Page 1

KRF

EMC Filters

Installation, Operation and Main t enance Manual

KRF EMC Filters limit high frequency noise, as well as:

• Reduce interference

• Protect sensitive equipment

• Eliminate drive cross-talk

• Meet FCC Regulation 15, Subpart J

Page 2

TCI, LLC

W132 N10611 Grant Drive

Germantown, Wisconsin 53022

Phone: 414-357-4480

Fax: 414-357-4484

Helpline: 800-TCI-8282

Web Site:

http://www.transcoil.com

© 2011

ii

Page 3

Introduction

K- Series

0

Max Current (amps)

3-Phase EMI/RFI Filter

ACBKRF060

TB = Terminal Block

CB = Copper Bus

Termination

Voltage Rating:

A = 480 V

V = 690 V

KRF EMC 3-Phase Filters are available:

• 520V or 760V

• Terminal Block (TB) or Copper Bus (CB) terminations

• 8 to 2500 amps

Part Number System:

This manual is split into sections depending on voltage, termination, and amp rating:

Section 1: 520V, TB, 8 – 150A

Part Numbers:

KRF0008ATB

KRF0016ATB

KRF0025ATB

KRF0036ATB

KRF0050ATB

KRF0066ATB

KRF0090ATB

KRF0120ATB

KRF0150ATB

Section 2: 520V, CB, 180 – 400A

Part Numbers:

KRF0180ACB

KRF0250ACB

KRF0320ACB

KRF0400ACB

i

Page 4

Section 3: 520V, CB, 150A & 600 – 2500A

Part Numbers:

KRF0150ACB

KRF0600ACB

KRF1000ACB

KRF1600ACB

KRF2500ACB

Section 4: 760V, TB, 25 – 180A

Part Numbers:

KRF0025VTB

KRF0036VTB

KRF0050VTB

KRF0080VTB

KRF0120VTB

KRF0150VTB

KRF0180VTB

Section 5: 760V, CB, 150 – 2500A

Part Numbers:

KRF0150VCB

KRF0180VCB

KRF0250VCB

KRF0320VCB

KRF0400VCB

KRF0600VCB

KRF1000VCB

KRF1600VCB

KRF2500VCB

ii

Page 5

Table of Contents

Cautions and Warnings ................................................................................................................... 1

Mounting Instructions ..................................................................................................................... 3

Section 1: 520V, TB, 8 – 150A................................................................................................... 11

Section 2: 520V, CB, 180 – 400A .............................................................................................. 21

Section 3: 520V, CB, 150A & 600 – 2500A .............................................................................. 25

Section 4: 760V, TB, 25 – 180A................................................................................................. 31

Section 5: 760V, CB, 150 – 2500A ............................................................................................ 38

iii

Page 6

iv

Page 7

!

!

Cautions and Warnings

Important Information

Please read all safety and warning notes carefully before installing the EMC filter and

putting it into operation (see ). The same applies to the warning signs on the filter.

Please ensure that the signs are not removed nor their legibility impaired by external

influences.

Death, serious bodily injury and substantial material damage to equipment may occur if

the appropriate safety measures are not carried out or the warnings in the text are not

observed.

The EMC filters may be used only for their intended application within the specified

values in low-voltage networks in compliance with the instructions given in the data

sheets and the data book. The conditions at the place of application must comply with

all specifications for the filter used.

Warnings

• It shall be ensured that only qualified persons (electricity specialists) engage on work

such as planning, assembly, installation, operation, repair and maintenance. They

must be provided with the corresponding documentation.

• Danger of electric shock. EMC filters contain components that store an electric charge.

Dangerous voltages can continue to exist at the filter terminals for longer than five

minutes even after the power has been switched off.

• The protective earth connections shall be the first to be made when the EMC filter is

installed and the last to be disconnected. Depending on the magnitude of the leakage

currents, the particular s pecifications for making the protec ti v e-earth connection must

be observed.

• Impermissible overloading of the EMC filter, such as impermissible voltages at higher

frequencies that may cause resonances etc. can lead to destruction of the filter

housing.

• EMC filters must be protected in the application against impermissible exceeding of

the rated currents by suitable overcurrent protective.

• All electrical connections must be re-torqued annually.

1

Page 8

Important Notes

The following applies to all products named in the publication:

1. Some parts of this publication contain statements about the sustainability of our

products for certain areas of application. These statements are based on our

knowledge of typical requirements that are often placed on our products in the areas of

application concerned. We nevertheless expressly point out that such statements

cannot be regarded as binding statements about the sustainability of our products

for a particular customer application. As a rule, TCI is either unfamiliar with individual

customer applications or less familiar with them than the customers themselves. For

these reasons, it is always ultimately incumbent on the customer to check and decide

whether a TCI product with the properties described in the product specification is

suitable for use in a particular customer application.

2. We also point out that in individual cases, a malfunction of passive electronic

components or failure before the end of their usual service life cannot be

completely ruled out in the current state of the art, even if they are operated as

specified. In customer applications requiring a very high level of operational safety and

especially in customer applications in which the malfunction or failure of a passive

electronic component could endanger human life or health (e.g. in accident prevention or

life-saving systems), it must therefore be ensured by means of suitable design of the

customer application or other action taken by the customer (e.g. installation of protective

circuitry or redundancy) that no injury or damage is sustained by third parties in the

event of malfunction or failure of a passive electronic component.

3. The warnings, cautions and product-specific notes must be observed.

4. In order to satisfy certain technical requirements, some of the products described in

this publication may contain substances subject to restrictions in certain

jurisdictions (e.g. because they are classed as “hazardous”). Should you have any

more detailed questions, please contact TCI Technical Support.

5. We constantly strive to improve our products. Consequently, the products described in

this publication may change from time to time. The same is true of the corresponding

product specifications. Please check therefore to what extent product descriptions and

specifications contained in this publication are still applicable before or when you place

an order.

We also reserve the right to discontinue production and delivery of products.

Consequently, we cannot guarantee that all products named in this publication will

always be available.

2

Page 9

Mounting Instructions

EMC cannot be ensured by the use of EMC filters alone. Every system should be considered as

an integrated whole and careful planning and preparation are required to ensure success.

Measures such as shielded motor cables, grounding and spatial separation are mandatory parts

of an integrated concept.

Plan your installation:

• Identify interference sources (with interference emissions) and disturbed equipment

(electrical equipment or components with limited interference immunity).

• Assign interference sources and disturbed equipment to specific zones and separate

them spatially from each other.

• Plan the cabling in wiring categories in accordance with interference emissions and

interference immunity.

EMC is an indispensable quality feature! The legally stipulated protection objectives and

technical risks must be taken into consideration as early as the development stage of the

system.

In order to achieve electromagnetic compatibility of the overall system the following points must

be observed:

1. The filter case should be connected across a large area to ground and to the other

equipment. For example, a blank metal mounting plate should be provided jointly for

filters and converters. It should be well grounded and connected to the switch cabinet via

a large-area low-inductance connection. If necessary, use short copper tapes and EMC

seals (e.g. connection to switch cabinet doors).

2. A distinction should be made between

a. The protective earth connection of the EMC filter, which is used to secure

protection against hazardous body currents, and

b. The large-area grounding of the filter, which is required for its interference

suppression function.

3

Page 10

For operating currents greater than 250 A, we recommend the PE connection to be set up

between the feed (filter: line) and output (filter: load) not via the PE terminal bolt in the filter

housing. This is because of the restricted area of the cable lug of the PE connection to the filter

housing. Ideally, the PE feed line should be connected with the PE output line to a PE busbar

which also carries the PE terminal(s) of the EMC filter. The number of necessary PE

connections to the filter depends on the cross-section and the required KU factor as a function

of the magnitude of the leakage current. The PE conductor connections must satisfy the

requirements defined in IEC 60364-5-54 (DIN VDE 0100 T540). For currents >1000 A and/or

short-circuit currents >25 kA, it is not permissible to loop the PE conductor through the filter

housing.

3. In your system, set up connections at the same reference potential in order to reduce

galvanically coupled interferences. All metallic reference potentials of housings,

machines and installations should be linked via a low-impedance connection suited for

RF and intermeshed as far as possible.

Set up large-area metallic connections, use equipotential busbars and set up short

connections to ground via flat ribbon cables.

The following conditions apply:

• Large-area ground connection,

• Low-inductance connection (preferably a copper ribbon and not circular conductors),

• Short connections (rule of thumb: length divided by width < 3).

4

Page 11

4. Keep cables from the interference source as short as possible!

Examples:

• Short connection from the converter to the EMC filter; ideally a flange mounted

filter to avoid emissions.

• Connection cables of minimum length between converter output and motor (also

to reduce asymmetrical currents caused by the parasitic capacitances of the

cable shield).

5. Interference-carrying cables must be shielded!

Examples:

5

Page 12

• Connection cables between frequency converter and motor, if no corresponding output

filter is used.

• Connection cables filter and converter on the line side, where not directly flange

mounted

• It should be noted that the shielding effect of different cables can differ widely (foil shield,

braided shield with various degree of coverage, combinations).

6. Connect shielded cables on both sides and across a large-area with reference potential,

as far as possible directly or close to the input or output sides of the housing.

Use:

• EMC-compliant cable fittings (360° contact)

• An EMC baseplate

• Large-area contacting of the cable shield by suitable metal clips.

Avoid shielded terminals connected via top lines (pig tails)!

(Twisted shield braiding; soldered cable lugs etc.)

Ensure that an EMC-compliant cable gland is provided at the motor terminal box. It must

correspond to the degree of protection for its respective location of use. The motor terminal box

shall be made of metal, the connection between cable gland and terminal box must be of largearea design. If the lacquer has been removed, it may be necessary to restore the corrosionprotection layer.

6

Page 13

7. Arrange EMC filters as far as possible directly at the entry or exit points of the

housing Examples:

• Line terminals are accessible via the corresponding opening of the equipment

(ensure protection ag ai nst electric shock).

• Use of suitable EMC filters.

• Use of corresponding housing matching elements to ensure the required

shielding attenuation

8. Spatial separation between interference-emitting and “clean” cables must be

ensured (noisy cables include those between converter and filter, whereas

“clean” cables include those between mains supply and filter).

Avoid running cables in parallel (to reduce coupled interferences).

Note the spatially separated laying of signal and power cables in order to avoid

coupling routes (minimum recommended spacing 20cm). Use separating metal

plates and ground them across a wide area if necessary.

As far as possible, run cable cross-overs at right angles and keep them well

separated.

7

Page 14

9. In order to reduce interference coupling, as far as possible run the cables close

to metal parts which are connected to the reference potential (mounting plates,

switch cabinet etc.)

Live cables should also be run as close as possible to the reference potential (to

reduce inductively coupled interferences).

In order to improve electromagnetic compatibility, cable channels, cable trays

and installation tubes which are made of metal rather than plastic parts should be

preferred.

10. In the case of unshielded signal cables (forward and return lines) use twisted-pair

cables in order to minimize the area between the wires (to avoid magnetic

coupling). The same applies to avoiding loops.

8

Page 15

11. Connect suitable EMC components close to switched inductors (e.g. contactors,

relays, magnetic valves etc.).

12. For control signals in the vicinity of high interference levels, use transmission

techniques such as:

• Differential-mode transmission systems with twisted-pair lines in

conjunction with data line chokes.

• Transmission of digital signals according to the RS-422 standard or in

extreme cases crossing the interference region with fiber-optic cables.

13. Note the mounting position of the filters! The assembly must always take care not

to impair natural convection. This includes the use of ventilation slits in the filter

housing and sufficient spacing to the other components. Over-head mou nti ng is

never permissible. In the event of unusual mounting situations, the thermal

conditions shall be checked after coordination with the factory.

14. Noise minimization

A choke made of highly diverse core materials represents a significant

frequency-dependent filter component. Electro-acoust ic e ff ects must inevitably

be expected in AC applications. The materials and processing used generate (for

industrial sector) suitable noise levels by operation in networks with harmonics

complying to EN 50160. However, these can rise significantly in the event of

higher harmonic components. For sensitive applications such as office

installation, therefore, customers should contact factory for advice.

15. Length of motor cables and motor types used

For converter applications, output voltages are generated that typically have

almost rectangular waveforms. These are essentially characterized by the rise

rate expressed as the dv/dt value and the switching frequency of the converter.

The cables and motors present in the output network of the converter with their

inductive and capacitive components significantly determine the EMC properties

of the system. Thus resonances of the cable/motor combination are often

reflected in the resonance of the interference voltage measurement at the

converter input.

The parasitic capacitances of the cable and motor should be treated with special

care. Whereas the parasitic capacitances of the motor depend on its design,

those of the cables depend on the insulation material, cable structure, type of

shielding and especially on their length. A high-frequency current flows through

the grounded parts of the equipment as a function of the switching frequency, the

dv/dt value and the magnitude of the parasitic capacitances.

Here are some of the possible effects:

9

Page 16

• As the parasitic currents flow via the ground connection of the installation,

the sum of the input currents into the filter is no longer equal to zero. A

specific magnitude of the parasitic current can lead to a saturation of the

common-mode choke in the EMC filter and consequently exceed the

permissible interference level. The interference voltage should therefore

be measured on the instal led equipment.

• The parasitic currents also flow to the interference source via the filter

housing and the capacitors connected in the filter! Impermissibly high

currents can overload the capacitors and thus endanger the equipment!

10

Page 17

Section 1: 520V, TB, 8 – 150A

EMC Filters

Phase: 3

Current: 8 to 150 A

Voltage: 520/300 V AC, 50/60 Hz

Termination: Terminal Block

Part Numbers:

KRF0008ATB

KRF0016ATB

KRF0025ATB

KRF0036ATB

KRF0050ATB

KRF0066ATB

KRF0090ATB

KRF0120ATB

KRF0150ATB

Construction

• 3-line filter

• Metal case

• Book size

Features

• Excellent price/performance ratio

• Ultra-compact design

• Low weight

• Easy to install

• Optimized for long motor cabl es and operation

under full load

• ENEC10, UL, and cUL approval

Applications

• Frequency converters for motor drives, e.g.

- elevators

- pumps

- traction systems

- HVAC systems (heating, ventilation and air conditioning)

• Power supplies

Terminals

• Finger-safe terminal bl ock s

11

Page 18

Marking

2236 V DC, 2 s (line/line)

2720 V DC, 2 s (lines/case)

1.5 · IR for 3 min per hour or

2.5 · IR for 30 s per hour

Approvals

EN 133200, UL 1283, CSA C22.2 No.8)

Marking on component:

Manufacturer’s logo, ordering code,

rated voltage, rated current, rated temperature,

climatic category, date code

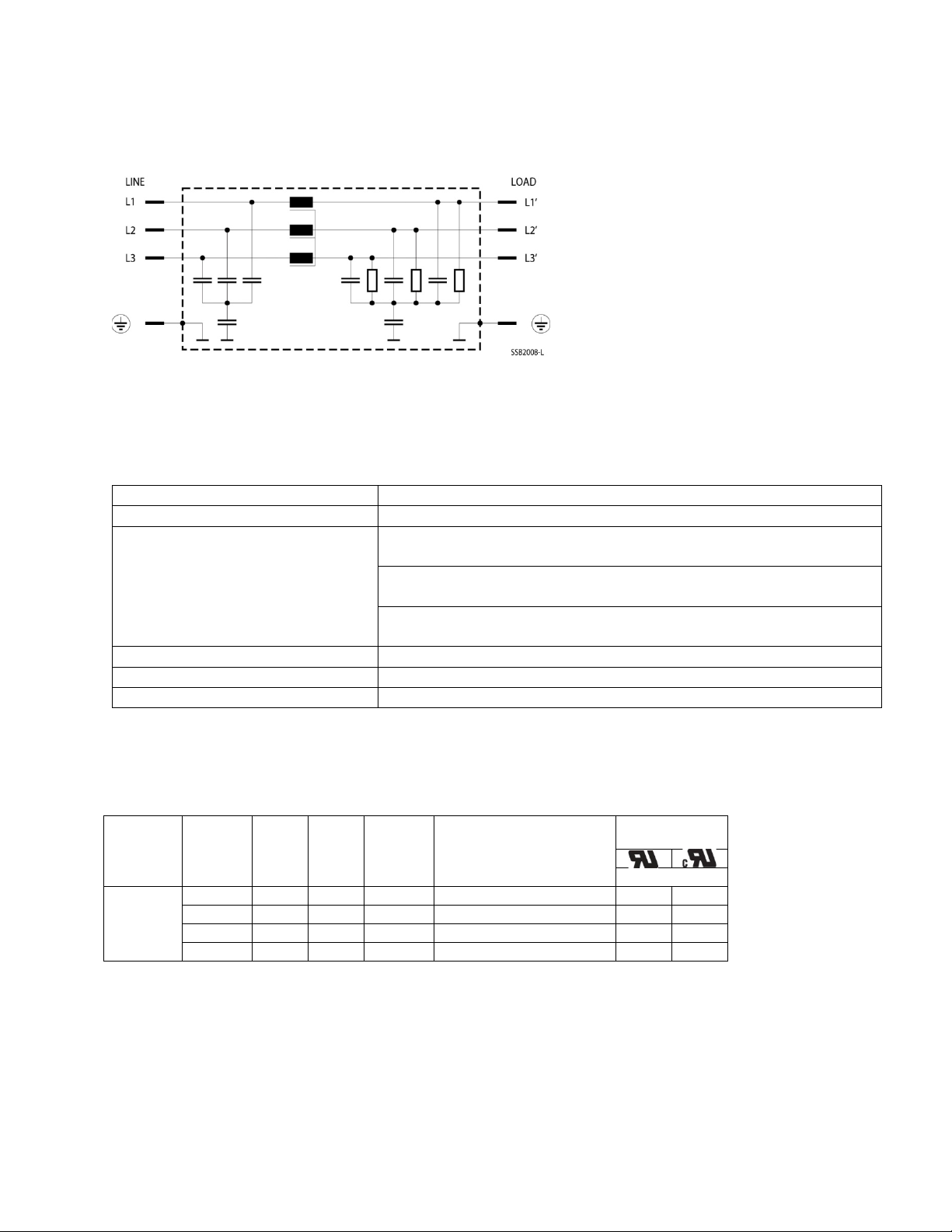

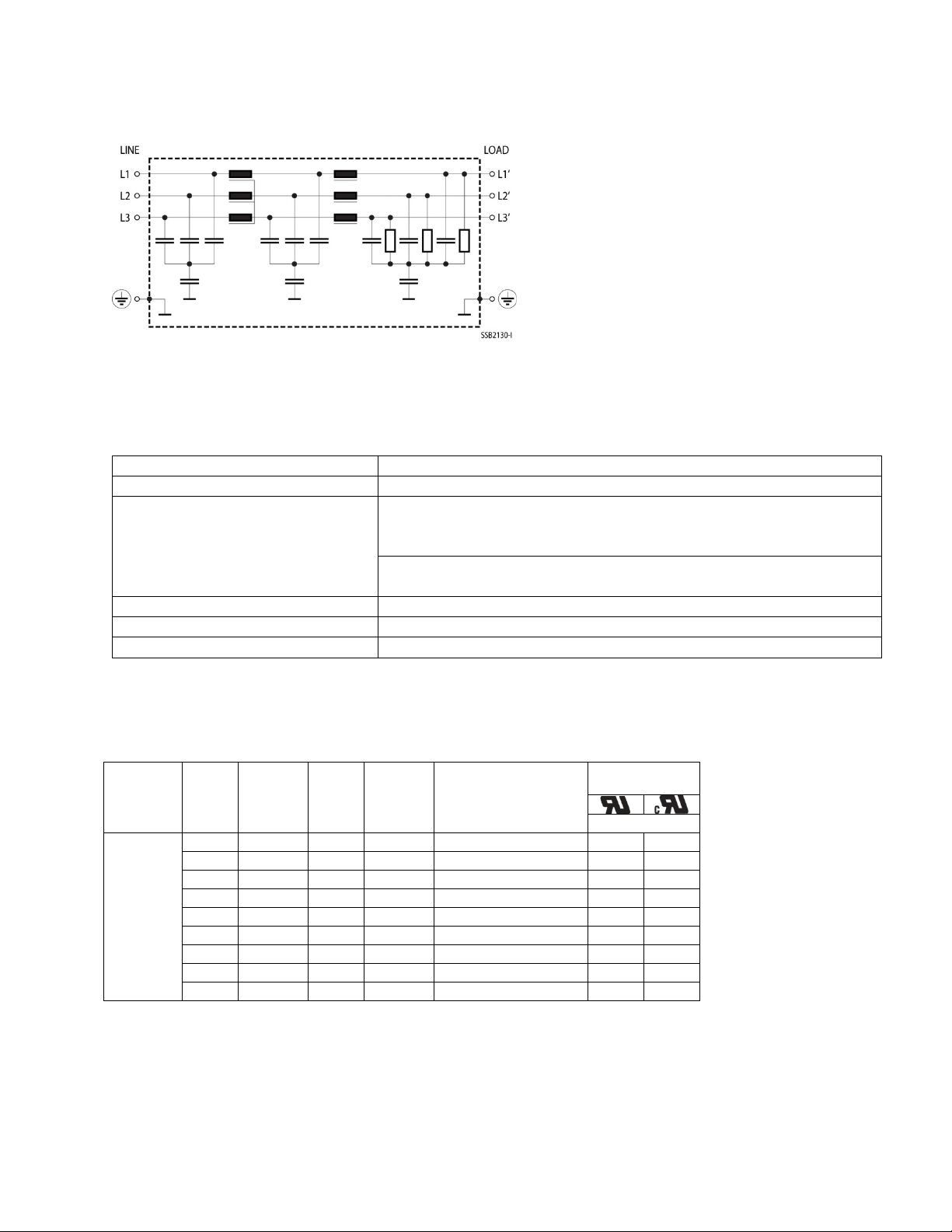

Typical Circuit diagram

Technical data and measuring conditions

Rated voltage VR 520/300 V AC, 50/60 Hz

Read current IR Referred to 40°C ambient temperature

Test voltage V

test

Overload capability (thermal)

Leakage current I

At 520 V AC, 50 Hz

leak

Climatic category (IEC 60068-1) 25/ 100/21 (-25°C/+100°C/21 days damp heat test)

12

Page 19

VR

IR

Terminal

mm2

I

R

Approx

Part Number

Approvals

520/300

8 4 13

16

0.58

KRF0008ATB

X X X

16 4 15 9 0.90

KRF0016ATB

X X X

25 4 15 5 1.10

KRF0025ATB

X X X

36

10

15 4 1.75

KRF0036ATB

X X X

50

10

15 2 1.75

KRF0050ATB

X X X

66

16

16

1.5

2.7

KRF0066ATB

X X X

90

35

18

1.1

4.2

KRF0090ATB

X X X

120

35

18

0.90

4.9

KRF0120ATB

X X X

150

50

18

0.55

5.3

KRF0150ATB

X X X

Characteristics and part numbers

AC

V

A

cross

section

leak

mA

µΩ

X = approval granted

typ

weight

kg

13

Page 20

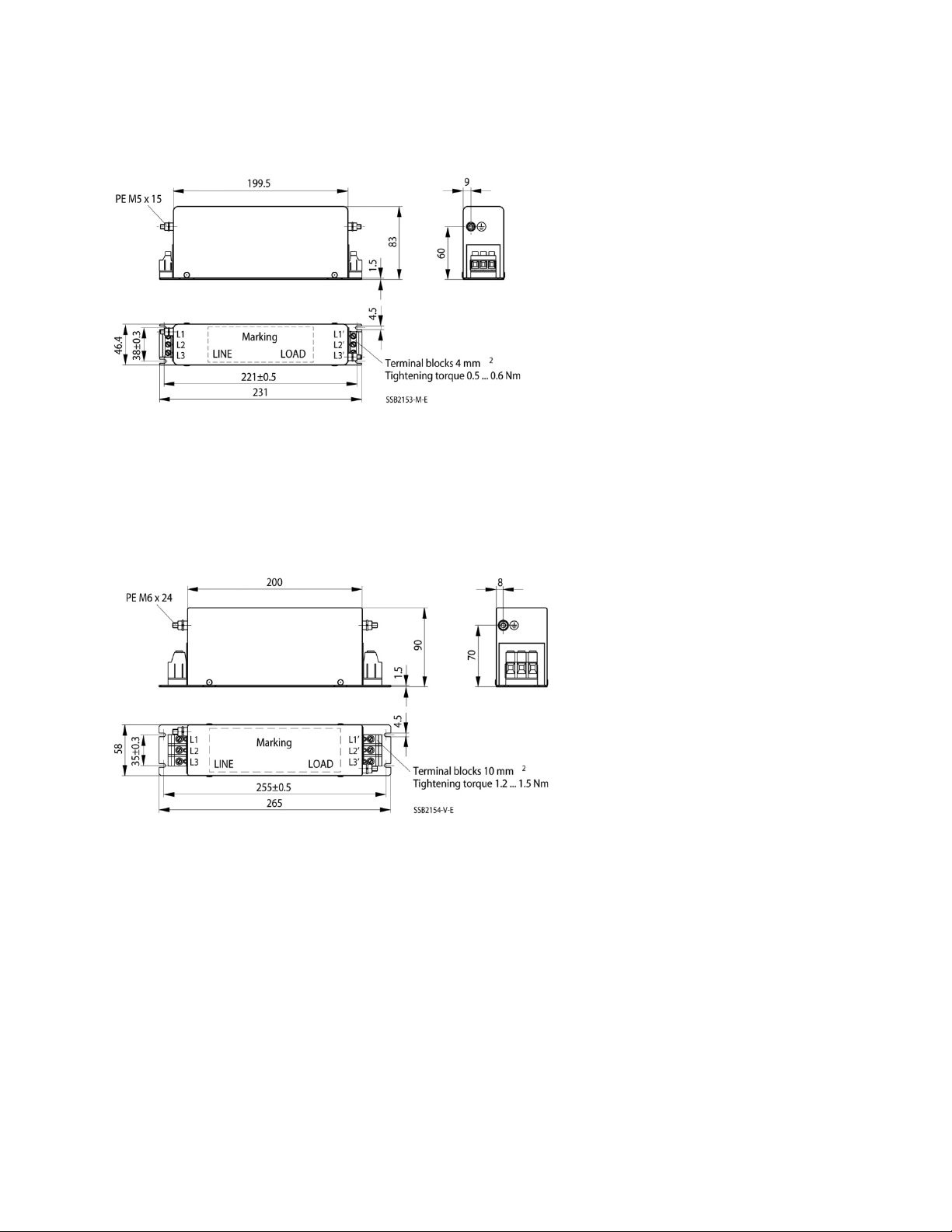

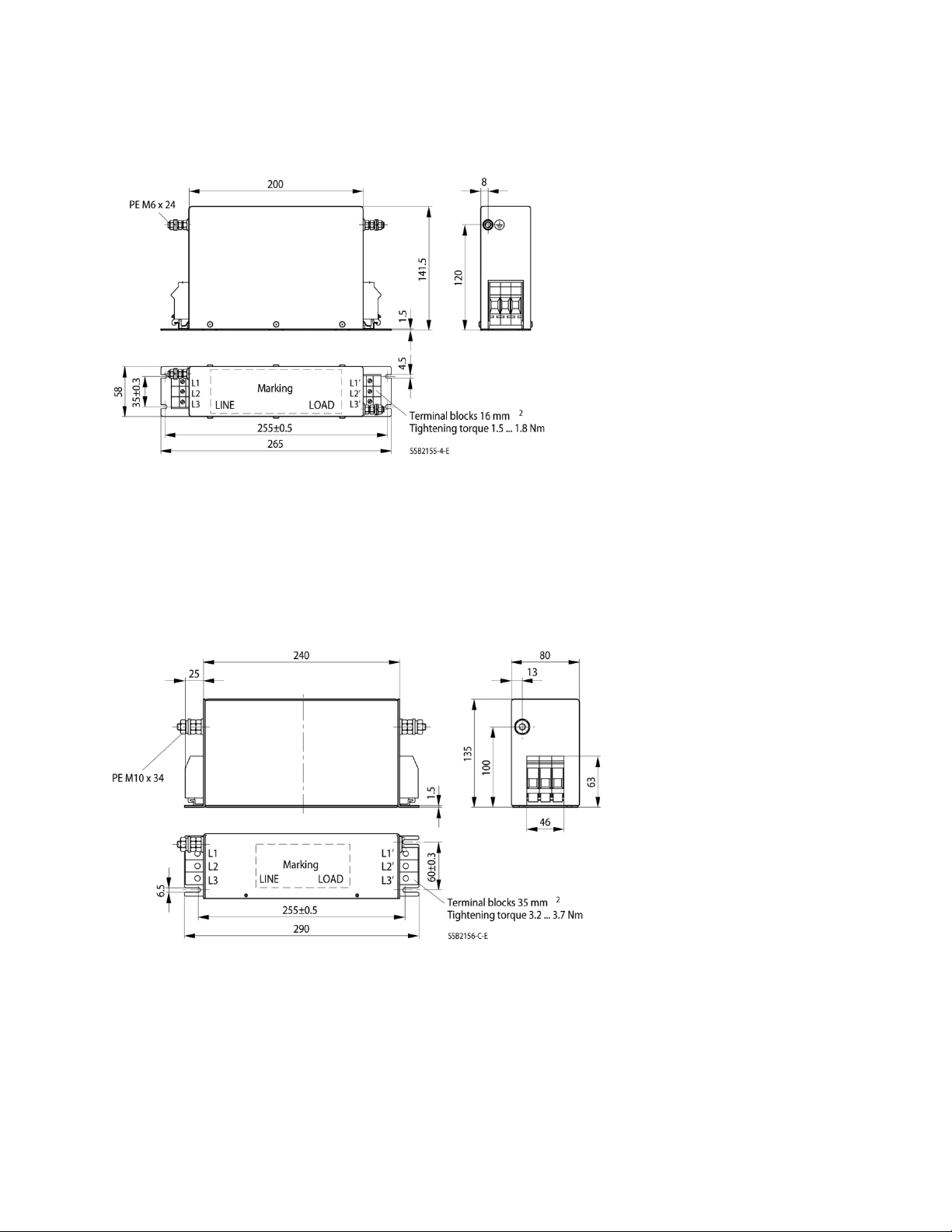

Dimensional drawings

(8 A) KRF0008ATB

(16 A) KRF0016ATB

14

Page 21

(25 A) KRF0025ATB

(600 A) KRF0036ATB, KRF0050ATB

15

Page 22

(66 A) KRF0066ATB

(90 A) KRF0090ATB

16

Page 23

(120 A) KRF0120ATB

(150 A) KRF0150ATB

17

Page 24

Insertion Loss (typical values at Z = 50 Ω)

Unsymmetrical, adjacent branches terminated

Common mode, all branches in parallel (asymmetrical)

Differential mode (symmetrical)

18

Page 25

Insertion Loss (typical values at Z = 50 Ω)

Unsymmetrical, adjacent branches terminated

Common mode, all branches in parallel (asymmetrical)

Differential mode (symmetrical)

19

Page 26

Insertion Loss (typical values at Z = 50 Ω)

Unsymmetrical, adjacent branches terminated

Common mode, all branches in parallel (asymmetrical)

Differential mode (symmetrical)

20

Page 27

Section 2: 520V, CB, 180 – 400A

EMC Filters

Phase: 3

Current: 180 to 400 A

Voltage: 520/300 V AC, 50/60 Hz

Termination: Copper Bus

Part Numbers:

KRF0180ACB

KRF0250ACB

KRF0320ACB

KRF0400ACB

Construction

• 3-line filter

• Metal case

Features

• Optimized leakage current

• Easy to install

• Very compact design

• Optimized for operation under full load

• Low weight

• Design complies with

EN 133200, UL 1283, CSA C22.2 No.8

• UL, cUL approval

Applications

• Frequency converters for motor drives

• Wind farms

• Power supplies

Terminals

• Busbars

Marking

Marking on component:

Manufacturer’s logo, ordering code,

rated voltage, rated current, rated temperature,

climatic category, date code

21

Page 28

Typical circuit diagram

Rated voltage VR

520/300 V AC, 50/60 Hz

Read current IR

Referred to 40°C ambient temperature (180 A filter at 60°C

Test voltage V

2240 V DC, 2 s (line/line)

2690 V DC, 2 s (lines, case)

3270 V DC, 2 s (line/line)

2890 V DC, 2 s (lines/case)

1.5 · IR for 3 min per hour or

2.5 · IR for 30 s per hour

Overload capability (thermal)

520 V AC, 50 Hz

Leakage current I

leak

25/100/21 (-25°C/+100°C/21 days damp heat test)

Climatic category (IEC 60068-1)

UL 1283; CSA C22.2 No.8

500/290V

1801

< 21

110

5.0

KRF0180ACB

X X 250

< 21

110

5.0

KRF0250ACB

X X 320

< 21

51

7.2

KRF0320ACB

X X 400

< 21

48

7.5

KRF0400ACB

X

X

Technical data and measuring conditions

test

Characteristics and ordering codes

VR

AC

V

520/300

I

A

R

I

leak

mA

R

typ

µΩ

Approx

weight

kg

TCI Number

X = approval granted

1) KRF0180ACB referred to 60°C ambient temperature

Approvals

22

Page 29

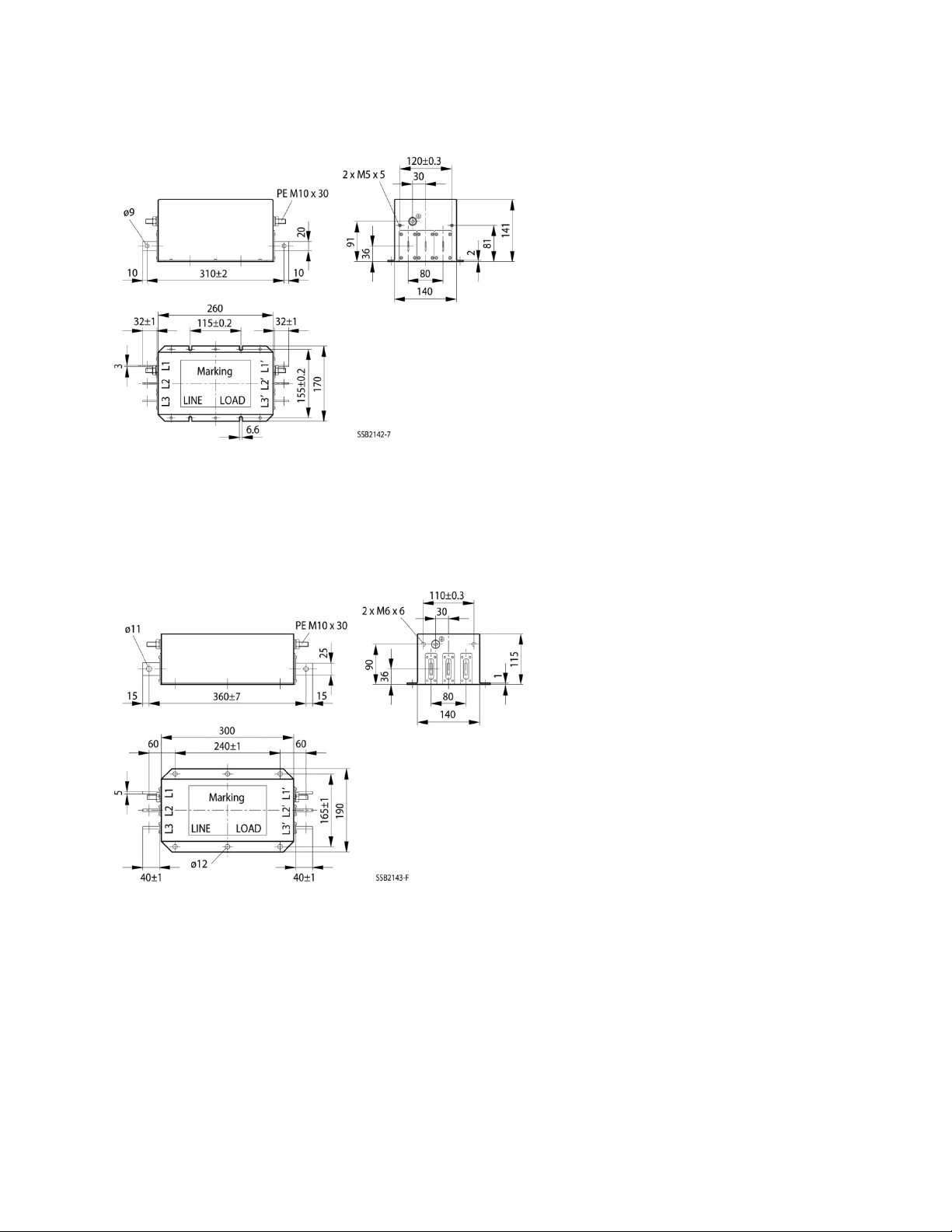

Dimensional drawings

(180 A, 250 A) KRF0180ACB, KRF0250ACB

(320 A, 400 A) KRF0320ACB, KRF0400ACB

23

Page 30

Insertion Loss (typical values at Z = 50 Ω)

Unsymmetrical, adjacent branches terminated

Common mode, all branches in parallel (asymmetrical)

Differential mode (symmetrical)

24

Page 31

Section 3: 520V, CB, 150 A & 600 – 2500A

EMC Filters

Phase: 3

Current: 150 A; 600 to 2500 A

Voltage: 520/300 V AC, 50/60 Hz

Termination: Copper Bus

Part Numbers:

KRF0150ACB

KRF0600ACB

KRF1000ACB

KRF1600ACB

KRF2500ACB

Construction

• 3-line filter

• Metal case

Features

• Optimized leakage current

• Easy to install

• Very compact design

• Optimized for operation under full load

• Low weight

• UL, cUL approval

Applications

• Frequency converters for motor drives

• Wind farms

• Power supplies

Terminals

• Busbars

Marking

Marking on component:

Manufacturer’s logo, ordering code,

rated voltage, rated current, rated temperature,

climatic category, date code

25

Page 32

Rated voltage VR

530/310 V AC, 50/60 Hz

Read current IR

Referred to 40°C ambient temperature

Test voltage V

2280 V DC, 2 s (line/line)

1.5 · IR for 3 min per hour or

2.5 · IR for 30 s per hour

Overload capability (thermal)

At VR, 50 Hz

Leakage current I

leak

25/100/21 (-25°C/+100°C/21 days damp heat test)

Climatic category (IEC 60068-1)

UL 1283; CSA C22.2 No.8

(Type: 500/290 V)

VR

IR

I

R

Approx

Approvals

500/290V

530/310

150

< 20

140

13

KRF0150ACB

X X 600

< 20

52

22

KRF0600ACB

X X 1000

< 20

33

28

KRF1000ACB

X X 1600

< 20

22

34

KRF1600ACB

X X 2500

< 20

15

105

KRF2500ACB

X

X

Typical circuit diagram

Technical data and measuring conditions

test

2690 V DC, 2 s (lines, case)

Characteristics and part numbers

AC

V

A

leak

mA

typ

µΩ

weight

kg

Part Number

X = approval granted

26

Page 33

Dimensional drawings

(150 A) KRF0150ACB

(600 A) KRF0600ACB

27

Page 34

(1000 A) KRF1000ACB

(1600 A) KRF1600ACB

28

Page 35

(2500 A) KRF2500ACB

Insertion Loss (typical values at Z = 50 Ω)

Unsymmetrical, adjacent branches terminated

Common mode, all branches in parallel (asymmetrical)

Differential mode (symmetrical)

29

Page 36

30

Page 37

Section 4: 760V, TB, 25 – 180A

EMC Filters

Phase: 3

Current: 25 to 180 A

Voltage: 760/440 V AC, 50/60 Hz

Termination: Terminal Block

Part Numbers:

KRF0025VTB

KRF0036VTB

KRF0050VTB

KRF0080VTB

KRF0120VTB

KRF0150VTB

KRF0180VTB

Construction

• 3-line filter

• Metal case

Features

• High insertion loss

• Low leakage current

• Easy to install

• Degree of protection IP 20 (IEC 60529:2001)

• Space saving design

• Design complies with

IEC/EN 60939, UL 1283, CSA 22.2 No. 8

• Optimized for long motor cabl es and operation

under full load

• UL and cUL approval

Applications

• Frequency converters for motor drives, e.g.

- elevators

- pumps

- traction systems

- conveyor systems

- HVAC systems (heating, ventilation and air conditioning)

• Wind farms

• Power supplies

31

Page 38

Test voltage line to case for 2 s

V

test

3000

V DC

Rated temperature

TR

40

°C

Overload capability (thermal)

for 30 s per hour

Leakage current I

leak

At 690

V AC, 50 Hz

Climatic category (IEC 60068-1)

25/100/21

Terminals

• Finger-safe terminal bl ock s

Marking

Marking on component:

Manufacturer’s logo, ordering code,

rated voltage, rated current, rated temperature,

climatic category, date code

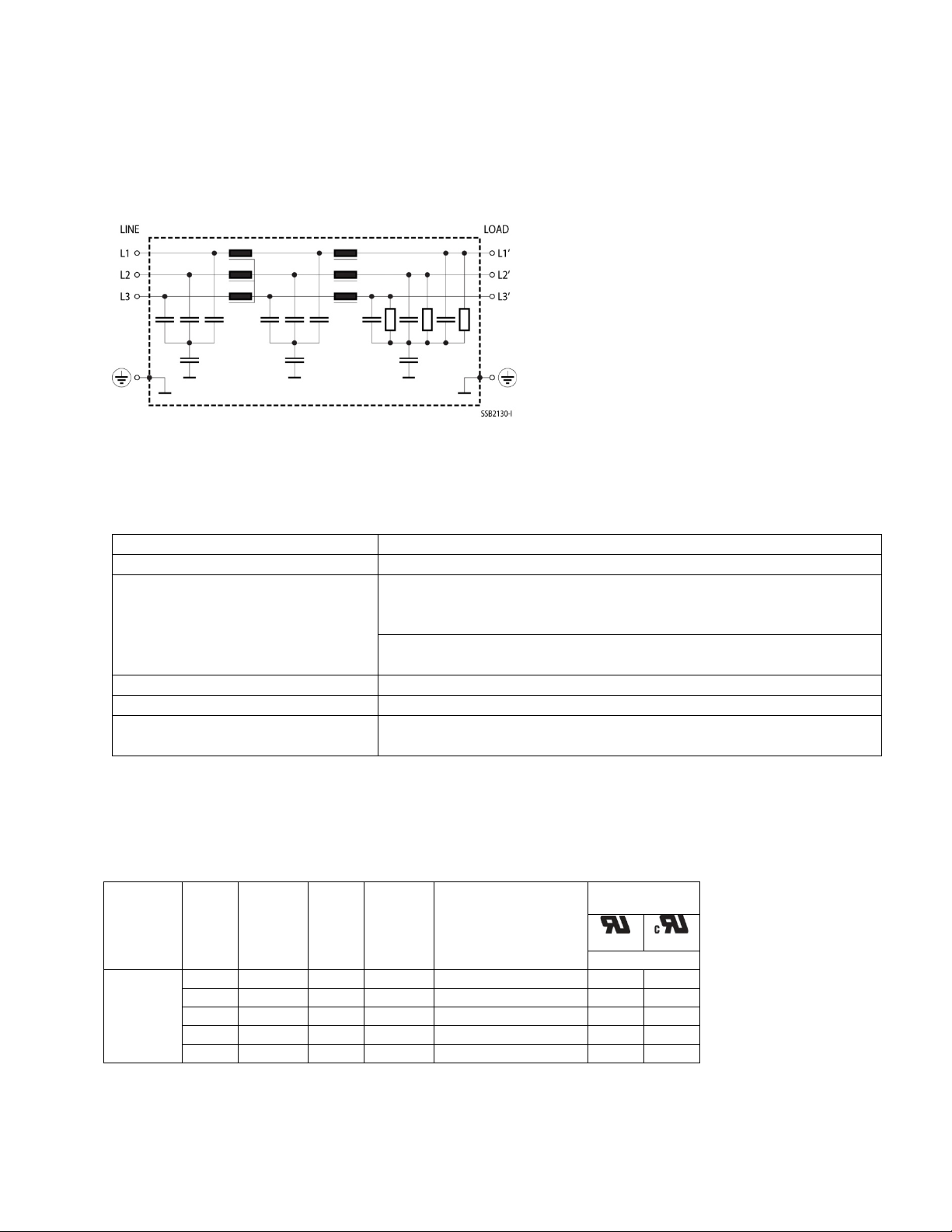

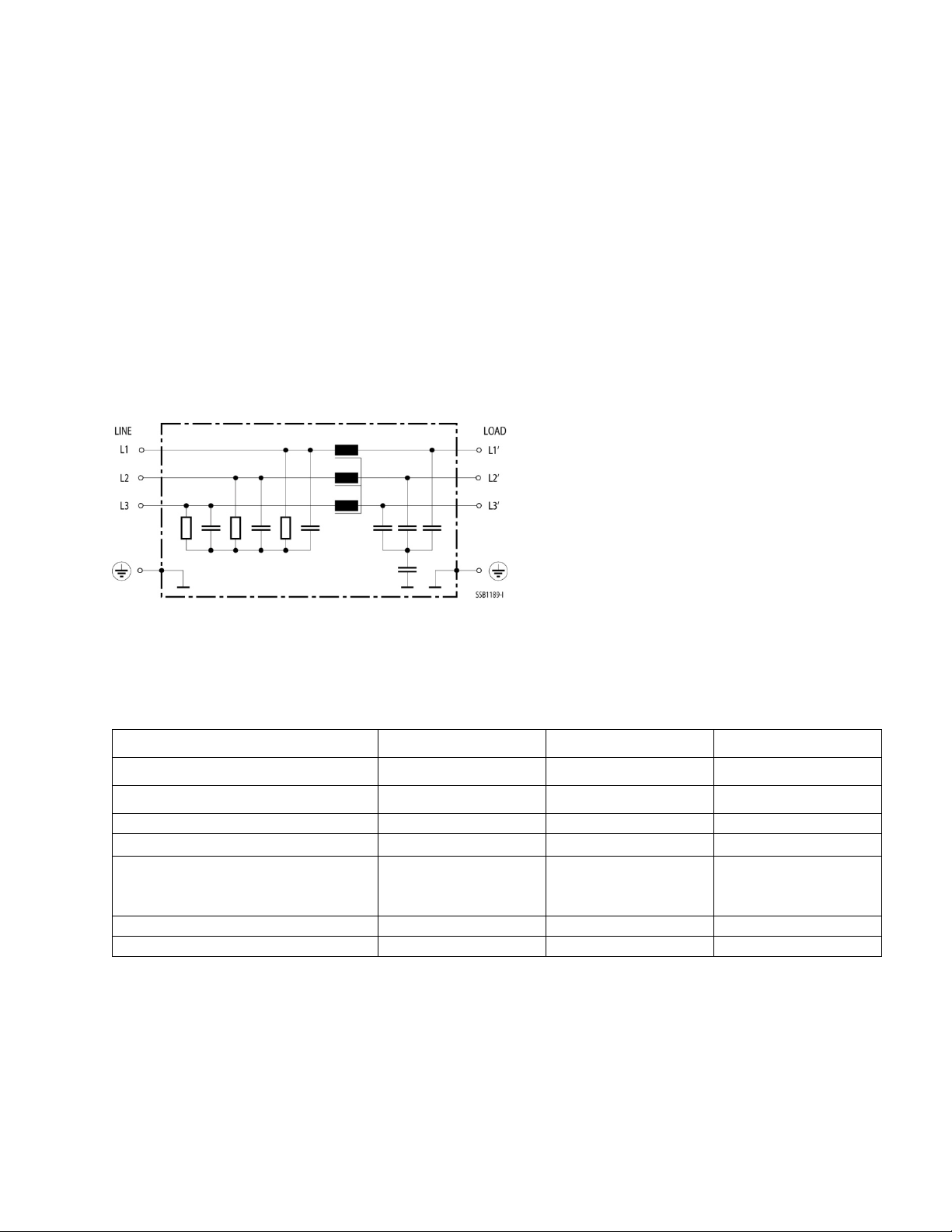

Typical Circuit diagram

Technical data and measuring conditions

Rated voltage VR 760/440 V AC

Rated frequency fR 50/60 Hz

Test voltage line to line for 2 s V

for 3 min per hour or

3270 V DC

test

1.5 x I

2.5 x I

R

R

32

Page 39

Characteristics and part numbers

IR

Terminal

mm2

I

R

Approx

Part Number

Approvals

600/350V

25

10

< 7

8.0

4

KRF0025VTB

- X X

-

-

-

-

-

-

A

cross

section

leak

mA

typ

µΩ

weight

kg

36 10 < 7 3.8 4 KRF0036VTB

50 10 < 12 2.0 4 KRF0050VTB

80 25 < 12 1.0 9.5 KRF0080VTB

120 50 < 12 0.75 10 KRF0120VTB

150 50 < 12 0.4 10 KRF0150VTB

180 95 < 12 0.4 13 KRF0180VTB

X = approval granted

X X

X X

X X

X X

X X

X X

33

Page 40

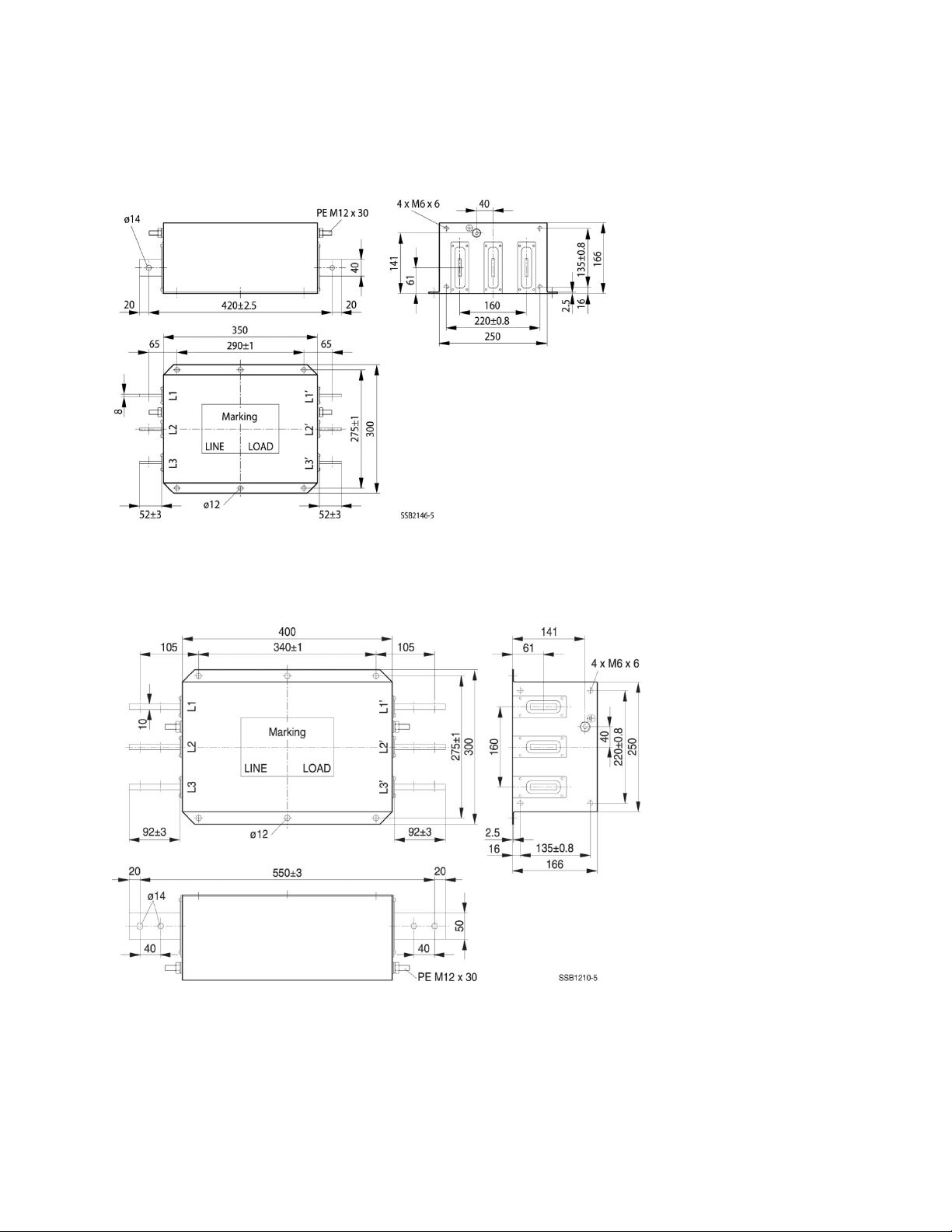

Dimensional drawings

(25 A, 50 A) KRF0025VTB, KRF0050VTB

(80 A) KRF0080VTB

34

Page 41

(120 A, 150 A) KRF0120VTB, KRF0150VTB

(180 A) KRF0180VTB

35

Page 42

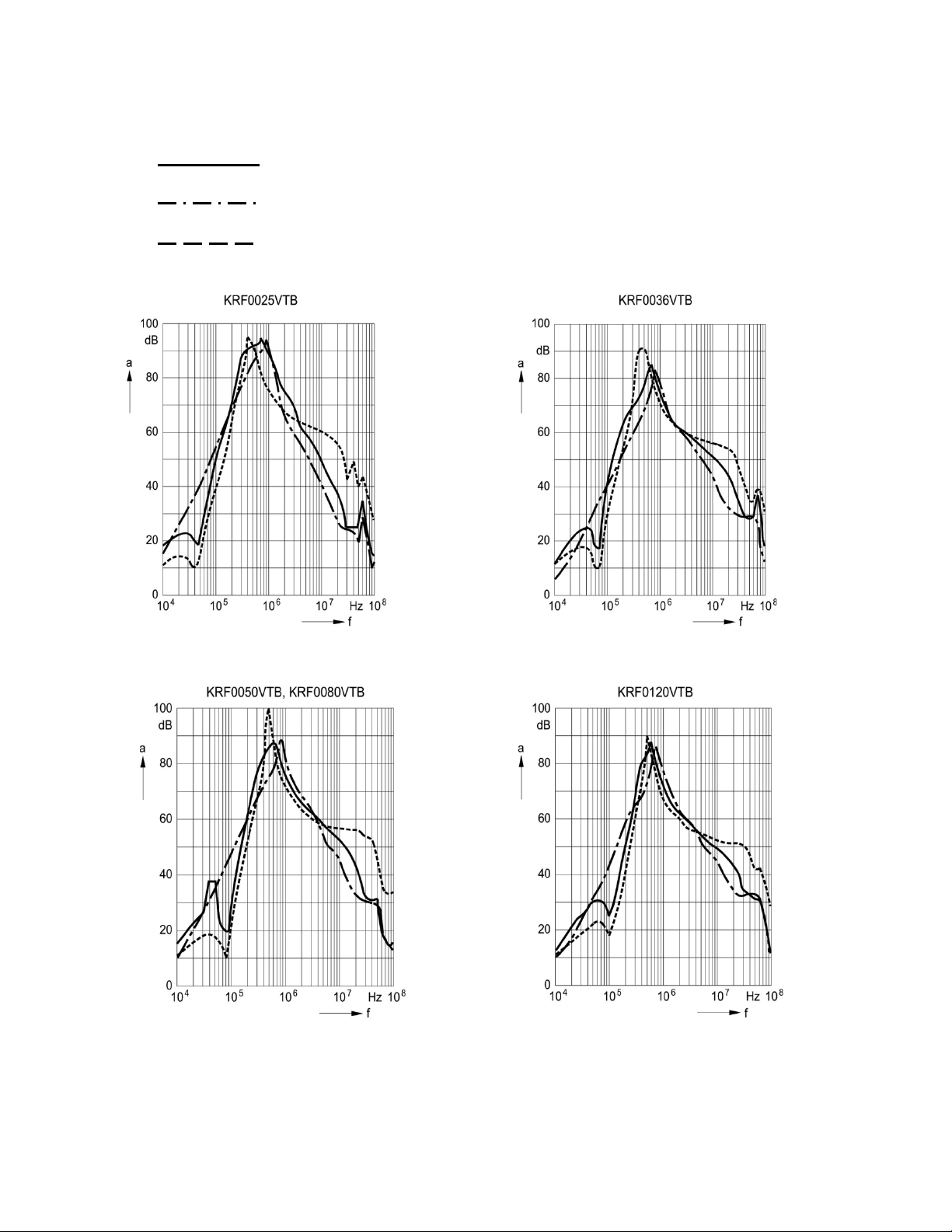

Insertion Loss (typical values at Z = 50 Ω)

Unsymmetrical, adjacent branches terminated

Common mode, all branches in parallel (asymmetrical)

Differential mode (symmetrical)

36

Page 43

37

Page 44

Section 5: 760V, CB, 150 – 2500A

EMC Filters

Phase: 3

Current: 150 to 2500 A

Voltage: 760/440 V AC, 50/60 Hz

Termination: Copper Bus

Part Numbers:

KRF0150VCB

KRF0180VCB

KRF0250VCB

KRF0320VCB

KRF0400VCB

KRF0600VCB

KRF1000VCB

KRF1600VCB

KRF2500VCB

Construction

• 3-line filter

• Metal case

Features

• Optimized leakage current

• Easy to install

• Very compact design

• Optimized for operation under full load

• Low weight

• UL, cUL approval

Applications

• Frequency converters for motor drives

• Wind farms

• Power supplies

Terminals

• Busbars

Marking

Marking on component:

Manufacturer’s logo, ordering code,

rated voltage, rated current, rated temperature,

climatic category, date code

Typical circuit diagram

38

Page 45

Rated voltage VR

Type: 760/440 V AC, 50/60 Hz

Read current IR

Referred to 40°C ambient temperature

Type:

2890 V DC, 2 s (lines/case)

1.5 · IR for 3 min per hour or

2.5 · IR for 30 s per hour

Overload capability (thermal)

At VR, 50 Hz

Leakage current I

leak

25/100/21 (-25°C/+100°C/21 days damp heat test)

Climatic category (I EC 60068-1)

UL 1283; CSA C22.2 No.8

VR

IR

I

R

Approx

Part Number

Approvals

600/350V

760/440

150

< 28

140

13

KRF0150VCB

X X 180

< 28

140

13

KRF0180VCB

X X 250

< 28

63

15

KRF0250VCB

X X 320

< 28

67

21

KRF0320VCB

X X 400

< 28

67

21

KRF0400VCB

X X 600

< 28

52

22

KRF0600VCB

X X 1000

< 28

33

28

KRF1000VCB

X X 1600

< 28

22

34

KRF1600VCB

X X 2500

< 28

15

105

KRF2500VCB

X

X

Technical data and measuring conditions

3270 V DC, 2 s (line/line)

Characteristics and part numbers

AC

V

A

leak

mA

typ

µΩ

weight

kg

X = approval granted

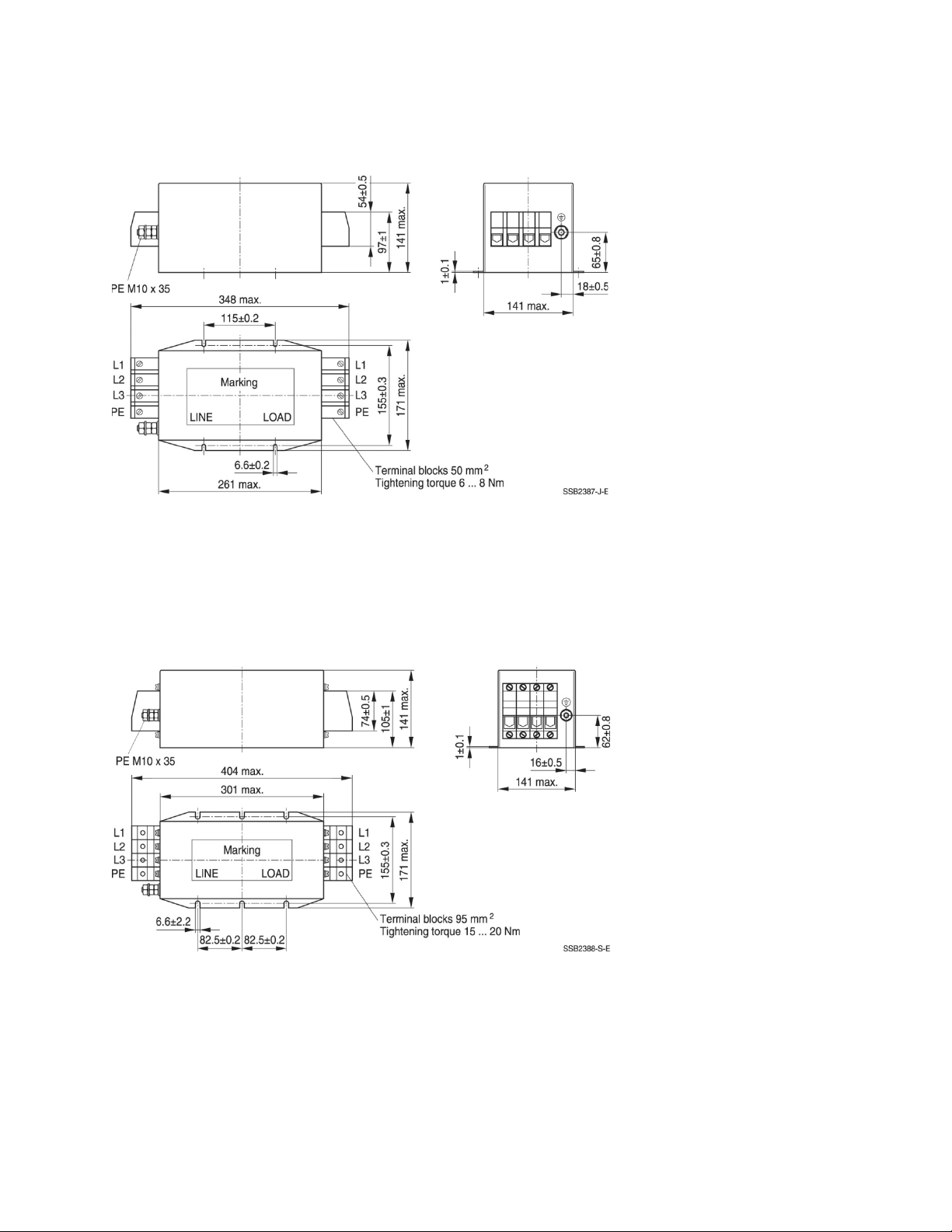

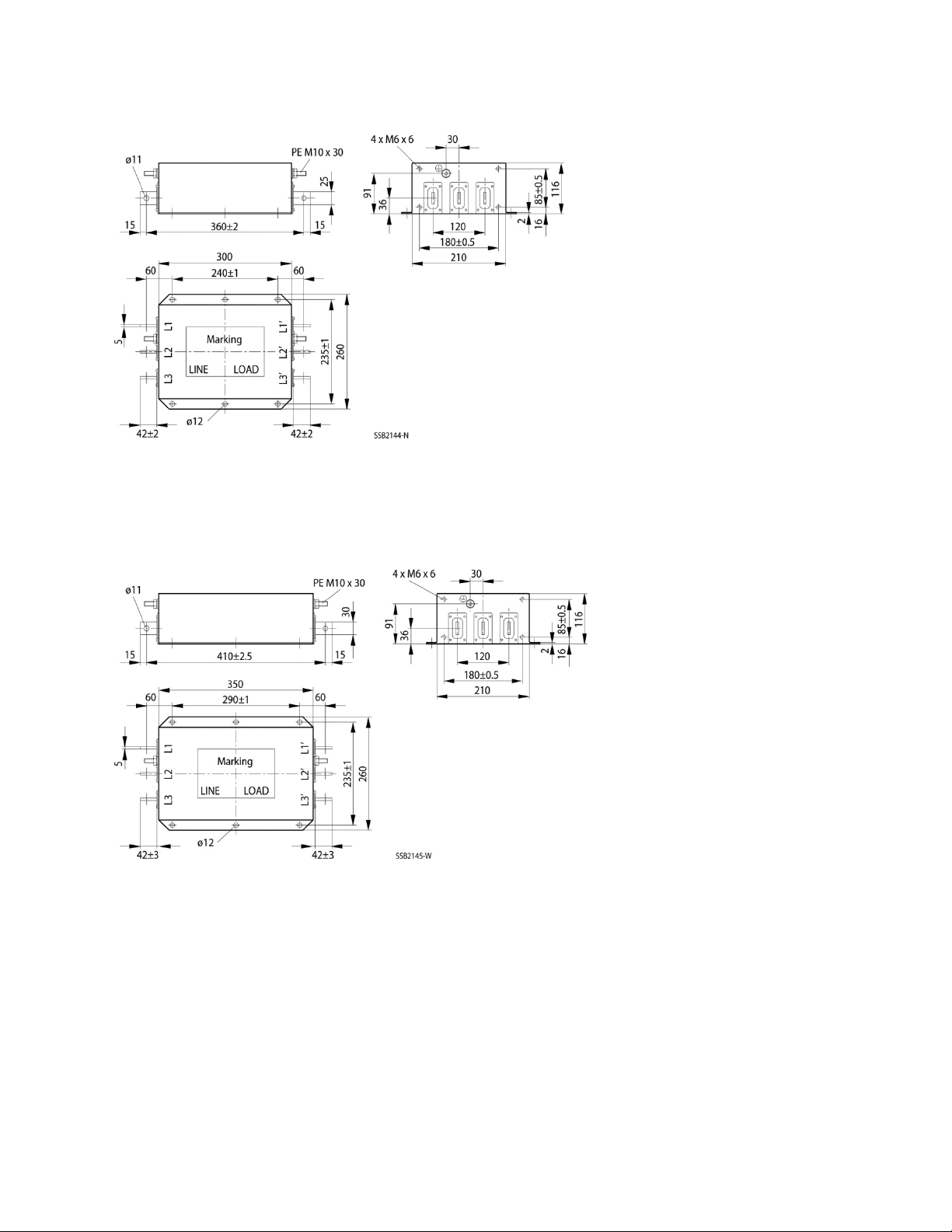

Dimensional drawings

39

Page 46

(150 A, 180 A) KRF0150VCB, KRF0180VCB

(250 A) KRF0250VCB

(320 A, 400 A) KRF0320VCB, KRF0400VCB

40

Page 47

(600 A) KRF0600VCB

(1000 A) KRF1000VCB

41

Page 48

(1600 A) KRF1600VCB

(2500 A) KRF2500VCB

42

Page 49

Insertion Loss (typical values at Z = 50 Ω)

43

Page 50

Unsymmetrical, adjacent branches terminated

Common mode, all branches in parallel (asymmetrical)

Differential mode (symmetrical)

44

Page 51

45

Page 52

Part Number: 27781 Version 1.2 07/24/12

TCI, LLC

W132 N10611 Grant Drive

Germantown, Wisconsin 53022

Phone: 414-357-4480

Fax: 414-357-4484

Helpline: 800-TCI-8282

Web Site:

http://www.transcoil.com

© 2011

Loading...

Loading...