Page 1

OPERATOR MANUAL FOR

EMBEDDED IEEE-488

PROGRAMMING INTERFACE

Document: 83-468-007 Rev B

MODEL _______________________

SERIAL _________________

405 Essex Road, Neptune, NJ 07753

Tel: (732) 922-9300

Fax: (732) 922-9334

Web: www.lambda-emi.com

Page 2

Table of Contents

1. THE DIGITAL PROGRAMMING OPTION................................................... 1

1.1 OVERVIEW: IEEE AND RS-232 PORTS ........................................................1

1.2 SCOPE

1.3 USING

OF MANUAL ......................................................................................2

DIGITAL PROGRAMMING .................................................................2

1.3.1 THE IEEE-488.2 INTERFACE............................................................2

1.3.2 THE RS-232 INTERFACE ..................................................................2

1.3.3 IEEE AND RS-232 INTERACTION ....................................................2

1.4 CONFIGURING

THE IEEE INTERFACE.........................................................3

1.4.1 CONFIGURING THE IEEE CONTROLLER .......................................3

1.4.2 CONFIGURING THE IEEE INTERFACE ...........................................3

1.5 GETTING

STARTED WITH THE SOFTWARE................................................4

1.5.1 EXAMPLE SESSION USING THE ‘IBIC’ CONSOLE.........................4

1.5.2 EXAMPLE PROGRAM WRITTEN IN VISUAL BASIC .......................4

1.5.3 EXAMPLE PROGRAM WRITTEN IN LABVIEW ................................5

1.6 PROGRAMMING

VOLTAGE AND CURRENT ...............................................6

1.6.1 PROGRAM OUTPUT VOLTAGE .......................................................6

1.6.2 PROGRAM OUTPUT CURRENT.......................................................6

1.6.3 DISABLE THE SUPPLY OUTPUT .....................................................6

1.6.4 ENABLE THE SUPPLY OUTPUT ......................................................7

1.6.5 READ PROGRAMMING MODE .........................................................7

1.7 MEASURING

VOLTAGE AND CURRENT......................................................8

1.7.1 MEASURE VOLTAGE ........................................................................8

1.7.2 MEASURE CURRENT........................................................................8

1.7.3 SET MEASUREMENT FILTERING ....................................................8

1.8 LIMITS

AND PROTECTIONS..........................................................................9

1.8.1 SET VOLTAGE LIMIT.........................................................................9

1.8.2 SET CURRENT LIMIT ........................................................................9

1.8.3 OVER-VOLTAGE PROTECTION......................................................9

1.8.4 OVER-CURRENT PROTECTION ...................................................10

1.9 COMMON

COMMANDS................................................................................12

1.9.1 READ DEVICE IDENTITY ................................................................12

1.9.2 GO TO LOCAL..................................................................................12

1.9.3 REMOTE ENABLE ...........................................................................12

1.9.4 READ STATUS BYTE REGISTER...................................................12

1.9.5 RESET THE POWER SUPPLY........................................................13

1.9.6 CHANGING THE POWER-UP DEFAULTS......................................13

1.10 USING

ERROR AND STATUS REGISTERS ................................................13

1.10.1 OVERVIEW: REGISTER FAN-OUT.................................................14

1.10.2 GLOSSARY OF REGISTER TERMS...............................................14

1.10.3 CLEAR ALL STATUS REGISTERS .................................................17

1.10.4 SERIAL POLL AND STATUS BYTE REGISTER ...........................17

1.10.5 STANDARD EVENT STATUS REGISTER .....................................18

1.10.6 THE OPERATIONAL REGISTERS ..................................................19

1.10.7 THE QUESTIONALBE REGISTERS................................................21

2. THE RS-232 INTERFACE ......................................................................... 22

Document: 83-468-007 Rev B

Page 3

2.1 CONFIGURING

2.1.1 THE RS-232 CABLE.........................................................................22

2.1.2 DEFAULT RS-232 CONFIGURATION.............................................22

2.2 RS-232

2.2.1 CHANGE CHARACTER ECHO........................................................24

2.2.2 GO TO LOCAL COMMAND..............................................................25

2.2.3 CHANGE THE BAUD RATE.............................................................25

2.2.4 CHANGE THE DATA BITS...............................................................25

2.2.5 CHANGE THE PARITY BITS ...........................................................26

2.2.6 CHANGE THE STOP BITS...............................................................26

2.3 ERROR

COMMAND SET ...............................................................................24

REGISTERS AND RS-232...............................................................27

THE RS-232 INTERFACE...................................................22

3. ADJUST THE IEEE CALIBRATION.......................................................... 28

3.1 INTRODUCTION ...........................................................................................28

3.2 CALIBRATE

3.3 CALIBRATE

3.4 CALIBRATE

3.5 CALIBRATE

THE VOLTAGE PROGRAMMING...........................................28

THE VOLTAGE MEASUREMENT...........................................30

THE CURRENT PROGRAMMING ..........................................31

THE CURRENT MEASUREMENT ..........................................32

4. SUMARY TABLE OF COMMANDS .......................................................... 35

List of Tables

Table 1. The *SAV 0 Command............................................ 13

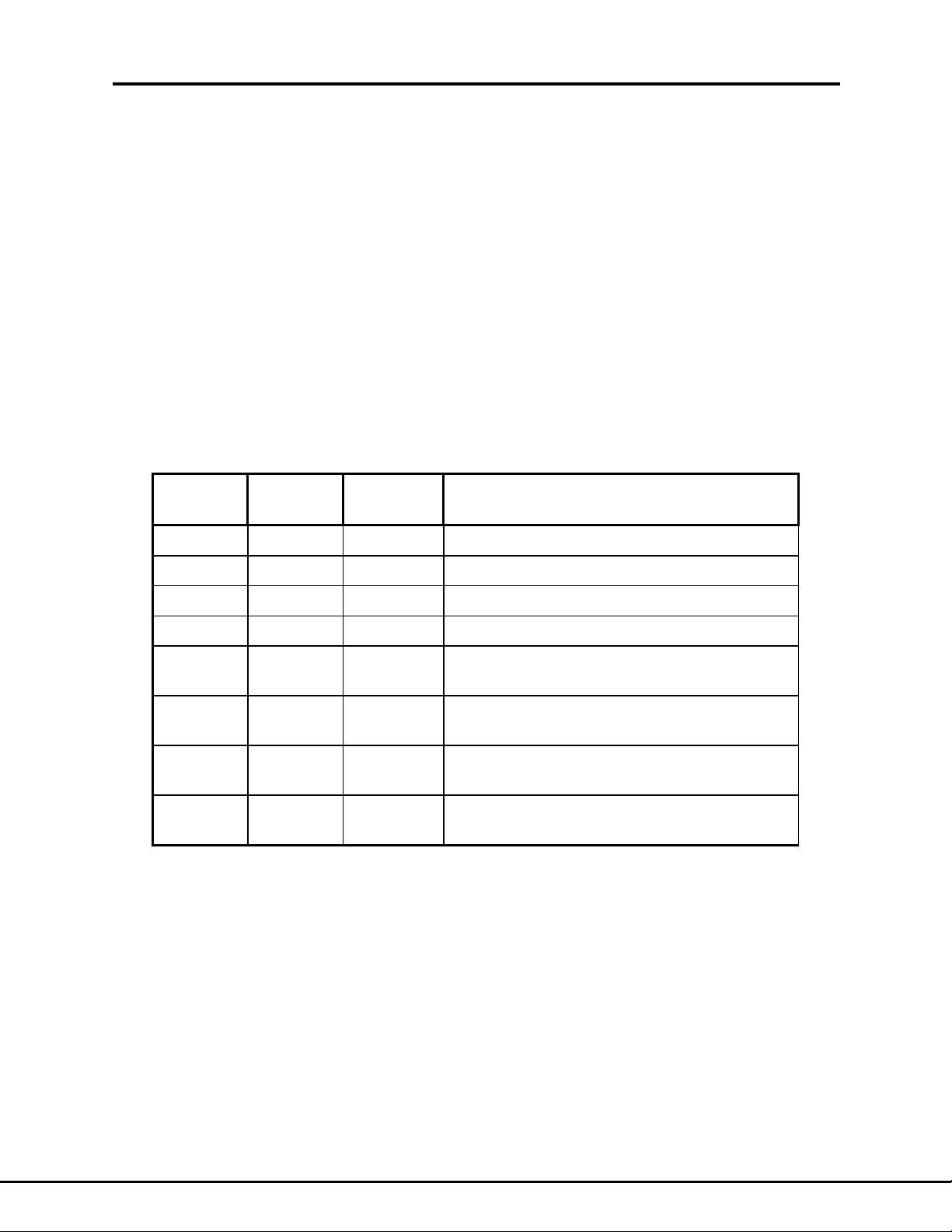

Table 2. The Status Byte Register......................................... 17

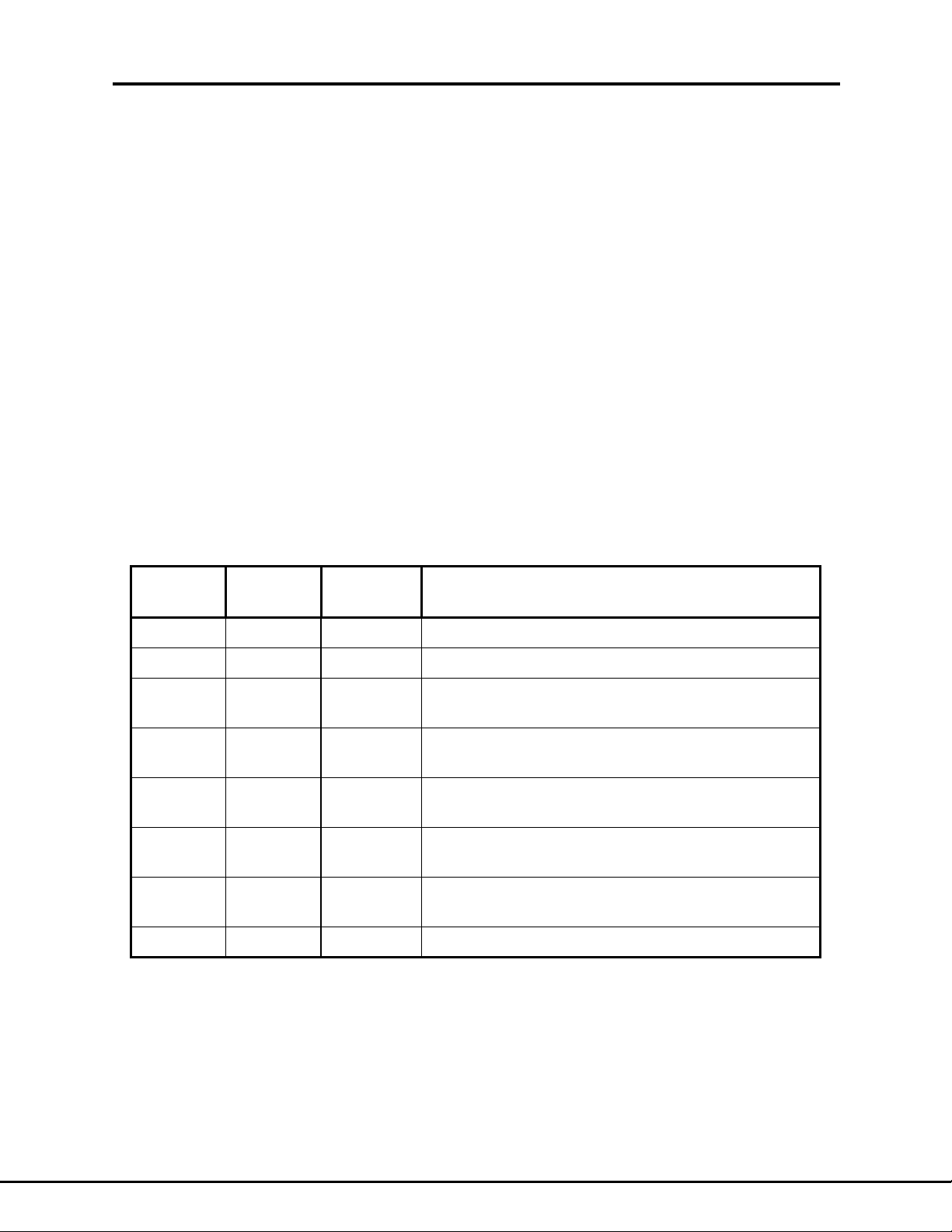

Table 3. The Standard Event Status Register ....................... 18

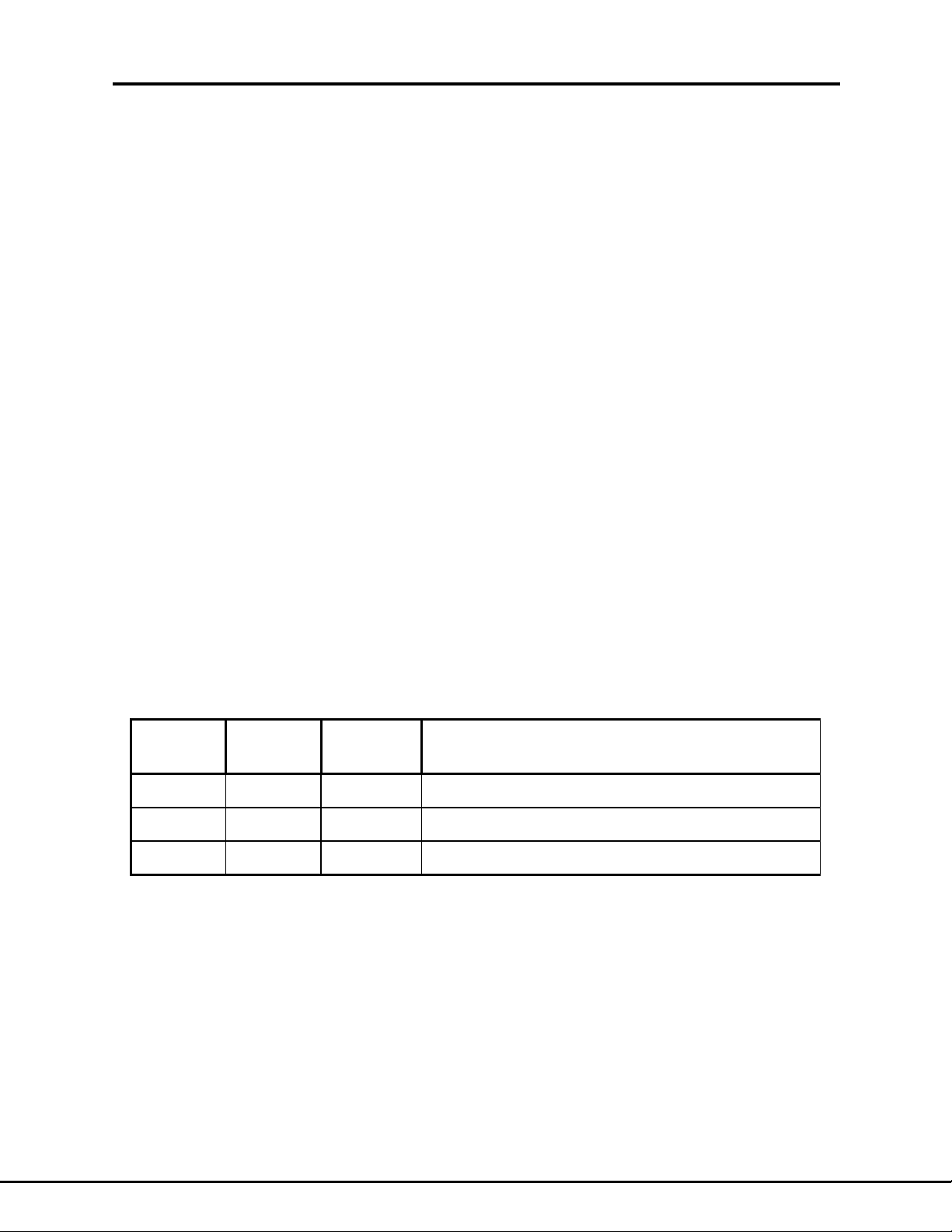

Table 4. The Operational Registers....................................... 19

Table 5. Default RS-232 Configuration .................................. 22

Table 6. RS-232 Echo Settings ............................................. 24

List of Figures

Figure 1. IEEE Address Switch Settings ................................... 3

Figure 2. Status and Error Register Diagram.......................... 15

Figure 3. Status and Error Handler ......................................... 16

Figure 4. RS-232 Cable Construction ..................................... 23

Document: 83-468-007 Rev B

Page 4

WARNING:

When a power supply with IEEE option is first powered ON, or when a

“Go To Local” command is sent, the supply output will jump to

whatever is set on the front panel knobs.

Therefore, it is recommended the front panel Voltage and Current

knobs be turned counter-clockwise to ZERO before REMOTE

programming.

1 THE DIGITAL PROGRAMMING OPTION

1.1 OVERVIEW: IEEE AND RS-232 PORTS

Most power supplies come standard with the Local and Analog Remote programming

modes which use the front panel knobs or the back panel 25 pin ‘D’ connector. A third

programming mode, Digital Remote, is available as an option. This option adds an embedded interface board with two extra connectors to the back of the supply.

The connectors allow cables to be run from the supply to a remotely located operator

terminal or to a computer running an automation program. A terminal allows the operator

to type commands to the power supply which take affect as soon as they are typed. An

automation program will allow several power supplies to be ‘daisy chained’ together. It

also allows other instruments, including relay switchers and measurement devices, to be

synchronized with the power supplies in complex power systems.

When the supply is running in the digital programming mode, the front panel knobs are

disabled but all the front panel indicators still show the status of the supply. The power

supply output levels and operating states may be monitored through the computer port.

Commands that are standard with digital programming include:

Introduction

1

• Program Voltage • Program Current

• Measure Voltage • Measure Current

• Set Maximum Voltage • Set Maximum Current

• Over-Voltage Shutdown • Over-Current Shutdown

• Error and Status Messages

• Computerized Calibration

• IEEE-488.2 Compliant • SCPI Compliant

Document: 83-468-007 Rev B

Page 5

1.2 SCOPE OF MANUAL

This manual contains the information needed to setup and operate the embedded digital

interface used in the Lambda EMI power supplies including the EMS and ESS models.

The interface is contained on one circuit card. It may be optionally installed by Lambda

facilities at the time of purchase.

This manual does NOT include specifications for digital accuracy and response rate.

These values are only valid for the power supply in which the interface is installed, so

the specifications are given in the User Manual for the power supply.

1.3 USING DIGITAL PROGRAMMING

1.3.1 THE IEEE-488.2 INTERFACE

The IEEE-488 digital programming interface (also called the GPIB interface) is a popular

way to connect instruments to a computer. It uses a specialized 24-pin cable with connectors that allow cables to be ‘stacked’ together. There are eight data wires, eight control wires and eight ground wires. If the system runs from a personal computer, there are

numerous vendors of IEEE controller cards and software.

The IEEE-488 standard has gone through several upgrades. The IEEE-488.1 focused

on the handshaking of the eight control lines. The IEEE-488.2 added status registers inside each instrument and it added common commands to make programming groups of

instrument easier. The latest specification, SCPI, adds guidelines for the command syntax so one vendor’s power supply will use the same commands as another’s. The

Lambda interface follows all of these standards.

Because up to 15 instruments may be connected and independently controlled by a single IEEE controller, each instrument must have a unique address. On the power supply,

the address is set by a DIP switch accessible through a slot in the back panel.

Introduction

2

1.3.2 THE RS-232 INTERFACE

The second connector on the interface board is for the RS-232 serial port. It uses a

9-pin “D” connector. Only three wires are used: transmit data, receive data, and ground.

Compared to the IEEE port, the RS-232 is slower and it has limited status and error reporting. Also, there is no instrument addressing so only one power supply can be run

from each controller port. The advantage of RS-232 is the cable is easy to make and

every personal computer and terminal comes standard with it.

The RS-232 specification does not include any requirements for command syntax. For

this port, a “short form” command set is available where each command has only a couple of characters. The short form commands are easy to type into a terminal program.

1.3.3 IEEE AND RS-232 INTERACTION

When the power supply is first powered up, the RS-232 serial port is active. If a command is sent over the IEEE bus, the IEEE port becomes enabled and the RS-232 port

will no longer function. To restore the function to the RS-232 port, the power supply must

be cycled off and on.

Document: 83-468-007 Rev B

Page 6

1.4 CONFIGURING THE IEEE INTERFACE

1.4.1 CONFIGURING THE IEEE CONTROLLER

A typical IEEE controller is a personal computer with a IEEE interface card. Each card

vendor supplies its own configuration instructions and interface software.

Each time the software is executed, the controller must be configured as follows:

Controller Address = 0. This is factory default for all controllers.

EOI Flag = TRUE. The “End or Identify” is a control line in the IEEE cable that

is asserted when the last character of a message string is sent. It is required

for Lambda EMI supplies

EOS Flag = FALSE: The “End of String” is used in some instruments to say a

character, such as a linefeed, marks the last character of a message. The

Lambda EMI supply does not require an end of string character.

1.4.2 CONFIGURING THE IEEE INTERFACE

The power supply is connected to the controller using a standard IEEE-488 cable. Standard connecting requirements are as follows:

Verify the power supply is switched OFF before connecting any cables to it.

ConfiguringBeginning Software

3

A maximum of 15 devices may be connected to any one IEEE bus. Maximum

cable length between any two devices should be six feet. Total cable length

should be less than 65 feet.

Before powering up the supply, set the IEEE address on its back panel switch.

It is labeled “IEEE ADDRESS”. Each device on the IEEE bus must have a

unique address. The controller is normally at address = 0 and address = 31 is

reserved, so the available addresses are from 1 to 30. See Figure 1.

Before powering up the supply, verify the FORCED LOCAL switch on IEEE

address switch is downward for OFF. Setting this switch ON will disable remote programming over the IEEE and RS-232 busses. See Figure 1.

Figure 1. IEEE Address Switch Settings

Document: 83-468-007 Rev B

Page 7

1.5 GETTING STARTED WITH THE SOFTWARE

A computer can use a variety of controllers, programs, and programming languages for

the IEEE bus. Here are three examples showing minimal programs to set the voltage,

set the current and measure the voltage from a Lambda EMI power supply.

1.5.1 EXAMPLE SESSION USING THE ‘IBIC’ CONSOLE

A popular console program is National Instruments “Win32 Interactive Control” (file:

ibic.exe). As the operator types each command on the computer, at the colon prompt, it

is immediately sent to the power supply. This example works only for computers with

National Instruments and compatible IEEE controller cards.

Win32 Interactive Control

Copyright 1996 National Instruments Corporation

All rights reserved.

Type 'help' for help or 'q' to quit.

: ibdev Controller address

enter board index: 0

enter primary address: 4

enter secondary address: 0

enter timeout: 13

enter 'EOI on last byte' flag: 1

enter end-of-string mode/byte: 10

ud0: ibwrt "sour:volt 100"

[0100] ( cmpl )

count: 12

Program supply to

ud0: ibwrt "sour:curr 5"

[0100] ( cmpl )

count: 11

ud0: ibwrt "meas:volt?" output voltage?”

[0100] ( cmpl )

count: 10

ud0: ibrd 50

[2100] ( end cmpl )

count: 11

31 30 30 2e 30 38 33 31 1 0 0 . 0 8 3 1

30 31 0a 0 1 .

Supply reported output voltage

Supply Address on DIP Switch

Program supply to

100 volts output

5 amps output

Query: “What is

Read response

4

1.5.2 EXAMPLE PROGRAM WRITTEN IN VISUAL BASIC

Microsoft’s Visual Basic is a windows programming language that may be used to create

“virtual instruments” and automation programs. Here is a simple program which sends

commands to a Lambda EMI power supply to set the voltage, set the current and measure the voltage. The program’s window only conatains two items: a “Start” button and a

text box to show the measured voltage. The syntax of the CALLed functions are correct

only for National Instruments and compatible IEEE controllers. Don’t forget to add the

forms “Ni-global.bas” and “Vbib-32.bas” to you project.

Document: 83-468-007 Rev B

Page 8

Beginning Software

Example Program Written in Visual Basic

Option Explicit

Dim LambdaUD As Integer 'supply device descriptor

Dim strMeasVolt As String * 50 'buffer for reading input message

Private Declare Function GetTickCount Lib "kernel32" () As Long

Private Sub cmdStart_Click()

'start program here after "Start" button clicked

'open IEEE port, get "User Device Description" = LambdaUD

'assume power supply address is set to "4" on DIP switch

Call ibdev(0, 4, 0, T3s, 1, 10, intLambdaUD)

Call ibwrt(LambdaUD, "volt 100") 'program output to 100 volts

Call ibwrt(LambdaUD, "curr 2") 'program output to 2 amps

Wait 500 'wait 0.5 sec for output to settle

Call ibwrt(LambdaUD, "meas:volt?") 'ask "What is output voltage?"

Call ibrd(LambdaUD, strMeasVolt) 'read back output voltage

txtOutVolt.Text = strMeasVolt 'display output voltage on window

End Sub

Private Sub Wait(mSecWait As Long)

'subroutine to wait "mSecWait" milliseconds

Dim StartTime As Long

StartTime = GetTickCount

Do

Loop While (GetTickCount - StartTime < mSecWait)

End Sub

5

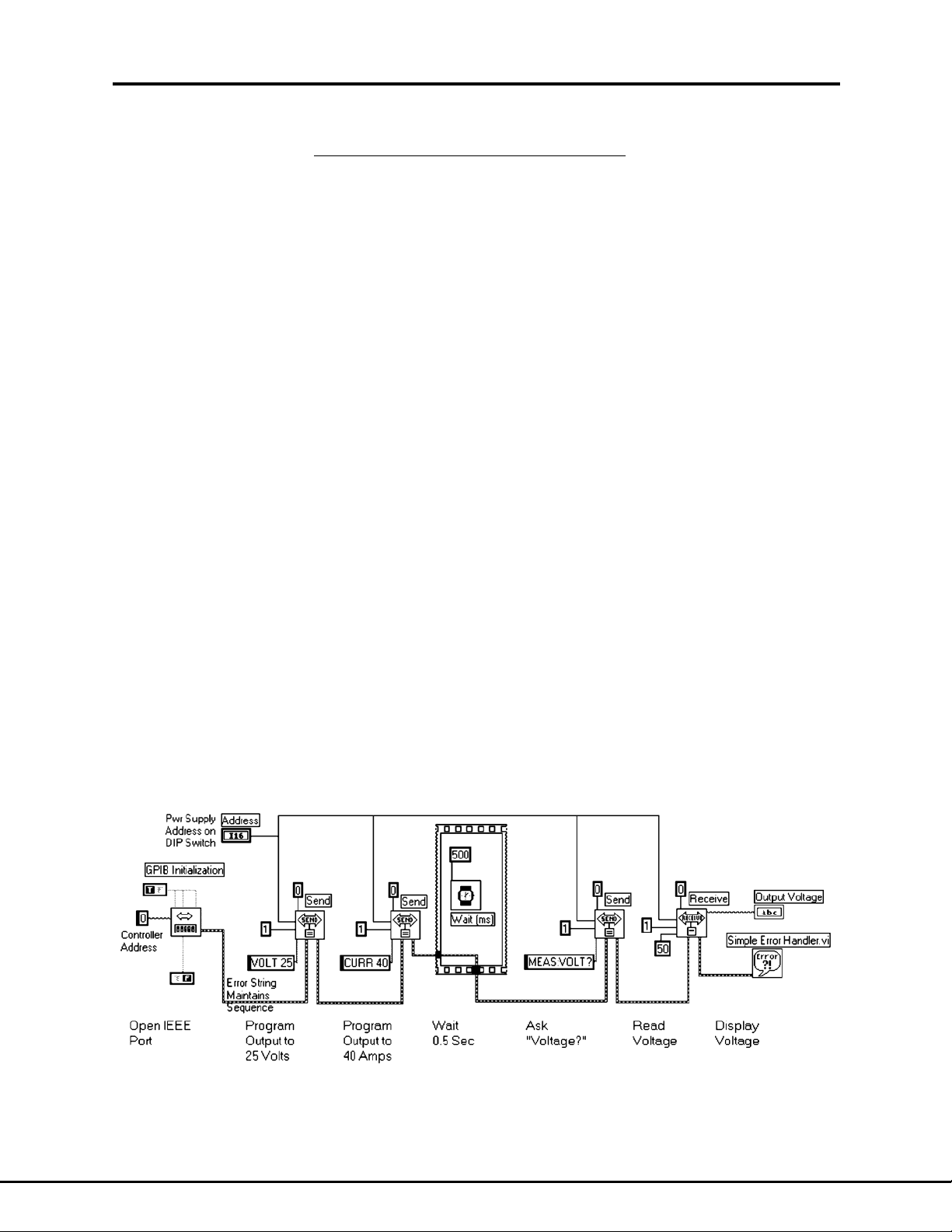

1.5.3 EXAMPLE PROGRAM WRITTEN IN LABVIEW

The National Instruments LabVIEW programming language is a popular language which

is optimized for instrument control and data analysis. It is a graphical language where

functions are shown as icons with connection points and data flows along drawn lines.

Here is a simple program which sends commands to a Lambda EMI power supply to set

the voltage, set the current and measure the voltage. The program’s window only conatains two items: a numeric control for the supply IEEE address and a text indicator to

show the measured voltage.

Document: 83-468-007 Rev B

Page 9

Program OutputBeginning Software

1.6 PROGRAMMING VOLTAGE AND CURRENT

1.6.1 PROGRAM OUTPUT VOLTAGE

The output voltage can be programmed by sending the command:

SOURCE:VOLTAGE:AMPLITUDE <nn.nn>

where <nn.nn> is any valid voltage with or without decimal places. There must be a

space before the number.

Per the Summary Table in Section 4, the command can be abbreviated in any of the following ways:

SOUR:VOLT:AMPL <nn.nn>

SOUR:VOLT <nn.nn>

VOLT:AMPL <nn.nn>

VOLT <nn.nn>

The power supply output will not reach the programmed voltage until a Program Current

command is also sent. To get the sharpest transition from zero to programmed output,

disable the output (Section 1.6.3), program voltage and current, then enable the output.

If the voltage is more than the supply output or less than zero, the command will be ignored and the Command Error bit of the Standard Event Status Register will be set. If

the voltage is higher than the limit set by the SOURCE:VOLTAGE:LIMIT value, the

command will be ignored and the Execution Error bit of the Standard Event Status Register will be set.

To read what voltage the supply was programmed to, regardless of the actual voltage,

send query SOUR:VOLT:AMPL? and read the response message.

The short form of “program voltage” is: PV <nn.nn>

6

1.6.2 PROGRAM OUTPUT CURRENT

The output current is programmed by sending the command:

SOURCE:CURRENT:AMPLITUDE <nn.nn> or “CURR” <nn.nn>

where <nn.nn> is any valid current with or without decimal places. There must be a

space before the number.

The power supply output will not reach the programmed current until a program voltage

command is also sent. To get the sharpest transition from zero to programmed output,

disable the output (Section 1.6.3), program voltage and current, then enable the output.

If the <nn.nn>is more than the supply output or less than zero, the command will be ignored and the Command Error bit of the Standard Event Status Register will be set. If

the current is higher than the limit set by the SOURCE:CURRENT:LIMIT value, the

command will be ignored and the Execution Error bit of the Standard Event Status Register will be set.

To read what current the supply was programmed to, regardless of the actual output current, send query SOUR:CURR:AMPL? and read the response message.

The short form of “program current” is: PC <nn.nn>

1.6.3 DISABLE THE SUPPLY OUTPUT

Document: 83-468-007 Rev B

Page 10

The power supply output can be shut off by sending this command:

SOURCE:VOLTAGE:OUTPUT OFF or VOLT:OUT OFF

This command will not disconnect the supply output. It is equivalent to programming the

output to zero volts.

To read if the supply output is disabled, send query VOLT:OUTP?. A “0” (zero) will be

returned if the output is disabled.

The short form for “supply off” is: SF

1.6.4 ENABLE THE SUPPLY OUTPUT

After the supply output has been shut off with the SOUR:VOLT:OUTP OFF command,

the output can be turned back on by sending this command:

SOURCE:VOLTAGE:OUTPUT ON or VOLT:OUTP ON

The output will immediately jump to the last programmed voltage and current.

To read if the supply output is enabled, send query VOLT:OUTP?. A “1” (one) will be returned if the output is enabled.

The short form for “supply on” is: SN

1.6.5 READ PROGRAMMING MODE

7

The power supply may be programmed in two modes. In Local Mode, the front panel

knobs or back panel analog connections set the supply output. In Remote Mode, the

IEEE/RS232 interface sets the output. The mode is indicated by the front panel

REMOTE LED (if it is installed). The mode may be read by sending this query:

SYSTEM:PROGMODE? or SYST:PROG?

The response will be one of three choices: LOCAL, REMOTE, OR FORCED_LOCAL.

Since sending a query takes the supply out of Local Mode, that response will not be received. The Forced Local Mode is set by the first rocker on the IEEE address switch

(see Figure 1).

The short form for this command is: MH?

Document: 83-468-007 Rev B

Page 11

1.7 MEASURING VOLTAGE AND CURRENT

1.7.1 MEASURE VOLTAGE

The output voltage can be measured by sending the command:

MEASURE:VOLTAGE? or MEAS:VOLT?

When the controller does the next IEEE Read, the supply will send the measured voltage to it. The measurement is always given to six decimal places even if the measurement is not so accurate. See the Specifications Section in the power supply User Manual

for actual measurement accuracy. If the back panel analog connector is wired for Remote Voltage Sensing, the measured value will be the voltage at the sense lines, not the

voltage at the supply output.

The short form for “measure voltage” is MV?

1.7.2 MEASURE CURRENT

The output current can be measured by sending the SCPI command:

MEASURE:CURRENT? or MEAS:CURR?

When the controller does the next IEEE Read, the supply will return the amperes of current being produced. The measurement is always given to six decimal places even if the

measurement is not so accurate. See the Specifications Section in the power supply

User Manual for actual measurement accuracy.

The short form for “measure current” is: MC?

Measure Output

8

1.7.3 SET MEASUREMENT FILTERING

The output voltage or current may be queried with MEAS:VOLT? or MEAS:CURR?. Because of noise, the measurements may have unacceptable random variations. Therefore, a routine is implemented so the board makes measurements every 16 milliseconds

and keeps a running average of the output.

The number of samples in the running average may be adjusted. A higher number will

“smooth” constant output readings but it will slow down the reported response to actual

changes in output.

The voltage measurement averaging is set by the command:

AFV nnn

Where nnn is a number between 1 and 250. The default is 20.

The current measurement averaging is set by the command:

AFC nnn

Where nnn is a number between 1 and 250. The default is 20.

Changing the averaging value will not slow down the bus speed or slow down the response time to an over-voltage and over-current shutdown.

Any changes in AFV or AFC may be made the power-up default by sending the *SAV 0

command.

Document: 83-468-007 Rev B

Page 12

1.8 LIMITS AND PROTECTIONS

1.8.1 SET VOLTAGE LIMIT

The maximum voltage that may be programmed to the power supply is set by the following command. It does not monitor the actual output voltage. It only inspects the numeric

value in a voltage programming command.:

SOURCE:VOLTAGE:LIMIT <nn.nn> or VOLT:LIM <nn.nn>

where <nn.nn> is a number between zero and the maximum supply output voltage. The

decimal is optional.. A space is required before the number.

By default, the voltage limit equals the power supply maximum voltage. A new voltage

limit will remain in effect until the supply power is switched off. A new voltage limit can be

made to be the power-up default by following VOLT:LIM with the *SAV 0 command.

See Section 1.9.6 for a description of the *SAV 0 command.

If a command is sent to set the supply to a voltage higher than the voltage limit, the

command will be ignored and the Execution Error bit of the Standard Event Status Register will be set.

To read what voltage limit has been set, send query VOLT:LIM? and read the response

message.

The short form for “set voltage limit” is: SVL <nn.nn>

Limit Output

9

1.8.2 SET CURRENT LIMIT

The maximum current that may be programmed to the power supply is set by the following command. It does not monitor the actual output current. It only inspects the numeric

value in a current programming command.

SOURCE:CURRENT:LIMIT <nn.nn> or CURR:LIM <nn.nn>

where <nn.nn> is a number between zero and the maximum supply output current in

amperes. The decimal is optional.. A space is required before the number.

By default, the current limit equals the power supply maximum current. A new current

limit will remain in effect until the supply power is switched off. A new current limit can be

made to be the power-up default by following CURR:LIM with the *SAV 0 command.

See Section 1.9.6 for a description of the *SAV 0 command.

If a command is sent which sets the supply to a current higher than the current limit, the

command will be ignored and the Execution Error bit of the Standard Event Status Register will be set.

To read what current limit has been set, send query CURR:LIM? and read the response

message.

The short form for “set current limit” is: SCL <nn.nn>

1.8.3 OVER-VOLTAGE PROTECTION

Lambda supplies feature two types of over-voltage protection that shuts down the output

if the output exceeds some settable voltage level. The analog method uses the OverVoltage Adjustment potentiometer on the front panel. The digital method uses the IEEE

board to constantly sample the supply output voltage. The analog pot setting always

takes priority over any digital programmed level. Therefore, for digital over-voltage protection, it is recommended the potentiometer be turned clockwise to maximum.

Document: 83-468-007 Rev B

Page 13

Using IEEE protection, the time between an over-voltage occurring and the supply shutting down is typically 20 milliseconds. This is the time for two successive readings to exceed the limit. The analog protection responds much faster. There is no analog overcurrent protection.

IEEE over-voltage protection is implemented with four commands:.

1.8.3.1 Set the over-voltage threshold:

SOURCE:VOLTAGE:LEVEL <nn.nn> or VOLT:LEV <nn.nn>

where <nn.nn> is a number between zero and the maximum supply output voltage. The

decimal is optional.The voltage may be more or less than the limit set by the

SOURCE:VOLTAGE:LIMIT command described in the previous paragraphs.

The set voltage level may be read by sending the query VOLT:LEV? and reading the response number.

The short form for “set voltage protection level” is: SVPL <nn.nn>

1.8.3.2 Enable the protection:

SOURCE:VOLTAGE:STATE ON or VOLT:STAT ON

The protection can be disabled by specifying OFF instead of ON.

The state of the protection may read by sending the query VOLT:STAT? and reading the

response. A “1” (one) means the protection is enabled..

The short form for “set voltage protection state” is: SVPS ON (or OFF)

Limit Output

10

1.8.3.3 Query for over-voltage shutdown:

SOURCE:VOLTAGE:TRIPPED? or VOLT:TRIP?

Read the response number. The normal response is “0” (zero). If a “1” (one) is returned,

it means an over-voltage has occurred and the output is shut down.

The response number is actually the value of the Operational Condition Register Bit 0.

Because an over-voltage can set bits in four IEEE registers, it is recommended that a

*CLS be sent to clear them after an over-voltage occurs. See the Section 0 on Status

and Error Register Programming for more details.

The short form for “set voltage protection tripped?” is: SVPT?

1.8.3.4 Reset after shutdown:

SOURCE:VOLTAGE:CLEAR or VOLT:CLE

After an over-voltage shut down has occurred, this command must be sent to clear the

error status before any new voltage commands will be accepted.

If and over-voltage is not cleared, and a new voltage command is sent, the command

will be ignored and the Command Error bit in the Standard Event Status Register will be

set.

The short form for “set voltage protection clear” is: SVPC

1.8.4 OVER-CURRENT PROTECTION

The IEEE Interface board constantly measures the power supply output current and the

board can be set to shut down the supply if the output current exceeds a settable level.

The time between an over-current occurring and the supply shutting down is typically

20 milliseconds.

Document: 83-468-007 Rev B

Page 14

Over-current protection is implemented with the following four commands:

1.8.4.1 Set the over-current threshold:

SOURCE:CURRENT:LEVEL <nn.nn> or CURR:LEV <nn.nn>

where <nn.nn> is a number between zero and the maximum supply output current. The

decimal is optional. The current may be more or less than the limit set by the

SOURCE:CURRENT:LIMIT command described in the previous paragraphs.

The set current level may be read by sending the query CURR:LEV? and reading the response number.

The short form for “set current protection level” is: SCPL <nn.nn>

1.8.4.2 Enable the protection:

SOURCE:CURRENT:STATE ON or CURR:STAT ON

The protection can be disabled by specifying OFF instead of ON.

The state of the protection may read by sending the query CURR:STAT? and reading

the response. A “1” (one) means the protection is enabled..

The short form for “set current protection state” is: SCPS ON (or OFF)

1.8.4.3 Query for over-current shutdown:

Limit Output

11

SOURCE:CURRENT:TRIPPED? or CURR:TRIP?

Read the response number. The normal response is “0” (zero). If a “1” (one) is returned,

it means an over-current has occurred and the output is shut down.

The response number is actually the value of the Operational Condition Register Bit 1.

Because an over-current can set bits in four IEEE registers, it is recommended that a

*CLS be sent to clear them after an over-current occurs. See Section 0 on Status and

Error Register Programming for more details.

The short form for “set current protection tripped?” is: SCPT?

1.8.4.4 Reset after shutdown:

SOURCE:CURRENT:CLEAR or CURR:CLE

After an over-current shut down has occurred, this command must be sent to reset the

error status before any new current commands will be accepted.

If and over-current is not reset, and a new current command is sent, the command will

be ignored and the Command Error bit in the Standard Event Status Register will be set.

The short form for “set current protection clear” is: SCPC

Document: 83-468-007 Rev B

Page 15

1.9 COMMON COMMANDS

1.9.1 READ DEVICE IDENTITY

The IEEE spec requires that every instrument be able to report its identify to the controller. The query is:

*IDN?

When the controller reads the output from the power supply, a single-line identity string

will be returned. A typical identity string format is:

LAMBDA, EMS <max volt>-<max curr>, S/N <supply serial>, REV <ieee brd rev>

1.9.2 GO TO LOCAL

This is not a command. It is a function whose syntax varies with the application being

executed in the controller computer.

When the first IEEE command is detected by the supply, it goes into remote mode. It’s

front panel voltage and current knobs cease to function. A “Go To Local” function may

be executed to temporarily return control to the front panel knobs. Queries such as

MEASURE:VOLTAGE? will put the supply back into remote mode.

In most applications, the “Go To Local” may be sent with or without a trailing address. If

no address is used, all devices on the bus will go to the local mode. If an address is

used, only the addressed device will go to the local mode.

The power supply may be returned from local to remote mode by either sending a programming command or by executing the Remote Enable function.

Common Commands

12

1.9.3 REMOTE ENABLE

This is not a command. It is a function whose syntax varies with the application being

executed in the controller computer.

This function will cause the controller to assert the Remote Enable (REN) line in the

IEEE cable. If the power supply was in local mode, it will go to remote mode when this

function is executed.

1.9.4 READ STATUS BYTE REGISTER

The Status Byte Register contains eight bits which are set to show that some other register has recorded an event or an error. This is the same register that is read by the Serial Poll function. See Section 1.10.4 (Serial Poll) for details.

*STB?

The response to this query will be a binary weighted number from 0 to 255. See description of Status Byte in Table 2 for the meaning of each of the bit positions.

Using the *STB? query is not recommended because it puts its response in the Output

Queue and it sets the Message Available bit in the Status Register. If a previous query

had already done these things, the IEEE bus will lock up until the controller generates a

Timeout Error.

Document: 83-468-007 Rev B

Page 16

1.9.5 RESET THE POWER SUPPLY

The supply will be reset to Local mode and all registers cleared to the power-up state by

sending:

*RST

1.9.6 CHANGING THE POWER-UP DEFAULTS

Many calibration, scaling, identity, and operational variables are stored in Electrically

Erasable Programmable Read-Only Memory (EEPROM). These values are the powerup default settings.

To change one or more default settings, enter the one or more commands with new settings and then enter this command:

*SAV 0

This will write any changed settings to the IEEE board EEPROM.

WARNING:

Common Commands

Error Registers

13

When a power supply is set to REMOTE mode, its output will jump

to the last voltage and current programmed before the last *SAV 0.

Therefore, it is recommended the commands “VOLT 0” and

“CURR 0” be sent immediately before *SAV 0 is sent.

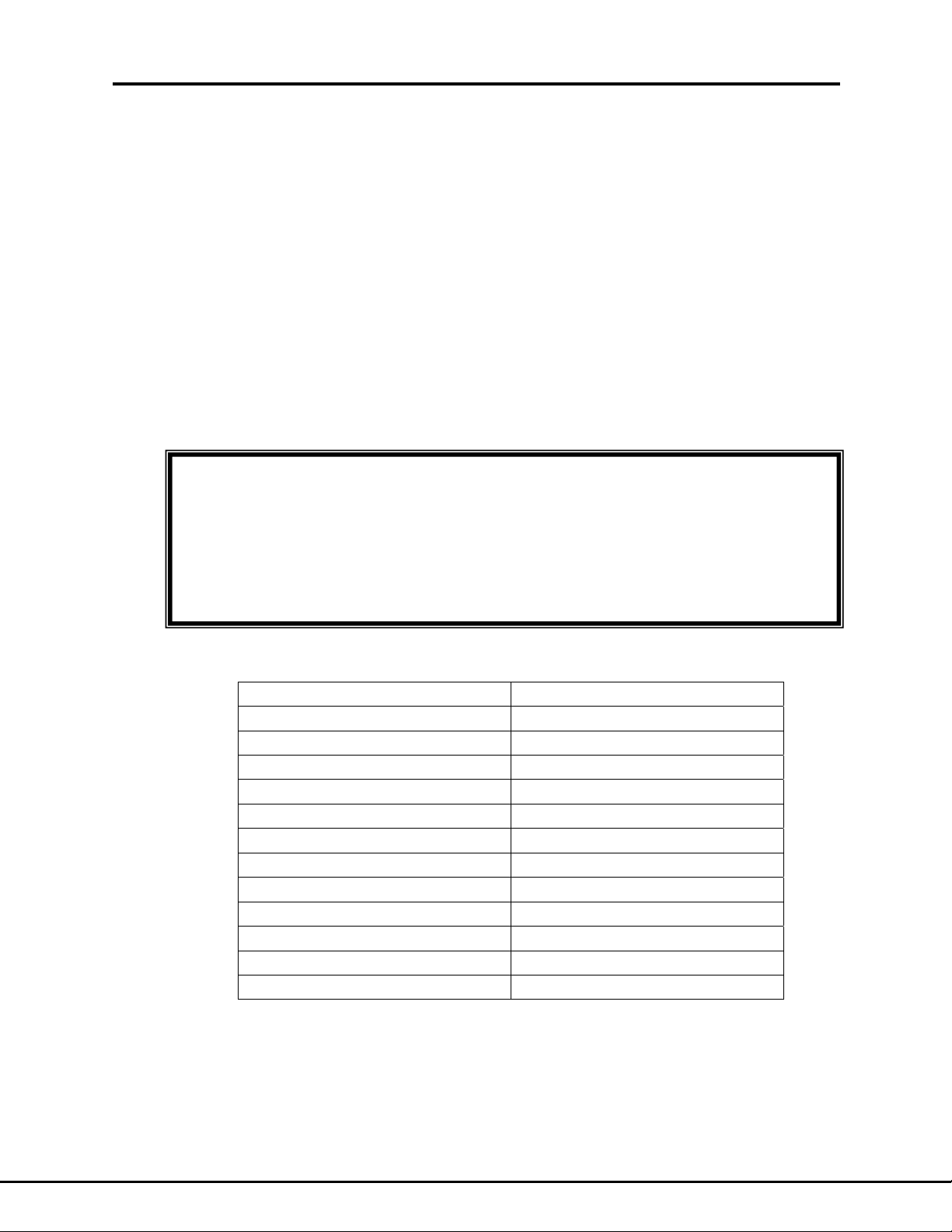

The following commands will load values that are stored by the *SAV 0 command:

CAL:IDN CAL:DATE

CAL:LOCK

AFV AFC

SOUR:VOLT:AMPLITUDE SOUR:CURR:AMPLITUDE

SOUR:VOLT:LIMIT SOUR:CURR:LIMIT

SOUR:VOLT:LEVEL SOUR:CURR:LEVEL

CAL:SOUR:VOLT:SLOPE CAL:SOUR:CURR:SLOPE

CAL:SOUR:VOLT:OFFSET CAL:SOUR:CURR:OFFSET

CAL:MEAS:VOLT:GAIN CAL:MEAS:CURR:GAIN

CAL:MEAS:VOLT:OFFSET CAL:MEAS:CURR:OFFSET

SYST:COMM:SERIAL:BAUD SYST:COMM:SERIAL:BITS

SYST:COMM:SERIAL:SBITS SYST:COMM:SERIAL:PARITY

ECHO (EN or EF)

Table 1. The *SAV 0 Command

1.10 USING ERROR AND STATUS REGISTERS

Document: 83-468-007 Rev B

Page 17

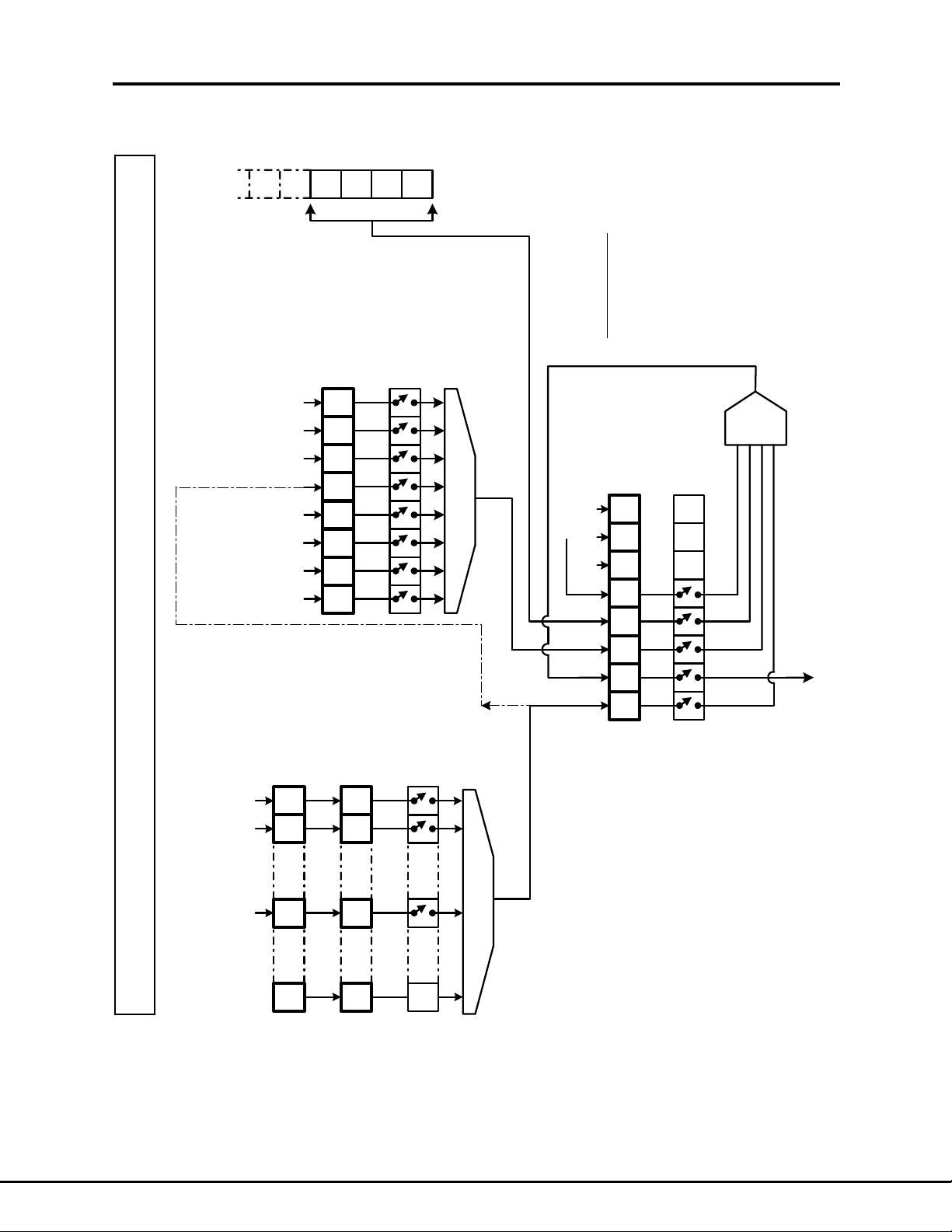

1.10.1 OVERVIEW: REGISTER FAN-OUT

The IEEE Interface board has a set of status and error registers. They are defined by the

IEEE-488.2 specification as part of the Common Command set required by all compliant

instruments.

These registers allow the IEEE controller to examine the operational state of the supply

in detail. A “fan-out” architecture is used so only one summary register needs to be read

to know if an event occurred in any other register. This fan-out allows automatic test

programs to efficiently manage the remote programming mode.

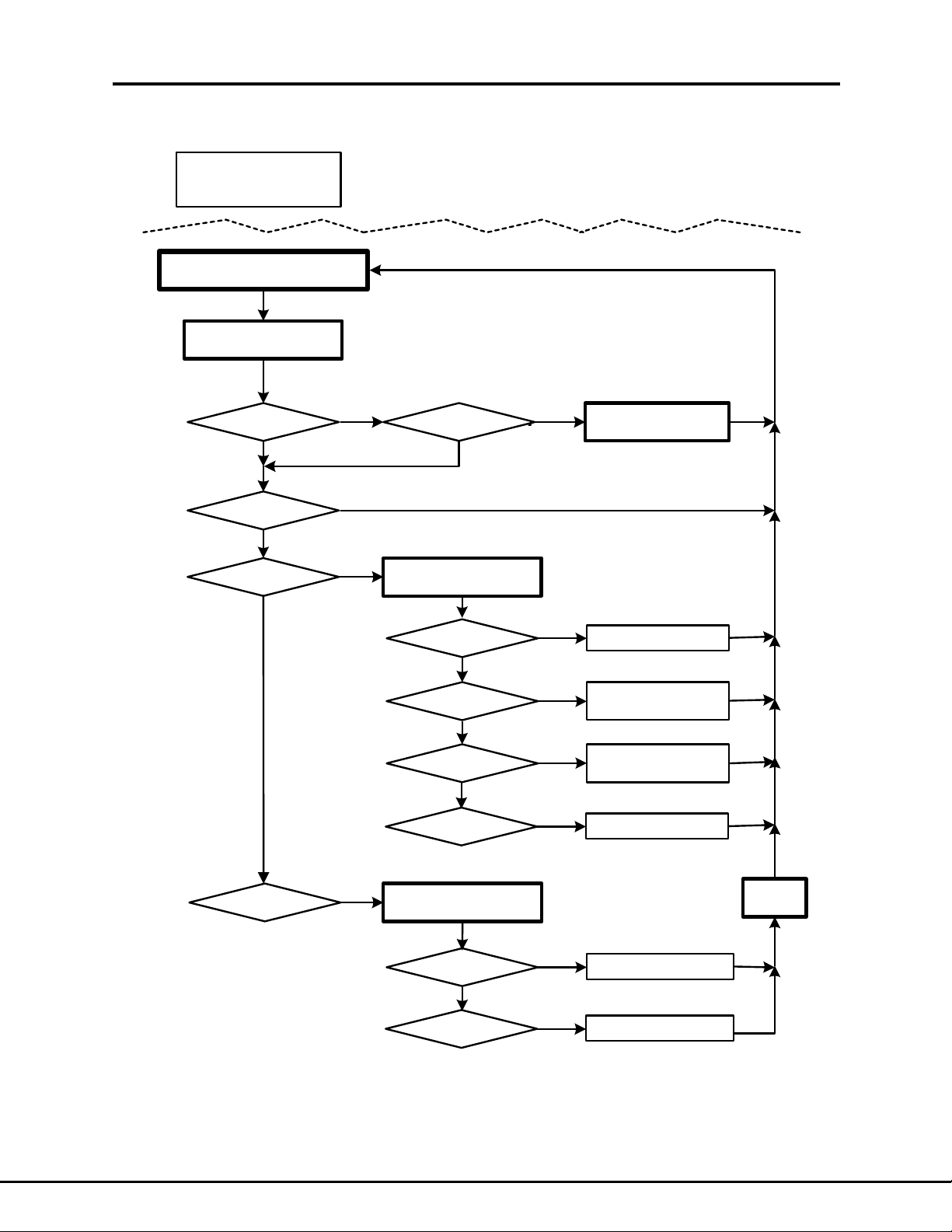

A diagram of the register structure is shown in Figure 2. This diagram does not show all

the registers in the IEEE-488.2 specification. It only shows the registers typically used in

the Lambda power supply. The algorithm for reading the register fan is part of a program

“device driver”. It is sketched in Figure 3.

1.10.2 GLOSSARY OF REGISTER TERMS

SERVICE REQUEST: When an instrument on the IEEE bus asserts the SRQ

line in the cable, it tells the controller that it has completed its task or that an

error has occurred.

SERIAL POLL: An IEEE function which reads back the data in an instrument’s

Status Byte Register. The controller should perform this function after every

command to verify the command was successful.

14

REGISTER QUERIES: Read the contents of registers. The contents are re-

turned as a binary weighted decimal number.

CONDITIONAL REGISTERS. These contain bits that are set when an event

or error occurs. The bits are only cleared when the event or error is cleared.

The contents may be read but not changed.

ENABLE REGISTERS: The various Enable Registers can be set to allow the

status and errors to be detectable by a Serial Poll.

EVENT REGISTERS: These contain bits that are set when an event or error

occurs. The bits are cleared when the contents of the register are queried.

Document: 83-468-007 Rev B

Page 18

Error Registers

15

Output

Queue

Operation Complete

Query Error

Device Depend Error

Execution Error

Command Error

Not Calibrated

Power-On

T

*ESR nn

Standard EVENT

Status Register

DDE OPC

URQ

PON CME EXE QUE

X

*ESR?

0123

567

T

E

Queue

Not

Empty

IEEE Comliance.

This diagram does

not exactly follow

the IEEE-488.2 example.

This diagram has been

modified for the example

of the Lambda EMI

power supply.

*ESE nn

*ESE?

Standard Event Status

ENABLE Register

Logical

OR

4

Logical OR

01234567

(not used)

Questionable Registers

QUE

Lambda IEEE Register Fan-Out

Over-Voltage

Over-Current

Remote

Operat. CONDITION

STAT:OPER:COND?

Register

OV

OC

RMO

Figure 2. Status and Error Register Diagram

STAT:OPER:EVEN nn

Operational EVENT

Register

0115 8

RMO OC OV

0

STAT:OPER:EVEN?

STAT:OPER:ENAB nn

Operational ENABLE

Register

0

STAT:OPER:ENAB?

OR

Logical

OPR RQS ESB MAV

Serial Poll

Status Byte Register

Service Request

Service Request Line

*SRE?

*SRE nn

ENABLE Register

Document: 83-468-007 Rev B

Page 19

Initialize Error Registers

Sample Error Handler

Error Registers

16

*SRE 240

*ESE 180

Routine Suitable for Automation Programming

OPER:STAT:ENAB 3

Send Command

SERIAL POLL

(read Status Byte)

(Last cmd end with "?")

QUERY?

Yes

Bit 4 (MAV)

Set?

NoNo

Yes

Read Output

Queue

Bit 6 (RQS)

Set?

Yes

Bit 5 (ESB)

Set?

No

Bit 7 (OPR)

Set?

No

Yes

Yes

*ESR?

Bit 2 (QUE)

Set?

No

Bit 4 (EXE)

Set?

No

Bit 5 (CME)

Set?

No

Bit 7 (PON)

Set?

STAT:OPER:EVEN?

Yes

Yes

Yes

Yes

Query Error Detected

Execution Error

Detected

Command Error

Detected

Power On Detected

*CLS

Figure 3. Status and Error Handler

Document: 83-468-007 Rev B

Bit 0 (OV)

Set?

No

Bit 1 (OC)

Set?

Yes

Yes

Over-Voltage Detected

Over-Current Detected

Page 20

1.10.3 CLEAR ALL STATUS REGISTERS

The contents of the status registers will be reset to zeroes by sending:

*CLS

This command will clear the Status Byte Register and the Event Registers. It will not affect the Conditional or the Enable registers. After an error, this command will also turn

off the red error LED on the interface board.

1.10.4 SERIAL POLL AND STATUS BYTE REGISTER

The Status Byte Register contains three bits that are set when a condition occurs in any

of three status registers. If any of these three bits are set, the Request Service (RQS) bit

can become set. The RQS bit is important because it will assert a signal onto the Service Request (SRQ) line in the IEEE cable. The controller program can detect the SRQ,

read what the problem is from the power supply, and clear the SRQ.

The bit assignments for the Status Byte Register are:

Error Registers Error Registers

17

BIT

NUMBER

0 1 Not Used

1 2 Not Used

2 4 Not Used

3 8 Not Used

4 16 MAV Message Available in Output Que.

5 32 ESB Status or error reported by

6 64 RQS Request For Service. Is set if any one of

7 128 OPR Over-volt or over-current error reported by

DECIMAL

VALUE

BIT

SYMBOL DESCRIPTION

Set after query message is received

Standard Event Status Register

MAV, ESB or OPR is enabled and set.

Operational Event Register

Table 2. The Status Byte Register

1.10.4.1 The Service Request Enable Register

The Status Byte Register may be set so if an event causes bits 4, 5 or 7 to go high then

the Service Request may or may not be asserted. The command to set the bits high in

the enable register is:

*SRE <nn>

where <nn> is a number between zero and 255. A space is required before the number.

The power-up default is all zeroes in the enable register. This means no status or errors

will be reported by the serial poll function.

Document: 83-468-007 Rev B

Page 21

Typically, the enable register will be initialized with *SRE 160 set bits 5 and 7. This will

enable a service request if an error occurs in the Standard Event Status Register or in

the Operational Event Register.

The contents of the Service Request Enable Register may be queried by sending:

*SRE?

The response will be a bit weighted number whose bits correspond to Table 2. Bit 6, the

Service Request bit, cannot be set. It is always zero.

1.10.5 STANDARD EVENT STATUS REGISTER

The Standard Event Status Register has eight bits that indicate status and errors for the

power supply and the interface. It is a very popular register. An error in this register will

illuminate the red error LED on the interface board. Resetting this register will turn off

the LED.

To read the contents of this register, use the common query:

*ESR?

The response message will be a binary weighted number from 0 to 255. Zero is returned

if there are no errors or events. The contents of the Standard Event Status Register will

be cleared to zeroes after the *ESR? Query is received.

Error Registers

18

The bit assignments for this register are:

BIT

NUMBER

0 1 OPC Operation complete. Not used.

1 2 Not used.

2 4 QUE Query Error. Set if illegal string ending with

3 8 DDE Device Dependant Error. Set if over-voltage or

4 16 EXE Execution Error. Typically set if programming

5 32 CME Command Error. Typically set if unrecognized

6 64 URQ User Request. Set at power-up if interface board

7 128 PON Power On. Set when power is switched on.

DECIMAL

VALUE

BIT

SYMBOL DESCRIPTION

a question mark is received.

over-current is enabled and detected.

command is outside of legal range.

command string was received.

has not been calibrated by manufacturer.

Table 3. The Standard Event Status Register

1.10.5.1 The Standard Event Enable Register

If the bits in the Standard Event Status Register are enabled, an error will propagate to

the Status Byte Register (see Section 1.10.4). If bit 5 in the Status Byte is enabled with

the *SRE 32 command, this error will cause the Service Request to be asserted. By

Document: 83-468-007 Rev B

Page 22

writing a binary weighted value to the Standard Event Enable Register, the bits in the

Standard Event Status Register may be individually enabled so only selected events will

cause a service request.

The syntax for writing to the Standard Event Enable Register is:

*ESE <nn>

where <nn> is a number between zero and 255. A space is required before the number.

The power-up default is all zeroes in the enable register. This means no status or errors

will be sent to the Status Byte Register. However, even if no bits are enabled, the contents of the Standard Event Status Register may always be read with the *ESR? query.

The contents of the Standard Event Enable Register may be read by sending:

*ESE?

The response will be a bit weighted number whose bits correspond to Table 3

1.10.6 THE OPERATIONAL REGISTERS

The Operational Registers are three 16-bit registers whose bits are not defined by the

IEEE specification but are specific to the IEEE device. In the power supply, bits 0 and 1

are set when an over-voltage or over-current event has occurred.

Digital over-voltage protection is enabled by sending the SOUR:VOLT:STAT ON command (see Section 1.8.3). If an over-voltage occurs, bit zero of the Operational Condition Register will be set high. If bit 0 of the Enable register is set high, the over-voltage

will set bit 0 of the Event register. This in turn sets bit 3 of the Standard Event Register to

illuminate the red ERROR LED. It also sets bit 3 in the Status Byte Register so the overvoltage error becomes detectable by a Serial Poll sent by the controller.

Digital over-current works in a similar manner, but it occupies bit 1 of the Operational

register.

The bit assignments for the Operational Registers are:

Error Registers

19

BIT

NUMBER

0 1 OV Set high if digital Over-Voltage detected.

1 2 OC Set high if digital Over-Current detected.

8 256 RMO Remote operation. Always set high.

DECIMAL

VALUE

BIT

SYMBOL DESCRIPTION

Table 4. The Operational Registers

1.10.6.1 The Operational Condition Register

Bits 0 and 1 of this register will contain zeroes unless over-voltage or over-current is

enabled and detected.

To read the contents of this register, use the common query:

Document: 83-468-007 Rev B

Page 23

STATUS:OPERATION:EVENT:CONDITION? or STAT:OPER:COND?

The response message will be a binary weighted number from 0 to 259. Since bit eight

is always set, 256 is returned if there are no errors.

Over-voltage bit 0 may also be read by using the query (see Section 1.8.3.3):

SOURCE:VOLTAGE:TRIPPED? or VOLT:TRIP?

After an over-voltage shutdown, the error may be cleared to zero by sending

SOURCE:VOLTAGE:CLEAR or VOLT:CLE

Over-current bit 1 may also be read by using the query (see Section 1.8.4.3):

SOURCE:CURRENT:TRIPPED? or CURR:TRIP?

After an over-current shutdown, the error may be cleared to zero by typing

SOURCE:CURRENT:CLEAR or CURR:CLE

1.10.6.2 The Operational Enable Register

An over-voltage or over-current can propagate to generate a Service Request signal that

will be detected by the controller performing a Serial Poll. The propagation is enabled by

sending the command:

STATUS:OPERATION:EVENT:ENABLE <nn> or STAT:OPER:ENAB <nn>

where <nn> is a number between 0 and 3. A space is required before the number. Although this is a 16-bit register, the most significant bit 15 is not used and trying to set it

high will cause a Command Error.

The power-up default is all zeroes in the enable register. This means no protection errors will be sent to the Status Byte Register. However, even if no bits are enabled, the

contents of the Operational Event Register may always be read with the

STAT:OPER:COND? query.

The contents of the Operational Enable Register may be queried by sending:

STATUS:OPERATION:EVENT:ENABLE? or STAT:OPER:ENAB?

The response will be a bit weighted number whose bits correspond to Table 4

20

1.10.6.3 The Operational Event Register

If over-voltage and over-current errors are reported by the Operational Condition Register, and they are enabled by the Operational Enable Register, the error will be loaded

into the Operational Event Register. The Event register differs from the Condition register because the Event register is cleared to all zeroes when its contents are read

whereas a bit set in the conditional register remains set until the condition is removed.

The contents of the Operational Event register is read by the command:

STATUS:OPERATION:EVENT? or STAT:OPER:EVEN?

Document: 83-468-007 Rev B

Page 24

The response message will be a binary weighted number from 0 to 3. Zero is returned if

there are no protection errors. The contents of the Operational Event Register will be

cleared to zeroes after the STAT:OPER:EVEN? is received.

1.10.7 THE QUESTIONABLE REGISTERS

These are a set of registers required by the IEEE-488.2 specification. They have a similar structure and command set as the Conditional Registers described in the previous

section. Since the Questionable Register is not used by Lambda supplies, it is not described here.

Error Registers

21

Document: 83-468-007 Rev B

Page 25

RS-232 Configuration

2 THE RS-232 INTERFACE

The optional IEEE interface board has a 9 pin “D” connector for the RS-232 serial port. It

uses only three wires to transmit data, receive data, and connect ground. The port is Full

Duplex where the power supply and the controller may both transmit messages at the

same time. Compared to the IEEE port, the RS-232 is slower and it has limited status

and error reporting. Also, there is no instrument addressing in the RS-232 port so only

one power supply can be run from each port in the controller. The advantages of RS-232

is the cable is easy to make and every personal computer comes standard with this

port.

2.1 CONFIGURING THE RS-232 INTERFACE

2.1.1 THE RS-232 CABLE

The power supply RS-232 port is configured as a “DCE” device. It has a 9-pin female

connector. A modem cable (not null-modem) is used to connect it to a personal computer. The cable may be up to 50 feet long. It has three wires: transmit data, receive

data and ground. The cable must be twisted and/or shielded. To reduce ground loops,

only one end of the shield should be connected to chassis (earth) ground. See Figure 4

for details of cable construction.

22

2.1.2 DEFAULT RS-232 CONFIGURATION.

The controller and the power supply must configured to the same signal timing and message control. The factory default settings are shown in Table 5 below. On the power

supply end, the default settings may be changed by using the commands in the following

section.

Parameter

Baud Rate 9600 Bits per Second

Data Bits 8 ASCII Characters

Parity None

Stop Bits 1

Flow Control None No Handshaking

Char. Echo On See “Echo” command

EOS LF (ASCII 10) End of String

Default Value

Table 5. Default RS-232 Configuration

Remember to verify the Forced Local switch is set down to OFF. The switch is rocker

number 1 on the IEEE Address selector shown in Figure 1.

Notes

Document: 83-468-007 Rev B

Page 26

RS-232 Configuration

23

Power

to 9-Pin PC

Supply

5

9

6

1

Ground

Data Flow

Data Flow

Shield

Pin to Pin

DCE

DB-9 Connector

Female Sockets

2 2

3 3

5 5

Power

to 25-Pin PC

Supply

NOTE: If a "25 to 9 Pin" adapter is used, it may reverse

pins 2 and 3. In this case, pins 2 and 3 in cable are straight.

5

9

6

1

DTE

DB-9 Connector

Male Pins

13

25

5

9

6

1

DCE

DB-9 Connector

Female Sockets

Figure 4. RS-232 Cable Construction

Ground

Data Flow

Data Flow

Shield

Pin to Pin

2 3

3 2

5 7

14

1

DTE

DB-25 Connector

Male Pins

Document: 83-468-007 Rev B

Page 27

2.2 RS-232 COMMAND SET

Most commands listed in the IEEE section of this document will also work with the RS232 interface. Some commands are applicable only to RS-232 programming and they

are listed here. The power supply will acknowledge every command by returning “OK”

followed by a linefeed character.

2.2.1 CHANGE CHARACTER ECHO

The serial port has a default power-up condition where any character received will be

sent back to the controller. This is the “Echo On” configuration and it is one method of

verifying message integrity. Echo on is typically used when the operator is sending

commands through a console terminal. The echo will typically be turned off when an

automatic computer program is the controller.

Echo On is set by sending the command:

EN

Echo Off is set by sending the command:

EF

The power supply echo may be set on or off, and the controlling terminal local echo may

be set on or off. The supply will respond correctly with any setting, but what the operator

sees will change with each setting. The combinations are shown in this table:

Controller

Local Echo OFF

Supply

Echo OFF

Supply

Echo ON

EOS = End-Of-String Terminator

EOS = LF Typed characters do

NOT appear on terminal

EOS =

CR-LF

Typed characters

appear on terminal

RS-232 Configuration

Controller

Local Echo ON

Typed characters

appear on terminal

Typed characters

appear TWICE on terminal

24

Table 6. RS-232 Echo Settings

Document: 83-468-007 Rev B

Page 28

2.2.2 GO TO LOCAL COMMAND

The power supply may be commanded into LOCAL mode where the front panel knobs

will set the output voltage and current. The command for “Set Local” is:

SL

After receiving the SL command, the supply will remain in LOCAL mode until the next

command or query is received. The SR command may also be used to set remote.

When a “Go To Local” command is sent, the supply output will

jump to whatever is set on the front panel knobs.

Therefore, it is recommended the front panel Voltage and Current

knobs be turned counter-clockwise to ZERO before REMOTE

programming.

RS-232 Configuration

WARNING:

25

2.2.3 CHANGE THE BAUD RATE

The serial port may be set to any speed specified by the RS-232 specification. The

speed, called the BAUD rate, is in bits per second. The actual message rate includes

the Bits per Byte, the Start Bit, the Stop Bits and the Parity Bit.

The default BAUD rate is 9600. The BAUD rate will be changed by sending command.

SYSTEM:COMM:SERIAL:BAUD <nnn> or SYST:COMM:SER:BAUD <nnn>

where <nnn> is one of these standard values:

110 1200 4800 19200

300 2400 9600 38400

This command will not take affect until a SYST:COMM:UP or a *SAV 0 is sent.

2.2.4 CHANGE THE DATA BITS

Each character sent over the RS-232 bus may use 7 or 8 data bits. The default ASCII

character set is eight bits. If a bit is taken for parity checking, only seven bits are allowed

for each character.

The number of data bits is set with the command:

SYSTEM:COMM:SERIAL:BITS <8 or 7> or SYST:COMM:SER:BITS <8 or 7>

This command will not take affect until a SYST:COMM:UP or a *SAV 0 is sent.

Document: 83-468-007 Rev B

Page 29

2.2.5 CHANGE THE PARITY BITS

Parity is error checking done by the interface hardware. If parity is enabled, the data

length may only be seven bits. Typically, parity checking is not needed so the default is

“None”.

The parity is set with the command::

SYSTEM:COMM:SERIAL:PARITY <Ptype>

or SYST:COMM:SER:PAR <Ptype>

where <Ptype> is ”NONE” or “ODD” or “EVEN”.

This command will not take affect until a SYST:COMM:UP or a *SAV 0 is sent.

2.2.6 CHANGE THE STOP BITS

1 or 2 stop bits may follow each character sent over the RS-232 bus. The default is 1.

The number of stop bits are set with the command::

SYSTEM:COMM:SERIAL:SBITS <1 or 2>

or SYST:COMM:SER:SBITS <1 or 2>

This command will not take affect until a SYST:COMM:UP or a *SAV 0 is sent.

RS-232 Configuration

26

Document: 83-468-007 Rev B

Page 30

2.3 ERROR REGISTERS AND RS-232

In the power-up default condition, the power supply acknowledges all commands by returning “OK”. The OK is returned even after an invalid command is sent.

The RS-232 in the supply may be set to asynchronously return a status value when an

invalid command is received. The value is the contents of the Status Byte Register. This

register is established by the IEEE-488 specification and it is described in detail in Section 1.10.4. Study that section to follow the example below.

The Status Byte Register must be enabled to report errors by sending these commands

over the RS-232 bus when the supply is first powered up:

*SRE 224 (Enable bits 5,6,7 in Status Byte)

*ESE 255 (Enable all bits in Std Event Status Reg)

STAT:OPER:ENAB 3 (Enable OV and OC protection report)

After this setup, any error condition will cause the power supply to send a Service Request Message (SRM). For example, if an illegal command is sent, the supply will respond by returning this message over the RS-232 line:

SRM 96

OK

The 96 equals 01100000 in binary. This indicates the Status Byte Register bits 5 (ESB)

and 6 (RQS) are set. To see why ESB is set, read the contents of the Standard Event

Status Register by sending this command:

*ESR?

RS-232 Error Registers

27

The response from the power supply will be “32”. This equals 00100000 in binary and it

means bit 5 (CME) of the Standard Event Status Register is set. This bit indicates a

Command Error occurred.

Reading these registers will clear the errors and reset the interface to report more errors.

NOTE:

If an “SRM” error is NOT cleared, no further errors will be reported.

Therefore, after an error message, send the command “*CLS” .

Document: 83-468-007 Rev B

Page 31

p

Calibrate: Volt Programming

3 ADJUST THE IEEE CALIBRATION

3.1 INTRODUCTION

It may be necessary to adjust the calibration of the digital programming and measurement circuit commands. The following instructions explain how to select new calibration

factors and save them into the interface nonvolatile memory.

NOTE:

These instructions are only good for slight adjustments to the

digital interface. The power supply must be in good operating

condition and it must have been previously calibrated by the

factory.

These instructions are NOT sufficient to setup a new IEEE

interface board into a

ower supply.

28

The following commands may be sent using a terminal connected to the IEEE-488 or the

RS-232 port. Only the short forms of the commands are shown. Commands are shown

inside double quotes. Do not type the quotes.

3.2 CALIBRATE THE VOLTAGE PROGRAMMING

Verify the load connected to the supply keeps it in voltage mode even when the voltage

is set to maximum. The load should not allow the current to exceed 90% of maximum

current. The load may be entirely disconnected from the output (open load), but for best

results use the load typical of your application.

Note: any change in calibration (“SVPG” or “SVPO” command) will not change the

supply output until a new program voltage “PV” command is sent.

3.2.1 ADJUST GAIN VALUE

Send commands:

“PV <Maximum supply voltage>”

“PC <Maximum supply current>”.

If it is not known, read voltage programming gain value by sending query:

“SVPG?” Save response message as <Old SVPG>

3.2.2 Measure supplies output voltage and calculate:

<New SVPG> = <Old SVPG> X <Maximum supply voltage>

<Voltage measured at output>

Send commands:

“SVPG <New SVPG>”

Document: 83-468-007 Rev B

Page 32

“PV <Maximum supply voltage>” .

Repeat this step until <Voltage measured at output> is within ±0.05% of the <Maximum

supply voltage>.

3.2.3 ADJUST OFFSET VALUE

Send commands to set supply to 10% of its maximum voltage:

“PV <Tenth of maximum supply voltage>”

“PC <Maximum supply current>”.

If it is not known, read voltage programming gain value by sending query:

“SVPO?” Save response message as <Old SVPO>

3.2.4 Measure supply output voltage. If it is higher than the target 10% of its maximum voltage then choose a lower value for the next SVPO factor. If the output is too low,

choose a higher SVPO. Picking the correct SVPO is a trial and error process. It is typically 0.001 and it must be between -0.3 and +0.5

Send commands:

“SVPO <New SVPO>”

Calibrate: Volt Programming

29

“PV <Maximum supply voltage>” .

Repeat this step until the measured output voltage is within ±0.05% of the expected 10%

of full output.

3.2.5 VERIFY VOLTAGE PROGRAMMING LINEARITY

Program the supply to various voltages between 10% and 100% of full output by sending

the command:

“PV <Program Volt>”

For each programmed voltage, measure the actual supply output. Verify the output error

is less than ±0.1% of the maximum voltage. If the measurement is out of tolerance, the

supply is NOT calibrated.

If the voltage programming is not calibrated, repeat procedure from step 3.2.1. to 3.2.4

3.2.6 SAVE CALIBRATION FACTORS

Enter commands:

“PV 0”

“PC 0”

“*SAV 0”

Document: 83-468-007 Rev B

Page 33

Calibrate: Volt Measurement

3.3 CALIBRATE THE VOLTAGE MEASUREMENT

Verify the load connected to the supply keeps it in voltage mode even when the voltage

is set to maximum. The load should not allow the current to exceed 90% of maximum

current. The load may be entirely disconnected from the output (open load), but for best

results use the load typical of your application.

3.3.1 ADJUST GAIN VALUE

Send commands to set supply to maximum voltage:

“PV <Maximum supply voltage>”

“PC <Maximum supply current>”.

If it is not known, read voltage measurement gain value by sending query:

“SVRG?” Save response message as <Old SVRG>

Use voltmeter to measure supply output voltage.

3.3.2 Use IEEE card to measure output voltage by sending:

“MV?” and record the response message

30

Calculate:

<New SVRG> = <Measured output voltage> X <Old SVRG>

<Response to MV?>

Send command:

“SVRG <New SVRG>”

Repeat this step until the response from the “MV? query is within ±0.05% of the measured output voltage.

3.3.3 ADJUST OFFSET VALUE

Send command to set supply to 10% of its maximum voltage:

“PV <Tenth of maximum supply voltage>”

“PC <Maximum supply current>”.

If it is not known, read existing voltage offset value by sending query:

“SVRO?” Save the response message as <Old SVRO>

3.3.4 Use IEEE card to measure output voltage by sending:

“MV?” Record the response message

Measure the supply output voltage. If the response to the MV? query is higher than this

measurement, you have to choose a lower value for SVRO. If the response message is

lower, choose a higher SVRO. Picking the correct SVRO is a trial and error process. It

is typically 0.001 and it must be between -0.1 and +0.1.

Send new calibration factor by sending command:

“SVRO <New SVRO>”

Repeat this step until the value returned from the “MV? query is within ±0.05% of the

measured output voltage.

Document: 83-468-007 Rev B

Page 34

g

3.3.5 VERIFY VOLTAGE MEASUREMENT LINEARITY

Program the supply to various voltages between 10% and 100% of full output by sending

the command:

“PV <Program Volt>”

For each programmed voltage, measure the actual supply output. Send “MV?” query

and record the response message. Verify the difference between the MV? response

and the actual output voltage is less than ±0.1% of the full output voltage.

If the error at any level is greater than ±0.1% of full output, then the voltage measurement on the IEEE card is NOT calibrated.

If the IEEE measurement is NOT calibrated, repeat procedure from step 3.3.1 to step

3.3.4

3.3.6 SAVE CALIBRATION FACTORS

Enter commands: (“0” is zero, not letter)

“PV 0”

“PC 0”

“*SAV 0”

Calibrate: Current Programmin

31

3.4 CALIBRATE THE CURRENT PROGRAMMING

Verify the load connected to the supply keeps it in current mode even when the current

is set to maximum. The load should not allow the voltage to exceed 90% of maximum

voltage. A cable may be connected across the output terminals (shorted load), but for

best results use the load typical of your application.

Throughout this section, references are made to <Actual output current>. Since we

cannot measure current directly, the <Actual output current> is found by connecting an

external shunt resister, measuring the shunt voltage and applying the formula:

<Actual output current> = <Meas’d shunt volt> X <Specified shunt current>

<Specified shunt voltage>

Note: any change in calibration (“SCPG” or “SCPO” command) will not change the supply output until a new program current “PC” command is sent.

3.4.1 ADJUST GAIN VALUE

Send commands:

“PV <Maximum supply voltage>”

“PC <Maximum supply current>”.

If it is not known, read the current programming gain by sending query:

“SCPG?” Save response message as <Old SCPG>

3.4.2 Measure supply output current and calculate:

<New SCPG> = <Old SCPG> X <Maximum supply current>

<Actual output current>

Document: 83-468-007 Rev B

Page 35

Send commands:

“SCPG <New SCPG>”

“PC <Maximum supply current>” .

Repeat this step until <Actual output current> is within ±0.05% of the <Maximum supply

current>.

3.4.3 ADJUST OFFSET VALUE

Send commands to set supply to 10% of its maximum current:

“PV <Maximum supply voltage>”

“PC <Tenth of maximum supply current>”

If not known, read existing current programming offset by sending query:

“SCPO?” Save response message as <Old SCPO>

3.4.4 Measure supply output current. If it is higher than the target 10% of its maximum current then choose a lower value for the next SCPO factor. If the output is too low,

choose a higher SCPO. Picking the correct SCPO is a trial and error process. It is typically 0.001 and it must be between -0.03 and +0.5

Calibrate: Current Programming Calibrate: Current Measurement

32

Send commands:

“SCPO <New SCPO>”

“PC <Tenth of maximum supply current>”

Repeat steps 3 and 4 until actual output current is within ±0.05% of the expected 10% of

full output.

3.4.5 VERIFY CURRENT PROGRAMMING LINEARITY

Program the supply to various voltages between 10% and 100% of full output by sending

the command:

“PV <Program Volt>”

For each programmed voltage, measure the actual supply output. Verify the output error

is less than ±0.1% of the maximum voltage. If the measurement is out of tolerance, the

supply is NOT calibrated.

If the voltage programming is not calibrated, repeat procedure Steps 3.4.1 to 3.4.4.

3.4.6 SAVE CALIBRATION FACTORS

Enter commands: (“0” is zero, not letter)

“PV 0”

“PC 0”

“*SAV 0”

3.5 CALIBRATE THE CURRENT MEASUREMENT

Verify the load connected to the supply keeps it in current mode even when the current

is set to maximum. The load should not allow the voltage to exceed 90% of maximum

Document: 83-468-007 Rev B

Page 36

voltage. A cable may be connected across the output terminals (shorted load), but for

best results use the load typical of your application.

Throughout this section, references are made to <Actual output current>. Since we

cannot measure current directly, the <Actual output current> is found by connecting a

series shunt resister, measuring the shunt voltage and applying the formula:

<Actual output current> = <Meas’d shunt volt> X <Specified shunt current>

<Specified shunt voltage>

3.5.1 ADJUST GAIN VALUE

Send commands to set supply to maximum current:

“PV <Maximum supply voltage>”

“PC <Maximum supply current>”.

If it is not known, read existing current measurement gain by sending query:

“SCRG?” Save response message as <Old SCRG>

3.5.2 Measure supply output current.

Calibrate: Current Measurement

33

Use IEEE card to measure output current by sending query:

“MC?” and record the response message

Calculate:

<New SCRG> = <Measured output current> X <Old SCRG>

<Response to MC?>

Send command:

“SCRG <New SCRG>”

Repeat this until the response from the “MC? query is within ±0.05% of the measured

output current.

3.5.3 ADJUST OFFSET VALUE

Send command to set supply to 10% of its maximum current:

“PV < Maximum supply voltage>”

“PC < Tenth of maximum supply current>”.

If it is not known, read existing current offset value by sending query:

“SCRO?” Save the response message as <Old SCRO>

3.5.4 Use IEEE card to measure output current by sending:

“MC?” Record response message

Measure the supply output current. If the response to the MC? query is higher than this

measurement, you have to choose a lower value for SCRO. If the response message is

lower, choose a higher SCRO. Picking the correct SCRO is a trial and error process. It

is typically 0.001 and it must be between -0.1 and +0.1.

Send new calibration factor by sending command:

Document: 83-468-007 Rev B

Page 37

“SCRO <New SCRO>”

Repeat this step until the value returned from the “MC? query is within ±0.05% of the

measured output current.

3.5.5 VERIFY CURRENT MEASUREMENT LINEARITY

Program the supply to various current between 10% and 100% of full output by sending

the command:

“PC <Program Current>”

For each programmed current, measure the actual supply output. Send “MC?” query

and record the response message. Verify the difference between the MC? response

and the actual output current is less than ±0.1% of the full output current.

If the error at any level is greater than ±0.1% of full output, then the current measurement on the IEEE card is NOT calibrated.

If the IEEE measurement is NOT calibrated, repeat procedure from Step 3.5.1 to Step

3.5.4

3.5.6 SAVE CALIBRATION FACTORS

Enter commands: (“0” is zero, not letter)

“PV 0”

34

“PC 0”

“*SAV 0”

Document: 83-468-007 Rev B

Page 38

Command List

4 SUMARY TABLE OF COMMANDS

This is summary of the IEEE and RS-232 command set.

In most cases, the long form (SCPI) and short form commands are both valid for either

IEEE or RS-232 programming.

When a command includes a value, that value can usually be read back by appending a

question mark to make the command into a query.

In the command format, small letters are optional and words in square brackets are optional. See example in Section 1.6.1

Command Name Description Command Format

SCPI Short Form

PROGRAMMING COMMANDS

Voltage Set power supply output voltage. [SOURce]

Value is 0 to 1000 :VOLTage

[:AMPLitude] PV

Voltage Prog Set maximum voltage program limit.

Limit Value is 0 to 1000 :LIMit SVL

Supply On Turn the Supply Output ON. :OUTPut ON SN

Supply Off Turn the Supply Output OFF. :OUTPut OFF SF

Current Set power supply output current. [SOURce]

Value =0 to 1000 [0] : CURRent

[:AMPLitude] PC

Current Prog Set maximum current program limit.

Limit Value = 0 to 1000 [100] :LIMit SCL

MEASUREMENT COMMANDS

35

Measure Measure the voltage present at MEASure

supply output :VOLTage? MV?

Measures the current present at :CURRent? MC?

supply output

Measure both voltage & current present at (none) MVC?

the output of supply (No IEEE cmd)

Filter Sets filter number for

voltage measurement, 1 to 250 [20] AFV

Sets filter number for

voltage measurement, 1 to 250 [20] AFC

Report Mode Report the program mode. SYSTem

Document: 83-468-007 Rev B

Page 39

Response is LOCAL, REMOTE, :PROGmode? MH?

or FORCED_LOCAL

Command List

PROTECTION COMMANDS

Set software overvoltage and overcurrent protection functions

Voltage Set Protection Level [SOURce]

Value = 0 to 1000 [1000] :VOLTage

:LEVel SVPL

Enable Protection ON | [Off] :STATe SVPS

Query the Protection Circuit state :TRIPped? SVPT?

Clear the tripped state :CLEar SVPC

Current Set Protection Level [SOURce]

Value = 0 to 1000 [1000] :CURRent

:LEVel SCPL

Enable Protection ON | [Off] :STATe SCPS

Query the Protection Circuit state :TRIPped? SCPT?

Clear the tripped state :CLEar SCPC

Report V-Prog Present program voltage MVP?

Report V-Limit Present voltage limit value. MVL?

Report 1-Prog Present current programming value. MCP?

Report I-Limit Present current limit value. MCL?

RS-232 SPECIFIC COMMANDS

Set Local Set Program Mode to Local. SL

Set Remote Set programming to Remote Mode. SR

Set Echo On Allows Controller to echo back EN

commands received plus OK CNTL-E

Set Echo Off Controller only returns OK EF

CNTL-F

Address Reads address switch setting EXTADR?

36

Document: 83-468-007 Rev B

Page 40

Following commands take affect

after a *SAV 0, *RCL 0, or an UPdate

Set BAUD Sets baud rate SYSTem

:COMM

50 to 38,400 [9600] :SERial

BAUD

Set Bits Set # of Data Bits, 7 or 8 [8] :BITS

Set Stop Bits Set # of Stop Bits, 1 or2 [1] :SBITS

Set Parity Sets parity, none, Odd or Even [none] :PARity

Update Updates UART with new settings :UPdate

Command List

STATUS COMMANDS (SCPI required Status Register Commands)

Operation Operational Registers STATus:OPERational

[:EVENt]?

:CONDition?

:ENABle

:PTRansition

:NTRansition

Questionable Questionable Registers STATus:QUEStionable

[:EVENt]?

:CONDition?

:ENABle

:PTRansition

:NTRansition

IEEE 488.2 COMMANDS

Clear Status *CLS

Service Request Enable (0 to 255) *SRE <value>

Service Request Enable Query *SRE?

Event Status Enable (0 to 255) *ESE <value>

Event Status Enable Query *ESE?

Event Status Register Query *ESR?

Identification Query *IDN?

Operation Complete Command *OPC

Operation Complete Query *OPC?

Recall Restores the power on setting. *RCL 0

37

Document: 83-468-007 Rev B

Page 41

Reset Restores its power-up state except *RST RS

that the state of IEEE-488 interface is

unchanged

Save Saves current SCPI configuration in flash *SAV 0

So it becomes the new power-on setting.

Read Status Byte *STB?

Self-Test Query Causes the controller to respond with *TST?

last self test status.

Wait-to-Continue *WAIt

Command List

CALIBRATE

Calibrate Establishes programming gain CALibrate

:SOURce

Slope range : VOLTage

Offset range :SLOPe SVPG

:OFFset SVPO

Slope range :CURRent