Page 1

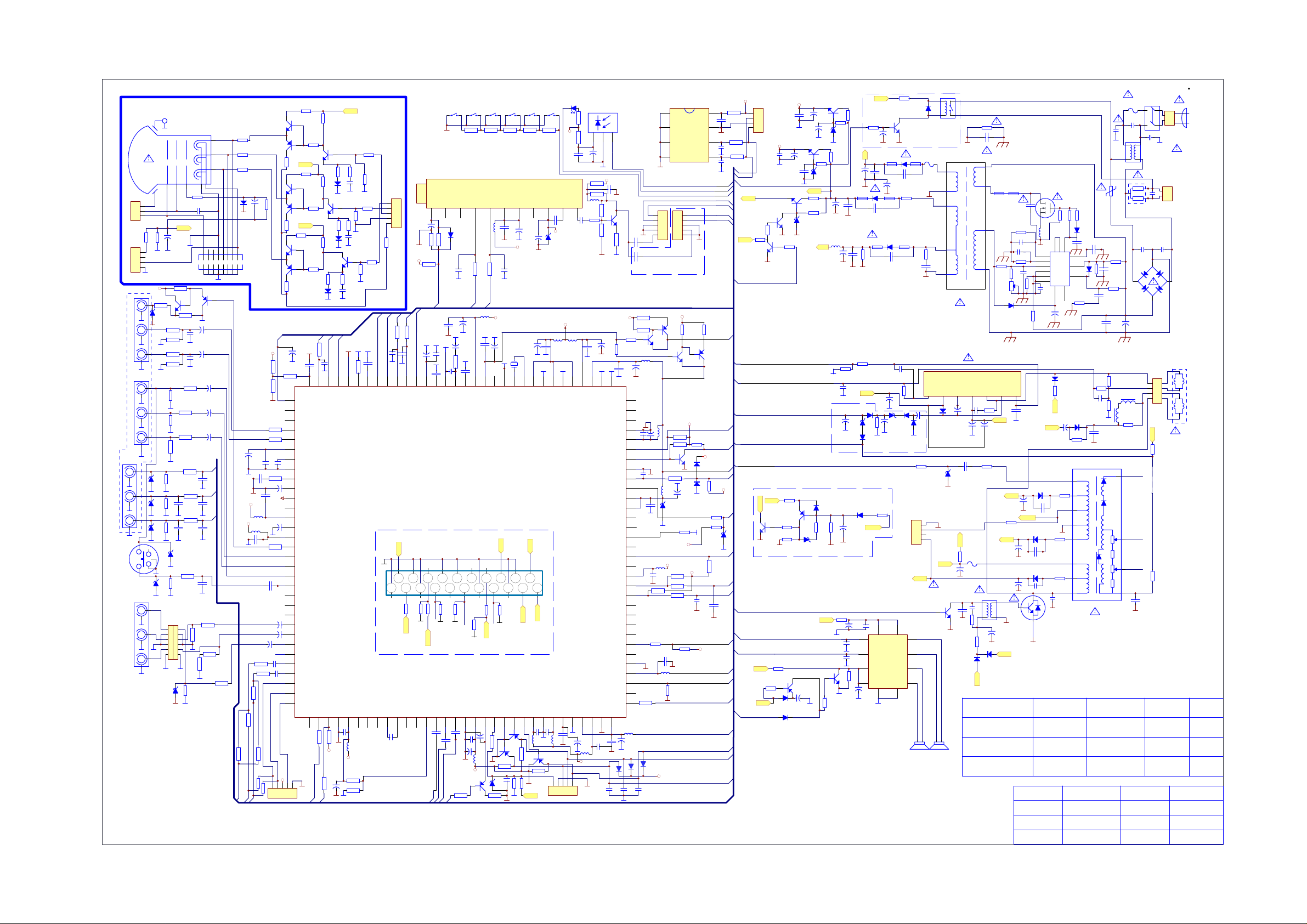

PCB CRT BD

P501

3

2

1

R505

33 1W

P502

4

3

2

1

REAR AV OUT

SVO

A.OUTSL

A.OUTSR

REAR INPUT

CVBS4/Y4

P901

A.IN4L

A.IN4R

REAR YUV INPUT

Cb

Cr

Y

P902

Y

S

S-VHS

C

P960

SIDE RUDIO INPUT

V

L

R

M66 (FS TUNER) PAL SECAM BG/DK/I AV-NTSC NICAM/TEXT

R516

+5V

C202

3n3

Test1

C236

2.2uF

C237

2.2uF

470 1/4W

Q512

BC422

R517

Q513

BC423

R518

470 1/4W

+200V

R526

470 1/4W

15K 2W

Q522

BC422

R527

Q523

BC423

R528

470 1/4W

+200V

R536 470 1/4W

15K 2W

Q532

BC422

R537

Q533

BC423

R538

470 1/4W

AGC

5

R205

+

C203

2.2uF

C204

2.2nF

R204

32

1K

33

AVL

34

A.IN5L

35

A.IN5R

36

A.OUTSL

1K

37

A.OUTSR

38

DECSDEM

39

AUDEEM

40

GND2

41

PLLIF

C234

1uF

42

+

SIFAGC

43

IFVEDIO OUT

44

DVB/FM OUT

45

VCC8V

46

+

AGC2SIF

47

VP2

48

SVO

49

A.IN4L

50

A.IN4R

51

CVBS4/Y4

52

C4

53

A.IN2L

54

A.IN2R

55

CVBS2/Y2

56

+

A.IN3L

57

+

A.IN3R

58

+

CVBS3/Y3

59

C2/C3

C239

60

A.OUTL

0.047uF

61

A.OUTR

0.047uF

C238

62

A.OUTHL

63

A.OUTHR

64

CVBSO

65

P501

GND

CRT

GNDSCREENFOCUS

150k 1/2W

R900

47K

R901

47K

82

82

82

R918

P961

D906

6V2

+

C503

4u7 250V

R904

330

R902

100K

R905

330

R903

100K

R921

82

C922

10pF

C923

10pF

R906

D900

P200

82

6V2

R908A

+200V

1K

Q900

BC847A

R908

R907

4.7K

1K

R909

100

R911

4.7K

100

R920

1

6

1.5k 1/2W

R927

100

C926

100pF

R928

100

R926

100

C927

100pF

R924

82

R540

C902

100pF

C903

100pF

C920 100P

R960

47K

C505

1000P 2KV

8

8

+

+

C908

2.2uF

C928

100pF

R962

R961

47K

ETH

R506

5V

R910

75

D901

6V2

D903

6V2

R922

D904

6V2

R923

D905

6V2

D902

6V2

1

6

1K

R963

Q901

BC857A

C904

10uF

C905

10uF

1K

R519

KR

1k 1/2W

R529

KG

1k 1/2W

R539

KB

1k 1/2W

C533

10u 250V

D533

+

IN4001

R541

1M1W

1234567

S501

1234567

R200

68K

C911

+

1uF

C909

+

2.2uF

+

Cb

Cr

Y

R929

100

47K 1/10W

+

C200

10uF

C229

+5V(8V)

L204

10uH

+5V

L205

0.1uF/50V

JP2

0

JP1

JP30JP4

C201

220nF

100nF

C230

4.7nF

10uH

C235

100nF

C231

R216

3.3K

R217

3.3K

0

0

R201

R203 1K

R202

R214 390

C234A 2.2u/50v

R215 1K

C233

22nF

5V

JP5

JP6

WOOFER

AOUTL

AOUTR

12345

P203

560

R525

560

R535

560

D531

1N4148

680

31

EHT

AGCOUT

FBISO66SVM

10K

R221

R222

100

SANDCAST

H OUT

R515

15K 2W

D511

1N4148

R523

D521

1N4148

67

5V

C241

10uF

Q511

BF422

Q521

BF422

270

R533

270

1

C205

22nF

29

SIF230SIF1

R223

1K

+

R513

270

R524

10

GNDIF

+200V

BF422

R534

10

C531

270P/50V

2

5V

R225

4.7K

Q531

28

GNDIF

+5V comb69GND comb68HOUT

C242

0.1uF

L206

10uH

2.2K

R224

R514

10

C511

270P/50V

C521

270P/50V

39K

R521

R522

10K

R532

10K

R206

27

IREF

BIN70GIN

R511

47

R512

10K

C206

R531

47

26

VSC

71

47

150nF

VIFIN225VIFIN1

GND

RIN

72

P503

R501

1K 1/4W

34

1nF

C207

24

73

GND

TU100

5

4

3

2

1

VDRA

100

R207

23

VDRA

UV1336

AGC1VT2Hi/n.c.3Mi/BS1(SCL)4Lo/BS2(SDA)5V+6i.c.(V+)7i.c.8i.c.(+33V)9IFGND10IF

+

C100

10uF

R100

R103

68K

39K

+5V

R101

10K

AGC

E-W

VDRB

100

R208

C208

C209

10uF

1nF

+

C210

22nF

C211

220nF

21

20

18

19

22

E-W

VDRB

DECBG

SECPLL

SCART

V1in

R943

VOUT

UOUT75YOUT74YSYNC

R9**

R945

100

75

75

GND

GND GND

R

UOC77

VOUT

INSSW3

78

76

77

C246

220n

C248

100nF

YCb

Cr

R942

75

C247A

0.1uF

C101

100P

100nF

C214

6n8

GND1

ABL

CIRCUIT CONSTANTS AND CIRCUIT ITSELF ARE SUBJECT TO CHANGE WITHOUT NOTICE

C004

R213A

1

Q202

BC327

+3.3VSTB

R033

+3.3VSTB

2K2

R031

10K

R030

10K

D010

R032

5.6K

8

7

6

5

MUTE

RELAY

IR IN

LED

KEY

KEY

X-RAY

C027

100P

TV STB

IR IN

+5VSTB

P003

100

R010

1

2

3

10nF

4

CON4/254

22 1/6W

R009

C003

56P

22 1/6W

R011

C005

56P

SCL

SDA

RELAY

5V

4

3

2

1

R829

5V-ST

10K

STANDBY

+5VSTB

R827

10K

Q804

1815

2SD882

C008

10n

Q806

c1815

R836A

10K

Q805

+3.3V-STB

+

C010

100uF

C009

10n

D832

5V6

C011

10n

C012

470u 16V

Q001

2SD667A

8V

R825

10 2W

R826

680 1/6W

+

C013

470uF 16V

+

1/6W

680

R012

D002

5.6V

107v

D003

3.9V

470u 25v

100u 160V

Q002

2SC1815Y

R013

10

C842

L802

100uH

C827

R015

33

+

C848

10n

+

A

VDRA

R350

VDRB

X-RAY

SYS

ABL

SANDCASE

B

R286

+14V

330

X-ray

Q281

c1815

SDA

SCL

H-OUT

L

LED

R

B

+12V

R603

10K

+8V

MUTE

Q280

A1015

R282

0

D280

R283

220

24V

R602

47K

Q600

A1015

C605

100uF/25V

D600

+

4148

D604

4148

2K2

C300

100u/16V

GND

X-RAY Protect Circuit

D281

1N4148

R285

R284

+

470

100K

R601

+12V

0.22/2W

GND

Q602

C1815

R605

10K

A

B

G

R

D001B

LED

R007

VOL-

R025A

390

MENU

TV/AV

R024A

K008K007

R023A

300

5VSTB

220

C002

10nF

K006

R027A

680

VOL+

P-

K004

K005

R026A

470

P+

K003

Iom

L101

C102

10uH

10n

D100

IN4148

R104

100

SCL SDA

+

C217

C212

10uF

C215

+

2.2uF

R210

12K

10nF

C216

15

17

VP1

PH2LF16PH1LF

P909

C103

100uF/10V

R109

C101A

100

100P

L200

+5V

10uH

+

Z200

10uF

C219

C218

24.576MHz

100nF

14

12

13

11

D.GND

VG/LED

DECDIG

XTALOUT

L1in

C106

10nF

+

+

+33V

D102

C105

+5V

BYV79C33

47uF/50V

+3.3V-STB

100uF/10V

L201

+

1uH

C222

C223

100nF

6

8

9

10

7

XTALIN

vrefP_Sdac

VrefP_Sdac

VrefN_Sdac

VrefN_Sdac

R1in

123456789101112131415161718192021

R946

75

R948

R949

15K

75

R947

GND

416K

G

B

UOC104

GND

B/PbIN380G/YIN379R/PrIN3

81

C251

C249

100nF

0.1uF

C250

+

10uF

5V

2SA1015

Q204

33K

R227

+

C253

22uF/16V

L207

10uH

Q232

4.7K

R229

Q231

1K

R230

C270

2200P

D204

5.6V

R228

220

BC857A

33K

LOUT

ROUT

VREFAD

VREFAD_NEG89VREFAD_POS

+3.3V analog88BO87GO86RO85BLKIN84BCLIN83LPF82GND3

C256

C255

220nF

220nF

91

90

BC857A

L208

C258

10uH

L209

10uH

100nF

BC857A

R231

1K

Q233

1K

R232

R270

R271

12345

18K

+5V

P202

1K

R008

47

47u/16V

11

C107

10nF

1uH

L202

4

5

VrefP_Sdac

TDA12066H

TDA12061H

TDA12011H

TDA12010H

TDA12027H

GNDA

93

92

C258A

47uF/16V

+

+

C001

R115

150

R111

470

L102

1uH

R114

56

C224

100nF

3

1.8VC4

3.3VA3

ROTATION P2.2

VDDA2

VDDA1

94

L210

C260

220nF

10uH

3.3V-STB

IR001

CP1

123

+8v

C108

0.01uF

R116

680

R117

150

+5VSTB

C225

+

10uF

C226

100nF

2

GND1GND

GAME L P1.5

GAME R P1.4

GND

MUTE P2.4

GND

KEYB P3.3

X-RAY P3.2

DECV1V8

SCART1 P3.1

SCART2 P3.0

TUNING P2.0

SDA P1.7

SCL P1.6

SDA2 P1.3

SCL2 P0.0

IBO D/A P0.1

IBO STB P0.2

LED P0.3

VSSC2

VDDC2

TV STB P1.1

IRQ P1.0

IR P0.5

VDD96VSS

95

C261

220nF

D201

C254

100P

P1.2

1.8V

P2.5

1.8V

P2.3

P2.1

3.3V

P0.4

1N4148

Q101

C3779

R118

R211A

4K7

1

WP

Vdd

2

n.c.

PTC

IC001

24C16

3

A2

SCL

4

Vss

SDA

Nicam

Z101

5

5

4

4

3

3

2

2

1

1

K9453K2966M

+5VSTB

Q201

R213B

BC327

4K7

Q287

BC847A

Z100

C110

22

10nF

C109

10nF

R213

1/2W

1

R212

4K7

R211

Q200

4K7

BC847A

C227

+

L203

10uH

10uF

IC200

128

127

126

L001

+5VSTB

10uH

125

124

C017100nF

123

122

121

120

119

118

117

116

115

114

113

112

111

110

109

108

107

C018

0.01uF

R029

C022

220nF

27K

+

R017

R218

10K

C019

10uF

BC847A

R024

L003

10uH

BZX79C2V4

47K

R018

Q203

D006

4148

100

D005

C024

4148

47uF

+

D004

R039

10K

+5VSTB

+3.3V STB

L002

10uH

C023

+5VSTB

3.3K

R027

220nF

100

R025

3.3K

100

R026

C026

100P

106

105

104

R036 100

L211

+

TDA12067H

C262

47uF

D202

C257

100P

103

102

C028

1N4148

220nF

10uH

L004

R047

3.3K 1/10W

100

R034

D203

1N4148

5V

C259

100P

101

100

99

98

97

1uH

+5VSTB

R046

3K3

R014

1K 1/6W

C845

1000u 25v

A.GND

C826

10n

C350

1500P

+

D304

3V9

C431

50V/47uF

+

C623

1000uF/16V

C600

5600/63v

C606

5600/63v

R607

47K

C607 22uF/16V

C840

220P 500v

R824

R314

1K

+14V

D413

IN4001

12

+

8V

R851

33 1W

R850

10K

Q850

C1815

+

C851

100u 16V

12V

+

C844

10n

+

C828

4u7 16V

D830

R836

FR104

HF70HF70

0.22 1W

D824

RU3C

HF70HF70

C830

15K 2W

330P 2kv

C351

2200P

C308

+

220uF/25V

D300

4148

+

D306

3V9

R300

C307

1K2

47u/16v

D305

4148

Vertical Protect Circuit

R407

11/2W

Heater

C604

13

0.1u 50V

3

4

IC600

TDA7266

7

6

8

9

GND

D850

1N4148

K850

Standby Power<3W

R819a

1

2

3

4

+

C313

R834

5A

A.GND

50V/4.7uF

D309

1

IN4001

P601

SPEAKER(R)

16

15

12

9

11

50PIN

D404

2

5V6

+107V

100u 160v

Q401

2235

T402

R404

15K/2W

C411

1000P / 500V

D831

FR104

220P 500v

220P 2KV

R316

1K

D307

4148

D308

4148

1

2

BF60BF60

C843

120 2W

C839

J401

0

P402

200V

15

14

P600

SPEAKER(L)

R835

8.2M 1W

C835A

2n2 AC400V

3

1

8

6

IC300

STV9302

C325

3

4

5

C323

0.33

1W

R313

+

100uF/35V

1

+

+

C360

C324

100uF

100uF/25V

C422

R408

10K/1W

5600P/63V

+33V

R403

2A

+

C414

T401

3300PF/500V

C401

R413

220

R402

4.7 1W

D405

1N4004

D833A

1N4004

12V

M66 CRT

Conversion table

44-14OFLN-IR3A

44-21OFLN-SS1A

21’TF SAMSUNG

()

L801

BF60X2 0.6uH

R811

15K 1/4W

R810

7K5

VR801

5KB

6

-14V

25v 470u

+14v

C415

470u 25v

10U 250v

+

C405

47u 25v

+14V

R420

2.2 2W

D806

FR104

-14V

C408

560P/2KV

C811

C810

22P

VREFVPOUTGNDPOMP UP VCCINPUT

GND

C413

C819

R803

C812

1n 50V PP

R812 56K

4.7M 1/2W

7

C334

2n2

+

+

SK3115

Q801

82K

L803

10n 63V

5

1

3

6

10

12

C850

R841

12K 1/6W

0.1u 50V

R813

C816

47UF/25V

D403

FR104

+

C403

390P 500V

Heater

D402

FR104

C412

390P 500V

D401

FR104

C409 390P 500V

BSC25-0252R

BSC25-0252S

BSC25-0252T

Prepared by

Reviewd by

Issued on

R808B

1K 1/2W

107V

Q402

2SC5885

T402

91487

IC801

+

D320

4148

R351

10K

-14V

R409

1 1W FUS

R405

1 1W

R418

1 1W FUS

C406B

0.012uF 1.6KV

R808A

R808

47 1/4W

100 1/4W

D807

1N4148

C808A

13

560PF

4

10n 63V

11

D810

IN4148

2

TDA16848

C815

0.001U 63V

R804

1.8K

C337

10u 100v

C420

D400

+

1n4002

R410

10K 1w

T402

BSC25-0252S

6

3

10

7

4

2

9

1

EC04028(M66)

Jiao jianpeng

Zhou songming

2005.01.26

C802A

102 400V

R801

3.3 /5W

C817

R805

4M7 1/2W

C814

R806

220n 63V

56K 1/6W

R807

1M 1/2W

C806

C808

150uF/400v

10n/500v

R324

220

2K2

1W

R315

L412

50uH

1000P

R321

1.8

2W

L411

0uH

GND

R411

C421

390n 250v

EHT

HV

C406B

0.011uF/1.6KV

0.012uF/1.6KV

0.012uF/1.6KV

F801

T2A

C801

220n/AC275V

RT801

PTC 20M

RL255 X4

+

1K2 1W

FOCUS

SCREEN

8

Serial No.Chassis Name

File No.

Version

Updated on

S801

C802B

102 400V

T801

36-LIF010-A X0

C803

100n/400V

C804

C805

4n7/250V

4n7/250v

D801-D804

P400

1

2

3

4

+14V

R414

7.5K

R415

1K

C410

0.033u 100V

C421

0.33uF/250V

0.39uF/250V

0.33uF/250V

P802

1

2

P801

1

2

1.5OHM 2W

2.2OHM 2W

1 OHM2W

01-000M66-MA1

0.1

2005.04.05

R420

Page 2

Alignment Procedure

1. GENERAL

1.1 Common Information

1.1.1 Use isolating transformer with low internal resistance.

1.1.2 Mains voltage is 90-260

1.1.3 All voltages and waveforms mentioned are with respect to Ground. Do not use

heat-sink as Ground.

1.2 How to enter factory Mode (Service menu, service mode)

1.2.1 Certain alignment procedures need to enter Factory Mode (Service Menu). There

are two ways to access factory mode:

One is :

A. Press and hold the VOLUME DOWN key tightly on the unit until minimum level

B. Don’t release the VOLUME DOWN key on the unit

C. Then press the CAPS key in 3 times on the RC

The other is:

Press “D-mode

shortcut key if “bit-0” of “mode 1” is at “0”.)

1.2.2 All system data in Factory Mode of “Key 8 & Key 9”

otherwise, the set will work abnormally.

1.2.3 It is suggested to disable the D-Mode key before the set leave the factory.

Navigation:

- Press “Pro+” “Pro -”

- Press “Vol+ ” “Vol-”

- Press “0” “1” “2” “3” “4” “5” “6” “7” “8” “9”

to access factory menu.; All change in factory data will be saved in EEPROM

automatically

- Press “BUS OPEN”

other ICs. This is only valid during automatic adjustment of white balance.

“ Key on the factory RC. (Please noted the “D-mode” key is the invalid

V AC, unless otherwise stated.

are not adjustable when servicing,

key to select option;

key to adjust or select option.

on the RC as the shortcut key

key on factory RC to cut off the I2C control from the CPU to

1.3 A few special modes:

1.3.1 Aging Mode is used before set alignment. It would operate in factory mode;

1.3.2 Vertical Stop mode

factory mode and repress “ mute” key to exit.

1.3.3 White balance alignment mode

1.3.4 Factory Mode (Initialization)

In factory mode, press RECALL button to initialize the FACTORY-OUT status.

is used to confirm the accelerating voltage. Press “Mute” key in

Volume: 30, PG password:0000, Favorite channel: ch1/ch2/ch3,

channel lock: disable, Picture mode: normal,

Color temp: normal, calendar:01-08-2004

2. Alignment procedure:

2.1 B+ voltage adjustment

2.1.1 Apply 110-240V AC (+5V) to mains power input, and Philips standard testing pattern

to RF input.

2.1.2 Adjust VR801 in STANDARD mode until voltage at TP2(B+) is 107V+

0.5V.

Page 3

Alignment Procedure

2.2 RF AGC adjustment

2.2.1 Input 58dB grey scale signal.

2.2.2 Press key “4” to enter RF AGC adjustment.

2.2.3 Press “OK” key to auto adjust RF AGC, also can adjust “RF AGC” key until the

letter change from “INACTIVE” to ”ACTIVE”.

* The others use default value.

2.3 Crystal oscillator frequency adjustment

2.3.1 Crystal oscillator frequency adjustment with NICAM

a. Input audio signal with NICAM.

b. Enter factory mode, press “game” key , then press “V+” key to adjust “DCXO

Auto”, until it displays “OKEY”.

2.3.2 Crystal oscillator frequency adjustment without NICAM

a. Input PAL color bar signal.

b. On factory mode, press “0” to adjust “DCXO Auto” until it steady at 128.

2.4 Screen & Focus voltage adjustment

2.4.1 Screen voltage adjustment

a. Input any signal.

b. Press “MUTE” key on the remote control and the screen will become a

horizontal line, here horizon stop vibration. Then adjust the “screen” VR on

the flyback until the horizontal line can just be seen (minimum visible

intensity).

2.4.2 Focus voltage adjustment

a. Input cross hatch pattern signal.

b. Adjust the “focus” VR on the flyback until the screen becomes clear.

2.5 White balance adjustment (NORMAL)

2.5.1 Choose Black and White pattern signal (PAL).

2.5.2 On factory mode, press “1” key enter white balance adjustment.

2.5.3 Measure the dark side of the picture with a color analyzer adjust RED and GRN

until the data on the analyzer become x=274+

2.5.4 Measure the bright side of the picture. Then adjust WPR, WPG and WPB until

the data on the analyzer become x=274+

2.5.5 Repeat step 1 and 2 until you get right color on both dark and bright side of the

screen.

Remark :

1. When adjusting, RED、GRN are used to adjust black balance and WPR、

WPB、WPG are used to adjust white balance .

2. On product line, the item which can be auto adjusted by auto test

equipment , its data according to auto adjust value.

3. White balance address please meet the fourth part in page 12.

8, y=280+8.

8, y=280+8.

2.6 Adjustment of Sub-brightness

2.6.1 Input grey scale + color bar signal.

2.6.2 Press key “6” enter sub-brightness adjustment.

2.6.3 At standard state, adjust “BRTC” parameter , until the secondary grey just be

seen.

* Do not change value “BRTS”.

Page 4

Alignment Procedure

2.7Picture geometric adjustment

2.7.1 Vertical geometric adjustment

a. Input a PAL cross hatch pattern signal .

b. Press key “2” enter Vertical geometric adjustment .

c. Use remote control to adjust one by one , watch the figure, until the center or the

corner grid has the same size .

d. When adjust vertical position , make the center of vertical intermediately.

e. In “5VSL”, the second half may blanking , adjust the first half at display range.

Remark: :

1 5VSC , 31 is fixed, don’t adjust .

2 5VPOS for vertical position.

3 5VAM for vertical amplitude.

4 5VSL for vertical slope.

5 5VL for vertical linearity.

6 5SCL for vertical S-correction.

7 5WBR for vertical start of blanking time on 4:3 mode (16:9 tube).

8 5WBF for vertical end of blanking time on 4:3 mode (16:9 tube).

9 5BSWBR for right side black width of blue screen .

10 5BSWBF for left side black width of blue screen.

* 5WBF/5WBR only use on matching 16:9 tube, at 4:3 picture mode, adjust

blanking time of R and F. First press “ZOOM” key switch to 4:3 mode, then adjust

5WBF and 5WBR respective to make the overscan meet the requirements.

*Adjustment is disabled when match 4:3 tube.

* 5BSWBR and 5BSWBF needn’t adjustment.

2.7.2 Horizontal geometry adjustment

a. Input a PAL cross hatch pattern with black and white background signal.

b. Press key “3” enter Horizontal geometric adjustment.

c. Use remote control to adjust one by one , watch the figure, until the center and the

vertical line at left and right side of the picture become straight.

Remark :

1. Adjust 5HSH for horizontal position, data should make H center mediacy .

2. 5PAR for parallelogram adjustment.

3. 5BOW for bow adjustment.

4. Adjust 5EWW for horizontal width.

5. 5EWP for pincushion correction.

6. 5UCR for upper corner correction.

7. 5LCR for low corner correction.

8. 5EWT for trapezia correction.

2.8 EHT/HEW ratio test:(test with PC program)

Equipment requirements : High Voltage Meter (Range: 0 - 40kV)、High voltage test

stick (1000:1)、Adjustable DC power supply、Dummy deflexion coil(as same

inductance as CRT which use to product).

Test method :

a. Mount the EHT cap on to the fixture and connect the EHT meter. Plug in the

dummy deflection coil. Connect the DC meter across C431.

b. Switch on the chassis and measure the ratio of EHT/HEW at I

= 0 ( brightness、

b

Page 5

Alignment Procedure

d. Apply PC program, V/V1 need satisfy request below :

2127P3 44-210FLN-SZ1A

contrast are minimum).

Here, the HEW is the DC voltage across C431.

EHT voltage V, HEW voltage V1.

EHT/HEW (V/V1)

A51KQK99X01

2.9 X rays over voltage protecting circuit test

Test method :

When TV ON with color bar signal, add more than 27V DV to C431, machine could

enter into protection mode, otherwise please inspect X rays over voltage protecting

circuit .

2.10 PS line polarities test

This test only the machines which will sell to NAFTA should be done.

Test method :

Connect as drawing below :

DC Power Supply

9V

- +

Sound clew equipment

DX 2.2k

Power Supply jack M

TO F801

Plug the card power connector plugs to Power Supply jack M, and use multimeter pen

touch F801 random pin, then LED DX should luminescence and clew with sound,

otherwise it is unqualified.

2.11 PS power test

Equipment requirements : Wattmeter

Test method :

a. Input more than 60dB color bar signal, audio 1K Hz, 100% modulation.

b. Brightness and contrast are maximum, adjust the volume to make the audio output

power at 0.5W.

c. Connect the wattmeter to test power consumption of Power Supply.

d. Switch the set to standby mode, and then measure the power consumption of

Power Supply again.

It should satisfy request below :

Type Power Standby power

Page 6

Alignment Procedure

2127P3

21”

14”

61W

5.3W

2.12 High voltage and Ib value limit test( random test )

Equipment requirements :Brandenburg High Voltage Meter (Range: 0 - 40kV)

Beam Current Meter

Input signal type : A 60dB white pattern signal.

Test method :

a. Connect the EHT-meter across the anode and aquadag of the CRT.

b. Connect a beam current meter between t he anode of picture tube and EHT-cable

of LOT.

c. Measure the EHT-voltage at zero beam current (I

d. Subsequently, measure the EHT-voltage at respective I

It should satisfy request below :

Beam current

Ib = 50µA

21” 14”

EHT-voltage (KV)

beam

= 0µA).

beam(s) .

Ib=50µA&1200µA

2.13 Heater voltage test ( random test )

Equipment requirements : True RMS Voltmeter

Input signal type : Philips test card ( from 1 mV rms(60dBuV)to 50 mV rms )

Test method :

a. Connect the true RMS voltmeter between the heater .

b. Adjust the brightness and contrast to maximum .

c. Then, test the heater voltage . It may be Vrms

2.14 Main function test (eg, NICAM, BTSC, TELTEXT and etc.)

NICAM test standard please reference

BTSC test standard please reference

TELTEXT test standard please reference Q/WP1259-2003.

CCD、V-CHIP test standard please reference EIA-744-A

3. EEPROM Data and Address.

Items marked with * are adjustable, the others are not. Take Model 2127 for reference only.

Model

No.

2127P3 32 26 35 23 33 35 35 33 33 31

RED* GRN* WPR* WPB* WPG* 5VPOS* 5VAM* 5VSL* 5VL* 5VSL

KEY1 KEY2

Page 7

Alignment Procedure

Model

No.

2127

P3

5SCL* 5WBF

25 5 4 5 5 28 29 41 36 28 48

Model

No.

2127

P3

5LCR* 5EWT*

44 25 20 32 3.5M 3.1M 4.0M 32 32 64

Model

No.

KEY2 KEY3

5BS

*

CPEK

PAL

5BSW

BR*

5WBR*

*

KEY3 KEY4

AGC*

WBF

RF

CFPEK

PAL

5HSH

*

CFPEK

5PAR

NTS

5BOW

*

CFPEK

YUV

5EWW* 5WEP* 5UCR

*

IFPL BBTC

PG

R/G/B

KEY4 KEY5

VG2BRI

* HDOL CNTX CNTN BRTX BRTN COLX COLN TNTX TNTN

*

2127P3 20 4 53 2 11 5 63 0 20 12

Model

No.

CNTC BRTC

* COLC TNTC COLP COLS BRTS SHPTV4 SHPX SHPN

KEY6 KEY7

2127P3 25 32 28 30 0 28 0 31 31 31

Page 8

Alignment Procedure

Model

No.

OSD

BRI

5CCDH 5CCDV 5OSDH 5OSDV 5MENUV MENUH OPT1

KEY 7 KEY 8

* OPT2*

2127P3 15 8 35 15 42 18 7 0A 80

Model

No.

* OPT4* OPT5* OPT6* OPT7* OPT8* OPT9* OPT10* MODE1* MODE2*

OPT3

KEY8 KEY9

2127P3 33 0 27 0B 58 0 4 0 26 97

Model

No.

MODE3

* MODE4* MODE5* MODE6* MODE7* MODE8* MODE9* MODE10*

KEY9

2127P3 50 AD 1F 8E 10 22 C2 10

Model

No.

VOL

01

VOL

25

VOL

50

VOL

100

YDFE

PAL

DEC

LVL

KEY0

MONO

LVL

NIC

LVL

ADC

LVL

DCXO

CAPV

*

NICLP

INV*

PSCALE

2127P3 27 121 135 148 15 0 0 0 0 54 Not 0.375

Page 9

Alignment Procedure

inverted

Mode

l No.

2127

P3

PLIM PCENTER

96 212 6 86 30 40 85 30 70 11 4 5

KEY0 KEY NOTEBOOK

* LOUNDESS

BASS TREBLE 300Hz

M S T M S T M S T

KEY NOTEBOOK KEY FAVORITE

Mode

l No.

500Hz 1K Hz 5K Hz 8K Hz Warm* Cool*

M S T M S T M S T M S T R G B R G B

2127

P3

9 7 6 6 6 7 9 7 9 11 4 11 4 0 6 6 0 4

Model

No.

SET

*

P1

SET

P2*

DATA

VL*

DATA

VH*

KEY SLEEP

DATA

UF*

SPE

POSI

SPE

DATA

SENSI

ON

2127P3 147M 423M 1 2 8 0 0 0 0

SENSI

OFF

Page 10

Alignment Procedure

4. White balance address

R G B R AMP G AMP B AMP R CUT G CUT B CUT Remark

Offset DATA 142 143 150 146 161 ***** Factual setup

IC write(LsB)

Sub Add 32 33 34 23 24 *****

Start Bit 6 6 6 6 6 *****

St0p Bit 0 0 0 0 0 *****

E2PROM

Sub Add(LsB) 122 123 124 119 120 *****

Reference

Slave Address(write)

16 Bit EEPROM

IC 138

Page Addr

E2PROM 160

5. CDRH Document ( If available)

6. REMARK

TV standard color TEM

B

BJ SanAi(SWB-301)

The items marked in Grey are invalid for this chassis.

Loading...

Loading...