Page 1

MotorGuard

KMG High Performance

Output Sine Wave Filter

Installation, Operation, and Maintenance Manual

Page 2

MotorGuard

™

KMG High Performance Output Sinewave Filter

Installation, Operation, and Maintenance Manual

TCI, LLC

W132 N10611 Grant Drive

Germantown, Wisconsin 53022

Phone: 414-357-4480

Fax: 414-357-4484

Helpline: 800-TCI-8282

Web Site: http://www.transcoi l. c om

© 2014

iv

Page 3

T able of Contents

Safety Instructions ........................................................................................ 5

Overview ................................................................................................................................................. 5

Warnings and Cautions ......................................................................................................................... 5

General Safety Instructions .................................................................................................................. 6

Introduction .................................................................................................... 7

Intended Audience ................................................................................................................................. 7

Additional Information ......................................................................................................................... 7

Installation Checklist ............................................................................................................................. 7

Receiving Inspection and Storage ............................................................... 8

Receiving Inspection .............................................................................................................................. 8

Warranty Information .......................................................................................................................... 8

Storage Instructions ............................................................................................................................... 8

Product Description ...................................................................................... 9

MotorGuard Sine Wave Filter .............................................................................................................. 9

Nameplate Data .................................................................................................................................... 10

Model Number Encoding .................................................................................................................... 11

Standard Product Ratings and Dimension Tables ............................................................................ 12

Product Technical Specifications........................................................................................................ 17

Pre-installation Planning ............................................................................. 19

Verify the Application ......................................................................................................................... 19

Select a Suitable Location ................................................................................................................... 19

Power Wiring ....................................................................................................................................... 20

Control Wiring (for units with boards).............................................................................................. 20

Optional Features ................................................................................................................................ 20

Installation Guidelines ................................................................................ 21

Mounting .............................................................................................................................................. 21

Wiring ................................................................................................................................................... 21

MotorGuard Operation ................................................................................ 24

Adjustments ......................................................................................................................................... 24

3

Page 4

Start Up (Commissioning) ................................................................................................................... 24

Operation .............................................................................................................................................. 24

Maintenance and Service ........................................................................... 25

MotorGuard Reliability and Service Life .......................................................................................... 25

Periodic Maintenance........................................................................................................................... 25

For Units with Boards:......................................................................................................................... 25

Troubleshooting .................................................................................................................................... 26

Replacement Parts ................................................................................................................................ 29

Factory Contacts and Tech Support ................................................................................................... 29

Drawings ...................................................................................................... 30

Typical Isometr i c Drawings and Schematic Diagrams ..................................................................... 30

4

Page 5

Safety Instructions

!

Overview

This section provides the safet y instructions which must b e followed when installing, operating and

servicing t he KMG MotorGuard Filter. If neglected, physical injury or death may follow, or damage

may occur to the MotorGuard or equipment connected to the MotorGuard. The material in this chapter

must be read and understood before attempting any work on, or with, the product.

The MotorGuard is intended to be connected to the output terminals of a variable frequency drive

(VFD). An AC motor is connected to the output terminals of the MotorGuard and receives power from

the VFD through the MotorGuard. The instructions, and particularly the safet y instructions, for the

VFD, motor and any other related equipment must be read, understood and followed when working on

any of the equipment.

Warnings and Cautions

This manual provides two types of safety instructions.

Warnings caution readers about conditions, which can, if proper steps are not taken, lead to a serious

fault condition, physical injury, or death.

Cautions are used to draw attention to instructions. Failure to properly follow such instr uctions may

lead to a malfunction and possible equipment damage.

Warnings

Readers are informed of situations that can result in serious physical injury and/or serious damage to

equipment wit h war ni n g stat e men t s mar ked wit h the fo ll o wi ng s ymb o ls:

Warning

Warning

Warning

Dangerous Voltage Wa rning: warns of situations in which a

high voltage can cause physical injury and/or equipment

damage. The text next to this symbo l describes ways to avoid

the danger.

General Warning: warns of situations that can cause physical

injury and/ or equipment damage by means other than

electrical. The text next to this symbol describes ways to avoid

the danger.

Electrostatic Discharge Warning: warns of situations i n which

an electrostatic discharge may damage equipment. The text

next to this symbol desc ribes ways to avoid the d anger.

Cautions

Readers are informed of situations that can lead to a malfunction and possible equipment damage with

caution statements:

Caution

General Caution: identifies situatio ns that can lead to a

malfunction and possible equipment damage. The text

describes ways to avoid the situatio n.

5

Page 6

General S afety Ins truct ions

torGuard for the cooling

urces of power have been disconnected

!

!

!

These safety instructions are intended for all work on the MotorGuard. Additional safety instructions

are provided at appropriate points o n other sec tions of this manual.

Warning

Warning

Warning

Warning

Warning

Warning

Be sure to read, understand, and follow all safety instructions.

Only qualified electricians should carry out all electrical installation and maintenance work on the

MotorGuard.

All wiring must be in accordance with the National Electrical Code (NEC) and/or any other codes that

apply to the installation site.

Disconnect all power before working on the equipment.

Do not attempt any work on a powered MotorGuard.

The MotorGuard, VFD, motor, and other connected equipment must be properly grounded.

The MotorGuard receives power from two or more sources.

Three-phase power from the output terminals of the VFD is c onnected to the main input terminals of

the MotorGuard.

Power from a single-phase 120, 240 or 480 volt supply is connected to the Mo

fan and monitor board.

The monitor board alarm contacts may be connected to a circuit that receives power from another

source.

All of these sources of power must be disconnected before working on the MotorGuard.

Warning

Warning

After switching off the power, always allow 5 minutes for the capacitors in the MotorGuard and in the

VFD to discharge before working on the MotorGuard, the VFD, the motor, or connecting wiring. It is

good practice to check with a voltmeter to make sure that all so

and that all capacitors have discharged before beginning work.

The VFD output terminals and the motor cables are at a dangerously high voltage when power is

applied to the VFD regardless of motor operation.

6

Page 7

Introduction

Caution

Select a mounting area that will allow adequate cooling air and maintenance access.

Make sure that all wiring conforms to the requirements of the National Electric Code (NEC)

Connect the MotorGuard equipment grounding lug to the system ground of the premises wiring

Wire the output power terminals, of the MotorGuard, T1, T2, & T3 to the motor.

Connect control power to the MotorGuard.

For monitor board option: Connect the MotorGuard fault relay contact to the appropriate fault

Make sure that the VFD is set for operating modes and ranges that are compatible with the

Thank you for se lec ti n g t he KMG MotorGuard High Performa nce O utput Filter. TCI has p rod uced this

filter for use in many PWM variable frequency drive (VF D) applications that require low distortion

sine wave o utput po wer. This manual de scribes how to i nstall, operate, and maintain the MotorGuard

filter.

Intended Audience

This manual is intended for use by all personnel responsible for the installation, operation, and

maintenance of the MotorGuard. Such personnel are expected to have knowledge of electrical wiring

practices, electronic components, and electrical schematic symbols.

Additiona l Infor mation

This manual provides general information describing your MotorGuard filter. More specific

information is provided by the drawings shipped with the unit. Be s ure to carefully review t he

information provided by these drawings. Information provided by the drawings shipped with the unit

takes precedence over the information provided in this manual.

Installation Checklist

The following are the key points to be followed for a successful installation. These points are

explained in detail in the following sections of this manual.

Make sure that the installation lo c a tion will not be exposed to direc t sunlight, c orrosive or

combustible airborne contaminants, excessive dirt, or liquids.

and/or other applicable electrical codes.

system. Use a properly sized grounding conductor.

Wire the output power termina ls o f the V FD, T1(U), T2(V), & T3(W) to the input terminals of

the MotorGuard, U, V, & W.

monitoring c ircuit.

Check the MotorGuard configuration settings to ensure proper voltage is selected.

MotorGuard.

Check ever ything thor oughly be fore operating the equipment.

7

Page 8

Receivi ng Inspection and Storage

Receiving Inspection

The MotorGuard has been thoroughly inspected and functionally tested at the factory and carefully

packaged for shipment.

When you receive the unit, you should immediately inspect the shipping container and report any

damage to the carrier that delivered the unit.

Verify that the part number of the unit you received is the same as the part number listed on your

purchase order.

Warranty Info rmatio n

TCI, LLC (“TCI”) warrants to the original purchaser only that MotorGuard products will be free from

defects in materials and workmanship under normal use and service for a period originating on the date

of shipment from TCI and expiring at the end of One (1) year of useful service, not to exceed 18

months from the date of shipment. The foregoing limited warranty is TCI’s sole warranty with respect

to its products and TCI makes no other warranty, representation or promise as to the quality or

performance of TCI’s products. THIS EXPRESS LIMITED WARRANTY IS GIVEN IN LIEU OF

AND EXCLUDES ANY AND ALL EXPRESS OR IMPLIED WARRANTIES INCLUDING,

WITHOUT LIMITATION, ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FIT NESS

FOR A PARTICULAR PURPOSE.

This warranty shall not apply if the product was:

a) altered or repaired by anyone other than TCI;

b) applied or used for situations other than those originally specified; or

c) subjected to negligence, accident, or damage by circumstances beyond TCI’s control, including

but not limited to, improper stor a ge, installation, operation or maintenance.

If, within the warranty period, any product shall be found in TCI’s reasonable judgment to be

defective, TCI’s liability and the Buyer’s exclusive remedy under this warranty is expressly limited, at

TCI’s option, to (i) repair or replace ment of that product, or (ii) return of the product and refund of the

purchase price.

Such remedy shall be Buyer’s sole and exclusive remedy. TCI SHALL NOT, IN ANY EVENT, BE

LIABLE FOR INCIDENTAL DAMAGES OR FOR CONSEQUENT IAL DAMAGES INCLUDING,

BUT NOT LIMITED TO, LOSS OF INCOME, LOSS OF TIME, LOST SALES, INJURY TO

PERSONAL PROPERTY, LIABILITY BUYER INCURS WITH RESPECT TO ANY OTHER

PERSON, LOSS OF USE OF THE PRODUCT OR FOR ANY OTHER TYPE OR FORM OF

CONSEQUENTIAL DAMAGE OR ECONOMIC LOSS.

The foregoing warranties do not cover reimbursement for removal, transportation, reinstallation, or any

other expenses that may be incurred in connection with the repair or replacement of the TCI product.

The employees and sales agents of TCI are not authorized to make additional warranties about TCI ’s

products. TCI’s employees and sales agents oral statements do not c onstitute warranties, shall not be

relied upon by the Buyer and are not part of any contract for sale. All warranties of TCI embodied in

this writing and no other warranties are given beyond those set forth here in.

TCI will not accept the return of any product witho ut its prior written approval. Please consult TCI

Customer Service for instructions on the Ret urn Authori zation Pr ocedure.

Storage Instructions

If the MotorGuard is to be stored before use, be sure that it is stored in a location that conforms to

published storage humidit y and temperature specifications stated in this manual. Store the unit i n its

original packaging.

8

Page 9

Product Descript ion

MotorGuard Sine Wave Filter

The MotorGuard is a low-pass sine wave filter designed and developed by TCI to deliver conditioned

power to motor loads driven by PWM drives at a variety of lead lengths. The MotorGuard is available

for 460/480 volt and 575/600 volt systems.

The MotorGuard is a passive filter connected in series with the output terminals of the variable

frequency drive. It is designed to remove the carrier frequency distortion from the output voltage

waveform. The use of this low-pass, L-R-C device will result in a nearly pure sine wave voltage

profile. This design will reduce the effects of the reflected wave phenomenon, (dv/dt), such as

insulation damage or premature failure in motors, transformers and VFD output cables. The

MotorGuard will also reduce the effects of stray high fre quency harmo nic current s, thereby red ucing

VFD ground fault prob l ems and noise interference in transducer signals.

The MotorGuard is available in t wo package configuration s: Industrial and GP. The Industrial filter is

a stand-alone device that can be furnis hed in it s o wn enclo sure a nd mo unted a dja cent to the VFD, and

is also avai lable on an op en panel for mo unting withi n an enclosure p rovided with t he VFD or othe r

equipment. The GP filter is furnished in its own enclosure and mounted adja c e nt to the VFD.

The MotorGuard is suitable for all lead lengths extending as far as 15,000 feet.

The MotorGuard consists of the following standard features and components:

♦ An R-L-C power filter circuit with:

A TCI 3-phase reactor specifically designed for the MotorGuard

Power resistors

High-endurance, harmonic-rated capacitors

♦ Bleeder resistors to ensure safe capacitor discharge upon filter shutdown.

♦ Compression terminals for ease and integrity of all power wiring.

♦ Cooling fans to ensure adequate cooling and safe operating temperatures.

Optional Monitor Board is available:

♦ A filter performance monitor and alarm circuit with:

Monitor board with relay and status indica ting lights

Control transformer for control voltage power

Compression terminal blocks for all control wiring

9

Page 10

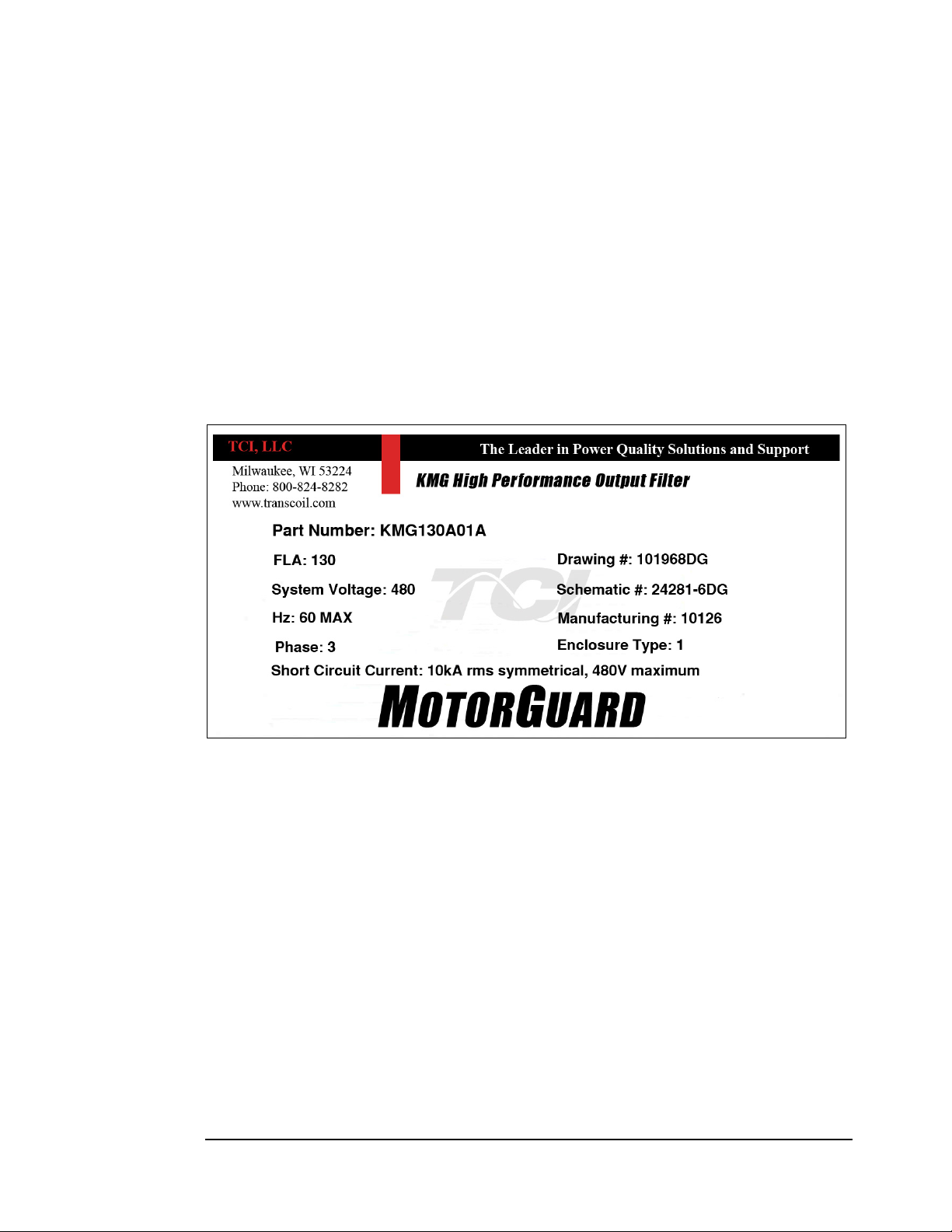

Nameplate Data

Figure 1 sho ws an example of a MotorGuard na meplate. The following i nformation is marked on the

nameplate:

♦ Part number: encoded model number explained on the following page

♦ FLA: the rated continuous ope rating current (RMS amps)

♦ System Voltage: the maximum VFD output voltage (fundamental)

♦ Hz: the maximum VFD output frequency (fundamental)

♦ Phase: 3 – The MotorGuard is designed for use only with 3 phase motors.

♦ Drawing #: outline and mounting dimension of filter

♦ Schematic #: schematic diagram of filter

♦ Manufacturing #: for TCI internal use

♦ Enclosure Type: Industrial filters are open panel construction or NEMA 1 enclosed. GP filters

are NEMA 1 or NEMA 3R enclosed.

Figure 1 – Example of MotorGuard Nameplate

10

Page 11

Model Number Enc oding

H = Space Heater

0 = No Thermal Switch

Monitor Board

B = Monitor Board

0 = No Monitor Board

Thermal Switch

L = Lugs

C = 600V

Voltage rating:

K

0 = No Space Heater

Space Heater

0 = No Lugs

S = Thermal Switch

Lugs

0

0

Options:

Enclosure:

Current Rating (amps)

A = 480V

K- Series

MotorGuard Product Line

0100A0G

G01 = General Purpose Indoor (gray)

G3R = General Purpose NEMA 3R (white)

MG3

1

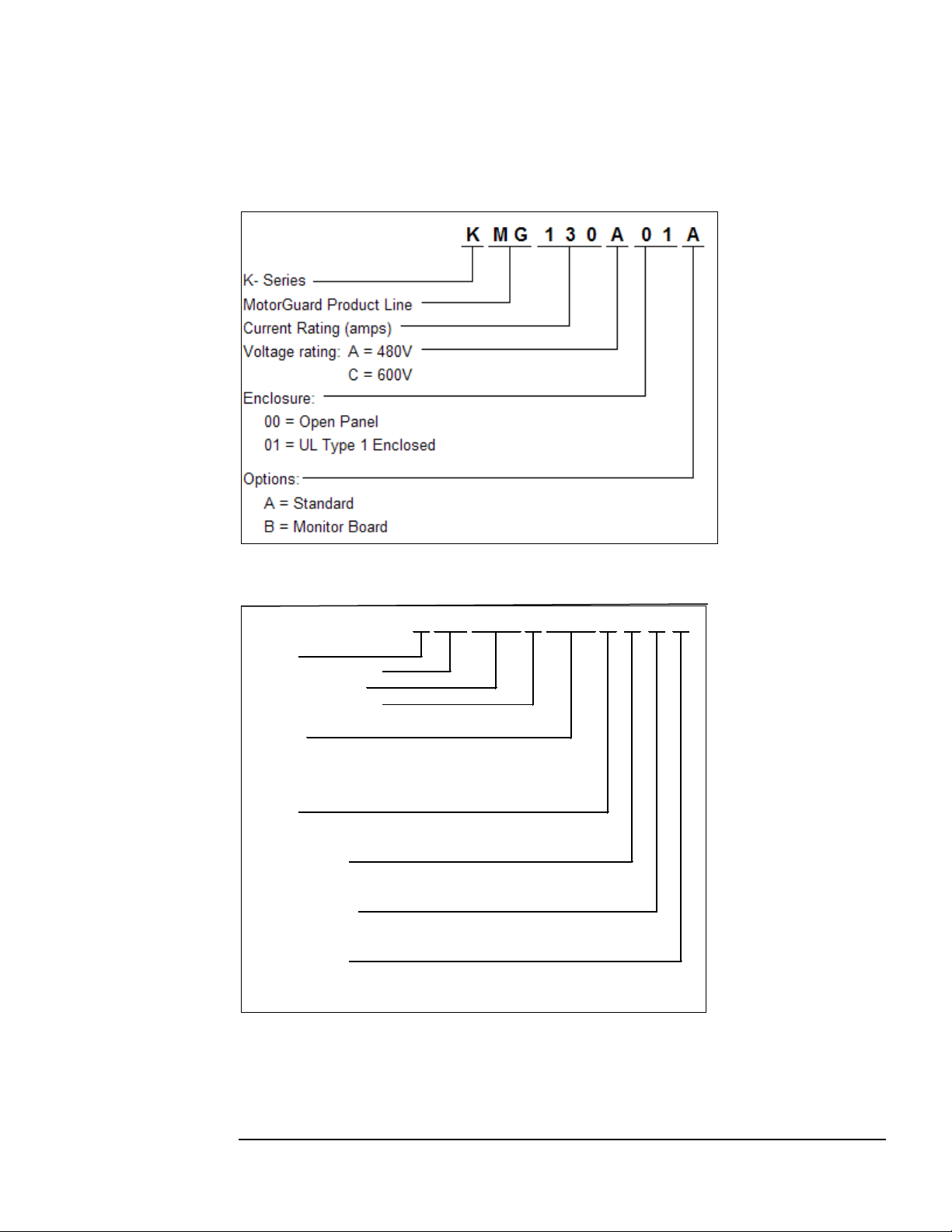

Figures 2a and 2b identify the significance of each character in the MotorGuard model number. The

example model number, KMG130A01A designate s an Industrial MotorGuard that is rated 130 amps,

480 volts, and is furnished in a NEMA 1 enclosure.

Figure 2a – MotorGuard Model Number Encodi ng – Industrial V ersion

Figure 2b – MotorGuard Model Number Encoding – General Purpose Version

The MotorGuard has a current rating rather than a horsepower rating. The rating and dimension tables

in the following section list the nominal horsepo wer ratings corr esponding to the current ratings of the

standard models.

11

Page 12

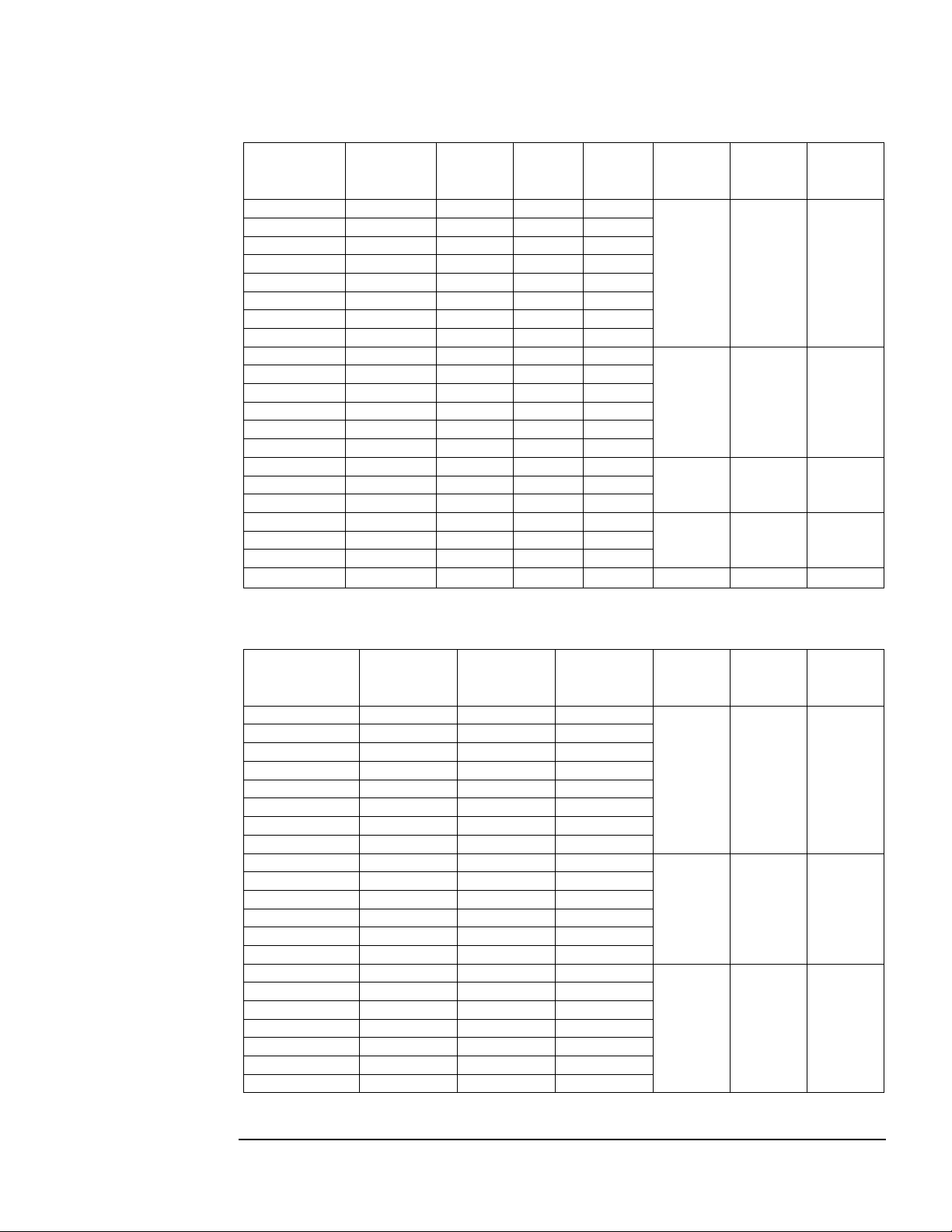

Standard Product Ratings and Dimension Tables

The following tables list the ratings and dimensions of the standard MotorGuard models:

♦ Table 1 lists 480 Volt models on open panels.

♦ Table 2 lists 480 Volt models in NEMA 1 enclosures.

♦ Table 3 lists 600 Volt models on open panels.

♦ Table 4 lists 600 Volt models in NEMA 1 enclosures.

♦ Table 5 lists 480 Volt models in NEMA 1 enclosures.

♦ Table 6 lists 480 Volt models in NEMA 3R enclosures.

♦ Table 7 lists 600 Volt models in NEMA 1 enclosures.

♦ Table 8 lists 600 Vo lt models in NEMA 3R enclosures.

12

Page 13

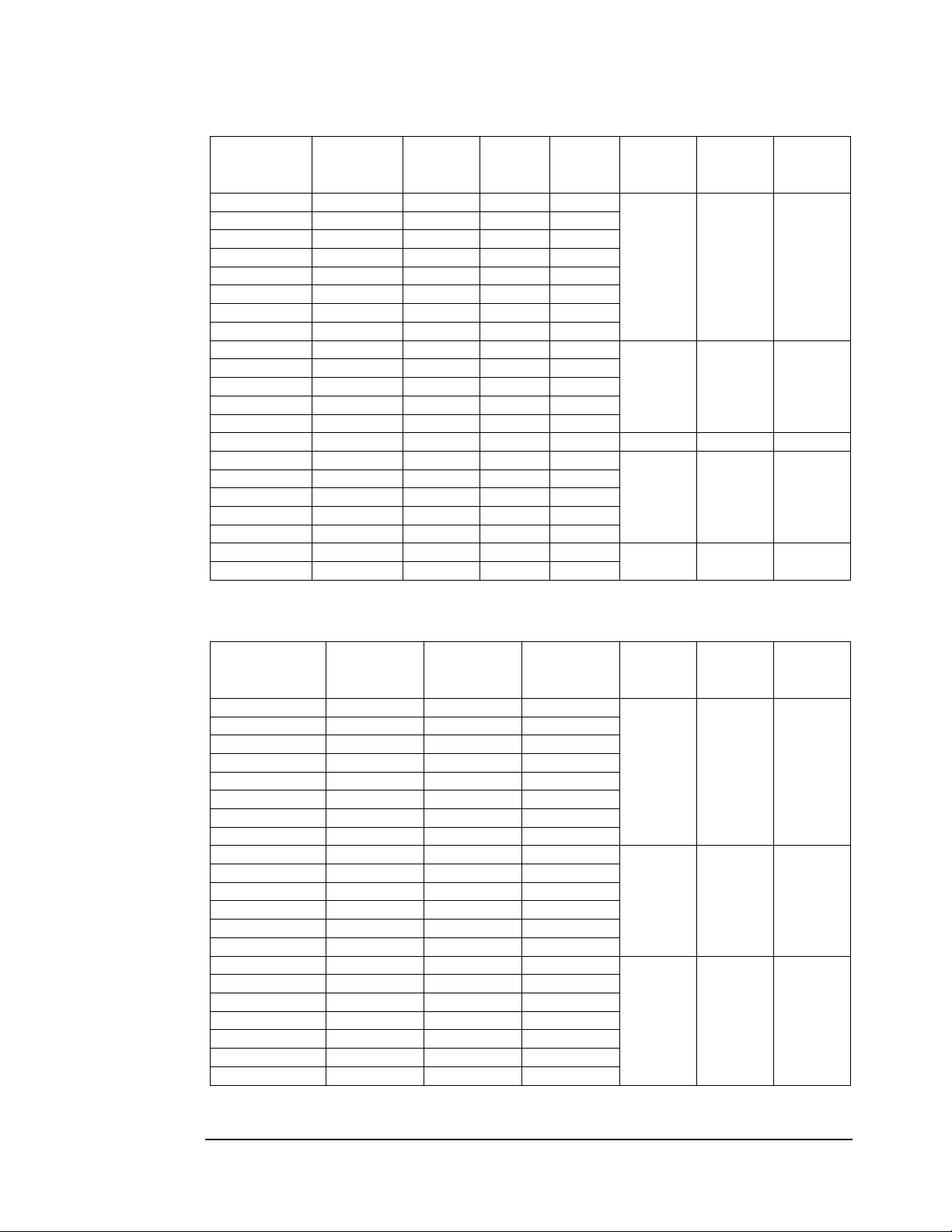

Table 1 – Industrial 4 80 Volt Models on Ope n Pane ls

KMG8A00A

5 8 300

60

KMG12A00A

7.5

12

350

60

KMG16A00A

10

16

400

70

KMG23A00A

15

23

550

75

KMG30A00A

20

30

650

85

KMG35A00A

25

35

750

85

KMG45A00A

30

45

850

100

KMG55A00A

40

55

1000

115

KMG65A00A

50

65

1100

160

KMG80A00A

60

80

1550

175

KMG110A00A

75

110

1700

195

KMG130A00A

100

130

2050

200

KMG160A00A

125

160

2450

250

KMG200A00A

150

200

3300

255

KMG250A00A

200

250

3700

445

KMG305A00A

250

305

4700

460

KMG362A00A

300

362

4650

475

KMG420A00A

350

420

5400

580

KMG480A00A

400

480

6050

635

KMG600A00A

500

600

7350

645

KMG750A00A

600

750

8800

760

60.00

32.00

17.75

(amps)

KMG8A01A

5 8 110

KMG12A01A

7.5

12

110

KMG16A01A

10

16

120

KMG23A01A

15

23

125

KMG30A01A

20

30

140

KMG35A01A

25

35

140

KMG45A01A

30

45

155

KMG55A01A

40

55

170

KMG65A01A

50

65

245

KMG80A01A

60

80

260

KMG110A01A

75

110

280

KMG130A01A

100

130

300

KMG160A01A

125

160

340

KMG200A01A

150

200

345

KMG250A01A

200

250

770

KMG305A01A

250

305

790

KMG362A01A

300

362

800

KMG420A01A

350

420

915

KMG480A01A

400

480

970

KMG600A01A

500

600

975

KMG750A01A

600

750

1085

Model

Number

Nominal

Horspower

Current

Rating

(amps)

Heat

Loss

(Watts)

Weight

(lbs.)

Height

(in.)

30.75 17.00 11.75

56.00 17.00 11.75

60.00 32.00 14.75

60.00 32.00 16.38

Width

(in.)

Depth

(in.)

Table 2 – Industrial 480 Volt Models in NEMA 1 Enclosures

Model

Number

Nominal

Horspower

Current

Rating

Weight

(lbs.)

Height

(in.)

31.38

Wall

Mounted

56.00

Wall

Mounted

76.50

Free

Standing

Width

(in.)

17.50 12.14

17.52 16.40

36.00 24.00

Depth

(in.)

13

Page 14

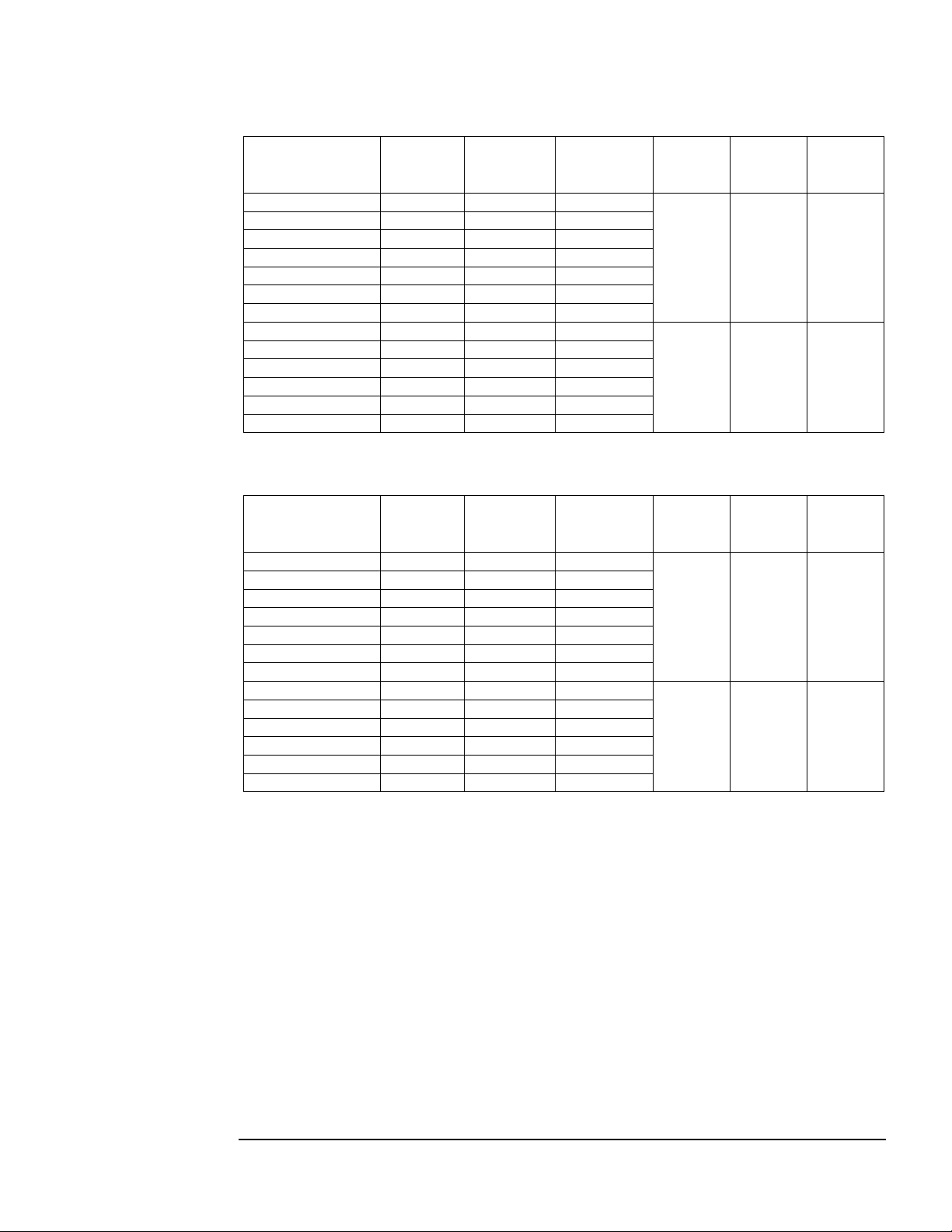

Table 3 – Industrial 6 00 Volt Models on Ope n Pane ls

KMG8C00A

5 8 400

60

KMG10C00A

7.5

10

400

65

KMG12C00A

10

12

400

70

KMG20C00A

15

20

550

75

KMG25C00A

20

25

700

85

KMG28C00A

25

28

750

90

KMG35C00A

30

35

800

100

KMG45C00A

40

45

950

115

KMG55C00A

50

55

1200

160

KMG65C00A

60

65

1600

175

KMG80C00A

75

80

1650

195

KMG110C00A

100

110

2250

225

KMG130C00A

125

130

2300

250

KMG160C00A

150

160

2500

260

56.00

17.00

14.78

KMG200C00A

200

200

3500

450

KMG250C00A

250

250

4500

460

KMG305C00A

300

305

5100

475

KMG362C00A

350

362

6100

580

KMG420C00A

400

420

6900

635

KMG500C00A

500

500

7900

645

KMG600C00A

600

600

9000

750

KMG8C01A

5 8 115

KMG10C01A

7.5

10

115

KMG12C01A

10

12

120

KMG20C01A

15

20

135

KMG25C01A

20

25

140

KMG28C01A

25

28

145

KMG35C01A

30

35

155

KMG45C01A

40

45

175

KMG55C01A

50

55

260

KMG65C01A

60

65

265

KMG80C01A

75

80

265

KMG110C01A

100

110

290

KMG130C01A

125

130

295

KMG160C01A

150

160

340

KMG200C01A

200

200

770

KMG250C01A

250

250

775

KMG305C01A

300

305

790

KMG362C01A

350

362

975

KMG420C01A

400

420

975

KMG500C01A

500

500

1015

KMG600C01A

600

600

1015

Model

Number

Nominal

Horspower

Current

Rating

(Amps)

Heat

Loss

(Watts)

Weight

(lbs.)

Height

(in.)

30.75 17.00 11.75

56.00 17.00 11.75

60.00 32.00 14.75

60.00 32.00 16.00

Width

(in.)

Depth

(in.)

Table 4 – Industrial 600 Volt Models in NEMA 1 Enclosures

Model

Number

Nominal

Horspower

Current

Rating

(Amps)

Weight

(lbs.)

Height

(in.)

31.38

Wall

Mounted

56.00

Wall

Mounted

76.50

Free

Standing

Width

(in.)

17.50 12.14

17.52 16.40

36.00 24.00

Depth

(in.)

14

Page 15

Table 5 – General Purpose 480 Volt Models in NEMA 1 Enclosures

KMG55AG010000

40

55

209

KMG65AG010000

50

65

215

KMG80AG010000

60

80

235

KMG110AG010000

75

110

220

KMG130AG010000

100

130

225

KMG160AG010000

125

160

250

KMG200AG010000

150

200

260

KMG250AG010000

200

250

595

KMG305AG010000

250

305

625

KMG362AG010000

300

362

630

KMG420AG010000

350

420

635

KMG480AG010000

400

480

635

KMG600AG010000

500

600

755

KMG55AG3R0000

40

55

209

KMG65AG3R0000

50

65

215

KMG80AG3R0000

60

80

235

KMG110AG3R0000

75

110

220

KMG130AG3R0000

100

130

225

KMG160AG3R0000

125

160

250

KMG200AG3R0000

150

200

260

KMG250AG3R0000

200

250

595

KMG305AG3R0000

250

305

625

KMG362AG3R0000

300

362

630

KMG420AG3R0000

350

420

635

KMG480AG3R0000

400

480

635

KMG600AG3R0000

500

600

755

Model

Number

Nominal

Horspower

Current

Rating

(Amps)

Weight

(lbs.)

Height

(in.)

36.50 18.67 29.50

64.00

Table 6 – General Purpose 480 Volt Models in NEMA 3R Enclosures

Model

Number

Nominal

Horspower

Current

Rating

(Amps)

Weight

(lbs.)

Height

(in.)

Width

(in.)

24.17

Width

(in.)

Depth

(in.)

42.00

Depth

(in.)

Hotel

36.50 18.67 29.50

64.00

24.17

42.00

15

Page 16

Table 7 – General Purpose 600 Volt Models in NEMA 1 Enclosures

KMG45CG010000

40

45

209

KMG55CG010000

50

55

235

KMG65CG010000

60

65

235

KMG80CG010000

75

80

266

KMG110CG010000

100

110

275

KMG130CG010000

125

130

280

KMG160CG010000

150

160

290

KMG200CG010000

200

200

570

KMG250CG010000

250

250

615

KMG305CG010000

300

305

620

KMG362CG010000

350

362

650

KMG420CG010000

400

420

675

KMG500CG010000

500

500

810

KMG600CG010000

600

600

(Amps)

KMG45CG3R0000

40

45

209

KMG55CG3R0000

50

55

235

KMG65CG3R0000

60

65

235

KMG80CG3R0000

75

80

266

KMG110CG3R0000

100

110

275

KMG130CG3R0000

125

130

280

KMG160CG3R0000

150

160

290

KMG200CG3R0000

200

200

570

KMG250CG3R0000

250

250

615

KMG305CG3R0000

300

305

620

KMG362CG3R0000

350

362

650

KMG420CG3R0000

400

420

675

KMG500CG3R0000

500

500

810

KMG600CG3R0000

600

600

Model

Number

Nominal

Horspower

Current

Rating

(Amps)

Weight

(lbs.)

Height

(in.)

36.50 18.67 29.50

64.00

Width

(in.)

24.17

Depth

(in.)

42.00

Table 8 – General Purpose 600 Volt Models in NEMA 3R Enclosures

Model

Number

Nominal

Horspower

Current

Rating

Weight

(lbs.)

Height

(in.)

Width

(in.)

Depth

(in.)

36.50 18.67 29.50

64.00

24.17

42.00

16

Page 17

Product Technical Specifications

Tables 9a, 9b, 10a, and 10b list the major technical specifications for the MotorGuard product line.

Table 9a – MotorGuar d Technical Spec ifications – Industrial

Current ratings Continuous current: 8 to 750 amps. See Rating and Dimension tables

Intermittent current: 150% for 1 minute out of every 60 minutes

VFD Drive output voltage 460/480 and 575/600 V, 3 ph, at fundamental base frequency

VFD Drive output

frequency

VFD Drive carrier

frequency

Control power input For fan operation.

Filter performance Maximum peak voltage of output waveform – 480 V models: 1000 V

Maximum elevation 3,000 feet (1,000 meters) as standard. Product must be equipped with

Maximum ambient

operating temperature

Maximum ambient storage

temperature

Maximum humi d it y,

operating or storage

Enclosure options Open panel for mounting in an enclosure furnished by others

Enclosure fi nis h Free standing enclosures: ANSI 61 gray

Agency approvals or

certifications

0 to 80 Hz

2 kHz and 12 kHz, ideally 4 kHz to 8 kHz

– 600 V models: 1500 V

Maximum dv/dt of output waveform – 480 V models: 500 V/μs

– 600 V models: 1500 V/μs

special cooling provisions for operation above this level

40 °C (104 °F) as standard. Product must be equipped with special

cooling provisions for operation above this temperature.

50 °C (122 °F)

95%, non-condensing.

NEMA 1 enclosure

Wall mount enclosures: White M a tte (beige) Munsel 5.8Y7.83/1

UL and cUL Listed to UL508A and CSA-C22.2 No. 14

Insertion impedance Approximately 6.5% at 60 Hz & full load current

Fusing and protection: Unit has internal fuse protection and a performance monitoring

circuit.

Capacitors Oil filled high endurance design (no PCBs)

Table 9b – Only with Board Option

Status indication LEDs Green LED indicates: "Control Power ON"

Yellow LED indicates: "Normal Operation" (not faulted)

Fault relay De-energized when a fault is detected.

Form C contact for customer use.

Rated 0.6 A at 125 VAC and 110 VDC, 2 A at 30 VDC.

17

Page 18

Table 10a – MotorGuard Technical Specifications – General Purpose

Current ratings Continuous current: 55 to 600 amps. See Rating and Dimension tables

Intermittent current: 150% for 1 minute out of every 60 minutes

VFD Drive output voltage 460/480 and 575/600 V, 3 ph, at fundamental base frequency

VFD Drive output

frequency

VFD Drive carrier

frequency

Control power input For fan operation.

Filter performance Maximum p eak voltage of output waveform – 480 V models: 1000 V

Maximum elevation 3,000 feet (1,000 meters) as standard. Product must be equipped with

Maximum ambient

operating temperature

Maximum ambient storage

temperature

Maximum humi d it y,

operating or storage

Enclosure options

Insertion impedance Approximately 6.5% at 60 Hz & full load current

Capacitors Oil filled high endurance desi gn (no PCBs)

0 to 80 Hz

2 kHz and 12 kHz, Ideally 4 kHz to 8 kHz

– 600 V models: 1500 V

Maximum dv/dt of output waveform – 480 V models: 500 V/μs

– 600 V models: 1500 V/μs

special cooling provisions for operation above this level

40 °C (104 °F) as standard. Product must be equipped with special

cooling provisions for operation above this temperature.

50 °C (122 °F)

95%, non-condensing.

General Purpose 3R enclosure

Table 10b – Only with Board Option

Status indication LEDs Green LED indicates: "Control Power ON"

Yellow LED indicates: "Normal Operation" (not faulted)

Fault relay De-energized when a fault is detected.

Form C contact for customer use.

Rated 0.6 A at 125 VAC and 110 VDC, 2 A at 30 VDC.

18

Page 19

Pre-installation Planning

!

Verify th e A pplicat ion

MotorGuard Ratings

Make sure that the MotorGuard is correct for the application. The voltage and current ratings of the

MotorGuar d must match the output voltage and current ratings of the connected variable frequency

drive as it is configured for use with the connected motor.

Variable Frequency Drive Settings

Make sure that the variable frequency drive will be set for operation modes and ranges that are

compatible with the MotorGuard:

♦ Maximum output frequency: 80 Hz

♦ PWM switching frequency between 2 kHz and 12 kHz, ideally 4 kHz to 8 kHz

♦ Mode of operation: "scalar" or "V/Hz" without DC brak ing unless the drive application has

been confirmed by TCI Technical Support

Select a Suitable Location

Environment

Locating the MotorGuard in a suitable environment will help ensure proper performance and a normal

operating life.

Warning

Unless specifically labeled as approved for such use, this equipment is not suitable for use in an

explosive atmosphere or in a "Hazardous (Classified) Location" as defined in article 500 of the

National Electrical Code.

The unit must be installed in a n ar e a where it will not be exposed to:

♦ Corrosi ve l i quids or gasses

♦ Explosive or combustible gases or dust

♦ Excessive airborne dirt and dust

♦ Excessive vibration

In addition to the above, products that are not in a 3R enclosure should not be exposed to:

♦ Direct sunlight

♦ Rain or excessive dripping liquids

Mounting Area

Select a mounting area that will allow sufficien t cooling air to flow through the unit. Adeq uate space

should be provided to allow access for maintenance.

Mounting an open panel unit

If you are mounting an open panel uni t in your own encl osure, you must p rovide a n enclo sure that is

adequately sized and ventilated sufficiently to pr e vent overheating. The rating and dimension tables for

open panel units list the watts of heat loss that is dissipated by the MotorGuard. The maximum

temperature of the air around the MotorGuard's capacitors and monitor board should not exceed 50 °C

(104 °F).

19

Page 20

Power Wiring

The conduit and wiring fr om the o utput o f the variab le freq uency d rive to the mo tor must be route d to

the MotorGuard and then to the motor. When selecting a mounting location for the MotorGuard, plan

for the routing of the power wiring.

Control Wiring (for u nits with boards)

Control Power

The MotorGuard requires 120 VAC single-phase power for the monitor board and cooling fan. The

control power source must be ensured to be energized whenever the variable frequency drive is

operating. A control power transformer is provided in the MotorGuard to allow control power to be

obtained from the three-phase source that provides input power to the VFD. Fuses are provided on the

control transformer, but the wires connecting control power to the MotorGuard will need to be

appropriately protected at the power source.

Control Power VA Requirement

Refer to the drawings furnished with your MotorGuard to determine the control power VA required.

Fault Alarm Contact

The fault alarm relay is energized when control power is applied to the MotorGuar d and the output

waveform dv/dt and peak voltage are within specified limits. If the dv/dt or peak voltage limits are

exceeded, the fault relay is de-energized. A set of form C contacts are provided for customer use.

Determine how the MotorGuard's performance alarm contact will be used. It may be connected to the

VFD external fault input or to some supervisory control or alarm annunciation equipment. A

MotorGuard fault alarm indicates that the MotorGuard is not providing adequate dv/dt and peak

voltage protection. If the drive operation continues during a fault condition, the motor or other

equipment may be damaged. To guard against damage, consider connecting the MotorGuard to

automatically shut down the drive if a fault occurs. The best alternative to shuttin g d own the drive is to

provide an alarm to personnel who will promptly investigate the problem.

Optional Features

Additional wiring require ments may appl y to M otor Guard units tha t ar e equip ped with cer tain op tional

features such as a space heater or 120 VAC control power supplied directly rather than through a

control power transformer. For instructions covering these additional requirements, refer to drawings

and/or other suppleme ntal information furnished with t he unit.

20

Page 21

Installa tion Guidelines

Mounting

The MotorGuard must be mounted vertically on a smooth, solid surface, free from heat, dampness, and

condensation.

Wiring

Cable Entry Locations

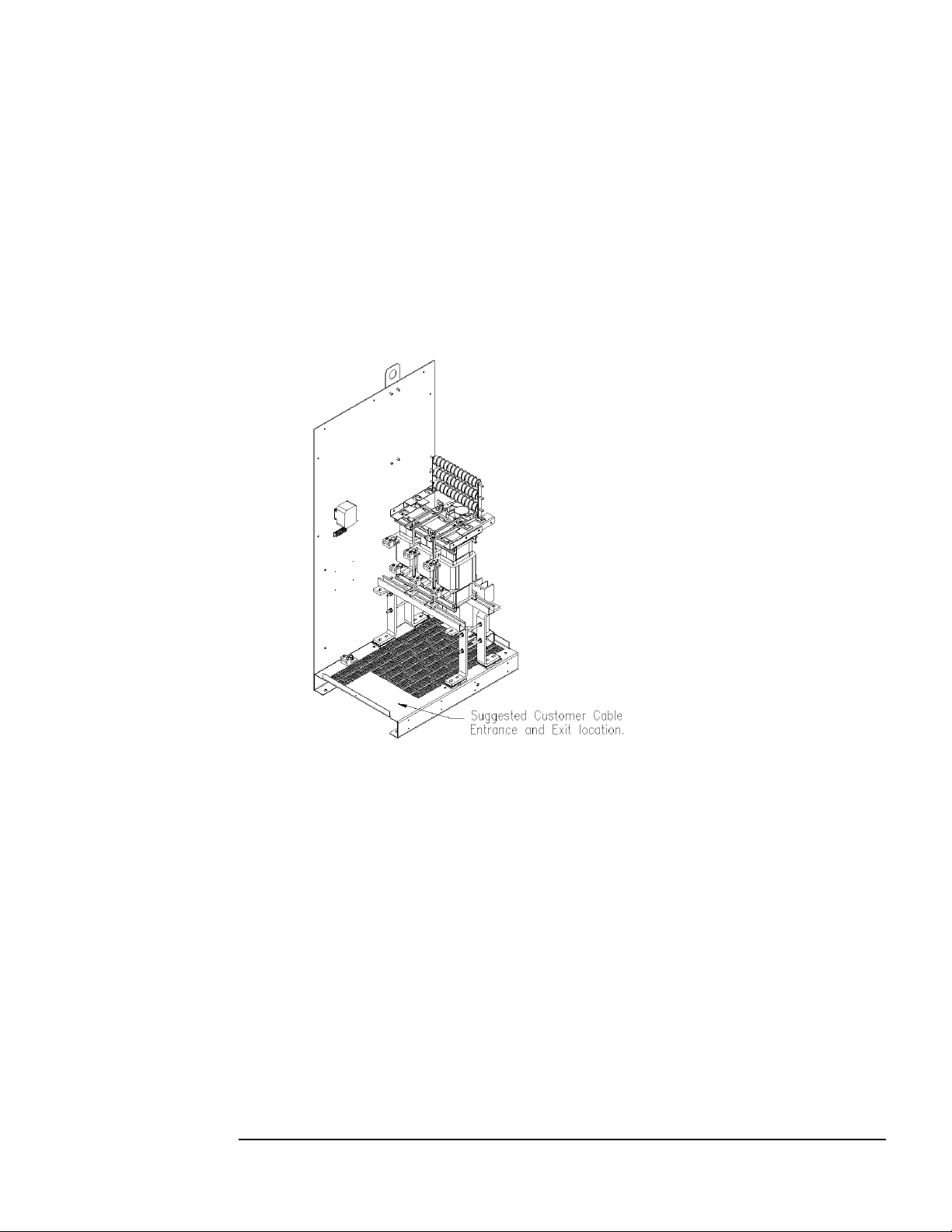

(Lifting eye is option al)

↓

Figure 3 – Cable Entry Location for Gener al Pur pose units

Field Wiring Connection Terminals

Compression type terminals may be provided for all field wiring connections. The control circuit

terminals will accommodate 18 AWG to 10 AWG wire and should be tightened to 18 in.-lbs. tor que.

The wire size capacity ranges and ti ght e nin g to r q ue fo r t he g r o undi ng a nd p o wer t erminals ar e list ed in

Tables 11a and 11b.

21

Page 22

Table 11 – Motor Power Terminal Wir e Size Cap acity Range and Tightenin g Tor que (Cu or

1 AWG (7 & 19 strand only)

KMG55C to KMG130C

KMG160C to KMG200C

KMG250A to KMG305A

KMG250C to KMG305C

4 AWG - 600 MCM or

(2) 1/0 AWG - 250 MCM

500

4 AWG - 600 MCM or

(2) 1/0 AWG - 250 MCM

500

KMG362A

KMG362C to KMG420C

(2) 4 AWG - 350 MCM

275

(2) 4 AWG - 350 MCM

275

KMG420A to KMG600A

KMG500C to KMG600C

(2) 2 AWG - 600 MCM

500

(2) 2 AWG - 600 MCM

500

KMG750A

(3) 2 AWG - 600 MCM

375

(3) 2 AWG - 600 MCM

375

KMG55A

14 - 1/0 AWG

200

22 - 16 AWG

1 AWG (7 & 19 strand only)

25

KMG65A to KMG130A

KMG55C to KMG130C

6 - 2/0 AW G

120

6 - 2/0 AW G

120

KMG160A to KMG200A

KMG160C to KMG200C

6 AWG - 250 MCM

275

6 AWG - 250 MCM

275

KMG250C to KMG305C

(2) 1/0 AWG - 250 MCM

(2) 1/0 AWG - 250 MCM

KMG362C to KMG420C

KMG420A to KMG600A

KMG500C to KMG600C

(2) 2 AWG - 600 MCM

500

(2) 2 AWG - 600 MCM

500

Al) - Industrial

KMG IND

Model Numbers

KMG8A to KMG55A

KMG8C to KMG45C

KMG65A to KMG130A

KMG160A to KMG200A

6 AWG - 250 MCM 275 6 AWG - 250 MCM 275

Ground Lug

Wire Size

14 - 1/0 AWG 200 22 - 16 AWG

6 - 2/0 AWG 120 6 - 2/0 AWG 120

Torque

(in.-lb.)

Input and Output

Motor Power

Wire Size

14 - 6 AWG

4 - 2 AWG and

Torque

(in.-lb.)

25

30

35

Table 11b – Motor Power Terminal Wire Size Capacity Range and Tightening Torque (Cu or

Al) – General Purpose

KMG GP

Model Numbers

KMG45C

KMG250A to KMG305A

KMG362A

4 AWG - 600 MCM or

(2) 4 AWG - 350 MCM 275 (2) 4 AWG - 350 MCM 275

Ground Lug

Wire Size

Input and Output

Motor Power

Torque

(in.-lb.)

500 4 AWG - 600 MCM or

Wire Size

14 - 6 AWG

4 - 2 AWG and

Torque

(in.-lb.)

30

35

500

Connection Diagram

Figure 4 shows the typical wiring connections between the MotorGuard and the VFD and motor. Note

that separate conduits may be required for the control power and fault contact wiring. Refer to the

instructions for the VFD or other eq uipment to which the fault contact is connecte d.

22

Page 23

Figure 4 – Typical Connection Diagram

Caution

For units rated less than 100 amps, use copper or aluminum wire with an insulation temperature rating

T1

T2

T3

G

Motor

U

V

W

G

T1

T2

T3

MotorGuard

6

7 8

Fault

Output

L1 L2

Control

Power

L1(R)

L2(S)

L3(T)

G

(U)T1

(V)T2

(W)T3

G

Ext Fault

Input

Variable

Frequency

Drive

Grounding

The MotorGuard panel equipment grounding lug must be connected to the ground of the premises

wiring syste m. T he eq ui p me nt gro und i n g c on ne ct io n mu st c o nform to the req uir e ments of the Na tional

Electric Code (NEC) and/or any other codes that apply to the installation site. The ground connectio n

must be made using a wire conductor. Metallic conduit is not a suitable grounding conductor. The

integrity of all ground connections should be periodically checked.

Power Wiring

Connect the o utput of the V FD, terminals T1(U), T2( V), & T3(W), to the input of the MotorGuard,

terminals U, V, & W. Connect the motor to the output of the MotorGuard, terminals T1, T2, & T3.

Use wire that is appropriate for the voltage and current rating of the motor.

of 60 °C or higher.

For units rated 100 amps or more, use copper or aluminum wire with an insulation temperature rating

of 75 °C or higher.

The wire size and the voltage rating s must conform to the requirements of the National Electrical

Code and/or other applicable electrical codes.

Be sure to also follow the moto r wirin g instructions provided in the instruction manual for the VFD.

Control Wiring (for units with boards)

Connect control power to the MotorGuard. Be sure to provide fuses or other appropriate protection for

the control power wiring. Make sure that the voltage and VA capacity of the control power source

matches the MotorGuard's control power input ratings. Refer to the drawings shipped with the unit.

Connect the MotorGuard faul t output relay contacts to the appropr iate fault monitoring cir cuit. It may

be connected to the VFD or to some supervisory control or alarm annunciation equipment.

23

Page 24

MotorGuard Operation

Caution

Adjustments

Monitor Board Settings (for units with boards)

The monitor board configuration switches are factory set and should not be changed. The monitor

board component layout is shown in Figure 5 in the Maint enance and Service sec tion on a follo wing

page. Make sure that the configuration switches are set as follows:

♦ For 480 volt models: Set all sections of S1 to ON.

Alarm level dv/dt = 1000 V/μs.

Alarm level peak voltage = 1000 V

♦ For 600 volt models: Set all sections of S1 to OFF.

Alarm level dv/dt = 1500 V/μs.

Alarm level peak voltage = 1500 V

Variable Frequency Drive Settings

Make sure that the variable frequency drive is set for operation modes and ranges that are compatible

with the Mot orGuard:

♦ Maximum output frequency: 80 Hz

♦ PWM switching fre quency between 2 kHz and 12 kHz, ideally 4 kHz to 8 kHz. Since the

MotorGuard removes most of the harmonic content from the output waveform, quiet

motor operation should be achieved with a swit ching frequency setting within this range.

♦ Mode of operation: "scalar" or "V/Hz" without DC brak ing unless the drive applications has

been confirmed by TCI Technical Support

Caution

Start Up (Commissioning)

Thoroughly check the i nstallation before applying power and operating the equ ipment for the

first time.

Never Operate the MotorGuard without a load connected to its output terminals.

Before Applying Power for the Fir st Time

Inspect the installation to make sure that all equipment has been completely and correctly installed in

accordance with the Installation Guidelines section of this manual.

Before Operating the VFD for the First Ti me

♦ Make sure that the MotorGuard monitor board configuration switches are properly set as

described above.

♦ Make sure that the variable frequency drive is set for operation modes and ranges that are

compatible with the MotorGuard as described above.

Operation

Since the MotorGuard is a passive filter, it is always operating whenever the variable frequency drive

is operating. Whenever the VFD is operating, control power should be applied to the MotorGuard so

that the MotorGuard's cooling fan will opera te and prevent it from overheating. Control p ower is also

required for the performance mo nito r i ng a nd fa ult wa r nin g c ir cui t.

24

Page 25

Maintenance a nd Service

MotorGuard Reliability and Service Life

The MotorGuard has been designed to provide a service life that equals or exceeds the life of the

variable frequency drive. It has been thoroughly tested at the factory to ensure that it will perform

reliably from the moment it is put into service. T he follo wing per iod ic maintenance is recommended to

ensure that the MotorGuard will always perform reliably and provide the expected service life.

Periodic Maintenance

Warning

Only qualified electricians should carry out all electrical installation and maintenance work on

the MotorGuard.

Disconnect all sources of power to the VFD and MotorGuard before working on the equipment.

Do not attempt any work on a powered MotorGuard.

Check to see that the installation environment remains free from exposure to excessive dirt and

contamina nts. Refer to the Pre-installatio n P lanning section of this manual.

Check to make sure that the enclos ure ventilation openings are clean and unobstructed.

Clean the air filter in units that have filtered a ir inlets. Clean as o ften as necessary to preve nt dirt build-

up from impeding air flow.

Inspect the interior of the enclosure for signs of overheated components. Clean the interior of the

enclosure whenever excess dirt has accumulated.

Check the integrity of al l power, ground, and co ntr ol wiri n g co nnec ti o ns.

All electrical connections must be re-torqued annually.

For Units with Boards:

Check the status indica ting lights on the monitor board.

Check the o peration of t he cooling fan.

25

Page 26

Troubleshooting

fore working on the equipment.

J1 J2

J3 J4 J5

J6

(T1)J7(T2)J8(T3)

1 2 3 4

O

N

D1

S1

D9

Fault

Relay

K1

120 VAC

Motor Voltage

(480/600 VAC)

Fault LED

(yellow)

Control

Power

LED

(red)

Configuration

Switch

1 2 3

4

O

N

4 3

2 1

ON

Warning

Only qualified electricians should carry out all electrical installation and maintenance work on

the MotorGuard.

Disconnect all sources of power to the VFD and MotorGuard be

Do not attempt any work on a powered MotorGuard.

Monitor Board (for units with boards)

Figure 5 shows the component layout of the monitor board. The monitor board contains the fault alarm

relay and the status lights which are d escribed b elow.

Figure 5 – Monitor Board Component Lay out

Fault Alarm Relay

The fault alarm relay is energized when control power is applied to the MotorGuard and the output

waveform dv/dt and peak voltage are within specified limits. If the dv/dt or peak voltage limits are

exceeded, the fault relay is de-energized. A set of form C contacts are provided for customer use.

The fault relay contact may be connected to the VFD external fault input or other supervisory control

or alarm annunciation equipment. A MotorGuard fault alarm indicates that the MotorGuard is not

providing adequate dv/dt and peak voltage protection. If the drive operation continues during a fault

condition, the motor or other equipment may be damaged.

26

Page 27

Status Lights (for units with LED s)

During normal operation, both the green LED and the yellow LED are illuminated. The green LED

indicates that control po wer is applied to the monitor board. The yellow LED indicates that the fault

relay is energized.

If the green LED is not illuminated, p ossible causes include:

♦ The source of control power is shut off.

♦ A fuse or other protective device external to the MotorGuard has interrupted control

power. There may be a short circuit, ground fault, or overload condition in the

MotorGuard or in some other wiring or equipment connected to the same source of

control power.

♦ A primary or secondary control power transformer fuse has blown in the MotorGuard.

There is probably a short circuit, ground fault, or overload condition in the MotorGuard.

Check for evidence of damaged, burned, or overheated wiring or components.

♦ Check the followi ng items:

Control circuit wiring

Control circuit transformer

Cooling fan

Monitor board

If the yellow LED is not illuminated, the monitor board has detected o ne or more of the following

MotorGuard output fault conditions:

♦ The output waveform dv/dt exceeds the rated maximum (1,000 V/μs for 480 V units and

1500 V/μs for 600 V units).

♦ The output waveform peak voltage exceeds the selected maximum (1000 V for 480 V units

and 1500 V for 600 V units).

The following conditions can cause MotorGuard output faults:

♦ Bl own R -C power circuit fuses

If fuses are blown, check for damaged components or wiring in the R-C power circuit.

Check for discolored or burned components and deformed or leaking capacitors.

Damaged components can be caused by overheating – check fan. Components can also

be damaged if the VFD has been operating improperly or out of range for proper

MotorGuard performance.

♦ Damaged R-L-C power circuit components

Components can be damaged without blowing f us es. See above.

♦ VFD operating improperly or out of range for proper MotorGuard performance

♦ Problem with VFD or motor

♦ Loose power circuit wiring connections

27

Page 28

Fuses

8

2

8

2

12

2.5

10 2 16 4 12

2.5

23 6 20 5 30 8 25

6

35 9 28

7

45

12

35 9 55

15

45

12

65

20

55

15

80

20

65

20

110

30

80

25

130

35

110

30

160

40

130

35

200

50

160

40

250

70

200

50

305

80

250

70

362

90

305

80

420

110

362

90

480

125

420

110

600

150

500

125

750

200

600

150

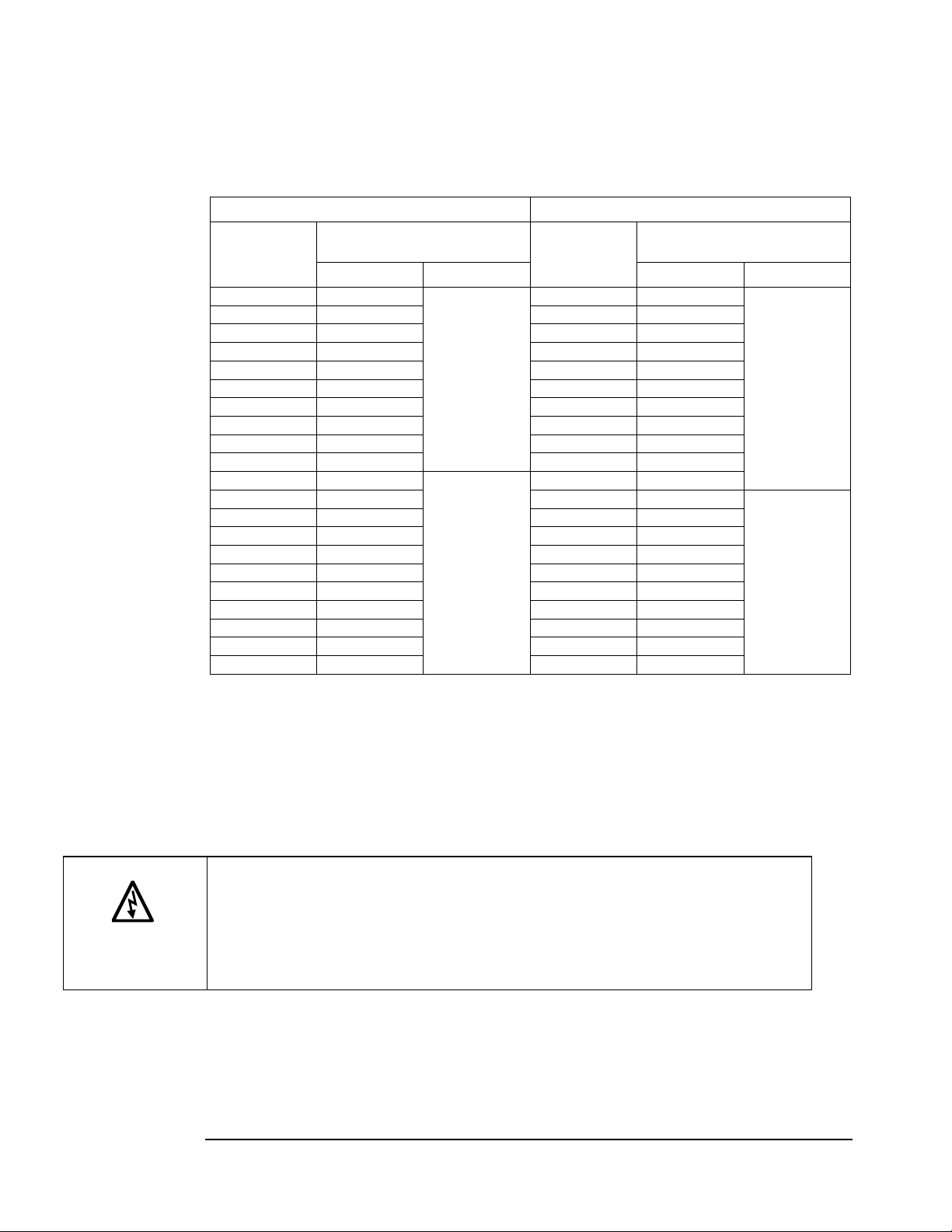

Table 12 lists the specifications for the RC po wer circuit fuses in the MotorGuard.

Table 12 – RC Power Circuit Fuses for Industrial Model

480 V Models 600 V Models

MotorGuard

Rating

(Amps)

Power Circuit

Fuse Rating

Amps Type Amps Type

MotorGuard

Rating

(Amps)

Power Circuit

Fuse Rating

Control Circuit Fuses

Refer to the drawings furnished with your MotorGuard for control circuit fuse specifications.

Evaluating MotorGuard Performance

The MotorGuard performance can be evaluated by checking the output voltage waveform with an

oscilloscope.

Class CC

Bussmann

type KLD-R

or equivalent

Class T

Bussmann

type JJS

or equivalent

Class CC

Bussmann

type KLD-R

or equivalent

Class T

Bussmann

type JJS

or equivalent

Warning

Only qualified electricians should carry out all electrical installation and maintenance work on

the MotorGuard.

Exercise ca ution when checking waveforms with an oscilloscope.

Use a dual probe, differential input set-up, or other means of isolating the scope chassis from

the motor voltage.

Disconnect power when attaching and removing the probes.

Typical VFD Waveforms without Filtering

Figure 6 shows two examples of output voltage waveforms for a typical PWM variable frequency

drive. The example labeled "VFD Output Voltage Waveform" is a "clean" waveform as it would

appear with no thing connec ted to the VFD output terminal s. The voltage peaks of this waveform are

about 650 volts for a 480 volt drive. The example labeled "Motor Voltage Waveform" shows the

28

Page 29

typical waveform at the terminals of a motor located a distance away from the VFD. This waveform

has voltage peaks of 1500 volts or higher due to the voltage spikes caused by the reflected wave

phenomenon.

Figure 6 VFD Output Voltage Waveform Motor Voltage Waveform

With Reflected Voltage Spikes

Filter Output Performance

Figure 7 s hows the voltage waveform at the output of the MotorGuard or at the terminals of a motor

connected to the MotorGuard.

Figure 7 Motor Voltage Waveform

Filter ed by the MotorGuard

Replacement Parts

If replacement parts are needed, please contact your TCI representative. To ensure that the

MotorGuard continues to perform to its original specifications, replacement parts should conform to

TCI specifications.

Factory Contacts and Tech Suppor t

For technical support, contact your lo c a l TCI distributor or sales representative.

You can contact TCI directly at 800-824-8282. Select "Customer Service" or "Technical Suppor t" and

have your MotorGuard nameplate information available.

29

Page 30

Drawings

Typical Isometric Drawings and Schematic Diagrams

Typical MotorGuard drawings are provided on the following pages. These drawings provide general

information describing your MotorGuard filter. More specific information is provided by the drawings

shipped wit h the unit. Be sure to ca refully review the information provided by these drawings. This

information takes precedence over the information provided in this manual.

Isometric Drawings

The isometric drawings provide three-dimensional representations of the MotorGuard units. Three

drawings are provided to cover units that are constructed on small, medium, and large size panels. The

rating and dimension tables list the dimensions for the various models. Two additional drawings are

provided to show the power wiring co nnection detail.

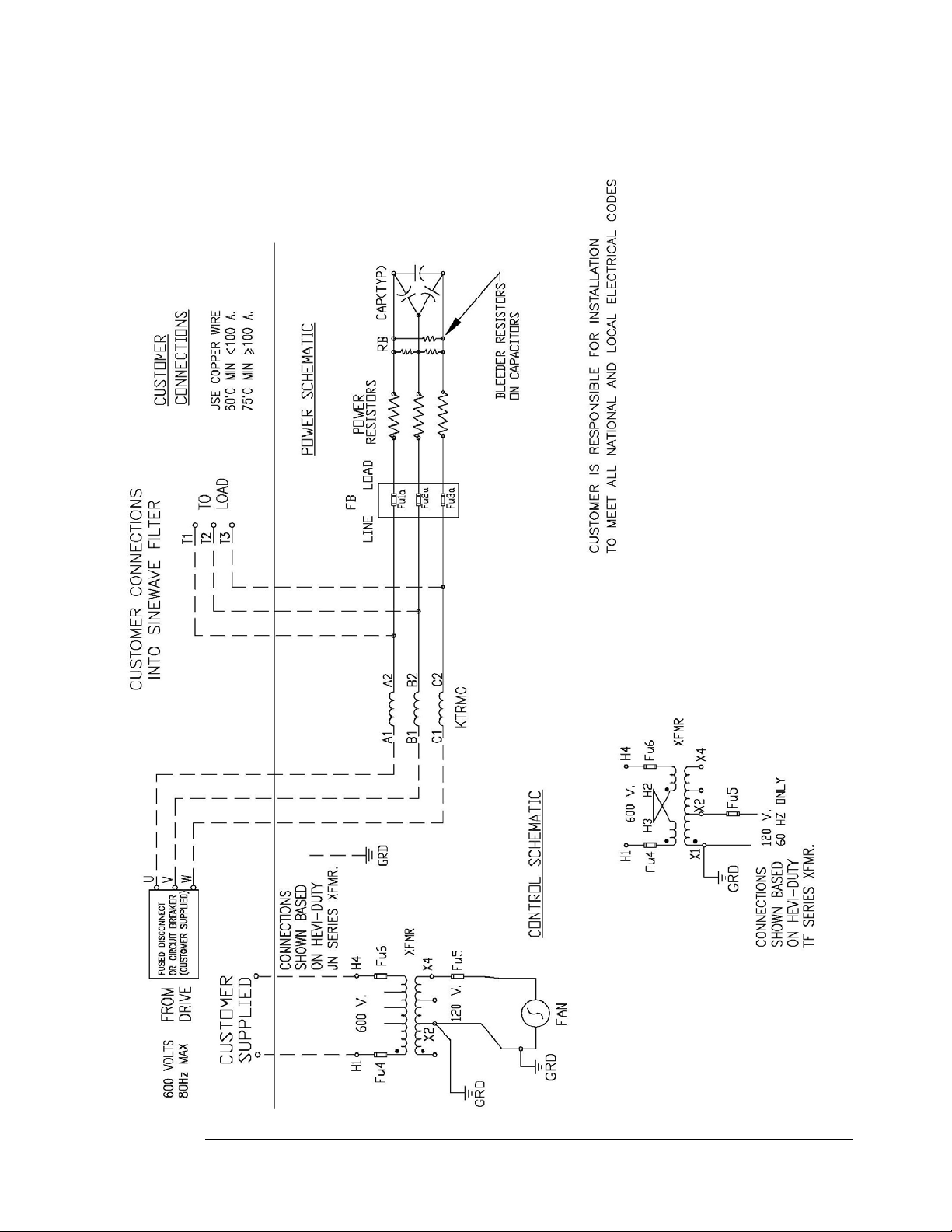

Schematic Diagrams

The schematic diagrams show the details of the MotorGuard circuitry. Two diagrams are provided.

The diagram for the smal l s iz e uni ts s hows the power block that is provided for input and output motor

power wirin g connections. The diagra m for the mediu m and large size units shows i nput and outp ut

motor power wiring connected to terminals on the 3-phase reactor.

30

Page 31

KMG – Capacitor connection may be WYE, consult factory

31

Page 32

KMG

32

Page 33

KMG with Board Option

33

Page 34

KMG with Board Option

34

Page 35

KMG GP NEMA 3R – Small enclosure

KMG GP NEMA 3R – Large enclosure

35

Page 36

KMG Industrial Filter Open – Small enclosure

36

Page 37

KMG Industrial Filter Open – Medium enclosure

37

Page 38

KMG Industrial Filter Open – Large enclosure

38

Page 39

KMG Industrial Filter Type 1 enclosure – Small enclosure

39

Page 40

KMG Industrial Filter Type 1 enclosure – Medium enclosure

40

Page 41

KMG Industrial Filter Type 1 enclosure – Large enclosure

41

Page 42

KMG Industrial Filter with Monitor Board Option (Shown in a small enclosure)

42

Page 43

43

Page 44

Publication No. 24362 Version 1.1 Effective 5/17/14

Printed in USA

TCI, LLC

W132 N10611 Grant Drive

Germantown, WI 53022

Phone: 414-357-4480

Fax: 414-357-4484

Helpline: 800-TCI-8282

Web Site: http://www.transcoi l. c om

44

Loading...

Loading...