Page 1

TCI’s New KDR Optimized Drive Reactors Deliver Superior Design

And Performance

Customers demand quality and performance at a price that translates to “optimum value”. TCI,

the drive industry’s leading provider of value added technology, is proud to introduce the KDR

Series of Optimized Drive Reactors. This is the latest addition to a family of reactor products with

a reputation for increasing the value and improving the system performance of power inverters.

This KDR product has been designed to provide the same

rugged reliability you’ve come to expect from TCI products

in the smallest, lightest product package currently available

in the market. Product models, covering the complete

range of impedance needs, are available for either the line

or load side of a PWM drive. Providing the optimum

selection for your application, TCI’s KDR Optimized Driv e

Reactors are your “Superior Design and Performance”

solution.

KDR Optimized Drive Reactors are warranted against

manufacturer’s defect for the life of the drive with which

they are installed.

Performance Guarantee

Properly sized for the application, a KDR reactor is

guaranteed to eliminate any AC drive o v ervoltage tripping

problems. If a KDR reactor is installed and the tripping

problem remains, TCI will take back the reactor and pay

shipping both ways . (Offer valid for 60 da ys from date of shipment.)

Drawings/Specifications

Autocad® compatible*.dxf drawings and Acrobat Reader® compatible*.pdf drawings of all KDR

Optimized Drive Reactors are available at www.transcoil.com or by contacting

TCI at (800) 824-8282.

UTILITY

KDR DRIVE MOTORKDR

KDR At The Input Of The Drive

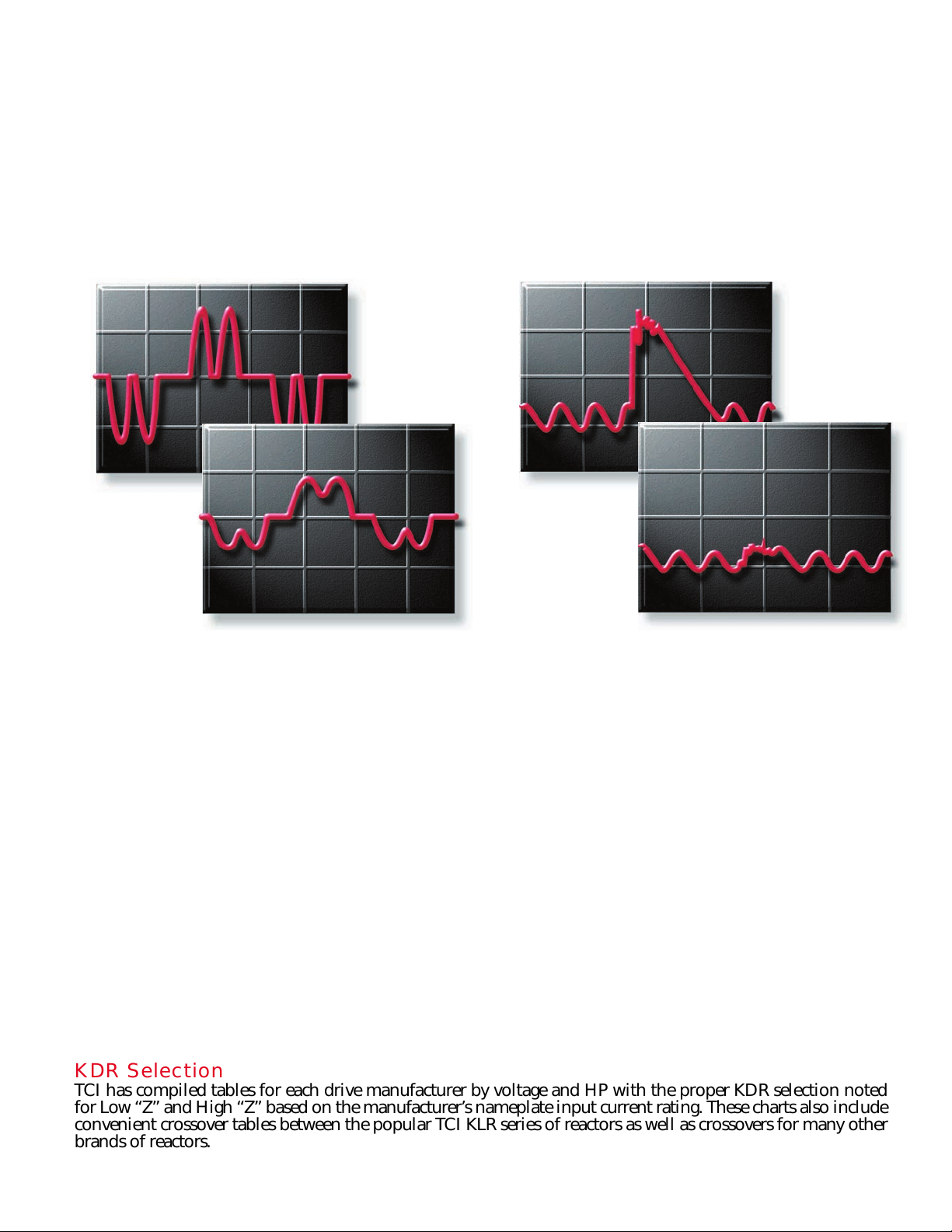

KDR Optimized Drive Reactors applied to the line side of a PWM drive will greatly improve the

overall performance of the drive. The additional circuit inductance will reduce AC voltage

waveform line notching, DC bus overvoltage trips, inverter overvoltage, poor total power factor,

and cross-talk.

Typical Problems, Superior Solutions With KDR Reactors:

KDR On The Input to DC Drives

• V oltage line notching, also kno wn as commutation notching, originates in SCR phase-controlled

rectifiers. As the transfer of current takes place, there is a brief period of time where two SCRs

connect during the switching process, causing a short between two of the AC lines. Additional

impedance will reduce the depth and rounds the edges of the notches. This will eliminate drive

cross-talk, interference, and equipment damage.

KDR On The Input to AC Drives

• Transient voltages, commonly caused by capacitor switching, or the switching of large load

blocks, can result in an overvoltage condition of the DC bus. This overvoltage condition will

cause the drive to shut down in order to protect its components. These transients can sometimes

be very severe and too quick for the drive to shut do wn. The addition of a KDR Optimized Drive

Reactor can prevent drive shutdown and even protect components from possible damage.

2

Page 2

• Input line distortion is caused by the non-linear characteristics of drives. The addition of a KDR Optimized

Drive Reactor will limit the inrush current to the rectifier, rounding the waveform, reducing the peak currents and

lowering the harmonic current distortion. High peak currents may cause distortion of the v oltage w a v eform. KDR’ s

reduction of those peak currents also reduces total harmonic voltage distortion at the point of common coupling.

• Drive input currents rich in harmonics result in a decrease in total input power factor to the drive. The addition

of a KDR Optimized Drive Reactor will reduce the RMS current through the reduction in harmonic content,

thereby improving the total power factor.

• Input voltage unbalance may prevent the drive from performing due to subsequent overcurrent conditions

which cause the drive to cease operating. Tests have prov en that the addition of a KDR Drive Reactor to the input

of every drive will help balance the drive input line currents.

500A

0A

-500A

80ms

75ms

Line

Current

0A

-500A

WITHOUT KDR

85ms

80ms

75ms

85ms 90ms 95ms 100ms

800V

750V

700V

WITH KDR

650V

600V

10ms 15ms

DC Bus

Voltage

WITHOUT KDR

WITH KDR

700V

650V

600V

10ms 15ms 20ms 25ms 30ms

Two Rating Levels, Two Choices, One “Optimized” Answer...the new KDR

Choose TCI’s new KDR Optimized Drive Reactors in two ratings versions, Low “Z” (low impedance) and High

“Z” (high impedance). Input impedance can significantly improve drive performance; however, it should be

noted that as impedance increases, the DC voltage on the VFD’s capacitors actually decreases. This decrease can

become significant enough to cause either an undervoltage trip or excessive motor current in the VFD. The KDR

Optimized Drive Reactors have been designed to provide the best protection for both your drive and your

application.

Use KDR Low “Z” Units For:

These units can be used in any applications where

traditionally either a 1.5% or 3% reactor would be

applied.

Reduction of nuisance tripping caused by:

• Transient voltages caused by capacitor switching

• Line notching

• DC bus overvoltage tripping

• Inverter overcurrent and overvoltage

Additional benefits include:

• Lowering injected percentage of harmonic current

• Improving true power factor

Use KDR High “Z” Units For:

These units can be used in any rugged application

where traditionally a 5% reactor would be applied.

KDR High “Z” offers the same superior benefits as

Low “Z” plus additional benefits which include:

• Helping prevent drive component damage

• Providing maximum harmonic mitigation without

adding capacitance

• Further improving true power factor

• Adding impedance to drives with or without DC

link chokes/reactors when more impedance is desired

due to a relatively stiff source.

• Reducing cross-talk between drives

KDR Selection

TCI has compiled tables for each drive manufacturer by voltage and HP with the proper KDR selection noted

for Low “Z” and High “Z” based on the manufacturer’s nameplate input current rating. These charts also include

convenient crossover tables between the popular TCI KLR series of reactors as well as crossovers for many other

brands of reactors.

3

Loading...

Loading...