Page 1

OPERATOR MANUAL FOR

303 Series 2 High Voltage

POWER SUPPLY

Document: 83489011 Rev A

405 Essex Road, Neptune, NJ 07753

Web: www.us.tdk-lambda.com/hp

TDK-LAMBDA AMERICAS

Tel: (732) 922-9300

Fax: (732) 922-1441

Page 2

Page 3

TABLE OF CONTENTS

Table of Contents

1. GENERAL INFORMATION..........................................................................1-1

1.1 INTRODUCTION....................................................................................................1-1

1.2 203 and 303 OVERVIEW.......................................................................................1-1

1.2.1 FEATURES..................................................................................................................... 1-1

1.2.2 BENEFITS....................................................................................................................... 1-1

1.2.3 APPLICATIONS:............................................................................................................. 1-1

1.3 CAPACITOR CHARGING TECHNOLOGY ............................................................1-2

1.4 CONTINUOUS DC OPERATION ...........................................................................1-2

1.5 ADDITIONAL FEATURES:.....................................................................................1-2

1.6 SAFETY PRECAUTIONS.......................................................................................1-3

1.7 SCOPE OF THIS MANUAL....................................................................................1-4

1.8 MODEL NUMBER FORMAT ..................................................................................1-4

2. SPECIFICATIONS .......................................................................................2-7

2.1 Output Power .........................................................................................................2-7

2.2 Polarity ............................................................................................................2-7

2.3 H.V. Return ............................................................................................................2-7

2.4 Pulse to Pulse Repeatability...................................................................................2-7

2.5 Rep Rate ............................................................................................................2-7

2.6 Protection ............................................................................................................2-7

2.7 Input Power:...........................................................................................................2-8

2.8 Phase Configuration...............................................................................................2-8

2.9 Power Factor..........................................................................................................2-8

2.10 Efficiency ............................................................................................................2-8

2.11 AC Line Filtering.....................................................................................................2-8

2.12 Inrush Current ........................................................................................................2-8

2.13 Max. Discharge ......................................................................................................2-8

2.14 Physical Specifications...........................................................................................2-8

2.15 Cooling Water........................................................................................................2-8

2.16 Water Fittings.........................................................................................................2-9

2.17 Weight ............................................................................................................2-9

2.18 Shock and Vibration...............................................................................................2-9

2.19 Shipping ............................................................................................................2-9

2.20 Air Temperature Range..........................................................................................2-9

2.21 Humidity ............................................................................................................2-9

2.22 Altitude ............................................................................................................2-9

i

3. OUT-OF-BOX-INSPECTION......................................................................3-11

3.1 VISUAL INSPECTION..........................................................................................3-11

3.2 ELECTRICAL INSPECTION.................................................................................3-11

3.2.1 TEST 1 .......................................................................................................................... 3-11

3.2.2 TEST 2 .......................................................................................................................... 3-11

3.3 CONTACTING TDK-LAMBDA AMERICAS CUSTOMER SERVICE.....................3-12

3.4 RETURNING DEFECTIVE UNITS .......................................................................3-12

4. INSTALLATION .........................................................................................4-13

4.1 19-INCH RACK MOUNTING ................................................................................4-13

4.2 VENTILATION REQUIREMENTS ........................................................................4-14

4.3 WATER COOLING REQUIREMENTS.................................................................4-14

4.4 ORIENTATION.....................................................................................................4-14

4.5 AC POWER CONNECTION.................................................................................4-15

83489011 Rev A

Page 4

ii

TABLE OF CONTENTS

4.6 CONNECTING THE HIGH VOLTAGE OUTPUT..................................................4-16

5. CONTROLS, INDICATORS, CONNECTORS..............................................5-1

5.1 FRONT PANEL LAYOUT (L Model).......................................................................5-1

5.2 HV ON (Ref 1)........................................................................................................5-2

5.3 OUTPUT STATUS LEDs (Ref 2)............................................................................5-2

5.3.1 HV ON LED..................................................................................................................... 5-3

5.3.2 HV OFF LED................................................................................................................... 5-3

5.3.3 INHIBIT LED....................................................................................................................5-3

5.3.4 END OF CHARGE LED ..................................................................................................5-3

5.3.5 INTERLOCK OPEN LED.................................................................................................5-3

5.3.6 LOAD FAULT LED.......................................................................................................... 5-3

5.3.7 OVERTEMP LED............................................................................................................ 5-3

5.4 LOCAL VOLTAGE CONTROL (Ref 3) ...................................................................5-3

5.5 VOLTAGE BAR GRAPH (Ref 4).............................................................................5-4

5.6 VOLTAGE DISPLAY (Ref 5) ..................................................................................5-4

5.7 CURRENT DISPLAY (Ref 6)..................................................................................5-4

5.8 HV OFF/RESET (Ref 7) .........................................................................................5-4

5.9 OFF/LOCAL/REMOTE KEYSWITCH (Ref 8).........................................................5-4

5.10 POWER SUPPLY STATUS LEDs (Ref 9)..............................................................5-4

5.10.1 STATUS LED GROUP....................................................................................................5-4

5.10.1.1 ENABLE............................................................................................................5-4

5.10.1.2 INHIBIT ............................................................................................................. 5-4

5.10.1.3 AUTOINHIBIT (Normally OFF) ......................................................................... 5-5

5.10.1.4 SUMMARY FAULT (NormallyOFF) ................................................................. 5-5

5.10.1.5 LOAD FAULT (Normally OFF)..........................................................................5-5

5.10.1.6 LINE FAULT (Normally OFF)............................................................................ 5-5

5.10.2 HIGH VOLTAGE LED GROUP....................................................................................... 5-5

5.10.2.1 HV ON............................................................................................................... 5-5

5.10.2.2 HV OFF.............................................................................................................5-5

5.10.2.3 END OF CHARGE (Normally OFF)..................................................................5-5

5.10.2.4 EXCESS REVERSAL (Normally OFF).............................................................. 5-5

5.10.2.5 INTERNAL ARC (Normally OFF)...................................................................... 5-6

5.10.2.6 CLAMP (NormallyOFF).................................................................................... 5-6

5.10.3 COOLANT LED GROUP.................................................................................................5-6

5.10.3.1 FULL (Normally ON) ......................................................................................... 5-6

5.10.3.2 WARNING (NormallyOFF)............................................................................... 5-6

5.10.4 FAULT (Normally OFF)................................................................................................... 5-6

5.10.4.1 OVERTEMP (Normally OFF)............................................................................ 5-6

5.10.4.2 PURGE VALVE (NormallyOFF)....................................................................... 5-7

5.10.4.3 OVER PRESSURE (NormallyOFF)................................................................. 5-7

5.10.5 INPUT POWER LED GROUP (External Faults)............................................................. 5-7

5.10.5.1 HIGH LINE (Normally OFF)..............................................................................5-7

5.10.5.2 LOW LINE (NormallyOFF)............................................................................... 5-7

5.10.5.3 IMBALANCE (NormallyOFF)............................................................................5-7

5.10.5.4 INTERLOCK OPEN (Normally OFF) ................................................................ 5-7

5.10.5.5 BIAS FAULT (Normally OFF)............................................................................5-8

5.10.5.6 FAN FAIL (Normally OFF) ................................................................................ 5-8

5.11 VIEW SET push button (Ref 10) ............................................................................5-8

5.12 CURRENT BAR GRAPH (Ref 11).........................................................................5-8

5.13 AC POWER (Ref 12)..............................................................................................5-8

5.14 FRONT PANEL LAYOUT (S Model).......................................................................5-8

5.15 REAR PANEL LAYOUT (L Models)........................................................................5-9

5.15.1 INHIBIT BNC (Ref 1).....................................................................................................5-11

5.15.2 Coolant Water Inlet/Outlet (Ref 2/4)..............................................................................5-11

5.15.3 HV Output Connector....................................................................................................5-11

83489011 Rev A

Page 5

TABLE OF CONTENTS

5.15.4 Cooling Fan ................................................................................................................... 5-11

5.15.5 Interlock/Power On Terminal strip.................................................................................5-11

5.15.6 Remote connector.........................................................................................................5-11

5.15.7 Slave connector.............................................................................................................5-11

5.15.8 Coolant service valve.................................................................................................... 5-11

5.15.9 Tank pressure gauge .................................................................................................... 5-11

5.15.10 Safety ground ................................................................................................................ 5-12

5.15.11 AC input terminal...........................................................................................................5-12

5.16 REAR PANEL LAYOUT (S Models) .....................................................................5-12

6. OPTIONAL FEATURES.............................................................................6-13

6.1 LOW ENABLE OPTION (-EN)..............................................................................6-13

6.2 5V PROGRAMMING OPTION (-5V).....................................................................6-13

6.3 LATCHING OVERLOAD PROTECTION OPTION (-LP).......................................6-13

6.4 CONTINUOUS DC OPTION (-DC).......................................................................6-13

6.5 REMOTE SENSE (-RS) .......................................................................................6-14

7. OPERATING INSTRUCTIONS ..................................................................7-15

7.1 LOCAL OPERATION (203/303L only)..................................................................7-15

7.2 REMOTE OPERATION (All models)....................................................................7-16

7.2.1 Remote Control Signals ................................................................................................7-17

7.2.2 Remote Operation with AUTOINHIBIT..........................................................................7-17

7.2.3 Remote Operation with INHIBIT....................................................................................7-19

7.3 Parallel Operation.................................................................................................7-20

7.3.1 Parallel system comprising 203/303L supplies ............................................................. 7-20

7.3.2 Parallel system comprising both 203/303L and 203/303S supplies.............................. 7-21

7.3.3 Parallel system comprising 203/303S supplies.............................................................7-21

iii

8. APPLICATION NOTES ..............................................................................8-23

List of Figures

FIGURE 4-1 203/303L FRONT VIEW......................................................................................... 4-13

FIGURE 4-2 203/303 REAR VIEW.............................................................................................4-14

FIGURE 4-3. AC INPUTTERMINAL BLOCK ................................................................................. 4-15

FIGURE 4-4 TYPICAL LOAD CIRCUIT CONNECTION..................................................................... 4-17

FIGURE 5-1. 203/303L FRONT PANEL CONTROLS AND INDICATORS............................................. 5-1

FIGURE 5-2 203/303S FRONT PANEL CONTROLS AND INDICATORS..............................................5-9

FIGURE 5-3 203/303L REAR PANEL CONNECTIONS ..................................................................5-10

FIGURE 5-4 203/303S REAR PANEL ........................................................................................5-12

FIGURE 7-1. EXTERNAL REMOTE INTERFACE CIRCUIT. ............................................................... 7-18

FIGURE 7-2 REMOTE INTERFACE WAVEFORMS FOR 303 OPERATED WITH AUTOINHIBIT........... 7-19

FIGURE 7-3 REMOTE INTERFACE WAVEFORMS FOR 303 OPERATED WITH INHIBIT......................7-20

FIGURE 7-4 PARALLEL OPERATION CONNECTIONS.................................................................... 7-21

83489011 Rev A

Page 6

iv

TABLE OF CONTENTS

List of Tables

TABLE 1-1 MODEL DESCRIPTION FORMAT .................................................................................. 1-5

TABLE 4-1 RECOMMENDED AC INPUT CABLE............................................................................ 4-16

TABLE 5-1 FRONT PANEL CONTROLS AND INDICATORS (L MODEL)............................................... 5-2

TABLE 5-3 FRONT PANEL CONTROLS AND INDICATORS (S MODEL) .............................................. 5-9

TABLE 5-4 203/303L REAR PANEL FUNCTIONS......................................................................... 5-11

TABLE 6-1 203/303 REMOTE INTERFACE DESCRIPTION............................................................. 7-17

83489011 Rev A

Page 7

GENERAL INFORMATION

1. GENERAL INFORMATION

1.1 INTRODUCTION

TDK-Lambda’s ALE series 203 and 303 are state of the art switch mode high voltage

power supplies, designed primarily for capacitor charging applications such as laser systems, modulators, and pulse forming networks. They can also be used in many continuous DC applications including beam power for magnetrons, gyrotrons, klystrons and

electron beam loads.

The 203L and 303L Models are fully instrumented with front panel meters displaying

output voltage and current, status LEDs, a key switch for OFF, LOCAL or REMOTE operation, HV ON/OFF push-button switches, and a control for output voltage adjustment.

The rear panel features external interlock, external inhibit, remote control and slave

(parallel operation) control connections.

The 203S and 303S Models can only be operated by remote control and feature only

front panel status LEDs. The "S" Models have been designed to operate as a slave unit

to the "L" Models or in systems where local control is not a requirement. As many 203 or

303 supplies as required, can be connected in parallel to provide greater output power.

1.2 203 and 303 OVERVIEW

1-1

1.2.1 FEATURES

203 - 20kJ/sec capacitor charging power, 30kW in continuous DC.

303 - 30kJ/sec capacitor charging power, 50kW in continuous DC.

Output voltages from 0-1kV to 0-50kV

Rep rates from single shot to several hundred hertz.

Local or remote operation (L Model) with comprehensive control interface.

Parallel operation (master/slave) for high power applications.

Water-cooling for major means of excess heat removal.

State of the art "Heat Pipe Cooling" system.

1.2.2 BENEFITS

Smallest package size available in this power range (50kW in 12.25” package)

Highest power available in a single package

Low EMI/RFI

Low ambient heating and quiet operation

Lightweight switchmode design

Rack mount chassis configuration

Low stored energy provides greater safety

Immunity to external EMI

1.2.3 APPLICATIONS:

Charging capacitors and capacitor banks.

Powering pulse forming networks/modulators.

83489011 Rev A

Page 8

1-2

Powering lasers: Excimer, flashlamp pumped dye, Yag, CO2, etc.

Line type modulators for RF generation and pulse discharge applications in re-

search.

Continuous power for RF tubes – magnetron, gyrotron, TWT, klystron etc.

Electron beam applications.

DC power source for pulsed hard-tube and solid state modulators.

1.3 CAPACITOR CHARGING TECHNOLOGY

Capacitor charging applications require a power supply designed specifically for the

task. The Series 203 and 303 supplies allow capacitors to be charged in pulse forming

networks and modulators in a very fast, efficient and controllable manner.

The units are compact high power constant current sources that can linearly and rapidly

charge a capacitive load to high voltage. Once the load capacitor is charged to the programmed voltage, the supply will switch over to a voltage regulation mode and maintain

the load voltage at the programmed level until the load is discharged.

The flexible design of the 203 and 303 allow the units to be ordered with (L model) or

without (S model) the front panel controls and meters. The front panel controls are ideal

in applications where local control and readbacks are necessary, such as R&D, laboratory use and diagnostics. All front panel controls and indicator signals are available at

the rear panel remote control connector regardless which front panel option (L or S) is

selected. The S models feature only front panel status indicators and remote controls

and are a cost effective solution for applications where local controls are unnecessary.

The unit is self-contained, requiring only AC power and water for cooling. Several units

may be connected in parallel for higher power operation. There is no theoretical limit to

the number of units that may be paralleled. Typically one master unit and one or more

slave units may be used to obtain as much output power as necessary. Consult the

factory before connecting parallel units in continuous or DC applications.

The 203 and 303 are also ideally suited to charge reservoir capacitors in resonant

charging circuits where high rep rates (several kilohertz) are required, such as in metal

vapor lasers or solid-state modulators.

GENERAL INFORMATION

1.4 CONTINUOUS DC OPERATION

Although the 203 and 303 series has been designed for capacitor charging applications,

they can also be used as a continuous DC High Power Source for RF tubes such as

klystrons, TWTs, or other DC loads such as DC-DC converters. The DC option must be

specified when ordering, and the supply will be factory setup and tested with a continuous DC load. When 203/303 supplies are operated in continuous DC applications it is

necessary to add an external capacitor between the load and ground to improve the ripple performance of the unit. Our online Application Note 505 describes operating capacitor charging supplies in DC applications, and gives guidance in determining the size of

any additional external filter capacitance required.

App Note 505 can be found at:

http://www.us.tdk-lambda.com/hp/pdfs/application%20notes/93008505rC.pdf

1.5 ADDITIONAL FEATURES:

Internal contactor and fuses for AC disconnect and protection

83489011 Rev A

Page 9

GENERAL INFORMATION

Standard AC power and control connectors

Documentation Manual Including -

Installation

Check out

Block diagram

Suggested remote interfaces and control circuits

10 ft (3m). output cable is standard, other lengths are optional.

NOTE: This manual contains information, instructions and diagrams which apply to

standard constructions. If special features or modifications have been installed, the

instructions specific to that modification are contained in Addenda and take precedence if conflicts exist. Please take care to refer to the correct information for your

unit.

1.6 SAFETY PRECAUTIONS

All 203 and 303 power supplies are designed to minimize the risk of fire or shock hazard. This instrument

received comprehensive mechanical and electrical inspection prior to shipment. Nevertheless, certain safety

precautions must be observed. Only TECHNICALLY

QUALIFIED SERVICE PERSONNEL familiar with the principles of electrical safety should

operate this supply. The power supply SHOULD NOT BE EXPOSED TO WATER

(EXCEPT COOLING CONNECTIONS) OR MOISTURE OR DUSTY ENVIRONMENTS.

Electrical safety must be maintained at all times.

Lethal voltages are developed within the power supply's enclosure and at the output cable. Therefore, the cover may not be removed by the user (see Warranty in preamble section for variance). Also, the large capacitors in the supply may store power even after the

AC input line is removed. ALLOW AT LEAST 40 SECONDS DISCHARGE TIME between

removing the AC input line and opening the cover. ALSO, ALLOW AT LEAST 40

SECONDS between switching the AC power off and switching it on again.

1. This product is designed for Indoor use

1-3

2. This product is designed for pollution degree 2.

3. This product is designed for Transient Overvoltage Category II

4. Ensure all covers are in place and securely fastened before switching ON the AC power.

5. Proper grounding from the input AC power is required to reduce the risk of electric

shock. Ensure that the AC Protective Earth Ground connection has at least the same

gauge wire as the supply leads shown in Table 4-1.

6. Where high leakage exists and there is a warning label on the rear panel, the Protective

Earth Ground must be connected. (Symbol for protective earth ground ).

7. Use extreme caution when connecting AC input power, and never apply the incorrect input voltage, refer to ratings label.

8. Use extreme caution when connecting the high voltage output cable to the load.

9. Ensure all load capacitors are completely discharged prior to connection. Never handle

the output cable when the power supply is operating.

83489011 Rev A

Page 10

1-4

GENERAL INFORMATION

10. Never attempt to operate the power supply in any manner not described in this manual.

11. Never remove DANGER and WARNING labels from the power supply. Replace lost or

damaged labels immediately.

12. The power supply should only be serviced by TDK-Lambda Americas factory authorized

personnel.

13. No user maintenance is required.

14. No cleaning is required.

1.7 SCOPE OF THIS MANUAL

This manual is used for installing and operating the 203 and 303 Series 2 Power Supply

with a revised front panel layout shown in Figure 4-1. For older model 303 supplies refer

to manual part number 83489009 which can be found on our web site. Suggestions and

requirements for connecting AC power, load cables and signal cables are given. Various

operating modes and programming modes are described.

1.8 MODEL NUMBER FORMAT

The model numbering system for the 203 and 303 Series power supply includes symbols for features and options. They are separated by dashes.

Examples are: 303L-10kV-POS-400VAC and 203S-20kV-POS-DC.

The 203 and 303 are available with two basic front panel configurations, the L, and S.

The choice of panel configuration is dependent upon the installation and system requirements. See section 5 for further details.

Table 1-1 shows a partial listing of the model description format for the 203/303 Power

Supply family. For additional options, the customer may contact the Sales Department

at TDK-Lambda Americas. Special options are typically shown as a four-digit suffix to

the model number.

83489011 Rev A

Page 11

GENERAL INFORMATION

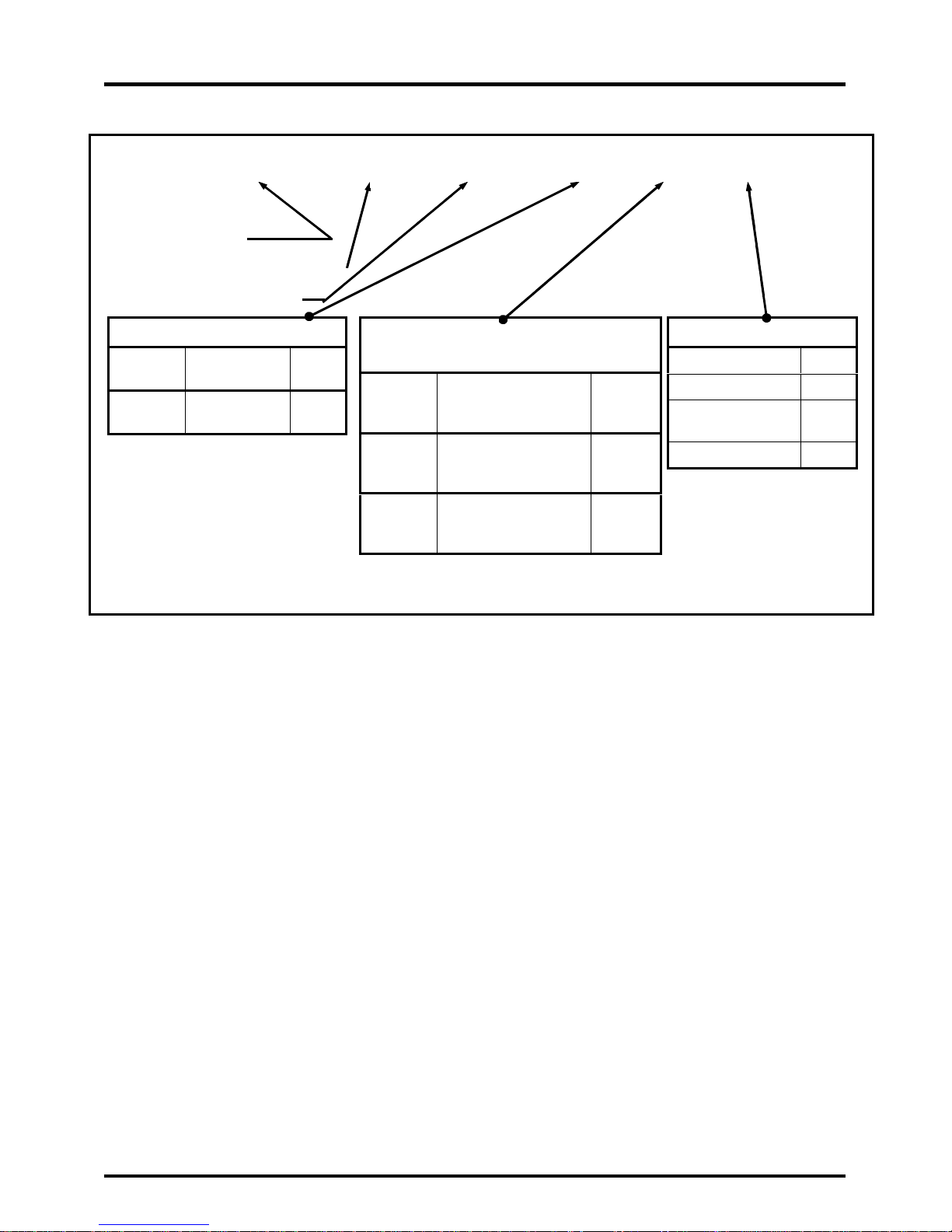

203/303(model) - (voltage) - (polarity) - (mode) - (input) - (options)

Model (L, or S)

Output Voltage Range kV

POS or NEG Polarity

Standard

DC

Mode

Capacitor

Charging

Continuous

DC Operation

Blank

DC

AC INPUT VOLTAGE

432-528 VAC,

Standard

400VAC

Option

50-60 Hz

3 (88A Max)

360-440 VAC,

50-60 Hz

3 (100A Max)

(1)

Input Suffix

Blank

400VAC

OPTIONS

5V Programming 5V

Low Enable EN

Custom cable

length

Other options xxxx

1-5

xxxx

208VAC

Option

180-264 VAC,

50-60 Hz

3(95A Max)

208VAC

Note 1. See Input power table specification section 4.5 for more details.

Table 1-1 Model Description Format

83489011 Rev A

Page 12

1-6

GENERAL INFORMATION

NOTES:

83489011 Rev A

Page 13

SPECIFICATIONS

2. SPECIFICATIONS

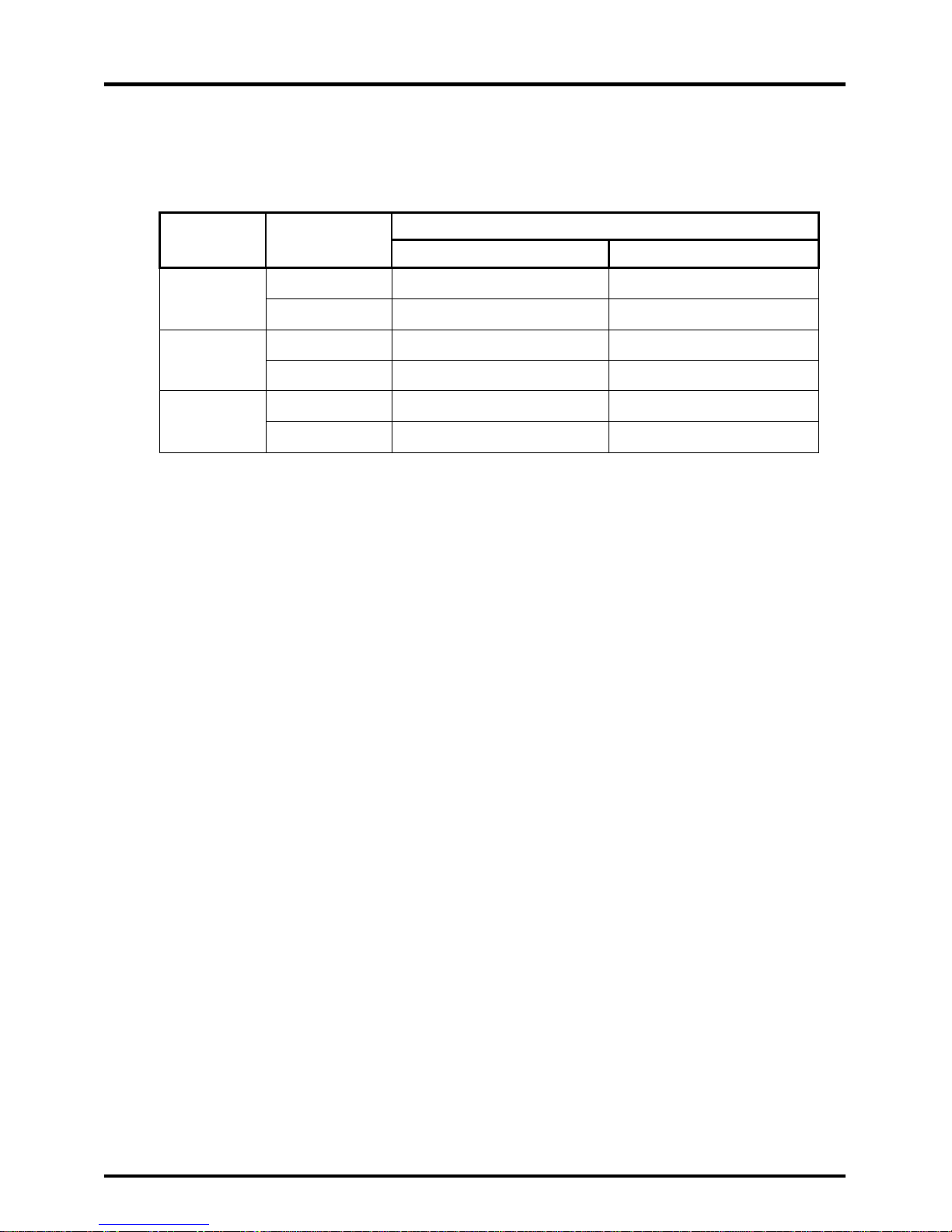

2.1 Output Power

2-7

AC INPUT

VOLTAGE

432-528 VAC,

50-60 Hz, 3

360-440 VAC,

50-60 Hz, 3

180-264 VAC,

50-60 Hz, 3

MODE

Cap Charging 20kJ/sec av, 25kJ/sec pk 30kJ/sec av, 37.5kJ/sec pk

Continuous DC 30kW 50kW

Cap Charging 20kJ/sec av, 25kJ/sec pk 25kJ/sec av, 32.5kJ/sec pk

Continuous DC 30kW 40kW

Cap Charging 20kJ/sec av, 25kJ/sec pk Not Available

Continuous DC 20kW Not Available

2.2 Polarity

Fixed positive or negative (specify when ordering)

2.3 H.V. Return

Ground through H.V. output cable shield to chassis, and through separate safety ground

cable.

2.4 Pulse to Pulse Repeatability

± 0.5% full load range and input voltage range into minimum capacitance (value dependent on

minimum voltage range).

MAXIMUM OUTPUT POWER RATING

MODEL 203 MODEL 303

2.5 Rep Rate

Single shot to 200 Hz. Lower regulation for 200Hz to 1 kHzrates.

2.6 Protection

Open circuit at turn on

Output over voltage

Output short circuit

AC input power failure

AC input power out of range

Excess voltage

Over and under temp

83489011 Rev A

Page 14

2-8

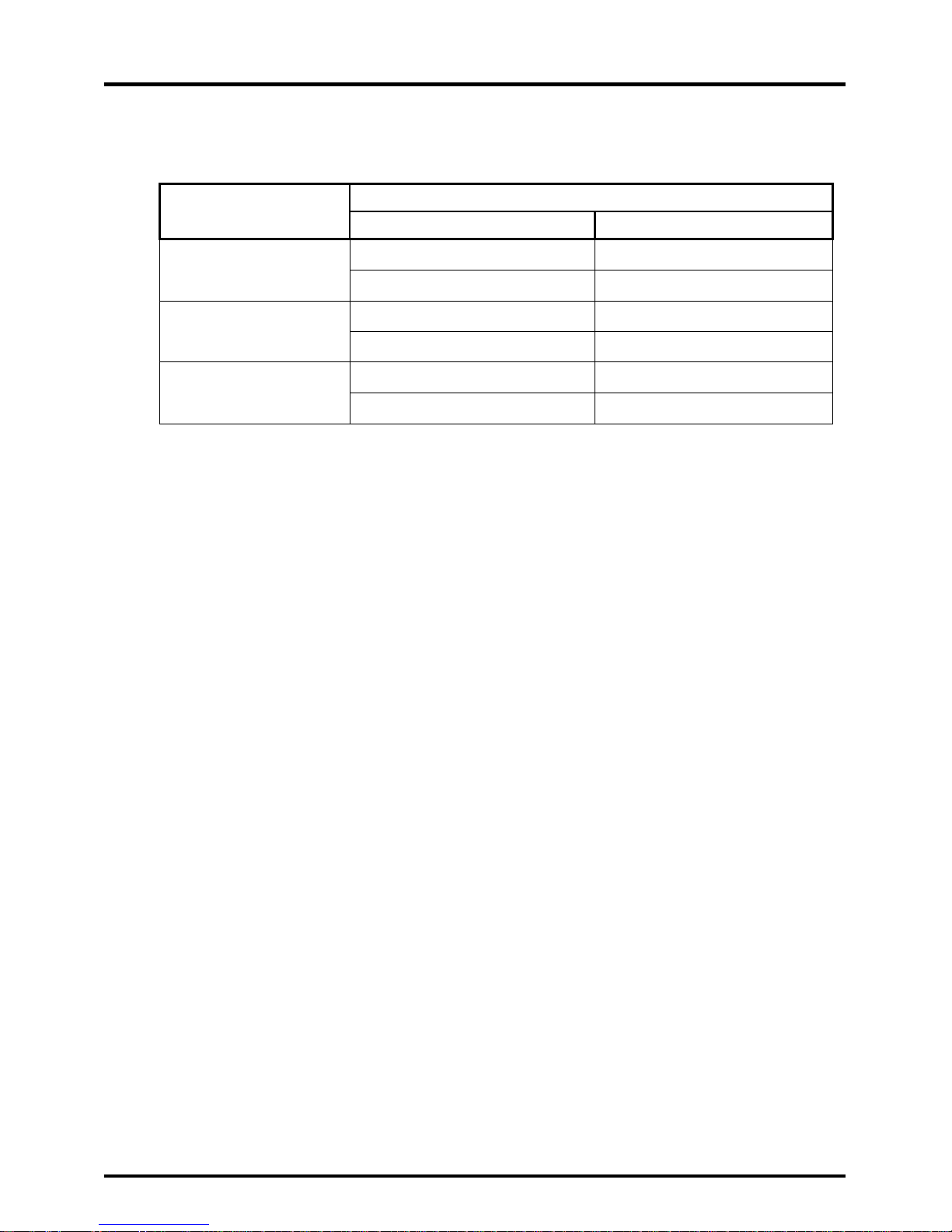

2.7 Input Power:

SPECIFICATIONS

AC INPUT VOLTAGE

432-528 VAC,

50-60 Hz, 3

360-440 VAC,

50-60 Hz, 3

180-264 VAC,

50-60 Hz, 3

Note (1): Refer to section 2.1 for output power rating

2.8 Phase Configuration

Wye or Delta, any rotation, separate ground.

2.9 Power Factor

0.9 at full load and nominal AC line

2.10 Efficiency

85% at full load and nominal AC line

MAXIMUM INPUT CURRENT

MODEL 203 MODEL 303

40A/Phase (Cap charging) 60A/Phase (Cap charging)

60A/Phase (Continuous DC) 98A/Phase (Continuous DC)

47A/Phase (Cap charging) 71A/Phase (Cap charging)

71A/Phase (Continuous DC) 94A/Phase (Continuous DC)

94A/Phase (Cap charging) Not Available

94A/Phase (Continuous DC) Not Available

(1)

2.11 AC Line Filtering

Passive power factor correction and EMI filters included

2.12 Inrush Current

Limited to below full power level

2.13 Max. Discharge

15 seconds to safe output level at output cable without external load consideration.

2.14 Physical Specifications

Size: 19" (483 mm) Rackmount standard front panel

17" (432 mm) chassis width

12.25" (311 mm) High

22" (559 mm) Deep + 5" (127 mm) for cables

2.15 Cooling Water

Maximum exit temperature for cooling water at approximately 2.0 US gpm (7.6 L/min) is 35°C

Minimum exit temperature for cooling water at approximately 2.0 US gpm (7.6 L/min) is 15°C

(Higher temperature water requires greater flow). All water paths are at ground potential and are

copper or brass.

83489011 Rev A

Page 15

SPECIFICATIONS

2.16 Water Fittings

1/4 inch NPT male threaded pipes

2.17 Weight

190 lbs. (86.4 kg) approx.

2.18 Shock and Vibration

Unboxed 0.5 g.

Factory packing2.0 g

2.19 Shipping

Gross weight with packingmaterial: 240 lbs. (109 kg) approx.

Size: 27"W X 21" H X 30"D (686 mm X 535 mm X 762 mm)

2.20 Air Temperature Range

Operating: 0°C to 55°C ambient air

Storage: -55°C to 70°C

2.21 Humidity

2-9

Operating: 0% to 90% (Non-condensing)

Storage: 0% to 90%

2.22 Altitude

Operating: 12,000 ft. (3658 m)

Storage: 30,000 ft. (9144 m) at 25°C or less

83489011 Rev A

Page 16

2-10

SPECIFICATIONS

NOTES:

83489011 Rev A

Page 17

OUT-OF-BOX-INSPECTION

3. OUT-OF-BOX-INSPECTION

3.1 VISUAL INSPECTION

Prior to shipment, this instrument was inspected and found to be free of mechanical and

electrical defects. As soon as the unit is unpacked, inspect for any damage that may

have occurred in transit. Verify the following:

A. Check the operation of the front panel control (knob should rotate smoothly).

B. Confirm that there are no dents or scratches on the panel surfaces.

C. Check front panel meters and LEDs for any broken or cracked lenses.

If any damage is found, follow the instructions in Section 3.3 and in the "Returning

Equipment" instructions in the preamble section of this manual.

3.2 ELECTRICAL INSPECTION

Before the power supply is installed in a system, verify that no internal damage occurred

during shipping. A simple preliminary electrical test should be performed. These tests

are described below. Note: The sequences described are for L models, for S models

the corresponding signals must be applied and monitored through the remote control interface.

3-11

3.2.1 TEST 1

Purpose: Verify general logic operation and generate maximum output current and

check overload protection circuits. With AC power "OFF" and disconnected, short the

H.V. output by connecting the center conductor of the output cable to its return shield

(braid). This dead short will allow the unit to generate full output current at zero voltage.

1. Set the output voltage control to zero. Connect the AC power to the unit. Turn "ON"

the AC power front panel switch.

2. Turn the front panel keyswitch to the LOCAL position (if applicable). Press the H.V.

"ON" button and turn up the H.V. control until the power supply is generating output

current into the dead short. The current meter will indicate max. current. The voltage

meter will read zero and the power supply will intermittently turn on and off indicating

the "overload" condition. The unit should continue to cycle in this mode with a 1 sec.

repetition rate indefinitely. (The power supply will go into overload when max. current

is drawn for more than half a second).

3. Turn off the H.V. and A.C. power switches.

This test indicates the inverter section is generating maximum current and the logic and

overload circuitry works correctly.

3.2.2 TEST 2

Purpose: Verify that the power supply generates maximum rated voltage, and the regu-

lation and feedback circuits are functioning.

1. With AC power OFF and disconnected, connect an appropriate load capacitor to the

power supply output cable.

2. Prepare to charge the capacitor. NOTE: Operating a 203 or 303 power supply into

an open circuit (no load operation) will instantly damage the power supply's H.V.

output diodes. Make sure the load (capacitor) is connected and the H.V. output cable is securely inserted and connected.

83489011 Rev A

Page 18

3-12

OUT-OF-BOX-INSPECTION

3. For L models turn the voltage control on the front panel turned all the way down to

zero (counter clockwise), apply AC power and press the HV ON button. By turning

up the H.V. control knob the capacitor will charge to the voltage indicated on the

front panel voltmeter. The power supply may be turned all the way up to its max.

output voltage provided the load capacitor is sufficiently rated.

4. By turning the voltage control down or depressing the H.V. OFF button, the capacitor

will "bleed" down through the internal voltage divider resistors used for regulation

feedback.

Test #2 indicates the H.V. section is working correctly. Tests 1 and 2 generally indicate

the unit is functioning as designed. Although 100% power had not been generated, these two tests give greater than 90% confidence that the unit is not damaged.

If any inconsistency from the above test procedure is noted, do not hesitate to call TDKLambda Americas Customer Service for assistance.

The supply and the coolant filled HV assembly should not be opened unless advised by

TDK-Lambda Americas personnel. The coolant filled HV tank has been cleaned and the

hermetically sealed at the factory, opening the supply or the assembly will void the factory warranty, and may compromise performance.

3.3 CONTACTING TDK-LAMBDA AMERICAS CUSTOMER SERVICE

When contacting customer service locate the product description, part number and serial number from the label located on the rear of the unit, and have this information available.

Phone: (732) 922-9300 x 342 E-mail: hp.service@us.tdk-lambda.com

Fax: (732) 922-5403

Customer Service, or an approved Service Center, should be contacted if:

The power supply is mechanically or electrically damaged.

The power supply requires on-site calibration, or replacement warning decals.

The customer has questions about a special application that is not described in this

manual.

Normally, the customer may NOT open any chassis covers that have a warranty seal.

Breaking a seal will void the warranty.

At the discretion of TDK-Lambda Americas, the customer may be granted permission to

break the warranty seal and open the chassis covers. Customer Service shall confirm

the permission by sending a replacement seal. Once the unit has been serviced, the

customer shall close the cover and apply the replacement seal adjacent to (not on top

of) the broken seal.

3.4 RETURNING DEFECTIVE UNITS

The procedure for returning defective products is given in section 3.3 of this manual.

83489011 Rev A

Page 19

INSTALLATION

4. INSTALLATION

4.1 19-INCH RACK MOUNTING

This power supply is intended for mounting in a conventional 19-inch rack. It’s 12.25

inch height makes it a “7U” size instrument. The rack should enclose the sides, top and

back to protect the operator from electrical shock and protect the supply from environmental contamination.

Never install the 203 or 303 so only the front panel screws

support its weight!

The 203/303 must never be installed without support in the back or sides of the unit. The

203/303 should be mounted on heavy-duty chassis slides –such as General Devices

CTS-124- or on a suitable shelf or supports inside the rack.

4-13

MODEL 303

STATUS

HV ON

HV OFF

STATUS COOLANT INPUT POWERHIGH VOLTAGE

HV ON

HV OFF

INHIBIT

END OFCHARGE

INTERLOCK OPEN

LOAD FAULT

OVERTEMP

CONTROL

OFF

ENABLE

INHIBIT

AUTOINHIBIT

SUMMARY FAULT

LINE FAULT

LOCALREMOTE

VOLTAGE

ADJUST

10 TURNINC

CURRENT

VIEWSET

HVON

HVOFF

END OFCHARGE

EXCESSREVERSAL

INTERNAL ARCLOAD FAULT

CLAMP

Figure 4-1 203/303L Front View

FULL

WARNING

FAULT

OVERTEMP

PURGE VALVE

OVERPRESSURE

kV

110%10080 90706050403020100

A

110%10080 90706050403020100

POWER

HIGH LINE

LOW LINE

IMBALANCE

INTERLOCK OPEN

BIAS FAULT

FANFAIL

83489011 Rev A

Page 20

4-14

(

115

mm)

(

107

mm)

(89mm)

(

152

mm)

(

294

mm)

(

294

mm)

12.22”

4.52”

INSTALLATION

19” (482mm)

17” (432mm)

4.21”

COOLANTWATERIN OUT

11.56”

INHIBITREMOTE

HV OUTPUT

6.0”

COOLANT

SLAVE

3.5”

Figure 4-2 203/303 Rear View

4.2 VENTILATION REQUIREMENTS

Ensure there is at least 5 inches (12.5 cm) of clearance at the rear of the unit for airflow, cables and water lines. If the power supply is to be installed in an enclosed system,

care must be taken to ensure the ambient inlet air to the power supply does not exceed

the maximum operating temperature of 55°C.

0

5

-

-

1

0

0

-10

-20

-30

inHg psi

0

0

5

0

1

0

0

10

1

5

20

0

30

0

0

2

kPa

438-528VAC

50/60 Hz

TB2 1 2 3 4

A B C N GND

1 2 3 4 5

!

INTERLOCK/POWERON

TB 1AC INPUT

4.3 WATER COOLING REQUIREMENTS

Water with a flow rate at 2 US gallons per minute (7.6litres/min) having an exit temperature of 15 to 35°C is required to cool the instrument. This is required to maintain the allowable tank temperature range of 15 to 48°C. Chilled water should not be used. ( If the supply is to be stored at temperatures below 4°C, the user should ensure all water

is blown out of the coolant pipes).

4.4 ORIENTATION

The power supply must be operated in a level horizontal orientation. More than a quarter of an inch (6.25mm) difference in height in any direction could potentially cause an

arcing condition and/or coolant fault in the high voltage tank and should be avoided.

83489011 Rev A

Page 21

INSTALLATION

B2C3N45

TB1 AC INPUT

B2C3N45

TB1 AC INPUT

4.5 AC POWER CONNECTION

The maximum voltage allowed between any two AC input

terminals is 550VAC. If this voltage is exceeded,

catastrophic damage will result, that is not covered by

TDK-Lambda Americas standard warranty.

The customer’s AC power line connects to the 203/303 via a UL/CSA approved 5 position terminal block on the rear panel of the unit (see Figure 4-3). Only use a power cable

with the correct voltage and current rating (see Table 4-1). The ground wire must be

equal to or larger than the recommended gauge. Proper grounding from the input AC

power is required to reduce the risk of electric shock. The metal chassis of the power

supply is grounded through the earth wire at the input AC power terminal block. Use extreme caution when connecting input AC power and never apply the incorrect input

power.

The Protective Earth Ground must be connected before

applying AC Line Power to the 203/303.

4-15

Connect the three lines of the input power to the L1, L2, L3 terminals and the earth

ground to the terminal marked with the ground symbol ( ). No neutral connection is

required for the 480, 400, or 208VAC configuration. The power connections are not

phase rotation sensitive, so any phase can be connected to any of the AC inputs. The

recommended torque for the AC input terminals is 35in-lb.

A

A

1

1

Figure 4-3. AC Input Terminal Block

83489011 Rev A

Page 22

4-16

INSTALLATION

AC INPUT

VOLTAGE

432-528 VAC,

50-60 Hz, 3

360-440 VAC,

50-60 Hz, 3

180-264 VAC,

50-60 Hz, 3

MODE

Cap Charging 5 AWG 4 AWG

Continuous DC 4 AWG 3 AWG

Cap Charging 5 AWG 4 AWG

Continuous DC 4 AWG 3 AWG

Cap Charging 3 AWG Not Available

Continuous DC 3 AWG Not Available

RECCOMENDED AC INPUT CABLE SIZE

MODEL 203 MODEL 303

Table 4-1 Recommended AC Input Cable

The AC input rating is marked on the rear terminal of the power supply. The rating is also part of the unit’s model description shown in Table 1-1.

4.6 CONNECTING THE HIGH VOLTAGE OUTPUT

Voltage reversal at the output of this power supply can potentially cause

damage to the high voltage section if reverse current is not limited. Refer to

Application Note 517 (available from the factory or at www.us.tdklambda.com/hp) for more information.

Ensure that the power supply is off and disconnected

from the AC input power and that all load capacitors are

discharged and shorted to ground before making any

connections. Never handle the HV cable while the supply

is operating. Never operate the supply without a load

capacitor connected.

Always use the HV connector and cable provided with the power supply or an equivalent

substitute provided by TDK-Lambda Americas. Fully insert the connector end of the HV

cable and tighten the locking nut only "hand tight".

When operating above 20kV and 200Hz rep rate a silicone grease (such as Dow Corning DC-4) must be applied to the HV cable before insertion into the HV connector. The

grease is used to displace air in the connector and reduce long-term corona effects. A

cable greasing procedure is available for download from the TDK-Lambda Americas

web site.

The load ground must be connected to the chassis ground through a separate safety

ground cable with a suggested minimum wire size of 6 AWG in addition to the H.V. output cable shield (see Figure 4-4).

Some peak current will flow out of the power supply during discharge and return through

the HV return and system chassis. This current comes from voltage reversal in under-

83489011 Rev A

Page 23

INSTALLATION

damped systems and from normal discharge of filter and cable capacitance. The path

for this current should not parallel control signal returns since the resulting voltages

could interfere with normal system operation.

Currents due to voltage reversal at high rep. rates could damage the power supply.

Generally, a resistor in series with the HV output can be added to limit this current to an

acceptable level. Refer to Application Note 517 (available from the factory or at

www.us.tdk-lambda.com/hp) for more information.

LOAD CIRCUIT

LOAD CIRCUIT

HV Switch

HV Switch

4-17

COOLANTWAT ER OUTIN

COOLANTWAT ER OUTIN

COOLANTWAT ER OUTIN

COOLANTWAT ER OUTIN

10

10

10

10

10

10

5

5

5

5

5

5

0

0

0

0

0

0

15

15

15

15

15

15

20

20

20

20

20

20

-10

-10

-10

-10

-10

-10

25

25

25

25

25

25

-20

-20

-20

-20

-20

INHIBIT

INHIBIT

INHIBIT

INHIBIT

HVOUTPUT

HVOUTPUT

HVOUTPUT

HVOUTPUT

COOLANT

COOLANT

COOLANT

COOLANT

TOSLAVE REMOTE

TOSLAVE REMOTE

TOSLAVE REMOTE

TOSLAVE REMOTE

-20

-30

-30

-30

-30

-30

-30

PRESSURE GAUGE

PRESSURE GAUGE

PRESSURE GAUGE

PRESSURE GAUGE

30

30

30

30

30

30

TB2 1 2 43

TB2 1 2 43

TB2 1 2 43

TB2 1 2 43

INTERLOCK/POWER ON

INTERLOCK/POWER ON

INTERLOCK/POWER ON

INTERLOCK/POWER ON

A1B2C3N4GND

A1B2C3N4GND

A1B2C3N4GND

A1B2C3N4GND

TB1 AC INPUT

TB1 AC INPUT

TB1 AC INPUT

TB1 AC INPUT

5

5

5

5

3 AC

3 AC

POWER

POWER

SAFETY

SAFETY

GROUND

GROUND

A

A

B

B

C

C

Figure 4-4 Typical Load Circuit Connection

Dress the high voltage cable creating a gentle curve making sure there are no sharp

bends as this will tend to reduce the cable's insulation strength. Strain relieve the load

end of the high voltage cable to prevent breaking of the center conductor. Keep the HV

cables as distant as possible from the input power and the control signals.

To connect the HV cable to the load it is necessary to remove the cable jacket, shield,

and any semiconducting layer that remains on the cable insulation after removing the

shield.

The cable outer jacket should be removed to reveal the cable shield. At least 12” or

300mm of outer jacket should be removed for suitable voltage hold-off. The exposed

shield should be trimmed to an appropriate length and terminated with a ground connection. With the shield removed, the black semiconducting layer is exposed. This layer

should be very carefully removed using a sharp craft knife, and a peeling action. Once

the semiconducting layer is removed the exposed EPR insulation should be cleaned

with IPA or an equivalent solvent. If any of the semiconducting layer remains on the HV

cable insulation it may cause the cable termination to fail.

83489011 Rev A

Page 24

4-18

INSTALLATION

NOTES:

83489011 Rev A

Page 25

CONTROLS, INDICATORS, CONNECTORS

78910121112345

6

5. CONTROLS, INDICATORS, CONNECTORS

5.1 FRONT PANEL LAYOUT (L Model)

The 203/303L series power supply is equipped with a fully instrumented front panel featuring output voltage control, voltage and current metering, and comprehensive status

LEDs, along with local/remote mode keyswitch, and power on switch. The 203/303L can

be operated locally from the front panel or remotely via the control connector located on

the rear panel (see Section 7.2).

Figure 5-1 below shows the front panel layout of the 203/303L power supply.

5-1

MODEL 303

STATUS

INHIBIT

END OFCHARGE

INTERLOCK OPEN

LOAD FAULT

OVERTEMP

CONTROL

OFF

ENABLE

INHIBIT

AUTOINHIBIT

SUMMARY FAULT

LINE FAULT

HV ON

HV OFF

LOCALREMOTE

HV ON

HV OFF

STATUS COOLANT INPUT POWERHIGH VOLTAGE

VOLTAGE

ADJUST

10 TURNINC

CURRENT

VIEWSET

HVON

HVOFF

END OFCHARGE

EXCESSREVERSAL

INTERNAL ARCLOAD FAULT

CLAMP

FULL

WARNING

FAULT

OVERTEMP

PURGE VALVE

OVERPRESSURE

kV

110%10080 90706050403020100

A

110%10080 90706050403020100

POWER

HIGH LINE

LOW LINE

IMBALANCE

INTERLOCK OPEN

BIAS FAULT

FANFAIL

Figure 5-1. 203/303L Front Panel Controls and Indicators

The function of each numbered item is outlined in Table 5-1

83489011 Rev A

Page 26

5-2

CONTROLS, INDICATORS, CONNECTORS

REF DESCRIPTION NOTE SECTION

1 HV ON Push Button Turns ON HV output 5.2

2 Output Status Output Status LEDs 5.3

3 Local Voltage Set 10 turn pot for setting output voltage in local mode 5.4

4 Voltage Bar Graph

5 Voltage Display Digital display of output or set voltage 5.6

6 Current Display Digital display of average output current 5.7

7 HV OFF Push Button Turns OFF HV output and resets latching faults 5.8

8

9 Status LEDs

10

11 Current Bar Graph

12 Power switch Turns on/off power to auxiliary circuits 5.13

Local/Remote

Keyswitch

View set push button Push to view the output voltage set point in local mode

Analog bar graph showing output voltage (%)

Switches control between remote, local, and off modes 5.9

Detailed status LED displaying showing operating condi-

tion and any faults

Analog bar graph showing output current (%)

Table 5-1 Front Panel Controls and Indicators (L Model)

The front panel controls/indicators are described in detail in the following sections.

5.2 HV ON (Ref 1)

DO NOT DEPRESS THE HV ON PUSH-BUTTON UNLESS A

SUITABLE CAPACITIVE LOAD IS CONNECTED TO THE

POWER SUPPLY'S OUTPUT CABLE, AND THE LOAD IS

CORRECTLY GROUNDED

5.5

5.10

5.11

5.12

The HV ON push button turns ON the high voltage output when depressed only after all

interlocks are closed, self checks are completed and the unit is switched to the LOCAL

mode. HIGH VOLTAGE will be generated immediately when the HV ON is depressed

and the HV ON LED will illuminate and remain illuminated while the HV is ON. The supply will charge the load to the voltage determined by the HV LEVEL ADJUST 10 turn

pot. It is good practice to turn the LOCAL VOLTAGE CONTROL pot fully counterclockwise (to zero) before pushing the HV ON button when first using this power supply. Later on during system usage, the LOCAL VOLTAGE CONTROL may be left set at the desired level.

If a fault is present when the HV ON push-button is depressed, the SUMMARY FAULT

LED will illuminate.

5.3 OUTPUT STATUS LEDs (Ref 2)

There are 6 output status LEDs on the front panel, indicating the state of the HV Output

circuit and some of the fault detection circuits in the control system.

83489011 Rev A

Page 27

CONTROLS, INDICATORS, CONNECTORS

5.3.1 HV ON LED

The HV ON LED indicates that the HV output circuit is enabled and the supply will deliver output current if it is not inhibited by an external inhibit input. HV ON LED is active in

local and remote modes.

5.3.2 HV OFF LED

The HV OFF LED indicates that the HV output circuit is disabled and the supply cannot

deliver output current. HV OFF LED is active in local and remote modes.

5.3.3 INHIBIT LED

If the Inhibit LED is illuminated it indicates the presence of an active inhibit signal, and

the supply will not deliver charging current after the HV ON button is pushed. Inhibit is

applied either via the rear panel mounted BNC connector or via the remote control connector, do not use both inputs at the same time. Inhibit LED is active in local and remote

modes.

5.3.4 END OF CHARGE LED

The END OF CHARGE indicator will illuminate when the load capacitor is charged to the

programmed output voltage. The END OF CHARGE indicator will be extinguished when

the high voltage is OFF or during load charging. END OF CHARGE may illuminate if

the output voltage is programmed to zero.

5-3

5.3.5 INTERLOCK OPEN LED

The INTERLOCK OPEN LED illuminates if the safety interlock circuit is not closed. The

power supply cannot be turned on if the interlock loop is open. If the interlock loop is

opened when the unit is running (ie when HV in ON), the unit will turn off with a latching

fault, requiring an HV ON/OFF reset cycle before it can be restarted. Interlock Open

LED is active in local and remote modes.

5.3.6 LOAD FAULT LED

The LOAD FAULT LED indicates the presence of a fault in the load circuit due to a short

circuit or large external capacitor. LOAD FAULT is activated if the charge voltage does

not meet the programmed voltage within 500milliseconds. The fault automatically clears

and the unit will restart charging after a further 500milliseconds unless the Latching Protection (LP) option is specified. Load Fault LED is active in local and remote modes.

5.3.7 OVERTEMP LED

The OVERTEMP LED indicates an overtemperature condition internal to the supply. The

temp fault will clear once the temperature is below the fault threshold, but the unit will

not restart without a reset cycle. Overtemp LED is active in local and remote modes.

5.4 LOCAL VOLTAGE CONTROL (Ref 3)

The LOCAL VOLTAGE CONTROL is a 10 turn potentiometer that adjusts the output

voltage between zero and 100% of rated voltage. The set point can be viewed on the

VOLTAGE DISPLAY by pushing the VIEW SET button. The output voltage can be set at

the desired level by turning the control to the required output voltage before depressing

the HV ON push button. It is good practice to turn the control fully counter clockwise after operating the supply. The local voltage control has no effect when the supply is operate in remote mode.

83489011 Rev A

Page 28

5-4

CONTROLS, INDICATORS, CONNECTORS

5.5 VOLTAGE BAR GRAPH (Ref 4)

The voltage bar graph is a 'quick view' analog percentage indication of the voltage

measured at the power supply output. Bar graph is active in local and remote modes.

5.6 VOLTAGE DISPLAY (Ref 5)

The Voltage Display is a 4 digit LED indicator showing the voltage measured at the

power supply output. This display momentarily shows the output program voltage after

the View Set button is depressed. Voltage Display is active in local and remote modes.

5.7 CURRENT DISPLAY (Ref 6)

The Current Display is a 4 digit LED indicator showing the average current delivered by

the power supply output. Current display is active in local and remote modes.

5.8 HV OFF/RESET (Ref 7)

The HV OFF push button is a momentary switch that when depressed turns off HV output. If the power supply shuts off with a summary fault (indicated by SUMMART FAULT

LED illuminating), then this condition can be reset by pushing the HV OFF button. If the

supply is operated in remote mode the HV OFF push button will still function.

5.9 OFF/LOCAL/REMOTE KEYSWITCH (Ref 8)

DO NOT MOVE THE KEYSWITCH POSITION FROM OFF TO

LOCAL OR REMOTE UNLESS A SUITABLE CAPACITIVE

LOAD IS CONNECTED TO THE POWER SUPPLY'S OUTPUT

CABLE, AND THE LOAD IS CORRECTLY GROUNDED.

The OFF/LOCA/REMOTE Keyswitch switches the power supply operating modes between OFF, LOCAL, and REMOTE. The key can be removed in the OFF position to

prevent unauthorized use. If the switch is in the LOCAL position the supply will operate

from the front panel. In the REMOTE position the supply can only be operated via the

remote control interface. An L model supply can simulate an S model with the key in the

REMOTE position.

5.10 POWER SUPPLY STATUS LEDs (Ref 9)

There are four distinct sets of status LEDs on the 203/303L/S front panel. Each group

indicates the status of a specific section of the power supply.

5.10.1 STATUS LED GROUP

5.10.1.1 ENABLE

Indicates the HV output circuitry is Enabled and HV may be present at the power supply

output.

5.10.1.2 INHIBIT

The INHIBIT indicator displays the logical OR of all the internal and external signals that

prevent HV output current, including EOC, AUTOINHIBIT, EXTERNAL INHIBIT,

OVERLOAD, and any fault. If the INHIBIT indicator is OFF and the unit is not delivering

charge current, there is an internal power supply failure that may require servicing by

authorized service personnel. If an inhibit signal (HIGH) is applied at the rear panel BNC

connector, the INHIBIT indicator will illuminate and output current cannot be delivered.

83489011 Rev A

Page 29

CONTROLS, INDICATORS, CONNECTORS

5.10.1.3 AUTOINHIBIT (Normally OFF)

The AUTOINHIBIT feature shuts OFF or inhibits the output current when the capacitive

load is discharged. This feature allows the HV switch in the external load circuit (if applicable) to better recover after a load switching event.

The AUTOINHIBIT feature overcomes the need for the external inhibit signal in most

cases. The AUTOINHIBIT circuit automatically creates an internal inhibit of approximately 1ms after the circuit detects high dv/dt at the output. The AUTOINHIBIT period

can be programmed via a 0-10 VDC signal applied to the AUTOINHIBIT input on the

rear panel remote interface connector. 0V input gives an AUTOINHIBIT period of approximately 500s, 10V gives an AUTOINHIBIT period of 10ms.

5.10.1.4 SUMMARY FAULT (Normally OFF)

SUMMARY FAULT LED indicates any internal or external fault condition that prevents

the power supply from operating. This condition can be cleared by pushing the HV OFF

button to reset the fault.

5.10.1.5 LOAD FAULT (Normally OFF)

The LOAD FAULT LED indicates the presence of a fault in the load circuit due to a short

circuit or large external capacitor. LOAD FAULT is activated if the charge voltage does

not meet the programmed voltage within 500milliseconds. The fault automatically clears

and the unit will restart charging after a further 500milliseconds unless the Latching Protection (LP) option is specified. Load Fault LED is active in local and remote modes.

5-5

5.10.1.6 LINE FAULT (Normally OFF)

The LINE FAULT LED illuminates when an input power fault occurs. The LINE FAULT

indicator will remain ON (latch ON) after the specific external fault condition detected

has cleared (the specific indicator goes OFF). The LINE FAULT LED will turn off the

power supply output and under certain conditions will open the main AC power contactor. The LINE FAULT indicator may be reset by depressing the HV OFF push-button on

the front panel.

5.10.2 HIGH VOLTAGE LED GROUP

5.10.2.1 HV ON

The HV ON LED indicates that the HV output circuit is enabled and the supply will deliver output current if it is not inhibited by an external inhibit input. HV ON LED is active in

local and remote modes.

5.10.2.2 HV OFF

The HV OFF LED indicates that the HV output circuit is disabled and the supply cannot

deliver output current. HV OFF LED is active in local and remote modes.

5.10.2.3 END OF CHARGE (Normally OFF)

The END OF CHARGE indicator will illuminate when the load capacitor is charged to the

programmed output voltage. The END OF CHARGE indicator will be extinguished when

the high voltage is OFF or during load charging. END OF CHARGE may illuminate if

the output voltage is programmed to zero.

5.10.2.4 EXCESS REVERSAL (Normally OFF)

This indicator will illuminate if excess voltage reversal is detected at the HV output. A

large reversal would cause damage to the power supply by drawing too much current

83489011 Rev A

Page 30

5-6

CONTROLS, INDICATORS, CONNECTORS

through the output diode rectifiers. While the EXCESS REVERSAL sense circuit does

not directly protect the diodes, it will stop the power supply from continuing to run in the

case where reversal may be building up and could cause damage if left unchecked.

This protection circuit will reset automatically after three (3) seconds and restart the

power supply. Repeated operation of this circuit indicates the presence of a persistent

problem that must be corrected by some form of protection, clipper circuit or series resistor. Refer to Application Note 517 (available from the factory or at www.us.tdklambda.com/hp) for more information.

5.10.2.5 INTERNAL ARC (Normally OFF)

When illuminated, the INTERNAL ARC indicator signals a major fault internal to the high

voltage tank of the power supply. This type of fault may be reset if the POWER is cycled; however, if it recurs, the unit should not be used any further because the output

may be uncontrolled if present and could cause further damage to the supply or its load.

The power supply should then be serviced by qualified personnel.

5.10.2.6 CLAMP (Normally OFF)

The CLAMP indicator illuminates when an overvoltage condition is detected on the output. The CLAMP indicator will also illuminate if the unit is being programmed to a higher

voltage than it is rated for. The power supply will turn OFF the high voltage output (inhibited) and may be reset by depressing the HV OFF push-button on the front panel when

the overvoltage condition is no longer present.

5.10.3 COOLANT LED GROUP

In the event of any coolant faults the user should verify installation orientation is in accordance with Section 4.4 prior to contacting TDK-Lambda Americas.

5.10.3.1 FULL (Normally ON)

When illuminated, this indicator signals that the high voltage tank in filled to the correct

level with coolant. This indicator may be extinguished if the unit is cold.

5.10.3.2 WARNING (Normally OFF)

This indicator will FLASH if the coolant drops below its safe operation level, indicating

that the coolant may be leaking (there are no environmental or safety hazards from this

coolant leaking. It will evaporate before it collects). The unit should be serviced if the

coolant is low.

5.10.4 FAULT (Normally OFF)

The FAULT indicator when illuminated indicates the coolant level is below the allowable

level to safely operate the power supply. The FAULT indicator will turn OFF the high

voltage output and it cannot be reset until the coolant level is corrected. The unit must

be serviced by authorized service personnel.

5.10.4.1 OVERTEMP (Normally OFF)

The OVERTEMP LED illuminates if the HV tank temperature is outside of its operating

limits. The fixed operating limits have minimum low temperature and a maximum high

temperature. When illuminated, the OVERTEMP indicator will turn OFF the high voltage

output. When the internal temperature returns to a normal level, the output may be

switched back on by depressing the HV ON push-button.

83489011 Rev A

Page 31

CONTROLS, INDICATORS, CONNECTORS

The coolant has a wide operating temperature range and is controlled and stabilized by

the cooling water flowing through the high voltage tank. The maximum allowable tank

temperature is 45°C, and the minimum is 15°C.

This temperature range can be maintained by running normal tap water through the

power supply at a rate of 2 gallons per minute (7.58 L/min). Chilled water should not be

used, it can cause the lower operating temperature limit to be reached, as well as causing condensation to form which should always be avoided. Condensation in the power

supply may result in damage and the warranty will be void.

5.10.4.2 PURGE VALVE (Normally OFF)

The PURGE VALVE indicator illuminates when the purge valve is operating. The valve

will operate automatically, cycling on and off when necessary. The interval of operation

should be only a few minutes at a time and not more than once in any continuous 24hour operating period. The power supply will continue to run normally during the automatic purge operation. The purge valve is designed to remove excess air that may accumulate in the high voltage tank, to allow the most efficient cooling and best possible

dielectric environment.

5.10.4.3 OVER PRESSURE (Normally OFF)

Indicates the presence of an OVER PRESSURE condition in the HV tank. Can be reset

by depressing the HV OFF button after the condition has cleared. Repeated OVER

PRESSURE faults are an indication of a problem in the HV tank. Contact the factory for

service.

5-7

5.10.5 INPUT POWER LED GROUP (External Faults)

5.10.5.1 HIGH LINE (Normally OFF)

The HIGH LINE LED illuminates when the external AC input voltage is above the maximum limit (typically 10% above nominal). Damage can result if the AC input exceeds the

rating and so the supply disconnects itself from the line by opening the contactor.

When the HIGH LINE condition is removed the indicator extinguishes and the power

supply can be reset by operating the HV OFF push-button.

5.10.5.2 LOW LINE (Normally OFF)

The LOW LINE LED will illuminate if the AC input voltage drops below approximately

85% of the nominal nameplate level. The power supply will continue to deliver output

current unless the AC input voltage dip is too great (either low voltage or for a long

time). The power supply will shut down the output until the AC line is restored. The line

fault resets the power supply automatically.

5.10.5.3 IMBALANCE (Normally OFF)

The IMBALANCE LED illuminates if an internal power imbalance occurs, which could

happen under abnormal power conditions. The fault will automatically reset when the

condition corrects itself.

The AC contactor is opened and the FAULT indicator is illuminated which may be reset

using the push-button after the IMBALANCE LED extinguishes. This does not indicate

an AC line to line imbalance.

5.10.5.4 INTERLOCK OPEN (Normally OFF)

INTERLOCK OPEN illuminates when the interlock loop on rear panel is opened. If the

interlock is opened while the supply is operating, the main AC line contactor will be

83489011 Rev A

Page 32

5-8

opened, disconnecting AC power from the HV circuitry. The INTERLOCK OPEN LED

indication is reset automatically when the interlock circuit is closed (LED extinguished),

but before power can be generated the fault condition must be reset by pushing the HV

OFF push-button.

5.10.5.5 BIAS FAULT (Normally OFF)

When illuminated indicates the internal DC control voltage is low, or out of range.

5.10.5.6 FAN FAIL (Normally OFF)

Indicates failure of the auxiliary cooling fan. The power supply should be removed for

service if this indicator is illuminated.

CONTROLS, INDICATORS, CONNECTORS

5.11 VIEW SET push button (Ref 10)

The view set push button changes the reading on the digital voltage display from the

power supply output voltage, to the programmed voltage set on the local voltage set potentiometer. After pushing this button the set voltage is displayed for approximately 3

seconds.

5.12 CURRENT BAR GRAPH (Ref 11)

The current bar graph is a 'quick view' analog percentage indication of the current

measured at the power supply output. Bar graph is active in local and remote modes.

5.13 AC POWER (Ref 12)

The front panel POWER switch controls the main input power to the unit. When closed,

AC power is applied to the control logic, and if no faults are present the AC input contactor will also close. The POWER switch only controls a low voltage signal, and is not directly connected to the main AC line. This low voltage control signal is wired in series

with two terminals on the rear panel. (4 position barrier strip) marked as

INTERLOCK/POWER ON (see Figure 5-3).

The INTERLOCK/POWER ON terminals at the rear of the unit must be jumpered or

wired to a remote switch or contactor. Both the remote contacts and the front panel

switch must be closed for the unit to turn on.

Once the unit is turned on using the front panel POWER switch, the internal control logic

begins a complete check of all operational circuits. The check includes all functions displayed on the front panel LED indicator lights. The check sequence begins with a tests

of all the lights by switching them all on for about one second to let the operator know

that all the LED's and the associated drivers are working, and that the power is applied

to the logic circuit and the internal self checks are underway.

Within 4 to 6 seconds after the POWER switch is closed and the self check sequence

commenced, all the tests are finished and the AC contactor automatically closes (a loud

‘thunk’ will be heard) applying AC power to the main power circuits, placing the power

supply in the READY state (FAULT LED is not illuminated). When READY the power

supply is considered to be armed and could be generating high voltage.

5.14 FRONT PANEL LAYOUT (S Model)

The 303S series power supply is equipped with a partially instrumented front panel featuring comprehensive status LEDs, and a power on switch. The 303S can only be operated remotely via the control connector located on the rear panel (see Section 7.2).

83489011 Rev A

Page 33

CONTROLS, INDICATORS, CONNECTORS

1

2

MODEL 303

STATUS

HV ON

ENABLE

COOLANT FULL

AUTO DWELL

EOC FANFAIL

INT CLOSED

INHIBIT

LOAD FAULT

PURGE

EXCESSREVERSAL

COOLANT WARNING

CURRENT

FAULT

UVLO

INT OPEN

LOW LINE

IMBALANCE

HIGH LINE

5-9

110%10080 90706050403020100

POWER

ARC

COOLANT FAIL

OVERTEMP

OVERP

CLAMP

LINE FAULT

Figure 5-2 203/303S Front Panel Controls and Indicators

REF DESCRIPTION NOTE SECTION

1 Status LEDs Indicates the status of the power supply 5.10

2 Power switch Turns on/off power to auxiliary circuits 5.13

Table 5-2 Front Panel Controls and Indicators (S Model)

A description of the function of the LEDs and the power switch are given in sections

5.10 and 5.13 respectively.

5.15 REAR PANEL LAYOUT (L Models)

All of the interconnect and service connections for the 203/303L are located on the

power supply rear panel. Figure 5-3 shows the rear panel layout and location of the various connectors.

83489011 Rev A

Page 34

5-10

101211

12345

6

789

CONTROLS, INDICATORS, CONNECTORS

COOLANTWATERIN OUT

5

0

1

0

10

0

-30

inHg psi

0

1

5

20

0

30

0

0

2

kPa

!

438-528VAC

50/60 Hz

TB2 1 2 3 4

INTERLOCK/POWERON

A B C N GND

1 2 3 4 5

0

-10

0

5

-

INHIBITREMOTE

HV OUTPUT

COOLANT

-20

-

1

0

0

SLAVE

TB 1 ACINPUT

Figure 5-3 203/303L Rear Panel Connections

REF DESCRIPTION NOTE SECTION

1 Inhibit BNC BNC socket for external inhibit signal 5.15.1

2 Coolant Water Inlet ¼ NPT male threaded coolant inlet pipe 5.15.2

3 HV Output Connector HV output connector 5.15.3

4 Coolant Water Out ¼ NPT male threaded coolant outlet pipe 5.15.2

5 Cooling Fan Input section cooling fan 5.15.4

Interlock/Power On

6

Terminal strip

7 Remote connector Remote control interface 25 pin D-sub plug 5.15.6

8 Slave connector Slave interface 25 pin D-sub socket 5.15.7

External interlock and remote power on terminals 5.15.5

9 Coolant service valve Coolant valve to allow external tank fill 5.15.8

10 Tank pressure gauge HV tank pressure gauge 5.15.9

11 Safety ground 10-32 safety ground connection 5.15.10

83489011 Rev A

Page 35

CONTROLS, INDICATORS, CONNECTORS

REF DESCRIPTION NOTE SECTION

12 AC input terminal AC input terminal block 5.15.11

Table 5-3 203/303L Rear panel Functions

The function of each item in Table 5-3 is described in the following sections.

5.15.1 INHIBIT BNC (Ref 1)

The inhibit BNC input is a standard BNC socket that allows an external connection to a

pulse generator or control system and gives the user control of the power supply output

current. A logic 1 (10-15V) input will inhibit the supply (shuts off the output current) and

a logic 0 (ground or open) allows the supply to operate.

5.15.2 Coolant Water Inlet/Outlet (Ref 2/4)

¼ NPT male threaded pipe connection for external cooling water supply.

5.15.3 HV Output Connector

Connector socket for mating HV cable supplied with unit. The connector should be kept

clean and free from debris at all times.

5.15.4 Cooling Fan

Although the supply is water cooled a small cooling fan is used to cool the AC input circuitry. Allow at least 5 inches of clearance and do not obstruct clear air flow around the

fan.

5-11

5.15.5 Interlock/Power On Terminal strip

Provides an external connection for the customer to allow both interlock and remote

power on functions to be controlled. The interlock terminals should be connected to any

safety interlock circuitry in the power supply installation. The remote power on terminals

are wired in series with the front panel ON switch, and can be used as a remote

ON/OFF switch if the front panel switch is left in the ON position. Note: The Inter-

lock/remote power on terminals are connected to floating chassis referenced

24VAC circuits and should never be connected to ground.

5.15.6 Remote connector

A 25 pin D-sub male connector that allows remote operation and monitoring of all power

supply functions when the unit is operated in REMOTE mode.

5.15.7 Slave connector

A 25 pin D-sub female connector that allows connection of a slave supply for increased

power operation.

5.15.8 Coolant service valve

External valve to allow topping up of the HV tank with coolant without the need for removing the top cover. Do not undertake this procedure without contacting the factory.

5.15.9 Tank pressure gauge

The tank pressure gauge indicates the pressure inside the coolant filled HV assembly.

With the power supply non operating at room temperature the gauge should show a

vacuum between 10 and 15in Hg. With the supply operating at full power the gauge

should read between 10 and 15PSI.

83489011 Rev A

Page 36

5-12

10121112345679

CONTROLS, INDICATORS, CONNECTORS

5.15.10 Safety ground

10-32 safety ground screw installed in chassis. Should be used for additional safety

ground cable between supply and load circuit.

5.15.11 AC input terminal

Main AC input power terminal block see section 4.5 for further details.

5.16 REAR PANEL LAYOUT (S Models)