Page 1

TCL

FLOOR-STANDING SPLIT-TYPE AIR CONDITIONERS

SERVICE MANUAL

No.20170622

Models

TFF-60HRA/TOF-60HSA

CONTENTS

1. IMPORTANT NOTICE

2. PRODUCT DIMENSIONS

3. REFRIGERATION CYCLE DIAGRAM

4. OPERATION DETAILS

5. WIRING DIAGRAM

6. EXPLOSION VIEW AND PART LISTS

Page 2

TCL Air Conditioner Service ManualTCL Air Conditioner Service ManualTCL Air Conditioner Service Manual

Air Conditioner Service Manual

2

IMPORTANT NOTICE

This service manual is intended for use by individuals possessing adequate

backgrounds of electrical, electronic and mechanical experience. Any

attempt to repair the appliance may result in personal injury and property

damage. The manufacturer or seller cannot be responsible for the

interpretation of this information, nor can it assume any liability in

connection with its use.

The information, specifications and parameter are subject to change due to

technical modification or improvement without any prior notice. The

accurate specifications are presented on the nameplate label.

How to order spare parts

To have your order filled promptly and correctly, please furnish the

following information:

1. Model No. with Indoor or Outdoor

2. No. in the Explosion View

3. Part Name

4. The quantity you ordered

Page 3

Air Conditioner Service Manual

2. PRODUCT DIMENSIONS

Indoor Unit:

Outdoor Unit:

Model A B C D E F G H I J K

60K 650 405 1920 940 1250 340 600 400 375 50 63

3

Page 4

Air Conditioner Service Manual

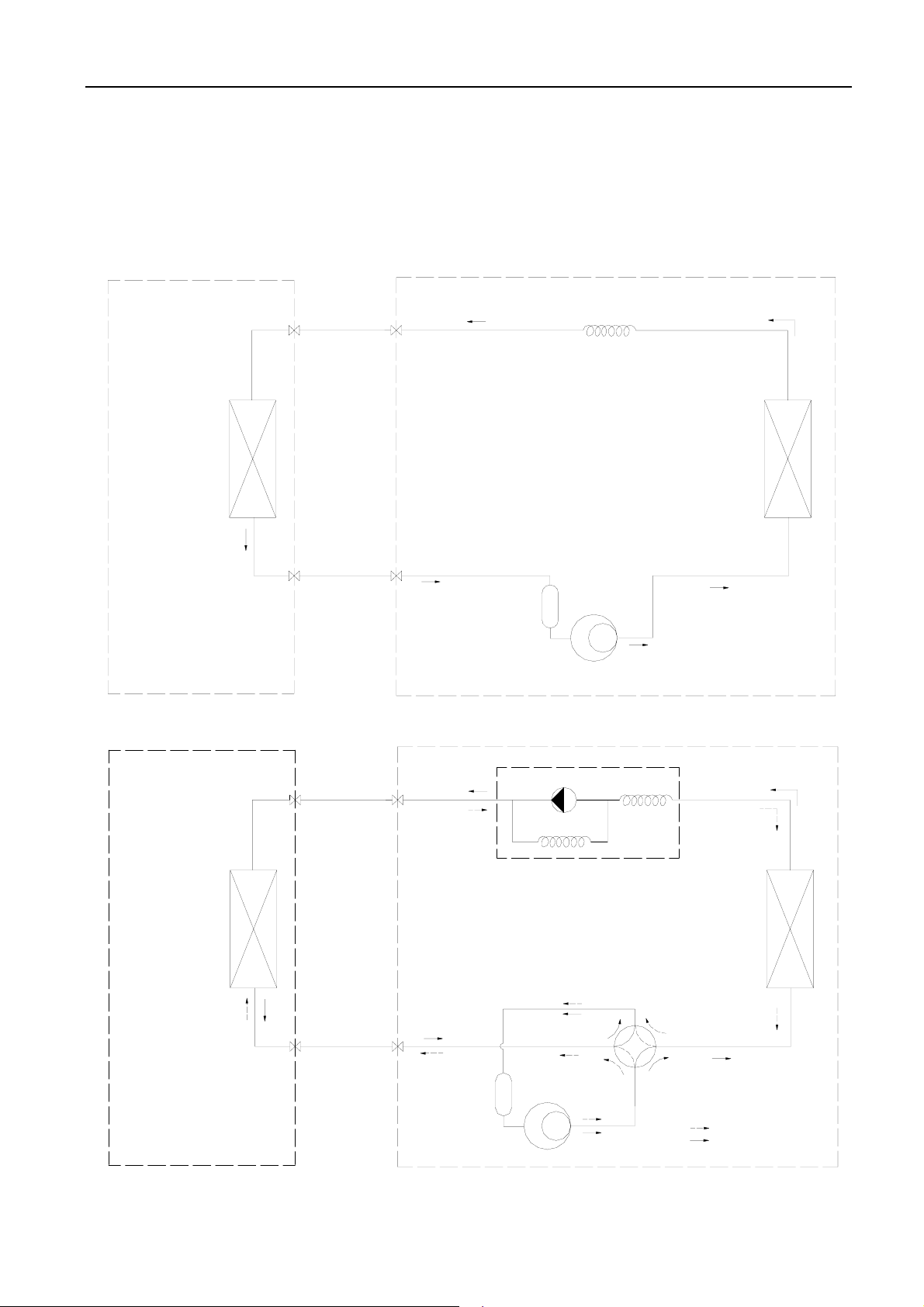

3. Refrigeration cycle diagram

Cooling only

Heat exchange

(Evaporator)

Heat pump

Heat exchange

(Evaporator)

Liquid side

2-way valve

Gas side

3-way valve

Accumulator

Liquid side

2-way valve

Gas side

3-way valve

Accumulator

Capillary

Compressor

Check valve

Capillary Assembly

4-way valve

Compressor

Heat exchange

(condenser)

Heat exchange

(condenser)

Heating

Cooling

3

Page 5

4.Operation Details

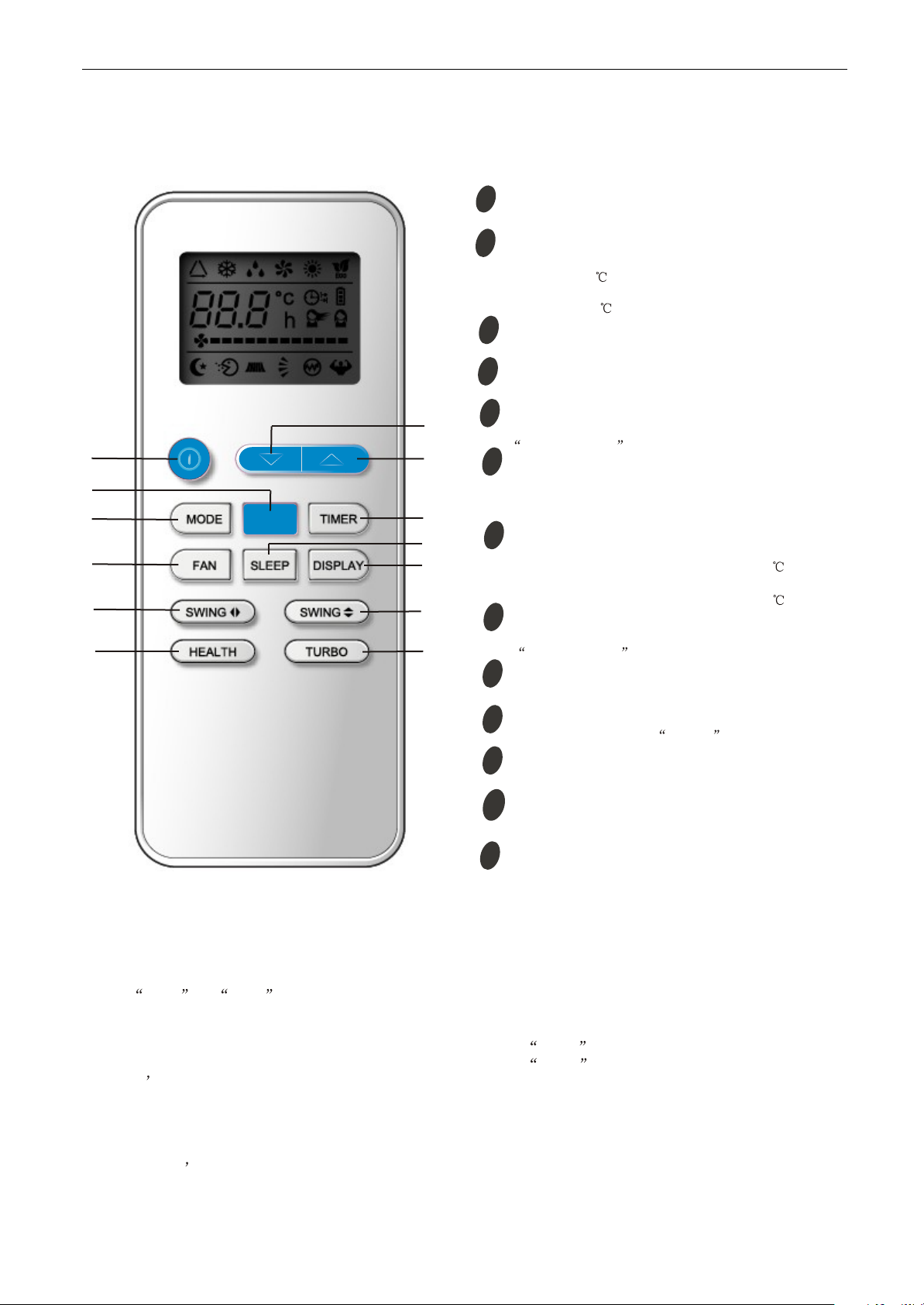

Remote controller

1

2

3

ECO

4

5

6

Air Conditioner Service Manual

ON/OFF button

1

To switch the conditioner on and off.

2

ECO button

In cooling mode,press this button ,the temperature

will increase 2 on the base of setting temperature:

In heating mode, press this button, the temperature

will decrease 2 on the base of setting temperature.

MODE button

3

To select the mode of operation.

FAN SPEED button

4

To select the fan speed of auto/low/mid/high.

SWING button

13

12

11

10

9

8

7

5

To activate or deactivate of the movement of the

DEFLECTORS .

6

HEALTH button

To switch - on /off HEALTHY funtion.

which controls the ionizer or plasma generator only

for inverter type.

TURBO button

7

In cooling mode, press this button, the unit will give

the maximum cooling temperature with 16

In heating mode, press this button, the unit will give

the maximum heating temperature with 31 .

8

SWING button

To activate or deactivate of the movement of the

DEFLECTORS .

DISPLAY button

9

To LED display (if present)switch on/off the

It is a button

SLEEP button

10

10

9

To activate the function SLEEP .

TIMER button

11

9

To set automatic switching-on/off.

12

TEMP UP button

Increase the temperature or time by 1 unit.

TEMP DOWN button

13

9

Decrease the temperature or time by 1 unit.

9

Note: Each mode and relevant function will be further specified in following pages.

Remote Control

The remote controller is not presetting as Cooling Only Air Conditioner or Heat Pump by manufacturer.

Each time after the remote controller replace batteries or is energized, the arrowhead will flashes on the

front of Heat or Cool on LCD of the remote controller.

User can preset the remote controller type depending on the air conditioner type you have purchased as

follows:

Press any button when the arrowhead flashes on the front of Cool , Cooling Only is set.

Press any button when the arrowhead flashes on the front of Heat , Heat Pump is set.

If you don t press any button within 10 seconds, the remote controller is preset as Heat Pump

automatically.

Note :

If the air conditioner you purchased is a Cooling Only one, but you preset the remote controller as Heat

Pump, it doesn t bring any matter. But if the air conditioner you purchased is a Heat Pump one, and you

preset the remote controller as Cooling Only, then you CAN NOT preset the Heating operation with the

remote controller.

4

Page 6

Air Conditioner Service Manual

Electronic Controller

1. Safety Control

(1) Time Delay Safety Control

z 3 minutes delay for compressor---The compressor is ceased for 3minutes to balance the pressure in the

refrigeration cycle in order to protect the compressor.

z 2 minutes delay for 4-way valve---The 4-way valve is ceased for 2 minutes to prevent the

refrigerant-gas abnormal noise when the HEATING operation is OFF or switch to the other operation

mode.

(2) Indoor Pipe Temperature Sensor Frost Prevention Control

When the indoor pipe temperature sensor reads 0℃ or below for 5 minutes, the indoor pipe temperature

sensor frost prevention control starts. The compressor and outdoor fan stop and indoor fan operates at high

speed for 3 minutes. After that, if the indoor pipe temperature sensor reads less than 5℃ this control

prolonged until the indoor pipe temperature sensor reads 5℃ or more.

(3) High Temperature Protection Control

During HEATING operation, the outdoor fan motor and compressor are controlled by the indoor pipe

temperature to prevent the high temperature of compressor.

Outdoor fan OFF: when the indoor pipe temperature is ≥53℃

Outdoor fan ON: when the indoor pipe temperature is ≤48℃

Compressor OFF: when the indoor pipe temperature is ≥62℃

Compressor ON: when the indoor pipe temperature is ≤48℃

2. “Feel” Mode Operation

(1) When the “I Feel” mode is selected, the operation mode and initial set temperature are determined by the

initial room temperature at start-up of the operation except to turn off the air conditioner and operates it

again.

(2) If the mode is change to “I Feel” mode from other mode, the “I Feel” mode doesn’t operate until compressor

stop for more than 3 minutes.

COOLING

DRY

HEATING for Heat Pump Type

FAN for Cooling Only Type

z In the “I Feel” mode , when the controller receives the up or down single of temperature, the set

3. “COOLING” Mode Operation

(1) When the COOLING mode is selected without setting temperature, the system will set the set temperature at

℃ automatically with the AUTO FAN speed.

26

(2) When selecting the COOLING mode operation, the system will operate according to the setting by the

remote controller and the operation is as following:

Mode

temperature can adjust by 1

Initial room temperature

26℃ or more

20℃ to 25 ℃

Less than 20℃

Initial set temperature

24℃

18℃

23℃

℃ upper or lower. The biggest you can adjust by 2℃ upper or lower.

5

Page 7

Air Conditioner Service Manual

Room Temp.

Set TEMP. +1℃

Set TEMP. -1℃

Time

More than 2 min

More than 2 min

More than 2 min

More than 2 min

More than 2 min

Indoor Fan

Set Speed

Set Speed

Set Speed

Set Speed

Set Speed

Compressor

ON

OFF

ON

OFF

ON

Outdoor Fan

ON

OFF

ON

OFF

ON

Set Temp. +1℃

Set Temp. -1℃

Room Temp.

Time

More than 2 min

More than 2 min

More than 2 min

More than 2 min

More than 2 min

Compressor

ON

OFF

ON

OFF

ON

Outdoor fan

ON

OFF

ON

OFF

ON

Temperature raise

Temperature drop

4. “DRY” Mode Operation

(1) The system for DRY operation used the same refrigerant circle as the cooling circle.

(2) When the system operates in DRY mode ,at first it operates in cooling mode at 16℃ or 18℃ for 3 minutes.

And then, the system operates in cooling mode with low speed that regards the temperature of the room

temperature sensor reads decrease 2℃ as the set temperature. During the course of this, the fan speed

set operation is failing but the vane motor can be controlled.

5. “HEATING” Mode Operation (Only available for Heat Pump)

(1) When the HEATING mode is selected without setting temperature, the system will set the temperature at

23℃ automatically with the AUTO FAN speed.

(2) When selecting the HEATING mode operation, the system will operate according to the setting by the

remote controller and the operation is as following:

(3) In HEATING mode, the indoor fan motor speed is controlled by Cold Air Prevention Control.

(4) Cold Air Prevention Control

The function is intend to prevent cold air from being discharged when the heating operation starts or

when defrosting.

The indoor fan speed will be controlled as following.

The vane angle is at the angle C(100°).

Set Speed Set Speed

34℃

Low Speed

27℃

Low Speed

25℃

Stop the fan

23℃

Stop the fan

During the heating operation, if the compressor stops that it will adjust the indoor fan speed, after 30

seconds to stop the fan.

6

Page 8

Air Conditioner Service Manual

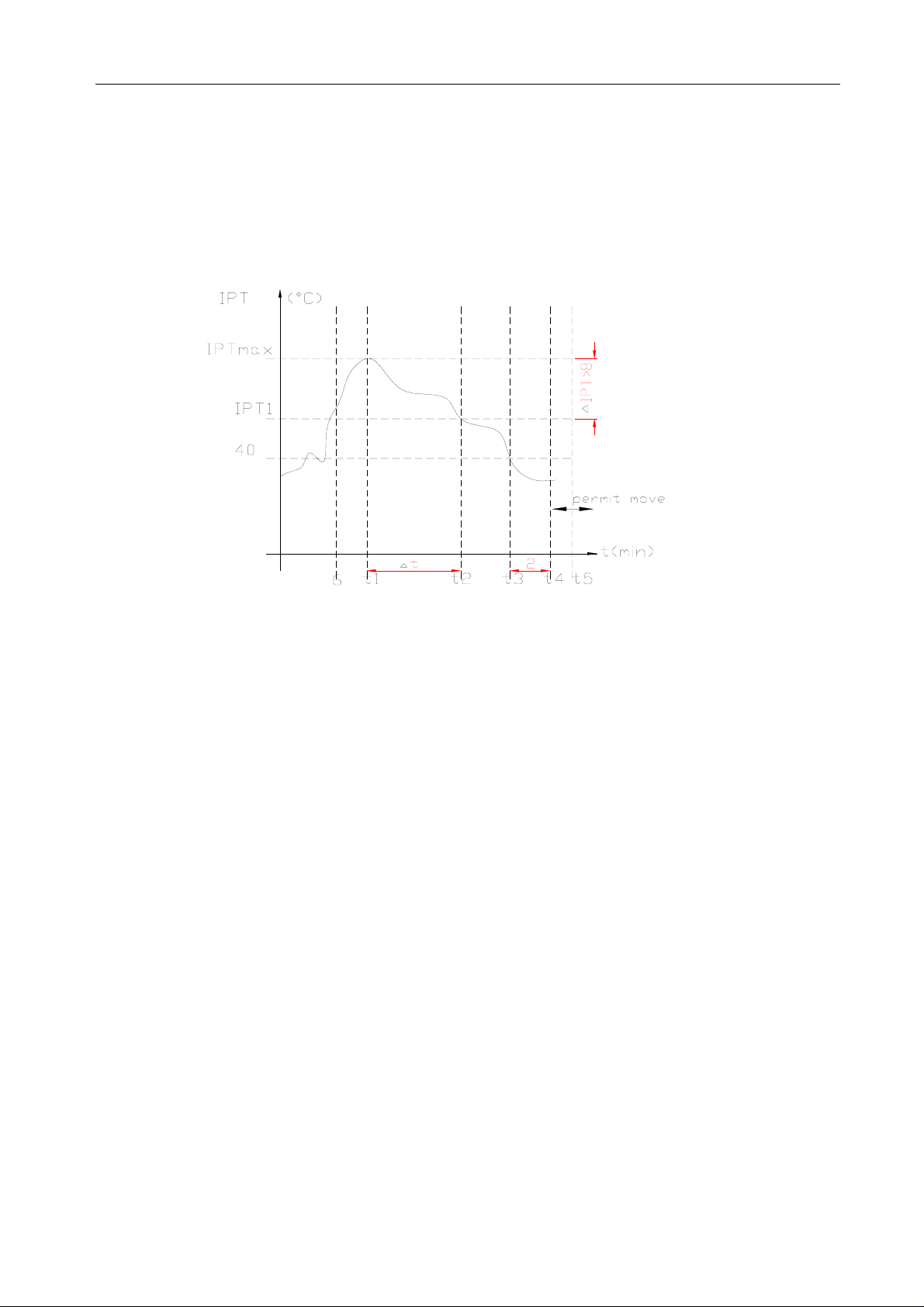

(5) Defrost

Defrosting of the outdoor heat exchange is controlled by the microprocessor with detection by the indoor

pipe temperature sensor.

Defrost control type is according to the JC on the PCB whether is connected.

z When the JC is connect on the PCB

When one of the conditions of A, Band C is satisfy, the defrosting operation stars.

A. IPT--- indoor pipe temperature

In the condition A, it must satisfy the conditions a), b)and c) then into defrosting operation.

a) IPT1 satisfy IPT1=IPT

b) t5≥50minutes(the compressor cumulative operation time≥50 minutes, t5 is permitted move

and lower than t1 too).

IPT<40℃,and keep 2 minutes.

c)

According to the condition A enter the defrosting operation, the first defrosting operation time is

8minutes; After defrosting operation one cycle, and then judge and regulate the defrosting operation

time.

B. After the compressor cumulative operation time exceeds 120 minutes and the temperature of the IPT

is less then 35

℃ for 2 minutes. When the defrosting operation time on this condition exceeds

-△IPT(8℃)

MAX

8minutes, it will terminate.

C. After the compressor operation continuously for 20 minutes and the IPT is less than 23℃ or from

the last time of defrosting operation is 50 minutes or more interval. When the defrosting operation

time on this condition exceeds 10 minutes, it will terminal.

z When the JC isn’t connected on the PCB

When the conditions of a) or b) is satisfy, the defrosting operation starts.

a) Have the outdoor sensor on the outdoor unit: Under the heating operation, the compressor cumulative

operation time exceeds 50 minutes and the temperature of the outdoor pipe temperature sensor reads

lower than -4

b) No the outdoor on the outdoor unit: Under the heating operation, the compressor cumulative

operation time exceeds 50 minutes, if the indoor pipe temperature sensor reads lower than 40

℃.

℃

continuously for 2minutes.

z Defrost terminating conditions

When the condition c) or d) is satisfy, the defrosting operation will terminal.

c) The outdoor defrost sensor reads 15

℃ or more.

d) The defrosting time exceeds 10 minutes.

7

Page 9

Air Conditioner Service Manual

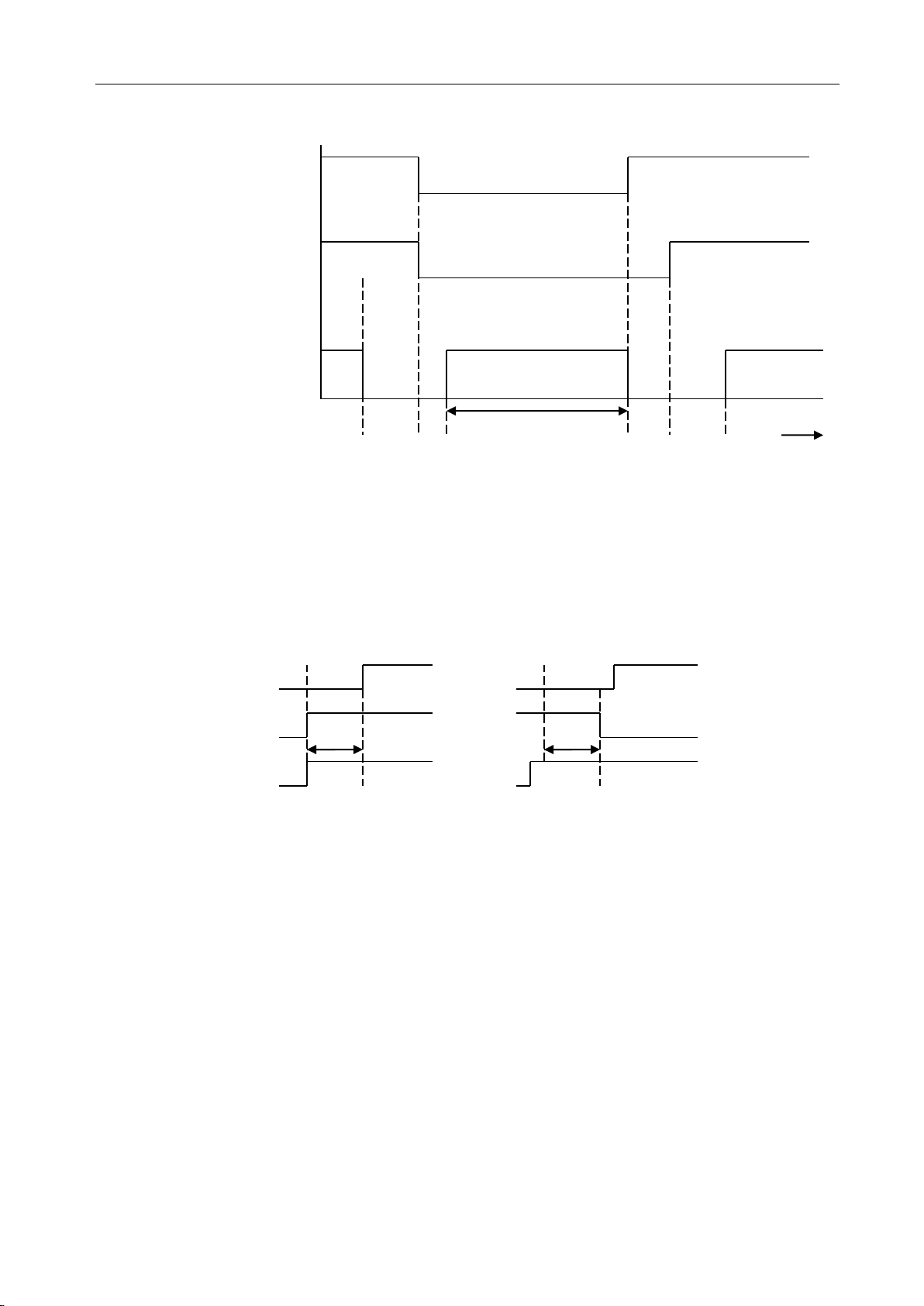

Defrosting time chart

Outdoor Fan ON OFF ON

Revering Valve ON OFF ON

Compressor Relay ON OFF ON OFF ON

39S 5S Defrost Count MAX 12min 19S 15S t

6. “FAN” mode operation

The indoor fan motor always turns on at the set speed and the vane motor turns on at the set fettle.

7. 4-way Valve control

HEATING ON

COOLING/DRY OFF

The 4-way valve reverses for 5 seconds right before start-up of the compressor as following chart:

COOLING/DRY TO HEATING HEATING TO COOLING/DRY

Compressor

4-way Valve

5s 2min

Outdoor Fan

8. Assistant Heater

1) The heater mode is automatically controlled.

2) The condition of the heater ON. (must accord with the following conditions)

a. The compressor has operated over 10 minutes.

b. The indoor fan motor has operated at normal over 15 minutes.

c. Not at the defrosting.

d. The heater latest off was over 30 seconds.

e. ST-RT≥3℃。

f. RT<22℃.

g. IPT≤43℃

3) The condition of the heater OFF. (accord with one of the following condition)

a. The compressor off.

b. RT≥24℃.

c. IPT≥48℃

d. Indoor motor off.

e. Enter the sleep mode.

9. “SLEEP” mode

When the SLEEP button is pressed, the SLEEP mode is selected as following:

8

Page 10

Air Conditioner Service Manual

motor is shut off. 10 seconds later, the electric current is applied to the fan motor again. During the fan motor

lock-up, the POWER indicator lamp flashes on and off 6times/cycle or E6 to show the fan motor

abnormality.

10. Auto Fan Speed Control

(1) When the auto fan speed is selected, the indoor fan motor speed is automatically controlled by the room

temperature and the set temperature.

(2) In COOLING mode, the indoor fan motor operates as following:

Fan Speed

Hi

Me

Lo

Room temperature minus set temperature: 1℃ 2℃ 4℃

(3) In HEATING mode, the indoor fan motor operates as following;

Fan Speed

Hi

Mi

Lo

Room temperature minus set temperature 1

℃ 2℃ 4℃

11. Auto V ane Operation control

(1) Vane motor drive

The unit is equipped with a stepping motor for the vane. The rotating direction, speed, and angle of the

motor are controlled by pulse signal transmitted from indoor microprocessor.

(2) Positioning

The vane is once pressed to the vane stopper below to confirm the standard position and then set to the

desired angle. The positioning is decided as follows:

z When the ON/OFF button is pressed.

z When the vane control is change from AUTO to MANUAL.

z When the SWING is finished.

z When the test run starts.

z When the power supply turns ON.

(3) The auto vane changes as follows by pressing the VANE CONTROL button.

(4) VANE AUTO mode

In vane auto mode, the microprocessor automatically determines the vane angle and operation to make the

optimum room-temperature distribution.

(5) SWING mode

When presses the SWING button, the vane swings.

12. TIMER Operation

(1) To activate the air conditioner at the desire time, follow the procedure specified below(the remote control

and air conditioner are switched off):

z Press the Timer button.

z Select the desired mode by pressing the Mode button.

z Select the desired temperature by pressing the ▲ ▼ button(only possible when the ‘cool’ or ‘heat’

mode is selected).

z Select the ventilator speed (low, medium or high) or automatic mode(only possible when the feel, Cool

or Heat mode is selected) by pressing the Fan button.

The ventilator always operates in the Auto mode when the Dry mode is selected.

z Select Swing or no Swing by pressing the Swing button.

9

Page 11

Air Conditioner Service Manual

z Press the Timer button(‘h’ flashes).

z Use the ▲▼ button to select the time at which the air conditioner must activate (between 0 and 10

hours can be set at every half hour-between 10 and 24 hours can be set at every hour).

z Press the Timer button (‘h’ stops flashing) and the preset time appears in the display.

z Press the Timer button again to delete the selected data from the memory.

Note : If no buttons are pressed during the programming of the timer function, thee remote control will

switch off automatically after 10 seconds.

(2) To switch the air conditioner off at the desired time, follow the procedure specified below (the remote control

and air conditioner are switched off):

z Press the timer button.

z Use the ▲▼ button to select the time at witch.

13. EMERGENCY Operation

When the EMERGENCY Operation switch is pressed once, COOLING mode is selected and if in 3 seconds the

EMERGENCY Operation switch is pressed again, mode is selected. Then pressed once again, the unit is switch

off.

When the remote controller is missing, has failed or the batteries run down, press the EMERGENCY Operation

switch on the front of the indoor unit. The unit will start.

The first 30 minutes of operation will be the test run operation. The operation is for servicing. The indoor fan runs

at high speed and the system is in continuous operation. The thermostat is ON and the timer is reset to normal.

After 30 minutes of test run operation the system shifts to AUTO COOLING/HEATING mode, and the indoor fan

runs in automatic speed. The operation continues unit the EMERGENCY operation switch is pressed or a button

on the remote controller is pressed, the normal operation will start.

NOTE: Do not press the EMERGEMCY Operation switch during normal operation.

14. AUTO RESTART Function(Option)

1.When the indoor unit is controlled with the remote controller, the operation mode, set temperature, and the fan

speed are memorized by the indoor electric control PCB. The AUTO RESTART function sets to work the

moment power has restored after power failure. Then, the unit will restart automatically.

2. How to set the AUTO RESTAR function.

z Press the emergency switch and power supply to the PCB following, keep 10seconds and the buzzer will

beep three times. The AUTO-RESTAR is set.

z Do the operation again, the buzzer will beep four times and the AUTO-RESTAR function is cancelled.

15. Electron Lock Function:

Press the fan button for 5 seconds, the buzzer beep one sound. The all button is invalidation for operate the air

conditioner except the remote controller.

16. Failure Display and Handling

a) Failure Display

When the controller is failure, the buzzer will voice long for three times, and displays the failure from the

failure lamp.

b) Failure Code

If have the digital pipe that display the failure code for digital pipe, or display for the run lamp.

Type of failure The lamp flash Display of digital pipe

The failure of room temperature sensor E1

The failure of indoor pipe temperature sensor E2

Outdoor unit protected E5

c) Failure Handling

z When the room temperature sensor or the indoor pipe temperature sensor is failure, the system will be

shut off, the compressor will be OFF, and the outdoor fan and the indoor fan will be OFF. The system

10

Page 12

Air Conditioner Service Manual

doesn’t receive the signal of remoter controller except the signal of shut off it. When the failure

disappear, the controller can operate in normal mode. before this, presses the “ON/OFF” to start the

system, and it will operate in COOLING or HEATING for 30 minutes, and follows shut off. During

this, it displays the failure and the protection is failing. You must be given the electric again to operate

it. In the failure, you can operate the FAN mode.

z When the outdoor protects in the COOLING or DRY, the outdoor unit stops, the indoor fan operates in

set speed ; and in the HEATING, the outdoor unit stops, the indoor fan operates in cold air prevention

control. The system doesn’t receive the signal of remoter controller except the signal of shut off it.

When the system check the voltage is 220V and the delay control is finished, it operates at normal

again.

z When the indoor fan motor is failure, the compressor is stopped, the outdoor fan and indoor fan is

stopped and display the failure. The system doesn’t receive the signal of remoter controller except the

signal of shut off it.

d) Display Of The Control

In the display board the lamp from left is the POWER lamp(Red), the SLEEP lamp(Yellow), the TIMER

lamp(Yellow), the RUN lamp(Green).

g) When gives the control electric, the buzzer voices a long for 0.3 second per cycle.

11

Page 13

Air Conditioner Service Manual

FM

~

5. WIRING DIAGRAM

MODEL: TFF-60HRA/TOF-60HSA

INDOOR UNIT:

OUTDOOR UNIT

12

Page 14

Air Conditioner Service Manual

1

2

3

4

5

6

7

8

9

19

18

17

20

21

10

11

12

13

14

15

16

22

2324

25

28

27

26

30

31

32

33

34

35

36

37

38

29

6. EXPLOSION VIEW AND PARTS

EXPLOSION VIEW

Mode: TFF-60HRA

INDOOR UNIT:

13

Page 15

Air Conditioner Service Manual

Part Name

Q’ty

Remark

1

210736221

Inside Base

1

2 230800121

Right Plate

1

3 230800122

Back Plate

1

4 230800120

Left Plate

1

5 211200107

Evaporator

1

6 230800124

Top Plate

1

7 210702134

Pipe Cover

1

8 230800123

Heat insulation board

1

9 1204090101

Rubber Water Drainage

1

10

210701012

Water Drainage

1

11

210800178

Inside Electrical Box

1

12

210901228A

Main PCB

1

13

1170200058

Terminal

1

14

230901276

Fan Motor Capacitor

1

15

1170240021

Transformer

1

16

1080520218

Inside Electrical Box Cover

1

17

210700120

Vertical Vane Connector

1

18

1170010008

Synchronization Motor

1

19

210800063

Synchronization Motor Cover

1

20

210736103

Out Blow Casing Foam

1

21

210736103

Step Motor

2

22

1071200014

Vertical Vane

1

23

210736100

Up-Left Ornamental Panel

1

24

210736098

Up Panel

1

25

210736101

Up-Right Ornamental Panel

1

26

210700116A

Horizontal Vane

1

27

210736102

Display PCB Supporter

1

28

210901229

Display PCB

1

29

210736099B

Display PCB Cover

1

30

210736105

Down-Left Ornamental Panel

1

31

210736104

Down panel

1

32

210736106

Down-Right Ornamental Panel

1

33

210826530

Air Filter Lead

2

34

210736108

Air Filter

1

35

1074090102

Lead Flow Circle

1

36

1070010004AA

Centrifugal Fan

1

37

1170030010

Indoor Motor

1

38

210700130

Volute Casing

1

39

1170230009

Indoor Sensor

1

Not shown in Explosion view

40

210900414A

Remote Controller

1

41

210708230

Remote Controller Supporter

1

42

1070110005

Drainage hose

1

43

211341339AD

Indoor Carton

1

Parts List

Indoor Unit- TFF-60HRA

No. Part No.

14

Page 16

TCL Air Conditioner Service Manual

MODEL: TOF-60HSA

OUTDOOR UNIT:

15

Page 17

Air Conditioner Service Manual

NO.

Part Number

Part Name

Q'ty

Remark

1

230800158

Left protection net

1

Optional

2

230900056

Outdoor fan motor

2

3 230800156

Cover

1

4 3210060247

Up condenser

1

3210060248

Down condenser

1

5 3120160027

Refrigerant tank

1

6 3072640201

Rear protection net

1

7 1170230005

Outdoor temp sensor

1

230901271A

Outdoor fan capacitor

2

3160080001

AC contactor

1

3171990066

Switch of low pressure

1

3171990210

Switch of high pressure

1

3172522102

Discharge temp sensor

1

3092520401AB

Outdoor PCB

1

8 1070350971

Handle

1

9 3210027077

Right back clapboard

1

10

3120120053

Three-way Valve

1

11

3210010257

Two-way Valve

1

12

3080028197

Partition plate

1

13

3120110018

4-way valve

1

3172510101

Winding of 4 way valve

1

3210010288

4-way valve assembly

1

14

3100070005

Compressor

1

15

3082510136

Outdoor base

1

16

3072510102

Front right clapboard

1

17

230700074

Outdoor Propeller Fan

2

18

230800157

Front board

1

19

1070251945

Air outlet griller

1

20

1191200310PX

Cabinet Carton

1

Indoor Unit- TOF-60HSA

16

Page 18

Air Conditioner Service Manual

7. Precaution

7.1 SAFETY RULES AND RECOMMENDATIONS FOR TH E INSTALLATION

z Read this guide before installing and using the appliance.

z During the installation of the indoor and outdoor units the access to the working area should

forbidden to children.

be

Unforeseeable accidents could happen.

z Make sure that the base of the outdoor unit is firmly fixed.

z Check that air cannot enter the refrigerant system and check for refrigerant leaks when

moving

z Check that air cannot enter the refrigerant system and check for refrigerant leaks when

moving

z The ratings of the fuse installed in the built in-control unit are T 5A / 250V.

the air conditioner.

the air conditioner.

z The user must protect the indoor unit with a fuse of suitable capacity for the maximum input

current or with another overload protection device.

z Ensure that the mains voltage corresponds to that stamped on the rating plate. Keep the switch or

power plug clean. Insert the power plug correctly and firmly into the socket, thereby avoiding the

risk of electric shock or fire due to insufficient contact.

z Check that the socket is suitable for the plug, otherwise have the socket changed.

z The appliance must be fitted with means for disconnection from the supply mains having a contact

separation in all poles that provide full disconnection under over voltage category III conditions, and

these means must be incorporated in the fixed wiring in accordance with the wiring rules.

z The air conditioner must be installed by professional or qualified persons. Do not install the appliance

at a distance of less than 50 cm from inflammable substances (alcohol, etc.) Or from pressurized

containers (e.g. spray cans).

z If the appliance is used in areas without the possibility of ventilation, precautions must be taken to

prevent any leaks of refrigerant gas from remaining in the environment and creating a danger of fire.

z The packaging materials are recyclable and should be disposed of in the separate waste bins .Take

the air conditioner at the end of its useful life to a special waste collection center for disposal.

z Only use the air conditioner as instructed in this booklet. These instructions are not intended to cover every

possible condition and situation. As with any electrical household appliance, common sense and caution

are therefore always recommended for installation, operation and maintenance.

The appliance must be installed in accordance with applicable national regulations.

z

z Before accessing the terminals, all the power circuits must be disconnected from the power supply.

z The appliance shall be installed in accordance with national wiring regulations.

This appliance can be used by children aged from 8 years and above and persons with reduced physical,

sensory or mental capabilities or lack of experience and knowledge if they have been given supervision or

instruction concerning use of the appliance in a safe way and understand the hazards involved. Children

shall not play with the appliance. Cleaning and user maintenance shall not be made by children without

supervision.

17

Page 19

Air Conditioner Service Manual

7.2 SAFETY RULES AND RECOMMENDATIONS FOR THE USER

z

Do not try to install the conditioner alone; always contact specialized technical personnel.

Cleaning and maintenance must be carried out by specialized technical personnel. In any case

disconnect the appliance from the mains electricity supply before carrying out any cleaning or

maintenance.

z Ensure that the mains voltage corresponds to that stamped on the rating plate. Keep the switch or

power plug clean. Insert the power plug correctly and firmly into the socket, thereby avoiding the

risk of electric shock or fire due to insufficient contact.

z Do not pull out the plug to switch off the appliance when it is in operation, since this could create a

spark and cause a fire, etc.

z This appliance has been made for air conditioning domestic environments and must not be used

for any other purpose, such as for drying clothes, cooling food, etc.

z The packaging materials are recyclable and should be disposed of in the separate waste bins.

Take the air conditioner at the end of its useful life to a special waste collection center for

disposal.

z Always use the appliance with the air filter mounted. The use of the conditioner without air filter

could cause an excessive accumulation of dust or waste on the inner parts of the device with

possible subsequent failures.

z The user is responsible for having the appliance installed by a qualified technician, who must check

that it is earthed in accordance with current legislation and insert a thermomagnetic circuit breaker.

z The batteries in remote controller must be recycled or disposed of properly. Disposal of Scrap

Batteries.

--- Please discard the batteries as sorted municipal waste at the accessible collection point.

z Never remain directly exposed to the flow of cold air for a long time. The direct and prolonged

exposition to cold air could be dangerous for your health .Particular care should be taken in the

rooms where there are children, old or sick people.

z If the appliance gives off smoke or there is a smell of burning, immediately cut off the power

supply and contact the Service Centre.

z The prolonged use of the device in such conditions could cause fire or electrocution.

z Have repairs carried out only by an authoritative Service Centre of the manufacturer. Incorrect

repair could expose the user to the risk of electric shock, etc.

z Unhook the automatic switch if you foresee not to use the device for a long

time. The airflow direction must be properly adjusted.

z The flaps must be directed downwards in the heating mode and upwards in the cooling mode.

Only use the air conditioner as instructed in this booklet. These instructions are not in

ended to cover every possible condition and situation. As with any electrical household

appliance, common sense and caution are therefore always recommended for installation,

operation and maintenance.

18

Page 20

Air Conditioner Service Manual

1

2

3

4

5

6

7

8

9

10

INDOOR UNIT

Indoor unit

No.

Name

1

Airflow direction flaps

2

Deflectors

3

Indoor unit rating label

4

Signal receiver

5

LED Display

6

Control panel

7

Front panel

8

Air filter

9

Front panel

10

Remote controller

Outdoor unit

No.

Name

8

Air outlet grille

9

Electronic box cover

10

2-way valve

11

3-way valve

8

9

10

11

OUTD OOR UNIT

8. Names of parts

19

Page 21

Air Conditioner Service Manual

Model

Pipe size(Inch)

Liquid

Gas

Outdoor unit:

Indoor

unit

Elbow to

prevent water

from entering room

be less than 5m

Height should

Should be less than 20 m

Indoo r unit

Outdoor unit

be less than 5m

Height should

Should be less than 20 m

Mode

Standard length:

m

Refrigerant piping

Max. length: m

Additional refrigerant

Calculation: ×g=20g/m(A-5m)

5.0

Appliance Amps

Wire Size

5

AWG21/0.75 mm2

10

AWG18/1.0 mm2

13

AWG15 /1. 5 mm2

18

AWG14/1.6 mm2

25

AWG12/2.0 mm2

30

AWG10/2.5 mm2

9. Installation manual

9.1 Installation Details

Connecting pipe length

TFF-60HRA/TOF-60HSA 1/2 7/8

TFF-60HRA/TOF-60HSA

Connecting cables

The power cord should be selected according to the following specifications sheet.

20 40g/m

20

Page 22

Air Conditioner Service Manual

Over 50mm

OOver 300mm

Over 100mm

300mm

500mm

2000mm

300mm

500mm

10.2 Installation for the first time

Indoor unit

Install the indoor unit on a strong wall that is

not subject to vibrations.

The in let and outlet ports should not be

obstructed: the air should be able to blow all

over the room.

Do not install the unit near a source of heat,

steam, or flammable gas.

Install the unit near an electric socket or private

circuit.

Do not install the unit where it will be exposed

to direct sunlight.

Install the unit where connection between indoor

and outdoor unit is as easy as possible.

Install the unit where it is easy to drain the

condensed water.

Check the machine operation regularly and

reserve the necessary spaces as shown in the

picture.

Select a place where the filter can be easily

taken out.

OUTDOOR UNIT

Do not install the outdoor unit near sources of

heat, steam or flammable gas.

Do not install the unit in too windy or dusty places.

Do not install the unit where people often

pass. Select a place where the air discharge

and operating sound level will not disturb the

neighbours.

Avoid installing the unit where it will be exposed

to direct sunlight (other wise use a protection, if

necessary, that should not interfere with the air

flow).

Reserve the spaces as shown in the picture

for The air to circulate freely.

Install the outdoor unit in a safe and solid place.

If the outdoor unit is subject to vibration, place

rubber gaskets onto the feet of the unit.

Minimum space to be left (mm) showing in the

picture.

21

Page 23

Air Conditioner Service Manual

Front panel

Terminal block cover

wiring diagram

1

3

3

2

1

2

5mm

Indoors

Out doors

A. Backward direction

B. Left or right direction

Gas pipe

Liquid pipe

Drain pipe

For connecting

pipes, drain pipe

and cables

For connecting

pipes and drain

pipe

Hole for cables

(both on left

and right sides)

To install, proceed as follows:

10.2.1 Drilling a hole in the wall for the piping

1) Decide where to drill the hole in the wall for the

piping (if necessary) according to the position of

the mounting plate

2) Install a flexible flange through the hole in the

wall to keep the latter intact and clean.

The hole must slope downwards towards the

exterior.

Note: Keep the drain pipe down towards the

direction of the wall hole, otherwise leakage may

occur.

10.2.2 Electrical connections---Indoor unit

1). Take off the front panel as indicated in the

picture (by removing the screws)

2). Take out the accessories from the indoor unit.

3). Take off the cover as indicated in the

picture (by removing a screw).

4). For the electrical connections, see the circuit

diagram on the right part of the unit under the

front panel.

5). Connect the cable wires to the screw

terminals by following the numbering, Use

wire size suitable to the electric power input

(see name plate on the unit) and according

to all current national safety code

requirements.

Note

The cable connecting the outdoor and indoor

units must be suitable for outdoor use.

An efficient earth connection must be ensured.

If the power cable is damaged, it must be

replaced by an authorized Service Centre.

10.2.3 Refrigerant piping connection

The piping can be run in the 3 directions indicated

by numbers in the picture. Select a most suitable

one for installation convenience.

Run the piping in the direction of the wall hole and

bind the copper pipes, the drain pipe and the

power cables together with the tape with the drain

pipe at the bottom, so that water can flow freely.

22

Page 24

Air Conditioner Service Manual

NO

YES

Extending the rolled pipe

torque wrench

YES

NO

NO

Indo or unit

In door u nit

Screw

Remove the upper cover

Outdoor unit

10.2.4 Connecting the pipes.

Do not remove the cap from the pipe until

connecting it, to avoid dampness or dirt

from entering.

If the pipe is bent or pulled too often, it will

become stiff. Do not bend the pipe more

than three times at one point.

When extending the rolled pipe, straighten

the pipe by unwinding it gently as shown in

the picture.

10.2.5 Connections to the indoor unit

1).Remove the indoor unit pipe cap (check that

there is no debris inside).

2).Insert the fare nut and create a flange at the

extreme end of the connection pipe.

3).Tighten the connections by using two wrenches

working in opposite directions.

10.2.6 Indoor unit condensed water drainage

The indoor unit condensed water drainage is

fundamental for the success of the installation.

1).Place the drain hose below the piping, taking

care not to create siphons.

2).The drain hose must slant downwards to aid

drainage.

3).Do not bend the drain hose or leave it protruding

or twisted and do not put the end of it in water.

If an extension is connected to the drain hose,

ensure that it is lagged when it passes into the

indoor unit.

Insert the pipe connection into the relative slot.

Press to join the pipe connection to the base.

10.2.7 Outdoor electronic connections

1. Take the cover away.

2. Connect the cable wires to the terminal board

using the same numbering as in the indoor unit.

3. For the electrical connections, see the wiring

diagram on the back of the cover

4. Fasten the cables with a cable-clamp.

5. An efficient earth connection must be ensured.

6. Replace the covers.

23

Page 25

Air Conditioner Service Manual

connection pipes

flare nuts

liquid tap

gas tap

indoor unit

protection caps

Liquid valve

gas valve

service port nut

tap

vacuu m pum p

ser vice port

10.2.8 Connecting the pipe

Screw the flare nuts to the outdoor unit coupling

with the same tightening procedures described for

the indoor unit.

Note: If the tightening torque is not sufficient, there

will probably be some leakage. With excessive

tightening torque there will also be some leakage,

as the flange could be damaged.

10.2.9 Bleeding

Air and humidity left inside the refrigerant circuit can

cause compressor malfunction. After having

connected the indoor and outdoor units, bleed the

air and humidity from the refrigerant circuit by using

a vacuum pump.

The air and humidity left inside the refrigerant

circulation can cause compressor malfunction.

After having connected the indoor and outdoor

units, bleed the air and humidity from the

refrigerant circulation using a vacuum pump.

24

Page 26

Air Conditioner Service Manual

10. Trouble shooting

10.1 Product does not operate at all.

Powerinputvoltage

Drivingloadterminal

DisplayPCBconnector

Powersupplyvoltagecheck

Powertransoutputvoltage

Powerreceptablevoltage

Productinputvoltage

PCBassembly

Connectorcontactcheck

ACabout12±3V

PCBassemblycheck

25

Page 27

Air Conditioner Service Manual

10.2 Compressor or outdoor fan does not operate at all.

Set the desired temperature of remote controller to be lower by 2°C or

over than room temperature, and start the cooling operation.

Does not operate at all.

Temperature sensor

open/short check

Connector check

(Contact & power)

Disconnection/short

circuit check of

connecting wire

Electric wire connection

check for outdoor side

Compressor & motor

detail check

Insulation resistance

Coil resistance

Capacitor capacity

Compressor OLP

Re-input after power off

Thermistor and evaporator

surface contact check.Clearance is needed (5mm).

PCB assembly check

Check:

Temperature sensing circuit

Relay output

Repeat running/stopping

at a short time period.

Connector check

(Contact & power)

OLP/High pressure

switch/Low pressure

switch check

Operation mode

(dehumidifying) check

26

Page 28

Air Conditioner Service Manual

10.3 Vane does not operate at all.

10.5 Cooling/heating conversion is disable.

Vane bending, structures

interference check

Connector check

(Broken/short circuit/malconnection)

Vane motor check

PCB assembly check(vane

motor driving circuit)

Heating operation ON by remote

controller

Connector check

If the 4-way valve is ON, "tick"

sounds.

4-way valve connection check

outdoor unit connecting wire check

Check the voltage of 4-way valve

coil

4-way valve coil resistance check

Replace the vane motor

Replace the PCB

PCB assembly

27

Page 29

Air Conditioner Service Manual

TEMP.

(℃)

Resistance

(k Ohm)

Voltage of

resistance

TEMP.

(℃)

Resistance

(k Ohm)

Voltage of

resistance

TEMP.

(℃)

Resistance

(k Ohm)

Voltage of

resistance

-30

63.513

4.628

15

7.447

2.968

60

1.464

1.115

-29

60.135

4.609

16

7.148

2.918

61

1.418

1.088

-28

56.956

4.589

17

6.863

2.868

62

1.374

1.061

-27

53.963

4.568

18

6.591

2.819

63

1.331

1.035

-26

51.144

4.547

19

6.332

2.769

64

1.290

1.009

-25

48.488

4.524

20

6.084

2.720

65

1.250

0.984

-24

45.985

4.501

21

5.847

2.671

66

1.212

0.960

-23

43.627

4.477

22

5.621

2.621

67

1.175

0.936

-22

41.403

4.452

23

5.404

2.572

68

1.139

0.913

-21

39.305

4.426

24

5.198

2.524

69

1.105

0.890

-20

37.326

4.399

25

5.000

2.475

70

1.072

0.868

-19

35.458

4.371

26

4.811

2.427

71

1.040

0.847

-18

33.695

4.343

27

4.630

2.379

72

1.009

0.825

-17

32.030

4.313

28

4.457

2.332

73

0.979

0.805

-16

30.458

4.283

29

4.292

2.285

74

0.950

0.785

-15

28.972

4.252

30

4.133

2.238

75

0.922

0.765

-14

27.567

4.219

31

3.981

2.192

76

0.895

0.746

-13

26.239

4.186

32

3.836

2.146

77

0.869

0.728

-12

24.984

4.152

33

3.697

2.101

78

0.843

0.710

-11

23.795

4.117

34

3.563

2.057

79

0.819

0.692

-10

22.671

4.082

35

3.435

2.012

80

0.795

0.675

-9

21.606

4.045

36

3.313

1.969

81

0.773

0.658

-8

20.598

4.008

37

3.195

1.926

82

0.751

0.641

-7

19.644

3.969

38

3.082

1.883

83

0.729

0.625

-6

18.732

3.930

39

2.974

1.842

84

0.709

0.610

-5

17.881

3.890

40

2.870

1.800

85

0.689

0.595

-4

17.068

3.850

41

2.770

1.760

86

0.669

0.580

-3

16.297

3.808

42

2.674

1.720

87

0.651

0.566

-2

15.565

3.766

43

2.583

1.681

88

0.633

0.552

-1

14.871

3.723

44

2.494

1.642

89

0.615

0.538

0

14.212

3.680

45

2.410

1.604

90

0.598

0.525

1

13.586

3.635

46

2.328

1.567

91

0.582

0.512

2

12.991

3.590

47

2.250

1.530

92

0.566

0.499

3

12.426

3.545

48

2.174

1.495

93

0.550

0.487

4

11.889

3.499

49

2.102

1.459

94

0.535

0.475

5

11.378

3.452

50

2.032

1.425

95

0.521

0.463

6

10.893

3.406

51

1.965

1.391

96

0.507

0.452

7

10.431

3.358

52

1.901

1.357

97

0.493

0.441

8

9.991

3.310

53

1.839

1.325

98

0.480

0.430

9

9.573

3.262

54

1.779

1.293

99

0.467

0.419

10

9.174

3.214

55

1.721

1.262

100

0.455

0.409

11

8.795

3.165

56

1.666

1.231

12

8.433

3.116

57

1.613

1.201

13

8.089

3.067

58

1.561

1.172

14

7.760

3.017

59

1.512

1.143

10.4 THERMISTOR TEMPERATURE CHARACTERISTICS

Indoor unit room temperature,exchange temperature and outdoor exchange temperature sensor characteristics

28

Page 30

Air Conditioner Service Manual

Resistance at 25℃: 5 kΩ.

TH1: indoor room temperature sensor and outside air temperature sensor

TH2: indoor exchange temperature sensor and outside exchange temperature sensor

Before measuring resistance, disconnect connectors as shown above.

29

Loading...

Loading...