:

Alignment Procedure

MODEL: 27F230T/24FS210T V3.0

File No.:YF-Fk07-2002

Page 1 8 pages in total

Serial number

TS-00

PREPARED BY : Jenny DATE: 2004-5-13

APPROVED BY : DATE:

No.:YF-Fk07-2002 ( Page 2, 9 pages in total)

Alignment Procedure

一、Summarize:

27F230T/24FS210T chassis Alignment Procedure

29185N6/25185N6,is NTSC only system model developed for NAFTA market

specially. In trial run, burn the software A27V01-TO to TMPA8809 or TMPA8827 IC by

OTP method. after the trial run, make the mask,please take care in production.

To solve the probable problems in production, for the workers participate

in alignment, please be familiar with the Alignment Procedure, and be master of the

features.

There are 2 operation modes:user mode and factory mode. You can use the

Remote control or buttons on the panel to operate in user mode, but only Remote

control works in factory mode.

The way to enter factory mode:Press “D-MODE”button on RC, press“OK”,

and“CH+”“ CH-”to select the parameter you want to adjust., Press“VOL+”

“ VOL-”to change the parameters. To quit factory mode,press“D-MODE”button

(on the right of SURR button),the factory data changed will be memorized.

A few special modes:

Aging mode — used before the aging before alignment. The aging could

start in factory mode.

Vertical stop mode—used to confirm the screen voltage. Press “INPUT”

button in factory mode to enter Vertical stop mode. Then press

“INPUT” button again to exit.

White balance alignment mode—used for white balance auto alignment.

Press“BUS OFF” button near the left of MTS button to

enter White balance alignment mode.

Factory mode— To initialize the set. Press “SURR” button in factory mode

to enter Factory mode,the screen displays“WAIT”, after the

initialization,the screen displays “OK

”,and exit the Factory

mode automatically.

Then press “D-MODE”button again,it will not enable you to enter

Factory mode,if you want to enter again,you need operate as

follows:turn down the volume to 0,press “Volume down”button

on the panel, press“INFO”button on the RC meantime.

2

No.:YF-Fk07-2002 ( Page 3, 9 pages in total)

t

Alignment procedure

二.Alignment contents:

1. Adjustment of B+ voltage:

Receive Philips standard testing pattern to RF input.

Adjust VR821 in STANDARD mode until voltage at B+=130V±0.5V。

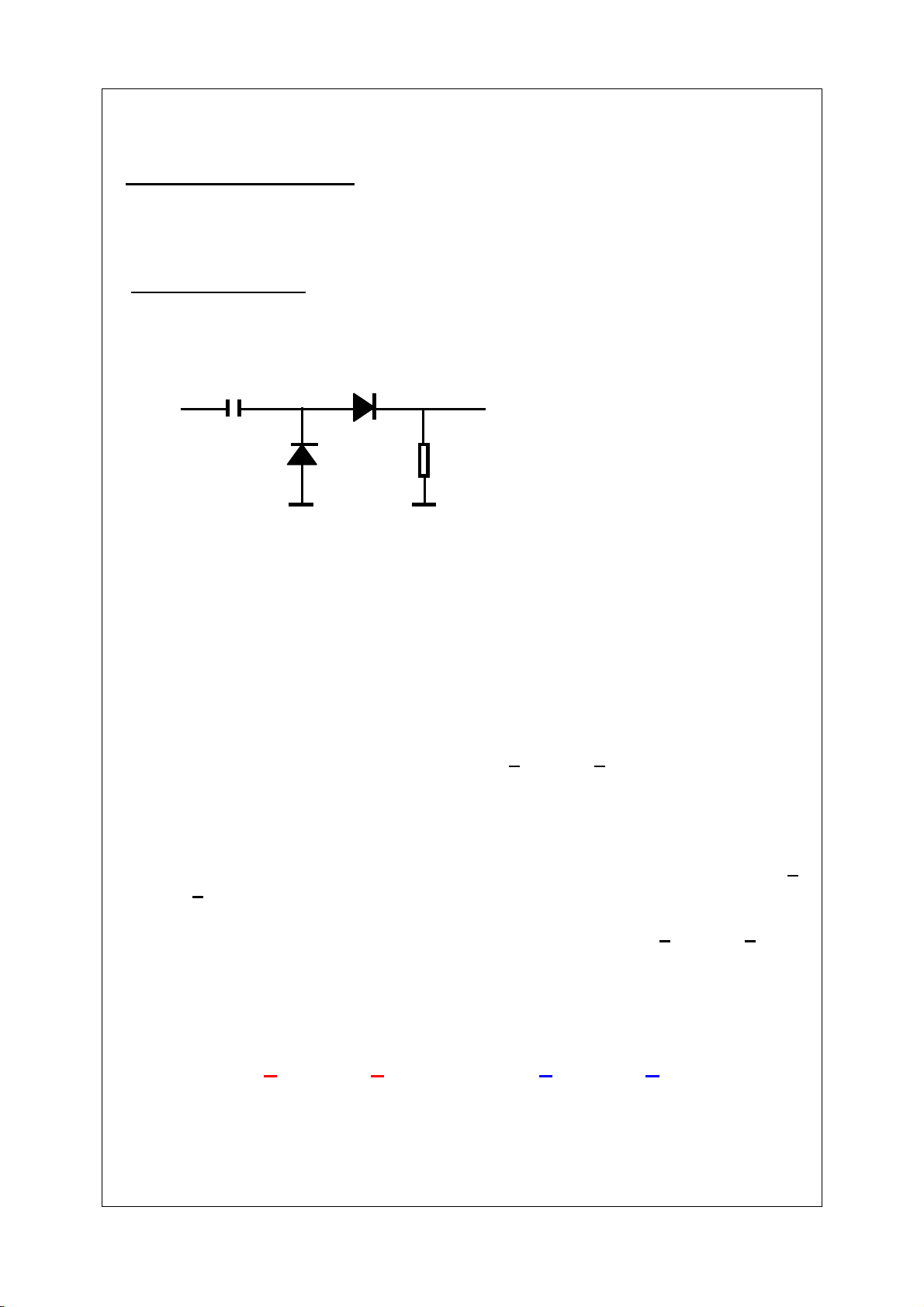

2. RF AGC adjustment

Observe monitor the collector waveform of Q101 with the probe of Oscilloscope as

illustration below. Select channel 2 (>70dB) from the antenna input. Enter D-mode,

select menu6 to adjust RFAGC item until the monitor peak value to 0.8V

p-p

.

IN60

outpu

input

3P f

3. Screen & Focus voltage adjustment

① Apply pattern signal in normal status, enter Factory mode,press“INPUT”button

to stop vertical scan.

(Note:the RC/GC/BC is preset to be 80,GD/BD is 40)

Adjust the SCRREEN switch on the flyback transformer to make a horizontal ②

shining line just visible on the screen.

Turn on the vertical output, adjust the “FOCUS” on the flyback transformer to ③

obtain the optimum focus.

4. White balance adjustment(NORMAL:X=285+8, Y=294+8)

1) Apply the black and white pattern in normal status;

2) Alignment of normal color temperature

① Change Color Temperature to normal status

② Use a color analyzer to measure the black side of the screen. By changing the

value of RC, GC and BC, set the reading of the color analyzer to X=285+8,

Y=294+8.

③ Use a color analyzer to measure the white side of the screen. By changing the

value of GD, BD, set the reading of the color analyzer to X=285+8, Y=294+8

④ Separately set the brightness and contrast from min. to max., repeat the step 2

and 3 until the reading of the color analyzer is correct.

Note: Provided the production line is equipped with the self- White balance

adjusting equipment, white balance can be adjusted automatically as following: Press

“BUS OFF” button under factory mode, the TV set will adjust automatically.

(Warm: X=310+8, Y=314+8;Cool: X=278+8, Y=282+8)

5. Adjustment of Sub-brightness,

Apply the Grey-scale/Color bar (NTSC signal) to the AV input, in normal status.

Enter factory alignment menu 5, Select BRTC to adjust the sub-brightness, until that

the 2nd dark bar of 8 level Grey scale just can be seen.

3

No.:YF-Fk07-2002 ( Page 4, 9 pages in total)

6. picture geometric adjustment

1) Apply the Philips standard testing pattern in normal status, then enter

menu 3, adjusting the following data to get the min-distortion.

HPOS6(Horizontal Center) PARA6 (Level) TRAP6 (Trapezia)

HSIZE6(Horizontal Size) CNRT6 (To p) CNRB6 (Bottom)

2) Apply the Philips standard testing pattern in normal status, then enter

menu 3, adjusting the following data to get the min-distortion.

HIGH6 (Height) VP60(Vertical Center)

VLIN6(Linearity) VSC6(Vertical-S Correction)

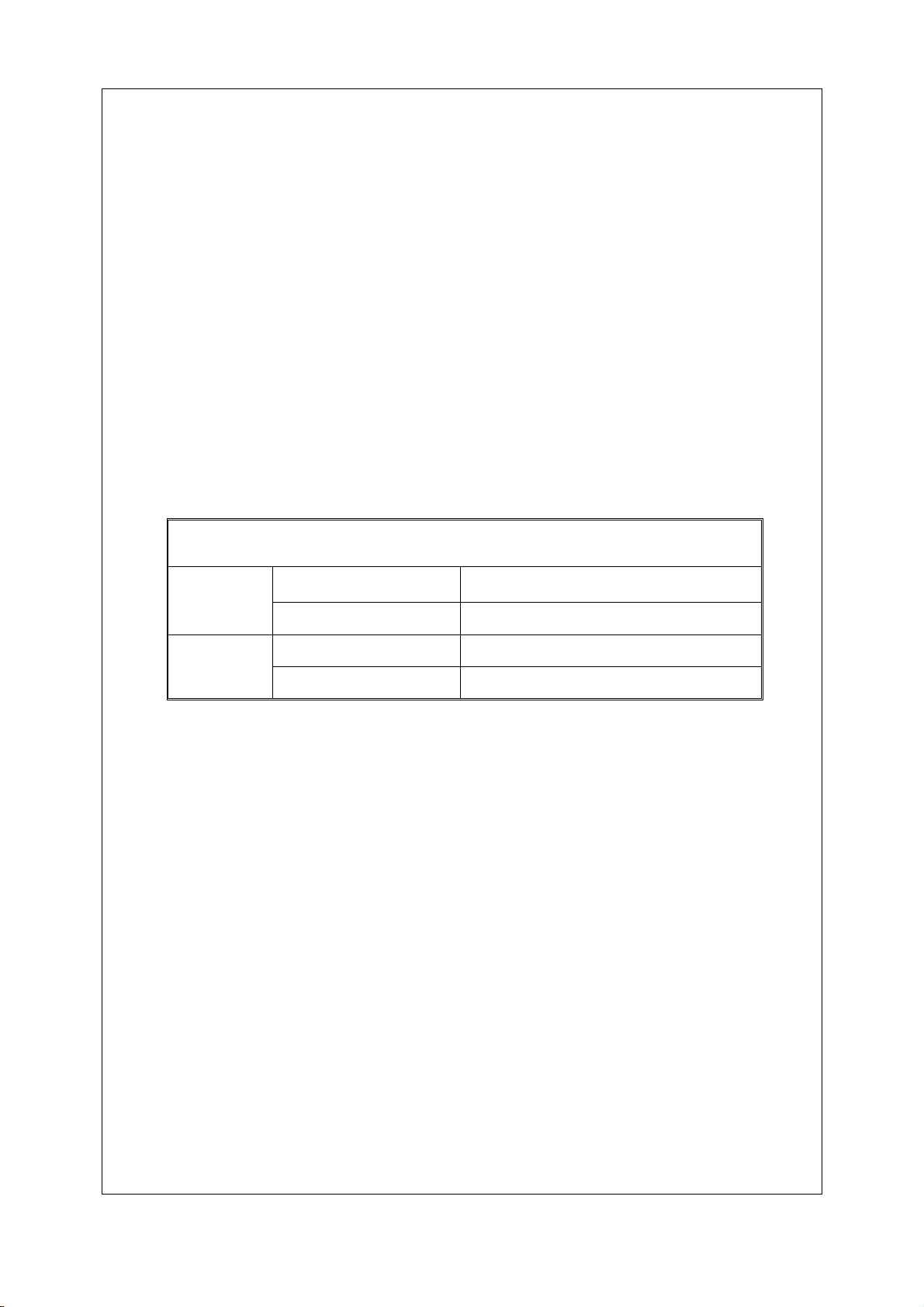

7、 EHT/HEW ratio test:(test with PC program)

Instruments: EHT test meter,EHT test bar(1000:1),adjustable power supply,virtual

DY( the same L value with CRT in production ).

Test means: Measure the EHT value V when Ib=0,HEW voltage value is V1(DC

voltage at 2 ends of C249).

Check means: apply PC test means,V/V1 should satisfy the requiments below:

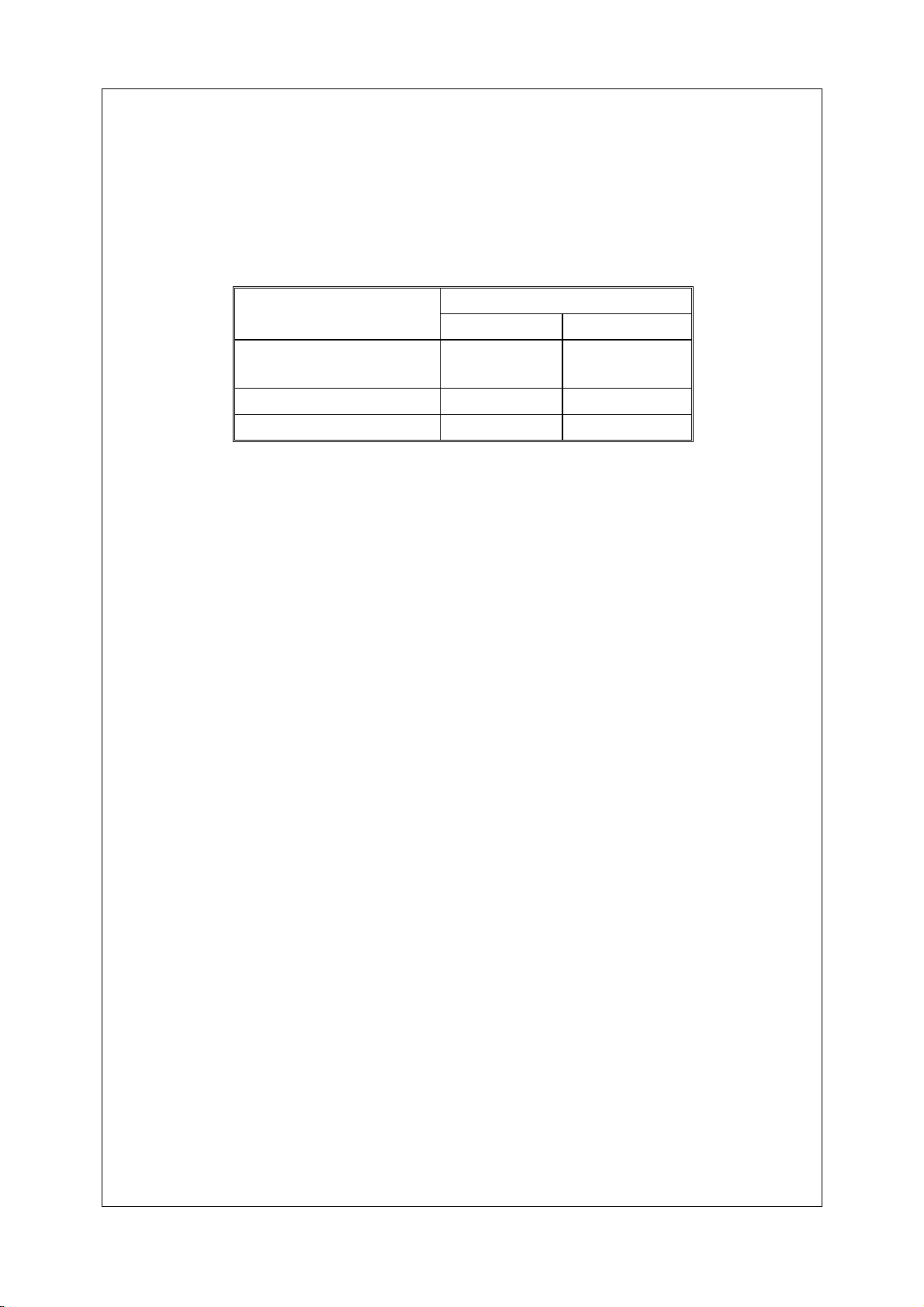

EHT/HEW ratio

29185N6

(27F230T)

25185N6

(24F210T)

44-29RFLW-TS2A

A60LVY196X15(O)

1245 ±3% ( 1207 ~ 1282)

1256±3% ( 1218 ~ 1293 )

8、X rays over voltage protecting circuit test:

TV enter working mode,apply more than 27V DC voltage between two ends of

C249,the set should enter protecting mode,or check X rays protecting circuit.

4

No.:YF-Fk07-2002 ( Page 5, 9 pages in total)

9、PS line polarities test:

Connect follow the graphic below:

DC PS

9V

- +

Sound reminder

DX 2.2k

PS socket M

TO F801

Plug the PS line onto the PS socket M, then touch any pin of F801 with the

probe, the LED DX will shine at the moment, with sound reminder, or it is

disqualification.

10、PS power test:(Random test)

Instruments: Power meter.

Input signal pattern: Color bar,Sound 1KHZ ,100% modulation.

Input signal intensity: ≥60dBuv (1 mV rms)

Test points: find the graphic below

Test means: Set the Brightness, CR to the highest, adjust the volume to make

the sound output to be 0.5W. Connect the power meter to test

the power consumption. Transfer the set to be standby, and test

the power consumption at the moment, which should meet the

requirements below:

Model Power Standby power (120V)

29185N6

25185N6

114 W ± 10%

109 W ± 10%

< 1W

< 1W

5

No.:YF-Fk07-2002 ( Page 6, 9 pages in total)

11、High voltage and Ib value limit test( random test )

Instruments: High voltage meter, Ib meter.

Input signal pattern: White vertical

Input signal intensity: 60dBuv (1 mV rms)

Test means: Connect High voltage meter and Ib meter. Test voltage of different

Ib separately, It

should meet the requirements below:

Ib

Anode high voltage (kV)

25’ 29’

I

= 50µA

b

I

= 50µA & 1200µA

b

30.0 ± 1.0 30.0 ± 1.0

Diff. < 2 Diff. < 2

12、Heater voltage test ( random test )

Instruments :RMS voltage meter

Input signal pattern : Philips test graphic

Input signal intensity :1 mVrms(60dBuV)to 50 mVrms

Connect the RMS voltage meter to the 2 ends of CRT glowers,test the heater

voltage of highest CR and Brightness, It should meet:6.3±0.3Vrms

13、BTSC/SAP function test

BTSC/SAP do not need test,but BTSC/SAP decoder function should be tested

normal or not.

14、CCD and VOL-CHIP function test

VOL-CHIP and CCD function test,please find the service manual in detail.

15、Initialization

Under the factory mode,press“SURR”button,the screen displays“WAIT”,

when the screen displays “OK”, the initialization finished,

You can enter the next working procedure.

6

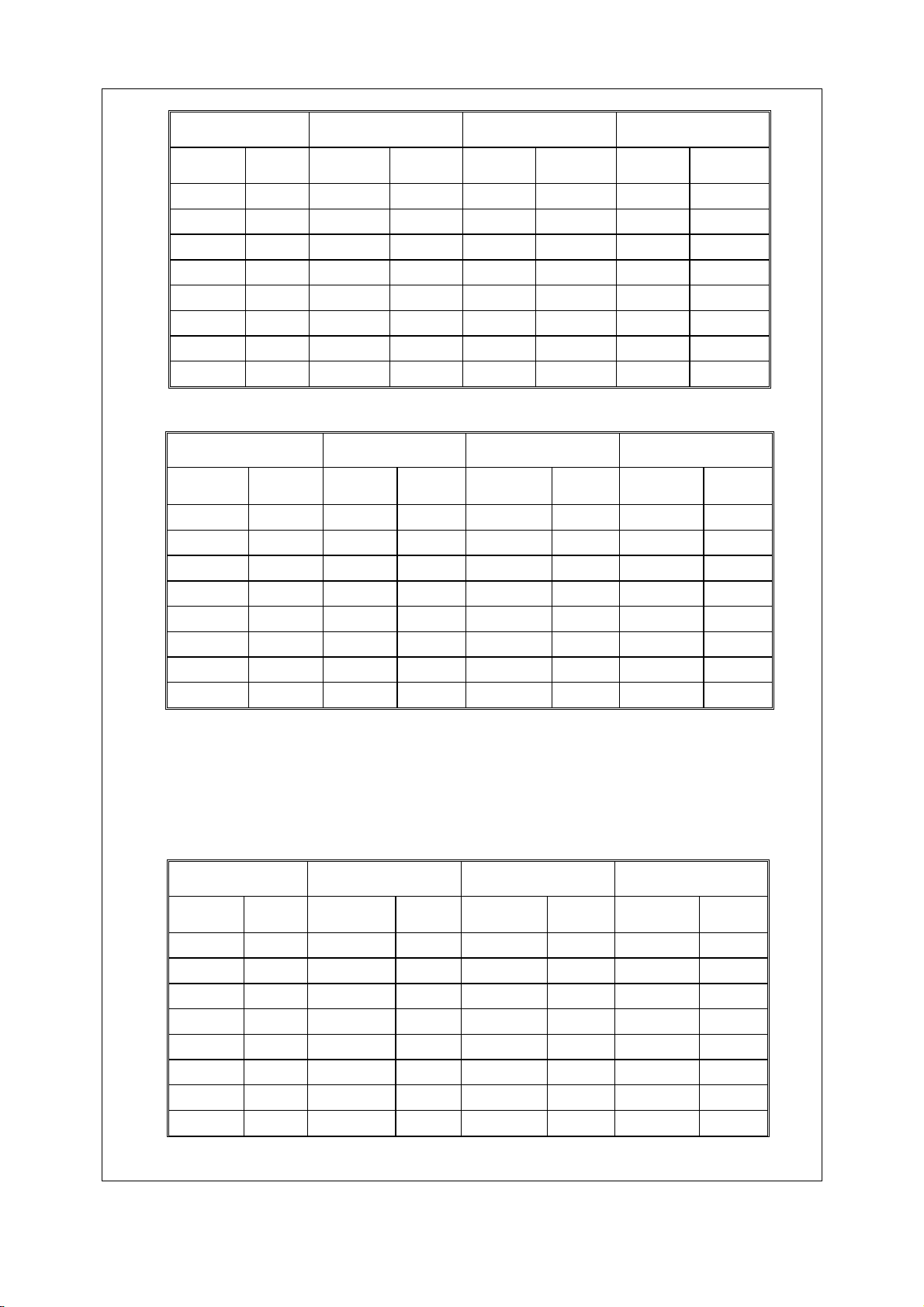

EEPROM DATA:

FAC 01 FAC 02 FAC 02 FAC 03

Item Data Item Data Item Data Item Data

RC * 80 HIGH5 1B/0D HIGH6* 1A/0E HPOS5 0C/0F

GC * 80 VP50 03/01 VP60 * 04/05 PARA5 10/11

BC * 80 VLIN5 0A/0B VLIN6* 0A/0B TRAP5 29/27

GD * 40 VSC5 0C/07 VSC6 * 0B/08 HSIZE5 1F/16

BD * 40 VBLK5 00/00 VBLK6 00/00 CNRT5 0A/08

VCEN5 32/33 VCEN6 33/35 CNRB5 06/08

VEHT5 03/03

HEHT5 03/03

FAC 03 FAC 04 FAC 05 FAC 06

Item Data Item Data Item Data Item Data

HPOS6 * 10/14 CNTX 7F BRTC 40 ST3 20

PARA6 * 0F/16 CNTN 08 COLC 2C SV3 20

TRAP6 * 27/25 BRTX 20 COLP 00 SV4 19

HSIZE6* 20/16 BRTN 20 SCOL 07 SVD 19

CNRT6 * 0B/09 COLX 35 SCNT 0C ASSH 07

CNRB6 * 07/0D COLN 00 CNTC 51/4C SHPN 10

VEHT6 03/03 TNTX 28 TNTCT 40 SHPN 2A

HEHT6 03/03 TNTN 28 TNTCV 40

No.:YF-Fk07-2002 ( Page 7, 9 pages in total)

FAC 07 FAC 08 FAC 09 FAC 10

Item Data Item Data Item Data Item Data

MOD1 60 RFAGC * 25 V01 46 MODE4 22

MOD2 B0/30 BRTS 00 V25 6B MODE5 0B

MOD3 F0 OSD 21 V50 75 MODE6 1F

OPT 37 OSDF 53 V100 7F MODE7 C4

OPTM1 C0 CCD OSD 4A VOLMAX 32 MODE8 2D

OPTM2 C0 CCD OSDF 65 CURTCEN A5 MODE9 02/0B

HDCNT 00 TXCN 1F GATE 2A

HSTOP FF RGCN 16 VOL-OUT 73

7

No.:YF-Fk07-2002 ( Page 8, 9 pages in total)

FAC 11 FAC 12 FAC 13 FAC 14

Item Data Item Data Item Data Item Data

MPB-STR 43 SVM 05 CLTM 4B HAFC 09

MPB-HMC 0D SVM1 05 CLVO 4B AGCC 1C

MPB-HP 07 OSD2 20 CLVS 53 NOIS 01

MPB-LP 11 OSDF2 64 ABL 27 ONTM 08

MPB-LIM 00 PYNX 28 DCBS 14 NSHP 1A

SUB-FRE 28 PYNN 18 FLG0 82 PVLVL 80

SUB-HP 02 PYXS 22 FLG1 0D PLMT 80

VOL-MAI 00 PYNS 10

FAC 15 FAC 16 FAC 17 FAC 18

Item Data Item Data Item Data Item Data

RC-C 0 RC-W 0 D-COL 32 S-COL 32

GC-C 0 GC-W 0 D-BRI 32 S-BRI 32

BC-C 0 BC-W 0 D-CON 5A S-CON 32

GD-C 00 GD-W 00 D-SHP 32 S-SHP 32

BD-C 00 BD-W 00

YUVGC 03

YUVBC 03

FAC 19 FAC 20 FAC 21 FAC 22

Item Data Item Data Item Data Item

M-COL 32 SEG-POINT1 173 T-Hz120-BAS 5A C-Hz120-BAS 32

M-BRI 32 SEG-POINT2 407 T-Hz500-TRE 5A C-Hz500-TRE 32

M-CON 1E DATA-VL 01 T-Hz1K5 0C C-Hz1K5 0C

M-SHP 32 DATA-VH 02 T-Hz5K 0C C-Hz5K 0C

DATA-UF 08 T-Hz10K 0C C-Hz10K 0C

SPE-POS1 06

SPE-DATA1 05

SENSI-ON 00

SENSI-OFF 00

Dat

a

8

No.:YF-Fk07-2002 ( Page 9, 9 pages in total)

FAC 23 FAC 24

Item Data Item Data

B-Hz120-BAS 14 COMB1 00

B-Hz500-TRE 14 COMB2 05

B-Hz1K5 0C COMB3 00

B-Hz5K 0C AV GAIN 19

B-Hz10K 0C

Note:the items with * are adjustable, other items are not, pls do not adjust them;

9

Q

p

Fuse Blown

Is it IC801 PIN1 shorted

to earth?

Yes

Check / Replace

IC801

No raster, abnormal + B

Voltage

Is the + B, +13V, +12V, +9V

resistance to earth?

No

Check/Replace the load of the

abnormal branch

Figure 1 Fuse Blown

No

Check the components such as C801,

C802, C806, C807, C815, R801, etc.

Figure2 No Raster, Abnormal +B

Yes

Is DB801 OK?

Yes

Check IC201, IC202

and their peripheral

components

No

Yes

Check IC801 and their

eripheral components

Replace DB801

Check Q820

Q821, Q823

822,Q825etc.

Yes

Yes

Check T802 etc.

NO

No

es

Q

No raster, +B ok

Is the +9V, +5V

resistance to earth?

Check/Replace

the load of the

abnormal branch

Is both +14V and -14V ok?

Is the wave ok at Pin6 of IC301?

Check vertical scan circuit

Figure3 No Raster, +B OK

Is there a output

Y

waveform Pin13

of IC101?

Is Pin2 of IC101 low

voltage level?

Is B of Q202 low

voltage level?

Yes

Yes

No

No

Yes

No

Y

No

Check horizontal scan circuit, such

as C412, C413, C419, etc

Is there the wave

at C of

Check\replace

the drive circuit

411?

Is the drive

circuit ok?

No

Yes

Replace FBT

Is R461

ok?

Increase

VG2

Yes

Yes

NG

No

Replace

R461

es No

No

es

C10

No picture, dense noise

dots

Is the antenna feed line

or the adapter broken

or unsoldered?

Y

Handing the antenna

fault

Figure 4 No Picture dense noise dots

Is the signal at

Pin41, Pin42 of

IC101 ok?

No

Is the signal at IF

pin of the tuner ok?

Is the signal at Pin SCL,

SDA of tuner ok?

No

Check signal at P5, P57, P58, P59,

and P60 of IC101 and replace the

abnormal relative circuit

Yes

Check EEPROM

Y

Yes

Yes

Check/Replace

1

I

Check the relative

circuit of Q101,

Z141 etc

Is the supply voltage

of tuner ok?

No

Check/Replace

IC201, IC202, D101.

Yes

Check/Replace

Tuner

g

y

g

Symptom: raster ok, no

picture, no sound, sparse

noise dots

Apply the pointer of

multimeter at R X 1 KΩ,

connect one probe to GND,

use another to touch Pin42 of

IC101. Are there interference

particles flashin

screen?

on the

No

Yes

Unsolder a pin of C107, apply the

pointer of multimeter at R X 1 K

Ω, connect the red probe to GND,

use the black probe to touch B of

Q101. Are there interference

particles flashing on the screen?

Yes

Replace the Tuner

Figure 5 Sparse noise dots

Is the voltage

at Pin29, P36

of IC101 ok?

Bridge a capacitor of 1000pF between

the input and output of Z141. Appl

the pointer of multimeter at R X 1 KΩ,

connect the red probe to GND, and use

No

the black probe to touch B of Q101 Are

there interference particles flashin

the screen

Replace Z141 (SAW)

No

Yes

Check and repair

the +9V power

supply

on

No

Yes

Does the IF

pre-amplifier

work

normally?

No

Check &

repair the IF

pre-amplifier

y

y

No sound

Is the speaker ok?

No

Replace the speaker

Yes

Apply the pointer of multimeter at

RX1KΩ connect one probe to GND,

use another to touch Pin4, Pin12 of

IC602, Is there interference noise

from the speaker.

Yes

Is the waveform

at Pin47 of

IC1001 ok?

Check/Replace the power

Yes

of IC1001. Then

suppl

RESET

No

Check/Replace

Q203, X202 etc.

NG

Figure 6 No Sound

No

Is the waveform at

Pin30 of IC101 ok?

Check power

of IC602

suppl

NG

Yes

Is the BUS

ok?

No

Replace IC101

Is it mute at P6

of IC602?

No

Check IC101 and

the relative circuit

No

Yes

Replace

IC602

Check/Replace

Q601, Q602

and Q603 etc.

yway

No Picture

Figure 7 no Picture

TV&AV

haven’t

Picture

TV has

Picture. AV

hasn’t

Picture.

AV has

Picture. TV

hasn’t

Picture.

Ok

Is RGB signal

ok?

Is the waveform at

Pin12, Pin14 of

IC901 ok?

Check Q901 ~

Q904 alle

circuit

Is the waveform

at P15 of IC901

ok?

Is +9V,

+200V ok?

No

No

No

Check Q203, Q204

and alleyway circuit

Is the waveform at

P30 of IC101 ok?

Check Pin20,

Pin24 of IC101

No

Yes

Yes

Yes

Check

Yes Yes

Q501~Q506

Yes

Check P13 of IC901

Is the logic at P9,

P10 of IC901 ok?

Yes

Replace IC901

Is the logic at

P9, P10 of

IC901 ok?

No

No

Yes

Check IC101 and

relative circ uit. plea se

reference the previous

page named Figure 5.

Check R516 ~ R521

etc.

Check P25, P49

of IC101 and the

relative circuit

Check Q917 and

NG

Video alleyway Circuit

Check P1 of IC101,

P4 of IC1001 and

the relative circuit

Replace

IC901

Check P1 of IC101, P4 of

No

IC1001 and the relative

circuit

NG

Replace

IC101

,

,

Figure 8 No Vertical Scanning

Yes

Is both +14V and -14V ok?

No

Yes

Is the signal at P1 of IC301

ok?

No

Check/Replace R431,

D431, D432 etc

R433

Check/Replace IC301

No

Check signal at P16 of

IC101

Yes

Check/Replace IC101

Check/Replace R245,

R313.

R311

g

k

y

y

g

f

y

Symptom:

Control

Tunin

not wor

Press

STANBY ke

on R/C. Can

the TV be

turn on and

turn off?

No

①

Yes

Does the channel

number displa

on the screen?

No

Yes

Start au to search. Is

the BUS ok?

No

Yes

After auto-search, Can

the searched pro

memorized?

ram be

Check the

waveform

at Pin60,

Pin61 of

IC101

Is there sync

No

pulse at P62 of

IC101?

Check the power

supply of IC101.

Are there H & V

back pulses at

fl

Pin12 of IC101

Yes

Check/Replace

IC101

No

Is the

Yes

+33V/+5V

A power

supply

ok?

No

Is there sync

pulse at B of

Q003?

Yes

Replace Q003

No

No

Check R314, R315,

R316, C311, D303

Check/Repair +33V

power supply

Is there the

short circuit

Yes

Check Q915, Q916

and the relative

circuit.

around the

integration

circuit?

Is the voltage at

IC001ok?

P8 o

No

Check/Repair +5V

power supply.

No

No

Yes

Replace IC001

Yes

Figure 9

Check/Replace

the tuner

Check/Repair the

integration circuit

g

①

Figure 10 Tuning Control no working

Is there any change on

the volta

of IC101?

e level at P64

No

Check the remote control

receiver and transmitter.

Yes

Is the VDD(+5V) at P9

and P55 of IC101 ok?

Yes

Is there the 8MHz/5Vp-p

sine wave oscillations at P6

of IC101?

Yes

No

Is the voltage at P5 of

IC101 ok?

Yes

Have P5 of IC101 shorted to

GND in an instant. Can the

IC101 work?

Yes

Check/Repair the reset

circuit.

No

Check

Q007 etc.

No

Are C031, C032

and X001 ok?

Replace the disabled

components

No

Check/Replace

IC101

Yes

No

Loading...

Loading...