Page 1

TCL

SERVICE MANUAL

L28E3500 MS82MT-LA

1. CautionĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ2

2. Specification

3. Alignment Procedure

4. Block Diagram

5. Scheme Diagram

6. PCB Layout

7. Trouble Shooting

8. Explode DiagramĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ35

9

ˊBOM ListĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ36

This manual is the latest at the time of printing, and does not

include the modification which may be made after the printing, by

the constant improvement of product

ĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ6

ĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ7

ĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ2

ĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ

ĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ27

ĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂĂ

2

Page 2

RISK OF

ELECTRIC

SHOCK DO

NOT

OPEN.

SCHNEIDER ELECTRONICS GMBH-GERMANY

1. CAUTION

CAUTION:

Use of controls, adjustments or procedures other than those specified herein may result in

hazardous radiation exposure.

CA UTION : TO RE DUCE THE RIS K OF

CA U T IO N

RISK

SHOCK

The lighting flash with arrowhead symbol, with an equilateral triangle is intended to

alert the user to the presence of uninsulated voltage within the products

enclosure that may be of sufficient magnitude to constitute a risk of electric shock to

the person.

The exclamation point within an equilateral triangle is intended to alert the user to the

presence of important operating and maintenance (servicing) instructions in the

literature accompanying the appliance.

ELECTRI

NOT

OPEN.

ELECTR ICAL SHOC K, DO NOT RE MOVE

COVER (OR BACK). NO USER SERVIC EABLE

PAR TS INSIDE . RE FER SER VIC ING T O

QUALIFIE D SERVIC E PERS ONNEL.

dangerous

WARNING: TO REDUCE RISK OF FIRE OR ELECTRIC SHOCK, DO NOT

EXPOSE THIS APPLIANCE TO RAIN OR MOISTURE.

2

Page 3

SCHNEIDER ELECTRONICS GMBH-GERMANY

IMPORTANT SAFETY INSTRUCTIONS

CAUTION:

Read all of these instructions. Sa ve these instructions for later use . Follo w all W arnings and

Instructions marked on the audio equipment.

1. Read Instructions-All the safety and operatinginstructionsshouldbe read before the productis operated.

2. Retain Instructions- The safety and operating instructions should be retained for future reference.

3. Heed Warnings- All warnings on the productand in the operating instructions should be adhered to.

4. Follow Instructions- All operating and use instructions should be followed.

FOR YOUR PERSONAL SAFETY

1. When the power cord or plug is damaged or frayed, unplug this television set from the wall outlet and refer servicing to

qualified service personnel.

2. Do not overload wall outlets and extension cords as this can result in fire or electric shock.

3. Do not allow anything to rest on or roll over the power cord, and do not place the TV where power cord is subject to

traffic or abuse. This may result in a shock or fire hazard.

4. Do not attempt to service this television set yourself as opening or removing covers may expose you to dangerous

voltage or other hazards. Refer all servicing to qualified service personnel.

5. Never push objects of any kind into this television set through cabinet slots as they may touch dangerous voltage

points or short out parts that could result in a fire or electric shock. Never spill liquid of any kind on the television set.

6. If the television set has been dropped or the cabinet has been damaged, unplug this television set from the wall outlet

and refer servicing to qualified service personnel.

7. If liquid has been spilled into the television set, unplug this television set from the wall outlet and refer servicing to

qualified service personnel.

8. Do not subject your television set to impact of any kind. Be particularly careful not to damage the picture tube surface.

9. Unplug this television set from the wall outlet before cleaning. Do not use liquid cleaners or aerosol cleaners. Use a

damp cloth for cleaning.

10.1. Do not place this television set on an unstable cart, stand, or table. The television set may fall, causing serious injury

to a child or an adult, and serious damage to the appliance. Use only with a cart or stand recommended by the

manufacturer, or sold with the television set. Wall or shelf mounting should follow the manufacturer s instructions, and

should use a mounting kit approved by the manufacturer.

10.2. An appliance and cart combination should be moved with care. Quick stops, excessive force, and uneven surfaces

may cause the appliance and cart combination to overturn.

3

3

Page 4

SCHNEIDER ELECTRONICS GMBH-GERMANY

PROTECTION AND LOCATION OF YOUR SET

11. Do not use this television set near water ... for example, near a bathtub, washbowl, kitchen sink, or laundry tub, in a

wet basement, or near a swimming pool, etc.

Never expose the set to rain or water. If the set has been exposed to rain or water, unplug the set from the wall

outlet and refer servicing to qualified service personnel.

12. Choose a place where light (artificial or sunlight) does not shine directly on the screen.

13. Avoid dusty places, since piling up of dust inside TV chassis may cause failure of the set when high humidity persists.

14. The set has slots, or openings in the cabinet for ventilation purposes, to provide reliable operation of the receiver, to

protect it from overheating. These openings must not be blocked or covered.

Never cover the slots or openings with cloth or other material.

Never block the bottom ventilation slots of the set by placing it on a bed, sofa, rug, etc.

Never place the set near or over a radiator or heat register.

Never place the set in enclosure, unless proper ventilation is provided.

a built-in

PROTECTION AND LOCATION OF YOUR SET

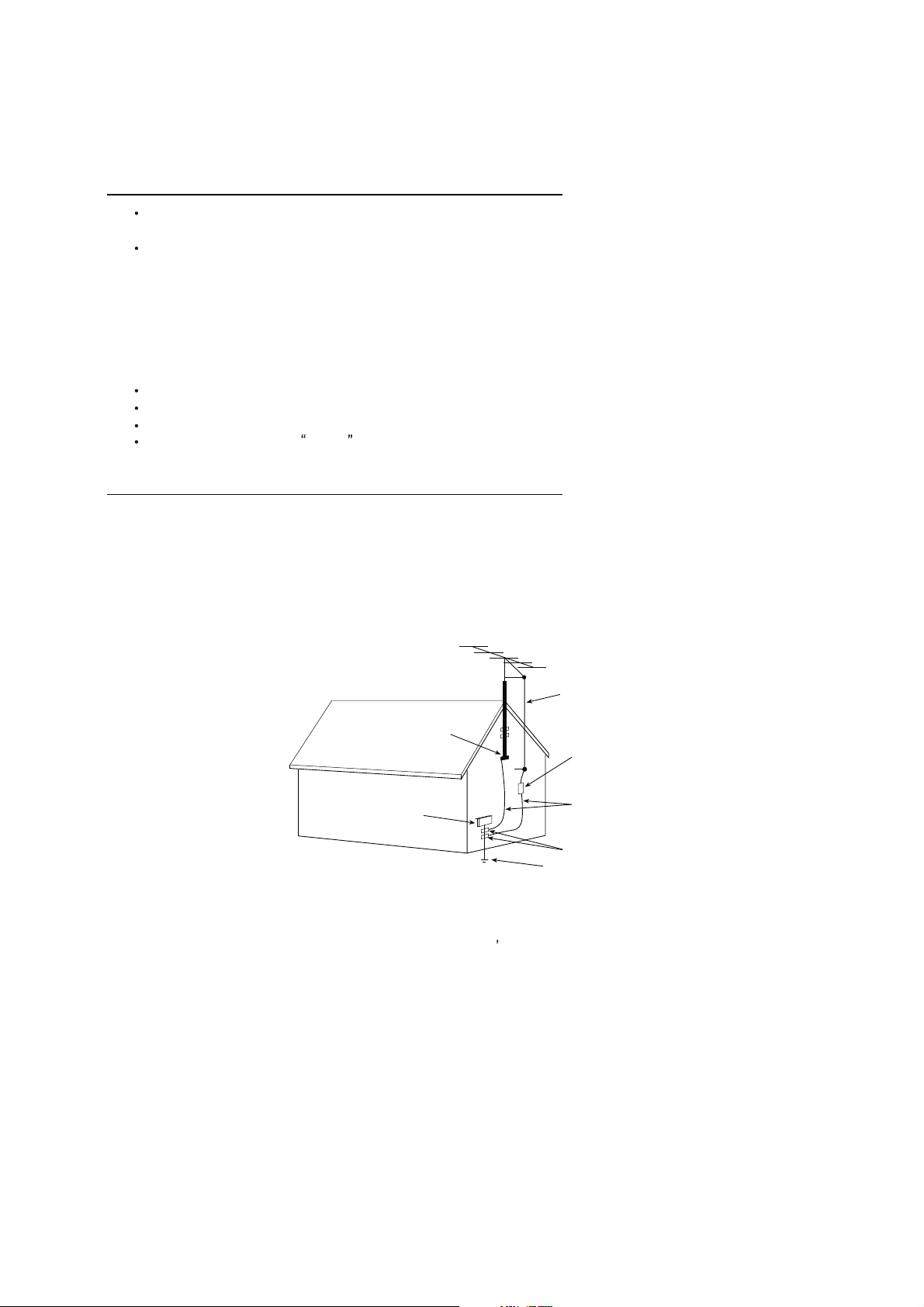

15.1. If an outside antenna is connected to the television set, be sure the antenna system is grounded so as to provide some

protection against voltage surges and built up static charges, Section 810 of the National Electrical Code, NFPA No.

70-1975, provides information with respect to proper grounding of the mast and supportingstructure, grounding of the

lead-in wire to an antenna discharge unit, size of grounding conductors, location of antenna discharge unit, connection

to grounding electrode, and requirements for the grounding electrode.

EXAMPLE OF ANTENNA GROUNDING AS PER NATIONAL ELECTRICAL CODE INSTR UCTIONS

EXAMPLE OF ANTENNA GROUNDING AS PER

NATIONAL ELECTRICAL CODE

ANTENNA

LEAD- IN WIRE

GROUND CLAMP

ELECTRIC SERVICE

EQUIPMENT

NEC-NATIONAL ELECTRICAL CODE

ANTENNA DISCHARGE

UNIT (NEC SECTION

810-20)

GROUNDING

CONDUCTORS

(NECSECTION 810-21)

GROUND CLAMPS

POWER SER VICE GROUNDING

ELECTRODE SYSTEM

(NEC ART 250. PART H)

15.2. Note to CATV system installer : (Only for the television set with CATV reception)

This reminder is provided to call the CATV system attention to Article 820-40 of the NEC that provides

installer s

guidelines for proper grounding and, in particular, specifies that the cable ground shall be connected to the grounding

system of the building, as close to the point of cable entry as practical.

16. An outside antenna system should not be located in the vicinity of overhead power lines or other electric lights or power

circuits, or where it can fall into such power lines or circuits. When installing an outside antenna system, extreme care

should be taken to keep from touching such power lines or circuits as contact with them might be fatal.

17. For added protection for this television set during a lightning storm, or when it is left unattended and unused for long

periods of time, unplug it from the wall outlet and disconnect the antenna. This will prevent damage due to lightning

and power-line surges.

4

4

Page 5

SCHNEIDER ELECTRONICS GMBH-GERMANY

OPERATION OF YOUR SET

18.

This television set should be operated only from the type of power source indicated on the marking label.If you are not

sure of the type of power supply at your home, consult your television dealer or local power company. For television

sets designed to operate from battery power, refer to the operating instructions.

19. If the television set does not operate normally by following the operating instructions, unplug this television set from the

wall outlet and refer servicing to qualifiedservice personnel. Adjust only those controls that are covered in the operating

instructions as improper adjustment of other controls may result in damage and will often require extensive work by a

qualified technician to restore the television set to normal operation.

20. When going on a holiday : If your television set is to remain unused for a period of time, for instance, when you go on

a holiday, turn the television set and unplug the television set from the wall outlet.

off

IF THE SET DOES NOT OPERATE PROPERLY

21. If you are unable to restore normal operation by following the detailedprocedurein your operating instructions,

do not attempt any further adjustment. Unplug the set and call your dealer or service technician.

22. Whenever the television set is damaged or fails, or a distinct change in performance indicates a need for

service, unplug the set and have it checked by a professional service technician.

23. It is normal for some TV sets to make occasional snapping or popping sounds, particularly when being

turned on or off. If the snapping or popping is continuous or frequent, unplug the set and consult your

dealer or service technician.

FOR SERVICE AND MODIFICATION

24. Do not use attachments not recommendedby the television set manufacturer as they may cause hazards.

25. When replacement parts are required, be sure the service technician has used replacement parts specified

by the manufacturer that have the same characteristics as the original part. Unauthorized substitutions

may result in fire, electric shock, or other hazards.

26. Upon completion of any service or repairs to the television set, ask the service technician to perform

routine safety checks to determine that the television is in safe operating condition.

5

5

Page 6

EM BUSINESS CENTER

r

TERMINALS

p()

Smart Volume

Yes

PACKAGE INFO

CC (Closed Caption)

Yes (CC1 CC4,Text1 Text4;

Gross Weight (Kg)

5.5

App

FTV PRODUCT MANAGEMENT DEPT.

SPECIFICATION RELEASE

Version: V2.1 Issued Date: 2013.03.27

Model:L28E3500/MS82MT-LA

PICTURE

Category LCD TV

Naturalight Technology Yes (Natural Light Engine ‖)

Dynamic Contrast Yes

Color Temperature Warm / Normal / Cold

Backlight Adjustable Yes

Scale Mode Zoom,Expand,Original,Natural Component Video Format Y,PB/CB,PR/CR:up to 1080P

Picture Effect Standard, Bright, Soft, Personal DVI Video Format Up to XGA for HDMI-PC

Film Mode (3:2 pull down) AUTO HDMI Video Format up to 1080P

VGA Dot to Dot Display Yes (Natural) PC Compatibility Up to SXGA

Light Senso

--

Picture Enhancement and Audio share with YPBPR Audio

Comb Filter 3D YP

Adaptive Deinterlacing 3D Audio Input for YP

Blue Stretch Yes YC

Black Stretch Yes Audio Input for YC

Motion Compensation Yes VGA(PC) Input 1 (D-Sub,15 Pins)---in side

DLTI Yes Audio Input for VGA(PC) Share with Audio for "YP

DCTI Yes HDMI 1 (HDMI1) ---in side

Dynamic Skin Correction Yes CVBS Output (Composite) 1 RCA Video Socket ---in side

PANEL SPECIFICATION

Back light Unit LED Headphone Output - Panel supplier CSOT RF Input(Antenna) 1 (F Type)---in side

Aspect Ratio 16:9 USB 1(Standard)---in side

Panel Size (inch) 27.5"

Display Resolution 1366*768 TV System NTSC-M;PAL-M;PAL-N

Brightness (cd/m2) 240 AV System PAL,NTSC

Contrast Ratio 3000:1 Channels

Response Time Tr/Tf 6.5ms Chassis MS82MT-LA

Viewing Angle (H/V) 178°/178° Certification CB

Life Time 30,000hrs Power Supply AC 100V-240V 50/60Hz

Color 16.7M Power Consumption-TV on 35W

SOUND

Speakers Integrated speakers (Bottom side) Default Color of Front Cabinet Black

Audio Power Output 2×2.5W Keyboard Position Back

Woofer Power Output -- Base Stand Detachable

Sound Effect Stereo, Music, Movie, News,Personal Unpackaged Dimension for Main Body (L*H*D) (mm)

Sound Control Balance, Sound EQ Adjust; With Base Stand (mm) 657.7x450.4x175

Sound Features MTS(BTSC) Without Base Stand (mm) 657.7x409.9x69.7

Scene Selecting(DeskTop mode and HangUp mode)

FUNCTION

OSD Language English/Spanish/Portuguese Speaker Box

OSD Features Motion Bmp Style Base Stand

Source in OSD Source Bmp Icon Selecting Net Weight (Kg) 4.5

CC (Closed Caption) Yes (CC1~CC4,Text1~Text4; Gross Weight (Kg) 5.5

Clock/Sleep Timers Yes 20 feet 693

Wake up/Turn off time Yes 40 feet 1408

Wake up Source/Chanel Yes 40 feet high 1557

Watch Time Limit Yes

Startup Setting Yes(User can set a picture for turning on Logo display) Operation Manual English(Default)

Smart Switch Yes(Signal Auto Detecting and Changing Source) Remote Control For TV control (with two batteries)

Picture Freeze Yes Base Stand Integrated Packaging

DNR(Dynamic Noise Reduction) Off、Low、Middle、High Speaker Box Integrated

Hotel Menu In factory mode Wall Mount WMB233(Optional)

USB Connection

CC OFF,CC ON,CC On Mute,) Container Loading

Movie:Support H.264、RM/RMVB、XVID、FLV Others AV Adapter cable

DivX、MPEG2

Photo: Support JPEG、BMP、PNG;

Music: support MP3、WMA、M4A;

、MPEG4、VC1

Design and specifications are subject to change without notice!

SIGNAL FORMAT CAPABILITY

AV1 Input (Composite)

AV2 Input (Composite)

BPR Input 1---in side

BPR 1---in side

BCR Input Share with "YPBPR"

BCR Share with Audio for "YPBPR"

SPDIF Output

Audio/CVBS---R/L+ Video in side

1 (coaxial digital audio output)---in side

BASIC INFO.

Cable 125 (1~125) , Antenna 68 (2~69)

Power Consumption-Standby

≤1W

Yes

.

Packaged Dimension (L*H*D)

Main Body (mm) 718X490X128

ACCESSORIES

Drafted by:

Checked by:

Video Share with Y

BPR"

roved by:

Page 7

TCL Multimedia Technology Holdings Ltd.

R&D Center

Alignment Procedure

MS82MT-AP/LA Chassis

Version: 1.0

Release Date: 2013-03-26

PREPARED BY: Kangwei

APPROVED BY:

DATE: 2013-03-26

DATE:

Page 8

MS82MT-AP/LA Chassis Aliment procedure

Content

1. General Description 3

2. Factory Menu 3

2.1 Way of accessing 3

2.2 Factory Menu 4

2.3 ADC calibration menu 5

2.4 White Balance adjustment 6

3. Design Menu 7

3.1 way of accessing 7

3.2 SHOP Menu 8

3.3 Other Menu 9

3.4 Service Menu 10

3.5 PARAM SETTING MENU 11

3.6 Hotel Menu 12

4. Steps of debugging 13

4.1 Device 13

4.2 steps of debugging 13

4.3 ADC calibration 13

4.4 White Balance adjustment 14

4.5 White Balance adjustment (automatically) 16

5. Chip list of software programming before SMT 16

6. Appendix 17

6.1 Software upgrading through USB 17

6.2 Check software version, release date and Project ID 18

6.3 FAQ 20

History Description of major changes Release

Date

V1.0 2013-03-26

Chassis Model

FHD MS82MT-AP/LA L28E3500 etc

PRELIMINARY INFORMATION ----- SUBJECT TO CHANGE

2

Page 9

MS82MT-AP/LA Chassis Aliment procedure

1. General Description

MS82MT-AP/LA is our latest design especially for LCDTV products selling in Asia

Pacific (AP) and Latin America (LA) market. It features by its high integration,

easy debugging as well as convenience in terms of maintenance. Fast software

upgrade through USB disk facilitates both manufacture and after-sale service.

Meantime, a variety of functions involved in Factory Main Menu can not only

bring benefits for production, but also satisfy various demands of customer.

Note: Factory Main Menu (FMM) is divided into Factory Menu, Design Menu, Service

Menu and Hotel Menu. Factory Menu covers all indispensable functions during

manufacture such as White Balance Adjustment, ADC Calibration, USB Upgrading e.g.,

while the items under Design Menu is exclusively used by R&D engineer, anyone else

shouldn’t change the settings in the menu. When you wish to learn the product

information like project ID, model name, chassis name, software version, release date,

you can access to Service Menu. In addition, in Hotel Menu, we also provide a great

deal of useful functions for specific applications in hotel.

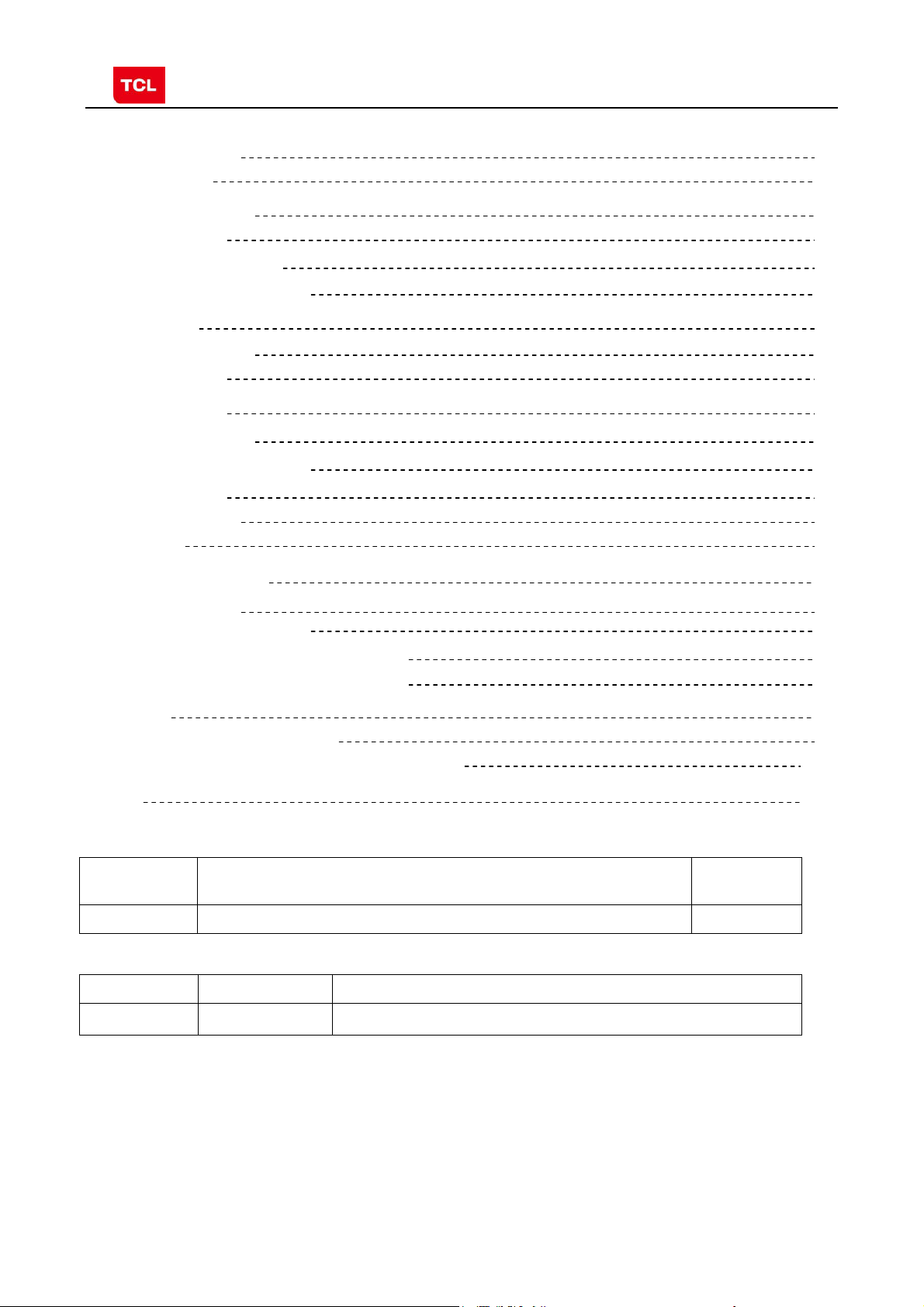

2. Factory Menu

2.1 Accessing way:

a. In the first place, press Menu button of

remote

control, then select Contrast item of Picture

submenu. Finally, press 9, 7, 3, 5 consecutively.

b. When the FAC HOTKEY item of Factory Menu

is enabled (ON), press Return button of remote

control.

PRELIMINARY INFORMATION ----- SUBJECT TO CHANGE

3

Page 10

MS82MT-AP/LA Chassis Aliment procedure

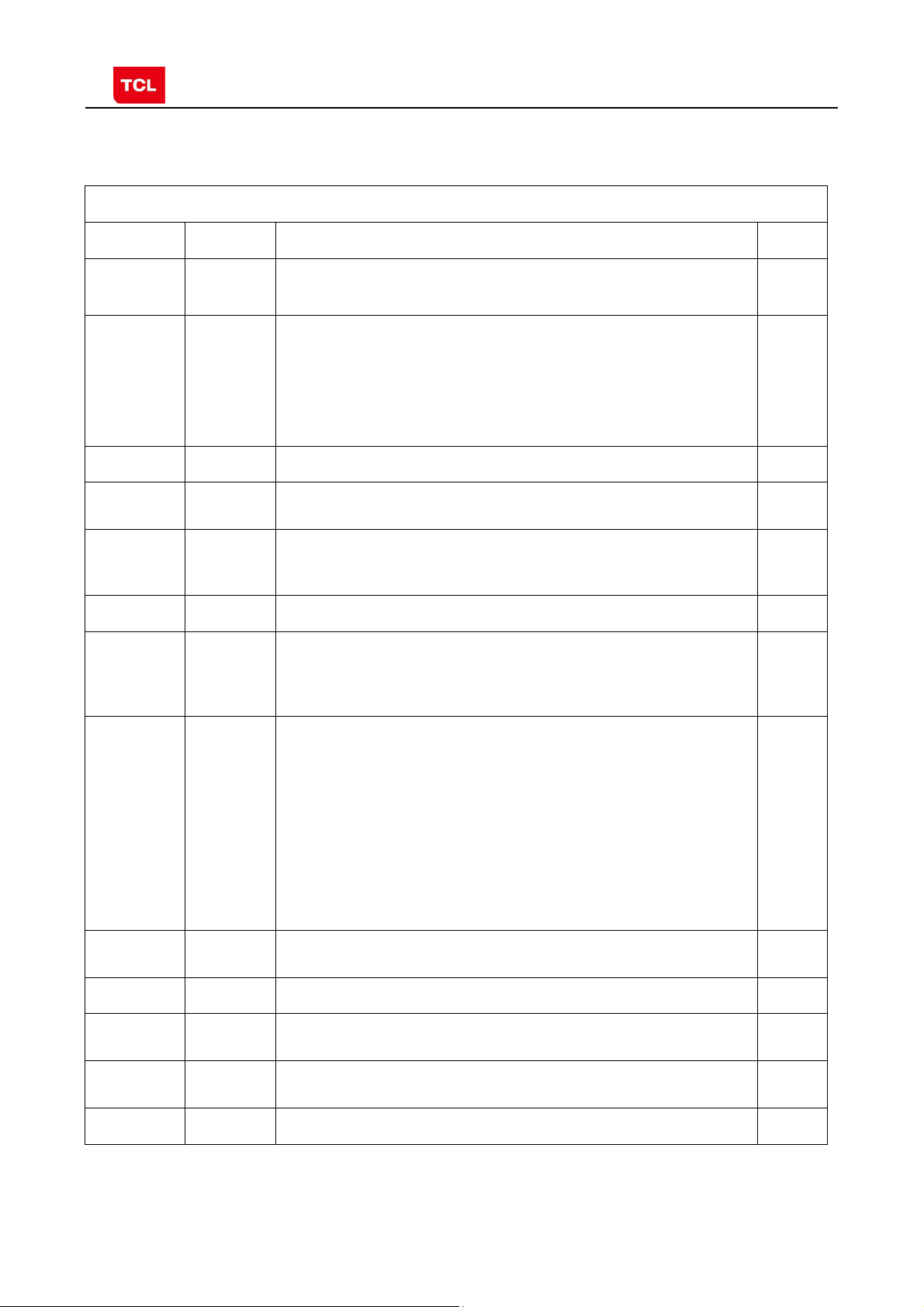

2.2 Factory Menu

Factory Menu

Name Default Description Status

FAC

HOTKEY

OFF Factory Menu shortcut button switch

The item must be disabled (OFF) after production

OK

WARM-

UP

ADC >> ADC calibration ( see details below) OK

WHITE

BALANCE

SHOP

NVM RESET DO Restore default value except WB and ADC data. OK

SET FAC CH DO Preset the channel table of factory. Option: HZ, WX, EGYPT-EL,

Power On

Mode

OFF OFF: Normal mode. Display blue screen when no signal. Turn to

automatically standby mode if keep the signal unavailable over

15 minutes.

ON: Aging mode. Display snow dot when no signal. The set will not

turn to standby even if the unavailability of signal;press

‘function’key to exit warm-up mode.

>> White Balance Adjustment ( see details below) OK

DO It is crucial that the function is executed after production aim to clear

information of production process, ensure user cannot access to

Factory Menu after executing the item.

ALGERIA e.g. To p reset th e ch annel table of certain factory, firstly,

choose the corresponding factory name, then press OK button of

remote control and wait until the disappearance of Factory Menu,

LAST/STB ON: the set will power on after switching on power.

STB: the set will remain standby status after switching on power.

Last: the set will turn to the status in which it lies when last switching

off.

If without requirement from certain customer,

by default, the Setting should be Last for MS82S-AP and STB for

MS82S-LA

OK

OK

OK

OK

USB

UPDATE

SW NO. OFF Version information of Main Software OK

Project

Name

SIACP

Version

Date Release date and time of main software OK

Upgrade software. Please see details below. OK

Product model OK

Serial port remote control protocol OK

PRELIMINARY INFORMATION ----- SUBJECT TO CHANGE

4

Page 11

MS82MT-AP/LA Chassis Aliment procedure

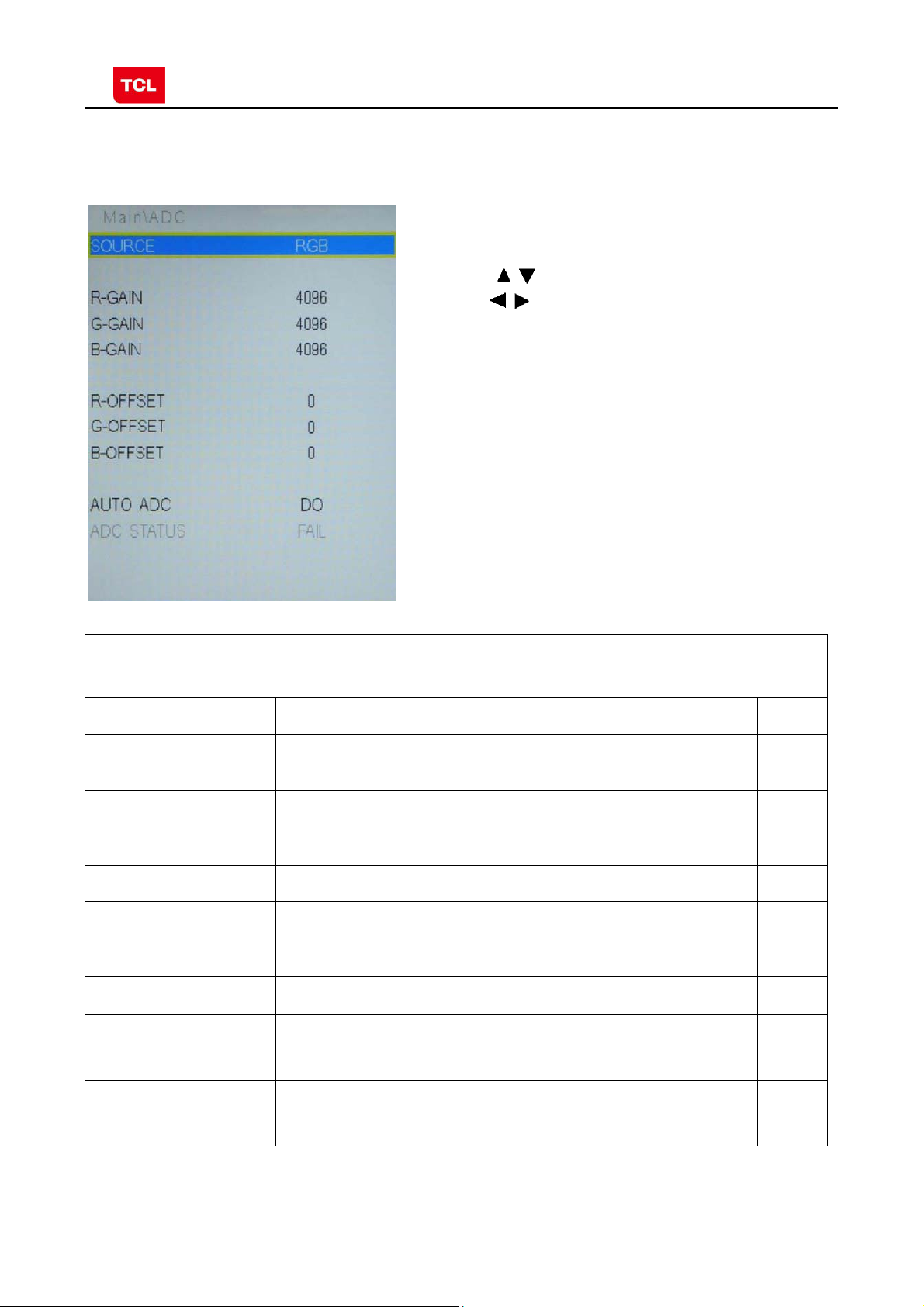

2.3 ADC calibration menu

ADC Menu

Press the button in remote control to select certain

item and

ADC calibration.

Notes:

1. Only YPBPR and RGB source should be calibrated.

to change the value of ADC data or start

ADC Calibration menu

Name Default Description Status

SOURCE Select the source you intend to ADC Calibrate.

R GAIN 4096 Gain of R channel ( cannot be changed after auto calibration) OK

G GAIN 4096 Gain of G channel ( cannot be changed after auto calibration) OK

B GAIN 4096 Gain of B channel ( cannot be changed after auto calibration) OK

R OFFSET 0 Offset of R channel ( cannot be changed after auto calibration) OK

Only YPBPR and RGB are available.

OK

B OFFSET 0 Offset of B channel ( cannot be changed after auto calibration) OK

G OFFSET 0 Offset of G channel ( cannot be changed after auto calibration) OK

AUTO ADC DO Select and execute the item, ADC Calibration starts. It indicates

ADC

STATUS

Show the ADC status of YPbPr/RGB Channel. SUCCESS will be

a successful calibration if prompt “OK” is displayed.

Otherwise, It is a failing calibration (“FAIL” is displayed).

display if YPbPr/RGB Channel has been correctly calibrated.

Otherwise FAIL will be displayed

OK

OK

PRELIMINARY INFORMATION ----- SUBJECT TO CHANGE

5

Page 12

MS82MT-AP/LA Chassis Aliment procedure

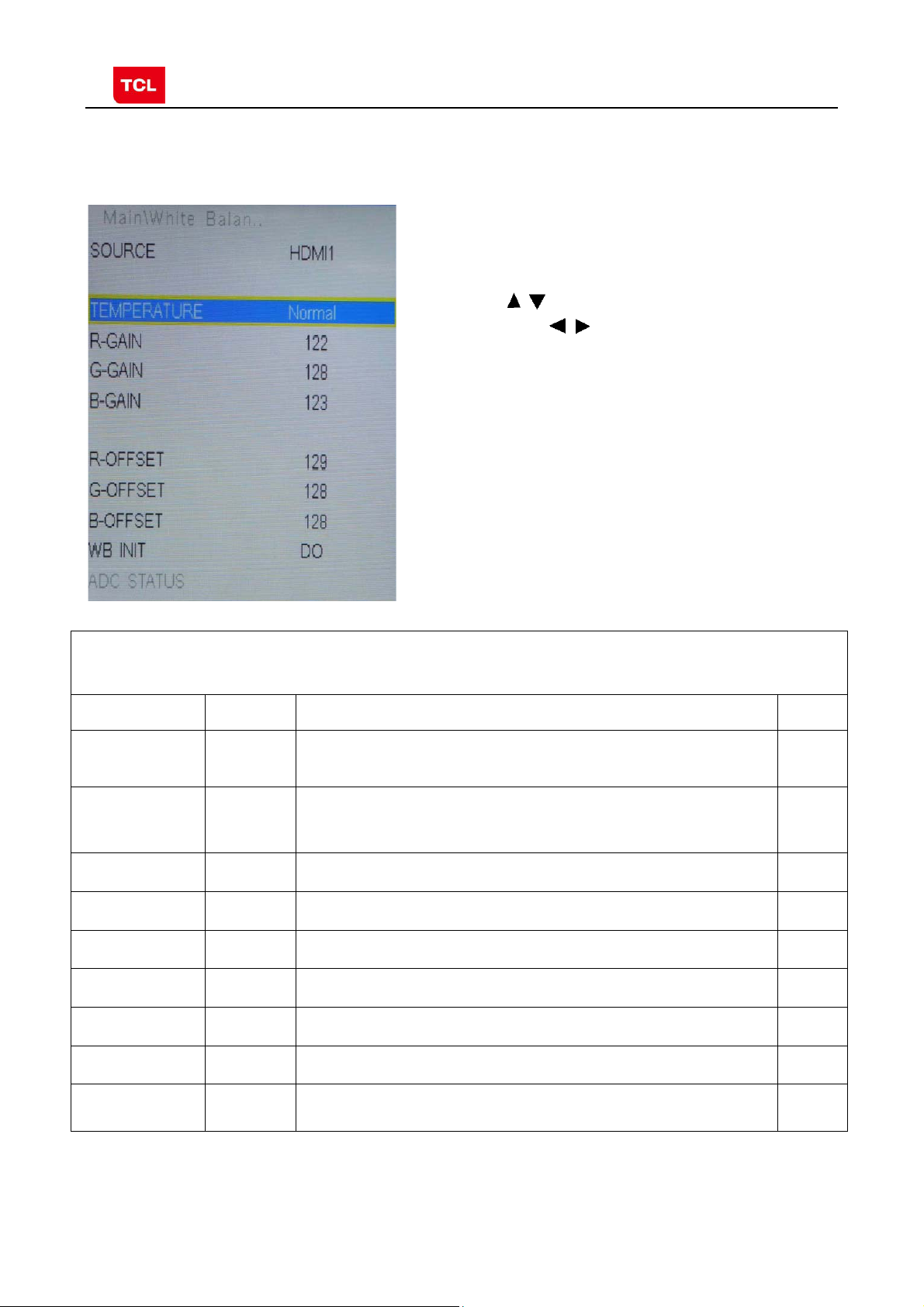

2.4 White Balance Adjustment menu

White Balance menu

Press the button in remote control to select

certain item and to adjust Wh ite Balance

White Balance Adjustment menu

Name Default Description Status

Source PC Select the source you intend to apply WB adjustment.

COLOR

TEMPERATURE

R GAIN

G GAIN

B GAIN

R OFFSET

Cool Select color temperature you intend to adjust Three groups of

-2

0

+9

+6

Only HDMI1, AV1, YPBPR, PC and should be adjusted.

color temperature: Normal, Warm, Cool are available for each

source.

Gain of R channel ( cannot be changed after auto calibration) OK

Gain of G channel ( cannot be changed after auto calibration) OK

Gain of B channel ( cannot be changed after auto calibration) OK

Offset of R channel ( cannot be changed after auto calibration) OK

OK

OK

G OFFSET

0

Offset of G channel ( cannot be changed after auto calibration) OK

B OFFSET

-2

Offset of B channel ( cannot be changed after auto calibration) OK

WB INIT

PRELIMINARY INFORMATION ----- SUBJECT TO CHANGE

White Balance Initalization. Before WB adjustment, this item should

be executed.

OK

6

Page 13

MS82MT-AP/LA Chassis Aliment procedure

3 Factory Main Menu

3.1 Accessing way:

1. In the first place, press Menu button of

remote control, then select Contrast item

of Picture submenu. Finally, press 1, 9, 5, 0

consecutively.

2. When the DESIGN HOTKEY item of Design

Menu is enabled (ON), press Return button of

remote control.

Press the button in remote control to select

certain item and

available options.

to toggle among or execute the

Main Menu

Name Default Description Status

DESIGN

HOTKEY

FACTORY

MENU

SHOP

INIT

OTHER

SERVICE

MENU

PARAM

SETTING

HOTEL

MENU

OFF Design Menu shortcut button switch

The item must be disabled (OFF) after production

>>> Access to Factory Menu OK

>>> Contain many options which can be chosen according to the

requirements of customers as default settings when leave factory.

See details below.

>>> The item includes a number of functions offering convenience for

R&D engineer to solve problems. It is exclusively used by R&D.

>>> Provide many useful information for aftersale service

Please reference to SERVICE MENU submenu

>>> Include volume, brightness, contrast, saturation, hue, sharpness,

backlight, volume, overscan Adjustment etc. Please reference to

PARAM SETTING submenu.

>>> Include special functions which bring benefits to hotel management.

The item is accessible only when HOTEL ENABLE item is enabled

(ON).

OK

OK

OK

OK

OK

OK

3.2 SHOP MENU

PRELIMINARY INFORMATION ----- SUBJECT TO CHANGE

7

Page 14

MS82MT-AP/LA Chassis Aliment procedure

Contain many options which can be chosen according

to the requirements of customers as default settings

when leave factory. Press the

control to select certain item and to toggle

among the available options..

button in remote

SHOP MENU

Name Default Description Status

VOLUME 30 Volume setting, 0~100 adjustable OK

PIC MODE STANDARD Picture mode. Options:

SOUND

MODE

STEREO Sound effects. Options:

BRIGHT, SOFT, PERSONAL,STANDARD

STAREO MISIC, MOVIE, NEWS

OK

OK

CH NUMBER 199 Maximum number of accessible channel NG

OSD

LANGUAGE

Preset CH 0 Preset channel. 0~199 optional OK

ENGLISH AP: English, French, Vietnamese, Russian, Arabic, Farsi, Hebrew,

Thai, Portuguese, Mongolian, LA: English, Portuguese, Spanish

OK

COLOR

TEMP

NORMAL Color temperature. Option: NORMAL, WARM, COOL OK

3.3 Other Menu

PRELIMINARY INFORMATION ----- SUBJECT TO CHANGE

8

Page 15

MS82MT-AP/LA Chassis Aliment procedure

Press the

certain item and to toggle among the available

options..

button in remote control to select

Other Menu

Name Default Description Status

VIF1 Exclusively used by R&D. OK

VIF2 Exclusively used by R&D. OK

VIF3 Exclusively used by R&D. OK

QMAP

ADJUST

SSC Spectrum Spread Control.

DBC

ENABLE

BP Parameter of DBC

CP Parameter of DBC

DBC MODE DBC Mode. Exclusively used by R&D. OK

MU0 DQS0 Manually adjust DQS1 phase of DDR2

MU1 DQS1 Manually adjust DQS1 phase of DDR1

Exclusively used by R&D. OK

OK

Exclusively used by R&D.

Dynamic Backlight Enable

Exclusively used by R&D.

Exclusively used by R&D.

Exclusively used by R&D.

Exclusively used by R&D

Exclusively used by R&D

OK

OK

OK

OK

OK

PRELIMINARY INFORMATION ----- SUBJECT TO CHANGE

9

Page 16

MS82MT-AP/LA Chassis Aliment procedure

TTX ON ON: enable teletext OFF: Disable teletext OK

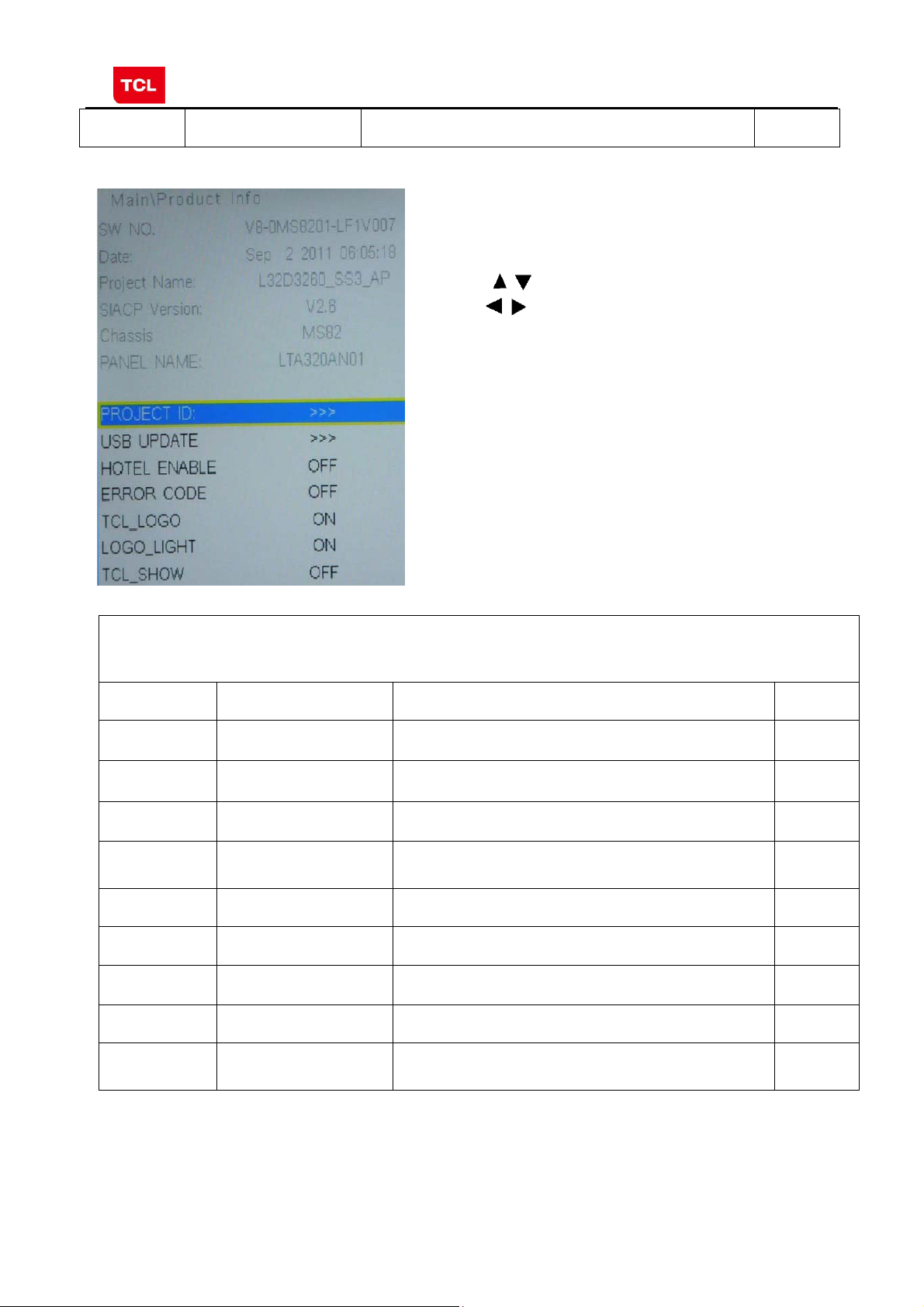

3.4 SERVICE MENU

Press the

item and to toggle among the available options..

button in remote control to select certain

SERVICE MENU (Product Info)

Name Default Description Status

SW NO. Software virtual code of Main Software OK

DATE Release date, time OK

Project Name Model of product OK

SIACP

Version

Chassis MS82S-AP/MS82S-LA Chassis name OK

Serial port remote control protocol

OK

P ANEL NAME Panel code OK

PROJECT ID Select project parameters through project ID. OK

USB UPDATE USB upgrad e. OK

HOTEL

ENABLE

Switch of Hotel Menu. OK

PRELIMINARY INFORMATION ----- SUBJECT TO CHANGE

10

Page 17

MS82MT-AP/LA Chassis Aliment procedure

ERROR

CODE

TCL_LOGO Display TCL Logo or not. On : display ,

LOGO_LIGHT OK

TCL_SHOW DEMO function ON/OFF OK

NG

OK

Off: not display

3.5 PARAM SETTING MENU

Press the

and

button in remote control to select certain item

to enter menu.

PARAM SETTING MENU (Setting menu)

Name Default Description Status

Brightness

Curve

Contrast

Curve

Saturation

Curve

>>> Brightness curve. Exclusively used by R&D. OK

>>> Contrast curve. Exclusively used by R&D. OK

>>> Saturation curves. Exclusively used by R&D. OK

Hue Curve >>> Hue Curve Exclusively used by R&D. OK

Volume

Curve

>>> Volume curve. Exclusively used by R&D. OK

Backlight

Curve

OverScan >>> Overscan adjustment. Exclusively used by R&D. OK

PRELIMINARY INFORMATION ----- SUBJECT TO CHANGE

>>> Backlight curve. Exclusively used by R&D. OK

11

Page 18

MS82MT-AP/LA Chassis Aliment procedure

3.6 HOTEL MENU

Press the

certain item and

button in remote control to select

to enter submenu.

Name Default Description Status

POWER

LOGO

CH LOCK OFF Channel scan lock. OK

ON LOGO select OK

HOTEL MENU

MAX VOL 100 Max volume OK

AUTO SET OFF The switch of PIC, SOUND etc.

PIC MODE Standard Picture mode. OK

SOUND

MODE

POWER

VOL.

POWER

SIGNAL

POWER

CHANNEL

KEY LOCK OFF Lock the keys. OK

SA VE DATA

TO

WRITE

DATA TO

PRELIMINARY INFORMATION ----- SUBJECT TO CHANGE

STEREO Sound mode OK

50 Default volume when power on OK

ATV Default signal source when power on OK

0 Default channel no. when power on OK

DO Save the settings of Hotel Menu to USB OK

DO Copy the settings of Hotel Menu from USB OK

When it is ON, these items are selectable.

OK

12

Page 19

MS82MT-AP/LA Chassis Aliment procedure

g

p

g

ging

4. The steps of debuggin

4.1 Device

Color Analyzer CA-210. Video Pattern Generator Chroma2329. Color TV Pattern

Generator PM5418, VGA cable, AV cable(RCA),YPBPR(RCA) cable.

。

Chroma2329

4.2 ste

s of debu

Fluke5418 CA-210

:

According to the requirement of order, we suggest take the below steps to finish

the appropriate settings.

A enter the Factory Menu, enable FAC HOTKEY

B Check the version of software, release date displayed at the bottom of Factory

Menu. If the information is correct, you can ignore step C and D.

C Enter Factory Main Menu, choose SERVICE MENU->PROJECT ID, choose

corresponding Project ID number of the product (Please refer to the description in

BOM about Project ID number).

D return to Factory Menu, check the Product model.

E choose Factory Menu-> NVM RESET and press and wait until prompt OK

appears.

F restart the set

G according to the requirement of order, set the items of Shop Menu and Hotel

Menu etc.

H After aging under normal temperature, calibrate ADC and adjust white balance.

I choose Factory Menu-> SHOP INIT and press button of remote control to

initialize the set.

Note: after step I (execute SHOP INIT), Hotel Menu will be disabled by default.

Therefore, if order requires hotel function, it is necessary to enable hotel function by

Factory Main Menu-> Service Menu->HOTEL ENABLE to ON.

set

4.3 ADC Calibration

Ⅰ.signal and generator

VGA: Chroma2329 Pattern42, Timing 14(1024x768@60Hz 5 MOSAIC)

YPBPR: Chroma2329 Pattern103, Timing 79(100% Color Bar, 720p)

5 MOSAIC 100% Color Bar

PRELIMINARY INFORMATION ----- SUBJECT TO CHANGE

13

Page 20

MS82MT-AP/LA Chassis Aliment procedure

Ⅱ.steps of debug:

1) Access to the Factory menu->ADC

2) Select PC source

3) Select AUTO ADC,Press button in your remote control to calibrate the

ADC automatically.

4) Select YPBPR source

5) Repeat step 3.

6) When the OK appears the calibration has been finished successfully.

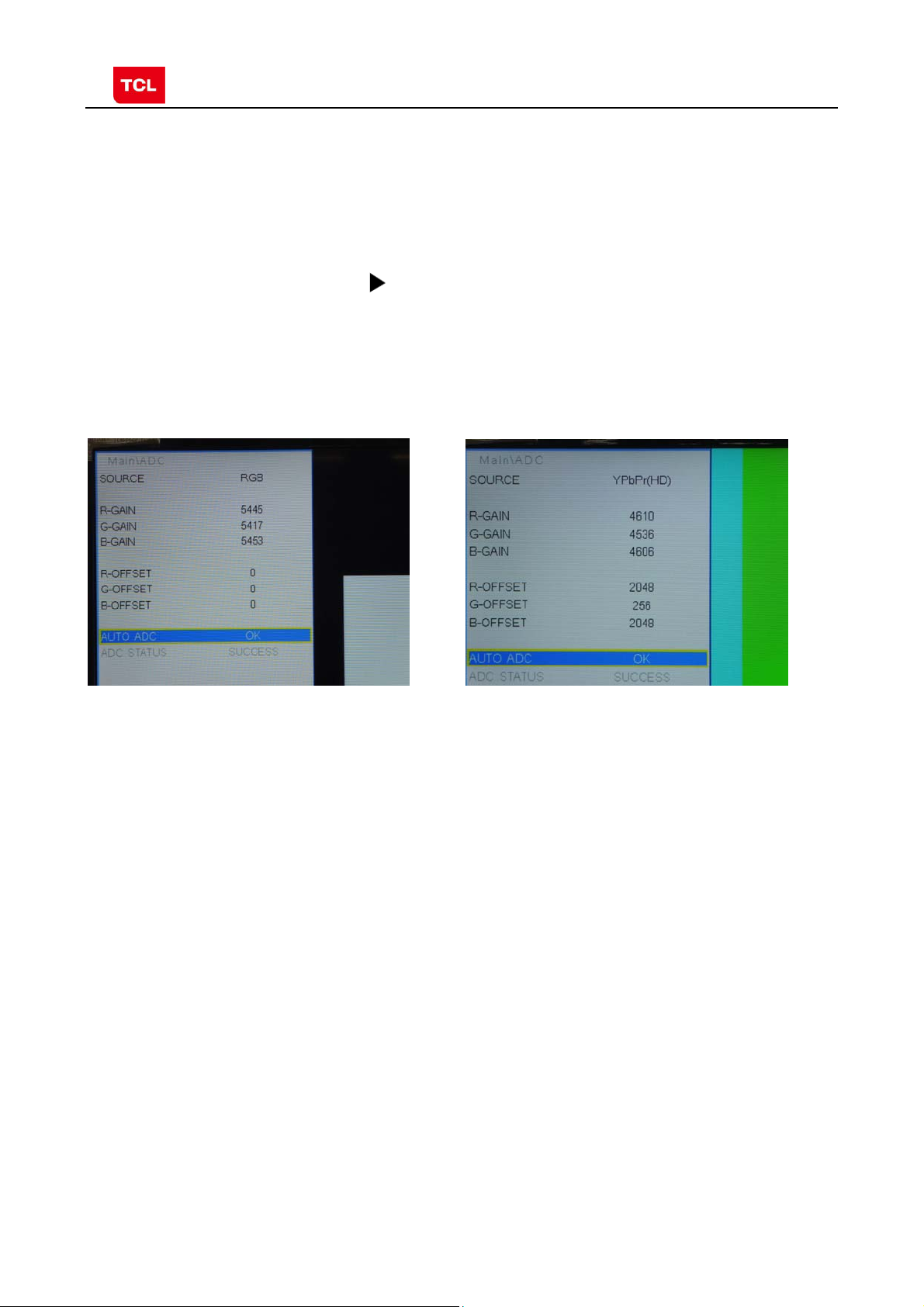

VGA calibration YPBPR calibration

4.4 White Balance adjustment (Manual)

Before adjustment, you must ensure Color Analyzer has been calibrated. Only AV1,

YPBPR, VGA , HDMI 1 need to be adjusted. It is necessary to adjustment HDMI 1

firstly.

a. signal and generator

The pattern of the signal should be used are White (Chroma2329 pattern113) and

Grey (pattern 114).The format of signal are respectively 720p for HDMI1

(Chroma2329 Timing 69), NTSC for AV1 (Chroma2329 Timing 37),1024×768@60Hz

(Chroma2329 Timing 14) for VGA and 720p (Chroma2329 Timing 79)for YPBPR

b. steps of adjustment

1) enter the factory menu->WHITE BALANCE, select source HDMI 1 and COLORTEMP

normal.

2) input grey signal in 720p format

3) change R OFFSET and B OFFSET to make sure the value of color coordination

equal to the value required by enterprise standard (x, y).

PRELIMINARY INFORMATION ----- SUBJECT TO CHANGE

14

Page 21

MS82MT-AP/LA Chassis Aliment procedure

4) input white signal in 720p format

5) change R Gain and B Gain to make sure the value of color coordination equal to

(x, y).

6) repeat step 2~5 until both of the value of color coordination of white and grey

equal to (x, y).

In addition to select COLORTEMP COOL/WARM, the adjustment method of COOL

and WARM color temperature is same with that of NORMAL. The color coordination

we recommend is as follows:

Device:CA-210; Accuracy:±0.015

Model WARM NORMAL COOL

L28E3500

L24E3500

L24E3510F

L28E4100

X 0.294 0.277 0.256

Y 0.305 0.293 0.268

X 0.280 0.265 0.250

Y 0.300 0.285 0.265

X 0.290 0.270 0.248

Y 0.310 0.292 0.278

X 0.282 0.267 0.250

Y 0.291 0.280 0.257

HDMI White Balance adjustment

PRELIMINARY INFORMATION ----- SUBJECT TO CHANGE

15

Page 22

MS82MT-AP/LA Chassis Aliment procedure

4.5 ADC Calibration and White Balance Adjustment (automatic)

The process of adjusting ADC and White Balance automatically is out of the range

of this file. Please refer to the relevant technical file of HuiZhou factory of TCL

5. Chip list of software programming before SMT

Following chips must be programmed before SMT by ALL-11 or other tools.

Position Chip type Chip name Part number Software

description

1 U502 Flash EN25Q32B 13-EN25Q3-2BBEO main software SO-8

2 U702 E2PROM M24C32MN 13-M24C32-MNB Tcon software SO-8

Note:

1) The software for U502 and U702 can be program using ISP tool.

2) Every set has its unique HDCP key which is purchased from suppliers or HDCP

certification authority. Please check HDCP function in the process of production.

3) Once in a while, the software of main board may be upgraded. Please pay attention to

use the latest software before production.

Decal

PRELIMINARY INFORMATION ----- SUBJECT TO CHANGE

16

Page 23

MS82MT-AP/LA Chassis Aliment procedure

Appendix:

1. Software upgrade through USB disk

1) Please ensure the software you are using has a correct file name

TCL_MS82_UPDATE.bin, then copy it to the root directory of a USB disk.

2) Insert the USB disk to the USB socket of the set for which you are

going to upgrade program.

3) Enter the Factory Menu (you can choose either a or b way below)

a. In the first place, press Menu button of remote

control, then select Contrast item of Picture

submenu. Finally, press 9, 7, 3, 5 consecutively.

b. When the Factory hotkey ite m of Factory Menu

is enabled (ON), press Return button of remote

control.

4) select USB UPDATE, press buttonof remote control, a pop menu

will appear prompting whether start upgradeor not. Press Yes to start upgrade,

press No to canel. Please wait patiently until the set restart automatically after

upgrade. Do not cut off the power supply during the process.

Upgrade Main Software

PRELIMINARY INFORMATION ----- SUBJECT TO CHANGE

17

Page 24

MS82MT-AP/LA Chassis Aliment procedure

2. Check software version, release date and Project ID

After upgrading, sometimes you may not certain whether the new software has

been successfully updated or not. In this case, you can check the software version

and release date in Factory Main Menu to make sure the success of upgrading.

In addition, for the convenience of software management, many models of same

chassis may share a same software, but are allocated with different Project ID.

In another words, every model has its unique Project ID. Obviously, Both software

version and Project ID are highly critical to ensure the set work properly. Therefore,

after upgrading software,we suggest you check these information by following

method.

1) Enter the Factory Main Menu(you can choose either a or b way below

a In the first place, press Menu button of remote control, then select Contrast item

of Picture submenu. Finally, press 1, 9 5, 0 consecutively.

b. When the DESIGN HOTKEY item of Factory Main Menu is enabled (ON), press

Return button of remote control.

2) Check the version of software, release date displayed at the bottom of Factory

Main Menu. If the information is correct, you can ignore step C and D.

3) choose SERVICE MENU->PROJECT ID, choose corresponding Project ID number of

the product (Please refer to the description in BOM about Project ID number).

4) choose Factory Menu and press OK button of the remote. Next, select NVM RESET

and press and wait until prompt OK appears.

5) choose SHOP INIT and press

button of remote control to initialize the set.

Note: after step I (execute SHOP INIT), Hotel Menu will be disabled by default.

Therefore, if order requires hotel function, it is necessary to enable hotel function by

set

Factory Main Menu-> Service Menu->HOTEL ENABLE to ON.

6) restart the set.

PRELIMINARY INFORMATION ----- SUBJECT TO CHANGE

18

Page 25

MS82MT-AP/LA Chassis Aliment procedure

Product

Information

Check product information

Remote Control name

Power Supply name

Audio Channel number

Change project ID

PRELIMINARY INFORMATION ----- SUBJECT TO CHANGE

19

Page 26

MS82MT-AP/LA Chassis Aliment procedure

3. FAQ

1) Why there is no picture after upgrading software or changing project ID?

It may be caused by fault of project ID. You can try below method to fix

the problem.

a. If the resolution of the panel of your set is 1366×768(HD panel), you can press

Menu, and 4976 of remote control in series after turning on.

b. If the resolution of the panel of your set is 1920×1080(FHD panel), you

can press Menu, and 4973 in series after turning on.

c. If you can see the picture at this time, please recheck the project ID again. If

the project ID is still wrong, correct it reference to above description.

PRELIMINARY INFORMATION ----- SUBJECT TO CHANGE

20

Page 27

8 7 6 5

4 3 2 1

R106

82K

R115

R107

R108

6K8

R109

510R

R116

30K

R117

51K

R118

2K2

C111

NC/

39K

NC/

GND

C122

GND

0.022U

0.022U

C113

22U

C123

22U

C114

10U

C124

22U

MAX_2A

GND

C125

10U

GND

C115

10U

MAX_2A

D101

NC/

D103

NC/

5V6

5V

F

5V6

E

VDDC

D

L101

8.2UH

U104

FB

VCC

BST

MP1494

10R

R105

12V---5V/1.5A

Fixed Fsw=500kHZ

L102

4.7UH

U105

FB

VCC

BST

MP1494

10R

R114

12V---1.2V/2A

Fixed Fsw=500kHZ

8

7

6

5

8

7

5

GND

GND

C108

0.1U

82K

C126

0.1U

VIN

3

GND

C106

0.1U

GND

U101

AS1117-1.8

VIN

3

GND

4

4

OUT

2

VIN

4

OUT

3

4

2

GND/ADJ

1

C129

0.1U

U102

AS1117-2.5

4

4

GND/ADJ

OUT

1

2

GND/ADJ

1

C127

0.1U

C128

0.1U

3V3_NORMAL

T

C102

100U

16V

2V5

T

1V8_DDR

T

C136

100U

16V

3V3_NORMAL

2V5

C137

100U

16V

1V8

12V

12V

C101

10U

C116

10U

GND

GND

C103

0.1U

C119

0.1U

R103

75K

R104

R110

75K

R113

20K

20K

GND

GND

1

AAM

2

IN

3

SW EN/SYNC

4

GND

GND

C107

0.1U

C104

0.1U

1

AAM

2

IN

3 6

SW EN/SYNC

4

GND

GND

C121

0.1U

C120

0.1U

AS1117-3.3

F

DIM

BL_ON

P_ON

E

3V3_STB

GND

1 2

3

5

7

9

11

13

P102

4

6

8

10

12

14

DIM

BL_ON

P_ON

3V3_STB

GND3

T T

12V_A

P_ON

T

GND4

12V_A212V_A1

T T

3V3_STB

T

GND

5V

D

3V3_STB

R127

3K3

(5)

POWER_ON

R123

330R

P_ON

U103

C130

0.1U

C118

0.1U

BL_ON

T

DIM_PWM

T

C

GND

R126

330R

1

2

3

4

5

GND

KEY

BL_ON

GND

KEY

C117

0.1U

T

LED

GND

T

C133

0.1U

3V3_STB

IR

GND

T

3V3STB

T

R121

220R

R122

1K

C132

1000P

D102

2

R120

47K

F2

BL_ON_OUT

R125

10K

B

P101

A

1000P

0BAV99NC/

3

C135

DIM

C131

0.01U

1

close to P100

GND

GND

R119

22K

C134

0.1U

R124

220R

3V3_STB

IR_IN

LED_OUT

KEY_IN

THIS DRAWING CANNOT BE COMMUNICATED TO UNAUTHORIZED PERSONS COPIED UNLES S PERMITTED IN WRITING

DIM_OUT

(5)

R102

4K7

NC/

GND

Q101

12V

R129

10K

G

GND

T

D

C139

4U7

1U

GND

R130

15K

C145

GND2

T

12V

P_ON

C

B

MDD3752

12V_A

R131

100K

Q102

BT3904

U106

C110

NC/

USB_5V

10U

1

FLG

2

GND

RT9711

NC/

VOUT

VINEN/EN#

5

R101

0R

43

5V

GND

C105

1U

NC/

GND

D104

MBRX14

D105

NC/

C

E

C140

1000P

NC/

R128

680R

S

6V8

B

SBU :

TCLNO:

Index-Lab

DATE

DESCRIPTION Last modifNAME

Last saved :

5

4678

.............

TCL Thomson Electronics Singapore Pte. Ltd.

8 Jurong Hall Road #28-01/06

The JTC Summit SINGAPORE 609434

DESIGNATION

DRAWN

DESIGNATION

3 2 1

ON:

BY:

Tel (65) 63092900 Fax (65) 63092999

CHECKED

PAGE:

ON:

BY:

OF :

A

FORMAT DIN A2

Page 28

8 7 6 5

TDA18273+CAN_TUNER_ONBOARD_COMP SCH, VER1.0 2012-7-25

4 3 2 1

F

TU_3V3

RT2

0R

TUNER_VCC

CT18

CT19

CT20

CT21

CT22

CT23

Caution:

CT24

TU_3V3 must be from LDO

GND

LT3

LT4

LT5

8.2NH

LT6

P

100NH

F

CT5

1

2

3

4

5

6

7

8

9

10

0.22U

VCC1-RF

RFIN

NC1

NC2

GND1

AS_XTSEL

GND2

TEST1

TEST2

GND3

TUNER_VCC

2.4NH

2.2NH

38

34

35

36

37

39

40

CAPRFAGC

RFAGC_SENSE

UHFSUPPLY

UHFLOW

VCC2-RF

VHFHIGH

UHFHIGH

TDA18273HN

UT1

TDA18273HN

CAPREGVCO

VCC-SYNTH

XTALN

XTALP

GND4

SDA

SCL

111213141516171819

CT6 0.1U

31

32

33

VHFSENSE

VHFLOW

VHFSUPPLY

VSYNC

VIFAGC

VCC-IF

XTOUT2

XTOUT1

VTUNE

GND5

CP

20

IRQ

GND7

IFP

IFN

GND6

GND

CT7

6800P

30

29

28

27

26

25

24

23

22

21

TUNER_VCC

0.1U

0.1U

T

Z12

CT10

CT11

CT8

10P

CT9

10P

RT8

0R

0R

RT9

RT7

1K

VIF+

VIF-

E

GND

10U

0.047U

0.047U

0.047U

0.047U

100P

0.047U

GND

3

0BAV99

DT1

TUNER_VCC

CT4

82P

2

GND

RT1

0R

GND

E

CT1 CT2

120P

LT1

0.33UH

GND

120P

LT2

CT3

150P

1

0.22UH

GND

TUN1

GND1

GND2

GND3

GND4

GND5

GND6

1

S1

2

3

4

5

6

7

FT1

GND

RT6

6800P

0.1U

TUNER_VCC

CT12

CT14

CT15

2700P

D

CT33

22P

CT34

22P

GND

430R

CT13

0.22U

D

GND

RT15

33R

33R

RT16

GND

CT16

30P

XT16M

CT17

30P

16M

TU_3V3

4

C202

0.1U

VIN

4

GND/ADJ

OUT

1

2

3

TU_3V3

T

300mA

C

TU_3V3

GND

C203

220U

16V

C204

GNDGND

B

C

ANT

3V3

SCL

SDA

GND

XOUT

IF_N

IF_P

IF_AGC

TUN2

NC/

IF_AGC

B

1

TU_3V3

2

3

4

5

6

7

8

9

T

TU3V3

T

T

GND1

GND

CT37

NC/

CT32

NC/

CT30

NC/

IF- IF+

22P

GND GND

RT14

NC/

1K

6800P

10U

T_SCL

GND

NC/

CT29

TT

CT38

NC/

22P

T

22P

T_SDA

T

NC/

GND

RT12

NC/

RT13

NC/

CT28

22P

33R

33R

RT10

4K7

4K7

RT11

TUNER_SCL

TUNER_SDA

IF_AGC

0.047U

C205

R201

10K

RF_AGC

TU_3V3

R202

10K

5V

RF_AGC

U201

AS1117-3.3

C201

10U 0.1U

GND

A

THIS DRAWING CANNOT BE COMMUNICATED TO UNAUTHORIZED PERSONS COPIED UNLES S PERMITTED IN WRITING

GND

SBU :

TCLNO:

Index-Lab

DATE

DESCRIPTION Last modifNAME

Last saved :

5

4678

.............

TCL Thomson Electronics Singapore Pte. Ltd.

8 Jurong Hall Road #28-01/06

The JTC Summit SINGAPORE 609434

DESIGNATION

DRAWN

DESIGNATION

3 2 1

ON:

BY:

Tel (65) 63092900 Fax (65) 63092999

CHECKED

PAGE:

ON:

BY:

OF :

A

FORMAT DIN A2

Page 29

8 7 6 5 4 3 2 1

AV IN 1

CLOSE TO SOC

C318

C301

560P

0.047U

C317

2U2

C316

2U2

AV1_V_IN

AV1_L_IN

AV1_R_IN

R307

12K

560P

C319

R316

100R

12K

R308

F

E

GND8

AV1_V

AV1_L

AV1_R

T

F4

R301

10K

R302

10K

R306

75R

GND

YPBPR_AV2_IN

(5)

(5)

(5)

HD_R

HD_L

GND

R303

10K

R304

10K

GND

R318

12K

C302

560P

R322

C303

560P

12K

CLOSE TO SOC

C314

2U2

C310

2U2

HD1_R_IN

HD1_L_IN

(5)

(5)

5V

R319

10R

AVOUT1_V

C320

10U

GND

R315

75R

C315

0.1U

BT3906

Q302

E

C

BT3904

220R

B

R314

R320

150R

Q301

C

E

R313

470R

C311

NC/

F

R321

8K2

B

R317

NC/

22P

15K

1K

R312

AVOUT1_V_OUT

E

AV OUT

CLOSE TO SOC

GND

AV1_L

D

P301

WHITE

WHITE

RED

RED

6

5

4

3

2

1

HD_L

HD_R

T

T

AV1_L

HD_L

AV1_R

T

T

F10

F9

F11

AV1_R

HD_R

F12

SPDIF

R325

120R

C313

33P

GND

C

GND

USB

GND7

T T

USB2_DP

USB2_DM

T

USB_5V1

T

USB_5V

B

VCC

GND

P302

1

2

D-

3

D+

4

F14

F13

C307

0.1U

GND

C306

220U

16V

R327

2R2

2R2

R326

USB2_D-_IN

USB2_D-_IN

USB2_D+_IN

USB2_D+_IN

(5)

(5)

A

THIS DRAWING CANNOT BE COMMUNICATED TO UNAUTHORIZED PERSONS COPIED UNLES S PERMITTED IN WRITING

R323

220R

C312

0.1U

...

...

...

...

SPDIF_OUT

T

HD_Y/AV2_IN

GND

DD-MM

DD-MM

DD-MM

DD-MM

DATE DESCRIPTION Last modifNAMEIndex-Lab

Last saved :

GND9

F7

F3

HD_PR

75R

HD_PB

75R

R328

75R

R329

...

...

...

...

(5)

R324

F8

...

...

...

...

1-26-2013_12:46

CLOSE TO SOC

R305

47R

R309

47R

R310

47R

10R

R311

45678

0.047U

C304

1000P

C309

0.047U

C308

C305

0.047U

D

AVOUT1_V

T

HD_Y/AV2_IN

HD_PB

T

GND

T

AVOUT1_V

SPDIF

T

SPDIF

HD_PB

AV1_VHD_PR

T

T

HD_PR

GND5

T

C

AV1_V

HD1_PR_IN

HD1_PB_IN

HD1_Y_IN+

HD1_SOG_IN

(5)

(5)

(5)

(5)

YELLOW

GREEN

BLACK

BLUE

YELLOW

RED

HD_Y/AV2_IN

P303

9

8

7

6

5

4

3

2

1

B

...

...

...

...

SBU :

TCLNO:

.............

DESIGNATION

...........

ADDRESS1

ADDRESS2

ADDRESS3

TELEPHONE

DRAWN

ON:

BY:

TCL

CHECKED

DD-MM-YY

ON:

BY:

......

PAGE:

OF :

A

10

3

123

FORMAT DIN A3

Page 30

8 7 6 5 4 3 2 1

P401

GND10

P402

17

RX2+

GND1

F

RX2-

RX1+

GND2

RX1-

RX0+

GND3

RX0-

RXC+

E

GND4

RXC-

NC1

NC2

DDCCLK

DDCDA

GND5

VCC

HPD

D

1

2

3

4

5

6

7

8

9

10

11

12

GND

CEC

H1_ARC

H1_SCL

H1_SDA

H1_5V

H1_HPD

C404

R423

R422

10K

R417

R406

1U

100R

100R

1K

13

14

15

16

17

18

19

10K

NC/

R414

H1_RX2+_IN

H1_RX2-_IN

H1_RX1+_IN

H1_RX1-_IN

H1_RX0+_IN

H1_RX0-_IN

H1_RXC+_IN

H1_RXC-_IN

R418

100R

0R

R421

R407

10K

R413

10K

C405

H1_ARC_OUT

0.1U

H_CEC

H1_SCL_IN

H1_SDA_OUT

H1_DET

R412

22K

6

11

1

7

12

2

8

13

3

9

14

4

10

15

5

16

T

GND

VGA_TX

T

T

VGA_SDA

T

VGA_SDA

VGA_GRN

VGA_HS

VGA_BLU

75R

R411

VGA_R

VGA_TXD

75R

R401

3V3_STB

VGA_G

T

T

VGA_HS

VGA_VS

VGA_VS

75R

R402

VGA_RED

VGA_B

T

T

VGA_RXD

2K2

R403

GND

2K2

R404

close to soc

R426

33R

R425

33R

R410

33R

R424

T

VGA_RX

T

VGA_SCL

VGA_SCL

10R

R409

100R

C406

C401

0.047U

C403

R405

100R

0.047U

C402

4700P

0.047U

VGA_RED_IN

VGA_GRN_IN

VGA_SOG_IN

VGA_HS_IN

VGA_BLU_IN

VGA_VS_IN

VGA_TXD

VGA_RED

GND

F16

VGA_SDA

VGA_GRN

F17

F19

F18

VGA_HS

VGA_BLU

F21

F20

VGA_VS

VGA_RXD

F23

F22

F

VGA_SCL

E

F24

D

GND

C

BT3904

Q401

R408

B

E

4K7

H1_HPD_OUT

C

GND

CEC

H1_5V

H1_SCL

H1_SDA

H1_HPD

F25

GND

H1_ARC

F27

F26

F28

F29

F30

B

A

THIS DRAWING CANNOT BE COMMUNICATED TO UNAUTHORIZED PERSONS COPIED UNLES S PERMITTED IN WRITING

...

...

...

...

DD-MM

DD-MM

DD-MM

DD-MM

DATE DESCRIPTION Last modifNAMEIndex-Lab

Last saved :

VGA_SDA

VGA_SCL

...

...

...

...

VGA_TXD

VGA_RXD

...

...

...

...

4-14-2009_15:30

45678

R415

R419

R420

100R

100RR416

100R

100R

R112

R111

4K7

4K7

C

UART_TX

UART_RX

B

...

...

...

...

SBU :

TCLNO:

.............

DESIGNATION

...........

ADDRESS1

ADDRESS2

ADDRESS3

TELEPHONE

DRAWN

ON:

BY:

TCL

CHECKED

DD-MM-YY

ON:

BY:

......

A

PAGE:

OF :

123

FORMAT DIN A3

Page 31

8 7 6 5

4 3 2 1

3V3_NORMAL

VDDC

600mA

2U2

C506

F

C539

GND

0.1U

0.1U

C538

0.1U

C537

0.1U

C536

0.1U

C535

0.1U

C527

2U2

C505

GND

C546

1V8

200MA

C501

10U

0.1U

C534

0.1U

C533

0.1U

C532

C531

0.1U

0.1U

C530

GND

E

GND

J9

H10

H9

R7

P7

P6

R5

R4

P4

G3

G2

G1

GND2

H_CEC

H1_HPD_OUT

H1_RXC-_IN

H1_RXC+_IN

H1_RX0-_IN

H1_RX0+_IN

H1_RX1-_IN

D

C524

R519

68R

R520

68R

R522

68R

C

GND

0.047U

C525

0.047U

C526

0.047U

H1_RX1+_IN

H1_SDA_OUT

H1_RX2-_IN

H1_RX2+_IN

H1_SCL_IN

H1_ARC_OUT

VGA_HS_IN

VGA_BLU_IN

VGA_SOG_IN

VGA_GRN_IN

GIN0M

VGA_RED_IN

VGA_VS_IN

HD1_PB_IN

HD1_SOG_IN

HD1_Y_IN+

HD1_Y_IN-

HD1_PR_IN

AV1_V_IN

VCOM0

AVOUT1_V_OUT

HD1_L_IN

HD1_R_IN

AV1_L_IN

AV1_R_IN

AUVAG

AUVRM

AMP_L_OUT

AMP_R_OUT

M1

M2

M4

M3

D6

D5

C7

B7

C6

B6

A6

C5

C4

A5

B5

B4

D4

A3

A2

B3

B2

B1

C3

D3

C1

C2

D1

D2

E4

E3

E2

F3

F2

F1

F4

H3

H2

J3

J2

J1

K3

K1

K2

L1

L2

N1

N2

P1

L3

P2

R1

N3

N4

P3

R2

T2

CEC

HOTPLUGD

RXCKN_D

RXCKP_D

RX0N_D

RX0P_D

RX1N_D

RX1P_D

DDCDD_DA

RX2N_D

RX2P_D

DDCDDD_CK

HOTPLUGA

RXCKN_A

RXCKP_A

RX0N_A

RX0P_A

RX1N_A

RX1P_A

DDCDA_DA

RX2N_A

RX2P_A

DDCDA_CK

ARC

HSYNC0

BINOP

SOGIN0

GIN0P

GIN0M

RIN0P

VSYNC0

BIN1P

SOGIN1

GIN1P

GIN1M

RIN1P

VSYNC1

CVBS2

CVBS1

CVBS0

VCOM

CVBSOUT

AUL0

AUR0

AUL1

AUR1

AUVAG

AUREFM

AUL2

AUR2

AUL3

AUR3

AUOUTL1

AUOUTR1

AUOUTL0

AUOUTR0

GND1

XIN

T3

M_XTALO

GND5

GND4

GND3

PGA-COM

VIFM

XOUT

P5

R6

R3

VIF-

VIF+

M_XTALI

AVSS_PGA

T5

GND6

GND7

VIFP

RFAGC

T6

T4

RF_AGC

P10

T7

GND9

GND8

B_ODD0/LVA4P

R10

GND13

GND12

GND10

GND11

B_ODD1/LVA4M

B_ODD2/LVA3P

B_ODD3/LVA3M

B_ODD4/LVACLP

B_ODD5/LVACKM

T11

P11

P12

R11

TXE3-

TXEC-

TXE3+

TXEC+

H11

J10

J11K9K10

GND15

GND14

GND16

GND17

B_ODD6/LVA2P

B_ODD7/LVA2M

G_ODD0/LVA1P

G_ODD1/LVA1M

T12

P13

P14

R12

R13

TXE1-

TXE2-

TXE0+

TXE1+

TXE2+

B

AUVRM

AUVRP

AUVAG

C504 0.1U

C510

10U

C511

10U

C512 0.1U

22P

L502

120R

CLOSE TO IC

A

GND

C520

24M

X24M

22P

C521

GND

THIS DRAWING CANNOT BE COMMUNICATED TO UNAUTHORIZED PERSONS COPIED UNLES S PERMITTED IN WRITING

0.1U

0.1U

C545

K11

A12

F13

G13

GND18

GND19

GND20

GND21

GND22

GND23

G_ODD2/LVA0P

G_ODD3/LVA0M

G_ODD4/LVB4P

G_ODD5/LVB4M

G_ODD6/LVB3P

G_ODD7/LVB3M

T14

T15

R14

R15

R16

TXE0-

TXO3-

TXO3+

M_XTALO

R512

1M

M_XTALI

0.1U

C544

VDDC ADC2P5

N6

GND24

U501

MST3M182VGC

R_ODD4/LVB1P

R_ODD3/LVB2M

R_ODD2/LVB2P

R_ODD1/LVBCKM

R_ODD0/LVBCKP

P16

P15

N15

N14

M15

M14

TXO2-

TXO1-

TXOC-

TXO2+

TXO1+

TXOC+

0.1U

C541

C542

0.1U

C543

L8

K8

L7

VDDC1

VDDC3

VDDC2

R_ODD6/LVBOP

R_ODD5/LVB1M

R_ODD7/LVB0M

GPIO21/TCON21/VGH_ODD_49

L16

K14

M16

TXO0-

TXO0+

H7

H8

J7

J8

K7

VDDC7

VDDC6

VDDC5

VDDC4

AVDD_1P2

GPIO16/TCON16/WPWM_44

GPIO17/TCON17/GCLK4_45

GPIO18/TCON18/GCLK5_46

GPIO20/TCON20/VGH_EVEN_48

GPIO19/TCON19/GCLK6_47

L15

F15

K15

K16

G16

CONFIG GPIO

DIM_OUT

CFG_PWM1

TCON4

TCON2

0.1U

0.1U

C518

0.1U

C289

+2V5_PGA

1V8

M11

M10

E13

D9

G8

AVDD_DDR4

AVDD_DDR5

AVDD_DDR3

AVDD_DDR2

AVDD_DDR1

GPIO10/TCON10/OPT_N_38

GPIO11/TCON11/HCON_39

GPIO12/TCON12/DPM_40

GPIO13/TCON13/LEDON_41

GPIO14/TCON14/SCAN_BLK_42

GPIO15/TCON15/SCAN_BLK1_43

F14

E14

D15

D16

D14

G15

J6

K6

H6

N5

AVDD_25

AVDD_REF

AVDD_PGA

AVDD_AU25

GPIO6/TCON6/FLK_34

GPIO8/TCON8/FLK3_36

GPIO9/TCON9/OPT_P_37

GPIO7/TCON7/FLK2_35

GPIO5/TCON5/SOE_33

J15

J16

L14

F16

H16

H15

TCON4

R518

4K7

R517

4K7

R516

4K7

R515

4K7

3V3_STB

100mA

3V3_NORMAL

K5

L5

J5

M5

AVDD_PLL

AVDD_AU33

AVDD_MOD1

PMGPIO_GPIO10/GPIO66

SAR3_GPIO14/INT_GPIO65

GPIO4/TCON4/GCLK3_32

GPIO3/TCON3/GCLK2_31

GPIO2/TCON2/GCLK1_30

GPIO1/TCON1/VST_29

J14

E16

E15

H14

3V3_STB

K4

J4

L6

M6

AVDD_33

AVDD_MOD4

AVDD_MOD3

AVDD_MOD2

DVDD_NODIE

GND_EFUSE

SAR2_GPIO13/GPIO73

SAR1_GPIO12/GPIO74

SAR0_GPIO11/GPIO75

PWM0_GPIO20/GPIO26

PWM1_GPIO21/GPIO25

PM1_GPIO6/GPIO67

PM4_GPIO7/GPIO68

PM5_GPIO8/GPIO69

PM6_GPIO9/GPIO70

DDCR_CK/GPIO63

DDCR_DA/GPIO64

NC/GPIO62

GPIO26/GPIO61

GPIO27/GPIO60

NC/GPIO59

GPIO23/GPIO58

GPIO25/GPIO57

GPIO24/GPIO56

GPIO22/GPIO55

GPIO27/LVSYNC

GPIO28/LHSYNC

GPIO29/LDE_75

GPIO30/LCK_74

GPIO0/TCON0/POL_28

N13

N12

N11

N10

TCON2

GND

5

0.1U

C540

C522

2U2

C507

GND

H4

AVDD_DVI

AVDD_DMPLL

K13

MVREF

D7

L4

VRP

D13

SCZ

SDO

SDI

SCK

IRIN

C13

C10

C11

B11

B15

B16

C16

C15

B13

A13

A14

A15

D11

D10

B9

A9

B12

C12

D12

A11

A10

B10

C9

G14

B14

C14

N9

P9

T9

N8

P8

R9

R8

T8

DATE

TESTPIN

USB1_DP

USB1_DM

USB0_DP

USB0_DM

DDCA_DA

DDCA_CK

HWRESET

Index-Lab

Last saved :

0.1U

C528

2V5

MDDR_VREF

DVDD_NODIE

AUVRP

LED_OUT

KEY_IN

SPI_CZ

SPI_SDO

SPI_SDI

SPI_SCK

USB2_D+_IN

USB2_D-_IN

R510

R511

SPDIF_OUT

0.1U

total 200mA

100R

UART_RX

100R

MCU_RESET

CFG_PWM1

POWER_ON

BL_ON_OUT

AMP_RESET

TUNER_SCL

TUNER_SDA

L501

120R

GND

UART_TX

IR_IN

DIM_OUT

F_WP

H1_DET

DESCRIPTION Last modifNAME

ADC_2V5

C549

GND

C502

2U2

1V8

R505

R506

GND

T

GND

1K

1K

MDDR_VREF

C513

0.1U

C550

4678

0.1U

ADC2P5

0.1U

C547

C529

1000P

0.1U

2V5

C109

2U2

L504

120R

+2V5_PGA

C548

0.1U

L503

GND

AVSS_PGA

120R

SBU :

TCLNO:

3V3_STB

3

C112

2U2

R501

47K

C503

2U2

1

0BAV99

R523

D501

47K

2

Q501

BT3906

E

B

C

R502

47K

10U

C508

GND

R503

1K

MCU_RESET

T

MCU_RESET

C519

1000P

GND

GND

3V3_STB

3V3_STB

1

2

3

4

U502(CPP)

CS

DO

WP

VSS

EN25Q32B

VCC

NC

CLK

8

7

SPI_SCK

6

SPI_SDI

5

DI

C514

0.1U

GND

0.1U

F_WP

C523

R524

SPI_CZ

SPI_SDO

10K

R521

4K7

GND

5V

T

P502

C509

MLV0P

MLV0N

MLV1P

MLV1N

MLV2P

MLV2N

MLVCKP

MLVCKN

MLV3P

MLV3N

MLV4P

MLV4N

MLV5P

MLV5N

POL

TP1

OE

CKV

GVON

STV

5V

0.1U

GND

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

.............

TCL Thomson Electronics Singapore Pte. Ltd.

8 Jurong Hall Road #28-01/06

The JTC Summit SINGAPORE 609434

DESIGNATION

DRAWN

DESIGNATION

3 2 1

ON:

BY:

Tel (65) 63092900 Fax (65) 63092999

CHECKED

PAGE:

ON:

BY:

OF :

F

E

D

C

B

A

FORMAT DIN A2

Page 32

8 7 6 5 4 3 2 1

R602

GNDGND

GNDGND

3K3

C602

1U

18 1

18 -INV1

17

17

16

16

15

15

14

14

13

13

12

12

11

11

10

10

NC/

GND

C612

R604

1U

3K3

TDA1517P

12V

U601

SGND

SVRR

OUT1

PGND

OUT2

VP

M/SS

-INV2

OUTRP

C609

2

3

4

5

6

7

8

9

C603

100U 16V

C604

16V

220U

C605

220U 16V

C606

1000P

GND

OUTRP

OUTLP OUTLP

C607

0.1U

GND

470U

16V

C608

12V

0.1U

R_GND

L_GND

GND

T T

GND

1

2

SPK_R+

SPK_L+

TT

2

1

C610

0.1U

P601

P602

E

D

F

AMP_R_OUT

F

(5)

R601

100R

C601

1000P

NC/

E

R603

(5)

AMP_L_OUT

100R

C611

1000P

D

R611

22K

R610

10K

3V3_STB

R612

3K9

C

R607

(5)

AMP_RESET

4K7

R606

1K

GND

D601

LL4148

B

E

C

10K

R613

Q602

BT3906

22U

GND

B

C615

B

C

E

GND

R609

220K

Q601

BT3904

C614

1U

GND

C613

NC/

R605

100R

1U

SP_MUTE

C

B

A

THIS DRAWING CANNOT BE COMMUNICATED TO UNAUTHORIZED PERSONS COPIED UNLES S PERMITTED IN WRITING

...

...

...

...

DD-MM

DD-MM

DD-MM

DD-MM

DATE DESCRIPTION Last modifNAMEIndex-Lab

Last saved :

...

...

...

...

...

...

...

...

4-14-2009_15:30

45678

...

...

...

...

SBU :

TCLNO:

.............

DESIGNATION

...........

ADDRESS1

ADDRESS2

ADDRESS3

TELEPHONE

DRAWN

ON:

BY:

TCL

CHECKED

DD-MM-YY

ON:

BY:

......

A

PAGE:

OF :

123

FORMAT DIN A3

Page 33

7

6 5 4 3 2

1

R701

0R

C704

C705

D D

0.1U

0.1U

GND

C701

R702

0R

VCC_LVDS

C702

0.1U

GND

3V3_NORMAL

1U

C C

GND

3V3_NORMAL

R707

4K7

R709

NC/

0R

UD_EN

UD_SEL

R708

NC/

4K7

B B

GND

3V3_NORMAL

R705

4K7

LV_SEL

LV_SEL

T

TCON_GND

3V3_NORMAL

R721

4K7

MGD_EN

T

C706

1000P

1000P

GND

VDDP

C703

close to ic

U702(CPP)

1

E0/NC

2

E1/NC

3

E2/NC

4

VSS

M24C32MN

VDDC

TCON_SCL

8

VCC

7

WC

6

SCL

5

SDA

L701

120R

0.1U

R725

4K7

3V3

T

T

EEPROM_WP

T

R716

22R

22R

T

TCON_SDA

VDD_1V2

C707

VDDP

TCON_SCL

R717

TCON_SDA

C708

1000P

GND

TXE0-

TXE0+

TXE1TXE1+

VCC_LVDS

TXE2TXE2+

TXECTXEC+

TXE3TXE3+

GND

R704

10K

R726

4K7

TXE0-

TXE1-

TXE0+

T T T T T TT T T T

0.1U

C709

C710

0.1U

R715

4K7

0.1U

R724

NC/

4K7

TXE2-

TXE1+

TXE2+

VDD_1V2

R710

4K7

GNDGND

3V3_NORMAL

C720

GND

C711 1000P

TXEC-

TXEC+

LV_SEL

0.1U

TXE3-

TXE3+

0.1U

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

C712

GND

GNDGND

R0N

R0P

R1N

R1P

VCC_LVDS

R2N

R2P

RCKN

RCKP

R3N

R3P

GND1

VDDC1

RESET

BIST

LV_SEL

VDDP

MGD_EN

VDD_1V2

TCON_SCL

TCON_SDA

646362616059585756555453525150

SCL

SDA

GND5

VDDP4

PWMI/PDI

VDDC3

MGD_EN/GPOB

MST6M30QST

U701

TEST

VDDP1

OD_EN/GPO8

GPO7

PWMO/GPO6

VDDC2

NC1

171819202122232425262728293031

GND4

GPOD

NC2

VDDP2

VDDP

REL

GPOE

VDDP3

STV_D

GPO3

UD_SEL/GPO2

C713

VDDP

0.1U

MLV0P

MLV0N

49

LV6P

LV6N

GND3

LV5P

LV5N

LV4P

VCC_MINI-LVDS

LV4N

LV3P

LV3N

LV2P

LV2N

LV1P

LV1N

LV0P

LV0N

GND2

KB/GPO1

VDDPOESTV_U

32

R713

R711

R712

GND

TP

POL

CPV

GND

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

VDDP

22R

VDDP

GVON

GNDGNDGND

OE

22R

STV

22R

NC/

C721

1000P

R703

4K7

0.1U

C716

GND

UD_EN

C717

0.1U

VDD_1V2

VDDP

C718 C719

0.1U

STV

22R

UD_SEL

R714

0.1U

R723

18K

R719

GND

C714

0.1U

R718

22R

22R

22R

R720

C715

MLV1P

MLV1N

MLV2P

MLV2N

MLVCKP

MLVCKN

MLV3P

MLV3N

MLV4P

MLV4N

MLV5P

MLV5N

TP1

POL

CKV

SBU :

A

THIS DRAWING CANNOT BE COMMUNICATED TO UNAUTHORIZED PERSONS COPIEDUNLESS PERMITTED IN WRITING

GND

R706

NC/

7

4K7

GND

R722

NC/

4K7

DATE DESCRIPTION Last modifNAMEIndex-Lab

6

Last saved :

TCLNO:

.............

DESIGNATION

DESIGNATION

ON:

BY:

TCL Thomson Electronics Singapore Pte. Ltd.

8 Jurong Town Hall Road #28-01/06

The JTC Summit SINGAPORE 609434

Tel (65) 63092900 Fax (65) 63092999

DRAWN

ON:

BY:

CHECKED

PAGE:

OF :

FORMAT DIN A4

GND

Page 34

Power OK, backlight

OK,no picture

Check the voltage of

pin ‘s’ of q208

2.

Check the output of Q208

2.

Measure the wave of

LVDS signal

1*

1*

1*

Replace R270

and R271

Check the voltage of ‘g’ of

Q208 OR replace Q208

Check the supply of U201

2.

Replace panel

Page 35

TV no picture

Measure the wave

of pin 8,9 of U1

OK

Check the circuit

between U1 and

U201

OK

Check the U201

1*

Check the voltage of

pin 6 ,7 of u1

OK

measure the wave of

SDA and SCL

OK

Replace u1

1*

1*

repair the circuit of

U101 and Q102

Check the U201

Page 36

AV no picture

Software of U202 ok?

1*

Upgrade

Check the components

1*

between AV port and U201

2.

VGA/YPbPr no picture

Check the components between

VGA/YPbPr port and U201

1*

OK

VGA/YPbPr no picture

Replace

the bad

Replace

the bad

OK

1*

Check U201 ok?

OK

Check the peripheral

components of U201

1*

Replace

the bad

Replace

U201

Check the components between

1*

VGA/YPbPr port and U201

OK

Replace

the bad

Page 37

Picture OK, all

source no sound

Check the voltage of

pin 3,13 of U602

2.

Check the pin 6 of u602

2.

Check the pin 7 of u602

2.

1*

Repair the 12v supply

1*

Check q607,q608,q609

1*

repair R691 and R692

Check the wave of PIN 4,12 of U602

2.

Replace U602 or replace

the wire of speaker

1*

check u601 and

volume control

Page 38

Standby +5.0VSB OK, +5.0V NG

Check the voltage of

pin ‘s’ of q305

2.

Check the output of Q305

2.

Check U303,U304

short to Gnd

1*

1*

1*

Check before Q305

Check the voltage of ‘g’ of

Q305 OR replace Q305

Replace the bad

Page 39

The picture bad

Replace the wire

from P202A to t-com

NG

Replace the

NG

chassis

OK

Check the circuit between

p202a and U201

OK

Upgrade the software

Replace panel

Loading...

Loading...