Page 1

Data Sheet: Belleta® iEA Series –Single Output Eighth Brick

℡ (877) 498

-

0099

Standard Features:

• Size – 58.4mm x 22.9 mm x 8.8

mm (2.3 in. x 0.9 in. x 0.347 in.)

• Thru-hole pins 3.68 mm (0.145”)

• High efficiency – greater than 89%

• 1500Vdc isolation voltage

• Meets basic insulation spacing

requirements

• Constant switching frequency

• Industry Standard Footprint

• Output Voltage Adjustment

• Remote on/off (positive logic)

• Remote sense

• Auto-recovering output over-

voltage protection

• Auto-recovering output over-

current protection

• Auto-recovering output short circuit

protection

• Auto-recovering over-temperature

protection

Belleta® iEA Series DC/DC Power Modules

The Belleta Series offers an industry standard

eighth brick power module with true useable

power. Thanks to its low component count and

single-board open-frame design, it provides both

better electrical and thermal performance, and

lower cost than many other suppliers’ eighth brick

product offerings. Belleta® modules are perfect

for both next generation planning and cost

reduction design environments

• UL 60950 (US and Canada), VDE

0805, CB scheme (IEC950), CE

Mark (EN60950)

• ISO Certified manufacturing

facilities

• Patented Design

Optional Features:

• Remote on/off (negative logic)

• Latching output over-voltage

protection

• Short Thru-hole pins 2.79 mm

(0.110”)

• Long Thru-hole pins 5.08 mm

(0.200”)

48V Input, 25A Output

Eighth Brick

©2004 TDK Innoveta® Inc.

iEAFullDatasheet 032707 3/29/2007 Revision 2.0

1/41

Page 2

Data Sheet: Belleta® iEA Series –Single Output Eighth Brick

℡ (877) 498

-

0099

http://www.tdkinnoveta.com/

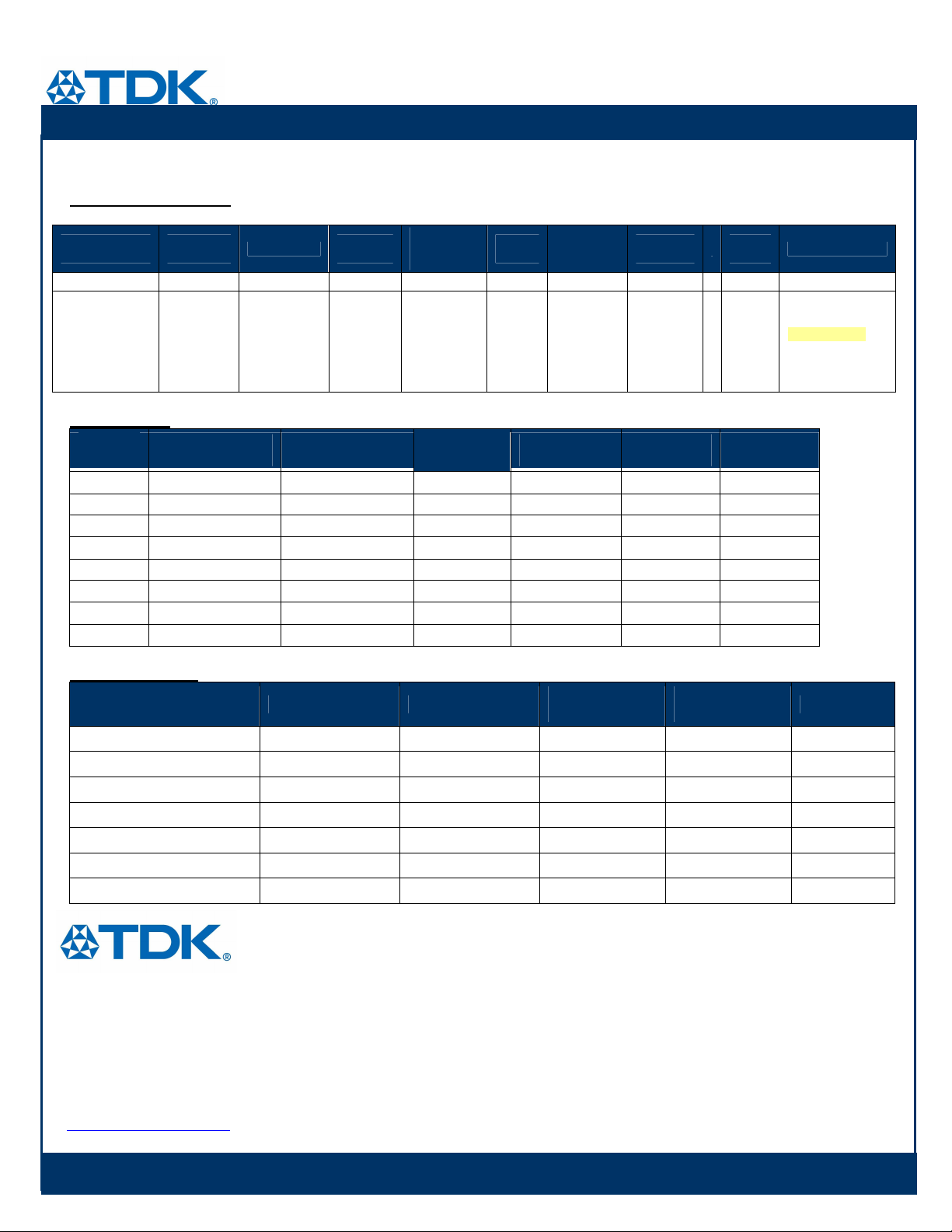

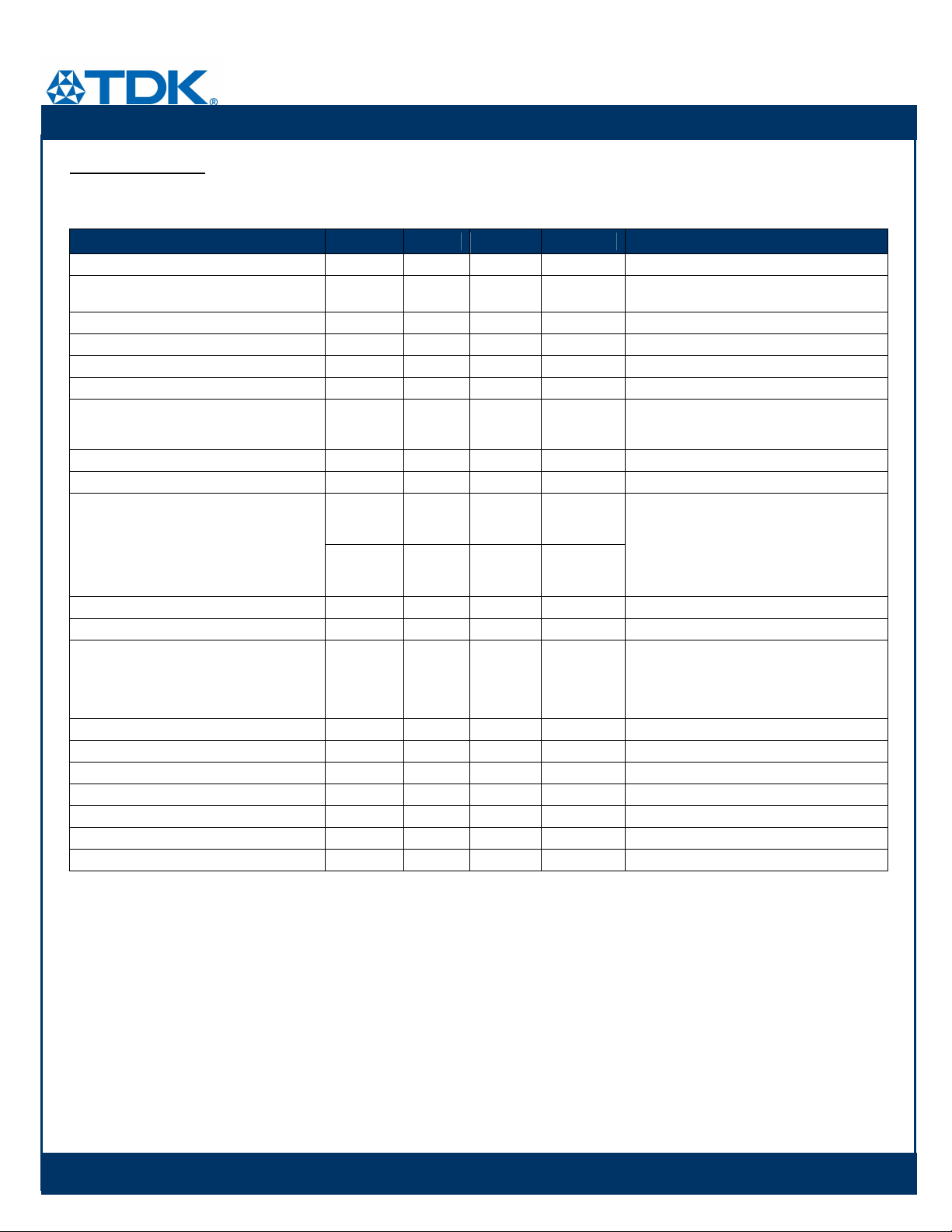

Ordering information:

Product

Identifier

TDK Innoveta

Option Table:

Feature

Product Offering:

iEA48007A120V 36-75V 12V 6.5A 78W 91%

iEA48015A050V 36-75V 5V 15A 75W 90%

iEA48020A033V 36-75V 3.3V 20A 66W 90%

iEA48025A025V 36-75V 2.5V 25A 62.5W 86%

iEA48025A018V 36-75V 1.8V 25A 45W 83%

iEA48025A015V 36-75V 1.5V 25A 37.5W 81%

iEA48025A012V 36-75V 1.2V 25A 30W 78%

Package

Size

i E A 48 020 A 033 V -

Eighthbrick

Platform

Belleta 36-75V

Input

Voltage

Output

Current/

Power

015 –15A

020 – 20A

025 – 25A

Output

Units

Amps

Main

Output

Voltage

120 – 12V

050 – 5V

033 – 3.3V

025 – 2.5V

018 – 1.8V

015 – 1.5V

012 – 1.2V

# of

Outputs

Single

Safety

Class

0 00

Positive Logic

Set

00 X X

01 X X

02 X X

03 X X

04 X X

05 X X

11 X X X

15 X X X

On/Off

Negative Logic

On/Off

0.110” Pin

Length

0.200” Pin

Length

0.145” Pin

Length

Latching

Code Input Voltage Output Voltage

Output

Current

Maximum

Output Power

00 – Standard

OVP

Feature Set

Efficiency

3320 Matrix Drive, Suite 100

Richardson, TX 75082

Phone (877) 498-0099 Toll Free

(469) 916-4747

Fax (877) 498-0143 Toll Free

(214) 239-3101

support@tdkinnoveta.com

©2004 TDK Innoveta® Inc.

iEAFullDatasheet 032707 3/29/2007 Revision 2.0

2/41

Page 3

℡ (877) 498

-

0099

6

4

Data Sheet: Belleta® iEA Series –Single Output Eighth Brick

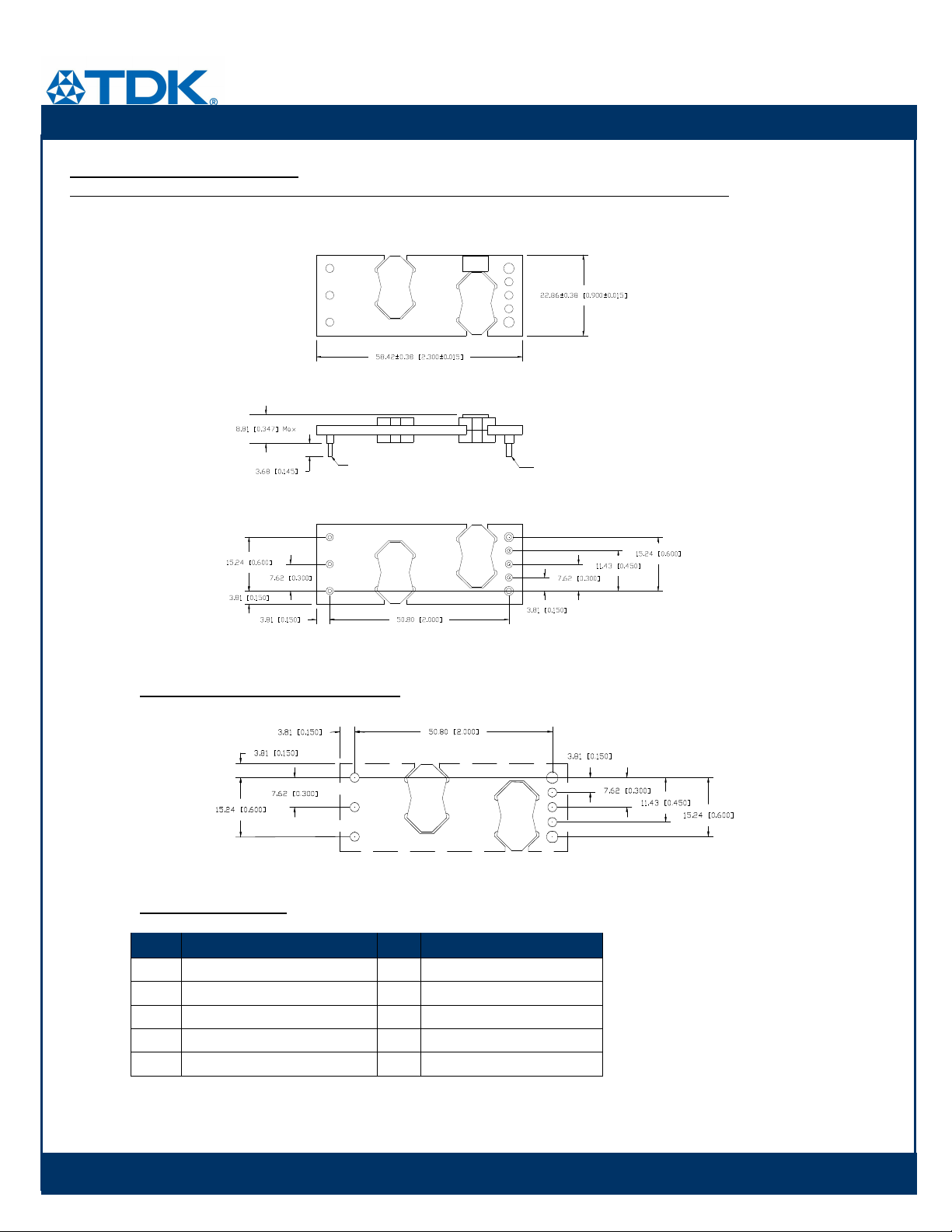

Mechanical Specification:

Dimensions are in mm [in]. Unless otherwise specified tolerances are: x.x ± 0.5 [0.02], x.xx and x.xxx ± 0.25 [0.010].

1.02 [0.040] DIA Pin

2.03 [0.080] DIA Stand-Offs

6 Pins

1.57 [0.062] DIA Pin

2.59 [0.102] DIA Stand-Offs

2 Pins

Recommended Hole Pattern: (top view)

1

2

3

8

7

5

Pin Assignment:

PIN FUNCTION PIN FUNCTION

1 Vin(+) 4 Vo(-)

2 On/Off 5 Sense(-)

3 Vin(-) 6 Trim

7 Sense(+)

8 Vo(+)

Pin base material is brass with tin plating; the maximum module weight is 30.4g (1.07 oz).

©2004 TDK Innoveta® Inc.

iEAFullDatasheet 032707 3/29/2007 Revision 2.0

3/41

Page 4

℡ (877) 498

-

0099

Data Sheet: Belleta® iEA Series –Single Output Eighth Brick

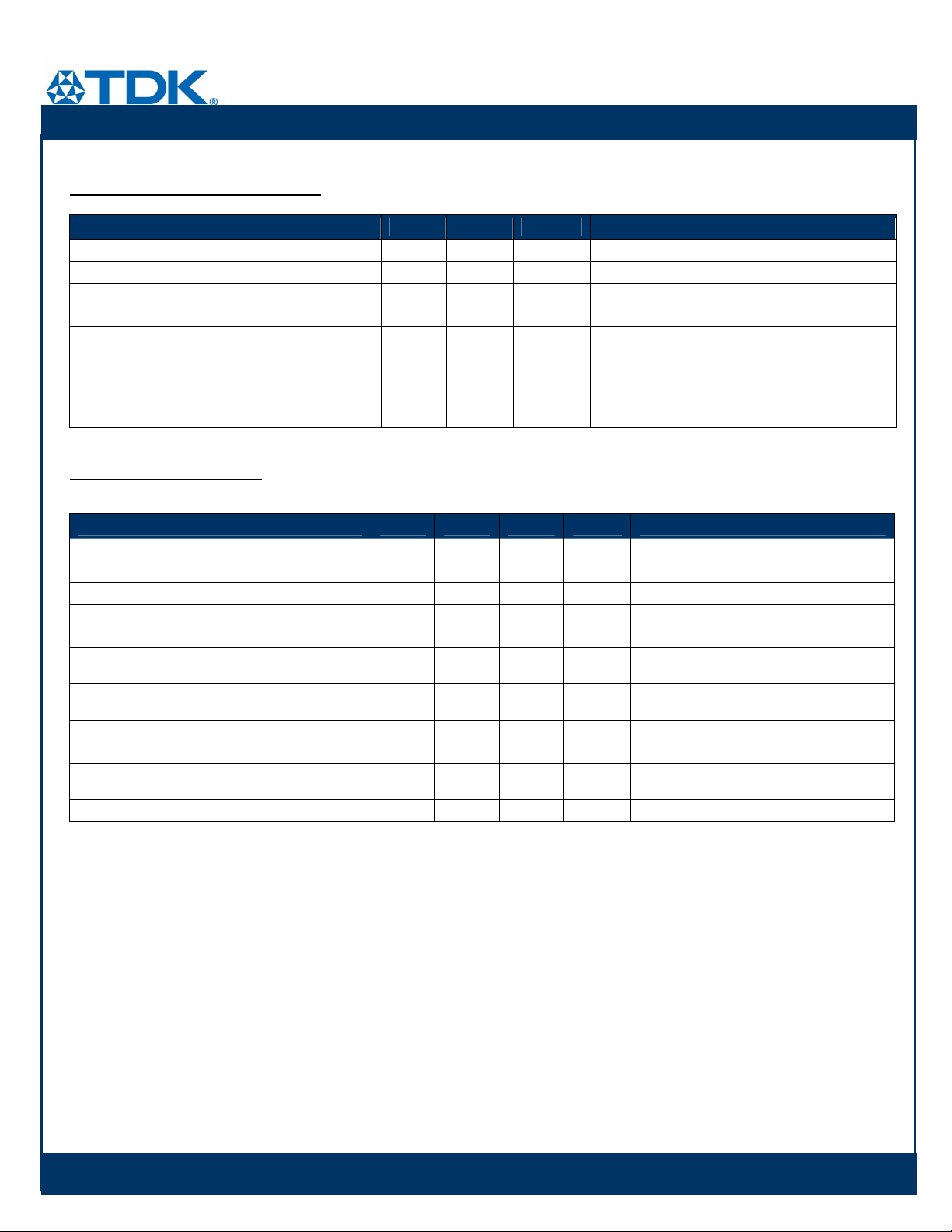

Absolute Maximum Ratings:

Stress in excess of Absolute Maximum Ratings may cause permanent damage to the device.

Characteristic Min Max Unit Notes & Conditions

Continuous Input Voltage -0.5 80 Vdc

Transient Input Voltage --- 100 Vdc 100mS max.

Isolation Voltage --- 1500 Vdc

Storage Temperature -55 125 ˚C

Operating Temperature Range (Tc)

Measured at the location specified in the thermal

-40 125 ˚C

measurement figure. Maximum temperature varies

with model number, output current, and module

orientation – see curve in thermal performance

section of the data sheet.

Input Characteristics:

Unless otherwise specified, specifications apply over all Rated Input Voltage, Resistive Load, and Temperature conditions.

Characteristic Min Typ Max Unit Notes & Conditions

Operating Input Voltage 36 48 75 Vdc

Maximum Input Current --- --- 4 A Vin = 0 to Vin,max

Turn-on Voltage --- 33 --- Vdc

Turn-off Voltage 26 30 --- Vdc

Hysteresis 0.5 3 --- Vdc

Startup Delay Time from application of input

voltage

Startup Delay Time from on/off --- 35 --- mS Vo = 0 to 0.1*Vo,nom; Vin = Vi,nom,

Output Voltage Rise Time --- 50 --- mS Io=Io,max,Tc=25˚C, Vo=0.1 to 0.9*Vo,nom

Inrush Transient --- --- 0.2 A2s

Input Reflected Ripple --- 15 --- mApp See input/output ripple and noise

Input Ripple Rejection --- 55 --- dB @120Hz

Caution: The power modules are not internally fused. An external input line normal blow fuse with a

maximum value of 10A is required, see the Safety Considerations section of the data sheet.

--- 35 --- mS Vo = 0 to 0.1*Vo,nom; on/off =on,

Io=Io,max, Tc=25˚C

Io=Io,max,Tc=25˚C

measurements figure; BW = 20 MHz

©2004 TDK Innoveta® Inc.

iEAFullDatasheet 032707 3/29/2007 Revision 2.0

4/41

Page 5

Data Sheet: Belleta® iEA Series –Single Output Eighth Brick

℡ (877) 498

-

0099

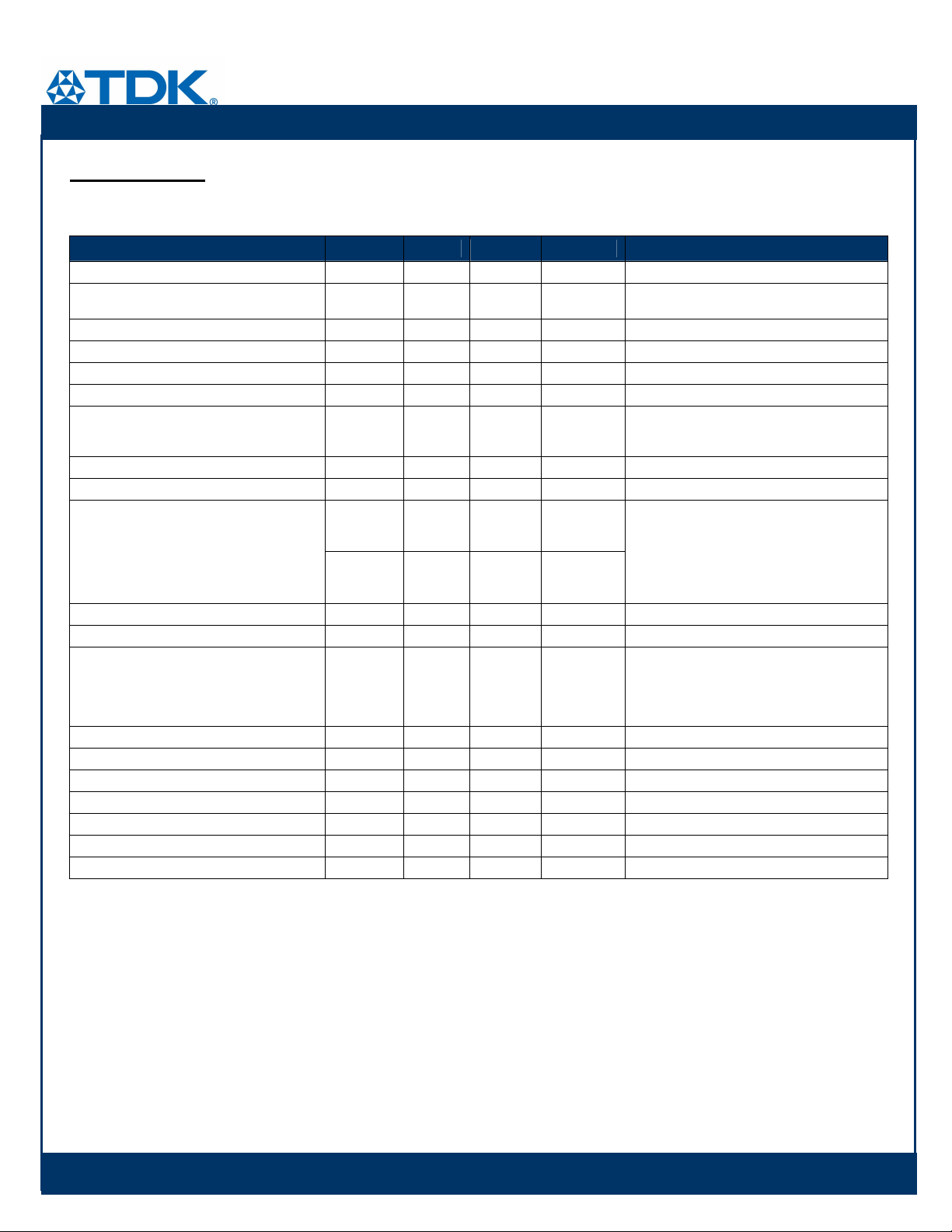

Electrical Data:

iEA48007A120V-000 through -015: 12V, 6.5A Output

Characteristic Min Typ Max Unit Notes & Conditions

Output Voltage Initial Setpoint 11.64 12 12.36 Vdc Vin=Vin,nom; Io=Io,max; Tc = 25˚C

Output Voltage Tolerance 11.58 12 12.42 Vdc

Efficiency --- 90.5 --- % Vin=Vin,nom; Io=Io,max; Tc = 25˚C

Line Regulation --- 10 24 mV Vin=Vin,min to Vin,max

Load Regulation --- 10 24 mV Io=Io,min to Io,max

Temperature Regulation --- 60 240 mV Tc=Tc,min to Tc,max

Output Current 0.5 --- 6.5 A

Output Current Limiting Threshold --- 8.5 --- A Vo = 0.9*Vo,nom, Tc<Tc,max

Short Circuit Current --- 12 --- A Vo = 0.25V, Tc = 25˚C

Over all rated input voltage, load, and

temperature conditions to end of life

At loads less than Io,min the module will

continue to regulate the output voltage, but

the output ripple may increase

--- 80 200

Output Ripple and Noise Voltage

--- 26 --- mVrms

Output Voltage Adjustment Range 90 --- 110 %Vo,nom

Output Voltage Sense Range --- --- 10 %Vo,nom

Dynamic Response:

Recovery Time

Transient Voltage

Output Voltage Overshoot during startup --- --- 5 % Vin=Vin,nom; Io=Io,max,Tc=25˚C

Switching Frequency --- 400 --- kHz Fixed

Output Over Voltage Protection 13.6 --- 15.7 V

External Load Capacitance 0 --- 2000& uF

Isolation Capacitance --- 1000 --- pF

Isolation Resistance 10 --- --- MΩ

Vref 1.225 V Required for trim calculation

& Contact TDK Innoveta for applications that require additional capacitance or very low esr

---

---

60

220

---

---

mVpp

uS

mV

Measured across one 1.0 uF ceramic

capacitor and a 10uF tantalum capacitor –

see input/output ripple measurement figure;

BW = 20MHz

di/dt = 0.1A/uS, Vin=Vin,nom; load step

from 50% to 75% of Io,max

©2004 TDK Innoveta® Inc.

iEAFullDatasheet 032707 3/29/2007 Revision 2.0

5/41

Page 6

℡ (877) 498

-

0099

Data Sheet: Belleta® iEA Series –Single Output Eighth Brick

Electrical Characteristics:

iEA48007A120V-000 through -015: 12V, 6.5A Output

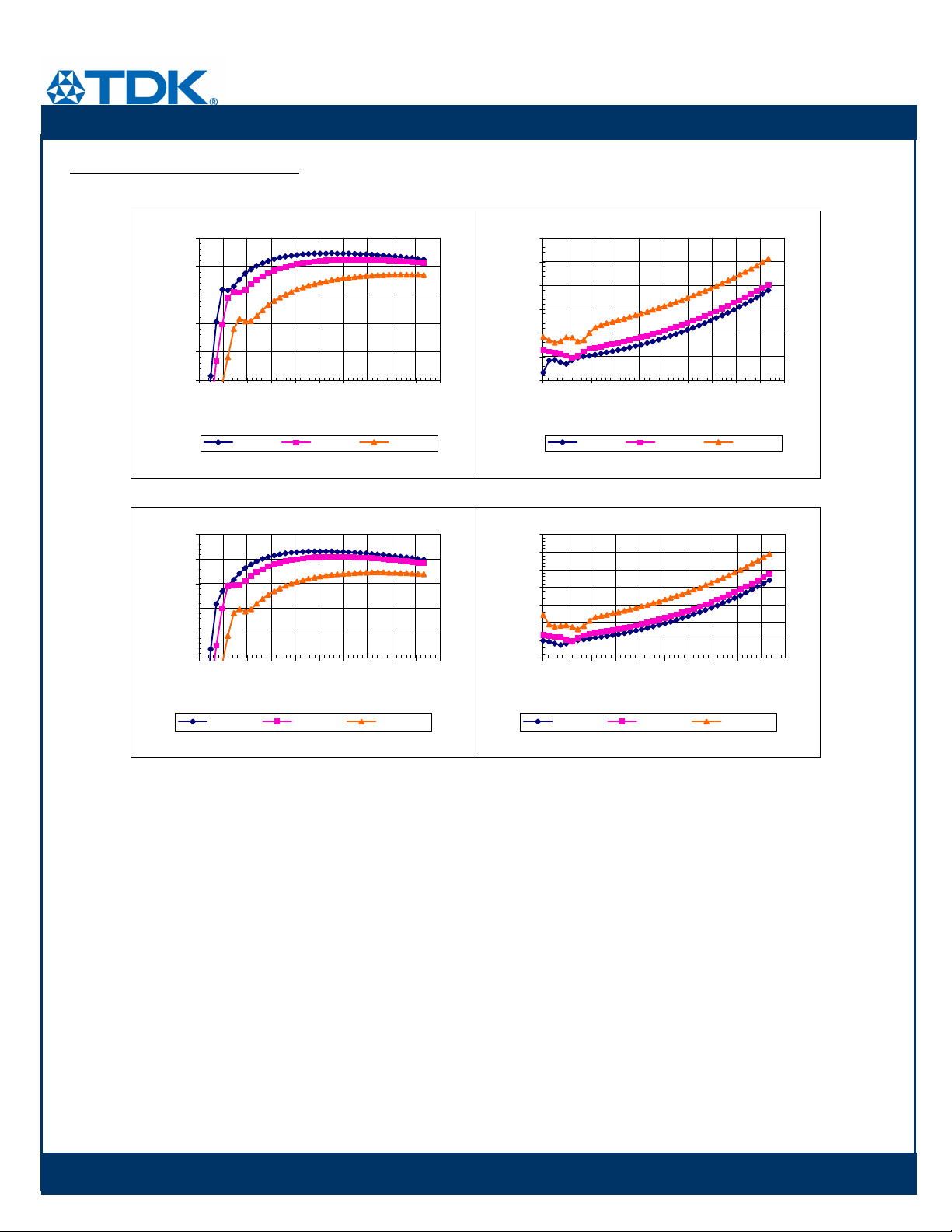

95

90

(%)

η

η

η

η

85

80

Efficiency,

75

70

0 0.7 1.4 2.1 2.8 3.5 4.2 4.9 5.6 6.3 7

Output Current (A)

Vin = 36V Vin = 48V Vin = 75V

iEA48007A120V-000 Typical Efficiency vs. Input

Voltage at Ta=25 degrees.

95

90

(%)

η

η

η

η

85

80

75

Efficiency,

70

0 0.7 1.4 2.1 2.8 3.5 4.2 4.9 5.6 6.3 7

Output Current (A)

12

10

8

6

4

2

Power Dissipation (W)

0

0 0.7 1.4 2.1 2.8 3.5 4.2 4.9 5.6 6.3 7

Output Current (A)

Vin = 36V Vin = 48V Vin = 75V

iEA48007A120V-000 Typical Power Dissipation vs.

Input Voltage at Ta=25 degrees

14

12

10

8

6

4

2

Power Dissipation (W)

0

0 0.7 1.4 2.1 2.8 3.5 4.2 4.9 5.6 6.3 7

Output Current (A)

Vin = 36V Vin = 48V Vin = 75V

iEA48007A120V-000 Typical Efficiency vs. Input

Voltage at Ta=85 degrees.

©2004 TDK Innoveta® Inc.

iEAFullDatasheet 032707 3/29/2007 Revision 2.0

Vin = 36V Vin = 48V Vin = 75V

iEA48007A120V-000 Typical Power Dissipation vs.

Input Voltage at Ta=85 degrees

6/41

Page 7

Data Sheet: Belleta® iEA Series –Single Output Eighth Brick

℡ (877) 498

-

0099

1.2255×

5

Electrical Characteristics (continued):

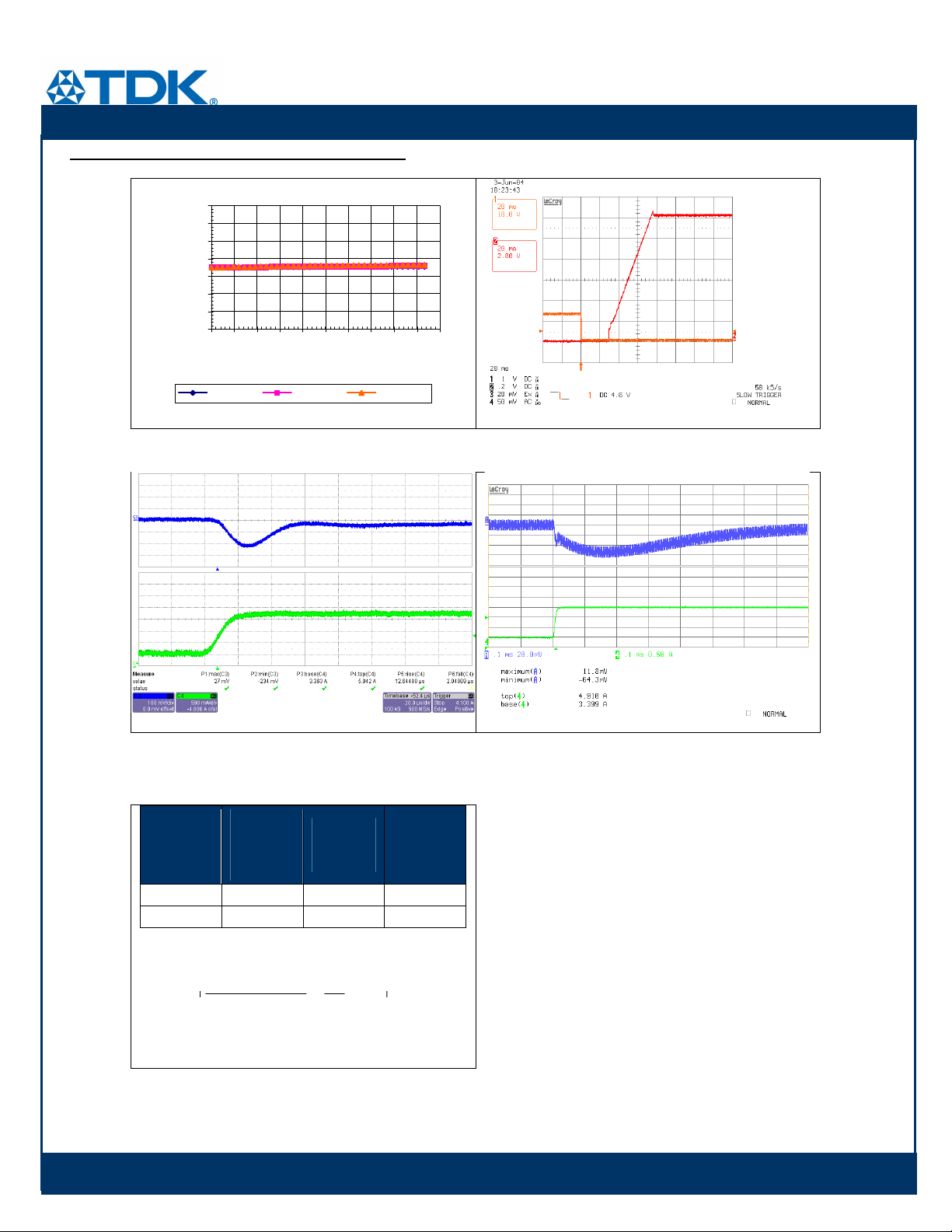

iEA48007A120V-000 through -015: 12V, 6.5A Output

12.34

12.24

12.14

12.04

11.94

11.84

11.74

Output Voltage (V)

11.64

0 0.7 1.4 2.1 2.8 3.5 4.2 4.9 5.6 6.3 7

Output Current (A)

Vin = 36V Vin = 48V Vin = 75V

iEA48007A120V-000 Typical Output Voltage vs. Load

Current at Ta = 25 degrees

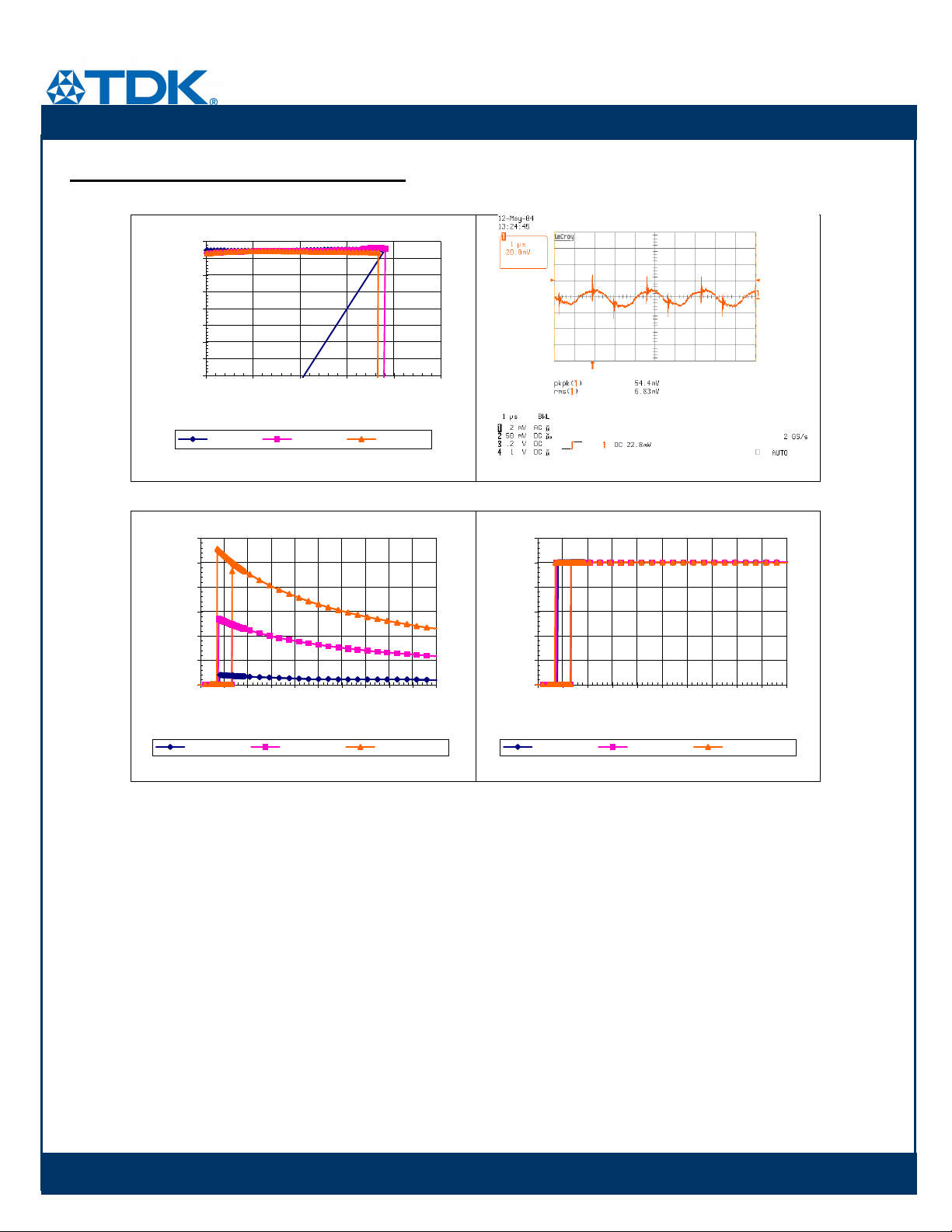

iEA48007A120V-001 Typical startup characteristic from

on/off at full load. Ch 1 - on/off signal, Ch 2 – output

voltage

iEA48007A120V-000 Typical Output voltage response

to load step from 50% to 75% of full load with output

current slew rate of 0.1A/uS.

5.1 12× 100 5+( )⋅

Trim

Down

Resistor

(Kohm)

%

Change

of Vout

510

− 10.2−

%

Change

of Vout

-5% 91.8K +5% 937K

-10% 40.8K +10% 488K

e.g. trim up 5%

Rup

iEA48007A120V-000 Calculated resistor values for

output voltage adjustment

©2004 TDK Innoveta® Inc.

iEAFullDatasheet 032707 3/29/2007 Revision 2.0

Trim Up

Resistor

(Kohm)

K⋅:=

iEA48007A120V-000 Typical Output voltage response

to load step from 50% to 75% of full load with output

current slew rate of 0.1A/uS and 2200uF external load.

7/41

Page 8

Data Sheet: Belleta® iEA Series –Single Output Eighth Brick

℡ (877) 498

-

0099

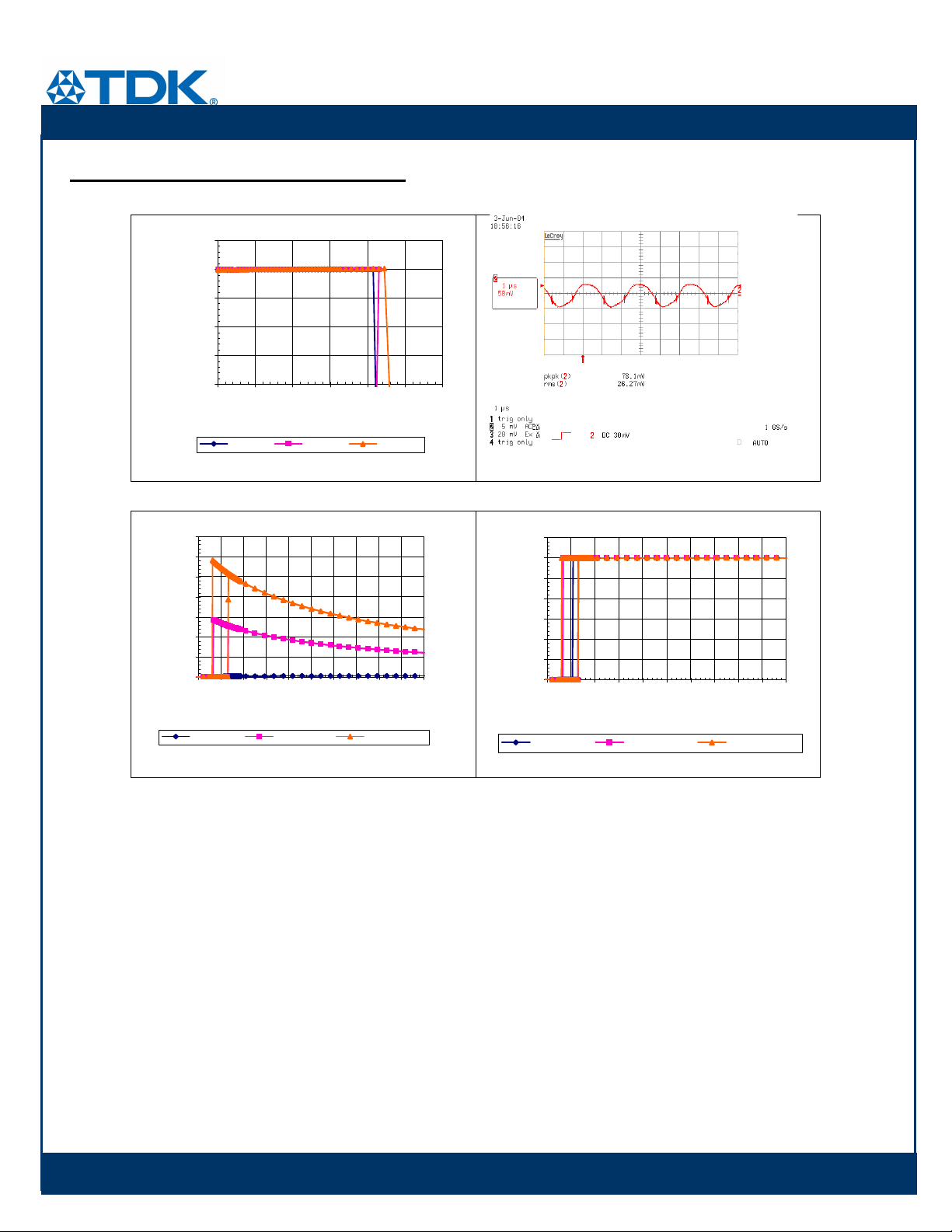

Electrical Characteristics (continued):

iEA48007A120V-000 through -015: 12V, 6.5A Output

12.5

12

11.5

11

Output Voltage (V)

10.5

10

0 2 4 6 8 10 12

Output Current (A)

Vin = 36V Vin = 48V Vin = 75V

iEA48007A120V-000 Typical Output Current Limit

Characteristics vs. Input Voltage at Ta=25 degrees.

3.5

3

2.5

2

1.5

1

Input Current (A)

0.5

0

27 32 37 41 46 51 56 61 65 7 0 75

Input Voltage (V)

Io_min = 0A Io_mid = 3.3A Io_max = 6.5A

iEA48007A120V-000 Typical Input Current vs. Input

Voltage Characteristics

iEA48007A120V-000 Typical Output Ripple at nominal

input voltage and full load at Ta=25 degrees

14

12

10

8

6

4

Output Voltage (V)

2

0

27 32 37 41 46 51 56 61 65 70 75

Input Voltage (V)

Io_min = 0A Io_mid = 3.3A Io_max = 6.5A

iEA48007A120V-000 Typical Output Voltage vs. Input

Voltage Characteristics

©2004 TDK Innoveta® Inc.

iEAFullDatasheet 032707 3/29/2007 Revision 2.0

8/41

Page 9

Data Sheet: Belleta® iEA Series –Single Output Eighth Brick

℡ (877) 498

-

0099

Thermal Performance:

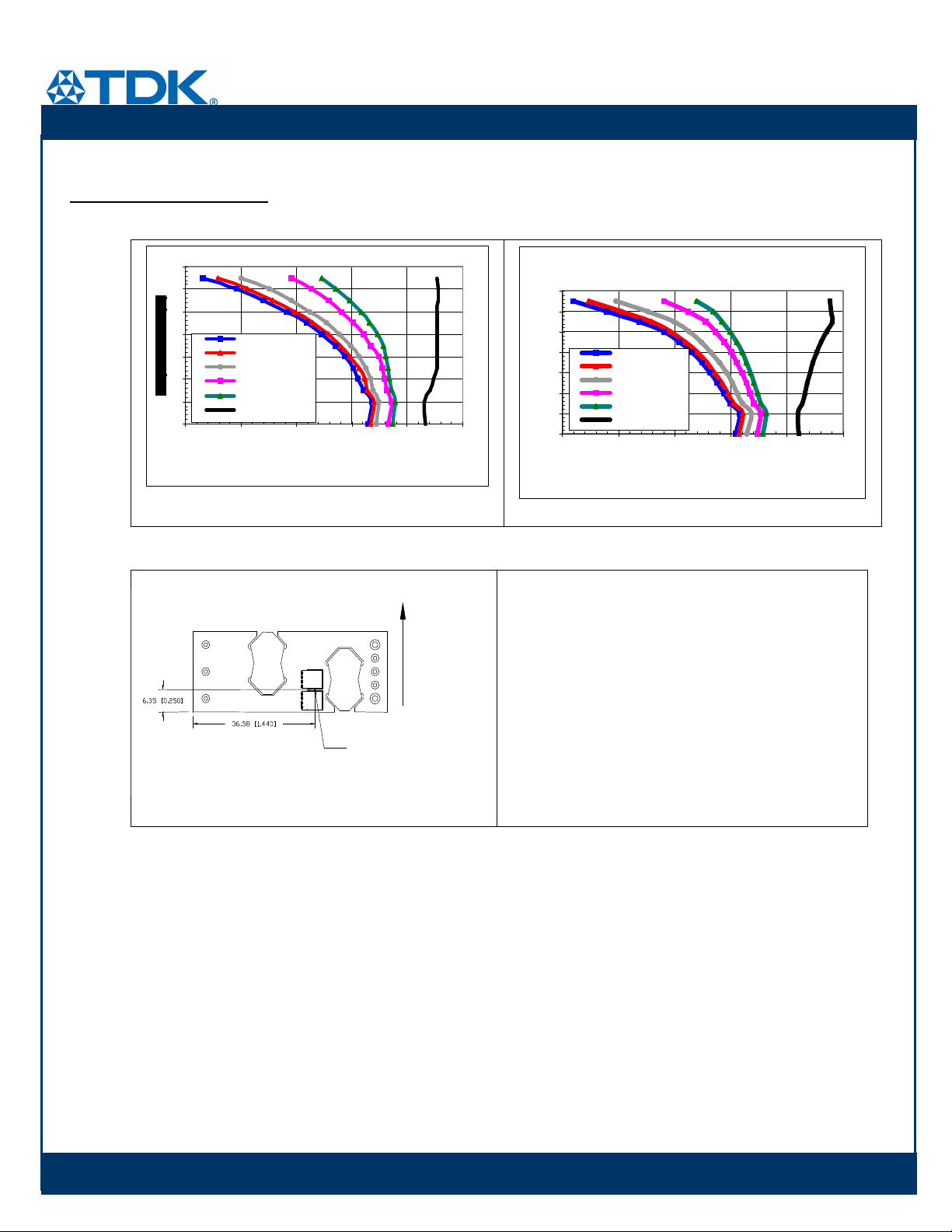

iEA48007A120V-000 through -015: 12V, 6.5A Output

7

6

5

4

3

2

1

0

25 45 65 85 105 125

NC

0.5 m/s (10 0 LFM)

1.0 m/ s (200 LFM)

2.0 m/s (400 LFM)

3.0 m/s (600 LFM)

Tc, Thermal Limi t

T emp er at ure ( oC )

7

6

5

4

3

2

Output Current (A)

1

0

25 45 65 85 105 125

NC

0.5 m/s (100 LFM)

1.0 m/s (200 LFM)

2.0 m/s (400 LFM)

3.0 m/s (600 LFM)

Tc, Thermal Limit

Temperature (oC)

iEA48007A120V-000 maximum output current vs. ambient

temperature at nominal input voltage for airflow rates natural

convection (60lfm) to 600lfm with airflow from pin 3 to pin 1.

iEA48007A120V-000 maximum output current vs.ambient

temperature at nominal input voltage for airflow rates natural

convection (60lfm) to 600lfm with airflow from pin 1 to pin 3.

Best orientation

airflow

Thermal measurement

location on PWB Cu

iEA48007A120V-000 thermal measurement location –

top view

Both the thermal curves provided and the example given above are based upon measurements made in TDK Innoveta’s

experimental test setup that is described in the Thermal Management section. Due to the large number of variables in

system design, TDK Innoveta recommends that the user verify the module’s thermal performance in the end application.

The critical component should be thermo coupled and monitored, and should not exceed the temperature limit specified in

the derating curve above. It is critical that the thermocouple be mounted in a manner that gives direct thermal contact or

significant measurement errors may result. TDK Innoveta can provide modules with a thermocouple pre-mounted to the

critical component for system verification tests.

©2004 TDK Innoveta® Inc.

iEAFullDatasheet 032707 3/29/2007 Revision 2.0

9/41

Page 10

Data Sheet: Belleta® iEA Series –Single Output Eighth Brick

℡ (877) 498

-

0099

Electrical Data:

iEA48015A050V-000 through -015: 5V, 15A Output

Characteristic Min Typ Max Unit Notes & Conditions

Output Voltage Initial Setpoint 4.92 5 5.08 Vdc Vin=Vin,nom; Io=Io,max; Tc = 25˚C

Output Voltage Tolerance 4.85 5 5.15 Vdc

Efficiency --- 90 --- % Vin=Vin,nom; Io=Io,max; Tc = 25˚C

Line Regulation --- 2 10 mV Vin=Vin,min to Vin,max

Load Regulation --- 1 10 mV Io=Io,min to Io,max

Temperature Regulation --- 30 75 mV Tc=Tc,min to Tc,max

Output Current 1 --- 15 A

Output Current Limiting Threshold --- 20 --- A Vo = 0.9*Vo,nom, Tc<Tc,max

Short Circuit Current --- 14 --- A Vo = 0.25V, Tc = 25˚C

Over all rated input voltage, load, and

temperature conditions to end of life

At loads less than Io,min the module will

continue to regulate the output voltage, but

the output ripple may increase

--- 55 125

Output Ripple and Noise Voltage

--- 7 --- mVrms

Output Voltage Adjustment Range 90 --- 110 %Vo,nom

Output Voltage Sense Range --- --- 10 %Vo,nom

Dynamic Response:

Recovery Time

Transient Voltage

Output Voltage Overshoot during startup --- --- 250 mV Vin=Vin,nom; Io=Io,max,Tc=25˚C

Switching Frequency --- 400 --- kHz Fixed

Output Over Voltage Protection 5.7 --- 6.7 V

External Load Capacitance 0 --- 5000& uF

Isolation Capacitance --- 1000 --- pF

Isolation Resistance 10 --- --- MΩ

Vref 1.225 V Required for trim calculation

& Contact TDK Innoveta for applications that require additional capacitance or very low esr

---

---

100

200

---

---

mVpp

uS

mV

Measured across one 0.1 uF ceramic

capacitor and a 22uF ceramic capacitor –

see input/output ripple measurement figure;

BW = 20MHz

di/dt = 0.1A/uS, Vin=Vin,nom; load step

from 50% to 75% of Io,max

©2004 TDK Innoveta® Inc.

iEAFullDatasheet 032707 3/29/2007 Revision 2.0

10/41

Page 11

℡ (877) 498

-

0099

Data Sheet: Belleta® iEA Series –Single Output Eighth Brick

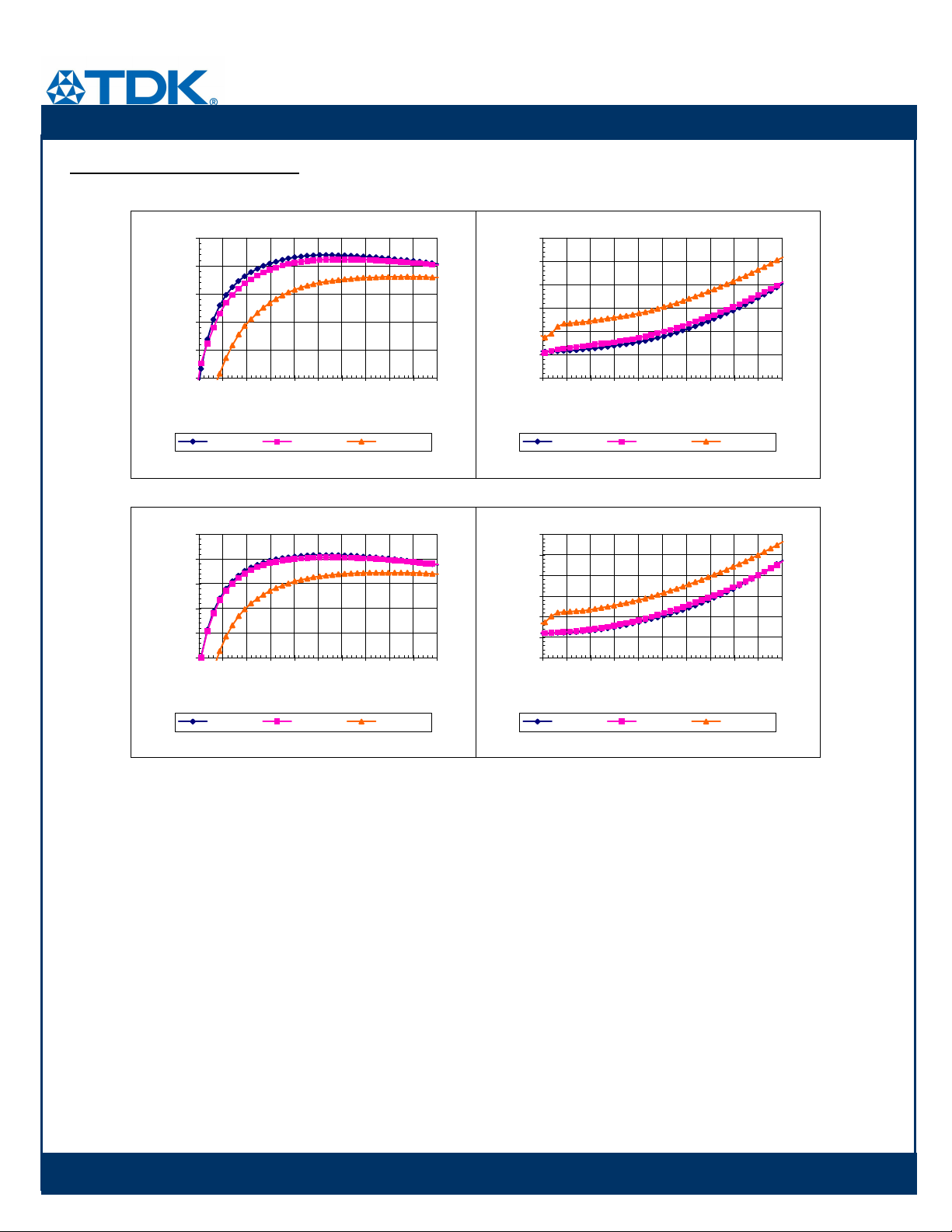

Electrical Characteristics:

iEA48015A050V-000 through -015: 5V, 15A Output

95

90

(%)

η

η

η

η

85

80

Efficiency,

75

70

1 2.4 3 .8 5.2 6.6 8 9.4 10.8 12.2 13.6 15

Output Current (A)

Vin = 36V Vin = 48V Vin = 75V

iEA48015A050V-000 Typical Efficiency vs. Input

Voltage at Ta=25 degrees.

95

90

(%)

η

η

η

η

85

80

75

Efficiency,

70

1 2.4 3 .8 5.2 6.6 8 9.4 10.8 12.2 13.6 15

Output Current (A)

12

10

8

6

4

2

Power Dissipation (W)

0

1 2.4 3 .8 5.2 6.6 8 9.4 10.8 12.2 13.6 15

Output Current (A)

Vin = 36V Vin = 48V Vin = 75V

iEA48015A050V-000 Typical Power Dissipation vs.

Input Voltage at Ta=25 degrees

12

10

8

6

4

2

Power Dissipation (W)

0

1 2.4 3 .8 5.2 6.6 8 9.4 10.8 12.2 13.6 15

Output Current (A)

Vin = 36V Vin = 48V Vin = 75V

iEA48015A050V-000 Typical Efficiency vs. Input

Voltage at Ta=85 degrees.

©2004 TDK Innoveta® Inc.

iEAFullDatasheet 032707 3/29/2007 Revision 2.0

Vin = 36V Vin = 48V Vin = 75V

iEA48015A050V-000 Typical Power Dissipation vs.

Input Voltage at Ta=85 degrees

11/41

Page 12

℡ (877) 498

-

0099

1.2255×

5

Data Sheet: Belleta® iEA Series –Single Output Eighth Brick

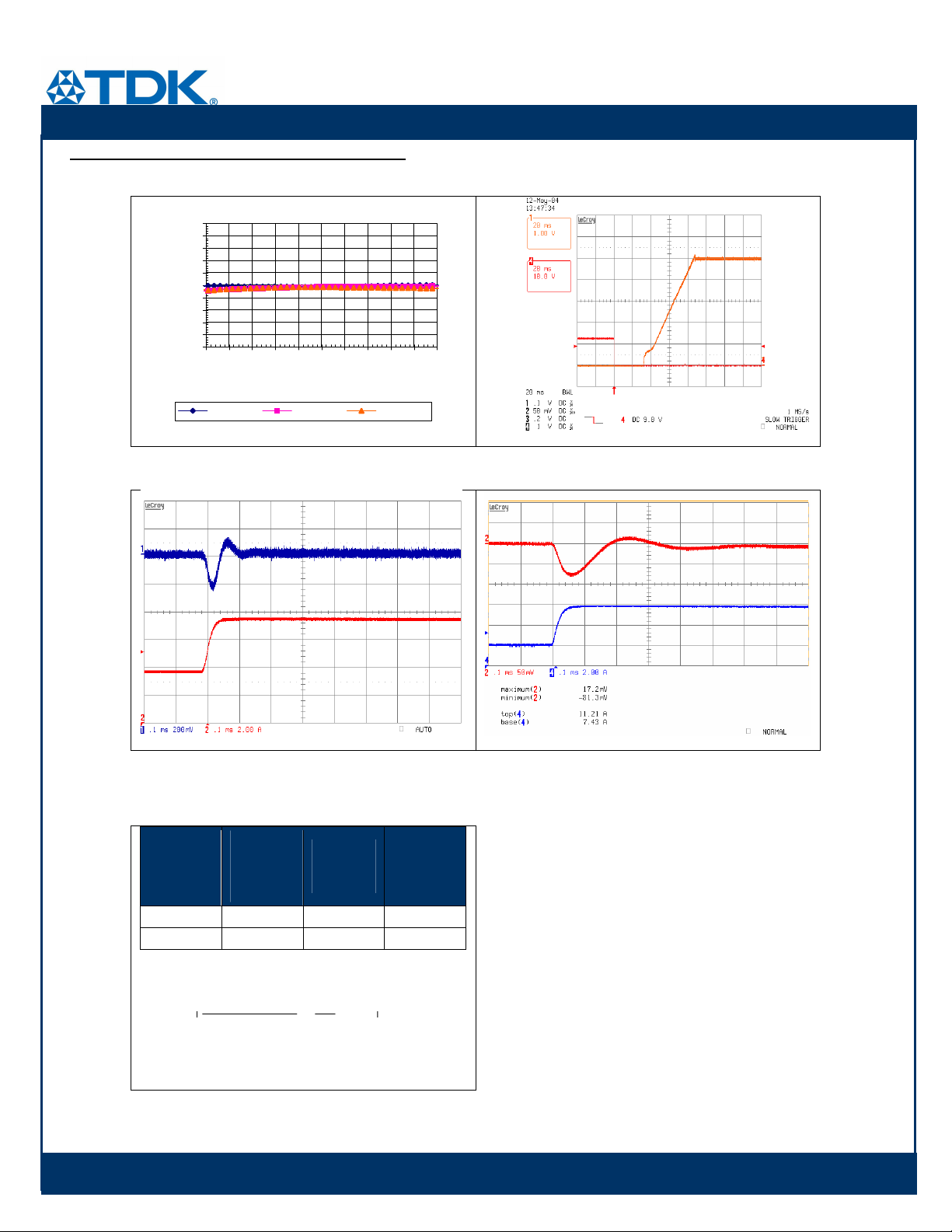

Electrical Characteristics (continued):

iEA48015A050V-000 through -015: 5V, 15A Output

5.05

5.04

5.03

5.02

5.01

5

4.99

4.98

4.97

Output Voltage (V)

4.96

4.95

1 2.4 3.8 5.2 6.6 8 9.4 10.8 12.2 13.6 15

Output Current (A)

Vin = 36V Vin = 48V Vin = 75V

iEA48015A050V-000 Typical Output Voltage vs. Load

Current at Ta = 25 degrees

iEA48015A050V-000 Typical Output voltage response

to load step from 50% to 75% of full load with output

current slew rate of 0.1A/uS.

5.1 5× 100 5+( )⋅

Trim

Down

Resistor

(Kohm)

%

Change

of Vout

510

− 10.2−

%

Change

of Vout

-5% 91.8K +5% 325K

-10% 40.8K +10% 168K

e.g. trim up 5%

Rup

Trim Up

Resistor

(Kohm)

K⋅:=

iEA48015A050V-001 Typical startup characteristic from

on/off at full load. Ch4 - on/off signal, Ch 1 – output

voltage

iEA48015A050V-000 Typical Output voltage response

to load step from 50% to 75% of full load with output

current slew rate of 0.1A/uS and 5000uF load.

iEA48015A050V-000 Calculated resistor values for

output voltage adjustment

©2004 TDK Innoveta® Inc.

iEAFullDatasheet 032707 3/29/2007 Revision 2.0

12/41

Page 13

Data Sheet: Belleta® iEA Series –Single Output Eighth Brick

℡ (877) 498

-

0099

Electrical Characteristics (continued):

iEA48015A050V-000 through -015: 5V, 15A Output

5.01

4.99

4.97

4.95

4.93

4.91

4.89

Output Voltage (V)

4.87

4.85

1 6 11 16 21 26

Output Current (A)

Vin = 36V Vin = 48V Vin = 75V

iEA48015A050V-000 Typical Output Current Limit

Characteristics vs. Input Voltage at Ta=25 degrees.

iEA48015A050V-000 Typical Output Ripple at nominal

input voltage and full load at Ta=25 degrees

3

2.5

2

1.5

1

Input Current (A)

0.5

0

27 32 37 41 46 51 56 61 65 7 0 75

Input Voltage (V)

Io_min = 0 .8A Io_mid = 7.5A Io_max = 15.1A

iEA48015A050V-000 Typical Input Current vs. Input

Voltage Characteristics

6

5

4

3

2

Output Voltage (V)

1

0

27 32 37 41 46 51 56 61 65 70 75

Input Voltage (V)

Io_min = 0.8A Io_mid = 7.5A Io_max = 15.1A

iEA48015A050V-000 Typical Output Voltage vs. Input

Voltage Characteristics

©2004 TDK Innoveta® Inc.

iEAFullDatasheet 032707 3/29/2007 Revision 2.0

13/41

Page 14

Data Sheet: Belleta® iEA Series –Single Output Eighth Brick

℡ (877) 498

-

0099

Output Current (A)

Thermal Performance:

iEA48015A050V-000 through -015: 5V, 15A Output

16

14

12

10

8

6

4

2

0

25 45 65 85 105 1 25

NC

0.5 m/s (100 LFM)

1.0 m/s (200 LFM)

2.0 m/s (400 LFM)

3.0 m/s (600 LFM)

Tc, Thermal Limit

Temperature (oC)

iEA48015A050V-000 maximum output current vs. ambient

temperature at nominal input voltage for airflow rates natural

convection (60lfm) to 600lfm with airflow from pin 3 to pin 1.

Best orientation

airflow

Thermal measurement

location on PWB Cu

iEA48015A050V-000 thermal measurement location –

top view

Both the thermal curves provided and the example given above are based upon measurements made in TDK Innoveta’s

experimental test setup that is described in the Thermal Management section. Due to the large number of variables in

system design, TDK Innoveta recommends that the user verify the module’s thermal performance in the end application.

The critical component should be thermo coupled and monitored, and should not exceed the temperature limit specified in

the derating curve above. It is critical that the thermocouple be mounted in a manner that gives direct thermal contact or

significant measurement errors may result. TDK Innoveta can provide modules with a thermocouple pre-mounted to the

critical component for system verification tests.

©2004 TDK Innoveta® Inc.

iEAFullDatasheet 032707 3/29/2007 Revision 2.0

14/41

Page 15

Data Sheet: Belleta® iEA Series –Single Output Eighth Brick

℡ (877) 498

-

0099

Electrical Data:

iEA48020A033V-000 through -015: 3.3V, 20A Output

Characteristic Min Typ Max Unit Notes & Conditions

Output Voltage Initial Setpoint 3.25 3.3 3.35 Vdc Vin=Vin,nom; Io=Io,max; Tc = 25˚C

Output Voltage Tolerance 3.20 3.3 3.40 Vdc

Efficiency --- 89.5 --- % Vin=Vin,nom; Io=Io,max; Tc = 25˚C

Line Regulation --- 2 7 mV Vin=Vin,min to Vin,max

Load Regulation --- 3 8 mV Io=Io,min to Io,max

Temperature Regulation --- 15 60 mV Tc=Tc,min to Tc,max

Output Current 1.5 --- 20 A

Output Current Limiting Threshold --- 29 --- A Vo = 0.9*Vo,nom, Tc<Tc,max

Short Circuit Current --- 20 --- A Vo = 0.25V, Tc = 25˚C

Over all rated input voltage, load, and

temperature conditions to end of life

At loads less than Io,min the module will

continue to regulate the output voltage, but

the output ripple may increase

--- 35 100

Output Ripple and Noise Voltage

--- 11 --- mVrms

Output Voltage Adjustment Range 90 --- 110 %Vo,nom

Output Voltage Sense Range --- --- 10 %Vo,nom

Dynamic Response:

Recovery Time

Transient Voltage

Output Voltage Overshoot during startup --- --- 165 mV Vin=Vin,nom; Io=Io,max,Tc=25˚C

Switching Frequency --- 400 --- kHz Fixed

Output Over Voltage Protection 3.75 --- 4.4 V

External Load Capacitance 100 --- 5000& uF Recommend TDK part C3225X5R0J107MT

Isolation Capacitance --- 1000 --- pF

Isolation Resistance 10 --- --- MΩ

Vref 1.225 V Required for trim calculation

& Contact TDK Innoveta for applications that require additional capacitance or very low esr

---

---

90

180

---

---

mVpp

uS

mV

Measured across one 1.0 uF ceramic

capacitor and a 10uF tantalum capacitor –

see input/output ripple measurement figure;

BW = 20MHz

The trim range is reduced to 105% when

the input voltage is below 40V.

The sense range is reduced to 5% when the

input voltage is below 40V.

di/dt = 0.1A/uS, Vin=Vin,nom; load step

from 50% to 75% of Io,max

©2004 TDK Innoveta® Inc.

iEAFullDatasheet 032707 3/29/2007 Revision 2.0

15/41

Page 16

℡ (877) 498

-

0099

Data Sheet: Belleta® iEA Series –Single Output Eighth Brick

Electrical Characteristics:

iEA48020A033V-000 through -015: 3.3V, 20A Output

95

90

(%)

η

η

η

η

85

80

Efficiency,

75

70

1 2.9 4.8 6.7 8.6 10.5 12.4 14.3 16.2 18.1 20

Output Current (A)

Vin = 36V Vin = 48V Vin = 75V

iEA48020A033V-000 Typical Efficiency vs. Input

Voltage at Ta=25 degrees.

95

90

(%)

η

η

η

η

85

80

Efficiency,

75

70

1 2.9 4 .8 6.7 8.6 10.5 12.4 14. 3 16.2 18.1 20

Output Current (A)

12

10

8

6

4

2

Power Dissipation (W)

0

1 2.9 4.8 6.7 8.6 10.5 12.4 14.3 16.2 18.1 20

Output Current (A)

Vin = 36V Vin = 48V Vin = 75V

iEA48020A033V-000 Typical Power Dissipation vs.

Input Voltage at Ta=25 degrees

12

10

8

6

4

2

Power Dissipation (W)

0

1 2.9 4 .8 6.7 8.6 10.5 12.4 14.3 16.2 18.1 20

Output Current (A)

Vin = 36V Vin = 48V Vin = 75V

iEA48020A033V-000 Typical Efficiency vs. Input

Voltage at Ta=85 degrees.

©2004 TDK Innoveta® Inc.

iEAFullDatasheet 032707 3/29/2007 Revision 2.0

Vin = 36V Vin = 48V Vin = 75V

iEA48020A033V-000 Typical Power Dissipation vs.

Input Voltage at Ta=85 degrees

16/41

Page 17

Data Sheet: Belleta® iEA Series –Single Output Eighth Brick

℡ (877) 498

-

0099

1.225

5

5

Electrical Characteristics (continued):

iEA48020A033V-000 through -015: 3.3V, 20A Output

3.35

3.33

3.31

3.29

3.27

Output Voltage (V)

3.25

1 2.9 4.8 6.7 8.6 10.5 12.4 14.3 16.2 18.1 20

Output Current (A)

Vin = 36V Vin = 48V Vin = 75V

iEA48020A033V-000 Typical Output Voltage vs. Load

Current at Ta = 25 degrees

iEA48020A033V-001 Typical startup characteristic from

on/off at full load. Ch2 - on/off signal, Ch 1 – output

voltage

iEA48020A033V-000 Typical output voltage response

to load step from 50% to 75% of full load with output

current slew rate of 0.1A/uS.

5.1 3.3× 100 5+( )⋅

Trim

Down

Resistor

(Kohm)

×

%

Change

of Vout

510

− 10.2−

%

Change

of Vout

-5% 91.8K +5% 176.3K

-10% 40.8K +10% 89.9K

e.g. trim up 5%

Rup

iEA48020A033V-000 Calculated resistor values for

output voltage adjustment

©2004 TDK Innoveta® Inc.

iEAFullDatasheet 032707 3/29/2007 Revision 2.0

iEA48020A033V-000 Typical output voltage response

to load step from 50% to 75% of full load with output

current slew rate of 0.1A/uS and 5000uF load.

Trim Up

Resistor

(Kohm)

K⋅:=

17/41

Page 18

Data Sheet: Belleta® iEA Series –Single Output Eighth Brick

℡ (877) 498

-

0099

Electrical Characteristics (continued):

iEA48020A033V-000 through -015: 3.3V, 20A Output

3.32

3.31

3.3

3.29

3.28

3.27

Output Voltage (V)

3.26

3.25

20 22 24 26 28 30 32

Output Current (A)

Vin = 36V Vin = 48V Vin = 75V

iEA48020A033V-000 Typical Output Current Limit

Characteristics vs. Input Voltage at Ta=25 degrees.

iEA48020A033V-000 Typical Output Ripple at nominal

input voltage and full load at Ta=25 degrees

3

2.5

2

1.5

1

Input Current (A)

0.5

0

27 32 37 41 46 51 56 61 65 70 75

Input Voltage (V)

Io_min = 1A Io_mid = 10A Io_max = 20A

iEA48020A033V-000 Typical Input Current vs. Input

Voltage Characteristics

3.5

3

2.5

2

1.5

1

Output Voltage (V)

0.5

0

27 32 37 41 46 51 56 61 65 70 75

Input Voltage (V)

Io_min = 1A Io_mid = 10A Io_max = 20A

iEA48020A033V-000 Typical Output Voltage vs. Input

Voltage Characteristics

©2004 TDK Innoveta® Inc.

iEAFullDatasheet 032707 3/29/2007 Revision 2.0

18/41

Page 19

Data Sheet: Belleta® iEA Series –Single Output Eighth Brick

℡ (877) 498

-

0099

Thermal Performance:

iEA48020A033V-000 through -015: 3.3V, 20A Output

25

20

15

Output Current (A)

10

5

NC

0.5 m/s (100 LFM)

1.0 m/s (200 LFM)

2.0 m/s (400 LFM)

3.0 m/s (600 LFM)

Tc, Thermal Limit

30 40 50 60 70 80 90 100 11 0 120 130

Temperature (C)

iEA48020A033V-000 maximum output current vs. ambient

temperature at nominal input voltage for airflow rates natural

convection (60lfm) to 600lfm with airflow from pin 3 to pin 1.

25

20

15

Output Current (A)

10

5

30 40 50 60 70 80 90 100 110 120 130

NC

0.5 m/s (100 LFM)

1.0 m/s (200 LFM)

2.0 m/s (400 LFM)

3.0 m/s (600 LFM)

Tc, Thermal Limit

Temperature (C)

iEA48020A033V-000 maximum output current vs. ambient

temperature at nominal input voltage for airflow rates natural

convection (60lfm) to 600lfm with airflow from pin 1 to pin 3.

Best orientation

airflow

iEA48020A033V-000 thermal measurement location –

Both the thermal curves provided and the example given above are based upon measurements made in TDK Innoveta’s

experimental test setup that is described in the Thermal Management section. Due to the large number of variables in

system design, TDK Innoveta recommends that the user verify the module’s thermal performance in the end application.

The critical component should be thermo coupled and monitored, and should not exceed the temperature limit specified in

the derating curve above. It is critical that the thermocouple be mounted in a manner that gives direct thermal contact or

significant measurement errors may result. TDK Innoveta can provide modules with a thermocouple pre-mounted to the

critical component for system verification tests.

©2004 TDK Innoveta® Inc.

iEAFullDatasheet 032707 3/29/2007 Revision 2.0

Thermal measurement

location on PWB Cu

top view

19/41

Page 20

Data Sheet: Belleta® iEA Series –Single Output Eighth Brick

℡ (877) 498

-

0099

Electrical Data:

iEA48025A025V-000 through -015: 2.5V, 25A Output

Characteristic Min Typ Max Unit Notes & Conditions

Output Voltage Initial Setpoint 2.46 2.5 2.54 Vdc Vin=Vin,nom; Io=Io,max; Tc = 25˚C

Output Voltage Tolerance 2.42 2.5 2.58 Vdc

Efficiency --- 85.5 --- % Vin=Vin,nom; Io=Io,max; Tc = 25˚C

Line Regulation --- 1 5 mV Vin=Vin,min to Vin,max

Load Regulation --- 1 7 mV Io=Io,min to Io,max

Temperature Regulation --- 10 50 mV Tc=Tc,min to Tc,max

Output Current 2.0 --- 25 A

Output Current Limiting Threshold --- 31 --- A Vo = 0.9*Vo,nom, Tc<Tc,max

Short Circuit Current --- 20 --- A Vo = 0.25V, Tc = 25˚C

Over all rated input voltage, load, and

temperature conditions to end of life

At loads less than Io,min the module will

continue to regulate the output voltage, but

the output ripple may increase

--- 35 100

Output Ripple and Noise Voltage

--- 11 --- mVrms

Output Voltage Adjustment Range 90 --- 110 %Vo,nom

Output Voltage Sense Range --- --- 10 %Vo,nom

Dynamic Response:

Recovery Time

Transient Voltage

Output Voltage Overshoot during startup --- --- 165 mV Vin=Vin,nom; Io=Io,max,Tc=25˚C

Switching Frequency --- 400 --- kHz Fixed

Output Over Voltage Protection 2.7 --- 3.5 V

External Load Capacitance 0 --- 5000& uF

Isolation Capacitance --- 1000 --- pF

Isolation Resistance 10 --- --- MΩ

Vref 1.225 V Required for trim calculation

& Contact TDK Innoveta for applications that require additional capacitance or very low esr

---

---

100*

200*

---

---

mVpp

uS

mV

Measured across one 1.0 uF ceramic

capacitor and a 10uF tantalum capacitor –

see input/output ripple measurement figure;

BW = 20MHz

di/dt = 0.1A/uS, Vin=Vin,nom; load step

from 50% to 75% of Io,max

©2004 TDK Innoveta® Inc.

iEAFullDatasheet 032707 3/29/2007 Revision 2.0

20/41

Page 21

℡ (877) 498

-

0099

Data Sheet: Belleta® iEA Series –Single Output Eighth Brick

Electrical Characteristics:

iEA48025A025V-000 through -015: 2.5V, 25A Output

95

90

(%)

η

η

η

η

85

80

Efficiency,

75

70

0 2.51 5.02 7.53 10 12.6 15 .1 17.6 20.1 22.6 25.1

Output Current (A)

Vin = 36V Vin = 48V Vin = 75V

iEA48025A025V-000 Typical Efficiency vs. Input

Voltage at Ta=25 degrees.

2.54

2.53

2.52

2.51

2.5

2.49

2.48

Output Voltage (V)

2.47

2.46

0 2.5 5 7.5 10 1 2.5 15 17.5 20 22.5 25

Output Current (A)

14

12

10

8

6

4

2

Power Dissipation (W)

0

0 2.51 5.02 7.53 10 12.6 15.1 17.6 20.1 22.6 25.1

Output Current (A)

Vin = 36V Vin = 48V Vin = 75V

iEA48025A025V-000 Typical Power Dissipation vs.

Input Voltage at Ta=25 degrees

Vin = 36V Vin = 48V Vin = 75V

iEA48025A025V-000 Typical Output Voltage vs. Load

Current at Ta = 25 degrees

iEA48025A025V-000 Typical startup characteristic

from input voltage application at full load. Ch3 - input

voltage, Ch 1 – output voltage

©2004 TDK Innoveta® Inc.

iEAFullDatasheet 032707 3/29/2007 Revision 2.0

iEA48025A025V-001 Typical startup characteristic from

on/off at full load. Ch3 - on/off signal, Ch 1 – output

voltage

2.55

2.5

2.45

2.4

2.35

Output Voltage (V)

2.3

15 20 25 30 35

Output Current (A)

Vin = 36V Vin = 48V Vin = 75V

iEA48025A025V-000 Typical Output Current Limit

Characteristics vs. Input Voltage at Ta=25 degrees.

21/41

Page 22

Data Sheet: Belleta® iEA Series –Single Output Eighth Brick

℡ (877) 498

-

0099

1.2255×

5

Electrical Characteristics (continued):

iEA48025A025V-000 through -015: 2.5V, 25A Output

3

2.5

2

1.5

1

Input Current (A)

0.5

0

27 31.8 36.6 41.4 46.2 5 1 55.8 60.6 65.4 70.2 75

Input Voltage (V)

Io_min = 0A Io_mid = 12.6A Io_max = 25.2A

iEA48025A025V-000 Typical Input Current vs. Input

Voltage Characteristics

5.1 2.5× 100 5+( )⋅

Trim

Down

Resistor

(Kohm)

%

Change

of Vout

510

− 10.2−

Trim Up

Resistor

(Kohm)

K⋅:=

%

Change

of Vout

-5% 91.8K +5% 106K

-10% 40.8K +10% 53.3K

e.g. trim up 5%

Rup

3

2.5

2

1.5

1

0.5

Output Voltage (V)

0

27 32 37 4 1 46 51 56 61 65 7 0 75

Input Voltage (V)

Io_min = 0A Io_mid = 12.6A

Io_max = 25.2A

iEA48025A025V-000 Typical Output Voltage vs. Input

Voltage Characteristics

iEA48025A025V-000 Calculated resistor values for

output voltage adjustment

©2004 TDK Innoveta® Inc.

iEAFullDatasheet 032707 3/29/2007 Revision 2.0

22/41

Page 23

Data Sheet: Belleta® iEA Series –Single Output Eighth Brick

℡ (877) 498

-

0099

Thermal Performance:

iEA48025A025V-000 through -015: 2.5V, 25A Output

30

25

20

15

10

Output Current (A)

5

0

25 45 65 85 105 125

Temperature (oC)

NC 0.5 m /s (100 LFM)

1.0 m/s (200 LFM) 2.0 m/s (400 LFM)

3.0 m/s (600 LFM) Tc, Thermal Limit

iEA48025A025V-000 maximum output current vs. ambient

temperature at nominal input voltage for airflow rates natural

convection (60lfm) to 600lfm with airflow from pin 3 to pin 1.

Best orientation

airflow

Thermal measurement

location on PWB Cu

iEA48025A025V-000 thermal measurement location –

top view

Both the thermal curves provided and the example given above are based upon measurements made in TDK Innoveta’s

experimental test setup that is described in the Thermal Management section. Due to the large number of variables in

system design, TDK Innoveta recommends that the user verify the module’s thermal performance in the end application.

The critical component should be thermo coupled and monitored, and should not exceed the temperature limit specified in

the derating curve above. It is critical that the thermocouple be mounted in a manner that gives direct thermal contact or

significant measurement errors may result. TDK Innoveta can provide modules with a thermocouple pre-mounted to the

critical component for system verification tests.

©2004 TDK Innoveta® Inc.

iEAFullDatasheet 032707 3/29/2007 Revision 2.0

23/41

Page 24

Data Sheet: Belleta® iEA Series –Single Output Eighth Brick

℡ (877) 498

-

0099

Electrical Data:

iEA48025A018V-000 through -015: 1.8V, 25A Output

Characteristic Min Typ Max Unit Notes & Conditions

Output Voltage Initial Setpoint 1.77 1.8 1.83 Vdc Vin=Vin,nom; Io=Io,max; Tc = 25˚C

Output Voltage Tolerance 1.74 1.8 1.86 Vdc

Efficiency --- 82.5 --- % Vin=Vin,nom; Io=Io,max; Tc = 25˚C

Line Regulation --- 1 5 mV Vin=Vin,min to Vin,max

Load Regulation --- 1 7 mV Io=Io,min to Io,max

Temperature Regulation --- 10 50 mV Tc=Tc,min to Tc,max

Output Current 2.0 --- 25 A

Output Current Limiting Threshold --- 35 --- A Vo = 0.9*Vo,nom, Tc<Tc,max

Short Circuit Current --- 20 --- A Vo = 0.25V, Tc = 25˚C

Over all rated input voltage, load, and

temperature conditions to end of life

At loads less than Io,min the module will

continue to regulate the output voltage, but

the output ripple may increase

--- 35 100

Output Ripple and Noise Voltage

--- 8 --- mVrms

Output Voltage Adjustment Range 90 --- 110 %Vo,nom

Output Voltage Sense Range --- --- 10 %Vo,nom

Dynamic Response:

Recovery Time

Transient Voltage

Output Voltage Overshoot during startup --- --- 165 mV Vin=Vin,nom; Io=Io,max,Tc=25˚C

Switching Frequency --- 400 --- kHz Fixed

Output Over Voltage Protection 2.12 --- 2.58 V

External Load Capacitance 0 --- 5000& uF

Isolation Capacitance --- 1000 --- pF

Isolation Resistance 10 --- --- MΩ

Vref 1.225 V Required for trim calculation

& Contact TDK Innoveta for applications that require additional capacitance or very low esr

---

---

120

130

---

---

mVpp

uS

mV

Measured across one 1.0 uF ceramic

capacitor and a 10uF tantalum capacitor –

see input/output ripple measurement figure;

BW = 20MHz

di/dt = 0.1A/uS, Vin=Vin,nom; load step

from 50% to 75% of Io,max

©2004 TDK Innoveta® Inc.

iEAFullDatasheet 032707 3/29/2007 Revision 2.0

24/41

Page 25

℡ (877) 498

-

0099

Data Sheet: Belleta® iEA Series –Single Output Eighth Brick

Electrical Characteristics:

iEA48025A018V-000 through -015: 1.8V, 25A Output

90

88

86

84

(%)

η

η

η

η

82

80

78

76

Efficiency,

74

72

70

2 4.3 6 .6 8.9 11.2 13.5 15.8 18.1 20.4 22.7 25

Output Current (A)

Vin = 36V Vin = 48V Vin = 75V

iEA48025A018V-000 Typical Efficiency vs. Input

Voltage at Ta=25 degrees.

1.83

1.82

1.81

1.8

1.79

1.78

Output Voltage (V)

1.77

2 4 7 9 11 14 16 18 20 23 25

Output Current (A)

12

10

8

6

4

2

Power Dissipation (W)

0

2 4.3 6 .6 8.9 11.2 13.5 15.8 18.1 20.4 22.7 25

Output Current (A)

Vin = 36V Vin = 48V Vin = 75V

iEA48025A018V-000 Typical Power Dissipation vs.

Input Voltage at Ta=25 degrees

Vin = 36V Vin = 48V Vin = 75V

iEA48025A018V-000 Typical Output Voltage vs. Load

Current at Ta = 25 degrees

iEA48025A018V-000 Typical startup characteristic

from input voltage application at full load. Ch1 - input

voltage, Ch 4 – output voltage

©2004 TDK Innoveta® Inc.

iEAFullDatasheet 032707 3/29/2007 Revision 2.0

iEA48025A018V-001 Typical startup characteristic from

on/off at full load. Ch1 - on/off signal, Ch 4 – output

voltage

iEA48025A018V-000 Typical transient response.

Output voltage response to load step from 50% to 75%

of full load with output current slew rate of 0.1A/uS.

25/41

Page 26

Data Sheet: Belleta® iEA Series –Single Output Eighth Brick

℡ (877) 498

-

0099

1.2255×

5

Electrical Characteristics (continued):

iEA48025A018V-000 through -015: 1.8V, 25A Output

1.85

1.8

1.75

1.7

1.65

1.6

Output Voltage (V)

1.55

1.5

20 25 30 35

Output Current (A)

Vin = 36V Vin = 48V Vin = 75V

iEA48025A018V-000 Typical Output Current Limit

Characteristics vs. Input Voltage at Ta=25 degrees.

2.5

2

1.5

1

0.5

Input Current (A)

0

26 31 36 41 46 51 55 60 65 70 75

Input Voltage (V)

Io_min = 1.8A Io_mid = 12.6A

Io_max = 25.2A

iEA48025A018V-000 Typical Input Current vs. Input

Voltage Characteristics

%

Change

of Vout

Trim

Down

Resistor

(Kohm)

%

Change

of Vout

Trim Up

Resistor

(Kohm)

-5% 91.8K +5% 45.2K

-10% 40.8K +10% 21.2K

e.g. trim up 5%

Rup

5.1 1.8× 100 5+( )⋅

510

− 10.2−

K⋅:=

iEA48025A018V-000 Typical Output Ripple at nominal

input voltage and full load at Ta=25 degrees

2

1.8

1.6

1.4

1.2

1

0.8

0.6

0.4

Output Voltage (V)

0.2

0

26 3 1 36 41 46 51 55 60 65 70 75

Input Voltage (V)

Io_min = 1.8A Io_mid = 12.6A

Io_max = 25.2A

iEA48025A018V-000 Typical Output Voltage vs. Input

Voltage Characteristics

iEA48025A018V-000 Calculated resistor values for

output voltage adjustment

©2004 TDK Innoveta® Inc.

iEAFullDatasheet 032707 3/29/2007 Revision 2.0

26/41

Page 27

Data Sheet: Belleta® iEA Series –Single Output Eighth Brick

℡ (877) 498

-

0099

Output Current (A)

Thermal Performance:

iEA48025A018V-000 through -015: 1.8V, 25A Output

30

25

20

15

10

5

0

10 30 50 70 90 110 1 30

NC

0.5 m/s (100 LFM)

1.0 m/s (200 LFM)

1.5 m/s (300 LFM)

2.0 m/s (400 LFM)

3.0 m/s (600 LFM)

Tc, Thermal Li mit

Temperature (oC)

iEA48025A018V-000 maximum output current vs. ambient

temperature at nominal input voltage for airflow rates natural

convection (60lfm) to 600lfm with airflow from pin 3 to pin 1.

Best orientation

airflow

Thermal measurement

location on PWB Cu

iEA48025A018V-000 thermal measurement location –

top view

Both the thermal curves provided and the example given above are based upon measurements made in TDK Innoveta’s

experimental test setup that is described in the Thermal Management section. Due to the large number of variables in

system design, TDK Innoveta recommends that the user verify the module’s thermal performance in the end application.

The critical component should be thermo coupled and monitored, and should not exceed the temperature limit specified in

the derating curve above. It is critical that the thermocouple be mounted in a manner that gives direct thermal contact or

significant measurement errors may result. TDK Innoveta can provide modules with a thermocouple pre-mounted to the

critical component for system verification tests.

©2004 TDK Innoveta® Inc.

iEAFullDatasheet 032707 3/29/2007 Revision 2.0

27/41

Page 28

Data Sheet: Belleta® iEA Series –Single Output Eighth Brick

℡ (877) 498

-

0099

Electrical Data:

iEA48025A015V-000 through -015: 1.5V, 25A Output

Characteristic Min Typ Max Unit Notes & Conditions

Output Voltage Initial Setpoint 1.47 1.5 1.53 Vdc Vin=Vin,nom; Io=Io,max; Tc = 25˚C

Output Voltage Tolerance 1.45 1.5 1.55 Vdc

Efficiency --- 81 --- % Vin=Vin,nom; Io=Io,max; Tc = 25˚C

Line Regulation --- 1 5 mV Vin=Vin,min to Vin,max

Load Regulation --- 1 7 mV Io=Io,min to Io,max

Temperature Regulation --- 10 50 mV Tc=Tc,min to Tc,max

Output Current 2.0 --- 25 A

Output Current Limiting Threshold --- 35 --- A Vo = 0.9*Vo,nom, Tc<Tc,max

Short Circuit Current --- 20 --- A Vo = 0.25V, Tc = 25˚C

Over all rated input voltage, load, and

temperature conditions to end of life

At loads less than Io,min the module will

continue to regulate the output voltage, but

the output ripple may increase

--- 30 100

Output Ripple and Noise Voltage

--- 8 --- mVrms

Output Voltage Adjustment Range 90 --- 110 %Vo,nom

Output Voltage Sense Range --- --- 10 %Vo,nom

Dynamic Response:

Recovery Time

Transient Voltage

Output Voltage Overshoot during startup --- --- 140 mV Vin=Vin,nom; Io=Io,max,Tc=25˚C

Switching Frequency --- 400 --- kHz Fixed

Output Over Voltage Protection 1.7 --- 2.3 V

External Load Capacitance 0 --- 5000& uF

Isolation Capacitance --- 1000 --- pF

Isolation Resistance 10 --- --- MΩ

Vref 1.225 V Required for trim calculation

& Contact TDK Innoveta for applications that require additional capacitance or very low esr

---

---

120

85

---

---

mVpp

uS

mV

Measured across one 1.0 uF ceramic

capacitor and a 10uF tantalum capacitor –

see input/output ripple measurement figure;

BW = 20MHz

di/dt = 0.1A/uS, Vin=Vin,nom; load step

from 50% to 75% of Io,max

©2004 TDK Innoveta® Inc.

iEAFullDatasheet 032707 3/29/2007 Revision 2.0

28/41

Page 29

℡ (877) 498

-

0099

Data Sheet: Belleta® iEA Series –Single Output Eighth Brick

Electrical Characteristics:

iEA48025A015V-000 through -015: 1.5V, 25A Output

88

86

84

(%)

82

η

η

η

η

80

78

76

Efficiency,

74

72

70

0 2.5 5 7.5 10 12.5 15 17.5 20 22.5 25

Output Current (A)

Vin = 36V Vin = 48V Vin = 75V

iEA48025A015V-000 Typical Efficiency vs. Input

Voltage at Ta=25 degrees.

1.53

1.52

1.51

1.5

1.49

Output Voltage (V)

1.48

1.47

0 2.5 5 7.5 10 12.5 15 17.5 20 22.5 25

Output Current (A)

12

10

8

6

4

2

Power Dissipation (W)

0

0 2.5 5 7.5 10 12. 5 15 17 .5 20 2 2.5 25

Output Current (A)

Vin = 36V Vin = 48V Vin = 75V

iEA48025A015V-000 Typical Power Dissipation vs.

Input Voltage at Ta=25 degrees

Vin = 36V Vin = 48V Vin = 75V

iEA48025A015V-000 Typical Output Voltage vs. Load

Current at Ta = 25 degrees

iEA48025A015V-000 Typical startup characteristic

from input voltage application at full load. Ch3 - input

voltage, Ch 1 – output voltage

©2004 TDK Innoveta® Inc.

iEAFullDatasheet 032707 3/29/2007 Revision 2.0

iEA48025A015V-001 Typical startup characteristic from

on/off at full load. Ch3 - on/off signal, Ch 1 – output

voltage

iEA48025A015V-000 Typical transient response.

Output voltage response to load step from 50% to 75%

of full load with output current slew rate of 0.1A/uS.

29/41

Page 30

Data Sheet: Belleta® iEA Series –Single Output Eighth Brick

℡ (877) 498

-

0099

1.2255×

5

Electrical Characteristics (continued):

iEA48025A015V-000 through -015: 1.5V, 25A Output

1.52

1.5

1.48

1.46

1.44

Output Voltage (V)

1.42

1.4

25 27 29 31 33 35 37

Output Current (A)

Vin = 36V Vin = 48V Vin = 75V

iEA48025A015V-000 Typical Output Current Limit

Characteristics vs. Input Voltage at Ta=25 degrees.

1.8

1.6

1.4

1.2

1

0.8

0.6

0.4

Input Current (A)

0.2

0

27 32 37 41 46 51 56 61 65 70 75

Input Voltage (V)

Io_min = 0A Io_mid = 12.6A Io_max = 25.2A

iEA48025A015V-000 Typical Input Current vs. Input

Voltage Characteristics

%

Change

of Vout

Trim

Down

Resistor

(Kohm)

%

Change

of Vout

Trim Up

Resistor

(Kohm)

-5% 91.8K +5% 18.9K

-10% 40.8K +10% 7.5K

e.g. trim up 5%

Rup

5.1 1.5× 100 5+( )⋅

510

− 10.2−

K⋅:=

iEA48025A015V-000 Typical Output Ripple at nominal

input voltage and full load at Ta=25 degrees

1.6

1.4

1.2

1

0.8

0.6

0.4

Output Voltage (V)

0.2

0

27.0 31.8 36.6 41.4 46.2 51.0 55.8

Input Voltage (V)

Io_min = 0A Io_mid = 12.6A Io_max = 25.2A

iEA48025A015V-000 Typical Output Voltage vs. Input

Voltage Characteristics

iEA48025A015V-000 Calculated resistor values for

output voltage adjustment

©2004 TDK Innoveta® Inc.

iEAFullDatasheet 032707 3/29/2007 Revision 2.0

30/41

Page 31

Data Sheet: Belleta® iEA Series –Single Output Eighth Brick

℡ (877) 498

-

0099

Thermal Performance:

iEA48025A015V-000 through -015: 1.5V, 25A Output

30

25

20

15

10

Output Current (A)

5

0

NC

0.5 m/s (100 LFM)

1.0 m/s (200 LFM)

2.0 m/s (400 LFM)

3.0 m/s (600 LFM)

Tc, Thermal Limit

25 45 65 85 105 125 145

Temperature (oC)

iEA48025A015V-000 maximum output current vs. ambient

temperature at nominal input voltage for airflow rates natural

convection (60lfm) to 600lfm with airflow from pin 3 to pin 1.

Best orientation

airflow

Thermal measurement

location on PWB Cu

iEA48025A015V-000 thermal measurement location –

top view

Both the thermal curves provided and the example given above are based upon measurements made in TDK Innoveta’s

experimental test setup that is described in the Thermal Management section. Due to the large number of variables in

system design, TDK Innoveta recommends that the user verify the module’s thermal performance in the end application.

The critical component should be thermo coupled and monitored, and should not exceed the temperature limit specified in

the derating curve above. It is critical that the thermocouple be mounted in a manner that gives direct thermal contact or

significant measurement errors may result. TDK Innoveta can provide modules with a thermocouple pre-mounted to the

critical component for system verification tests.

©2004 TDK Innoveta® Inc.

iEAFullDatasheet 032707 3/29/2007 Revision 2.0

31/41

Page 32

Data Sheet: Belleta® iEA Series –Single Output Eighth Brick

℡ (877) 498

-

0099

Electrical Data:

iEA48025A012V-000 through -015: 1.2V, 25A Output

Characteristic Min Typ Max Unit Notes & Conditions

Output Voltage Initial Setpoint 1.182 1.2 1.218 Vdc Vin=Vin,nom; Io=Io,max; Tc = 25˚C

Output Voltage Tolerance 1.164 1.2 1.236 Vdc

Efficiency --- 78 --- % Vin=Vin,nom; Io=Io,max; Tc = 25˚C

Line Regulation --- 1 5 mV Vin=Vin,min to Vin,max

Load Regulation --- 1 7 mV Io=Io,min to Io,max

Temperature Regulation --- 10 50 mV Tc=Tc,min to Tc,max

Output Current 2.5 --- 25 A

Output Current Limiting Threshold --- 33 --- A Vo = 0.9*Vo,nom, Tc<Tc,max

Short Circuit Current --- 20 --- A Vo = 0.25V, Tc = 25˚C

Over all rated input voltage, load, and

temperature conditions to end of life

At loads less than Io,min the module will

continue to regulate the output voltage, but

the output ripple may increase

--- 45 100

Output Ripple and Noise Voltage

--- 10 --- mVrms

Output Voltage Adjustment Range 90 --- 110 %Vo,nom

Output Voltage Sense Range --- --- 10 %Vo,nom

Dynamic Response:

Recovery Time

Transient Voltage

Output Voltage Overshoot during startup --- --- 125 mV Vin=Vin,nom; Io=Io,max,Tc=25˚C

Switching Frequency --- 300 --- kHz Fixed

Output Over Voltage Protection 1.5 --- 2.0 V

External Load Capacitance 0 --- 5000& uF

Isolation Capacitance --- 1000 --- pF

Isolation Resistance 10 --- --- MΩ

Vref 1.225 V Required for trim calculation

& Contact TDK Innoveta for applications that require additional capacitance or very low esr

---

---

175

100

---

---

mVpp

uS

mV

Measured across one 1.0 uF ceramic

capacitor and a 10uF tantalum capacitor –

see input/output ripple measurement figure;

BW = 20MHz

di/dt = 0.1A/uS, Vin=Vin,nom; load step

from 50% to 75% of Io,max

©2004 TDK Innoveta® Inc.

iEAFullDatasheet 032707 3/29/2007 Revision 2.0

32/41

Page 33

℡ (877) 498

-

0099

Data Sheet: Belleta® iEA Series –Single Output Eighth Brick

Electrical Characteristics:

iEA48025A012V-000 through -015: 1.2V, 25A Output

86

84

82

(%)

η

η

η

η

80

78

76

74

Efficiency,

72

70

1 3.4 5.8 8.2 10.6 13 15.4 17.8 20.2 22.6 25

Output Current (A)

Vin = 36V Vin = 48V Vin = 75V

iEA48025A012V-000 Typical Efficiency vs. Input

Voltage at Ta=25 degrees.

1.22

1.215

1.21

1.205

1.2

1.195

1.19

Output Voltage (V)

1.185

1.18

1 3.4 5.8 8.2 10.6 13 15.4 17.8 20.2 22.6 25

Output Current (A)

12

10

8

6

4

2

Power Dissipation (W)

0

1 3.4 5.8 8.2 10.6 1 3 15.4 17.8 2 0.2 22 .6 25

Output Current (A)

Vin = 36V Vin = 48V Vin = 75V

iEA48025A012V-000 Typical Power Dissipation vs.

Input Voltage at Ta=25 degrees

Vin = 36V Vin = 48V Vin = 75V

iEA48025A012V-000 Typical Output Voltage vs. Load

Current at Ta = 25 degrees

iEA48025A012V-000 Typical startup characteristic

from input voltage application at full load. Ch1 - input

voltage, Ch3 – output voltage

©2004 TDK Innoveta® Inc.

iEAFullDatasheet 032707 3/29/2007 Revision 2.0

iEA48025A012V-001 Typical startup characteristic from

on/off at full load.Ch1-on/off signal, Ch3 –output voltage

iEA48025A012V-000 Typical transient response.

Output voltage response to load step from 50% to 75%

of full load with output current slew rate of 0.1A/uS.

33/41

Page 34

Data Sheet: Belleta® iEA Series –Single Output Eighth Brick

℡ (877) 498

-

0099

5

Electrical Characteristics (continued):

iEA48025A012V-000 through -015: 1.2V, 25A Output

1.25

1.2

1.15

1.1

1.05

Output Voltage (V)

1

20 25 30 35

Output Current (A)

Vin = 36V Vin = 48V Vin = 75V

iEA48025A012V-000 Typical Output Current Limit

Characteristics vs. Input Voltage at Ta=25 degrees.

iEA48025A012V-000 Typical Output Ripple at nominal

input voltage and full load at Ta=25 degrees

1.6

1.4

1.2

1

0.8

0.6

0.4

Input Current (A)

0.2

0

27 32 37 41 46 51 56 61 65 70 75

Input Voltage (V)

Io_min = 1.3A Io_mid = 12.6A Io_max = 25.2A

iEA48025A012V-000 Typical Input Current vs. Input

Voltage Characteristics

%

Change

of Vout

Trim

Down

Resistor

(Kohm)

%

Change

of Vout

Trim Up

Resistor

(Kohm)

-5% 18K +5% 20K

-10% 8K +10% 10K

e.g. trim up 5%

Rup

K⋅:=

100

1.4

1.2

1

0.8

0.6

0.4

Output Voltage (V)

0.2

0

27 32 37 41 46 51 56 61 65 70 75

Input Voltage (V)

Io_min = 1.3A Io_mi d = 12.6A Io_max = 25.2A

iEA48025A012V-000 Typical Output Voltage vs. Input

Voltage Characteristics

iEA48025A012V-000 Calculated resistor values for

output voltage adjustment

©2004 TDK Innoveta® Inc.

iEAFullDatasheet 032707 3/29/2007 Revision 2.0

34/41

Page 35

Data Sheet: Belleta® iEA Series –Single Output Eighth Brick

℡ (877) 498

-

0099

Thermal Performance:

iEA48025A012V-000 through -015: 1.2V, 25A Output

30

25

20

15

10

Output Current (A)

5

0

NC

0.5 m/s (100 LFM)

1.0 m/s (200 LFM)

2.0 m/s (400 LFM)

3.0 m/s (600 LFM)

Tc, Thermal Limit

25 45 65 85 105 125 145

Temperature (oC)

iEA48025A012V-000 maximum output current vs. ambient

temperature at nominal input voltage for airflow rates natural

convection (60lfm) to 600lfm with airflow from pin 3 to pin 1.

Best orientation

airflow

Thermal measurement

location on PWB Cu

iEA48025A012V-000 thermal measurement location –

Both the thermal curves provided and the example given above are based upon measurements made in TDK Innoveta’s

experimental test setup that is described in the Thermal Management section. Due to the large number of variables in

system design, TDK Innoveta recommends that the user verify the module’s thermal performance in the end application.

The critical component should be thermo coupled and monitored, and should not exceed the temperature limit specified in

the derating curve above. It is critical that the thermocouple be mounted in a manner that gives direct thermal contact or

significant measurement errors may result. TDK Innoveta can provide modules with a thermocouple pre-mounted to the

critical component for system verification tests.

top view

©2004 TDK Innoveta® Inc.

iEAFullDatasheet 032707 3/29/2007 Revision 2.0

35/41

Page 36

℡ (877) 498

-

0099

A

Data Sheet: Belleta® iEA Series –Single Output Eighth Brick

Thermal Management:

An important part of the overall system

design process is thermal management;

thermal design must be considered at all

levels to ensure good reliability and lifetime

of the final system. Superior thermal design

and the ability to operate in severe

application environments are key elements

of a robust, reliable power module.

A finite amount of heat must be dissipated

from the power module to the surrounding

environment. This heat is transferred by the

three modes of heat transfer: convection,

conduction and radiation. While all three

modes of heat transfer are present in every

application, convection is the dominant

mode of heat transfer in most applications.

However, to ensure adequate cooling and

proper operation, all three modes should be

considered in a final system configuration.

The open frame design of the power module

provides an air path to individual

components. This air path improves

convection cooling to the surrounding

environment, which reduces areas of heat

concentration and resulting hot spots.

Test Setup: The thermal performance data

of the power module is based upon

measurements obtained from a wind tunnel

test with the setup shown in the wind tunnel

figure. This thermal test setup replicates the

typical thermal environments encountered in

most modern electronic systems with

distributed power architectures. The

electronic equipment in networking, telecom,

wireless, and advanced computer systems

operates in similar environments and utilizes

vertically mounted PCBs or circuit cards in

cabinet racks.

The power module, as shown in the figure,

is mounted on a printed circuit board (PCB)

and is vertically oriented within the wind

tunnel. The cross section of the airflow

passage is rectangular. The spacing

between the top of the module and a parallel

facing PCB is kept at a constant (0.5 in).

The power module’s orientation with respect

to the airflow direction can have a significant

impact on the module’s thermal

performance.

Thermal Derating: For proper application of

the power module in a given thermal

environment, output current derating curves

are provided as a design

AIRFLOW

Air Velocity and Ambient

Temperature

Measurement Location

Wind Tunnel Test Setup Figure

in millimeters and (inches).

guideline on the Thermal Performance

section for the power module of interest.

The module temperature should be

measured in the final system configuration

to ensure proper thermal management of

the power module. For thermal performance

verification, the module temperature should

be measured at the component indicated in

the thermal measurement location figure on

the thermal performance page for the power

module of interest. In all conditions, the

power module should be operated below the

maximum operating temperature shown on

the derating curve. For improved design

margins and enhanced system reliability, the

power module may be operated at

temperatures below the maximum rated

operating temperature.

Module

Centerline

76 (3.0)

I

R

F

L

O

W

Air Passage

Centerline

Dimensions are

Adjacent PCB

12.7

(0.50)

©2004 TDK Innoveta® Inc.

iEAFullDatasheet 032707 3/29/2007 Revision 2.0

36/41

Page 37

℡ (877) 498

-

0099

Data Sheet: Belleta® iEA Series –Single Output Eighth Brick

Heat transfer by convection can be

enhanced by increasing the airflow rate that

the power module experiences. The

maximum output current of the power

module is a function of ambient temperature

) and airflow rate as shown in the

(T

AMB

thermal performance figures on the thermal

performance page for the power module of

interest. The curves in the figures are

shown for natural convection through 2 m/s

(400 ft/min). The data for the natural

convection condition has been collected at

0.3 m/s (60 ft/min) of airflow, which is the

typical airflow generated by other heat

dissipating components in many of the

systems that these types of modules are

used in. In the final system configurations,

the airflow rate for the natural convection

condition can vary due to temperature

gradients from other heat dissipating

components.

Operating Information:

Over-Current Protection: The power

modules have current limit protection to

protect the module during output overload

and short circuit conditions. During overload

conditions, the power modules may protect

themselves by entering a hiccup current limit

mode. The modules will operate normally

once the output current returns to the

specified operating range. There is a typical

delay of 30mS from the time an overload

condition appears at the module output until

the hiccup mode will occur.

Output Over-Voltage Protection: The

power modules have a control circuit,

independent of the primary control loop that

reduces the risk of over voltage appearing at

the output of the power module during a

fault condition. If there is a fault in the

primary regulation loop, the over voltage

protection circuitry will cause the power

module to enter a hiccup over-voltage mode

once it detects that the output voltage has

reached the level indicated on the Electrical

Data section for the power module of

interest. When the condition causing the

over-voltage is corrected, the module will

operate normally.

An optional latching over-voltage protection

is available. On modules with this feature,

the power module will shut down once it

detects that the output voltage has reached

the level indicated on the Electrical Data

section for the power module of interest.

The module remains off unless the input

voltage is recycled.

Thermal Protection: When the power

modules exceed the maximum operating

temperature, the modules may turn off to

safeguard the power unit against thermal

damage. The module will auto restart as the

unit is cooled below the over temperature

threshold. On modules with the latching

over-voltage protection feature, the unit may

latch off during a severe over temperature

condition; the module remains off unless the

input voltage is recycled.

Remote On/Off: - The power modules have

an internal remote on/off circuit. The user

must supply an open-collector or compatible

switch between the Vin(-) pin and the on/off

pin. The maximum voltage generated by

the power module at the on/off terminal is

15V. The maximum allowable leakage

current of the switch is 50uA. The switch

must be capable of maintaining a low signal

Von/off < 1.2V while sinking 1mA.

The standard on/off logic is positive logic.

The power module will turn on if terminal 2 is

left open and will be off if terminal 2 is

connected to terminal 3. If the positive logic

circuit is not being used, terminal 2 should

be left open.

An optional negative logic is available. The

power module will turn on if terminal 2 is

connected to terminal 3, and it will be off if

terminal 2 is left open. If the negative logic

feature is not being used, terminal 2 should

be shorted to terminal 3.

©2004 TDK Innoveta® Inc.

iEAFullDatasheet 032707 3/29/2007 Revision 2.0

37/41

Page 38

Data Sheet: Belleta® iEA Series –Single Output Eighth Brick

℡ (877) 498

-

0099

Vref

%Vo

%Vo

Vin (+)

On/ Off

Vin(-)

On/Off Circuit for positive or negative

logic

Output Voltage Adjustment: The output

voltage of the power module may be

adjusted by using an external resistor

connected between the Vout trim terminal

(pin 6) and either the Sense (+) or Sense (-)

terminal. If the output voltage adjustment

feature is not used, pin 6 should be left

open. Care should be taken to avoid

injecting noise into the power module’s trim

pin. A small 0.01uF capacitor between the

power module’s trim pin and Sense (-) pin

may help avoid this.

Vout(+)

Sense(+)

Trim

Sense(-)

Vout(-)

Rdown

Circuit to decrease output voltage

With a resistor between the trim and Sense

(-) terminals, the output voltage is adjusted

down. To adjust the output voltage down a

percentage of Vout (%Vo) from Vo,nom, the

trim resistor should be chosen according to

the following equation:

For all outputs except 1.2V:

Rdown

510

10.2−

1000⋅:=

%Vo

For 1.2V output only:

Rdown

The current limit set point does not increase

as the module is trimmed down, so the

available output power is reduced.

Circuit to increase output voltage

With a resistor between the trim and sense

(+) terminals, the output voltage is adjusted

up. To adjust the output voltage up a

percentage of Vout (%Vo) from Vo,nom the

trim resistor should be chosen according to

the following equation:

For all outputs except 1.2V:

5.1Vonom 100 %Vo+( )⋅

Rup

For 1.2V output only:

Rup

The value of Vref is found in the Electrical

Data section for the power module of

interest. The maximum power available

from the power module is fixed. As the

output voltage is trimmed up, the maximum

output current must be decreased to

maintain the maximum rated power of the

module. As the output voltage is trimmed,

the output over-voltage set point is not

adjusted. Trimming the output voltage too

high may cause the output over voltage

protection circuit to be triggered.

100

%Vo

Vout(+)

Sense(+)

Trim

Sense(-)

Vout(-)

⋅

100

%Vo

1000⋅:=

2−

1000⋅:=

510

− 10.2−

Rup

1000⋅:=

©2004 TDK Innoveta® Inc.

iEAFullDatasheet 032707 3/29/2007 Revision 2.0

38/41

Page 39

℡ (877) 498

-

0099

Data Sheet: Belleta® iEA Series –Single Output Eighth Brick

Remote Sense: The power modules feature

remote sense to compensate for the effect

of output distribution drops. The output

voltage sense range defines the maximum

voltage allowed between the output power

terminals and output sense terminals, and it

is found on the electrical data page for the

power module of interest. If the remote

sense feature is not being used, the

Sense(+) terminal should be connected to

the Vo(+) terminal and the Sense (-)

terminal should be connected to the Vo(-)

terminal.

The output voltage at the Vo(+) and Vo(-)

terminals can be increased by either the

remote sense or the output voltage

adjustment feature. The maximum voltage

increase allowed is the larger of the remote

sense range or the output voltage

adjustment range; it is not the sum of both.

As the output voltage increases due to the

use of the remote sense, the maximum

output current must be decreased for the

power module to remain below its maximum

power rating.

EMC Considerations: TDK Innoveta power

modules are designed for use in a wide

variety of systems and applications. For

assistance with designing for EMC

compliance, please contact TDK Innoveta

technical support.

Input Impedance:

The source impedance of the power feeding

the DC/DC converter module will interact

with the DC/DC converter. To minimize the

interaction, a 10-100uF input electrolytic

capacitor should be present if the source

inductance is greater than 1.5uH.

Reliability:

The power modules are designed using TDK

Innoveta’s stringent design guidelines for

component derating, product qualification,

and design reviews. Early failures are

screened out by both burn-in and an

automated final test. The MTBF is

calculated to be greater than 4.8M hours at

full output power and Ta = 40˚C using the

Telcordia SR-332 calculation method.

Improper handling or cleaning processes

can adversely affect the appearance,

testability, and reliability of the power

modules. Contact TDK Innoveta technical

support for guidance regarding proper

handling, cleaning, and soldering of TDK

Innoveta’s power modules.

Quality:

TDK Innoveta’s product development

process incorporates advanced quality

planning tools such as FMEA and Cpk

analysis to ensure designs are robust and

reliable. All products are assembled at ISO

certified assembly plants.

©2004 TDK Innoveta® Inc.

iEAFullDatasheet 032707 3/29/2007 Revision 2.0

39/41

Page 40

℡ (877) 498

-

0099

Data Sheet: Belleta® iEA Series –Single Output Eighth Brick

Input/Output Ripple and Noise Measurements:

12uH

1 2

Battery

12

220uF

esr<0.1

100KHz

12

33uF

esr<0.7

100KHz

+

Vinput

-

Voutput

+

-

12

Cext

12

RLoad

The input reflected ripple is measured with a current probe and oscilloscope. The ripple

current is the current through the 12uH inductor.

The output ripple measurement is made approximately 9 cm (3.5 in.) from the power module

using an oscilloscope and BNC socket. The capacitor Cext is located about 5 cm (2 in.) from

the power module; its value varies from code to code and is found on the electrical data page

for the power module of interest under the ripple & noise voltage specification in the Notes &

Conditions column.

Safety Considerations:

For safety agency approval of the system in

which the DC-DC power module is installed,

the power module must be installed in

compliance with the creepage and clearance

requirements of the safety agency. The

isolation is basic insulation. For

applications requiring basic insulation, care

must be taken to maintain minimum

creepage and clearance distances when

routing traces near the power module.

As part of the production process, the power

modules are hi-pot tested from primary and

secondary at a test voltage of 1500Vdc.

To preserve maximum flexibility, the power

modules are not internally fused. An

external input line normal blow fuse with a

maximum value of 10A is required by safety

agencies. A lower value fuse can be

selected based upon the maximum dc input

current and maximum inrush energy of the

power module.

When the supply to the DC-DC converter is

less than 60Vdc, the power module meets

all of the requirements for SELV. If the

input voltage is a hazardous voltage that

exceeds 60Vdc, the output can be

considered SELV only if the following

conditions are met:

1) The input source is isolated from the

ac mains by reinforced insulation.

2) The input terminal pins are not

accessible.

3) One pole of the input and one pole

of the output are grounded or both

are kept floating.

4) Single fault testing is performed on

the end system to ensure that under

a single fault, hazardous voltages

do not appear at the module output.

Warranty:

TDK Innoveta’s comprehensive line of

power solutions includes efficient, highdensity DC-DC converters. TDK Innoveta

offers a three-year limited warranty.

Complete warranty information is listed on

our web site or is available upon request

from TDK Innoveta.

Ground Plane

©2004 TDK Innoveta® Inc.

iEAFullDatasheet 032707 3/29/2007 Revision 2.0

40/41

Page 41

Data Sheet: Belleta® iEA Series –Single Output Eighth Brick

℡ (877) 498

-

0099

http://www.tdkinnoveta.com/

3320 Matrix Drive, Suite 100

Richardson, TX 75082

Phone (877) 498-0099 Toll Free

(469) 916.4747

Fax (877) 498-0143 Toll Free

(214) 239.3101

support@tdkinnoveta.com