Page 1

TAC-09CSC/K TAC-09CHSC/K

TCL

14. ANNEX 5 INSTALLATION INSTRUCTION Part 1

SERVICE MANUAL

TAC-07CSC/K TAC-07CHSC/K

TAC-12CSC/K TAC-12CHSC/K

TAC-18CSC/K TAC-18CHSC/K

TAC-24CSC/K TAC-24CHSC/K

No.TE031229

TAC-18CS/K TAC-18CHS/K

WALL MOUNTED SPLIT-TYPE AIR CONDITIONERS

Models

TAC-07CS/K TAC-07CHS/K

TAC-09CS/K

TAC-12CS/K

TAC-24CS/K

TAC-24CHS/K

TAC-09CHS/K

TAC-12CHS/K

CONTENTS

1. IMPORTANT NOTICE ···································2

2. TECHNICAL SPECIFICATION ·····················3

3. DIMENSIONS ················································8

4. REFRIGERATING CYCLE SYSTEM ············· 9

5. PERFORMANCE CURVES ····························12

6. OPERATION DETAILS ·············16

7. WIRING DIAGRAM ······························23

8. EXPLOSION VIEW ···················29

9. PARTS LIST ·································33

10. ANNEX 1 THERMISTOR CHARACTERISTIC

11. ANNEX 2 GENERAL

12. ANNEX 3 TROUBLE SHOOTING

13. ANNEX 4 R407C REFRIGERANT

Page 2

IMPORTANT NOTICE

This service manual is intended for use by individuals possessing adequate

backgrounds of electrical, electronic and mechanical experience. Any

attempt to repair the appliance may result in personal injury and property

damage. The manufacturer or seller cannot be responsible for the

interpretation of this information, nor can it assume any liability in

connection with its use.

The information, specifications and parameter are subject to change due to

technical modification or improvement without any prior notice. The

accurate specifications are presented on the nameplate label.

How to order spare parts

To have your order filled promptly and correctly, please furnish the

following information:

1. Model No. with Indoor or Outdoor

2. No. in the Explosion View

3. Part Name

4. The quantity you ordered

TCL Air Conditioner Service ManualTCL Air Conditioner Service ManualTCL Air Conditioner Service Manual

TCL Air Conditioner Service Manual

2

Page 3

TCL Air Conditioner Service Manual

3

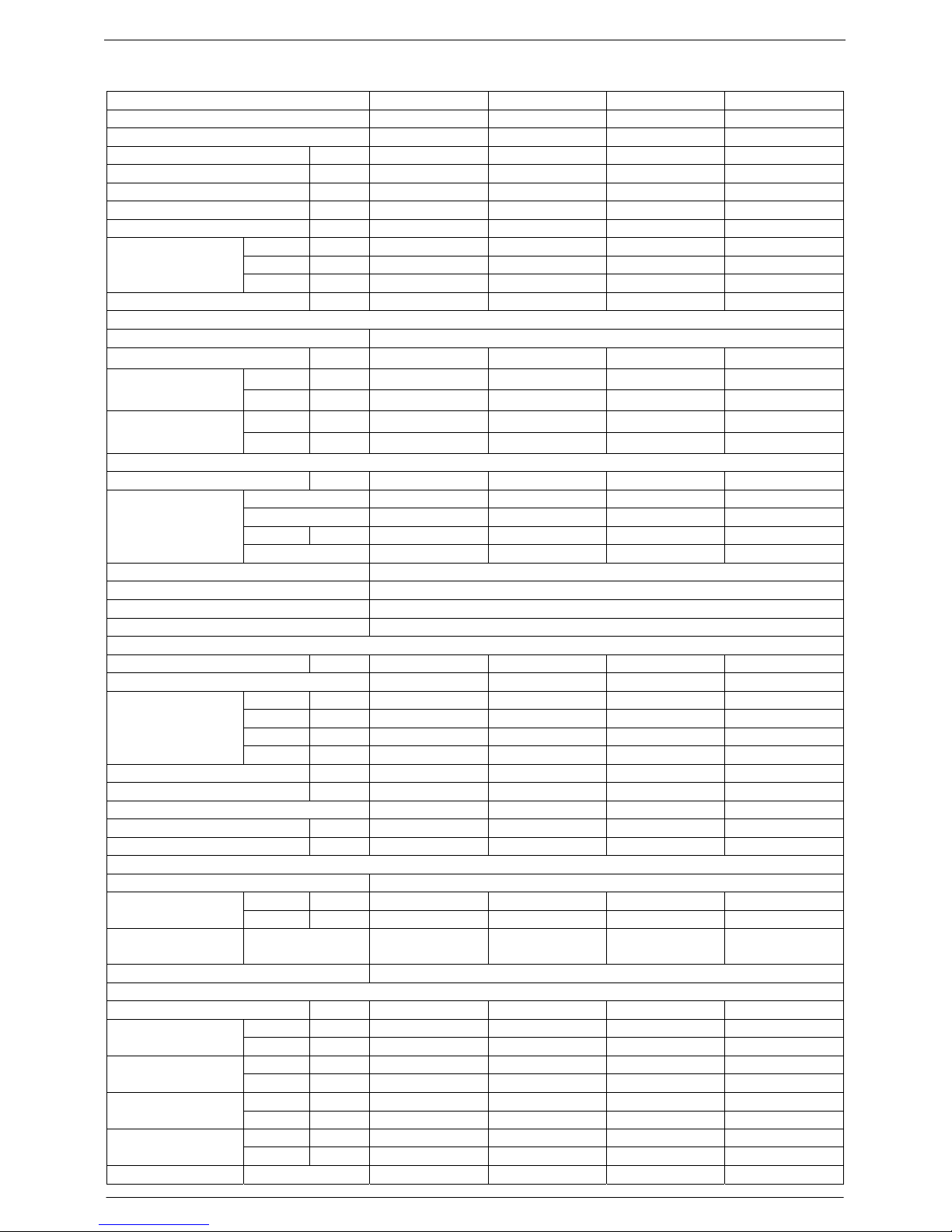

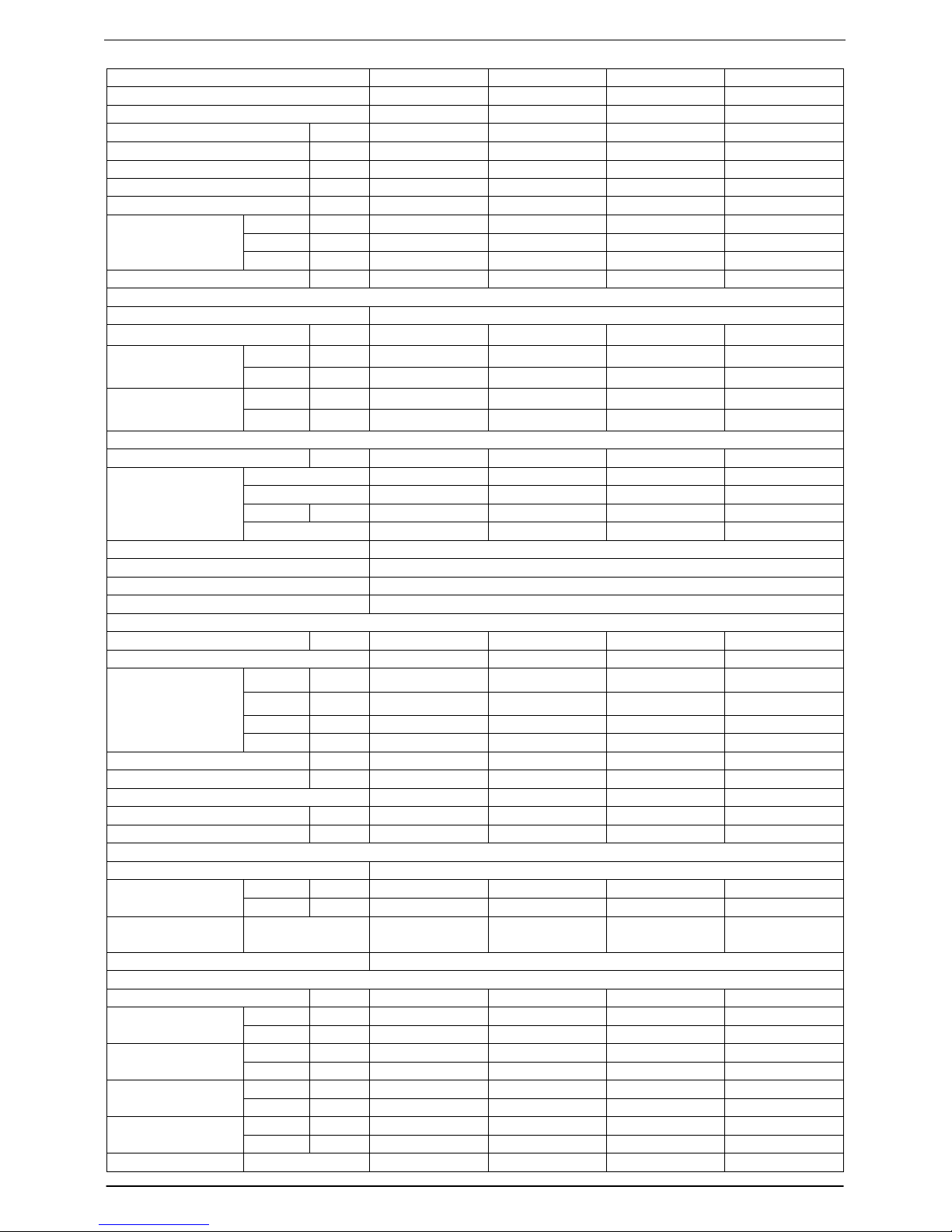

Technical Specifications

Model No. TAC-07CS/K TAC-07CHS/K TAC-09CS/K TAC-09CHS/K

Type Cooling Only Heating Pump Cooling Only Heating Pump

Control type Remote Remote Remote Remote

Rated cooling capacity Btu/h 7,000 7,000 9,000 9,000

Rated heating capacity Btu/h N/A 7,500 N/A 9,500

EER for cooling Btu/h.w 9.6 9.6 9.6 9.6

COP for heating W/W N/A 2.8 N/A 2.8

Moisture removal Liters/h 0.8 0.8 0.8 0.8

High dB(A) 36 36 36 36

Med. dB(A) 32 32 32 32

Indoor noise level at

cooling

Low dB(A) 29 29 29 29

Outdoor noise level dB(A) 50 50 50 50

Electrical Data

Power supply 220-240V~/50Hz

Voltage Range V 198~264 198~264 198~264 198~264

Cooling A 4.2 4.2 4.2 4.2

Rated current

Heating A N/A 4.1 N/A 4.1

Cooling W 895 895 900 900

Rated input

Heating W N/A 880 N/A 880

Refrigerating System

Refrigerant/Charge Gram R22/700g R22/700g R22/700g R22/700g

Type Rotary Rotary Rotary Rotary

Model ------------------ ----------------- ------------------ -----------------LRA A ------ ------- ------ ------

Compressor

MFG ----------------- ----------------- ---------------- -----------------

Evaporator Louver fin and Grooved tube type (φ7)

Condenser Corrugated fin and Grooved tube type (φ9.53)

Expansion device Capillary tube

Defrosting system Microcomputer controlled reverse system

Fan System

Indoor air circulation m3/h 430 430 430 430

Indoor fan type Cross flow Cross flow Cross flow Cross flow

Cooling rpm 1000/950/900 1000/950/900 1000/950/900 1000/950/900

Heating rpm N/A 970/900/800 N/A 970/900/800

Dry rpm 900 900 900 900

Indoor fan speed

H/M/L

Sleep rpm 650 650 650 650

Indoor fan motor output W 12 12 12 12

Outdoor air circulation m3/h --- --- --- --Outdoor fan type Propeller fan Propeller fan Propeller fan Propeller fan

Outdoor fan speed rpm 895 895 895 895

Outdoor fan motor output W 31 31 31 31

Connections

Refrigerant coupling Flare type

Gas Inches 5/8 5/8 5/8 5/8

Connecting Pipe

Liquid Inches 7/16 7/16 7/16 7/16

Connecting Wiring

Size × Core

number

Drainage Pipe O.D 16mm

Others

Suitable area m2 12~19 12~19 12~19 12~19

Indoor mm 710×250×179 710×250×179 710×250×179 710×250×179Net dimensions

(W x H x D)

Outdoor mm 600×500×232 600×500×232 600×500×232 600×500×232

Indoor kg 7.5 7.5 7.5 7.5

Net weight

Outdoor kg 25 25 25 25

Indoor mm 805×325×270 805×325×270 805×325×270 805×325×270Packing dimensions

(W x H x D)

Outdoor mm 745×352×542 745×352×542 745×352×542 745×352×542

Indoor kg 10 10 10 10

Gross weight

Outdoor kg 28 29 28 29

Loading Capacity 40’/40’HC 132/280/318 132/280/318 132/280/318 132/280/318

Page 4

TCL Air Conditioner Service Manual

4

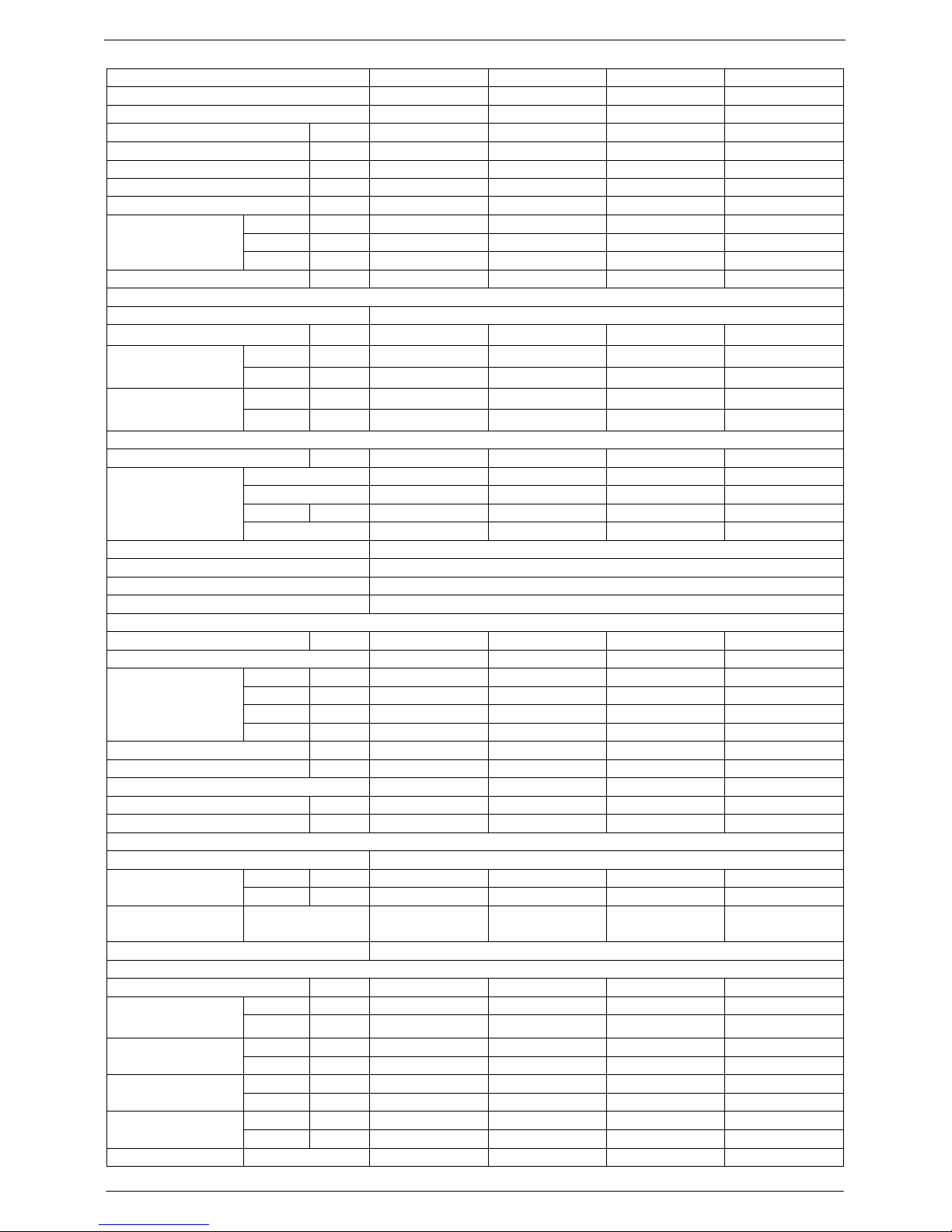

Model No. TAC-07CSC/K TAC-07CHSC/K TAC-09CSC/K TAC-09CHSC/K

Type Cooling Only Heating Pump Cooling Only Heating Pump

Control type Remote Remote Remote Remote

Rated cooling capacity Btu/h 7,000 7,000 9,000 9,000

Rated heating capacity Btu/h N/A 7,500 N/A 9,500

EER for cooling Btu/h.w 11.0 11.0 11.0 11.0

COP for heating W/W N/A 3.2 N/A 3.2

Moisture removal Liters/h 0.8 0.8 0.8 0.8

High dB(A) 38 38 38 38

Med. dB(A) 36 36 36 36

Indoor noise level at

cooling

Low dB(A) 32 32 32 32

Outdoor noise level dB(A) 50 50 50 50

Electrical Data

Power supply 220-240V~/50Hz

Voltage Range V 198~264 198~264 198~264 198~264

Cooling A 4.1 4.1 4.1 4.1

Rated current

Heating A N/A 4.1 N/A 4.1

Cooling W 880 880 880 880

Rated input

Heating W N/A 880 N/A 880

Refrigerating System

Refrigerant/Charge Gram R407C/700g R407C/700g R407C/700g R407C/700g

Type Rotary Rotary Rotary Rotary

Model ------------------ ----------------- ------------------ ------------------

LRA A ------ ------- ------ ------

Compressor

MFG ----------------- ----------------- ---------------- ----------------Evaporator Louver fin and Grooved tube type (φ7)

Condenser Corrugated fin and Grooved tube type (φ9.53)

Expansion device Capillary tube

Defrosting system Microcomputer controlled reverse system

Fan System

Indoor air circulation m3/h 480 480 480 480

Indoor fan type Cross flow Cross flow Cross flow Cross flow

Cooling rpm 1230/1150/1000 1230/1150/1000 1230/1150/1000

1230/1150/1000

Heating rpm N/A 1230/1150/1000 N/A

1230/1150/1000

Dry rpm 1000 1000 1000 1000

Indoor fan speed

H/M/L

Sleep rpm 1000 1000 1000 1000

Indoor fan motor output W 12 12 12 12

Outdoor air circulation m3/h --- --- --- --Outdoor fan type Propeller fan Propeller fan Propeller fan Propeller fan

Outdoor fan speed rpm 860 860 860 860

Outdoor fan motor output W 31 31 31 31

Connections

Refrigerant coupling Flare type

Gas Inches 7/16 7/16 3/4 3/4

Connecting Pipe

Liquid Inches 3/4 3/4 7/16 7/16

Connecting Wiring

Size × Core

number

Drainage Pipe O.D 16mm

Others

Suitable area m2 12~19 12~19 12~19 12~19

Indoor mm 770×250×179 770×250×179 770×250×179 770×250×179Net dimensions

(W x H x D)

Outdoor mm 700×255×540 700×255×540 700×255×540 700×255×540

Indoor kg 8.0 8.0 8 8

Net weight

Outdoor kg 31 32 31 32

Indoor mm 863×325×270 863×325×270 863×325×270 863×325×270Packing dimensions

(W x H x D)

Outdoor mm 803×380×598 803×380×598 803×380×598 803×380×598

Indoor kg 10 10 10 10

Gross weight

Outdoor kg 35 36 35 36

Loading Capacity 40’/40’HC 111/238/276 111/238/276 111/238/276 111/238/276

Page 5

TCL Air Conditioner Service Manual

5

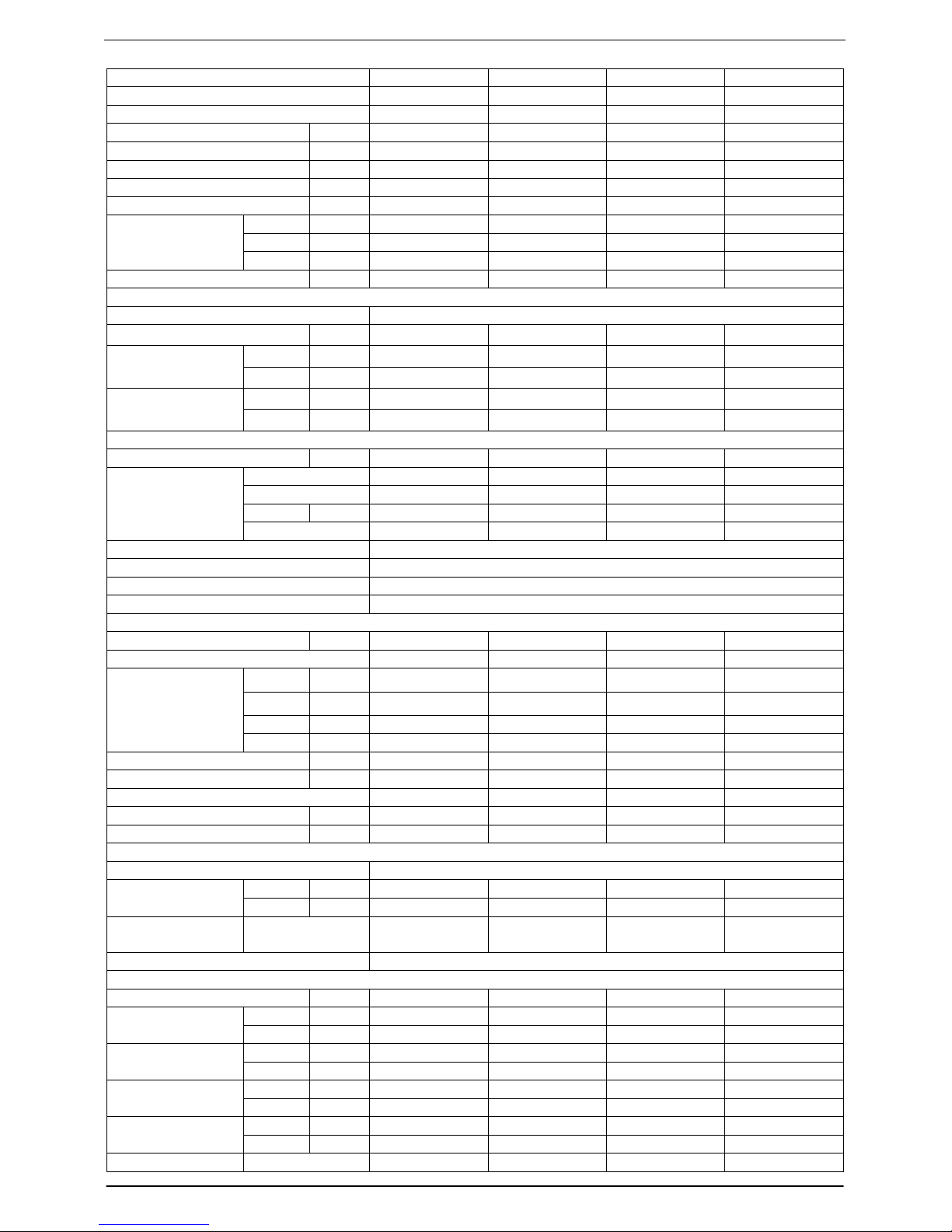

Model No. TAC-12CS/K TAC-12CHS/K TAC-18CS/K TAC-18CHS/K

Type Cooling Only Heating Pump Cooling Only Heating Pump

Control type Remote Remote Remote Remote

Rated cooling capacity Btu/h 12,000 12,000 18,000 18,000

Rated heating capacity Btu/h N/A 12,800 N/A 19,000

EER for cooling Btu/h.w 9.2 9.2 8.8 8.8

COP for heating W/W N/A 2.65 N/A 2.65

Moisture removal Liters/h 1.0 1.0 1.0 1.5

High dB(A) 38 38 42 42

Med. dB(A) 36 36 40 40

Indoor noise level at

cooling

Low dB(A) 32 32 36 36

Outdoor noise level dB(A) 52 52 58 58

Electrical Data

Power supply 220-240V~/50Hz

Voltage Range V 198~264 198~264 198~264 198~264

Cooling A 5.6 5.6 9.6 9.6

Rated current

Heating A N/A 5.9 N/A 9.0

Cooling W 1270 1270 2100 2100

Rated input

Heating W N/A 1335 N/A 1970

Refrigerating System

Refrigerant/Charge Gram R22/870g R22/870g R22/1700g R22/1700g

Type Rotary Rotary Rotary Rotary

Model ------------------ ----------------- ------------------ ------------------

LRA A ------ ------- ------ ------

Compressor

MFG ----------------- ----------------- ---------------- ----------------Evaporator Louver fin and Grooved tube type (φ7)

Condenser Corrugated fin and Grooved tube type (φ9.53)

Expansion device Capillary tube

Defrosting system Microcomputer controlled reverse system

Fan System

Indoor air circulation m3/h 530 530 800/850 800/850

Indoor fan type Cross flow Cross flow Cross flow Cross flow

Cooling rpm 1150/1060/900 1150/1060/900 1300/1200/1100 1300/1200/1100

Heating rpm N/A 1150/1060/900 N/A 1300/1200/1100

Dry rpm 900 900 840 840

Indoor fan speed

H/M/L

Sleep rpm 650 650 900/1000 900/1000

Indoor fan motor output W 12 12 25 25

Outdoor air circulation m3/h --- --- --- --Outdoor fan type Propeller fan Propeller fan Propeller fan Propeller fan

Outdoor fan speed rpm 860 860 820 820

Outdoor fan motor output W 55 55 90 90

Connections

Refrigerant coupling Flare type

Gas Inches 7/16 7/16 3/4 3/4

Connecting Pipe

Liquid Inches 3/4 3/4 7/16 7/16

Connecting Wiring

Size × Core

number

Drainage Pipe O.D 16mm

Others

Suitable area m2 16~28 16~28 30~40 30~40

Indoor mm 770×250×179 770×250×179 1036×313×204 1036×313×204Net dimensions

(W x H x D)

Outdoor mm 700×255×540 700×255×540 760×255×540 760×255×540

Indoor kg 8.0 8.0 14 14

Net weight

Outdoor kg 31 32 42 43

Indoor mm 863×325×270 863×325×270 1103×395×280 1103×395×280Packing dimensions

(W x H x D)

Outdoor mm 803×380×595 803×380×595 863×376×605 863×376×605

Indoor kg 10 10 19 19

Gross weight

Outdoor kg 34 35 44 45

Loading Capacity 40’/40’HC 111/238/276 111/238/276 90/188/218 90/188/218

Page 6

TCL Air Conditioner Service Manual

6

Model No. TAC-12CSC/K TAC-12CHSC/K TAC-18CSC/K TAC-18CHSC/K

Type Cooling Only Heating Pump Cooling Only Heating Pump

Control type Remote Remote Remote Remote

Rated cooling capacity Btu/h 12,000 12,000 18,000 18,000

Rated heating capacity Btu/h N/A 12,800 N/A 1,9000

EER for cooling Btu/h.w 10.9 10.9 9.5 9.5

COP for heating W/W N/A 3.2 N/A 2.8

Moisture removal Liters/h 1.0 1.0 1.5 1.5

High dB(A) 38 38 43 43

Med. dB(A) 36 36 40 40

Indoor noise level at

cooling

Low dB(A) 32 32 36 36

Outdoor noise level dB(A) 52 52 58 58

Electrical Data

Power supply 220-240V~/50Hz

Voltage Range V 198~264 198~264 198~264 198~264

Cooling A 5.5 5.5 8.7 8.7

Rated current

Heating A N/A 5.5 N/A 8.7

Cooling W 1170 1170 1900 1900

Rated input

Heating W N/A 1170 N/A 1900

Refrigerating System

Refrigerant/Charge Gram R407C/1450g R407C/1450g R407C/1800g R407C/1800g

Type Rotary Rotary Rotary Rotary

Model ------------------ ----------------- ------------------ ------------------

LRA A ------ ------- ------ ------

Compressor

MFG ----------------- ----------------- ---------------- ----------------Evaporator Louver fin and Grooved tube type (φ7)

Condenser Corrugated fin and Grooved tube type (φ9.53)

Expansion device Capillary tube

Defrosting system Microcomputer controlled reverse system

Fan System

Indoor air circulation m3/h 550 550 730 730

Indoor fan type Cross flow Cross flow Cross flow Cross flow

Cooling rpm 1230/1150/1000 1230/1150/1000 1060/970/880

1060/970/880

Heating rpm N/A 1230/1150/1000 N/A

1060/970/880

Dry rpm 1000 1000 880 880

Indoor fan speed

H/M/L

Sleep rpm 1000 1000 880 880

Indoor fan motor output W 12 12 25 25

Outdoor air circulation m3/h --- --- --- --Outdoor fan type Propeller fan Propeller fan Propeller fan Propeller fan

Outdoor fan speed rpm 860 860 850 850

Outdoor fan motor output W 55 55 85 85

Connections

Refrigerant coupling Flare type

Gas Inches 3/4 3/4 3/4 3/4

Connecting Pipe

Liquid Inches 7/16 7/16 7/16 7/16

Connecting Wiring

Size × Core

number

Drainage Pipe O.D 16mm

Others

Suitable area m2 16~28 16~28 30~40 30~40

Indoor mm 770×250×179 770×250×179 1036×313×204 1036×313×204Net dimensions

(W x H x D)

Outdoor mm 760×255×540 760×255×540 890×307×660 890×307×660

Indoor kg 8.0 8.0 13 13

Net weight

Outdoor kg 37 37 48 48

Indoor mm 863×325×270 863×325×270 1103×395×280 1103×395×280Packing dimensions

(W x H x D)

Outdoor mm 863×376×605 863×376×605 990×405×705 990×405×705

Indoor kg 10 10 10 10

Gross weight

Outdoor kg 35 36 35 36

Loading Capacity 40’/40’HC 112/236/248 112/236/248 66/142/162 66/142/162

Page 7

TCL Air Conditioner Service Manual

7

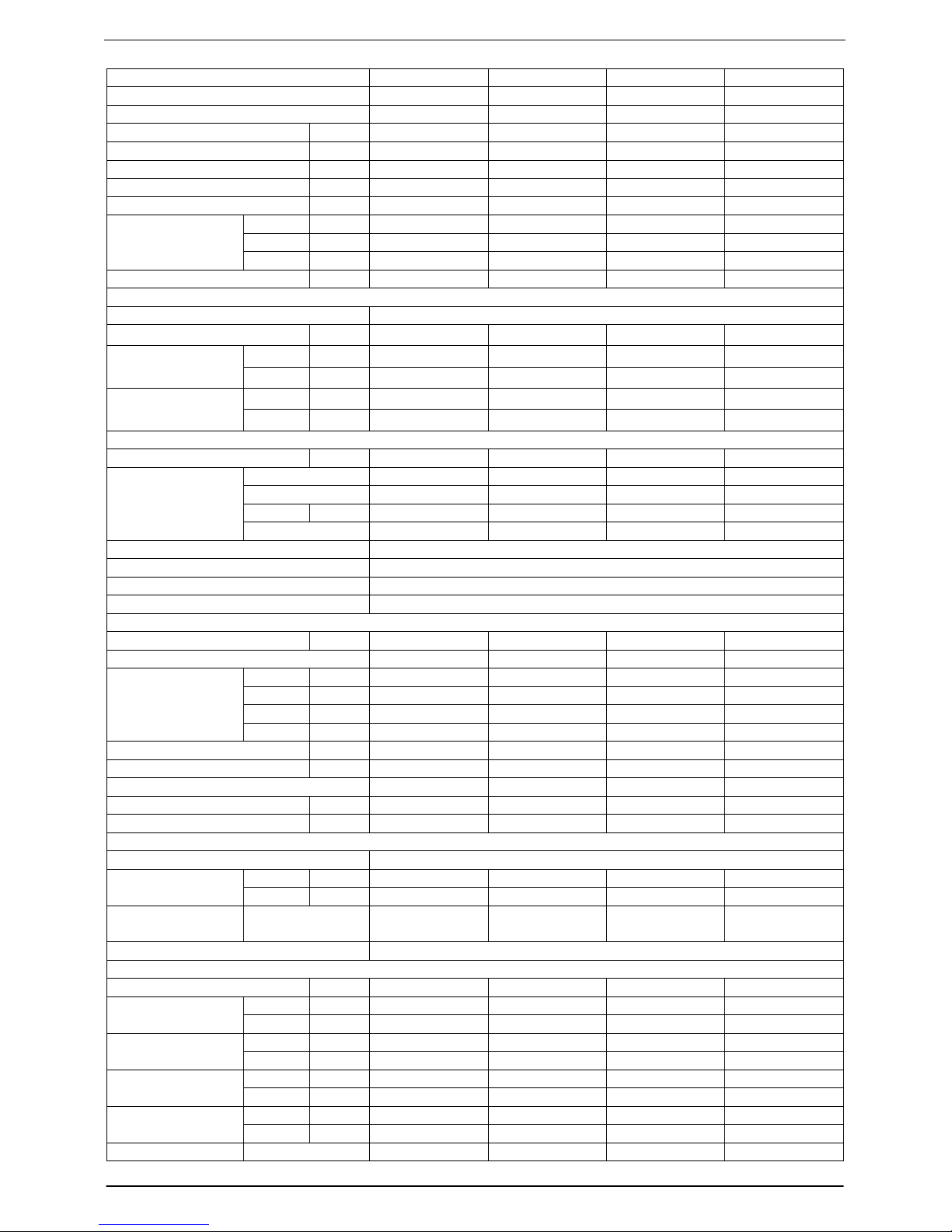

Model No. TAC-24CS/K TAC-24CHS/K TAC-24CSC/K TAC-24CHSC/K

Type Cooling Only Heating Pump Cooling Only Heating Pump

Control type Remote Remote Remote Remote

Rated cooling capacity Btu/h 24,000 24,000 24,000 24,000

Rated heating capacity Btu/h N/A 26,000 N/A 26,000

EER for cooling Btu/h.w 9.0 9.0 9.2 9.2

COP for heating W/W N/A 2.55 N/A 2.8

Moisture removal Liters/h 2.2 2.2 2.2 2.2

High dB(A) 47 47 47 47

Med. dB(A) 44 44 44 44

Indoor noise level at

cooling

Low dB(A) 40 40 40 40

Outdoor noise level dB(A) 58 58 58 58

Electrical Data

Power supply 220-240V~/50Hz

Voltage Range V 198~264 198~264 198~264 198~264

Cooling A 13 13 11.8 11.8

Rated current

Heating A N/A 13.8 N/A 11.8

Cooling W 2600 2600 2600 2600

Rated input

Heating W N/A 2800 N/A 2600

Refrigerating System

Refrigerant/Charge Gram R22/2500g R22/2500g R407C/2540g R407C/2540g

Type Rotary Rotary Rotary Rotary

Model ------------------ ----------------- ------------------ ------------------

LRA A ------ ------- ------ ------

Compressor

MFG ----------------- ----------------- ---------------- ----------------Evaporator Louver fin and Grooved tube type (φ7)

Condenser Corrugated fin and Grooved tube type (φ9.53)

Expansion device Capillary tube

Defrosting system Microcomputer controlled reverse system

Fan System

Indoor air circulation m3/h 1000 1000 1000 1000

Indoor fan type Cross flow Cross flow Cross flow Cross flow

Cooling rpm 1300/1200/1100 1300/1200/1100 1300/1250/1150 1300/1250/1150

Heating rpm N/A 1300/1200/1100 N/A 1300/1250/1150

Dry rpm 1000 1000 1150 1150

Indoor fan speed

H/M/L

Sleep rpm 1000 1000 1150 1500

Indoor fan motor output W 35 35 35 35

Outdoor air circulation m3/h --- --- --- --Outdoor fan type Propeller fan Propeller fan Propeller fan Propeller fan

Outdoor fan speed rpm 850 850 850 850

Outdoor fan motor output W 110 110 85 85

Connections

Refrigerant coupling Flare type

Gas Inches 7/8 7/8 7/8 7/8

Connecting Pipe

Liquid Inches 5/8 5/8 5/8 5/8

Connecting Wiring

Size × Core

number

Drainage Pipe O.D 16mm

Others

Suitable area m2 35~48 35~48 35~48 35~48

Indoor mm 1036×313×204 1036×313×204 1036×313×204 1036×313×204

Net dimensions

(W x H x D)

Outdoor mm 890×307×660 890×307×660

890×307×660

890×307×660

Indoor kg 16 16 16 16

Net weight

Outdoor kg 57 60 57 60

Indoor mm 1103×395×280 1103×395×280 1103×395×280 1103×395×280Packing dimensions

(W x H x D)

Outdoor mm 990×405×705 990×405×705 990×405×705 990×405×705

Indoor kg 20 20 20 20

Gross weight

Outdoor kg 63 65 63 65

Loading Capacity 40’/40’HC 66/142/162 66/142/162 66/142/162 66/142/162

Note: The technical specifications is only reference.

Page 8

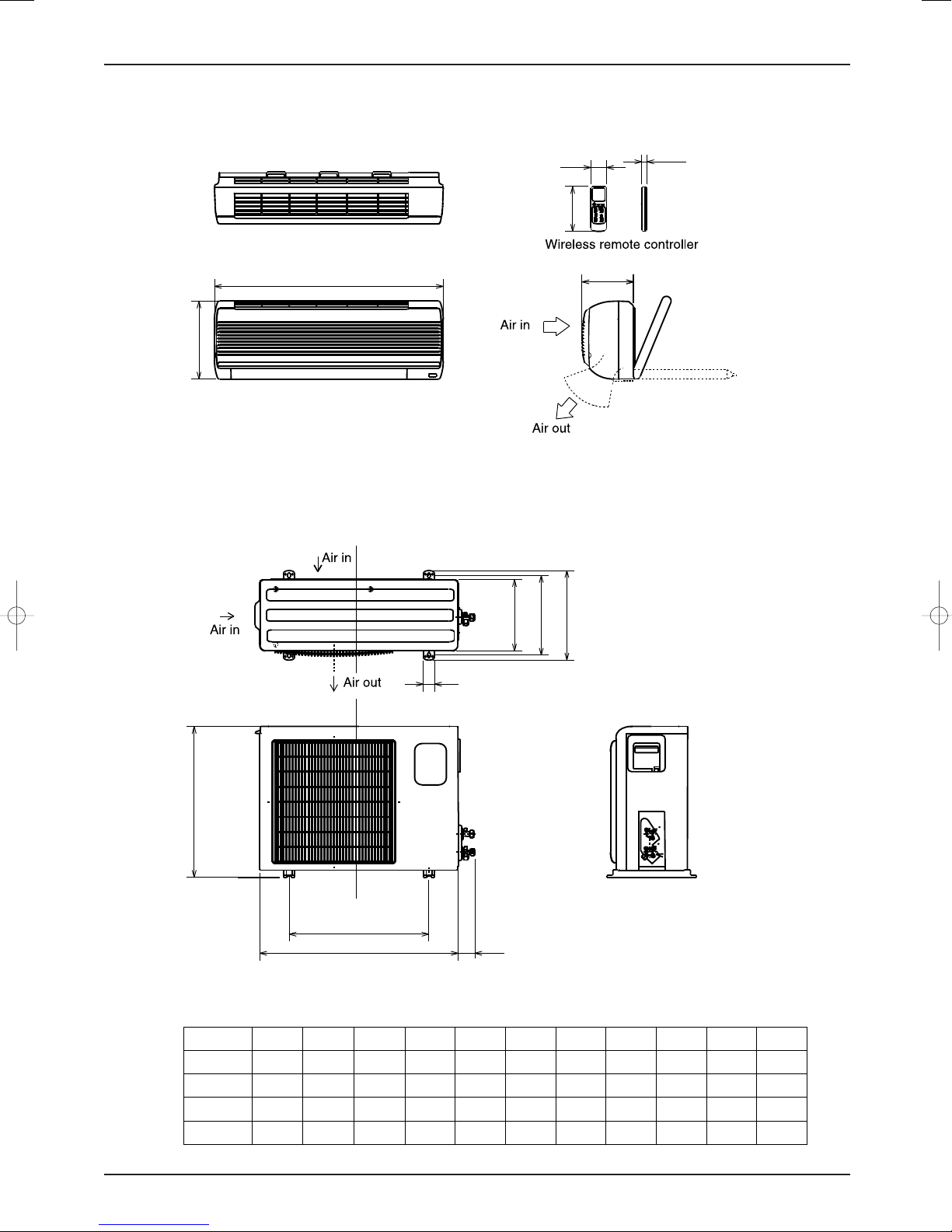

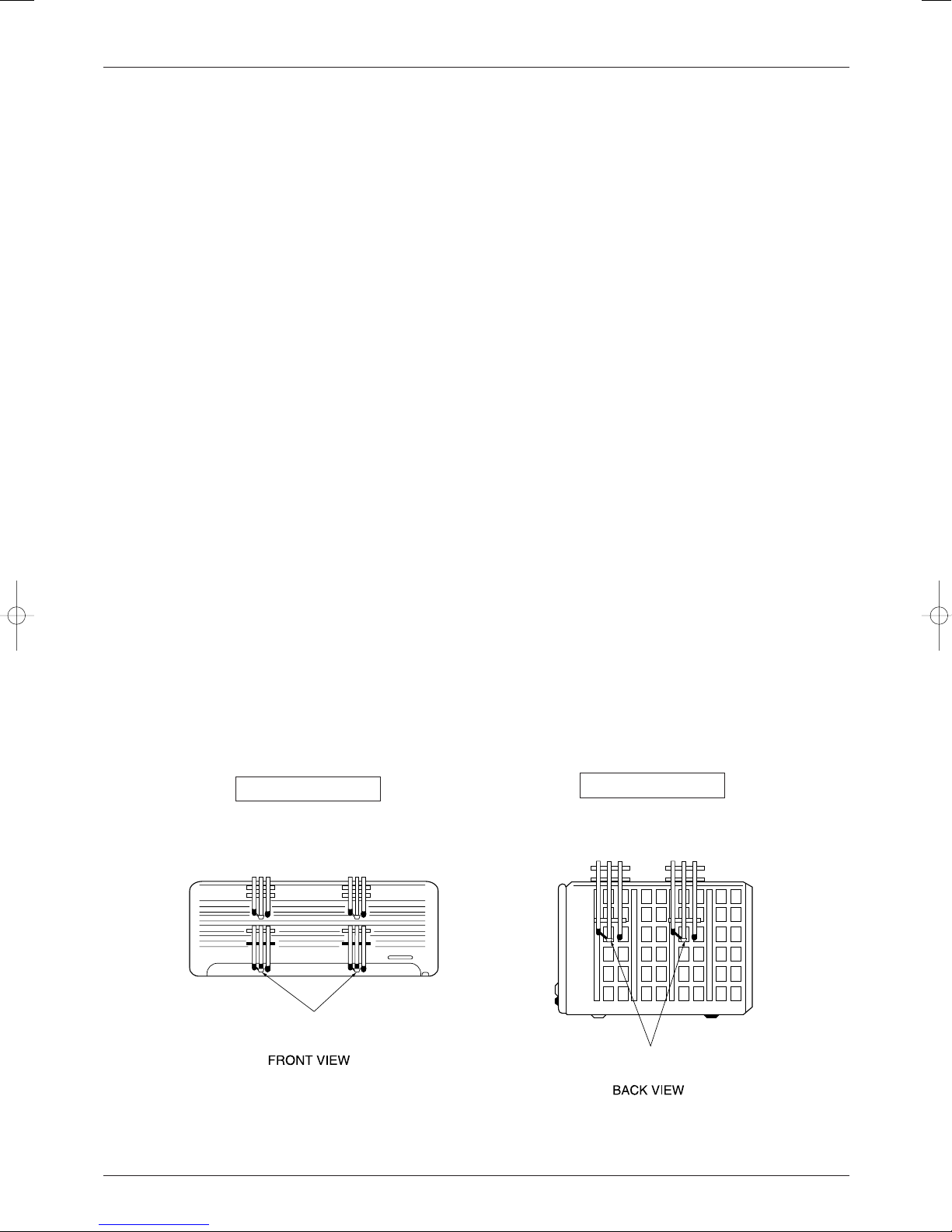

Product Dimensions

Outdoor Unit

Indoor Unit

A

B

16mm

124mm

54 mm

C

H

G

F

I

K

J

D

E

Unit: mm

TCL Air Conditioner Service Manual

8

Capacity A B C D E F G H I J K

7K&9K 710 250 179 600 500 231 271 296 52 365

12K 770865 250 179 700 540 255 290 320 40 439 55

18K 1036 313 204 760 540 255 340 370 62 635 63

24K 1036 313 204 860 730 307 340 370 62 635 63

55

Page 9

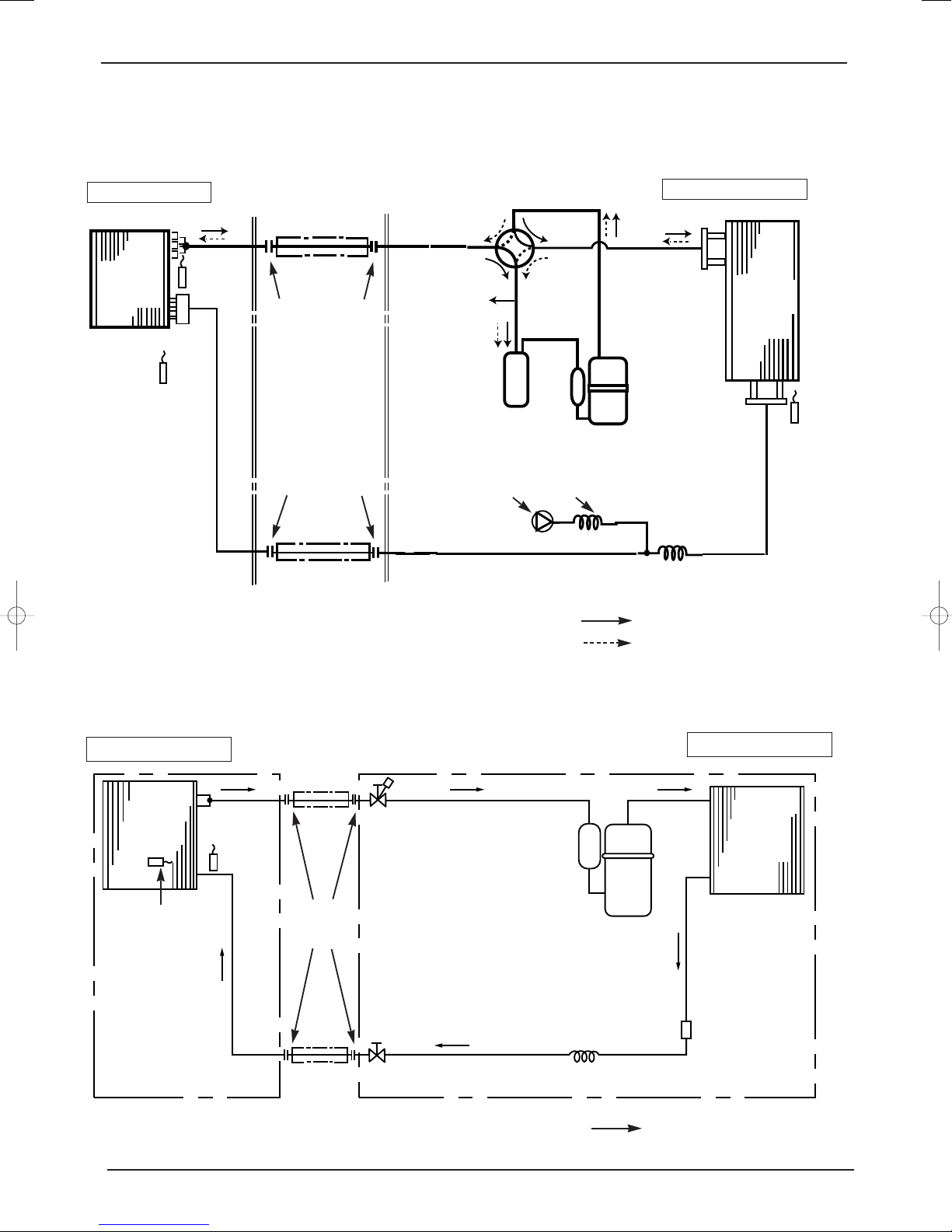

Heat Pump

Cooling Only

Refrigerating Cycle System

TCL Air Conditioner Service Manual

9

INDOOR UNIT

Indoor coil

Indoor

heat

exchanger

Room temperature

thermistor

thermistor

Distributor

Refrigerant pipe

(Option)

(with heat insulator)

Flared connection

Flared connection

Refrigerant pipe

(Option)

(with heat insulator)

Reversing valve

(4- way valve)

Accumulator

Check

valve

Compressor

Capillary tube

Capillary tube

OUTDOOR UNIT

Outdoor

heat

exchanger

Defrost

thermistor

Refrigerant flow in cooling or Defrosting

Refrigerant flow in heating

INDOOR UNIT

Indoor

heat

exchanger

Room temperature

thermistor

Indoor coil

thermistor

Refrigerant pipe

(Optional)

(with heat insulator)

Flared

connection

Refrigerant pipe

(Option)

(with heat insulator)

Stop valve

(with service port)

Stop valve

Compressor

Capillary tube

OUTDOOR UNIT

Outdoor

heat

exchanger

Strainer

Refrigerant flow in cooling

Page 10

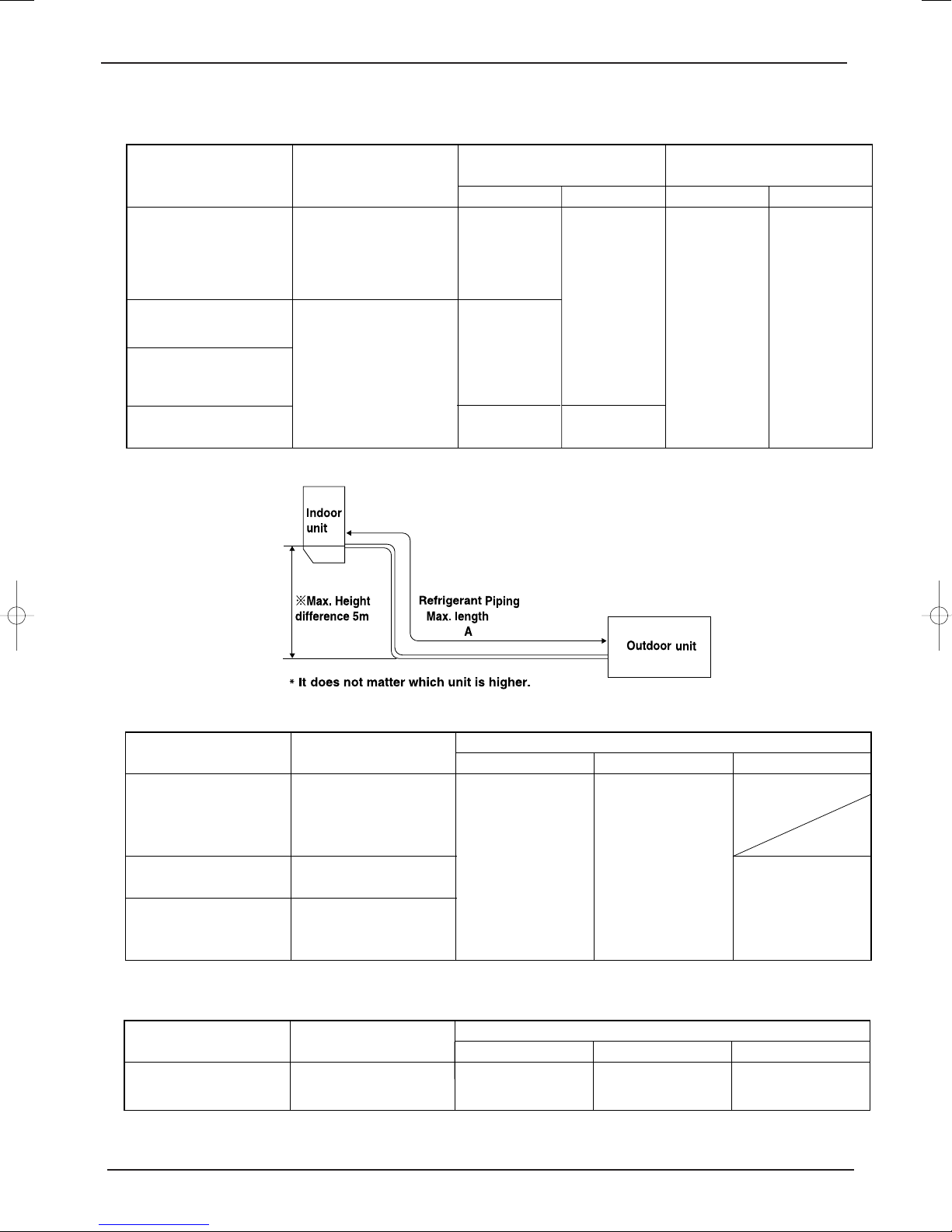

MAX. REFRIGERANT PIPING LENGTH

Models

Outdoor unit precharged

(up to 7m)

Refrigerant piping length (one way)

15m

240

7m

0

10m

90

24

K

10

TCL Air Conditioner Service Manual

Refrigerant piping

Models

07K

09K

Max. length : m

A

10

Piping size O.D : mm Length of connecting pipe : m

Gas

Liquid

Indoor unit

Outdoor unit

9.52

12K

18K

15

24K

MAX. HEIGHT DIFFERENCE

ADDITIONAL REFRIGERANT CHARGE(R-22 : g)

Models

07K

09K

12K

18

K

Outdoor unit precharged

(up to 7m)

see <<Specification>>

see <<Specification>>

see <<Specification>>

12.7

15.88

6.35

9.52

Refrigerant piping length (one way)

7m

0

10m

60

0.40

0

15m

160

see <<Specification>>

Calculation : Xg=20g/m ✕ (A-7)m

Calculation : Xg=30g/m ✕ (A-7)m

Page 11

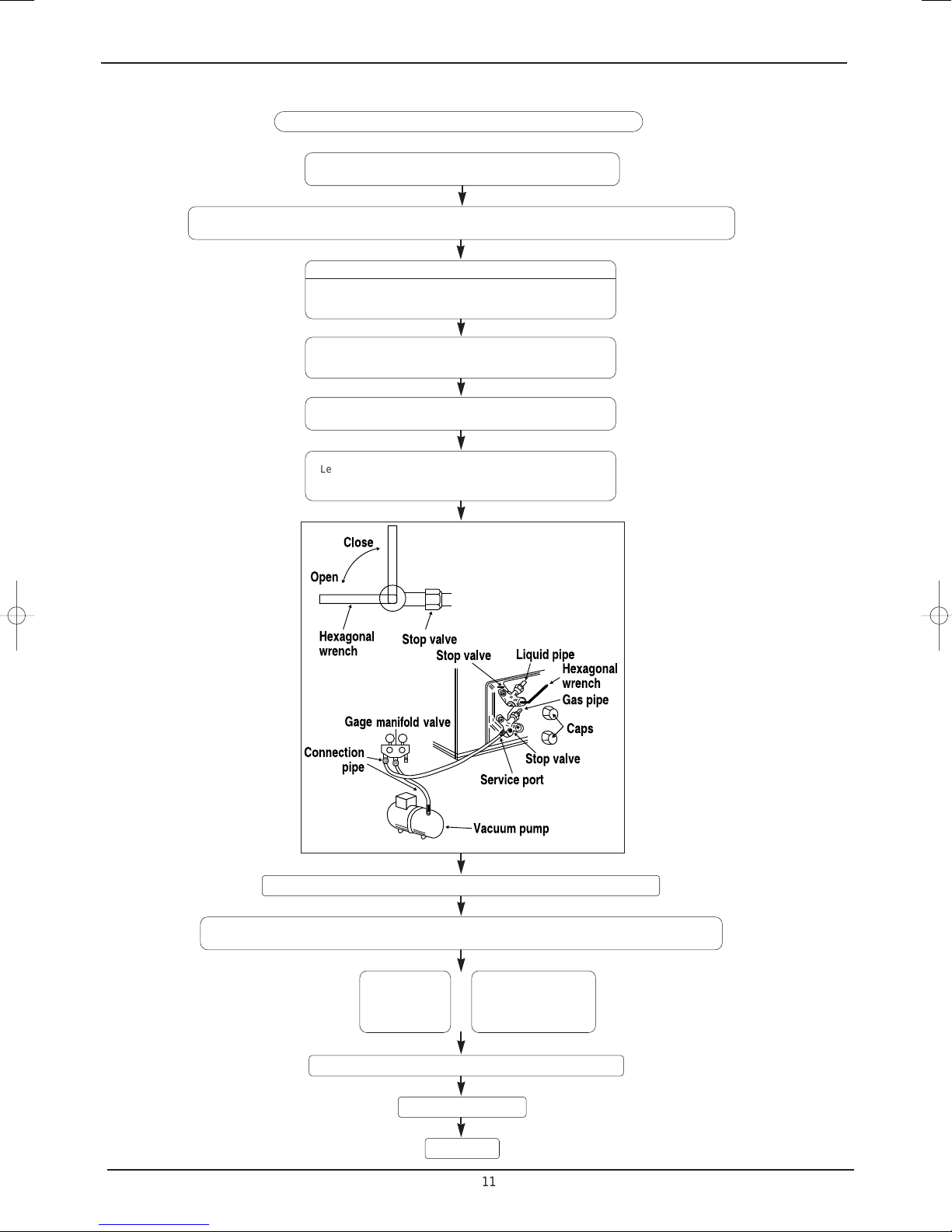

EVACUATION PROCEDURES(AIR PURGE)

11

TCL Air Conditioner Service Manual

Connect the refrigerant pipes (both the liquid and gas pipes)

between the indoor and the outdoor units.

Remove the service port cap of the stop valve on the side of the outdoor unit gas pipe.(The stop valve will not

work in its initial state fresh out of the factory (totally closed with cap on))

When vacuuming

Connect the gage manifold valve and the vacuum pump to

the service port of the stop valve on the liquid pipe side of the

outdoor unit.

Run the vacuum pump for more than 15 minutes and at this

time confirm that the pressure gage indicates – 0.1 Mpa.

Check the vacuum with the gage manifold valve, then close

the gage manifold valve, and stop the vacuum pump.

Leave it as it is for one or two minutes. Make sure the pointer

of the gage manifold valve remains in the same position.

Remove the gage manifold valve quickly from the service port of the stop valve.

After refrigerant pipes are connected and evacuated, fully open all stop valves on gas and liquid pipe sides.

Operating without fully opening lowers the performance and causes trouble.

Pipe length :

7m maximum

No gas charge

is needed

Tighten the cap to the service port to obtain the initial status.

Pipe length

exceeding 7m

Charge the prescribed

amount of gas

Retighten the cap.

Leak test

Page 12

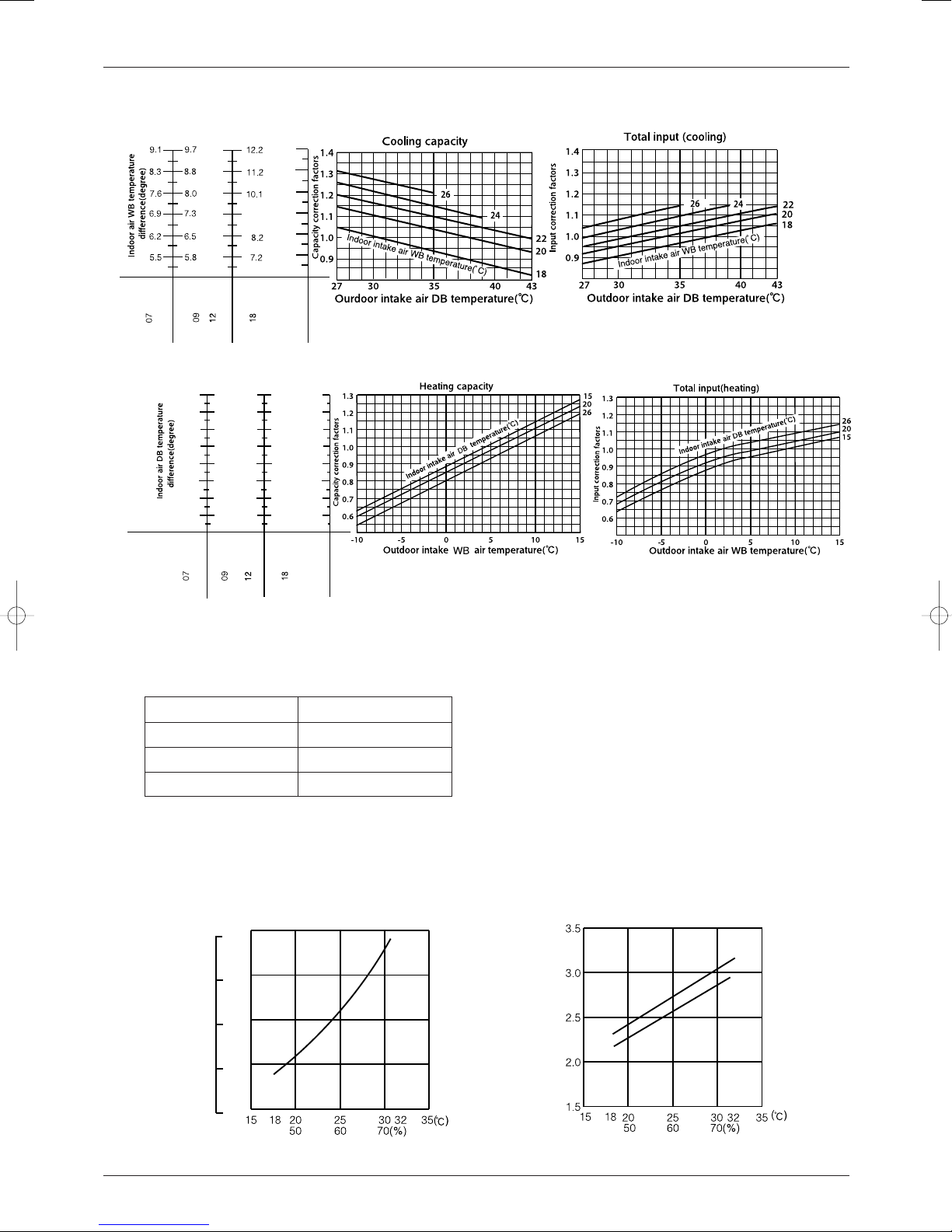

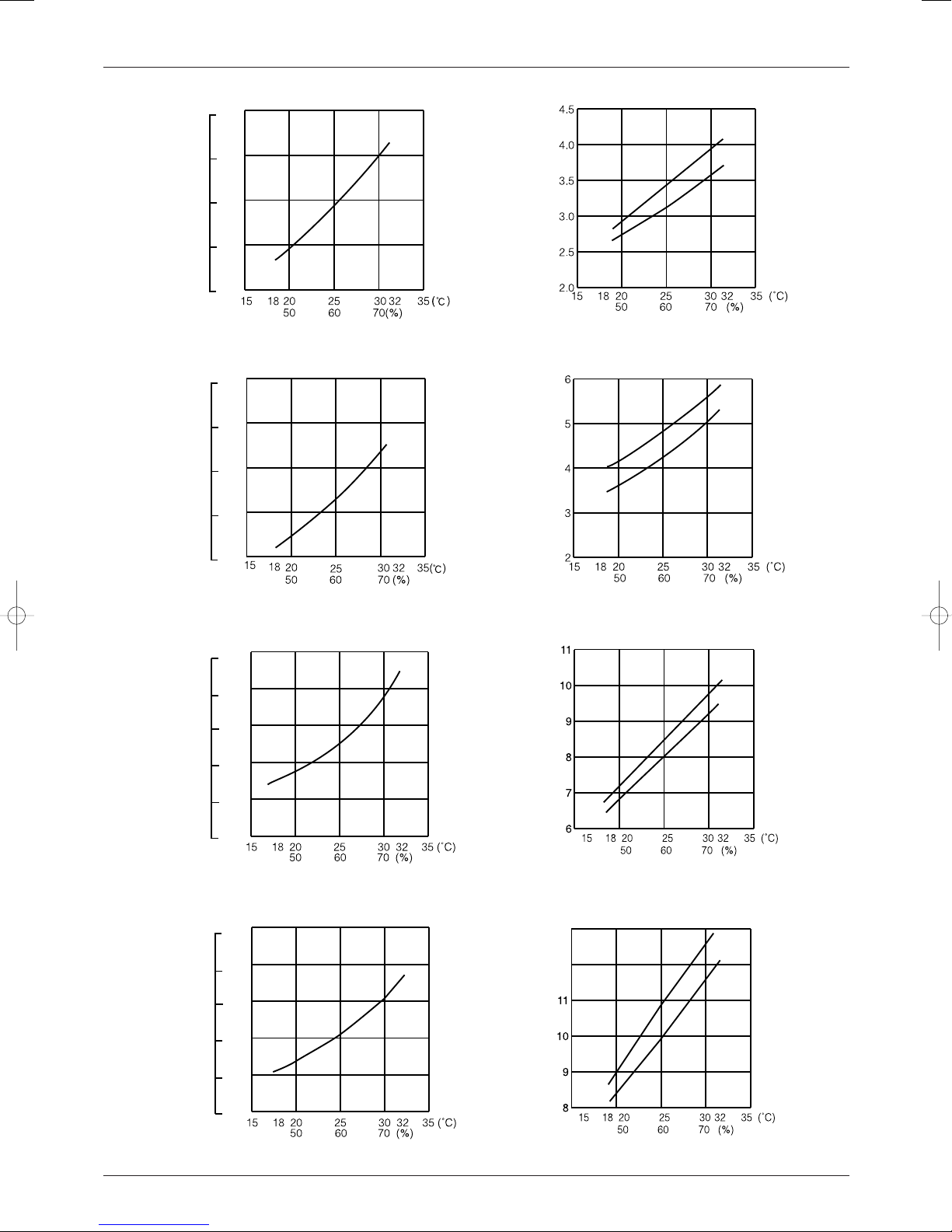

12

The standard data contained in these specifications apply only to the operation of the air conditioner under normal conditions,

Wet-and dry-bulb

thermometers

Wet-and dry-bulb

thermometers

TCL Air Conditioner Service Manual

PERFORMANCE CURVES

since operating conditions vary according to the areas where these units are installed. The following information has been provided to clarify the operating characteristics of the air conditioner under the conditions indicated by the performance curve.

(1) GUARANTEED VOLTAGE

Rated voltage : ±10% (198 ~ 264V

),50Hz

(2) AIR FLOW

Air flow should be set at MAX.

(3) MAIN READINGS

(1) Indoor intake air wet-bulb temperature : °CWB

(2) Indoor outlet air wet-bulb temperature : °CWB

(3) Outdoor intake air dry-bulb temperature : °CDB

(4) Total input: W

(5) Indoor intake air dry-bulb temperature : °CDB

(6) Outdoor intake air wet-bulb temperature : °CWB

(7) Total input : W

Indoor air wet/dry-bulb temperature difference on the left side of the chart on next page shows the difference between the

indoor intake air wet/dry-bulb temperature and the indoor outlet air wet/dry-bulb temperature for your reference at service.

How to measure the indoor air wet-bulb/dry-bulb temperature difference

1. Attach at least 2 sets of wet-and dry-bulb thermometers to the indoor air intake as shown in the figure, and at least 2 sets

of wet-and dry-bulb thermometers to the indoor air outlet. The thermometers must be attached to the position where air

speed is high.

2. Attach at least 2 sets of wet-and dry-bulb thermometers to the outdoor air intake.

Cover the thermometers to prevent direct rays of the sun.

3. Check that the air filter is cleaned.

4. Open windows and doors of room.

5. Press the EMERGENCY OPERATION switch once(twice) to start the EMERGENCY COOL(HEAT) MODE.

6. When system stabilizes after more than 15 minutes, measure temperature and take an average temperature.

7. 10 minutes later, measure temperature again and check that the temperature does not change.

}

}

Cooling

Heating

INDOOR UNIT

OUTDOOR UNIT

Page 13

13

0.7

0.6

0.5

0.4

0.3

7

6

5

4

3

Outdoor low pressure

Ambient temperature(˚C)

Ambient humidity(%)

Ambient temperature(˚C)

Ambient humidity(%)

07K

07K

Outdoor unit current (A)

220V

240V

220/240V

(kgf/F•G)(MPa•G)

9.1

11.4

7.6

8.5

9.4

10.4

12.0

12.7

8.1

9.2

10.3

11.5

14.0

24

25.5

23.5

21.6

19.6

17.6

15.6

13.7

11.7

28.7

26.5

24.3

22.5

19.9

17.7

15.5

13.2

28.0

25.9

23.7

21.6

19.4

17.2

15.1

12.9

28.0

25.9

23.7

21.6

19.4

17.2

15.1

12.9

19.9

18.4

16.9

15.3

13.8

12.3

10.7

9.2

24

NOTE:The above curves are for the heating operation without any frost.

OUTDOOR LOW PRESSURE AND OUTDOOR UNIT CURRENT

COOL operation

① Both indoor and outdoor unit are under the same temperature/humidity condition.

➁ Air flow should be set at MAX.

Dry-bulb temperature

Relative humidity(%)

20

50

25

60

30 70

③ The unit of pressure has been changed to MPa on the international system of units(SI unit system).

The conversion factor is : 1(MPa • G) =10.2(kgf/

ff

• G)

TCL Air Conditioner Service Manual

Page 14

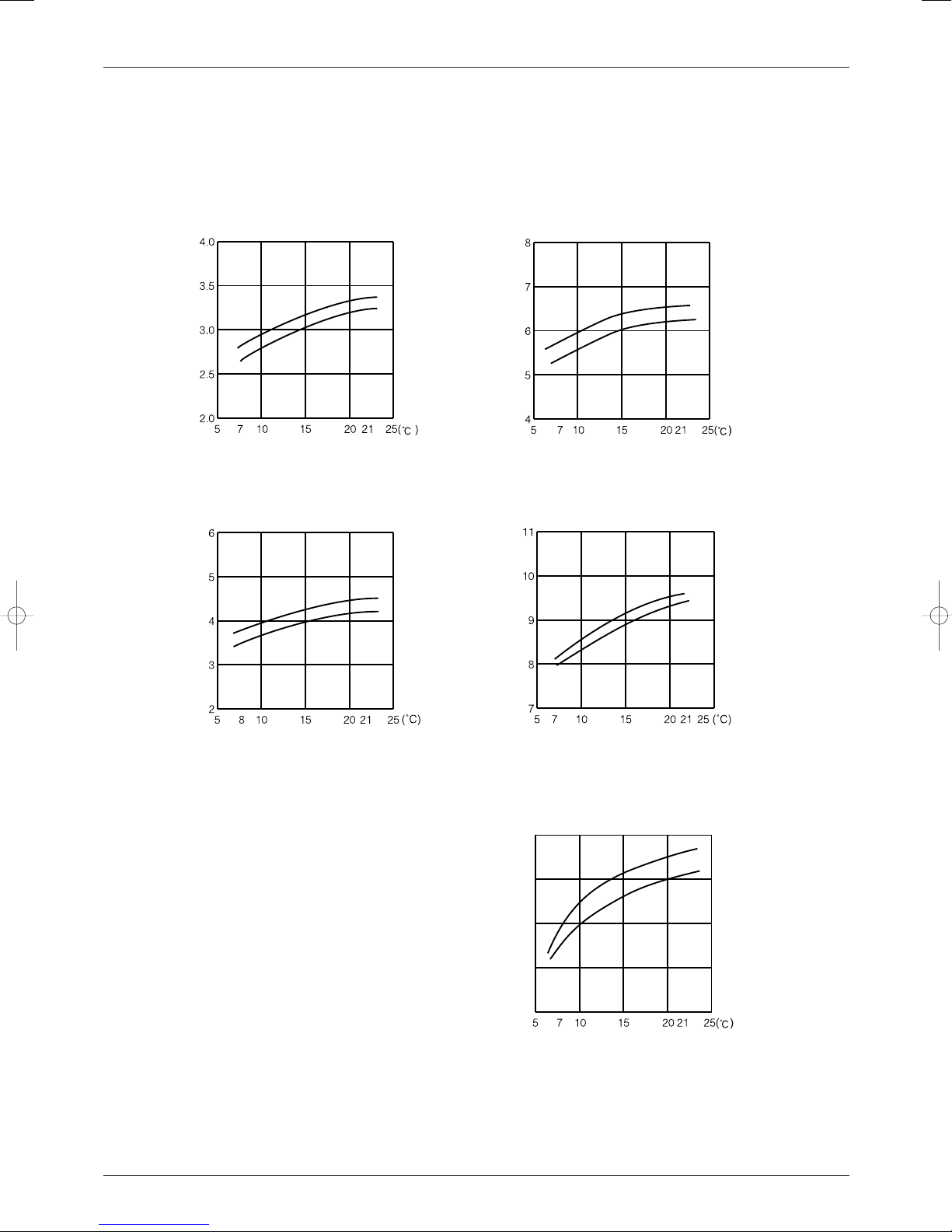

12K

12K

Outdoor low pressure

Ambient temperature(˚C)

Ambient humidity(%)

Ambient temperature(˚C)

Ambient humidity(%)

Outdoor unit current (A)

220V

240V

0.7

0.6

0.5

0.4

0.3

7

6

5

4

3

09K

09K

Outdoor low pressure

220V

240V

Ambient temperature(˚C)

Ambient humidity(%)

Ambient temperature(˚C)

Ambient humidity(%)

Outdoor unit current (A)

220/240V

220/240V

(kgf/F•G)(MPa•G)

(kgf/F•G)(MPa•G)

0.7

0.6

0.5

0.4

0.3

0.2

7

6

5

4

3

2

18K

18K

Outdoor low pressure

Ambient temperature(˚C)

Ambient humidity(%)

Ambient temperature(˚C)

Ambient humidity(%)

220V

240V

220/240V

Outdoor unit current (A)

(kgf/F•G)(MPa•G)

0.7

0.6

0.5

0.4

0.3

0.2

7

6

5

4

3

2

24K

Outdoor low pressure

Ambient temperature(˚C)

Ambient humidity(%)

220V

12

13

24K

Ambient temperature(˚C)

Ambient humidity(%)

220V

240V

Outdoor unit current (A)

(kgf/F•G)(MPa•G)

TCL Air Conditioner Service Manual

14

0.7

7

0.6

6

0.5

5

0.4

4

0.3

3

Page 15

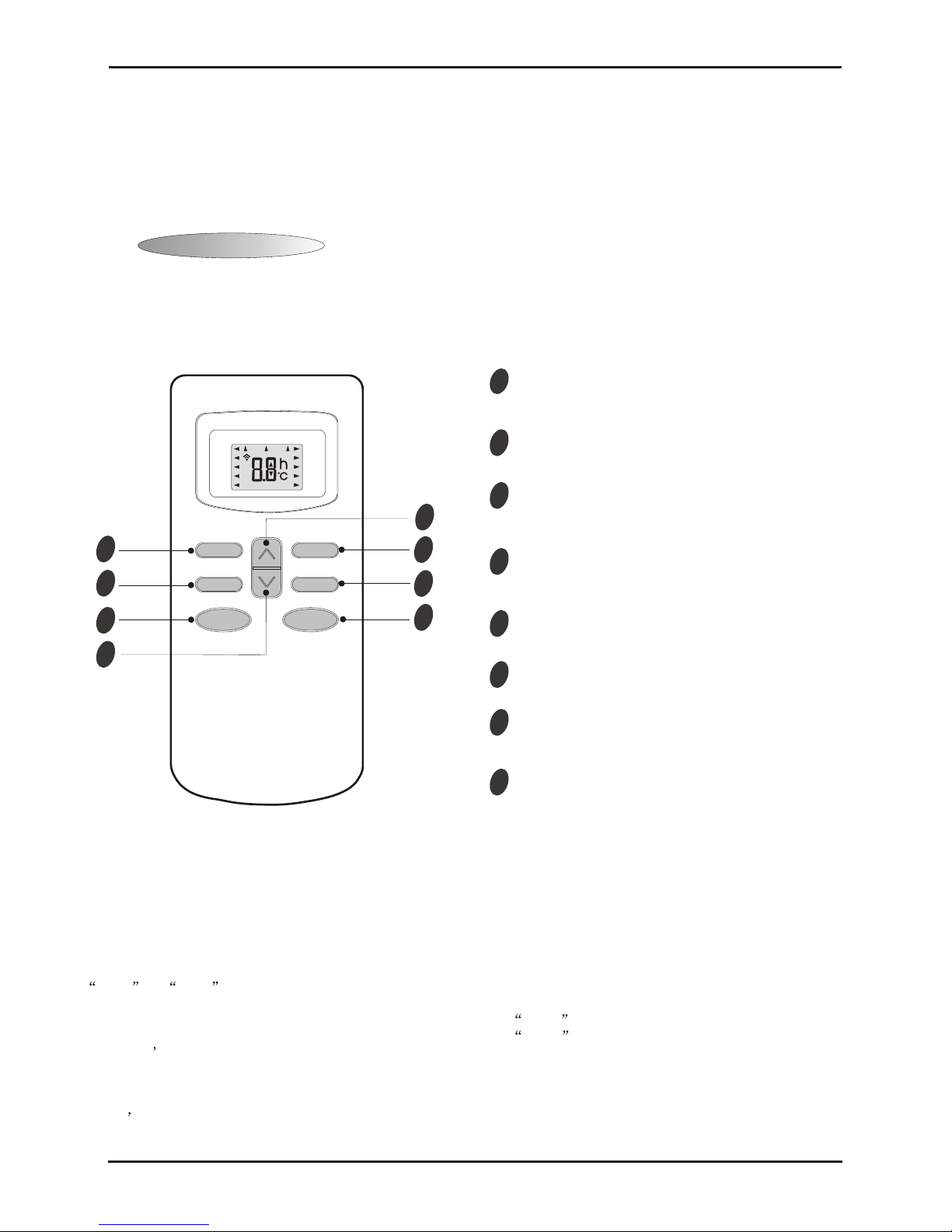

HEAT operation

Condition indoor:Dry bulb temperature 20.0°C

Wet bulb temperature 14.5°C

Outdoor:Dry bulb temperature 7,15,20°C

Wet bulb temperature 6,12,14.5°C

18K

07K

12K

13

12

11

10

9

TCL Air Conditioner Service Manual

15

Outdoor unit current (A)

Ambient temperature(˚C)

09K

220V

240V

220V

240V

220V

240V

Outdoor unit current (A)

Ambient temperature(˚C)

220V

240V

Outdoor unit current (A)

Ambient temperature(˚C) Ambient temperature(˚C)

Outdoor unit current (A)

24K

220V

Outdoor unit current (A)

Ambient temperature(˚C)

240V

Page 16

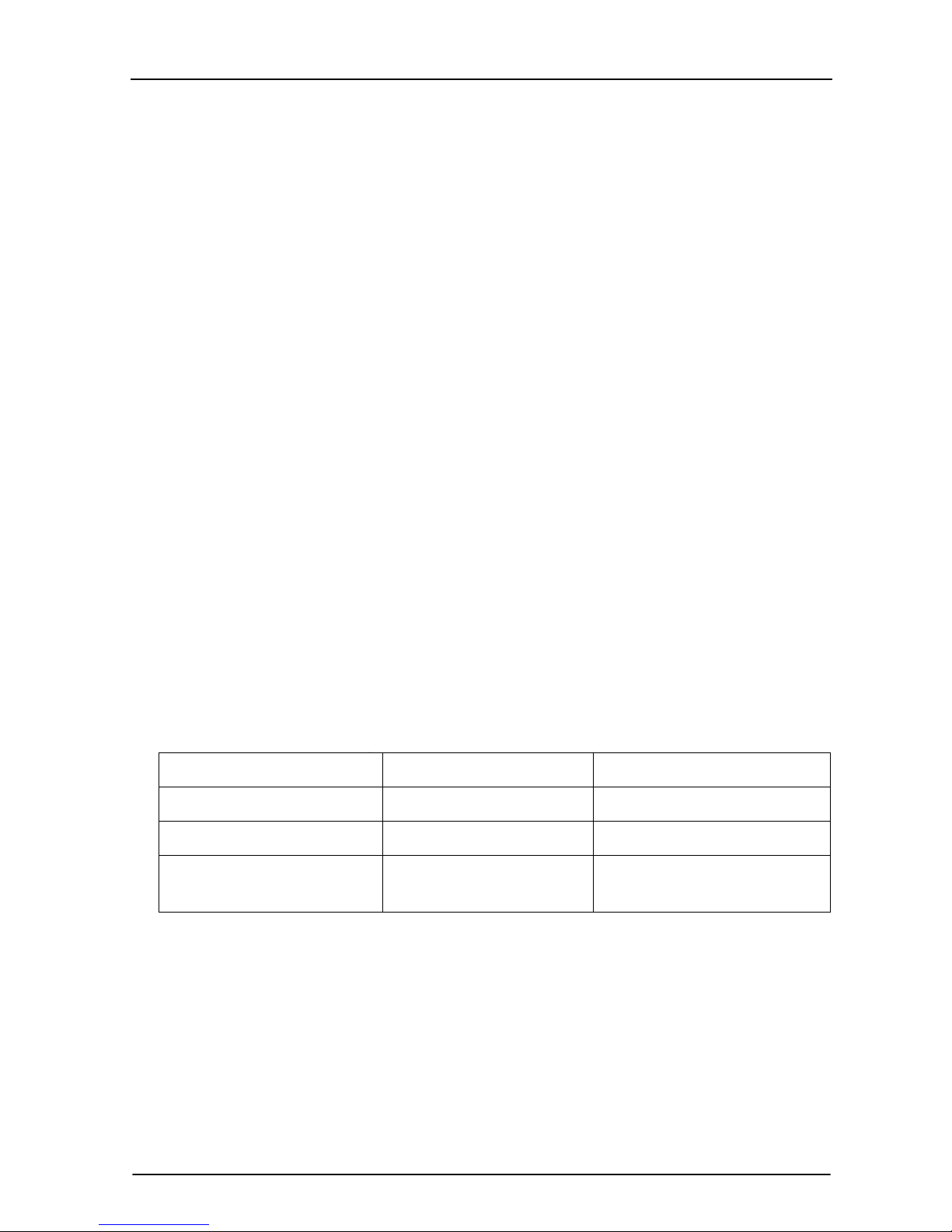

16

Note: Each mode and relevant function will be further specified in following pages.

SLEEP

FAN

TIMER

SWING

ON/OFF

MODE

MID

SWING

AUTO

DRY

FAN

HEAT

COOL

FEEL

SLEEP

TIMER ON

HIGH

LOW

TMIER OFF

The remote controller transmits signals to the system.

Remote controller

1

2

4

3

5

6

7

8

8

4

MODE button

FAN SPEED control button

UP button (TOO COOL button)

DOWN button (TOO WARM button)

ON/OFF button

SLEEP button

VANE control button

TIMER button

Used to select the type of operation mode: Feel,

Cooling, Dry, Fan and Heating(Only for Heat Pump).

Used to select the indoor fan motor speed:

Auto, High, Mid and Low.

Used to increase the set room temperature

and time.

Used to decrease the set room temperature

and time.

Used to set or cancel sleep mode operation.

Used to start and stop operation

when pressed.

Used to adjust airflow direction.

Used to select TIMER operation.

Remote controller

6

2

5

3

7

1

11

TCL Air Conditioner Service Manual

Operation Details

Remote Controller presetting

er presetting presetting as Cooling Only Air Conditioner or Heat Pump by

manufacturer.

Each time after the remote controller replace batteries or is energized, the arrowhead will flashes on the front of

Heat or Cool on LCD of the remote controller.

User can preset the remote controller type depending on the air conditioner type you have purchased as follows:

Press any button when the arrowhead flashes on the front of Cool , Cooling Only is set.

The remote controller is not

Press any button when the arrowhead flashes on the front of Heat , Heat Pump is set.

If you don t press any button within 10 seconds, the remote controller is preset as Heat Pump automatically.

Note :

If the air conditioner you purchased is a Cooling Only one, but you preset the remote controller as Heat Pump, it

doesn t bring any matter. But if the air conditioner you purchased is a Heat Pump one, and you preset the

remote controller as Cooling Only, then you CAN NOT preset the Heating operation with the remote controller.

Page 17

TCL Air Conditioner Service Manual

17

Elctronic Controller

1. Safety Control

(1) Time Delay Safety Control

3 minutes delay for compressor---The compressor is ceased for 3minutes to balance the pressure in the

refrigeration cycle in order to protect the compressor.

2 minutes delay for 4-way valve---The 4-way valve is ceased for 2 minutes to prevent the

refrigerant-gas abnormal noise when the HEATING operation is OFF or switch to the other operation

mode.

20 seconds delay for indoor fan--- When the assistant thermistor turn s off, the indoor fan operates in

low speed for 20 seconds to release the heat of indoor unit.

(2) Indoor Pipe Temperature Sensor Frost Prevention Control

When the indoor pipe temperature sensor reads 0℃ or below for 5 minutes, the indoor pipe temperature

sensor frost prevention control starts. The compressor and outdoor fan stop and indoor fa n operates at high

speed for 3 minutes. After that, if the indoor pipe temperature sensor reads less than 5℃ this control

prolonged until the indoor pipe temperature sensor reads 5℃ or more.

(3) High Temperature Protection Control

During HEATING operation, the outdoor fan motor and compressor are controlled by the indoor pipe

temperature to prevent the high temperature of compressor.

Outdoor fan OFF: 52℃

Outdoor fan ON:48℃

Compressor OFF:62℃

Compressor ON:48℃

2. “I Feel” Mode Operation

(1) When the “I Feel” mode is selected, the operation mode and initial set temperature are d etermined by the

initial room temperature at start-up of the operation except to turn off the air conditioner and operates it

again.

(2) If the mode is change to “I Feel” mode from other mode, the “I Feel” mode doesn’t operate until compressor

stop for more than 3 minutes.

In the “I Feel” mode , when the controller receives the up or down single of temperature, the set

temperature can adjust by 1

℃ upper or lower. The biggest you can adjust by 2℃ upper or lower.

3. “COOLING” Mode Operation

(1) When the COOLING mode is selected without setting temperature, the system will set the set temperature at

26

℃ automatically with the AUTO FAN speed.

(2) When selecting the COOLING mode operation, the system will operate according to the setting by the

remote controller and the operation is as following:

Mode

Initial room temperature

COOLING

DRY

HEATING for Heat Pump Type

FAN for Cooling Only Type

26℃ or more

20℃ to 25 ℃

Less than 20℃

Initial set temperature

24℃

18℃

23℃

Page 18

TCL Air Conditioner Service Manual

18

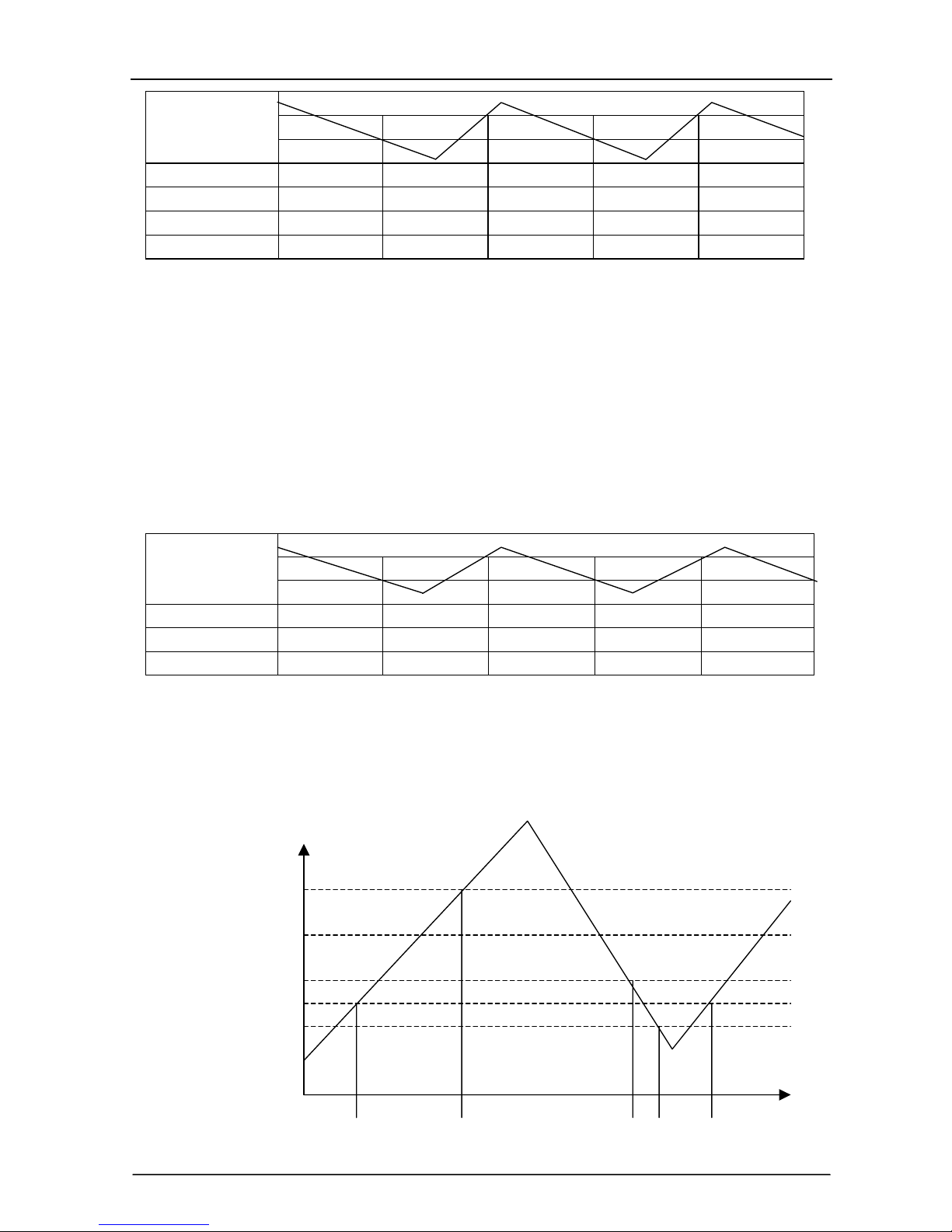

Room Temp.

Set TEMP. +1

℃

Set TEMP. -1

℃

Time

More than 2 min More than 2 min More than 2 min More than 2 min More than 2 min

Indoor Fan Set Speed Set Speed Set Speed Set Speed Set Speed

Compressor ON OFF ON OFF ON

Outdoor Fan ON OFF ON OFF ON

4. “DRY” Mode Operation

(1) The system for DRY operation used the same refrigerant circle as the cooling circle.

(2) When the system operates in DRY mode ,at first it operates in cooling mode at 18

℃ for 3 minutes, and

then, the system operates in cooling mode with low speed that regards the temperature of the room

temperature sensor reads decrease 2℃ as the set temperature. During the course of this, the fan speed

setted operation is failing but the vane motor can be controlled.

5. “HEATING” Mode Operation (Only available for Heat Pump)

(1) When the HEATING mode is selected without setting temperature, the system will set the temperature at 23

℃ automatically with the AUTO FAN speed.

(2) When selecting the HEATING mode operation, the system will operate according to the setting by the

remote controller and the operation is as following:

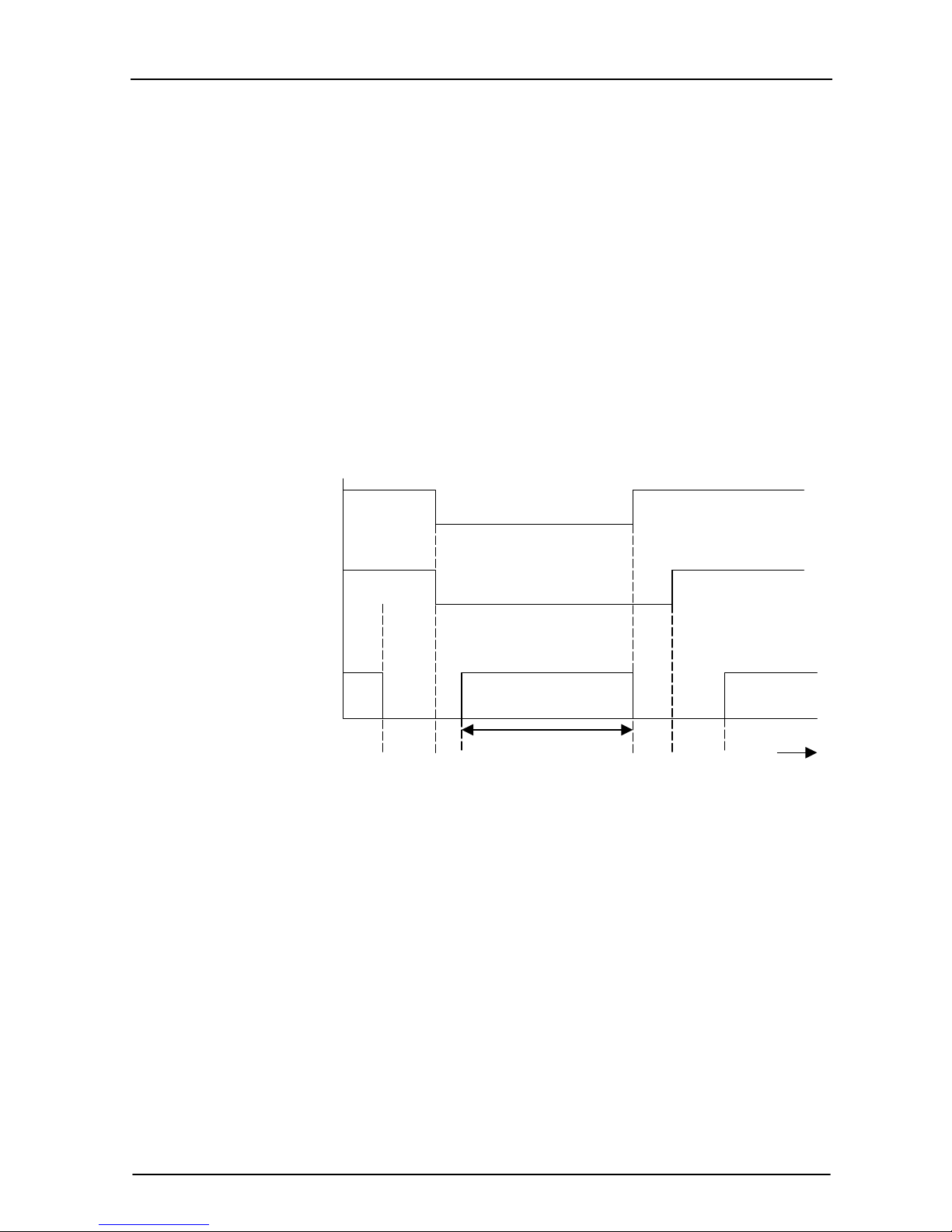

Set T emp. +1℃

Set T emp. -1

℃

Room Temp.

Time

More than 2 min More than 2 min More than 2 min More than 2 min More than 2 min

Compressor ON OFF ON OFF ON

Outdoor fan ON OFF ON OFF ON

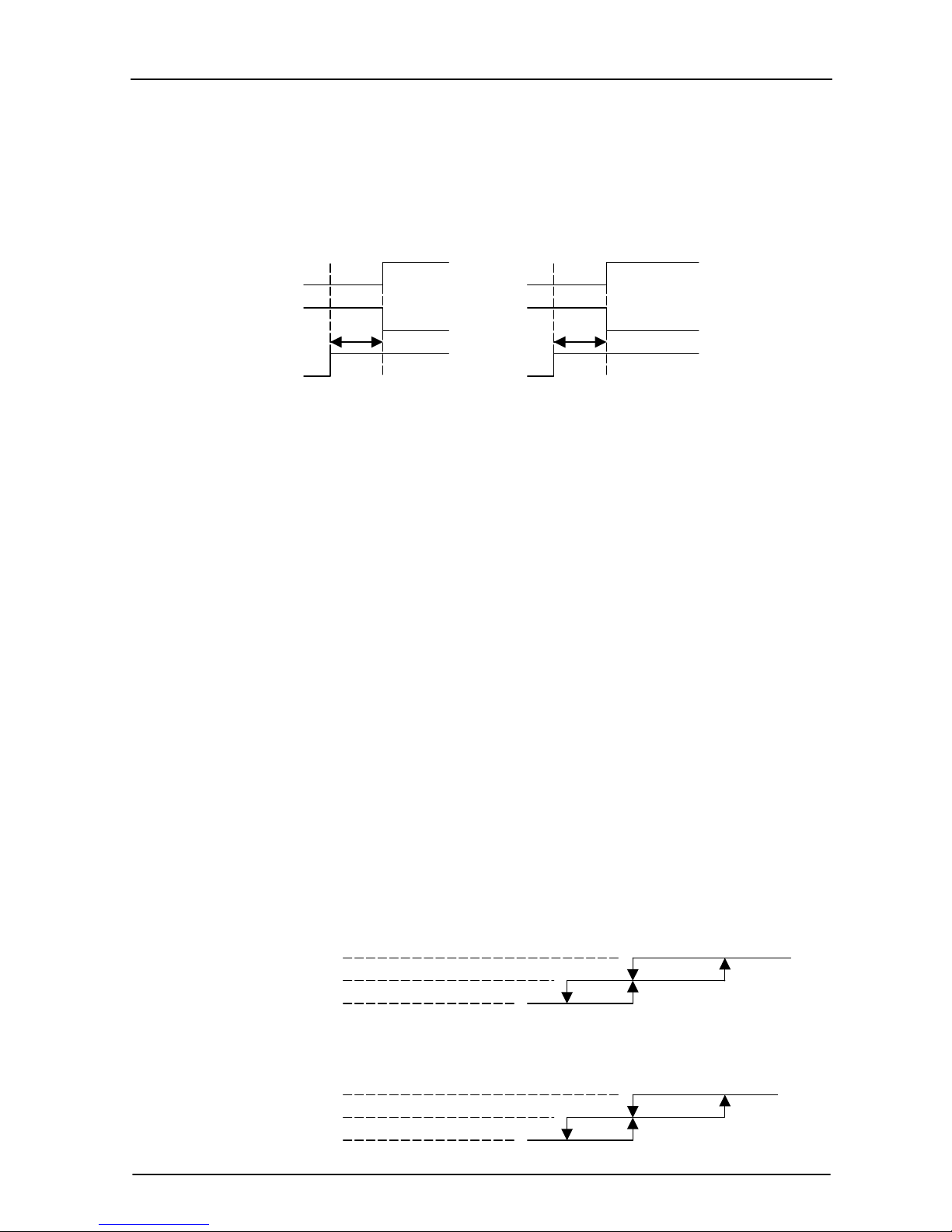

(3) In HEATING mode, the indoor fan motor is controlled by Cold Air Prevention Control.

(4) Cold Air Prevention Control

The function is intend to prevent cold air from being discharged when the heating operation starts or

when defrosting.

The indoor fan speed will be controlled as following:

The vane angle is at the angle C(100°).

34

℃

30

℃

27

℃

25

℃

23

℃

OFF UL Set Speed UL OFF UL

Indoor Pipe Temperature

Page 19

TCL Air Conditioner Service Manual

19

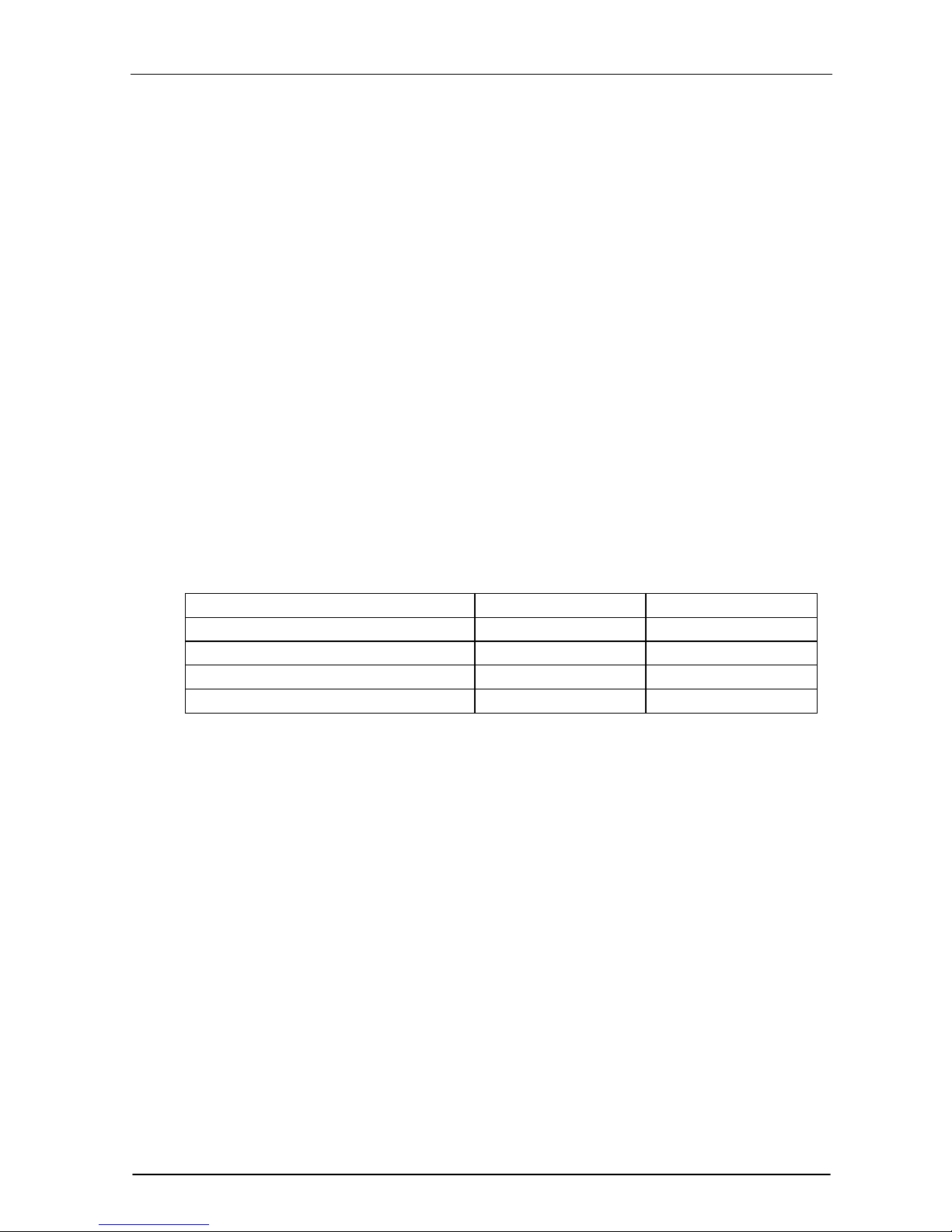

(5) Defrost

Defrosting of the outdoor heat exchange is controlled by the microprocessor with detection by the defrost

sensor.

Defrost starting conditions

When the conditions of a) or b) is satisfy, the defrosting operation starts.

a) Under the heating operation, the compressor cumulative operation time exceeds 50 minutes and the

temperature of the outdoor defrost sensor reads lower than -8

℃

b) Under the heating operation, the compressor cumulative operation time exceeds 50 minutes, if the

indoor pipe temperature sensor reads lower than 40

℃ continuously for 2minutes.

Note: If haven’t the outdoor pipe temperature sensor that use the condition b) to defrost, against

use the condition a).

Defrost terminating conditions

When the condition c) or d) is satisfy, the defrosting operation stops.

c) The outdoor defrost sensor reads 15

℃ or more.

d) The defrosting time exceeds 10 minutes.

Defrosting time chart

Outdoor Fan ON OFF ON

Revering Valve ON OFF ON

Compressor Relay ON OFF ON OFF ON

39S 5S Defrost Count MAX 12min 19S 15S t

(6) Assistant Thermistor Function

Assistant thermistor is add the thermitor of the electricity to rise the heating capacity automatically not

effected by the signal of the remote controller about assistant thermistor ON/OFF buttons.

1) When the condition all of A~G are satisfy, the assistant thermistor opens.

A. Under the heating operation, the compressor operates over than 3 minutes.

B. The indoor fan operates in normal.

C. The system operates not in defrosting.

D. The assistant thermistor turn off over than 30 seconds.

E. The set temperature is 3

℃ or more than the room temperature.

F. The room temperature sensor reads less than 22

℃.

G.

The indoor pipe temperature reads 43℃ or less.

2) When one of the conditions of A~E is satisfy, the assistant thermistor is off.

A. The compressor is turned off.

B. The room temperature sensor reads 24℃ or more.

C.

The indoor pipe temperature sensor reads 48℃ or more.

D.

The indoor fan is stopped.

6. “FAN” mode operation

Page 20

TCL Air Conditioner Service Manual

20

The indoor fan motor always turns on at the set speed and the vane motor turns on at the set fattle.

7. 4-way Valve contro

HEATING ON

COOLING/DRY OFF

The 4-way valve reverses for 5 seconds right before start-up of the compressor as following chart:

COOLING/DRY HEATING

Compressor

4-way Valve

5s 5s

Outdoor Fan

8. “SLEEP” mode

When the SLEEP button is pressed, the SLEEP mode is selected as following:

The indoor fan speed is set at the super low speed.

When selecting COOLING/DRY operation with SLEEP mode, the set te mperature will be raised by 1

℃ 1

hour later and by 2℃ 2 hour later.

When selecting HEATING operation with SLEEP mode, the set temperature will be dropped by 1℃ 1

hour later and 2℃ 2hour later.

After the System operates in SLEEP mode for 8 hours, it will stop automatically.

9. Fan motor control

(1) Rotational frequency feedback control

The indoor fan motor is equipped with a rotational frequency sensor, and outputs signal to the

microprocessor to feedback the rotational frequency. Comparing the cu rrent rotational frequency with the

target rotational frequency, the microprocessor adjusts fan motor electric to make the current rotational

frequency close to the target rotational frequency. With this control, when the fan speed is switched, the

rotational frequency changes smoothly.

(2) When the rotational frequency feedback signal has not output for 5 seconds (or when the microprocessor

can’t detect the signal for 5 seconds), the fan motor is regarded locked-up . Then the el ectric curren t to the

fan motor is shut off. 10 seconds later, the electric current is applied to the fan motor again. During the fan

motor lock-up, the POWER indicator lamp flashes on and off to show the fan motor abnormality.

10. Auto Fan Speed Control

(1) When the auto fan speed is selected, the indoor fan motor speed is automatically controlled by the room

temperature and the set temperature.

(2) In COOLING mode, the indoor fan motor operates as following:

Fan Speed

Hi

Me

Lo

Room temperature minus set temperature: 1℃ 2℃ 4℃

(3) In HEATING mode, the indoor fan motor operates as following;

Fan Speed

Hi

Mi

Lo

Room temperature minus set temperature 1

℃ 2℃ 4℃

Page 21

TCL Air Conditioner Service Manual

21

11. Auto Vane Operation Control

(1) Vane motor drive

The unit is equipped with a stepping motor for the vane. The rotating direction, speed and ang le of the

motor are controlled by pulse signal transmitted from indoor microprocessor.

(2) Positioning

The vane is once pressed to the vane stopper below to confirm the standard position and then set to the

desired angle. The positioning is decided as follow:

When the ON/OFF button is pressed.

When the vane control is change from AUTO to MANUAL.

When the SWING is finished.

When the test run starts.

When the power supply turns ON.

(3) The auto vane changes as follows by pressing the VANE CONTROL button.

(4) VANE AUTO mode

In vane auto mode, the microprocessor automatically determines the vane angle and operation to make the

optimum room-temperature distribution.

(5) SWING mode

When presses the SWING button, the vane swings.

12. TIMER Operation

How to set the timer

Press ON/OFF button to start the air conditioner.

Press TIMER CONTROL button for once in timer on--- SET the TIME of TIMER; press for second

time---START operation for SHUT OFF; press third time---CANCEL operation for TIMER.

Press TIMER CONTROL button for once in timer off---SET the TIME of TIMER; press for second

time---START operation for TURN ON; press for third time---CANCEL operation for TIMER.

Press UP and DOWN button to set the time, time setting is 30-minutes units.

After setting the timer, check that TIMER INDICATOR lamp of the indoor unit lights.

Press the ON/OFF button for the air conditioner operates in timer, the timer will be cancelled.

TIMER setting can be cancelled by power failure or breaker functioning.

13. EMERGENCY-TEST Operation

When the EMERGENCY Operation switch is press once, COOLING mode is selected and if in 3 seconds the

EMERGENCY Operation switch is pressed again, HEATING mode is selected. Then presses once again, the

unit switch off.

When the remote controller is missing, has failed or the batteries run down, press the EMERGENCY

Operation switch on the front of the indoor unit, The unit will start.

The first 30 minutes of operation will be the test run operation. The operation is for servicing in set mode. The

indoor fan runs at high speed and the system is in continuous operation. The vane motor is ON and the timer

is reset to normal.

After 30 minutes of test run operation the system shifts to AUTO COOLING/HEATING mode. and the indoor

fan runs in outomatic speed. The vane motor is on. The operation continues until the EMERGENCY

operation switch is pressed or a button on the remote controller is pressed, the normal operation will start.

NOTE: Do not press the EMERGENCY Operation switch during normal operation.

14. AUTO RESTART function (Option)

When the indoor unit is controlled with the remote con troller, the operation mode, set temperature, and the

fan speed are memorized by the indoor electric control PCB. The AUTO RESART function sets to work the

Page 22

TCL Air Conditioner Service Manual

22

moment power has restored after power failure. Then, the unit will restart automatically.

Auto-restart presetting:

The appliance is preset as no auto-restart function by manufacture. If Auto-restart function is needed, follow the

below step to active this function:

1) Make sure air conditioner is turned off.

2) Press down and hold the Emergency button (ON/OFF) on the indoor unit white turn on the air conditioner.

3) Keep pressing th e Emergency button for ov er 10s until three short beeps are heard.

Then Auto-restart function is activated. To cancel the Auto-restart function, repeat above procedure until four

short beeps are heard.

15. Failure Display and Handling

a) The failure of the resistance of heat sensitive:

When the resistance of heat sensitive reads the temperature is lower than -50

℃ o r over than 110℃ that

judge the heat sensitive is bad.

b) The Outdoor Protection Control

When the system checks the signal from outdoor of the voltage is 0V, the system delay 1second to start for

check the signal again, if checks the signal of the voltage is 0V too, that the system not to star, or operates on

normal.

c) Failure Display

When the controller is failure, the buzzer will voice long for three times, and displays the failure from the

failure lamp.

d) Failure Code

If have the digital pipe that display the failure code for digital pipe, or display for the run lamp.

Type of failure The lamp flash Display of digital pipe

The failure of room temperature sensor Once/cycle E1

The failure of indoor pipe temperature sensor Twice/cycle E2

Outdoor protection function 5 times/cycle E5

The failure of indoor fan 6 times/cycle E6

e) Failure Handling

When the room temperature sensor or the indoor pipe temperature sensor is failure, the system will be

shut off, the compressor will be OFF, and the outdoor fan and the indoor fan will be OFF. The system

doesn’t receive the signal of remoter controller except the signal of shut off it. When the failure

disappear, the controller can operate in normal mode. before this, presses the “ON/OFF” to start the

system, and it will operate in COOLING or HEATING for 30 minutes, and follows shut off. During

this, it displays the failure and the protction is failing. You must be give the electric ag ain to operate it.

In the failure, you can operate the FAN mode.

When the outdoor protects in the COOLING or DRY, the outdoor unit stops, the indoor fan operates in

set speed ; and in the HEATING, the outdoor unit stops, the assistant thermistor stops, the indoor fan

operates in cold air prevention control. The system doesn’t receive the signal of remoter controller

except the signal of shut off it. When the system check the voltage is 220V and the delay control is

finished, it operates at normal again.

When the indoor fan motor is failure, the compressor is stopped, the outdoor fan and indoor fan is

stopped and display the failure. The system doesn’t receive the signal of remoter controller except the

signal of shut off it.

f) Display Of The Control

In the display board the lamp from left is the POWER lamp(Red), the SLEEP lamp(Yellow), the TIMER

lamp(Yellow), the RUN lamp(Green).

(7) When gives the control electric, the buzzer voices a long for 0.3 second per cycle.

Page 23

TCL Air Conditioner Service Manual

23

Wiring Diagram

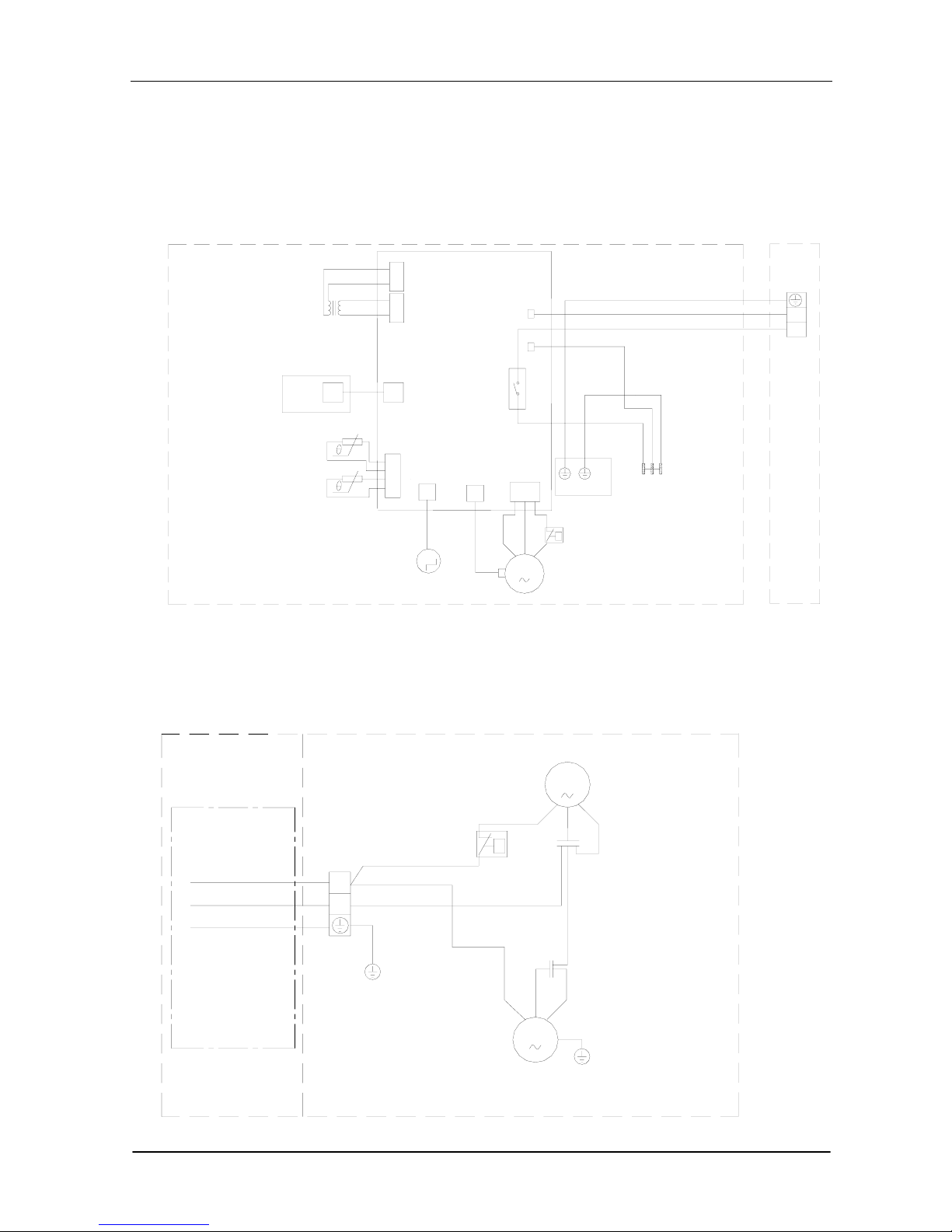

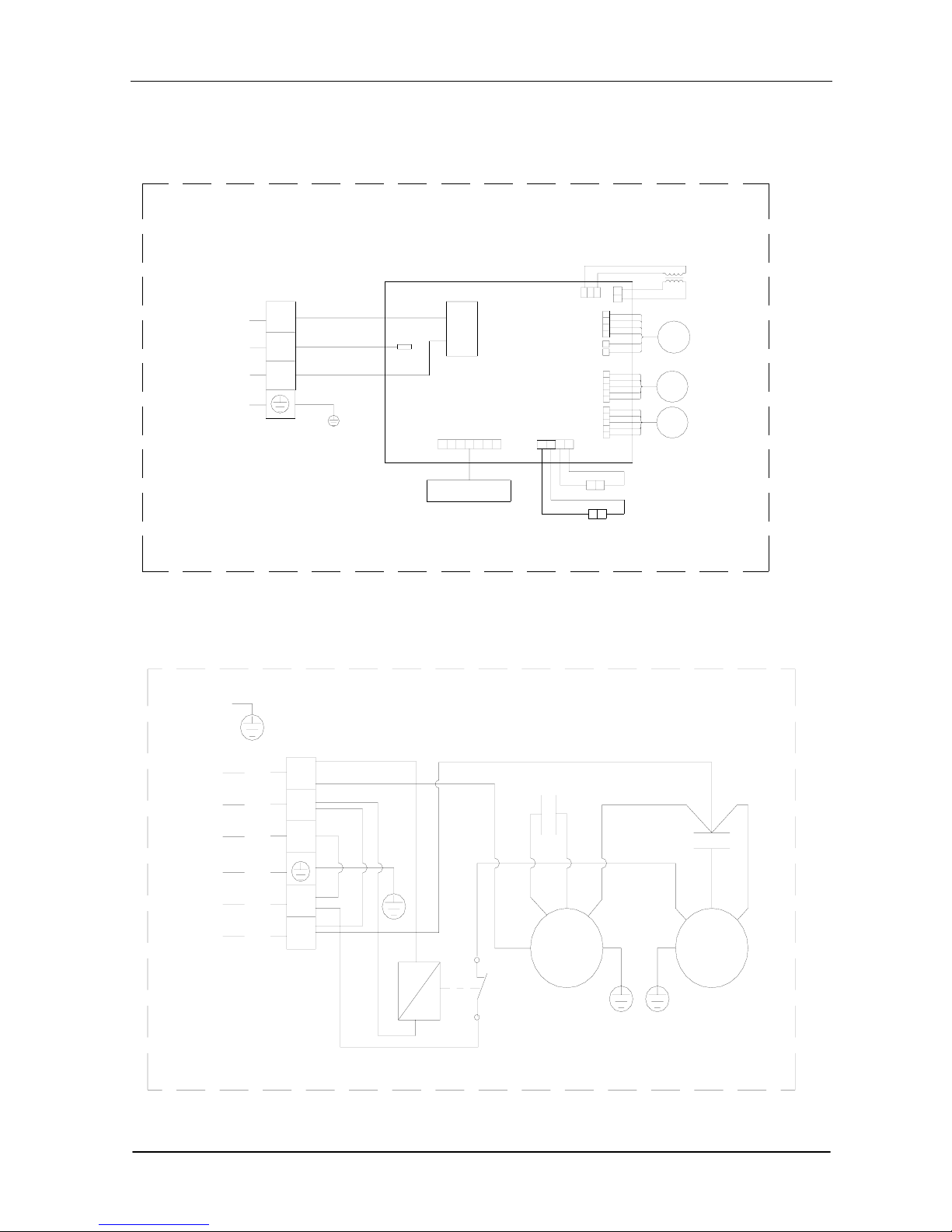

Mode No.: TAC-07CS/K, TAC-09CS/K, TAC-12CS/K

TAC-07CSC/K, TAC-09CSC/K, TAC-12CSC/K

INDOOR UNIT

Pipe Temp.Sensor

Room Temp.Sensor

Display PCB

transformer

protector

Fan Motor

Vane Motor

M

M

θ

Indoor Unit

Power supply

Brown

Yellow/Green

evaporator

K1

TH2

TH1

CN6

CN8

CN3

CN4

CN5

3

COM

CN1

CN2

4

N.O.

P2-2

P2-1

PCB

Brown

Blue

Yellow/Green

Outdoor

Unit

Blue

1

N

OUTDOOR UNIT

Brown

Blue

Yellow/Green

Compressor

White

Red

Blue

Blue

Black

White

Blue

Yellow/Green

Blue

Yellow/Green

Fan Motor

Outdoor UnitIndoor Unit

Fan Capacitor

Compressor Capacitor

Orange

θ

Protector

R(M)

C

S

CM

1

N

M

Page 24

TCL Air Conditioner Service Manual

24

Mode No.: TAC-07CHS/K, TAC-09CHS/K, TAC-12CHS/K

TAC-07CHSC/K, TAC-09CHSC/K, TAC-12CHSC/K

INDOOR UNIT

Protecter

Fan Motor

Note: The thermistor is only with

the assistant thermistor type.

Vane Motor

Indoor Unit

Evaporator

Yellow/Green

Brown

Red

Yellow

Blue

Yellow/Green

Display PCB

Pipe Temp. sensor

Room Temp. sensor

Theimistor

Transformer

Power Supply

Brown

Blue

PCB

CN1

CN2

TH1

TH2

P2-1

P5

P4

P2-2

CN11

CN10

NO

K1

COM

4

3

CN8

CN6

CN5 CN4

CN3

M

M

θ

N

3

2

1

Outdoor

Unit

OUTDOOR UNIT

θ

Co m pressor

4-way Vane

White

CM

R

(M )

C

S

Blue

Co m pressor

Capacitor

Red

Protecter

Black

Brown(W hite)

Red

Y ello w

Blue

Yellow/Green

Blue

Yellow/Green

Outdoor UnitIndoor Unit

Fan Motor

Blue

Fan Capaciter

Blue

Yellow/Green

1

2

3

N

Blue

Blue

Orange

M

Page 25

TCL Air Conditioner Service Manual

25

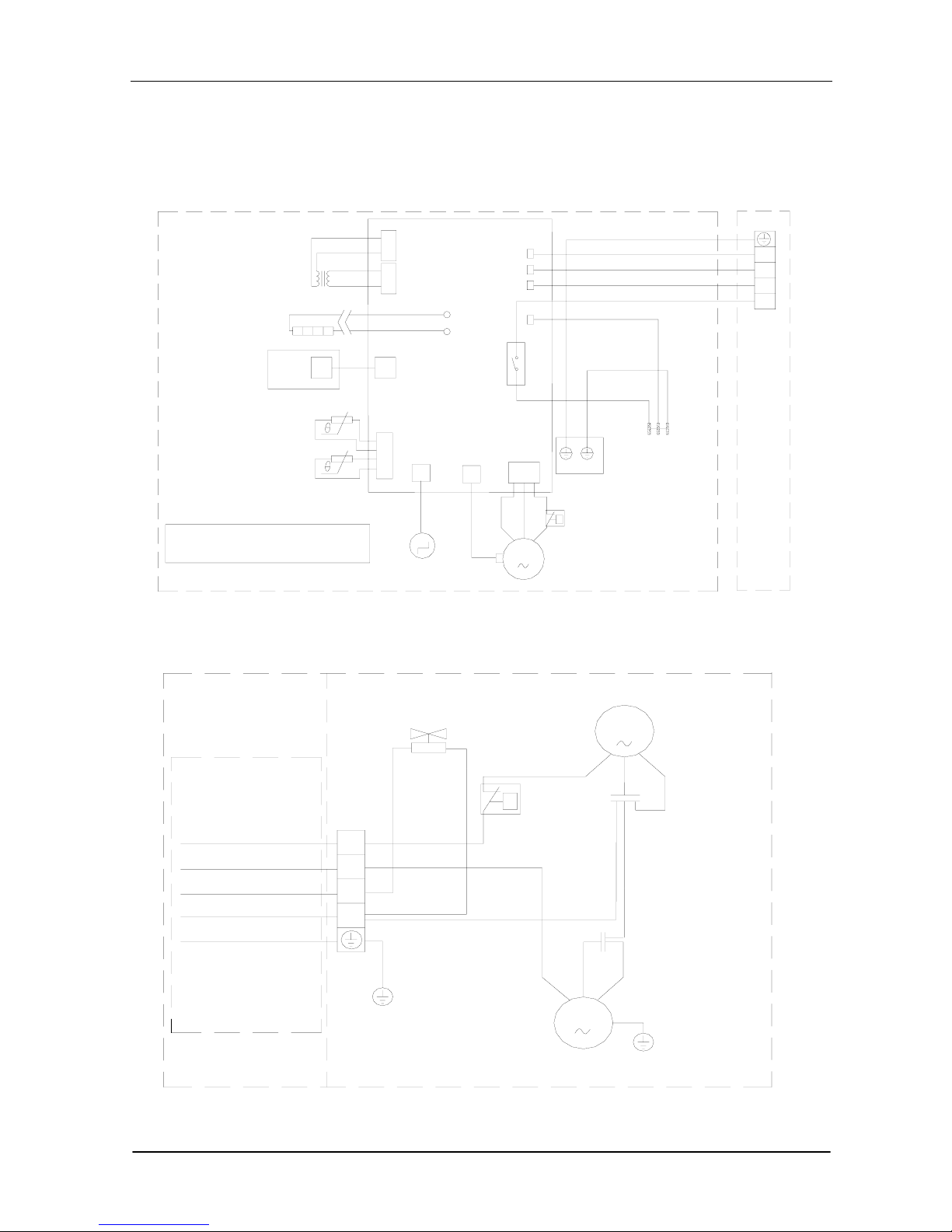

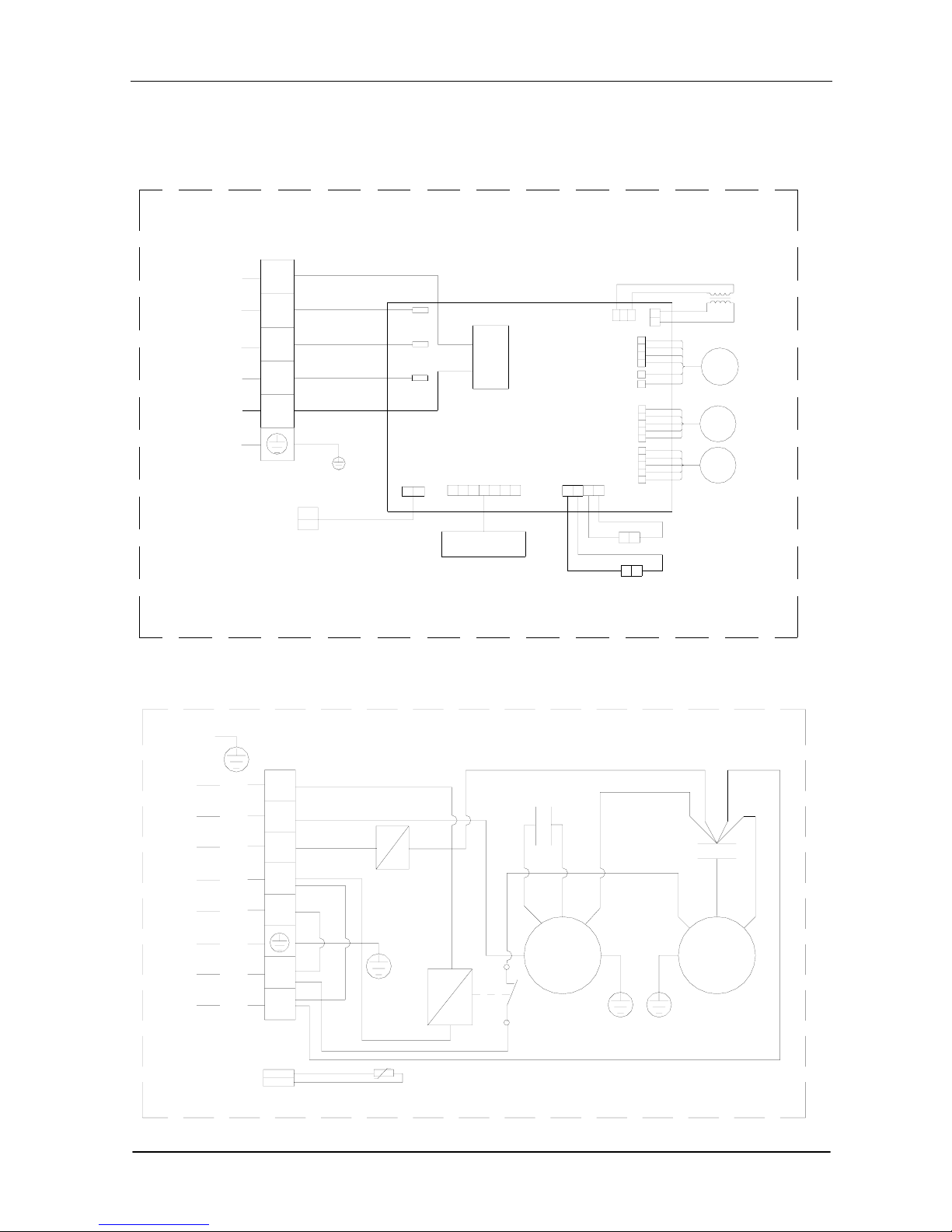

Mode No.: TAC-18CS/K, TAC-18CSC/K

INDOOR UNIT

PCB

Transformer

Brown

Blue

White

Blue

Yellow/Green

Yellow/Green

Yellow/Green

Yellow/Green

AC(N)

N.O

COM

Relay

1

N

N

L

Display PCB

Fan Motor

FM

SM

SM

Vane Motor

To The Outdoor

Room Temp. Sensor

Pipe Temp. Sensor

Blue

Brown

Blue

Brown

L

N

1234

1

2

3

4

5

1

2

3

4

5

OUTDOOR UNIT

Brown

Blue

Yellow/Green

Compressor

White

Red

Blue

Blue

Black

White

Blue

Yellow/Green

Blue

Yellow/Green

Fan Motor

Outdoor UnitIndoor Unit

Fan Capacitor

Compressor Capacitor

Orange

θ

Protector

R(M)

C

S

CM

1

N

M

Page 26

TCL Air Conditioner Service Manual

26

Mode No.: TAC-18CHS/K, TAC-18CHSC/K

INDOOR UNIT

1

N

L

N

N

To The Outdoor Unit

Yellow

Blue

PCB

2

3

White

Red

Brown

Yellow

Yellow/Green

To The Outdoor Sensor

Red

Blue

O.FAN

N.O

COM

VAL

AC(N)

Relay

Transformer

Fan Motor

Vane Motor

Room Temp. Sensor

Pipe Temp. Sensor

FM

SM

Display PCB

SM

Yellow/Green

Yellow/Green Yellow/Green

Blue

Blue

Brown

Brown

L

OUTDOOR UNIT

θ

Compressor

4-way Vane

White

CM

R

(M)

C

S

Blue

Compressor

Capacitor

Red

Protecter

Black

Brown(White)

Red

Yellow

Blue

Yellow/Green

Blue

Yellow/Green

Outdoor Unit

Indoor Unit

Fan Motor

Blue

Fan Capaciter

Blue

Yellow/Green

1

2

3

N

Blue

Blue

Orange

M

Pipe Temp. Sensor

Page 27

TCL Air Conditioner Service Manual

27

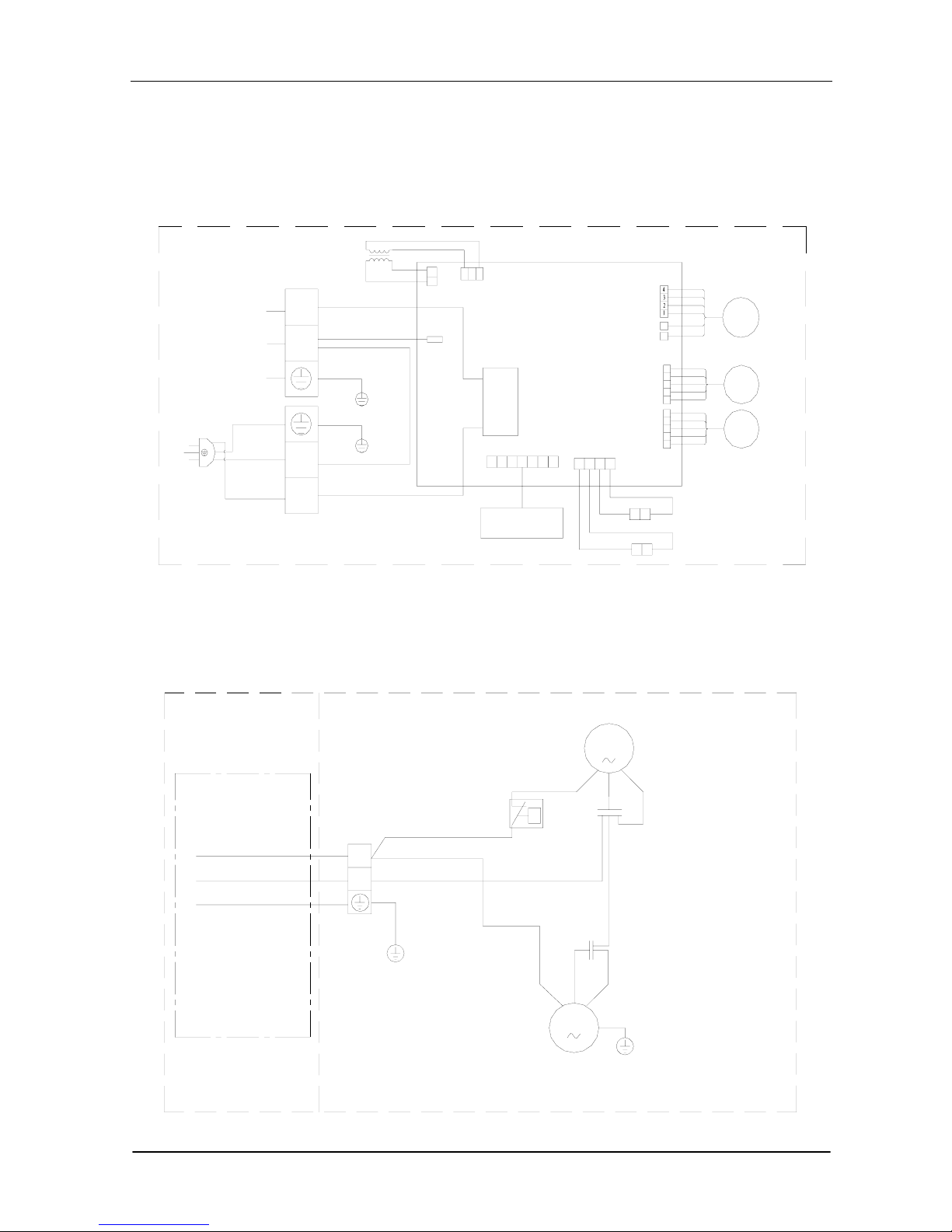

Mode No.: TAC-24CS/K, TAC-24CSC/K

INDOOR UNIT

Blue

N

Brown

Yellow/Green

L

White

White

1

PCB

Yellow/Green

Brown

Blue

N.O

COM

AC(N)

Relay

Transformer

FM

SM

Fan Motor

SM

Vane Motor

Display PCB

Room Temp. Sensor

Pipe Temp. Sensor

12

3

4

4

5

3

2

1

5

4

3

2

1

To Outdoor Unit

OUTDOOR UNIT

Conpressor

W hite

W hite

Yellow/Green

Blue

Brown

Yello w/Green

Brown

Blue

Blue

Brown

Brown

Brown

Yellow/Green

Red

W hite

Yellow

Red

C1

Blue

Blue

W hite

Fan Capacitor

Cap a cito r

Red

Blue

C2

To Power Supply

To Indoor Unit

Yellow/Green

Relay

Fan Motor

Conpressor

Motor

C

S

R

FM

CM

1

N

L

L

N

Page 28

TCL Air Conditioner Service Manual

28

Mode No.: TAC-24CHS/K, TAC-24CHSC/K

INDOOR UNIT

White

Red

White

Yellow

Blue

Brown

Yellow/Green

Red

Yellow

Blue

Brown

O.FAN

Yellow/Green

PCB

VAL

N.O

COM

Relay

AC(N)

To Outdoor Unit

Display PCB

Transformer

FM

SM

SM

Fan Motor

Vane Motor

Room Temp. Sensor

Pipe Temp. Sensor

To Outdoor Unit

1

2

3

N

L

12

3

4

5

1

2

3

4

5

4

3

2

1

OUTDOOR UNIT

White

White

Red

Yellow

Blue

Brown

Yellow/Green

White

White

Red

Brown

Yellow/Green

Brown

Blue

Blue

Brown

Blue

To Power Supply

To Indoor Unit

4-way Vane

Yellow

Red

C1

Fan Capacitor

Blue

Blue

Red

Compressor

Capacity

White

C2

Yellow/Green

Compressor

Blue

Motor

Fan Motor

Relay

Pipe Temp. Sensor

FM

FM

C

S

R

1

2

3

N

L

L

N

Yellow/Green

Page 29

TCL Air Conditioner Service Manual

29

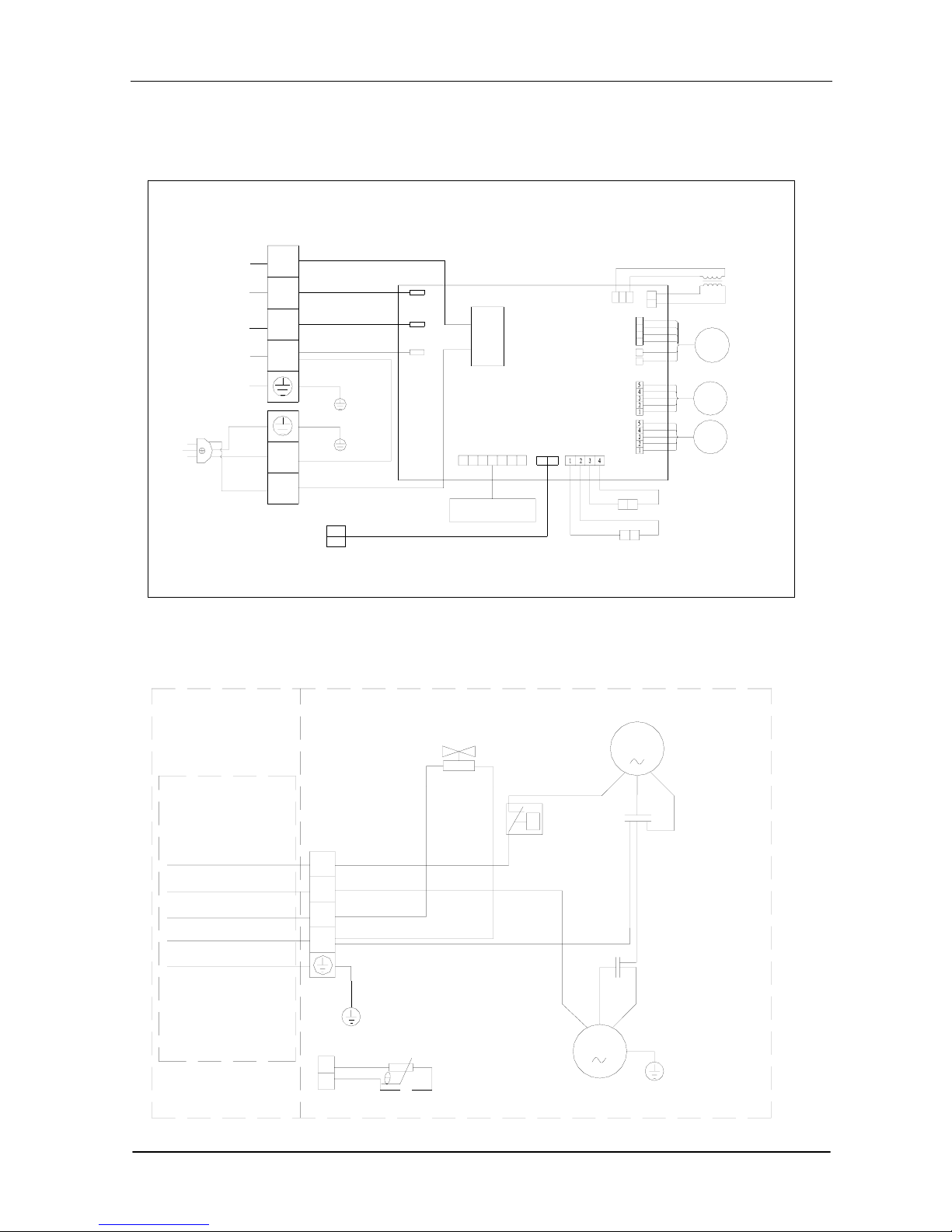

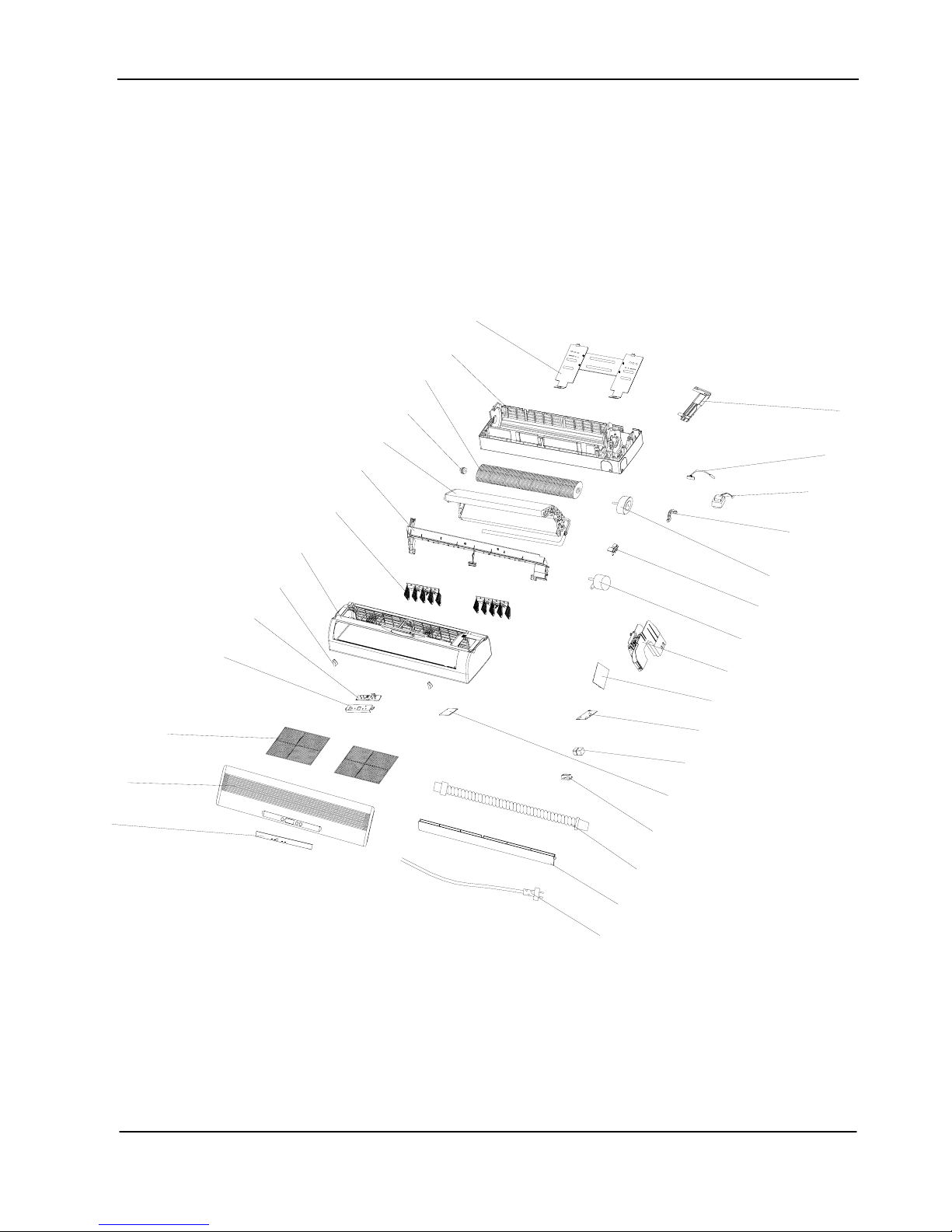

INDOOR UNIT

TAC-07CS/K,TAC-07CSH/K,TAC-07CSC/K,TAC-07CHSC/K,TAC-09CS/K,TAC-09CHS/K,TAC-09CSC/K,

TAC-09CHSC/K, TAC-12CS/K, TAC-12CHS/K, TAC-12CSC/K, TAC-12CHC/K,

1

2

3

5

14

6

7

8

9

10

15

16

17

18

19

20

21

22

23

24

25

26

27

11

12

13

4

28

29

30

Page 30

TCL Air Conditioner Service Manual

30

INDOOR UNIT

T A C-18CS/K, TAC-18CSC/K, TAC-18CHS/K, TAC-18CHSC/K

T A C-24CS/K, TAC-24CSC/K, TAC-24CHS/K, TAC-24CHSC/K

1

2

3

4

5

6

7

8

9

10

11

12

13

29

28

27

26

25

24

23

22

21

20

19

18

17

14

15

30

16

Page 31

TCL Air Conditioner Service Manual

31

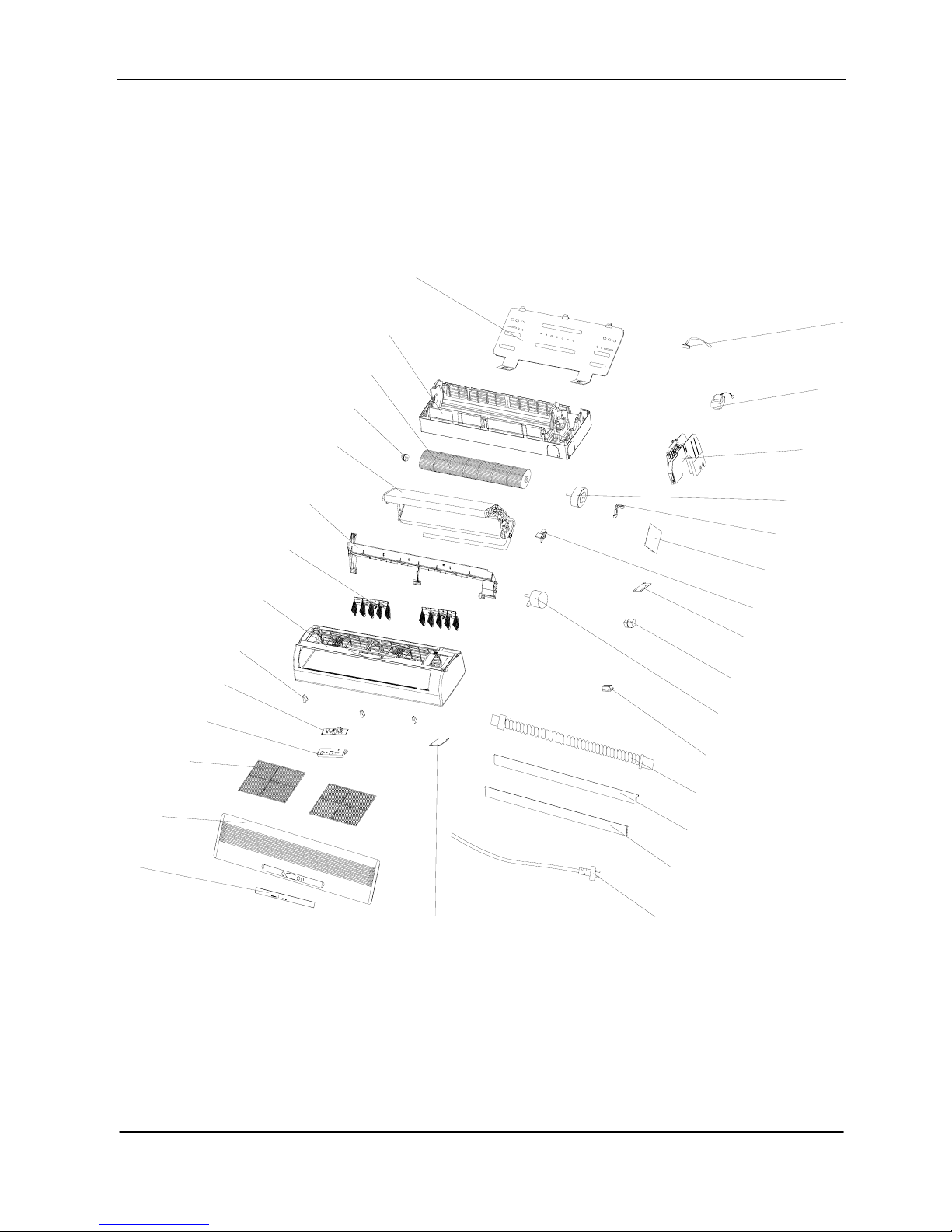

Outdoor Unit: TAC-07CS/K, TAC-07CSC/K, TAC-09CS/K, TAC-09CSC/K, TAC-12CS/K,

TAC-12CSC/K, TAC-18CS/K, TAC-18CSC/K, TAC-24CS/K, TAC-24CSC/K

1

2

3

5

4

6

7

9

10

11

12

13

14

15

16

17

20

~28

8

18

19

Page 32

TCL Air Conditioner Service Manual

32

Outdoor Unit: TAC-07CHS/K, TAC-07CHSC/K, TAC-09CHS/K, TAC-09CHSC/K, TAC-12CHS/K

TAC-12CHSC/K, TAC-18CHS/K, TAC-18CHSC/K, TAC-24CHS/K, TAC-24CHSC/K

1

2

3

4

5

6

7

9

10

11

12

13

14

15

16

19~

28

8

17

18

Page 33

TCL Air Conditioner Service Manual

33

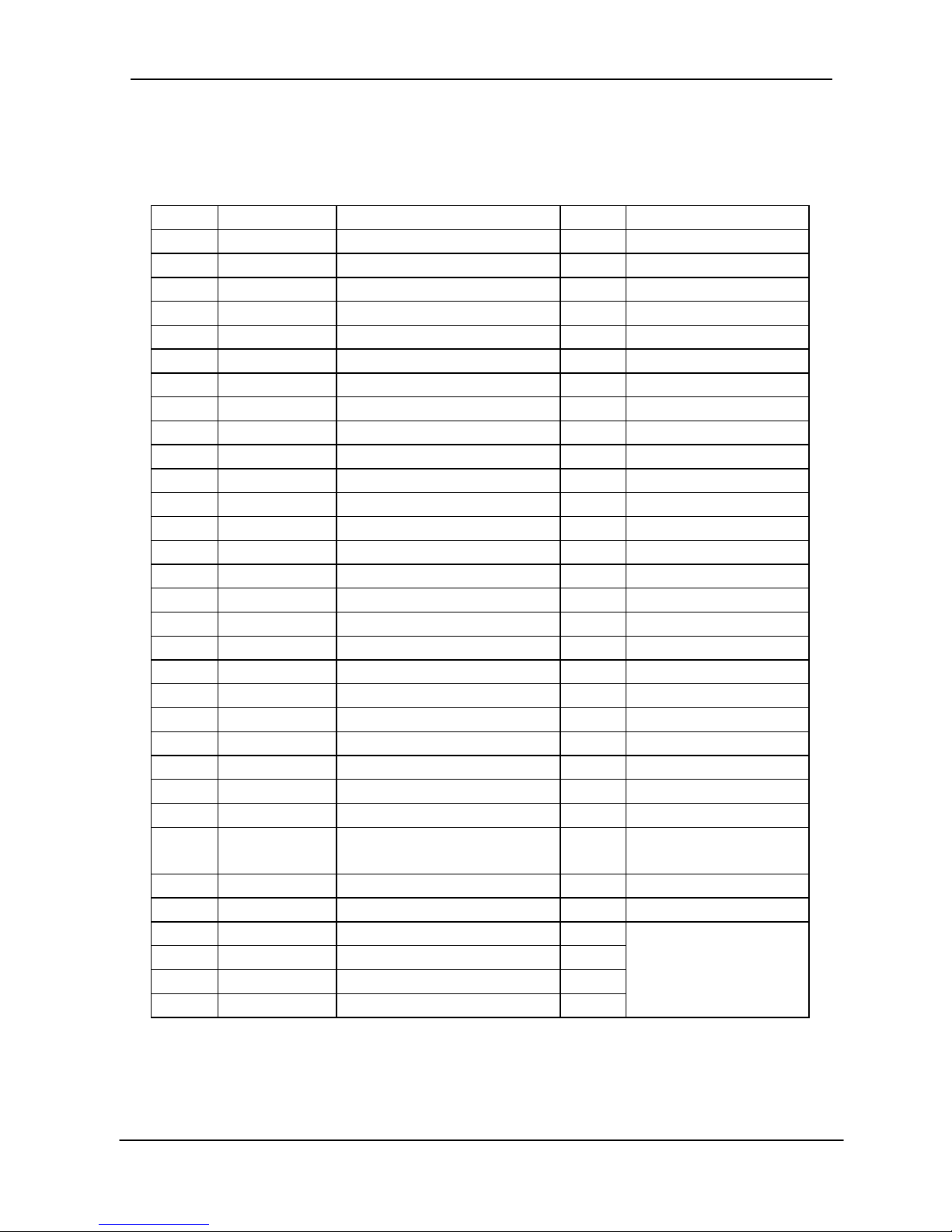

Parts List

Indoor Unit- TAC-07CS/K, TAC-09CS/K

No. Part No. Part Name Q’ty Remark

1 1080030003 Installation Plate 1

2 1210250103 Base 1

3 1070020017 Cross Fan 1

4 1070100010 Bearing Mount 1

5 1210230101 Evaporator 1

6 1070250102 Water Drainage Assembly 1

7 1070320105 Vertical Vane Assembly 2

8 1070250104 Face Frame 1

9 1070320112 Screw Cover 2

10 1090320102 Display PCB 1

11 1070320115 Display PCB Box 1

12 1070250106 Air Filter 2

13 1070251801 Front Panel 1

14 1070251001 Display PC Board Cover 1

15 1170120042 Power Supply Cord 1

16 1070250103 Vane 1

17 1070110008 Drainage Hose 1

18 1070040006 Electrical Box Cover 1

19 1070040004 Cable Clamp 1

20 1170200039 Terminal 1

21 1070250109 Terminal Fixing Board 1

22 1170020011 Vane Motor 1

23 1090250602 Main PCB 1

24 1110040001 Sensor Holder 1

25 1070320113 Electrical Box 1

26 1070320111 Indoor Motor Cover 1

27 1170030052 Indoor Motor 1

28 1170240001 Transformer 1

29 1170230001 Pipe Temp. Sensor & Room

Temp. Sensor Assembly

1

30 1070320101 In And Out Pipe Fixer 1

31 1090010071 Remote Controller 1

31 1073030303 Remote Controller Supporter 1

32 1190250204 Indoor Carton 1

33 1190060008 Left Foaming 1

34 1190060009 Right Foaming 1

Not shown in Explosion

view

Page 34

TCL Air Conditioner Service Manual

34

Indoor Unit- TAC-07CHS/K, TAC-09CHS/K

No. Part No. Part Name Q’ty Remark

1 1080030003 Installation Plate 1

2 1210250103 Base 1

3 1070020017 Cross Fan 1

4 1070100010 Bearing Mount 1

5 1210230101 Evaporator 1

6 1070250102 Water Drainage Assembly 1

7 1070320105 Vertical Vane Assembly 2

8 1070250104 Face Frame 1

9 1070320112 Screw Cover 2

10 1090320102 Display PCB 1

11 1070320115 Display PCB Box 1

12 1070250106 Air Filter 1

13 1070251801 Front Panel 2

14 1070251001 Display PC Board Cover 1

15 1170120042 Power Supply Cord 1

16 1070250103 Vane 1

17 1070110008 Drainage Hose 1

18 1070040006 Electrical Box Cover 1

19 1070040004 Cable Clamp 1

20 1170200040 Terminal 1

21 1070250109 Terminal Fixing Board 1

22 1170020011 Vane Motor 1

23 1090250202 Main PCB 1

24 1110040001 Sensor Holder 1

25 1070320113 Electrical Box 1

26 1070320111 Indoor Motor Cover 1

27 1170030052 Indoor Motor 1

28 1170240001 Transformer 1

29 1170230001 Pipe Temp. Sensor & Room

Temp. Sensor Assembly

1

30 1070320101 In And Out Pipe Fixer 1

31 1090010071 Remote Controller 1

31 1073030303 Remote Controller Supporter 1

32 1190250204 Indoor Carton 1

33 1190060008 Left Foaming 1

34 1190060009 Right Foaming 1

Not shown in Explosion

view

Page 35

TCL Air Conditioner Service Manual

35

Indoor Unit- TAC-07CSC/K , TAC-09CSC/K

No. Part No. Part Name Q’ty Remark

1 1080030008 Installation Plate 1

2 1210320107 Base 1

3 1070020016 Cross Fan 1

4 1070100010 Bearing Mount 1

5 1210320601 Evaporator 1

6 1070320103 Water Drainage Assembly 1

7 1070320105 Vertical Vane Assembly 2

8 1070320107 Face Frame 1

9 1070320112 Screw Cover 2

10 1090320102 Display PCB 1

11 1070320115 Display PCB Box 1

12 1070320109 Air Filter 2

13 1070321501 Front Panel 1

14 1070251001 Display PC Board Cover 1

15 1170120047 Power Supply Cord 1

16 1070320104 Vane 1

17 1070110008 Drainage Hose 1

18 1070040006 Electrical Box Cover 1

19 1070040004 Cable Clamp 1

20 1170200039 Terminal 1

21 1070250109 Terminal Fixing Board 1

22 1170020011 Vane Motor 1

23 1090320102 Main PCB 1

24 1110040001 Sensor Holder 1

25 1070320113 Electrical Box 1

26 1070320111 Indoor Motor Cover 1

27 1170030047 Indoor Motor 1

28 1170240001 Transformer 1

29 1170230001 Pipe Temp. Sensor & Room

Temp. Sensor Assembly

1

30 1070320101 In And Out Pipe Fixer 1

31 1090010071 Remote Controller 1

31 1073030303 Remote Controller Supporter 1

32 1190350102 Indoor Carton 1

33 1190060005 Left Foaming 1

34 1190060006 Right Foaming 1

Not shown in Explosion

view

Page 36

TCL Air Conditioner Service Manual

36

Indoor Unit- TAC-07CHSC/K, TAC-09CHSC/K

No. Part No. Part Name Q’ty Remark

1 1080030008 Installation Plate 1

2 1210320107 Base 1

3 1070020016 Cross Fan 1

4 1070100010 Bearing Mount 1

5 1210320601 Evaporator 1

6 1070320103 Water Drainage Assembly 1

7 1070320105 Vertical Vane Assembly 2

8 1070320107 Face Frame 1

9 1070320112 Screw Cover 2

10 1090320102 Display PCB 1

11 1070320115 Display PCB Box 1

12 1070320109 Air Filter 2

13 1070321501 Front Panel 1

14 1070251001 Display PC Board Cover 1

15 1170120047 Power Supply Cord 1

16 1070320104 Vane 1

17 1070110008 Drainage Hose 1

18 1070040006 Electrical Box Cover 1

19 1070040004 Cable Clamp 1

20 1170200040 Terminal 1

21 1070250109 Terminal Fixing Board 1

22 1170020011 Vane Motor 1

23 1090320103 Main PCB 1

24 1110040001 Sensor Holder 1

25 1070320113 Electrical Box 1

26 1070320111 Indoor Motor Cover 1

27 1170030047 Indoor Motor 1

28 1170240001 Transformer 1

29 1170230001 Pipe Temp. Sensor & Room

Temp. Sensor Assembly

1

30 1070320101 In And Out Pipe Fixer 1

31 1090010071 Remote Controller 1

31 1073030303 Remote Controller Supporter 1

32 1190350102 Indoor Carton 1

33 1190060005 Left Foaming 1

34 1190060006 Right Foaming 1

Not shown in Explosion

view

Page 37

TCL Air Conditioner Service Manual

37

Indoor Unit- TAC-12CS/K, TAC-12CSC/K

No. Part No. Part Name Q’ty Remark

1 1080030008 Installation Plate 1

2 1210320107 Base 1

3 1070020016 Cross Fan 1

4 1070100010 Bearing Mount 1

5 1210320601 Evaporator 1

6 1070320103 Water Drainage Assembly 1

7 1070320105 Vertical Vane Assembly 2

8 1070320107 Face Frame 1

9 1070320112 Screw Cover 2

10 1090320102 Display PCB 1

11 1070320115 Display PCB Box 1

12 1070320109 Air Filter 2

13 1070321501 Front Panel 1

14 1070251001 Display PC Board Cover 1

15 1170120047 Power Supply Cord 1

16 1070320104 Vane 1

17 1070110008 Drainage Hose 1

18 1070040006 Electrical Box Cover 1

19 1070040004 Cable Clamp 1

20 1170200039 Terminal 1

21 1070250109 Terminal Fixing Board 1

22 1170020011 Vane Motor 1

23 1090320102 Main PCB 1

24 1110040001 Sensor Holder 1

25 1070320113 Electrical Box 1

26 1070320111 Indoor Motor Cover 1

27 1170030047 Indoor Motor 1

28 1170240001 Transformer 1

29 1170230001 Pipe Temp. Sensor & Room

Temp. Sensor Assembly

1

30 1070320101 In And Out Pipe Fixer 1

31 1090010071 Remote Controller 1

31 1073030303 Remote Controller Supporter 1

32 1190350102 Indoor Carton 1

33 1190060005 Left Foaming 1

34 1190060006 Right Foaming 1

Not shown in Explosion

view

Page 38

TCL Air Conditioner Service Manual

38

Indoor Unit- TAC-12CHS/K , TAC-12CHSC/K

No. Part No. Part Name Q’ty Remark

1 1080030008 Installation Plate 1

2 1210320107 Base 1

3 1070020016 Cross Fan 1

4 1070100010 Bearing Mount 1

5 1210320601 Evaporator 1

6 1070320103 Water Drainage Assembly 1

7 1070320105 Vertical Vane Assembly 2

8 1070320107 Face Frame 1

9 1070320112 Screw Cover 2

10 1090320102 Display PCB 1

11 1070320115 Display PCB Box 1

12 1070320109 Air Filter 2

13 1070321501 Front Panel 1

14 1070251001 Display PC Board Cover 1

15 1170120047 Power Supply Cord 1

16 1070320104 Vane 1

17 1070110008 Drainage Hose 1

18 1070040006 Electrical Box Cover 1

19 1070040004 Cable Clamp 1

20 1170200040 Terminal 1

21 1070250109 Terminal Fixing Board 1

22 1170020011 Vane Motor 1

23 1090320103 Main PCB 1

24 1110040001 Sensor Holder 1

25 1070320113 Electrical Box 1

26 1070320111 Indoor Motor Cover 1

27 1170030047 Indoor Motor 1

28 1170240001 Transformer 1

29 1170230001 Pipe Temp. Sensor & Room

Temp. Sensor Assembly

1

30 1070320101 In And Out Pipe Fixer 1

31 1090010071 Remote Controller 1

31 1073030303 Remote Controller Supporter 1

32 1190350102 Indoor Carton 1

33 1190060005 Left Foaming 1

34 1190060006 Right Foaming 1

Not shown in Explosion

view

Page 39

TCL Air Conditioner Service Manual

39

Indoor Unit- TAC-18CS/K ,TAC-18CSC/K , TAC-24CS/K , TAC-24CSC/K

No. Part No. Part Name Q’ty Remark

1 1080030001 Installation Plate 1

2 1073090101 Base 1

3 1070020014 Cross Fan 1

4 1070100010 Bearing Mount 1

5 1213090106 Evaporator 1

6 1073090104 Water Drainage Assembly 1

7 1073090106 Vertical Vane Assembly 2

8 1073090110 Face Frame 1

9 1073090111 Screw Cover 3

10 1093090102 Display PCB 1

11 1073090126 Display PCB Box 1

12 1073090112 Air Filter 2

13 1070500205 Front Panel 1

14 1070500208 Display PCB Cover 1

15 1073090122 Electrical Box Cover 1

16 1170120006 Power Supply Cord 1

17 1073090108 Vane A 1

18 1073090125 Vane B 1

19 1070110008 Drainage Hose 1

20 1070040003 Cable Clamp 2

21 1170020011 Vane Motor 1

22 1170200038 Terminal 2

23 1083090108 Terminal Fixing Board 1

24 1110040001 Sensor Holder 1

25 1093090201 Main PCB 1

26 1073090120 Indoor Motor Cover 1

27 1170030045 Indoor Motor 1

28 1093090201 Electrical Box 1

29 1173090107 Transformer 1

30 1170230001 Pipe Temp. Sensor & Room

Temp. Sensor Assembly

1

31 1090010071 Remote Controller 1

31 1073030303 Remote Controller Supporter 1

32 1130120008 Indoor Carton 1

33 1073030303 Left Foaming 1

34 1190250204 Right Foaming 1

35 1190060002 Middle Pasteboard Supporter 1

36 1190060021 Middle Foaming Supporter 1

Not shown in Explosion

view

Page 40

TCL Air Conditioner Service Manual

39

Indoor Unit- TAC-18CHS/K,TAC-18CHSC/K, TAC-24CHS/K, TAC-24CHSC/K

No. Part No. Part Name Q’ty Remark

1 1080030001 Installation Plate 1

2 1073090101 Base 1

3 1070020014 Cross Fan 1

4 1070100010 Bearing Mount 1

5 1213090106 Evaporator 1

6 1073090104 Water Drainage Assembly 1

7 1073090106 Vertical Vane Assembly 2

8 1073090110 Face Frame 1

9 1073090111 Screw Cover 3

10 1093090102 Display PCB 1

11 1073090126 Display PCB Box 1

12 1073090112 Air Filter 2

13 1070500205 Front Panel 1

14 1070500208 Display PCB Cover 1

15 1073090122 Electrical Box Cover 1

16 1170120006 Power Supply Cord 1

17 1073090108 Vane A 1

18 1073090125 Vane B 1

19 1070110008 Drainage Hose 1

20 1070040003 Cable Clamp 2

21 1170020011 Vane Motor 1

22 1170200040 Terminal 2

23 1083090108 Terminal Fixing Board 1

24 1110040001 Sensor Holder 1

25 1093090101 Main PCB 1

26 1073090120 Indoor Motor Cover 1

27 1170030045 Indoor Motor 1

28 1093090201 Electrical Box 1

29 1173090107 Transformer 1

30 1170230001 Pipe Temp. Sensor & Room

Temp. Sensor Assembly

1

31 1090010071 Remote Controller 1

31 1073030303 Remote Controller Supporter 1

32 1130120008 Indoor Carton 1

33 1073030303 Left Foaming 1

34 1190250204 Right Foaming 1

35 1190060002 Middle Pasteboard Supporter 1

36 1190060021 Middle Foaming Supporter 1

Not shown in Explosion

view

Page 41

TCL Air Conditioner Service Manual

40

Outdoor Unit- TAC-07CS/K, TAC-09CS/K

No. Part No. Part Name Q’ty Remark

1 1083510901 Grille 1

Optional

2 1080050016 Top Cover 1

3 1210250112 Condenser 1

4 1080050015 Outdoor Motor Supporter 1

5 1170040062 Outdoor Motor 1

6 1070030006 Propeller Fan 1

7 1080050012 Left Plate 1

8 1080050018 Front Plate 1

9 1080050019 Fan Guard 1

10 1210250101 Capillary Assembly 1

11 --------------- Compressor and its Accessories 1

12 1120250608 Discharge Pipe 1

13 1123521402 Suction Pipe 1

14 1213530414 Base 1

15 1120120008 Two-way Valve 1

16 1080050014 Valve Supporter 1

17 1120130011 Three-way Valve 1

18 1080050013 Right Plate 1

19 1073521301 Electrical Box Cover 1

20 1080020001 Electrical Parts Box 1

21 1080010002 Capacitor Strip 1

22 1170100014 Compressor Capacitor 1

23 1170100031 Fan Motor Capacitor 1

24 1170200019 Terminal 1

25 1070040002 Cable Clamp(φ7) 1

26 1173570501 Compressor Power Supply

Wiring

1

27 1173570502 Earthing Wiring 1

28 1190070014 Base Carton 1

29 1190250201 Cabinet Carton 1

30 1190070016 Base Foaming 1

31 1190070015 Cover Forming 1

Not shown in the Explosion

view.

Page 42

TCL Air Conditioner Service Manual

41

Outdoor Unit- TAC-07CSC/K, TAC-09CSC/K

No. Part No. Part Na me Q’ty Remark

1 1083510901 Grille 1

Optional

2 1080050011 Top Cover 1

3 1210350207 Condenser 1

4 1080050004 Outdoor Motor Supporter 1

5 1170040059 Outdoor Motor 1

6 1070030012 Propeller Fan 1

7 1080050012 Left Plate 1

8 1080050009 Front Plate 1

9 1080320112 Fan Guard 1

10 1210250101 Capillary Assembly 1

Consist The Filter For Dry

11 --------------- Compressor and its Accessories 1

12 1120250608 Discharge Pipe 1

13 1123521402 Suction Pipe 1

14 1210500106 Base 1

15 1120120017 Two-way Valve 1

16 1080050003 Valve Supporter 1

17 1120130025 Three-way Valve 1

18 1080050002 Right Plate 1

19 107351103 Electrical Box Cover 1

20 1080020001 Electrical Parts Box 1

21 1080010006 Capacitor Strip 1

22 1170100007 Compressor Capacitor 1

23 1170100027 Fan Motor Capacitor 1

24 1170200019 Terminal 1

25 1070040002 Cable Clamp1(φ7) 1

26 1173570501 Compressor Power Supply

Wiring

1

27 1173570502 Earthing Wiring 1

28 1190070020 Base Carton 1

29 1190070002 Cabinet Carton 1

30 1190070022 Base Foaming 1

31 1190070021 Cover Forming 1

Not shown in the Explosion

view.

Page 43

TCL Air Conditioner Service Manual

42

Outdoor Unit- TAC-07CHS/K , TAC-09CHS/K

No. Part No. Part Na me Q’ty Remark

1 1083510901 Grille 1

2 1080050016 Top Cover 1

3 1210250112 Condenser 1

4 1080050015 Outdoor Motor Supporter 1

5 1170040062 Outdoor Motor 1

6 1070030006 Propeller Fan 1

7 1080050012 Left Plate 1

8 1080050018 Front Plate 1

9 1080050019 Fan Guard 1

10 1213530404 4-way Assembly 1

11 --------------- Compressor and its Accessories 1

12 1120250608 Discharge Pipe 1

13 1123521402 Suction Pipe 1

14 1213530414 Base 1

15 1120120008 Two-way Valve 1

16 1080050014 Valve Supporter 1

17 1120130011 Three-way Valve 1

18 1080050013 Right Plate 1

19 1073521301 Electrical Box Cover 1

20 1080020001 Electrical Parts Box 1

21 1080010002 Capacitor Strip 1

22 1170100014 Compressor Capacitor 1

23 1170100031 Fan Motor Capacitor 1

24 1170200020 Terminal 1

25 1070040001 Cable Clamp(φ6) 1

26 1070040002 Cable Clamp(φ7) 1

27 1173570501 Compressor Power Supply

Wiring

1

28 1173570502 Earthing Wiring 1

29 1190070014 Base Carton 1

30 1190250201 Cabinet Carton 1

31 1190070016 Base Foaming 1

32 1190070015 Cover Forming 1

Not shown in the Explosion

view.

Page 44

TCL Air Conditioner Service Manual

43

Outdoor Unit- TAC-07CHSC/K, TAC-09CHSC/K

No. Part No. Part Na me Q’ty Remark

1 1083510901 Grille 1

Optional

2 1080320105 Top Cover 1

3 1210320101 Condenser 1

4 1080050004 Outdoor Motor Supporter 1

5 1170040058 Outdoor Motor 1

6 1070030016 Propeller Fan 1

7 1080050001 Left Plate 1

8 1080320113 Front Plate 1

9 1080320112 Fan Guard 1

10 1210250605 Capillary Assembly 1

11 --------------- Compressor and its Accessories 1

12 1210250606 4-way Vane Assembly 1

13 1210320103 Base 1

14 1120120017 Two-way Valve 1

15 1080050003 Valve Supporter 1

16 1120130025 Three-way Valve 1

17 1080050002 Right Plate 1

18 1073551103 Electrical Box Cover 1

19 1080020001 Electrical Parts Box 1

20 1080010006 Capacitor Strip 1

21 1170100003 Compressor Capacitor 1

22 1170100032 Fan Motor Capacitor 1

23 1170200020 Terminal 1

24 1070040001 Cable Clamp(φ6) 1

25 1070040002 Cable Clamp(φ7) 1

26 1173570501 Compressor Power Supply

Wiring

27 1173570502 Earthing Wiring 1

28 1190070017 Base Carton 1

29 1190500302 Cabinet Carton 1

30 1190070019 Base Foaming 1

31 1190070018 Cover Forming 1

Not shown in the Explosion

view.

dry

Consist

the

filter

for

Page 45

TCL Air Conditioner Service Manual

44

Outdoor Unit- TAC-12CS/K

No. Part No. Part Na me Q’ty Remark

1 1083510901 Grille 1

Optional

2 1080320105 Top Cover 1

3 1210320106 Condenser 1

4 1080050004 Outdoor Motor Supporter 1

5 1170040058 Outdoor Motor 1

6 1070030016 Propeller Fan 1

7 1080050001 Left Plate 1

8 1080320113 Front Plate 1

9 1080320112 Fan Guard

10 1210320701 Capillary Assembly 1

11 --------------- Compressor and its Accessories 1

12 1120320701 Discharge Pipe 1

13 1120320702 Suction Pipe 1

14 1210320103 Base 1

15 1120120016 Two-way Valve 1

16 1080050003 Valve Supporter 1

17 1120130021 Three-way Valve 1

18 1080050002 Right Plate 1

19 1073551103 Electrical Box Cover 1

20 1080020001 Electrical Parts Box 1

21 1080010006 Capacitor Strip 1

22 1170100003 Compressor Capacitor 1

23 1170100032 Fan Motor Capacitor 1

24 1170200019 Terminal 1

25 1070040002 Cable Clamp 1

26 1173570501 Compressor Power Supply

Wiring

1

27 1173570502 Earthing Wiring 1

28 1190070017 Base Carton 1

29 1190500302 Cabinet Carton 1

30 1190070019 Base Foaming 1

31 1190070018 Cover Forming 1

Not shown in the Explosion

view.

Page 46

TCL Air Conditioner Service Manual

45

Outdoor Unit- TAC-12CSC/K

No. Part No. Part Na me Q’ty Remark

1 1083510901 Grille 1

Optional

2 1080050011 Top Cover 1

3 1210350207 Condenser 1

4 1080050004 Outdoor Motor Supporter 1

5 1170040059 Outdoor Motor 1

6 1070030012 Propeller Fan 1

7 1080050012 Left Plate 1

8 1080050009 Front Plate 1

9 1080320112 Fan Guard 1

10 1210250101 Capillary Assembly 1

Consist The Filter For Dry

11 --------------- Compressor and its Accessories 1

12 1120250608 Discharge Pipe 1

13 1123521402 Suction Pipe 1

14 1210500106 Base 1

15 1120120017 Two-way Valve 1

16 1080050003 Valve Supporter 1

17 1120130018 Three-way Valve 1

18 1080050002 Right Plate 1

19 107351103 Electrical Box Cover 1

20 1080020001 Electrical Parts Box 1

21 1080010006 Capacitor Strip 1

22 1170100007 Compressor Capacitor 1

23 1170100027 Fan Motor Capacitor 1

24 1170200019 Terminal 1

25 1070040002 Cable Clamp(φ7) 1

26 1173570501 Compressor Power Supply

Wiring

1

27 1173570502 Earthing Wiring 1

28 1190070020 Base Carton 1

29 1190070002 Cabinet Carton 1

30 1190070022 Base Foaming 1

31 1190070021 Cover Forming 1

Not shown in the Explosion

view.

Page 47

TCL Air Conditioner Service Manual

46

Outdoor Unit- TAC-12CHS/K

No. Part No. Part Na me Q’ty Remark

1 1083510901 Grille 1

Optional

2 1080320105 Top Cover 1

3 1210320101 Condenser 1

4 1080050004 Outdoor Motor Supporter 1

5 1170040058 Outdoor Motor 1

6 1070030016 Propeller Fan 1

7 1080050001 Left Plate 1

8 1080320113 Front Plate 1

9 1080320112 Fan Guard 1

10 1210320701 Capillary Assembly 1

11 --------------- Compressor and its Accessories 1

12 1210320701 4-way Vane Assembly 1

13 1210320103 Base 1

14 1120120016 Two-way Valve 1

15 1080050003 Valve Supporter 1

16 1120130021 Three-way Valve 1

17 1080050002 Right Plate 1

18 1073551103 Electrical Box Cover 1

19 1080020001 Electrical Parts Box 1

20 1080010006 Capacitor Strip 1

21 1170100003 Compressor Capacitor 1

22 1170100032 Fan Motor Capacitor 1

23 1170200020 Terminal 1

24 1070040001 Cable Clamp(φ6) 1

25 1070040002 Cable Clamp(φ7) 1

26 1173570501 Compressor Power Supply

Wiring

27 1173570502 Earthing Wiring 1

28 1190070017 Base Carton 1

29 1190500302 Cabinet Carton 1

30 1190070019 Base Foaming 1

31 1190070018 Cover Forming 1

Not shown in the Explosion

view.

Page 48

TCL Air Conditioner Service Manual

47

Outdoor Unit- TAC-12CHSC/K

No. Part No. Part Na me Q’ty Remark

1 1083510901 Grille 1

Optional

2 1080050011 Top Cover 1

3 1210350207 Condenser 1

4 1080050004 Outdoor Motor Supporter 1

5 1170040059 Outdoor Motor 1

6 1070030012 Propeller Fan 1

7 1080050001 Left Plate 1

8 1080050009 Front Plate 1

9 1080320112 Fan Guard 1

10 1210350204 Capillary Assembly 1

11 --------------- Compressor and its Accessories 1

12 1210350205 4-way Vane Assembly 1

13 1210500106 Base 1

14 1120120017 Two-way Valve 1