Page 1

Warnings and Cautions

OUTPUT

Warning

Warning

!

General Safety Instructions

Warning

Dangerous Voltage Warning: warns of

situations in which a high voltage can

cause injury and/or equipment damage.

e text next to this symbol describes

ways to avoid danger.

General Warning: warns of situations

that can cause physical injury and/

or equipment damage by means other

than electrical. e text next to this

symbol describes ways to avoid the

danger.

Be sure to read, understand, and follow

all safety instructions.

!

Warning

Only qualied electricians should

carry out all electrical installation and

!

Warning

!

Warning

Warning

maintenance work on reactors.

All wiring must be in accordance with

the National Electrical Code (NEC)

and/or any other codes that apply to

the installation site.

Disconnect all power before working

on the equipment. Do not attempt any

work on a powered reactor.

e reactor, VFD, motor, and other

connected equipment must be properly

grounded.

When installing the KLR/KDR Reactors

on the OUTPUT side of the Variable

Frequency Drive (VFD), please use the

following guidelines:

TCI recommends 1.5% impedance

reactors to be used on the output of the

VFD. In case of the KDR line, use only the

KDR OUTPUT reactors

Reactors should be mounted as

close to the output terminals of the VFD as

possible

TCI suggests that the reactor be

used in applications where the motor lead

length is less than 100 feet. For applications

with motor lead lengths greater than 100

feet, TCI oers V1k/KLC Output Filters

and KMG MotorGuard High Performance

Sinewave Filters.

Reactors are sized by the Full Load

Amps located on the motor nameplate.

Please contact TCI Technical Support

or your TCI distributor for application

information regarding the use of these

reactors on the load or output side of the

VFD or in applications where inductors are

used.

Reactor

Installation

Guide

Warning

All electrical connections must be re-torqued

annually.

e VFD terminals and connected

cables are at a dangerously high voltage

when power is applied to the VFD,

regardless of motor operation.

TCI, LLC

W132 N10611 Grant Drive

Germantown, WI 53022

Ph: 800-TCI-8282

www.transcoil.com

TCI, LLC

W132 N10611 Grant Drive

Germantown, WI 53022

Ph: 800-TCI-8282

www.transcoil.com

Revision 3.4 Part # 24774 Mar. 29, 2011

Page 2

KLR/KDR Line Reactor

Installation Instruction

INPUT

TCI recommends that these reactors

be wired and located as close to the front

end of the VFD as possible to have the

greatest success in both protecting the VFD

as well as mitigating line harmonics.

Field Wiring Information

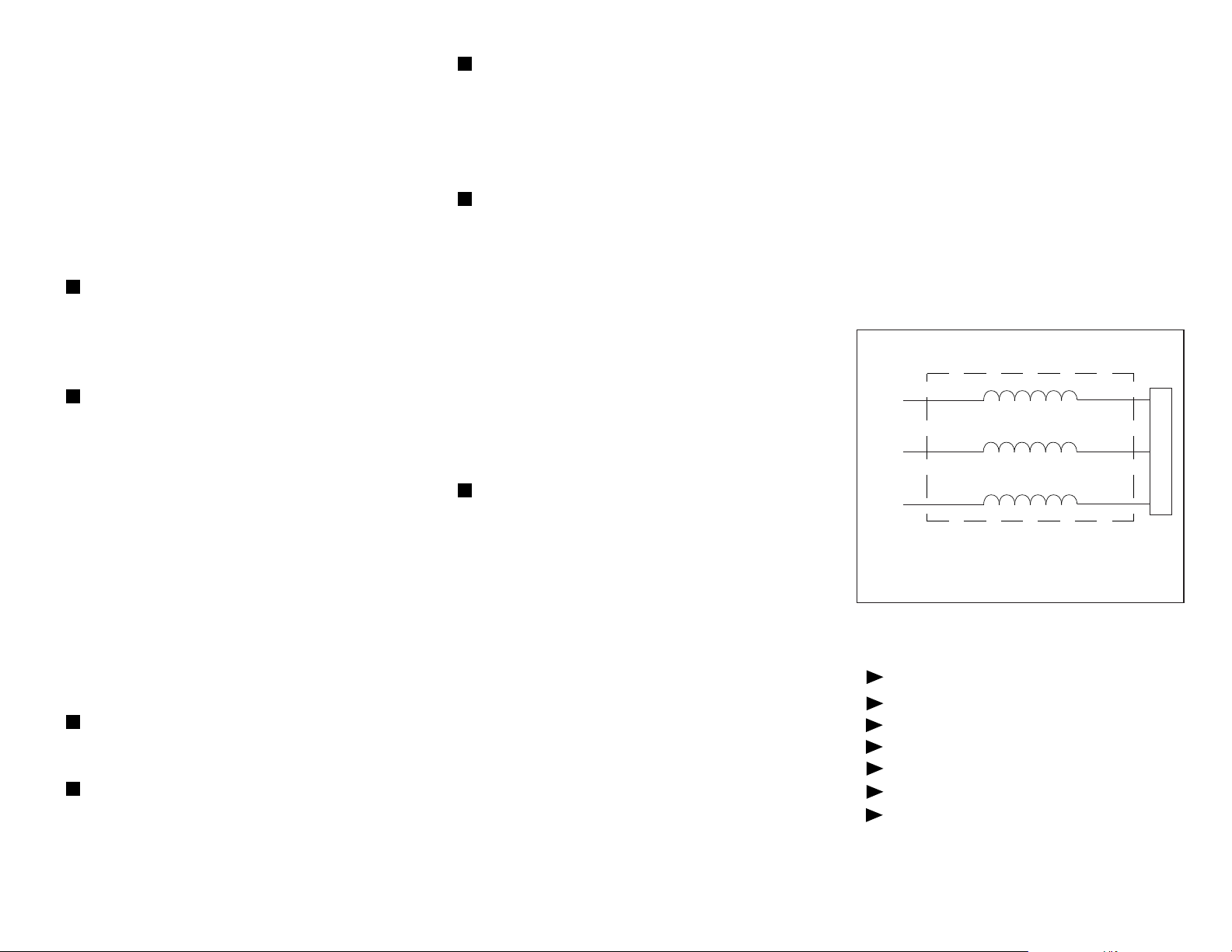

Below is the typical wiring diagram for the

3-phase reactor applied to the front end of

the Variable Frequency Drive (VFD).

When installing the KLR/KDR Line Reactors

on the INPUT side of the Variable Frequency

Drive (VFD), please use the following

guidelines when wiring the unit:

e KLR/KDR Line Reactor is a

3-phase device and should be wired in a

series and positioned on the input side of the

VFD.

All Terminal Block connectors will

be marked. A1, B1, and C1 are the input

terminals where the 3 phases of incoming

power are to be wired. As a result, A2, B2,

and C2 are the output terminals. Units with

copper bus or ring lug terminals are not

marked. In these cases, either the upper

terminals or lower terminals can be used as

the input terminals as long as the selection is

consistent. For example, if an upper terminal

is selected as the input, all upper terminals

must be input terminals. Wiring from the

output terminals should connect to the input

of the VFD.

Refer to NEC wiring practices for

appropriate wire sizes for your application.

Power Wiring: Only use 75°C copper

conductors unless the wire connector is

marked for Al/Cu, then the use of aluminum

wire is permitted.

In standard 40°C ambient or less

installations, a clearance of 3 inches on

all sides of the reactors and its enclosure

is recommended for assisting in heat

dissipation and ample wire bending space.

is is a general guideline for typical

applications. If the reactor is being installed

next to a heat sensitive instrument or

control device, we recommend reviewing

specic requirements or heat limitations.

Line reactor heat loss information is

available on the web at www.transcoil.com.

ese reactors are designed to be

oor-mounted or wall-mounted. Large

open-style devices should be panel

mounted by incorporating a bracket that

would act as a shelf to support the reactor

and/or enclosure. When installing an open

style device in an existing control cabinet,

drive cabinet, motor control center, or

other large enclosure, the reactor should be

mounted in the lower half of the cabinet to

prevent hot spots or pockets of heat (this

typically allows better thermal dissipation

and heat convection). Reactors with ducts

must be mounted in such a way that

maximizes air ow. Reactors with ducts

are designed to be mounted vertically for

proper cooling.

Single-phase applications are acceptable,

however, it is important to size the unit

based on the single phase Full Load

Amperage of the VFD. e input and

output connections should be on terminals

A and C to ensure proper performance.

Wiring Diagram

A1

L1

LINE

B1*

L2

C1

L3

LINE REACTOR

* For single-phase applications, use coils A and C.

Isolate terminals B1 and B2.

A2

LOAD

B2*

C2

Product Specications

3-Phase, 600 Volt Class

UL Recognized; File E-116124

CE Marked

CSA Certied

Current-rated device

200% rated current for 3 minutes

Ambient Temperature: 40°C

Loading...

Loading...