Page 1

OPERATOR MANUAL FOR

802 Series High Voltage

POWER SUPPLY

Document: 83488001 Rev N

TDK-LAMBDA AMERICAS

405 Essex Road, Neptune, NJ 07753

Tel: (732) 922-9300

Fax: (732) 922-9334

Web: www.us.tdk-lambda.com/hp

Page 2

PAGE LEFT INTENTIONALLY BLANK

Page 3

83-000-005 Rev F

ONE YEAR WARRANTY

TDK-Lambda Americas

, Inc. (405 Essex Road, Neptune, N.J. 07753), warrants that the unit is free from defects in

material or workmanship for a period of ONE YEAR from the date of initial shipment.

TDK-Lambda Americas

Inc.

will

service and,

at its option, repair or replace parts which prove to be defective. This will be done free of charge during

the stated warranty period. This warranty excludes defects resulting from mi

s

use, unauthorized modification,

operation outside the environmental or

safety specifications of the power supply, or improper site preparation or

maintenance. The customer shall contact

TDK-Lambda Americas Inc.

, for warranty service or repair as described in

the RETURNING EQUIPMENT section. The customer shall prepay shipping

charges. If the unit is covered under the

foregoing warranty, then

TDK-Lambda Americas Inc.

shall pay the return shipping charges.

The “WARRANTY”, “CLAIM FOR DAMAGE IN SHIPMENT”, and “RETURNING EQUIPMENT” i

n

formation applies to

equipment purchased directl

y from

TDK-Lambda Americas Inc

. End users receiving equi

p

ment from a third party

should consult the appropriate service organization for assistance with these issues.

THIS LIMITED WARRANTY IS IN LIEU OF, AND

TDK

-

LAMBDA AMERICAS INC.

DISCLAIMS AND EXCLUDES

,

ALL OTHER WARRANTIES, STATUTORY, EXPRESS OR IMPLIED, INCLUDING, WITHOUT LIMITATION, ANY

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, OR OF CONFORMITY TO

MODELS OR SAMPLES.

CERTIFICATION

All test and measuring equipment used by

TDK-La

mbda Americas

Inc.

for Final Acceptance Testing are traceable to

primary standards certified by the National Institute of Standards and Technology.

LETHAL VOLTAGES PRESENT!

All power supplies contain hazardous voltage and energy. The power supply must

only be operated by qualified

personnel who have read this operator’s manual and are familiar with the operation, hazards and application of the

power supply. Proper care and jud

g

ment must always be observed.

1.

Before connecting input AC power, ensure all c

overs are in place and securely fastened. E

n

sure the required

safety ground to chassis is installed and sufficient cooling is su

p

plied.

2.

Proper grounding from the input AC power is required to reduce the risk of electric shock, and to comply with

safety age

ncy and code requirements.

3.

Use extreme caution when connecting input AC power. Only apply the input voltage specified on the rating label.

4.

Use extreme caution when connecting any high voltage cables. Never handle any output c

a

bles when the power

supply is

operating.

5.

After a power supply is switched OFF, its output section will retain a charge which may be lethal. Allow sufficient

time for self

-

discharge before handling anything connected to the output. The di

s

charge time specified in the

Safety Notes does

NOTinclude extra time required to discharge the energy stored in the user’s load.

6.

When user serviceable fuses are present, always replace fuses with the same type and Volt/Amp ra

t

ing.7.Never attempt to operate the power supply in any manner not described in

this manual.

8.

Never remove DANGER or WARNING labels from the power supply. Replace lost or damaged labels

immediately. Contact

TDK-Lambda Americas

Customer Service for replacement labels.

9.

The power supply may be serviced only by

TDK-Lambda Americas Inc.

fa

ctory qualified service personnel.

Breaking the warranty seal will void the warranty. Prior to opening the power supply, contact

TDK-Lambda

Americas

Inc.

Customer Service for a written Service Waiver and a replacement warranty seal.

Page 4

TDK-Lambda

MANUFACTURER'S PRODUCT DECLARATION

INTENDED PURPOSE (USE)

The Power Supplies described by this manual are defined by TDK-Lambda Americas Inc.

as a component for use in the composition of an apparatus as defined in Article 1 (1) of

the EMC Directive (89/336/EEC). These products, as individual components, do not

perform in themselves a direct function for the user of the end product. They are not

intended to be placed on the market with a direct function to a final user! As such, the

products described by this manual are not subject to the provisions of the EMC Directive

(89/336/EEC, with amendment 92/31/EEC).

The products described by this manual are intended for incorporation into a final product

by a professional assembler. It is the responsibility of the assembler to ensure that the

final apparatus or system incorporating our products complies with all relevant EMC

standards for that final product.

OPERATING ENVIRONMENT

The operating environment as defined by TDK-Lambda Americas Inc., for the products

described by this manual is stated as follows:

The Power Supplies described by this manual are intended for use in a protected

industrial environment or in proximity to industrial power installations. These locations are

often referred to as industrial locations containing establishments that are not connected

to the low voltage public mains network.

Industrial locations are characterized by the existence of one or more of the following

conditions:

1) industrial, scientific and medical (ISM) apparatus are present;

2) heavy inductive or capacitive loads are frequently switched;

3) currents and associated magnetic fields are high;

4) location supplied by their own transformer.

These components are not intended for connection to a public mains network, but are

intended to be connected to a power network supplied from a high or medium-voltage

transformer dedicated for the supply of an installation feeding manufacturing or similar

operations. They are suitable for use in all establishments other than domestic and those

directly connected to a low voltage power supply network which supplies buildings used

for domestic purposes.

Page: 83-000-006 Rev D

Page 5

TDK-Lambda

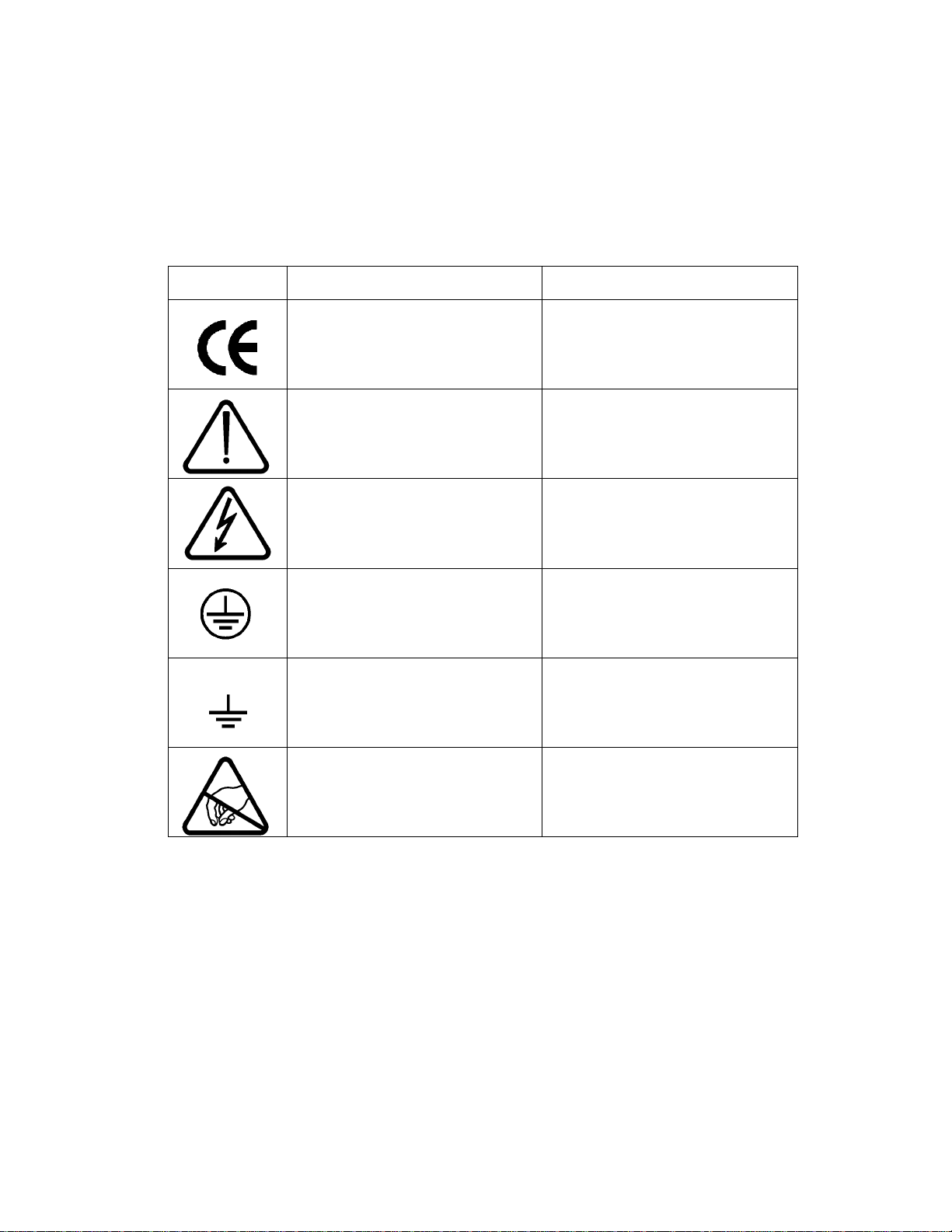

Description of symbols used in product labeling

SYMBOL PUBLICATION DESCRIPTION

EC Council

Directive 93/68/EEC

European Community

Conformity Assessment

Product Mark

IEC 348 Attention, consult

Accompanying documents

IEC 60417-1-5036 Dangerous voltage

IEC 60417-1-5019 Protective earth

(e.g. power line earth ground)

IEC 60417-1-5017 Functional earth

IEC 60417-1-5134 Electrostatic Discharge

(e.g. chassis ground)

(ESD) Sensitive Device

Page: 83-000-007 Rev E

Page 6

ELECTRICAL STANDARDS

All company primary standards are either certified or are traceable to certification by the

National Institute of Standards and Technology.

CLAIM FOR DAMAGE IN SHIPMENT

This instrument received comprehensive mechanical and electrical inspection before

shipment. Immediately upon receipt from the carrier, and before operation, this instrument

should be inspected visually for damage caused in shipment. If such inspection reveals

damage in any way, a claim should be filed with the carrier. A full report of damage should

be obtained by the claim agent and this report should be forwarded to us. We will then

provide a disposition of the equipment and arrange for repair or replacement.

When referring to this equipment, always include the model and serial numbers.

The “WARRANTY”, “CLAIM FOR DAMAGE IN SHIPMENT”, and “RETURNING

EQUIPMENT” information applies to equipment purchased directly from TDKLambda Americas Inc. End users receiving equipment from a third party should

consult the appropriate service organization for assistance with these issues.

RETURNING EQUIPMENT

Before returning any equipment to the factory, the following steps shall be taken.

1.

Notify TDK-Lambda Americas Inc. at 732-918-6888 or follow the instructions at

www.US.TDK-Lambda.com/HP/service.htm. Give a full description of the difficulty

including the model and serial number of the unit in question. Upon receipt of this

information, we will assign a Return Material Authorization (RMA) number and

provide shipping instructions.

2.

The customer shall prepay shipping charges. Equipment returned to us must be

packed in a manner to reach us without damage. The shipping container must be

marked with the RMA number in an area approximate to the shipping label with

numbers that are easy to read. All returned units that do not show the RMA number

on the outside of the container will be refused.

If the equipment is repaired within the warranty agreement, than TDK-Lambda

Americas Inc. shall pay for the return shipping to the customer.

3.

For non-warranty repairs, we will submit a cost estimate for your approval prior to

proceeding. The customer shall pay return shipping charges.

MECHANICAL INSTALLATION

Most power supplies are heavy and, when rack mounted, they should be supported by

rails along the sides of the supply from front to rear. The rails must adequately support the

unit and not block airflow. Do not support the power supply from the front panel only.

Page: 83-000-011 Rev K

Page 7

Table of Contents

1. GENERAL INFORMATION ................................................................................. 5

1.1. User Manual Content .......................................................................................... 5

1.2. Introduction ......................................................................................................... 5

1.3. 802 Overview ...................................................................................................... 6

1.4. Capacitor Charging Technology .......................................................................... 6

1.5. Continuous DC Operation ................................................................................... 7

1.6. Additional Features: ............................................................................................ 7

1.7. Safety Precautions .............................................................................................. 7

1.8. Model Number Format ........................................................................................ 8

2. SPECIFICATION ................................................................................................. 9

2.1. Average Charging Power .................................................................................... 9

2.2. Peak Charging Power ......................................................................................... 9

2.3. Average DC Power .............................................................................................. 9

2.4. Output Voltage Range ......................................................................................... 9

2.5. Polarity ................................................................................................................ 9

2.6. HV Output Cable ................................................................................................. 9

2.7. HV Insulating Medium ......................................................................................... 9

2.8. AC Input Voltage ................................................................................................. 9

2.9. AC Input Current ................................................................................................. 9

2.10. AC Connector ...................................................................................................... 9

2.11. AC Line Contactor ............................................................................................... 9

2.12. Power Factor ....................................................................................................... 9

2.13. Efficiency ............................................................................................................. 9

2.14. Front Panel.......................................................................................................... 9

2.15. Stability ............................................................................................................... 9

2.16. Temperature Coefficient ...................................................................................... 9

2.17. Stored Energy ................................................................ ..................................... 9

2.18. Pulse to Pulse Repeatability ................................................................................ 9

2.19. Dimensions - inches (mm) ................................................................................... 9

2.20. Weight - lbs (kg) .................................................................................................. 9

2.21. Ambient Temperature .......................................................................................... 9

2.22. Altitude ................................................................................................................ 9

2.23. Humidity .............................................................................................................. 9

2.24. Protection ................................................................ ............................................ 9

2.25. Remote Control (all models) ................................................................................ 9

2.26. Accessories ......................................................................................................... 9

2.27. Options .............................................................................................................. 10

2.28. Ordering Info ..................................................................................................... 10

2.29. Ordering Examples ............................................................................................ 10

3. OUT OF BOX INSPECTION ............................................................................. 11

3.1. Visual Inspection ............................................................................................... 11

3.2. Electrical Inspection .......................................................................................... 11

3.3. Contacting TDK-Lambda Americas Customer Service ...................................... 12

3.4. Returning Defective Units .................................................................................. 12

4. INSTALLATION ................................................................................................. 13

4.1. 19-Inch Rack Mounting ..................................................................................... 13

4.2. Ventilation Requirements .................................................................................. 15

4.3. Orientation......................................................................................................... 15

4.4. AC Power Connection ....................................................................................... 15

1

83488001 Revision N

Page 8

4.5. Connecting the High Voltage Output ................................................................. 17

5. CONTROLS, INDICATORS, CONNECTORS ................................................... 19

5.1. Front Panel Layout (L Model) ............................................................................ 19

5.2. HV ON Push Button (Ref 1) ............................................................................... 20

5.3. Status LEDs (Ref 2) .......................................................................................... 20

5.4. Local Voltage Set (Ref 3) .................................................................................. 21

5.5. Voltage bar graph (Ref 4) .................................................................................. 21

5.6. Voltage Display (Ref 5) ..................................................................................... 21

5.7. HV OFF Push Button (Ref 6) ............................................................................. 21

5.8. Off/Local/Remote Keyswitch (Ref 7) .................................................................. 21

5.9. View set push button (Ref 8) ............................................................................. 21

5.10. Current bar graph (Ref 9) .................................................................................. 21

5.11. Current Display (Ref 10) .................................................................................... 22

5.12. Power switch (Ref 11) ....................................................................................... 22

5.13. Front Panel Layout (S Model) ............................................................................ 22

5.14. Front Panel Layout (OEM Model) ...................................................................... 22

5.15. Rear Panel Layout (L Models) ........................................................................... 23

5.16. Rear Panel Layout (S Models)........................................................................... 25

5.17. Rear Panel Layout (OEM Models) ..................................................................... 26

5.18. REMOTE CONTROL CONNECTOR PIN DIAGRAM ........................................ 27

6. OPERATING INSTRUCTIONS .......................................................................... 29

6.1. Local Operation (802L only) .............................................................................. 29

6.2. Remote Operation (All models) ......................................................................... 30

6.3. Remote Control Sequence ................................................................................ 33

6.4. Parallel Operation.............................................................................................. 34

7. APPLICATION NOTES ..................................................................................... 39

2

83488001 Revision N

Page 9

List of Figures

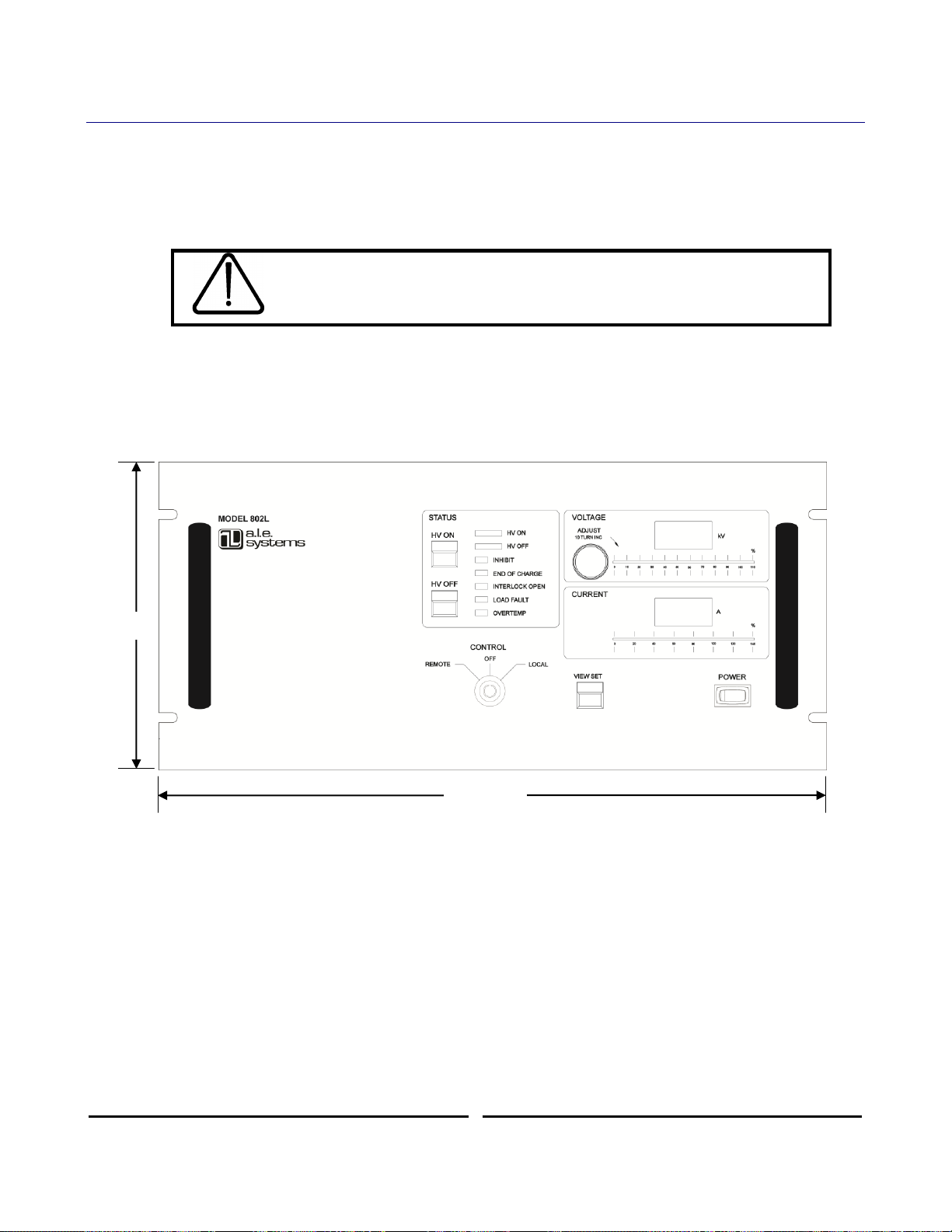

Figure 1. 802L Front View ................................................................................................ .................. 13

Figure 2. 802L Rear View .................................................................................................................. 14

Figure 3. 802L Side View ................................................................................................................... 14

Figure 4 AC Input Terminal Block ..................................................................................................... 16

Figure 5 Typical Load Circuit Connection .......................................................................................... 17

Figure 6 802L Front Panel Controls and Indicators ........................................................................... 19

Figure 7 Front Panel Controls and Indicators (S Model) .................................................................... 22

Figure 8 802L Rear Panel Connections ............................................................................................ 23

Figure 9 802S Rear Panel ................................................................................................................. 25

Figure 10 802OEM Rear Panel ......................................................................................................... 26

Figure 11 Remote Interface Connector and Signals. ......................................................................... 27

Figure 12 Suggested external remote interface circuit. ..................................................................... 31

Figure 13 Typical remote Interface waveforms .................................................................................. 34

Figure 14 802L Parallel System Control Connections. ...................................................................... 35

Figure 15 802L and 802S/OEM Parallel System control Connections. .............................................. 36

Figure 16 Parallel Operation Connections for 802S/OEM Supplies ................................................... 37

List of Tables

Table 1 :802 Model Description Format . ............................................................................................. 8

Table 2 Recommended AC Input Cable ............................................................................................. 16

Table 3 Front Panel Controls and Indicator Functions (L Model) ........................................................ 19

Table 4 Front Panel Controls and Indicators (S Model) ...................................................................... 22

Table 5 802L Rear panel Functions ................................................................................................... 23

Table 6 802 Remote Interface Description ........................................................................................ 31

3

83488001 Revision N

Page 10

Notes

4

83488001 Revision N

Page 11

1. GENERAL INFORMATION

1.1. User Manual Content

This User’s Manual contains the operating instructions, installation instructions and

specifications for the ALE 802 series high voltage power supply. The instructions refer to

standard power supply models, and include checkout, installation, and operation of the 802

series. Suggestions and requirements for connecting AC power, load cables and signal

cables are given. Various operating modes and programming modes are described.

The model 802 is just one model in a broad family of HV power supplies covering the power

range from 500J/sec to 30kJ/sec in a single package, and to 1MW and beyond in parallel

systems. For more information please visit our web site at:

http://www.us.tdk-lambda.com/hp/product_html/high_volt.htm.

This manual contains information, instructions and diagrams which apply to standard

constructions. If special features or modifications have been installed, the instructions

specific to that modification are contained in Addenda and take precedence if conflicts

exist. Please take care to refer to the correct information for your unit.

NOTE

1.2. Introduction

TDK-Lambda Americas ALE model 802 are state of the art constant current switch mode

high voltage power supplies, designed to rapidly and efficiently charge capacitors in laser

systems, modulators, pulse forming networks, and a broad range of pulse generator circuits,

without the need for a series current limiting resistor. They can also be used in many

continuous DC applications including beam power for RF devices such as magnetrons,

gyrotrons, klystrons and electron beam loads.

The 802 series utilize a high frequency IGBT based series resonant inverter topology which

operates as a constant current source. This makes the supply perfect for rapidly charging

capacitors which represent a challenging load for conventional HV DC supplies using

multiplier designs.

The 802 series is available with a choice of three different front panel configurations

designed to suit different applications and end uses. All models feature the same

comprehensive remote control interface which is detailed in Section 6.2.

The 802L Model is fully instrumented with front panel meters displaying output voltage and

current, status LEDs, a key switch for OFF, LOCAL or REMOTE operation, HV ON/OFF

push-button switches, and a 10 Turn output voltage control. The rear panel features external

interlock, inhibit, remote control and slave (parallel operation) control connections.

The 802S Model can only be operated by remote control and features only status LEDs and

a power switch on the front panel. The "S" Models have been designed to operate as a slave

unit to the "L" Models or in systems where local control is not a requirement.

The 802OEM features a blank aluminum front panel and can only be operated by remote

control.

As many 802 supplies as required, can be connected in parallel to provide greater output

power.

5

83488001 Revision N

Page 12

1.3. 802 Overview

1.3.1. Features

8kJ/sec capacitor charging power, 8kW in continuous DC applications.

Output voltages from 0-1kV to 0-50kV.

Rep rates from single shot to kilohertz.

Local (L Model) or remote operation with comprehensive control interface.

Cost effective blank front panel version for OEM applications.

Constant current topology for rapid efficient charging.

Parallel operation (master/slave) for high power applications.

Compact Air Cooled design.

Passive Power Factor Correction reduces RMS current draw.

1.3.2. Benefits

Lightweight switchmode design.

Rack mount chassis configuration.

Low stored energy provides greater safety.

Constant current design eliminates series current limit resistance in charge circuit.

Immunity to external EMI.

1.3.3. Applications

Charging capacitors and capacitor banks.

Powering pulse forming networks/modulators.

Powering lasers: Excimer, flashlamp pumped dye, Yag, CO2, etc.

Continuous power for RF tubes – magnetron, gyrotron, TWT, klystron etc.

Electron beam applications.

DC power source for pulsed hard-tube and solid state modulators.

1.4. Capacitor Charging Technology

Capacitor charging applications require a power supply designed specifically for the task.

The 802 series supplies allow capacitors to be charged in pulse forming networks and

modulators in a very fast, efficient and controllable manner.

The units are compact high power constant current sources that can linearly and rapidly

charge a capacitive load to high voltage. Once the load capacitor is charged to the

programmed voltage, the supply will switch over to a voltage regulation mode and maintain

the load voltage at the programmed level until it is discharged.

The flexible design of the 802 allows the unit to be ordered with (L model) or without (S and

OEM model) the front panel controls and meters. Front panel controls are ideal in

applications where local control and read backs are necessary, such as R&D, laboratory

use and diagnostics. All front panel controls and indicator signals are available at the rear

panel remote control connector regardless which panel option (L, S, or OEM) is selected.

The unit is self-contained, requiring only AC power and appropriate controls. Several units

may be connected in parallel for higher power operation. There is no theoretical limit to the

number of units that may be paralleled. Typically one master unit and one or more slave or

OEM units may be used to obtain as much output power as necessary. The 802 is also

ideally suited to charge reservoir capacitors in resonant charging circuits where high rep

rates (several kilohertz) are required, such as in metal vapor lasers or solid-state

modulators.

6

83488001 Revision N

Page 13

All 802 power supplies are designed to minimize the risk of fire or shock

hazard. This instrument received comprehensive mechanical and

electrical inspection prior to shipment. Nevertheless, certain safety

precautions must be observed. Only TECHNICALLY QUALIFIED

SERVICE PERSONNEL familiar with the principles of electrical safety

should operate this supply. The power supply SHOULD NOT BE

EXPOSED TO WATER OR MOISTURE OR DUSTY ENVIRONMENTS.

Electrical safety must be maintained at all times.

Lethal voltages are developed within the power supply's enclosure and

at the output cable. Therefore, the cover may not be removed by the

user (see Warranty in preamble section for variance). Also, the large

capacitors in the supply may store power even after the AC input line is

removed. ALLOW AT LEAST 40 SECONDS DISCHARGE TIME

between removing the AC input line and opening the cover. ALSO,

ALLOW AT LEAST 40 SECONDS between switching the AC power off

and switching it on again.

1.5. Continuous DC Operation

Although the 802 series has been designed for capacitor charging applications, they can

also be used as a continuous DC High Power Source for RF tubes such as klystrons,

TWTs, or other DC loads such as DC-DC converters. The DC option must be specified

when ordering, and the supply will be factory setup and tested with a continuous DC load.

When 802 supplies are operated in continuous DC applications it is often necessary to add

an external capacitor between the load and ground to improve the ripple performance of

the unit. Our online Application Note 505 describes operating capacitor charging supplies

in DC applications, and gives guidance in determining the size of any additional external

filter capacitance required. App Note 505 can be found at:

http://www.us.tdk-lambda.com/hp/pdfs/application%20notes/93008505rC.pdf

Consult the factory before connecting parallel units in continuous DC applications.

1.6. Additional Features:

Internal contactor and fuses for AC disconnect and protection

Standard AC power and control connectors

Documentation Manual Including -

Installation, check out, suggested remote interfaces and control circuits

10 ft (3m). Output cable is standard, other lengths are optional.

1.7. Safety Precautions

1.7.1. This product is designed for Indoor use.

1.7.2. This product is designed for pollution degree 2.

1.7.3. This product is designed for Transient Overvoltage Category II

1.7.4. Ensure all covers are in place and securely fastened before switching ON the AC

power.

1.7.5. Proper grounding from the input AC power is required to reduce the risk of electric

shock. Ensure that the AC Protective Earth Ground connection has at least the same

gauge wire as the supply leads shown in Table 2.

83488001 Revision N

7

Page 14

1.7.6. Use extreme caution when connecting AC input power, and never apply the incorrect

input voltage, refer to ratings label.

1.7.7. Use extreme caution when connecting the high voltage output cable to the load.

1.7.8. Ensure all load capacitors are completely discharged prior to connection. Never

handle the output cable when the power supply is operating.

1.7.9. Never attempt to operate the power supply in any manner not described in this

manual.

1.7.10. Never remove DANGER and WARNING labels from the power supply. Replace lost

or damaged labels immediately.

1.7.11. The power supply should only be serviced by factory authorized personnel.

1.7.12. No user maintenance is required.

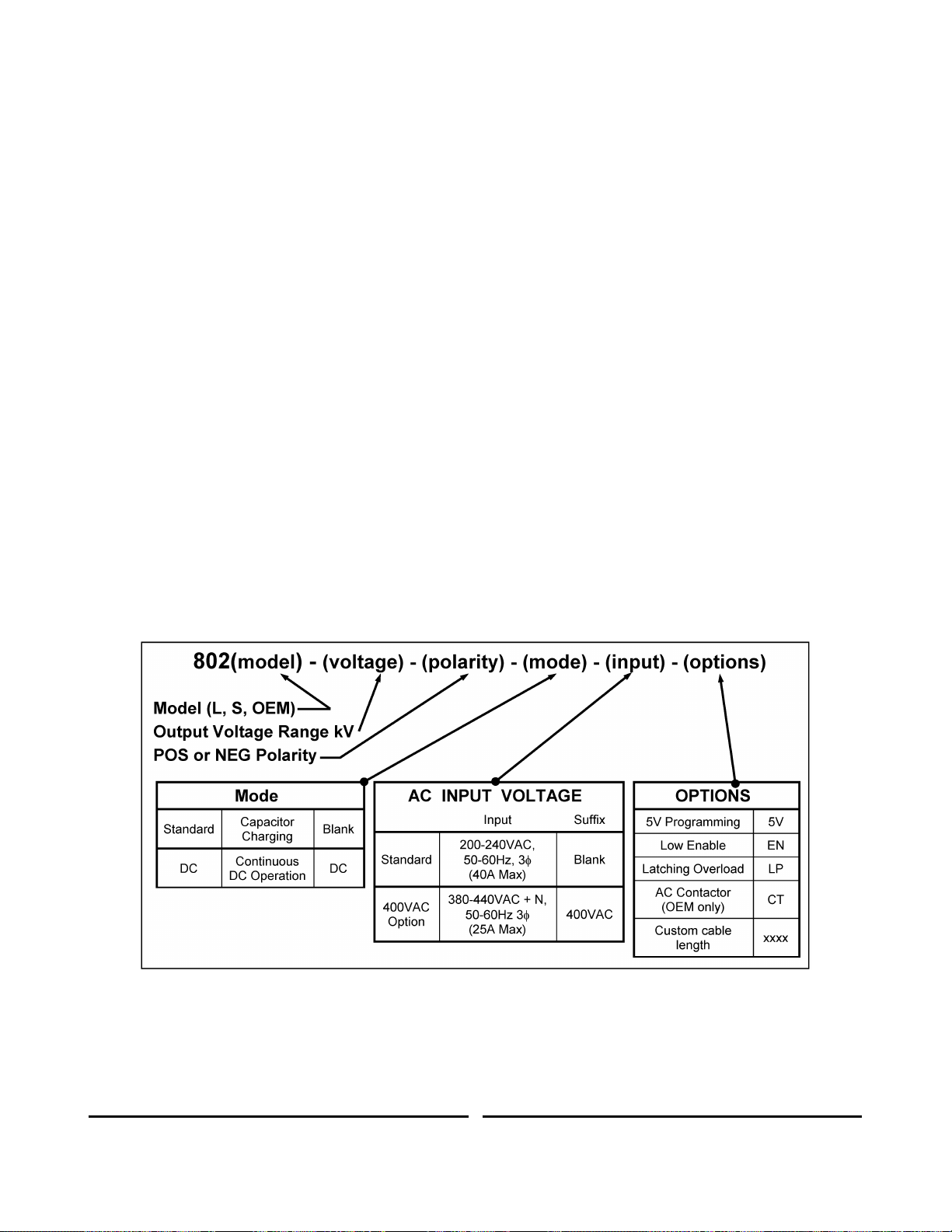

1.8. Model Number Format

The model numbering system for the 802 Series power supply includes symbols for features

and options. They are separated by dashes.

Examples are: 802L-10kV-POS-400VAC and 802S-20kV-POS-DC.

The 802 is available with three front panel configurations, the L, S, and OEM. The choice of

panel configuration is dependent upon the installation and system requirements. See section

5 for further details.

Table 1 shows a partial listing of the model description format for the 802 Power Supply

family. For additional options, the customer may contact the Sales Department at TDKLambda Americas. Special options are typically shown as a four-digit suffix to the model

number.

Table 1 :802 Model Description Format .

8

83488001 Revision N

Page 15

2.1. Average Charging Power

8,000 Joules/sec (½CV2 x Rep Rate)

2.2. Peak Charging Power

9,000 Joules/sec (½CV

2 ∕

t

charge

)

2.3. Average DC Power

8,000 Watts

2.4. Output Voltage Range

1, 2, 4, 5, 10, 15, 20, 30, 40, 50kV, variable from 10-100% of rated.

Other voltages on request, please contact the factory.

2.5. Polarity

Available as fixed Positive or Negative. Please specify at time of ordering

2.6. HV Output Cable

1-39kV Models - DS2124 Coaxial cable with proprietary HV connector

40-50kV Models - DS2214 Coaxial cable with proprietary HV connector

2.7. HV Insulating Medium

Exxon Mobil Univolt N61B or equivalent insulating oil

2.8. AC Input Voltage

200-240VAC (180-264), 3Ø or 380-440VAC (340-460), 3Ø + N, 50-60Hz

Please specify at time of ordering

2.9. AC Input Current

40A for 200-240VAC Input / 25A for 380-440VAC input

2.10. AC Connector

UL/CSA approved terminal block. 3Ø + GND for 200-240VAC, 3Ø + N +

GND for 380-440VAC

2.11. AC Line Contactor

UL/CSA approved AC line contactor (standard on 802L and 802S, option for

802OEM)

2.12. Power Factor

Passive PFC pf = 0.85 at full load and nominal AC line

2.13. Efficiency

Better than 85% at full load

2.14. Front Panel

802L - Voltage Control, Voltage & Current Meters, Status Indicators

802S - On/Off Switch, Status Indicators

802-OEM - Blank front panel

2.15. Stability

0.2% per hour after 1 hour warmup

2.16. Temperature Coefficient

100ppm per °C typical

2.17. Stored Energy

Less than 0.3J all models

2.18. Pulse to Pulse Repeatability

±2% to 1000Hz, consult factory for higher rep rates

2.19. Dimensions - inches (mm)

19 (483) W x 8.75 (222) H x 17 (432) D

2.20. Weight - lbs (kg)

80 (37)

2.21. Ambient Temperature

Storage: -20 to +70°C. Operating: -20 to +45°C

2.22. Altitude

Storage: 40,000ft (12,000m), Operating: 9,900ft (3,000m)

2.23. Humidity

10-90%, non-condensing

2.24. Protection

Open/short circuits, Overloads, Arcs, Overtemp, Overvoltage, Safety

Interlock

2.25. Remote Control (all models)

Via 25-pin D-sub connector on rear of unit, Signals include, Vprogram (010V), HV Enable/Reset, Inhibit, Summary Fault, Load Fault, Vanalog, Vpeak

2.26. Accessories

10ft HV cable, operating manual

2. SPECIFICATION

83488001 Revision N

9

Page 16

2.27. Options

EN - Low Enable. Replaces standard high enable

5V - 0-5V Analog programming. Replaces standard 0-10V programming.

LP - Latching Overload Protection, requires HV reset after overload fault

DC - Continuous DC operation

CT - AC line contactor (option for 802-OEM only, standard on 802L and

802S)

Double terminated HV cable, and mating bulkhead connector

2.28. Ordering Info

Model - XXkV - POS (or NEG) - YYYVAC - ZZ (options)

2.29. Ordering Examples

802L-10kV-POS, 802S-1kV-NEG-DC, 802-OEM-50kV-POS-400VAC

All specifications subject to change without notice

83488001 Revision N

10

Page 17

3. OUT OF BOX INSPECTION

3.1. Visual Inspection

Prior to shipment, this instrument was inspected and found to be free of mechanical and

electrical defects. As soon as the unit is unpacked, inspect for any damage that may have

occurred in transit. Verify the following:

a) Check the operation of the front panel control (knob should rotate smoothly).

b) Confirm that there are no dents or scratches on the panel surfaces.

c) Check front panel meters and LEDs for any broken or cracked lenses.

If any damage is found, follow the instructions in Section 3.3.

3.2. Electrical Inspection

Before the power supply is installed in a system, verify that no internal damage occurred

during shipping. A set of simple preliminary electrical test can be performed if desired. These

tests are described below.

The sequences described are for L model supplies with local controls, for S and OEM

models the corresponding signals must be applied and monitored through the remote control

NOTE

interface.

3.2.1. Test 1

Purpose: Verify general logic operation, generate maximum output current, and check

overload protection circuits. With AC power "OFF" and disconnected, short the HV

output by connecting the center conductor of the output cable to its return shield

(braid). This dead short will allow the unit to generate full output current at zero voltage.

1. Set the output voltage control to zero. Connect AC power to the unit. Turn "ON" the

AC power front panel switch.

2. Turn the front panel keyswitch to the LOCAL position (if applicable). Press the HV

"ON" button and turn up the HV control until the power supply is generating output

current into the dead short. The current meter will indicate max. current. The

voltage meter will read zero and the power supply will intermittently turn on and off

indicating the "overload" condition. The unit should continue to indefinitely cycle in

this mode with a 1 second period. (The power supply will go into overload when

max. current is drawn for more than half a second). If the LP option is installed, the

unit will shut down and indicate a fault after delivering full current for 500milliS.

3. Turn off the HV and AC power switches.

This test indicates the inverter section is generating maximum current and the logic and

overload circuitry works correctly.

3.2.2. Test 2

Purpose: Verify that the power supply generates maximum rated voltage, and the

regulation and feedback circuits are functioning.

1. With AC power OFF and disconnected, connect an appropriate load capacitor to

the power supply output cable. Select the capacitor size so the charge time is

several milliseconds or more.

2. Prepare to charge the capacitor. NOTE: Operating a 802 power supply into an open

circuit (no load operation) will instantly damage the power supply's HV output

11

83488001 Revision N

Page 18

diodes. Make sure the load (capacitor) is connected and the HV output cable is

securely inserted and connected.

3. Turn the voltage control on the front panel all the way down to zero (counter

clockwise), apply AC power, turn the front panel keyswitch to the LOCAL position (if

applicable), and press the HV ON button. By turning up the HV control knob the

capacitor will charge to the voltage indicated on the front panel voltmeter. The

power supply may be turned all the way up to its max. output voltage provided the

load capacitor is sufficiently rated.

4. By turning the voltage control down or depressing the HV OFF button, the capacitor

will slowly "bleed" down through the internal voltage divider resistors used for

regulation feedback. Use an external discharge wand to ensure the capacitor is fully

discharged.

Test #2 indicates the HV section is working correctly. Tests 1 and 2 generally indicate

the unit is functioning as designed. Although 100% power had not been generated,

these two tests give greater than 90% confidence that the unit is not damaged.

If any inconsistency from the above test procedure is noted, do not hesitate to call TDKLambda Americas Customer Service for assistance.

3.3. Contacting TDK-Lambda Americas Customer Service

When contacting customer service locate the product description, part number and serial

number from the label located on the rear of the unit, and have this information available.

Phone: (732) 922-9300 E-mail: hp.service@us.tdk-lambda.com

Fax: (732) 922-1441

Customer Service, or an approved Service Center, should be contacted if:

The power supply is mechanically or electrically damaged.

The power supply requires on-site calibration, or replacement warning decals.

The customer has questions about a special application that is not described in this

manual.

Normally, the customer may NOT open any chassis covers that have a warranty seal.

Breaking a seal will void the warranty.

At the discretion of TDK-Lambda Americas, the customer may be granted permission to

break the warranty seal and open the chassis covers. Customer Service shall confirm the

permission by sending a replacement seal. Once the unit has been serviced, the customer

shall close the cover and apply the replacement seal adjacent to (not on top of) the broken

seal.

3.4. Returning Defective Units

If a unit needs to be returned to the factory for repair, the factory must first assign an RMA

number. Please complete and send the online RMA request form at http://www.us.tdk-

lambda.com/hp/RMA_request.htm and an RMA number will be assigned. Follow the return

instructions on the form or at http://www.us.tdk-lambda.com/hp/returns.htm.

12

83488001 Revision N

Page 19

Never install the 802 so its weight is supported only by the front panel

screws!

8.72”

(222mm)

19” (483mm)

4. INSTALLATION

4.1. 19-Inch Rack Mounting

This power supply is intended for mounting in a conventional 19-inch equipment rack. It’s

8.75 inch height makes it a “5U” size instrument. The rack should enclose the sides, top and

back to protect the operator from electrical shock and protect the supply from environmental

contamination.

The 802 must never be installed without support in the back or sides of the unit. The 802

should be mounted on support rails or chassis slides –such as General Devices CTS-124- or

on a suitable shelf or supports inside the rack.

The mechanical outline of the 802 is shown in Figures1 through 3.

Figure 1. 802L Front View

13

83488001 Revision N

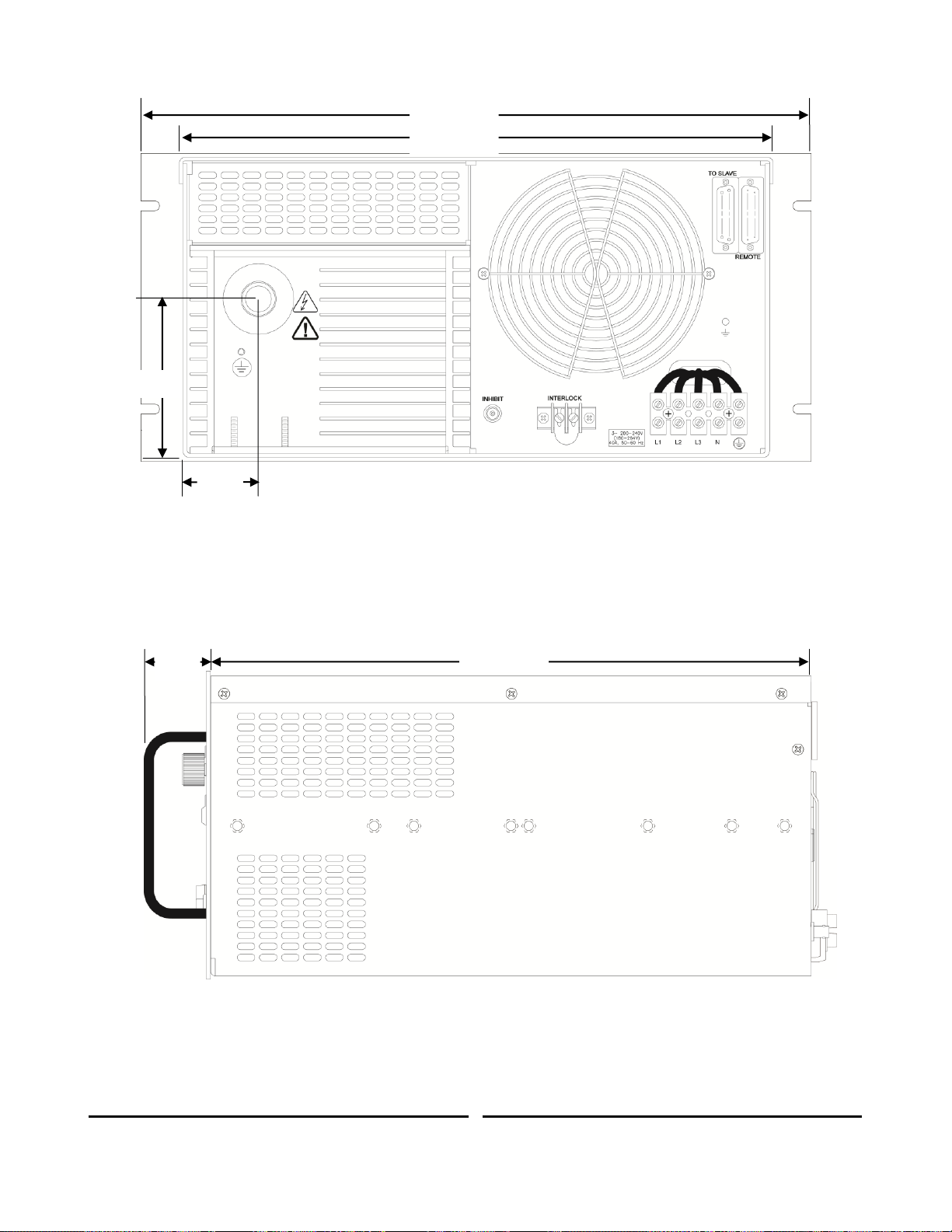

Page 20

4.5”

(114mm)

2.15”

(55mm)

19” (483mm)

17” (432mm)

1.875”

(48mm)

17” (432mm)

Figure 2. 802L Rear View

Figure 3. 802L Side View

14

83488001 Revision N

Page 21

For 200-240VAC models, the maximum voltage allowed between any

two AC input terminals is 264VAC. For 380-440VAC models, the

maximum voltage allowed between any two AC input terminals is

460VAC. If this voltage is exceeded, catastrophic damage will result,

that is not covered by TDK-Lambda Americas standard warranty.

The Protective Earth Ground must be connected before applying

AC Line Power to the 802.

4.2. Ventilation Requirements

This instrument is fan cooled. Sufficient space must be allocated so that a free flow of

cooling air can reach the back and sides of the instrument when it is in operation. Ensure

these clearances are met for adequate air flow:

4 inches (10 cm) rear

1 inch (2.5 cm) on each side.

Cooling air exits through the rear of the unit, and enters through the side panels and around

the HV tank. This power supply should not be operated with its cover removed since the

cover directs the flow from the internal fan.

When operating in an enclosed system, care must be taken to ensure the ambient inlet air to

the power supply does not exceed the maximum operating temperature of 45°C. This may

require addition of a system heat exchanger.

4.3. Orientation

The power supply must be operated in a level horizontal orientation. More than a quarter of

an inch (6.25mm) difference in height in any direction could potentially cause an arcing

condition in the high voltage tank and should be avoided.

4.4. AC Power Connection

The customer’s AC power line connects to the 802 via a UL/CSA approved 5 position

terminal block on the rear panel of the unit (see Figure 1). Only use a power cable with the

correct voltage and current rating (see Table 2). The ground wire must be equal to or larger

than the recommended gauge. Secure grounding of the input AC power is required to reduce

the risk of electric shock. The metal chassis of the power supply is grounded through the

earth wire at the input AC power terminal block. Use extreme caution when connecting input

AC power and never apply the incorrect input power.

An external switch or circuit breaker with the following parameters must be used as means of

disconnection:

a) Rated voltage not less than maximum rated voltage of the power supply

b) Rated current not less than 150% of the power supply rated current

The switch or circuit breaker must be located in proximity to the power supply and within

easy access of the operator. The switch or circuit breaker must be marked as disconnecting

device for the equipment.

15

83488001 Revision N

Page 22

AC INPUT VOLTAGE

MODE

RECCOMENDED AC INPUT CABLE

SIZE & RATING

200-240VAC

(180-264VAC), 50-60 Hz, 3

Cap Charging

9mm2/8 AWG, 600V

Continuous DC

9mm2/8 AWG, 600V

380-440VAC

(340-460VAC), 50-60 Hz, 3

Cap Charging

6mm2/10 AWG, 600V

Continuous DC

6mm2/10 AWG, 600V

Connect the three lines of the input power to the L1, L2, L3 terminals and the earth ground to

the terminal marked with the ground symbol ( ). No neutral connection is required for the

200-240VAC configuration. For models with the 380-440VAC input configuration (340460VAC) the neutral wire must be connected to terminal marked N. The power connections

are not phase rotation sensitive, so any phase can be connected to any of the AC inputs.

Figure 4 AC Input Terminal Block

If the power supply was purchased with the 400VAC input configuration, in

addition to the three phases, the neutral wire must be connected to terminal

marked N. Failure to connect the Neutral wire in a 400VAC unit may result in

damage to the supply.

Table 2 Recommended AC Input Cable

The AC input rating is marked on the rear terminal of the power supply. The rating is also

part of the unit’s model description shown in Table 1.

16

83488001 Revision N

Page 23

Ensure that the power supply is off and disconnected from the AC

input power and that all load capacitors are discharged and shorted to

ground before making any connections. Never handle the HV cable

while the supply is operating. Never operate the supply without a load

capacitor connected.

!

L1 L2 L3 N

HV Switch

LOAD CIRCUIT

SAFETY

GROUND

C

B

A

3 AC

POWER

N

4.5. Connecting the High Voltage Output

Before connecting the HV output cable, inspect the cable and check for signs of damage.

Always use the HV connector and cable provided with the power supply or an equivalent

substitute provided by TDK-Lambda Americas. Fully insert the connector end of the HV

cable and tighten the locking nut only "hand tight".

When operating above 20kV or 200Hz rep rate, silicone grease (such as Dow Corning DC-4)

must be applied to the HV cable before insertion into the HV connector. The grease is used

to displace air in the connector and reduce long-term corona effects. A cable greasing

procedure is available for download from the TDK-Lambda Americas web site.

The load ground must be connected to the chassis ground through a separate safety ground

cable with a minimum wire size of 10 AWG in addition to the HV output cable shield (see

Figure 5).

Figure 5 Typical Load Circuit Connection

Some peak current will flow out of the power supply during discharge and return through the

HV return and system chassis. This current comes from voltage reversal in under damped

systems and from normal discharge of filter and cable capacitance. The path for this current

should not parallel control signal returns since the resulting voltages could interfere with

normal system operation.

83488001 Revision N

17

Page 24

Currents due to voltage reversal, particularly at high repetition rates

can damage the power supply. Generally, a resistor in series with

the HV output can be added to limit this current to an acceptable

level, but an additional clamp diode may also be required.

Refer to Application Note 517 (available from the factory or at

http://www.us.tdk-lambda.com/hp/product_html/high_volt.htm) for

more detailed information.

Dress the high voltage cable to create a gentle curve ensuring there are no sharp bends as

this will tend to reduce the cable's insulation strength. Strain relieve the load end of the high

voltage cable to prevent breaking of, or damage to the center conductor. Keep the HV

cables as distant as possible from the input power and the control signals.

To connect the HV cable to the load it is necessary to remove the cable jacket, shield, and

any semiconducting layer (if applicable) that remains on the cable insulation after removing

the shield.

The cable outer jacket should be removed to reveal the cable shield. At least 12” or 300mm

of outer jacket should be removed for suitable voltage hold-off. The exposed shield should

be trimmed to an appropriate length and terminated with a ground connection.

For models shipped with DS2214 HV cable (>40kV rated voltage), after the shield is

removed, the black semiconducting layer is exposed. This layer should be very carefully

removed using a sharp craft knife, and a peeling action. Once the semiconducting layer is

removed, the exposed EPR insulation should be cleaned with IPA or an equivalent solvent. If

any of the semiconducting layer remains on the HV cable insulation it may cause the cable

termination to fail.

For models shipped with the DS2124 HV cable (<40kV rated voltage), there is no

semiconducting layer to be removed from the cable insulation, however the exposed

polythene cable insulation should be cleaned with IPA.

18

83488001 Revision N

Page 25

REF

DESCRIPTION

NOTE

SECTION

1

HV ON Push Button

Turns on HV output

5.2

2

Status LEDs

Indicates status of supply and presence of any faults

5.3

3

Local Voltage Set

10 turn pot for setting output voltage in local mode

5.4

4

Voltage bar graph

Analog bar graph showing output voltage (%)

5.5

5

Voltage Display

Digital display of output or set voltage

5.6

6

HV OFF Push Button

Turn off HV output

5.7

7

Off/Local/Remote Key

Switches control between remote, local, and off modes

5.8

8

View set push button

Push to view the output voltage set point in local mode

5.9

9

Current bar graph

Analog bar graph showing average output current (%)

5.10

10

Current Display

Digital display of average output current

5.11

11

Power switch

Turns on/off power to auxiliary circuits

5.12

5 1 2 3 4 6 7 8 9

10

11

5. CONTROLS, INDICATORS, CONNECTORS

5.1. Front Panel Layout (L Model)

The 802L series power supply is equipped with a fully instrumented front panel featuring

output voltage control, voltage and current metering, and comprehensive status LEDs, along

with local/remote mode keyswitch, and power on switch. The 802L can be operated locally

from the front panel or remotely via the control connector located on the rear panel (see

Section 6.2). Front panel layout of the 802L power supply is shown in Figure 3 below.

Figure 6 802L Front Panel Controls and Indicators

Table 3 Front Panel Controls and Indicator Functions (L Model)

The front panel controls/indicators are described in detail in the following sections.

19

83488001 Revision N

Page 26

DO NOT DEPRESS THE HV ON PUSH-BUTTON UNLESS A

SUITABLE CAPACITIVE LOAD IS CONNECTED TO THE POWER

SUPPLY'S OUTPUT CABLE, AND THE LOAD IS CORRECTLY

GROUNDED.

5.2. HV ON Push Button (Ref 1)

The HV ON push button is a momentary switch that when depressed turns on HV output in

local mode (keyswitch in local position) only if there are no faults present within the supply. If

faults are present when the HV ON button is pushed the supply will not turn on, and both

the HV ON and HV OFF LEDs will illuminate. When both the HV ON and HV OFF LEDS are

illuminated together this indicates a Summary Fault. If the keyswitch is in the remote position

the HV ON push button has no function.

5.3. Status LEDs (Ref 2)

There are 6 status LEDs on the front panel, indicating the state of the HV Output circuit and

various fault detection circuits in the control system.

5.3.1. HV ON LED

The HV ON LED indicates that the HV output circuit is enabled and the supply will

deliver output current if it is not inhibited by an external inhibit input. If the HV ON and

HV OFF LEDs are illuminated together this indicates a Summary Fault. HV ON LED

is active in local and remote modes.

5.3.2. HV OFF LED

The HV OFF LED indicates that the HV output circuit is disabled and the supply

cannot deliver output current. If the HV OFF and HV ON LEDs are illuminated

together this indicates a Summary Fault. HV OFF LED is active in local and remote

modes.

5.3.3. Inhibit LED

If the Inhibit LED is illuminated it indicates the presence of an active inhibit signal, and

the supply will not deliver charging current after the HV ON button is pushed. Inhibit is

applied either via the rear panel mounted BNC connector or either inhibit input via the

remote control connector. Inhibit LED is active in local and remote modes.

5.3.4. END OF CHARGE LED

The END OF CHARGE or EOC LED indicates that the load or output voltage has

reached the programmed voltage. EOC LED is active in local and remote modes.

5.3.5. Interlock Open LED

The interlock open LED illuminates if the safety interlock circuit is not closed. The

power supply cannot be turned on if the interlock loop is open. If the interlock loop is

opened when the unit is running (ie when HV in ON), the unit will turn off with a

latching fault, requiring an HV ON/OFF/ON reset cycle before it can be restarted.

Interlock Open LED is active in local and remote modes.

5.3.6. Load Fault LED

The load fault LED indicates the presence of a fault in the load circuit due to a short

circuit large external capacitor, or an output Overvoltage. An output Overvoltage

condition will cause a latching fault requiring an HV ON/OFF/ON reset cycle before it

can be restarted. Load Fault LED is active in local and remote modes.

20

83488001 Revision N

Page 27

DO NOT MOVE THE KEYSWITCH POSITION FROM OFF TO

LOCAL OR REMOTE UNLESS A SUITABLE CAPACITIVE LOAD IS

CONNECTED TO THE POWER SUPPLY'S OUTPUT CABLE, AND

THE LOAD IS CORRECTLY GROUNDED.

5.3.7. Overtemp LED

The overtemp LED indicates an inverter overtemperature condition internal to the

supply. The temp fault will clear once the temperature is below the fault threshold, but

the unit will not restart without a reset cycle. Overtemp LED is active in local and

remote modes.

5.4. Local Voltage Set (Ref 3)

The local voltage set control is an analog 10-turn potentiometer for adjusting the output

voltage from zero to full rated output. This control will only operate in local mode. If the

supply is operated in remote mode the local voltage set control has no effect.

5.5. Voltage bar graph (Ref 4)

The voltage bar graph is a 'quick view' analog percentage indication of the voltage measured

at the power supply output. Bar graph is active in local and remote modes.

5.6. Voltage Display (Ref 5)

The Voltage Display is a 4 digit LED indicator showing the voltage measured at the power

supply output. This display momentarily shows the output program voltage after the View Set

button is depressed. Voltage Display is active in local and remote modes.

5.7. HV OFF Push Button (Ref 6)

The HV OFF push button is a momentary switch that when depressed turns off HV output. If

the power supply shuts off with a summary fault (indicated by HV ON and HV OFF LEDs

both illuminated), then this condition can be reset by pushing the HV OFF, HV ON, HV OFF

button sequence. If the supply is operated in remote mode the HV OFF push button will still

function.

5.8. Off/Local/Remote Keyswitch (Ref 7)

The Off/Local/Remote Keyswitch switches the 802L power supply operating modes between

OFF, LOCAL, and REMOTE. The key can be removed in the OFF position to prevent

unauthorized use. If the switch is in the LOCAL position the supply will operate from the front

panel. In the REMOTE position the supply can only be operated via the remote control

interface. An L model supply can simulate an S or OEM model with the key in the REMOTE

position.

5.9. View set push button (Ref 8)

The view set push button changes the reading on the digital voltage display from the power

supply output voltage, to the programmed voltage set on the local voltage set potentiometer.

After pushing this button the set voltage is displayed for approximately 3 seconds.

5.10. Current bar graph (Ref 9)

The current bar graph is a 'quick view' analog percentage indication of the average current

delivered by the supply. Bar graph is active in local and remote modes.

21

83488001 Revision N

Page 28

REF

DESCRIPTION

NOTE

SECTION

2

Status LEDs

Indicates status of supply and presence of any faults

5.3

11

Power switch

Turns on/off power to auxiliary circuits

5.12

2

11

5.11. Current Display (Ref 10)

The Current Display is a 4 digit LED indicator showing the average current delivered by the

power supply output. Current display is active in local and remote modes.

5.12. Power switch (Ref 11)

The power switch connects AC input power to the control circuitry and causes the internal

AC contactor to close if the interlock loop is closed.

5.13. Front Panel Layout (S Model)

The 802S series power supply is equipped with a partially instrumented front panel featuring

status LEDs, and a power on switch. The 802S can only be operated remotely via the control

connector located on the rear panel (see Section 6.2).

Figure 7 Front Panel Controls and Indicators (S Model)

Table 4 Front Panel Controls and Indicators (S Model)

A description of the function of the LEDs and the power switch are given in sections 5.3 and

5.12 respectively.

5.14. Front Panel Layout (OEM Model)

The 802OEM front panel is completely blank and features no indicators or switches.

22

83488001 Revision N

Page 29

REF

DESCRIPTION

NOTE

SECTION

1

HV Output

HV Output connector, mates with supplied cable via proprietary

connector

5.15.1

2

Cooling fan

Main AC cooling fan. Leave at least 4" clearance

5.15.2

3

Slave Interface

25pin male sub-D type plug for control of slave supplies in a

parallel system (AMPHENOL 17BDFRA25P)

5.15.3

4

Remote Interface

25pin sub-D type receptacle for remote control of supply in

remote mode (AMPHENOL 17BDFRA25S)

5.15.4

5

GND stud

10-32 UNC ground stud

5.15.5

6

GND stud

M5 ground stud (2 positions)

5.15.6

7

Inhibit input

BNC input to allow inhibit of output current

5.15.7

8

Interlock

Terminal for connection to interlock circuit. Contacts are isolated

from ground and require dry contact closure for supply to

operate.

5.15.8

9

AC Input

5 position terminal block for AC input power

5.15.9

1 3 4

2

!

L1 L2 L3 N

5 9 6 7 8

5.15. Rear Panel Layout (L Models)

All of the interconnect and HV connections for the 802L are located on the power supply rear

panel.

Figure 8 shows the rear panel layout and location of the various connectors.

Figure 8 802L Rear Panel Connections

23

83488001 Revision N

Page 30

Table 5 802L Rear panel Functions

The function of each item in Table 5 is described in the following sections.

5.15.1. HV Output Connector (Ref 1)

Connector socket for mating HV cable supplied with unit. The connector should be

kept clean and free from debris at all times. If supply is operated at 20kV or 200Hz rep

rate or above the cable should be greased to ensure corona free operation. The cable

connector should only be hand tightened, never use a wrench or apply excessive

force.

5.15.2. Cooling Fan (Ref 2)

Allow at least 4 inches of clearance and do not obstruct clear air flow around the fan.

Cooling air exits through the rear of the unit, and enters through the side panels and

around the HV tank.

5.15.3. Slave Connector (Ref 3)

A 25 pin D-sub female connector that allows connection to a slave supply for

increased power operation.

5.15.4. Remote Connector (Ref 4)

A 25 pin D-sub male connector that allows remote operation and monitoring of all

power supply functions when the unit is operated in REMOTE mode.

5.15.5. Safety Ground (Ref 5)

10-32UNC threaded safety ground stud installed in HV tank. Should be used for

additional safety ground cable between supply and load circuit.

5.15.6. Safety Ground (Ref 6)

M5 threaded safety ground stud installed in HV tank. Should be used for additional

safety ground cable between supply and load circuit.

5.15.7. INHIBIT BNC (Ref 7)

The inhibit BNC input is a standard BNC socket that allows an external connection to

a pulse generator or control system and gives the user control of the power supply

output current. A logic 1 (5-15V) input will inhibit the supply (shuts off the output

current) and a logic 0 (ground or open) allows the supply to operate.

5.15.8. Interlock Terminal strip (Ref 8)

Provides an external dry contact connection for the customer to allow interlock

functions to be controlled. The interlock terminals should be connected to any safety

interlock circuitry in the power supply installation. When the interlock is open the AC

line contactor disconnects the AC line from the power circuitry. The power supply is

shipped with a factory installed shorting link across the interlock terminals.

NOTE

The Interlock terminals are chassis referenced 24VAC

circuits and must never be connected to ground.

24

83488001 Revision N

Page 31

1 4 2

!

L1 L2 L3 N

5

6 8 9

5.15.9. AC Input Terminal (Ref 9)

Main AC input power terminal block see section 4.4 for further details. For 200-

240VAC connect three phases and ground. For 380-440VAC option connect three

phases, Neutral and Ground. AC input is not phase rotation sensitive.

5.16. Rear Panel Layout (S Models)

The 802S rear panel is similar to the 802L except these is no SLAVE or INHIBIT BNC

connector. If a number of units are to be connected in parallel, a daisy chain type ribbon

cable should be used to connect the supplies together. See section 6.4 for more details.

The numbers in Figure 9 refer to Table 5.

Note:

Figure 9 802S Rear Panel

25

83488001 Revision N

Page 32

!

L1 L2 L3 N

1 2 4 5 6

9

5.17. Rear Panel Layout (OEM Models)

The 802OEM rear panel is similar to the 802S except there is no interlock terminal, unless

the CT option is installed. If a number of units are to be connected in parallel, a daisy chain

type ribbon cable should be used to connect the supplies together. See section 6.4 for more

details.

The numbers in Figure 10 refer to Table 5.

Note:

Figure 10 802OEM Rear Panel

26

83488001 Revision N

Page 33

Pin 1. Analog Out

Pin 3. Inhibit LED

Pin 5. End of Charge LED

Pin 7. Inhibit Input

Pin 8. HV On/Off

Pin 9. Peak output volts

Pin 10. HV On LED

Pin 12. GND

Pin 13. Charge current

Pin 14. +15V

Pin 16. Overtemp LED

Pin 17. Interlock LED

Pin 18. Load fault LED

Pin 19. Summary fault LED

Pin 20. Inhibit Input

Pin 22. Vprogram input

Pin 23. HV Off LED

Pin 24. GND

PIN 25, +12V Unfiltered

5.18. REMOTE CONTROL CONNECTOR PIN DIAGRAM

Figure 11 shows a summary of the remote control signals on the connector labeled 4 in

Figure 5 through 8. The connector is a 25-pin sub D-type receptacle (female).

Figure 11 Remote Interface Connector and Signals.

27

83488001 Revision N

Page 34

Notes

28

83488001 Revision N

Page 35

HIGH VOLTAGES MAY POTENTIALLY EXIST FROM THIS POINT

FORWARD.

6. OPERATING INSTRUCTIONS

The 802 power supply is designed for operation in two modes. The first mode is local, where

the power supply can be controlled from the front panel. Local operation is only possible with

the L model supply. The second mode is remote, where control signals are passed via the

25pin remote connector. Remote operation is possible with all 802 model power supplies (L,

S, or OEM).

6.1. Local Operation (802L only)

The model 802L has full front panel instrumentation and controls for use in laboratory,

prototype or OEM systems. The front panel controls include power on/off, remote/local and

HV on/off switches, output voltage adjust, view set switch, digital voltage and current meters,

quick reference bar graphs and status indicators. An internal AC contactor is included which

is controlled by the front panel power switch and the interlock terminals located on the rear of

the unit. A BNC connector is provided on the rear panel for easily connecting a pulsed

INHIBIT signal when operating from the front panel. The model 802L can be operated as a

"master" unit in parallel with several model 802S or OEM "slave" units for increased output

power. Refer to Section 6.4 "Paralleling Units".

Before operating the power supply ensure a load capacitor is connected between the

power supply output, and the other terminal of the capacitor is connected to ground

or the appropriate point in the load circuit. Failure to correctly connect a capacitive

load prior to operating the power supply may result in damage.

The power supply should be connected to 3 phase AC power as described in section 4.4.

The interlock terminals should be closed either with the supplied shorting link or by an

isolated external dry contact. Follow the steps below;

1. Ensure the output voltage potentiometer is turned fully counter clockwise.

2. Turn on the AC power switch, the cooling fan should start and the front panel indicators

will illuminate.

3. Turn the control key to the local position.

4. Push the View Set button and turn the Voltage potentiometer until the required load

voltage is displayed. The view set mode stays active for approximately 3 seconds before

the voltage display reverts to the output voltage mode.

5. Push the HV ON button. The load will charge to the preset voltage and once this voltage

is reached the End of Charge LED will illuminate. The supply will maintain this voltage

until the HV OFF button is pushed, or the load capacitor is discharged via the HV switch

in the load circuit.

After the load has been discharged the external Inhibit function can be used to shut down the

power supply output current which aids in the HV switch recovery. Application of an inhibit

signal will typically shut down the output current in approximately 15microseconds.

To turn OFF the power supply depress the HV OFF button, or use the Inhibit input to shut off

the output current but leave the supply in the HV ON condition. Opening the interlock

terminals will also cause the power supply to turn off. In this case the unit can only be turned

back on after the interlock has been closed and the HV ON button depressed followed by the

HV OFF button to RESET the fault. Any other fault occurring in the internal protection

29

83488001 Revision N

Page 36

Pin

Signal Name

I/O

Description

1

Analog Out

O

0-10V (±1%) Analog of output voltage waveform. Impedance 1kIf the 5V option is

installed the voltage level is 0-5V.

3

Inhibit LED

O

Open collector through 100. Low impedance when INHIBIT signal applied. See Note

1.

5

End of Charge

LED

O

Open collector through 100. Low impedance when power supply reaches End of

Charge. See note 1.

7

Inhibit Input

I

5-15V Inhibits unit, open or ground allows operation. Input impedance >10kNote use

either INHIBIT or INHIBIT, never both signals. Do not use the INHIBIT BNC as well as

the INHIBIT signal.

8

HV ON/OFF

I

15V=On, ground or open =Off. Also used to reset latching faults by cycling from On to

Off. Input impedance >1M If the EN option is installed 15V=Off, Ground or open = On

9

Peak output volts

O

0-10V (±1%) Peak detector of output voltage waveform. Can be used to drive a meter

displaying peak charging voltage. Impedance 10k. If the 5V option is installed the

voltage level is 0-5V.

10

HV ON LED

O

Open collector through 100. Low impedance when HV output is enabled. See Note 1.

12

GND

Control circuit return. Also chassis/earth ground.

13

Charge current

O

Uncalibrated Analog of output current waveform. Impedance 10k

14

+15V

O

+15V through 100

16

Overtemp LED

O

Open collector through 100. Low impedance when inverter over temperature

condition occurs. See Note 1.

17

Interlock LED

O

Open collector through 100. Low impedance when external interlock circuit is open.

See Note 1.

18

Load fault LED

O

Open collector through 100. Low impedance when load fault condition occurs. Load

fault is normally a non-latching fault and will self-reset after approximately 500ms,

unless caused by an output overvoltage where the supply will latch off. For models with

the LP option, an external RESET cycle is required to restart the unit. See Note 1.

19

Summary Fault

LED

O

Open collector through 100. Low impedance indicated a summary fault condition.

Summary fault is a logical OR of Overvoltage, Overtemp, AC Line, and Open Interlock

conditions. See Note 1.

20

Inhibit Input

I

0V Inhibits unit, 15V or open allows operation. Input impedance >10 kNote use

either INHIBIT or INHIBIT, never both signals. Do not use the INHIBIT BNC as well as

the INHIBIT signal.

22

Vprogram

I

0-10V = 0-100% of rated output voltage. Input impedance >1M. If the 5V option is

installed the voltage level is 0-5V.

23

HV OFF LED

O

Open collector through 100. Low impedance when HV output is off/disabled. See

Note 1.

24

GND

Control circuit return. Also chassis/earth ground.

25

+12V Unfiltered

O

+12V Raw, unfiltered

circuitry will interrupt the power supply's operation causing it to turn OFF. For a full

explanation of each control and indicator refer to Section 5.

6.2. Remote Operation (All models)

All 802 models are easily controlled through the 25 pin sub D-type remote interface

connector located on the rear panel. The minimum required signals for remote control

operation are; HV ON/OFF, Vprogram and GND. The remaining signals are provided for

status monitoring and fault diagnosis, or more sophisticated control methodologies. The

function each signal is shown in Table 6, with a schematic showing a suggested remote

interface circuit shown in Figure 12.

30

83488001 Revision N

Page 37

Table 6 802 Remote Interface Description

Note 1 – For 802L or 802S models, the front panel LEDs are driven by open collector drivers

that are common to the remote control interface indicator signals. A pullup resistor is not

required to sense the remote interface voltage on these signals. The user should expect the

Active logic level (low) to be between 2 and 4V. If an external pullup resistor is added, the

Active logic level (low) voltage will be higher.

For 802-OEM models, a pullup resistor is required to sense voltage levels at these outputs.

For applications that require logic level inputs the use of an opto-isolation device is

recommended.

Figure 12 Suggested external remote interface circuit.

31

83488001 Revision N

Page 38

A detailed description of each remote control signal is given in the following sub-sections.

6.2.1. Analog Out

Pin 1. Analog of output voltage waveform as measured at the output terminals of the

power supply. Signal is 0-10V +/-1% (0-5V if 5V option installed).

6.2.2. Inhibit LED

Pin 3. Open collector Active Low output indicating presence of an external Inhibit

signal. Max rated voltage - 60V, 100Ω series resistance.

6.2.3. End Of Charge (EOC) LED

Pin 5. Open collector Active Low output indicating power supply output voltage has

reached the programmed voltage or end of charge cycle. Max rated voltage - 60V,

100Ω series resistance.

6.2.4. Inhibit Input

Pin 7. 5-15V Inhibits unit (turns off output current), open or ground allows operation.

Input impedance >10kΩ. Signal can be used to aid load switch recovery.

6.2.5. HV ON/OFF

Pin 8. +15V = HV ON, ground or open = HV OFF. Also used to reset latching faults by

cycling from ON to OFF. Input impedance > 1MΩ. If EN option is installed +15V =

OFF, Open or Ground = ON.

6.2.6. Peak Output Volts

Pin 9. Peak detector of Analog output voltage waveform. Can be used to drive a

meter displaying peak charging voltage. Signal is 0-10V +/-1% (0-5V if 5V option

installed).

6.2.7. HV ON LED

Pin 10. Open collector Active Low output indicating power supply output is

ON/Enabled. Max rated voltage - 60V, 100Ω series resistance. If the HV ON and HV

OFF signals are both active at the same time, this indicates a Summary Fault.

6.2.8. Ground

Pin 12. Control circuit return. Also chassis/earth ground.

6.2.9. Charge current

Pin 13. Analog of output current waveform. Signal is not calibrated.

6.2.10. +15V Output

Pin 14. +15V through 100Ω, maximum current is 20mA.

6.2.11. Overtemp LED

Pin 16. Open collector Active Low output indicating an inverter overtemperature

condition has occurred. Once temperature has returned to normal levels this fault will

clear, but the power supply will not restart without a Reset Cycle. Max rated voltage 60V, 100Ω series resistance.

6.2.12. Interlock LED

Pin 17. Open collector Active Low output indicating the external interlock circuit is

open. Max rated voltage - 60V, 100Ω series resistance.

32

83488001 Revision N

Page 39

6.2.13. Load Fault LED

Pin 18. Open collector Active Low output indicating a load fault condition. Load fault

is a non-latching fault and will self-reset after approximately 500ms (for models

without LP option). Load fault is caused by an output overvoltage condition (110% of

rated voltage) or an output short circuit/large capacitor (load charges for 500ms

without reaching programmed voltage). Max rated voltage - 60V, 100Ω series

resistance.

6.2.14. Summary Fault LED

Pin 19. Open collector Active Low output indicating a summary fault condition.

Summary fault is a logical OR of Overvoltage, Overtemp, AC Line, and Open Interlock

conditions. Summary Fault is also indicated by both HV ON and HV OFF

LEDs/indicators being illuminated at the same time. Max rated voltage - 60V, 100Ω