Page 1

Harmonics & Power Quality

KDR Line Reactor

Variable frequency drives (VFD) are benecial to a wide

range of applications, but contain a power conversion

process that creates current and voltage distortion,

known as harmonics.

Issues caused by harmonics may include:

• Transformer and distribution equipment overheating

• Random breaker tripping

• Sensitive equipment failure

• Poor power factor

KDR Line Reactor

The KDR Line Reactor offers impedance against the ow

of harmonics and other high frequencies that can cause

tripping and equipment failure.

Drives and other sensitive devices are protected by the

KDR from electrical distortion on the line including

harmonics.

Advantages of the KDR Line Reactor

• Extend the life of the motor on the output of the VFD

• Protect other equipment on the line from

operational issues caused by voltage distortion

• Dramatically increase drive uptime by reducing the

likelihood of the drive tripping

• Improve power factor

• Reduce motor heating and audible noise

• Increase system productivity

• Meet IEEE 519-2014

Typical Applications

• Pulp & Paper

• Machining

• Wastewater Treatment Plants

• Oil & Gas

• HVAC Systems

• Irrigation Fields, Farms

• Extruders

• Steel Industry

Harmonic Current Distortion Without KDR

300

200

100

0

Amps

-100

-200

-300

0 403530252015105

Time (ms)

Harmonic Current Distortion With KDR

300

200

100

0

Amps

-100

-200

-300

0 403530252015105

Time (ms)

Warranty

Every TCI line reactor is manufactured in Wisconsin

with high quality materials and is backed by a lifetime

warranty.*

Transient Voltage Without KDR

800

750

700

650

Bus Volts

600

0.48 0.49 0.50 0.51 0.52 0.53 0.54

Time (ms)

Transient Voltage With KDR

800

750

700

650

Bus Volts

600

0.48 0.49 0.50 0.51 0.52 0.53 0.54

Time (ms)

Manufactured in

Germantown, Wisconsin

Page 2

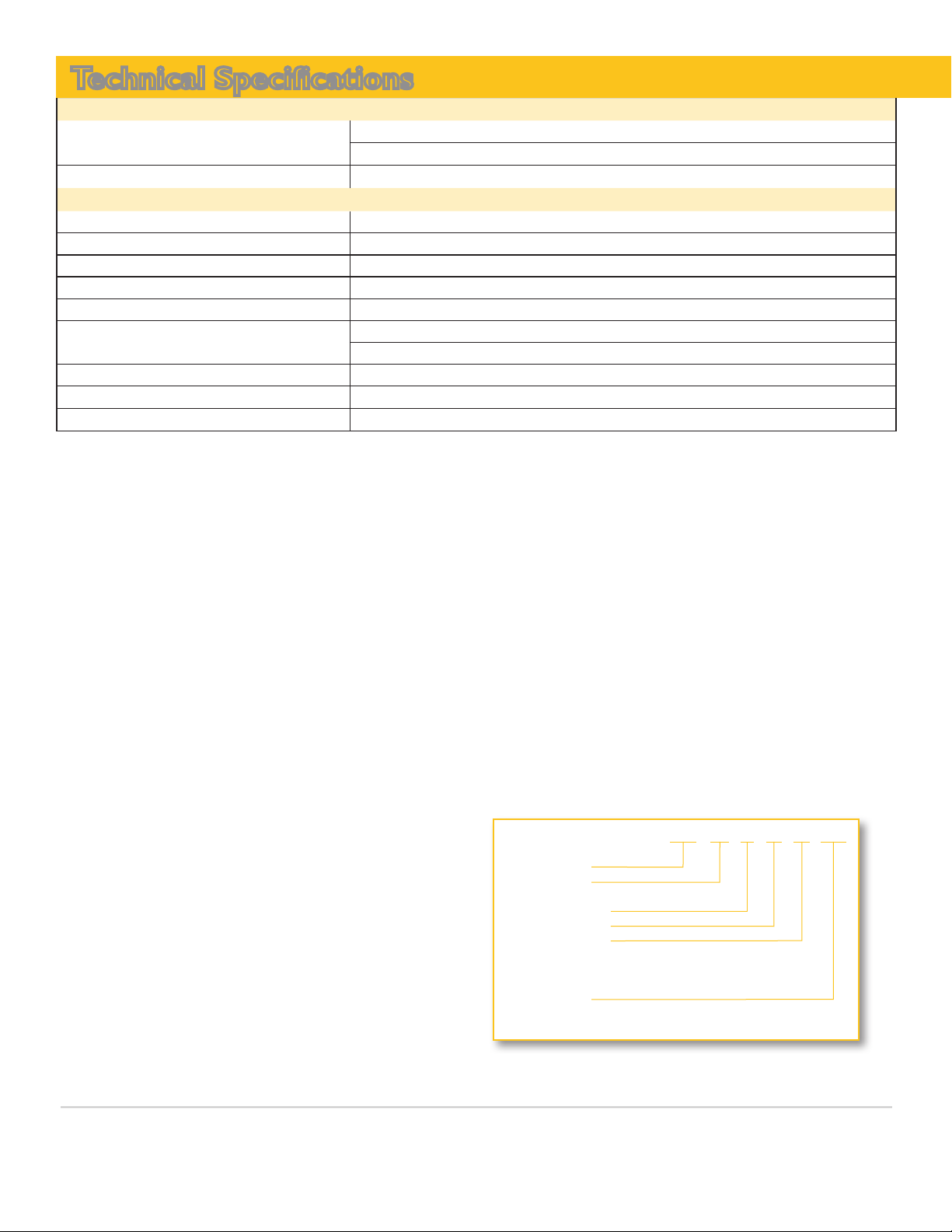

Technical Specications

Environmental Conditions

Operating Temperature

Operating Altitude 2,000 m (6,000 ft) Derating necessary above 2,000 m

Reference Technical Standards

Agency Approvals cUL, UL; UL Recognized, CE Marked

Fundamental Frequency 50/60 Hz

Impedance Protetion Low “Z” and High “Z”

System Voltage 208/240 VAC, 480 VAC, 575/600 VAC, 690 VAC

Short Term Overload Rating Tolerate 200% rated I for a minimum of 3 minutes

Inductance Characteristics

Input and Output Available for either the line or load side of a VFD

Protection (enclosure) Open, UL Type 1, UL Type 3R

DIN Rail version available See website for details

Impedance Options

KDR Line Reactors have been designed to provide the best protection for both your drive and your application.

KDR Optimized Drive Reactors are available in two ratings versions, Low “Z” (low impedance) and High “Z” (high

impedance). Input impedance can signicantly improve drive performance. Select impedance based on the guidelines

below:

Open: 50° C (122° F)

Enclosed: 40° C (104° F)

Minimum 95% L at 110% Load

Minimum 80% L at 150% Load

Use KDR Low “Z” Units For:

Any application where either a 1.5% or 3% reactor

would be applied.

Reduction of nuisance tripping caused by:

• Transient voltages caused by capacitor switching

• Line notching

• DC bus overvoltage tripping

• Inverter overcurrent and overvoltage

Additional benets include:

• Lowering injected percentage of harmonic current

• Improving true power factor

• Reducing cross-talk between drives

• Adding impedance to drives with DC link chokes/

reactors when more impedance is desired due

to a relatively stiff source

Performance Guarantee

Properly sized for the application, a KDR reactor is

guaranteed to eliminate any AC drive overvoltage

tripping problems. If a KDR reactor is installed and the

tripping problem remains, TCI will take back the reactor

and pay shipping both ways. (Offer valid for 60 days

from date of shipment.)

Use KDR High “Z” Units For:

Any application where a 5% reactor would be applied.

KDR High “Z” offers the same superior benets

as Low “Z” plus additional benets which include:

• Helping prevent drive component damage

• Providing maximum harmonic mitigation without

adding capacitance

Part Numbering System

KDR UL A 55 H E3R

KDR Series

UL Listed

(Blank if UL Recognized)

Design Frame

Sequence Code

Impedance Rating

L = Low Impedance

H = High Impedance

P = Output Reactor

Enclosure

E01 = UL Type 1

E3R = UL Type 3R

*For the life of the drive

Loading...

Loading...