ON

0. 1

UVP.DL

25.5

FOLD

OFF

FLD.DL

CV

UVP

ON

FOLD

CC/ CV

CC

0. 1 25.5

PROTECTION MENU

OCL

OFF ON

UVP

OFF

FOLD

OFF

Voltage encod er 1 step r otate

Current encod er 1 step r otate

Function (Voltage Display)

Parameter (Current Dis play)

ENTER

Level down

Note: Press Current enc oder to select required parameter. Cur rent d isplay blinks - Parameter accepted

Voltage encod er multiple steps rotate

Current encod er multiple steps rotate

Figure 2–6: PROTECTION Menu Diagram

22

Page 31

START

CONF

ENTER

CURRENT

ENCODER

VOLTAGE

ENCODER

V. SRC

PANEL E.RES

5

RANGE

10

E. VOL

CONFIGURATI ON MENU

R. SRC

V. SRC

C. SRC

PANEL E.RES

E. VOL

R. INT

OFF

ON

RES

0. 001 1 . 000

POWER

MIN MAX

C.P OW

ON

C. PWR

OFF

ON

SAFE AUTO

R. SRC

V. SRC

SLEW

OFF VOLT

CURR

CSL.UP

0. 0001 999.99

VSL.UP

CSL.DN

0. 0001 999.99

VSL.DN

SLEW

OFF

SLEW

VOLT

SLEW

CURR

C.P OW

OFF

R.I NT

OFF

R.I NT

ON

Voltage encod er 1 step rotate

Current encod er 1 step rotate

Function (Voltage Display)

Parameter (Current Display)

ENTER

Level down

Note: Press Current enc oder to select required para meter. Current d isplay blinks - Parameter accepted

Voltage encod er multiple steps rotate

Current encod er multiple step s rotate

Figure 2–7: CONFIGURATION Menu Diagram

23

Page 32

DM.DL

SENSE

PANEL

SYST/

ENTER

CURRENT

ENCODER

VOLTAGE

ENCODER

SYSTEM MENU

LOCAL REM

ENA

OFF ON

ILC

OFF ON

PSO.DL

0. 000 10.000

SAVE

1 2 3

4

RECAL

1 2 3

4

FRST

DEFLT

NO

SURE

YES

ENTER

PIN 1

OFF ON

PIN 2

OFF ON

PREL

DISP

BRT

DM.BRT

DM.DL

Note: Max DM.BRT value is limited to BRT v alu e - 1

DM.BRT

0 3

15 30

115. 2

60

BRT

1 4

DM.B RT

0--3

LOCK

ULOCK

Present mode

LOCA L

Present mode

REMOTE / LOCKED

ENA.PL

REV NORM

Note: M enu dis play s alter native

para meter o nly, no selection.

OFF

ENTER

ENTERENTER

DM.B RT

OFF

OFF

ON

DM.B RT

0--3

DM.B RT

OFF

Voltage encod er 1 step rotate

Current encod er 1 step rotate

Function ( Voltage Display)

Parameter ( Current Display)

ENTER

Level down

Note: Press Current encoder to selec t required pa ramete r. Cur rent d isplay blinks - Parameter acce pted

Voltage encod er mult iple steps rotate

Current encod er mult iple steps rotate

Figure 2–8: SYSTEM Menu Diagram

24

Page 33

TRIG

PROG

ENTER

CURRENT

ENCODER

TRIG

VOLTAGE

ENCODER

TRG.OU

OFF TRIG

EXT

TRG.IN

BUS

FSTR

PROG RAM MENU

INIT

ABORT

Aborted / No inita ilzed

Inita ilzed

LOAD

1 2 3 4

OFF

CONT

ON

0. 000

TRG.DL

10.00

Voltage encod er 1 step rotate

Current encod er 1 step rotate

Function (Voltage Disp lay)

Parameter (Current Dis play)

ENTER

Level down

Note: Press Current enc oder to select required parameter. Current display b links - Parameter a ccepted

Voltage encod er m ultiple steps rotate

Current encod er multiple steps rotate

Note : Menu di sp lays alternativ e

para meter o nly, no selection.

2.7.2 Exiting a Menu

There are three ways to exit a Menu:

• Press the active Menu button.

Appropriate MENU LED turns OFF. The display shows the present power supply status.

• Press the Back button multiple times, corresponding to the depth inside the Menu.

Appropriate MENU LED turns OFF. The display shows the present power supply status.

Figure 2–9: PROGRAM Menu Diagram

• No action for 15 sec.

Appropriate MENU LED turns OFF. The Display shows the present power supply status.

25

Page 34

CHAPTER 3: LOCAL OPERATION

Load lines, twisted pair, shortest length possible.

+V

POWER

SUPPLY

+

LOAD

-

-V

3.1

Introduction

This Chapter describes the operating modes that do not require programming and monitoring the

power supply via its communication interfaces: LAN, USB, RS232/RS485, Optional communication

or by remote analog signals. Ensure that the REM indicator on the display is off (indicating Local

mode). If the REM indicator is on, press the Front Panel SYST button, PANEL ULOCK is seen on the

display. Press Current encoder to unlock.

For information regarding remote analog programming, refer to CHAPTER 4:

For information regarding usage of the LAN, USB or serial communication interfaces refer to

section 5.2.2.

The power supply has three operating modes. The two basic operating modes are: Constant

Voltage mode and Constant Current mode. The mode in which the power supply operates at any

given time depends on the output voltage setting, output current limit setting, and the load

resistance. The third operation mode is the Constant Power mode. In this mode a power limit is

created by an internal algorithm. Refer to section 6.5 for further explanation.

3.2

Load Connections Options

3.2.1 Connecting Single Loads, Local Sensing (Default)

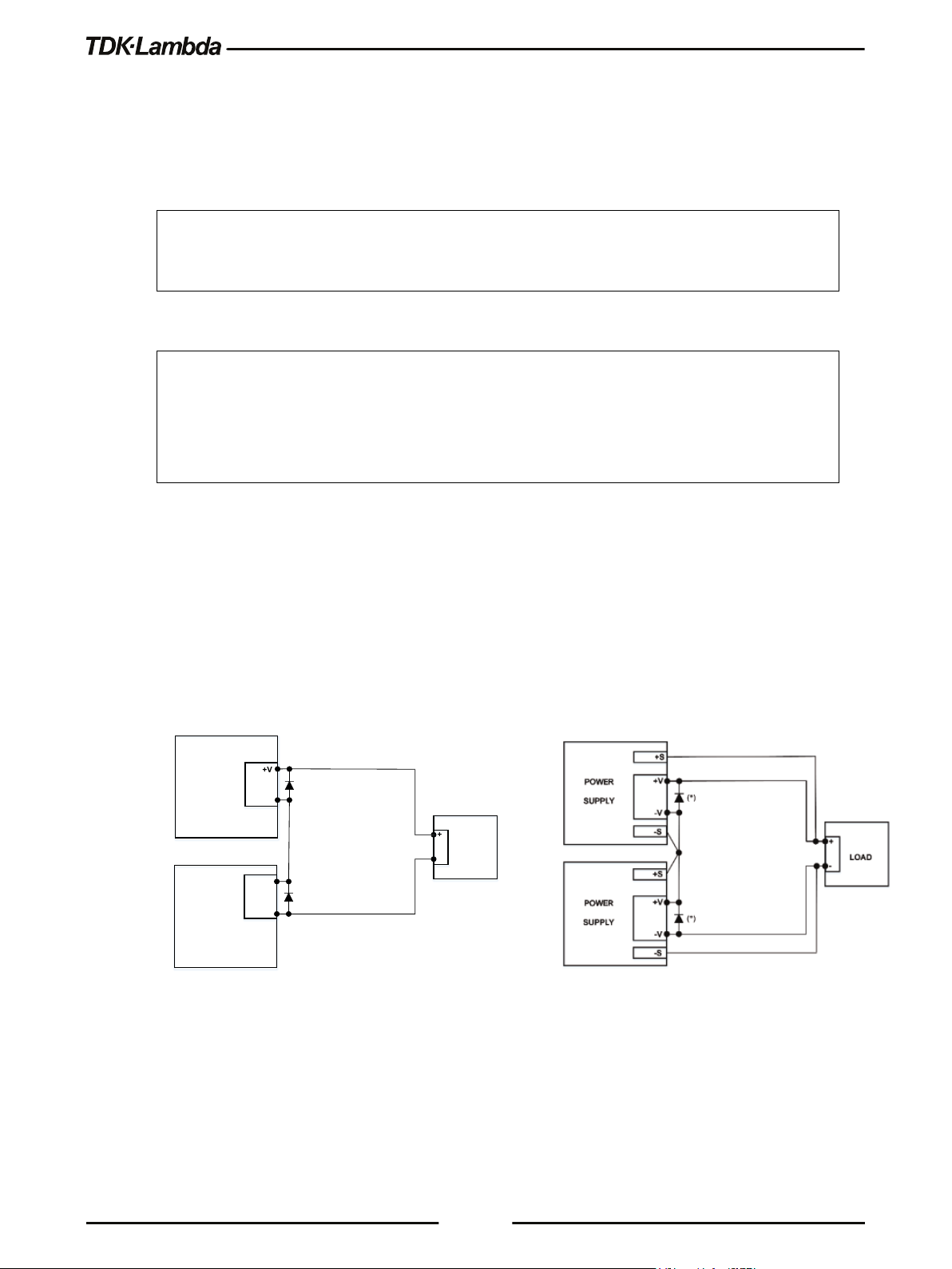

Figure 3–1 shows recommended load connections for a single load. This connection is for local

sensing mode. Local sensing is suitable for applications where load regulation is less critical.

Figure 3–1: Single Load Connection, Local Sensing

3.2.2 Connecting Single Loads, Remote Sensing

There is a potential shock hazard at the sense point when using power supply with an output

voltage greater than 60VDC. Ensure that the connections at the load end are shielded to prevent

accidental contact with hazardous voltages.

26

WARNING

Page 35

+V

POWER

SUPPLY

c

c

+

LOAD

-

c

c

-V

+S

-S

Load lines, twisted pair, shortest length possible.

Sense lines.

Twisted pair o r shielded

WARNUNG

Bei Einsatz einer Stromversorgung mit einer Ausgangsspannung von über 60VDC besteht am

lastseitigen Sense-Punkt die potentielle Gefahr eines elektrischen Schlags. Stellen Sie sicher,

dass die Anschlüsse an der Last abgedeckt sind, um versehentlichen Kontakt mit gefährlicher

Spannung zu vermeiden.

CAUTION

When using shielded sense wires, ground the shield in one place only. The location can be the

power supply chassis or one of the output terminals.

Figure 3–2 shows recommended remote sensing connection for single loads. Remote sensing is

used when, in Constant Voltage mode, the load regulation is important at the load terminals. Use

twisted or shielded wires to minimize noise pick-up. If shielded wires are used, the shield should be

connected to the ground at one point, either at the power supply chassis or the load ground. The

optimal point for the shield ground should be determined by experimentation.

Figure 3–2: Remote Sensing, Single Load

27

Page 36

3.2.3 Connecting Multiple Loads, Radial Distribution Method

Load lines,

Twisted pa irs, sh ortest length possible

LOA D #1

-

+

LOA D #2

-

+

LOA D #3

-

+

+V

POWER

SUPPLY

-V

POWER

SUPPLY

c

c

+V

c

c

-V

+S

-S

LOA D #1

-

+

LOA D #2

-

+

LOA D #3

-

+

Distribution ter minal

Figure 3–3 shows multiple loads connected to one supply. Each load should be connected to the

power supply’s output terminals using separate pairs of wires. It is recommended that each pair of

wires will be as short as possible and twisted or shielded to minimize noise pick-up and radiation.

Figure 3–3: Multiple Loads Connection, Radial Distribution, Local Sense

3.2.4 Multiple Load Connection with Distribution Terminals

If remotely located output distribution terminals are used, the power supply output terminals should

be connected to the distribution terminals by a pair of twisted and/or shielded wires. Each load

should be separately connected to the remote distribution terminals (see Figure 3–4).

If remote sensing is required, the sensing wires should be connected to the distribution terminals or

at the most critical load.

In remote sense, the power supply will compensate for voltage drop on the load wires. Refer to the

Specifications (1.1) for the maximum voltage drop on load wires. The voltage drop is subtracted

from the total voltage available at the output.

28

Figure 3–4: Multiple Loads Connection with Distribution Terminal

Page 37

3.2.5 Constant Voltage Mode and Voltage Setting

In Constant Voltage mode, the power supply regulates the output voltage at the selected value,

while the load current varies as required by the load.

While the power supply operates in Constant Voltage mode, the CV indicator on the display

illuminates.

1. Adjust the output voltage, when the power supply output is enabled (Output On) or disabled

(Output Off). There are three options to set output voltage:

(a) When the output is enabled, rotate the Voltage encoder knob to program the output

voltage. This method affects output voltage immediately.

(b) When the output is enabled, press the PREV button and then rotate the Voltage encoder to

a required value. Press the Voltage encoder to select the required value. The display will

blink once to acknowledge the setting. This method affects output voltage only after

acknowledgement by encoder press. Exit the PREV menu by pressing the Back button or

the PREV button.

(c) When the output is disabled, press the PREV button and then rotate the Voltage encoder

to a required value. Press the Voltage encoder to select the required value. The display will

blink once to acknowledge the setting. Exit the PREV menu by pressing the Back button or

the PREV button.

2. Set voltage programming resolution to the Coarse or Fine adjustment.

(a) Press the FINE button to select between the lower (about 1% of rated voltage) and higher

(setting least significant digit seen on the voltage display) resolution.

(b) The FINE LED illuminates when the resolution is set to Fine.

NOTE:

If after completing the adjustment, the display shows a different value than the setting, the power

supply may be at current limit. Check the load condition and the power supply current limit setting.

NOTE:

The maximum and minimum setting values of the output voltage are limited by the Over Voltage

protection and Under Voltage limit settings. Refer to section 3.3.2 and section 3.3.3 for more

details.

3.2.6 Constant Current Mode and Current Setting

In the Constant Current mode, the power supply regulates the output current at the selected value,

while the voltage varies with the load requirement.

While the power supply is operating in Constant Current mode, the CC indicator in the display

illuminates.

29

Page 38

1. Adjust the output current, when the power supply output is enabled (Output On) or disabled

(Output Off). There are three options to set output voltage:

(a) When the output is enabled, rotate the Current encoder knob to program the output

current. This method affects output current immediately.

(b) When the output is enabled, press the PREV button and then rotate the Current encoder to

a required value. Press the Current encoder to select the required value. The display will

blink once to acknowledge the setting. This method affects output current only after

acknowledgement by encoder press. Exit the PREV menu by pressing the Back button or

the PREV button.

(c) When the output is disabled, press the PREV button and then rotate the Current encoder

to a required value. Press the Current encoder to select the required value. The display will

blink once to acknowledge the setting. Exit the PREV menu by pressing the Back button or

the PREV button.

2. Set current programming resolution to Coarse or Fine adjustment.

(a) Press the FINE button to select between the lower (about 1% of rated voltage) and higher

(setting least significant digit seen on the voltage display) resolution.

(b) The FINE LED illuminates when the resolution is set to Fine.

3.2.7 Automatic Crossover

When the power supply operates in the Constant Voltage mode, while the load current is increased

to greater than the current limit setting, the power supply will automatically switch to the Constant

Current mode. If the load is decreased to less than the current limit setting, the power supply will

automatically switch back to the Constant Voltage mode.

3.2.8 Output On/Off Control

The Output On/Off enables or disables the power supply output.

The Output On/Off can be activated from the front panel using the OUTPUT button or from the

communication interface. The OUTPUT button can be pressed at any time (except in the Front

Panel Lock mode, Remote control mode by communication, LLO mode or when a Fault condition

exists).

When the output is disabled, the output voltage and current fall to zero, the display shows OUTP OFF.

Press the OUTPUT button to recover from Faults such as: OVP, UVP, and FOLD faults, after the

Fault conditions have been removed.

30

Page 39

3.2.9 Safe-Start and Auto-Restart Modes

At AC turn on, the power supply can start at the last setting of the Output Voltage and Current limit

with the output enabled (Auto-restart), or it can start with the output disabled (Safe mode).

1. Press the Configuration button. Display shows START SAFE or START AUTO, depending on the

currently selected start mode.

2. Rotate the Current encoder to select between SAFE or AUTO start mode.

3. Press the current encoder to select Safe mode or Auto-restart mode.

The default setting is Safe mode.

Automatic Start Mode (AUTO)

The power supply is restored to last operation setting. Upon start-up, the output is enabled or

disabled according to the last setting.

Safe Start Mode (SAFE)

The power supply is restored to last operation setting and sets the Output to Off state.

At start-up, the output is disabled and the output voltage and current are zero (settings are

preserved). To enable the output momentarily, press the OUTPUT button.

3.2.10 Viewing Software Revision

Via the Front Panel Menu, it is possible to view the installed software revision.

1. Press the COMM button. COMM (GREEN) LED illuminates.

2. Rotate the Voltage encoder until the Rev. message appears on the Voltage display, and the

installed software revision number appears on the Current display.

3.3

Alarms and Protective Functions

3.3.1 Introduction

There are several conditions that cause alarm (RED LED blinks). All alarms affect the output.

When an alarm occurs, the respective fault will appear on the display and the alarm LED

illuminates. It is possible that more than one fault (alarm) may be triggered, but only the first will be

shown on the display. If the second fault is still active when the first fault is removed, then the

second fault will be displayed.

The following protective functions are incorporated in the power supply:

• OVP - Over Voltage Protection

• UVP - Under Voltage Protection

• ILC - Interlock

• ENA - Enable

• FOLD - Fold Back Constant Current or Constant Voltage

• AC FAIL - AC Power failure

• OTP - Over Temperature Protection

31

Page 40

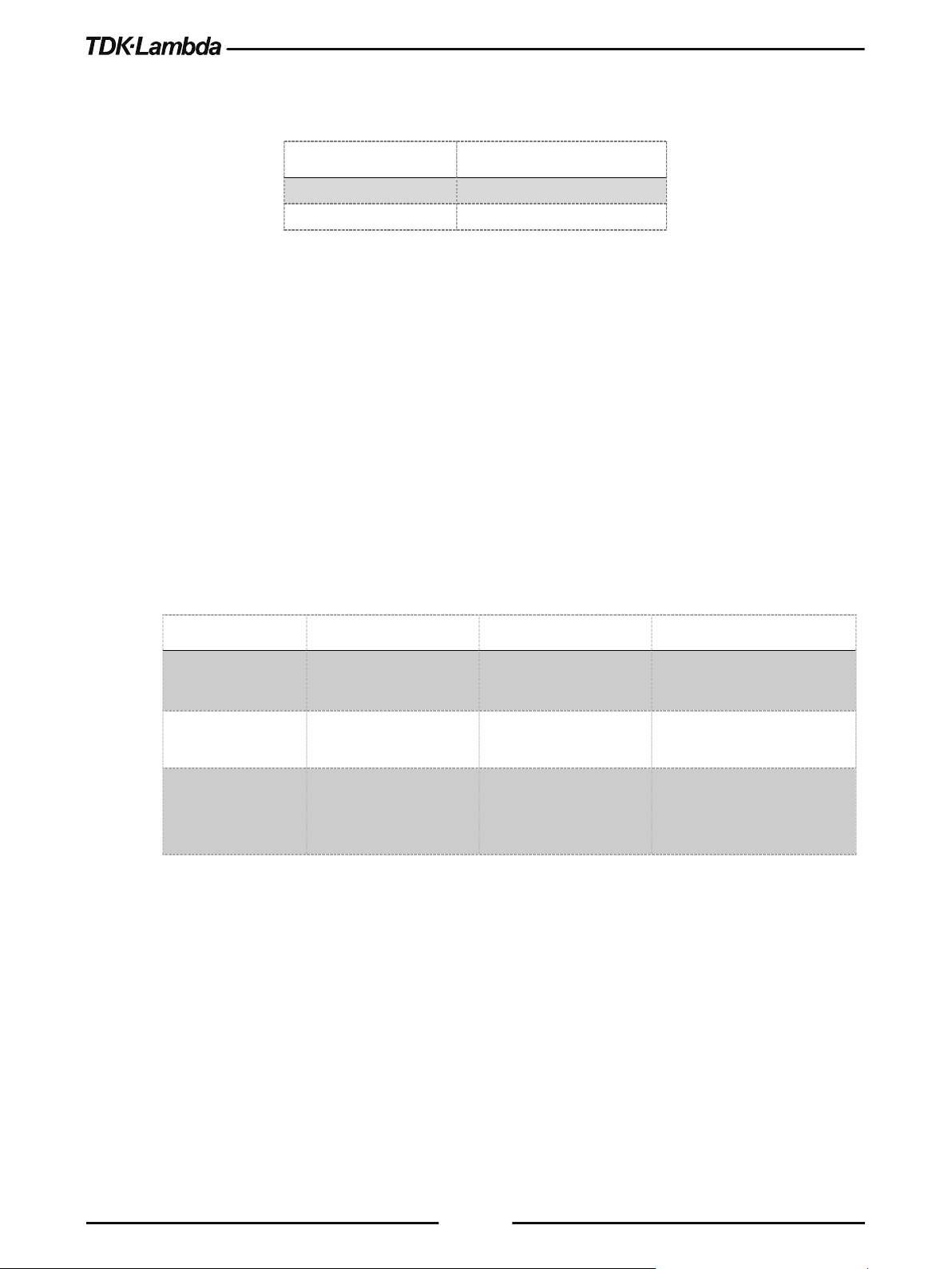

3.3.2 Over Voltage Protection

Model

Max. OVP

Min. OVP

10V

12.0V

0.5V

20V

24.0V

1.0V

30V

36.0V

2.0V

40V

44.1V

2.0V

60V

66.15V

5.0V

80V

88.2V

5.0V

100V

110.2V

5.0V

150V

165.37V

5.0V

300V

330.75V

5.0V

600V

661.5V

5.0V

The OVP circuit protects the load in the event of a remote or local programming error or a power

supply failure. The protection circuit monitors the voltage at the power supply sense points thus

providing the protection level at the load. Upon detection of an Over Voltage condition, the power

supply output will shut down.

Setting the OVP Level

The OVP can be set when the power supply output is Enabled (On) or Disabled (Off). The

minimum setting level is 5% above the output voltage, or the value in Table 3-1, whichever is

higher. The maximum setting level is shown in Table 3-1.

1. Press the PROT button.

PROT (GREEN) LED illuminates. OVP message appears on the display.

2. Rotate the Current encoder to adjust the OVP level.

3. Press the Current encoder to select the required OVP level.

The display blinks once to acknowledge the setting.

4. Exit the PROT menu by pressing the Back button or the PROT button.

Table 3-1: Maximum/Minimum OVP Setting Levels

3.3.2.1 Resetting the OVP Circuit

To reset the OVP circuit after activation:

1. Reduce the power supply Output Voltage setting below the OVP set level.

2. Ensure that the load and the sense wiring is connected properly.

Four methods to reset the OVP circuit.

• Pressing the OUTPUT button

• AC recycle

• On/Off recycle by analog control (Interlock/Enable)

• Sending a communication command to enable output.

32

Page 41

3.3.3 Under Voltage Protection and Under Voltage Limit

The UVL function prevents output voltage setting below the UVL set value, and prevents an

adjustment of the output voltage below a certain limit.

The UVP function prevents power supply operation, if the output voltage is below the UVL set

value. Upon detection of an Under Voltage condition, the power supply output will shut down. The

combination of the UVP/UVL and the OVP functions, enables the user to create a protection

window for the sensitive load circuitry.

Setting the UVP/UVL Mode and Level

The UVP/UVL can be set when the power supply output is Enabled (On) or Disabled (Off).

UVL setting value is limited at the maximum level to approximately 5% below the Output Voltage

setting. Attempting to adjust the value above this limit will result in no response to the adjustment

attempt. The minimum value setting is zero. UVP must be turned "ON" to be operational.

1. Press the PROT button. PROT (GREEN) LED illuminates.

2. Rotate the Voltage encoder until UVL appears on the Voltage display.

3. Rotate the Current encoder to set the required UVL level.

4. Press the current encoder to select the required level. The display blinks once to acknowledge

the setting.

5. Rotate the Voltage encoder until UVP Appears on the Voltage display.

6. Rotate the Current encoder to set UVP ON/OFF.

7. Press the Current encoder for selection. The display blinks once to acknowledge the setting.

8. Set the UVP delay time by rotating the Voltage encoder until UVP.DL appears.

The delay can be set by the Current encoder between 0.1~25.5sec.

9. Press the Current encoder to select the required delay.

The display blinks once to acknowledge the setting.

10. Exit the PROT menu by pressing the Back button or the PROT button.

3.3.3.1 Activated UVP Alarm

When the UVP is activated, the power supply output shuts down. The display shows UVP FAULT.

RED alarm LED blinks 1/2Hz frequency.

33

Page 42

3.3.4 Foldback Protection

Foldback protection will shut down the power supply output if power supply operation mode

crosses over from CC to CV or from CV to CC, according to a selected operation mode.

There are three states of Foldback protection.

• OFF (default)

• CV

• CC

For CC (or CP) to CV protection mode, the setting should be CV.

For CV (or CP) to CC protection mode, the setting should be CC.

Setting the Foldback Protection

The Foldback can be set when the power supply output is Enabled (On) or Disabled (Off).

1. Press the PROT button. PROT (GREEN) LED illuminates.

2. Rotate Voltage encoder until FOLD OFF Appears.

3. Rotate the Current encoder to set the required Foldback state (CV or CC).

4. Press the Current encoder for selection of Foldback state. The display blinks once to

acknowledge the setting.

If the CC state is selected, the FOLD I indicator appears on the display.

If the CV state is selected, the FOLD V indicator appears on the display.

5. To turn off the Foldback protection, select FOLD OFF, following the same procedure above.

Foldback indicator disappears from the display.

6. Exit the PROT menu by pressing the Back button or the PROT button.

7. Set the Foldback delay time by rotating the Voltage encoder until FLD.DL appears.

The delay can be set by the Current encoder between 0.1~25.5sec.

8. Press the Current encoder to select the required delay.

The display blinks once to acknowledge the setting.

9. Exit the PROT menu by pressing the Back button or the PROT button.

3.3.4.1 Activated FOLD Alarm

When the Foldback is activated the power supply output shuts off. The display shows FOLD FAULT,

and the alarm LED blinks with 1/2 Hz frequency.

34

Page 43

3.3.5 Protection Delay

Foldback protection delay is the time between feedback transition (CV to CC transition or vice

versa) event occurrences to output shutdown.

UVP protection delay is the time between UVL crossover point events to output shutdown.

At output OFF -> ON transition, additional 500ms delay is added.

Total protection delay = 500ms + delay setting.

3.3.6 Over Temperature Protection

The OTP circuit shuts down the power supply before the internal components can exceed their

safe internal operating temperature. When an OTP shutdown occurs, the display shows OTP FAULT,

and the alarm LED blinks RED with 1/2 Hz frequency. Resetting the OTP circuit can be automatic

(non-latched) or manual (latched) depending on the power supply mode: Safe start mode or Auto-

restart mode.

NOTE

• Safe start mode: The power supply stays off after the OTP condition has been removed. The

display shows OUT OFF.

• Auto-restart mode: The power supply recovers to its last setting automatically after the OTP

condition is removed.

3.3.7 AC Fail Alarm

The AC Fail alarm indicates whether the AC input has been shut down or AC input is incorrect.

When any of these faults occur, the display shows AC FAULT, Output power is disabled, and the

alarm RED LED blinks 1/2 Hz frequency.

Safe start mode: The power supply stays off after AC power returns. The display shows OUT OFF.

Auto-restart mode: The power supply recovers to its last setting automatically when the AC power

returns.

35

Page 44

3.4

+V

POWER

SUPPLY

+

LOAD

-V

POWER

SUPPLY

-V

+V

-

(*)

(*)

Series Operation

Power supplies of the same model can be connected in series to obtain an increased output

voltage. Split connection of the power supplies gives positive and negative output voltage.

WARNING

When power supplies are connected in series, and the load or one of the output terminals is

grounded, no point may be at a greater potential of +/- 200VDC from ground for models up to

100VDC rated output and +/- 600VDC from ground for models 150 ~ 600VDC rated output.

WARNUNG

Wenn Stromversorgungen in Reihe geschaltet werden und die Last oder eine der

Ausgangsklemmen geerdet ist, darf kein Anschluss ein größeres Spannungspotential bei den

Ausgangsmodellen bis 100VDC von +/- 200VDC gegenüber Erde aufweisen. Bei den

Ausgangsmodellen 150 ~ 600VDC kann das maximale Spannungspotential bis zu +/- 600VDC

betragen.

3.4.1 Series Connection for Increased Output Voltage

Two units are connected so that their outputs are summed. Set the current limit of each power

supply to the maximum that the load can handle without damage. It is recommended that diodes be

connected in parallel with each unit output to prevent reverse voltage during start up sequence or

in case one of the units shuts down. Each diode should be rated to at least the power supply rated

output voltage and output current. Refer to Figure 3–5 for series operation with local and remote

sensing.

Series connection, local sensing

(*) Diodes are user supplied.

Figure 3–5: Series Connection, Local and Remote Sensing

36

Series connection, remote sensing

Page 45

(*)

(*)

POWER

SUPPLY

+

LOAD

COM.

-V

POWER

SUPPLY

-V

+V

-

+V

connected in series.

Section 4.5 for details.

3.4.2 Series Connection for Positive and Negative Output Voltage

In this mode, two units are configured as positive and negative output.

Set the current limit of each power supply to the maximum that the load can handle without

damage. It is recommended that diodes be connected in parallel with each unit output to prevent

reverse voltage during start-up or in case one of the units shuts down. Each diode should be rated

to at least the power supply rated output voltage and output current. Refer to Figure 3–6 for this

operating mode.

3.4.3 Remote Programming in Series Operation

Programming by external voltage: The analog programming circuits of this power supply

Using the SO function and (\PS_OK_OUT)

signal:

Programming by external resistor : Programming by external resistor is possible. Refer to

37

Figure 3–6: Series Connection for Positive/Negative Output Voltages

(*) Diodes are user supplied.

are isolated from the output potentials. Therefore, the

circuits used to control each series connected unit don't

have to be separated and floated from each other.

DAISY_IN signal (J1-1) serves as Output Shut OFF (SO)

via daisy chain connection.

This signal is used only for the Daisy Chain application,

connected to DAISY_OUT signal (J1-2) of a master unit.

The signal is referenced to the isolated interface

(COM_SELV: J1-11, 12, 13, 14). The function is active

after initial high to low transition.

(\PS_OK_OUT) signal is Power Supply OK– Open

Collector type which indicates output status (DC

On/Off). The signal is referenced to the isolated