Page 1

Motor Protection

MotorShield Sinewave Output Filter

As Pulse Width Modulated (PWM) Drives are

incorporated into various applications and processes, the

increased energy savings and decreased maintenance on

drives can be offset by increases in motor failures.

High voltage spikes caused by a phenomenon known as

reected wave (dv/dt) occur when there are long cable

runs between the drive and the motor. The impedance

on either end of the cable run does not match, causing

voltage pulses to be reected back in the direction from

which it arrived. As these reected waves encounter

other waves, their values add, causing higher peak voltage.

Peak voltages on a 480V system can reach 1,600V. These

high peak voltages will cause a rapid breakdown of motor

insulation, leading to motor failure.

TCI’s MotorShieldTM improves system performance

by protecting the motor from the harmful effects of

reected waves and preventing motor failure associated

with insulation failure, overheating, and noise.

Industry Application: Fans & Pumps

The MotorShield is designed to extend motor life in

variable torque applications such as fans and pumps

with lead lengths up to 15,000 feet. Motors on these

systems typically produce a large amount of heat as they

run. The MotorShield is the perfect solution to prevent

overheating and motor failure.

Typical Applications

• Wastewater Treatment Plants

• Mining

• Material Handling

• Oil & Gas

• HVAC Systems

• Chemical Processing

• Power Plants

• Data Centers

• Renewable Energy

• Pulp & Paper

Motor Input Waveform Without MotorShield

1500

1000

500

0

Volts

-500

-1000

-1500

0 403530252015105

Time (ms)

Motor Input Waveform With MotorShield

1500

1000

500

0

Volts

-500

-1000

-1500

0 403530252015105

Time (ms)

Page 2

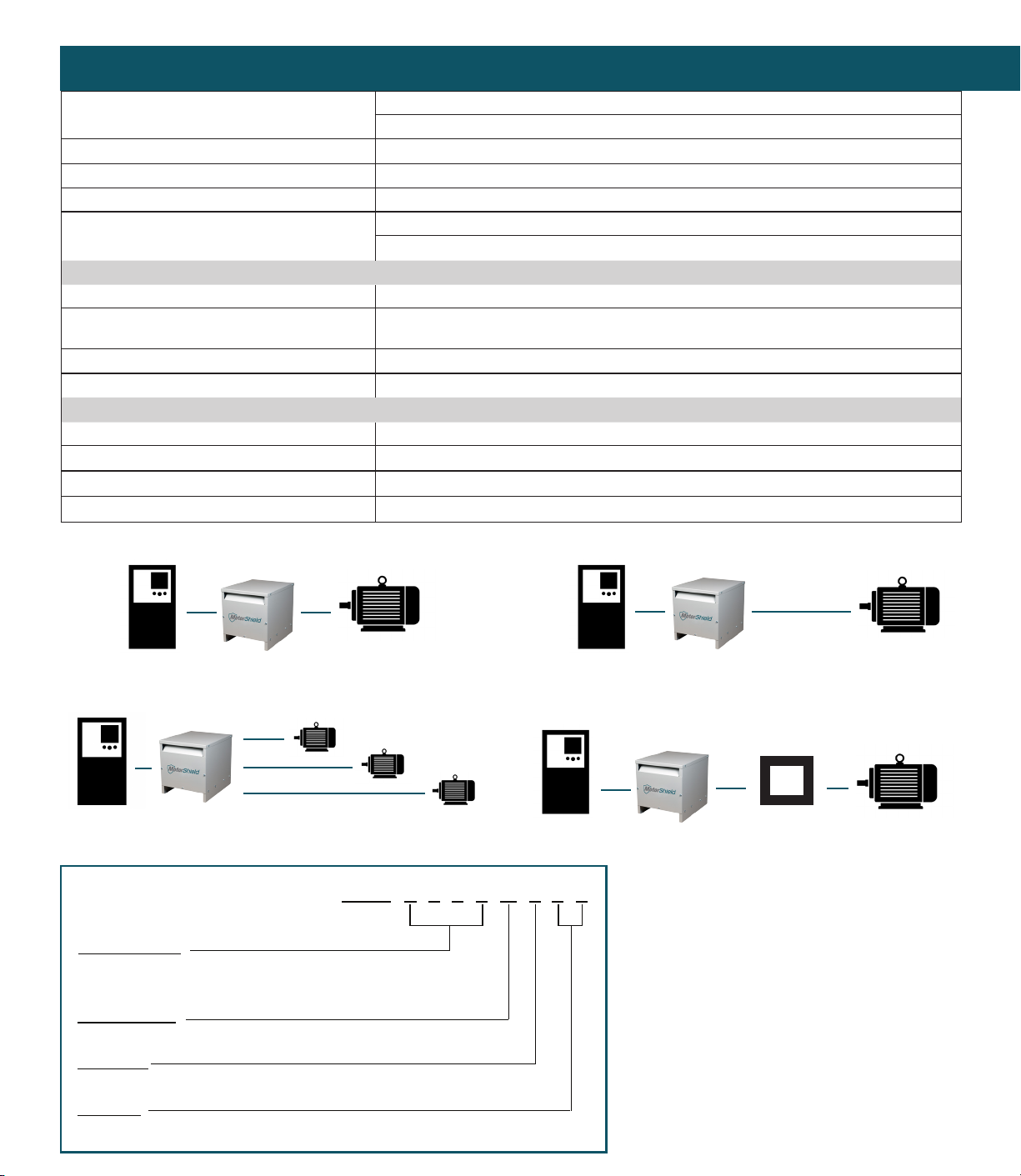

MSD 0110A3 0 0

MSD Part Numbering System

3 = Type 1 / 3R

Current Rating

Voltage Rating

A = 480

Enclosure

00 = Default

Options

480V = 9, 12, 16, 23, 30, 35, 45, 55, 65,

80, 110, 130, 160, 200, 250, 305

Technical Specications

Current Ratings

Available continuous currents: 9 to 305 amps

Intermittent current: 150% for 1 minute out of every 60 minutes

VFD Output Voltage Up to 480 V, 3-phase, at fundamental base frequency congured to Volts per Hz

VFD Output Frequency Up to 80 Hz

VFD Carrier Frequency 2 kHz to 16 kHz

Filter Performance

Maximum peak voltage of output waveform - 480 V: 1000V

Maximum dv/dt of output waveform - 480 V: 500V/μs

Environmental Conditions

Maximum Elevation 3,300 ft (1,000 m), derating required for operation above this level

Ambient Operating Temperature Range

-40 °C (-40 °F) to 40 °C (104 °F)

Cooling provisions required for operation above this temperature

Ambient Storage Temperature Range -40 °C (-40 °F) to 50 °C (122 °F)

Maximum Humidity, Operating or Storage 95%, non-condensing

Reference Technical Standards

Enclosure Options NEMA 1/3R enclosure

Insertion Impedance 6.5% nominally at 60 Hz & full load current

Capacitors High endurance design (no PCBs)

Warranty One year or 18 months from date of shipment

Block Diagram Test Stand

Extreme Long Lead Applications

VFD

Multiple Motor Applications

MOTO R

VFD

Part Numbering System

MOTO R

MOTO R

MOTO R

VFD

Low Voltage PWM Power Supply to Medium

Voltage Motor

VFD

STEP-UP

XFMR

Performance Guarantee

Properly sized and applied, the addition of

a MotorGuard Sinewave Output Filter is

guaranteed to bring the application into

compliance with NEMA Standards Publication

No. MG-1. If the system fails to meet MG-1

standards with the addition of a MotorGuard

lter, TCI will take back the output lter and

pay shipping both ways. This offer is valid for 60

days from the installation date.

MOTO R

MOTO R

Loading...

Loading...