Page 1

2i

blu

Module

User Guide

The information contained in this document is subject to change without notice. TDK Systems Europe makes no warranty of

any kind with regard to this material including, but not limited to, the implied warranties of merchant ability and fitness for a

particular purpose. TDK Systems Europe shall not be liable for errors contained herein or for incidental or consequential

damages in connection with the furnishing, performance, or use of this material.

© Copyright 2004 TDK Systems Europe Limited.

All rights reserved.

This document contains information that is protected by copyright. All rights reserved. No part of this document may be

photocopied, reproduced, or translated to another language without the prior written consent of TDK Systems Europe.

Other product or company names used in this publication are for identification purposes only and may be trademarks of their

respective owners.

1 of 36

Page 2

Contents

BEFORE YOU BEGIN.................................................................................................................................................................... 3

AFETY GUIDELINES................................................................................................................................................................... 3

S

APPROVALS .......................................................................................................................................................................... 3

RF

1 FUNCTIONS ...................................................................................................................................................................... 4

2 APPLICATION INTERFACE ............................................................................................................................................. 5

2.1 S

2.2 P

2.3 POWER-ON-RESET (POWER CYCLING AND BROWN OUT CONSIDERATIONS)..................................................................... 6

2.4 SPI

2.5 P

2.6 PCM CODEC INTERFACE................................................................................................................................................ 8

3 ELECTRICAL SPECIFICATION OF THE INTERFACE .................................................................................................... 9

3.1 E

4 PHYSICAL CHARACTERISTICS.................................................................................................................................... 13

4.1 M

4.2 M

4.3 BOARD TO BOARD CONNECTOR.................................................................................................................................... 14

5 ELECTRICAL AND RADIO CHARACTERISTICS.......................................................................................................... 16

5.1 A

5.2 OPERATING TEMPERATURES......................................................................................................................................... 16

5.3 P

5.4 L

5.5 RF

5.6 R

6 RS232 MODEM SIGNALS............................................................................................................................................... 24

6.1 M

6.2 BREAK

6.3 R

7 PURE CABLE REPLACEMENT MODE.......................................................................................................................... 27

7.1 D

7.2 A

7.3 MODEM CONTROL AND STATUS SIGNALS ...................................................................................................................... 29

8 GETTING STARTED ....................................................................................................................................................... 30

8.2 F

8.3 S

APPENDIX A ................................................................................................................................................................................ 34

E

FCC

APPENDIX B ................................................................................................................................................................................ 35

ESD

A

WARRANTY ................................................................................................................................................................................. 36

ERIAL INTERFACE......................................................................................................................................................... 5

OWER SUPPLY ............................................................................................................................................................. 6

BUS ........................................................................................................................................................................ 8

ARALLEL PIO PORT ..................................................................................................................................................... 8

LECTRIC CHARACTERISTICS ....................................................................................................................................... 11

ECHANICAL DIMENSIONS............................................................................................................................................ 13

OUNTING THE BLU2I MODULE ONTO THE APPLICATION PLATFORM .................................................................................14

BSOLUTE MAXIMUM RATINGS ...................................................................................................................................... 16

OWER CONSUMPTION ................................................................................................................................................ 16

OW POWER MODES USING SNIFF ................................................................................................................................ 19

PERFORMANCE ....................................................................................................................................................... 21

5.5.1 Transmit Power .............................................................................................................................................21

5.5.2 Receive Sensitivity ........................................................................................................................................ 21

5.5.3 Range ............................................................................................................................................................ 21

5.5.4 Performance against Temperature................................................................................................................ 22

ELIABILITY ................................................................................................................................................................. 23

ODEM SIGNALLING OVER BLUETOOTH ......................................................................................................................... 25

SIGNAL ON RX LINE .........................................................................................................................................25

ESET ......................................................................................................................................................................... 26

ATA CABLE ................................................................................................................................................................ 27

UDIO CABLE............................................................................................................................................................... 28

2i

8.1.1 Two blu

8.1.2 One blu

ACTORY DEFAULT MODE ............................................................................................................................................ 32

OFTWARE ..................................................................................................................................................................32

UROPE – EU DECLARATION OF CONFORMITY .......................................................................................................................... 34

AND INDUSTRY CANADA STATEMENTS ............................................................................................................................... 34

(ELECTROSTATIC DISCHARGE).......................................................................................................................................... 35

DDITIONAL STATEMENT ........................................................................................................................................................... 35

Modules.......................................................................................................................................... 30

2i

Module and Bluetooth PC using TDK’s USB Adaptor or PC Card................................................. 31

2 of 36

Page 3

Before You Begin

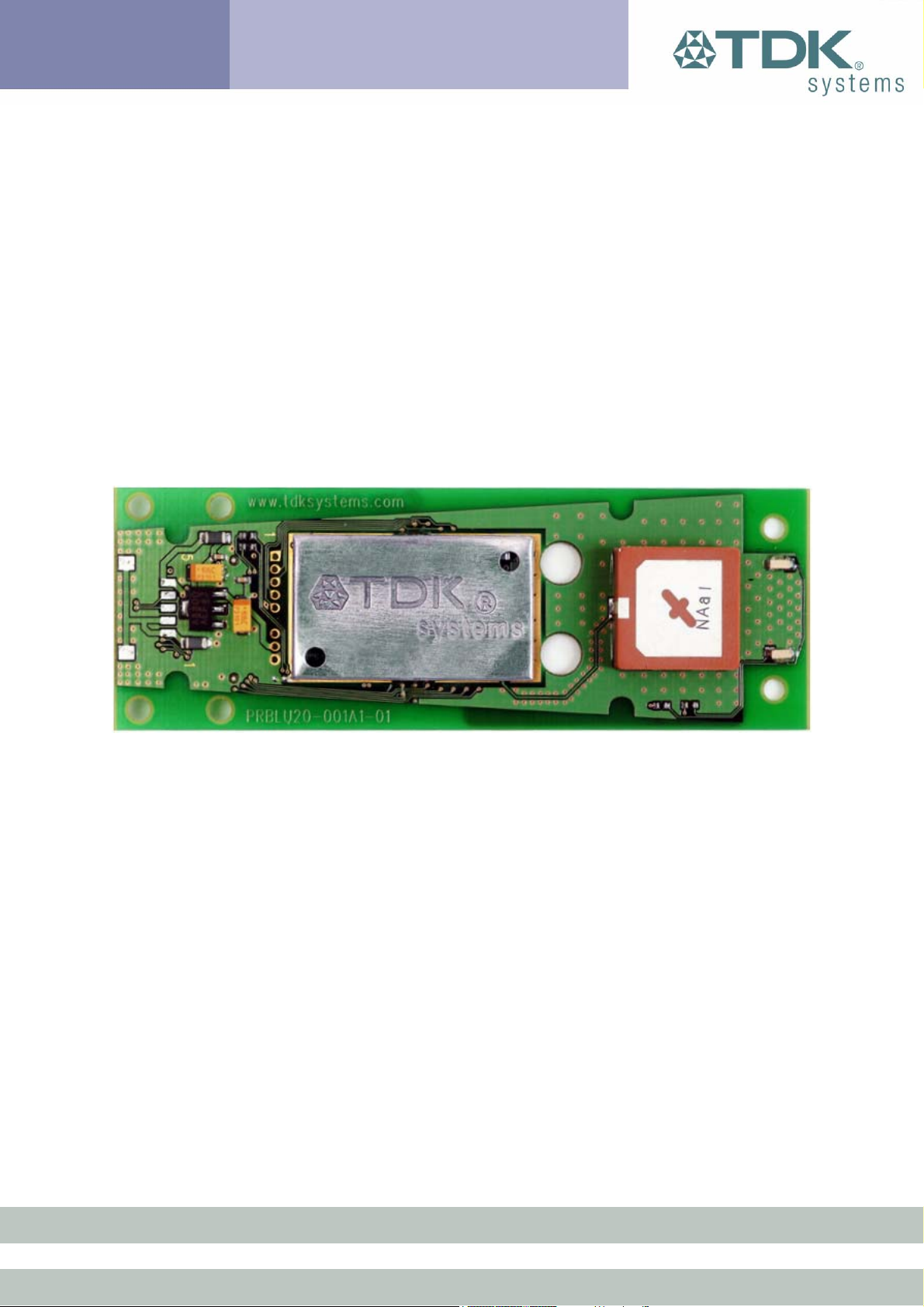

Congratulations on your purchase of the TDK Systems blu

2i

Module.

The Module is designed to be built into a device and to provide a simple,

low cost Bluetooth interface. The module is designed to integrate with a

wide range of applications and platforms with a simple electrical and

software interface using AT commands.

This guide aims to provide all the electrical and mechanical information

needed to design applications using the blu

document, blu

2i

Module - AT Command Set, outlines the protocol for the

2i

Module. A separate

software interface.

Safety Guidelines

The following safety precautions must be observed during all phases of

the operation, usage, service or repair of any application incorporating

this Bluetooth Module. Manufacturers of the RF equipment are advised

to convey the following safety information to users and operating

personnel and to incorporate these guidelines into all manuals supplied

with the product. Failure to comply with these precautions violates safety

standards of design, manufacture and intended use of the product. TDK

Systems assumes no liability for customer failure to comply with these

precautions.

RF Approvals

The blu

Bluetooth SIG Program Reference Document (PRD). This means that it

can be integrated into end products without further testing or approval

listing. The manufacturer must state the TDK part number and product

reference in his literature in order to meet the requirements of the

Bluetooth and regulatory approvals.

A list of the countries where the module is approved will be provided by

TDK Systems as required. As a minimum the product is listed in Europe,

Scandinavia and USA. TDK Systems assumes no liability for customer

failure to comply with national RF approvals.

2i

Module is listed as a Bluetooth Product in terms of the

3 of 36

Page 4

Functions 1

The blu

2i

Module contains a complete Bluetooth interface and requires

no further hardware to implement full Bluetooth communication. The

module has an integrated, high performance antenna together with all

RF and Baseband circuitry, it interfaces to the host over a straight

forward serial port using AT commands. The module runs specific

firmware within the Virtual Processor that includes a serial Port Profile

and AT command interpreter. The module can be configured so that it

can be attached to a ‘dumb’ terminal or attached to a PC or PDA for

cable replacement applications.

The module provides access to 5 General I/O lines and 2 analogue I/O

lines to provide Bluetooth connection to simple devices such as switches

or LEDs without requiring any processing at the module end.

2i

blu

Module features at a glance:

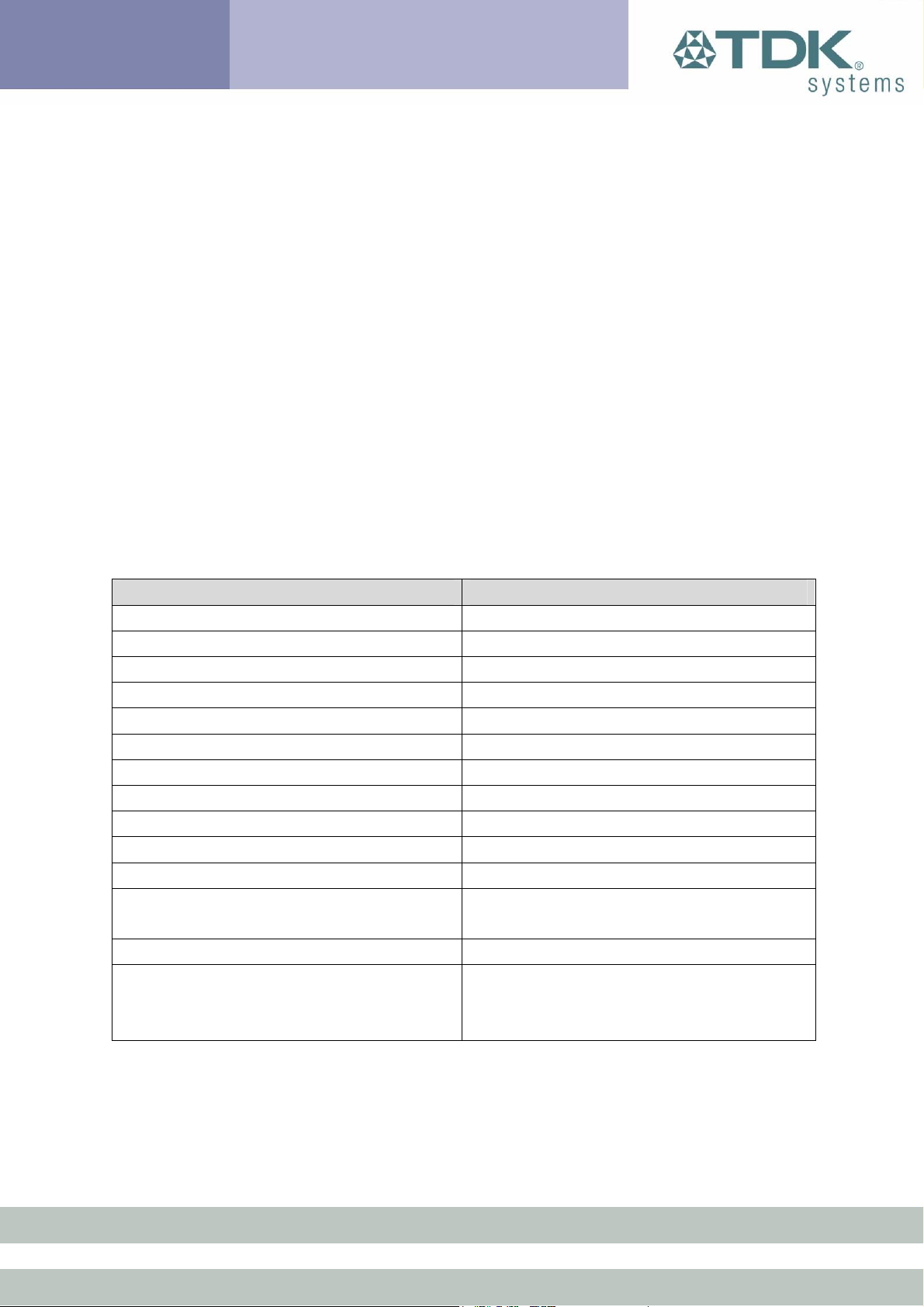

Feature Implementation

Bluetooth Transmission Class 1

Frequency 2.400 – 2.485Ghz

Minimum Transmit Power +0dBm

Maximum Transmit Power +6dBm

Receive Sensitivity Better than -85dB

Antenna Gain +2dBi

Range (see Section 6.1.3) Up to 100 metres, free space

Data Transfer Rate Up to 200Kbps

Physical size 24 x 69 x 5 mm

Weight 8g

Fully Bluetooth pre-qualified Bluetooth 1.1 PRODUCT listing

Current consumption Less than 36mA during data

transfer

Temperature Range -20°C to +75°C

Audio Audio can be transferred over

SCO channels through the PCM

interface at 64Kbps

4 of 36

Page 5

Application Interface 2

The blu

connector that connects to the application platform. Electrical and

mechanical characteristics of the board-to-board connector are specified

in Chapter 3.

2i

Module is equipped with a 40-pin 0.5mm pitch board to board

• Serial interface (see Section 3.0)

• Electrical specification of the interface (see Section 3.1)

2.1 Serial Interface

UART_TX, UART_RX, UART_RTS and UART_CTS form a conventional

asynchronous serial data port. The interface is designed to operate

correctly when connected to other UART devices such as the 16550A.

The signalling levels are nominal 0V and 3.3V and are inverted with

respect to the signalling on an RS232 cable. The interface is

programmable over a variety of bit rates; no, even or odd parity; stop bit

and hardware flow control. The default condition on power-up is preassigned in the external Flash. Two-way hardware flow control is

implemented by UART_RTS and UART_CTS. UART_RTS is an output

and is active low. UART_CTS is an input and is active low. These

signals operate according to normal industry convention.

By writing different values to the S register the UART_RI can be

continuously polled to detect incoming communication. The UART_RI

signal serves to indicate incoming calls.

UART_DSR is an active low input. It should be connected to DTR output

of the host. When the module is running in high speed mode (See

definition for S Register 512), this pin should be asserted by the host to

ensure connection is maintained. A deassertion is taken to mean that the

connection should be dropped, or an online command mode is being

requested.

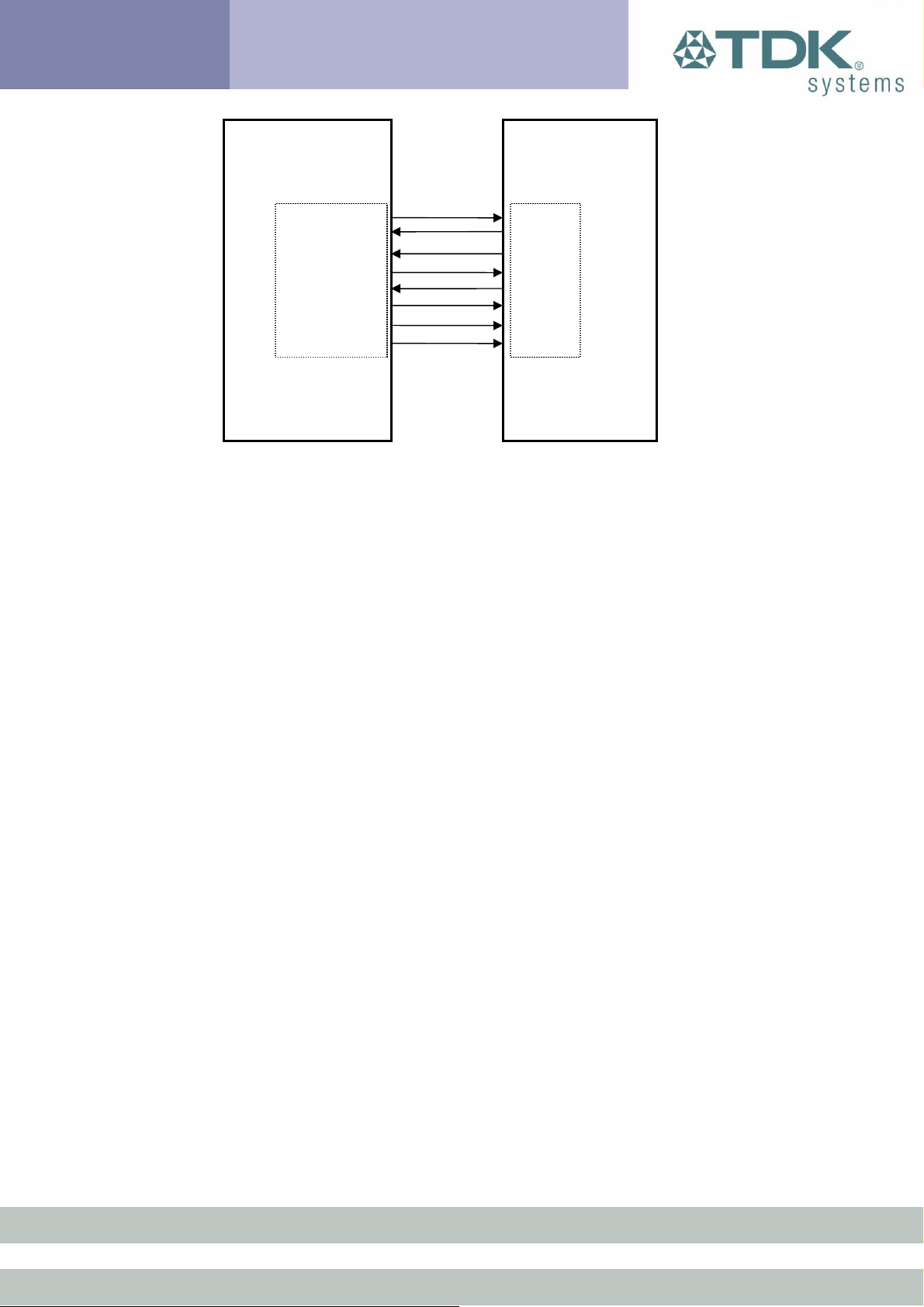

The module communicates with the customer application using the

following signals:

RS-232

• Port /TXD @ application sends data to the module’s UART_RX

signal line

• Port /RXD @ application receives data from the module’s

UART_TX signal line

5 of 36

Page 6

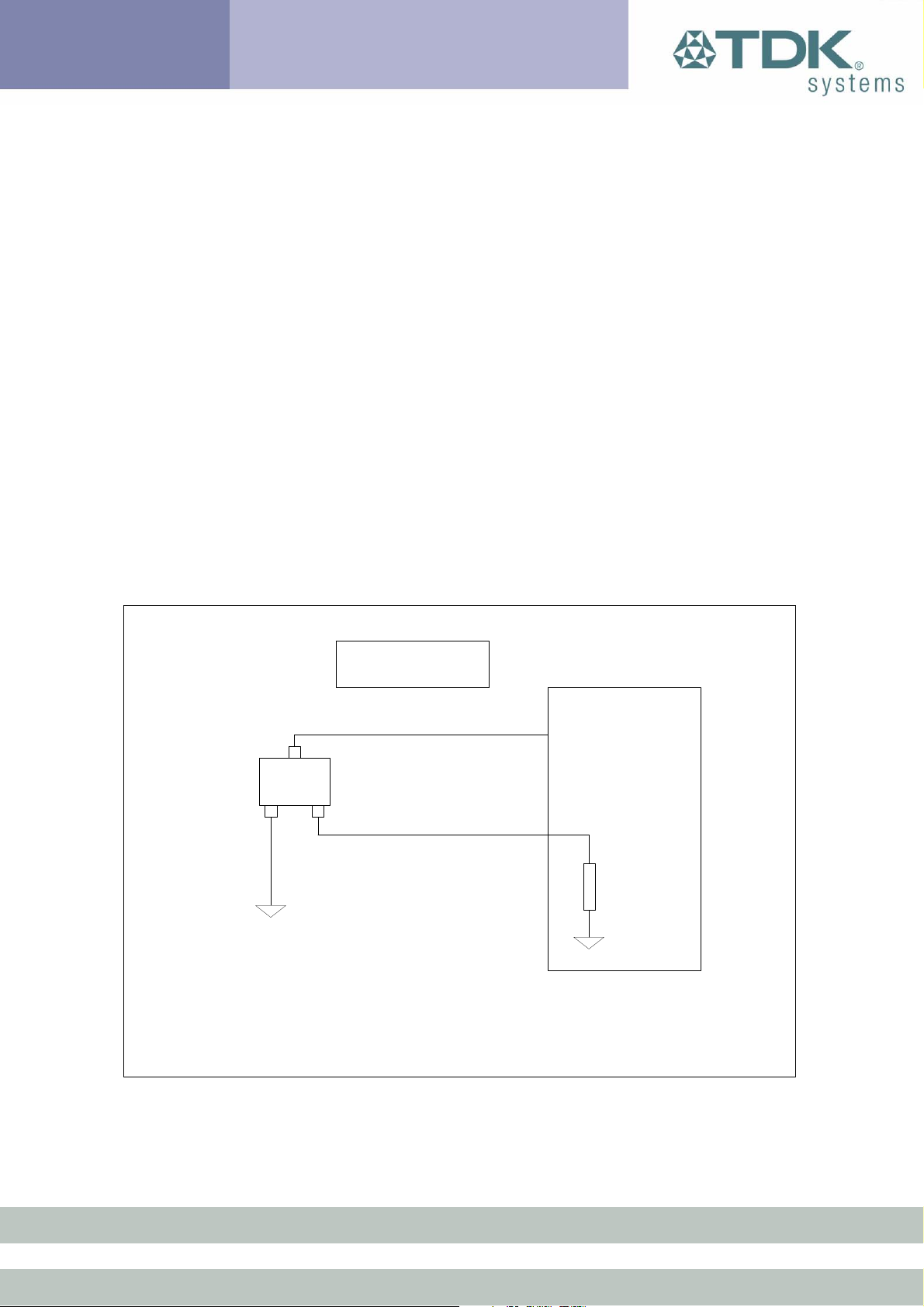

blu2i Module Application

/

UART Interface

UART_TX /RXD

UART_RX /TXD

UART_CTS /RTS

UART_RTS /CTS

UART_DTS /DTR

UART_DTR /DSR

UART_DCD /DCD

UART RI

RING

RS232 Interface

Figure: UART interfaces

2.2 Power Supply

The power supply for the blu

of Vcc= 3.6V to 6V. It must be able to provide sufficient current in a

transmit burst which can rise to 65mA.

The module includes regulators to provide local 3.3V and 1.8V. These

rails are accessible on connector J2 for monitoring.

Power (Vcc) should be provided via the board-to-board connector Pin 29

on J2.

Section 5.3 details the power consumption in different modes.

2i

Module has to be a single voltage source

2.3 Power-On-Reset (Power Cycling and Brown Out

considerations)

The Module is provided with an active high reset pin (Hirose 40 way

DF12C connector pin 13). This pin whose electrical specification may be

found in section 3.3 is internally pulled to ground through a 10KΩ

resistor. Upon the application of power, the Power On Reset circuit built

into the module will ensure that the unit starts correctly.

However the module utilises a split rail design with some components

working at 3V3 and some at 1V8. Under certain extreme conditions, for

6 of 36

Page 7

example when the supply voltage to the module experiences a BrownOut (momentary dip in the supply voltage level), or a rapid power cycle

i.e. the power is switched off and then on within 1second, there is a

possibility that the module can enter an unknown state of operation.

It is strongly recommended that the application hardware onto which the

module is mounted provides a Power-On-Reset circuit with a Brown-Out

detection capability. This will guarantee that under all circumstances the

module will operate in a known state.

A device such as the Maxim MAX6382XR26D3-T would be a suitable

part to perform the reset – it has an active high push-pull output, a 2.63V

detection threshold, and an active reset period of 140ms. This

inexpensive device is available in a SC70-3 package (2.2mm x 2.4mm)

and requires no additional components to operate. The device is used to

monitor the output of the voltage regulator on the module (through pin

27), and drives the Reset line (pin13) high when the supply voltage falls

out of tolerance. The schematic below illustrates its use.

1

GND

3

Vcc

MAX6382

Please note that this 3V3 is the output of

the 3V3 regulator on the blu2i Module and

should not be connected to any other

supplies on the application hardware.

ResetGnd

2

BC02 3V3

BC02 MRESET

blu2i Module

Pin27

Pin13

10K

GND

7 of 36

Page 8

2.4 SPI Bus

The module is a slave device that uses terminals SPI_MOSI, SPI_MISO,

SPI_CLK and SPI_CSB. This interface is used for program firmware

update.

Note: The designer should be aware that no security protection is built

into the hardware or firmware associated with this port, so the terminals

should not be permanently connected in a PC application.

2.5 Parallel PIO Port

Five lines of programmable bi-directional input/outputs (I/O) are

provided. GPIO[1:5] are powered from VCC. The mode of these lines

can be configured and the lines are accessed via S Registers 621 to

625.

Auxiliary functions available via these pins include an 8-bit ADC and an

8-bit DAC. This function is not implemented at this time.

2.6 PCM Codec Interface

PCM_OUT, PCM_IN, PCM_CLK and PCM_SYNC carry up to three bidirectional channels of voice data, each at 8K samples/s. The format of

the PCM samples can be 8-bit A-law, 8-bit µ-law, 13-bit linear or 16-bit

linear. The PCM_CLK and PCM_SYNC terminals can be configured as

inputs or outputs, depending on whether the module is the Master or

Slave of the PCM interface.

The blu

interfaces directly to PCM audio devices including the following:

2i

module is compatible with the Motorola SSI TM interface and

• Qualcomm MSM 3000 series and MSM 5000 series CDMA

baseband devices

• OKI MSM7705 four channel A-law and µ-law CODEC

• Motorola MC145481 8-bit A-law and µ-law CODEC

• Motorola MC145483 13-bit linear CODEC

8 of 36

Page 9

Electrical specification of the interface 3

The Hirose DF12C board to board connector on the module is a 40 way

double-row receptacle. The pin allocation is as follows:

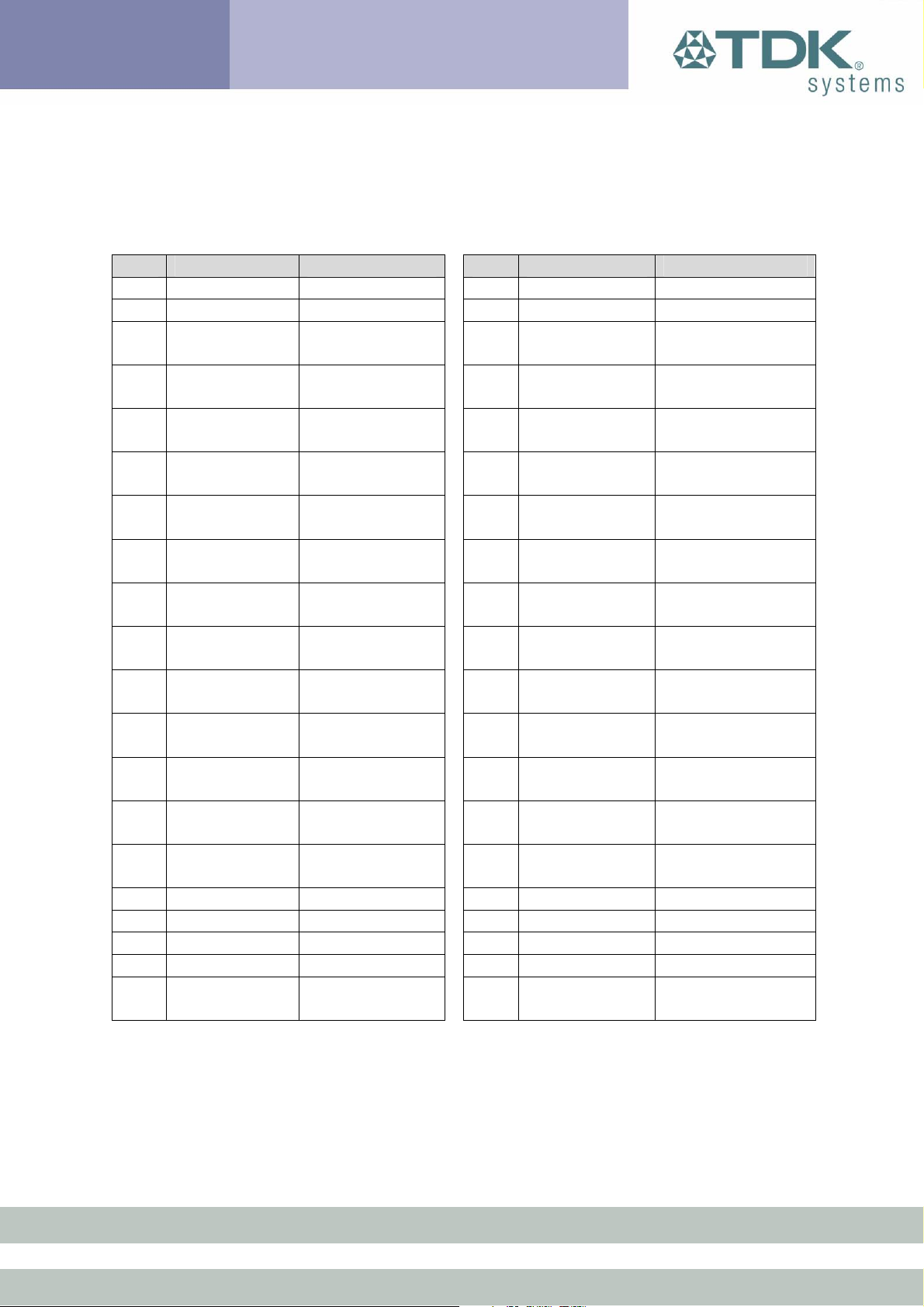

Pin Signal Description Pin Signal Description

1 Analogue 0 1.8v Max 2 GPIO1 I/O for Host

3 Analogue 1 1.8v Max 4 GPIO2 I/O for Host

5 SPI_MISO SPI bus serial

O/P

7 SPI_CSB SPI bus chip

select I/P

9 SPI_CLK SPI bus clock

I/P

11 GND 12 GPIO3/UART

13 RESET Reset I/P 14 GPIO4 I/O for Host

15 GND 16 GPIO5 I/O for Host (Left

17 SPI_MOSI SPI bus serial

I/P

19 UART_CTS Clear to Send

I/P

21 UART_TX Transmit Data

O/P

23 UART_RTS Request to

Send O/P

25 UART_RX Receive Data

I/P

27 VCC_3V3 3.3V Output

(Note 3)

29 VCC_5V 3.6V < VIN <

6.0V

31 N/C 32 RESERVED Do not connect

33 N/C 34 RESERVED Do not connect

35 N/C 36 GND

37 N/C 38 GND

39 VCC_1V8 1.8V Output

(Note 3)

6 UART_RI ‘Ring’ Input or

Output

8 UART_DCD Input or Output

10 UART_DSR Input

I/O for Host

_DTR

(Right LED)(2)

LED) (2)

18 GND

20 PCM_CLK PCM Clock I/P

22 PCM_IN PCM Data I/P

24 PCM_SYNC PCM Sync I/P

26 PCM_OUT PCM Data O/P

28 N/C

30 GND

40 N/C

9 of 36

Page 10

Notes:

• UART_RX, UART_TX, UART_CTS, UART_RTS, UART_RI,

UART_DCD and UART_DSR are all 3.3v level logic. For example,

when RX and TX are idle they will be sitting at 3.3V. Conversely

for handshaking pins CTS, RTS, RI, DCD, DSR a 0v is treated as

an assertion.

• Pin 6 (UART_RI) is active low. It is normally 3.3v. When a remote

device initiates a connection, this pin goes low. This means that

when this pin is converted to RS232 voltage levels it will have the

correct voltage level for assertion.

• Pin 8 (UART_DCD) is active low. It is normally 3.3v. When a

connection is live this pin is low. This means that when this pin is

converted to RS232 voltage levels it will have the correct voltage

level for assertion.

• Pin 10 (UART_DSR) is an input, with active low logic. It should be

connected to the DTR output of the host. When the blu

2i

Module is

in high speed mode (See definition for S Register 512), this pin

should be asserted by the host to ensure that the connection is

maintained. A deassertion is taken to mean that the connection

should be dropped, or an online command mode is being

requested.

• The GPIOn pins can be accessed using S Registers 621 to 625

• GPIO4 and GPIO5 are also connected to LEDs on the module. If

these I/O pins are set for input, then the LED will be driven by the

host and appropriate drive current requirements must be satisfied.

By default GPIO4 is used to drive the right LED which indicates

connection status. A Logic 1 switches on the LED.

• Analogue 0 and 1 should not exceed 1.8v and S Registers 7xx are

used to access them.

• GPIO3 is used for DTR output (active low).

10 of 36

Page 11

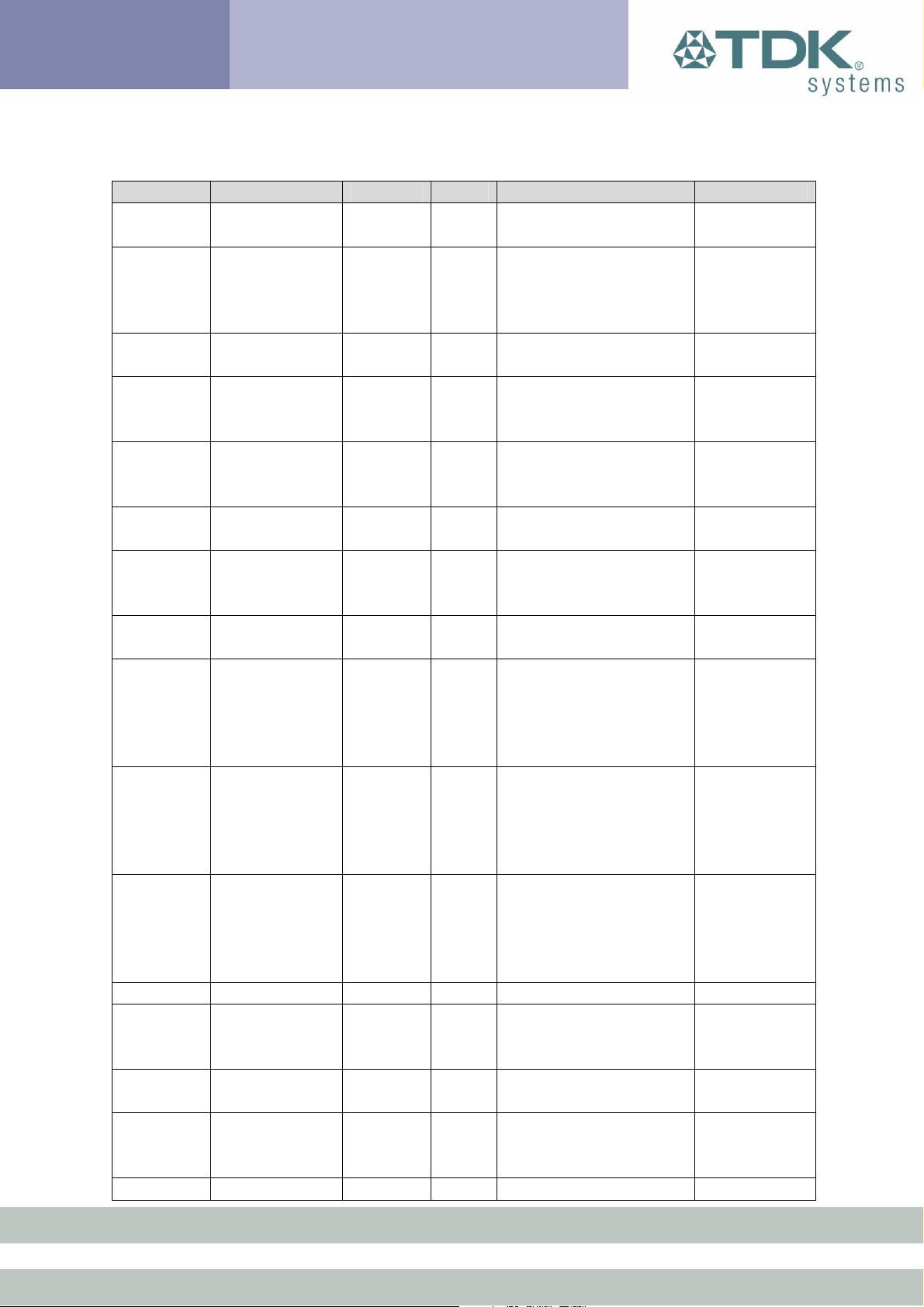

3.1 Electric Characteristics

Function Signal Name Pin No I/O Signal level Comments

Power

Supply

GND 11, 15,

RS232

Interface

UART_RX 25 I

UART_CTS 19 I

UART_RTS 23 O

UART_DSR 10 I

UART_DTR 12 O

UART_RI 6 I or O

UART_DCD 8 I or O

External

Power

Supply

VCC_3V3 27 O 3.3V typical

SPI Bus SPI_MOSI 17 I

SPI_MISO 5 O

SPI_CSB 7 I

SPI_CLK 9 I

Vcc 29 I 3.6V to 6V Ityp = 50mA

6 Ground

18, 30,

36, 38

terminals to

be attached

in parallel

UART_TX 21 O

max=0.2V

V

OL

V

min=2.8V

OH

max=0.8V

V

IL

V

min=2.10V

IH

VIHmax=3.7V

max=0.8V

V

IL

V

min=2.10V

IH

V

max=3.7V

IH

max=0.2V

V

OL

V

min=2.8V

OH

max=0.8V

V

IL

V

min=2.10V

IH

V

max=3.7V

IH

max=0.2V

V

OL

V

min=2.8V

OH

O/P : V

V

I/P : V

V

V

max=0.2V

OL

min=2.8V

OH

max=0.8V

IL

min=2.10V

IH

max=3.7V

IH

O/P : VOLmax=0.2V

VOHmin=2.8V

I/P : V

V

max=0.8V

IL

min=2.10V

IH

Shared with

GPIO3

Direction

may be

programme

d.

Direction

may be

programme

d.

VIHmax=3.7V

VCC_1V8 39 O 1.8V typical For

monitoring

only. No

current

source

max=0.8V

V

IL

V

min=2.10V

IH

V

max=3.7V

IH

max=0.2V

V

OL

V

min=2.8V

OH

max=0.8V

V

IL

V

min=2.10V

IH

V

max=3.7V

IH

max=0.8V

V

IL

Used to

reprogram

Flash

11 of 36

Page 12

VIHmin=2.10V

V

max=3.7V

IH

PCM

Interface

PCM_IN 22 I

PCM_SYNC 24 I or O

PCM_OUT 26 O

Reserved BC02

BC02

GPIO GPIO 1 - 5 2,4,12,

Analog

I/O

PCM_CLK 20 I or O

O/P : V

V

I/P : V

V

V

V

V

V

O/P : VOLmax=0.2V

V

I/P : V

V

V

V

V

32 I

USB D-

34 I

USB D+

I or O

14,16

VILmax =0.3vdd_pads

V

V

V

O/P : V

V

I/P : V

V

V

AIO_0,

AIO_1

1, 3 I/O Vout max=VDD_PIO-

.3

OL

OH

IL

IH

IH

max=0.8V

IL

min=2.10V

IH

max=3.7V

IH

OH

IL

IH

IH

max=0.2V

OL

min=2.8V

OH

min =0.7cdd_pads

IH

max =0.3vdd_pads

IL

min =0.7cdd_pads

IH

OL

OH

IL

IH

IH

Vout min=VDD_PIO

Reset RESET 13 I

V

DD

falling

threshold=1.5V typ

V

rising

DD

threshold=1.6V typ

max=0.2V

min=2.8V

max=0.8V

min=2.10V

max=3.7V

min=2.8V

max=0.8V

min=2.10V

max=3.7V

max=0.2V

min=2.8V

max=0.8V

min=2.10V

max=3.7V

If unused

keep pins

open

Normally

inactive.

Pull to GND

through 10K

12 of 36

Page 13

Physical Characteristics 4

4.1 Mechanical Dimensions

13 of 36

Page 14

4.2 Mounting the blu2i Module onto the application

platform

There are many ways to properly install the Module in a host device. An

efficient approach is to mount the PCB to a frame, plate, rack or chassis.

Fasteners can be M1.8 or M2 screws plus suitable washers, circuit

board spacers, or customized screws, clamps, or brackets in 2.2mm

diameter holes. Note that care should be taken to ensure the head of the

fixing does not interfere with the circuit. Nylon fixings are recommended.

In addition, the board to board connection can also be utilized to achieve

better support.

The antenna (Brown square component on top side of PCB) must not be

influenced by any other PCBs, components or by the housing of the host

device. The proximity of the antenna to large metallic objects can affect

the range and performance of the system. Designers should carefully

consider the location of the module and the type of enclosure material

that is used.

To prevent mechanical damage, be careful not to force, bend or twist the

module. Be sure it is positioned flat against the host device.

4.3 Board to Board Connector

This section provides specifications for the 40 way board-to-board

connector which serves as physical interface to the host application. The

receptacle assembled on the blu

Item Part number Stacking height HRS number

Receptacle

on Module

DF12C-40DS-

0.5V(81)

2i

Module is type Hirose DF12C.

3.5mm - 5mm CL537-0007-7-

14 of 36

Page 15

Mating headers from Hirose are available in different stacking heights.

Details are available at:

http://www.hirose.co.jp/cat2002e/500/e53700036.pdf

Item Part number Stacking height HRS number

Headers

DF12 series

DF12(4.0)-40DP-

DF12(5.0)-40DP-

Note: The headers listed above are without boss and metal fitting.

Electrical and mechanical characteristics of the Hirose DF12C

connector:

Parameter Specification (40 pin Board to

Number of Contacts 40

Quantity delivered 2000 Connectors per Tape & Reel

Voltage 50V

Current Rating 0.5A max per contact

Resistance 0.05 Ohm per contact

Dielectric Withstanding Voltage 500V RMS min

Operating Temperature -45°C to +125°C

Contact Material phosphor bronze (surface: gold

Insulator Material PA , beige natural

Stacking height 3.0 mm; 3.5 mm; 4.0 mm; 5.0 mm

Insertion force 21.8N

Withdrawal force 1st 10N

Withdrawal force 50th 10N

Maximum connection cycles 50

DF12(3.5)-40DP-

0.5V(81)

0.5V(81)

0.5V(81)

3.5mm CL537-0032-4-

4.0mm CL537-0057-5-

5.0mm CL537-0157-0-

Board connector)

plated)

**

**

**

15 of 36

Page 16

Electrical and radio characteristics 5

5.1 Absolute Maximum ratings

Absolute maximum ratings for supply voltage and voltages on digital and

analog pins of the module are listed below. Exceeding these values will

cause permanent damage.

Minimum Maximum

Peak current of power supply 0mA 100mA

Voltage at digital pins -0.3V 3.7V

Voltage at POWER pin 3.3V 7V

5.2 Operating temperatures

Minimum Typical Maximum

Operating temperature -20°C 25°C +75°C

5.3 Power Consumption

The current drain from the Vcc power input line is dependent on various

factors. The three most significant factors are the voltage level at Vcc,

UART baud rate and the operating mode.

The hardware specification for the blu

range of 3.6 to 6.0v at Vcc. Tests have shown that there is no significant

difference in current draw when Vcc is 5 or 6V. Therefore the data

presented below, pertains to Vcc levels of 3.6 and 5v only. Tests have

shown that where power drain is an issue, it is best to keep Vcc at the

lower end of the range.

The UART baud rate has a bearing on power drain because as is normal

for digital electronics, the power requirements increase linearly with

increasing clocking frequencies. Hence higher baud rates result in a

higher current drain.

Finally with regards to operating mode the significant modes are; idle,

waiting for a connection, inquiring, initiating a connection and connected.

With connected mode, it is also relevant to differentiate between no data

2i

module allows for a voltage

16 of 36

Page 17

being transferred and when data is being transferred at the maximum

rate possible.

The operating mode can best be described by stating the AT commands

required to enter that mode. In addition, there are certain S Registers

which have a direct impact on power consumption, which are described

next.

The blu

2i

Module has 2 LEDs which can be configured to display

connection status. One led is used to display connection status, while

the other is used to either display ‘Ring Indicate’ status or follow the

state of the incoming DSR line on the UART interface. Tests have shown

that these LEDs can consume up to 5.3mA which is more than double

the current draw when in Idle mode. Therefore S Registers 533 and 534

can be used to completely disable these indications.

Finally S Registers 508 to 511, which specify the page and inquiry scan

intervals and windows, can be used to adjust the average current drain

when in discoverable and or connectable modes. Registers 508 and 509

specify the interval and window for page scans and registers 510 and

511 specify the interval and window for inquiry scans. Register pairs

508/509 and 510/511 describe duty cycles when the blu

2i

module goes

into scan modes. It is while scanning that the highest current draw

occurs. The average current draw is determined by simple arithmetic

using the values stored in the 508/509 and 510/511 register pairs.

The operating modes described above are entered using AT commands

as follows

Idle On power up, with S Register 512 = 1

Wait for Connection AT+BTG (100% page scan duty cycle)

Discoverable Only AT+BTQ (100% inquiry scan duty cycle)

Connecting ATD

Connected No Data

Connected Max data transfer

All current consumption values in the table below assume that the

connection status indication functionality of the LEDs has been disabled

by setting S Registers 533 and 534 to 0.

All current values are in milliamps (mA).

17 of 36

Page 18

Baud rate

9600 38400 115200 460800

3.6V 3.20 3.20 3.20 3.20 Current per LED

Baud rate

9600 38400 115200 460800

Discoverable Mode,

AT+BTP

S508=S510=640,

S509=S511=320

Discoverable Mode,

AT+BTP

S508=S510=1000,

S509=S511=11

(ATDxxx)

Mode (No Data Transfer)

Sniff NOT activated

Mode (Max Data

Transfer)

Sniff NOT activated

Mode (No Data Transfer)

Mode (No Data Transfer)

Sniff Enabled (AT&F1

setting)

As can be seen, the current drain while waiting for a connection or

discoverable mode is about 30 times higher than in idle mode. This is

when the page/inquiry scan duty cycle is 100%. These modes give the

quickest response to a page or inquiry request from a remote peer.

5.0V 5.30 5.30 5.30 5.30

3.6V 1.60 1.80 1.96 3.00 Idle Mode, S512=1

5.0V 2.00 2.10 2.30 3.40

3.6V 59.00 59.00 59.00 59.00 Wait for Connection Or

5.0V 65.00 65.00 65.00 65.00

3.6V 2.75 2.94 3.10 4.12 Wait for Connection Or

5.0V 3.26 3.36 3.55 4.63

3.6V 50.00 50.00 50.00 50.00 Inquiring Mode, AT+BTI

5.0V 54.00 54.00 54.00 54.00

3.6V 50.00 50.00 50.00 50.00 Connecting Mode

5.0V 54.00 54.00 54.00 54.00

3.6V 6.00 6.10 6.40 7.20 Connected as Master

5.0V 7.20 7.20 7.40 8.20

3.6V 21.50 22.50 24.50 32.50 Connected as Master

5.0V 24.50 26.00 28.00 36.00

Connected as Slave

5.0V 32.00 33.00 33.50 34.00

Connected as Slave

5.0V 4.90

18 of 36

Page 19

It is possible to reduce the duty cycle down to as low as 0.5% at the

expense of response time. The response time can be specified via S

Registers 508 and 510 for page and inquiry respectively, where the

worst case response time can be as high as 2.5 seconds. Then the duty

cycle can be varied by changing the value of S Registers 509 and 511

appropriately.

For example, if S Register 508 and 510 are both set to 1000ms and S

Register 509 and 511 are both set to 11ms then the duty cycle is

reduced to 1%, this means that average current drain at 5.0v will be 2%

of 65mA plus the normal idle mode current, that is, it is as low as

2.75mA. However, in this case, it can take up to 1 second to establish a

connection.

The connected state current consumption while a master or slave can be

considerably reduced by enabling Sniff mode, described in detail in the

next section.

5.4 Low Power Modes using Sniff

Bluetooth connections are master/slave in nature. A master sends

packets and a slave has to acknowledge that packet in the next timeslot.

Timeslots in Bluetooth are 625 microseconds wide. This implies that a

master will always know when packets will be sent and received, which

further means it is able to optimise power usage by switching on power

hungry circuitry only when needed.

A slave on the other hand does NOT have prior knowledge of when a

packet will be received and has to assume that a packet will be received

from a master on every receive slot. This means that it has to leave it’s

receiving circuitry on for most of the receive slot duration. The result of

this is high power consumption as illustrated in the power table above,

where a slave with no data transmission still consumes around 31mA

whereas a master consumes only 6mA.

This problem was identified very early in the evolution of Bluetooth

(especially since headsets spend all their time as a slave in a Bluetooth

connection) and it was solved by having a mode called Sniff, with

appropriate lower layer negotiating protocol.

Sniff mode during connection is basically an agreement between the

slave and its master that data packets will only be exchanged for N

timeslots every M slots. The slave can then assume that it will never be

19 of 36

Page 20

contacted during N-M slots, and so can switch its power hungry circuitry

off. The specification goes further by also specifying a third parameter

called ‘timeout’ (T) which specifies ‘extra’ timeslots that the slave will

agree to listen for after receiving a valid data packet. Put another way, if

a data packet is received by the slave, then it knows that it MUST carry

on listening for at least T more slots. If within that T slot time period

another data packet is received, then the timer is restarted. This

mechanism ensures low power consumption when there is no data

transfer – at the expense of latency. When there is a lot of data to be

transferred, it acts as if sniff mode were not enabled.

It is stated above that during sniff mode, a slave listens for N slots every

M slots. The Bluetooth specification states that a master can have up to

7 slaves attached to it with all slaves having requested varying sniff

parameters. It may therefore be impossible to guarantee that each slave

gets the M parameter it requested. In light of this, the protocol for

enabling sniff mode specifies that a requesting peer specify the M

parameter as a minimum and maximum value. This will allow the master

to interleave the sniff modes for all slaves attached.

For this reason, the sniff parameters are specified in TDK module via

four S registers. S Register 561 is used to specify ‘N’, S Register 562 is

used to specify ‘T’ and S Registers 563/564 are used to specify

minimum ‘M’ and maximum ‘M’ respectively. Although the specification

defines these parameters in terms of timeslots, the S register values

have to be specified in units of milliseconds and the firmware does the

necessary translation to timeslots.

High Power Consumption

N

Data Exchange

Slots

Data Exchange

T

Slots

M

Slots (Negotiated)

Data Exhange

Data Exchange

T

T

Slots

Slots

Low Power Consumption

Data Exchange

T

Slots

Data Exchange

T

Slots

N

Slots

M

Slots (Negotiated)

N

Slots

20 of 36

Page 21

5.5 RF performance

5.5.1 Transmit Power

Conducted Transmit Power: minimum: 1mW (0dBm)

maximum: 4mW (6dBm)

Power class 1

Antenna Gain: +2dBi typical.

Effective Transmit Power: min: 2dBm max:8dBm

5.5.2 Receive Sensitivity

Receive Sensitivity: -86dBm (at 25ºC)

Antenna Gain: +2dBi typical

Effective Receive Sensitivity: -88dBm (at 25ºC)

Receive Sensitivity

0

-40 deg

-10

-20

-30

-40

-50

-60

Attenuation Setting dBm

-70

-80

-90

-100

-20 deg 0 deg 20 deg 40 deg 60 deg 80 deg 100 deg

5.5.3 Range

Temperature Deg. C.

NOTE: Measured as attenuation required

to achieve better than 0.1% BER

See Data Transfer Rate vs distance. The data throughput of the blu

2i

Module is limited to 200Kbps by the parsing of the data being transferred

through the AT command processor. The graph below shows the best

21 of 36

Page 22

case data though-put with and without the AT command processing.

Distances are measured in free space between 2 blu

2i

Modules.

Data Transfer Rate / Distance

800

700

600

500

400

300

Data Transfer Rate (kbps)

200

100

0

10m 50m 100m 150m 200m 250m 300m

Distance (meters)

5.5.4 Performance against Temperature

Data Transmit Rate with Temperature and Attenuation

800

700

RF data rate

Serial port data rate

600

500

400

300

Data Transmission Rate kbs

200

100

0

-60dBm -65dBm -70dBm -75dBm -80dBm -85dBm -90dBm

dBm attenuation

22 of 36

-40 deg

-20 deg

0 deg

20 deg

40 deg

60 deg

80 deg

100 deg

Page 23

5.6 Reliability

Parameter Minimum Maximum

Thermal Shock 200cycles -40ºC

/+85ºC 30 min

Vibration Continuous operation

at 60 Hz, 2mm stroke

Shock 50G 11ms Half Sine

Wave

Moisture Resistance

High Temp Storage 85ºC, 360 hours

Low Temp Storage -40ºC, 240 hours

High Temp/Humidity

Operation

High Temp/Humidity

Storage

Thermal shock -40 to 60ºC in 30min 200 cycles with

Electro Static

Discharge

Drop Test 75cm to concrete, 3

60ºC, 90%RH, 360

hours

EN55024:1998 &

IEC61000-4-3

axis x 2 cycles per

corner

1 cycle/hour

15g max sine wave,

12 hours

6 axis x 3 cycles each

axis

continuous operation

23 of 36

Page 24

RS232 Modem Signals 6

Just as a telephony modem has control and status lines, the blu

2i

Module

also provides for 6 control and status lines as per the table below. The

direction column is as seen from the modules viewpoint.

Direction Function

IN or OUT CI also known as RI (Ring Indicate)

IN or OUT DCD (Data Carrier Detect)

IN DSR (Data Set ready)

OUT DTR (Data Terminal Ready)

IN CTS (Clear to Send)

OUT RTS (Request to Send)

The first four lines are under program control and as such require GPIO

pins and they are mapped to I/O as per the table below. The last two are

under control of the UART driver and their functionality is always

enabled.

PIO

Direction Connector Pin Label Function

Pin

0 IN/OUT GPIO1 General Purpose I/O

1 IN/OUT GPIO2 General Purpose I/O

2 IN/OUT UART_RI Input/Output from module

3 IN/OUT UART_DCD Input/Output from module

4 IN UART_DSR Input to Module

5 IN/OUT GPIO3/UART_DTR General Purpose I/O (or

DTR functionality)

6 IN/OUT GPIO4 General Purpose I/O

(Right LED)

7 IN/OUT GPIO5 General Purpose I/O (Left

LED)

Notes:

1 PIO4 (DSR) is used by the blu

2i

module to sense that the host is

connected, and is intricately linked with connections. For outgoing calls,

if this line is not asserted then an error is immediately. Similarly for

AT+BTP and AT+BTG.

While in a call, for appropriate modes, a deassertion means fall into

command state. If the deassertion exists for longer than the period

24 of 36

Page 25

specified in S Register 519 then the connection is dropped as if an ATH

command was received.

2 PIO2 (RI), is normally deasserted. When an incoming connection

is detected it will be asserted, until the connection is either answered or

rejected using ATA and ATH respectively. See S Registers 552 & 553

for more details

3 PIO3 (DCD) will be deasserted when the device is in the

unconnected state. Asserted when a connection is active. See S

Registers 552 and 553 for more details.

4 PIO5 is either used as GPIO or driven as UART_DTR. When the

unit is configured in pure host mode, this pin is forced into UART_DTR

and is asserted when there is a Bluetooth connection.

GPIO Pins 1,2,3,4 and 5 are available for general purpose use.

6.1 Modem signalling over Bluetooth

The RFCOMM protocol used in Bluetooth for implementing the serial

port profile allows for the exchange of four modem signals. This

information is contained in a special transparent message which

contains bits identified as RTR, RTC, DV and IC which depending on the

type of serial device being emulated maps to DTR or DSR, RTS, DCD

and RI respectively. In addition, this message also includes the ability to

convey a BREAK input from one end to the other.

So to allow for the greatest flexibility and variability in how the modem

control signals are used out in the real world, S Registers 551, 552 and

553 have been provided which allow for any of RTR,RTC,DV and IC to

be mapped to any modem control/status line.

6.2 BREAK signal on RX line

If the host sends a break signal of duration greater than 100ms, then the

2i

blu

module is configured to treat that as a signal to perform a hardware

reset.

This being the case it is not possible to convey a BREAK over Bluetooth

to the peer device.

25 of 36

Page 26

Future enhancement may allow the BREAK signal to be used to map to

GPIO which with appropriate external hardware may allow for a BREAK

to be reproduced on the TX line.

6.3 Reset

The module can be reset by the host without the need of any I/O using a

BREAK signal. The module has been configured to reset when the RX

line detects a break condition for durations greater than 100

milliseconds.

26 of 36

Page 27

Pure Cable Replacement Mode 7

7.1 Data Cable

The module has the capability of being preset into a pure 5-wire data

cable replacement mode. The 5 wires being RX, TX, CTS, RTS and

GND. This mode requires no changes to a host application since the

Bluetooth connection is automatically set up on power up and will retry

when the connection drops.

By implication, two devices are needed to replace a cable. One device is

pre-configured to always be a master and the other, a slave.

Assuming the Bluetooth address of the master to be <bdaddr_m> and

that of the slave to be <bdaddr_s>, the master module is configured by

sending it the following AT commands.

AT&F

ATS512=1

ATS504=1

ATS507=2

ATS530=2000

AT&W

AT+BTR<bdaddr_s>

Where the ATS507=2 setting puts the device in DSR drop mode only.

This means that when the device needs to be reconfigured, deasserting

the DSR line will ensure that the module responds quickly to AT

commands. This further means that in stand alone mode, the DSR input

line MUST be asserted e.g. 0v in TTL signal mode.

The slave is configured by,

AT&F

ATS512=4

ATS0=-1

AT&W

AT+BTR<bdaddr_m>

27 of 36

Page 28

Where <bdaddr_m> is optional. If it is not specified, then the slave unit

will accept connections from any device. If specified then only

connections from the device specified will be accepted.

If it is desired that the slave unit not be discoverable (the master is by

default not discoverable), then the configuration commands are,

AT&F

ATS512=3

ATS0=-1

AT&W

AT+BTR<bdaddr_m>

Where <bdaddr_m> is optional. If it is not specified, then the slave unit

will accept connections from any device. If specified then only

connections from the device specified will be accepted.

When the units are next power cycled, the slave unit will wait for the

master to connect to it and the master will continually look for the slave.

If a connection attempt fails, the master will wait for 2 seconds before

reattempting a connection. This 2 second delay can be varied by issuing

it an ATS530 command with an appropriate value in the range 100ms to

15000ms.

IMPORTANT NOTE: When S Register 507 = 0, the DSR input to the

module MUST be asserted for the auto connection to succeed. When

operating at TTL levels a 0V is seen as an assert state. When operating

at RS232 levels and voltage greater than 3V is seen as assert. It is usual

to connect the DTR line of the host to the DSR line of this device.

7.2 Audio Cable

With a pair of these modules it is possible to replace a mono audio cable

with two way traffic. That is, a setup where a microphone is connected to

a speaker at the remote end and vice versa. So this mode effectively

replaces two audio cables.

Assuming the Bluetooth address of the master to be <bdaddr_m> and

that of the slave to be <bdaddr_s>, the master module is configured by

sending it the following AT commands.

AT&F

ATS512=1

28 of 36

Page 29

ATS504=1

ATS530=2000

ATS532=1

AT&W

AT+BTR<bdaddr_s>

And the slave is configured by,

AT&F

ATS512=4

ATS0=-1

AT&W

AT+BTR<bdaddr_m>

7.3 Modem Control and Status Signals

A serial port has DTR, DSR, RTS, CTS, DCD and RI control lines. RTS

and CTS are locally controlled to prevent local buffer overflow.

However the status of DTR, DRS, DCD and RI can be exchanged with

the remote peer device. If for example, the DTR/DSR lines are to be

exchanged between the two peers to simulate the performance of a

physical cable, then it is possible to do so. Refer to the description for S

Registers 551, 552 and 553 for more details.

29 of 36

Page 30

Getting Started 8

This section describes how to quickly make your first Bluetooth

connection based on the following combinations of Bluetooth hardware:-

1. Two blu

2. One blu

Blue USB Adaptor or PC Card.

Note: The following examples assume that a PC is used to control the

2i

blu

Module using a Terminal Emulation application.

8.1.1 Two blu2i Modules

Assuming your PC has 2 serial ports (COM1 and COM2) or that you

have 2 PCs that each have one free serial port, attach a blu

each COM port. Launch a terminal emulation for each COM port and

start off with comms parameters 9600,N,8,1.

Type AT<enter> and confirm that you see it echoed and then an OK

response. If you do not see this behavior, close the application and

restart with comms parameters 115200,N,8,1 and try again.

On the first terminal emulator application, enter the following

commands:-

ATI4

ATS0=1

AT+BTP

The response to ATI4 will be the modules Bluetooth address in the form

of a 12 digit hex number.

On the second terminal emulator app, enter the following command:-

ATD<bd_addr>

Where <bd_addr> is the 12 digit Bluetooth address you saw in response

to ATI4 above.

After a moment, you will see the response “CONNECT <bd_addr>” on

both terminal emulators. This confirms that you have a Bluetooth

connection between the two.

2i

Modules.

2i

Module and a Bluetooth Enabled PC using TDK’s Go

2i

Module to

30 of 36

Page 31

Now typing characters on one terminal emulator will result in them being

displayed on the other terminal emulator, proving wireless

communications.

8.1.2 One blu2i Module and Bluetooth PC using TDK’s USB

Adaptor or PC Card

Assuming your PC has 1 serial port (COM1) with a blu

2i

Module attached

and the latest Windows Bluetooth stack from TDK installed. Also confirm

that the TDK Go Blue USB Adaptor or PC Card is connected to your PC

and that it is functional. You can confirm this by checking that the

Bluetooth icon in the system tray area has a White B on a blue

background. Red on blue implies no Bluetooth device is attached to the

PC.

Run a terminal emulation application and attach to COM1 at either

9600,N,8,1 or 115200,N,8,1 and confirm that you get an OK response

when you type in the following command:

AT

Then enter the following commands to prepare it for an incoming

Bluetooth connection:

ATS0=1

AT+BTP

Then launch “My Bluetooth Places” on your PC and perform an inquiry.

You will see a device appear named “TDK blu2i XXXXXX”. Double click

on that item and you will see the service profiles screen where the SPP

profile will be displayed.

Double click on that profile item and eventually you will get a dialog box

to confirm that a connection has been established. It will also advise

which virtual COM port it uses for communication with peer device.

Run a terminal emulation application and attach to that virtual COM port

at 115200,N,8,1.

Typing characters will see them being echoed in the other terminal

emulation application.

31 of 36

Page 32

8.2 Factory Default Mode

The module is capable of operating at a very wide range of baud rates

and S Registers 520 and 521 allow the baud rate to be set very easily.

The baud rate clock generator in the module is more versatile that that

available in a standard 16550 UART commonly available in PCs.

In fact, as long as the equation BAUDRATE * 0.004096 produces an

integer value, then there will be 0% error in clocking for that baud rate.

So it is possible to set a baud rate that a PC cannot cope with, and in

that circumstance it is virtually impossible to communicate with it.

To cater for this circumstance, the blu

using 9600,N,8,1 comms settings for exactly 750 milliseconds and then

revert to the comms parameters as per the S Registers.

If the host sends the string !<BISM>!<cr> where <cr> is the carriage

return character within that 750ms period, then the module will remain at

9600,N,8,1 and will also configure itself using factory default S Register

values.

Please see the next section for a discussion on Terminal Emulators and

how you can obtain a terminal emulator which has this ‘reset’ feature

built in.

2i

module will come out of reset

8.3 Software

The Bluetooth Module described in this document uses the serial

interface to accept commands and provide responses. While in

command mode all interaction between it and a host is done purely in

text mode. This means that virtually all terminal emulators available are

adequate for testing and prototyping. HyperTerminal, Procomm or the

TDK Terminal application supplied are all suitable terminal emulators.

TDK Terminal is a terminal emulation application capable of running on

Windows 98, Me, 2000 and XP operating systems. It was developed

specifically to aid development and testing of the blu

connection to serial devices using any combination of the following

communications parameters:

COM Port: 1 to 255

2i

Module. It allows

32 of 36

Page 33

Baud rate: 300 to 921600

Parity: None, Odd, Even

Data Bits: 7 or 8

Stop Bits: 1 or 2

Handshaking: None or CTS/RTS

The unique benefits of using TDK Terminal are:

• Status of DSR, CTS, DCD and RI are continuously displayed

• DTR can be directly controlled via a check box

• RTS can be directly controlled

• BREAK signals can be sent

Also, there is a “Data Transfer Test” mode allowing data to be sent as

fast as the handshaking will permit. This feature is very useful for testing

the bit transfer rate of a Bluetooth connection.

TDK Terminal is included on the blu

download from http://www.blu2i.com

2i

CD and is also available for

.

33 of 36

Page 34

Appendix A

Europe – EU Declaration of Conformity

DECLARATION OF CONFORMITY

In accordance with Annex IV of the EU di rective 1999/5/EC

Notified Body consulted: Phoenix Test-Lab

ID-Number of Notified Body: 0700

declare under our responsibility that the blu2i Module

complies with the appropriate essential requirements of the Article 3 of the R&TTE and the

other relevant provisions, when used for its intended purpose.

Health and Safety requirements contained in Article 3 (1) a)

EN 60 950: 1992 Safety of information technology equipment + Amendment A1:1993,

Amendment A2:1993, Amendment A3:1995, Amendment A4:1997, Amendment A11:1997

EENN 5500337711:: GGeenneerriicc ssttaannddaarrdd ttoo ddeemmoonnssttrraattee tthhee ccoommpplliiaannccee ooff llooww--ppoowweerr eelleeccttrroonniicc aanndd

eelleeccttrriiccaall aappppaarraattuurreess wwiitthh tthhee bbaassiicc rreessttrriiccttiioonnss rreellaatteedd ttoo hhuummaann eexxppoossuurree ttoo

eelleeccttrroommaaggnneettiicc ffiieellddss ((1100 MMHHzz -- 330000 GGHHzz)) –– GGeenneerraall ppuubblliicc

Protection requirements with respect to electromagnetic compatibility Art.3 (1) b)

EENN 330011448899--1177 VV11..11..11 ((0099--22000000)),, EElleeccttrroommaaggnneettiicc CCoommppaattiibbiilliittyy aanndd rraaddiioo ssppeeccttrruumm

MMaatttteerrss ((EERRMM));; EElleeccttrrooMMaaggnneettiicc CCoommppaattiibbiilliittyy ((EEMMCC)) ssttaannddaarrdd ffoorr rraaddiioo eeqquuiippmmeenntt aanndd

sseerrvviicceess;; PPaarrtt 1177:: SSppeecciiffiicc ccoonnddiittiioonnss ffoorr wwiiddeebbaanndd ddaattaa HHiippeerrllaann eeqquuiippmmeenntt

Means of the efficient use of the radio frequency spectrum

EENN 330000332288--22 VV11..22..11 ((1111--22000011)),, RRaaddiioo EEqquuiippmmeenntt aanndd SSyysstteemmss ((RREESS));; WWiiddeebbaanndd

ttrraannssmmiissssiioonn ssyysstteemmss;; TTeecchhnniiccaall cchhaarraacctteerriissttiiccss aanndd tteesstt ccoonnddiittiioonnss ffoorr ddaattaa ttrraannssmmiissssiioonn

eeqquuiippmmeenntt ooppeerraattiinngg iinn tthhee 22,,44 GGHHzz IISSMM bbaanndd aanndd uussiinngg sspprreeaadd ssppeeccttrruumm mmoodduullaattiioonn

tteecchhnniiqquueess.. PPaarrtt 22:: HHaarrmmoonniizzeedd EENN ccoovveerriinngg eesssseennttiiaall rreeqquuiirreemmeennttss uunnddeerr aarrttiiccllee 33((22)) ooff tthhee

RR&&TTTTEE ddiirreeccttiivvee..

TDK Systems Europe Ltd tel: +44 (0)20 8938 1000

126 Colindale Avenue, Colindale fax: +44 (0)20 8905 8608

London NW9 5HD, United Kingdom www.tdksys.com Registered in England No. 2348741

FCC and Industry Canada Statements

This device complies with part 15 of the FCC Rules. Operation is subject

to the following two conditions: (1) This device may not cause harmful

interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

Changes or modifications not expressly approved by the party

responsible for compliance could void the user's authority to operate the

equipment.

34 of 36

Page 35

Appendix B

ESD (Electrostatic Discharge)

If your TDK Bluetooth device is affected by ESD, it is recommended that

you restart any Bluetooth processes that were active at the time.

Additional Statement

TDK SYSTEMS' BLUETOOTH PRODUCTS ARE NOT AUTHORISED

FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES

OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF

THE MANAGING DIRECTOR OF TDK SYSTEMS EUROPE.

The definitions used herein are:

a) Life support devices or systems are devices which (1) are intended for

surgical implant into the body, or (2) support or sustain life and whose

failure to perform when properly used in accordance with the instructions

for use provided in the labelling can reasonably be expected to result in

a significant injury to the user.

b) A critical component is any component of a life support device or

system whose failure to perform can be reasonably expected to cause

the failure of the life support device or system, or to affect its safety or

effectiveness.

35 of 36

Page 36

Warranty

TDK warrants that its products shall conform to TDK’s published

specifications and remain free from defects in materials and

workmanship under normal, proper and intended use for a period of two

(2) years from date of purchase, provided that proof of purchase be

furnished with any returned equipment.

If during the warranty period any component part of the equipment

becomes defective by reason of material or workmanship, and TDK is

immediately notified of such defect, TDK shall at its option supply a

replacement part or request return of equipment, freight prepaid, to its

designated facility for repair. In the event no trouble is found on products

returned for repair, TDK reserves the right to charge the customer its

standard published repair charge.

This warranty shall not apply to any products that have been subject to

misuse, bending, twisting, neglect, alteration, improper installation,

testing or unauthorized repair performed by anyone other than a TDK

designated repair facility. Any non-warranty repairs or maintenance shall

be at TDK’s standard rates in effect at the time.

This warranty is in lieu of all other warranties, whether expressed,

implied, or statutory, including but not limited to, implied warranties or

merchantability and fitness for a particular purpose. In no event shall

TDK be liable, whether in contract, in part, or on any other basis, for any

damage sustained by its customers or any other person arising from or

related to loss of use, failure or interruption in the operation of any

products, or delay in maintenance, or for incidental, consequential, in

direct, or special damages or liabilities, or for loss of revenue, loss of

business, or other financial loss arising out of or in connection with the

sale, lease, maintenance, use, performance, failure, or interruption of

these products.

36 of 36

Loading...

Loading...