Page 1

TCL

Service Manual

CHASSIS MT62LV

Content s

1. Caution .…………………...................................................................…………...………..2

2. Test and Alignment………………….………………………………...………..7

3. Block Diagram………………………………….…….. .......................……..25

4. MB Schematic Diagram……………… …………….......................……….26

5. PSU Schematic Diagram..........................................................................43

6. Exploded View

....................................

................

.................................

44

Page 2

CAUTION:

1、

Use of controls, adjustments or procedures other than those specified herein may result in

hazardous radiation exposure.

CAUTION: TO REDUCE THE RISK OF

CAUTION

RISK RISK OF OF ELECTRIELECTRICC

SHOCK SHOCK DO DO NOT NOT OPEN.OPEN.

The lighting flash with arrowhead symbol, with an equilateral triangle is intended to

alert the user to the presence of uninsulated voltage within the product s

enclosure that may be of sufficient magnitude to constitute a risk of electric shock to

the person.

The exclamation point within an equilateral triangle is intended to alert the user to the

presence of important operating and maintenance (servicing) instructions in the

literature accompanying the appliance.

ELECTRICAL SHOCK, DO NOT REMOVE

COVER (OR BACK). NO USER SERVICEABLE

PARTS INSIDE. REFER SERVICING TO

QUALIFIED SERVICE PERSONNEL.

dangerous

WARNING: TO REDUCE RISK OF FIRE OR ELECTRIC SHOCK, DO NOT

EXPOSE THIS APPLIANCE TO RAIN OR MOISTURE.

Page 3

IMPORTANT SAFETY INSTRUCTIONS

CAUTION:

Read all of these instructions. Save these instructions for later use . Follow all Warnings and

Instructions marked on the audio equipment.

1. Read Instructions- All the safety and operating instructions should be read before the product is operated.

2. Retain Instructions- The safety and operating instructions should be retained for future reference.

3. Heed Warnings- All warnings on the product and in the operating instructions should be adhered to.

4. Follow Instructions- All operating and use instructions should be followed.

FOR YOUR PERSONAL SAFETY

1. When the power cord or plug is damaged or frayed, unplug this television set from the wall outlet and refer servicing to

qualified service personnel.

2. Do not overload wall outlets and extension cords as this can result in fire or electric shock.

3. Do not allow anything to rest on or roll over the power cord, and do not place the TV where power cord is subject to

traffic or abuse. This may result in a shock or fire hazard.

4. Do not attempt to service this television set yourself as opening or removing covers may expose you to dangerous

voltage or other hazards. Refer all servicing to qualified service personnel.

5. Never push objects of any kind into this television set through cabinet slots as they may touch dangerous voltage

points or short out parts that could result in a fire or electric shock. Never spill liquid of any kind on the television set.

6. If the television set has been dropped or the cabinet has been damaged, unplug this television set from the wall outlet

and refer servicing to qualified service personnel.

7. If liquid has been spilled into the television set, unplug this television set from the wall outlet and refer servicing to

qualified service personnel.

8. Do not subject your television set to impact of any kind. Be particularly careful not to damage the picture tube surface.

9. Unplug this television set from the wall outlet before cleaning. Do not use liquid cleaners or aerosol cleaners. Use a

damp cloth for cleaning.

10.1. Do not place this television set on an unstable cart, stand, or table. The television set may fall, causing serious injury

to a child or an adult, and serious damage to the appliance . Use only with a car t or stand recommended by the

manufacturer, or sold with the television set. Wall or shelf mounting should follow the manufacturer s instructions, and

should use a mounting kit approved by the manufacturer.

10.2. An appliance and car t combination should be moved with care. Quick stops, excessive force, and uneven surfaces

may cause the appliance and cart combination to overturn.

Page 4

PROTECTION AND LOCATION OF YOUR SET

11. Do not use this television set near water ... for example, near a bathtub, washbowl, kitchen sink, or laundry tub, in a

wet basement, or near a swimming pool, etc.

Never expose the set to rain or water. If the set has been exposed to rain or water, unplug the set from the wall

outlet and refer servicing to qualified service personnel.

12. Choose a place where light (artificial or sunlight) does not shine directly on the screen.

13. Avoid dusty places, since piling up of dust inside TV chassis may cause failure of the set when high humidity persists.

14. The set has slots, or openings in the cabinet for ventilation purposes, to provide reliable operation of the receiver, to

protect it from overheating. These openings must not be blocked or covered.

Never cover the slots or openings with cloth or other material.

Never block the bottom ventilation slots of the set by placing it on a bed, sofa, rug, etc.

Never place the set near or over a radiator or heat register.

Never place the set in enclosure, unless proper ventilation is provided.

a built-in

PROTECTION AND LOCATION OF YOUR SET

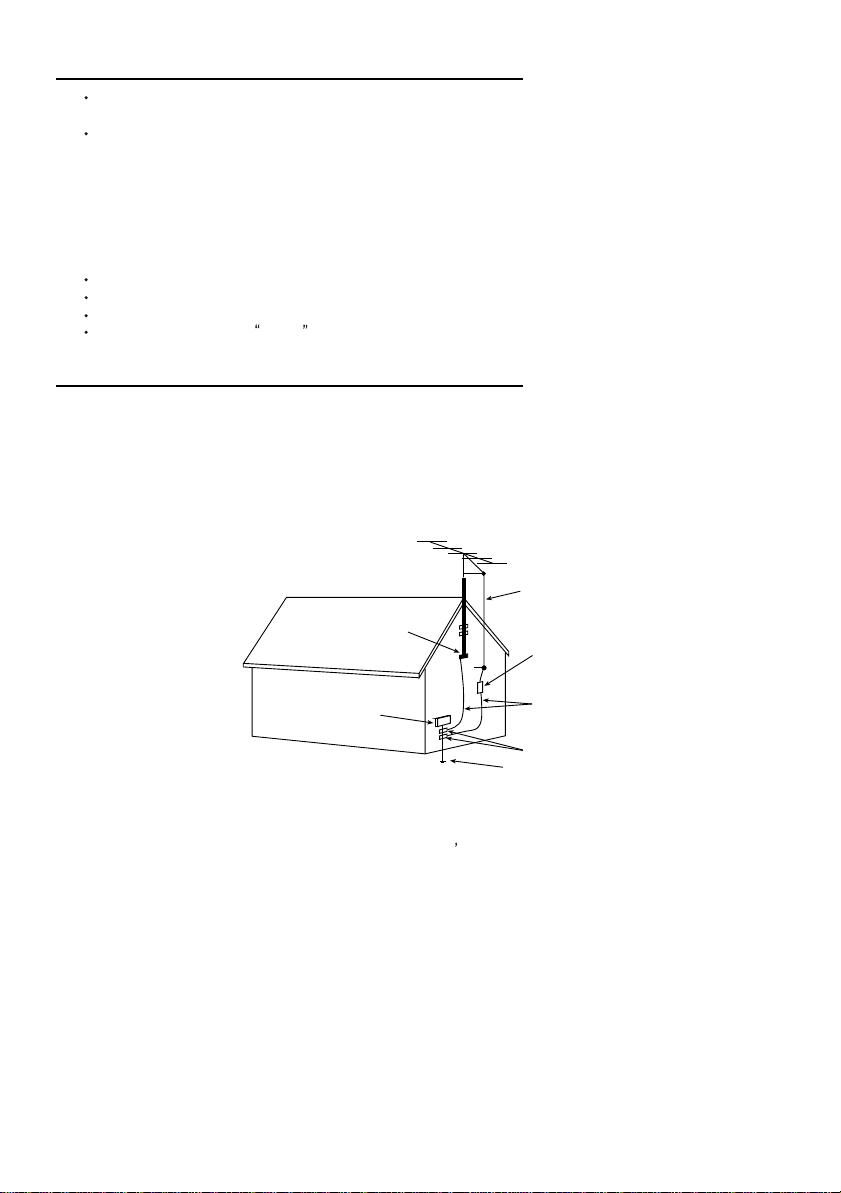

15.1. If an outside antenna is connected to the television set, be sure the antenna system is grounded so as to provide some

protection against voltage surges and built up static charges, Section 810 of the National Electrical Code, NFPA No.

70-1975, provides information with respect to proper grounding of the mast and supporting structure, grounding of the

lead-in wire to an antenna discharge unit, size of grounding conductors, location of antenna discharge unit, connection

to grounding electrode, and requirements for the grounding electrode.

EXAMPLE OF ANTENNA GROUNDING AS PER NATIONAL ELECTRICAL CODE INSTRUCTIONS

EXAMPLE OF ANTENNA GROUNDING AS PER

NATIONALELECTRICAL CODE

ANTENNA

LEAD- INWIRE

GROUND CLAMP

ELECTRIC SERVICE

EQUIPMENT

NEC-NATIONALELECTRICAL CODE

ANTENNA DISCHARGE

UNIT (NEC SECTION

810-20)

GROUNDING

CONDUCTORS

(NECSECTION 810-21)

GROUND CLAMPS

POWER SERVICE GROUNDING

ELECTRODE SYSTEM

(NEC ART 250. PARTH)

15.2. Note to CATV system installer : (Only for the television set with CATV reception)

This reminder is provided to call the CATV system attention to Article 820-40 of the NEC that provides

installer s

guidelines for proper grounding and, in part icular, specifies that the cable ground shall be connected to the grounding

system of the building, as close to the point of cable entry as practical.

16. An outside antenna system should not be located in the vicinity of overhead power lines or other electric lights or power

circuits, or where it can fall into such power lines or circuits. When installing an outside antenna system, extreme care

should be taken to keep from touching such power lines or circuits as contact with them might be fatal.

17. For added protection for this television set during a lightning storm, or when it is left unattended and unused for long

periods of time, unplug it from the wall outlet and disconnect the antenna. This will prevent damage due to lightning

and power-line surges.

Page 5

OPERATION OF YOUR SET

18.

This television set should be operated only from the type of power source indicated on the marking label. If you are not

sure of the type of power supply at your home, consult your television dealer or local power company. For television

sets designed to operate from battery power, refer to the operating instructions.

19. If the television set does not operate normally by following the operating instructions, unplug this television set from the

wall outlet and refer servicing to qualified service personnel. Adjust only those controls that are covered in the operating

instructions as improper adjustment of other controls may result in damage and will often require extensive work by a

qualified technician to restore the television set to normal operation.

20. When going on a holiday : If your television set is to remain unused for a period of time, for instance, when you go on

a holiday, turn the television set and unplug the television set from the wall outlet.

off

IF THE SET DOES NOT OPERATE PROPERLY

21. If you are unable to restore normal operation by following the detailed procedure in your operating instructions,

do not attempt any further adjustment. Unplug the set and call your dealer or service technician.

22. Whenever the television set is damaged or fails, or a distinct change in performance indicates a need for

service, unplug the set and have it checked by a professional service technician.

23. It is normal for some TV sets to make occasional snapping or popping sounds, particularly when being

turned on or off. If the snapping or popping is continuous or frequent, unplug the set and consult your

dealer or service technician.

FOR SERVICE AND MODIFICATION

24. Do not use attachments not recommended by the television set manufacturer as they may cause hazards.

25. When replacement parts are required, be sure the service technician has used replacement parts specified

by the manufacturer that have the same characteristics as the original part. Unauthorized substitutions

may result in fire, electric shock, or other hazards.

26. Upon completion of any service or repairs to the television set, ask the service technician to perform

routine safety checks to determine that the television is in safe operating condition.

Page 6

Factory Alignment Specification of normal SIACP

TCL WW R&D

FPD CENTER

Factory Alignment Specification of normal SIACP

For MT5362 serial

Version:V0.51

For the following Chassis:

MT62L:A mini edition of MT62B

MT62S: MT62B + MS6M20(MEMC module) for super slim LCD

MT62F:A full function edition of MT62B

MT62S2: MT62S + DVB-S/S2 for super slim LCD

MT62LV:MT62L + VGA source + headphone output

PREPARED BY : Lance Deng

APPROVED BY : DATE :

DATE : 2011-01-18

Page 7

Factory Alignment Specification of normal SIACP

Disclosure

The information contained in this document is proprietary to TCL SZ FPD lab and shall not be

disclosed by the recipient to third persons without the written permission of the team leader or

GM of R&D.

Revision History

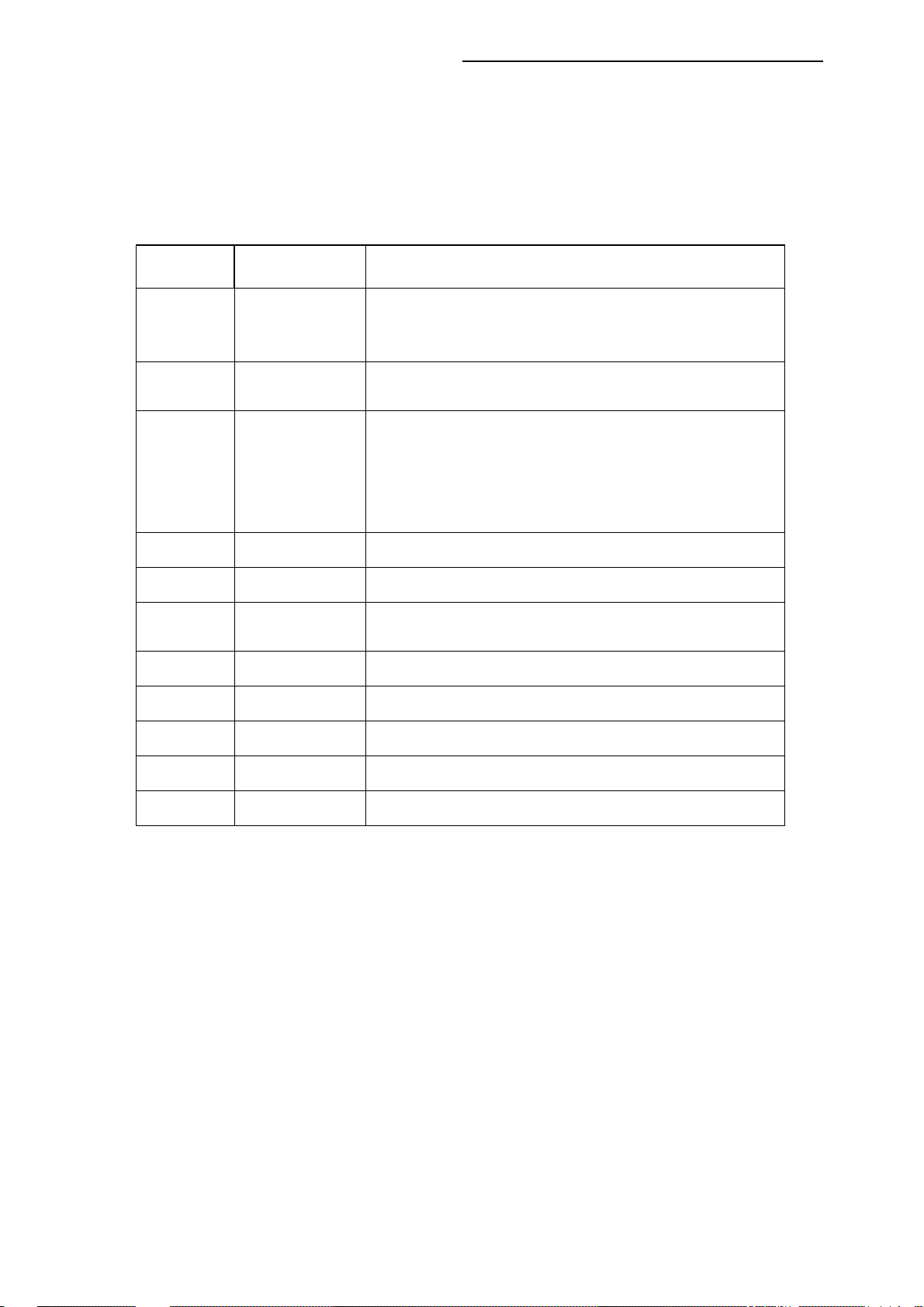

Status, Ver Date, Drafter Description of changes

V0.10 2010-02-07 This is the first version of normal SIACP

·HDMI as the main absolute input

·The password of factory menu is 9735

V0.20 2010-04-14 ·Upgrade specs for High Pot. and Insulating Resist ance Tests

·Upgrade USB upgrade SW met ho d

V0.30 2010-06-09 ·Add RCU(remote control unit) selection for the models IP

before May of 2010 in factory menu:( “feature” sub page in

MT62L, “Project info” sub page in MT62F and MT62S)

RC199:RC1994***

RC200:RC3000***

V0.42 2010-10-15 Add MT62S2 Chassis,

V0.50 2010-10-26 Add MT62LV Chassis,

V0.51 2010-12-22 Add the statement that the adapter should meet the High Pot.

and Insulating Resistance requirement.

Page 8

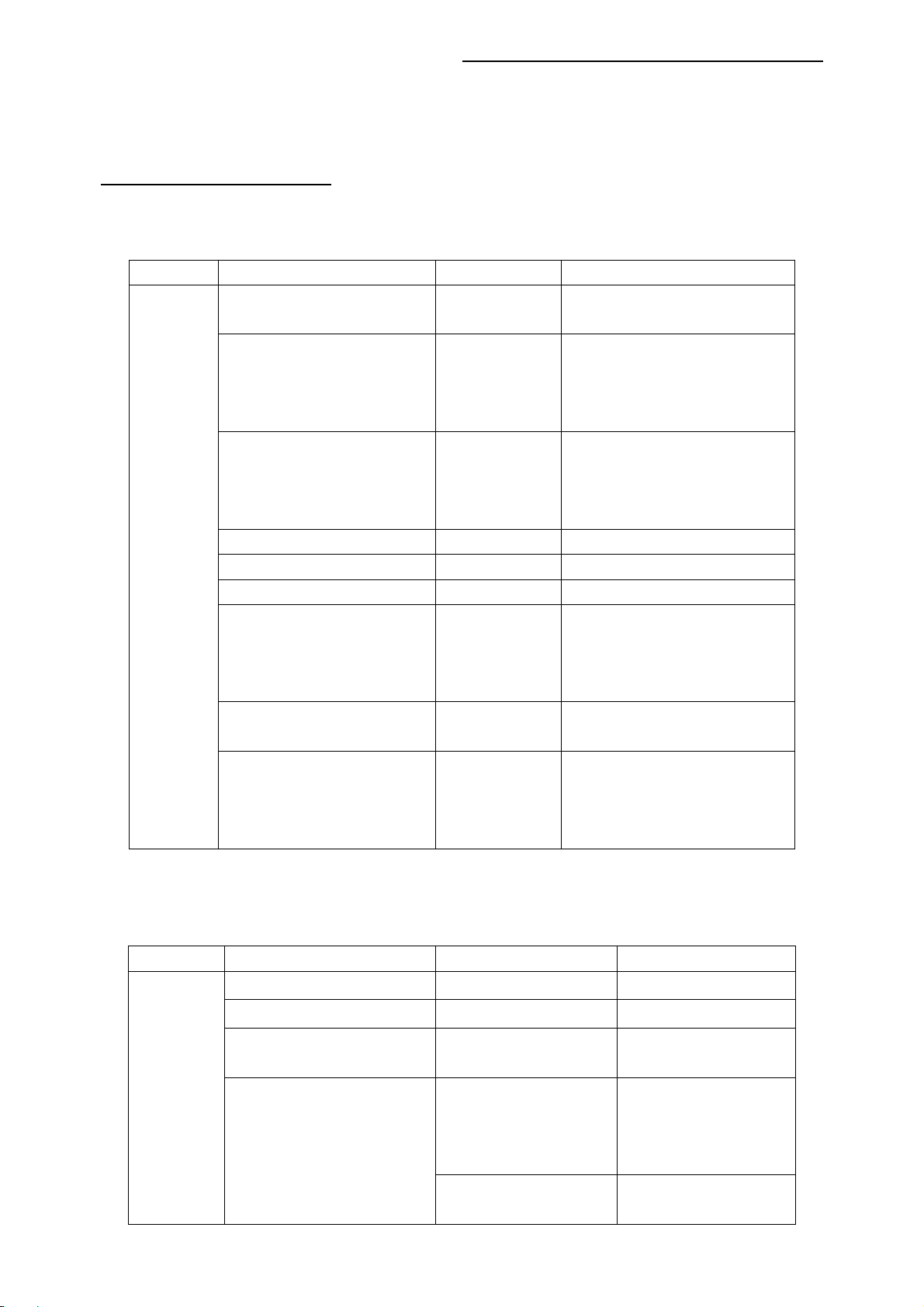

Factory Alignment Specification of normal SIACP

These chassises are designed for European LCD TV with MPEG4. The main chip is from

Mediatec (MT5362 series) and supports below inputs and outputs:

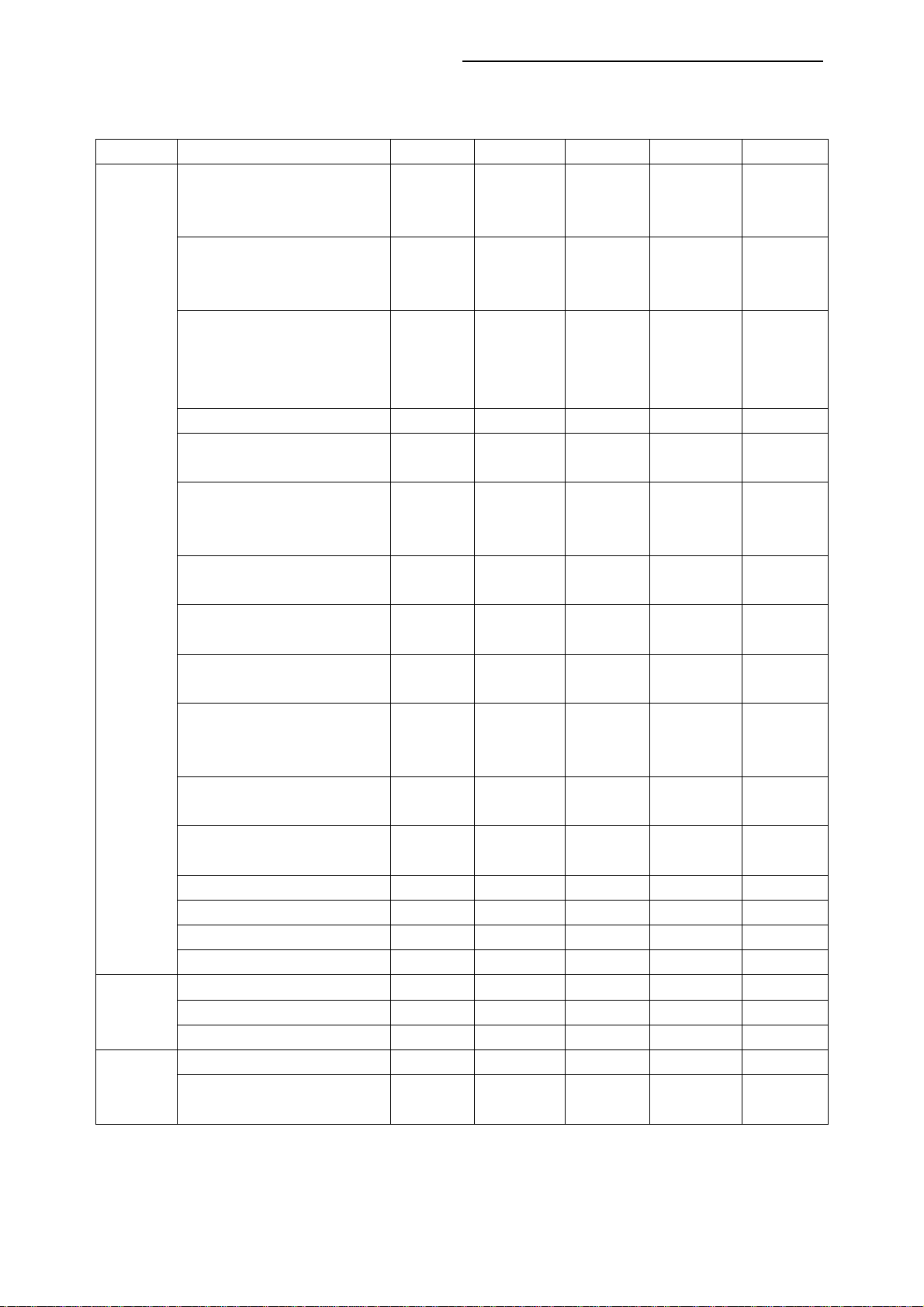

class item MT62L MT62S MT62F MT62S2 MT62LV

ATV

( PAL B/G D/K I, SECAM

B/G D/K L/L)

DTV

(DVB-T,DVB-C,DVB-S/S2)

HDMI

(480i/p, 576i/p, 720p up to

1080i/p, compliant v1.2.

with HDCP)

VGA

VGA/DVI audio

CMP

(YPrPb can support from

input

&

output

function

Others

Serial connector of MT5362 definition:

Pin1:VCC Pin2:RXD Pin3:TXD Pin4:GND (MT62LV: Pin1:RXD Pin2:TXD Pin3:GND)

I2C connector of MEMC definition:

Pin1:VCC Pin2:GND Pin3:SCL Pin4:SDA

480i up to 1080p,audio)

SCART1

(CVBS & RGB,audio)

SCART2

(CVBS & YC,audio)

Side AV or back AV

(CVBS,audio)

USB player

(picture,video,audio)

SCART1 output

(CVBS,audio)

SCART2 output

(CVBS,audio)

Headphone output

SPDIF output

MEMC

CI+

Serial connector

I2C connector of MEMC

module

√ √ √ √ √

DVB-T DVB-T

DVB-C

2 5 3 5 2

√ √ √ √

√

√ √ √ √ √

√ √ √ √ √

Picture

(up to

SW)

√ √ √ √ √

√ √ √

Coaxial Optical Coaxial Optical Coaxial

√ √

√ √ √

P5 P16 P3 P16 P5

PM3 PM3

Share

with CMP

Picture,

Video,

audio

DVB-T

DVB-C

√

Back

AV

Picture,

Video,

audio

DVB-T

DVB-C

DVB-S/S2

Share

with CMP

Picture,

Video,

audio

DVB-T

√

Picture

(up to

SW)

Page 9

Factory Alignment Specification of normal SIACP

INFO:

ª All tests and measurements mentioned hereafter have to be carried out at a normal mains voltage

(220 ~ 240 VAC)

ª All voltages have to be measured with respect to ground, unless otherwise stated

ª All final tests have to be done on a complete set including LCD panel in a room with temperature of

25+/-7°C

ª The White Balance (color temperature) has to be performed into subdued lighted room after at

least 1 hour of warm-up/burn-in. This is applicable for both Alignment and Picture Performance

evaluation at OQA in order to be set free of any temperature drift ( colorimetry vs time)

1. Electrical Assembly Alignment

Preconditions – DC/DC Check

1.1.

Before power on, please check the board according to the relevant block diagram and circuit

diagram, and make sure that no serious error should destroy the board. For example,the output

of DC/DC and LDO should not shorted to ground.

Supply a suited voltage and power on , then check the voltage according to the relevant

block diagram , circuit diagram and voltage spec . the error should less than 5% .For example,

the voltage for main chip(DV33, AV33,DV18,DV11,etc.), the voltage for DDR (DDRV) , the

voltage for amplifier(AUDIO_PWR),etc. Only the standby voltage is necessary if there is no

software in the flash .

SW download

1.2.

Download the latest release MT62_SW into the flash using MTK SW tool. See Appendixo

“How to download FLASH SW”. Or upgrade the SW from USB port See Appendixp” How to

upgrade FLASH SW from USB”.

Download the latest release MEMC_SW (skip this step if no MEMC module on the chassis).

See Appendixs

“How to download FLASH SW for MEMC module”.

1.3. Panel ID check and modify

There is different ID stored in the NVM depended on different Panels. Modify it with Hyper

terminal if the initial ID or a wrong ID make the set can not display clearly. See Appendixr

. It can

be checked and modified in Factory menu->Feature->Panel ID if the set can display clearly .

The set should be restart if the panel ID is changed .

1.4. Functional Test

Once the boards (chassis, KB, IR, PSU…) and the panel are well interconnected, connect all

external generator devices to relevant inputs/outputs below according to their respective test

patterns format and check picture content and sound quality accordingly

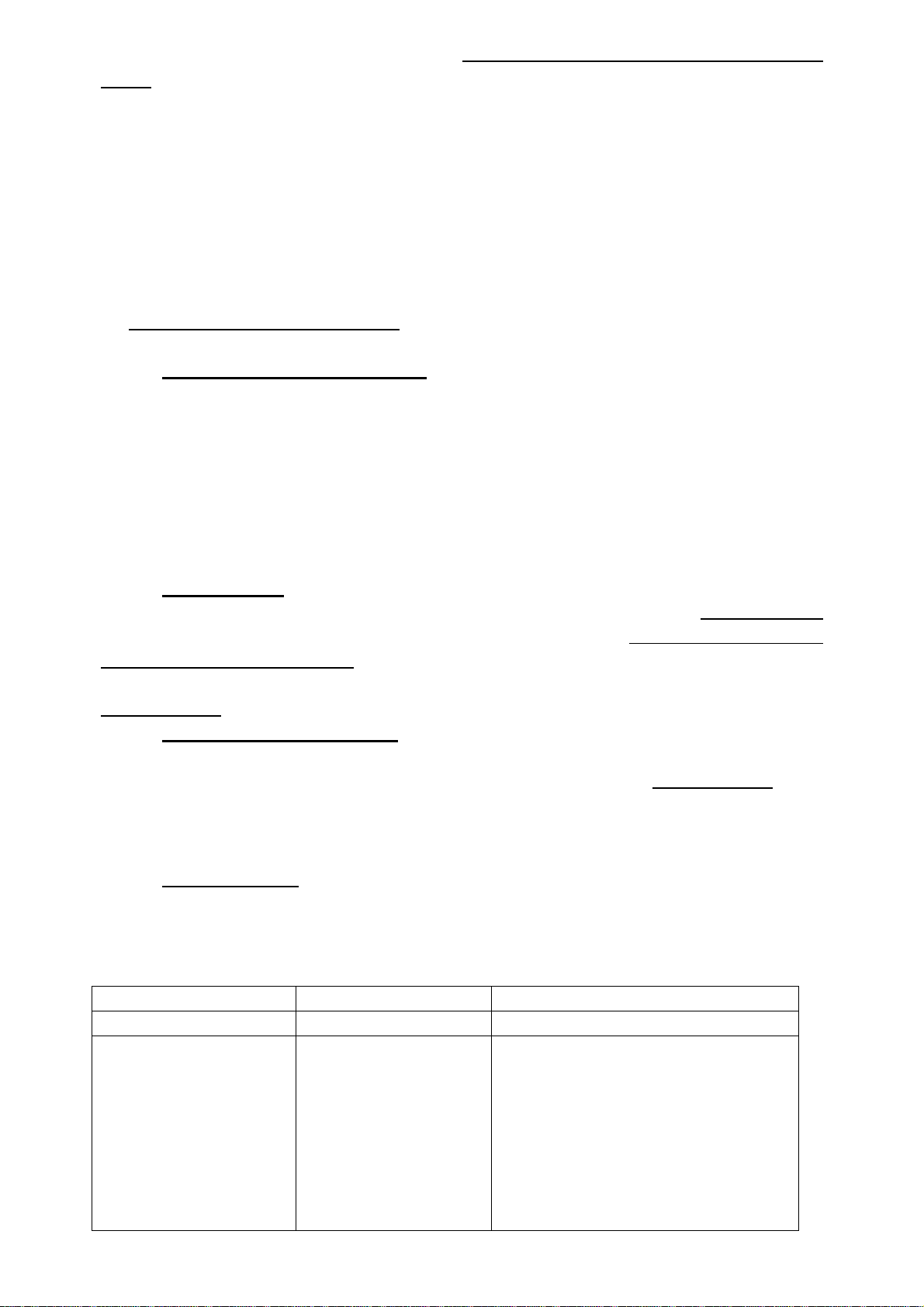

Source Test signal (generator) Test pattern (format/image)

Analog /Digital Tuner RF cable Full Band (VHF/UHF) + CATV DVB-T

DVB-S/S2 Tuner

(only for MT62S2 mode)

DVB-S/S2 generator

1.Frequency : 950MHZ~2150MHZ

2. Symbol rate

DVB-S2:1~45MHZ(for QPSK)

DVB-S: 1~30MHZ(for QPSK)

3. LNB supply power:

Vertical voltage:12.85V ~14.2V

Horizonal voltage:17.6v~19.5v

:

1~30MHZ(for 8PSK)

Page 10

Factory Alignment Specification of normal SIACP

4. DiSEqC 1.0 and Tone Burst

(Diseqc input: A,B,C,D,Tone A,Tone B)

5. Double LNB frequency. changing

band by 22kHz tone

6. 22kHz tone spec :

frequency range: 20.5KHZ~23.5KHZ

amplitude: 400mv~900mv

current: at least 400mA

Composite(CVBS) Chroma/Fluke PAL Half Color & Gray bars

SCART1 (CVBS)

SCART1 (RGB)

SCART2 (CVBS)

SCART2 (Y/C)

VGA Chroma/QuantumData 1024x768@60Hz

CMP (YPrPb) Chroma/QuantumData 1080i@60Hz

HDMI DVD with HDMI

Headphone RF cable First channel

Loud Speakers RF cable First channel

Chroma/Fluke PAL Half Color & Gray bars

Half Color & Gray bars

Chroma/Fluke PAL Half Color & Gray bars

Half Color & Gray bars

Half Color & Gray bars

Movie 720p@60Hz

compliancy

SCART1 (CVBS out) RF cable First channel

SCART2 (CVBS out) Chroma/Fluke PAL Half Color & Gray bars

Audio tones can be defined by the factory (ie: 1KHz & 3KHz, sweep, …).

Picture video formats can be changed by the factory according to their own standard.

1.5. ADC Calibration

To ensure the ADC performance, the error of “generator+cable” must be less than 2%. The

following inputs require an ADC calibration for the time being.

VGA(skip this step if no VGA input on the chassis)

Provide a test signal 1024×768@60Hz with WhiteBlack squares.

Select the corresponding FactoryMenu->

key on

RemoteControl

to start. Value of status will change to “OK” if succeed.

ADC Calibration

CMP

Provide a test signal 720p@60Hz with 100% 8 steps ColorBar.

Select the corresponding FactoryMenu-> ADC Calibration-> Auto Color , then press ”OK”

key on

RemoteControl

to start. Value of status will change to “OK” if succeed.

Scart RGB

Provide a test signal PAL 576i with 100% 8 steps ColorBar.

Select the corresponding FactoryMenu->

key on

RemoteControl

The mean of status value:

“NONE”= no input is successful in ADC calibration.

“OK”= current input is successful in ADC calibration.

“NOK”= current input is fail in ADC calibration.

“ALL”= all inputs required are successful in ADC calibration.

to start. Value of status will change to “OK” if succeed.

ADC Calibration

R Gain, G Gain, B Gain, R Offset, G Offset, B Offset in

-> Auto Color , then press ”OK”

-> Auto Color , then press ”OK”

FactoryMenu->

ADC Calibration

Page 11

Factory Alignment Specification of normal SIACP

page

can be fine-tuned if necessary but not required.

1.6. DDC & EDID Test

The E-EDID data structure are according to VESA Enhanced EDID 1.3 (and EIA/CEA-861B for

HDMI).

Both VGA and HDMI have their own separate bin files:

For EDID check, it’s needed to check whether the correct EDID is downloaded by checking

corresponding EDID NVM Checksum or read them out to check bit by bit if it is in line with the

released EDID bin file.

1.7. HDCP Test

For HDCP compliancy, it’s needed to check whether the HDCP key has been well set.

1.8. CI+ Key activation and test(This step is only for the models with CI+ function )

Select factory menu-> Update CI+ Credential-> Update CI+ Credential , then press ”OK” key

RemoteControl

on

Code(Custom Code), Serial Num display if succeed. Download the CI+ Key and try to active it

again if fail.

to active the CI+ KEY. The Valid(CI+ state) state turn to “Yes” and Cus

2. Final Assembly Alignment

2.1. FactoryMenu

Follow the below steps to pop-up the Factory Menu in case of “FactoryKey” is disable

-

press RemoteControl key “MENU” to display main menu

:

- Select “Picture” and press “OK” key to enter the picture submenu

- Select “Contrast” item

press the subsequence RemoteControl keys “9”, “7”, “3” and “5”

-

Press RemoteControl key “Blue” To pop-up the Factory Menu in case of “FactoryKey” is

enable.

The status of “FactoryKey” can be changed in

RemoteControl “OK” key or “RIGHT” key to enter the submenu.

Press

FactoryMenu->

System

FactoryKey

->

Press RemoteControl “Menu” key to go back to the root menu.

Press RemoteControl “RIGHT”or “LEFT” key to change the values.

Press RemoteControl “OK” key run the function.

RemoteControl “Exit” key exit the factorymenu.

Press

2.2. Entering to “P” Mode

Turned on the factory key to enter into “P” mode.The TV will display “P” in bottom left corner

in “P” mode.

Page 12

Factory Alignment Specification of normal SIACP

2.3. White Balance Alignment

Make sure that the picture mode is “vivid”, enter to “P” mode(

switch off “Pic. Enhance” in Factory Menu-> WD Alignment before white balance alignment .

VGA,CMP,SCART RGB,DTV,CVBS_PAL Color Coordinates are relative to HDMI.

CVBS_SECAM and CVBS_NTSC Color Coordinates are relative to CVBS_PAL.

Warm and Cool Color Coordinates are relatives to Normal mode.

Only HDMI(YUV 720p@60Hz) input requires color temperature adjustment.

turned on the factory key

All the Relative

) and

Matrix Offsets should be set while doing alignment.

Expected Targets and Tolerances

The measured parameters should be “x, y” coordinates.

The White Balance alignment should be performed using a contact less analyzer (ei: Minolta

CA-210). The analyzer may not touch the screen surface, and measurement must be performed in a

dark environment keeping the probe(s) at 90+/-2° from the panel.

The result should measure up the relevant spec.

The alignment have to fulfill the requirements in Application Form.

Alignment FlowChart

Provide a test signal on the input and align the WB as described inside attached document

ensuring first that the BackLight value is matching below table:

MTK_EuroAlignmentF

lowchart.doc

2.4. High Pot. and Insulating Resistance Tests

At the end of the process, a High Pot. and an Insulating Resistance tests are required for

matching Safety Electrical requirements (ei: xxxx), even the adapter should meet the

requirement.

High Voltage Withstanding requirements

- “Voltage” Ö 3500 VAC

- “Max Leakage Current” Ö 10 mA

- “Test Time” Ö 5 sec

Insulating Resistance requirements

- “Voltage” Ö DC500V

- “Threshold Max” Ö

- “Threshold Min” Ö 4MΩ

- “Test Time” Ö 3 sec

Page 13

Factory Alignment Specification of normal SIACP

3.

Factory default settings

Do the “Reset shop” before packing.The detail of reset shop follow OOB setting.

“Factory Menu” Definition

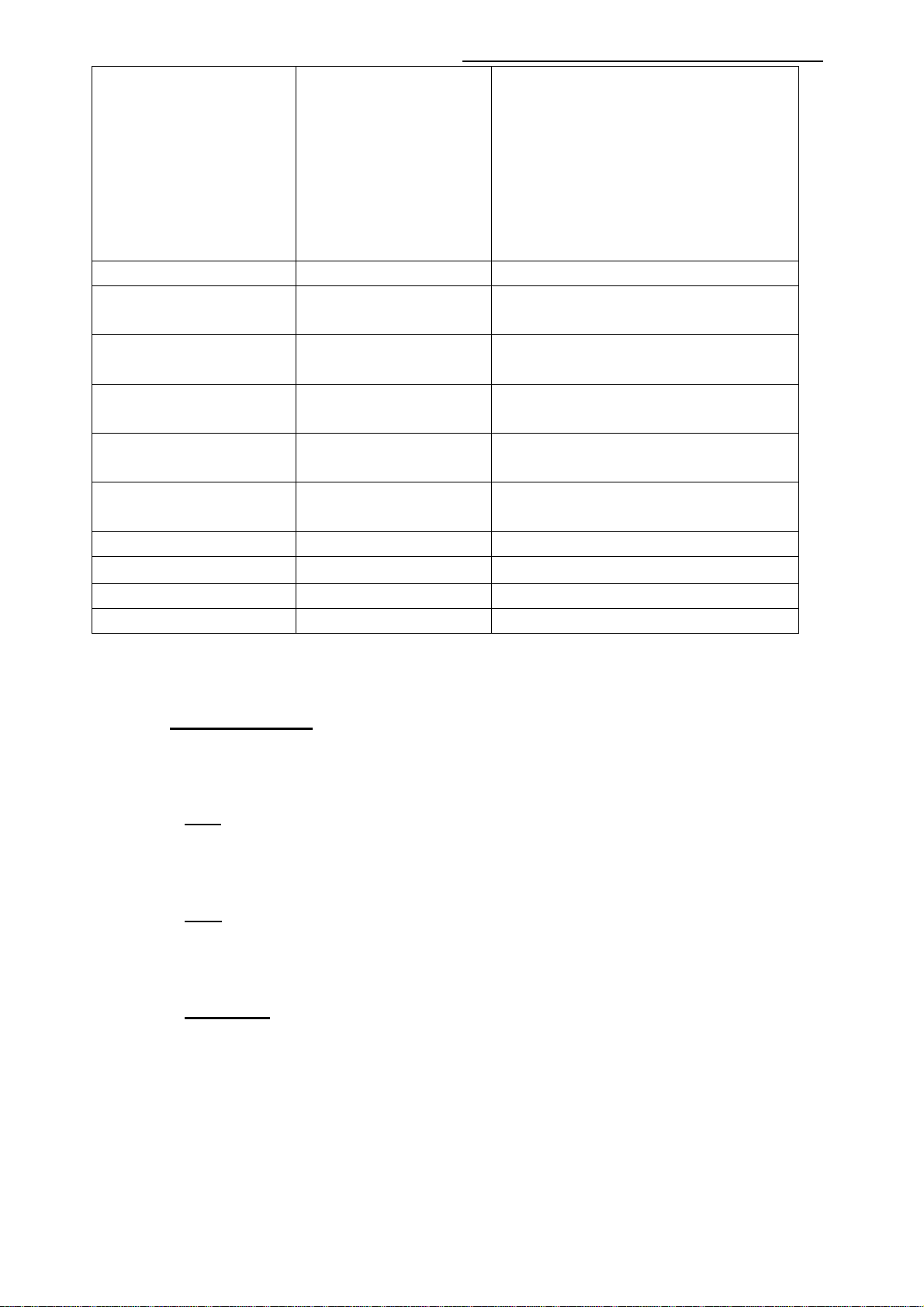

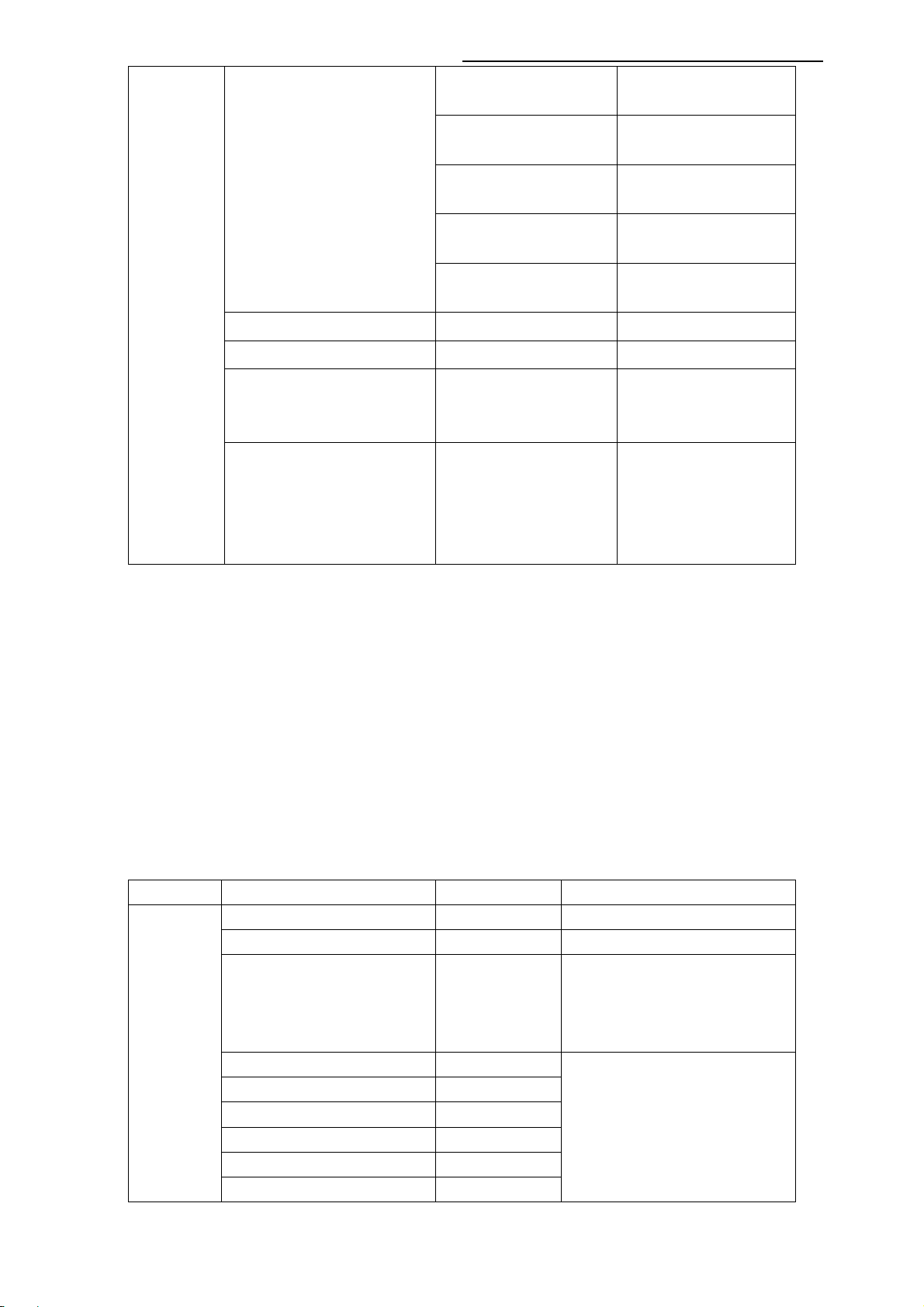

1). System

Item Sub-item Value Note

System

Factory Key Off/On

Power Mode Boot/Standby/

Last Status

Burning Mode Off/On

Pre-Frequency Poland Run

Pre-Frequency Huizhou Run

Pre-Frequency Thailand Run

Reset User

Reset All

Reset Shop

OFF:hotkey is invalid

ON :hotkey(blue key) is availability

Boot: Enter power on mode

Standby: Enter standby mode

Last Status: power on according to last

status

Select panel On with left/right key, Press

“EXIT” key to enter the burning mode;

Press “Menu” key on keyboard to exit the

burning mode

Press “OK” key to run

Press “OK” key to run

Press “OK” key to run

Clear date of NVM in user menu,except

the value of language / related

installation/Factory setting,then set to the

default value.

clear NVM values,and set to default

value。

Clear date of NVM in user menu,include

the value related installation,and Clear

date of factory menu except the item of

Balance and sound ,set to default value

2).Feature

Item Sub-item Value/Sub-item Note

Feature

FleshTone Off/On

Adaptive Luma Control Off/On

Light sensor Off/On

Adaptive Backlight

(note1)

Auto/Low/Mid/High

(it should be “On/Off

Some models have have no

this feature.

Set the backlight mode

“ in 26 inch and

smaller ones)

Backlight Low

Set the backlight value of Low

mode

Page 14

Factory Alignment Specification of normal SIACP

Backlight Mid

Backlight High

ADP low control point

ADP mid control point

ADP high control point

White Peak Limitator Off/On

Set the backlight value of Mid

mode

Set the backlight value of High

(or Off) mode

Set the low point in dynamic

backlight control curve

Set the mid point in dynamic

backlight control curve

Set the high point in dynamic

backlight control curve

TunerAGC

Project ID

(note2)

RCU type

(note2)

-44~127

ID

RC199/RC200

Select panel ID with left/right

key, restart the set to take

effect.

Select remoe control unit for

the models wich IP before

May of 2010

RC199:RC19949**

RC200:RC3000E01

Note1:

In MT62F and MT62S chassises:

There is no “Adaptive Backlight” item, “Auto/Low/Mid/High” “Backlight” “ADP low control

point” “ADP mid control point” “ADP high control point” are in the “feature” page. There is

only “Backlight” item instead of “Backlight Low” “Backlight Mid” “Backlight High”. It set the

backlight value of current backlight mode.

Note2:

In MT62F and MT62S chassises:

“Project ID” and “RCU type” item is in the “Project info” sub-page.

3). ADC Calibration

Item Sub-item Value Note

ADC

Calibration

Source HDMI,etc

Auto color Run

Status NONE

/ NOK

/ OK

/ ALL

VGA\CMP\scart RGB require Calibration

Press “OK” key to run

NONE:No source has been calibrated

NOK:Current source hasn’t been calibrated

OK: Current source has been calibrated

ALL:All sources have been calibrated

R Gain

G Gain

B Gain

For fine tune ADC manually.

R Offset

G Offset

B Offset

Page 15

Factory Alignment Specification of normal SIACP

4). WD Alignment

Item Sub-item Value Note

WD

Pic. Enhance ON/OFF

Alignment

Source HDMI,etc

Color Temperature Normal

/Warm/Cool

R Gain

G Gain

B Gain

R Offset

G Offset

B Offset

Scaling Brightness

Scaling Contrast

Scaling Saturation

Auto phase Run

Press “Right” key to switch off all of the

items in the feature submenu. This should

be done before white balance alignment.

If it’s off, the way to switch it on is to reset

user/shop or set on the features in

Feature sub-item manually.

For balance source:

HDMI,VGA,DTV,PAL,SECAM,NTSC,Scar

t RGB,CPM, HDMI

The value of Warm and cool is the offset

of Normal mode.

R White balance

G White balance

B White balance

R Gray balance

G Gray balance

B Gray balance

Press “OK” key to adjust the signal to

avoid the ripple in CMP source, it is not

necessary.

5).Sound

Item Sub-item Value Note

Sound

VOL_0 0

VOL_10 5

VOL_50 20

VOL_90 145

VOL_100 255

6). Version info (In MT62F and MT62S chassises,it is “Project info”)

Item Sub-item Value Note

Version

info

Project: ***

Panel: ***

MT62 Ver: ***

Date: ***

MCU Ver: ***

Page 16

Factory Alignment Specification of normal SIACP

7) . Factory Clone& User Clone (MT62S,MT62F have no this function now)

Select “Factory Clone” in the factory menu to ernter the factory clone menu

Item Sub-item Value Note

Fac Clone

TV TO USB(Factory) DO

USB TO TV(Factory) DO

Press “Right” key to copy the

data(WB,ADC,picture setting,etc) to USB

Press “Right” key to set the

data(WB,ADC,picture setting,etc) from

USB

Enter another password “6” “4” “0” “5” in “menu” -> “picture” -> “contrast” status to ernter the user

clone menu

Value Note

TV TO USB(user) DO

USB TO TV(user) DO

Press “Right” key to copy the data(channel map,picture setting,etc)

to USB

Press “Right” key to set the data(channel map,picture setting,etc)

from USB

8) . Update CI+ Credential (only for the chassises with CI+ function)

Item Sub-item Value Note

Update

CI+

Credential

Update CI+ Credential DO

Update from USB DO

Erase CI+ Credential DO

Press “OK” key to active the CI+ KEY

Press “OK” key to download the CI+ KEY

from USB

Press “OK” key to erase the CI+ KEY

Valid

Cus Code

Serial Num

Show the CI+ state

Show the CI+ custom code

Show the CI+ serial number

Page 17

Factory Alignment Specification of normal SIACP

Appendix n “How to download MCU SW”

Prepare WT_MCU_ISP SW tool for update.

1. Connect the PC to the serial connector on board using a special serial device(USB or

COMx).

2. Provide the a correct voltage to the board.

3. Start “Weltrend MCU ISP.exe” and download the MCU SW. (please see file

Visio-ISPToolGuide_ver090.pdf)

Appendix o “How to download FLASH SW”

Prepare MTK SW tool for update.

1. Connect the PC to the serial connector on board using a special serial device (USB or

COMx).

2. Provide the a correct voltage to the board

3. Start “MTKTOOL.exe” application under MTKxx folder, and set the parameters as below

picture(notice:select MT836X chassiss):

4. Press “Browse” button to select the corresponding SW bin file to upload

5. Press “Upgrade” button to start downloading the SW and wait the gauge displayed “100%”

that means the SW has been successfully downloaded.

In the meanwhile, all operations such erasing flash and so… are parsed into the debug

window script.

6. Once the SW is downloaded, switch-off/on the chassis board and wait few seconds for

eeprom update.

See Appendixp” How to upgrade FLASH SW from USB”

Upgrade with loader:

1. Save the new software file(*.pkg) in the root directory of USB, and modify it’s name as

upgrade.pkg.

2. Plug in the USB when TV set is “power off” or “standby” (TV set should be on “standby” status

if using a touch sensing keyboard).

Page 18

Factory Alignment Specification of normal SIACP

\

3. Press down “power” key on keyboard, power on if it is on “power off” status , release the

“power” key 2~5 second later , the LED on IR board will flash after upgrade begin, the TV set

will start up if upgrade succeed.The LED is on but no flash if upgrade fail,check the set and

try again.

Upgrade without loader(The TV set should be able to display normally):

1. Save the new software file(*.pkg) in the root directory of USB, and modify it’s name as

upgrade.pkg.

2. Plug in the USB.

3. Upgrade the SW follow the indication display on the screen

Appendix r “

Modify panel ID with Hyper terminal

”

①. Connect the PC to the board using a special serial device (USB or COMx).

②. Provide a correct voltage to the board

③. Save the password file “password for hyperTerminal.txt” to your computer.

D:\MT62\调试说明

已发布\password f

④. Start HyperTerminal “HyperTrm.exe” in your computer.

⑤. Fill the name.

⑥. Select the Com Port you are using.

⑦. Set the items as below picture.

Page 19

Factory Alignment Specification of normal SIACP

.

Select “File->Save->” to Save the setting. Then start HyperTerminal “atsc.ht” in your

computer instead of step ③ to ⑦ later

⑧. Send the password.

⑨. Select the password file saved in your computer.

Page 20

Factory Alignment Specification of normal SIACP

⑩. Under the folder “DTV>” enter “pmx.s.p +ID”,e.g.: pmx.s.p 102

See the panel ID in another document <Panel list for MT62>.

⑪. Press “Enter”, the panel signal will be printed in the window

Page 21

Factory Alignment Specification of normal SIACP

Appendix s “

Prepare MSTAR SW tool for update:

Install the driver:CDM_Setup.exe

Save the MS_TV folder to your PC,

1. Connect the PC to the I2C connector on board using a special I2C device (USB or COMx).

2. Provide a correct voltage to the board.

3. Start “ISP_Tool.exe” application under MS_TV folder:

How to download FLASH SW for MEMC module

”

4. Press “config” button On the Menu to enter the corresponding page, change the ISP slave

address to “0x94” and confirm that if the Port Type is correct, correct it if not.

Page 22

Factory Alignment Specification of normal SIACP

5. Press “Read” button on the Menu to enter the corresponding page and Press “Read” button

on this page to load the software(*.bin) on your PC

6. Press “Auto” button on the Menu to enter the corresponding page

Page 23

Factory Alignment Specification of normal SIACP

7. Press “Conect” button on the Menu. A message will popup

to tell you the result. Press “OK” button to close the

message. If fail to connect with “Can’t find the Device

Type!! ” Message ,Check the hardware and parameters

setting of the ISP_Tool , Press “Dis Con” button , then

“Conect” button again, until it identify the flash memory IC.

8. Press “Run” button in the current page to download the software.”Pass” will display on the

right bottom corner if succeed.

Page 24

Factory Alignment Specification of normal SIACP

Page 25

MT62L&LV

Block

Diagram_V1.0

Lines of dashes

is only user at

MT62LV MB.

Key&IR Pad

U24

EEPROM

M24C16MN

RX

TX

KEY

IR

I2C

POWER

SUPPLY

SCL

SDA

ENV57S01D8/

07-361AI5-TE1G

AGC

U201

MT5362ANG

IF+/IF-

TV_CVBS

SERIAL TS

DTV-T

DEMO

U10

MT8295B

communication

LVDS

OUT

DACOUT1

(DTV_CVBS)

SERIAL TS

LVDS

PARALLEL TS

PARALLEL TS

I2C

CARD

BL On/Off

Dimming

CI

PANEL

FLASH

64Mbit

U12

DDR2

512M

U13

DDR2

512M

HDMI1

EDID

MEMOFRY

IF

DDR IF

CRYSTAL

HDMI_Rx I2C

EDID

SPDIF

OUT

Y/C

IN

ADC

CVBS DECODER

3D COMB FILTER

SCALER

MPEG4 DECODER

LVDS

TRANSIMITER

HDMI RECEIVER

AUDIO DECODER

RGB

CVBS

IN

VSYNC

HSYNC

VGA

Y

Pb

Pr

U700

Digital AMP

IIS_A OUT

AL1 L/R OUT

AL2 L/R OUT

IIS_B OUT

Audio IN

TV CVBS OUT

CVBS IN

RGB IN

FS

FB

YPbPr

CVBS

RGB

CVBS IN

Y/C IN

MONITOR OUT

USB

IF

U18

AUDIO SW

STA*** BW

Audio OUT

U3

RC4558

R

L

Head

Phoone out

CEC

HDM2

VGA

YPbPr SCART1 SPDIF

DVI/VGA Audio IN

USB

Page 26

Main board picture

Page 27

8 7 6 5

12V

L29

200R

L30

5VOUT

4U7

C52

200R

L32

0.1U

200R

L33

200R

C244

+5V

LD1117S33

U9

T

6V3

6V3

VIN

3

Z50

C236

0.1U

100U

C70

NC/LD1117S33

C461

47U

C235

0.1U

4

4

OUT

2

GND/ADJ

U8

1

U33

NC/AIC1084

VOUTVIN

ADJ/GND

1

VIN

3

4

OUT

U31

AZ1084

ADJ/GND

23

4

2

R6

330R

1

6V3

GND/ADJ

1

VOUTVIN

23

100U

C72

R5

DV33A

2R7

C80

100U

C234

0.1U

LD1117S

R1

6V3

2R7

L34

200R

4

4

GND/ADJ

OUT

VIN

U7

1

2

3

0.1U

C232

0.1U

C239

Z14

T

R2

AV33AV33

T

120R

DV33

Z15

F

10R

1000P

6V3

C230

L1

15UH

R456

C231

0.1U

R448

10K

D11

L809

LL4148

C250

1U

120R

C

BT3904

AV_5V

Q47

E

L82

NC/600R

B

E

220P

C497

+3V3SB

D

C824

1U

U16

1

BOOT

2

3 6

4

PHASE

UGATE

DRIVE

FB GND

LGATE

VCC

RT8110

6V3

0.1U

C825

8

7

5

C809

100U

GND

RT9166-33

2

G2

4

S2

3

G1

2

S1

1

L95

NC/120R

D13N03LT

Q38

U811

GND

1

about 1mm

D2B

D2A

D1B

D1A

3

INOUT

C826

5

6

7

8

C440

0.1U

0.1U

C243

0.01U

100U

C872

C53

4U7

5VSB

16V

R445

220R

1K2

R459

C75

1000U

1000U

16V

C74

4 3 2 1

12V

8K2

R89

D12

LL4148

D8

D10

LL4148

D9

LL4148

D2

LL4148

LL4148

D5

LL4148

LL4148

D7

R84

R83

R88

2K2

1K8

2K2

R85

4K7

+3V3SB

B

R86

E

C

4K7

Q6

4K7

DV33

6V3

100U

C71

AV125AV125

C245

0.1U

12V

+5V

TUNER_5V

8V

DV33

AV33

AV25

L8

15UH

CI_VCC

BT3906

R87

L151

10UH

L37

200R

PWR_PROTECT

Z67

T

DDRV

F

E

D

R483

100K

U20

BS

IN

SW COMP

GND

MP1482

SS

EN

FB

100K

U21

1

BS

2

IN

3 6

SW COMP

4

GND

MP1482

R557

R555

10K

220P

0.1U

L9

15UH

C447

220P

C449

R556

10K

8

7

0.1U

8

7

5

C246

3300P

2K2

R482

C241

C248

C252

3300P

5

SS

EN

FB

R485

4K7

R484

20K

4U7

C60

4U7

C61

C62

470U

C76

470U

6V3

6V3

0.1U

C450

0.1U

C448

L152

L38

200R

10UH

T

Z66

DV11

C

B

2K2

R480

16V

12V

R33

5R1

C11

100U

0R/NC

R3

LD1117S50

R32

5R1

8V

16V

U1

47U

C3

VIN

Z13

T

VIN

4

4

GND/ADJ

OUT

1

2

3

6V3

100U

C81

AV25

0.1U

C237

4

4

GND/ADJ

OUT

1

2

3

C15

0.1U

TUNER_5V

16V

100U

C10

0.1U

C14

U6

LD1117S25

0.1U

C238

L118

30R

16V

C82

100U

C446

0.1U

C219

0.01U

1

2

3 6

4

C

R467

R466

R431

B

NC/1K

B

+5V

Back Light circuit

10K

C

Q29

BT3904

E

R453

6K8

C

Q28

E

BT3904

R583

47K/NC

D21

LL4148

C240

1U

BL ON/OFF

DIMMING

VBR_EXT

L113

600R

L112

600R

PAN_ON/OFF

PANEL_DIM

12V

L150

30R

16V

C83

100U

C451

0.1U

C251

0.01U

+3V3SB

HI = > POWER_OFF

24V_MAYBE

T

Z1

T

Z18

B

Z17

T

+5VOUT

T

ON/OFF_PWR

T

PAN_ON/OFF

Z16

T

2

10

P19

AUDIO_PWR

T

1

34

56

78

9

1112

1314

1516

24V_MAYBE

L114

200R

PANEL_DIM

R11

NC/0R

5VSB

AUDIO_PWR

12V_IN

R9

0R

R10

0R

LO = > POWER_ON

GPIO_7

10K

R460

GPIO_9

R446

4K7

R471

4K7

+5V

R470

10K

AV33

R170

NC/0R

3K9

T

PANEL_DIM

T

PAN_ON/OFF

T

ON/OFF_PWR

+5VOUT

A

THIS DRAWING CANNOT BE COMMUNICATED TO UNAUTHORIZED PERSONS COPIED UNLES S PERMITTED IN WRITING

0.1U

C463

24V_MAYBE

AUDIO_PWR

0.01U

C462

+5VOUT

C456

0.1U

PANEL_DIM

PAN_ON/OFF

0.1U

C442

0.1U

C438

...

...

...

...

Index-Lab

Last saved :

5

DD-MM

DD-MM

DD-MM

DD-MM

DATE

...

...

...

...

...

...

...

...

DESCRIPTION Last modifNAME

5-5-2008_15:52

4678

...

...

...

...

SBU :

TCLNO:

.............

DESIGNATION

...........

ON:

BY:

DRAWN

TCL Thomson Electronics Ltd.

B Building, TCL Tower, Nanhai Road

Nanshan District, Shenzhen, Guangdong

Tel +86-755-3331xxxx Fax +86-755-3331xxxx

CHECKED

DD-MM-YY

ON:

BY:

......

PAGE:

OF :

A

3 2 1

FORMAT DIN A2

Page 28

8 7 6 5

DV33

54MHz CRYSTAL

OXTALI

R31

820K

X10

54M

OXTALO

F

L36

0.82UH

C532

1000P

10P

C20

C21

10P

SYSTEM EEPROM

R112NC/0R

LO = > Wp

HI = > Write

OPCTRL2

B

BT3904

C

Q5

E

R1194K7

OSCL0

OSDA0

R132

R121

4K7

4K7

T

T

E2PROM_OSDA0

E2PROM_OSCL0

33R

R104

C259

47P

E2PROM_W/C

T

C260

47P

E2PROM_VCC

T

C22

1000P

8

7

6

5

VCC

WC

SCL

SDA

IIC ADDRESS "A0"

E0/NC

E1/NC

E2/NC

M24C16MN

U24

VSS

DV33

1

2

CB70

0.1U

3

4

4 3 2 1

AV33

+3V3SB

L42

NEAR IC NEAR IC

AVDD33_USB

600R

CB87

0.1U

C0402/SMD

AV125

L43

600R

AVDD12_USB

CB85

0.1U

MUST NEAR IC

600R

L44

AV125

AVDD33_XTAL

C27

1U

CB73

0.1U

F

5VSB

E

12V

R101

1K/NC

R102

4K7

1K8

R100

2.9V(12V)

10U

C1

2.1V(9V)

R94

R95

33K

100K

MCU-RESET

T

R97

0R

E

R96

C

47K

Q10

2.7V

BT3906

C17

0.1U

10K

R147

B

+3V3SB

BT3906

Q9

ORESET#

L45

R92

R90

10K

E

C

B

C46

10P

10K

BT3904

Q1

C

E

R93

4K7

B

OPCTRL1

4K7

R110

JTAG Port

R501

D

U0RX

U0TX

L35

L39

30R

30R

System Reset#

+3V3SB

R38

R37

4K7

4K7

SERVICE_RX

T

SERVICE_TX

T

JTRST#

JTDI

JTMS

JTCK

JTDO

R11733R

1

2

3

4

C19

C18

10P

10P

C

V270RA

V270RA

R34

2 1

R35

2 1

F3

F4

P5

USB_DM0

T

USB_DP0

T

Z11

T

Z21

T

P7

GND

C153

NC/10P

4

D+

3

D-

2

VCC

1

B

+5V

L109

30R

100U

6V3

C87

0.1U

C156

USB_DP0

USB_DM0

NC/10P

C452

R12

21

21

R13

MUST NEAR IC

600R

DV33

6

8

AVDD12_PLL

C31

4U7

5472

10K

1

3

R122

10K

10P

C454

10P

C465

C42

0.01U

C466

10P

R123

10K

10P

CB78

0.1U

C464

C467

10P

C922

3300P

R111

1K

TVTREF#1

JTAG_DBGRQ

JTAG_DBGACK

R125

10K

C536

1000P

R120

10K

T T T T T T T T T T

ADIN2

DV33

TVTREF#1

JTRST#

JTDI

JTMS

JTCK

DV33_PU

JTDO

JTAG_DBGRQ

JTAG_DBGACK

USB_DM0

USB_DP0

C25

4U7

PEND_MUTE

DV33

R1311K

PWRDET

R222

0R

0R

R280

R137

R109

4K7

PEND_MUTE

R116

4K7

KEY

1R

C_XREG

JRTCK

VCXO

PBS_TX

PBS_RX

OIRO

T

100R

OPCTRL2

R143

STB

33R

PWR_PROTECT

R525

ADIN3

R146 180K

For 3.3V Tarp

R136

5K1

REMARK=1%

T

T

T T

T

R291

OPCTRL1

ORESET#

OPWRSB

180K

AE6

Z54

JRTCK

JTDI

JTCK

OPWM1

OPWM0

JTMS

JTDO

JTRST#

VCXO

OSDA0

GPIO_6

BOLRCK

PBS_TX

OSCL0

BOMCLK

BOSDATA0

PBS_RX

BOBCK

GPIO_1

GPIO_19

GPIO_18

GPIO_14

GPIO_15

GPIO_7

GPIO_16

GPIO_13

GPIO_12

GPIO_0

OSDA2

OSCL2

LED

OIRO

GPIO_10

GPIO_9

GPIO_8

U0TX

U0RX

OPCTRL5

OPCTRL4

OPCTRL3

OPCTRL0

IR

C_XREG

AVDD12_PLL

AVDD12_PLL

AVDD12_PLL

AVDD12_PLL

AVDD12_PLL

AVDD12_PLL

ADIN5

AVDD12_USB

AVDD33_USB

AVDD33_USB

TT

AF6

USB_VRT

OXTALI

AVDD33_XTAL

OXTALO

AC1

AE1

AC2

AD2

AE2

AF2

AB3

AC3

AD3

AE3

AF3

AB4

AC4

AD4

AE4

AA5

AB5

AD5

AA6

A12

B14

A15

B15

B16

C16

D16

E16

E17

E18

E20

D21

E21

C22

D22

C23

D23

E23

AB8

AC8

AD8

AB9

AC9

AB10

AC10

AD10

AB11

AC11

AD11

V13

R23

N24

P24

R24

N25

N26

W23

W24

Y24

Y25

AA25

AA26

V10

AC6

AD6

AE5

AF5

AE6

AF6

AF4

V26

W25

V24

V25

AC7

AD7

V11

P22

N23

P23

U201

JRTCK

OPWM2

JTDI

JTCK

OPWM1

OPWM0

JTMS

JTDO

JTRST_

VCXO

OSDA0

GPIO6

GPIO4

OSCL1

OSCL0

GPIO5

GPIO2

OSDA1

GPIO3

GPIO1

GPIO19

GPIO17

GPIO18

GPIO14

GPIO15

GPIO7

GPIO16

GPIO13

GPIO12

GPIO0

OSDA2

OSCL2

GPIO11

OIRO

GPIO10

GPIO9

GPIO8

U0TX

U0RX

OPCTRL5

OPCTRL4

OPCTRL3

OPCTRL2

OPCTRL1

OPCTRL0

ORESET_

OPWRSB

OIRI

AVDD12_LDO

AVDD12_DMPLL

AVDD12_ADCPLL

AVDD12_TVDPLL

AVDD12_DTDPLL

AVDD12_SYSPLL

AVDD12_APLL

ADIN5_SRV

ADIN4_SRV

ADIN2_SRV

ADIN3_SRV

ADIN1_SRV

ADIN0_SRV

AVDD12_USB

AVDD33_USB

AVDD33_USB1

USB_DM0

USB_DP0

USB_DM1

USB_DP1

USB_VRT

XTALI

AVSS33_XTAL

AVDD33_XTAL

XTALO

AVSS33_USB

AVSS33_USB1

AVSS12_USB

AVSS12_PLL

AVSS12_PLL1

AVSS12_PLL2

MT5362

E

D

C

B

A

THIS DRAWING CANNOT BE COMMUNICATED TO UNAUTHORIZED PERSONS COPIED UNLES S PERMITTED IN WRITING

...

...

...

...

Index-Lab

Last saved :

5

DD-MM

DD-MM

DD-MM

DD-MM

DATE

...

...

...

...

...

...

...

...

DESCRIPTION Last modifNAME

5-5-2008_15:52

4678

...

...

...

...

SBU :

TCLNO:

.............

DESIGNATION

...........

ON:

BY:

By Ada.Du

DRAWN

TCL Thomson Electronics Ltd.

B Building, TCL Tower, Nanhai Road

Nanshan District, Shenzhen, Guangdong

Tel +86-755-3331xxxx Fax +86-755-3331xxxx

CHECKED

DD-MM-YY

ON:

BY:

......

PAGE:

OF :

A

3 2 1

FORMAT DIN A2

Page 29

8 7 6 5

4 3 2 1

POOE#

DV33S

PDD1

GND

T T

DV33

R157 4K7

T

F

FRESET#

U2

1 16

HOLD

2

VCC

3

DU1

4

DU2

5

DU3

6

DU4

7

S

8

Q

C

D

DU8

DU7

DU6

DU5

VSS

W

M25P64

15

14

13

12

11

10

9

POOE#

PDD1

FRESET#

C202

0.1U

T

DV33S

DV33S

Z22

DV33

F

L110

600R

DV11

T

C73

47U

6V3

C90

1U

C268

0.1U

C263

0.1U

C264

0.1U

C265

0.1U

C266

0.1U

C267

0.1U

C279

0.1U

C269

0.1U

C270

0.1U

C280

0.01U

Bottom SideCORE BYPASS

C271

0.1U

C272

0.1U

C281

3300P

C273

0.1U

C274

0.1U

C275

0.1U

PDD0

R156 0R

POCE0#

T

PDD0

DV33

E

C276

0.1U

C282

3300P

C277

0.1U

C278

0.1U

C91

1U

E

DV33

AOLRCK

OPCTRL5

OPCTRL4

OPCTRL3

OPWM0

OPWM1

Bottom Side

MT5362 STRAPPING MODE

Strapping Mode

R1034K7

NC/4K7 R159

R1614K7

R1634K7

R1654K7

R1674K7

R1694K7

Normal mode

ICE mode

CPU model mode 0

Trap Mode

Core Reset 1us

Core Reset 3.3V

SCAN mode

Core Reset 0.9V

Strapping Mode

XTAL 54MHz

XTAL 27MHz

Strapping Mode

Nor Boot

NAND Boot

large NAND Boot

AOLRCKAOBCKOPWM2

0 0 0

0

0 1

0 1

OPCTRL4OPCTRL5

0

0

0 1

1

0

1 1

OPCTRL2(O)OPCTRL3(O)

0 0

1

0

OPWM1(O)OPWM0(O)

0 0

0 1

1

0

DV33

DV11

POCE1#

POCE0#

PACLE

PAALE

POWE#

PDD6

PDD7

POOE#

PARB#

PDD2

PDD5

PDD4

PDD3

PDD1

POCE1#

T

PDD0

I / O BYPASS

D

DV33

AOBCK

DV33

R1584K7

R160NC/4K7

DV33

C

R164NC/4K7

DV33

R166NC/4K7

R168NC/4K7

B

AC5

AB6

K10

R10

U10

L11

P11

R11

U11

V12

U13

V14

L15

U15

K16

V16

L17

N17

R17

U17

V17

K18

M18

P18

T18

A16

B17

C17

D17

A18

B18

C18

D18

A19

B19

C19

D19

E19

C20

D20

F18

F19

F21

F22

C6

C7

D7

E7

C8

D8

E8

U201

VCC3IO

VCC3IO1

VCCK

VCCK1

VCCK2

VCCK3

VCCK4

VCCK5

VCCK6

VCCK7

VCCK8

VCCK9

VCCK10

VCCK11

VCCK12

VCCK13

VCCK14

VCCK15

VCCK16

VCCK17

VCCK18

VCCK19

VCCK20

VCCK21

VCCK22

VCCK23

VCCK24

VCCK25

VCCK26

VCCK27

VCCK28

VCCK29

POCE0_

PACLE

PAALE

POWE_

PDD6

PDD7

POOE_

PARB_

PDD2

PDD5

PDD4

PDD3

PDD1

POCE1_

PDD0

VCC3IO_1

VCC3IO_1_1

VCC3IO_1_2

VCC3IO_1_3

DVSS

DVSS1

DVSS2

DVSS3

DVSS4

DVSS5

DVSS6

DVSS7

DVSS8

DVSS9

DVSS10

DVSS11

DVSS12

DVSS13

DVSS14

DVSS15

DVSS16

DVSS17

DVSS18

DVSS19

DVSS20

DVSS21

DVSS22

DVSS23

DVSS24

DVSS25

DVSS26

DVSS27

DVSS28

DVSS29

DVSS30

DVSS31

DVSS32

DVSS33

DVSS34

DVSS35

DVSS36

DVSS37

DVSS38

DVSS39

DVSS40

DVSS41

DVSS42

DVSS43

DVSS44

DVSS45

DVSS46

DVSS47

DVSS48

DVSS49

DVSS50

DVSS51

DVSS52

DVSS53

DVSS54

DVSS55

DVSS56

DVSS57

DVSS58

DVSS59

DVSS60

DVSS61

DVSS62

DVSS63

DVSS64

DVSS65

DVSS66

DVSS67

B1

C2

K2

U2

V2

D3

L3

V3

D4

L4

U4

E5

K5

T5

G6

T6

Y6

AA7

L10

P10

T10

M11

N11

T11

L12

M12

N12

P12

R12

T12

U12

L13

M13

N13

P13

R13

T13

L14

M14

N14

P14

R14

T14

U14

K15

M15

N15

P15

R15

T15

L16

M16

N16

P16

R16

T16

U16

F17

K17

M17

P17

T17

L18

N18

R18

U18

F20

E22

D

C

B

MT5362

A

THIS DRAWING CANNOT BE COMMUNICATED TO UNAUTHORIZED PERSONS COPIED UNLES S PERMITTED IN WRITING

...

...

...

...

Index-Lab

Last saved :

5

DD-MM

DD-MM

DD-MM

DD-MM

DATE

...

...

...

...

...

...

...

...

DESCRIPTION Last modifNAME

5-5-2008_15:52

4678

...

...

...

...

SBU :

TCLNO:

.............

DESIGNATION

...........

ON:

BY:

DRAWN

TCL Thomson Electronics Ltd.

B Building, TCL Tower, Nanhai Road

By Ada.Du

Nanshan District, Shenzhen, Guangdong

Tel +86-755-3331xxxx Fax +86-755-3331xxxx

CHECKED

DD-MM-YY

ON:

BY:

......

PAGE:

OF :

A

3 2 1

FORMAT DIN A2

Page 30

8 7 6 5

4 3 2 1

U201

RDQS0

RDQS0#

RDQM0

RDQ0

RDQ1

RDQ2

F

E

RDQ3

RDQ4

RDQ5

RDQ6

RDQ7

RDQS1

RDQS1#

RDQM1

RDQ8

RDQ9

RDQ10

RDQ11

RDQ12

RDQ13

RDQ14

RDQ15

RDQS2

RDQS2#

RDQM2

RDQ16

RDQ17

RDQ18

RDQ19

RDQ20

RDQ21

RDQ22

RDQ23

RDQS3

RDQS3#

RDQM3

RDQ24

RDQ25

RDQ26

RDQ27

RDQ28

RDQ29

RDQ30

RDQ31

D

D2

D1

C4

C3

D5

C1

G4

G3

G5

U1

U3

R3

R4

R5

W1

W2

U5

W4

W3

AA2

W5

E4

B2

A2

A4

B3

E1

E2

F5

F3

F1

F2

E3

F4

V1

V4

T1

T4

T2

T3

Y2

Y3

V5

Y1

RDQS0

RDQS0_

RDQM0

RDQ0

RDQ1

RDQ2

RDQ3

RDQ4

RDQ5

RDQ6

RDQ7

RDQS1

RDQS1_

RDQM1

RDQ8

RDQ9

RDQ10

RDQ11

RDQ12

RDQ13

RDQ14

RDQ15

RDQS2

RDQS2_

RDQM2

RDQ16

RDQ17

RDQ18

RDQ19

RDQ20

RDQ21

RDQ22

RDQ23

RDQS3

RDQS3_

RDQM3

RDQ24

RDQ25

RDQ26

RDQ27

RDQ28

RDQ29

RDQ30

RDQ31

MT5362

RCLK1_

RCLK0_

REXTUP

REXTDN

AVSS12_MEMPLL

AVDD12_MEMPLL

VCC2IO22

VCC2IO21

VCC2IO20

VCC2IO19

VCC2IO18

VCC2IO17

VCC2IO16

VCC2IO15

VCC2IO14

VCC2IO13

VCC2IO12

VCC2IO11

VCC2IO10

VCC2IO9

VCC2IO8

VCC2IO7

VCC2IO6

VCC2IO5

VCC2IO4

VCC2IO3

VCC2IO2

VCC2IO1

RA12

RA11

RA10

RA9

RA8

RA7

RA6

RA5

RA4

RA3

RA2

RA1

RA0

RCS_

RRAS_

RCAS_

RWE_

RBA0

RBA1

RODT

RCLK1

RCLK0

RCKE

RVREF

VCC2IO

M1

K4

M5

M3

L5

M2

L2

M4

M6

N5

L1

N6

K3

J2

J4

J1

P1

N3

P2

J3

AB2

AB1

H2

H1

N4

P6

B5

A5

N10

M10

W6

V6

R6

J6

E6

D6

Y5

P5

J5

H5

C5

AA4

Y4

P4

H4

B4

AA3

P3

H3

A3

R2

N2

G2

RA12

RA11

RA10

RA9

RA8

RA7

RA6

RA5

RA4

RA3

RA2

RA1

RA0

RCS#

RRAS#

RCAS#

RWE#

RBA0

RBA1

RODT

RCLK1

RCLK1#

RCLK0

RCLK0#

RCKE

MEM_VREF

33R

33R

R171

AV12_MEMPLL

R172

DDRV

DDRV

MEM_VREF

RDQ15

RDQ14

RDQ13

RDQ12

RDQ11

RDQ10

RDQ9

RDQ8

RDQ7

RDQ6

RDQ5

RDQ4

RDQ3

RDQ2

RDQ1

RDQ0

A9

C1

C3

C7

C9

E9

G1

G3

G7

G9

A1

E1

M9

R1

C8

G2

G8

J9

J1

J7

J2

B9

B1

D9

D1

D3

D7

C2

F9

F1

H9

H1

H3

H7

VDDQ1

VDDQ2

VDDQ3

VDDQ4

VDDQ5

VDDQ6

VDDQ7

VDDQ8

VDDQ9

VDDQ10

VDD1

VDD2

VDD3

VDD4

VDD5

VDDL

VSSDL

VREF

DQ15

DQ14

DQ13

DQ12

DQ11

DQ10

DQ9

DQ8

DQ7

DQ6

DQ5

DQ4

DQ3

DQ2

DQ1

DQ0

HYB18TC512160BF

VSSQ10

VSSQ9

VSSQ8

VSSQ7

VSSQ5

VSSQ4

VSSQ3

VSSQ6

H8H2F8F2D8D2B8B2A7P9N1J3E3

E7

DDR#1

U12

VSSQ2

VSSQ1

VSS5

VSS4

VSS3

NC/A13

VSS2

VSS1

ODT

BA1

BA0

A12

A11

A10

CS

RAS

CAS

UDM

LDM

WE

UDQS

UDQS

LDQS

LDQS

CKE

CK

CK

A3

K9

MRODT

L3

MRBA1

L2

MRBA0

R8

R2

MRA12

P7

MRA11

M2

MRA10

P3

A9

A8

A7

A6

A5

A4

A3

A2

A1

A0

P8

P2

N7

N3

N8

N2

M7

M3

M8

L8

K7

L7

B3

F3

K3

B7

A8

F7

E8

K2

J8

K8

MRA9

MRA8

MRA7

MRA6

MRA5

MRA4

MRA3

MRA2

MRA1

MRA0

MRCS#

MRRAS#

MRCAS#

RDQM1

RDQM0

MRWE#

RDQS1

RDQS1#

RDQS0

RDQS0#

MRCKE

CLK0

DDRVDDRV

MEM_VREF

RDQ31

RDQ30

RDQ29

RDQ28

RDQ27

RDQ26

RDQ25

RDQ24

RDQ23

RDQ22

RDQ21

RDQ20

RDQ19

RDQ18

RDQ17

RDQ16

A9

C1

C3

C7

C9

E9

G1

G3

G7

G9

A1

E1

M9

R1

C8

G2

G8

J9

J1

J7

J2

B9

B1

D9

D1

D3

D7

C2

F9

F1

H9

H1

H3

H7

VDDQ1

VDDQ2

VDDQ3

VDDQ4

VDDQ5

VDDQ6

VDDQ7

VDDQ8

VDDQ9

VDDQ10

VDD1

VDD2

VDD3

VDD4

VDD5

VDDL

VSSDL

VREF

DQ15

DQ14

DQ13

DQ12

DQ11

DQ10

DQ9

DQ8

DQ7

DQ6

DQ5

DQ4

DQ3

DQ2

DQ1

DQ0

HYB18TC512160BF

VSSQ10

VSSQ9

VSSQ8

VSSQ7

VSSQ5

VSSQ4

VSSQ3

VSSQ6

H8H2F8F2D8D2B8B2A7P9N1J3E3

E7

U13

VSSQ2

VSSQ1

VSS5

VSS4

VSS3

VSS2

DDR#2

ODT

BA1

BA0

NC/A13

A12

A11

A10

CS

RAS

CAS

UDM

LDM

WE

UDQS

UDQS

LDQS

LDQS

CKE

CK

VSS1

CK

A3

K9

L3

L2

R8

R2

P7

M2

P3

A9

P8

A8

P2

A7

N7

A6

N3

A5

N8

A4

N2

A3

M7

A2

M3

A1

M8

A0

L8

K7

L7

B3

F3

K3

B7

A8

F7

E8

K2

J8

K8

MRODT

MRBA1

MRBA0

MRA12

MRA11

MRA10

MRA9

MRA8

MRA7

MRA6

MRA5

MRA4

MRA3

MRA2

MRA1

MRA0

MRCS#

MRRAS#

MRCAS#

RDQM3

RDQM2

MRWE#

RDQS3

RDQS3#

RDQS2

RDQS2#

MRCKE

CLK1

CLK1#CLK0#

NEAR IC

RCLK0

RCLK0#

RCLK1

RCLK1#

22R

22R

22R

22R

R538

R537

R535

R536

NEAR DRAM

R486

100R

CLK0#

CLK1

R487

100R

CLK1#

CLK0

NEAR IC

R173

MRODT

MRCAS#

MRCS#

MRA0

MRA6 RA6

MRA2

MRA7

MRBA0

MRCKE RCKE

MRWE#

MRRAS#

MRA8

MRA11

MRA4

MRA1

MRA9

MRA12

MRA5

22R

R502

22R

1

3 6

R503 22R

1

3 6

R17822R

R177

22R

R176

22R

R504

3 6

1

22R

R505

3 6

1

8

72

54

8

72

54

RODT

RWE#

RBA1MRBA1

54

72

8

54

72

8

RCAS#

RCS#

RA0

RA2

RA7

RBA0

RRAS#

RA11

RA8

RA4

RA1

RA9

RA12

RA5

F

E

22R

R174

22R

22R

R175

RA10MRA10

RA3MRA3

D

DDRV

C77

220U

6V3

C96

1U

C

C94

0.1U

C289

0.1U

C288

0.1U

C287

0.1U

C293

3300P

Bottom Side DDR#1

C286

0.1U

C285

0.1U

C284

0.1U

C291

0.1U

C292

3300P

C95

1U

DDRV

C78

220U

6V3

C98

0.1U

C299

0.1U

C300

0.1U

C301

0.1U

C302

3300P

Bottom Side DDR#2

C296

0.1U

C295

0.1U

C294

0.1U

C297

0.1U

C298

3300P

C99

1U

C

AV125

L48

600R

MEM_VREF

AV12_MEMPLL

DDRV

C319

C93

0.1U

0.1U

C312

0.1U

C313

0.1U

C314

0.1U

C315

3300P

0.1U

C309

C304

0.1U

C303

0.1U

C310

0.1U

C311

3300P

B

C316

0.1U

0.1U

0.1U

B

C318

C317

DDRV

DDR BYPASS BOTTOM SIDE

1K

R292

MEM_VREF

L49

600R

C321

0.1U

R293

1K

GND

GND

A

THIS DRAWING CANNOT BE COMMUNICATED TO UNAUTHORIZED PERSONS COPIED UNLES S PERMITTED IN WRITING

C320

0.1U

C101

0.1U

...

...

...

...

Index-Lab

Last saved :

5

DD-MM

DD-MM

DD-MM

DD-MM

DATE

...

...

...

...

...

...

...

...

DESCRIPTION Last modifNAME

5-5-2008_15:52

4678

...

...

...

...

SBU :

TCLNO:

.............

DESIGNATION

...........

ON:

BY:

DRAWN

TCL Thomson Electronics Ltd.

B Building, TCL Tower, Nanhai Road

By Rockie

Nanshan District, Shenzhen, Guangdong

Tel +86-755-3331xxxx Fax +86-755-3331xxxx

CHECKED

DD-MM-YY

ON:

BY:

......

PAGE:

OF :

A

3 2 1

FORMAT DIN A2

Page 31

8 7 6 5

4 3 2 1

P16

RX1_2

P15

RX0_2

F

47K

B

Q12

R196

C

E

LL4148

D6

R197

R198

R194

HDMICAB0

NC/100K

1K

R193

27K

R186

100R

100R

HDMI5V_0

CEC

21 R50

R47

21

V270RA

21 R49

V270RA

V270RA

SDDCDA

+3V3SB

HDMI5V_0

47K

R195

HDMI_SCL0

E

OPCTRL4

HDMI_SDA0

R192

1K

BT3904

RX0_2B

RX0_1

RX0_1B

RX0_0

RX0_0B

RX0_C

RX0_CB

SDDCCLK

D

HDMI port 0(side)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

GND1

RX1+

RX1-

GND3

RXC+

RXC-

NC2

DDCDA

VCC

RX2+

RX2-

GND2

RX0+

RX0-

GND4

NC1

DDCCLK

GND5

HPD

C103

0.1U

1

2

3

4

U27

A0

A1

A2

GND

HDMI5V_0

AT24C02

VCC

WP

SCL

SDA

HDMI5V_0

8

7

6

HDMI_SCL0

5

HDMI_SDA0

HDMI5V_0

T

R191

10K

Z23

T

R41

10K/NC

HDMI_SCL1

HDMI_SDA1

OPCTRL3

H1-EDID-WP

T

HDMI5V_1

R203

47K

R200

R204

47K

1K

BT3904

R205

R206

B

Q15

HDMICAB1

C

E

100R

100R

1K

R202

R201

NC/100K

CEC

21 R56

V270RA

HDMI5V_1

RX1_2B

RX1_1

RX1_1B

RX1_0

RX1_0B

RX1_C

RX1_CB

R53

21

21 R55

V270RA

V270RA

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

GND1

RX1+

RX1-

GND3

RXC+

RXC-

NC2

DDCDA

VCC

NC20

NC21

RX2+

RX2-

GND2

RX0+

RX0-

GND4

NC1

DDCCLK

GND5

HPD

RX1_2

RX1_2B

RX1_1

RX1_1B

C104

0.1U

R22

1 2

R24

R25

1 2

R23

1

2

3

4

A0

A1

A2

GND

21

21

HDMI5V_1

U28

8

VCC

7

WP

6

HDMI_SCL1

SCL

5

HDMI_SDA1

SDA

AT24C02

HDMI port 1

RX1_0

RX1_0B

RX1_C

RX1_CB

HDMI5V_1

T

T

HDMI_SDA1

R199

T

HDMI_SCL1

R26

R28

1 2

R30

R27

1 2

10K

R151

Z2

10K/NC

21

21

F

T

H2-EDID-WP

T

E

D

RX0_2

RX0_2B

RX0_1

RX0_1B

C

HDMI BYPASS CAP.

AV33

B

L50

600R

C105

1U

NEAR IC

AVDD33_H

C322

0.1U

1 2

1 2

CEC

AV125

NEAR IC

L51

600R

C106

1U

A

THIS DRAWING CANNOT BE COMMUNICATED TO UNAUTHORIZED PERSONS COPIED UNLES S PERMITTED IN WRITING

AVDD12_CVCC

C323

0.1U

ALIN

R183

0R

R14

R15

R16

R17

21

21

T

ASPDIF

AVDD12_CVCC

HDMI_SDA2

HDMI_SCL2

HDMI5V_2

CEC_T

HDMI_SDA1

HDMI5V_1

HDMI_SCL1

HDMI_SDA0

HDMI_SCL0

HDMI5V_0

AVDD33_H

AVDD33_H

RX0_CB

RX0_C

RX0_0B

RX0_0

RX0_1B

RX0_1

RX0_2B

RX0_2

RX1_CB

RX1_C

RX1_0B

RX1_0

RX1_1B

RX1_1

RX1_2B

RX1_2

RX2_CB

RX2_C

RX2_0B

RX2_0

RX2_1B

RX2_1

RX2_2B

RX2_2

ALIN

D26

E26

V15

AB12

AC12

AD12

AC13

AC14

AD14

AC15

AB16

AC16

AD16

AB17

AC17

AD17

AD18

AE15

AF15

AE16

AF16

AE17

AF17

AE18

AF18

AE11

AF11

AE12

AF12

AE13

AF13

AE14

AF14

AE7

AF7

AE8

AF8

AE9

AF9

AE10

AF10

RX0_0

RX0_0B

RX0_C

RX0_CB

U201

ALIN

ASPDIF

AVDD12_HDMI

HDMI_SDA2

HDMI_SCL2

PWR5V_2

HDMI_CEC

HDMI_SDA1

PWR5V_1

HDMI_SCL1

HDMI_SDA0

HDMI_SCL0

PWR5V_0

AVSS33_HDMI

AVSS33_HDMI1

AVDD33_HDMI

AVDD33_HDMI1

RX0_CB

RX0_C

RX0_0B

RX0_0

RX0_1B

RX0_1

RX0_2B

RX0_2

RX1_CB

RX1_C

RX1_0B

RX1_0

RX1_1B

RX1_1

RX1_2B

RX1_2

RX2_CB

RX2_C

RX2_0B

RX2_0

RX2_1B

RX2_1

RX2_2B

RX2_2

MT5362

T

HDMI_SDA0

R20

1 2

R19

R18

1 2

R21

HDMI_SCL0

21

21

T

C

B

...

...

...

...

Index-Lab

Last saved :

5

DD-MM

DD-MM

DD-MM

DD-MM

DATE

...

...

...

...

...

...

...

...

DESCRIPTION Last modifNAME

5-5-2008_15:52

4678

...

...

...

...

SBU :

TCLNO:

.............

DESIGNATION

...........

ON:

BY:

DRAWN

TCL Thomson Electronics Ltd.

B Building, TCL Tower, Nanhai Road

Nanshan District, Shenzhen, Guangdong

Tel +86-755-3331xxxx Fax +86-755-3331xxxx

CHECKED

DD-MM-YY

ON:

BY:

......

PAGE:

OF :

A

3 2 1

FORMAT DIN A2

Page 32

8 7 6 5

4 3 2 1

F

F

U201

AV33

AV125

E

AV125

C107

1U

600R

600R

600R

L52

L54

L53

C23

4U7

NEAR IC

NEAR IC

AVDD33_LVDS

C324

0.1U

AVDD12_LVDS

C109

0.1U

AVDD12_VPLL

C108

NEAR IC

AVDD12_LVDS

AVDD33_LVDS

AVDD33_LVDS

O0P

O0N

O1P

O1N

O2P

O2N

OCKP

OCKN

E0P

E0N

O3P

O3N

E1P

E1N

O4P

O4N

E2P

E2N

ECKP

ECKN

E3P

E3N

E4P

E4N

AVDD12_VPLL

0.1U

K12

AVDD12_LVDS

E10

AVDD33_LVDSA

E12

AVDD33_LVDSB

A6

O0P

B6

O0N

A7

O1P

B7

O1N

A8

O2P

B8

O2N

A9

OCKP

B9

OCKN

C9

E0P

D9

E0N

A10

O3P

B10

O3N

C10

E1P

D10

E1N

A11

O4P

B11

O4N

C11

E2P

D11

E2N

C12

ECKP

D12

ECKN

C13

E3P

D13

E3N

C14

E4P

D14

E4N

K13

AVSS12_VPLL

K14

AVDD12_VPLL

B12

TP_VPLL

E9

AVSS_LVDS

E11

AVSS_LVDS1

K11

AVSS_LVDS2

MT5362

12V

+5V

+5VOUT

L55

NC/500R

L56

L145

200R

200R

L120

NC/200R

GPIO_1

LVDS POWER CONTROL

C455

16V

10U

LO = > LVDS POWER OFF

HI = > LVDS POWER ON

R39

10K

R40

10K

LVDS OUT

C360

0.1U

GNDGND

C436

L131

200R

Q16

L132

200R

PMV65XP

S

D

LVDSVDD

LVDSVDD

T

LVDS_VDDOUT

T

NC

R217

D23

G

C361

1U

R582

10K

E

R216

22K

R548

6K8

R220

0R

C537

0.1U

470K

LL4148

GND

C

Q18

B

BT3904

E

0.1U

D

O0N

O0P

O1N

O1P

O2N

O2P

OCKP

O3N

C

O3P

O4N

O4P

E0N

E0P

E1N

E1P

B

E2N

E2P

ECKN

ECKP

E3N

E3P

E4N

E4P

L16

EXC24C

1 4

2

L15

EXC24C

1 4

2

L14

EXC24C

1 4

2

L13

EXC24C

1 4

2

L17

EXC24C

1 4

2

L26

EXC24C

1 4

2

L19

EXC24C

1 4

2

L20

EXC24C

1 4

2

L21

EXC24C

1 4

2

L22

EXC24C

1 4

2

L18

EXC24C

1 4

2

L27

EXC24C

1 4

2

3

3

3

3

3

3

3

3

3

3

3

3

AN00

AP00

AN11

AP11

AN22

AP22

CLK11-OCKN

CLK11+

AN33

AP33

AN44

AP44

AN55

AP55

AN66

AP66

AN77

AP77

CLK22CLK22+

AN88

AP88

AN99

AP99

C354

C355

C350

C351

C348

C349

C346