Page 1

Active Harmonic Filter

Installation, Operation, and Maintenance Manual

TCI, LLC

W132 N10611 Grant Drive

Germantown, Wisconsin 53022

Phone: 414-357-4480

Fax: 414-357-4484

Helpline: 800-TCI-8282

Web Site: http://www.transcoi l. c om

© 2014

Page 2

No part of this publication may be re produced, stored in a retrieval system, or transmitted in any form

or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior

written permission of TCI, LLC. The information in this manual is subject to change without notice.

Every precaution has been taken in the preparation of this manual. TCI, LLC assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the

use of the information contained in thi s p ub lic a tion.

Page 3

T able of Contents

■ Section 1

HGA Quick Start Unit Software Setup.......................................................... 6

■ Section 2

Safety Instructions ...................................................................................... 11

Overview ............................................................................................................................................... 11

Warnings and Caution s ....................................................................................................................... 11

General Safety Instructions ................................................................................................................ 12

General Terminology ................................................................................... 13

■ Section 3

Introduction .................................................................................................. 14

Intended Audience ............................................................................................................................... 14

Additional Information ....................................................................................................................... 14

Installation Checklist ........................................................................................................................... 14

Receiving Inspection and Storage ............................................................. 15

Receiving Inspection ............................................................................................................................ 15

TCI Limited Warranty Policy ............................................................................................................ 15

Storage Instructions ............................................................................................................................. 15

Product Description .................................................................................... 16

Nameplate Data .................................................................................................................................... 18

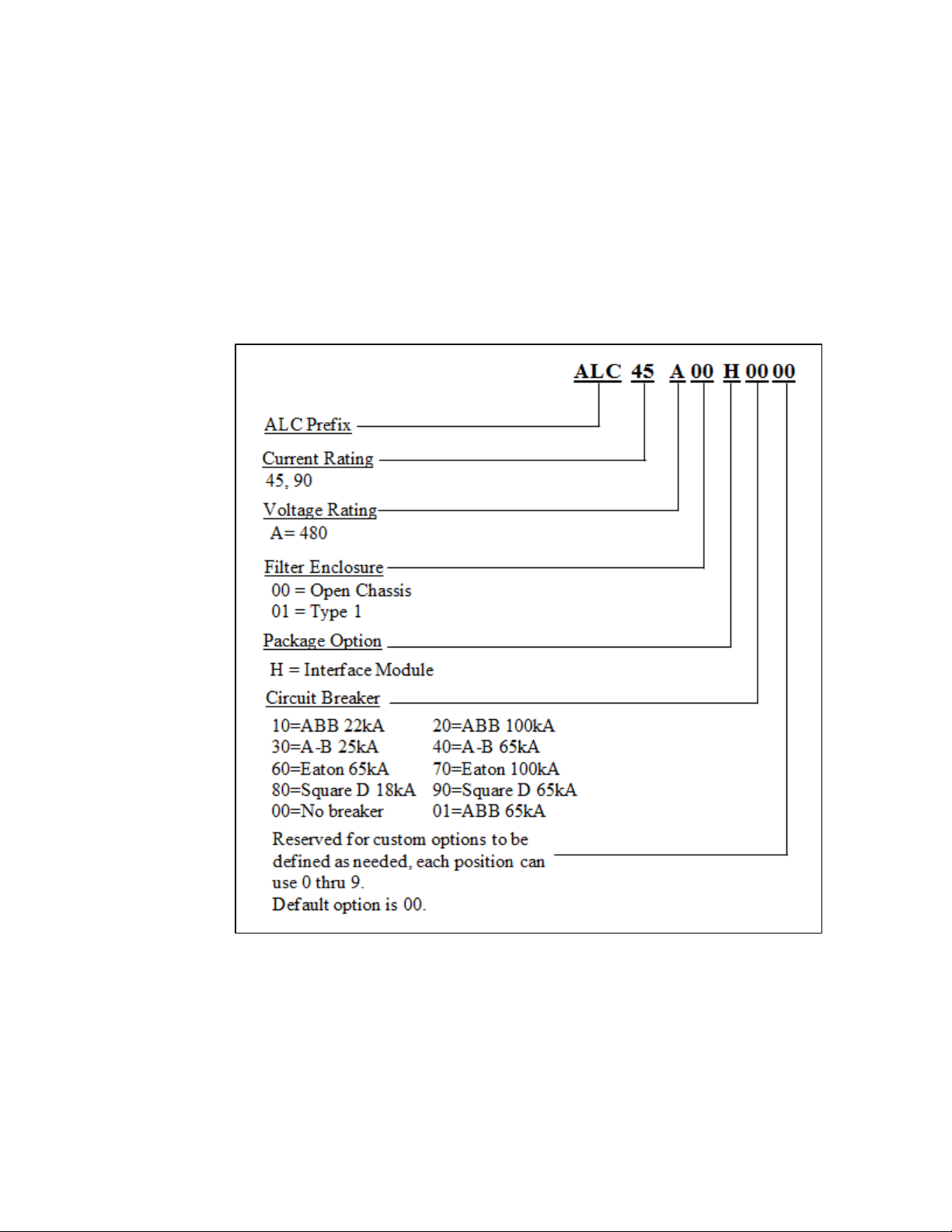

Part Number Encoding ....................................................................................................................... 19

■ Section 4

Pre-installation Planning ............................................................................. 26

Verify the Application ......................................................................................................................... 26

Select a Suitable Location ................................................................................................................... 26

Mounting an Open Chassis Unit ......................................................................................................... 26

Cooling Diagrams ................................................................................................................................ 26

Page 4

Installation Guidelines ................................................................................ 29

Mounting .............................................................................................................................................. 29

Wiring ................................................................................................................................................... 29

Current Transformer Installation ...................................................................................................... 31

HGA Filter Operation ......................................................................................................................... 45

Adjustments ......................................................................................................................................... 45

Start Up (Commissioning) ................................................................................................................... 45

General Operation ............................................................................................................................... 45

■ Section 5

Maintenance and Service ............................................................................ 46

HGA Reliability and Serv ic e Lif e ....................................................................................................... 46

Periodic Maintenance .......................................................................................................................... 46

Troubleshooting ................................................................................................................................... 51

■ Section 6

HMI Introduction .......................................................................................... 67

Overview ............................................................................................................................................... 67

Additional Information ....................................................................................................................... 68

Receiving Inspection ............................................................................................................................ 68

Installation Guidelines ................................................................................ 69

Checklist ............................................................................................................................................... 69

Location ................................................................................................................................................ 69

Mounting .............................................................................................................................................. 69

Wiring ................................................................................................................................................... 70

■ Section 7

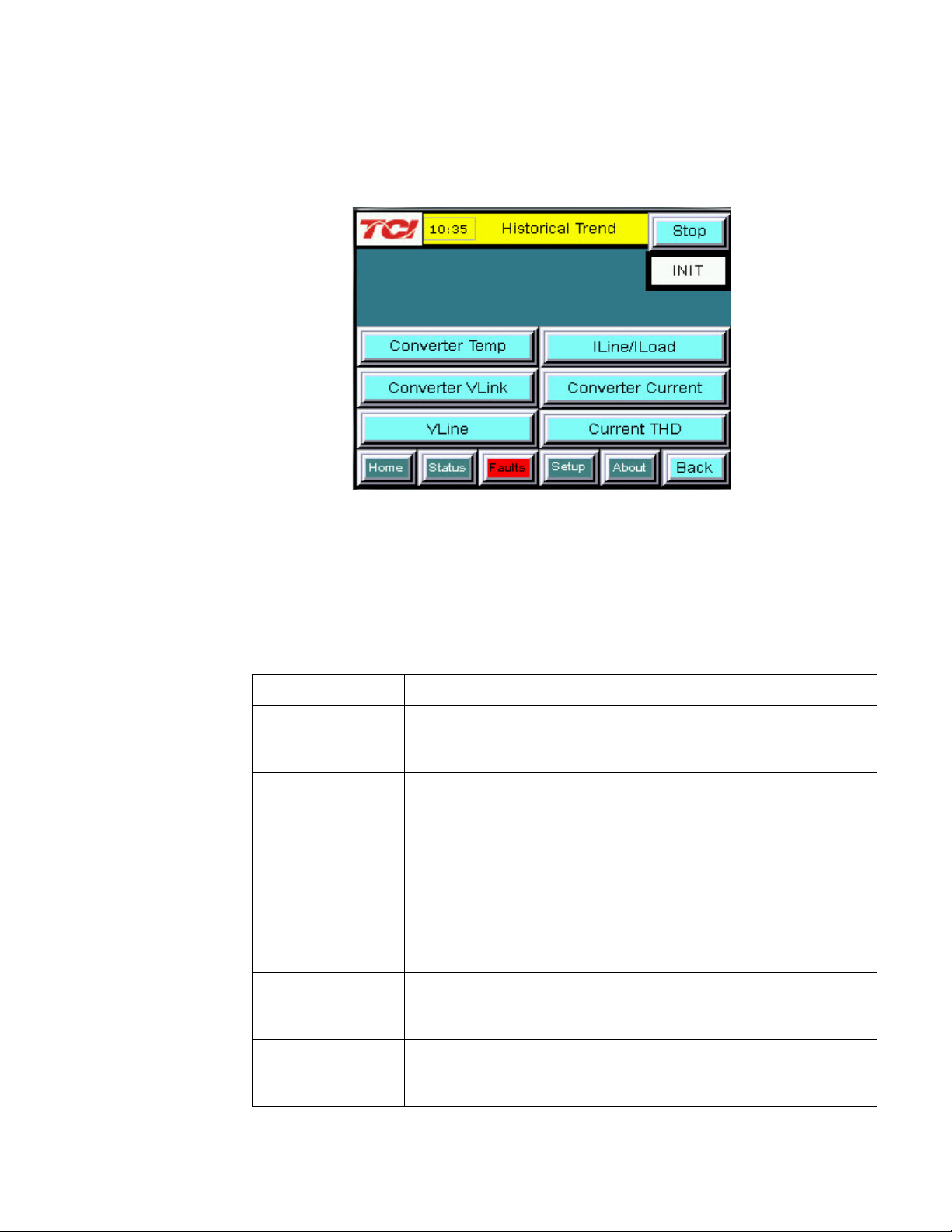

Operation ...................................................................................................... 74

HMI Screen Elements .......................................................................................................................... 75

Initialization ......................................................................................................................................... 76

HMI Screens ......................................................................................................................................... 76

Network Interface ................................................................................................................................ 94

Page 5

■ Section 8

Maintenance ................................................................................................. 96

Clock Battery Replacement ................................................................................................................ 97

Software Field Upgrades ..................................................................................................................... 97

Troubleshooting .......................................................................................... 97

HGA Filter Fault .................................................................................................................................. 98

Interface Module Problem .................................................................................................................. 98

Troubleshooting Notes ......................................................................................................................... 99

Troubleshooting Flow Chart ............................................................................................................... 99

■ Section 9

Appendix – Installation Diagram ................................................................ 99

Appendix – Part Numbering ..................................................................... 101

Appendix – Ethernet/IP Gateway Option ................................................. 101

Introduction ....................................................................................................................................... 101

Wiring ................................................................................................................................................. 101

Configuration ..................................................................................................................................... 102

Register Map ...................................................................................................................................... 103

Operation ............................................................................................................................................ 103

Page 6

!

!

!

■ Section 1

HGA Quick Start Unit Software Setup

Warning

Be sure to read, understand, and follow all safety instructions.

Warning

Warning

Warning

Warning

Warning

Warning

Only qualified electricians should carry out all electrical installation and maintenance work on the

HarmonicGuard Active (HGA) filter.

All wiring must be in accordance with the National Electrical Code (NEC) and/or any other codes that

apply to the installation site.

Disconnect all power before working on the equipment.

Do not attempt any work on a powered HGA filter.

The HGA filter, drive, motor, and other connected equipment must be properly grounded.

The HGA filter may receive power from two or more sources.

Three-phase power is connected to the main input terminals of the HGA filter.

All of these sources of power must be disconnected before working on the HGA filter.

After switching off the power, always allow 5 minutes for the capacitors in the HGA filter and in the

drive to di s charge before working on the HGA filter, the drive, the motor, or the connecting wiring. It

is good practice to check with a voltmeter to make sure that all sources of power have been

disconnected and that all capacitors have discharged before beginning work.

6

Page 7

Select language setting from the language setup

!

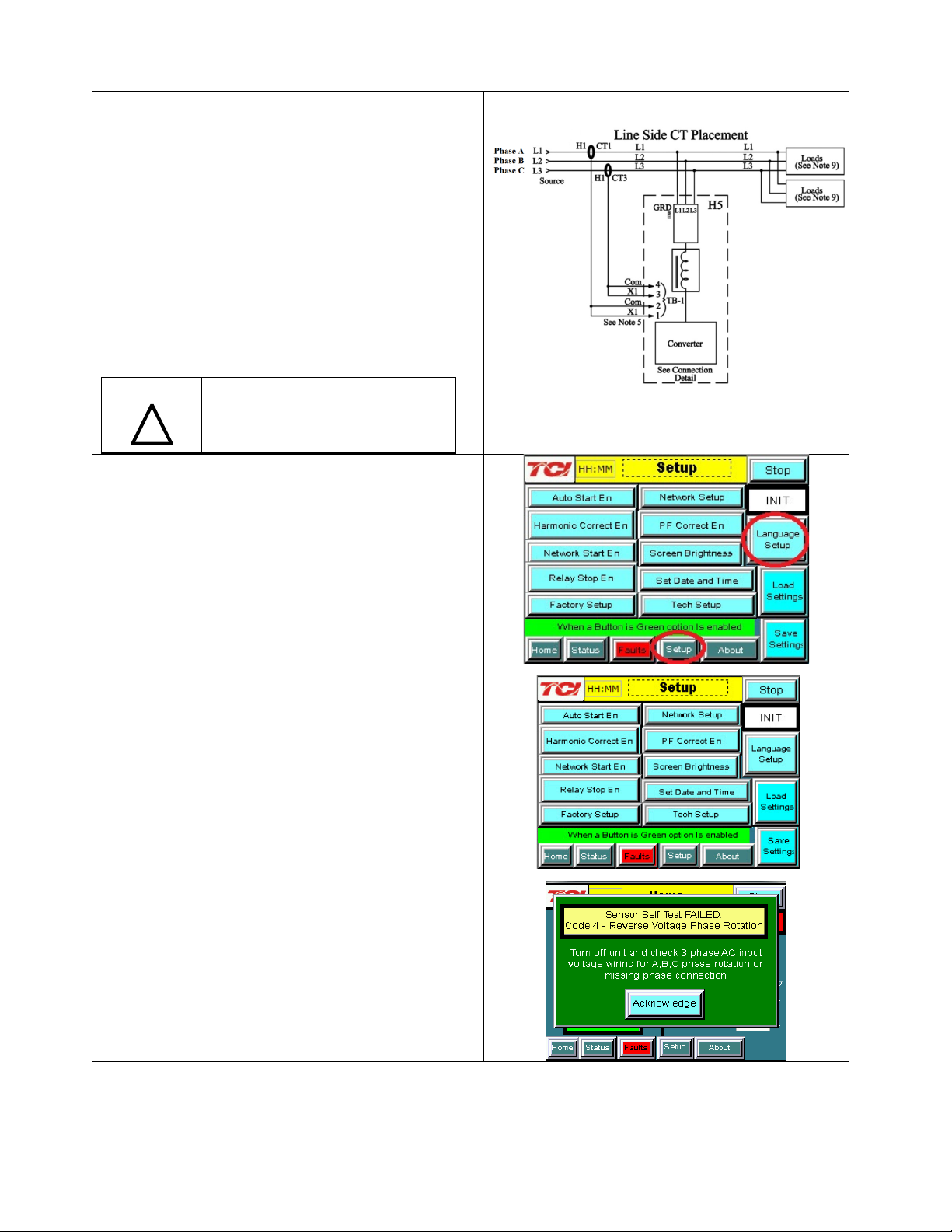

1) Verify unit external connections

• Phase A, B, C power connection,

with positive A-B-C phase rotation expected

• CT H1 Terminal is pointing toward the source

• CT feedback on phases A & C to TB-1

• Leave CT shorting bars in place o n TB-1

• With the HGA circuit breaker open,

energize the source to the HGA

• Close the HGA circuit breaker

• Fans and HMI should come on in < 5 seconds

• HMI will start on Home screen

• Load(s) have an integral 5% line reactance or

equivalent dc bus choke

Warning

Hazardous voltages are present when

unit is ener gi zed

NOTE: Language Selection

• The active filter supports several languages

including English, French and S panish

• Press “Setup” to navigate to Setup screen and

press the “Language Setup” button.

•

pop-up screen.

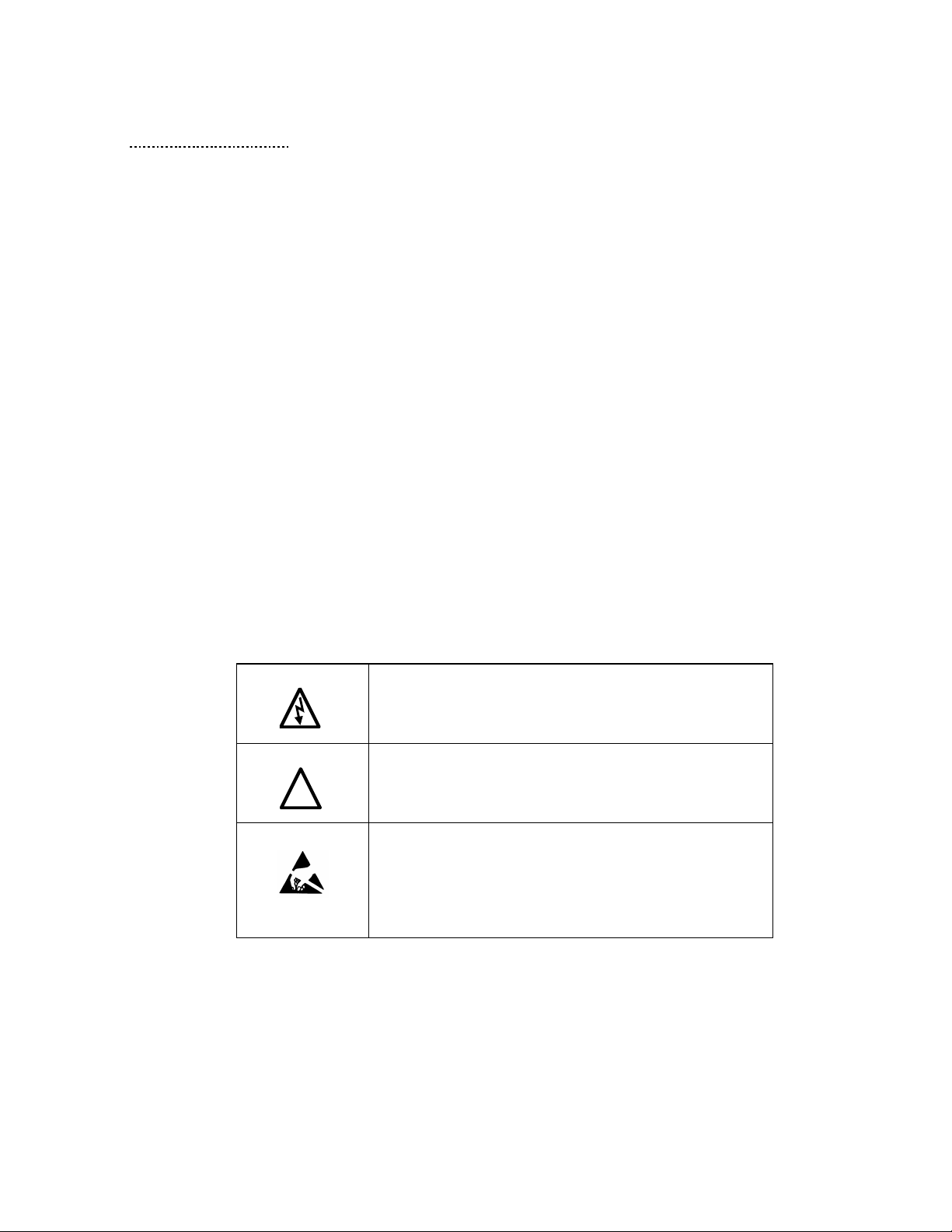

2) Converter check - 1

• Press “Setup” to navigate to Setup screen

• Ensure that “Auto Start En,” “Harmonic

Correct En,” and “PWR Fact Correct En”

buttons are off (blue color)

• If they are ON (green) press them to toggle to OFF

(blue)

• Press “Save Settings”

• Press “Status” to navigate to Status screen

• Press “Home” to navigate to Home screen

NOTE: Built In Sensor Wiring Error De tection

• The active filter has an automatic sensor wiring

error detection algorithm built in to the controls.

• If a sensor wiring error is detected please reference

the Sensor Error Auto Detection sectio n on page

93.

7

Page 8

Warning

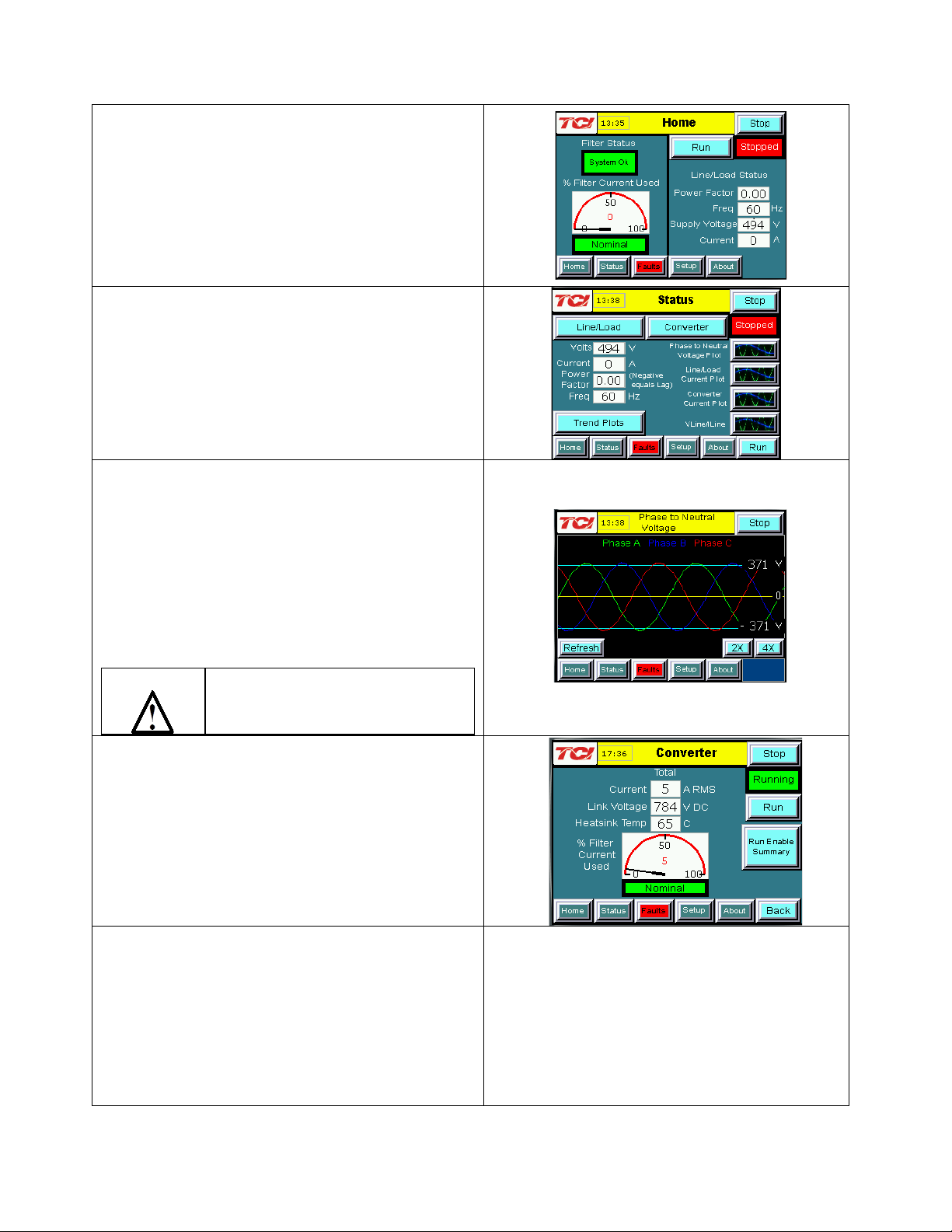

3) Home screen check

• Compare “Freq” to expected line frequency

• Compare “Supply Voltage” to expected

line voltage

• “Current” expected to be zero because unit is not

running and CT inputs ar e shorted

• If status indicates a Fault, press “Stop” button to

reset condition

4) Status screen check

• Press “Status” to navigate to Status screen

• Compare “Volts” to expected line voltage

• Compare “Freq” to expected line frequency

• “Current” expected to be zero if unit is not running

and CT inputs are shorted

5) Phase rotation check

• Press “Phase to Neutral Voltage Plot”

• Check that the current p eaks follow the follo wing

sequence from left to right: Phase A (green), Phase

B (blue), Phase C (red)

• Equipment is phase rotation sensit ive, if phase

rotation is incorrect, power down unit and rewire

to adjust pha s e rotation by swapping two inco ming

phase connections

Improper operation will occur when input

voltage phase rotation is incorrec t.

6) Converter check - 2

• Press “Setup” to navigate to Setup screen

• Ensure that “Auto Start En,” “Harmonic

Correct En,” and “PWR Fact Correct En”

buttons are off (blue color)

• Press “Status” to navigate to Status screen

• Press “Run” to start unit operation

8

Page 9

from CTs connected to TB-1

Warning

7) Remove CT shorting bars

• Press “Stop” to turn off unit

• Disconnect power from cabinet

o Turn off the built in door breaker A ND

o Turn off the upstream feeder breaker

Lethal voltages may be present. Wait 5

minutes for DC bus voltage to drop to

safe levels.

Warning

Check for vol t age in cabinet with a

DMM before working inside cabinet.

• Open the cabinet door and remove shorting bars

8) Current polarity - 1

• Power up unit

• From Home screen press “Run” to turn on unit

• Press “Status” to navigate to Status screen

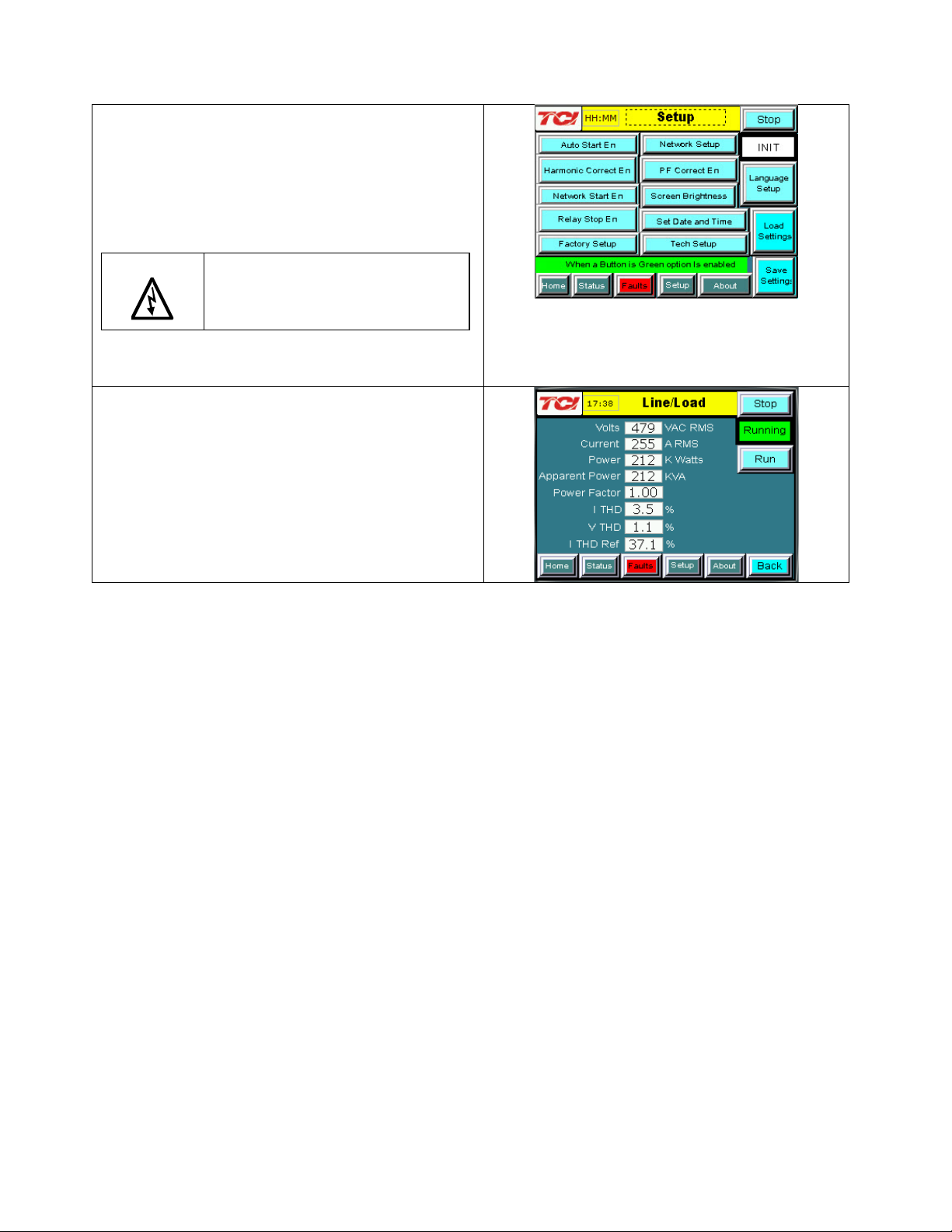

• Select “Vline/Iline” screen

• Note: Lightly loaded conditions (less than 20% CT

rating) wil l not have enough current to

show up on Iline plot

• Check that Phase A to Neutral voltage peak lines

up with Phas e A current (use zoom if necessary)

• Check that Phase C to Neutral voltage peak lines

up with Phas e C current

• Power system down and check CT inst allation

location and orientation if Phase A plots differ

significantly from Phase C plots

Warning

Improper operation and damage may

occur if CTs are installed incor r e c tly.

9) Current Polarity – 2

• Navigate to Status screen

• Navigate to Line/Load status

• Verify that “Volts,” “Current,” “Power,” “I THD,"

and “V THD” match expected values for the

power system

• If they do not, verify CTs are corr e c tly insta lle d

Warning

Improper operation and damage may

occur if CTs are installed incor r e c tly.

9

Page 10

Warning

• Let the unit come on automatically (about 30 s)

10) Final setup

• Press “Setup” to navigate to Setup screen

• Press “Harmonic Correct En” to enable

harmonic correction

• If unit is sized with sufficient cap a c ity to provide

power factor correction, press “PF Correct En”

• Press “Auto Start En” to enable Autostart

When Auto Start is enable d unit may

operate without operator input.

• Press “Save Settings” to save settings

and restart converter

11) Final check

• Navigate to Status screen

• Navigate to Line/Load status

• Note the corrected voltage, current, power

and THD

10

Page 11

!

■ Section 2

Safety Instructions

Overview

This section provides the safety instructions which must b e followed when installing, oper ating, and

servicing t he HarmonicGuard Active (HGA) filter. If negle cted, phys ical injur y or death ma y follow,

or damage may occur to the HGA filter or equipment connected to the HGA filter. The material in this

chapter must be read and understood before attempting any work on or with the product.

The HGA filter is intended to be connected to the bus or power cables where one or more loads are

connected. Three-phase power is connected to the input terminals of the unit and corrective current is

supplied to the system through the HGA filter in respo nse to the i nput signal being received from the

CTs connect ed to the moni tored bus. T he instructio ns, and pa rticularly t he safety ins tructions, fo r the

drives, motors, and any other related equipment must be read, understood, and followed when working

on any of the equipment.

Warnings and Cautions

This manual provides two types of safety instructions. Warnings are used to call attention to

instructions, which describe steps, which must be taken to avoid conditions, which can lead to a

serious fault condition, physical injury, or death.

Cautions are used to call attention to instructions that describe steps that must be taken to avoid

conditions that can lead to a malfunction and possible equipment damage.

Warnings

Readers are informed of situations that can result in serious physical injury and/or serious damage to

equipment wit h war ni n g stat e men t s mar ked wit h the fo ll o wi ng s ymb o ls:

Warning

Warning

Warning

Dangerous Voltage Wa rning: warns of situations in whic h a

high voltage can cause physical injury and/or damage

equipment. The text ne xt to this symbol describes ways to

avoid the danger.

General Warning: warns of situations that can cause physical

injury and/ or damage equipment by means othe r than

electrical. The text next to this symbol describes ways to avoid

the danger.

Many electronic components located within the filter are

sensitive to static electricity. Voltages imperceptible to human

touch can reduce the life, and affect performance, or

completely destroy sensitive electronic devices. Use proper

electrostatic discharge (ESD) procedur es when servic ing the

filter and its circuit boards.

11

Page 12

Warning

Warning

!

!

!

!

Cautions

Readers are informed of situations that can lead to a malfunction and possible equipment damage with

caution statements:

Caution

Warning

Warning

Warning

General Caution: Identifies situations that can lead to a malfunction and possible equipment damage.

The text describes ways to avo id the situation.

General S afety Ins truct ions

These safety instructions are intended for all work on the HGA filter. Additional safety instructions are

provided at appropriate points on other sections of this manual.

Be sure to read, understand, and follow all safety instructions.

Only qualified electricians should carry out all electrical installation and maintenance work on the

HGA filter.

All wiring must be in accordance with the National Electrical Code (NEC) and/or any other codes that

apply to the installation site.

Disconnect all power before working on the equipment.

Do not attempt any work on a powered HGA filter.

Warning

Warning

The HGA filter drive, motor, and other connected equipment must be properly grounded.

The HGA filter may receive power from two or more sources.

Three-phase power is connected to the main input terminals of the HGA filter.

All of these sources of power must be disconnected before working on the HGA filter.

After switching off the power, always allow 5 minutes for the capacitors in the HGA filter and in the

drive to di s charge before working on the HGA filter, the drive, the motor, or the connecting wiring. It

is good practice to check with a voltmeter to make sure that all sources of power have been

disconnected and that all capacitors have discharged before begin ni ng wor k.

12

Page 13

General T erminology

Throughou t this manual, many d ifferent terms are used. A list of so me typical terms ca n be found

below. These are provided in order to assist with the overall understanding of the manual. Please feel

free to contact TCI directly if there are any questions regarding any portion of this manual.

HarmonicGuard Active Filter - TCI’s brand name for a real ti me filter that mitigates harmonic s while

also maintaining near unity power factor. An Active Har monic Filter is any piece of equipment that

actively moni to rs and chan ges the incoming AC line current.

HGA – The term commonly used in place of the entire brand name of HarmonicGuard Active filter.

Active Harmonic Filter - An active harmonic filter is a piece of equipment that reads the incoming

voltage and curre nt and i nje cts curr ent wavefor ms tha t canc el di storti on. T his ter m is co mmonl y used

in place of the entire brand name of HarmonicGuard Active filter.

Bus-Applied Filter – A shunt device connected in parallel to the load. This is an active filter designed

to mitigate the harmonics associa ted with multiple load s. The filter is dir ectly co nnected to a main bus

as can be found in a typical Motor Control Center. The filter is sized for the amount of corrective

current needed to be injected to cancel the offending harmonics. A Digital Signal Processor (DSP)

pulse width modulated controller is used for switching Insulated Gate Bip olar Transistor (IGBT) in

order to cancel the harmonic s .

Power Converter - The power converter is the digital filter module of the HarmonicGuard Active filter.

Non-Linear Load Input Line Inductor – The three phase line reactor connected at the input of an

adjustable frequency drive or other non-linear load.

Converter Inductor – The three phase inductor maintains a unifor m air gap to give high ly consistent

and predictable inductance. These inductors are connected to the inverter which buffers the inverter

output from the analog portion o f the filter , the source, and connected drives.

Current Transfor mer (CT) – The device that monitors t he incoming AC curre nt waveform typicall y

sized to handle the total connected load.

13

Page 14

o

o

o

o

o

o

o

o

!

■ Section 3

Introduction

Thank you fo r selecting TCI’s HarmonicGuard Active filter. TCI has produced this filter for use in

variable speed drive and non-linear load applications that require input power line harmonic current

reduction and power factor correction. This manual describes how to install, operate, and maintain the

HarmonicGuard Active filter.

Intended Audience

This manual is intended for use by all personnel responsible for the installation, operation, and

maintenance of the HarmonicGuard Active filter . Such personnel are expected to have knowledge of

electrical wiring practices, electronic components, and electrical schematic symbols.

Additiona l Infor mation

Caution

This manual pro vid es gene ra l i nfo r mati o n desc ri b i ng yo ur H GA filter. Be sure to carefully review the

more specific information that is provided by the drawings shipped with the unit. Information

provided by the drawings takes precedence over the information provided in this manual.

The ratings, dimensions, and weights given in this manual are approximate and s hould not be used for

any purpose requiring exact data. Contact the factory in situations where certified data is required. All

data is subject to change without notice.

Installation Checklist

The following are the key points to be followed for a successful installation. These points are

explained in detail in the following sections of this manual.

Make sure that the installation location will not be exposed to direct sunlight, excessive

vibration, corrosive or combus tible airborne contaminants, excessive d ir t, or liquids.

Select a mounting area that will allow adequate cooling air and maintenance access.

Make sure that all wiring conforms to the requirements of the National Electric Code

(NEC) and/or other applicable electrical codes.

Connect the HGA filter equipment-grounding lug to the system ground of t he premises

wiring system. Use a properly sized grounding conductor.

Connect three-phase power to the input terminals o f the HGA filter, L1, L2, & L3.

Ensure that the CTs are properly installed and connected to the proper terminals inside

the HGA filter (see CT Installation section of IOM Manual).

Check ever ything thor oughly before appl yi ng power to t he equipment.

Check the panel and the inside of the enclosure for any foreign objects, dirt, or

loose hardware.

14

Page 15

Receivi ng Inspection and Storage

Receiving Inspection

The HarmonicGuard Active filter ha s been thoro ughly i nspecte d and fu nctiona lly te sted at the fac tory

and carefully packaged for shipment. When you receive the unit, you should immediately inspect the

shipping container and report any damage to the carrier that delivered the unit. Verify that the part

number of the unit you received is the same as the part number listed on your purchase order.

TCI Limited Warranty Policy

TCI, LLC (“TCI”) warrants to the original purchaser only that its products will be free from defects in

materials and workmanship under normal use and service for a period originating on the date of

shipment from TCI and expiring after one (1) year of useful service, not to exceed eighteen (18)

months from the date of shipment.

The foregoing limited warranty is TCI’s sole warranty with respect to its products and TCI makes no

other warranty, representation or promise as to the quality or performance of TCI’s products. THIS

EXPRESS LIMITED WARRANTY IS GIVEN IN LIEU OF AND EXCLUDES ANY AND ALL

EXPRESSED OR IMPLIED WARRANTIES INCLUDING, WITHOUT LIMITATION, ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE.

This warranty shall not apply if the product wa s :

a) Altered or repaired by anyone other than TCI;

b) Applied or used for situations other than those originally specified; or

c) Subjected to negligence, accident, or damage by circumstances beyond TCI’s control,

including but not limited to, imprope r storage, installation, operation or maintenance.

If, within the warranty period, any product shall be found in TCI’s reasonable judgment to be

defective, TCI’s liability and the Buyer’s exclusive remedy under this warranty is expressly limited, at

TCI’s option, to (i) repair or replacement of that product, or (ii) return of the product and refund of the

purchase price. Such remedy shall be Buyer’s sole and exclusive remedy. TCI SHALL NOT, IN ANY

EVENT, BE LIABLE FOR INCIDENTAL DAMAGES OR FOR CONSEQUENTIAL DAMAGES

INCLUDING, BUT NOT LIMITED TO, LOSS OF INCOME, LOSS OF TIME, LOST SALES,

INJURY TO PERSONAL PROPERTY, LIABILITY BUYER INCURS WIT H RESPECT TO ANY

OTHER PERSON, LOSS OF USE OF THE PRODUCT OR FOR ANY OTHER TYPE OR FORM

OF CONSEQUENTIAL DAMAGE OR ECONOMIC LOSS.

The foregoing warranties do not cover reimbursement for removal, transportation, reinstallation, or any

other expenses that may be incurred in connection with the repair or replacement of the TCI product.

The employees and sales agents of TCI are not authorized to make additional warranties about TCI’s

products. TCI’s employees and sales agents oral statements do not c onstitute warranties, shall not be

relied upon by the Buyer and are not part of any contract for sale. All warranties of TCI embodied in

this writing and no other warranties are given beyond those set fo rth herein.

TCI will not accept the return of any prod uct without its prior written approval. Please co nsult TCI

Customer Service for instructions on the Return Authorization Procedure.

Storage Instructions

If the HarmonicGuar d Active filter is to be stored before use , be sure that it is stored in a location that

conforms to published s torage h umidity a nd temperat ure sp ecificatio ns stated in this manual. Sto re the

unit in its original pac kaging.

Long-Term Storage

In the case of long-term storage, defined as any period greater than eighteen (18) months, TCI

Technical Support must be contacted prior to applying power.

15

Page 16

Product Descript ion

HarmonicGuard Active filter

The HarmonicGuard Active filter is an active harmonic filter designed and developed by TCI to relieve

the power distribution system o f the issues associated with harmonic currents that flow within the

power distribution network caused by non-linear loads. The typical configuration can be found in

Figure 3.1.

The topology of the bus-applied (three phase, three wire) HGA consists of major components or

modules:

Component 1 is mad e up of two current transformers (CTs) installed on phases A and C of the AC bus

that is to be acted upon by the filter. The purpose of the CTs are to supply information to the HGA

regarding t he integrity of the composite AC bus c urrent with rega rd to the distor tion (non-sinusoidal

waveform) and displacement power factor relative to the AC bus voltage. These signals will result in

the HGA inje cting currents th at will return the AC line current to near sinusoidal s hape and at unit y

power factor. Note that the CTs are located outside the HGA enclosure.

Component 2 is the HGA input circuit breaker (optional) . This is provided to protect the HGA for

destructi ve ove r cur rent c ond itio ns if a malfu nctio n oc curs withi n the HGA circ uitry. It also p rovides a

convenient disconnect means and field wiring point for the installer of the filter equipment.

Components 3 and 4 are the high freq uency co nverter i nductors . These i nductors provid e the prop er

inductance to the power converter.

Component 5 is the power electronic converter module. The Power converter module (PCM) is the

heart of the HarmonicGuard Active filter and is what differentiates the HGA from other types of

harmonic mitigation. The PCM provides several highly complex electronic functions controlled by the

on board DSP controller. The PCM continuously senses the AC bus line voltage and currents,

processes the information at “nearly real time” by means of the instructions resident within the DSP

program code, properly controls the six IGBT’s to operate in a safe manner that injects current into the

AC bus grid that ensures the AC bus current is sinusoidal and near unity power factor. Power converter

contains a pre-charge circuit which consists of two SCRS and two pre-charging resistances which

control the inrush current.

16

Page 17

Filter Configuration

Figure 3.1 – Typi cal Configur ation of the HarmonicGuard Active filter

*This drawing is for gene ral reference only. Us e the drawings supplied with the unit for inst allation.

17

Page 18

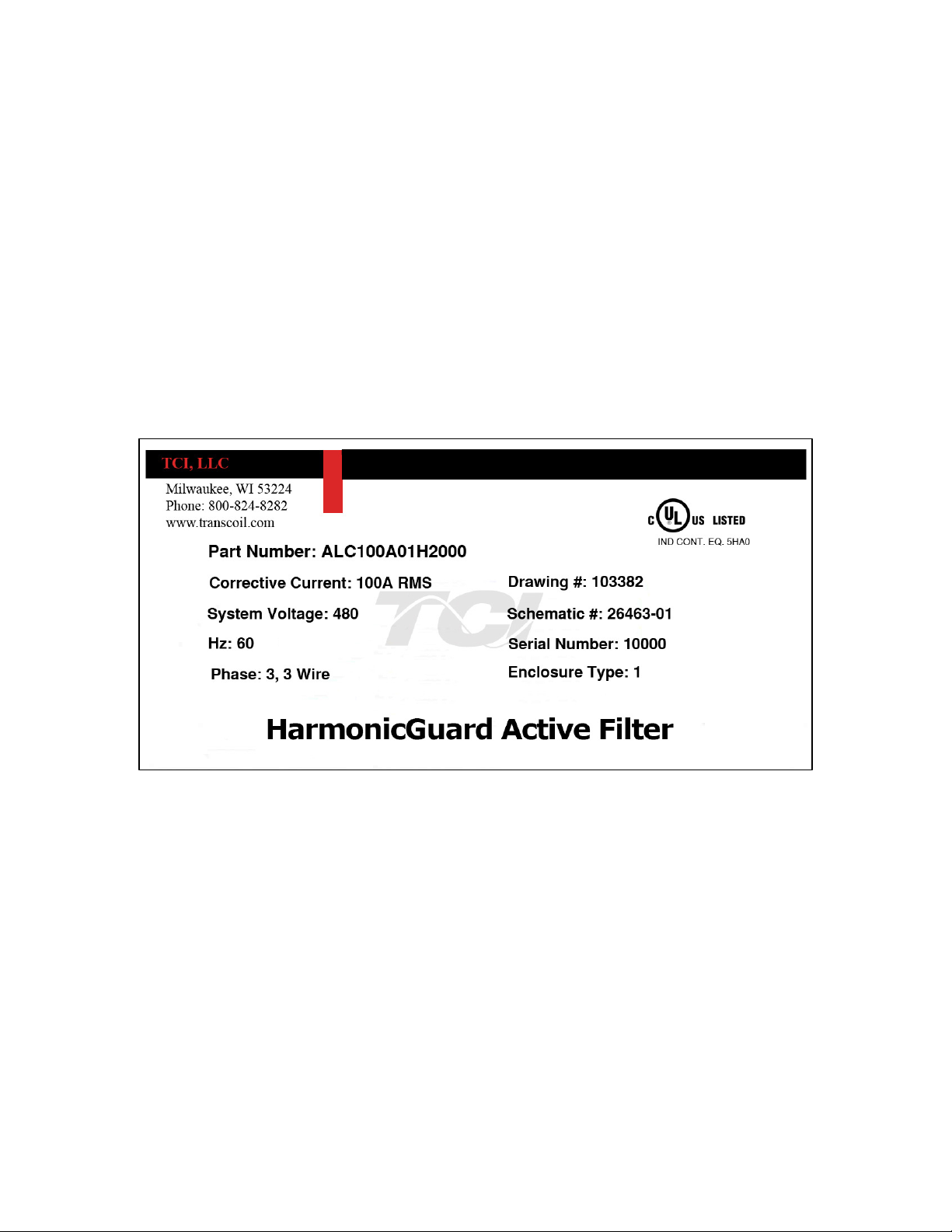

Nameplate Data

Figure 3.2 shows a typical HarmonicGuard Active filter nameplate. The following information is

marked on the nameplate:

Part number : encoding is explaine d on the following page

Corrective Current: The maximum amount of RMS Corrective Current the unit can deliver.

System Voltage: the rated 3-phase line voltage (RMS volts)

Hz: the rated frequency (60 Hz)

Phase: 3, 3 Wire – The HGA is designed for use with only 3 wire systems with balanced 3-

phase voltage sour ce.

Drawing #: outline and mounting dimension drawing number

Schematic #: schematic diagra m drawing number

Serial #: fo r unit tracking purposes

Enclosure Type: Open, UL Type 1, UL Type 3R

Figure 3.2 – Typical HarmonicGuar d Ac tive filter Nameplate

18

Page 19

ALC 100 A 01

H 00

00

ALC

Prefix

Current Rating

Voltage Rating

A= 480

Filter Enclosure

00 = Open Chassis

01 = UL Type 1

Package Option

Circuit Breaker

H = Interface Module

10=ABB 22kA

2

0=ABB 100kA

30=A-B 25kA 40=A-B 65kA

60=Eaton 65kA 7

0=Eaton 100kA

80=Square D 18kA 90=Square D 65kA

00=No breaker 01=ABB 65kA

Reserved for custom options to be

defined as needed, each position can

use 0 thru 9.

Default option is 00.

50, 100, 200

Part Number Encoding

Figure 3.3 identifies the significance of each character in the HarmonicGuard Active filter part

number. An example of a completed part number would be ALC100A01H2000. This designates an

enclosed HarmonicGuard Active filter that i s rated for 100 amps, 480 volts, and has an HMI Interface

Module Package.

HGA Part Numbering System – 480V Open and T ype 1

Temperature: 40° C

Current: 50, 100, 200

Voltage: 480

Enclosure: Open Chass is or UL Type 1

Figure 3.3 – Harmoni cGuard A ctive filte r par t number encoding

19

Page 20

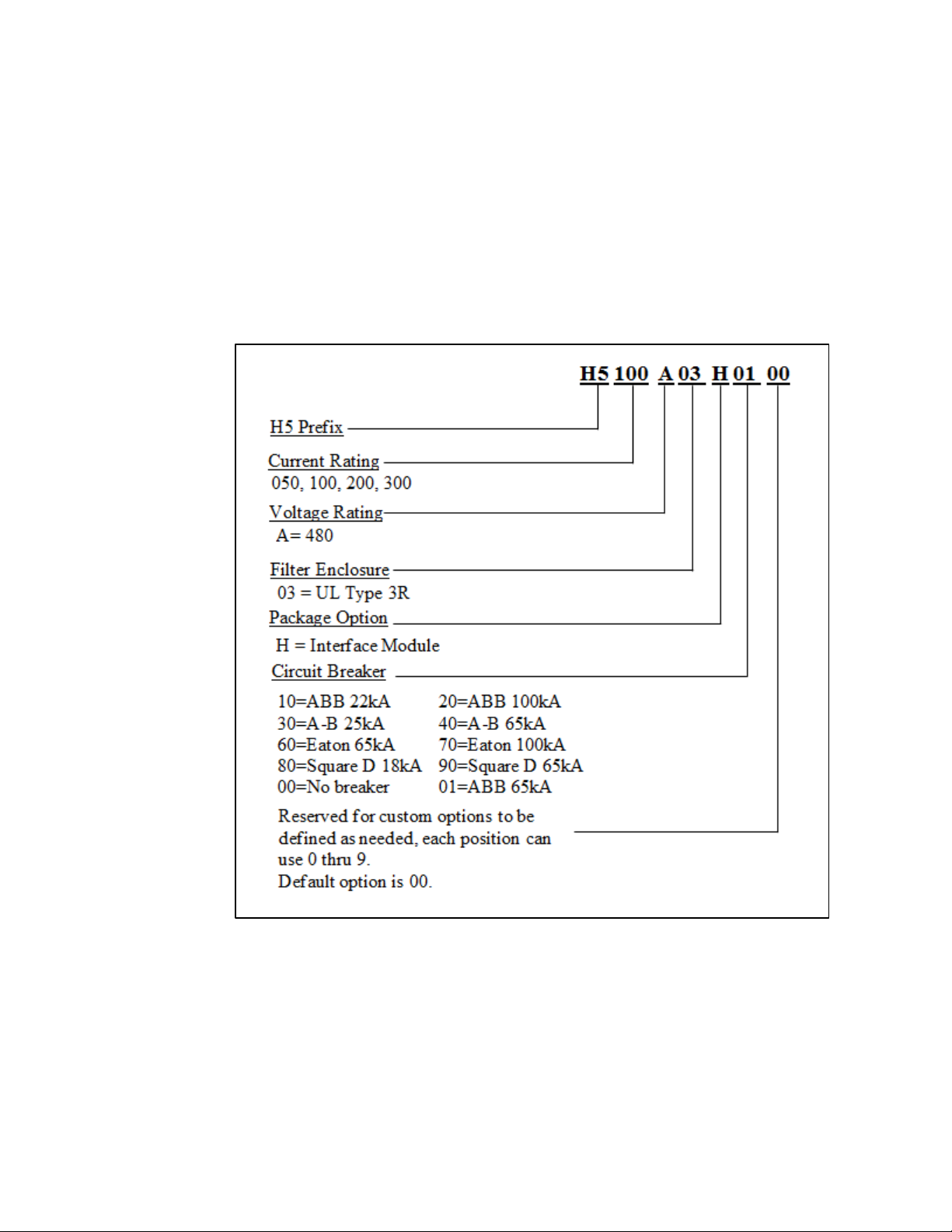

Figure 3.4 identifies the significance of each character in the HarmonicGuard Active filter part

number. An example of a completed part number would be H5100A03H4000. This designates an

enclosed HarmonicGuard Active filter that is rated for 100 amps, 480 volts, and has an HMI Interface

Module Package.

HGA Part Numbering System – 480V 3R

Temperature: 40° C Current: 50, 100, 200, 300 Voltage: 480 Enclosure: UL Type 3R

Figure 3.4 – Harmoni cGuard A ctive filte r Part number Encoding

20

Page 21

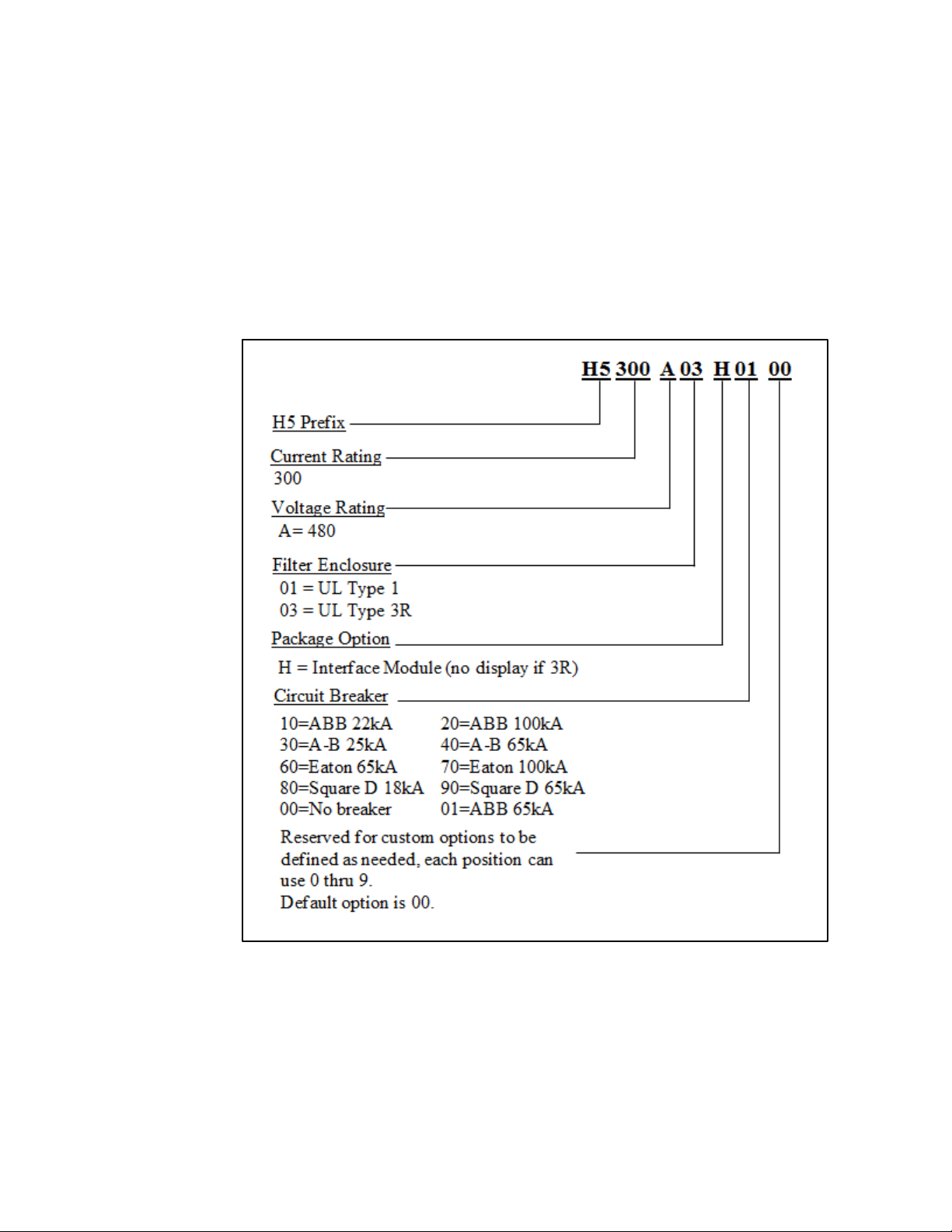

Figure 3.5 identifies the significance of each character in the HarmonicGuard Active filter part

number. An example of a completed part number would be H5300A00H1000. This designates an

enclosed HarmonicGuard Active filter that i s rated for 300 amps, 480 volts, and has an HMI Interface

Module Package.

HGA Part Numbering System – 480V 300A

Temperature: 40° C

Current: 300

Voltage: 480

Enclosure: U L Type 1 or UL Type 3R

Figure 3.5 – Harmoni cGuard A ctive filte r Part number Encoding

21

Page 22

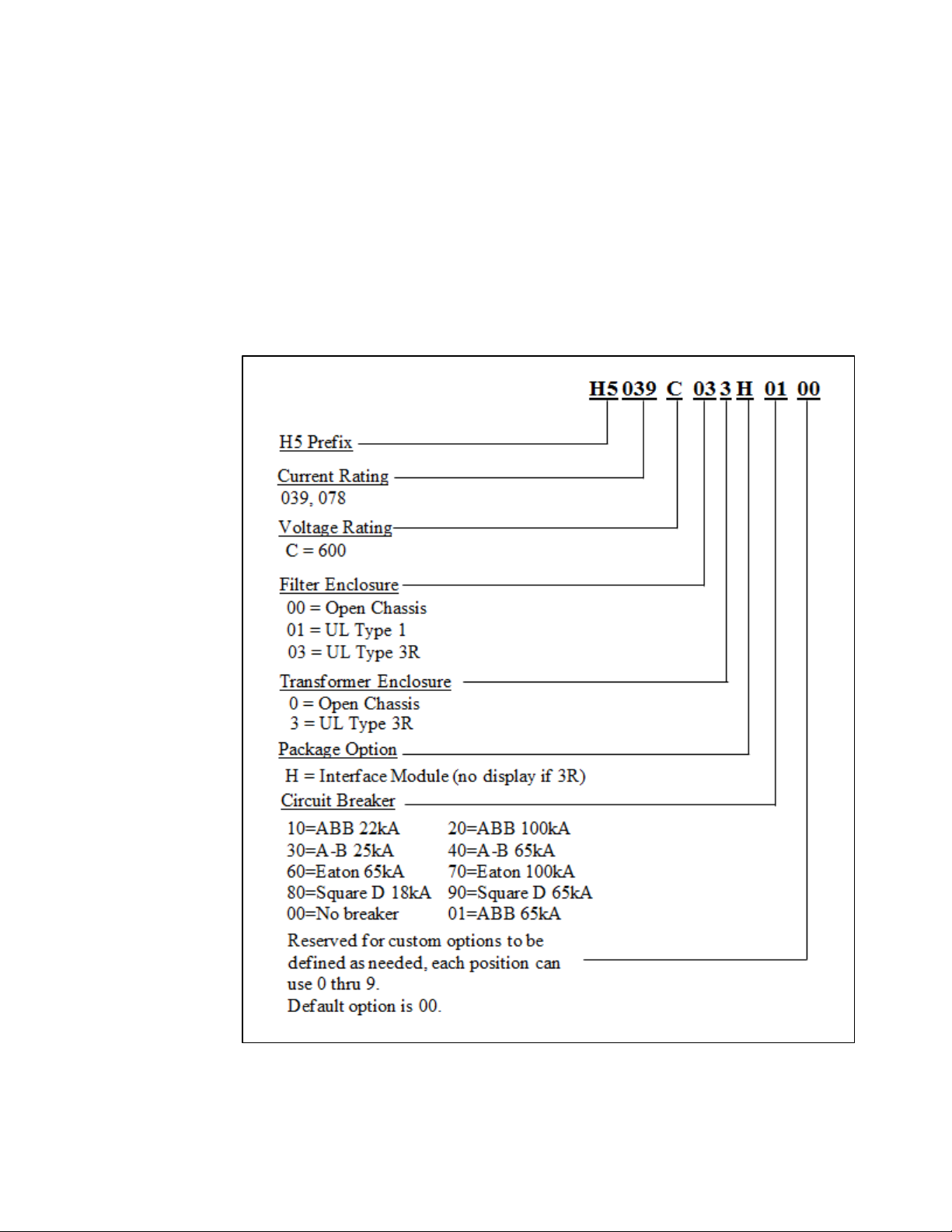

Figure 3.6 identifies the significance of each character in the HarmonicGuard Active filter part

number. An example of a completed part number would be H5039C033H0100. This desig nates an

enclosed Har monicGuard Active filter that is rated for 39 amps, 600 volts, and has an H MI Interface

Module Package.

HGA Part Numbering System – 600V

Temperature: 40° C

Current: 39, 78

Voltage: 600

Enclosure: Open Chassis, UL Type 1 or UL Type 3R

Figure 3.6 – Harmoni cGua rd Active Part number Encoding

22

Page 23

Figure 3.7 identifies the significance of each character in the HarmonicGuard Active filter part

number. An example of a completed part number would be ALC45A01H10. This designates an

enclosed HarmonicGuard Active filter that is rated for 45 amps, 480 volts, and has an HMI Interface

Module Package.

HGA Part Numbering System – 480V Open & Type 1 (50° C)

Temperature: 50° C Current: 45, 90 Voltage: 480 Enclosure: Open Chass is or UL Type 1

Figure 3.7 – Harmoni cGuard A ctive filte r Part number Encoding

23

Page 24

CM

Communications

39, 45, 50, 78, 90, 100,

200, 300

A

Voltage rating of 480V

C

Voltage rating of 600V

00

Modbus RTU over RS485

01

Ethernet/IP

Dimensions Inch (cm)

39

2676

167 (75.8)

56 (142.2)

17 (43.2)

14.18 (36.6)

45 & 50

2676

167 (75.8)

56 (142.2)

17 (43.2)

14.18 (36.6)

78

3500

167 (75.8)

56 (142.2)

17 (43.2)

14.18 (36.6)

90 & 100

3500

167 (75.8)

56 (142.2)

17 (43.2)

14.18 (36.6)

200

7000

340 (154.22)

57.97 (147.25)

32 (81.28)

14.18 (36.6)

Dimensions Inch (cm)

39

2676

254 (115.2)

60.15 (152.8)

17.57 (44.5)

*16.4 (41.7)

50

2676

254 (115.2)

60.15 (152.8)

17.57 (44.5)

*16.4 (41.7)

78

3500

254 (115.2)

60.15 (152.8)

17.57 (44.5)

*16.4 (41.7)

100

3500

254 (115.2)

60.15 (152.8)

17.57 (44.5)

*16.4 (41.7)

200

7000

480 (217.72)

64.17 (163)

32.62 (82.86)

*17.2 (43.7)

300

10500

1042.4 (472.9)

84.20 (213.9)

63.3 (160.8)

*23.9 (60.7)

*Add Two Inches for Disconnect/Circuit Breaker Handle,

Communications Part Numbering

Table 3.1 bel ow shows the HGA part numbering with the communications part numbers. The base

communications unit is CM100A00 which has both the HMI and Modbus.

Table 3.1 – Communcation Part Numbering

Options Descriptions

Amp rating

A, C

00, 01

Standard Product Ratings and Dimension Tables

The following tables list the ratings and dimensions of the standard HarmonicGuard Active filter

models. See drawing at the end of this manual.

• Table 3.2 – Open Chassis

• Table 3.3 – UL Type 1 Enclosed

• Table 3.4 – UL Type 3R Enclosed

• Table 3.5 – 600V Open and Type 3R

Table 3.2 – Open Chassis

Amps

Heat Loss

(watts)

Weight lbs.

(kg)

H x W x D

Table 3.3 – UL Type 1 Enclosed

Amps

24

Heat Loss

(watts)

Weight lbs.

(kg)

H x W x D

Page 25

Dimensions Inch (cm)

39

Consult Factory

50

3176

371 (168.3)

80.00 (203.2)

32.00 (81.3)

25.00 (63.5)

78

Consult Factory

100

3500

371 (168.3)

80.00 (203.2)

32.00 (81.3)

25.00 (63.5)

200

7000

1040 (472)

80.00 (203.2)

57.00 (144.78)

25.00 (63.5)

300

Consult Factory

Heat Loss

(watts)

Weight

lbs. (kg)

Dimensions Inch (cm)

H x W x D

39

Open

345

180 (81.7)

16.00 (40.7)

19.50 (49.6)

12.20 (31)

78

Open

740

180 (81.7)

16.00 (40.7)

19.50 (49.6)

12.20 (31)

39

3R

345

270 (122.5)

24.90 (63.3)

24.40 (62)

20.80 (52.9)

78

3R

740

270 (122.5)

24.90 (63.3)

24.40 (62)

20.80 (52.9)

Table 3.4 – UL Type 3R Enclosed

Amps

HeatLoss

(watts)

Weight lbs.

(kg)

H x W x D

Table 3.5 – Transformer for 600V units – Open and Type 3 R

Amps Encl.

25

Page 26

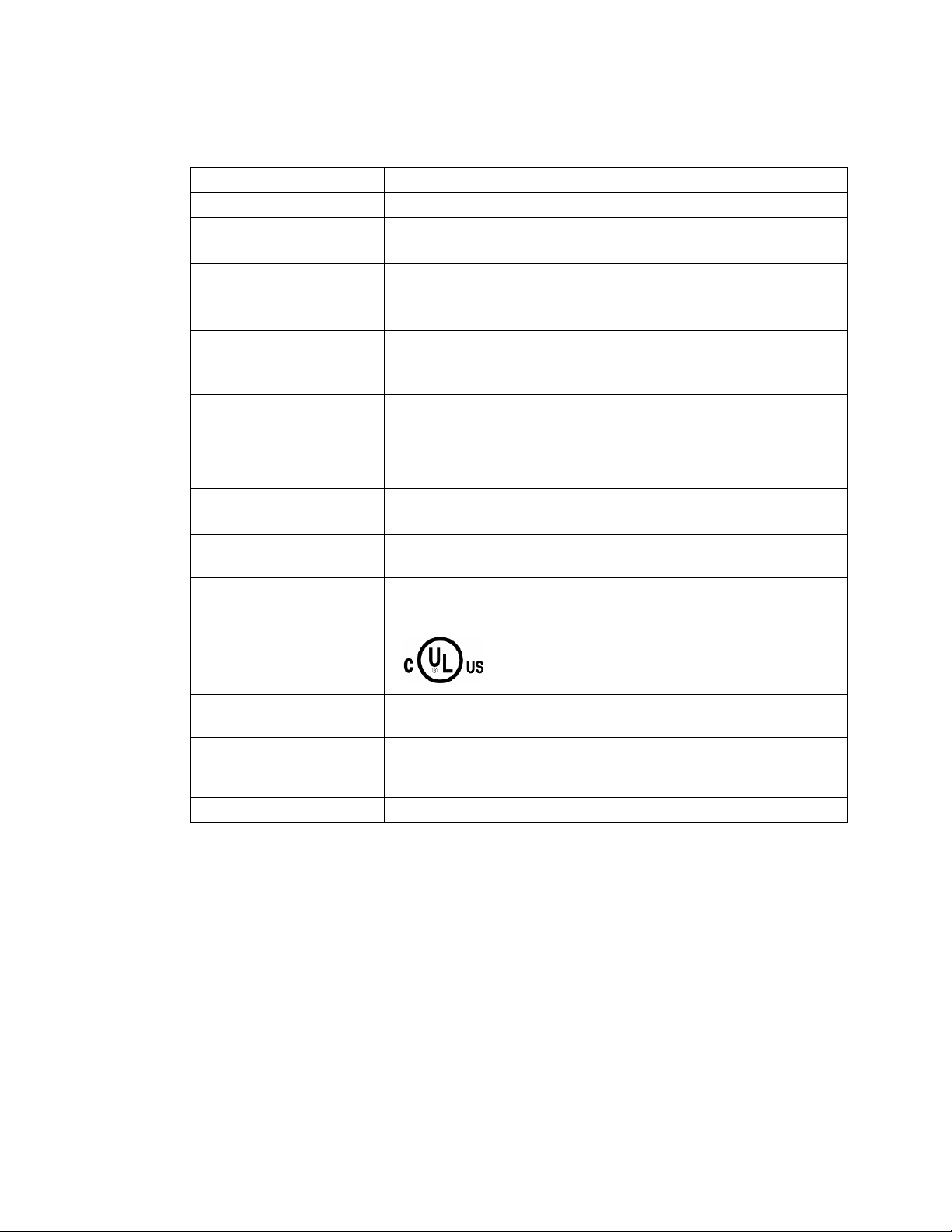

Table 3.6 – HarmonicGuard Ac tive filter Technical Specifications

Voltage ratings 480V, 3 phase, 60 Hz, three wire systems

Phase Sequence Positive phase rotation: A-B-C (or L1-L2-L3)

Load types

Current ratings See Ratings in Standard Product Rating and Dimensi ons tables.

Maximum elevation

Maximum Amb ient

operating temperature

Minimum Amb ie n t

operating temperature

Ambient storage temperature

Maximum humi d it y,

operating or storage

Enclosure options

Agency approvals or

certifications

3-phase diode bridge rectifier loads such as PWM AC drives

*3-phase controlled rectifier (SCR or thyristor) loads such as DC drives

1,000 meters (3,280 feet) For every 100 meters (328 feet) over 1,000,

de-rate by 1%. Maximum elevation is 2,000 meters (6,560 feet).

All units 40°C (104°F) except 45 & 90 amp open chassis units rated for

50°C (122°F) surrounding air. Product must be equipped with special

cooling provisions for operation above this temperature.

0°C (32°F) for open chassis and Type 1 enclosures.

-20°C (-4°F) for Type 3R enclosures.

Product must be equipped with special heating provisions for operation

below this temperature.

-20°C to 60°C for Open Chassis and UL Type 1

-40°C to 60°Cfor UL Type 3R

95%, non-condensing

Standard: Open Chassis and UL Type 1 enclosed, UL Type 3R enclosed

Contact TCI Technical Support for other enclosure options.

UL and cUL Listed

Electronic overload / over

current protection

Over current protection:

*

Status indication LEDs Numerous LED indicators on converter unit

P

*Please consult TCI regarding optimum filter performance when applied to DC drives.

Factory calibrated processor controlled electronic over current fault, and

over load.

All units have internal circuit bre a ker for protection of the converter

section of the HGA. The customer must supply branch circuit

protection.

26

Page 27

!

■ Section 4

Pre-installation Planning

Verify th e A pplicat ion

HGA Ratings

Make sure that the HarmonicGuard Active filter is correct for the application and sized for load. The

voltage ratings of the HGA m us t match the input voltage rating of t he connected AC bus.

Select a Suitable Location

Environment

Locating the HarmonicGuard Active filter in a suitable environment will help assure proper

performance and a normal op erating life. Re fer to t he enviro nmental spec ifications listed in Table 3.6,

marked on the unit's nameplate and/or noted on the drawings furnished with the unit.

Warning

Unless specifically labeled as approved for such use, this equipment is not suitable for use in an

explosive atmosphere or in a "Hazardous (Classified) Location" as defined in article 500 of the

National Electrical Code (NEC).

UL Type 1 and open chassis units must be installed in an area where it will not be exposed:

• Direct sunlight

• Rain or dripping liquids

• Corrosive liquids or gasses

• Explosive or combustible gases or dust

• Excessive airborne dirt and dust (Pollution Degree 2, according to EN50178 and UL508)

• Excessive vibration [0.152 mm (0.006 in.) displacement, 1G peak]

Please note that custom enclosure options may vary available installation areas.

Working Space

Provide sufficient access and working space around the unit to permit ready and safe installation,

operation and maintenance. Make sure that the installation conforms to all working space and

clearance requirements of the National Electrical Code (NEC) and/or any other applicable codes.

Provide sufficient uno bstructed space to allow cooling air to flow through the unit.

Mounting an Open Chassis Unit

If you are mount in g an o pe n c has sis unit in your o wn enc los ure , yo u mu st p rovi de a n e ncl osur e tha t i s

adequately sized and ventilated sufficiently to p revent o verheati ng. Re fer to Table 3.2 for dimensions

and heat loss that is dissipated b y the HGA. The maximum ambient temperature should not exceed 40°

C (104° F). The 45 and 90 amp open chassis units have an ambient surrounding air temperature of

50ºC (122ºF).

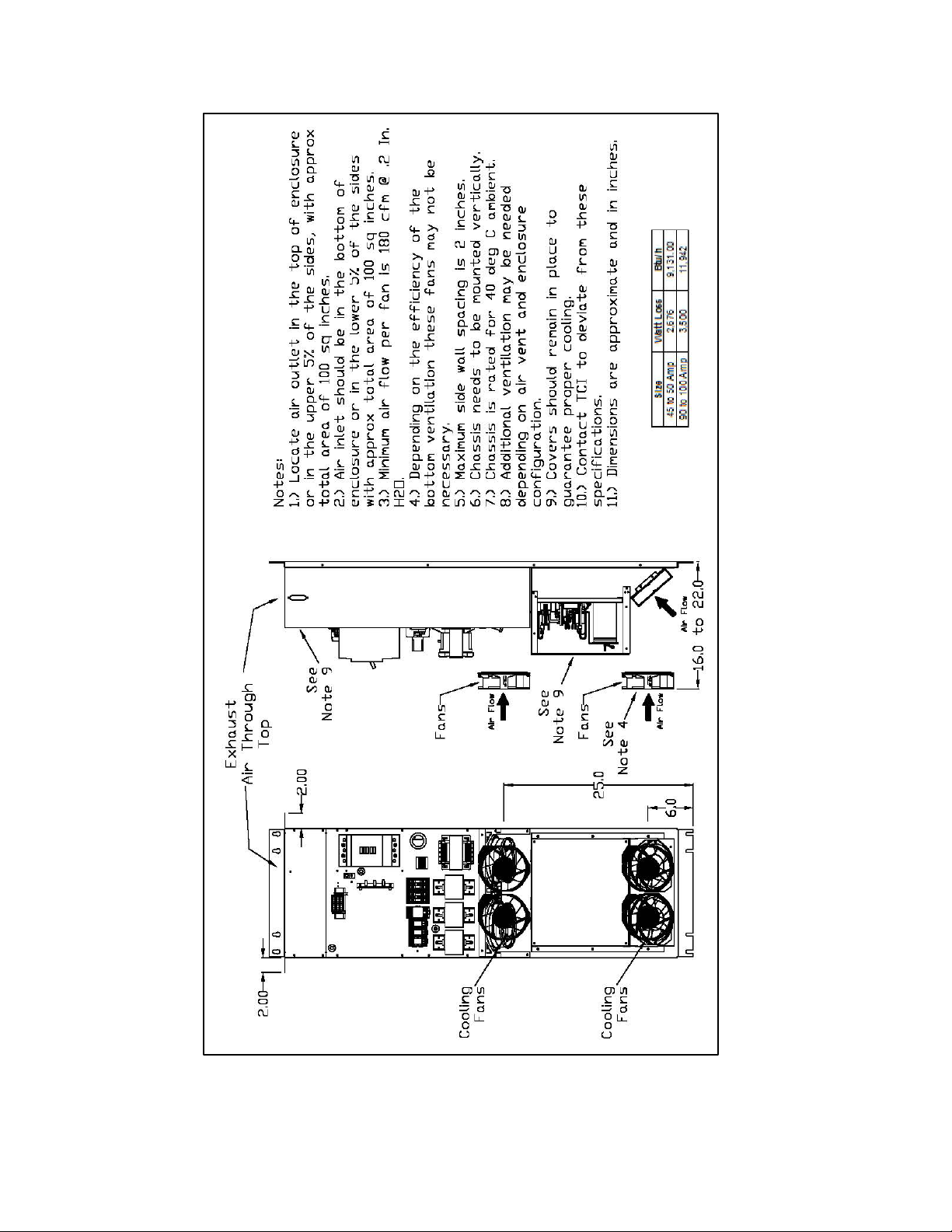

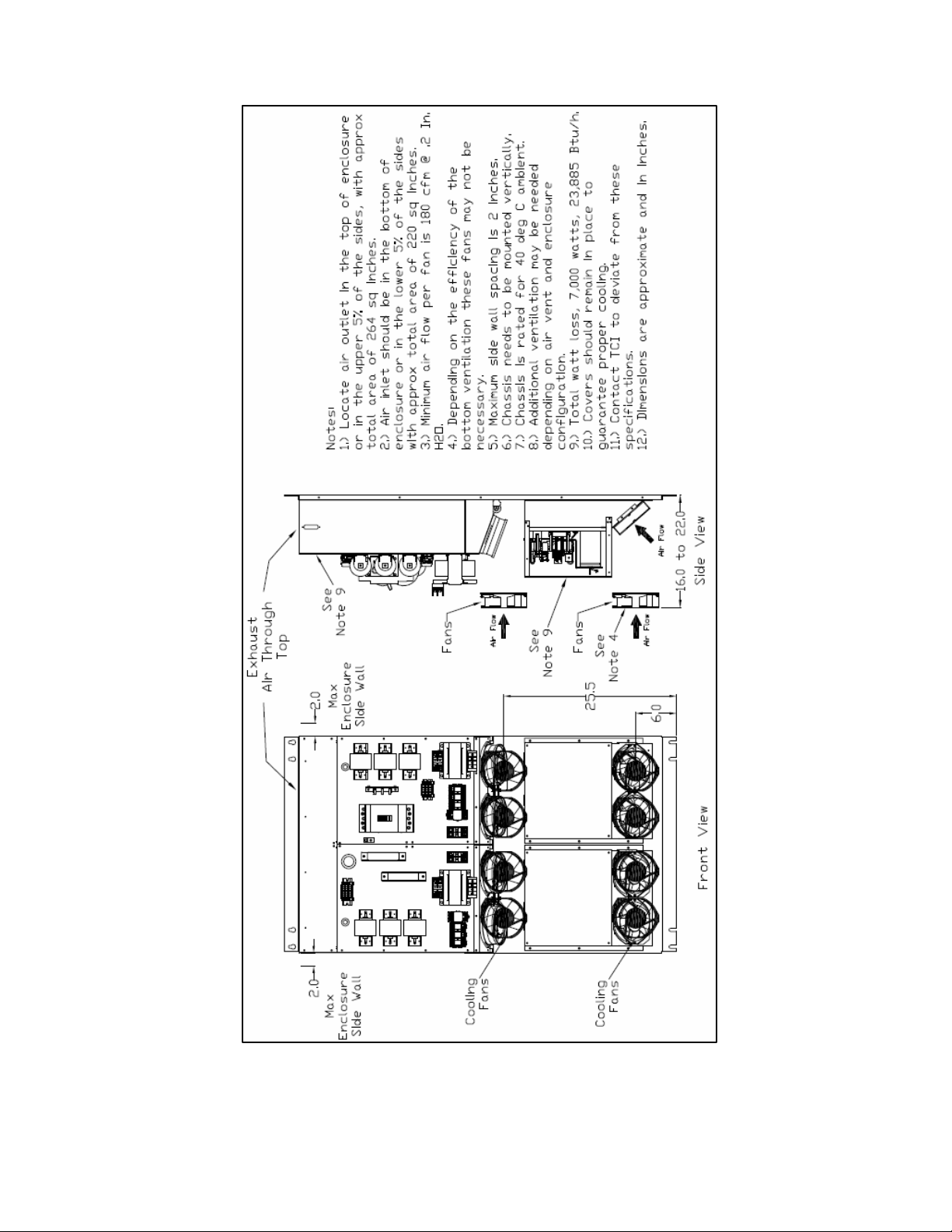

Cooling Diagrams

Please see Figures 4.1 and 4.2 for cooling diagrams of the HGA.

27

Page 28

Figure 4.1 – Cooling Diagram for 39, 45, 78, 90 and 100 amp uni ts

28

Page 29

Figure 4.2 – Co oling Dia gram for 200 amp units

29

Page 30

Ground Lug

Power Terminals

(Nm)

IC

(Nm)

39 & 78 Amp

14 AWG - 2/0

120 (13.6)

22 kA

14 - 1/0 AWG

70 (7.9)

39 & 78 Amp

14 AWG - 2/0

120 (13.6)

65 kA

4 AWG – 350 MCM

250 (28.2)

70 (7.9)

274 (31)

274 (31)

25 to

100 kA

Two 3/0 AWG – 250

MCM

274 (31)

45, 50, 100, 200

Amp

!

Installa tion Guidelines

Mounting

The HGA must be mounted vertically on a smooth, solid surface, free from heat, dampness, and

condensation.

Wiring

Cable Entry Locations

The enclosed HarmonicGuard Active filters are not provided with enclosure wiring knockouts,

however, a removable wire entry plate is provided. A selection can be made at the time of installation.

Typical or recommended cable entry locations are shown in the drawings shipped with the unit.

Caution

Refer to circuit breaker section on page 50.

Field Wiring Connection Terminals

Compression type terminals are provided for all field wiring connections. The wire size (75° C copper)

capacity ranges and tightening torque for the grounding and power terminals are listed in Table 4.1a

and 4.1b. Refer also to the drawings and other information shipped with the unit. A disconnecting

means is the responsibility of the customer.

Table 4.1a – Exa mple Power Termi nal Wire Size Ca pacity Ra nge and Tightenin g Torque for ABB Circuit Breakers

Filter Size

45 & 50 Amp 14 AWG - 2/0 120 (13.6) 22 kA 14 - 1/0 AWG 70 (7.9)

39 & 78 Amp 14 AWG - 2/0 120 (13.6) 25 kA 2 - 4/0 AWG 250 (28.2)

100 Amp 14 AWG - 2/0 120 (13.6) 25 kA 4 AWG – 300 MCM 200 (22.6)

Wire Size

Torque In-lbs

Breaker

Wire Size

Torque In-lbs

45 & 50 Amp 14 AWG - 2/0 120 (13.6) 65 kA 14 - 1/0 AWG

100 Amp 14 AWG – 2/0 120 (13.6) 65 kA 6 AWG – 350 MCM

39 to 100 Amp 14 AWG – 2/0 120 (13.6) 100 kA 6 AWG – 350 MCM

200 Amp Two 6 AWG – 250 MCM 275 (31.1)

300 Amp Consult Factory

39 & 78 Amp Control Terminals Wire Size 30 to 12 AW G Torque 4.4 in-lb. (.5 Nm)

Note: The values in this table are representative of ABB switch gear. For other manufacturer’s switch gear please contact

TCI.

Control Terminals Wire Size 28 to 14 AWG Torque 4.4 in-lb. (.5 Nm)

30

Page 31

Ground Lug

Power Terminals

Wire Size

Torque In-lbs (Nm)

Breaker IC

Wire Size

Torque In-lbs (Nm)

39 to 100 Amp

14 AWG – 2/0

120 (13.6)

25 to 100 kA

14 – 2/0 AWG

180 (20.3)

25 to 100 kA

None

Control Terminals Wire Size 28 to 14 AWG Torque 4.4 in-lb (0.5 Nm)

!

Table 4.1b – Power Termi nal Wire Size (wi thout brea ker) Ca pacity Range and Tightenin g Torque

Chassis Size

150 to 200 Amp 14 AWG – 2/0 120 (13.6)

150 to 200 Amp 14 AWG – 2/0 120 (13.6)

Caution

Use copper wire that is appropriate for the voltage and current rating of the equipment. The wire

selection must conform to the requirements of the National Electrical Code and/or other applicable

electrical codes.

Use wire with an insulation temper ature rati ng of 75°C or higher.

Connection Diagram

Figure 4.3 sho ws the typical wiring connections between the models of the HGA and the load. Refer

to the drawings furnished with the unit for more specific information.

• The input 3-p hase AC voltage source must be connected in a positive ABC phase rotation

from L1-L2-L3 for correct unit operation.

6 AWG – 350 MCM 274 (31)

6 AWG – 350 MCM 274 (31)

Figure 4.3 – Typical Load Connection Di agram

Notes:

1.) Wiring should be 75°C or higher insulated copper, with the appropriate voltage and current rating.

2.) Chassis ground must be connected to the ground of the premises wiring system, in accordance

with NEC and local codes. Connection must be made using a wire conductor.

3.) Terminal TB-I & J25 wire range is 30-12 AWG, tightening torque is 4.4 IN-LB (0.5 NM).

4.) Operating current transformers with the secondary winding open can result in a high voltage

across the secondary terminals which may be dangerous to personnel or equipment.

31

Page 32

39

250:5

3000:5

50

250:5

3000:5

79

250:5

3000:5

100

250:5

3000:5

200

750:5

3000:5

300

750:5

5000:5

!

Current Transformer Installation

For accurate sensing of the load it is important that the load sensing current transformers are properly

installed.

Warning

Only qualified electricians should carry out all electrical installation and maintenance work on the HGA.

Failure to follow standard safety procedures may result in death or serious inj ury.

Disconnect all sources of power to the drive and HGA before working on the equipment. Do not attempt

any work on a powered HGA. Also, check for zero voltage between all phases of the input and output

lines.

Operating current transformers with the secondary winding open can r esult in a high volta ge

across the secondary terminals which may be dangerous to personnel or equipment.

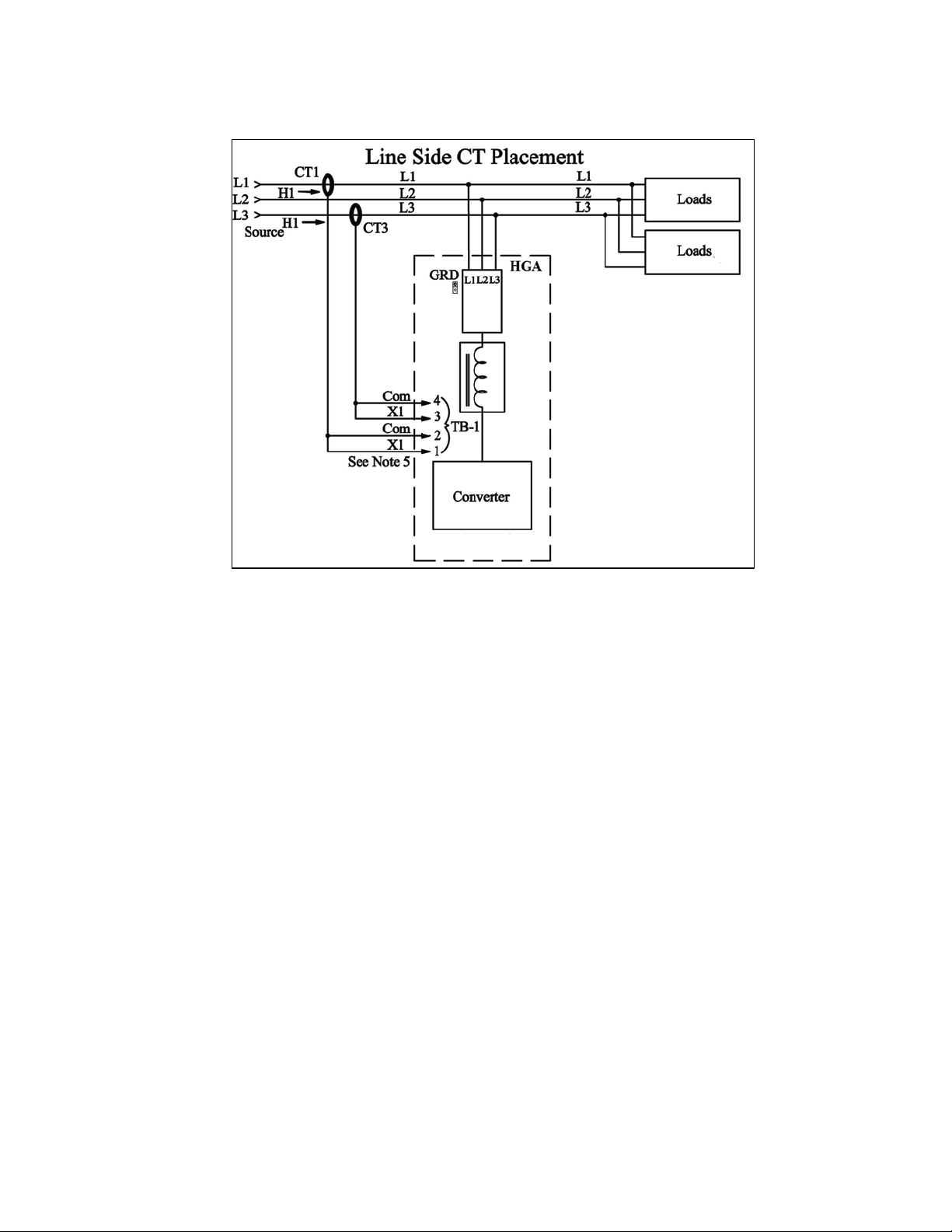

It is necessary for the HGA to moni tor the cur rent in P ha se “ A” ( L1) a nd P hase “C” ( L3). Stand-alone

HGA filters are designed for Line Side current transformer (CT) placement as shown in Figure 4.4a. It

is important that both CTs are on the same side of the HGA. The CTs sho uld be cente red around the

conductor. Optional Load Side CT placement is available for sin gle units as shown in Figure 4.4a.

The polarity of the CT is important; the “H1” marking on the CT must face the source. The secondary

windings o f the CT around conductor L1 should connect to TB-1 terminals 1 & 2 and the CT around

conductor L3 should connect to TB-1 terminals 3 & 4. The secondary wire of the CT identified as

“X1” must connect to the “X1” terminal of TB-1 for both CTs. Failure to maintain the correct polarity

and phasing wi l l cause an over-current fa ult . If this shoul d happen refer to the troubleshoo ting section.

The exact CT placement is dependent on the HGA’s configuration and size. Please refer to Figures

4.4a through 4.4i for the installation that applies.

Note: Units with black “TB-1” terminal blocks are shipped with two position shorting jumpers

installed between positions 1 & 2 and 3 & 4. This is done for your safety and to prevent equipment

damage. The jumpers are installed in the center of the block and can be identi fied by the gray to p.

After the load CTs are installed and wired, these jumpers must be removed for correct unit operation.

They can be removed with a standard flat blade screw driver (See Figure 5.3).

Note: CT operation can be verified via the HMI touchscreen feedback waveform plot screens.

Reference the HMI VLine & ILine Waveform Plot Sub Screen in Section 6 for details.

Table 4.2 – CT Range by Model Size

Amps CT Min Ratio

CT Max

Ratio

Notes

Factory technician start up required to

use CTs outside of the published range

32

Page 33

Current Transformer Diagrams

The following pages contain de ta ile d diagrams on the placement of CTs in relation to the HGA.

Figure 4.4a Line Side or Load Side CT Placement for stand-alone HGA filters rated at 45 to 100

amps, 480V.

Figure 4.4b Line Side or Load Side CT Placement for stand-alone HGA filters rated at 39 to 78 amps,

600V.

Figure 4.4c Line Side or Load Side CT Placement for stand-alone HGA filters rated at 200 amps,

Open or Type 1, 480V.

Figure 4.4d Line Side CT Placement for stand-alone HGA filters rated at 200 amps, Type 3R, 480V.

Figure 4.4e Line Side CT Placement for stand-alone HGA filters rated at 300 amps 480V.

Figure 4.4f Master and M ultiple Slave Para llel Units CT Plac ement for HGA filters rated at 45 to 100

amps, 480V.

Figure 4.4g Master and Multiple Slave Parallel Un its CT Placement for HGA filters rated at 3 9 to 78

amps, 600V.

Figure 4.4h optional Multiple Slave Parallel Units CT P lacement for HGA filter s rated at 39 to 100

amps.

Figure 4.4i Master and Multiple Slave Parallel Units CT Placement for HGA filters rated at 200 amps.

The pages after the CT Placement diagrams contain detailed diagrams on the current ratios and

dimensions of TCI Current Transformers. Contact TCI for CTs not found in figures 4.5, 4.6, or 4.7.

Figure 4.5 is the diagr am for Round Current Transformers.

Figure 4.6 is the diagram for Rectangular Current Transformers.

Figure 4.7 is the diagram for Solid Core Current Transformers.

33

Page 34

Figure 4.4a – Line Side or Load Side CT Placement – 45, 50, 90 and 100 am p, 480 volt

34

Page 35

Figure 4.4b – Line Side or Load Side CT Pl aceme nt – 39 and 78 amp, 600 volt

35

Page 36

Figure 4.4c – Line Side or Load Side CT Place ment – 200 amp, Open or Type 1, 480 volt

36

Page 37

Figure 4.4d – Line Side CT Placement – 200 amp, Type 3R, 480 volt

37

Page 38

Figure 4.4e – Line Side CT Placement – 300 amp, 480 volt

38

Page 39

Figure 4.4f – Master and Multiple Parallel Units CT Placement – 45, 50, 90 and 100 amp, 480 volt

39

Page 40

Figure 4.4g – Master and Multiple Slave Parallel Units CT Placement – 39 and 78 amp, 600 volt

40

Page 41

Figure 4.4h – Optional Multipl e Sla ve Parallel Units CT Placement – 39, 45, 78, 90 and 100 amp, 480 volt

41

Page 42

Figure 4.4i – Master/Slave CT Placement – 200 amp, 480 volt

42

Page 43

43

Page 44

Figure 4.5 – Current Transformer Diagram – Round

Figure 4.6 – Current Transformer Diagram – Rectangular

44

Page 45

Figure 4.7 – Current Transformer Diagram – Solid Core

45

Page 46

is not receiving power from an

!

Grounding

The HarmonicGuard Active filter p anel equip ment-grounding lug must be connected to the ground of

the premises wiring system. The equipment grounding connection must conform to the requirements of

the National Electric Code (NEC) and/or any other codes that ap ply to the installation site . T he gro und

connection must be made using a wire conductor. Metallic conduit is not a suitable grounding

conductor . The integrity of all ground connec tions should be periodically checked.

HarmonicGuard Active Filter Operation

Adjustments

• The HGA has been factory calibrated and thoroughly tested. There is no need to make

any adjustments.

Start Up (Commissioning)

Caution

Warning

Thoroughly check the i nstallation before applying power and operating the equipment for the

first time.

Before Applying Power for the First Time

Inspect the installation to make sure that all equipment has been completely and correctly

installed on accordance with the Installation Guidelines section of this manual.

• If it is a floor mount unit, check to see that it is securely anchored to the floor.

• Check the panel and the inside of the enclosure for any foreign objects, dirt, metal filings,

wire whiskers, and loose hardware.

• Verify that any covers or guards that were removed during installation were reinstalled.

• Ensure that the unit is properly grounded.

• Check for properly tightened co nnections.

General Operation

Please reference the Quick Start Guide in Section 1 for the first time power up procedure.

Since the HGA is an active filter, it is always operating whenever the power is applied.

Warning

Only qualified electricians should carry out all electrical installation and maintenance work on the

HarmonicGuard Active filter.

Disconnect all sources of power to the drive and HGA before working on the equipment . Do not

attempt any work on a powered unit.

Warning

Be aware everything ahead of the circuit breaker will still be energized. It is important to note

that the lack of lit LEDs does not necessarily mean that the HGA

external source.

46

Page 47

Warning

Only qualified electricians should carry out all electrical installation and maintenance work on the

■ Section 5

Maintenance and Service

HGA Reliability and Service L ife

The HGA has been designed and thoroughly tested at the facto ry to ensure tha t it will per form reliabl y

from the time it is put into service. The following periodic maintenance is recommended to ensure that

the HarmonicGuard Active filter will always perform reliably and provide the expected service life.

Periodic Maintenance

The following checks should be conducted monthly or more frequently when installed in harsh or

dusty environments.

• Check to see that the installation environment remains free from excessive vibration, exposure

to excessive dirt, moisture, and contaminants. Refer to the Pre-installation Planning section

of this manual.

• Check to make sure that the enclosure ventilation openings are clean and unobstructed.

• Clean the air filter in units that have filter ed air inlets. Clean as often as necessary to prevent

dirt build-up from impeding air flow.

• Check for any dust or dirt build-up on the fans and heat s ink fins.

• Check the o peration o f t he cooling fan.

• Inspect the interior of the enclosure for signs of overheated components. Clean the interior of

the enclosure whenever excess dirt has accumulated.

• Check the integrity of all power , ground, and control wiring connec t ions.

• All electrical connections must be re-torqued annually.

Many electronic components located within the filter are sensitive to static electricity. Voltages

imperceptible to human touch can reduce the life, and affect performance, or destroy sensitive

electronic devices. Use proper electrostatic discharge (ESD) procedures when se rvicing the filter

and its circuit boards.

Warning

HGA.

Disconnect all sources of power to the drive and HGA before working on the e quipment. Do not

attempt any work on a powered HGA.

This HGA unit contains high voltages and c a pacitors. Wait at least five minutes after

disconnecting power from the filter before you attempt to service the conditioner. Check for zero

voltage between all terminals on the capacitors. Also, check for zero voltage between all phases

of the input and output lines. All maintenance and troubleshooting must be done by a qualified

electrician. Failure to follow standard safety procedures may result in death or serious injury.

Unless an external disconnect means has been provided everything ahead of the filter circuit

breaker will still be energized.

47

Page 48

Reference Drawings

Typical HGA configurations are illustrated in Figures 5.1a, 5.1b, and 5.1c. There could be slight

differences between your unit and the configurations shown below. It is recommended that you refer to the

drawings provided with your specific equipment when conducting troubleshooting operations.

Figure 5.1a – General Schematic Bus Applied 39, 45, 78, 90 and 100 amp

*This drawing is for general reference only. Use the drawings supplied with the unit for installat ion.

48

Page 49

Figure 5.1b – General Schematic Bus Applied 200 Amp, Open and Type 1, Master/Master

*This drawing is for gene ral reference only. Us e the drawings supplied with the unit for inst allation.

49

Page 50

Figure 5.1c – General Schematic Bus Applied 200 Amp, Type 3R, Parallel

*This drawing is for general reference only. Use the drawings supplied with the unit for installatio n.

50

Page 51

!

Overload / Over Current Protected

The filter has factory set built-in electronic overload and over current protection. If the converter

current exceeds the preset instantaneous peak, the converter will shut do wn to prevent p ermanent

damage to the converter, and at which time it will indicate a fault. Faults that do not automaticall y

reset can be cleared by pressing the stop button on the HMI display.

An indicati on that the filter is going into overload will be observed by a gradual worsening of the

total harmonic distortion (THD), o r power factor, as the load increases. The HGA filter units can

be paralleled to increase total corrective current capability if a unit is undersized for a particular

application. Call TCI sales support for options to expand the installe d system current capabilit y.

Circuit Breaker Protection

Each converter section is protected by a thermo magnetic circuit breaker; in the event the HGA

experiences a catastrophic failure, or a destructive over current condition should occur. It also

provides a convenient disconnect means to isolate the converter from the power source. The size

and type of circuit breaker must not be altered without consulting TCI engineering since the circuit

breaker is an integral part of the UL file.

Notes:

• Open chassis units can be provided without circuit breakers. The end user must protect the

HGA with the following UL listed thermal magnetic common trip molded case circuit

breaker.

Warning

• 39, 45, 78 & 50 Amp: A max peak let-through current of 26 kA in correspondence with a

short circuit of 100 kA at 480 volt, and a trip current of 100 amps.

• 90 to 100 Amp: A max peak let-through current of 26 kA in correspondence with a short

circuit of 100 kA at 480 volt, and a trip current of 125 amps .

• 200 Amp: A max peak let-t hro ugh c urr ent o f 35 kA in correspondence with a short circuit

of 100 kA at 480 volt, and a trip current of 225 amps.

If the system breaker has been tripped, do not attempt to re-energize the HGA unit. Until the

cause of the trip has been determined.

Pre-Charge Circuit Over Current Protec tion

SCR’s are used to limit the converter power up in-rush current to a safe level once the converter

DC voltage has reached the threshold, SCRS will be turne d on and the charging resisto r will

be cut off from the unit. If fo r so me reas on thi s circ uitr y shoul d mal func tion, c lass CC f uses ar e

in the circuit to limit the max current as not to exceed the ratin gs of the components. Note: on the

50 to 100 amp units the fuses are located on the chassis; on the 175 and 225 amp unit s the fuses

are located on the interface/mother printed circuit board.

Over Temperature Protection

The converter has a thermal fold back mechanism that will automatically reduce unit output

current as the converter temperature approaches its shutdown threshold. Additionally, the

converter ha s an i nt er nal he a t sin k o ver temperatur e p r ot ec tio n whic h will sh ut d o wn t he c o nver te r

if the threshold is exceeded. The fans will continue to run and o nce the hea t sink co ols do wn the

converter will automatically restart.

There are secondary over temperature circuits which monitor the temperature of the power

resistors and inductors locate d on the chassis of the HGA. The sensors are snap action switches

activated when the threshold is reached. This over temp would be an indication that cooling fans

51

Page 52

have failed or something more serious with the operation of the converter. For this reason this

fault will latch and will remain latched until po wer is cycled. The indicator light located on relay

CR-2 will not be lit with this type of over temp fault.

Troubleshooting

Current Transformer Orientation Troubleshoo ting

Failure to maintain the correct p olarity and phasing of the current trans formers (CTs) will cause an

over current fault on power up. The converter will never attempt to run; it will stay in a stopped

condition. Possibly the CTs are installed backwards or the secondary wiring is incorrect, if this is

suspected refer to the steps below to isolate the error.

Note: CT operation can be verified via the HMI touchscreen feedback waveform plot screens.

Reference the HMI VLine & ILine Waveform Plot Sub Screen in Section 6 for details.

Warning

Only qualified electricians should carry out all electrical installation and maintenance work on the

HGA. Failure to follow standard safety procedures may result in death or serious injury.

Disconnect all sources of power to the drive and HGA befo re working on the equipment. Do not

attempt any work on a powered HGA. Also, check for zero voltage between all phases of the input and

output lines .

Operating current transformers with the secondary winding open can r esult in a high voltage

across the secondary terminals which may be dangerous to personnel or equipment.

1.) If the CTs and wiring is easily accessible double check the CT orientation for proper direction, and

trace the secondary wiring against Figure 4.3 for polarity, phasing and connection to terminal TB-

1. Correct any errors and apply power for proper power-up, if it doesn’t clear the fault or if

accessibility is too difficult pro c e e d to step #2.

2.) There is a possibility that the CTs markings are different from Figure 4.3. This could a ffect the

polarity, to verify this try reversing the two leads on TB-1 positions 1 &2, do the same with wires

in positions 3 & 4. Apply power for proper power-up; if it doesn’t proceed to #3.

3.) Reverse just one set of CT leads at a time, first # 1 & 2; verify power-up. If it doesn’t work put

wires 1 & 2 back and now try the same with wires 3 & 4. Apply power for proper power-up; if it

doesn’t replace all wiring to its original positions, and proceed to #4.

4.) There is a possibility that the phasi ng of the CT L1 and L3 are incorrect. To test this theory swap

the two wires o n TB-1 positions 1 & 2 with the two wires in positions 3 & 4. Apply power for

proper power-up; if it doesn’t repeat steps 2 and 3.

5.) If the HGA doesn’t indicate a run status after completion of steps 1 through 4 contact TCI

technical support for further assistance.

Warning

System Failure

The Digital Signal Processor is continually mo nitoring the perfor mance and fault statu s of the filter. It

will shut do wn the converte r section if the p rocessor should sense a fault. The filter is also equipped

with a circuit breaker providing a second layer of over current protecting for the converter section. The

circuit breaker can also serve as a means of electrical isolation from the system power grid. It is

recommended by TCI that all power to the HarmonicGuard Ac tive filter be disconnected. If you elect

to service the HGA by using the circuit breaker to isolate the converter section, please take special note

of the following warnings:

Many electronic components located within the filter are sensitive to static electricity. Voltages

imperceptible to human touch can reduce the life, and affect performance, or destroy sensitive

electronic devices. Use proper electrostatic discharge (ESD) procedures when se rvicing the filter and its

circuit boards.

52

Page 53

Warning

Only qualified electricians should carry out all electrical installation and maintenance work on the

HGA.

Disconnect all sources of power to the drive and HGA before working on the e quipment. Do not

attempt any work on a powered HGA.

This HGA unit contains high voltages and c a pacitors. Wait at least five minutes after disconnecting

power from the filter before you attempt to service the conditioner. Check for zero voltage between all

terminals on the capacitors. Also, check for zero voltage between all phases of the input and output

lines. All maintenance and troubleshooting must be done by a qualified ele c trician. Failure to follow

standard safety procedures may result in death or serious injury. Unless an external disconnect means

has been provided everything ahead of the filter circuit breaker, including the reactors, will still

be energized.

Required Equipment

• AC voltmeter and ammeter or multimeter designed for true RMS measurements in a

harmonic rich circuit and suitab le for the r a te d current and voltage marked on the

nameplate. The meter should have 1000 volt minimum isolation.

• Clamp-on current probe suitable for the rated current and voltage marked on the

nameplate.

• Clip-on voltage probes suitable for the rated voltage marked on the nameplate Select

probes that can be securely clipped on to the test points without shorting between

points or falling off.

Note: when disconnecting wires from components and terminations, mark the wires to

correspond to their component and terminal connection. Extr eme Care should be ta ken when

removing the fast-on terminals from the circuit board. Excessive force will result in damaging

the interface board and require the converter to be repaired by TCI authorized personnel only.

53

Page 54

Converter Inspection

• Verify that power has been removed from converter, and 5 minutes has passed before

inspection.

• Remove plastic cover from over converter section.

• Visually check the circuit boards for debris; contamination; overheated traces; burnt

circuit board; overheated, cracked, or broken components; corrosion; and poor solder

joints.

• Check all wires and terminals connected to the circuit boards.

• Check the four electrolytic cap acitors for bulges, ruptures, pop ped vent plugs,

discoloration, or leakage.

• Check the p ower semiconductors mounted to heat-sink for cracked cases, ruptures,

debris, arcing, and burning.

• Check for any loose connections if no apparent damage is found to the power

semiconductors.

• Measure resistance of power semiconductors using a multimeter set on the diode check

setting, see Figure 5.2. Look for opens, ∞,

your meter connected to the far right negative terminal of the capacitor bank, measure

with the black lead of the meter to each of the three output terminals (bus bars), the

reading should be approximately 0.35Ω. Reverse the meter leads and repeat measuring to

each terminal. This time a low reading will be present which will continue to increase;

this is an indication of a capacitor charging. Next connect the black meter lead to the

“positive capacitor terminal” and again measure to each of the output terminals with the

other lead; the reading should be approximately 0.35Ω

repeat measuring to each terminal. Again it will be a low reading which will continue to

increase. If the readings are as described, in all likelihood the power semiconductors are

good. If any readings are opens or dead shorts it will be an indication that something is

bad in the power section. Do not reapply power if you are not sure the IGBT’s are good.

or dead short readings. With the red lead of

. Reverse the meter leads and

Figure 5.2 – 39, 45, 78, 90, 100, and 200 Amp Power Component Layout

54

Page 55

Warning

Figure 5.3 – TB-1 Terminal Block

Only qualified personnel should operate the HarmonicGuard Active filter with the door open. Failure

to follow standard safety procedures may result in death or serious injury. Do not attempt any work

on a powered filter converter.

The HGA contains high voltages and capacitors. Wait a t le ast five min utes after disconnecting po wer

from the converter before you attempt servicing. Check for zero voltage between all terminals to the

converter. Be aware everything ahead of the circuit breaker will still be energized.

55

Page 56

Figure 5.4 – Troubleshooting Flow Chart

56

Page 57

Replacement Parts

If replacement parts are needed, please contact your TCI representative. To ensure that the

HarmonicGuard Active filter continues to perform to its original specifica tions, replacement parts

should conform to TCI specifications. Use of non-TCI approved components will void all

warranties.

Factory Contacts and Techni cal S upport

For technical suppor t, contact your local T CI distributor or sales representative. You can contact

TCI directly at 1-800-824-8282. Select "Customer Service" or "Technical Support" and have your

HarmonicGuard Active filter nameplate information available and any drawings.

Outline and Mounting Dimension Drawings

Outline and mounting dimension drawings show the overall enclosure dimensions, the conduit access areas

and the wiring connection points. The major internal components are shown pictorially.

57

Page 58

Figure 5.5 – 39 and 78 amp Open Chassis Filter, Open Transformer

58

Page 59

Figure 5.6

59

– 39 and 78 amp Open Chassis Filter, Type 3R Transformer

Page 60

Figure 5.7

60

– 39 and 78 amp Type 1 Filter, Type 3R Transformer

Page 61

61

Figure 5.8 – 45, 50, 90 and 100 amp Open Chassis

Page 62

62

Figure 5.9 – 45, 50, 90 and 100 amp Type 1 Enclosed

Page 63

63

Figure 5.10 – 200 amp Open Chassis

Page 64

Figure 5.11 – 200 Amp Type 1 Enclosed

64

Page 65

Figure 5.12 – 200 Amp Type 3R Enclosed

65

Page 66

Figure 5.13 – 300 amp Type 1 Enclosed

66

Page 67

Figure 5.14 – 300 amp Type 3R Enclosed

67

Page 68

■ Section 6

HMI Introduction

The Interface Module provides the user with a convenient way to monitor the operation of TCI’s

HarmonicGuard Active filter and allows for the ability to adjust run-time set-points under password control.

This section describes how to insta ll, operate, and maintain the Interface Module.

Overview

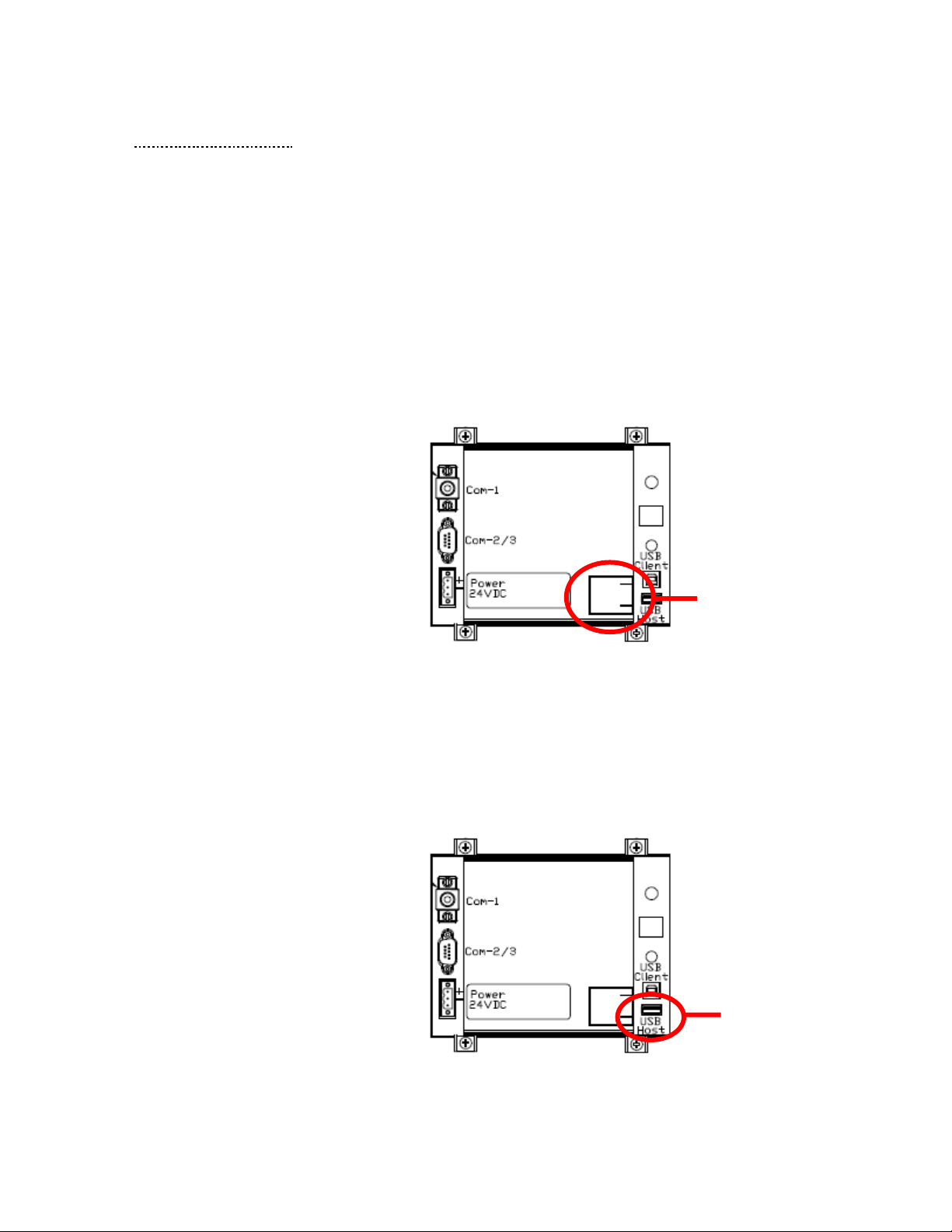

The Interface Module has three major components; the Interface PCB, the HMI Display and an option

network Communications Gateway (see Figure 6.1).

The interface PCB contains a Chassis Communications Port that connects to the power converter of the

HarmonicGuard Active filter. The interface PCB translates status and commands data between the power

converter controls and the HMI Display. The interface PCB also contains the 24V Relay I/O for basic status

monitoring and run/stop control of the HarmonicGuard Active filter.

The HMI Display is a 6” color Touchscreen display containing a series of status screens that provide the user

with a convenient way to monitor the operation of the HarmonicGuard Active filter. The HMI display also

contains an integrated ModbusRTU network connection for remote monitoring of the HarmonicGuard Active

filter.

The optional network Communications Gateway can be connected to the integrated ModbusRTU network

connection in the HMI Di s play to translate the ModbusRTU protocol to an alternate Field bus or Industrial

Ethernet protocol such as Ethernet/I P.

Figure 6.1 – Interface Module Components

68

Page 69

Caution

review the more specific information provided by the drawings shipped with the module. Information

!

Additiona l Infor mation

This section provides general information describing the Interface Module. Be sure to carefully

from by the drawings takes precedence over the information provided in this section.

The information and rat ings given in this manual are approximate and should not be used for any

purpose requiring exact data. Contact the factory in situations where certified data is required. All

data is subject to change without notice.

Receiving Inspection

The Interface Module has been thoroughly inspected and functionally tested at the factory and carefully

packaged for shipment. After receiving the unit, immediately inspect the shipping container and report any

damage to the carrier that delivered the unit. Verify that the part number of the unit received is the same as

the part number listed on the purchase order. See appendix for part numbering details.

69

Page 70

o Make sure the installation location will not be exposed to direct sunli ght, excessive

o Select a mounting area that will allow adequate cooling air.

o Make sure that all wiring conforms to the requirements of the National Electric Code