Page 1

KLR™ Series

Three Phase Reactors

Applications

PRODUCTSPECIFICATIONS

• Lifetime Warranty

• Performance Guarantee

• K-Rated, UL/ULC-Recognized; CSA-Certified

• 3 Phase, 600V Class

• Gapped Iron Core Inductor

• All Copper Windings

• 40° C Ambient Temp.

• Available with Terminal Options and in NEMA 1

• High quality Bobbin Construction, units 80A and below

• Distributed Gap™ Technology, units 110A and above

• Can tolerate 200% rated l, for at least 3 minutes

• Universal Footprint

TCI KLR™ series three phase AC reactors are intended for use as input filters for

adjustable speed DC drives and as input or output filters for AC-PWM variable

frequency drives. Drive performance is significantly improved, the drives input

rectifier is protected from failure or damage, and drive harmonic demands are tamed

with the addition of a K-rated reactor. KLR reactors act as interface buffers between

solid state power circuits and the line or the motor. (Not unlike the surge protector for

your desk-top PC). All drives, in any application, will benefit when applied with

KLR series reactors.

Before KLR

After KLR

Drives are susceptible to problems caused at their interface to the line or motor.

Some of these issues include AC voltage waveform line notching or cross-talk, DC

bus overvoltage trips, inverter overcurrent and overvoltage, and poor total power

factor. Since all drives demand nonlinear current and voltage, drives demand currents

rich in harmonics.

KLR reactors provide additional circuit inductance which slows rapid changes in

current that are the heart of the problems listed above.

1.) Voltage line notching, or

commutation notching, is caused by

SCR phase-controlled rectifiers. KLR

reactors provide a voltage-dividing

impedance which reduces the depth and

rounds the edges of the notches, thereby

eliminating drive cross-talk, interference,

and equipment damage.

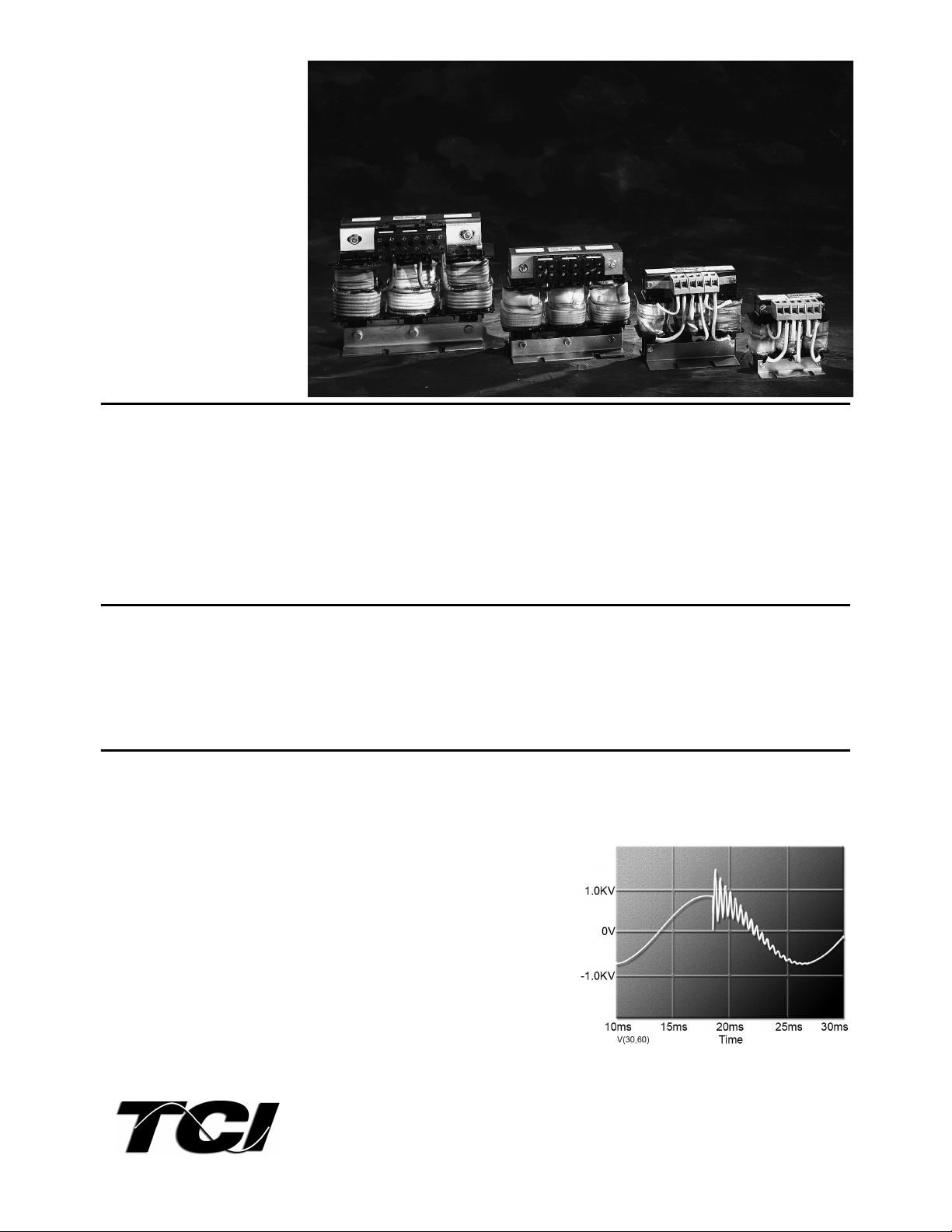

2.) Transient voltages (See Figure 1)

on the AC power lines can cause inrush

currents to an AC-PWM drive, resulting in

an overvoltage condition of the DC bus.

Figure 1

These transient voltage conditions are often caused by utility capacitor switching and

will cause VFDs to shut down without warning. The addition of a KLR reactor will

limit the magnitude of inrush current, preventing trips and component failures. (See

Figure 2.)

Page 2

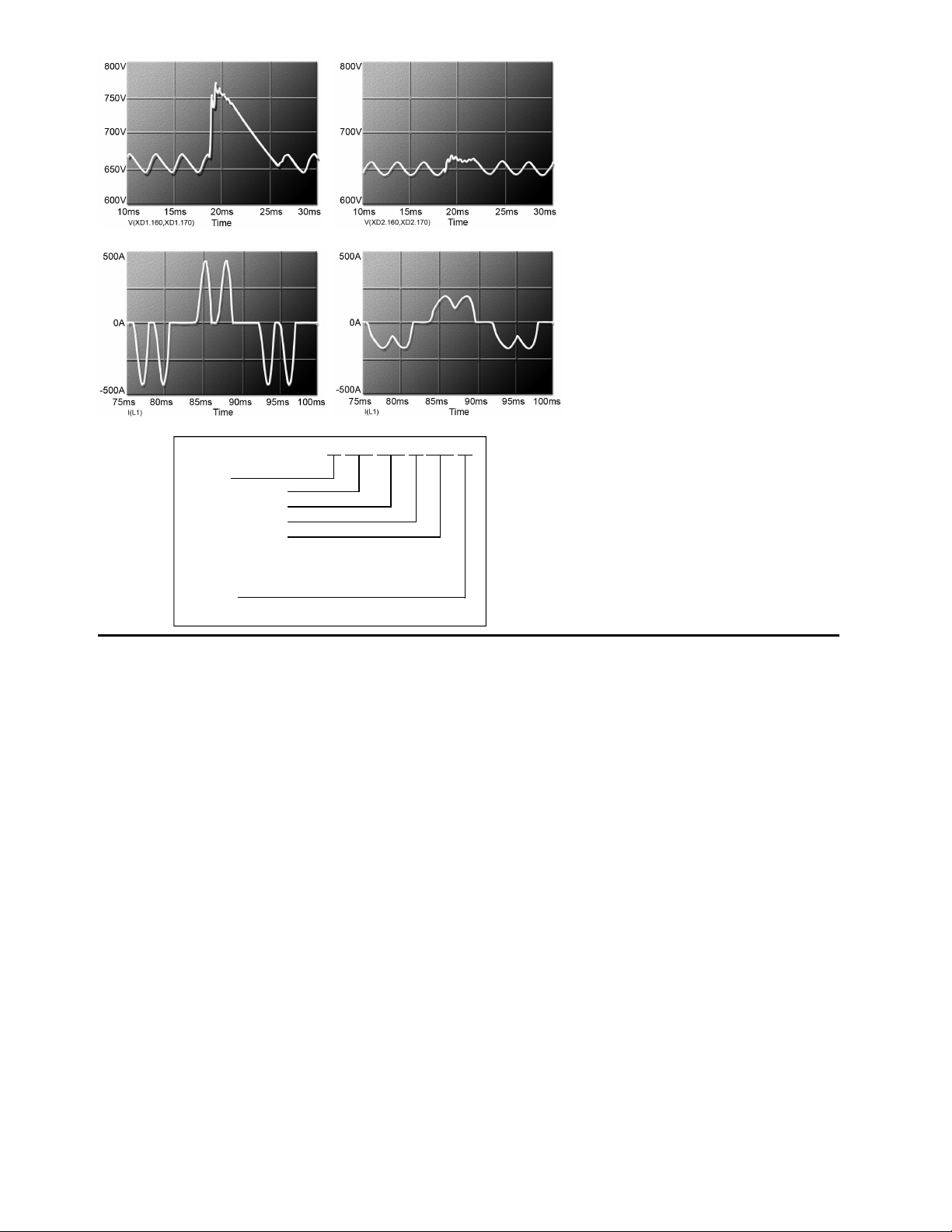

Figure 2

3.) When used as output filters, KLR

reactors prevent inverter instantaneous

overcurrent trips because they provide

needed inductance when the load on an

inverter has an abnormally high

capacitance. For example, if a single

inverter is powering multiple motors, the

load may look capacitive, causing inverter

shutdown.

4.) The addition of a KLR reactor limits

inrush current to the rectifier, rounding the

waveform, reducing peak currents, and

lowering harmonic current distortion.

High peak currents may cause “flattopping” of the voltage waveform.

Reducing those peak currents also reduces

total harmonic voltage distortion. (See

Figure 3.)

KLR

K- Series

Three Phase Reactors

Current Rating (amps)

Impedance Rating

Terminations:

TB: Terminal Block

CB: Copper Bus

PT: Pressure Terminal

Enclosure:

NEMA 1 Sizes: 1-5, 7

Application Instructions

Line reactors are current-rated devices. Therefore, in

order to apply one, you simply need to know the full

load AMPs of the drive with which it will be used and

the amount of impedance that is necessary in the

application. (See NEC Table 430.250 for HP Full Load

Currents.)

Recommendedimpedance levels:

• 2.4 to 3% eliminates bus overvoltage tripping.

• 5 to 6% protects against physical damage to most drive

components and offers harmonic reduction without

added capacitance.

• 1.5% is the recommended input minimum to protect the

drive and is the recommended maximum impedance

when the filter is used as an output device.

Figure 3

48 A B0 T

5.) The addition of a KLR reactor reduces

total RMS current without affecting the

work being done. Therefore, total power

factor is improved.

Universal Footprint/Termination Options

KLR reactors are available with a universal mounting

design. This makes installation much easier for large

distributors, systems integrators, and drive manufacturers

who have pre-drilled back panels or customers with predrilled back panels. Termination options make handling

and connection easier.

Drawings/Specifications

AutoCad compatible *.dxf drawings and Sample Bidding

Specifications of all KLR units are available at

www.transcoil.com or by calling (800) 824-8282.

Manufacturer’s Warranty

KLR reactors are warranted against manufacturer's defect

for the life of the drive they are installed with.

Distributed Gap™ Technology

As reactors and their required air-gaps get bigger, flux

fringing and eddy currents can cause heating and

insulation breakdown. TCI has addressed this issue in

larger KLR reactors by utilizing Distributed Gap™

technology - a construction technique that subdivides a

large gap into two or more smaller gaps. A KLR reactor

built with this technique will run cooler and last longer

than the competitions cheaper single gap products.

Performance Guarantee

Properly sized for the application, a KLR reactor is

guaranteed to end an AC Drive overvoltage tripping

problem. If you install a KLR reactor and a tripping

problem remains, TCI will take back the reactor and pay

shipping both ways. (Offer valid for 60 days from date of

purchase.)

The information contained in this brochure is subject to

update without notice.

Loading...

Loading...