Page 1

CM4 App Note 260424 issue 2.1.docx Document No.260424 Page 1 of 29

CM4

AC/DC Modular Power Supply Series

APPLICATION NOTES

Page 2

CM4 App Note 260424 issue 2.1.docx Document No. 260424 Page 2 of 29

Contents

Contents 2

1. Theory of Operation 3

2. Input Module Operation 4

3. Input Module Protection 5

4. Efficiency Performance 6

5. Power Ratings 7

6. System Cooling 8

7. Signalling 11

8. Output Module Operation 13

9. Advanced Output Module Features 16

10. Series Connected Outputs 20

11. Parallel Connected Outputs 21

12. Mechanical Dimensions and Mounting 24

13. Connector details 25

14. EMC Compliance 26

15. Reliability 27

16. Output Modules 28

17. Accessories 29

Page 3

CM4 App Note 260424 issue 2.1.docx Document No. 260424 Page 3 of 29

1. Theory of Operation

The diagram below outlines the topology and major internal components of a fully assembled CM4 configurable power supply. Four output slots

are provided and can be populated by any combination of output modules. The remaining components in the block diagram are housed in the

input and transformer modules.

The input module is responsible for receiving the AC mains line voltage and converting it to an appropriate DC voltage whilst providing protection

from AC line disturbances and preventing excessive EMI emissions and current harmonics. The integrated EMI filter attenuates high frequency

current emissions to levels below EN55032 class B. It also provides dual pole fusing, one fuse in each conductor and protection from line

disturbances as outlined in EN61000.

Inrush current is controlled by a resistive element upon initial connection to the AC line. Once the internal capacitances have been charged, the

resistive element is bypassed to reduce losses.

Active Power Factor Correction (PFC) is used to ensure an accurate input current waveform with extremely low harmonic content, exceeding the

requirements of EN61000. This stage also provides active input current limiting which prevents overloading of the input stage while maintaining

high power factor.

The output of the PFC stage charges the hold-up electrolytic capacitors which store enough energy to allow the CM4 configured product to

continue operating during minor line disturbances. Long lifetime and high temperature capacitors are used which ensures extended lifetime and

product reliability.

A highly efficient zero voltage switching circuit is used to drive the isolated transformer from the hold-up capacitors. The output modules connect

to the transformer secondary and provide safe isolated power to a high performance synchronous rectifier power converter. This power converter

is controlled using the latest analog control technology to produce superior output performance in a miniature size.

Page 4

CM4 App Note 260424 issue 2.1.docx Document No. 260424 Page 4 of 29

2. Input Module Operation

Startup & Shut Down

The CM input module operates from a universal input voltage range and starts automatically upon application of adequate AC mains voltage

(>84Vrms). After a short delay, the global 5V bias supply starts and the ACOK signal goes high to indicate that the mains voltage is present and

input stage is operating correctly. Once the ACOK signal is high, the output modules turn on and deliver power to the application loads. The

power good signals will indicate that the output voltages are within specification. The diagram below shows the normal start up/shut down

sequence and gives typical timings.

Typical timing values: t

1

≤2000 ms, t2 ≤400 ms, t3 ≤600 ms, t4 ≥15 ms, t5 ≥5ms (minimum), t6 ≥100 ms

When the AC mains voltage is removed, the internal hold-up capacitors will supply power to the load for typically 20 ms (t4+t5) at maximum

power. The ACOK signal will go low at least 5 ms before the output voltages fall below the power good threshold level. This allows the application

to prepare for the impending loss of power. The 5V bias supply will remain on for typically 100 ms, after the output modules have turned off.

Standby control

The unit may be completely shut down by shorting (<10Ω) the terminals of J2. The unit will restart once the short is released.

The control uses transformer coupled pluses to detect the short and is fully isolated to 2xMOPP. The voltage present on J2 ranges from +3.3V to

-0.8V with a peak current of 15mA. In active mode, the control is pulsed every 1.3 ms while in standby mode the control is pulsed every 400 ms.

A signal MOSFET or switch may be used to activate this control. This shutdown will not generate the ACOK warning signal.

Programmable start-up state

The start-up and standby control logic can be inverted by shorting J11 with a jumper. The functionality is shown in the table below.

J11

J2

Operational mode

Comments

Open

Open

NORMAL

Default. Unit will start into NORMAL mode

Open

Closed

STANDBY

<1W power consumption

Closed

Open

STANDBY

Unit will start into STANDBY mode. <1W power consumption

Closed

Closed

NORMAL

J11 LOCATION

J2 LOCATION

- +

J11

J12

Page 5

CM4 App Note 260424 issue 2.1.docx Document No. 260424 Page 5 of 29

Note - J12 is reserved for internal use. Do not short J12

Hold-up

For short line distubances (<20 ms), the output voltages will not be affected*. However, the ACOK signal may still go low to warn that there is an

impending loss of output power. The ACOK signal will return to the high state once the unit has recovered from the disturbance.

*Output modules that are adjusted above the hold-up voltage (as detailed in Section 16), may experience a dip in voltage but never below the

hold-up voltage specified.

No Load Power/Standby Power Consumption

The no-load power consumption of the CM4 series power supply is extremely low when compared to similar configurable power supplies. With

the output modules enabled the unit typically only requires less than 15W with no output load. To reduce the no-load power further the outputs

can be disabled using the inhibit pins. With the outputs disabled the unit typically requires less than 10W. When the unit is in the standby (latched

off) state, the power consumption is less than 1W.

Peak Power capability

The input module can provide a peak output power of up to 750W for a period of up to 5 seconds, provided the input current remains below the

over current protection threshold. Peaks of power lower than 750W can be supported for longer times provided the excess watt-seconds are

equivalent. For example, 750W peak for 5 seconds is an excess power of 150W*5s = 750Ws. 650W can be supported for 750Ws/50W = 15s.

When using peak power capability, the user must ensure the average power remains within ratings. Note that input module de-ratings apply to

both rated power and peak power.

3. Input Module Protection

Over current protection (OCP)

The input module is protected from excessive input current by means of an over current protection circuit which limits the input current to

approximately 7Arms. If the OCP threshold is exceeded the unit may shut down and attempt to automatically restart. This shutdown will generate

the usual ACOK warning.

Under voltage protection (UVP) & Brown-Out Protection (BOP)

The input module is protected from excessively low input voltages by under voltage and brown out protection circuits that senses the input line

voltage. The under-voltage protection circuit maintains the unit in standby mode until the input voltage rises above the UVP threshold as detailed

in the datasheet. Once the unit is active, the brown out protection monitors the input voltage and shuts down the unit when input voltage goes

below approximately 60Vrms. This shutdown will generate the usual ACOK warning. The unit will restart once the input voltage increases above

the UVP threshold.

Over Temperature Protection (OTP)

The input module is protected from excessive temperatures by means of various internal temperature sensors. If temperature thresholds are

exceeded the entire unit may latch off, with no ACOK warning. To re-enable the unit, it must be allowed to cool, then either disconnect the AC

mains for approximately 20 seconds, or toggle the standby control on J2.

Over Power Protection (OPP)

The input module is protected from excessive power by means of an over power protection circuit. Should the rated power be exceeded the unit

will shut down and attempt to recover automatically. This shutdown will not generate the usual ACOK warning.

Page 6

CM4 App Note 260424 issue 2.1.docx Document No. 260424 Page 6 of 29

4. Efficiency Performance

The efficiency of the configured CM4 product is dependent on parameters such as input line voltage, load level and on the combination of output

modules. The plots below show typical efficiencies of a CM4 product fitted with all modules S1, S2, S3 or S4. The plots cover the full load and

line voltage range. All modules are adjusted to nominal voltages and are equally loaded.

An estimate of the overall efficiency for any configured system may be obtained from these graphs.

Page 7

CM4 App Note 260424 issue 2.1.docx Document No. 260424 Page 7 of 29

5. Power Ratings

CM4 series products must always be operated within stated operating limits. Equipment manufacturers and other users must take the appropriate

de-rating into account when specifying a unit for the intended application. If in doubt, contact TDK-Lambda for assistance.

There are three main de-ratings for the CM4 series of configurable power supplies when used in a conduction cooled application,

1. Ambient air temperature

(1)

Ambient air temperature de-ratings apply to the input

module rated and peak power only.

(3)

The input module must be de-rated by 2.5% per

degree Celsius above 50°C, up to a maximum of

70°C.

2. Baseplate temperature

(2)

Baseplate temperature de-ratings apply to output

module rated power, peak power and rated current,

and bias supply power.

The output module parameters must be de-rated by

2.5% per degree Celsius above 85°C, up to a

maximum of 105°C.

3. Input line voltage

Input line voltage de-ratings apply to the rated power

and peak power for both the input module and output

module.

(3)

All parameters must be de-rated by 2.5% for every 3

volts below 120Vrms, down to a minimum of 85Vrms.

Notes:

1. Ambient air temperature is the air temperature immediately surrounding the power supply.

2. Baseplate temperature is measured at baseplate temperature sensing location TS1 (see mechanical drawings for location.

3. A normalized value of 1 is equivalent to 100%.

4. Input line voltage de-ratings are cumulative with temperature de-ratings.

Examples of power ratings calculation for various input voltages, ambient temperatures and baseplate temperatures

1 2 3 4 5 6

7

VIN (V

RMS

)

120

85

85

120

120

100

120

Normalised VIN Rating [A]

1

0.708

0.708 1 1

0.833

1

T

AMBIENT

(⁰C)

70

50

70

50

60

60

50

Normalised T

AMBIENT

Rating [B]

0.5 1 0.5 1 0.75

0.75

1

T

BASE

(⁰C)

85

85

85

95

105

95

105

Normalised T

BASE

Rating [C]

1 1 1

0.75

0.5

0.75

0.5

Normalised Total input rating [A*B = D]

0.5

0.708

0.354 1 0.75

0.624

1

Normalised Total output rating [A*C = E]

1

0.708

0.708

0.75

0.5

0.624

0.5

Input module P

RATED/PEAK

[600W/750W*D]

300/375

424.8/531

212.4/265.5

600/750

450/562.5

374.4/468

600/750

Bias supply power [5W*C]

5 5 5

3.75

2.5

3.75

2.5

S1 P

RATED/PEAK

[125W/187.5W*E]

125/187.5

88.5/132.75

88.5/132.75

93.75/140.625

62.5/93.75

78/117

62.5/93.75

S1 I

RATED

[25A*C]

25

25

25

18.75

12.5

18.75

12.5

S2 P

RATED/PEAK

[150W/225W*E]

150/225

106.2/159.3

106.2/159.3

112.5/168.75

75/112.5

93.6/140.4

75/112.5

S2 I

RATED

[15A*C]

15

15

15

11.25

7.5

11.25

7.5

S3 P

RATED/PEAK

[150W/225W*E]

150/225

106.2/159.3

106.2/159.3

112.5/168.75

75/112.5

93.6/140.4

75/112.5

S3 I

RATED

[7.5A*C]

7.5

7.5

7.5

5.625

3.75

5.625

3.75

S4 P

RATED/PEAK

[150W/217.5W*E]

150/217.5

106.2/154

106.2/154

112.5/163.125

75/108.75

93.6/135.72

75/108.75

S4 I

RATED

[3.75A*C]

3.75

3.75

3.75

2.8125

1.875

2.8125

1.875

0.4

0.5

0.6

0.7

0.8

0.9

1

1.1

-40 -30 -20 -10 0 10 20 30 40 50 60 70

Normalised output power rating

Ambient Temperature (Celsius)

Ambient Temperature Derating

Derate at 2.5% per degree Celsius

above 50 degree Celsius

0.4

0.5

0.6

0.7

0.8

0.9

1

1.1

80 100 120 140 160 180 200 220 240 260 280

Normalised Output Power rating

Input Voltage (RMS)

Input Line voltage Derating

Derate at 2.5% per every

3 volts below 120Vrms

0.4

0.5

0.6

0.7

0.8

0.9

1

1.1

-40 -30 -20 -10 0 10 20 30 40 50 60 70 80 90 100 110

Normalised Power & Current Rating

Baseplate Temperature (Celsius)

Temperature Derating

Derate at 2.5% per degree Celsius

above 85 degree Celsius

Page 8

CM4 App Note 260424 issue 2.1.docx Document No. 260424 Page 8 of 29

6. System Cooling

The power ratings shown in the previous section are for conduction cooling, however the unit may be operated with forced air cooling, convection

cooling or combinations of all three. To assist in specifying the product for these applications, the typical thermal performance has been

characterised under controlled conditions. The ratings achieved are based on maintaining the baseplate temperature within the conduction

cooled ratings specified in section 5.

CONVECTION PERFORMANCE

Natural Convection, No Heatsink, Free Air, Mounting Orientations A/B/C/D/E/F

CONVECTION PERFORMANCE WITH HEATSINK

(1)

Natural Convection, With Heatsink, Free Air, Mounting Orientations A/B/C/D/E/F

Orientation definitions

A B C D E

F

Orientation

definitions

Notes

1. Standard TDK-Lambda heatsinks type 1 and type 2 used. Type 1 used for mounting orientations A, B, E and F. Type 2 used for mounting orientations A, B, C and D.

0

50

100

150

200

250

300

350

400

450

500

550

-40 -30 -20 -10 0 10 20 30 40 50 60 70 80

Pout

Ambient Temperature

S1 120Vin, 4x5Vout

A B CD EF

0

50

100

150

200

250

300

350

400

450

500

550

-40 -30 -20 -10 0 10 20 30 40 50 60 70 80

Pout

Ambient Temperature

S1 220Vin, 4x5Vout

A B CD EF

0

50

100

150

200

250

300

350

400

450

500

550

600

650

-40 -30 -20 -10 0 10 20 30 40 50 60 70 80

Pout

Ambient Temperature

S2/S3/S4 120Vin, 4x10/20/40Vout

A B CD EF

0

50

100

150

200

250

300

350

400

450

500

550

600

650

-40 -30 -20 -10 0 10 20 30 40 50 60 70 80

Pout

Ambient Temperature

S2/S3/S4 220Vin, 4x10/20/40Vout

A B CD EF

0

50

100

150

200

250

300

350

400

450

500

550

-40 -30 -20 -10 0 10 20 30 40 50 60 70 80

Pout

Ambient Temperature

S1 120Vin, 4x5Vout

A B CD EF

0

50

100

150

200

250

300

350

400

450

500

550

-40 -30 -20 -10 0 10 20 30 40 50 60 70 80

Pout

Ambient Temperature

S1 220Vin, 4x5Vout

A B CD EF

0

50

100

150

200

250

300

350

400

450

500

550

600

650

-40 -30 -20 -10 0 10 20 30 40 50 60 70 80

Pout

Ambient Temperature

S2/S3/S4 120Vin, 4x10/20/40Vout

A B CD EF

0

50

100

150

200

250

300

350

400

450

500

550

600

650

-40 -30 -20 -10 0 10 20 30 40 50 60 70 80

Pout

Ambient Temperature

S2/S3/S4 220Vin, 4x10/20/40Vout

A B CD EF

Page 9

CM4 App Note 260424 issue 2.1.docx Document No. 260424 Page 9 of 29

FORCED AIR PERFORMANCE

No Heatsink, Air Direction X or Y at 2m/s/1.5m/s/1m/s/0.5m/s

FORCED AIR PERFORMANCE WITH HEATSINK

(2)

With Heatsink, Air Direction X or Y at 2m/s/1.5m/s/1m/s/0.5m/s

Airflow definitions

X Y Z

Notes

1. Each 0.5m/s is approximately 100LFM. Eg. 2m/s ≈ 400LFM, 1.5m/s ≈ 300LFM etc.

2. Standard TDK-Lambda heatsinks type 1 and type 2 used. Type 1 used for airflow direction X. Type 2 used for airflow direction Y.

The ratings provided above are for guidance only and all CM4 configured solutions must be evaluated in the end application to ensure the

conditions set out in the power ratings section are met.

0

50

100

150

200

250

300

350

400

450

500

550

-40 -30 -20 -10 0 10 20 30 40 50 60 70 80

Pout

Ambient Temperature

S1 120Vin, 4x5Vout

2MS-1 1.5MS-1 1MS-1 0.5MS-1

0

50

100

150

200

250

300

350

400

450

500

550

-40 -30 -20 -10 0 10 20 30 40 50 60 70 80

Pout

Ambient Temperature

S1 220Vin, 4x5Vout

2MS-1 1.5MS-1 1MS-1 0.5MS-1

0

50

100

150

200

250

300

350

400

450

500

550

600

650

-40 -30 -20 -10 0 10 20 30 40 50 60 70 80

Pout

Ambient Temperature

S2/S3/S4 120Vin, 4x10/20/40Vout

2MS-1 1.5MS-1 1MS-1 0.5MS-1

0

50

100

150

200

250

300

350

400

450

500

550

600

650

-40 -30 -20 -10 0 10 20 30 40 50 60 70 80

Pout

Ambient Temperature

S2/S3/S4 220Vin, 4x10/20/40Vout

2MS-1 1.5MS-1 1MS-1 0.5MS-1

0

50

100

150

200

250

300

350

400

450

500

550

-40 -30 -20 -10 0 10 20 30 40 50 60 70 80

Pout

Ambient Temperature

S1 120Vin, 4x5Vout

2MS-1 1.5MS-1 1MS-1 0.5MS-1

0

50

100

150

200

250

300

350

400

450

500

550

-40 -30 -20 -10 0 10 20 30 40 50 60 70 80

Pout

Ambient Temperature

S1 220Vin, 4x5Vout

2MS-1 1.5MS-1 1MS-1 0.5MS-1

0

50

100

150

200

250

300

350

400

450

500

550

600

650

-40 -30 -20 -10 0 10 20 30 40 50 60 70 80

Pout

Ambient Temperature

S2/S3/S4 120Vin, 4x10/20/40Vout

2MS-1 1.5MS-1 1MS-1 0.5MS-1

0

50

100

150

200

250

300

350

400

450

500

550

600

650

-40 -30 -20 -10 0 10 20 30 40 50 60 70 80

Pout

Ambient Temperature

S2/S3/S4 220Vin, 4x10/20/40Vout

2MS-1 1.5MS-1 1MS-1 0.5MS-1

Page 10

CM4 App Note 260424 issue 2.1.docx Document No. 260424 Page 10 of 29

Specifying the CM4 product for convection or forced air cooling

To specify a CM4 series product for an end application, the required output power, minimum input line voltage, maximum ambient, mounting

orientation and air flow rate (if applicable) should be determined. Check the requirements against the closest characteristic plot from the tables

above to ensure ratings can be achieved. Be conservative when specifying the product as convection and forced air cooling can be highly

dependent on the end application enclosure and power supply mounting. The estimated performance must be verified in the end application and

temperatures may exceed predicted levels. It is also important to note that ambient temperature refers to the ambient temperature immediately

surrounding the PSU. If the PSU is mounted within an enclosure the enclosure ambient temperature is likely to be higher than the external air

ambient temperature.

Evaluating the CM4 product in the end application

To ensure the product is operating within its ratings in the end application the following procedure should be performed during the design stage.

1. Install a thermocouple in position TS1 of the product. (See Section 12 - Mechanical dimensions and mounting for details.) The

thermocouple wire should exit on the top side between slots 2 and 3. The bottom side should be flush for heatsink mounting if

necessary. Glue should be used to hold the thermocouple in place.

2. Setup the application in worst case conditions, considering Input line voltage, Output power, ambient temperature, airflow and cooling

restrictions.

3. Power the system and monitor the baseplate temperature until it reaches steady state.

4. Ensure that under worst case conditions, the baseplate temperature cannot exceed the rated temperature as outlined in the power

ratings section of this manual.

If a cover is placed over the primary components, then the following component temperatures must also be measured to ensure they are below

the maximum specified temperatures.

Description

Reference

Maximum allowed

temperature

Drawing

Fuse

FS1, FS2

125°C

Electrolytic

capacitors

C12

105°C*

Inductors

L1, L2, L3,

L5

130°C

Other capacitors

C1, C4

110°C

* For a 3 year life with 24/7 operation, the case temperature of C12 should not exceed 88C.

If excessive temperatures are measured during this evaluation, then one or more of the following remedies may improve thermal performance.

Increase heatsink size

Increase airflow rate

Improve air intake & outlet

Reduce power requirement

Using the internal temperature sensor to control external application cooling

An internal temperature sensor T

SNS

is available on J3 pin 9 (See Internal Temperature sensor section below for details). The output voltage of

this sensor gives a measurement of the internal transformer temperature and can be used to control external cooling systems or to provide a

warning of impending over temperature protection.

The internal temperature (T

SNS

) should never exceed 120⁰C (2.74V), however, system reliability will be maximised if the PSU temperature is

maintained as low as possible in any given application.

Page 11

CM4 App Note 260424 issue 2.1.docx Document No. 260424 Page 11 of 29

7. Signalling

Global Signals

To reduce cabling in the end system, all major input and output signals and the global 5V bias supply are wired to a single signals circuit that is

accessed through connector J3 on the transformer module as shown in the diagram below.

J3 – Global Signals

Pin

Name

Description

1

PG4

Slot 4 Power Good

2

INH4

Slot 4 Inhibit

3

PG3

Slot 3 Power Good

4

INH3

Slot 3 Inhibit

5

PG2

Slot 2 Power Good

6

INH2

Slot 2 Inhibit

7

PG1

Slot 1 Power Good

8

INH1

Slot 1 Inhibit

9

T

SNS

Temperature sense

10

ACOK

AC mains signal

11

+5V

5V Bias supply

12

COM

Common

All the signals are referenced to the bias supply common rail (COM) and external control and/or monitoring circuits can be easily powered and

interfaced to the PSU through this connector. The entire signals circuit is fully medically isolated and can be considered a SELV output. The table

below lists the isolation voltages.

Signals isolation voltages

Signals to Input

4000

VAC

Signals to Chassis

500

VDC

Signals to Output

500

VDC

Bias Supply (+5V [Power])

The CM4 series has one isolated bias supply located on the transformer module (J3) beside slot 4. The output side bias supply generates 5V and

is rated up to 1A. The supply is available whenever the AC mains voltage is connected and the input module is operating correctly. A shutdown

through the standby control on J2 or any of the following abnormal conditions will disable the 5V bias supply:

Over temperature of any part of the unit

Over voltage on any output module

Internal over current (device failure)

AC Mains Signal (ACOK [Output])

An ACOK signal is provided to indicate to the user that the AC mains voltage is applied and the input module is operating correctly. The output

signal is driven from an internal operational amplifier. Under normal operating conditions this signal gives a warning of 5 ms before the output

voltage falls below the power good threshold. A shutdown through the standby control on J2 or any of the following abnormal conditions may

cause the unit to turn off without the minimum 5 ms ACOK warning:

Over temperature of any part of the unit

Over voltage on any output module

Internal over current (device failure)

1 2 11

12

Page 12

CM4 App Note 260424 issue 2.1.docx Document No. 260424 Page 12 of 29

Power Good Signals (PG1-PG4 [Output])

Each output module provides a power good (PG) signal to indicate when the output

voltage is above approximately 90% of the pre-set voltage for that module. Each

PG signal on an output module is internally connected through an opto-isolator to

the signals circuit, which provides and open collector output, as shown.

The LED on the front of each module gives a visual confirmation of the PG status.

Note that remote adjustments of the output voltage using the V

CONTROL

and I

CONTROL

pins do not change the PG signal threshold. The PG threshold is always

approximately 90% of the voltage set with the manual potentiometer.

Output Inhibits (INH1-INH4 [Input])

The signals circuit provides an inhibit input to disable each output module individually. Each inhibit input is internally connected through an optoisolator to the respective output modules. The basic internal electrical circuit and timing diagrams are shown below.

Internal circuit

Timing: Typically, t

OFF

= 100 μs and tON = 8 ms.

Internal Temperature sensor (T

SNS

[Output])

An internal temperature sensor is embedded in the transformer module. The output voltage of this sensor gives a measurement of the internal

transformer temperature and can be used to control external cooling systems or to provide a warning of impending over temperature protection.

The sensor output voltage is related to temperature as follows,

V = 0.4 + 0.0195*T

The sensor will accurately measure temperatures in the range -10⁰C to

+125⁰C.

The internal temperature should never exceed 120⁰C (2.74V)

-20

0

20

40

60

80

100

120

0 0.5 1 1.5 2 2.5

T

SNS

output voltage Vs Internal Temperature

Page 13

CM4 App Note 260424 issue 2.1.docx Document No. 260424 Page 13 of 29

8. Output Module Operation

Power Profile

The power profile diagram below is a voltage/current plot that together with the associated table provides details of the main features of the

currently available output modules.

Output Voltage Adjustment

Each output can be adjusted within the range as described in Section 16 or in the datasheet. Voltage adjustment can be achieved by two

methods;

1. Manual potentiometer adjustment

Using the manual adjust potentiometer (located beside the “Power Good” indicator on the top of each output module), the preset output voltage

(V

SET

) of each output module is adjustable over the entire range of V

MIN

to V

MAX

as specified in the power profile table above. A clockwise rotation

of the potentiometer results in an increase of the output voltage while an anti-clockwise rotation results in a decrease of the output voltage.

2. Remote Voltage Programming

Using remote voltage programming, the output voltage may be adjusted beyond the V

MIN

and V

MAX

range specified in the power profile table

above. However, certain precautions must be taken to ensure correct operation. Please see the “Advanced output module features” section for

more details.

Over Voltage Protection (OVP)

In the event of an output module fault, the modules are protected against excessive output voltages. This is implemented as a fixed voltage

threshold V

OVP

, in the table above. If the output voltage exceeds this threshold, all outputs will be disabled temporarily. If the fault persists after 20

ms the entire unit will be latched off, otherwise the outputs will auto-recover. To resume operation of a latched unit, disconnect the AC input

voltage for 5 seconds or toggle the standby control on J2. Note that no warning is given on the AC_OK signal for faults of this type.

Over Current & Short Circuit Protection (OCP & SCP)

For increased safety and reliability all output modules in the CM series have over current and short circuit protection. The over current threshold

is typically set at 115% of the rated current and has a constant current, straight line characteristic that reduces the output voltage as the load

resistance decreases. If the output voltages falls below the short circuit voltage threshold (V

SCP

) the module enters short circuit protection mode.

In this mode the output module uses a hiccup scheme to reduce system losses and potential damage. When in this mode, the output will be

enabled for approximately 3% of the time, disabled for 97% and will attempt to restart at approximately 125 ms intervals. The module remains in

this state until the short circuit condition is removed, at which point normal operation resumes.

Page 14

CM4 App Note 260424 issue 2.1.docx Document No. 260424 Page 14 of 29

Reverse Current Protection (RCP)

The standard output modules use synchronous rectification in the output stages to achieve high efficiency and as a result the outputs can both

source and sink current. The sink current is internally limited to approximately -6% of the maximum rated current. However, in applications where

the output modules are connected to external power sources such as batteries or other power supplies certain precautions must be observed to

prevent damage to the unit.

The outputs should never be directly connected to to external power sources without some form of reverse current protection such as an external

diode or controlled mosfet. If protection is not used, large reverse currents which will ultimately result in damage to the unit will occur, especially

when the AC mains is disconnected.

Output Module Average and Peak Power

All modules have an average and peak power rating. The average power of each unit must at all times remain below it’s specified limit. However,

each output can deliver up to 150% of it’s average power rating for a maximum of 5 seconds at 50% duty cycle, subject to the current limit not

being exceeded and subject to the overall average power drawn being less than the specified average power rating (including any input derating

due to temperature or line voltage). The available peak power is a function of the output voltage and maximum current for each module. Full peak

power is only possible when the output voltage is adjusted to V

MAX

and the maximum current is drawn from the module. Note that both average

and peak power ratings are subject to the same temperature derating as the input module (derate by 2.5% per °C above 50°C), but are not

subject to any line derating.

Start-up & Shut Down

All outputs are designed to have a regulated monotonic start-up with a rise time of

approximately 3 ms as shown in the diagram right. The power good signal will not

assert until the voltage exceeds the power good threshold (≈90%).

Where multiple output modules are used, the default start up scheme is ratio-metric

with all outputs starting at the same time as shown in the diagram right. External

control circuits may be used to implement tracking or sequenced start up if

necessary.

The outputs are not designed to start into pre-biased loads and may discharge any

externally capacitance before beginning to ramp the output voltage up in the normal

way.

At shutdown, the outputs enter a high impedance state. Where no external load is

present it may take some time for the voltage to decay. When driving inductive loads,

care must be taken to limit the voltage at the output terminals to prevent damage to

the unit.

Synchronisation

All output modules in the same product are synchronised. The typical operating

frequency is 260 kHz and paralleled or series connected units will not produce ripple beat frequencies.

External capacitance

All outputs can support a large external capacitance as detailed in the table shown.

The capacitances specified ensure monotonic start-up with rated load applied.

Larger capacitances can be applied for lower load currents.

Module

C

EXT_MAX

S1

12mF

S2

4mF

S3

1mF

S4

500uF

Page 15

CM4 App Note 260424 issue 2.1.docx Document No. 260424 Page 15 of 29

Ripple and Noise

The ripple and noise figures stated in the datasheet are defined based on a standard measuring method. To obtain the same results the same

test setup must be used and care must be taken to eliminate any parasitic noise pickup. The diagram below shows details of the setup and

sources of noise pickup.

Over Temperature Protection (OTP)

Each output module is protected against excessive temperatures. In the event of an internal temperature exceeding safe levels the output

module will shut off. If the temperature reduces the output module will automatically recover. Should the temperature continue to rise a second

over temperature circuit will shut down the input module and all outputs. To resume operation of the unit, disconnect the AC input voltage for 20

seconds then reconnect. If all temperatures are within specifications the unit will restart. Note that no warning is given on the AC_OK signal for

faults of this type.

Transient Response

The CM output modules have been especially designed to have high reliability. To achieve this all electrolytic capacitors have been eliminated

from the design. As a result of this, high dynamic load transients can cause relatively high voltage deviations at the output and although the

outputs have a very high loop bandwidth with typical recovery times of less than 100μs, the voltage deviations may still be excessive for some

applications.

An example application is detailed in the diagram below and shows typical responses at the terminals of the output module and at the load.

Notice that the voltage deviation due to cable inductance exceeds the module response and hence a capacitor located at the module terminals

will have little effect at the load. The optimum solution is to locate a low impedance electrolytic capacitor at the load which will eliminate the

inductive cable drop and reduce the typical voltage deviation at the module.

Page 16

CM4 App Note 260424 issue 2.1.docx Document No. 260424 Page 16 of 29

9. Advanced Output Module Features

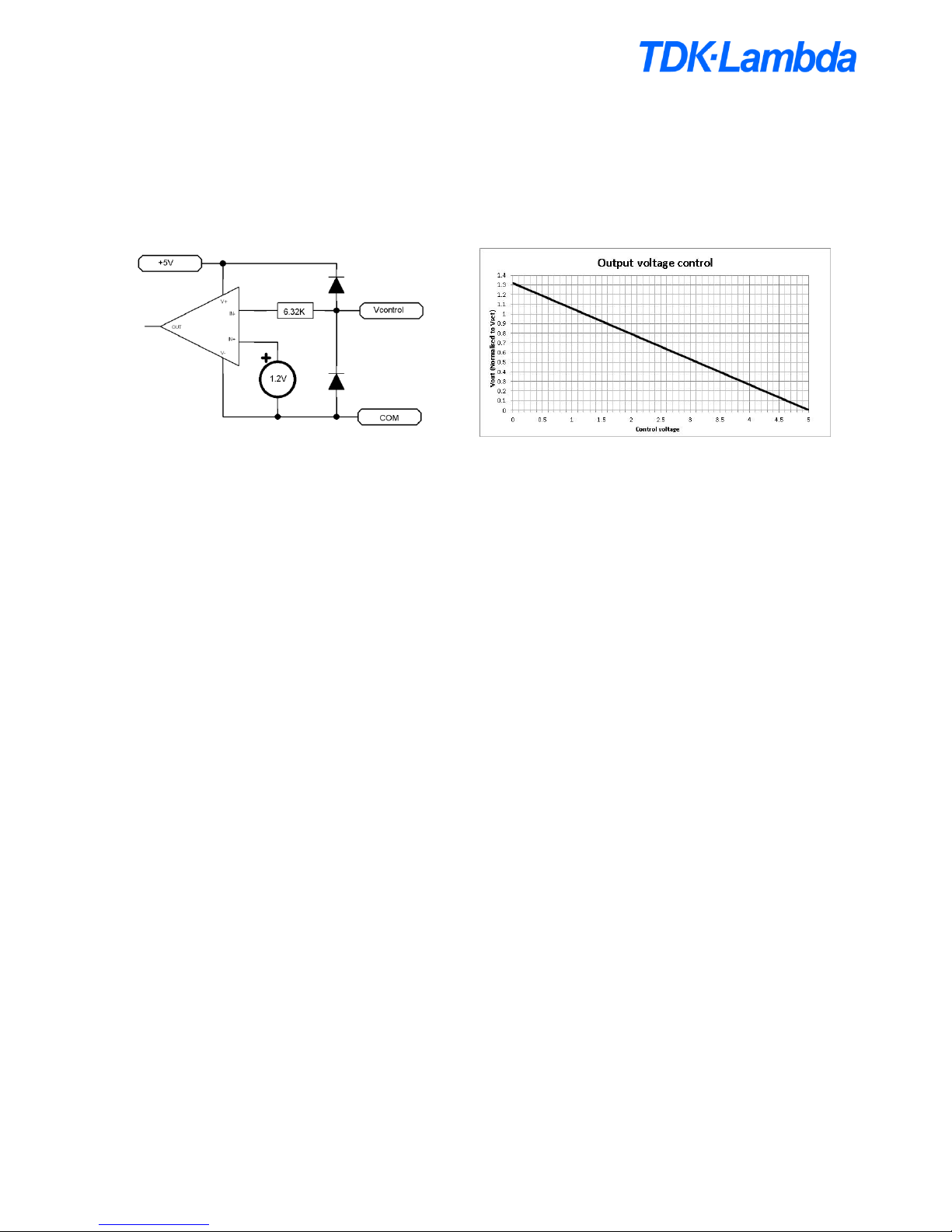

Remote Voltage Programming (External Voltage Control)

The output voltage of the module can be adjusted using an external voltage source connected between the COM and V

CONTROL

pins on the

signals connector J4 as shown below.

In this configuration the output voltage will follow the typical equation below,

VO = V

SET

((5-V

CONTROL

) / 3.8), where V

SET

is the manual preset voltage of the module.

Equivalent internal circuit

Control function

The output voltage can be controlled from 0% to 131.5% of the preset voltage using this control method. However, care must be taken to ensure

the output voltage does not exceeed the OVP level, as this will trigger OVP protection.

Remote adjustment of the output voltage using the V

CONTROL

pin does not affect the preset power good threshold. Hence, remotely adjusting the

output voltage below 0.9*Vset will cause the power good signal to go low.

Where tight voltage adjustment tolerances are required, it is recommended to use external circuitry to provide closed loop control of the V

CONTROL

pin.

Page 17

CM4 App Note 260424 issue 2.1.docx Document No. 260424 Page 17 of 29

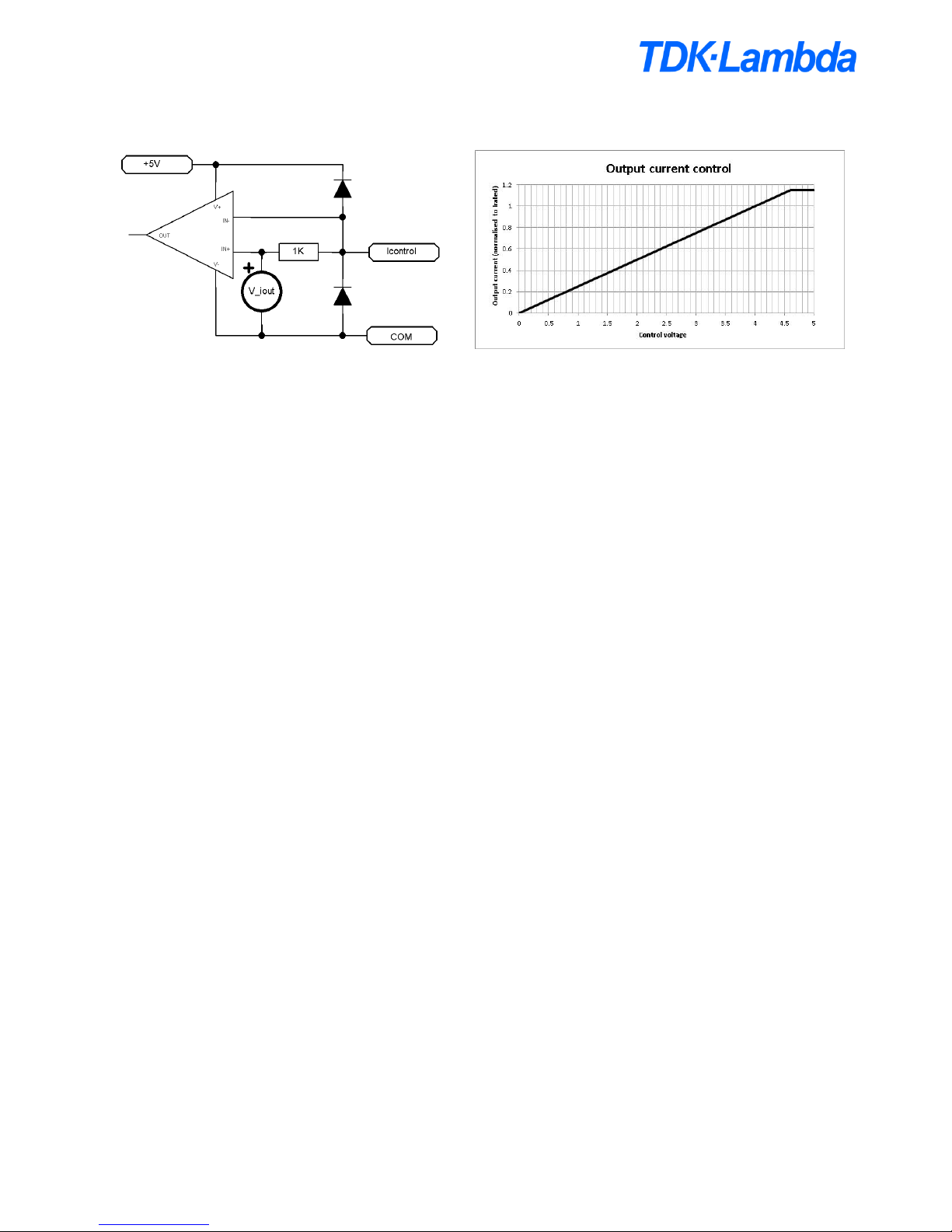

Remote Current Programming (External Voltage Control)

The output current limit of the module can be reduced using an external voltage source connected between the COM and I

CONTROL

pins on the

signals connector as shown below. In practice this also means that the output can be used as a modulated or constant current source.

Equivalent internal circuit

Control function

In the diagram above, Vi_out is an internal voltage source that is proportional to the internal inductor current and approximates the equation,

V

I_OUT

= 4*I

OUT/IRATED

, where Irated is the maximum rated current for the module.

In this configuration the output current limit will approximate the following equation,

I

LIMIT

= I

RATED*VCTRL

/4, where I

RATED

is the maximum rated current for the module.

It is not possible to increase the maximum current limit of the module, and control voltages exceeding 4.6V will have no effect on the current limit.

When using an output module as a modulated current source, the output voltage should be manually adjusted to the maximum that will be

required by the application and this will be the upper voltage limit. Once the load is connected, the output current can then be modulated by

applying a control voltage as described above.

Note that the power-good threshold level is fixed and defined by the manually preset voltage. Hence, while the output module is limiting or

modulating the output current the PG signal may go low.

Where tight current adjustment tolerances are required, it is recommended to use external circuitry to provide closed loop control of the I

CONTROL

pin.

Page 18

CM4 App Note 260424 issue 2.1.docx Document No. 260424 Page 18 of 29

Output Current Measurement

The output current of the module can be measured using the I

CONTROL

signal. If this pin is not loaded its output voltage will follow the typical

equation,

V

I_OUT

= 4*I

OUT/IRATED

, where I

RATED

is the maximum rated current for the module.

Note that the I

CONTROL

output voltage is representative of the internal inductor current not the actual load current. However, this will only have an

influence during dynamic events. It is recommended to add an external buffer amplifier (as shown below) when using the I

CONTROL

signal to

measure the output current as loading the I

CONTROL

signal, even with microamps can cause the current limit to be reduced. If it is required to

measure the output current and adjust the output current limit simultaneously, this can be achieved by using a clamp circuit instead of a voltage

source to adjust the current limit, while continuing to use an amplifier to measure the output current. An example circuit is shown below. In this

case V

CONTROL

will control the current limit while the buffered I

CONTROL

signal will provide a measurement of the output current.

Measuring output current

Measuring & controlling output current

Page 19

CM4 App Note 260424 issue 2.1.docx Document No. 260424 Page 19 of 29

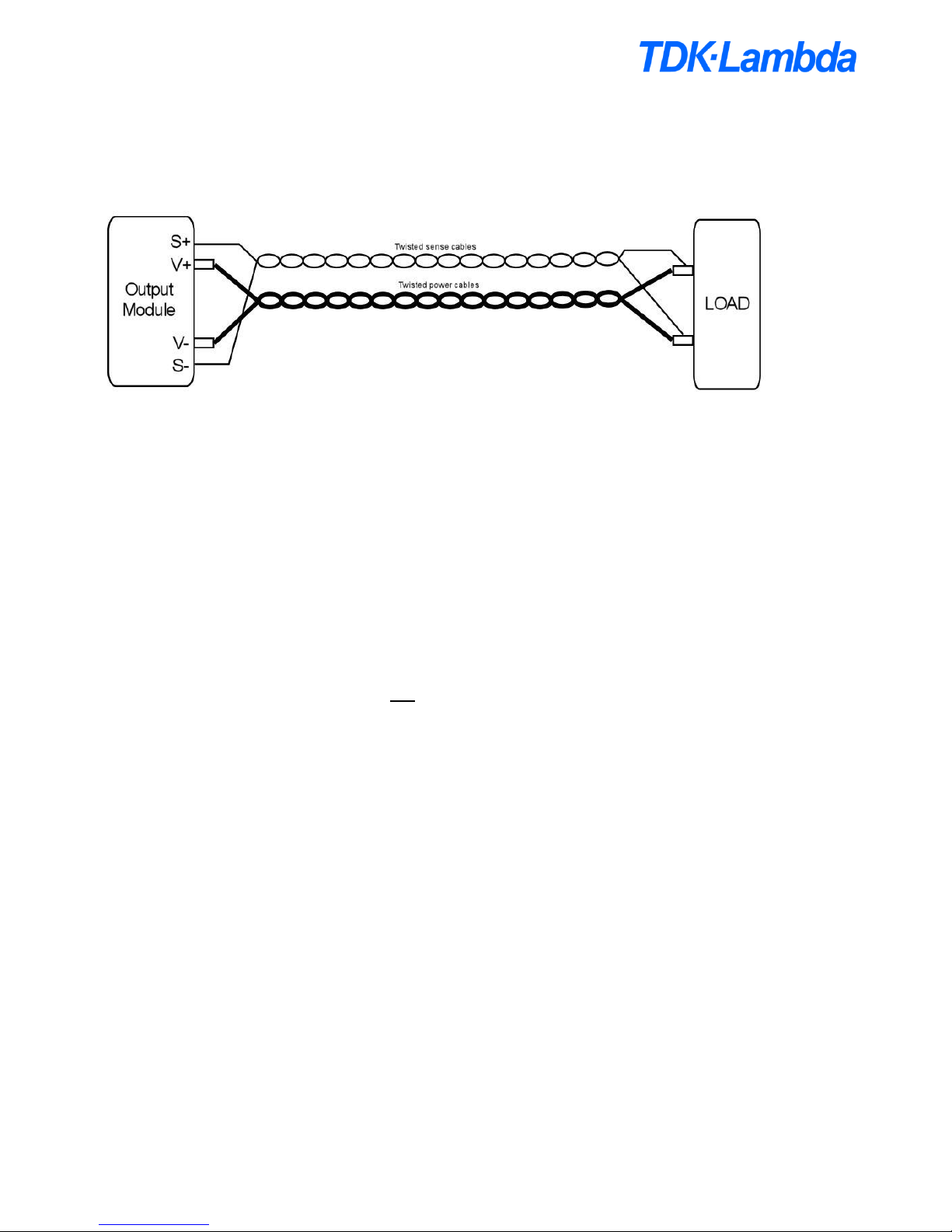

Remote Sensing

Remote sensing is available on all output modules and can be used to compensate for a voltage drop in the power leads connecting the power

supply to the load. To implement remote sensing connect the positive sense pin (S+, connector J4.2) to the positive side of the remote load and

the negative sense pin (S-, connector J4.1) to the negative side of the remote load. The voltage will be regulated at the points where the sense

cables are connected.

Active protection against damaged power cables or accidental power cable removal is provided and prevents damage to the unit in each case.

An internal circuit measures the voltage between S+ to V+ and S- to V-, when this voltage exceeds the thresholds specified in the datasheet, the

output voltage is reduced to benign levels. During system design, care must be taken to ensure power cables have a sufficiently low voltage drop

at maximum load current to ensure this protection does not activate unintentionally.

In systems where remote sensing is not used, the output voltage at the power terminals will be slightly higher than that at the sense terminals.

This voltage difference is termed, “open sense offset” and occurs due to internal bias currents in the sensing circuit. Factory set units are set with

the sense cables connected unless otherwise specified.

Local Bias Supply

A local non-isolated +5V bias supply is provided on each output module (+5 V on J4.6, referenced to COM on J4.3). This supply is intended to

power interface circuits for monitoring and controlling the output modules. The output can supply up to 10mA maximum, and exceeding this can

damage the unit.

Also, as COM is connected to an internal voltage that is NOT equivalent to S- or V-, particular attention must be given to grounding issues when

interfacing COM to any control circuit in the application. Connecting COM to S- or V- may result in damage to the unit.

Page 20

CM4 App Note 260424 issue 2.1.docx Document No. 260424 Page 20 of 29

10. Series Connected Outputs

CM output modules of the same type can be series connected to achieve higher output voltages. Links for series connecting modules are

available directly from TDK-Lambda.

The following instructions must be followed for output modules configured in this manner.

Isolation to Ground

Care must be taken not to exceed the output module isolation to chassis ground when series connecting modules. Each output module is rated

for 500 Volts maximum between each output terminal and chassis ground. Exceeding this voltage may damage the module.

Remote Sensing

For series connected modules, remote sensing is achieved by connecting the upper most positive sense terminal (S+) and the lower most

negative sense terminal (S-) from the series of modules to their respective load regulation points. All inner sense terminals in the series must be

daisy chained i.e. S+ to S- from the first module in the series to the last module in the series. An example of two series connected modules is

shown below.

Series Connected Remote Voltage/Current Control

Remote voltage and/or current control is possible with series connected modules using the advanced V

CONTROL

and I

CONTROL

functions described

earlier. However, individual control of each module can be complex as the various control terminals are referenced to the positive output of the

preceding module and require the use of multiple isolated control voltages to attain control over the full voltage range. Please contact TDKLambda or your distributor for assistance if remote voltage or current control is required for series connected modules.

SELV Precautions

Modules with a Vnom of greater than 36V can no longer be considered SELV (Safety Extra Low Voltage) and hence the final equipment

manufacturer must provide suitable protection for both users and service personnel.

External capacitance

When large external capacitances are connected to series connected outputs, the maximum input power can be exceeded at start-up and the

unit can latch off. Consider sequencing output start-up to prevent exceeding the input power limit when charging large external capacitances.

WARNING!

Energy and Voltage hazards may arise when individual modules are series connected. See the Safety section for more details.

When modules are connected in series, their inhibit lines (J3), if used, should be paralleled.

Inhibiting series connected modules individually may cause damage

Page 21

CM4 App Note 260424 issue 2.1.docx Document No. 260424 Page 21 of 29

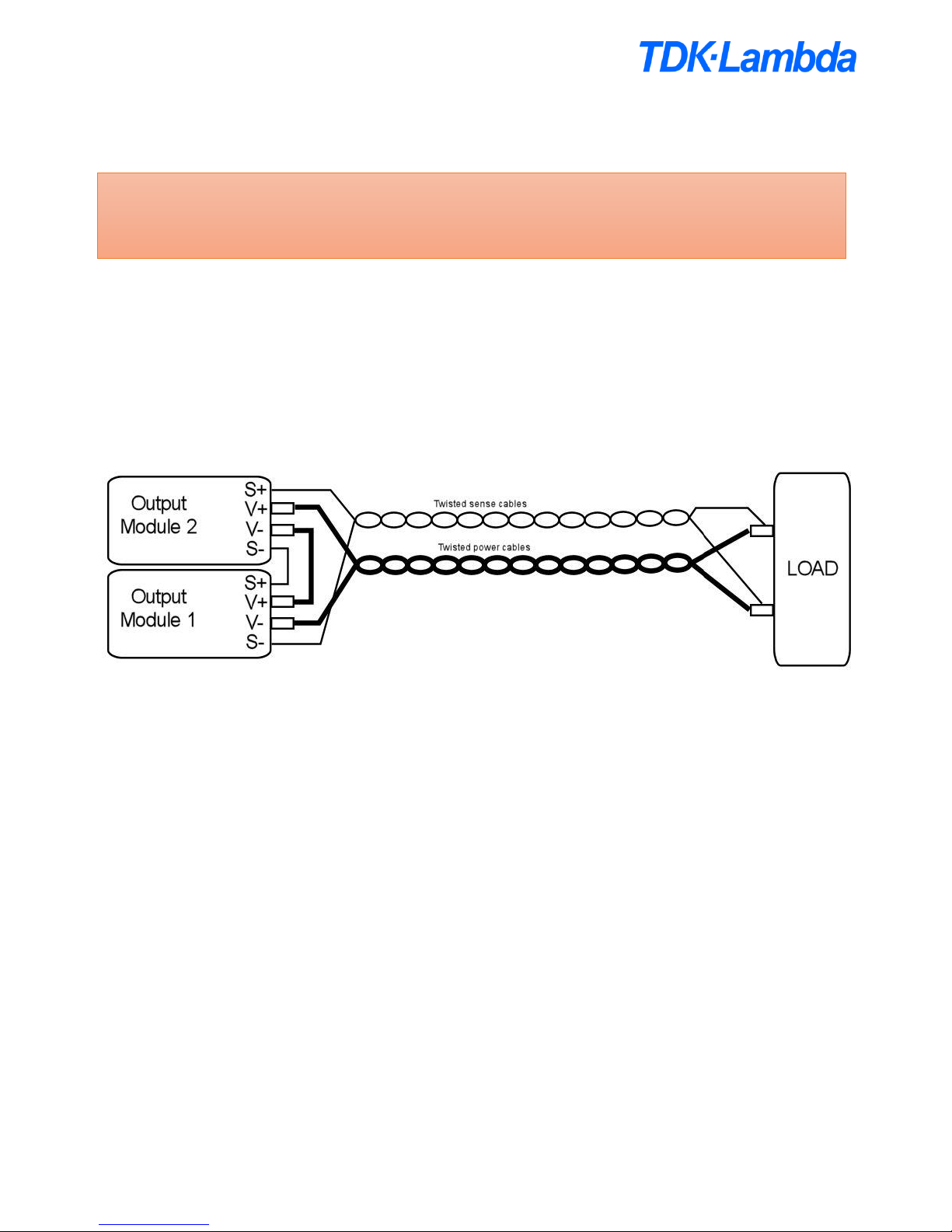

11. Parallel Connected Outputs

CM output modules of the same type can be paralleled within the same product to achieve higher output currents. Links for paralleling modules

are available directly from TDK-Lambda.

The following instructions must be followed for output modules configured in this manner.

When paralleled, the outputs can operate in two distinct modes, Normal parallel mode or Share parallel mode.

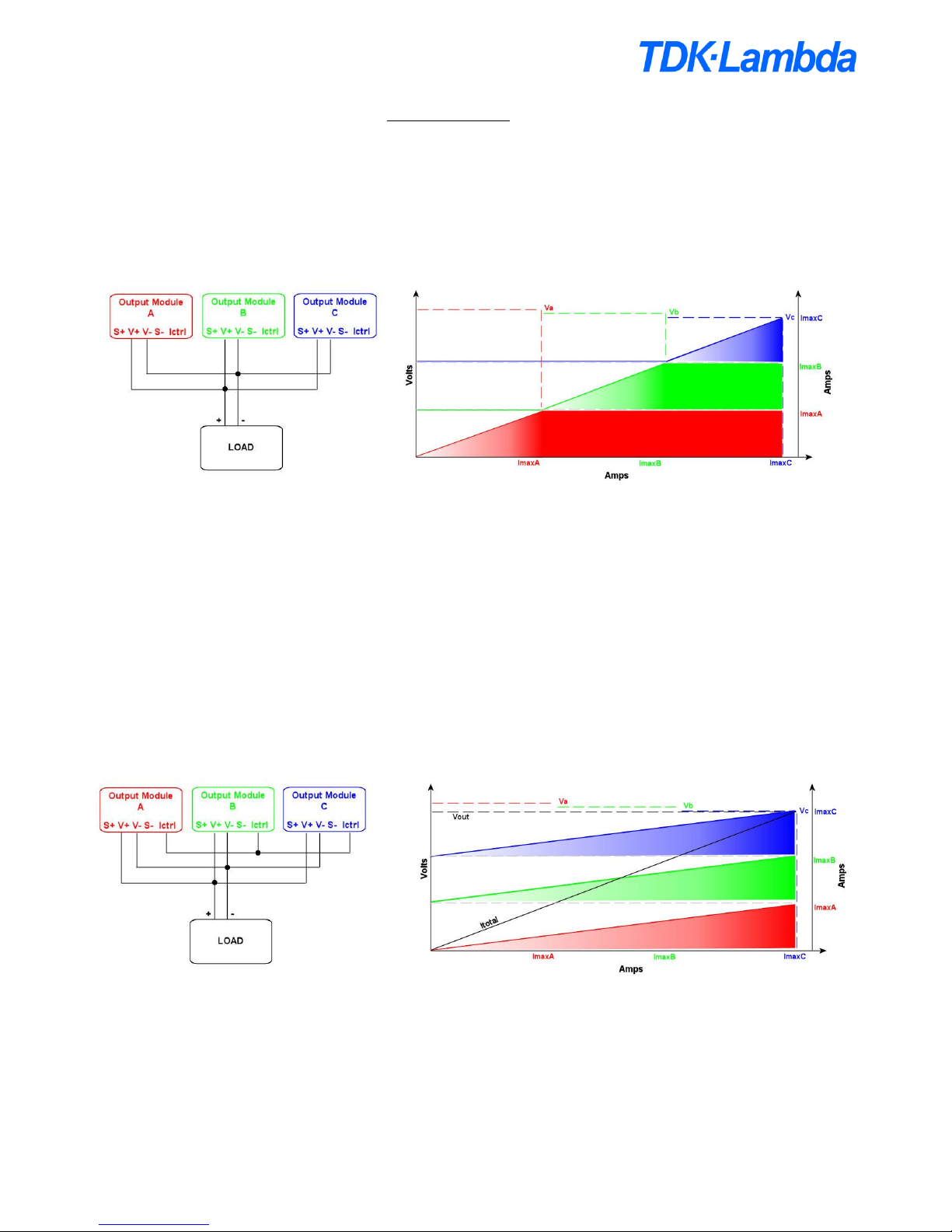

Normal Parallel Mode

For normal parallel mode, the positive power cables should be connected together and the negative power cables should be connected together.

No other connections are required as shown in the diagram below.

In this mode, the highest adjusted output module will supply all of the load current until its current limit is reached. If the load demand exceeds

this level the output voltage will drop to the level of the next highest adjusted module and that module will begin to supply the load current while

the first module continues delivering full current. This process repeats for the total number of paralleled modules. The diagram above shows the

VI curve for such a system.

Output modules that are not delivering current will typically sink a small amount of current from the other outputs, but this will not exceed -6% of

each module’s maximum rated current.

Typically, system reliability is reduced in this mode as the higher adjusted modules will do most of the work with the lower adjusted modules only

delivering current during peak load demand.

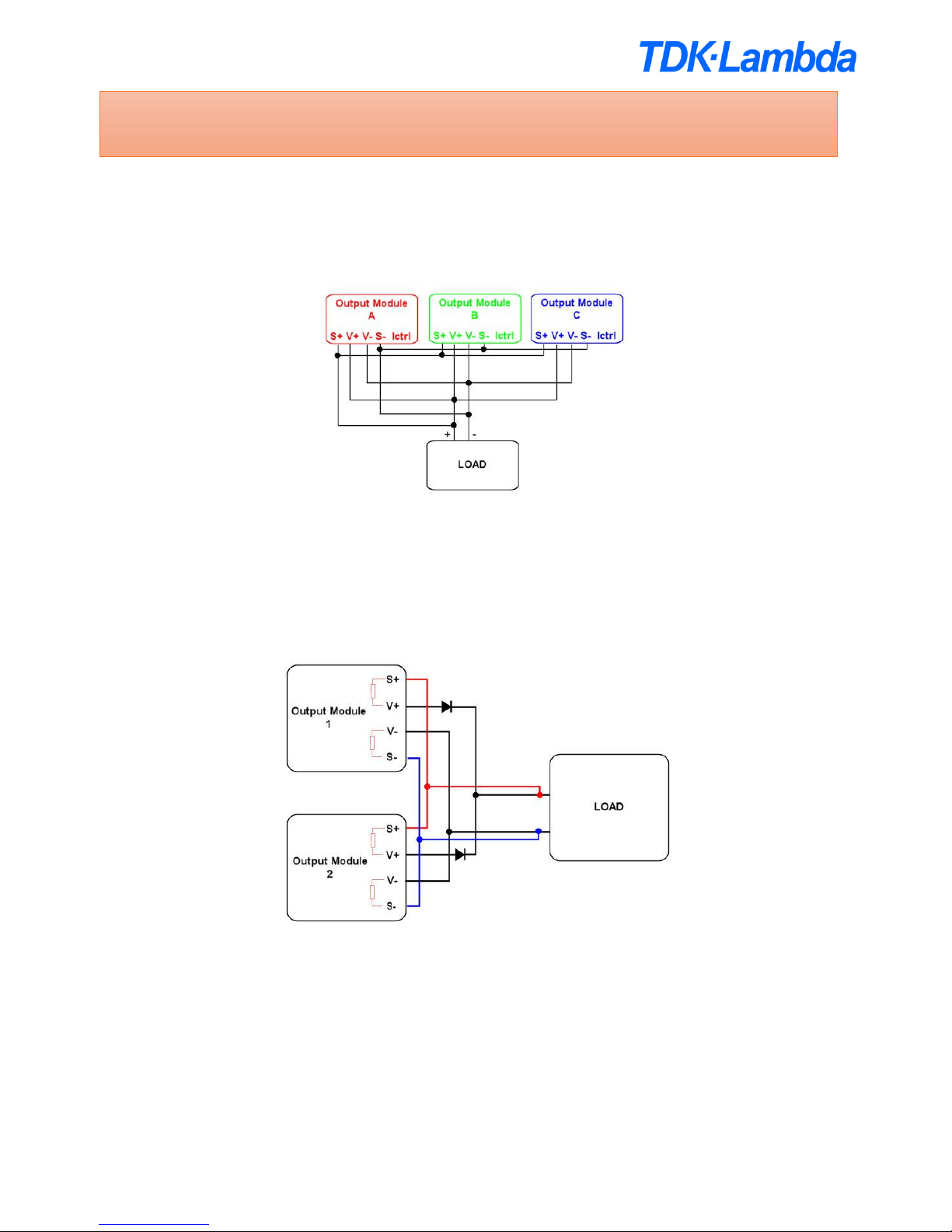

Share Parallel Mode

In share parallel mode, the outputs are paralleled as before and the I

CONTROL

pin of each module connected together as shown in the diagram

below.

Connecting the I

CONTROL

pins together forces all the outputs to deliver the same current, ensuring that the system reliability is maximised and the

work load is distributed evenly across all paralleled modules.

In this mode, the lowest adjusted output module will determine the actual output voltage and all higher adjusted outputs will reduce their voltage.

The current output signal (I

CONTROL

) can still be used to measure the output current but it must be scaled by N, where N is the number of

paralleled modules.

Page 22

CM4 App Note 260424 issue 2.1.docx Document No. 260424 Page 22 of 29

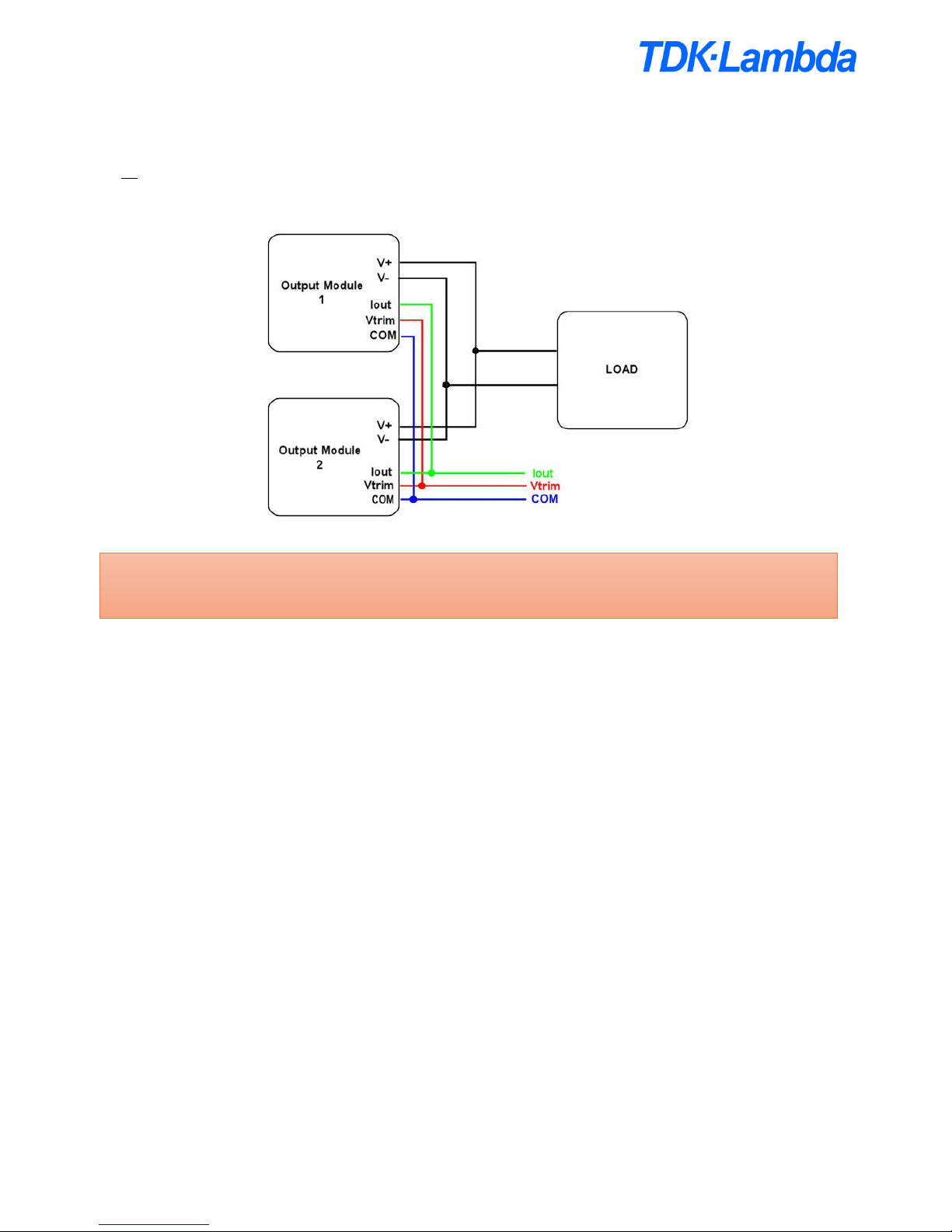

Parallel Remote Sensing

Remote sensing can be used as normal with paralleled modules. The sense lines (S+ and S-) from each of the output modules should be

connected together, S+ to S+, and S- to S- as shown below. This should be done close to the power supply output and a single pair of cables

brought from these sense lines to the load. Keeping cable lengths to a minimum and using twisted pairs where necessary will help reduce noise

pickup in the sense lines.

N+1 Configurations

When using N+1 redundant configurations, a suitably rated diode (or controlled MOSFET) must be used on each output to prevent a device

failure from causing a system failure. However, the diode introduces voltage drops between the supply and the load that significantly degrade the

load regulation. To counteract this, the remote sense lines can be used to regulate the voltage at the load as shown below.

Typically, this configuration can damage the internal sense resistors used within a power supply. However, the CM outputs have integrated

protection to prevent this type of damage and are completely N+1 compatible without any additional external protection circuitry. Note that only

the positive sense terminal is protected and diodes should be used in the positive connection only.

WARNING!

Care must be taken to avoid differential voltages between the negative power output terminals of share mode paralleled modules as this can cause

errors at the control pins. To avoid this, it is recommended to use TDK-Lambda parallel links to parallel modules in share mode.

Page 23

CM4 App Note 260424 issue 2.1.docx Document No. 260424 Page 23 of 29

Paralleled Remote Voltage/Current Adjustments

The simplest way to achieve remote voltage/current programming with paralleled outputs is to operate the modules in share parallel mode.

Follow the procedure outlined earlier to configure the outputs in share parallel mode and once configured in this mode, all the V

CONTROL

and COM

pins can be connected together. Remote voltage/current programming can then be performed exactly as with a stand-alone module.

It is not recommended to use remote voltage/current programming in normal parallel mode.

Paralleling Across Multiple Products

Paralleling across multiple products is not possible without external protection (such as external diodes or controlled MOSFETs) to prevent

circulating currents between each product. Failure to provide such protection may result in damage to the power supplies. Consult TDK-Lambda

for details on how best to implement such applications.

When modules are paralleled across multiple products, the outputs in each product will not be synchronised and the peak to peak output ripple

may contain beat frequencies in the audio spectrum.

WARNING!

Care must be taken to avoid differential voltages between the negative power output terminals of share mode paralleled modules as this can cause

errors at the control pins. To avoid this, it is recommended to use TDK-Lambda parallel links to parallel modules in share mode.

Page 24

CM4 App Note 260424 issue 2.1.docx Document No. 260424 Page 24 of 29

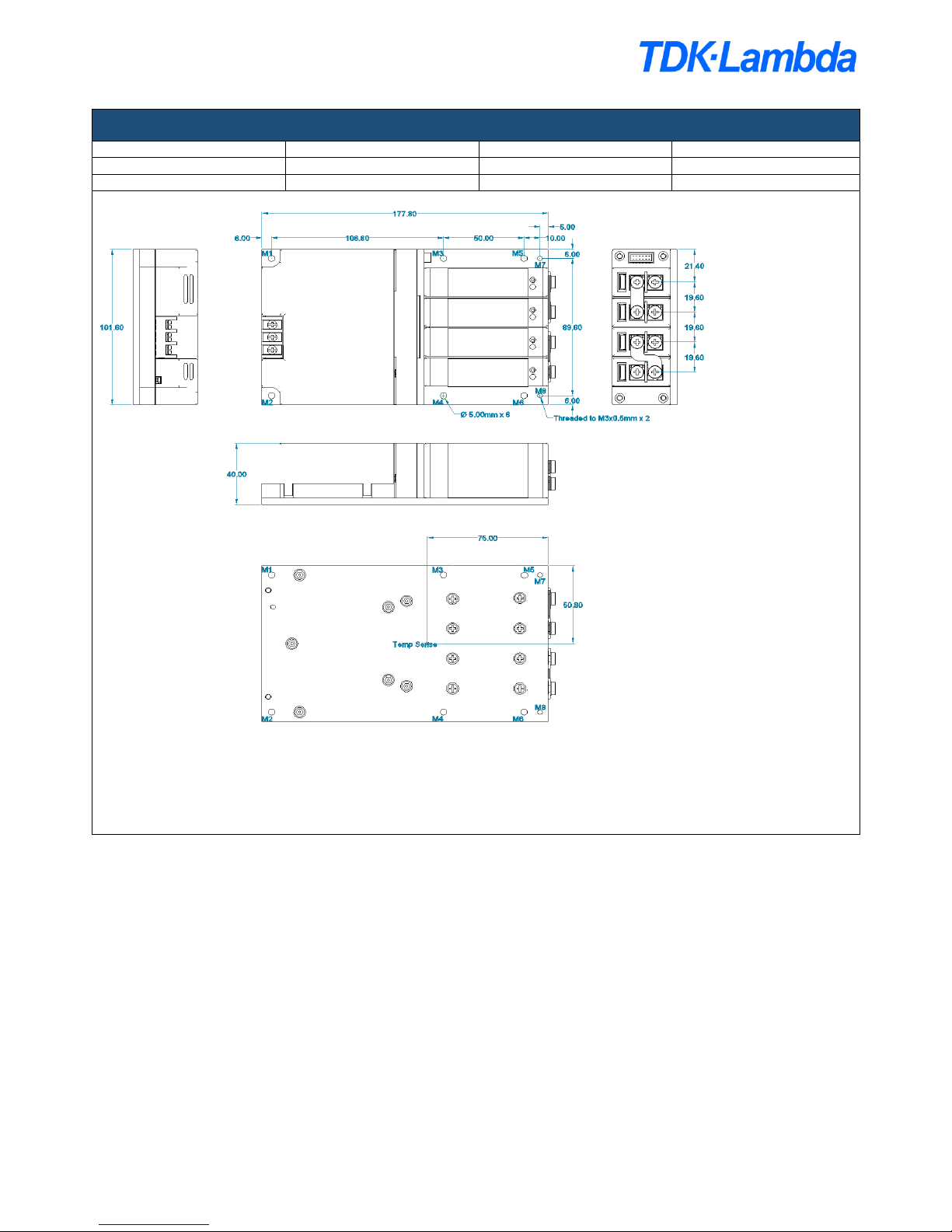

12. Mechanical Dimensions and Mounting

SCREWS

Location

Details

Penetration

Tightening

Baseplate Mount: M1 – M6

Hole size, Diameter 5.00mm

4mm Baseplate thickness

0.55 NM

Output Module Connection

M4

-

0.35 NM

Input Module Connection

6-32

-

0.8 NM

Unless stated otherwise, all dimensions are in millimeter s and in accordance with DIN2768 -1/2 CLASS C

Page 25

CM4 App Note 260424 issue 2.1.docx Document No. 260424 Page 25 of 29

13. Connector details

PINOUTS

Circuit

Details

J1 – Mains Input

1

Live

2

Neutral

3

Earth

J2 – Standby control

1 Standby control negative

2 Standby control positive

J3 – Global Signals

1 Slot 4 - Power Good

2

Slot 4 - Inhibit

3 Slot 3 - Power Good

4

Slot 3 - Inhibit

5 Slot 2 - Power Good

6

Slot 2 - Inhibit

7 Slot 1 - Power Good

8

Slot 1 - Inhibit

9 Temperature sense (T

SNS

)

10

AC OK

11

+5V (Bias Supply 1A)

12

COM

J4 -Output Signals

1

- Sense

2

+ Sense

3

COM

4

I Control

5

V Control

6

+5V (Bias Supply 10mA)

MATING CONNECTORS

Ref.

Details

Manufacturer

Housing

Terminal

J1 - Mains Input

3 Pin, Barrier, 6-32 Steel Screws, 0.8 Nm or 7 Lb-In Torque

(1)

J2 - Standby control

2 Pin, 1.25mm, with Friction Lock, 28-30AWG

MOLEX

0510210200

0500588000

J3 - Global Signals

12 Pin, 2mm, with Friction Lock, 24-30 AWG, WIRE TO BOARD

MOLEX

0511101260

0503948051

12 Pin, 2mm, with Friction Lock, 24-30 AWG, IDT CABLE TO BOARD

MOLEX

0875681273

J4 - Output Signals

6 PIN, 1.25mm, with Friction Lock, 28-30AWG

MOLEX

0510210600

0500588000

Output Power

Positive/Negative, M4 terminal, use appropriately rated crimp terminal

Notes 1. Cable 14-18AWG, 300V, 16A, 105°C, use appropriately rated crimp terminal.

2. Direct equivalents may be used for any connector parts.

3. All cables must be rated 105°C min, equivalent to UL1015

Page 26

CM4 App Note 260424 issue 2.1.docx Document No. 260424 Page 26 of 29

14. EMC Compliance

Typical Conducted emissions

Typical Radiated emissions

For radiated and conducted emissions, compliance of the final system relies on proper installation of the PSU component. The installation

guidelines detailed below should be followed.

Installation Guidelines for optimum EMC performance

CM units should be mounted within a metal enclosure using the mounting fixtures provided.

If the application enclosure is not metal, then a metal ground plate should be used to mount both the power supply and the load.

Both input and output cables should be fixed as close as possible to the ground plate or metal enclosure.

Input and output cables should be separated as much as possible from each other or a shield/screen used to isolate RF currents

Output power and sense cables should be twisted pairs and routed parallel to each other. Do not twist sense and power cables

together.

All cables lengths and loop areas should be minimised.

Where cables must enter or exit the enclosure, good high frequency 100nF decoupling capacitors of sufficient voltage rating should be

connected to the cables as close to the entry/exit point as possible.

For further details or assistance contact TDK-Lambda.

Page 27

CM4 App Note 260424 issue 2.1.docx Document No. 260424 Page 27 of 29

15. Reliability

The CM4 series has undergone extensive testing, including HALT and Environmental testing. Reliability data is collected on an ongoing basis.

Please contact TDK-Lambda for the most up to date reliability data.

The reliability data quoted in the datasheets are the calculated failures per million hours (FPMH) using the Telcordia SR-332, issue 2 standard.

The procedure defined in SR-332 allows several different techniques to be used for calculating MTBF and when evaluating competing MTBF

figures it is important that only the same techniques are compared.

The quoted CM reliability figures use Method I Case 3, Ground, Fixed, Controlled which specifies an ambient temperature of 30°C and an upper

confidence level of 90%. It is also assumed that the product is operated at 100% duty cycle, has an input voltage of 220V

RMS

, an output power of

600W and that the baseplate temperature is the same as the ambient temperature.

The table below shows a summary of the FPMH & MTBF for all system components and for a typical fully assembled system.

Assembly

Failure Rate (FPMH)

MTBF (Hrs)

Input module

0.962972

1038452

Transformer

0.371919

2688754

S1

0.415368

2407499

S2

0.397808

2513774

S3

0.398170

2511487

S4

0.405630

2465300

CM4 with 4 S1 modules

2.996363

333737.934

To calculate the MTBF of any CM system,

Add the FPMH figures for each system component to give the total FPMH.

Get the MTBF by dividing 1,000,000 by the total FPMH.

The variation in FPMH is shown in the graph and table below.

Temp

Input module

Transformer

S1

S2

S3

S4

CM4 with 4 S1 modules

0

0.41329578

0.127619

0.192619

0.185396

0.186105

0.186243

1.291276945

10

0.54688976

0.178886

0.245347

0.235357

0.235992

0.2362

1.678671789

20

0.72397837

0.255159

0.316147

0.302737

0.30326

0.305183

2.206465072

30

0.96297168

0.371919

0.415369

0.397808

0.39817

0.40563

2.951868534

40

1.29407059

0.555049

0.560829

0.538309

0.538452

0.559393

4.046103211

50

1.76616217

0.846405

0.782692

0.754326

0.754185

0.803972

5.707742381

60

2.46010898

1.315415

1.130884

1.095712

1.095216

1.202005

8.299340054

70

3.50420104

2.067304

1.686039

1.643019

1.642101

1.855247

12.39791075

80

5.09894211

3.266645

2.575169

2.523173

2.52177

2.925702

18.91140128

90

7.55815578

5.160517

3.995269

3.93316

3.931214

4.659641

29.23795696

100

11.3495991

8.112606

6.236851

6.163284

6.160733

7.430093

45.4531658

Page 28

CM4 App Note 260424 issue 2.1.docx Document No. 260424 Page 28 of 29

16. Output Modules

Refer to datasheet for output module ratings

Adjusting output voltages

Each CM output module contains a built-in potentiometer to allow for accurate output voltage adjustments. To adjust the output voltage, connect

a calibrated voltmeter (or DMM) to the output terminals and insert an appropriate trimming tool (e.g. Bourns Model H-90, maximum diameter

3mm) through the hole marked “Adjust” at the top of the output module as shown below. Do not use excessive force as this may damage the unit.

Ensure the trimming tool mates correctly with the internal potentiometer and slowly turn the tool clockwise to increase the voltage or counterclockwise to decrease the voltage. Once the desired voltage has been achieved, remove the trimming tool and disconnect the voltmeter. Repeat

this step for each output module in need of adjustment.

Attaching a heatsink or cooling plate

For improved performance, the baseplate of the CM4 unit can be attached to a heatsink or cooling plate. TDK-Lambda has a range of heatsinks

available to allow the CM4 to be mounted horizontally or vertically.

Each heatsink comes pre-assembled with a high performance thermal interface pad and 6 x M4 x 10mm Pozi Pan screws which can be used to

attach the heatsink to the baseplate.

The diagrams below show a CM4 unit attachment to a Type 1 and Type 2 heatsink. Before assembly ensure both the baseplate and heatsink

surfaces are clean and free from debris. The final assembly can then be mounted into the end system via the four holes (Type 1: 2 each side,

Type 2: 2 each end) on the flange of the heatsink.

It is recommended to tighten the baseplate mounting screws to 0.55 NM. In high vibration environments, an appropriate thread lock should be

used.

All recommended screw tightening torques are nominal values and should be verified in the application where appropriate.

CM4 Heatsink 1

CM4 Heatsink 2

Voltage Adjust

Page 29

CM4 App Note 260424 issue 2.1.docx Document No. 260424 Page 29 of 29

17. Accessories

Description

Photo/Drawing

Part number*

Current share cables

2 way = 200451

3 way = 200452

4 way = 200451

Output

Cable Set

1x Signals cable

(~200mm)

2x Power terminals

200450

Input

Cable Set

1x Signals cable

(~200mm)

1x Standby cable

(~200mm)

3x Power terminals

200449

CM4 Heatsink1

(Provided with 6x M4 x

10mm Posi-Drive screws

for baseplate mounting

and thermal interface ACC-

TF)

200445

CM4 Heatsink2

(Provided with 6x M4 x

10mm Posi-Drive screws

for baseplate mounting

and thermal interface

200447)

200446

Thermal interface

(170mmx80mm)

200447

* For larger pack size part numbers, please contact TDK-Lambda.

4 WAY SHARE CABLE

Loading...

Loading...